Patents

Literature

458results about How to "Avoid thermal decomposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

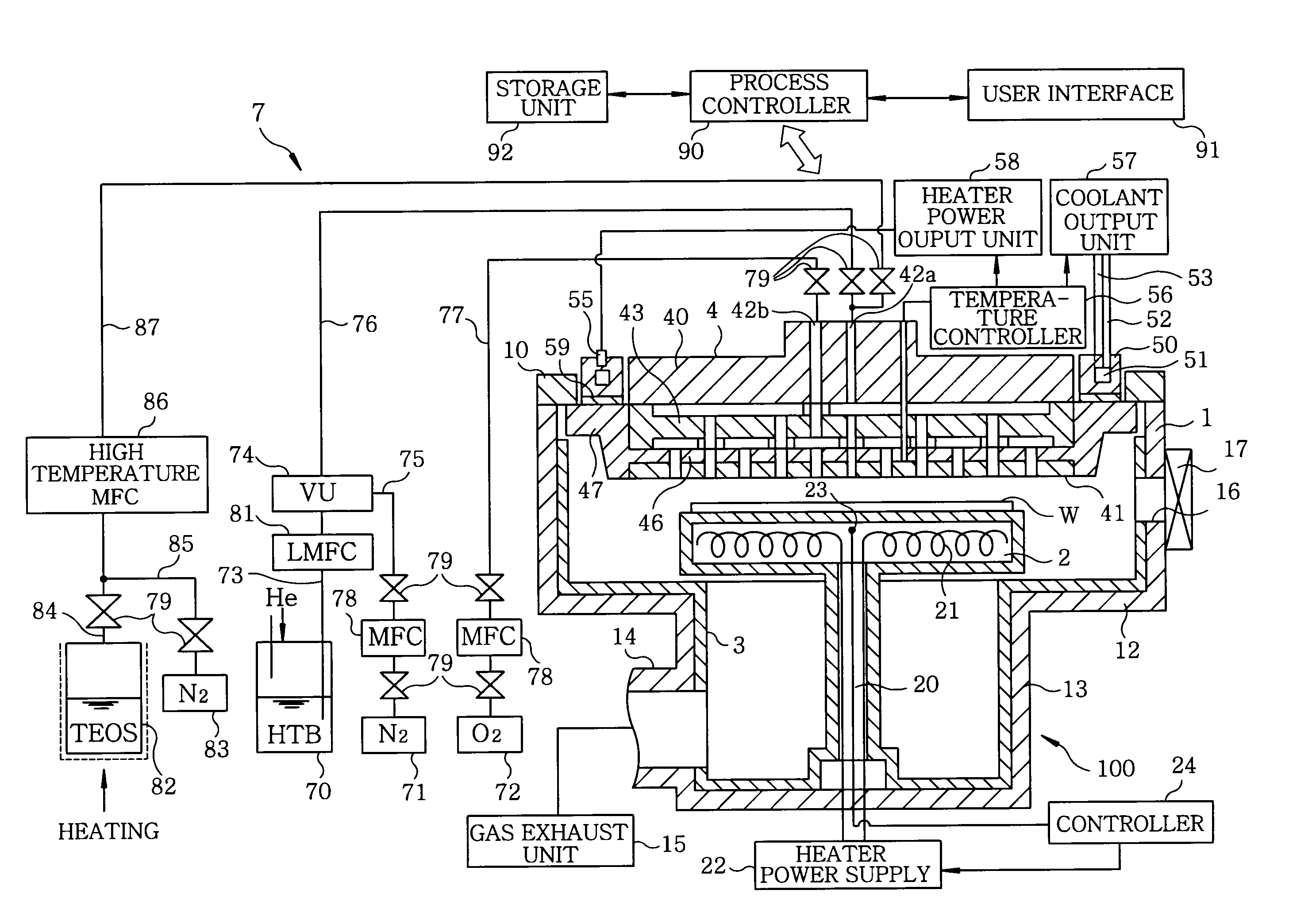

Method for depositing silicon oxide film having improved quality by peald using bis(diethylamino)silane

ActiveUS20210057214A1Avoid thermal decompositionImprove film qualitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingSusceptorOxygen plasma

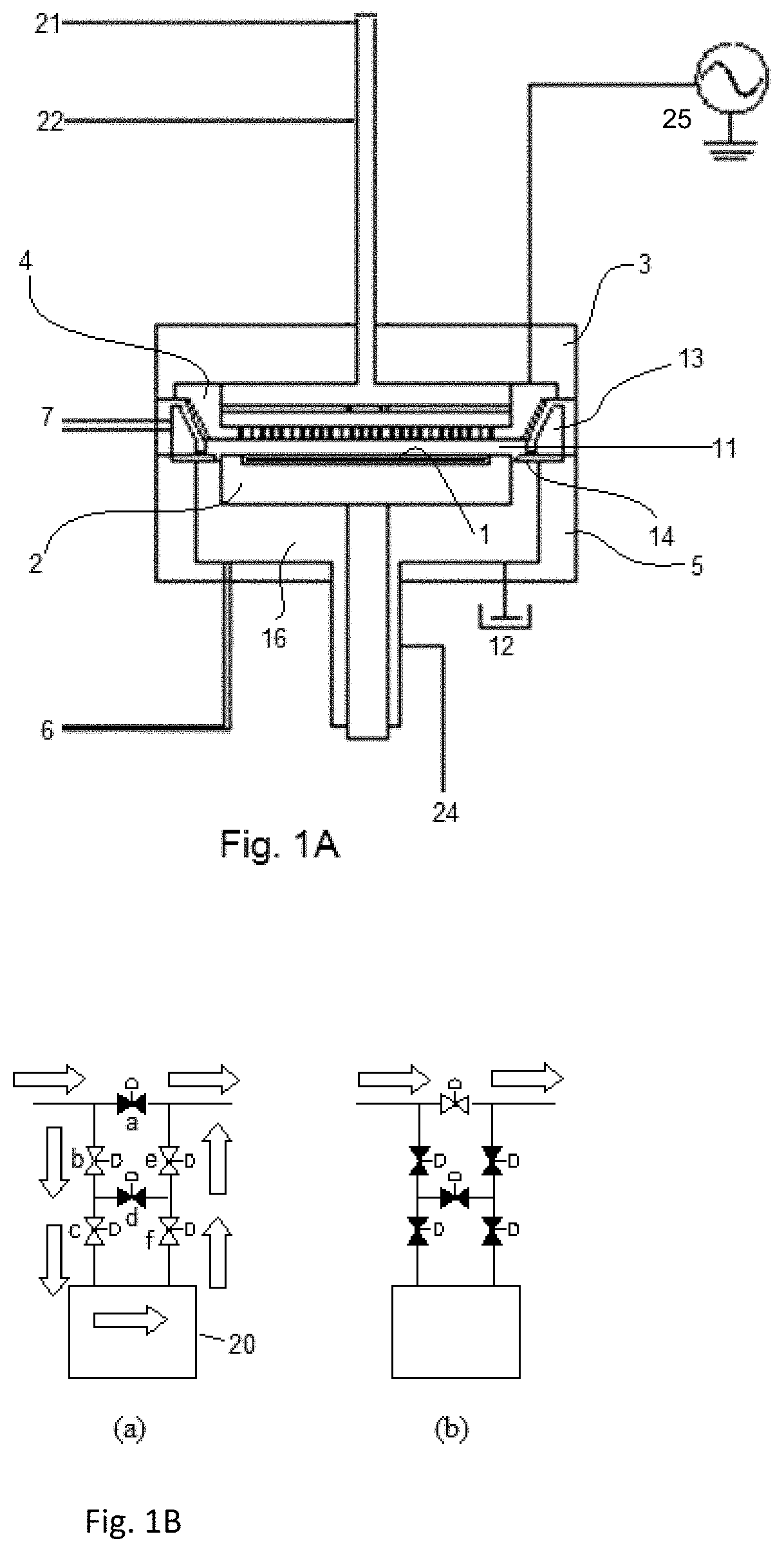

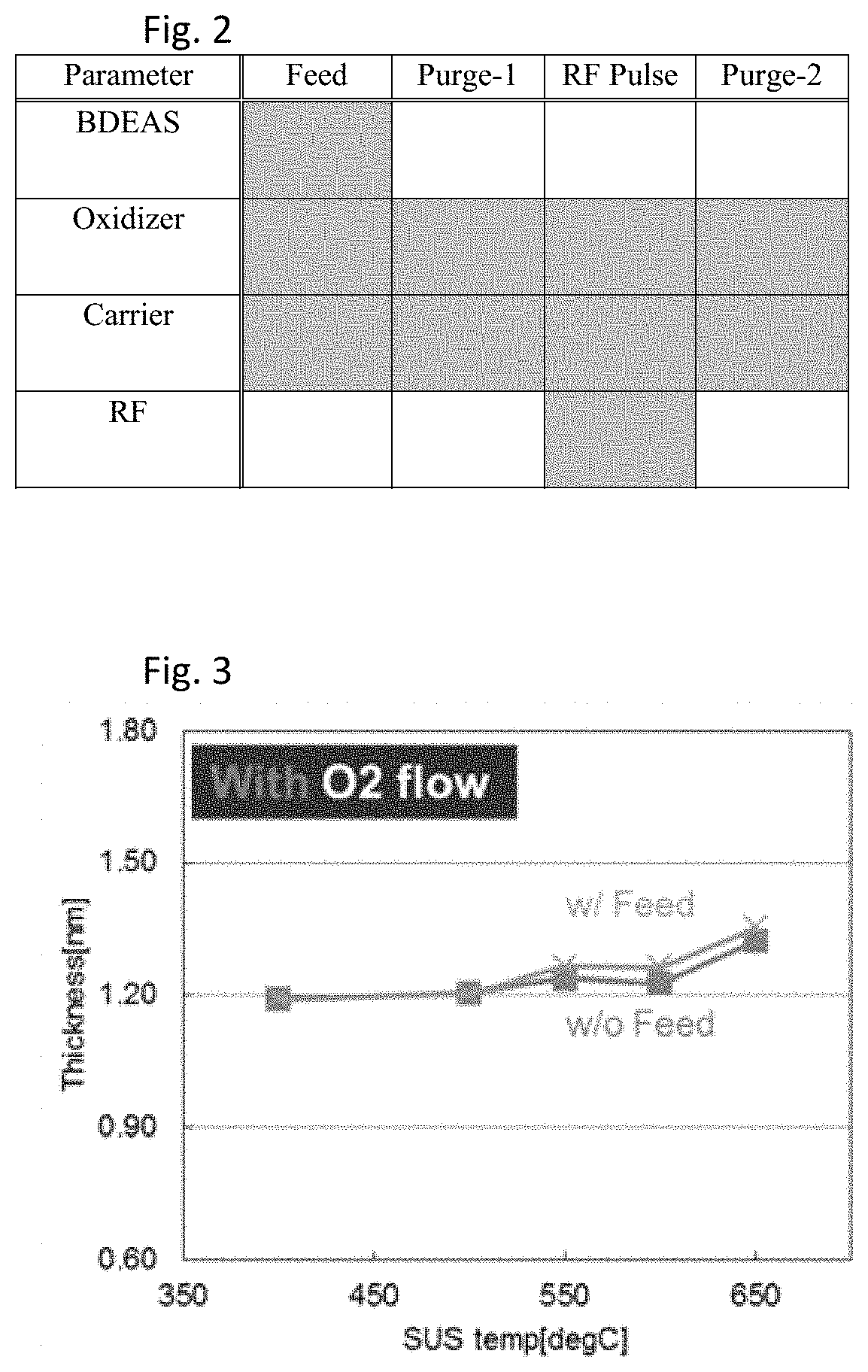

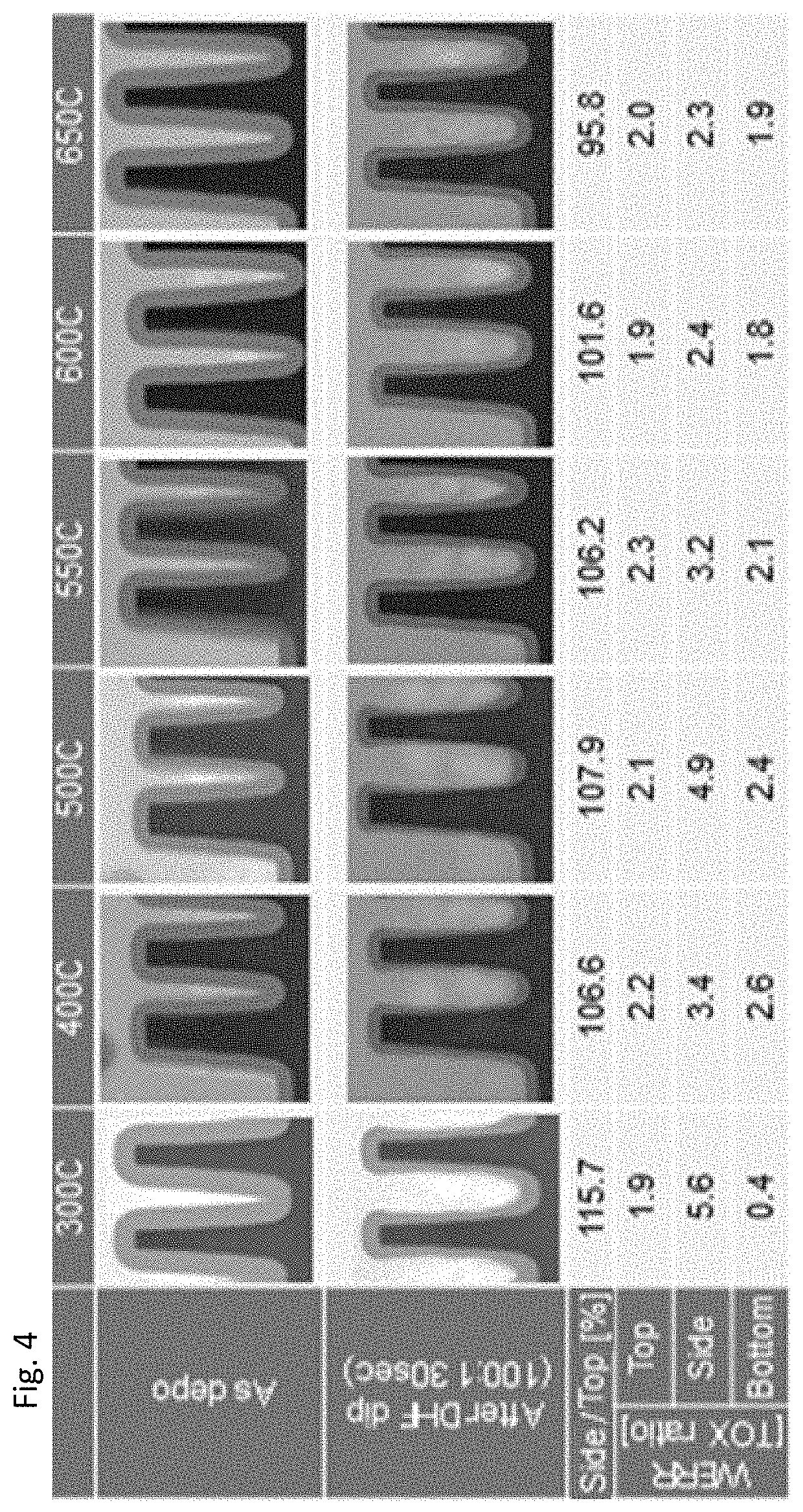

In a method of depositing a silicon oxide film using bis(diethylamino)silane (BDEAS) on a substrate in a reaction space by plasma-enhanced atomic layer deposition (PEALD), each repeating deposition cycle of PEALD includes steps of: (i) adsorbing BDEAS on the substrate placed on a susceptor having a temperature of higher than 400° C. in an atmosphere substantially suppressing thermal decomposition of BDEAS in the reaction space; and (ii) exposing the substrate on which BDEAS is adsorbed to an oxygen plasma in the atmosphere in the reaction space, thereby depositing a monolayer or sublayer of silicon oxide.

