Mn3O4-MnO2 nano rod composite oxide as well as preparation method and application of Mn3O4-MnO2 nano rod composite oxide

A technology of composite oxides and nanorods, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, nanotechnology, etc. Step-by-step operation and other problems, to achieve the effect of low production cost, mild synthesis conditions, simple and efficient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] a kind of Mn 3 o 4 -MnO 2 Its preparation method of nanorod composite oxide comprises the following steps:

[0026] Use a pipette to pipette 20mL of deionized water into a 50mL polytetrafluoroethylene-lined hydrothermal kettle, then place 0.32mol potassium permanganate, 0.06moL glucose and 0.02moL sodium chloride in the above hydrothermal kettle Inside, after fully stirring evenly, seal and tighten the hydrothermal kettle, place it in an oven at 120°C, react for 6 hours, wash the product obtained by the reaction with distilled water for 3 times, separate and dry at 20°C for 24 hours, and you can obtain about 30 μm, Mn with a diameter of about 50-100 nm 3 o 4 -MnO 2 Nanorod two-component composite oxide.

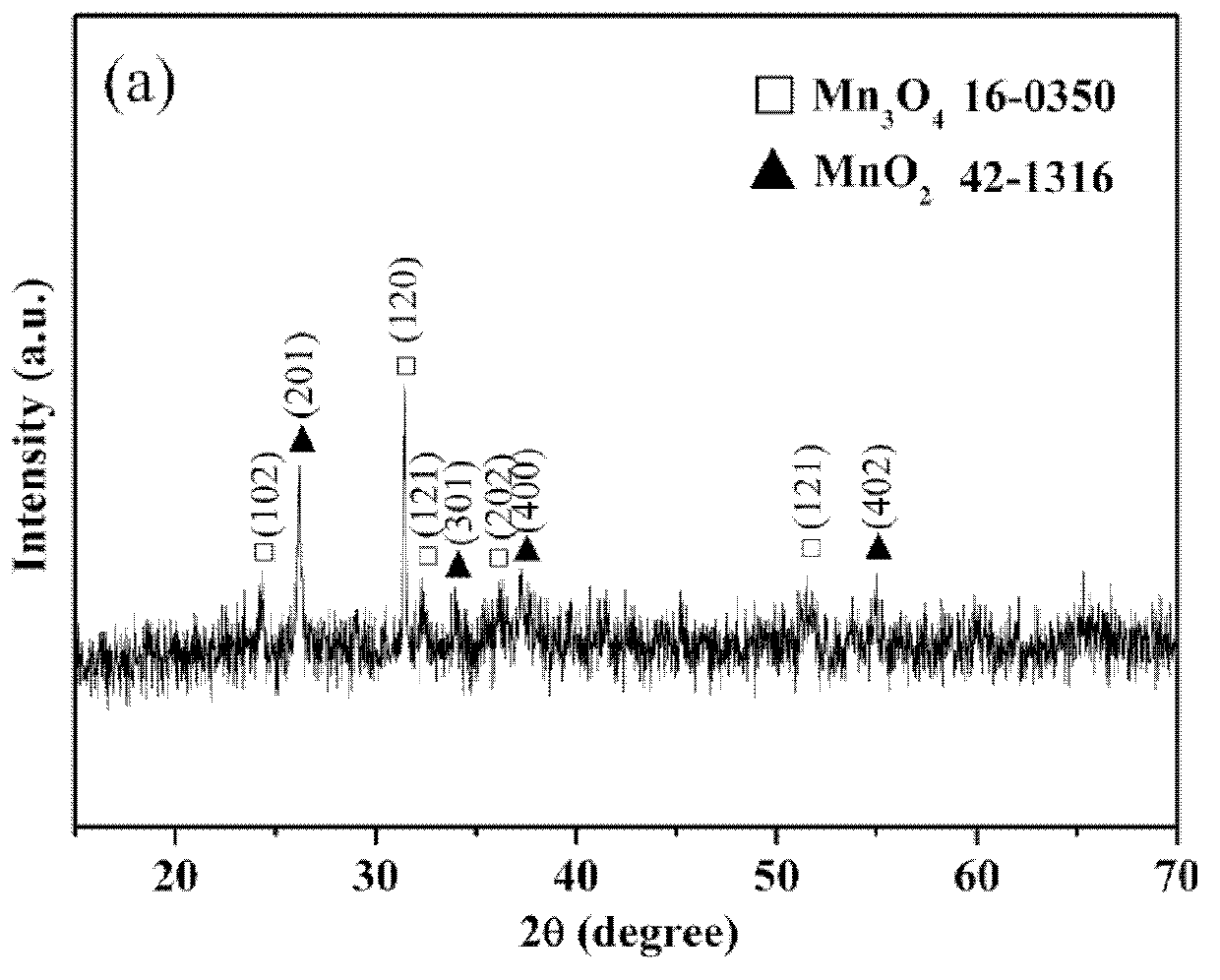

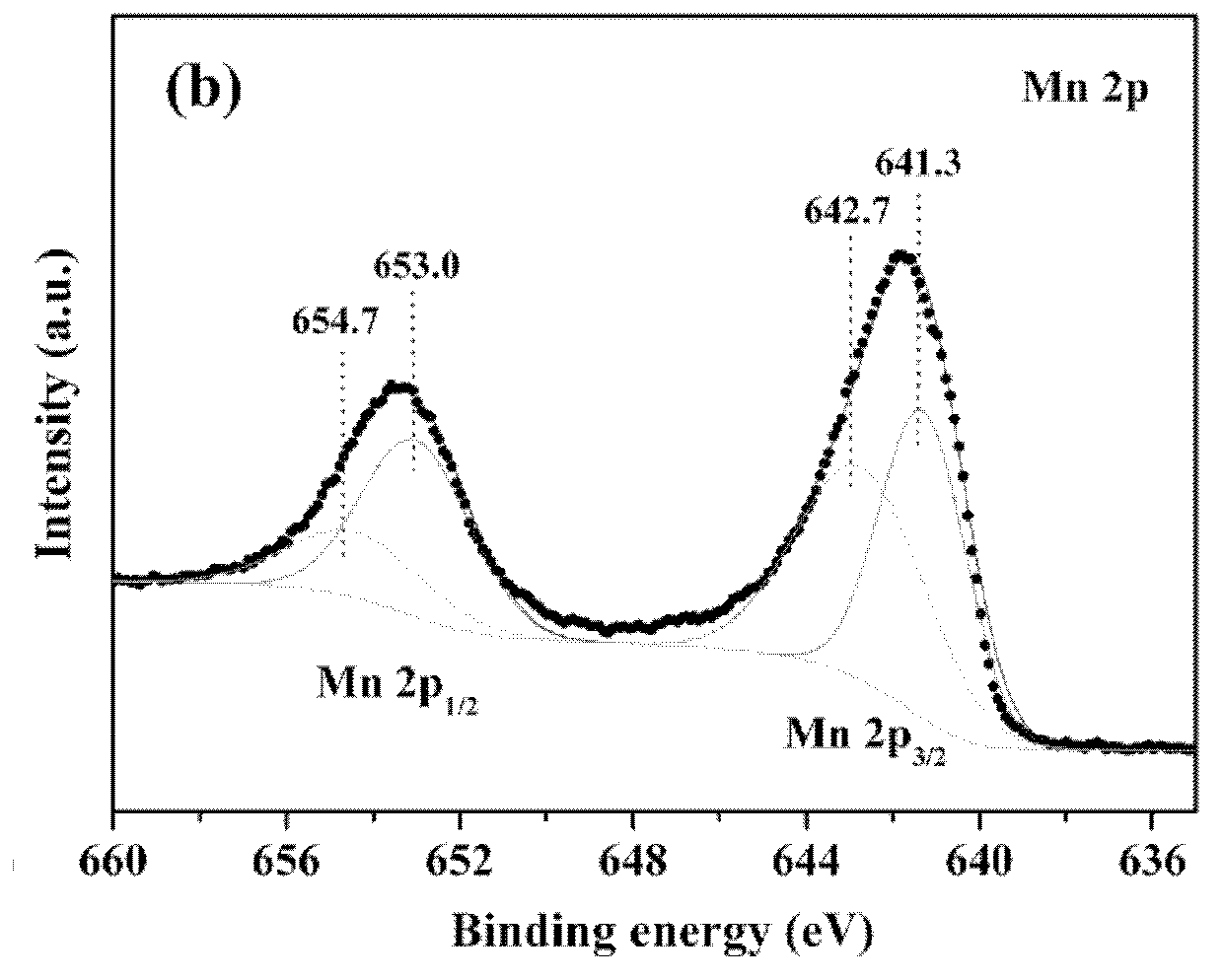

[0027] The SEM characterization of the as-synthesized nanorod composites is as follows figure 1 Shown; From the XRD crystal form shown in Figure 2 and the chemical composition of XSP, it can be seen that the synthesized product is Mn 3 o 4 -MnO 2 Two-componen...

