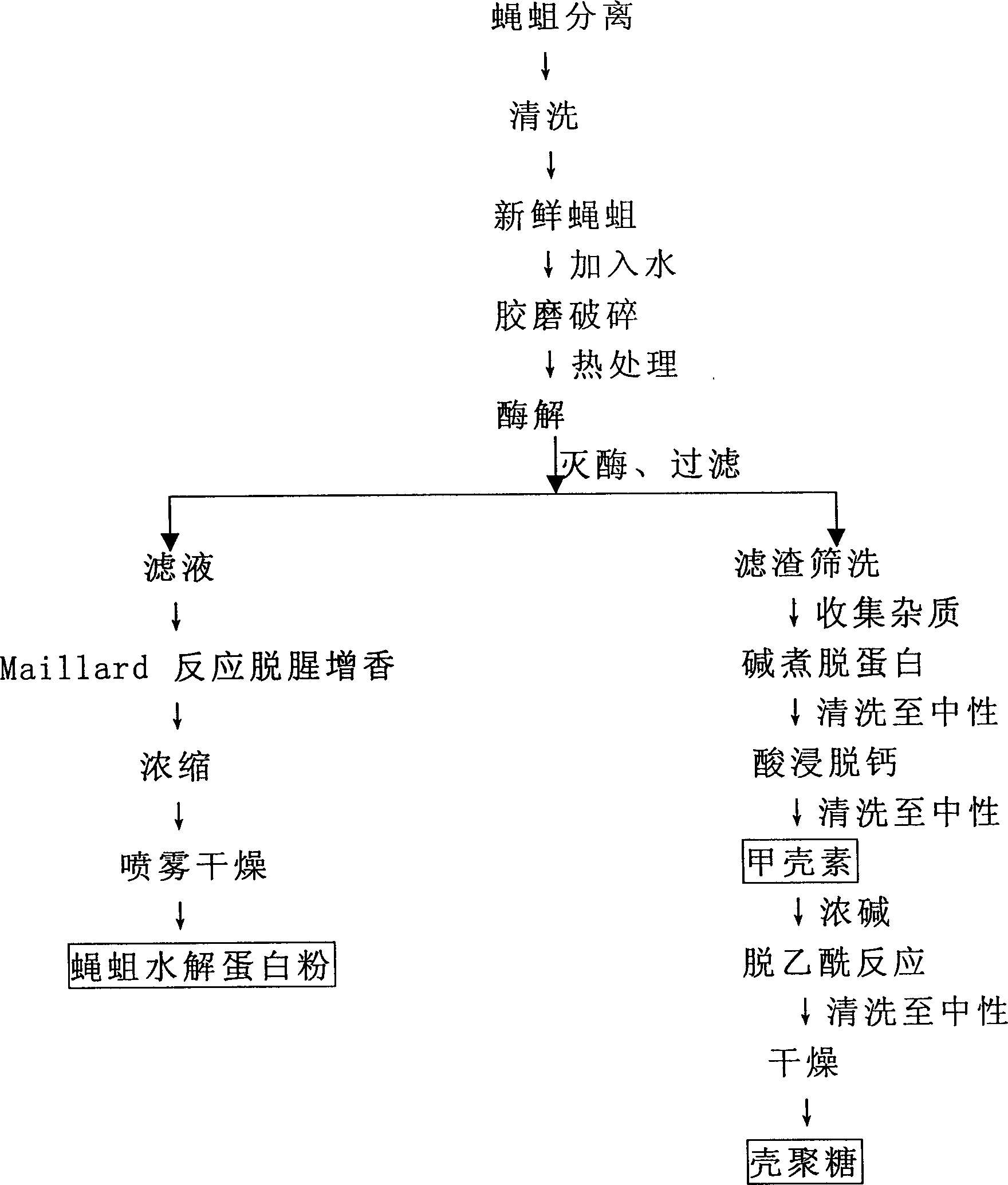

Method for extracting protein and chitin from fly maggot by using enzyme hydrolysis as well as preparing chitosan from chitin

A technology of fly maggot chitin and hydrolyzed protein powder, which is applied in the field of biotechnology enzymatic hydrolysis of fly maggot protein, can solve problems such as large waste of protein resources, pollution in production process, complicated processing, etc., achieve important economic and social benefits, improve Storage safety, the effect of improving nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Hydrolyzed protein and chitin were extracted from fly maggots by enzymatic hydrolysis. Fresh fly maggots are crushed by rubber mill, and the slurry is heat-treated, then hydrolyzed for 3 hours with AS.1398 protease at an enzyme-to-substrate ratio of 500u / g, 45°C and pH 7.0. At this time, the degree of hydrolysis was 18%, the dissolution rate of protein was 81%, and the hydrolyzate had no bitter taste.

[0042] The enzyme hydrolyzate is used to inactivate the enzyme, filtered, and the filtrate undergoes Maillard reaction. When the reaction is carried out at 120°C for 60 minutes, the product has a strong fragrance and the fishy smell disappears. Spray drying to obtain fly maggot protein powder.

[0043] The filter residue of fly maggot skin is used to extract chitin, and the method is the same as in Example 4 below.

Embodiment 2

[0045] Hydrolyzed protein and chitin were extracted from fly maggots by enzymatic hydrolysis. Using AS.1398 protease and flavor enzyme, the two are combined with a 1:1 (w / w) compound enzyme for enzymolysis, and the rest of the conditions are the same as in Example 1. The degree of hydrolysis and protein dissolution rate after hydrolysis can also achieve satisfactory results.

Embodiment 3

[0047] Hydrolyzed protein was extracted from fly maggots by enzymatic hydrolysis. After the fly maggots are enzymatically hydrolyzed, the enzymatic hydrolyzate is directly enriched by Maillard reaction, spray-dried to obtain fly maggot protein powder, and the protein content is more than 60%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com