Owner:ASM IP HLDG BV

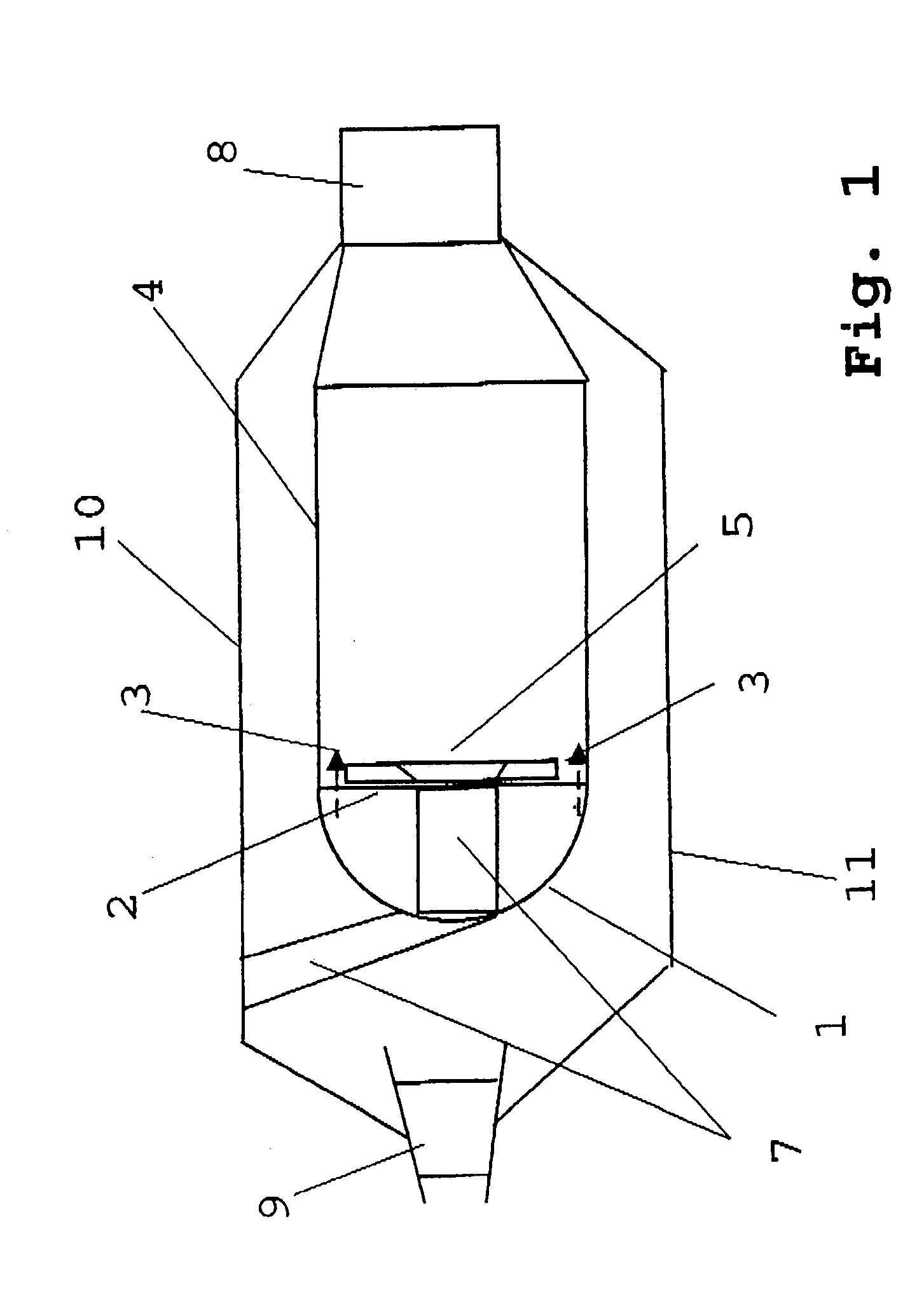

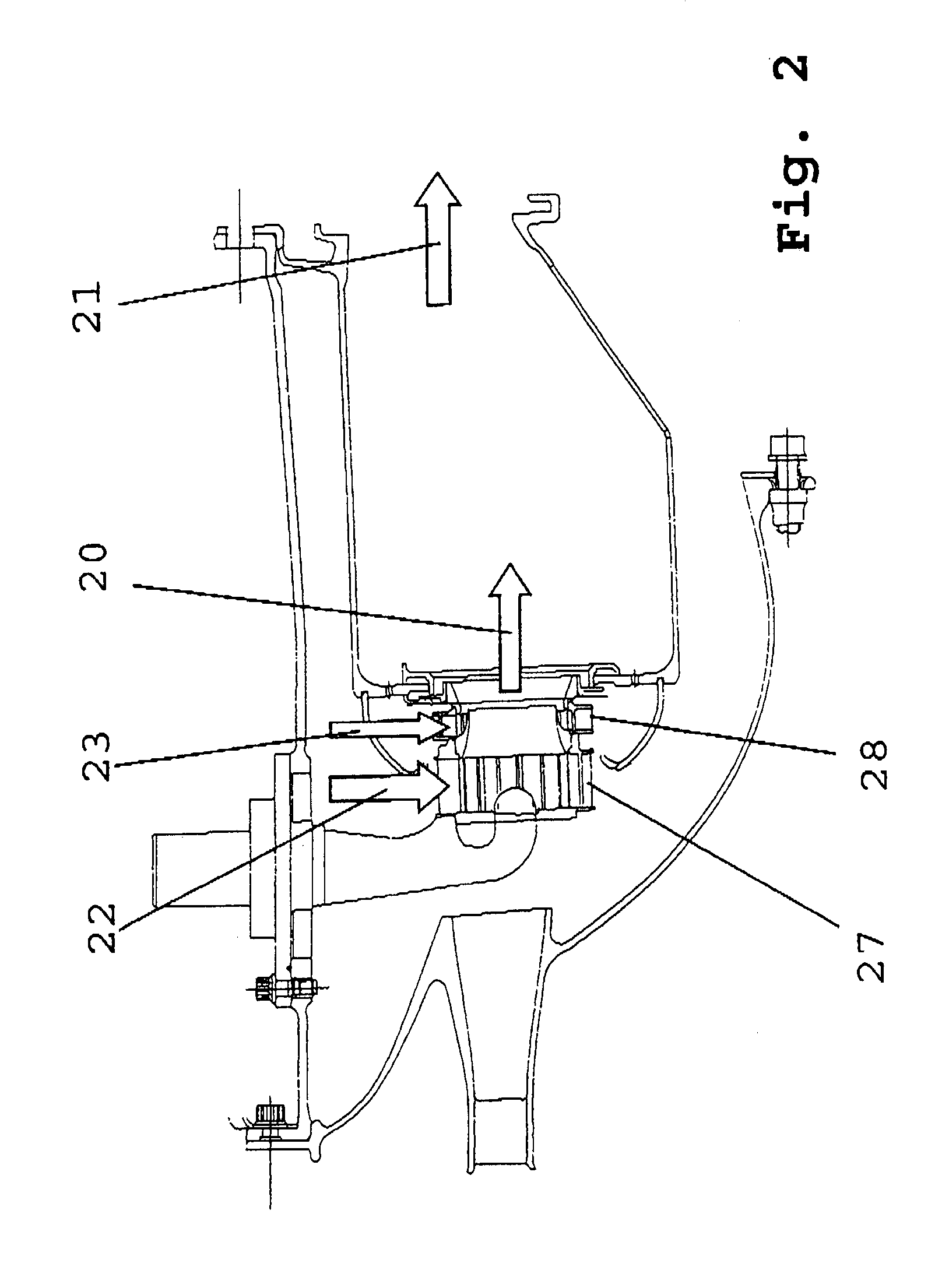

Equipment and method for extracting biologically active ingredients from subcritical fluid

InactiveCN101905091AKeep intactGuaranteed production costExtraction purification/separationSolid solvent extractionAutomatic controlSeparation technology

The invention discloses equipment and a method for extracting biologically active ingredients from subcritical fluid, aims to solve the problems of low extraction efficiency and the like existing in the aspects of biologically active ingredient separation technology in the prior art and provides a set of subcritical equipment which comprises an extracting agent supply system, an entrainer supply system, an extraction system, a separation system, a solvent recycling system, a desolvation system, a heat supply system, a computer control system and the like, has high automatic control degree and is used for extracting the biologically active ingredients. Simultaneously, the invention also provides a new technological method for extracting the biologically active ingredients by adopting a subcritical extraction process. The method has the advantage of relatively low cost on the conventional extraction of an organic solvent, and the equipment has the characteristics of no solvent residue, no pollution, high bioactivity and the like in a product obtained by supercritical CO2 extraction technology and has the advantages of low investment on production equipment, high production efficiency within unit time, low energy consumption, flexible operation, high degree of automation and the like.

