Separation and purification method of garlic essential oil

A technique for separation and purification of garlic essential oil, which is applied in the direction of essential oil/spice, fat production, etc., can solve problems such as difficult to obtain garlic essential oil in extraction rate, and achieve the effects of avoiding thermal decomposition, improving purity, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

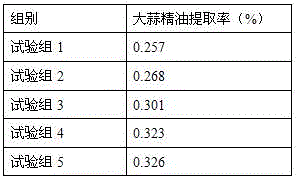

Examples

Embodiment 1

[0026] A method for separation and purification of garlic essential oil, comprising the following steps:

[0027] (1) Washing and beating, select the garlic without pests, mildew and rot, soak it in water, wash it with clean water, and beat it into garlic paste;

[0028] (2) Enzymolysis, adding cellulase and butyl hydroxyanisole to the garlic paste for enzymolysis, the reaction temperature is 37°C, the enzymolysis time is 90 minutes, and the enzymolysis solution is filtered to obtain the filter residue and the first filtrate;

[0029] (3) extraction, adding an extraction solvent to the filter residue, ultrasonic extraction, and filtration to obtain a second filtrate;

[0030] (4) Extracting, combining the first filtrate and the second filtrate, extracting, and separating to obtain the extract;

[0031] (5) Centrifuge, send the extract into a high-speed centrifuge for high-speed centrifugation at a speed of 12000r / min, collect the supernatant after centrifugation,

[0032] (6...

Embodiment 2

[0040] A method for separation and purification of garlic essential oil, comprising the following steps:

[0041] (1) Washing and beating, select the garlic without pests, mildew and rot, soak it in water, wash it with clean water, and beat it into garlic paste;

[0042] (2) Enzymolysis, adding cellulase and butylated hydroxyanisole to the garlic paste for enzymolysis, the reaction temperature is 37°C, the enzymolysis time is 100min, and the enzymolysis solution is filtered to obtain the filter residue and the first filtrate;

[0043] (3) extraction, adding an extraction solvent to the filter residue, ultrasonic extraction, and filtration to obtain a second filtrate;

[0044] (4) Extracting, combining the first filtrate and the second filtrate, extracting, and separating to obtain the extract;

[0045](5) Centrifuge, send the extract into a high-speed centrifuge for high-speed centrifugation at a speed of 12000r / min, collect the supernatant after centrifugation,

[0046] (6)...

Embodiment 3

[0054] A method for separation and purification of garlic essential oil, comprising the following steps:

[0055] (1) Washing and beating, select the garlic without pests, mildew and rot, soak it in water, wash it with clean water, and beat it into garlic paste;

[0056] (2) Enzymolysis, add hemicellulase and 2,6-di-tert-butylcresol to the garlic paste for enzymolysis, the reaction temperature is 35°C, the enzymolysis time is 120min, and the enzymolysis solution is filtered to obtain the filter residue and the second primary filtrate;

[0057] (3) extraction, adding an extraction solvent to the filter residue, ultrasonic extraction, and filtration to obtain a second filtrate;

[0058] (4) Extracting, combining the first filtrate and the second filtrate, extracting, and separating to obtain the extract;

[0059] (5) Centrifuge, send the extract into a high-speed centrifuge for high-speed centrifugation at a speed of 10000r / min, collect the supernatant after centrifugation,

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com