Method for preparing orientation molecular sieve membrane

A technology of molecular sieve membrane and molecular sieve, which is applied in the direction of crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminosilicate zeolite, etc., can solve problems such as fast hydrolysis speed of germanium source, mismatching degree of hydrolysis, and influence of molecular sieve membrane formation , to achieve the effect of easy control of synthesis conditions and reduction of adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

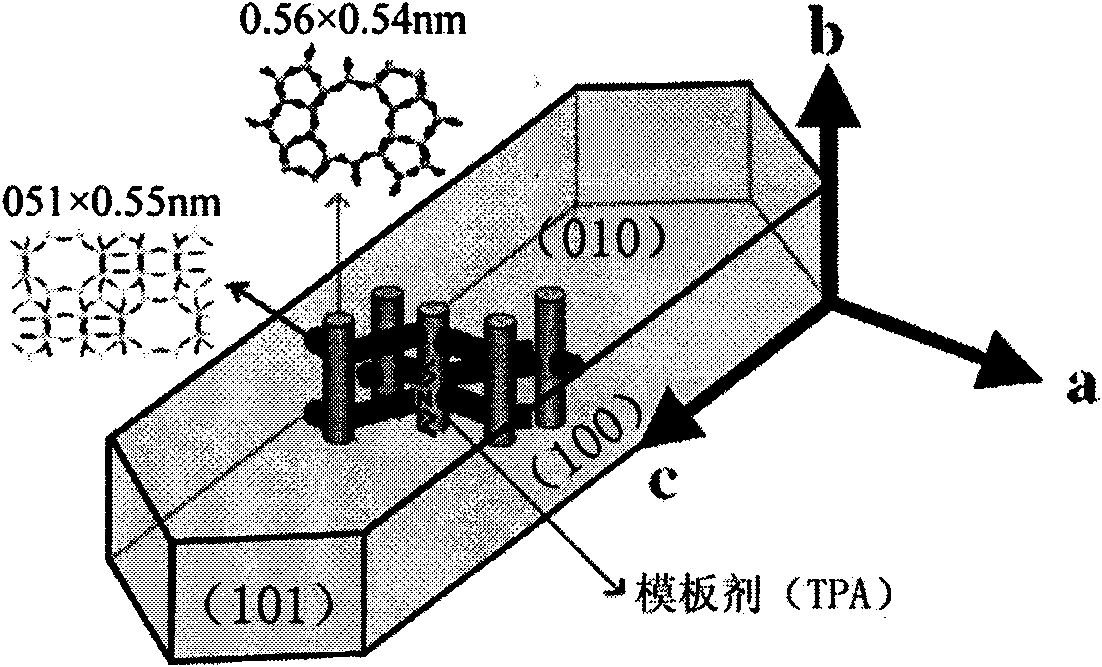

[0022] Add 14.46ml of water to the aqueous solution of 1ml of tetrapropyl ammonium hydroxide (50%), stir for 10 minutes, then add 7.21 grams of silica sol dropwise therein, and dissolve 0.125 grams of tetraethyl germanate in 11.10 grams of Add isopropanol dropwise to the aforementioned liquid, stir for 10 minutes, raise the temperature to 80°C, keep the temperature constant for 20 minutes, add water to the original liquid level, cool to room temperature, and stir for 5 hours to obtain the molecular sieve membrane precursor glue, which Composed of: 1SiO 2 : 0.01GeO 2 :0.05TPAOH:23H 2 O,