Owner:XINJIANG UNIVERSITY +1

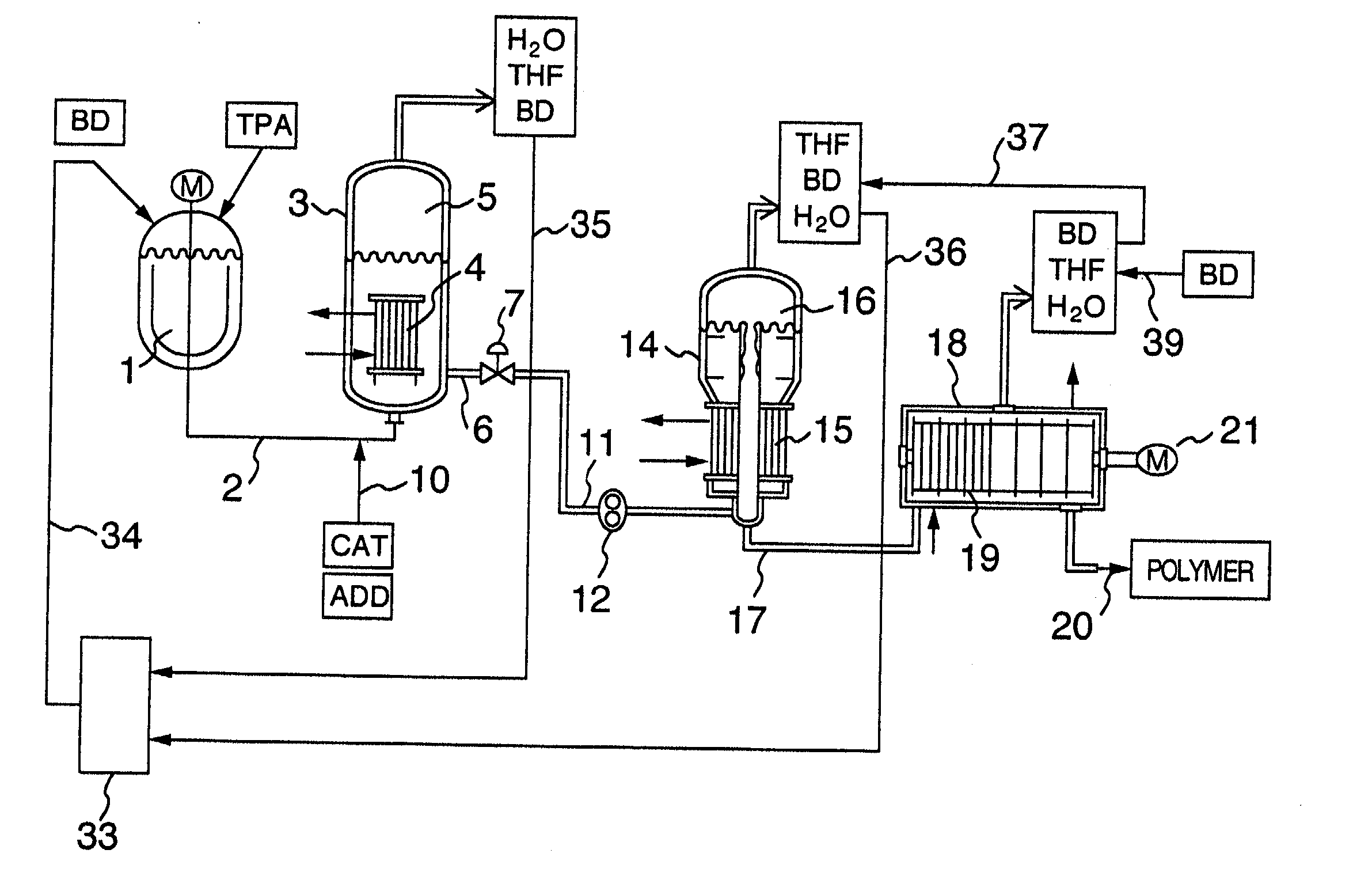

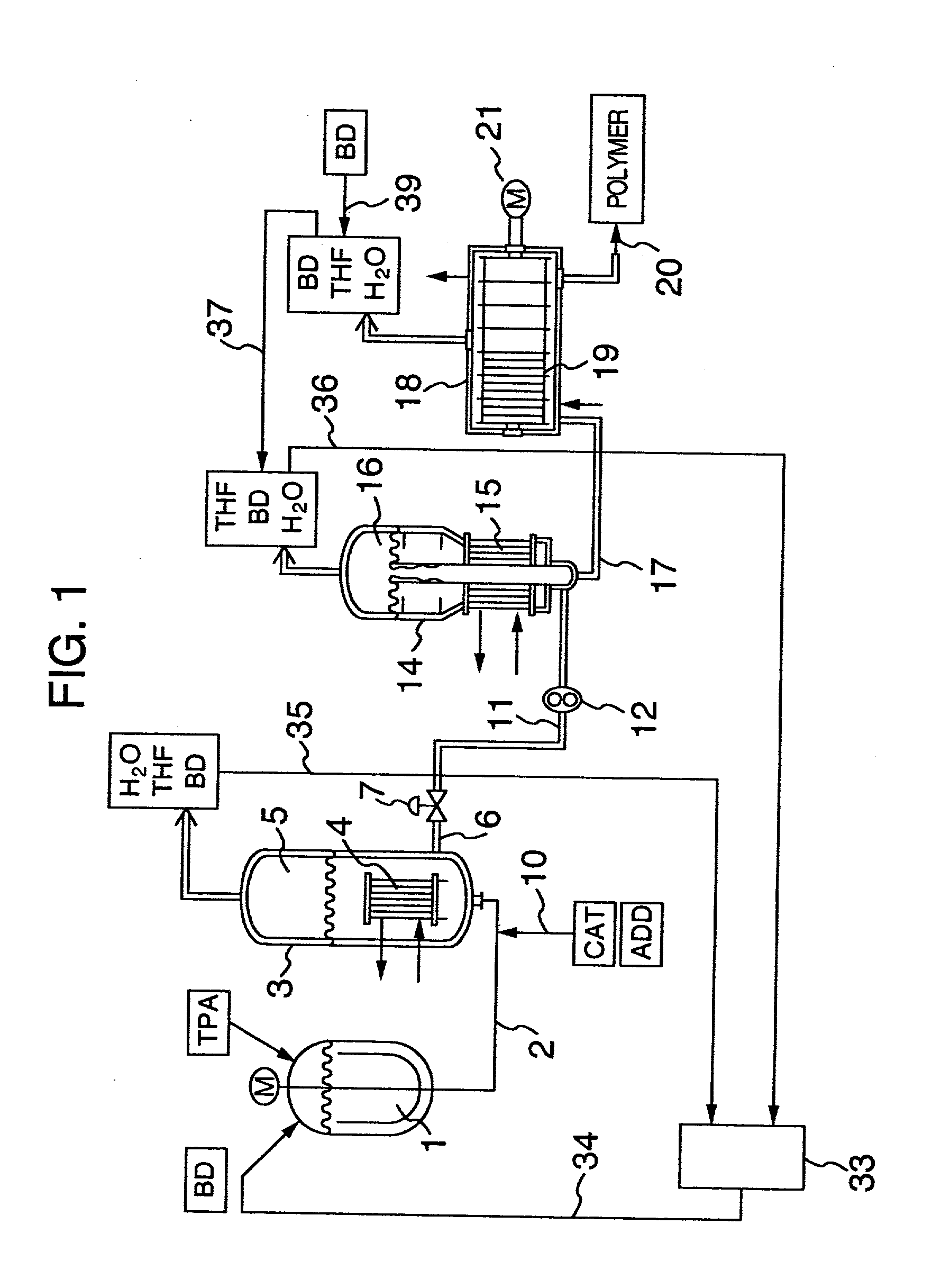

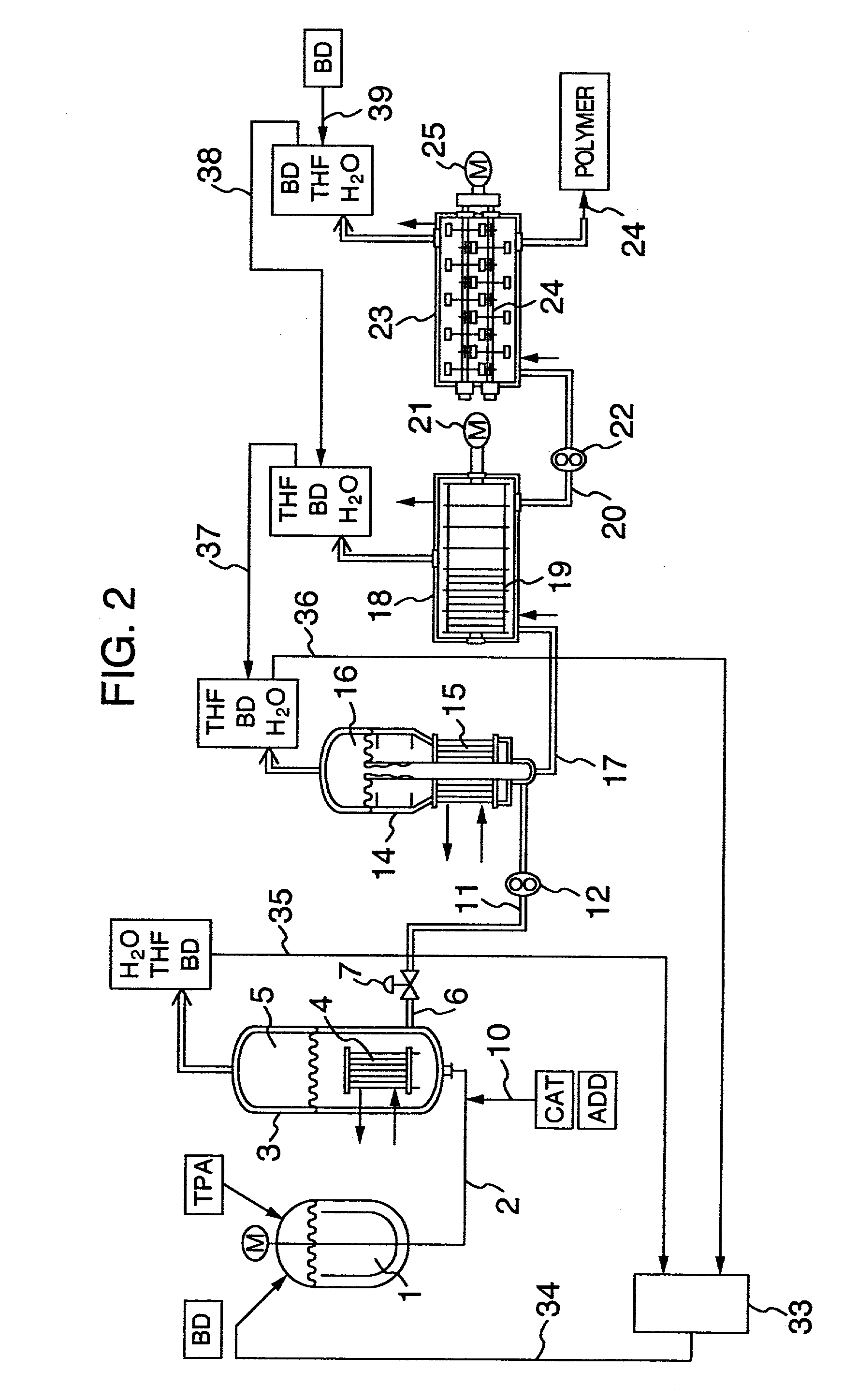

Process for continuously producing polybutylene terephthalate

InactiveUS20020128399A1Improve effectivelyGood molding effectChemical/physical/physico-chemical stationary reactorsLiquid-gas reaction processesPolytetramethylene terephthalatePolybutylene

Polybutylene terephthalate having good heat stability and excellent hydrolysis resistance is continuously produced in a series of a first reactor for reacting an aromatic dicarboxylic acid comprising terephthalic acid as a main ingredient or a derivative thereof with a glycol comprising 1,4-butanediol as a main ingredient, thereby producing an oligomer with an average degree of polymerization of 2.2 to 5, a second reactor for polycondensating the oligomer from the first reactor, thereby preparing a low polymerization product with an average degree of polymerization of 25 to 40, and a third reactor for further polycondensating the low polymerization product from the second reactor, thereby producing a high molecular weight polyester with an average degree of polymerization of 70 to 130, or followed by a fourth reactor for further polycondensing the polyester from the third reactor to an average degree of polymerization of 150 to 200, thereby producing a high molecular weight polyester. Another third reactor or a plurality of third reactors can be provided in parallel to the third reactor, thereby producing different kinds of polybutylene phthalate with different degrees of polymerization from that produced in the main line of the third and fourth reactors or adjusting operating conditions of each of a plurality of the third reactors to increase kinds, precise quality.

Owner:HITACHI LTD

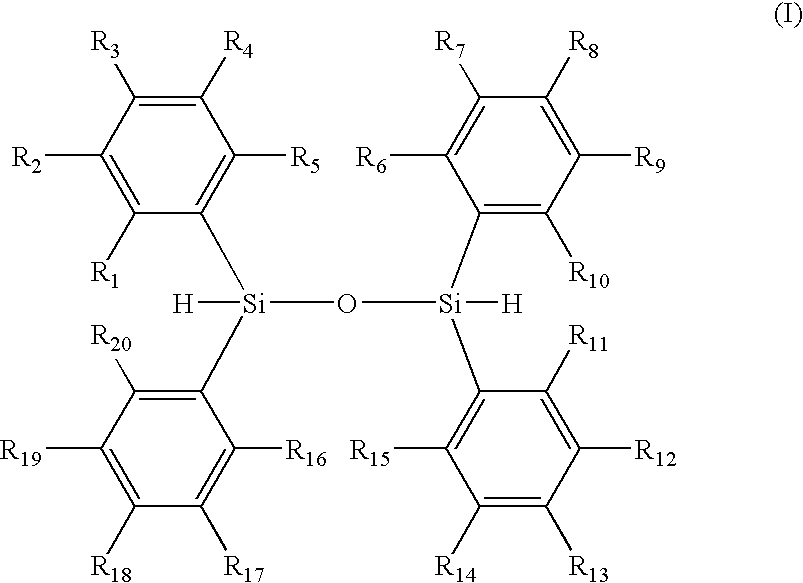

Organic Silicon-Based Compound And Method Of Producing The Same

InactiveUS20070203275A1Good lookingAvoid thermal decompositionSilicon organic compoundsPlastic/resin/waxes insulatorsArylCompound (substance)

Provided are an organic silicon compound of the following formula (I): (wherein, R1 to R20 represent each independently alkyl, alkoxy, aryloxy, cycloalkyl, alkylcycloalkyl, aryl, dialkylamino or the like, and the aryloxy and aryl may be substituted with a substituent selected from the group consisting of alkyl, alkoxy and alkoxyalkyl.) which can be used for suppression of coloration and thermal deterioration of an organic material in molding, and an organic material composition containing the organic silicon compound and a method of producing the organic silicon compound.

Owner:SUMITOMO CHEM CO LTD

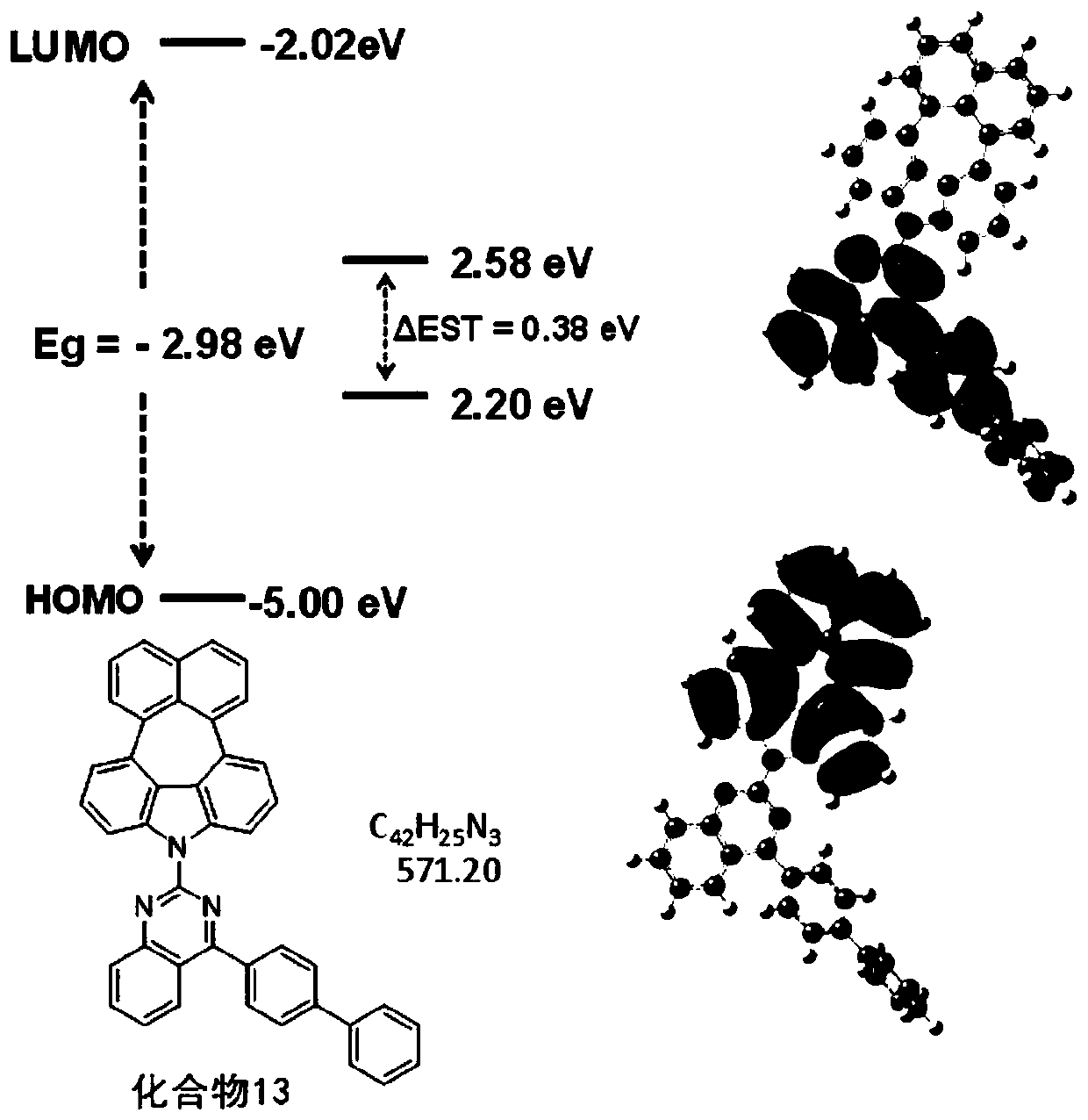

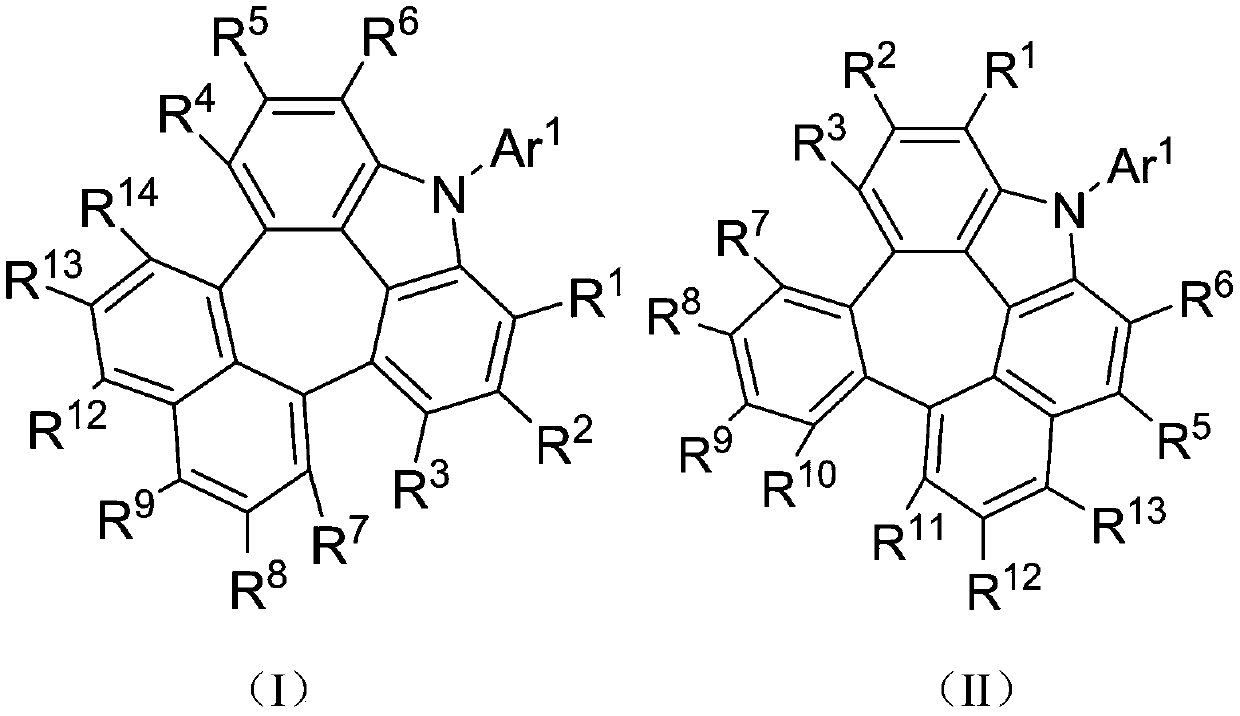

Condensed-ring compound and preparation method and application thereof

InactiveCN110698387AReduced bandgap widthPrevent backflowGroup 5/15 element organic compoundsSolid-state devicesOrganic electroluminescenceMaterials science

