Patents

Literature

124results about How to "Synthesis conditions are easy to control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Honeycomb-ceramic-type monolithic catalyst, and preparation method and application thereof

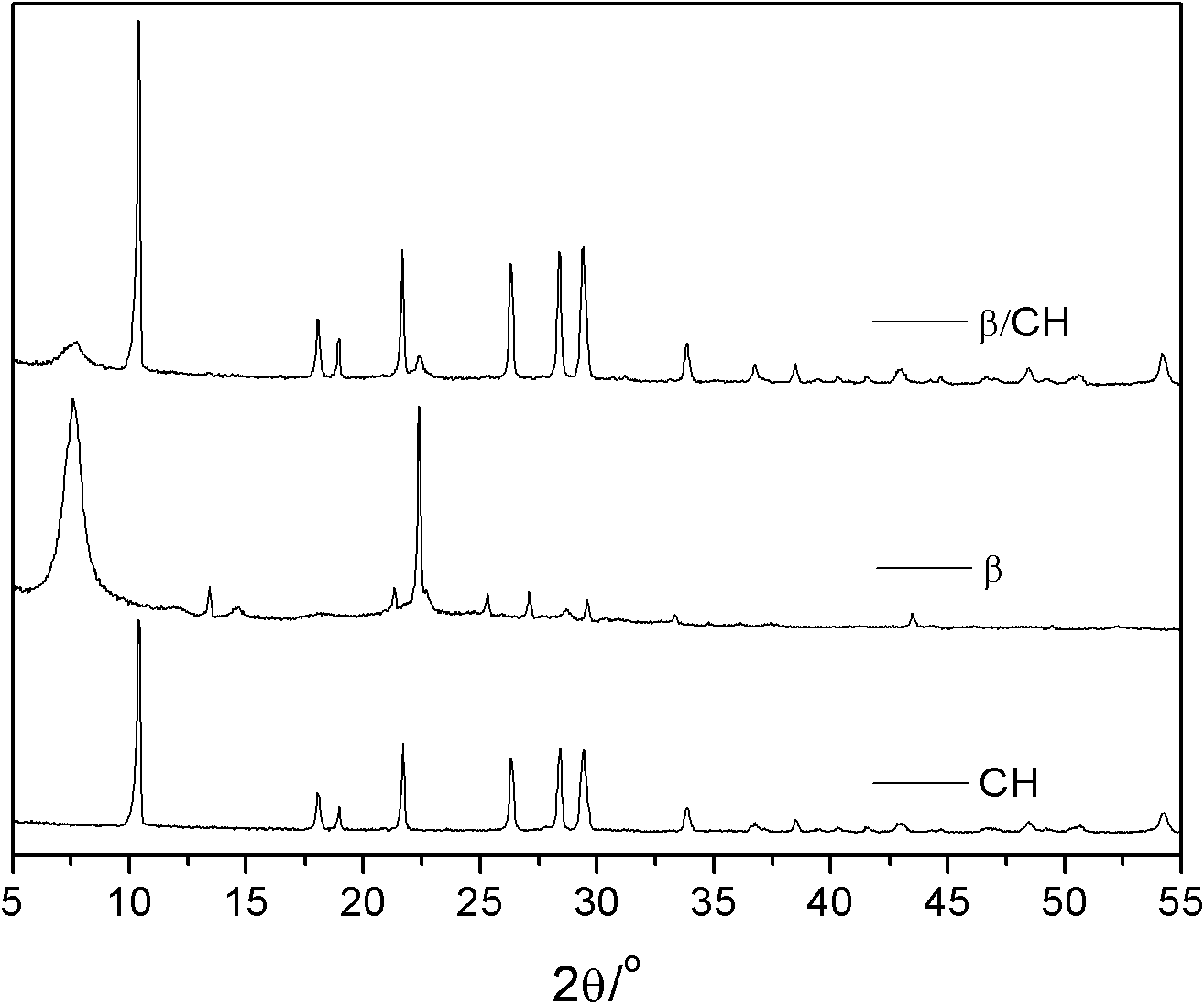

InactiveCN102133537AIncrease roughnessPromote nucleationMolecular sieve catalystsDispersed particle separationMass ratioCordierite

The invention discloses a honeycomb-ceramic-type monolithic catalyst, and preparation method and application thereof. The monolithic catalyst takes honeycomb ceramic as a carrier, a Beta molecular sieve is coated on the surface of the honeycomb ceramic and taken as a coating layer, and then active component, namely precious metal, is loaded on the surface of Beta molecular sieve; the active component of the precious metal is one or two selected from palladium or platinum; in the honeycomb-ceramic-type monolithic catalyst, the mass ratio of the coating layer of the Beta molecular sieve to the honeycomb ceramic is 0.02-0.2:1, the mass ratio of the precious metal to the coating layer of the Beta molecular sieve is 0.02-0.2:1, the honeycomb ceramic is cordierite honeycomb ceramic; and in the invention, the high-silicon or full-silicon Beta molecular sieve is taken as the coating layer of the monolithic catalyst, and has the characteristics of good water resistance, high heat stability andthe like, and the monolithic burning catalyst taking the Beta molecular sieve as the coating layer can keep better activity and stability under high temperature, and suitable for being taken as catalytic combustion catalyst for application.

Owner:ZHEJIANG CENWAY MATERIALS CO LTD

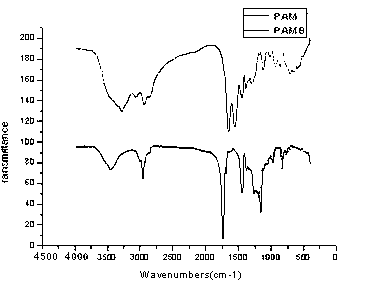

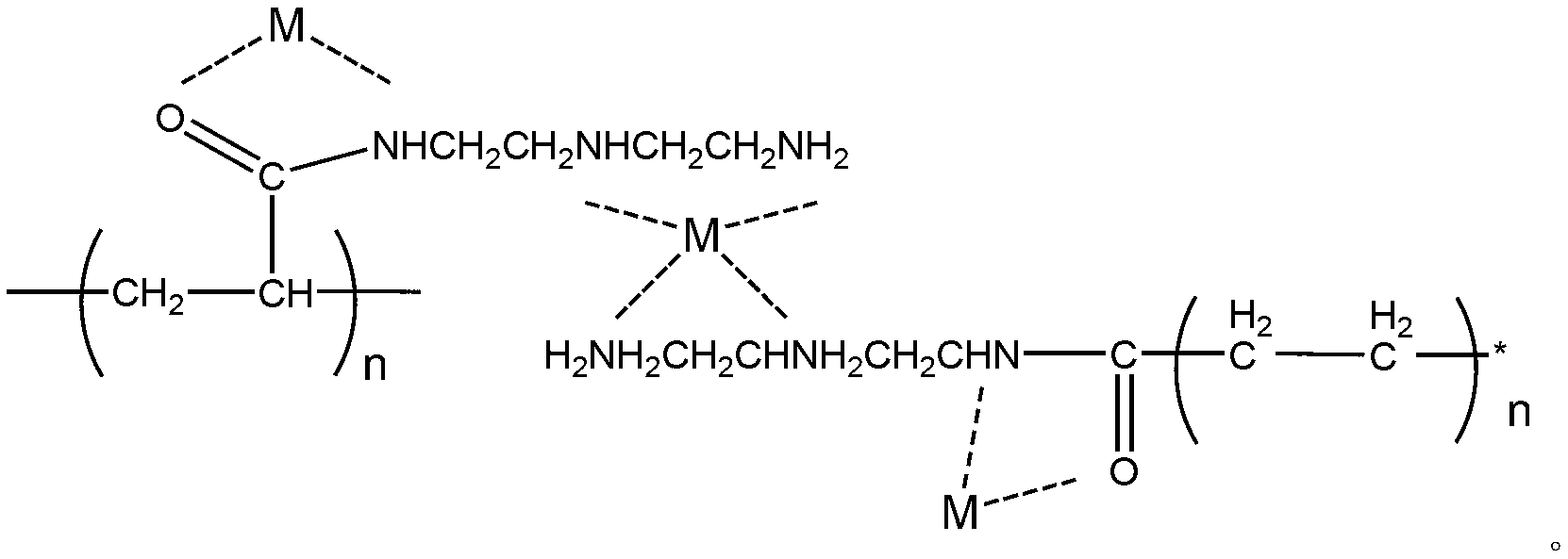

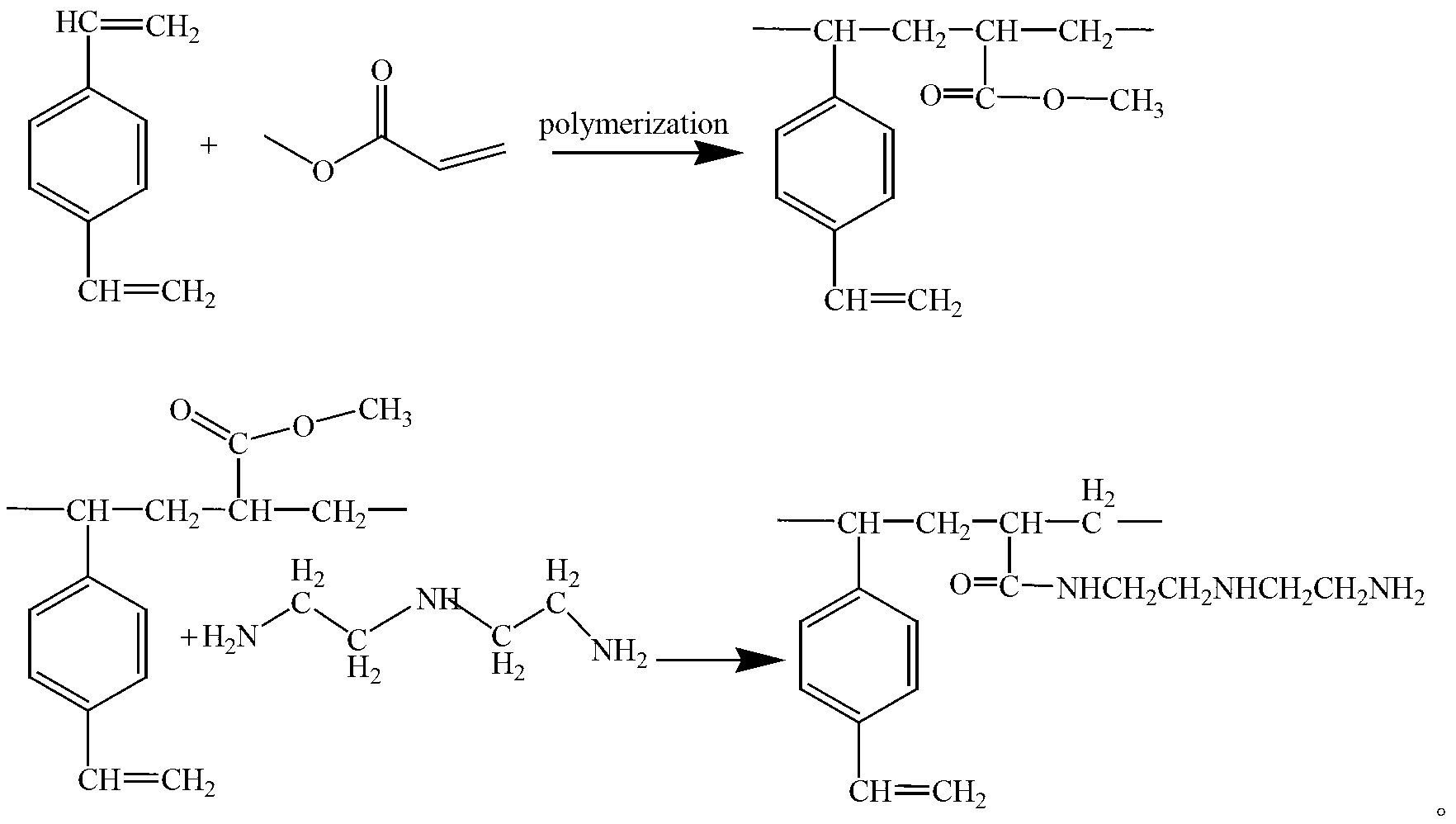

Acrylic-acid high-capacity primary-amino chelate resin for trapping copper ions and preparation method thereof

ActiveCN103159888ALarge adsorption capacityImprove adsorption capacityOther chemical processesWater contaminantsWastewaterAminolysis

The invention discloses an acrylic-acid high-capacity primary-amino chelate resin for trapping copper ions and a preparation method thereof, belonging to the field of polyamine resin wastewater treatment. The structural unit of the primary-amino chelate resin disclosed by the invention is disclosed in the specification, wherein x represents a repetitive structure unit of different aminolysis reagents. The preparation method disclosed by the invention has the advantages of wide material sources, low cost, simple operation steps and controllable synthesis conditions; and the synthesized resin has superhigh adsorption capacity for copper ions.