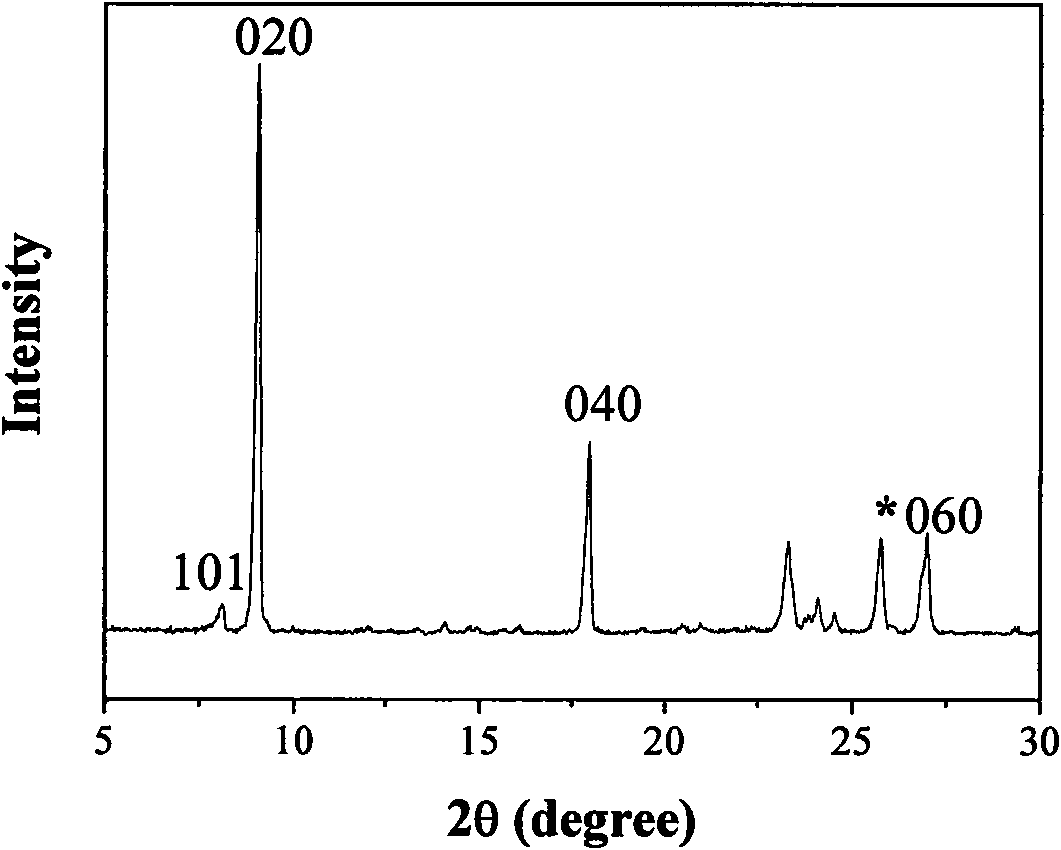

[0023] The above precursor glue and α-Al 2 o 3 The carrier is placed in the crystallization reactor together, and the α-Al 2 o 3The lower surface of the carrier is in contact with the synthesis solution, heated and crystallized at 180°C for 24 hours, then taken out and cooled to room temperature, washed with deionized water until neutral, dried, and calcined at 550°C for 8 hours to remov...

Embodiment approach 2

[0025] On the basis of Example 1, according to the method of Example 1, the hydrolysis temperature of the silicon source and the germanium source was raised to 80°C, the crystallization time of the molecular sieve membrane was shortened to 12 hours, and the crystallization preparation of the molecular sieve membrane was carried out again. and cooled to room temperature, then washed with deionized water until neutral, dried at 550°C, and fired for 8 hours to remove the template agent to prepare a molecular sieve film grown along the b-axis orientation, such as Figure 5 with 6 .

Embodiment approach 3

[0027] According to the method of embodiment 1, in the aqueous solution of the tetrapropyl ammonium hydroxide (50%) of 0.89ml, add the water of 14.39ml, stir for 10 minutes, then dropwise add the silica sol of 8.23 grams wherein, the germanium of 0.125 grams After dissolving 11.10 g of isopropanol, add tetraethyl ester dropwise to the aforementioned liquid, stir for 10 minutes, increase the hydrolysis temperature to 90°C, extend the constant temperature time to 30 minutes, add water to the original liquid level, and cool to room temperature , stirred for 5 hours to obtain the composition of the molecular sieve membrane precursor glue solution: 1SiO 2 : 0.009GeO 2 :0.04TPAOH:20H 2 O,

[0028] The crystallization temperature of the molecular sieve membrane was lowered to 175° C., and the crystallization time was extended to 40 hours for crystallization and film formation, and a molecular sieve membrane grown along the b-axis orientation was prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com