The invention discloses a condensed-ring compound and a preparation method and an application thereof. The condensed-ring compound has a structure represented by formula (I) or formula (II). The HOMOand LUMO energy levels of the fused-ring compound are completely separated, so that the energy gap width of the material is reduced, the three-wire energy level is improved, and the energy backflow from the object material to the main material is avoided to reduce the luminous efficiency; HOMO and LUMO energy levels are matched with adjacent materials, and the driving voltage is small. The devicehas large molecular structure size and good intramolecular conjugation, so it has good thermal stability, can avoid thermal decomposition of materials during film formation or use, avoids loss of material layer function, and improves luminous efficiency and luminous performance of the device. The invention also provides a preparation method of the fused-ring compound and its application as an organic electroluminescent material.

Owner:NINGBO LUMILAN NEW MATERIAL CO LTD

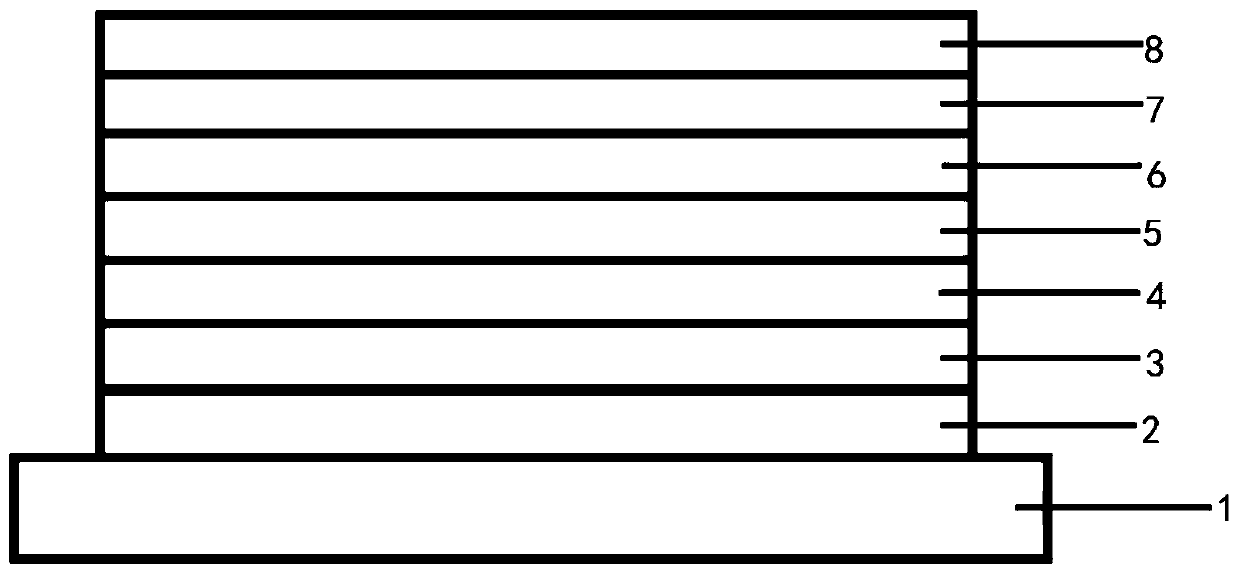

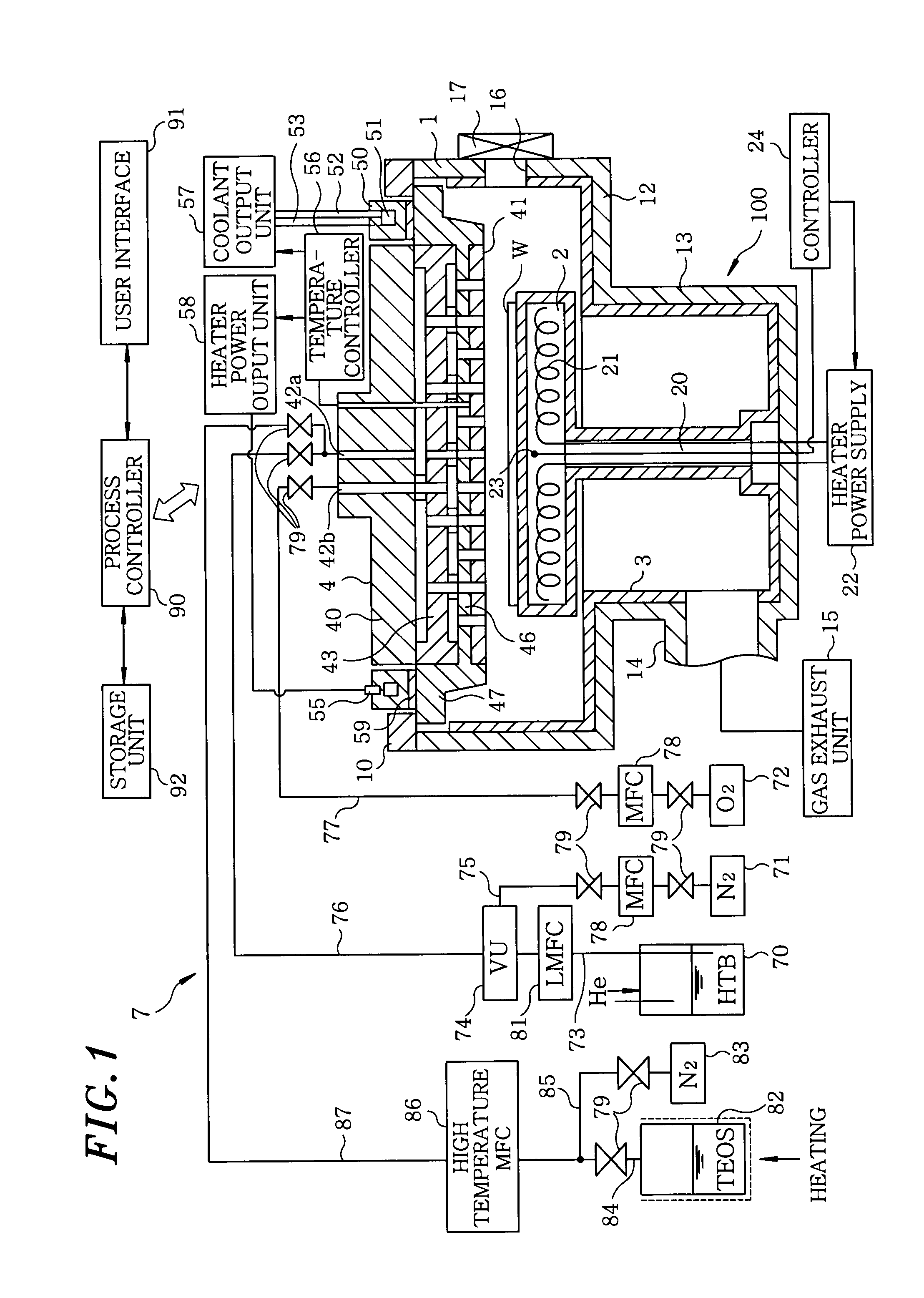

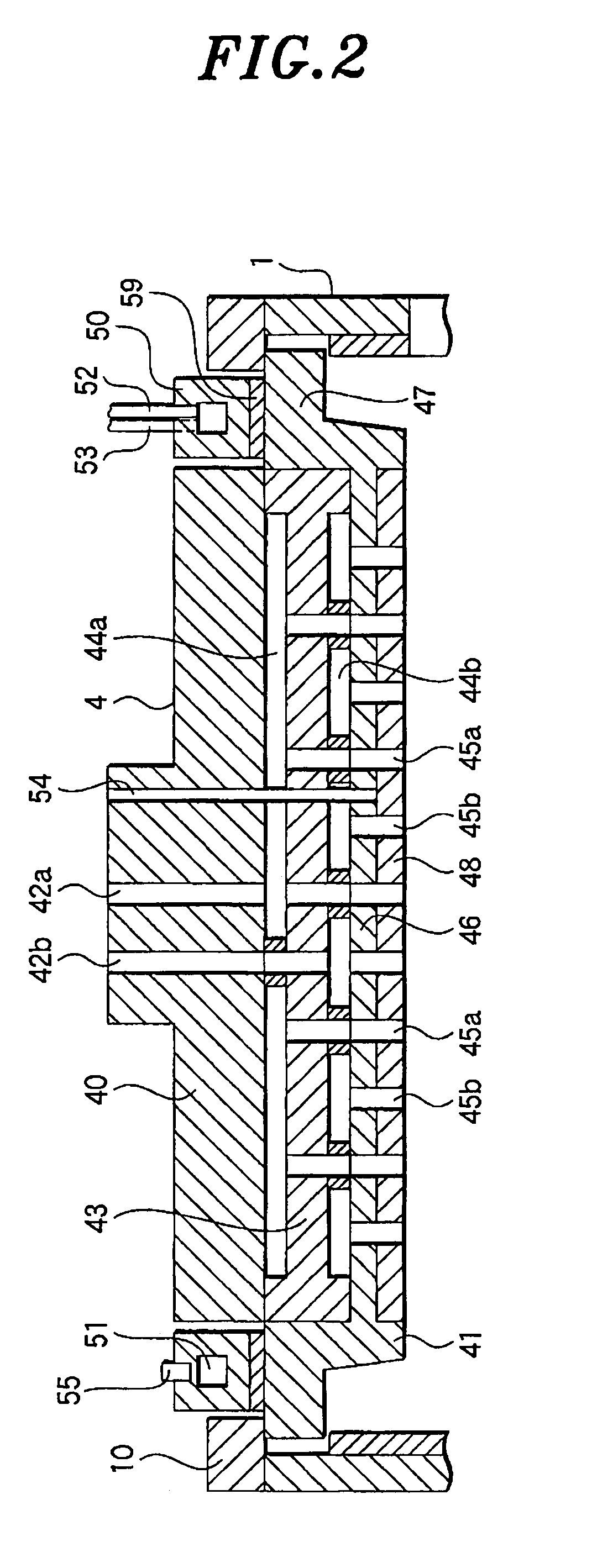

Gas treatment apparatus

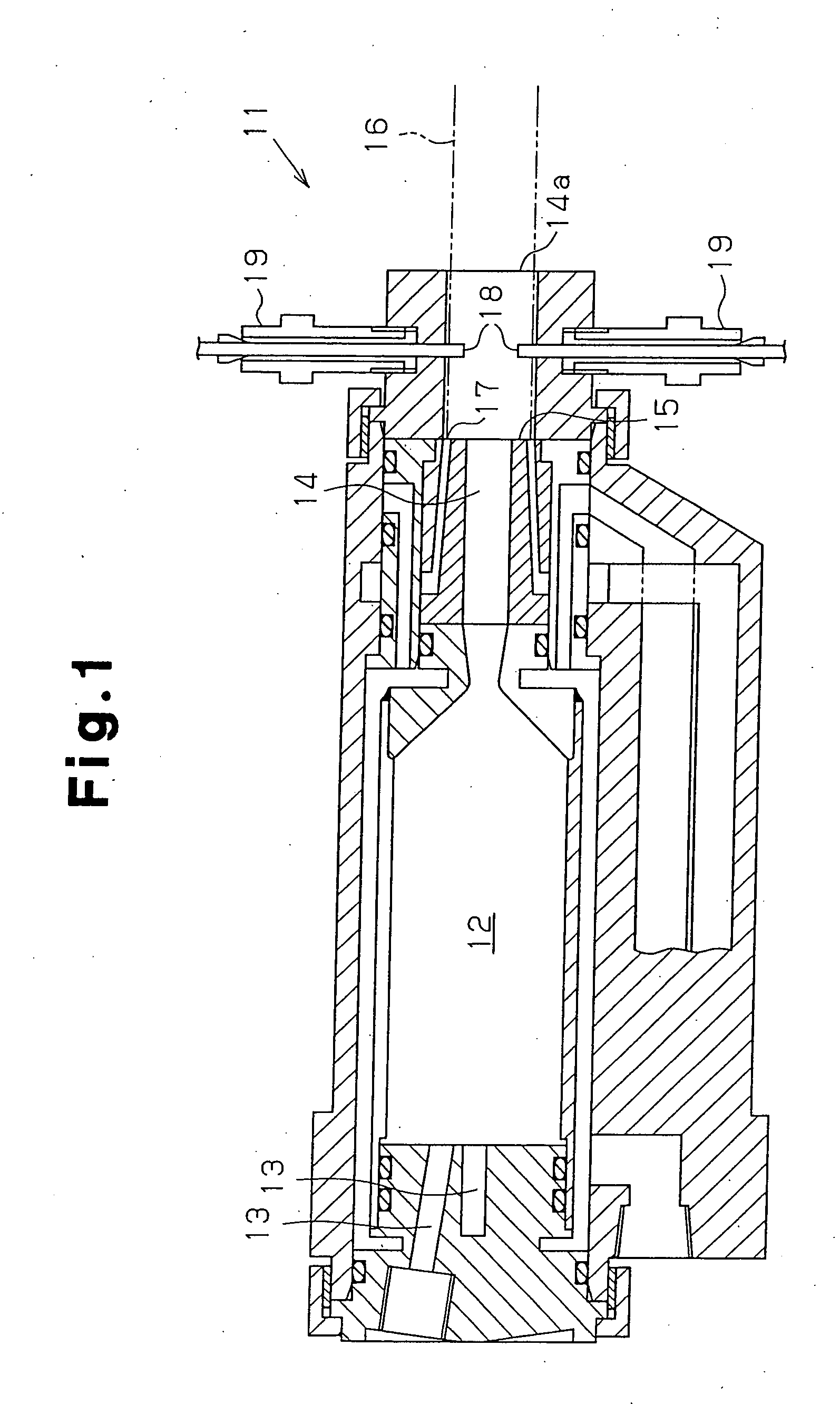

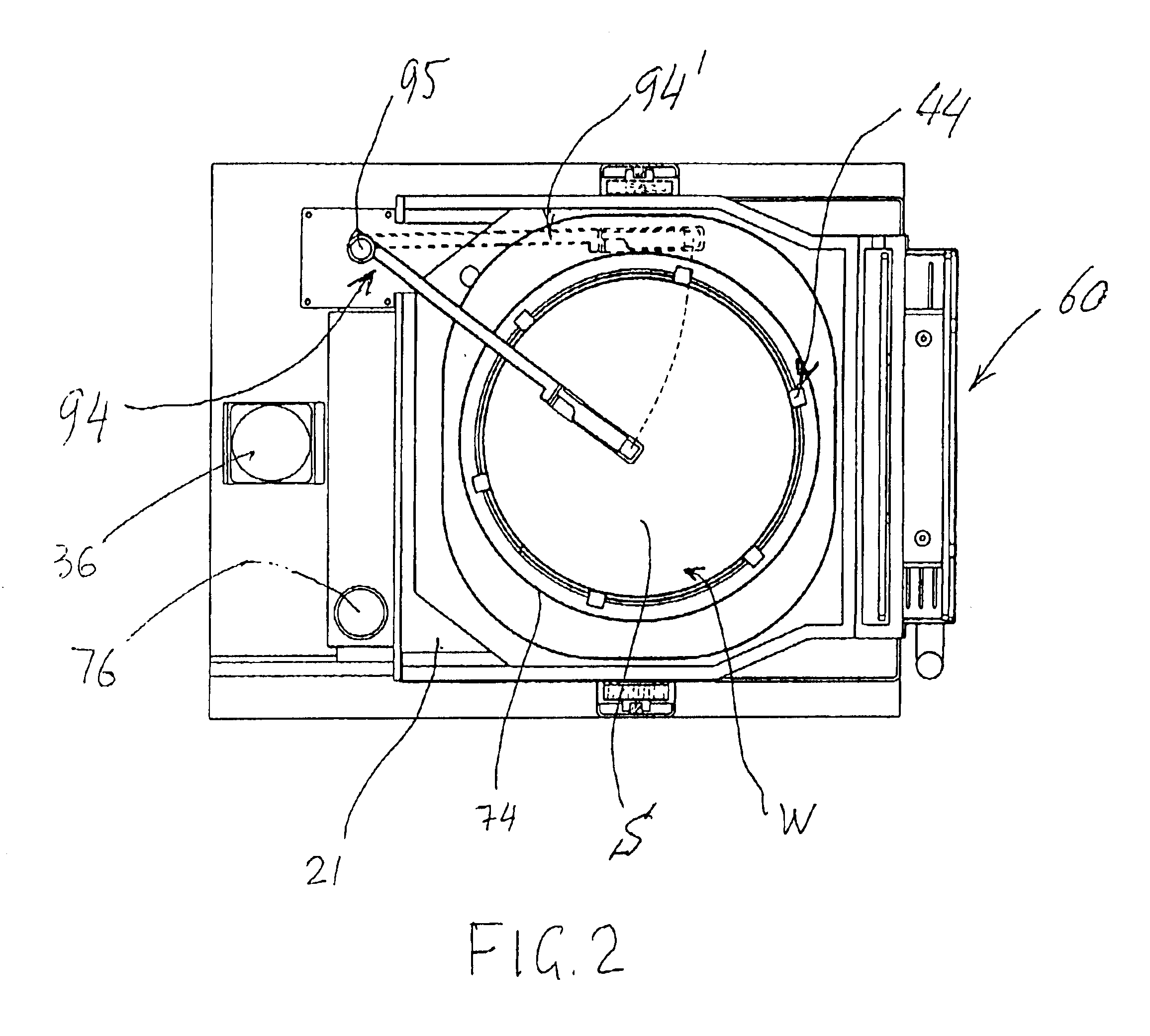

InactiveUS20090250008A1Reducing defect and nonuniformityInhibit temperature riseSemiconductor/solid-state device manufacturingChemical vapor deposition coatingAtmospheric airProduct gas

A film forming apparatus includes a chamber for accommodating a wafer; a mounting table arranged in the chamber to mount the wafer thereon; a shower head arranged to face the mounting table for injecting a processing gas into the chamber; and a gas exhaust mechanism for evacuating the chamber. The shower head is provided with a center portion in which a plurality of gas injection holes are formed for injecting the processing gas; and an outer peripheral portion disposed at outside of the center portion without having the gas injection holes. The film forming apparatus further includes a heat dissipating mechanism for dissipating heat of the shower head from the entire circumference of the outer peripheral portion to the atmosphere.

Owner:TOKYO ELECTRON LTD

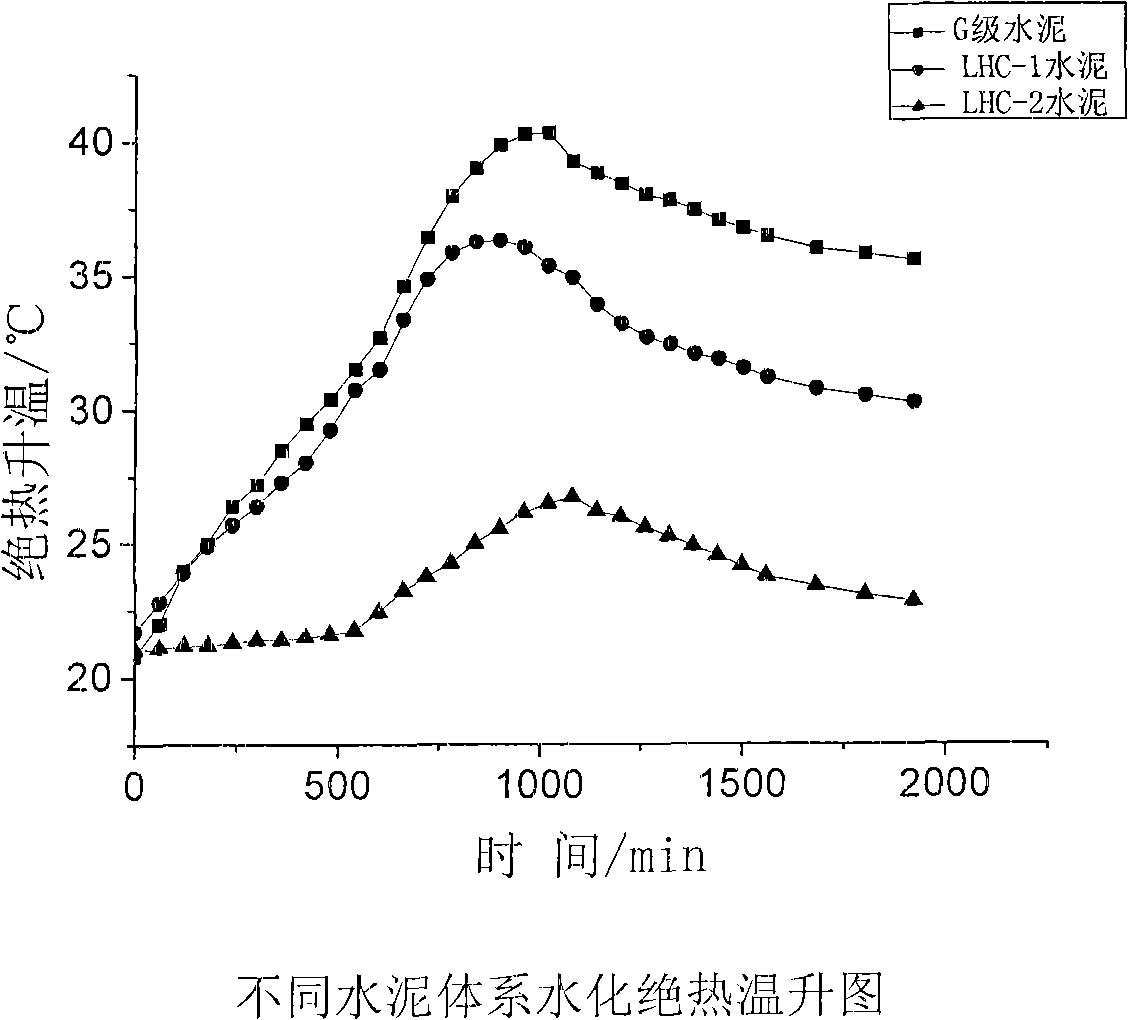

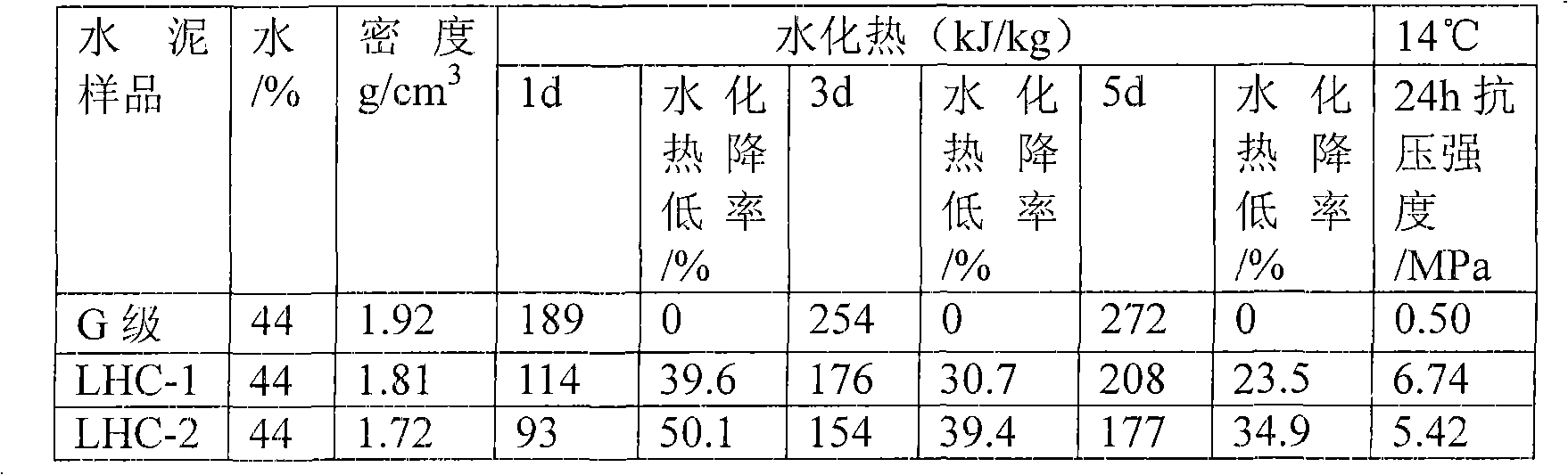

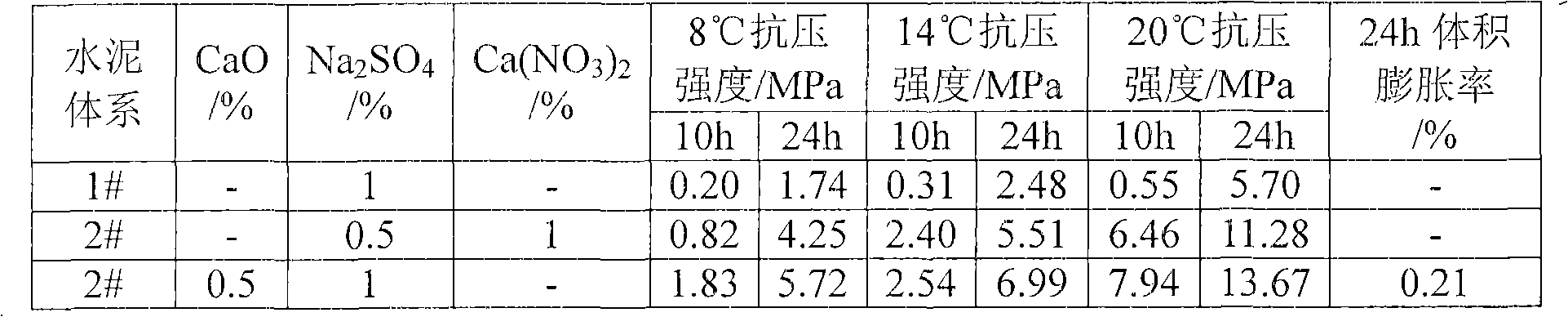

Low temperature low hydration heat cementing cement system