Owner:NANJING UNIV

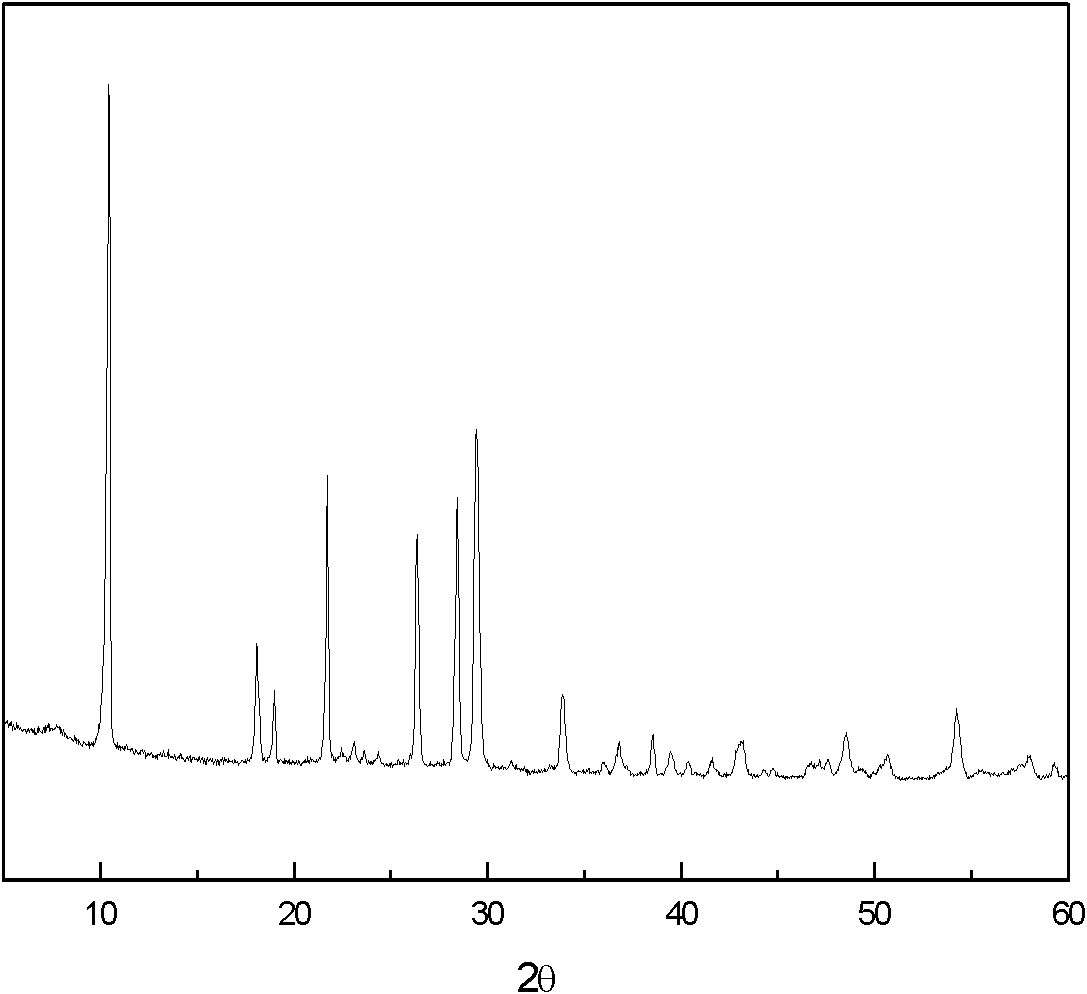

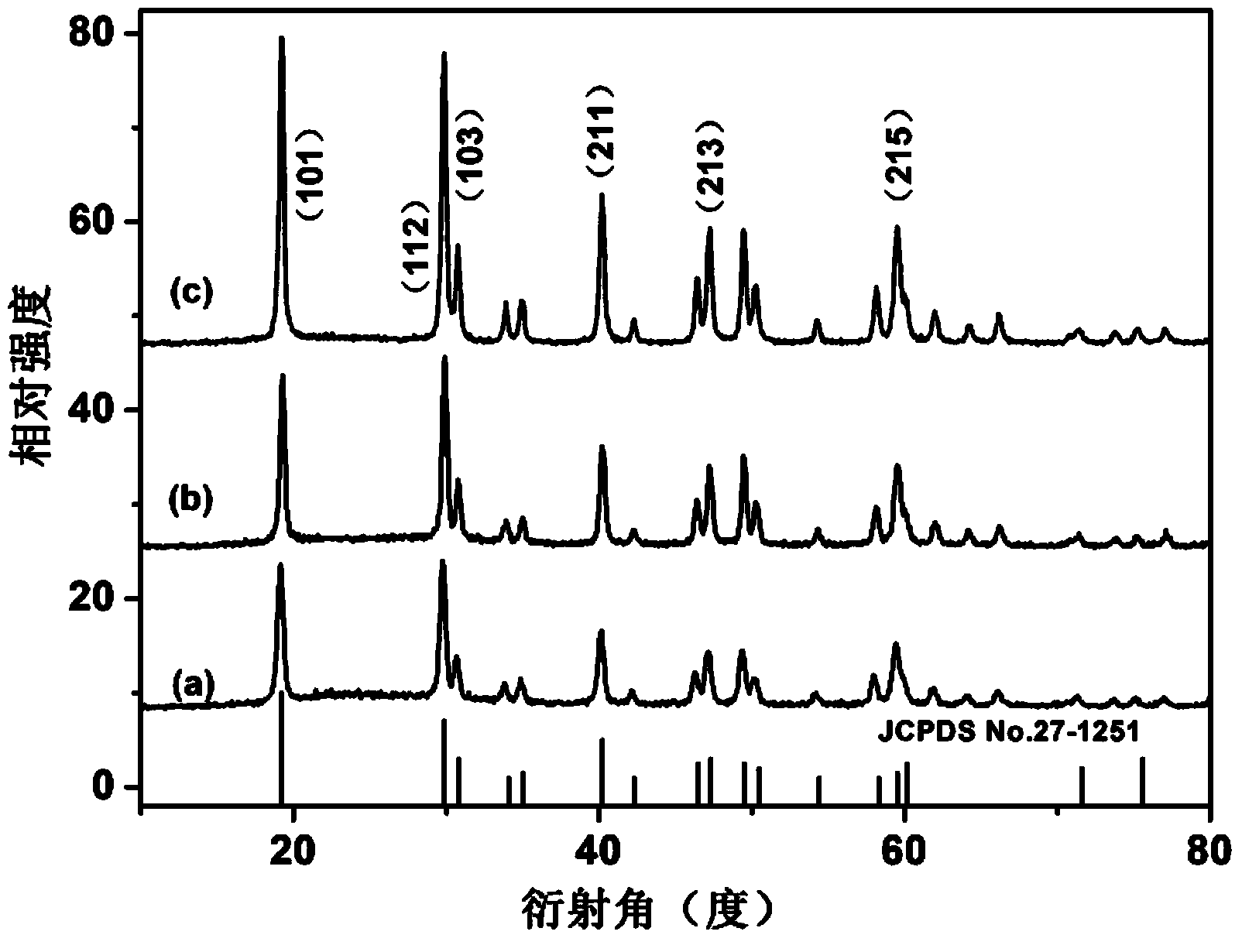

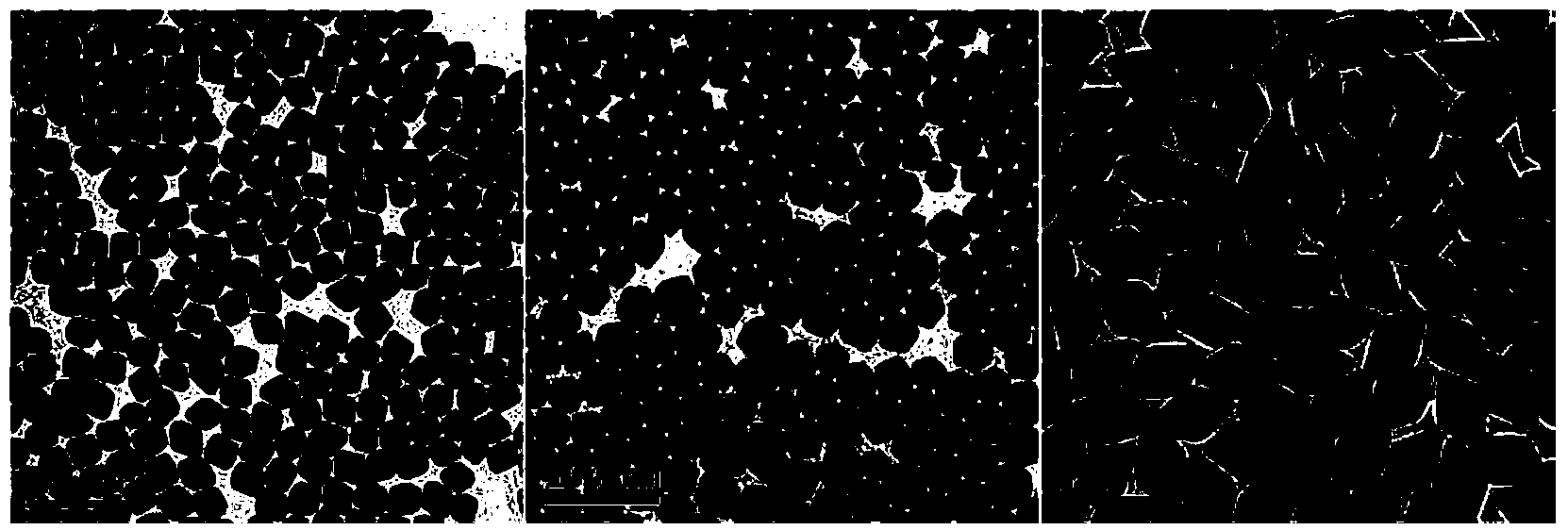

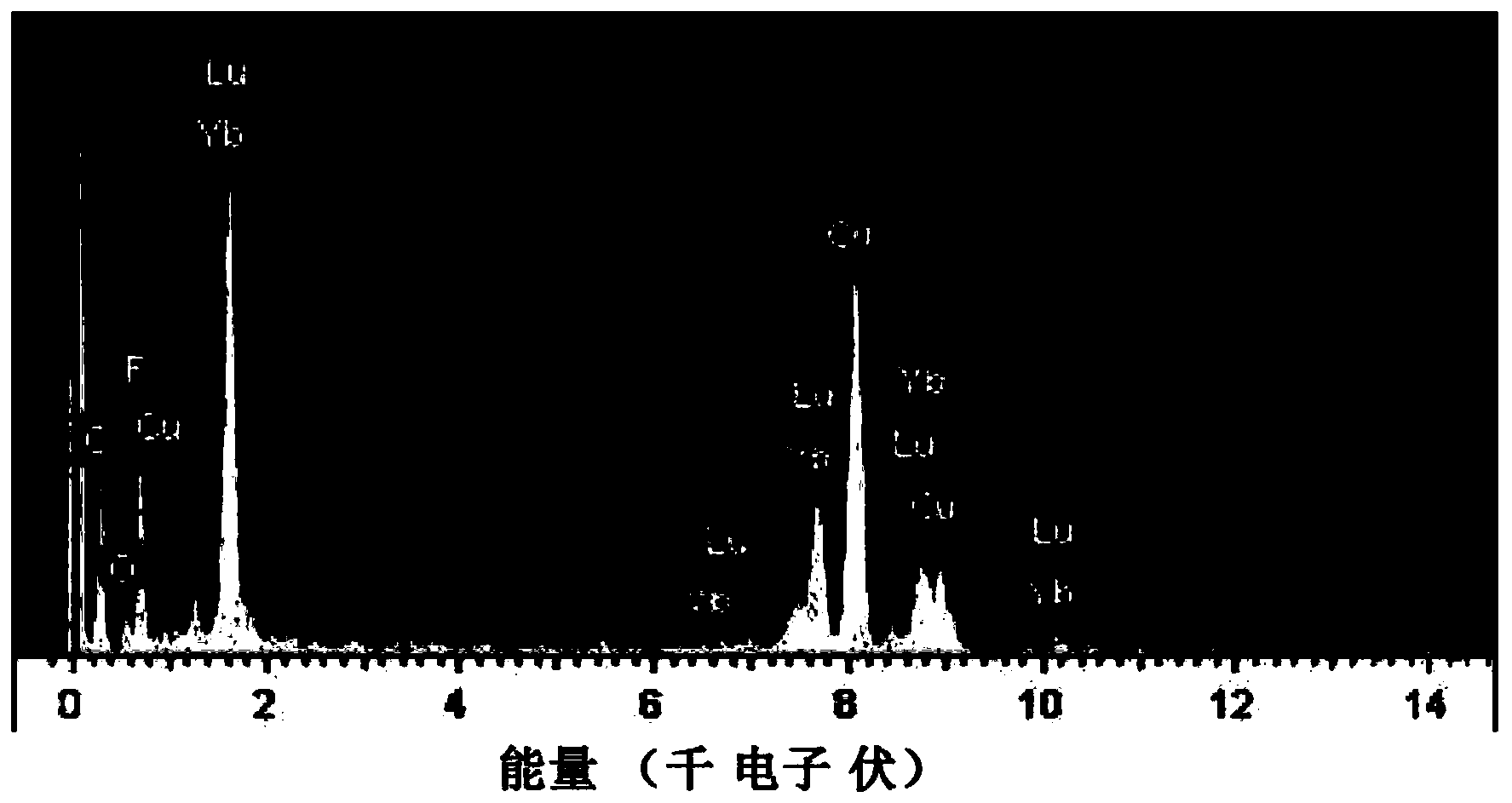

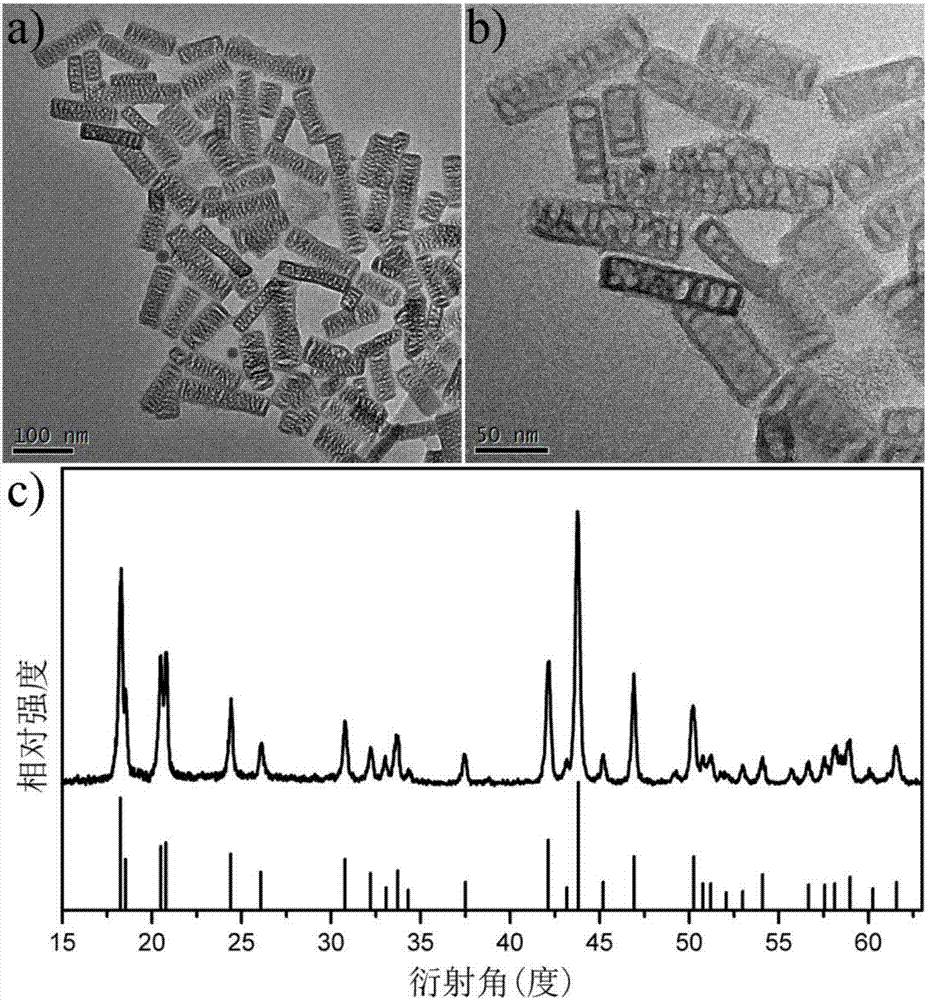

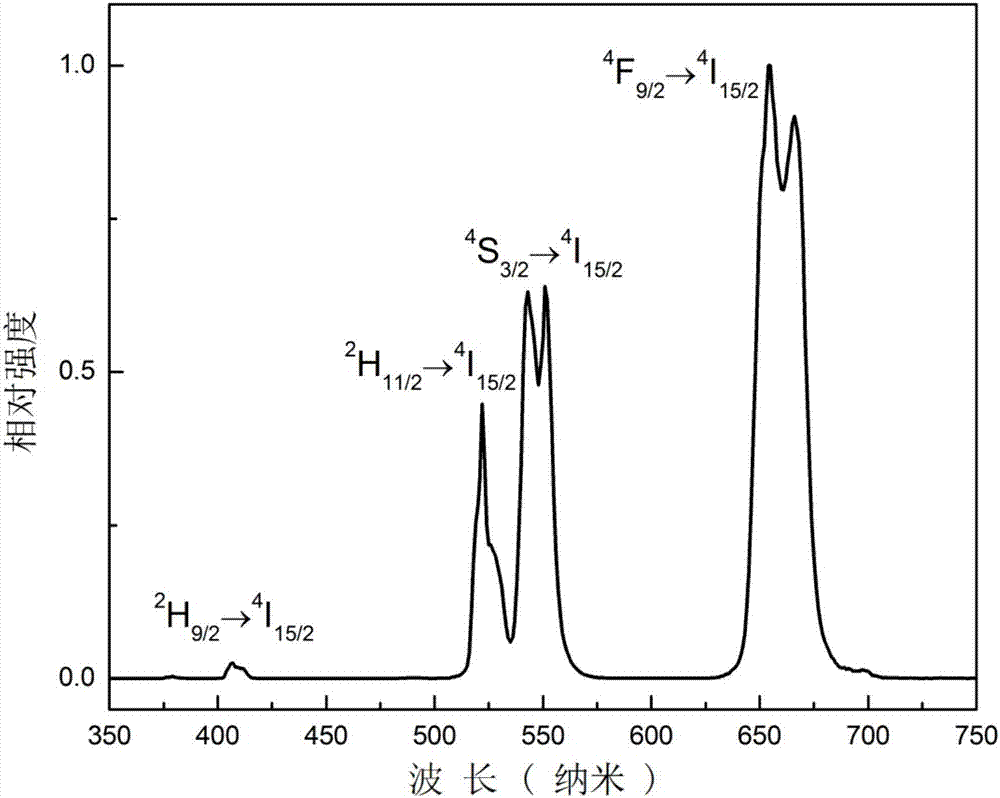

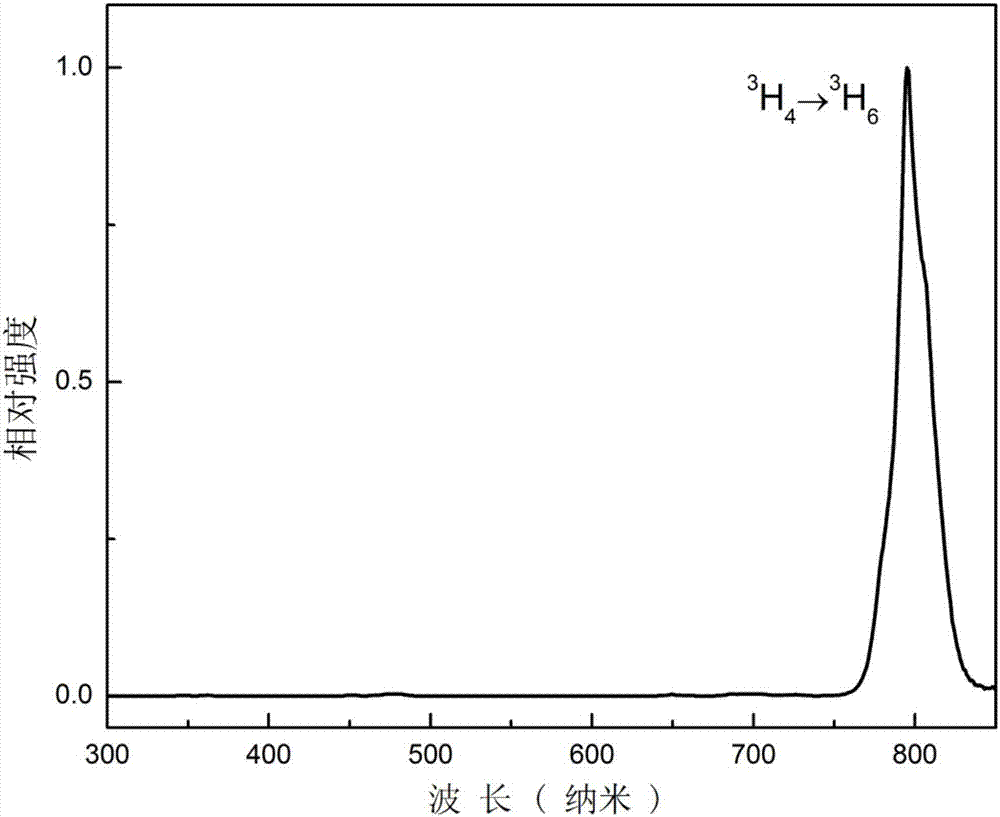

Rare earth-doped lithium lutetium fluoride nano-material, and preparation method and application thereof

ActiveCN103589432AEasy to makeSynthesis conditions are easy to controlFluorescence/phosphorescenceLuminescent compositionsBio moleculesContrast medium

The invention discloses a rare earth-doped lithium lutetium fluoride nano-material, and a preparation method and an application thereof. The material is obtained by doping Yb / Er(20 / 1%) or Yb / Tm(20 / 0.5%) luminescent ions into a lithium lutetium fluoride matrix, can emit visible light under the excitation of 980nm infrared light, and can be used for the up-conversion heterogeneous detection and cell imaging through the connection with biological molecules. Additionally, heavy rare earth ions in the matrix also have a strong X-ray attenuation capability, and can be used as a computer tomography imaging contrast agent. The invention also provides the preparation method of the nano-material. The nano-material has a water solubility and excellent performances, so the nano-material can be applied in the fields of the biological detection, the biological imaging and the like.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

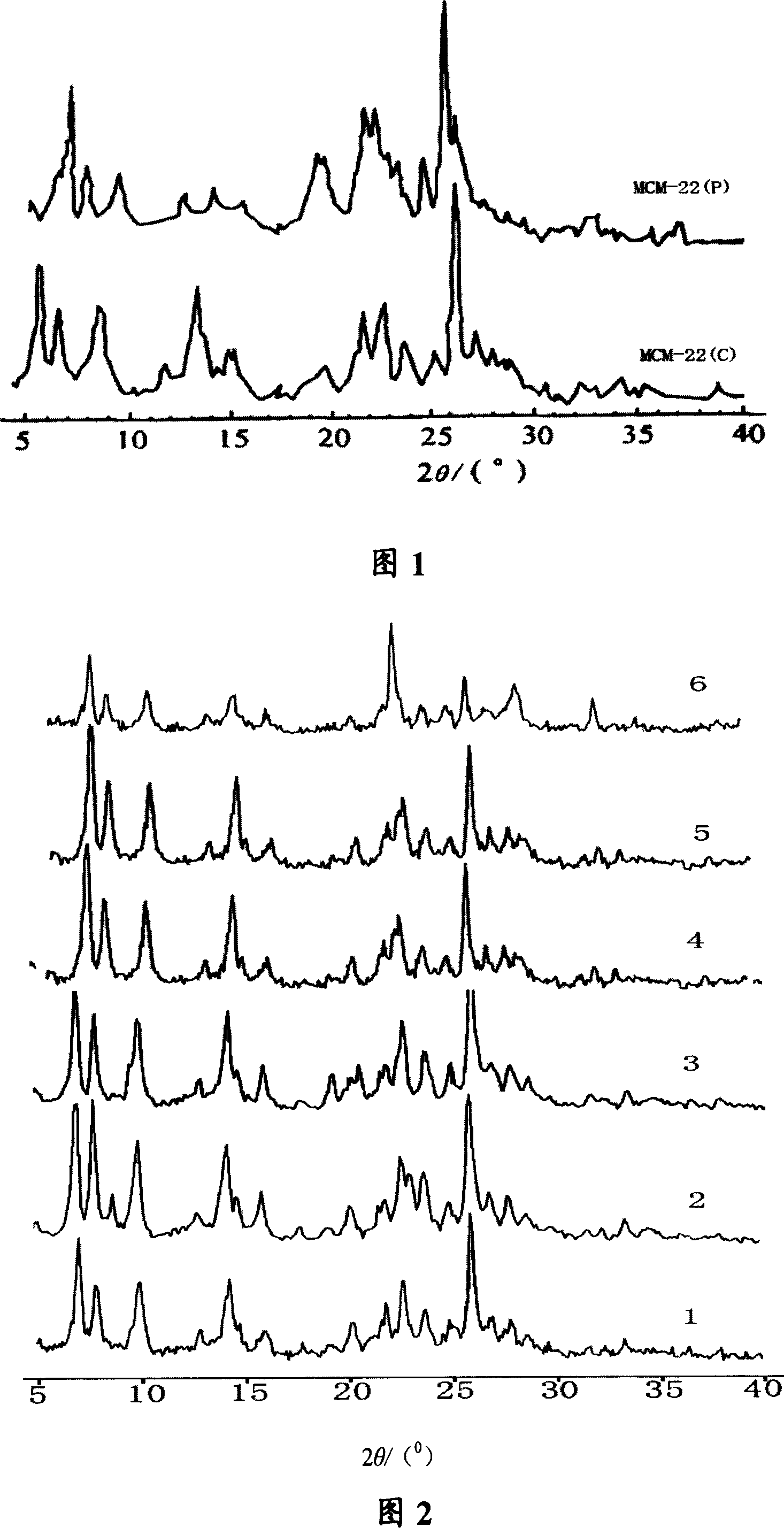

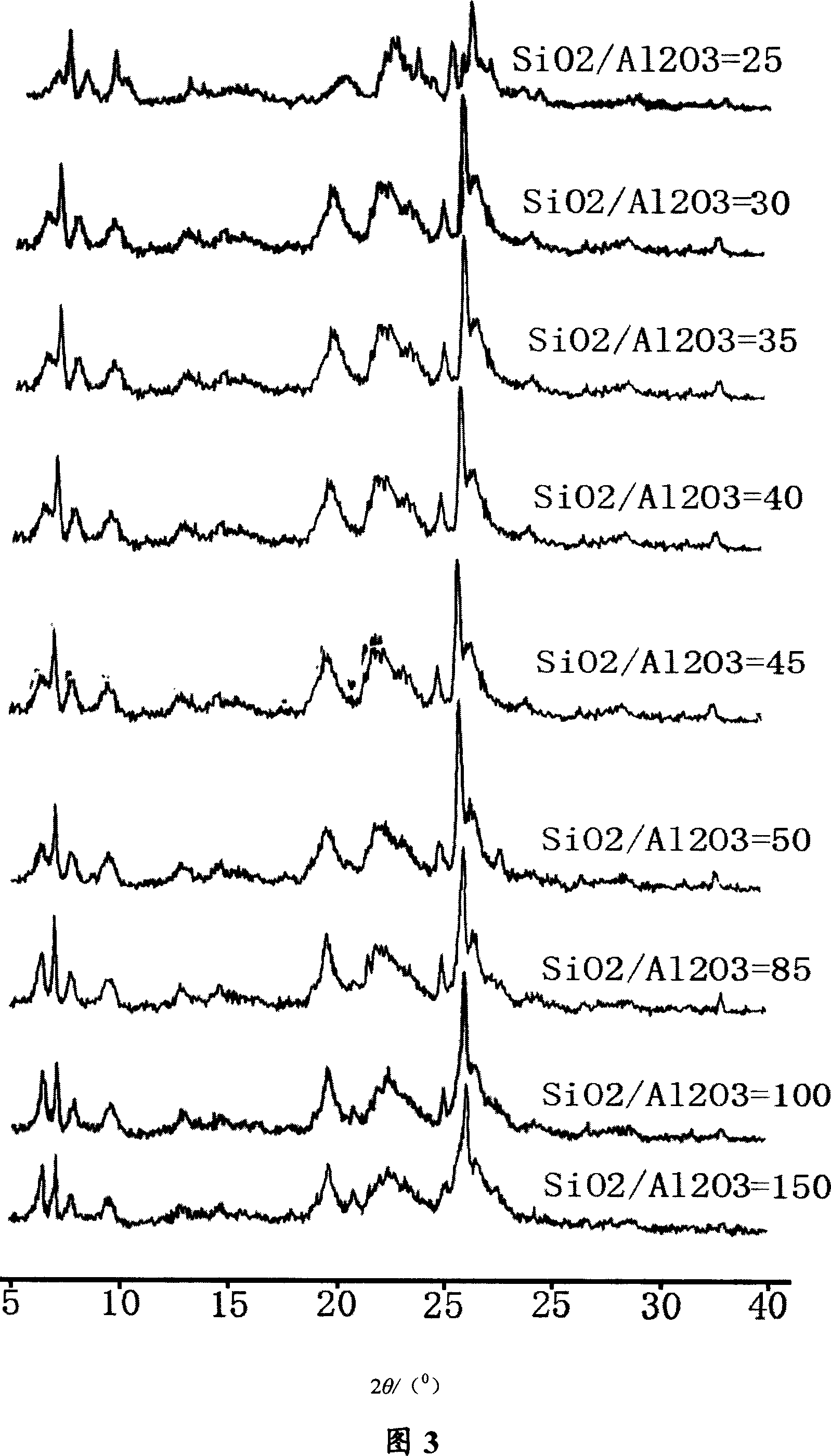

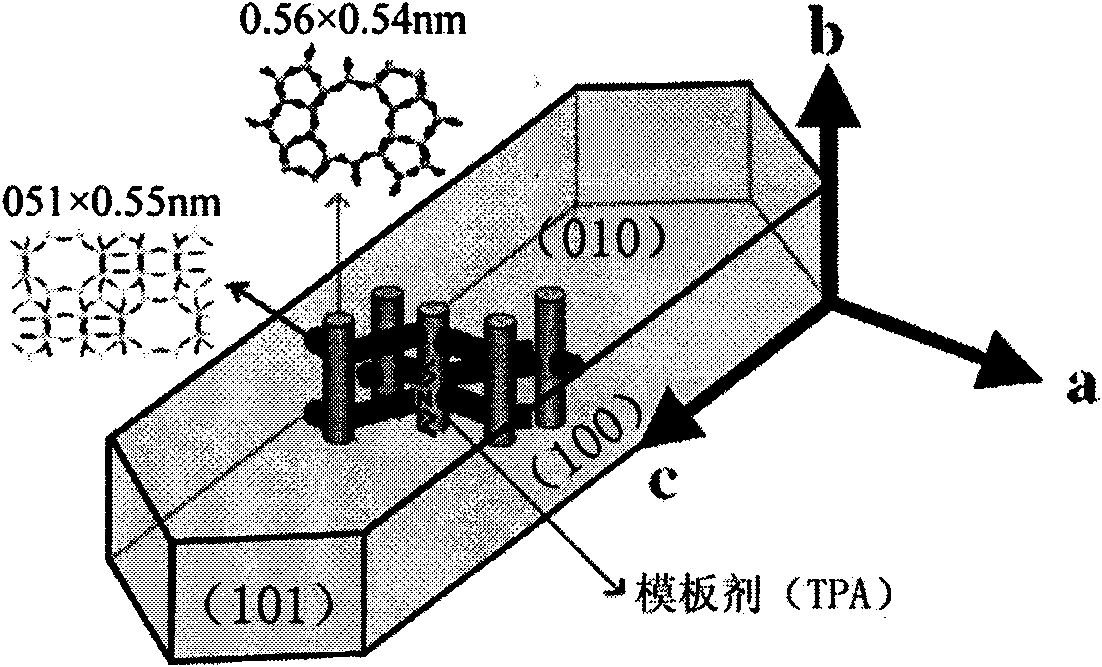

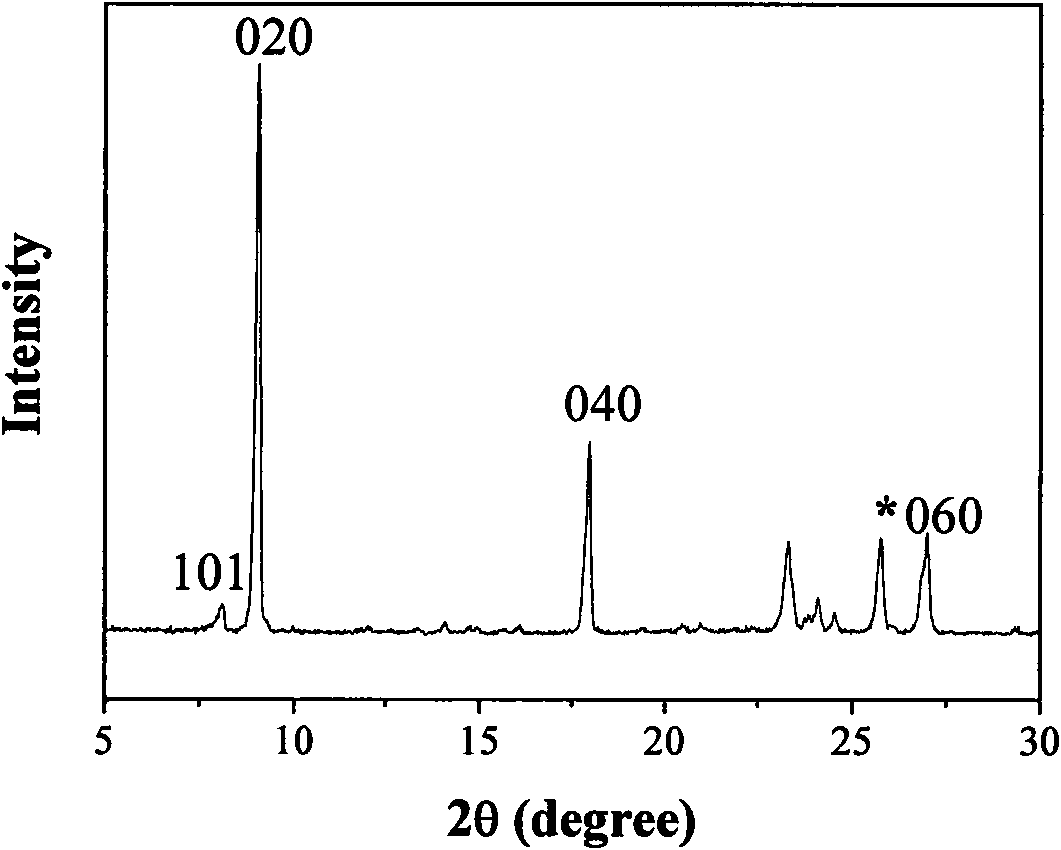

Method for synthesizing MWW mole cular sieve

InactiveCN101024499AQuality improvementAvoid problemsCrystalline aluminosilicate zeolitesMolecular-sieve compoundsChemistryMolecular sieve

The invention supplies a method to compound MWW molecular sieve. It adopts two-stage hydrothermal crystallization method that the room temperature at -119.9 degree centigrade is the first stage and 120-180 degree centigrade is the second stage. The alkali resource is one or two or three of hydroxide of Na, K and Ba. The silicon resource could be solid silica gel or liquid silica gel. And template agent could be HMI or the mixture of HMI and organic amine, quaternary ammonium salt, alcohols, and polyether. The invention has the advantages of compound method and condition is easy to control and low cost. The acid of the product could be altered by changing alkali resources.

