Composite copper-based molecular sieve catalyst and preparation method thereof

A technology of molecular sieves and catalysts, applied in the field of composite copper-based molecular sieve catalysts and their preparation, can solve problems such as difficult to achieve large-scale industrial mass production, uneven distribution of active components, cumbersome impregnation process, etc., to solve unqualified NOX emissions, The effect of easy control of synthesis conditions and easy industrial mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

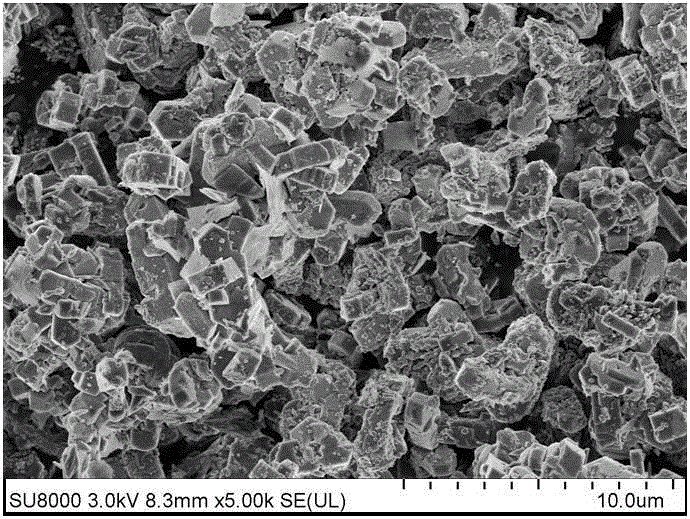

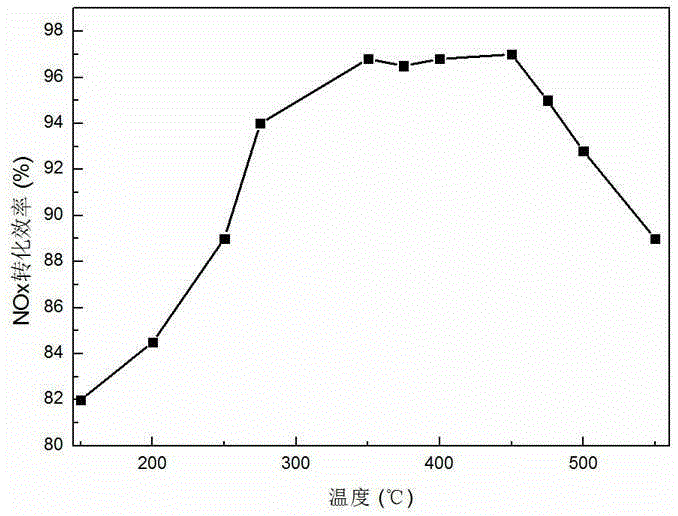

[0021] Weigh 1800g of Cu(NO 3 ) 2 ﹒ 3H 2 O and 300gMn(CH 3 COO) 2 ﹒ 4H 2 O is dissolved in 2550g deionized water with stirring; add 1320g of NH 3 ﹒ h 2 O, mix and stir for 2 hours; add 240g of ethanol and 3000g of ZSM-5 molecular sieve with a SAR ratio of 12.5, mix and stir for 2 hours; put the impregnation solution in a closed stainless steel tank, vacuumize, apply a pressure of 0.15MPa, and impregnate the mixture for 2 hours. Put them into disks and dry them in an oven at 105°C, crush the dried massive solids with a pulverizer, place them in a muffle furnace for calcination at 420°C for 6 hours, and use a grinder to further process the calcined powder into A powder with a particle size of 100 meshes obtained a composite copper-based molecular sieve catalyst. figure 1 The SEM of the invention product of this embodiment shows that many small particles are loaded on the ZEM-5 molecule, and these particles are relatively evenly distributed; use a fixed-bed micro-reacti...

Embodiment 2

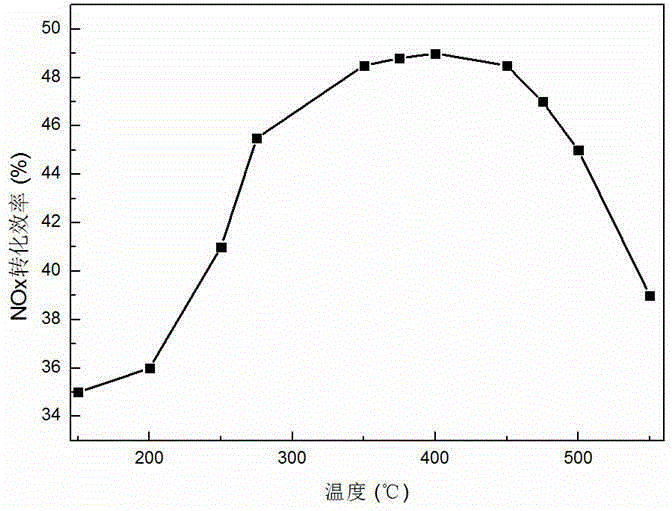

[0025] Weigh 1395g of Cu(NO 3 ) 2 ﹒ 3H 2 O and 100gCe(NO 3 ) 3 ﹒ 6H 2O was dissolved in 1200g deionized water with stirring; 870g of NH was added 3 ﹒ h 2 O, mixing and stirring for 4 hours; adding 60g of isopropanol and 3000g of ZSM-5 molecular sieve with a SAR ratio of 60, mixing and stirring for 4 hours; putting the impregnating solution in a closed stainless steel tank, after vacuuming, and applying a pressure of 0.15MPa, impregnating for 5 hours, and Put the mixture into disks and dry in an oven at 150°C, crush the dried block solids with a pulverizer, place them in a muffle furnace for calcination at 450°C for 6 hours, and grind the calcined powder with a grinder A powder with a particle size of 300 meshes obtained a composite copper-based molecular sieve catalyst. Figure 4 For the SEM of the product invented in this example, the dispersion of small particle oxides on the ZSM-5 molecular sieve is relatively uniform, indicating that the addition of additive Ce i...

Embodiment 3

[0027] Weigh 1500g of Cu(CH 3 COO) 2 ﹒ h 2 O and 200gCo(CH 3 COO) 2 ﹒ 4H 2 O was dissolved in 2000g deionized water by stirring; adding 1160g of NH 3 ﹒ h 2 O, mix and stir for 2h; add 150g of 90% ethylene glycol and 3000g of SAPO-34 molecular sieve with a Si / Al ratio of 0.95, mix and stir for 4h; put the impregnating solution in a closed stainless steel tank, after vacuuming, add 0.30MPa pressure, impregnated for 5 hours, put the mixture into disks and dry in an oven at 125°C, crush the dried block solids with a pulverizer, and place them in a muffle furnace for calcination at 530°C for 4 hours. The powder is further processed into a powder with a particle size of 300 mesh with a grinder, and a composite copper-based molecular sieve catalyst is obtained, and the BET test value is 246BET / m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com