InactiveCN101328050AImprove performanceAvoid thermal decompositionSolid waste managementDrilling compositionSlagHydrate decomposition

The invention relates to a low temperature and low hydration heat cementing concrete system used in the natural gas hydrate layer cementing field. The objective of the invention is to effectively reduce the heat release of the cement hydration, prevent the hydrate from decomposing because of large heat and reduce the harm of the hydrate to the cementing. The whole performance of the cement under the low heat release condition is improved by adding materials which can reduce the whole hydration heat release of the cement using G grade oil well cement as base material. (1) The proper addition of superfine slag with a specific surface area between 6000 and 12000cm2 / g can make sure the strength properties of the early and later stage of the cement. (2) The hydration heat is further reduced by adding fly ash with a lower hydration activity. (3) An amount of gypsum component is added so that the cement paste has certain expansion property at a low temperature to prevent the cement paste shrinking at a low temperature. The low temperature and low hydration heat cementing concrete provided by the invention has an obvious effect for reducing the whole cement hydration heat and a good effect for preventing the deep water hydrate decomposition.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Electrolyte, electrolyte solution for lithium-ion secondary battery comprising the electrolyte, and lithium-ion secondary battery using the electrolyte solution

ActiveUS20100003597A1Excellent cycle characteristicsImprove securityAlkaline accumulatorsElectrolytic capacitorsPhosphoniumLithium-ion battery

An object of the present invention is to provide an electrolyte solution for lithium-ion secondary batteries comprising a tetraalkylphosphonium salt which improves the cycle characteristics and safety of lithium-ion batteries, and to provide a lithium-ion secondary battery using the electrolyte solution. Disclosed is an electrolyte comprising a tetraalkylphosphonium salt represented by general formula (1)wherein R1 represents a linear, branched or alicyclic alkyl group having 2 to 6 carbon atoms and R2 represents a linear, branched or alicyclic alkyl group having 1 to 14 carbon atoms, provided that R1 and R2 are different from each other and the total number of carbon atoms in the phosphonium cation is 20 or less; and X represents an anion.