Owner:EAST CHINA UNIV OF SCI & TECH

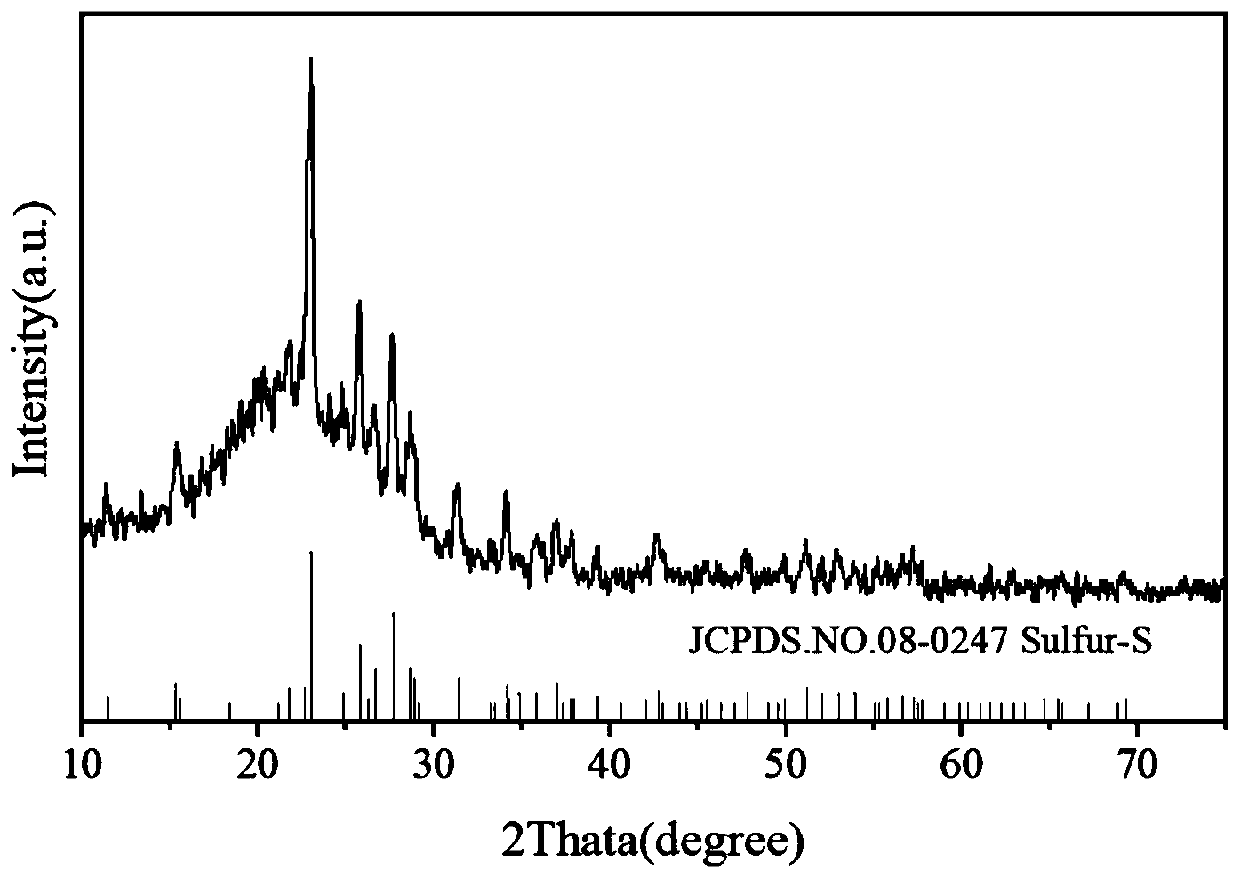

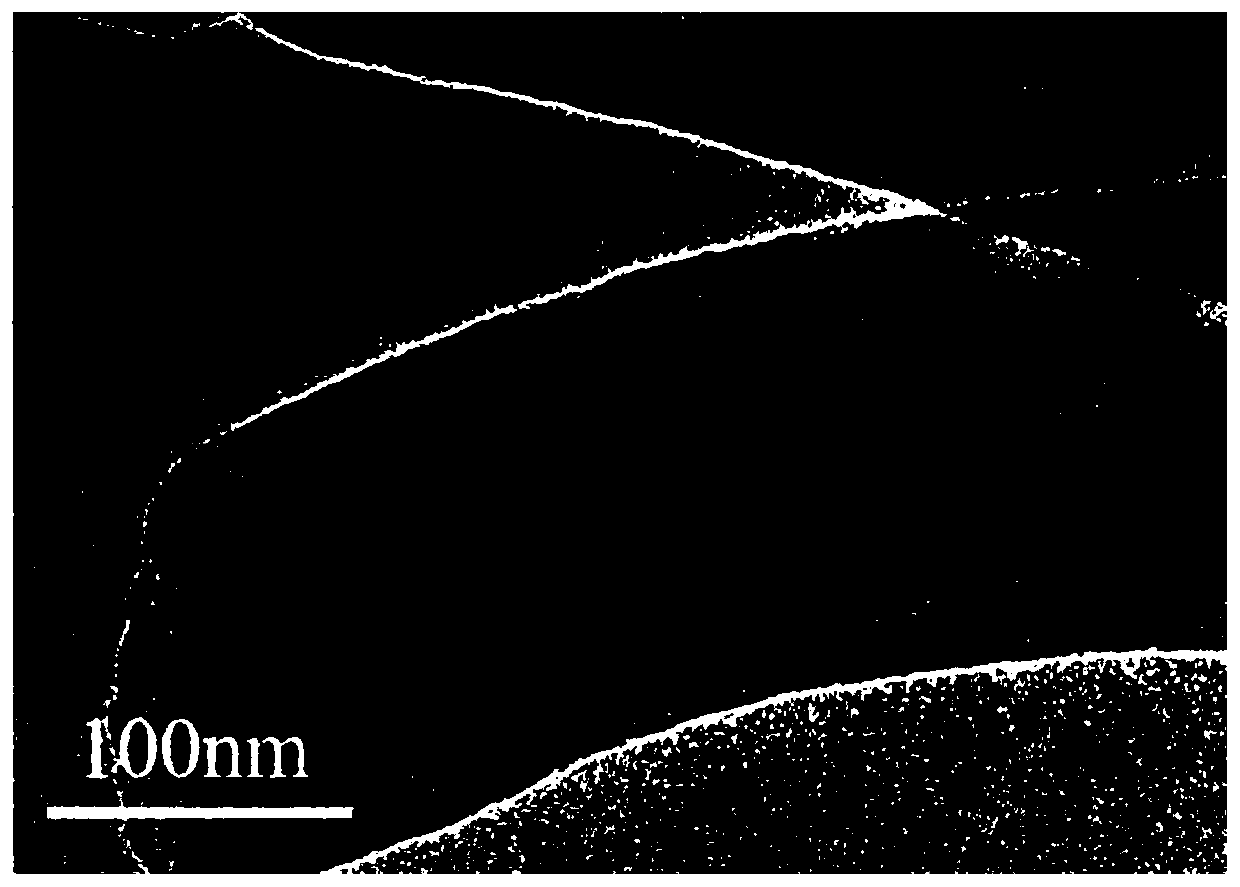

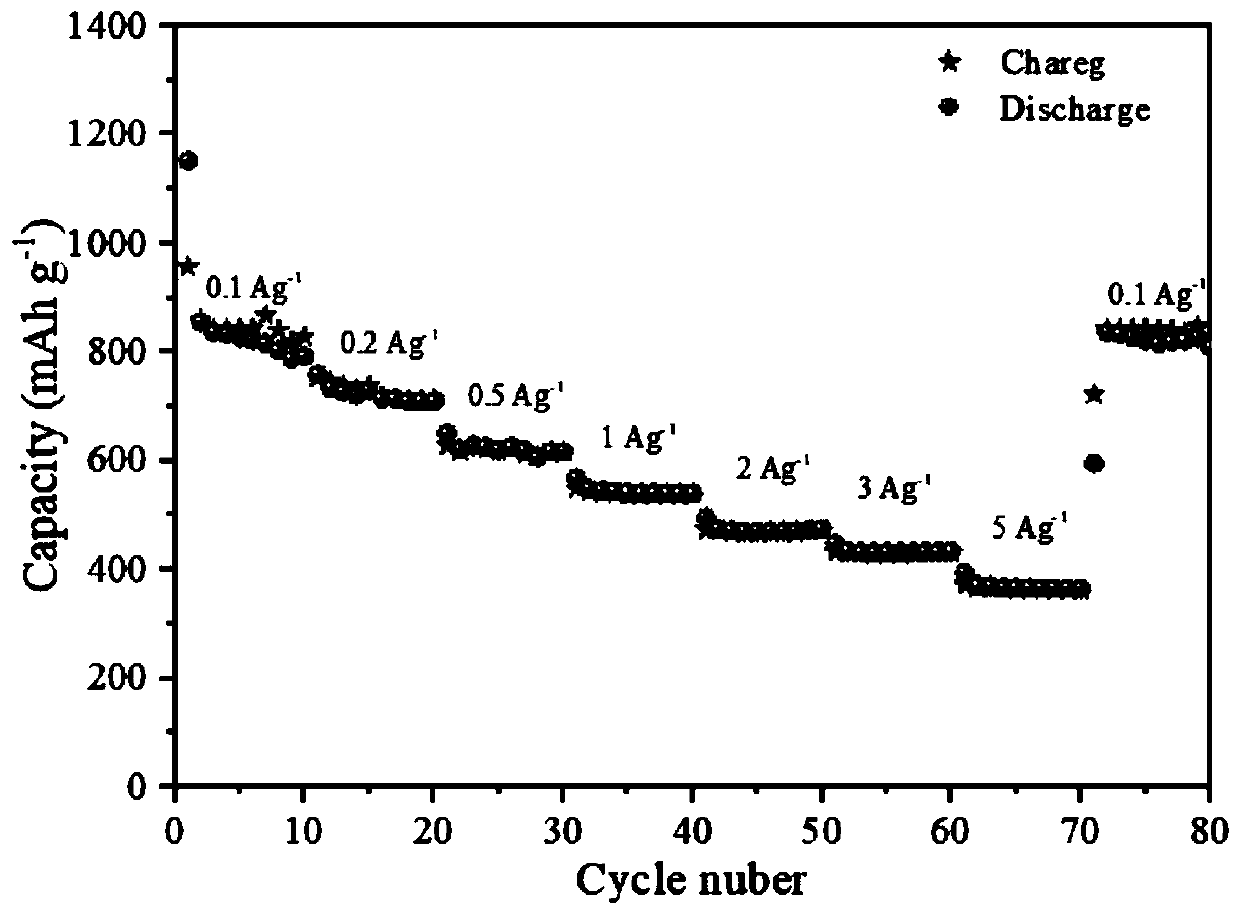

Lithium-sulfur battery self-supporting cathode material and electro-spinning preparation method thereof

InactiveCN110438798ASolve the shortcomings of poor conductivityInhibition of the shuttle effectCarbon fibresPositive electrodesPorous carbonArgon atmosphere

The invention provides a lithium-sulfur battery self-supporting cathode material and an electro-spinning preparation method thereof. Polyacrylonitrile and polymethyl methacrylate serve as precursors of electrostatic spinning yarns, composite nano-fiber membranes are prepared by an electro-spinning method, pre-oxidation and carbonization heat treatment of the electrostatic spinning fiber membranesare implemented to form a self-supporting in-situ nitrogen doped porous carbon nano-fiber structure, self-supporting in-situ nitrogen doped porous carbon nano-fiber membranes are soaked in carbon disulfide solution of sulfur, drying and heat treatment in the argon atmosphere are implemented to obtain the self-supporting lithium-sulfur cathode material. According to the material, the polymethyl methacrylate serves as a template agent, self-supporting in-situ nitrogen doped carbon nano-fibers with porous structures are formed in a heat treatment and pyrolysis manner, the loading capacity of thesulfur is improved, dissolution of polysulfide is restrained, and the nano-fibers can directly serve as electrode materials.

Owner:SHAANXI UNIV OF SCI & TECH

Nano-crystal large poresize mesopore oxide material and its preparation method

InactiveCN1948161AWell-ordered pore structureHighly ordered pore structureTantalum compoundsTitanium dioxideSpace groupOrganic solvent

Owner:FUDAN UNIV

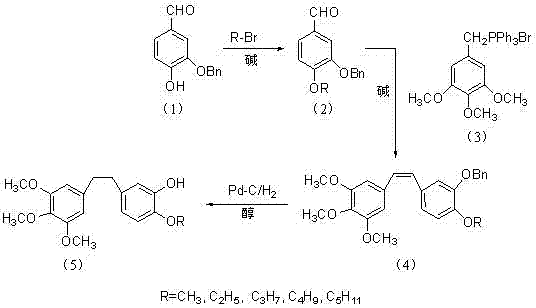

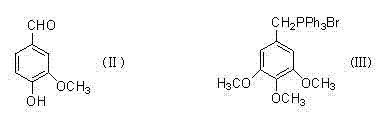

Method for preparing 3,4,5-trimethoxy-3'-hydroxy-4'-alkoxy diphenylethane

InactiveCN103539642AImprove protectionSignificant technological progressOrganic compound preparationCarbonyl compound preparationPalladium on carbonBenzaldehyde

Owner:SHANGHAI INST OF TECH

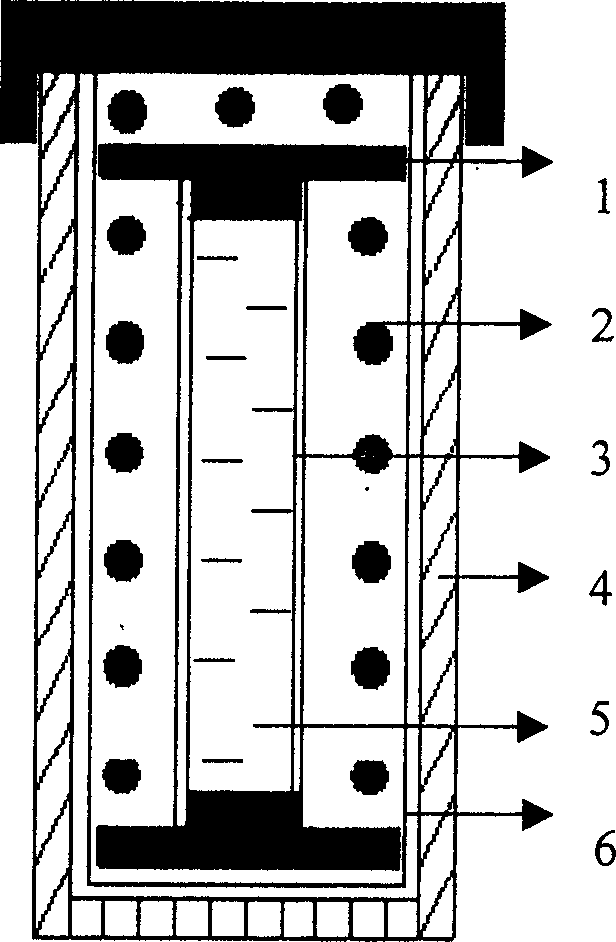

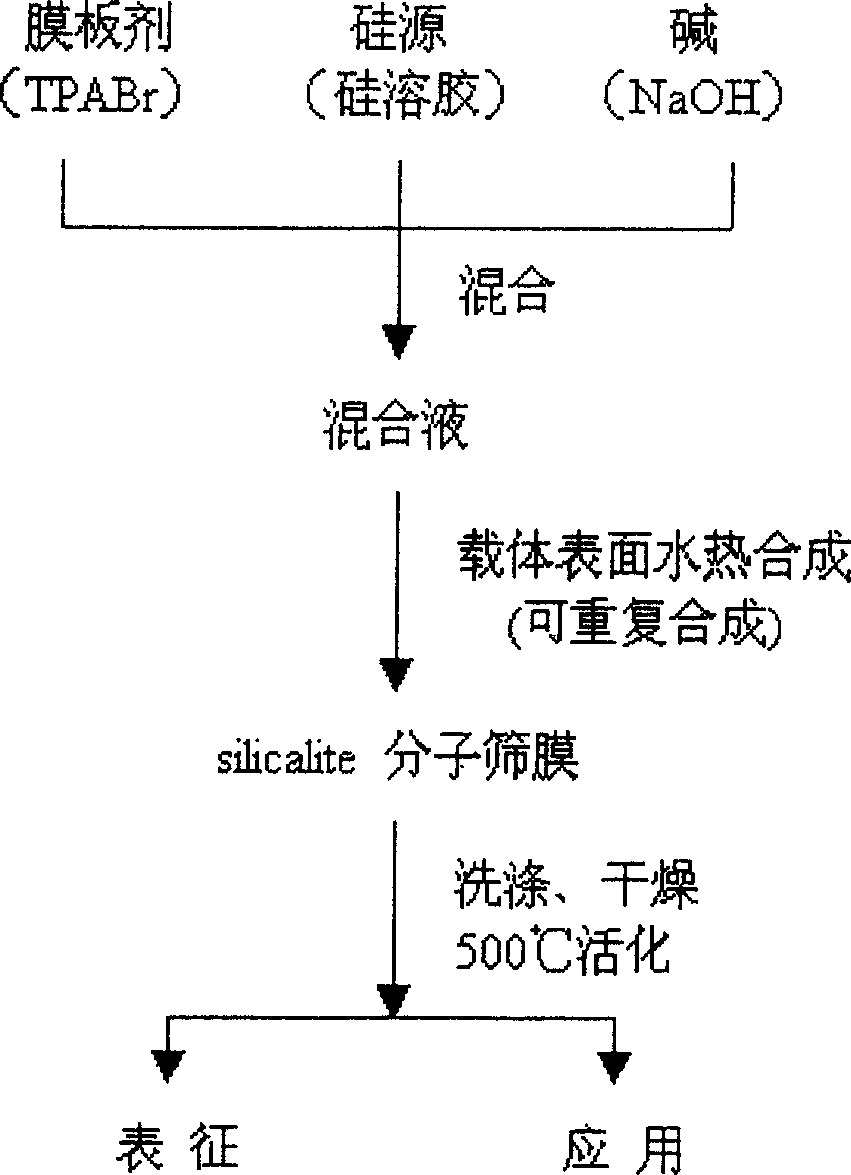

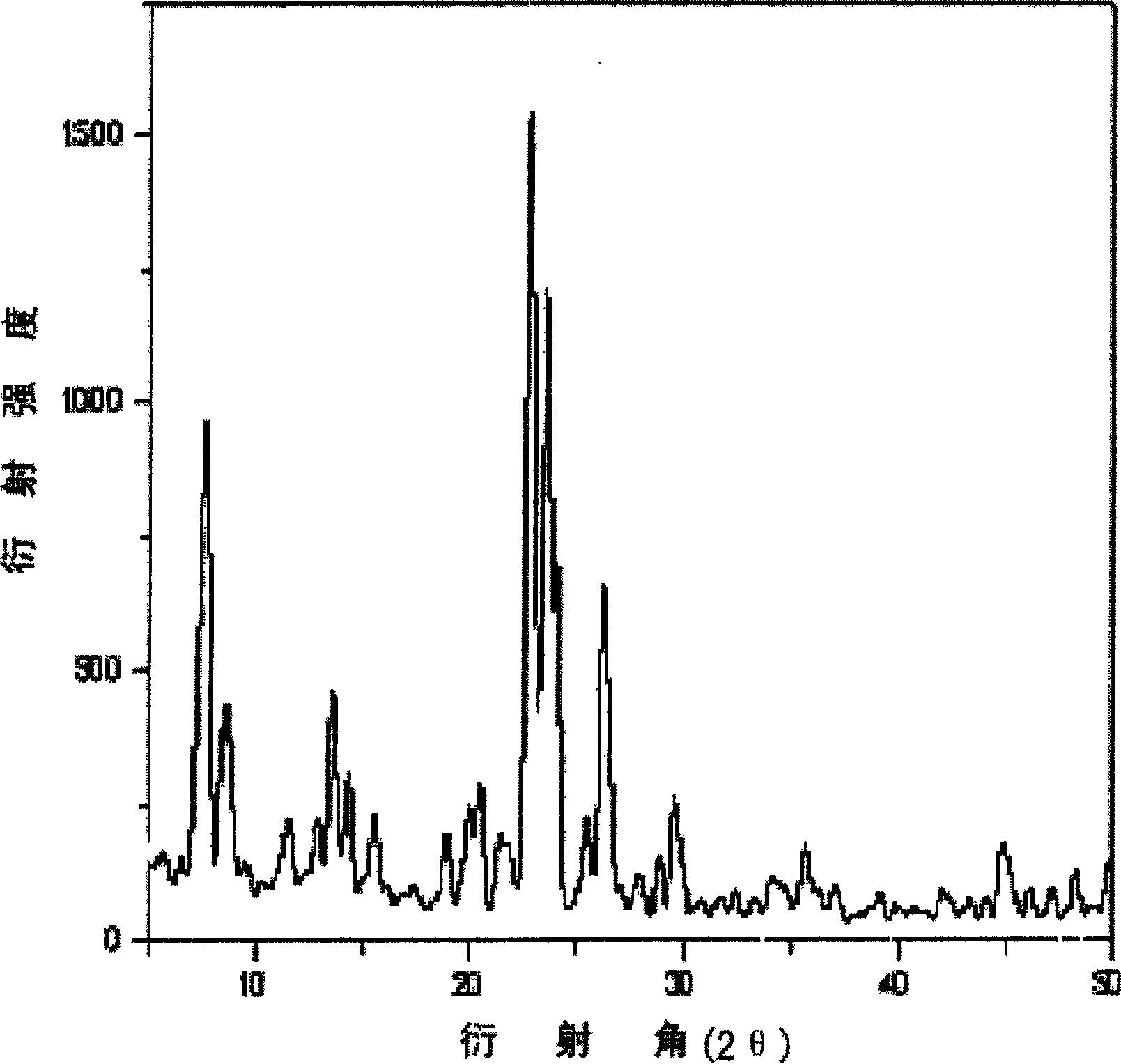

High performance molecular sieve membrane of silicon by using ceramics of silicon dioxide as carrier, and preparation method

InactiveCN1795971ASimple and fast operationSynthesis conditions are easy to controlSemi-permeable membranesMolecular sieveCrystal structure

The invention relates to a high-performance silicon molecular sieve membrane. It uses porous silicon dioxide ceramics as carrier, and its surface has MFI crystal structure. The average pore diameter of said silicon dioxide ceramics carrier is 0.1-2 microns, and its average porosity is 10-60%. Its preparation method uses porous silicon dioxide ceramics as carrier, uses TPABr as template agent and adopts in-situ hydration process to synthesize the invented silicon molecular sieve membrane.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

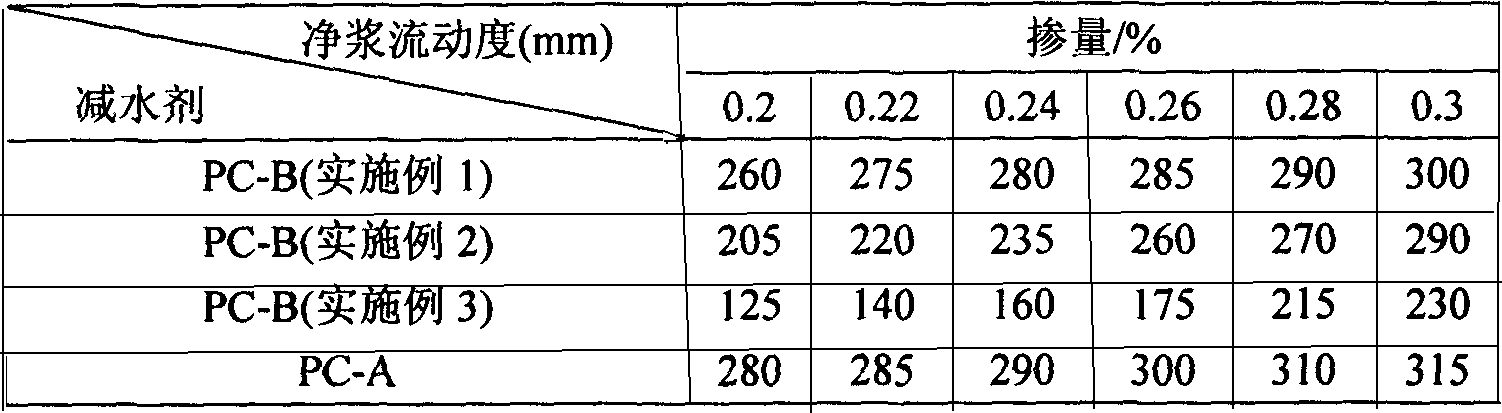

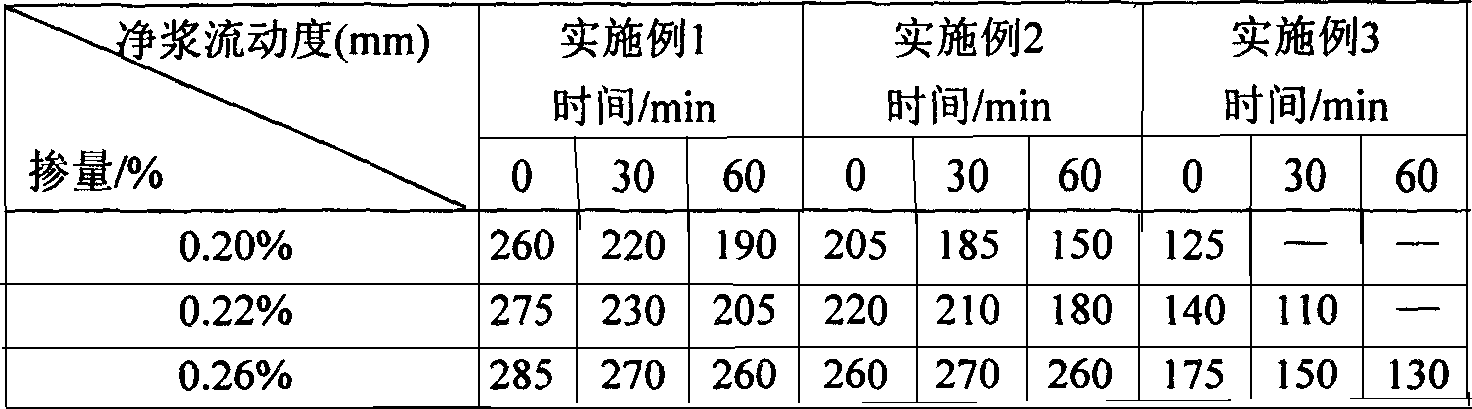

Poly carboxylic acid series super plasticizer and its preparing method

The present invention is serial polycarboxylic acid super plasticizers and their preparation process, and belongs to the field of concrete admixture technology. The super plasticizer is prepared with acrylic acid, methoxy polyglycol-1000 and sodium vinyl sulfonate, and through the esterification of acrylic acid and methoxy polyglycol-1000 in water bath to prepare intermediate polyglycol acrylate, and the subsequent free radical polymerization of polyglycol acrylate, sodium vinyl sulfonate and acrylic acid under the action of initiator in water solution. The preparation process has easily controlled condition, simple operation, no pollution, low cost and other features. The product of the present invention may be used as concrete super plasticizer suitable for different kinds of cement.