Embodiment 2

[0031] a kind of Mn 3 o 4 -MnO 2 Its preparation method of nanorod composite oxide comprises the following steps:

[0032] Use a pipette to pipette 20mL of deionized water into a 50mL polytetrafluoroethylene-lined hydrothermal kettle, then place 0.32mol potassium permanganate and 0.096moL glucose in the above hydrothermal kettle, and stir well , seal and tighten the hydrothermal kettle, place it in an oven at 125°C, react for 12 hours, rinse the product obtained by the reaction with distilled water for 3 times, separate and dry at 10°C for 30 hours, and then obtain a product with a length of about 5 μm and a diameter of about 80 -120nm Mn 3 o 4 -MnO 2 Nanorod two-component composite oxide.

Embodiment 3

[0034] a kind of Mn 3 o 4 -MnO 2 Its preparation method of nanorod composite oxide comprises the following steps:

[0035] Use a pipette to pipette 20mL of deionized water into a 50mL polytetrafluoroethylene-lined hydrothermal kettle, then place 0.32mol potassium permanganate, 0.032moL glucose and 0.128moL sodium chloride in the above hydrothermal kettle Inside, after fully stirring evenly, seal and tighten the hydrothermal kettle, place it in an oven at 110°C, react for 24 hours, wash the product obtained by the reaction with distilled water for 3 times, separate and dry at 15°C for 10 hours, and you can obtain a 50 μm, Mn with a diameter of about 30-80 nm 3 o4 -MnO 2 Nanorod two-component composite oxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com