Owner:NIPPON CHECMICAL IND CO LTD

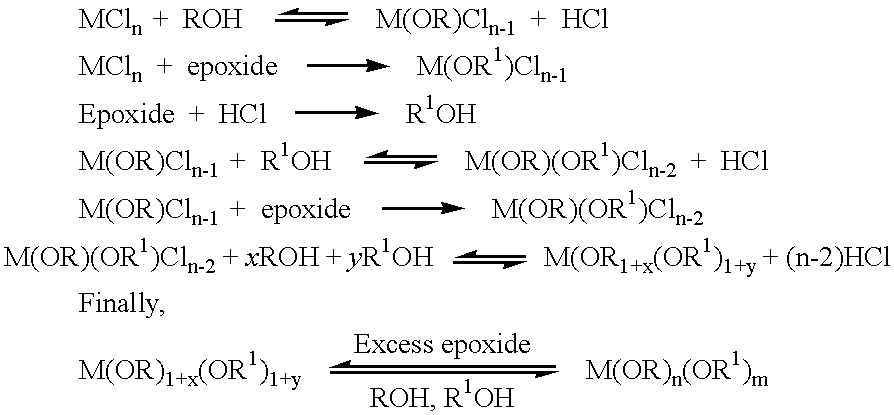

Preparation of metal alkoxides

InactiveUS6355821B1Heat dissipationReduce thermal decompositionPlatinum group organic compoundsCopper oxides/halidesSolventEthanol

Methods of forming metal alkoxides and methods of forming precursor solutions of metal alkoxides suitable for the coating of glass in the manufacture of electrochromic devices are disclosed. The method of forming metal alkoxides involves dissolving the metal halide in an anhydrous solvent and reacting it with an alcohol and (together with the addition of the alcohol or subsequently) adding an epoxide, and then evaporating-off the volatile components of the reaction product to leave a solid metal alkoxide that is substantially free of halide. The alkoxide may then be dissolved in a solvent including an alcohol (preferably ethanol) containing a small proportion of water to produce a precursor solution suitable for coating glass, the coating then being hydrolyzed to form a sol-gel and then baked to remove volatile components and to yield a thin layer of metal oxide.

Owner:DYESOL PTY LTD

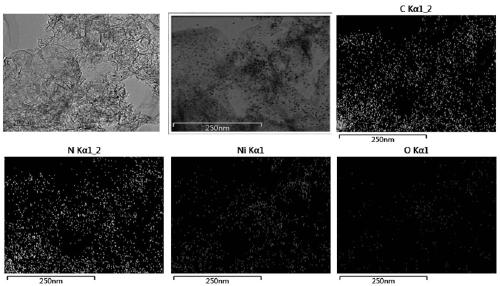

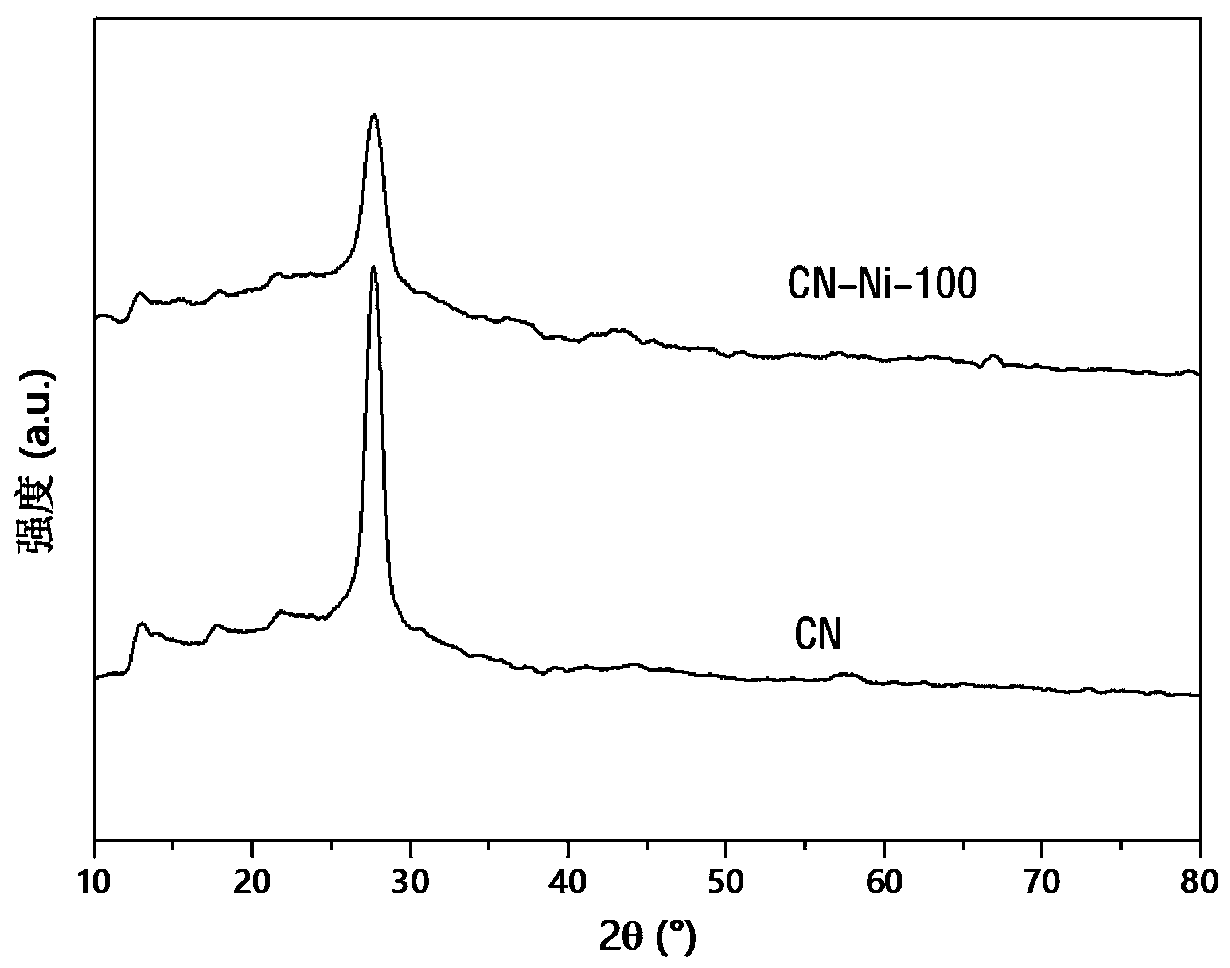

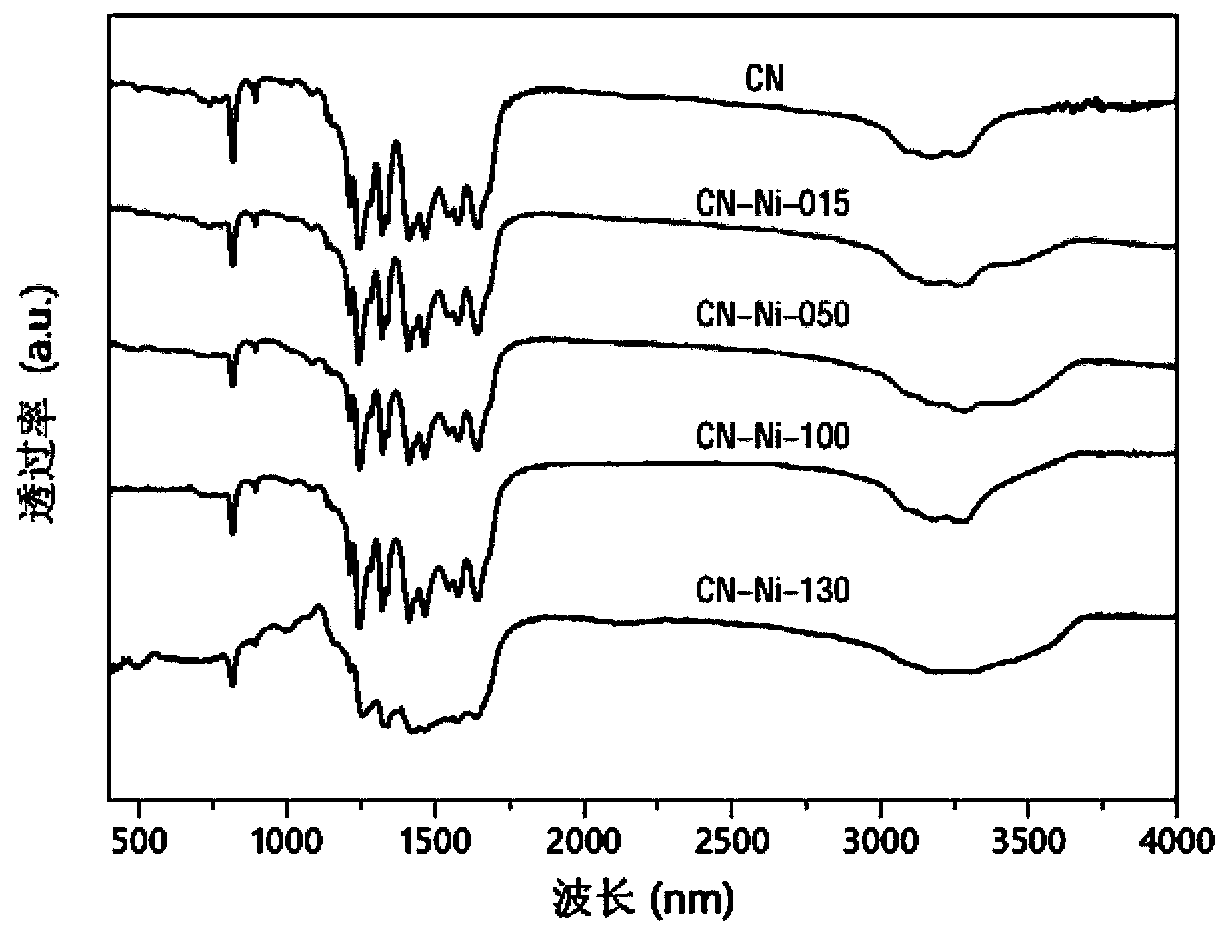

Nickel single-active site graphite-phase carbon nitride-based photocatalytic material as well as preparation method and application thereof

InactiveCN109420514AReduce manufacturing costImproved response to visible lightPhysical/chemical process catalystsHydrogen productionNickelAqueous solution

The invention relates to a Nickel single-active site graphite-phase carbon Nitride-based photocatalytic material as well as a preparation method and application thereof, in the photocatalytic material, Ni is dispersed in a g-C3N4 framework in a single-atom-level degree to form active sites, and the molar content of the Ni is 1-5%. the nickel single-active site graphite-phase carbon nitride-based photocatalytic material has a large specific surface area, is good in dispersion in an aqueous solution, and can effectively inhibit the recombination of photo-generated carriers, the reaction activitysites of the surface of the g-C3N4 are increased, the photocatalytic hydrogen production efficiency can be remarkably improved, and the photocatalytic reaction activity of the g-C3N4 can be improved.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