Owner:CHONGQING UNIV

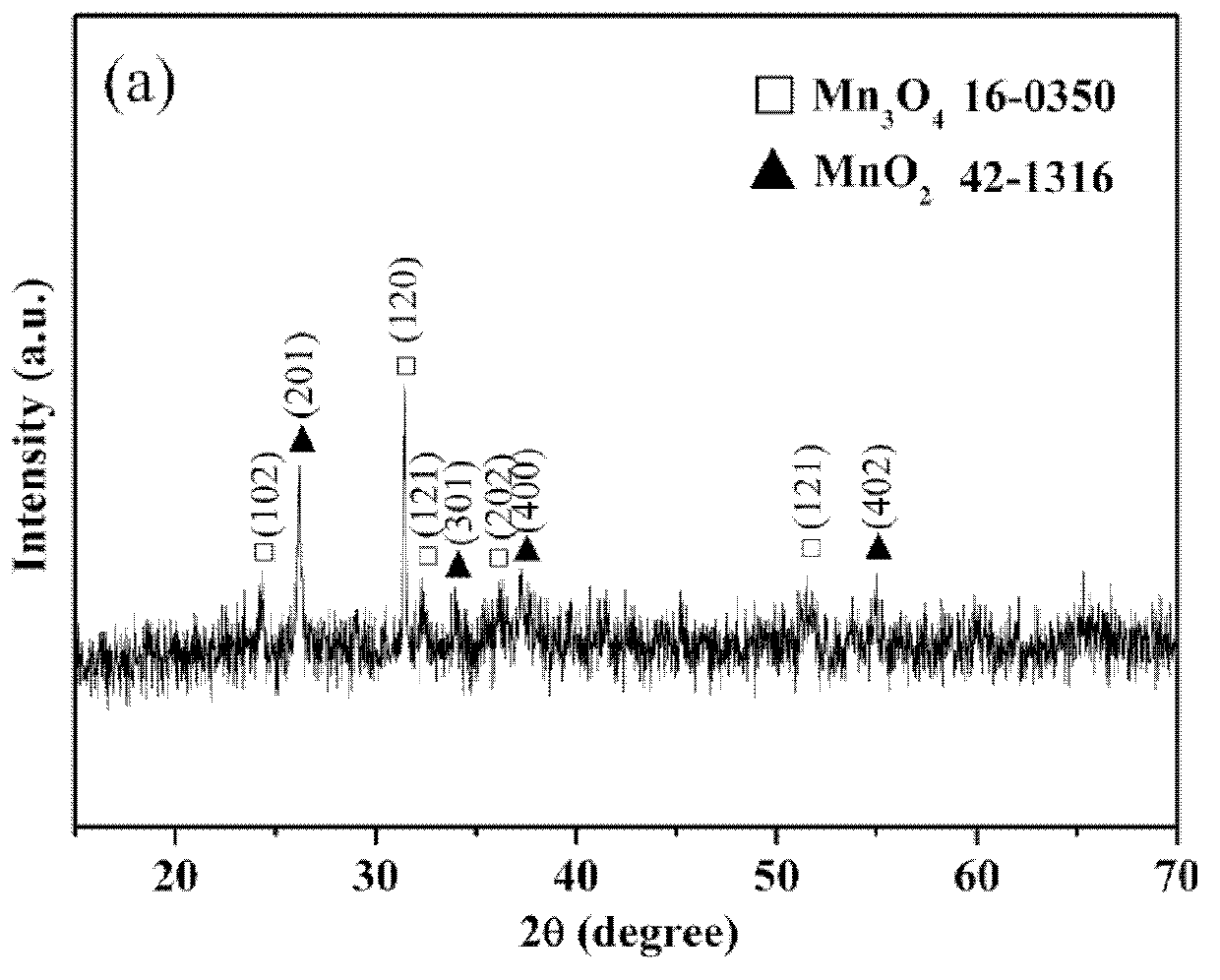

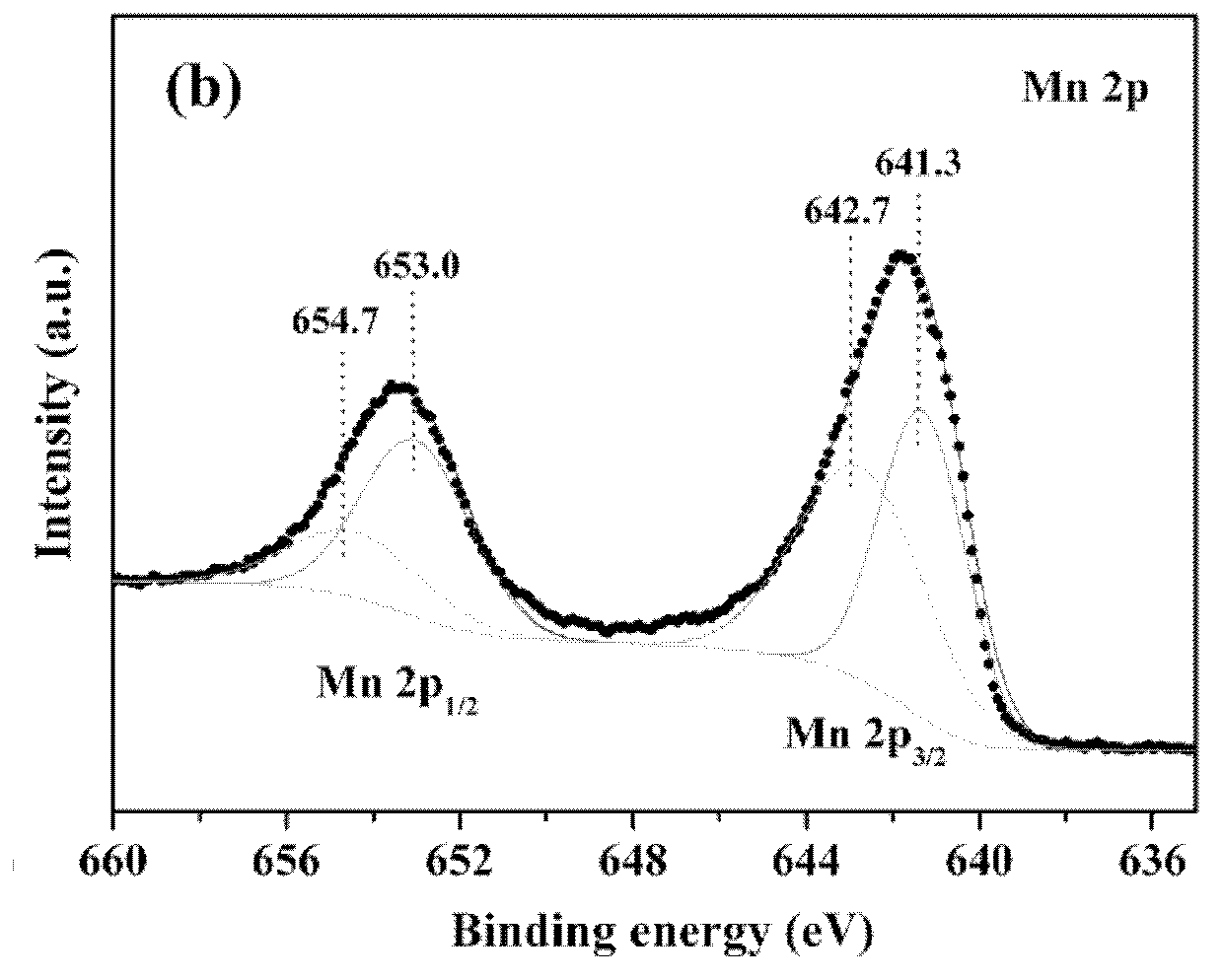

Mn3O4-MnO2 nano rod composite oxide as well as preparation method and application of Mn3O4-MnO2 nano rod composite oxide

ActiveCN104209119AControl reaction temperatureNo pollution in the processMaterial nanotechnologyManganese oxides/hydroxidesCatalytic oxidationPollution

The invention provides a Mn3O4-MnO2 nano rod composite oxide as well as a preparation method and application of Mn3O4-MnO2 nano rod composite oxide. The preparation method comprises the following steps: adding potassium permanganate, glucose and sodium chloride into de-ionized water, wherein the ratio of substance amounts is 1 to (0.1-0.3) to (0-0.4) and the concentration of potassium permanganate in the de-ionized water is 12mol / L-18mol / L; agitating uniformly and sealing; carrying out heating reaction a temperature of 110-125 DEG C for 6-24 hours; and washing a product obtained by the reaction with distilled water, carrying out centrifugal separation, and drying in vacuum to obtain the Mn3O4-MnO2 nano rod composite oxide. The prepared product is of a rod-shaped structure and has the length of 5-50 microns and the diameter of 30-120nm. The prepared Mn3O4-MnO2 nano rod composite oxide has an important effect in the aspect of catalytic oxidation. Compared with the prior art, the process is very simple and controllable and multi-step operation is not needed; any surfactant, any template agent and any acid-base reagent are not introduced, so that no pollution and no emission are caused; and synthesis conditions are very moderate and the production cost is low.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

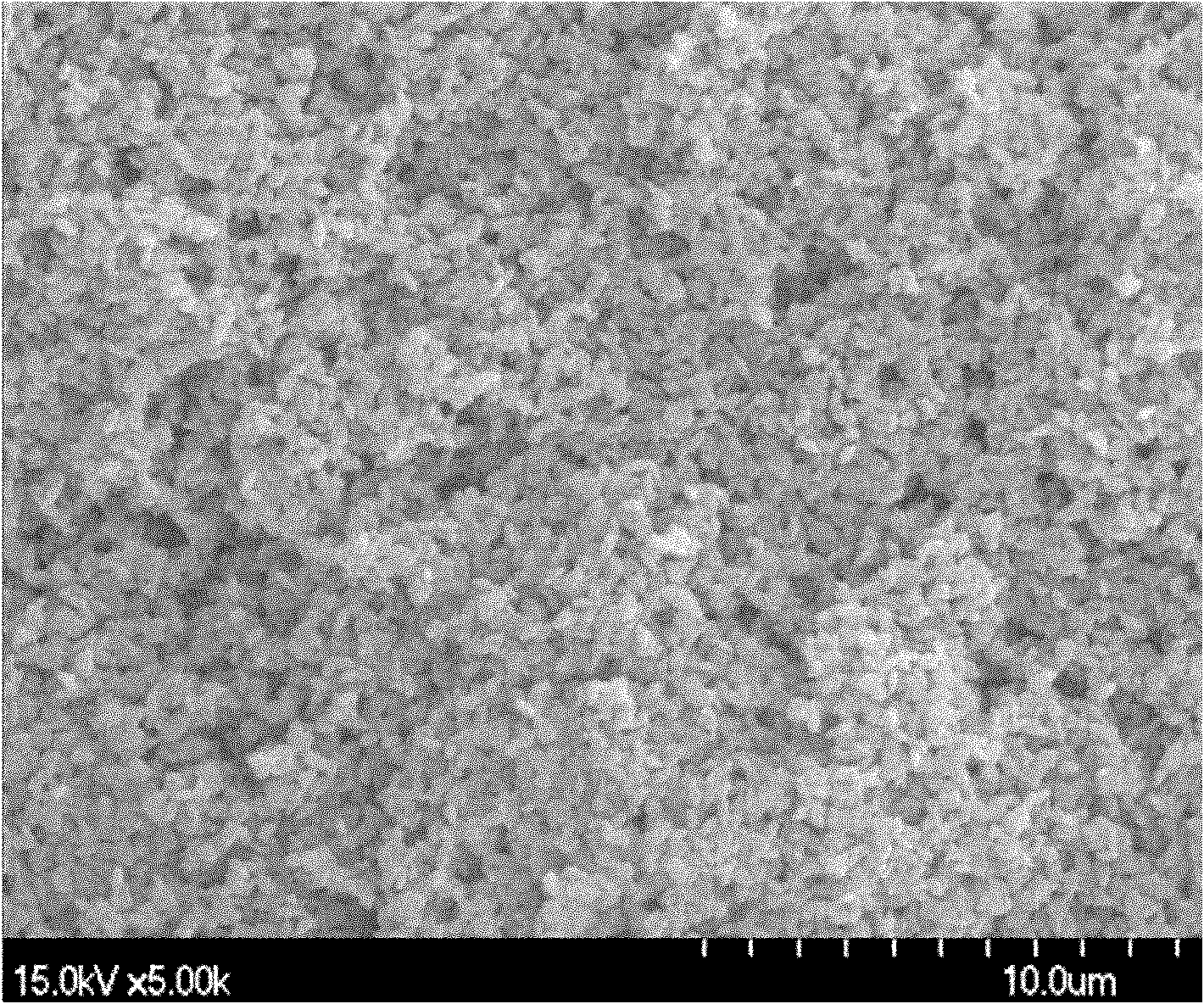

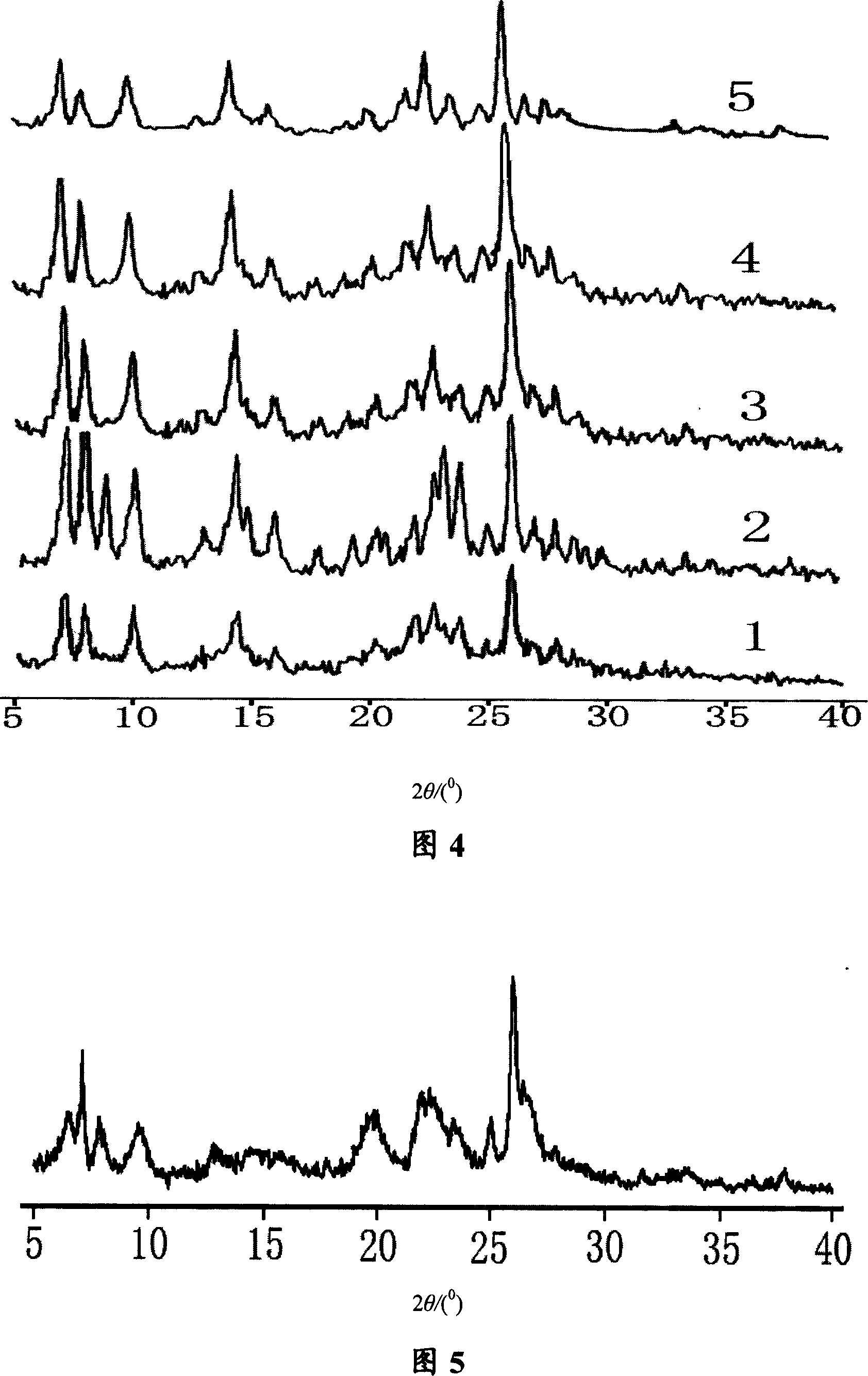

Method for synthesizing zeolite on cordierite carrier

InactiveCN101574664AIncrease the external specific surfaceGood for load growthMolecular sieve catalystsDispersed particle separationCordieriteHigh pressure

The invention provides a method for in-situ synthesis of zeolite on a cordierite carrier, which comprises the following steps: performing acidizing on cordierite by acid; processing the cordierite by alkali; and synthesizing in MCM-22 synthetic fluid at high temperature and high pressure. The method of the invention performs combined treatment on the cordierite by the acid and the alkali, not only can increase the external surface area of the cordierite, but also can form a great deal of -OH in the zeolite synthetic fluid, contributes to MCM-22 load synthesis, and has simplicity, easy grasp and easy control of synthetic conditions; and the obtained loaded zeolite has firm combination.

Owner:BEIJING UNIV OF CHEM TECH

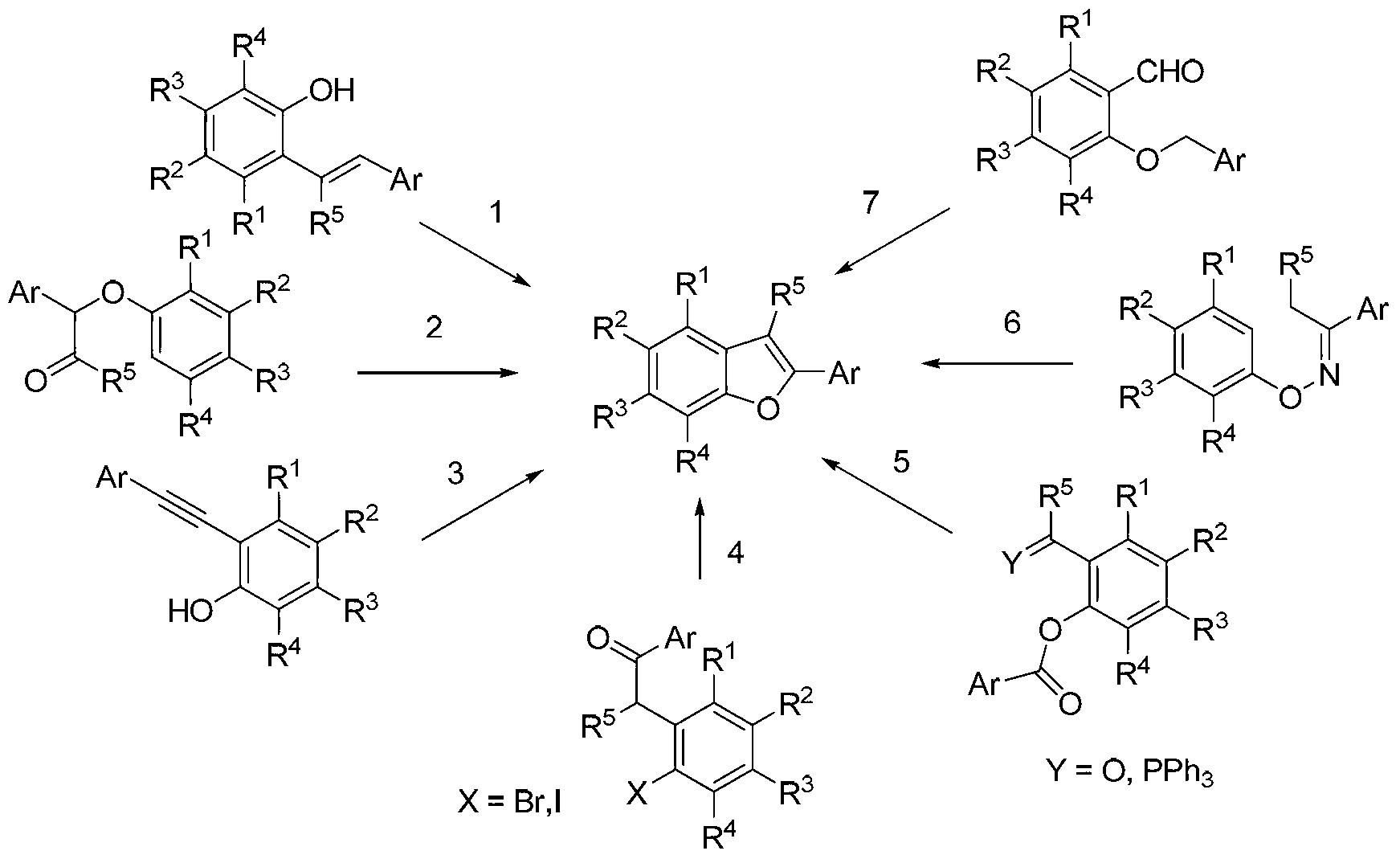

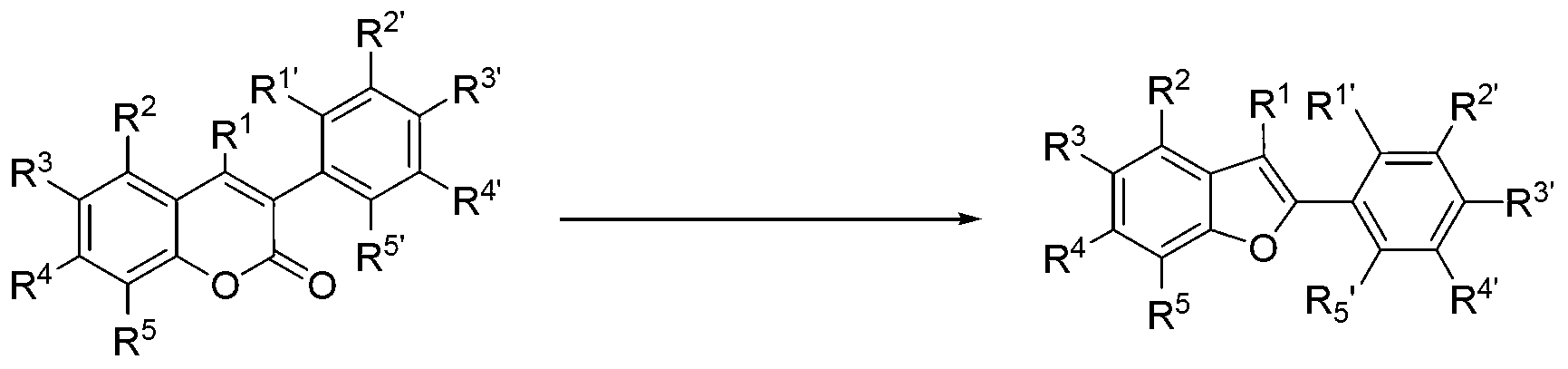

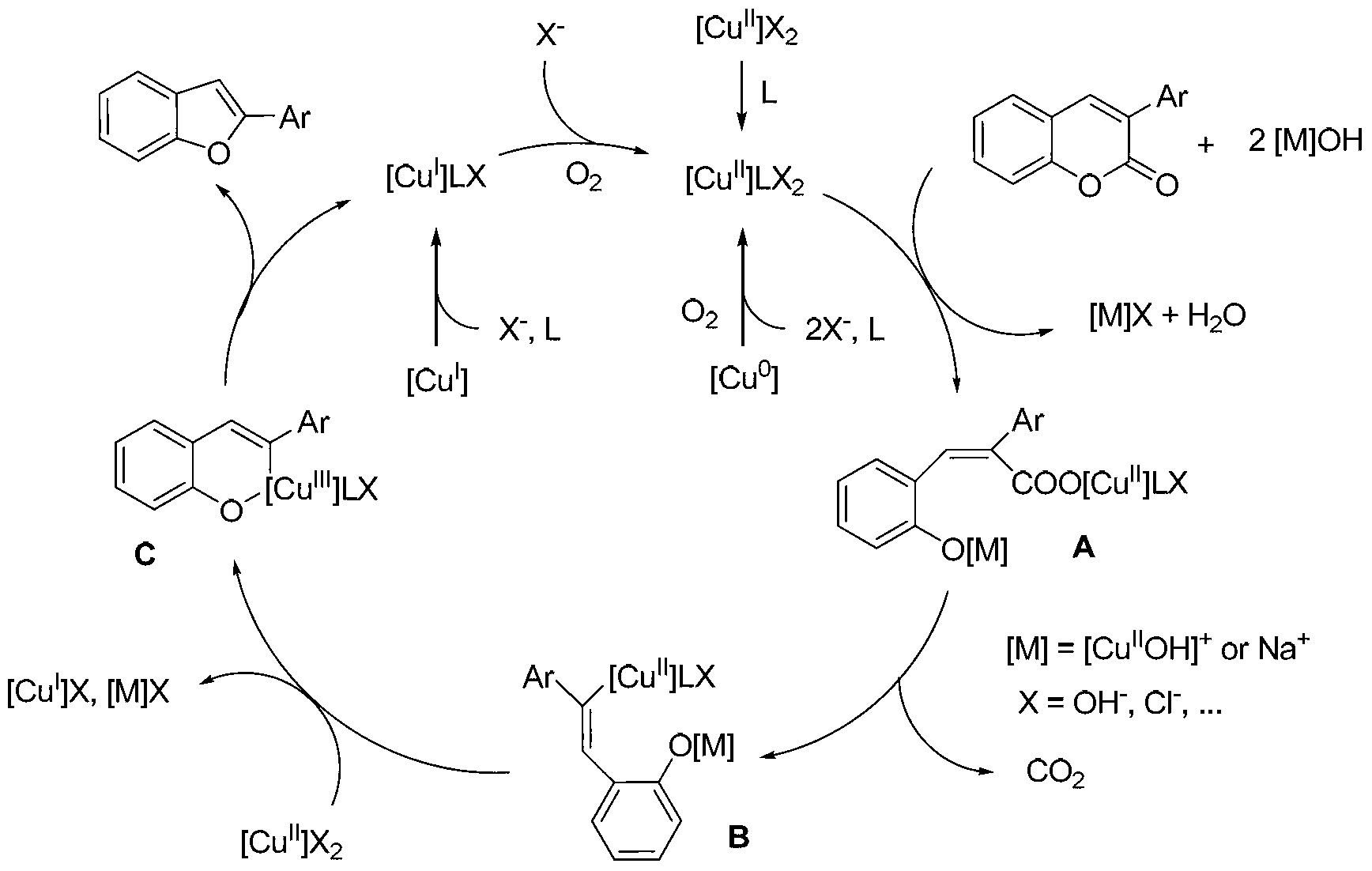

Synthesis method for 2-arylbenzofuran and derivative thereof

The invention discloses a synthesis method for 2-arylbenzofuran and a derivative thereof, aims at various degrees of technical defects existing in the conventional synthesis method for 2-arylbenzofuran and the derivative thereof, and provides a method for synthesizing 2-arylbenzofuran and the derivative thereof by taking 3-arylcumarin and a derivative of 3-arylcumarin as the raw materials. The method utilizes carbon-oxygen coupling based on metal catalysis in molecules to achieve synthesis of 2-arylbenzofuran and the derivative thereof by taking 3-arylcumarin and the derivative of 3-arylcumarin as the raw materials. A basic reaction system comprises the raw materials, an alkaline reactant, a copper catalyst, a ligand and a reaction medium, is stirred and heated to a temperature higher than 190 DEG C under an aerobic condition, maintained for 24 hours or more to prepare a reaction liquid, and is subjected to extraction and coarse product purification to prepare a final product. Optimization conditions can adopt two technical means including sectional heating and post-adding of the catalyst. The synthesis method has the advantages that the synthesis raw materials are convenient to obtain, substrate applicability is good, the synthesis technology is simple, the synthesis cost is low, and the synthesis method is particularly suitable for large-scale industrial production.

