Composite elemental phosphorus with favorable crystallinity and preparation method and application thereof

A technology of elemental phosphorus and crystallinity, applied in the field of elemental phosphorus, can solve problems such as poor cycle performance and large first-time irreversible specific capacity, and achieve the effects of low cost, controllable synthesis conditions, and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The present invention also provides a method for preparing the above-mentioned composite elemental phosphorus with good crystallinity, the preparation method comprising:

[0024] 1) carrying out solvothermal reaction with amorphous red phosphorus and nitrogen-containing compound under airtight conditions;

[0025] 2) The system solution is post-treated to produce complex elemental phosphorus.

[0026] In step 1) of the above-mentioned preparation method, the consumption of material can be selected in a wide range, but in order to make the composite elemental phosphorus obtained have more excellent crystallinity, specific capacity, structural stability and cycle performance; preferably , in step 1), the dosage ratio of amorphous red phosphorus to nitrogen-containing compound is (0.3-2.5g): (30-50mL). More preferably, in step 1), the dosage ratio of amorphous red phosphorus to nitrogen-containing compound is (0.4-0.6g): (30-50mL).

[0027] In step 1) of the above prepar...

Embodiment 1

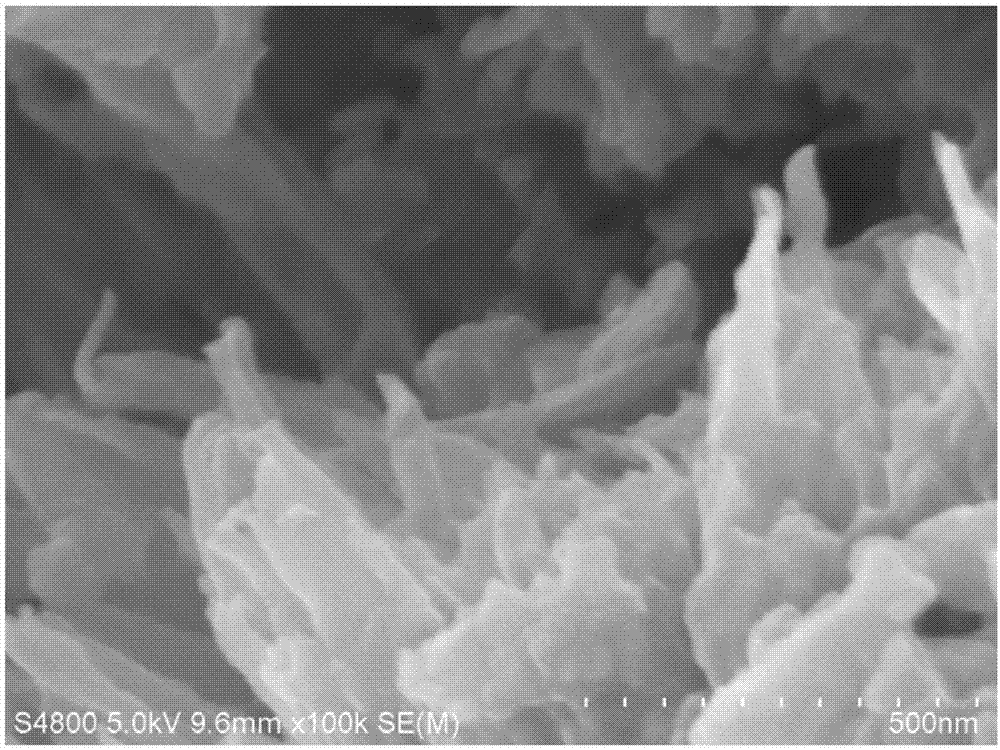

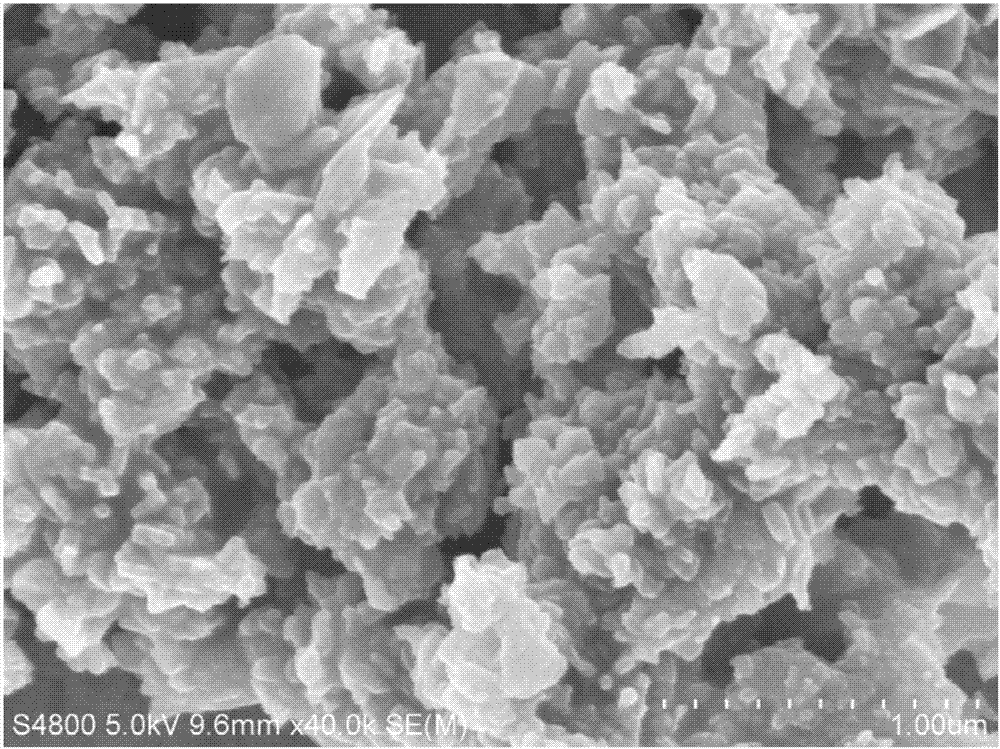

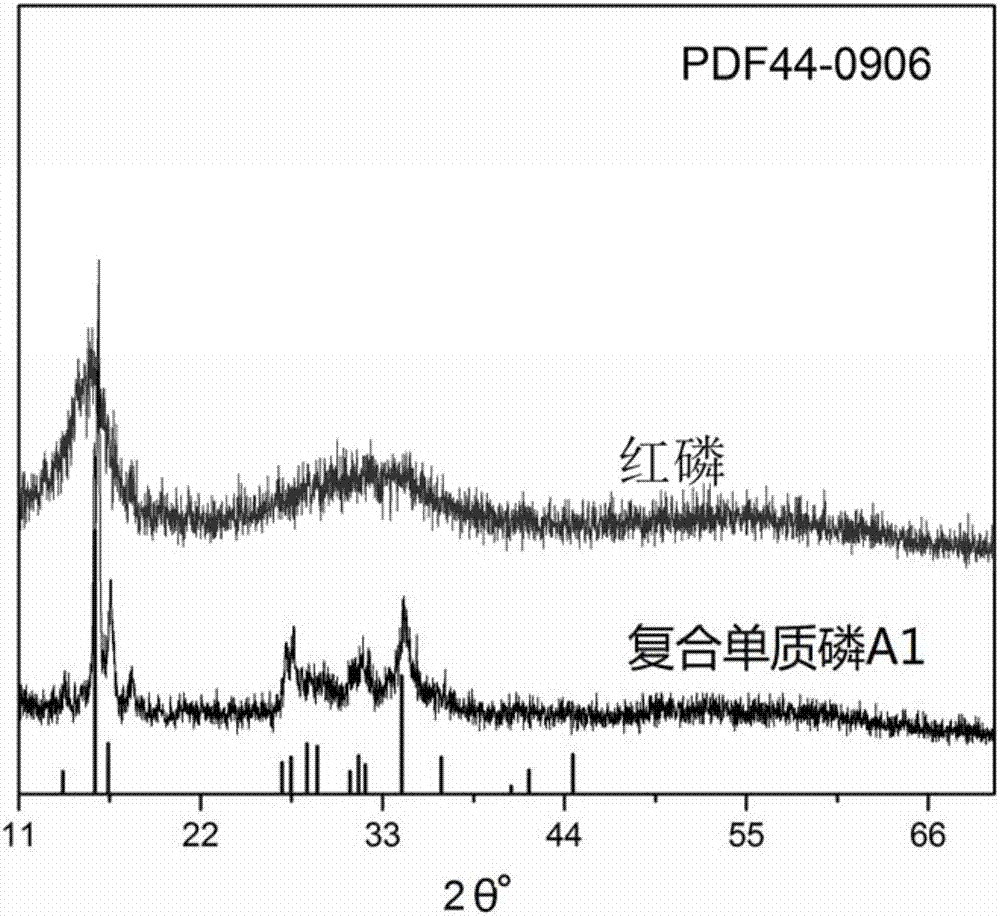

[0034] Weigh 0.5g of amorphous red phosphorus and put it into the reaction kettle, add 40mL of ethylenediamine to it to make a suspension and seal it; then, react at 200°C for 48 hours; finally, the system solution is centrifuged, washed, The precipitate was dried at 70°C for 15 hours to obtain complex elemental phosphorus A1 (brown-black lumpy particles).

Embodiment 2

[0036] Composite elemental phosphorus A2 (brown black massive particles) was obtained according to the method of Example 1, except that the amount of amorphous red phosphorus was 1.0 g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com