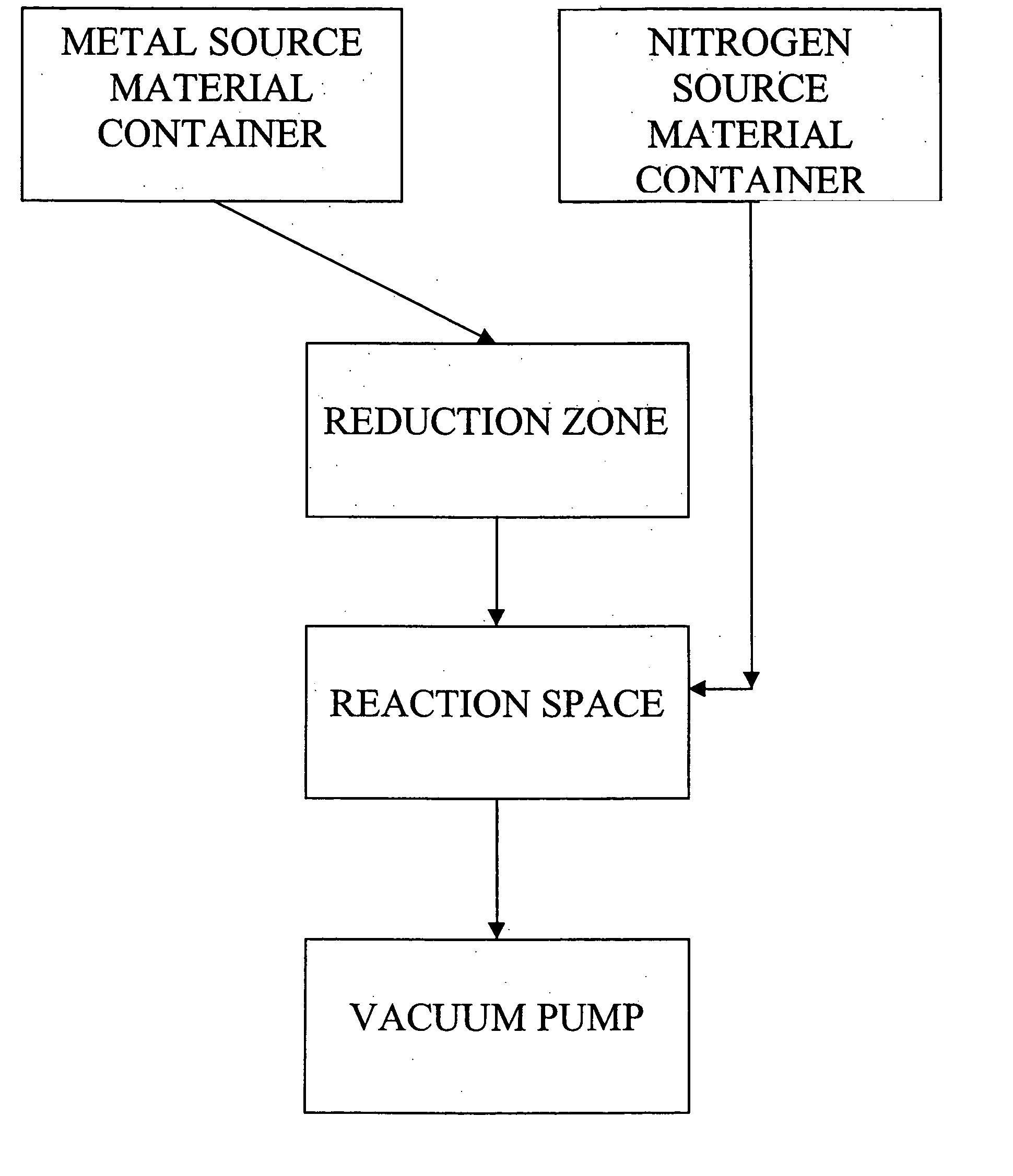

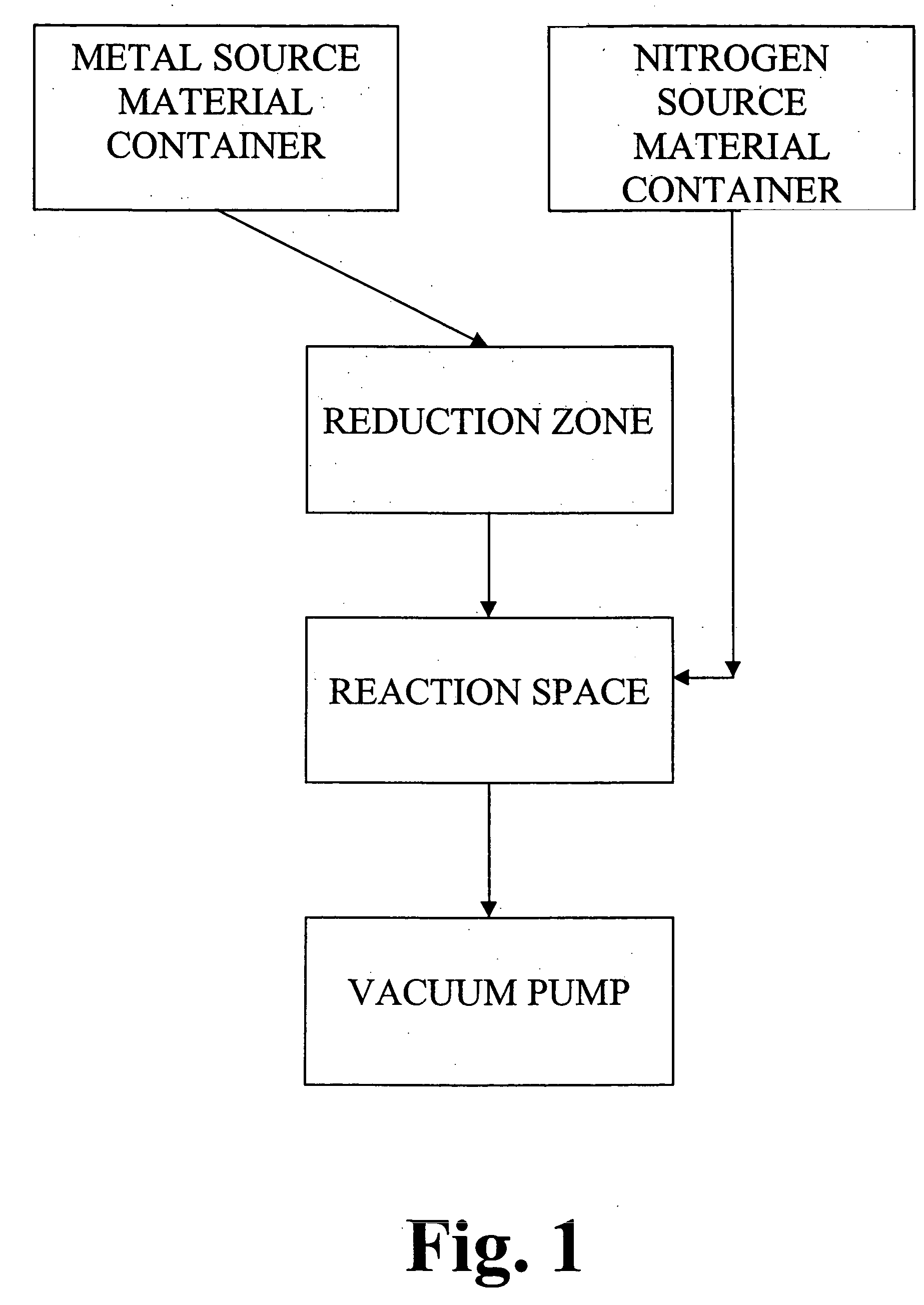

Method of modifying source chemicals in an ALD process

InactiveUS20050000431A1Short cycleEfficient growth processPolycrystalline material growthSolid-state devicesSource materialCompound (substance)

The invention concerns a method for modifying a source material used in an ALD process, a method for depositing transition metal nitride thin films by an ALD process and apparatus for use in such process. According to the present invention, transition metal source materials are reduced by vaporizing a metal source material, conducting the vaporized metal source material into a reducing zone comprising a solid reducing agent maintained at an elevated temperature. Thereafter, the metal source material is contacted with the solid or liquid reducing agent in order to convert the source material into a reduced metal compound and reaction byproducts having a sufficiently high vapor pressure for transporting in gaseous form.

Owner:ELERS KAI ERIK

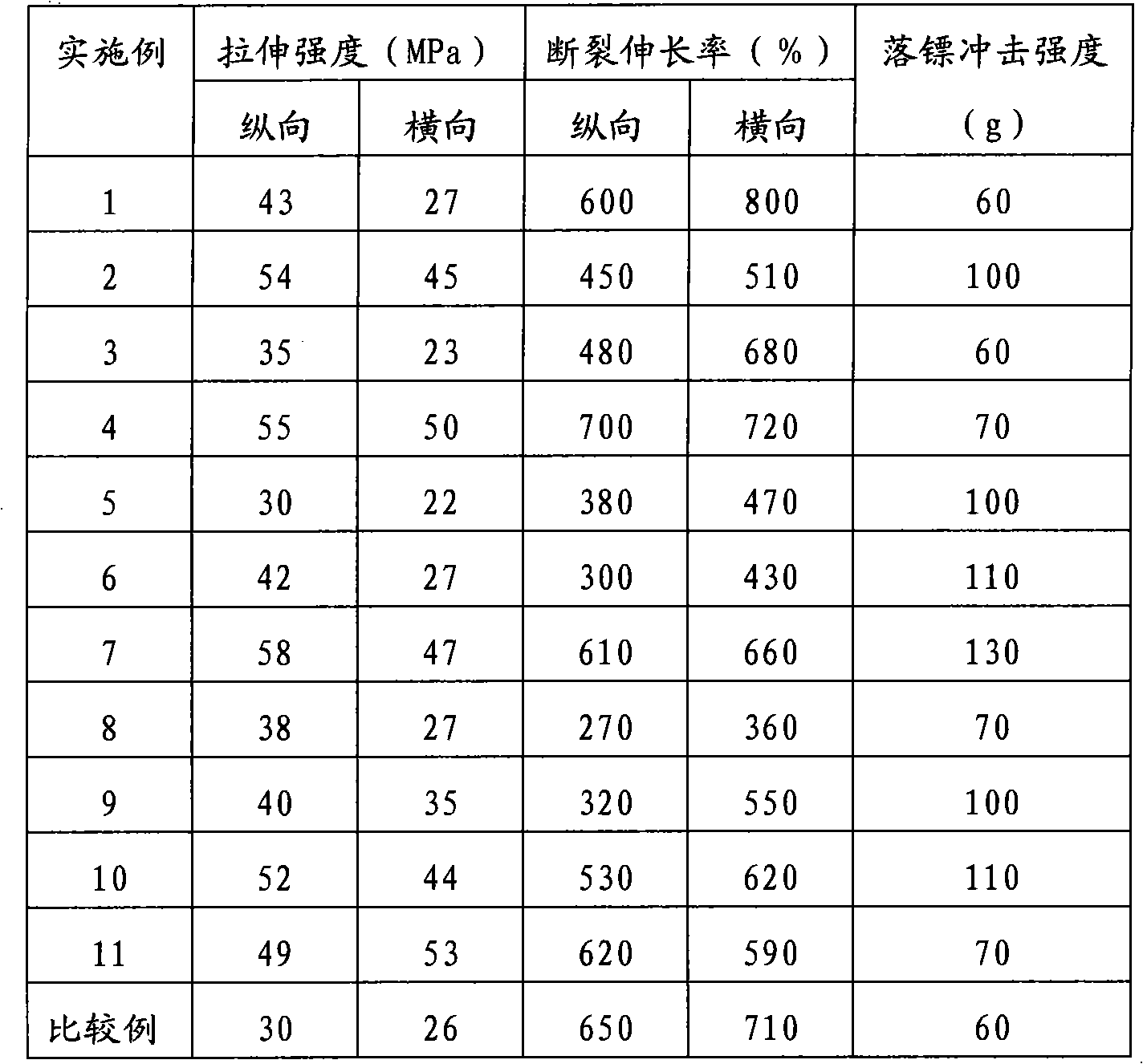

Biodegradable film containing aliphatic polycarbonate and preparation method thereof

InactiveCN101857718ABiodegradableRaise the processing temperatureFlat articlesPolymer scienceButanedioic acid

The invention, which belongs to the technical field of biodegradable films, relates to a biodegradable film containing aliphatic polycarbonate. The biodegradable film is characterized in that the biodegradable film consists of the following components in part by weight: 30 to 60 parts of polycarbonate1, 2-malonic ester; 40 to 70 parts of one or the mixture of poly(butanediol succinate) and poly(butanediol succinate / adipate) copolyester; 5 to 15 parts of toughening agent; 0.5 to 5 parts of plasticizer; 0.5 to 3 parts of heat stabilizer; and 1 to 40 parts of inorganic filler. The prepared film is biodegradable, and can be directly contacted with food. By adding the heat stabilizer, the thermolysis of bend is inhibited, so that the processing temperature of the film can be increased to 190 DEG C; by adding the toughening agent and the plasticizer, the impact resistance of the finished film product is enhanced, the maximum dart drop impact on the film with the thickness of 20Mum can be up to 130g, the tensile strength is higher than 50MPa, the elongation at break is higher than 600 percent, and therefore the film can fully meet the requirements of ordinary packaging materials.

Owner:NANTONG HUASHENG PLASTIC PRODS +1

Composition for producing synthetic timber and its prepn process

InactiveCN1432605AExtended shelf lifeSimple equipment requirementsPolyvinyl chlorideChlorinated polyethylene

A composition for producing synthetic timber includes polyvinyl chloride resin; wood dust, nut shell powder, crop straw powder, waste paper powder or their mixture; and at least one of chlorinated polyethylene, acrylonitrile-butadiene-styrene polymer and methyl methacrylate-butadiene-styrene polymer as impact modifier. The materials in certain weight ratio are produced into granulated material through mixing, extrusion and pelletizing; or produced into powdered material through thrice mixing. The said composition can be used for producing synthetic timber with the grains and other characteristics simmilar to natural timber for use in building.

Owner:常怀春

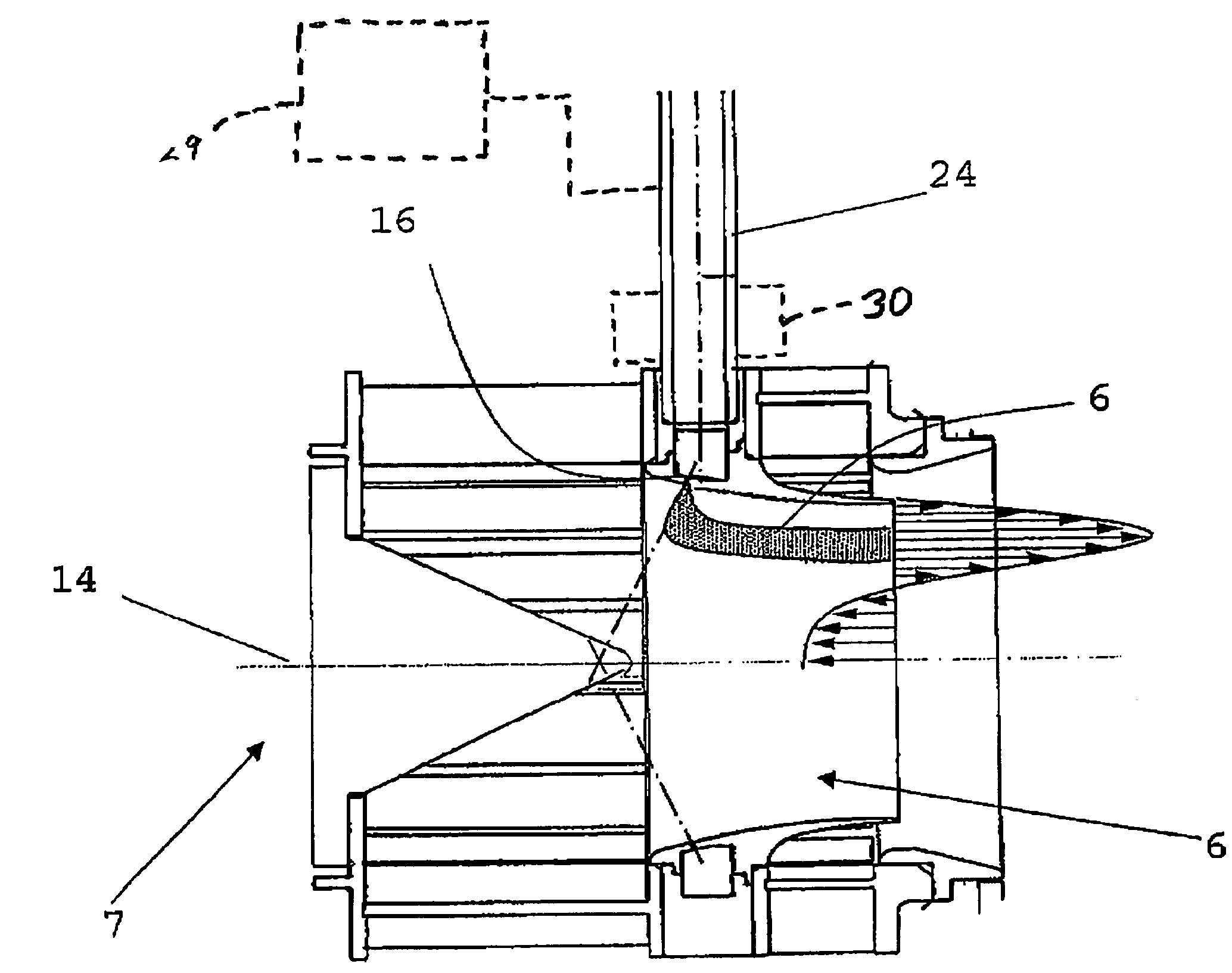

Gas turbine combustion chamber with defined fuel input for the improvement of the homogeneity of the fuel-air mixture

InactiveUS7086234B2Guaranteed cost-effective operationEvenly distributedBurnersContinuous combustion chamberCombustion chamberCombustor

A gas turbine combustion chamber with a burner 7, includes means for the supply of fuel and an atomizer 6, wherein the means for the supply of fuel are provided such that the fuel is injected in areas with maximum airflow velocity.

Owner:ROLLS ROYCE DEUT LTD & CO KG

Distillation method of oxime

The present invention relates to a distillation method of oxime. Tower bottom materials are usually heated by still distillation, a U-shaped outer tube or a rotary film evaporator, long-term operation of the tower bottom is easy to coking, and the distillation efficiency is low. The invention is characterized in that: in the distillation and separation section of oxime, at least one high boiling point solvent is added in the distillation process, the content of the high boiling point solvent in the tower bottom is maintained in proportional to that of oxime, and finally oxime is effectively separated by distillation. Oxime is fed into a rectifying tower, and is distilled at an absolute pressure of 0-0.4 MPa and at 20-300 DEG C to collect fractions. The unevaporated liquid left in the tower bottom is subjected to the processes of removing water and impurities, and is recycled to the rectifying tower as a high boiling point solvent. The present invention can reduce total production costs, simplify operation processes, prevent the product from coking in the tower bottom or decomposing due to overheating, ensure product distillation to be efficient, continuous, safe and stable, and improve product quality.