Owner:CHENGDU INST OF BIOLOGY CHINESE ACAD OF S

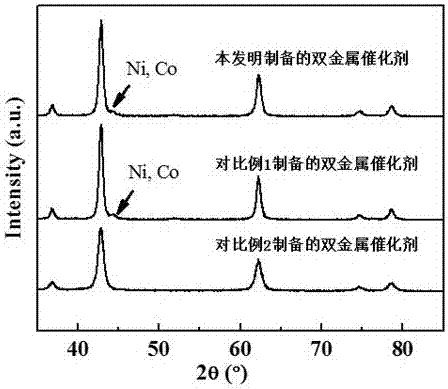

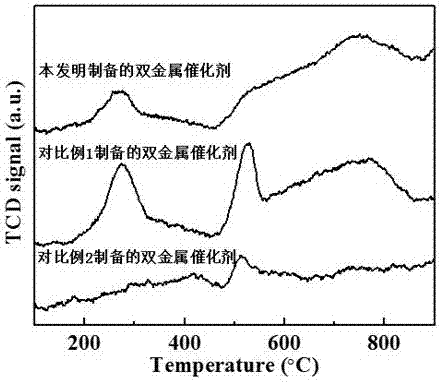

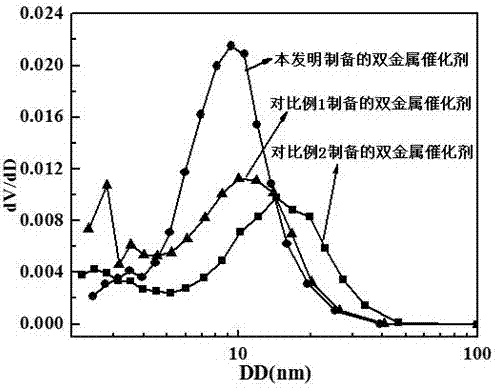

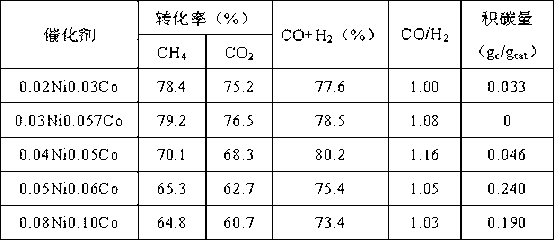

Supported bimetallic reforming catalyst and preparation method and application thereof

ActiveCN106902829AHigh catalytic activityImprove anti-coking performanceHydrogenHydrogen/synthetic gas productionDeposition precipitationFiltration

The invention discloses a supported bimetallic reforming catalyst and a preparation method and an application thereof. The catalyst is characterized in that active components metallic nickel and metallic cobalt are supported on an oxide carrier, wherein the mass ratio of the oxide carrier to metallic nickel to metallic cobalt is 1: 0.01-0.1: 0.01-0.1; and the oxide carrier is one of magnesium oxide, alumina, silica, cerium oxide and zirconia. The preparation method is characterized in that a deposition-precipitation method is employed, a precipitating agent is slowly added in a solution of the oxide carrier, metallic nickel and metallic cobalt, a reaction is carried out, and steps of pumping filtration, washing, drying and calcining are carried out to obtain the catalyst. The catalyst solves the problems of poor anti-carbon formation capability, complex preparation method and high catalyst cost in the prior art. The whole preparation has the advantages of simple process, convenient operation, and easy control of the synthesis condition, and the prepared catalyst has high catalytic activity and anti-carbon formation performance.

Owner:TAIYUAN UNIV OF TECH

Hydrogel applicable to cell adhesion and preparation method of hydrogel

InactiveCN105363070ALower synthesis costSynthesis conditions are easy to controlProsthesisSpecific immunityNon specific

The invention discloses hydrogel applicable to cell adhesion and a preparation method of the hydrogel. The hydrogel is formed by Ac-IIISLGK-NH2 and L-Glutamine (L-Gln) under the action of an enzymatic reaction, wherein the N-terminal of the Ac-IIISLGK-NH2 is acetylated, the C-terminal of the Ac-IIISLGK-NH2 is aminated, the mole ratio of the Ac-IIISLGK-NH2 to the L-Gln is 1:1, reaction temperature is 37-40 DEG C, and reaction time is 24-48 hours. The hydrogel has the advantages that the prepared hydrogel can allow cells to be well adhered to cell surfaces, is low in toxicity and good in biocompatibility, does not cause the non-specific immunity reaction of lymphocyte, is ideal nano tissue engineering material and is significant to human life health.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

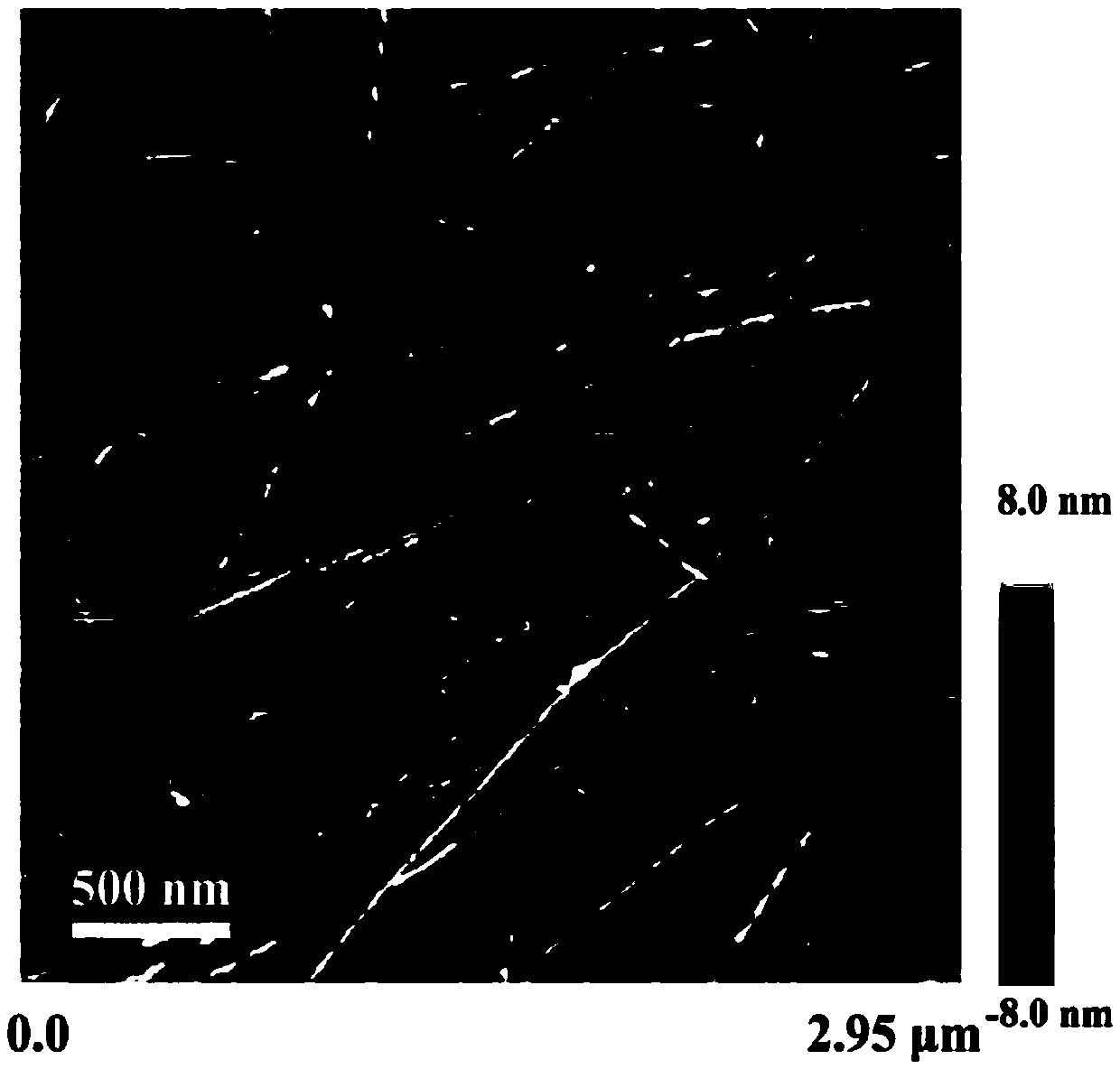

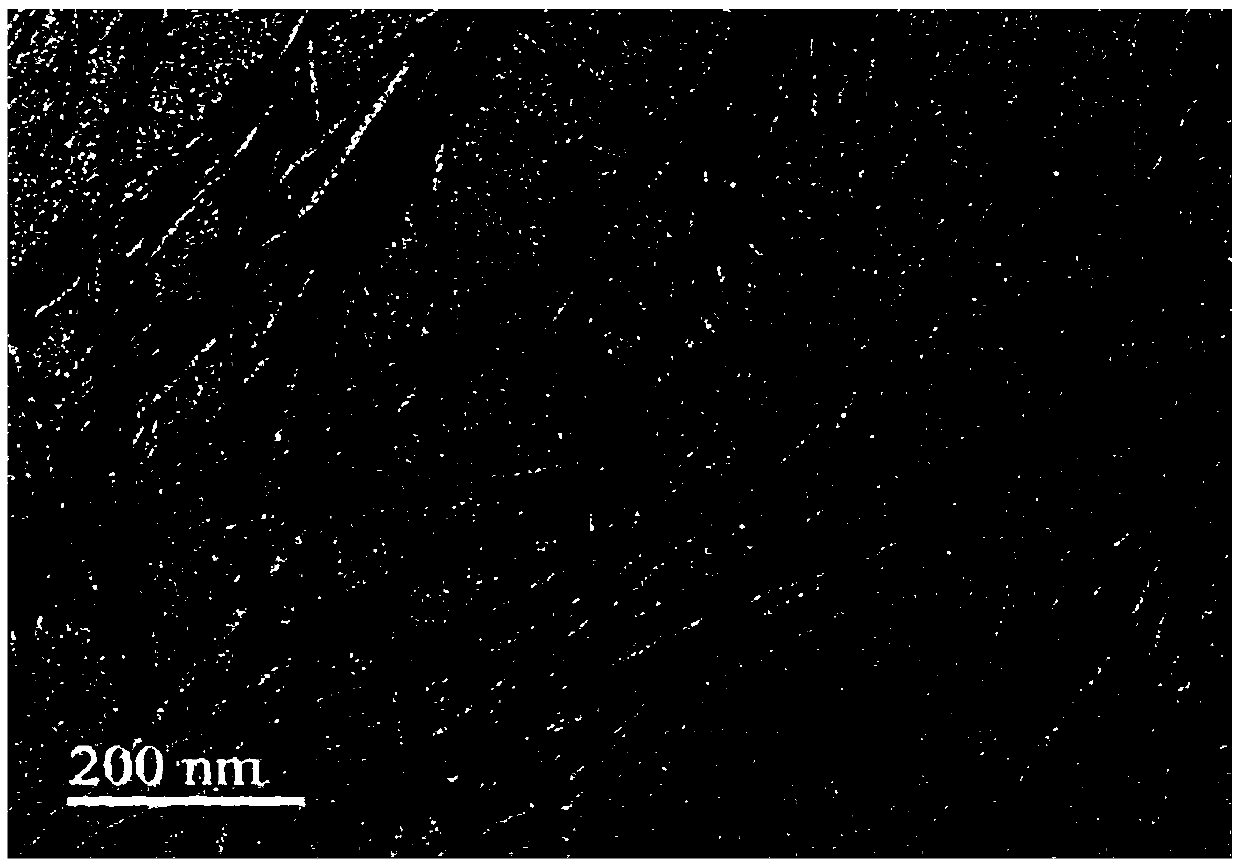

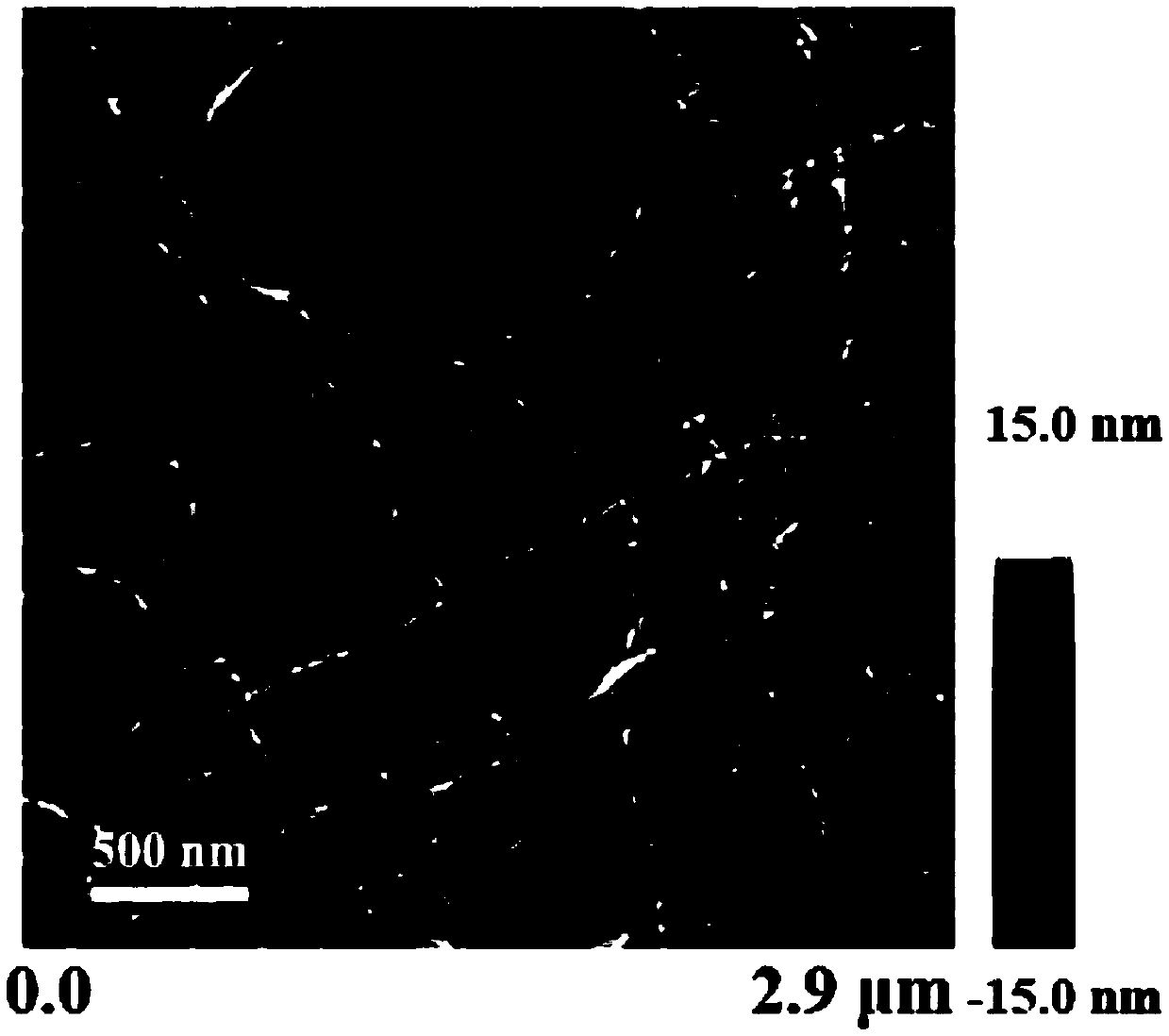

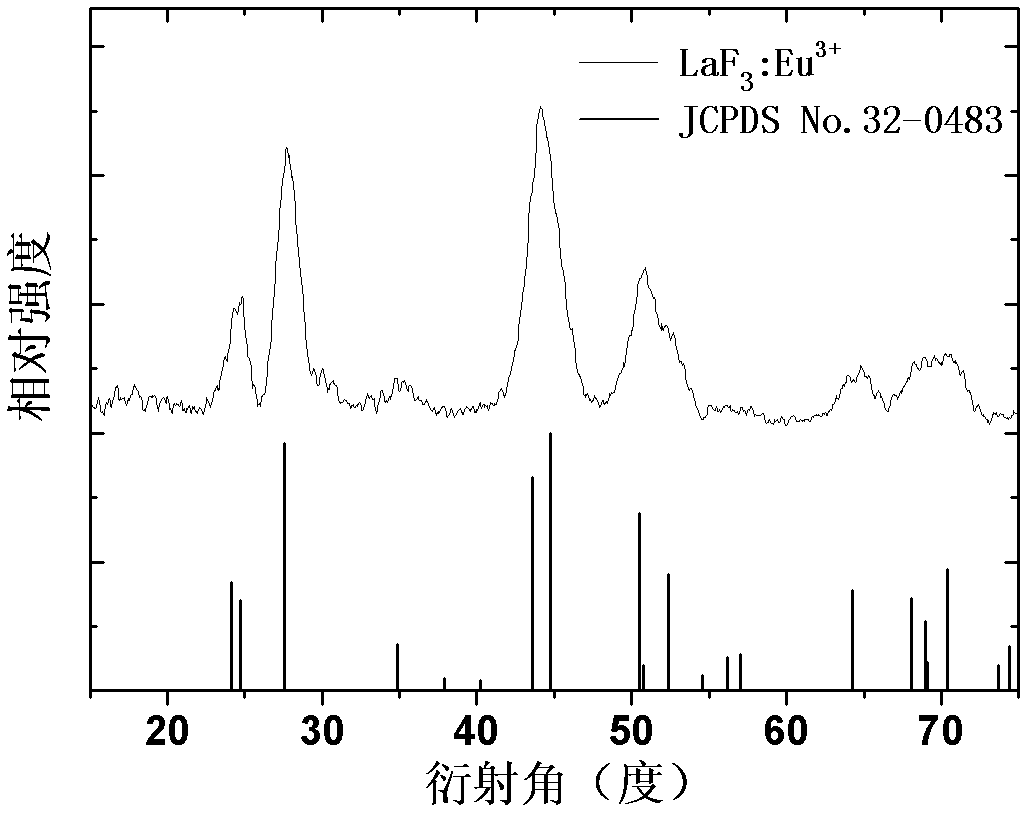

Method for synthesizing amino functionalized rare earth-doped lanthanum fluoride nano fluorescent marker material

InactiveCN102676171AGood water solubilitySimple preparation equipmentFluorescence/phosphorescenceLuminescent compositionsLanthanum fluorideActive agent

The invention relates to a method for synthesizing an amino functionalized rare earth-doped lanthanum fluoride nano fluorescent marker material, which comprises the steps of: with phosphorylethanolamine as a surface active agent, mixing sodium fluoride, lanthanum nitrate and rare earth nitrate in distilled water, carrying out heat preservation at the temperature of 30-90 DEG C, and stirring for a period of time, washing and drying to obtain the aminated rare earth-doped lanthanum fluoride nanocrystalline with the component of xLn<3+>-(1-x) LaF3, wherein Ln<3+>=Ce<3+>, Yb<3+>, Er<3+>, Tm<3+>, Ho<3+>, Eu<3+>, Gd<3+>, Tb<3+>, Dy<3+>, Sm<3+>, Nd<3+> and Pr<3+>, and x=0-50mol%. The rare earth-doped LaF3 nano fluorescent marker material prepared by the method has the advantages that the size of nanoparticles can be controlled to be about 5nm, water solubility is good and the surface amino can be used to realize the connection with biomolecule. Furthermore, different rare earth ions can be doped into the nanoparticles, so that the specific fluorescence emission can be realized so that the biological connection can be detected sensitively; and the nano fluorescent marker material prepared by the method has the potential in application in the biological marking field.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

C-SiC catalyst, its preparation and its application thereof

ActiveCN103846101ARaw materials are cheap and easy to getSuitable for industrial applicationsPhysical/chemical process catalystsPreparation by halogen halide additionHigh activityPollution

The invention discloses a novel non-metal catalyst used for preparing vinyl chloride by an acetylene method, a preparation method and an application thereof. The catalyst is a SiC-based composite material, by controlling the growth condition and post-treatment condition, a thin C layer with different morphology and chemical composition is grown on SiC, acetylene and hydrogen chloride are directly catalyzed to react for generating vinyl chloride, and high activity, stability and vinyl chloride selectivity of the catalyst can be presented. The C-SiC catalyst has the advantages that the nonmetal catalysis of vinyl chloride by the acetylene method can be realized, high pollution problem of a mercuric chloride catalyst on industry can be solved, usage of precious metal even a metal catalyst can be avoided, and the C-SiC catalyst has high environment benefit and economic value.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

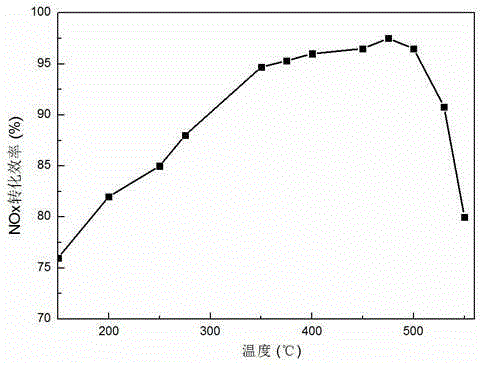

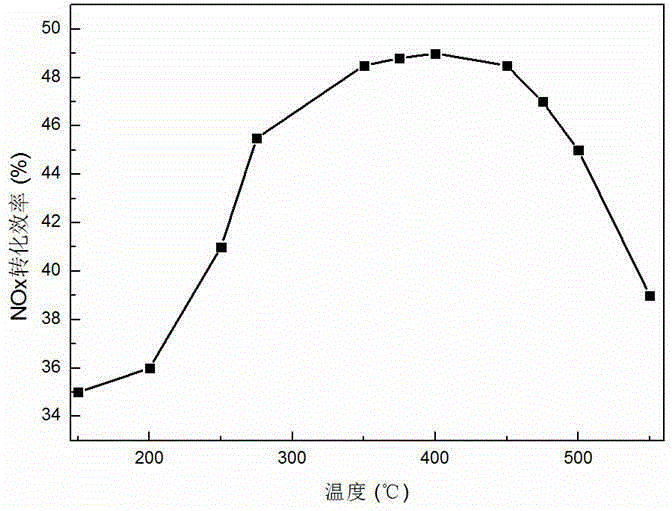

Composite Fe-based molecular sieve based catalyst and preparing method thereof

ActiveCN105289711AHigh load rateHigh activityMolecular sieve catalystsDispersed particle separationMolecular sievePtru catalyst

The invention relates to a composite Fe-based molecular sieve based catalyst. The catalyst is characterized by being prepared from, by mass, 18-22 parts of Fe active components, 2.2-6 parts of active component auxiliaries, 24-30 parts of deionized water, 18-24 parts of active component onophore, 22-26 parts of molecular sieve carriers and 3-5.4 parts of dispersing agents. The load rate of the active components is high, so SCR reactivity is remarkably improved, and the catalyst has higher actual application value; the preparation flow of the catalyst is simplified, the synthesis condition is easy to control, and the catalyst is easy to apply in an industrialized mode.

Owner:CHINA FIRST AUTOMOBILE

Method for preparing high-molecular-weight conducting polyaniline material

The invention discloses a novel method for synthesizing high-molecular-weight conducting polyaniline, which comprises the following steps of: mixing p-phenylenediamine with an organic mutually-soluble system of a 1,4-dioxane-acetic acid / sodium acetate buffer solution and stirring at N2 atmosphere and the water bath of 40 DEG C till the mixture is completely dissolved; slowly adding Fe3O4 magneticnano particles and an initiator hydrogen peroxide solution, then continuously reacting for 12 hours; after a polymerized product precipitates, filtering, washing, reprecipitating, removing Fe3O4 magnetic nano particles by utilizing a strong magnet and filtering a suspension; dissolving sediments into DMF (Dimethyl Formamide); slowly dropwise adding into anhydrous ethanol so that a polymer is precipitated; and filtering and drying the sediments in vacuum to obtain the high-molecular-weight eigenstate black product conducting polyaniline. The method has the advantages of simple synthesis conditions, easiness in control and simple and convenient postprocessing processes, such as separation, purification, and the like; the magnetic nano particles are easy for magnetic separation; and the eigenstate conducting polyaniline has superhigh molecular weight, is easy to dissolve in a common organic solvent and has the characteristics of favorable oxidoreduction reversibility and heat stability.

Owner:SICHUAN AGRI UNIV

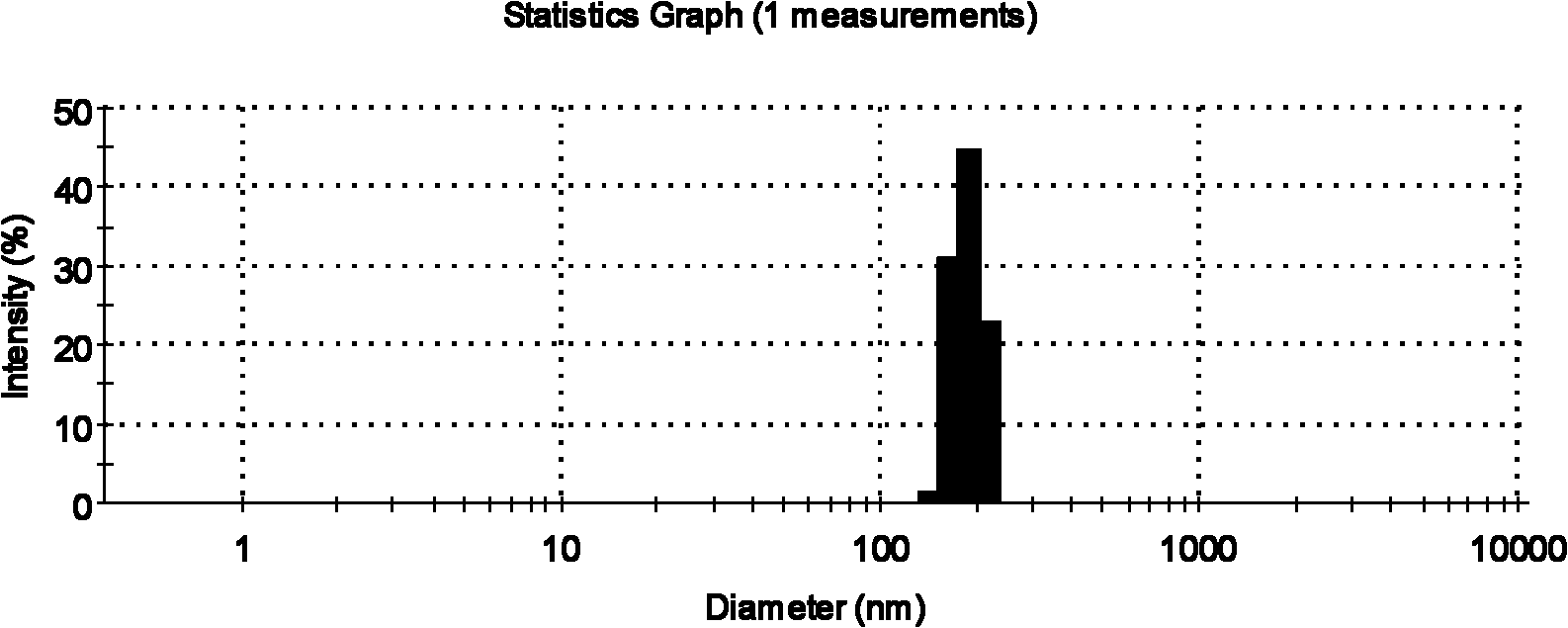

Magnetic ordered mesopore composite material, as well as preparation and application thereof

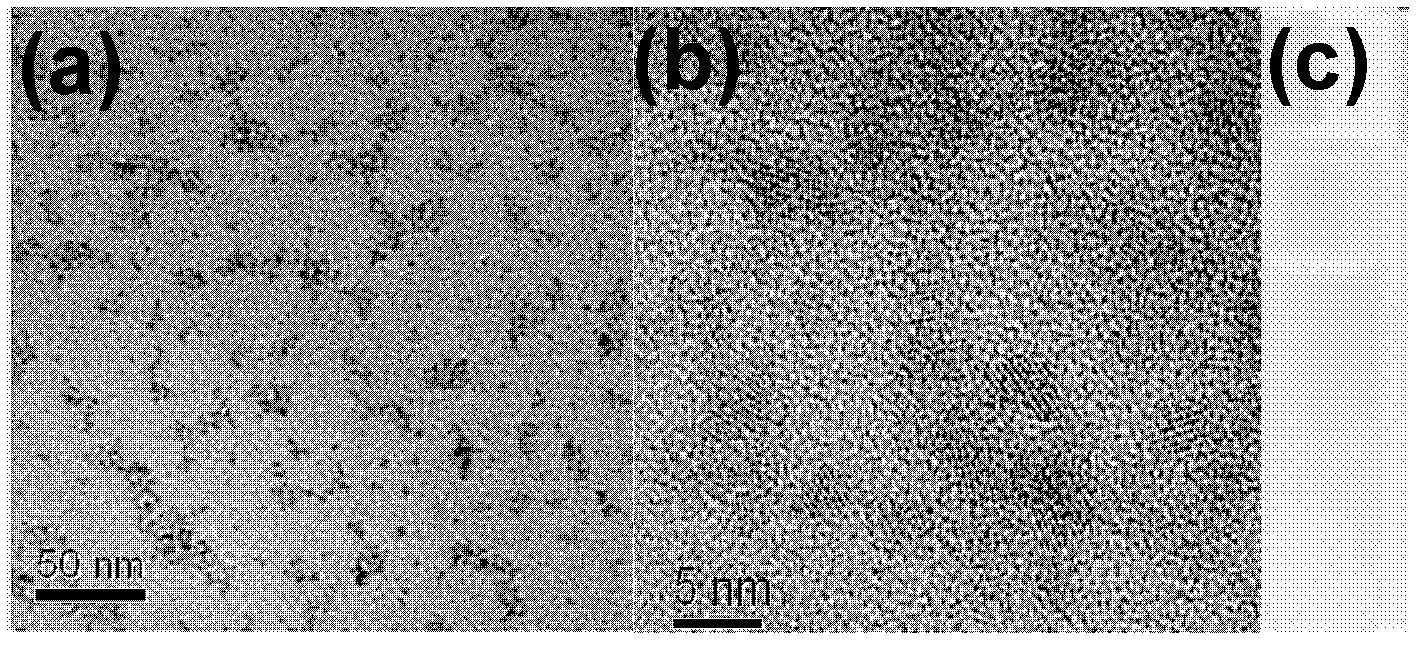

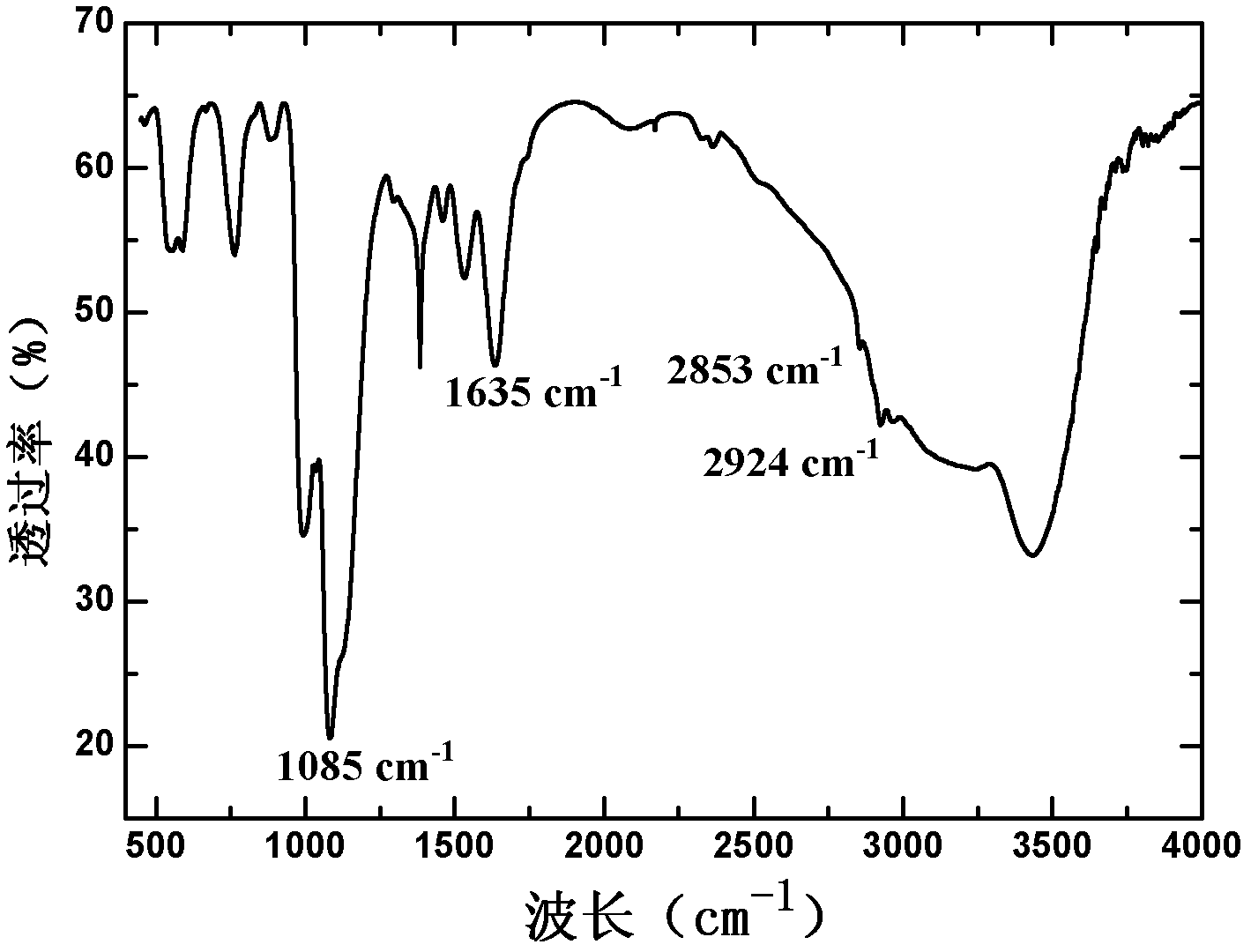

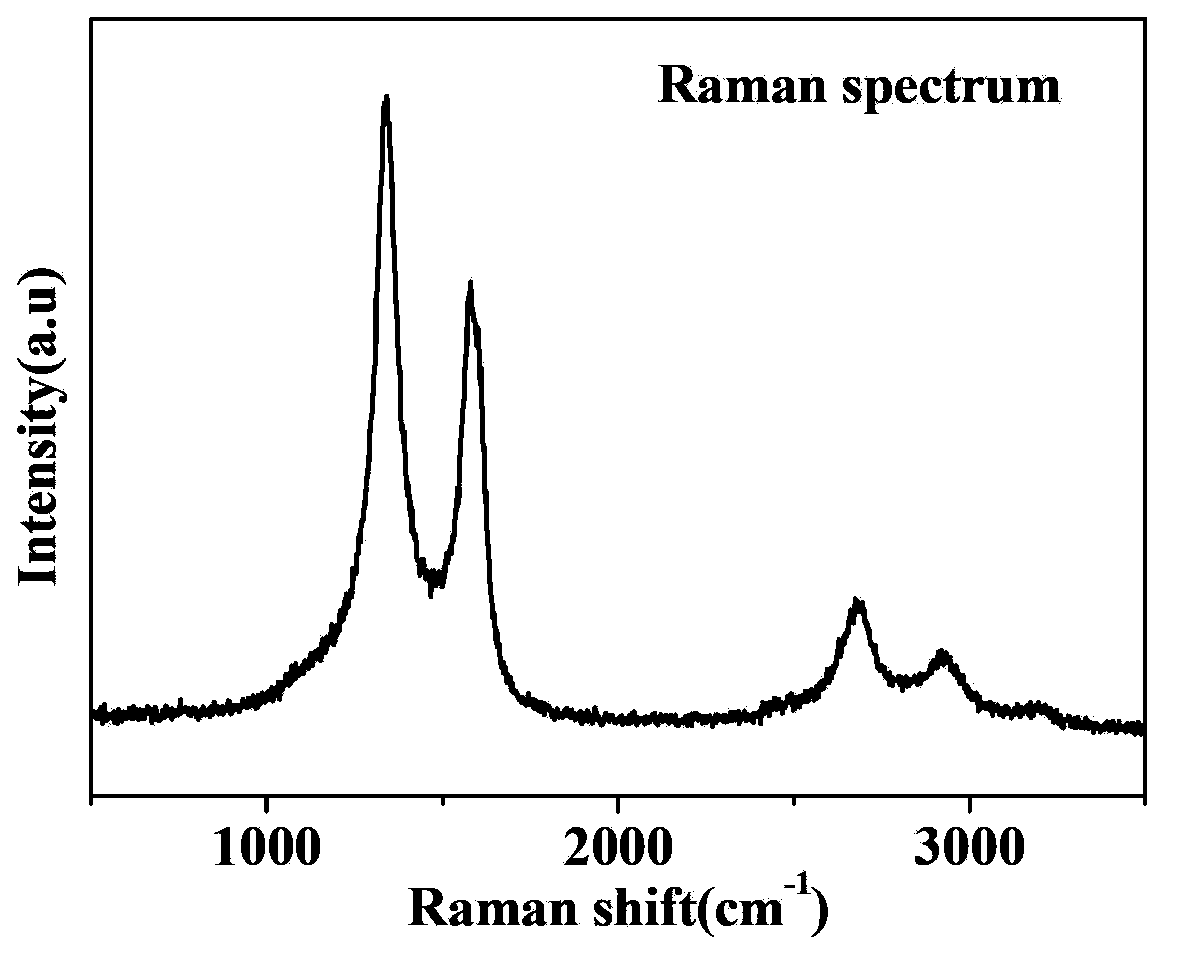

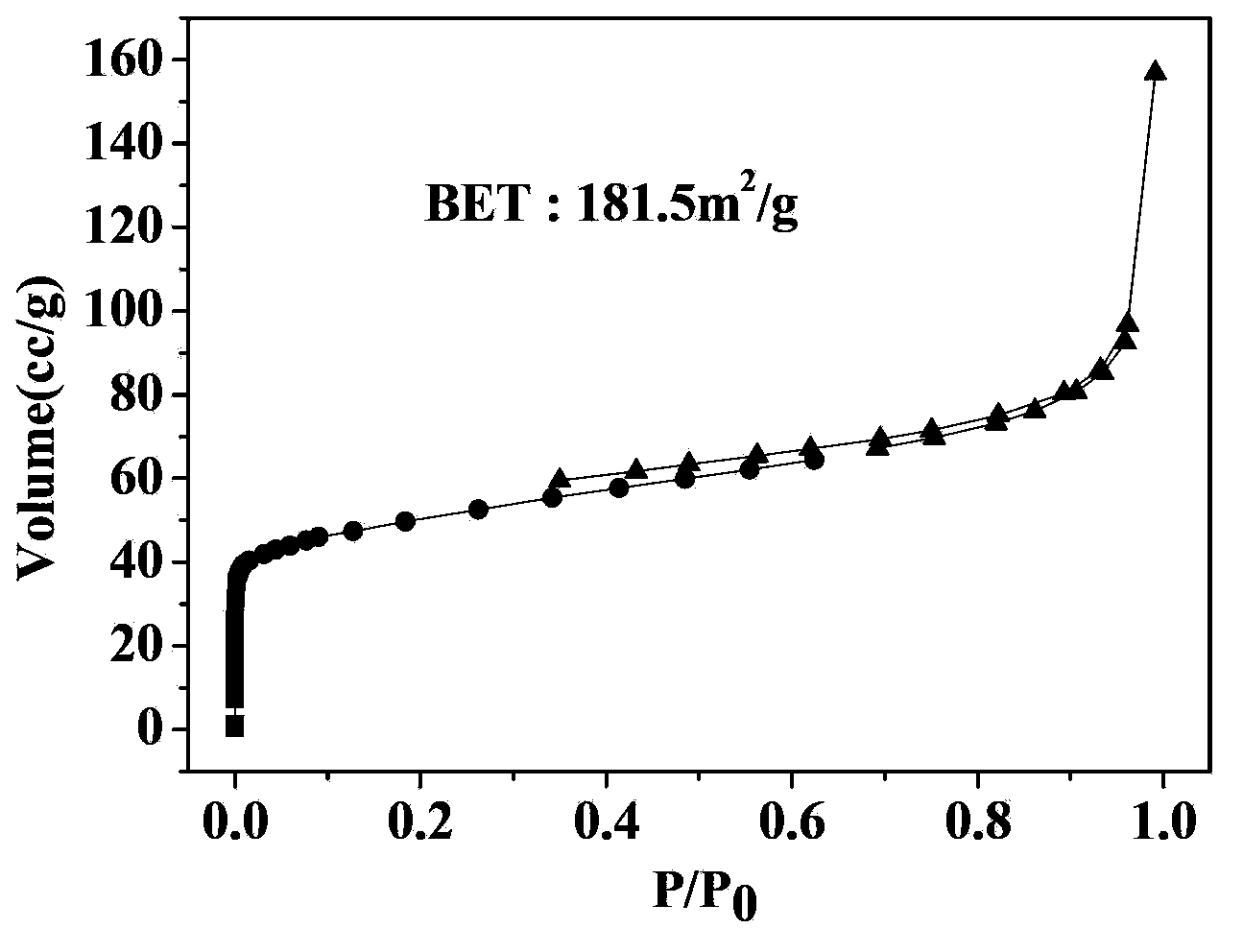

InactiveCN104353416AUniform sizeEasy to introduceOther chemical processesWater contaminantsMagnetite NanoparticlesMicroscopic scale

The invention discloses a magnetic ordered mesopore composite material, as well as a preparation and application thereof. The preparation method of the material comprises the following steps: modifying the surfaces of cobalt ferrite nano particles with a cationic surfactant, namely hexadecyl trimethyl ammonium bromide (CTAB), uniformly mixing the product with a segmented copolymer, namely EO130PO70EO130 (F108) and CTAB in an alcohol water system, and adding tetraethyl orthosilicate. The composite material is of a spherical microstructure with uniform size under the observation of a transmission electron microscope, and the magnetic nano particles are coated with the inside of MCM-48 silicon dioxide balls; the magnetic ordered mesopore composite material which is synthesized by the method has excellent magnetic property, maintains large specific surface area and pore volume, and can be applied to the field of adsorption, separation, catalysis, information storage, biological medicine, and the like.

Owner:NANJING UNIV OF SCI & TECH

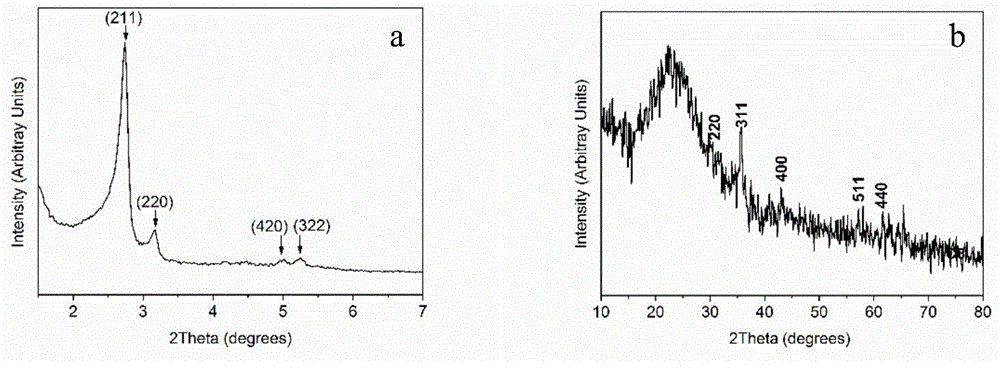

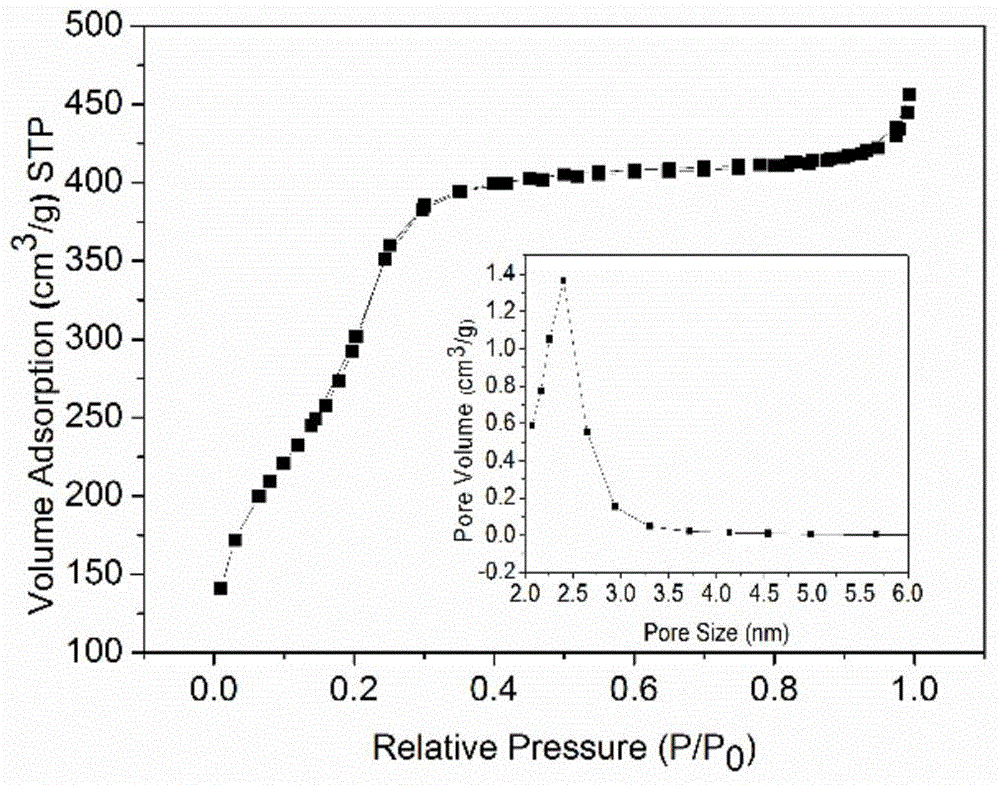

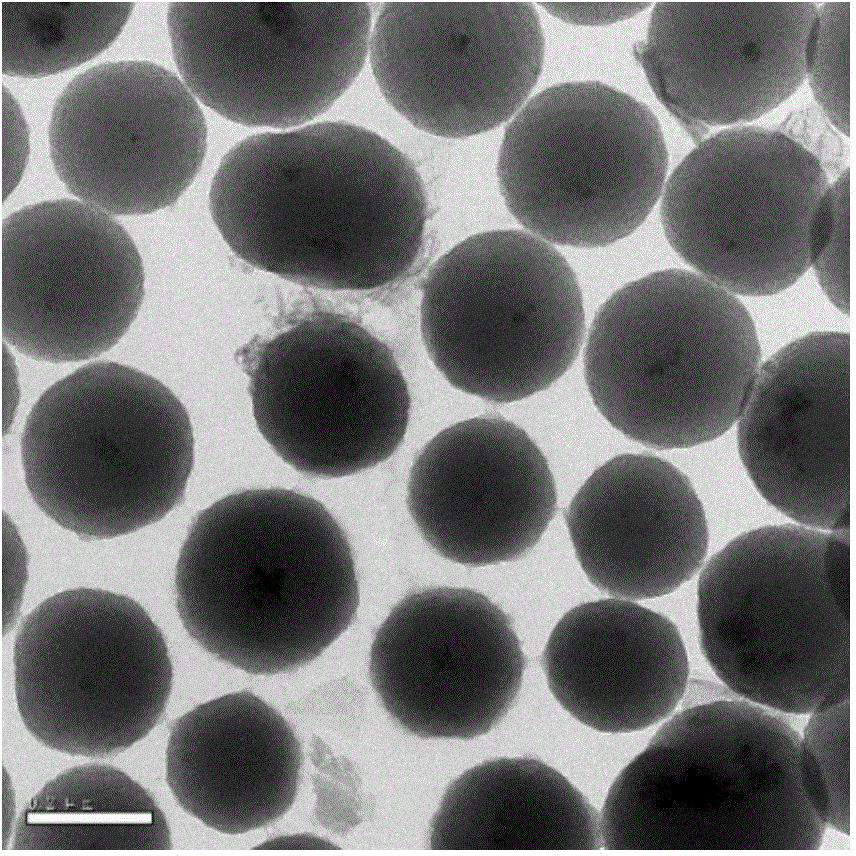

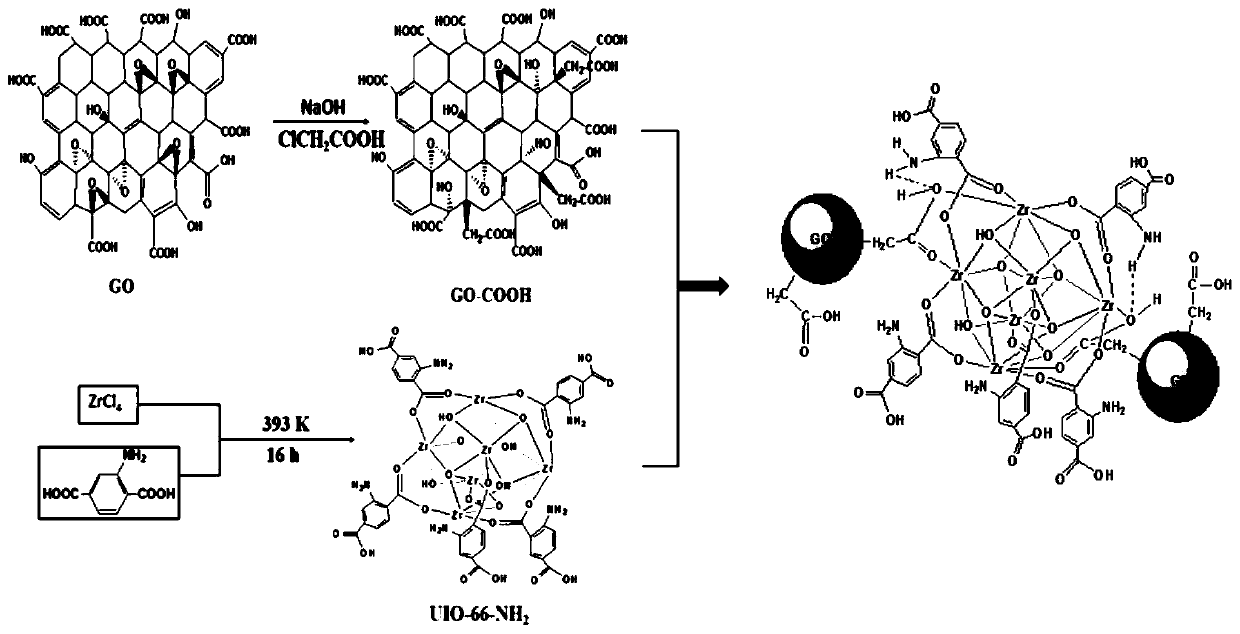

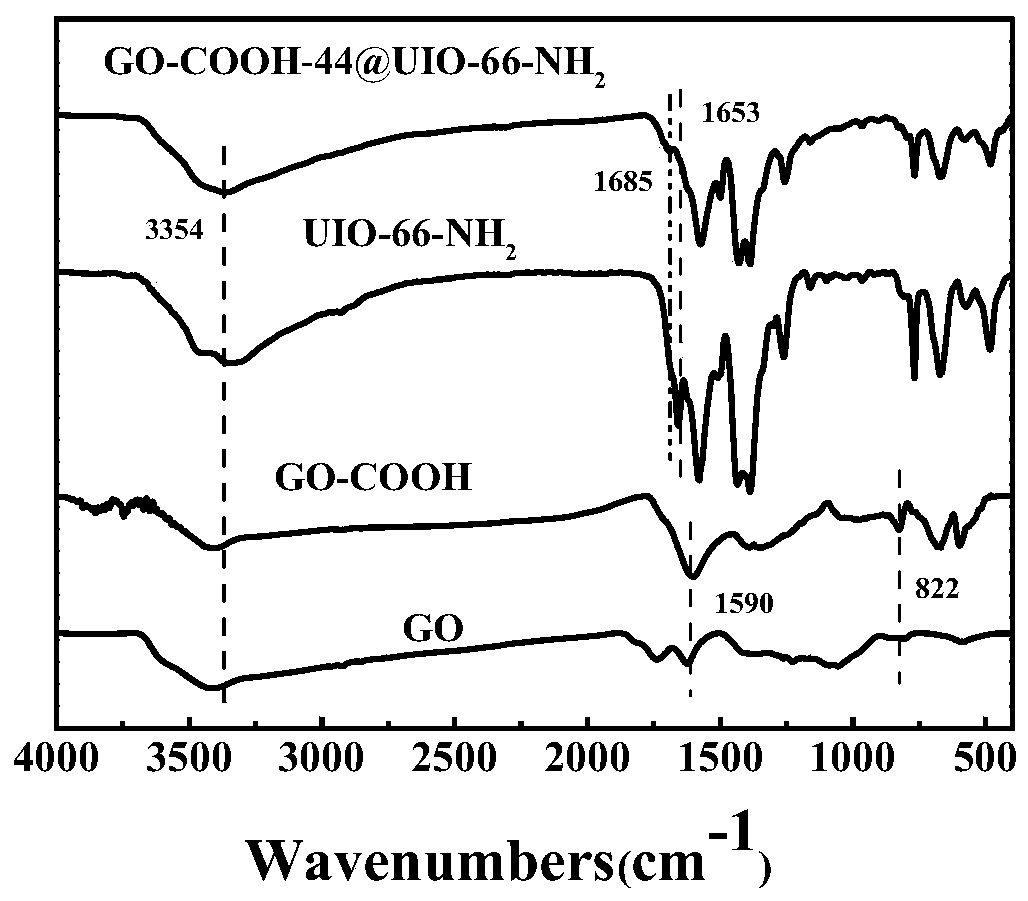

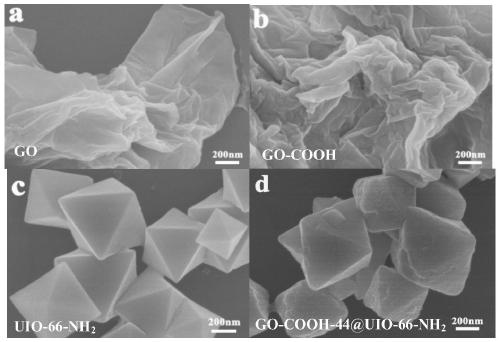

Carboxyl modified graphene oxide-metal organic framework composite material and preparation method and application thereof

InactiveCN111266091AImprove separation efficiencyImprove stabilityIon-exchange process apparatusOther chemical processesMetal-organic frameworkPhysical chemistry

The invention relates to the technical field of environment and chemical engineering, in particular to a carboxyl modified graphene oxide-metal organic framework composite material and a preparation method and application thereof. According to the composite material, chloroacetic acid modified graphene oxide GO-COOH-X and a metal organic framework UIO-66-NH2 are compounded, X represents the mass percentage of GO-COOH in the composite material, and X is equal to 9%, 17%, 23%, 33%, 44% and 50%. The metal organic framework is used as a matrix, and carboxyl modified graphene oxide is used as an adsorption functional group to synthesize the adsorbent. The adsorbent has the advantages of simple preparation method, strong regeneration capability, good stability, very high adsorption capacity on Nd (III), wide application range and practical applicability, and the maximum adsorption capacity can reach 146mg. g <-1 >.

Owner:LIAONING UNIVERSITY

Method for preparing orientation molecular sieve membrane

InactiveCN101654260AReduce adverse effectsSynthesis conditions are easy to controlPentasil aluminosilicate zeoliteAlcoholEvaporation

The invention provides a method for preparing an orientation molecular sieve membrane, comprising the following steps: removing alcohol in pro-glue solution in an evaporation way by improving the hydrolysis temperature of silicon source and germanium source and promoting the hydrolysis thereof; directly contact heating up the pro-glue solution and a carrier; crystallizing under self-generated pressure; and preparing b-axial orientation Ge-ZSM-5 molecular sieve membrane. The orientation molecular sieve membrane is even and compact, and has no defect of large holes, wherein molecular sieve membrane crystalloid is oriented along the b axis, thereby being good for the process of mass transferring. The method can obviously improve the capability of the synthetic Ge-ZSM-5 molecular sieve membrane, has high repetitiveness and high raw materials utilization factor, and is suitable for industrial production.

Owner:TAIYUAN UNIV OF TECH

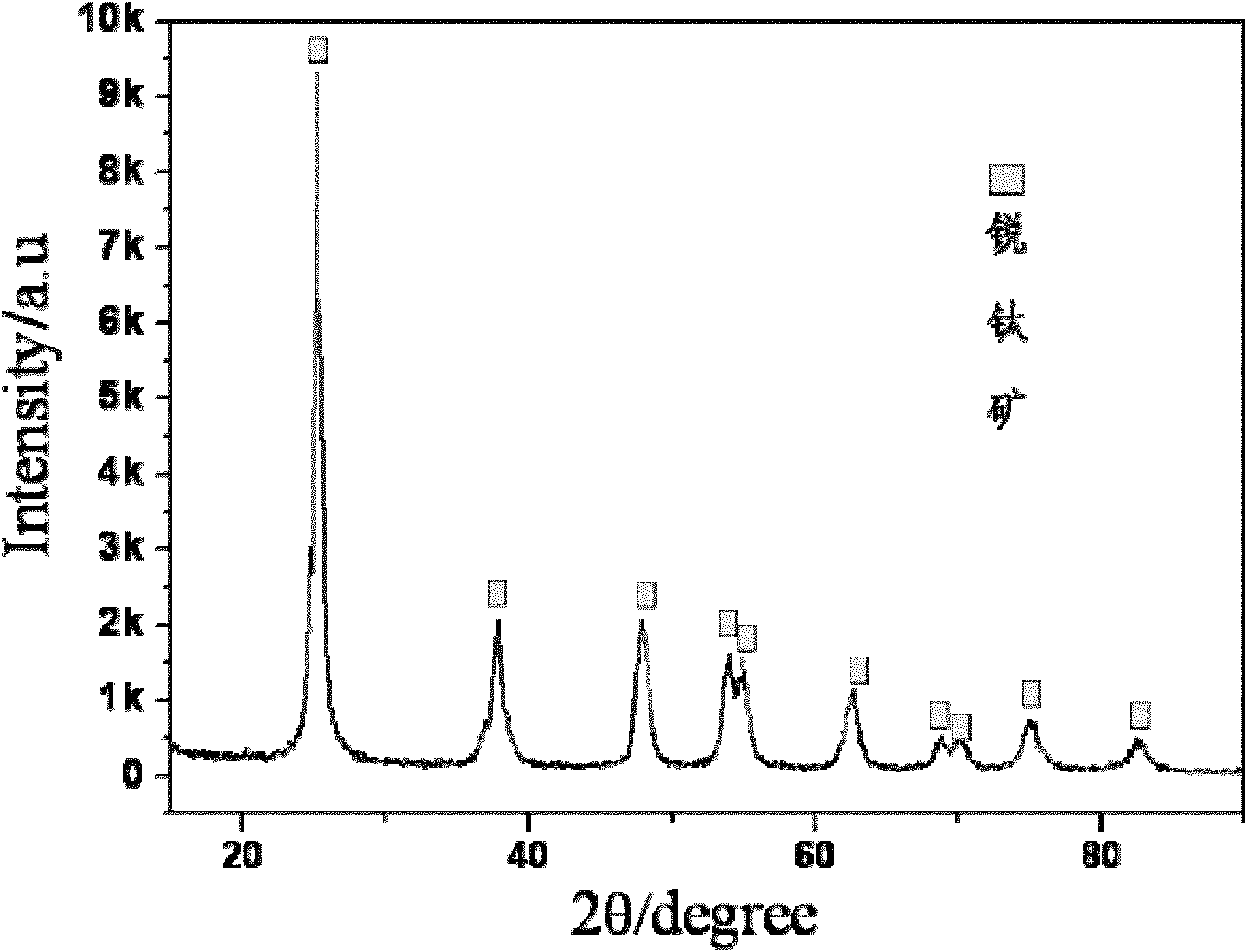

Preparation method of titanium dioxide powder with big particle diameter

The invention provides a preparation method of titanium dioxide powder with big particle diameters, which comprises the following steps of: firstly, adding 1mol / L of ammonia water into a titanyl sulfate solution with the titanium ion concentration of 1-4mol / L to obtain a white precipitate after the reaction is completed; then washing the white precipitate until no sulfate radical remains; then mixing the white precipitate with polyethylene glycol, an acid solution and hydrogen peroxide at the temperature of 30-80 DEG C to carry out peptizing reaction; then standing and aging for 12h at the temperature of 30-80 DEG C to obtain a titanium dioxide gel; and finally carrying out thermal treatment on the titanium dioxide gel for 18-24h at the temperature of 500-1,000 DEG C to obtain the titanium dioxide powder suitable for dye sensitization solar cell light scattering.

Owner:IRICO

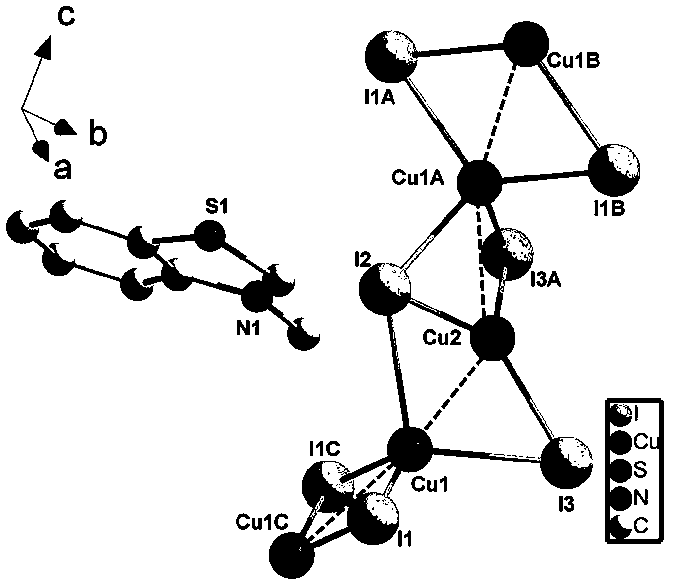

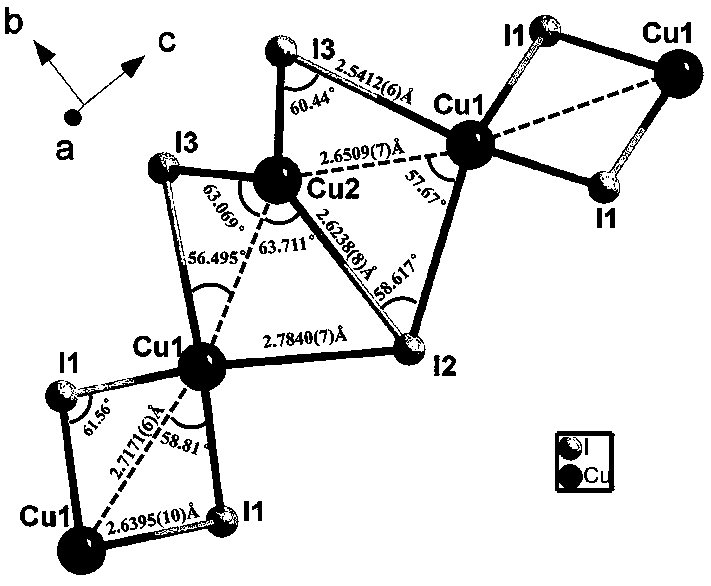

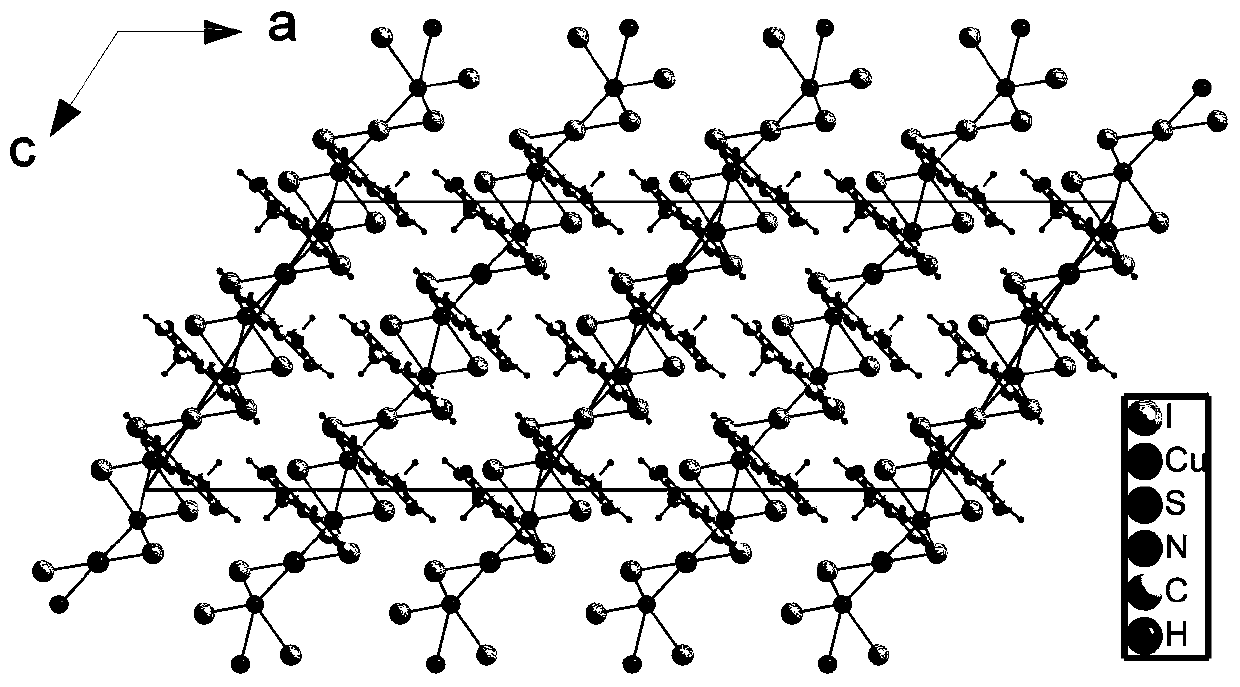

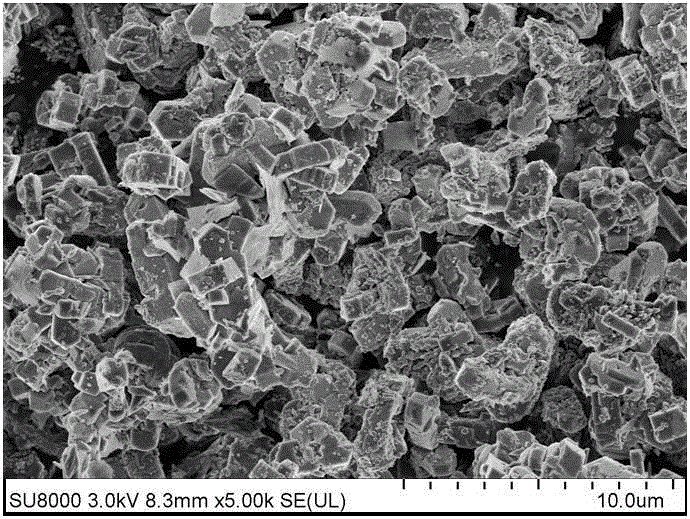

Copper iodine hybrid semiconductor material and photoelectric application thereof

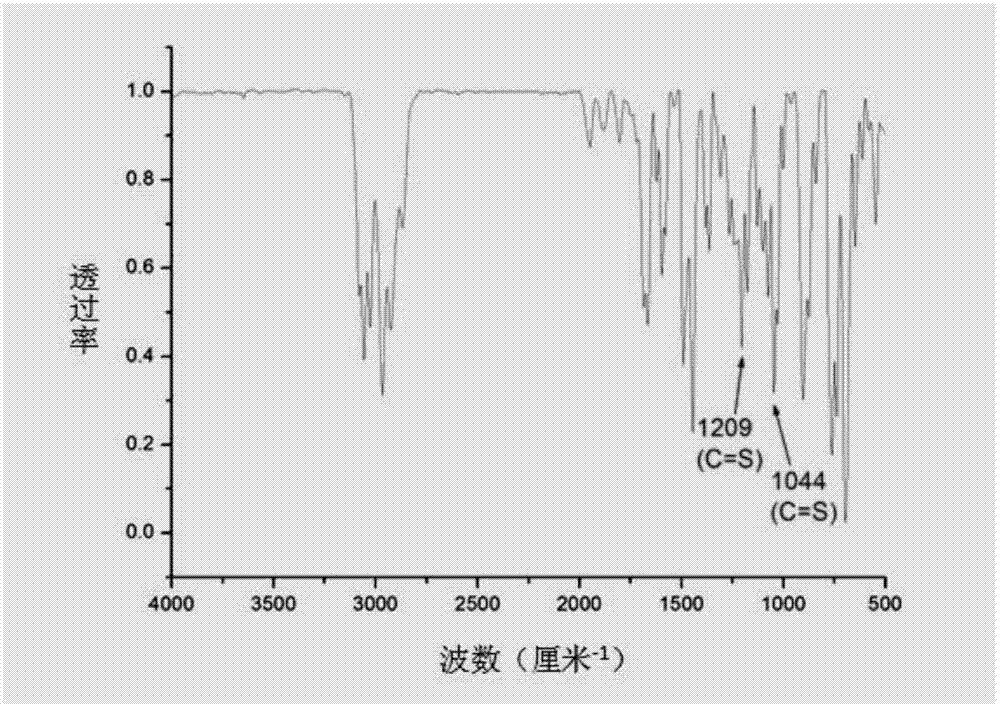

InactiveCN110054638ASynthesis conditions are simpleSynthesis conditions are easy to controlCopper organic compoundsSolid-state devicesSemiconductor materialsIodide

The invention discloses a copper iodine-based inorganic-organic hybrid semiconductor material and a preparation method and an application thereof. The structural formula of the hybrid semiconductor molecule is (Mebtz)2Cu3I5, wherein Mebtz is a methylated benzothiazole cation with a positive charge, and the Cu3I5 anion in the material is a one-dimensional anion chain formed by alternately connecting binuclear (Cu2I6) units and planar triangles (CuI3). By selecting cuprous iodide, benzothiazole, potassium iodide, methanol, acetonitrile and hydroiodic acid as reaction raw materials, a single crystal of the compound (Mebtz)2Cu3I5 is obtained under a solvothermal condition, which is used in the fields of photoelectric detection and solar cell materials.

Owner:UNIV OF JINAN

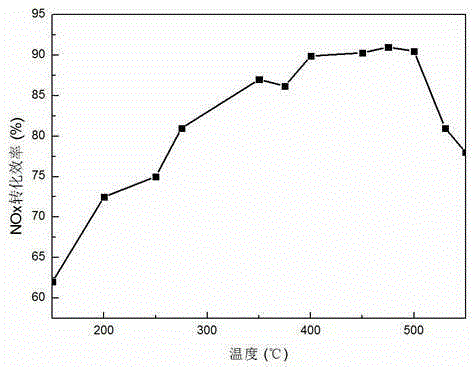

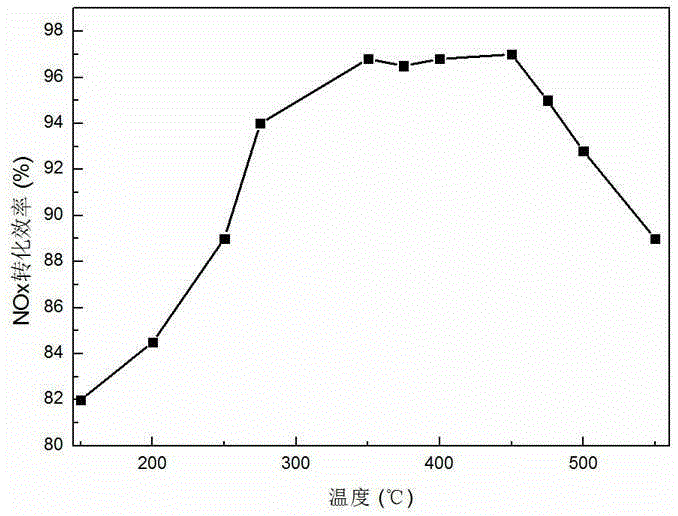

Composite copper-based molecular sieve catalyst and preparation method thereof

ActiveCN105396610AEasy to prepareSynthesis conditions are easy to controlMolecular sieve catalystsMolecular sievePtru catalyst

The invention relates to a composite copper-based molecular sieve catalyst which is characterized in that a hygrometric-state catalyst comprises the following components in parts by mass: 17-22 parts of a metal Cu main active component, 1.5-3.7 parts of a metal Cu active component assistant, 18-29 parts of deionized water, 12-15 parts of an active component guiding agent, 33-45 parts of a molecular sieve carrier and 0.9-1.9 parts of a dispersing agent. The catalyst is high in active component load rate, so that the reaction activity of SCR is obviously improved, the relatively high practical application value is realized, the catalysts preparation flow is simplified, synthesis conditions are easy to control and the industrialized application is easily realized.

Owner:CHINA FIRST AUTOMOBILE

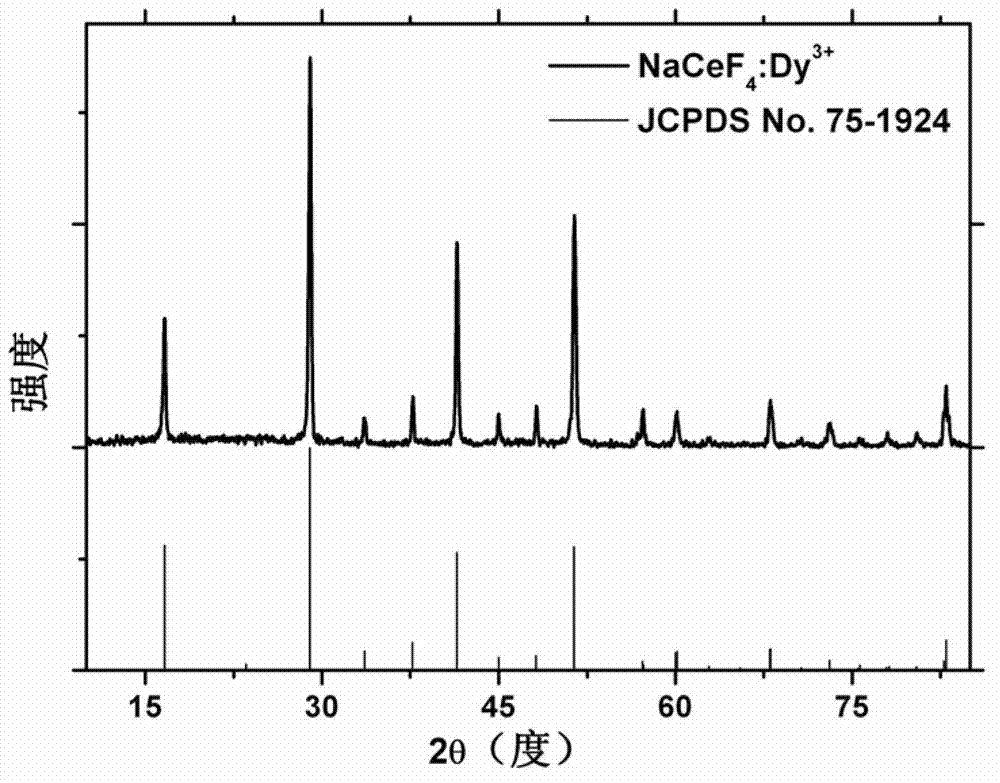

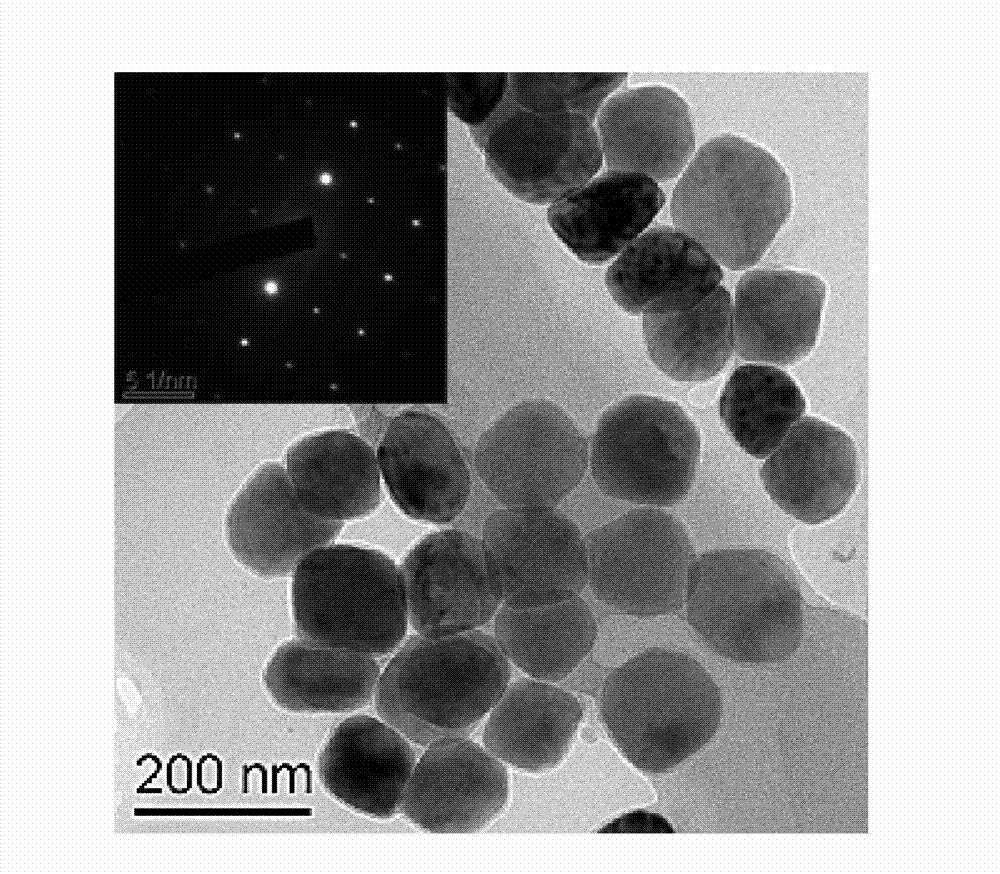

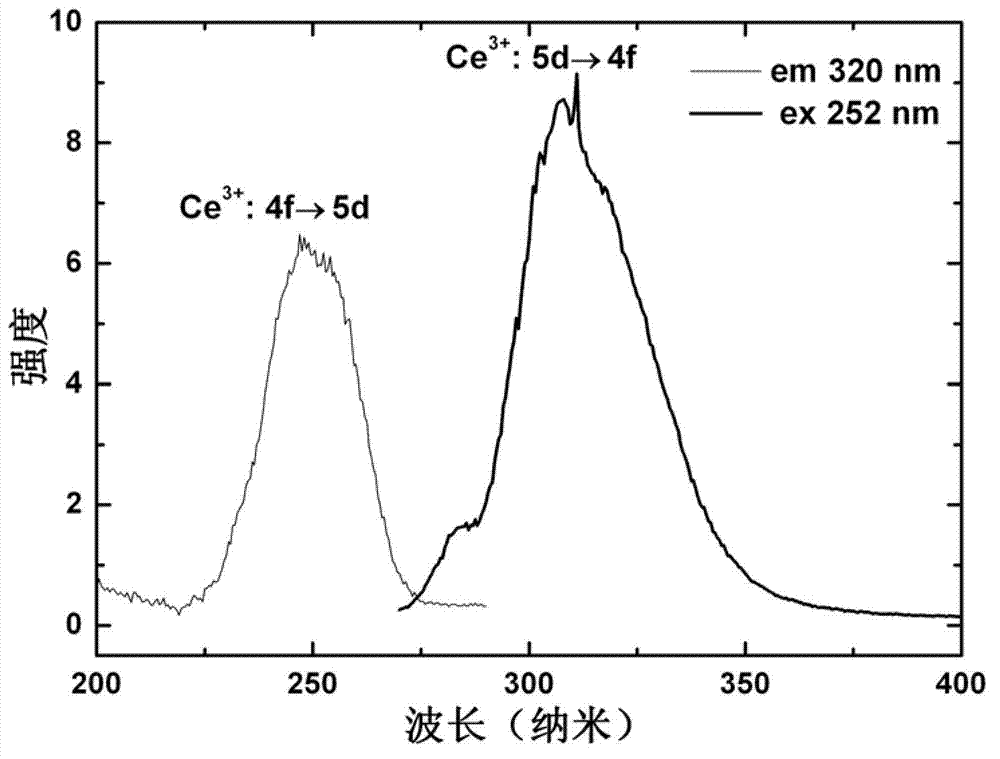

Synthesis method of rare earth doped hexagonal-phase cerium sodium fluoride nanocrystalline

InactiveCN103087716AEasy to makeSynthesis conditions are easy to controlLuminescent compositionsDispersitySynthesis methods

The invention provides a synthesis method of rare earth doped hexagonal-phase cerium sodium fluoride nanocrystalline. The synthesis method comprises the following steps of: using oleic acid and octadecene as solvents, mixing the cerium chloride and rare-earth chloride under the atmosphere of nitrogen, maintaining the temperature at 120-160 DEG C, stirring for a certain peroid of time, cooling the mixture to the room temperature, adding a methanol solution containing sodium hydroxide and ammonium fluoride to the cooled mixture, stirring for a certain peroid of time, heating the stirred mixture under the atmosphere of nitrogen so as to remove methanol, heating to 250-320 DEG C under the atmosphere of nitrogen to react for a certain peroid of time, cooling to room temperature, carrying out centrifugal separation to obtain a reactant, and washing and drying the reactant to obtain the rare earth doped hexagonal-phase cerium sodium fluoride nanocrystalline. The rare earth doped hexagonal-phase cerium sodium fluoride nanocrystalline prepared by using the synthesis method is better in uniform dispersity and excellent in down-conversion and up-conversion luminescence properties.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Preparation method of cuprous oxide nano material and hydrogen evolution performance of cuprous oxide nano material

InactiveCN108910933AThe synthesis process is simpleExcellent electrocatalytic hydrogen evolution performanceMaterial nanotechnologyCopper oxides/halidesHydrogenBasic copper carbonate

The invention discloses a preparation method of a cuprous oxide nano material and hydrogen evolution performance of the cuprous oxide nano material, and belongs to the technical field of nanometer materials. According to the preparation method, ethylene glycol and diethylene glycol are used as reducing agents, copper hydroxide and basic copper carbonate with specific morphology are used as coppersources, and the copper hydroxide and the basic copper carbonate copper are reduced to form cuprous oxide nano material with maintained morphology under the protection of inert gas through a gas phasereduction method. The reaction steps are simple and are environmentally friendly, the obtained product does not need to be washed, and a pure cuprous oxide product can be obtained. According to the preparation method provided by the invention, the simple and rapid method is adopted for synthesizing the cuprous oxide nano material with the maintained morphology, and the prepared cuprous oxide nanomaterial has the performance of electro-catalytic hydrogen evolution.

Owner:ANHUI NORMAL UNIV

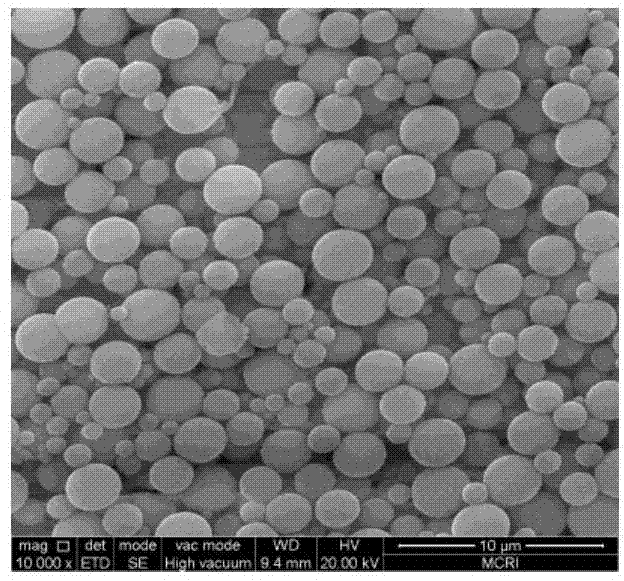

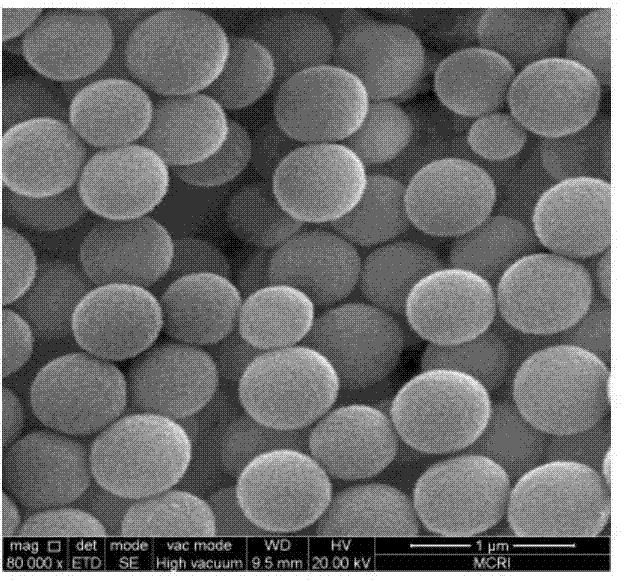

Preparation method for monodisperse functionalized polymer microsphere with surface chain transfer activity

The invention relates to a preparation method for a monodisperse functionalized polymer microsphere with the surface chain transfer activity. An RAFT (Reversible Addition-Fragmentation Chain-Transfer) distillation-precipitation polymerization method is adopted, and polyene monomers or polyene and monoene mixed monomers are used, as a result, the monodisperse polymer microsphere of which the crosslinking degree is greater than 30 percent, particle diameter is within a range of 50 nanometers-8 micrometers, particle dispersion index is 1.038-1.164, surface chain transfer functional group content is 0.75-1.88 mmol / g, and surface can be further modified, is prepared. The preparation method has the characteristics that a particle diameter and surface functional group content are controllable; surface functional groups are stable; chain transfer activity is high; metal impurities difficult to treat are not introduced; synthesis conditions are easy to be controlled; the price of the raw material is low, and the like. The prepared monodisperse surface functionalized polymer microsphere can be applied to a chromatogram stationary phase, medicine slow release, catalysts, active bio-molecule carries and the like.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Rare-earth-doped Li4ZrF8 nano-luminescence material with porous structure and preparation method and application thereof

ActiveCN107163937ASynthesis conditions are easy to controlGood repeatabilityLuminescent compositionsDispersityHost material

The invention discloses a rare-earth-doped Li4ZrF8 nano-luminescence material with a porous structure and a preparation method and application thereof. The rare-earth-doped Li4ZrF8 nano-luminescence material is an orthorhombic-phase Li4ZrF8 nano-material with the grain size of 50-120 nanometers, and is a porous material with the specific surface area of 100-500 m<2> / g and the aperture of 5-20 nm. The preparation method is characterized in that zirconium acetate serves as metal salt of Zr, a high-temperature co-precipitation method is utilized to synthesize the rare-earth-doped Li4ZrF8 nano-luminescence material, and the prepared rare-earth-doped Li4ZrF8 nano-luminescence material is easy-to-control in synthesis condition, good in repeatability, and excellent in dispersity and homogeneity; and the rare-earth-doped Li4ZrF8 nano-luminescence material has favorable luminescence property, can serve as a host material with ideal up-conversion and down-conversion luminescence and has a huge development potential in the field of luminescent imaging, drug delivery, biological application and the like.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

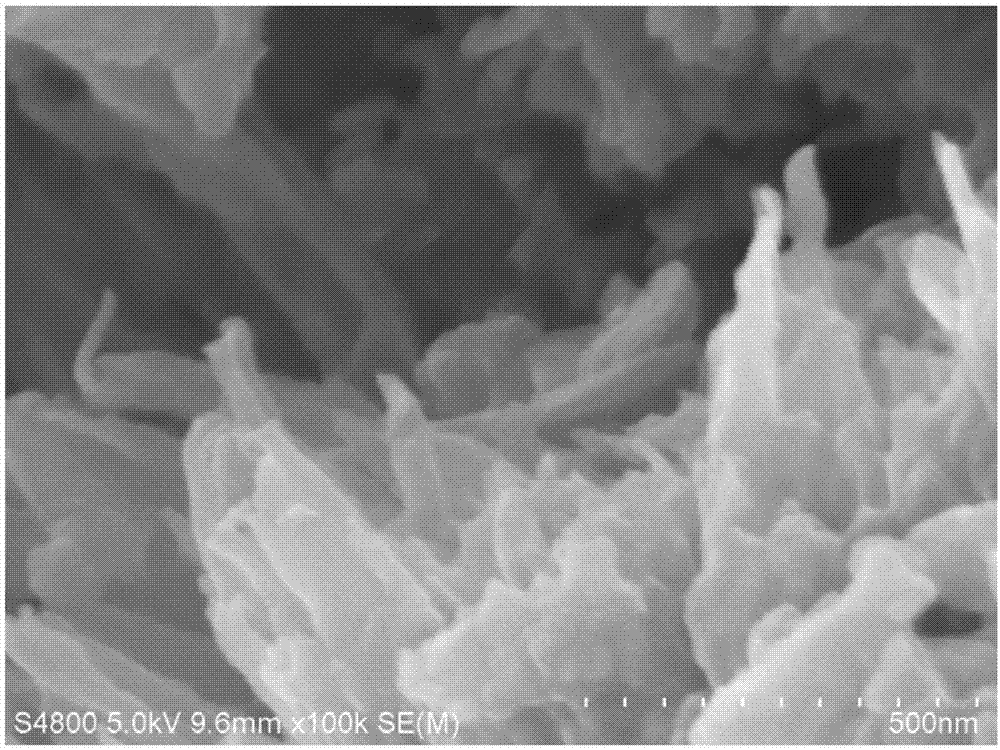

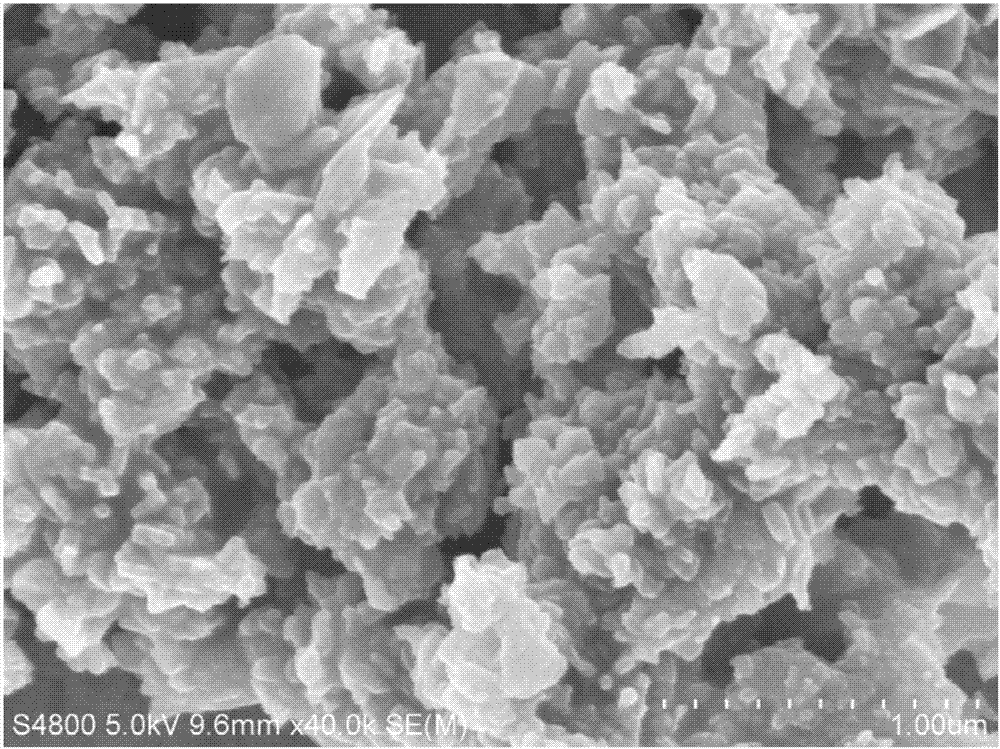

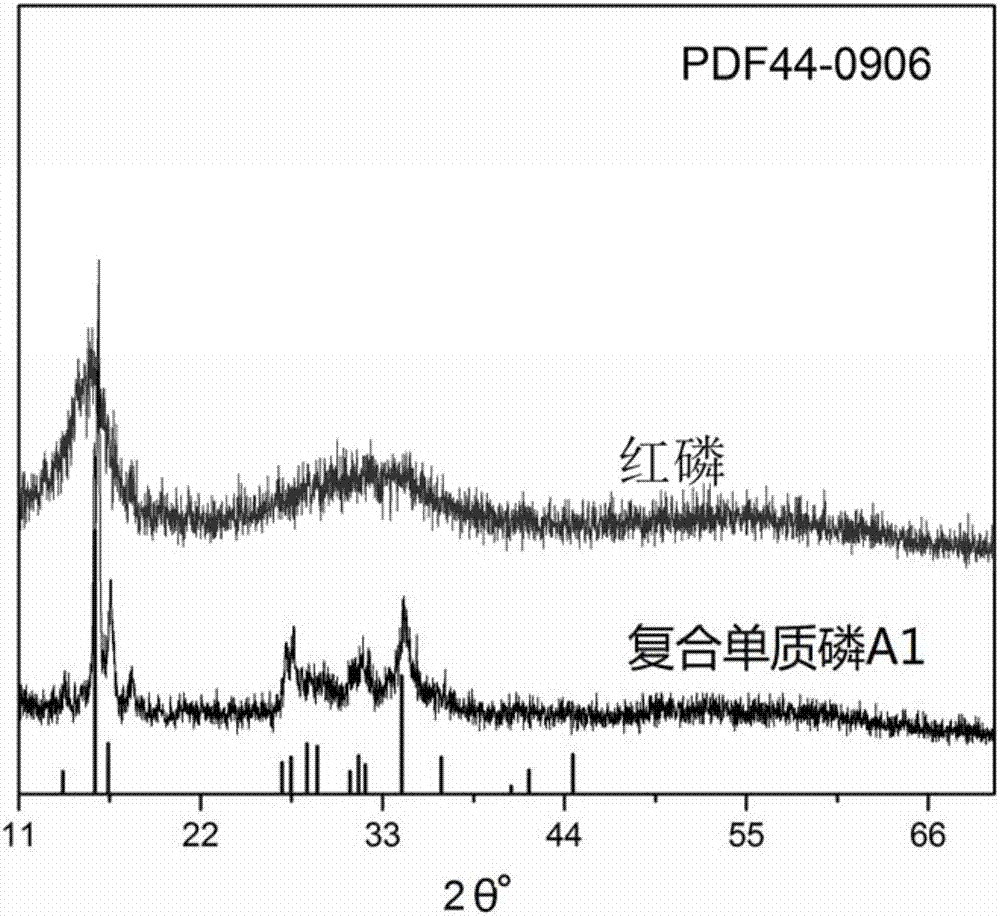

Composite elemental phosphorus with favorable crystallinity and preparation method and application thereof

ActiveCN107039647AHigh crystallinityHigh specific capacityCell electrodesSecondary cellsMicroparticleCrystallinity

The invention discloses composite elemental phosphorus with favorable crystallinity and a preparation method and application thereof. The composite elemental phosphorus comprises red phosphorus and black phosphorus and is a brownish black block-shaped particle. The preparation method comprises the steps of 1) performing solvothermal reaction on amorphous red phosphorus and a nitrogen-containing compound in a closed condition; and 2) performing post-treatment on a system solution to obtain the composite elemental phosphorus. The invention further provides the application of the composite elemental phosphorus with favorable crystallinity in a lithium ion battery. The composite elemental phosphorus has excellent crystallinity, specific capacity, structural stability and cycle performance; and moreover, the preparation method has the advantages of simple process, available raw material, low cost, good repeatability and controllable synthesis condition.

Owner:ANHUI NORMAL UNIV

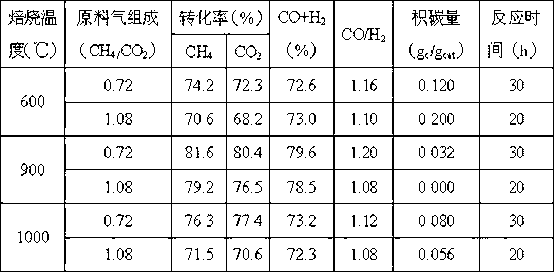

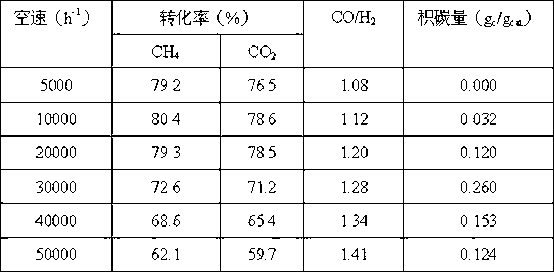

Cordierite matrix catalyst used for preparing synthesis gas by reforming methane and carbon dioxide and preparation method thereof

InactiveCN102407119BUniform growthImprove bindingHydrogenMetal/metal-oxides/metal-hydroxide catalystsSynthesis methodsCordierite

The invention relates to a cordierite matrix catalyst used for preparing synthesis gas by reforming methane and carbon dioxide and a preparation method thereof. In the method, cellular cordierite is taken as the matrix of the catalyst, and the mixture of metallic oxide sosoloid NixMg(1-x)Al2O4 and CoxMg(1-x)Al2O4 is taken as active components and a carrier. The preparation method comprises the following steps of: processing the cellular cordierite in a salpeter solution, then washing and drying to obtain a cordierite matrix; preparing the cobalt nitrate, nickel nitrate, magnesium nitrate and aluminium nitrate into a solution according to the different contents of the catalyst, dropwise adding ammonia, and stirring to form a precipitation solution; and finally placing the cordierite and precipitation solution together into an autoclave and then placing the autoclave in a muffle furnace, then carrying out crystallization, drying and roasting to obtain the cordierite matrix catalyst. In the invention, an in-situ synthesis method is used, and the preparation process is simple; the prepared catalyst has a coating layer which is firmly combined with the matrix, and is applied to carbonyl synthesis; and in the synthesis chemical process of F-T, the catalyst has low bed pressure and good thermostability and the active component Ni is dispersed highly and has small possibility of sintering.

Owner:TAIYUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com