Owner:ZHEJIANG SAINON CHEM

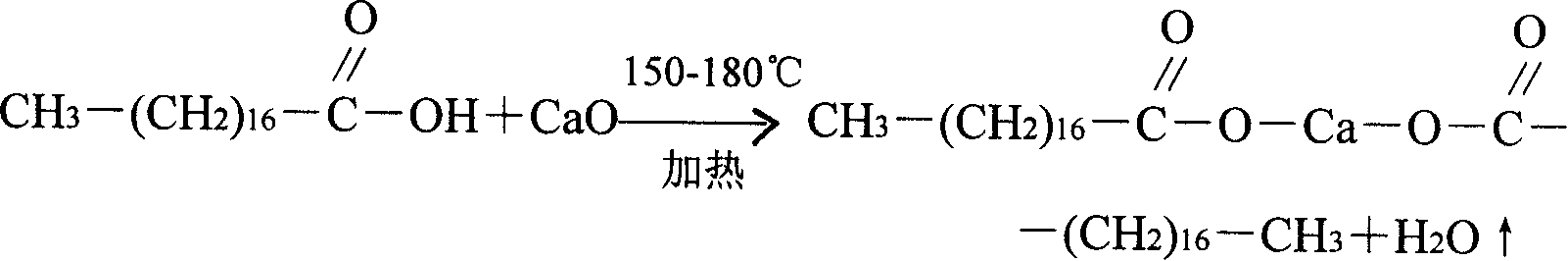

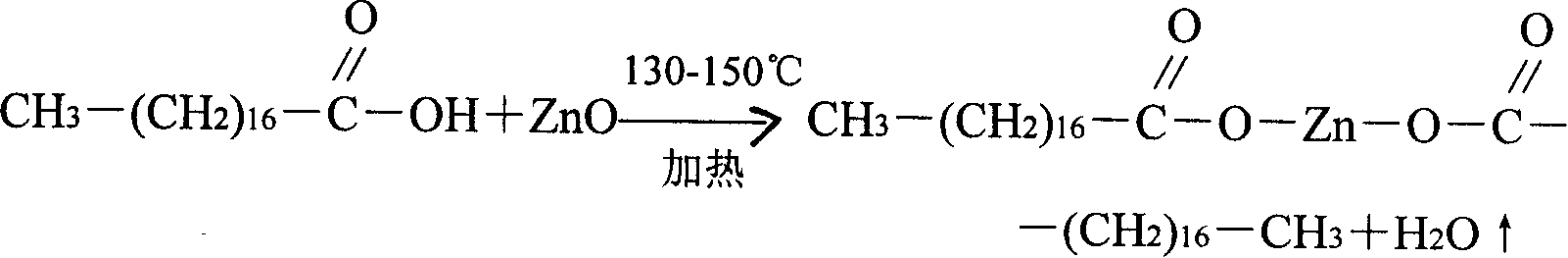

Environmental-protection efficient PVC stabilizer system and its use

The invention relates to vinyl stabilizer system and the application that includes the following steps: mixing stearic acid and lime, heating to 150-180 degree centigrade to take reaction to form calcium stearate, mixing stearic acid with zinc oxide, heating to 130-150 degree centigrade to take reaction to form zinc stearate, mixing calcium stearate with benzoyl stearyl methane, organiotin, polhydric alcohol, white wa, SG-16 inside and outside lubricant to take compounding to form several types high efficient calcium zinc composite stabilizer. It could be used in producing PVC-U feed pipe and drain pipe, soft PVC wire, cable, etc. It lowers process temperature, improves thermal stability and ageing resistance, improves the performace of engineering plastics.

Owner:吕飞华

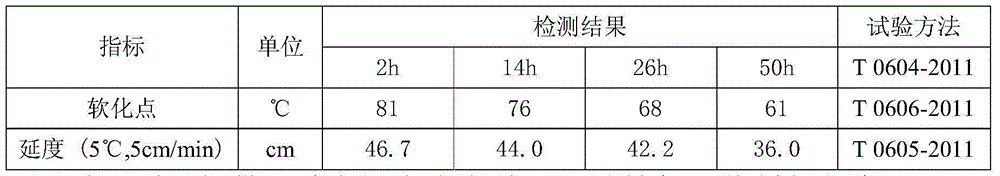

Direct-adding type instant SBS (Styrene Butadiene Styrene) modifier as well as preparation method and application thereof

The invention discloses a direct-adding type instant SBS (Styrene Butadiene Styrene) modifier prepared from the following raw materials in parts by mass: 60-85 parts of SBS, 5-25 parts of ethylene-vinyl acetate copolymer (EVA), 5-10 parts of naphthenic oil, 1-3 parts of a compatilizer and 2-4 parts of an antioxidant. The SBS modifier disclosed by the invention can be directly added into a blending tower (a process for directly adding the modifier into the blending tower is called a 'dry method' according to industry habits) to quickly melt with an aggregate and base asphalt during short-time mixing, thereby achieving micron-scale dispersion and giving play to a modification effect which is the same as that of a wet method.

Owner:BEIJING ZHONGLU PAVING TECH

Extruded expanded thermoplastic polyurethane elastomer bead and preparation method therefor

The present invention relates to an extruded expanded thermoplastic polyurethane elastomer bead and a preparation method therefor. The bead consists of components of the following parts by weight: 100 parts by weight of a thermoplastic polyurethane elastomer, 0.01-0.5 parts of a foaming nucleating agent, and 0.01-0.2 parts by weight of an antioxidant. The preparation method comprises: mixing materials, then putting the mixture into an extruder for granulation to produce a particle raw material suitable for foaming, finally, putting the particle into a foam extruder, and die foaming then underwater pelletizing, thus obtaining a product bead. The present invention utilizes an extrusion method to prepare expanded thermoplastic polyurethane beads. Control of the working conditions of the foaming process could lead to acquiring an expanded=bead of a controllable density, the cell density evenly distribute. The overall production process is easy to operate. Without any special limit or requirement placed on the equipment, this method is suitable for industrial continuous production.

Owner:MIRACLL CHEM

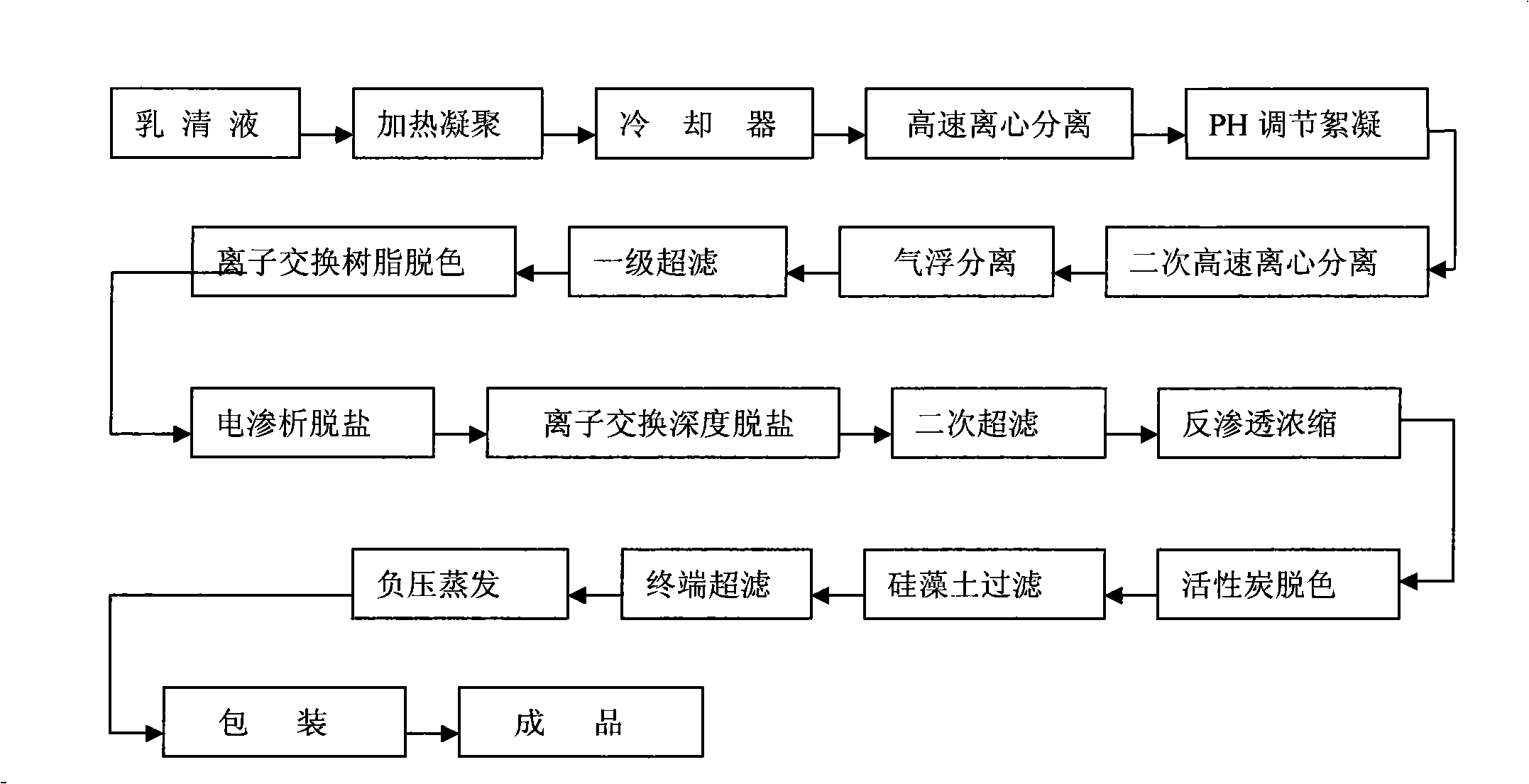

Process for extracting the soyabean oligosaccharides by air-float purification and film integration

The invention relates to a method for extracting edible oligosaccharides, specifically a method for extracting soybean oligosaccharides from soybean whey liquid by flotation purification and membrane concentration. The method comprises the following steps: thermal coagulation, cooling, high-speed centrifugal separation, pH adjustment and flocculation, secondary high-speed centrifugal separation, flotation separation, first-stage ultrafiltration, decolorization with ion exchange resin, electrodialysis desalination, further desalination with ion exchange resin, second-stage ultrafiltration, reverse osmosis concentration, activated carbon decolorization, diatomite filtration, terminal ultrafiltration and negative-pressure evaporation concentration. The invention has the advantages that: 1. based on the reasonable combination of proper molecular weight cut-off of ultrafiltration membrane and membrane assembly, operation mode and efficient cleaning, the method works continuously and stably for long time; 2. the method realizes the pretreatment by using multi-stage high-efficiency centrifugal separation technique, without using filter aids and producing pollutants, and the separated protein residue can be recycled; and 3. the method has simple process and low equipment and operation costs.

Owner:逄镜萍

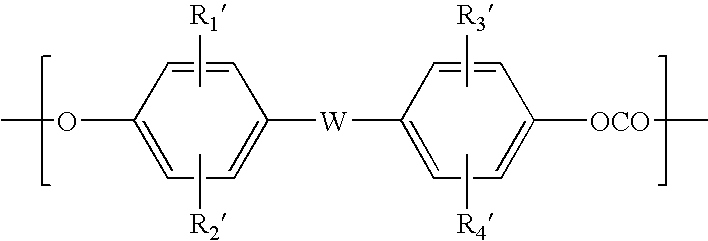

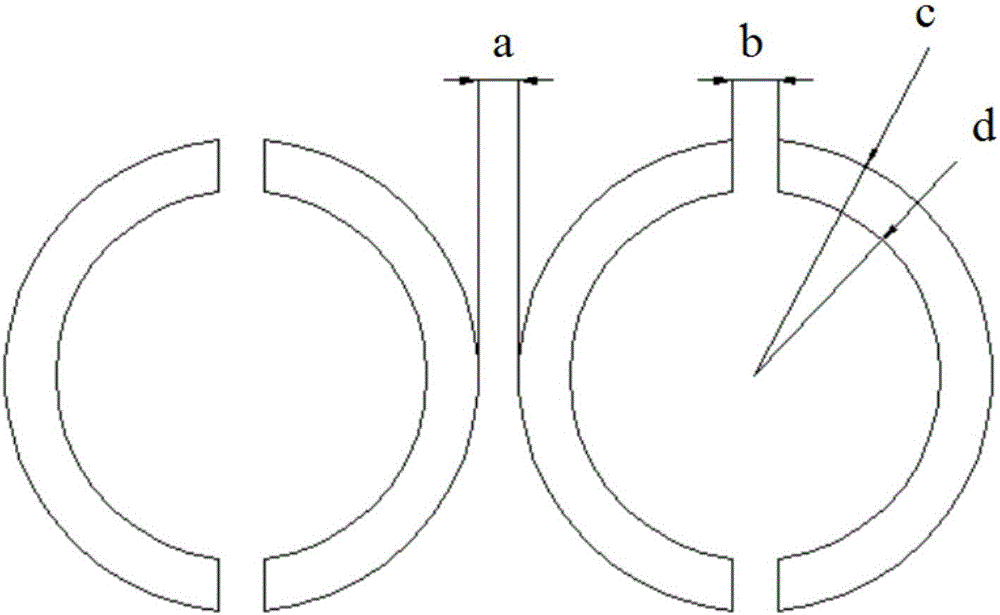

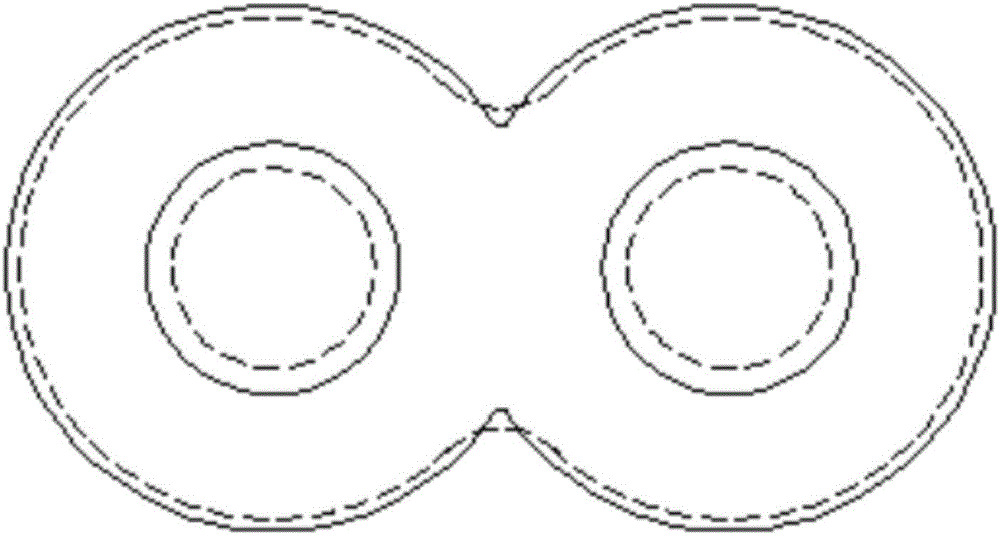

8-shaped hollow polyester fiber FDY (Fully Drawn Yarn) and preparation method thereof

ActiveCN106801265AReduce extrusion swelling effectImprove featuresMelt spinning methodsMonocomponent polyesters artificial filamentYarnFiber

The invention belongs to the polyester spinning field and relates to an 8-shaped hollow polyester fiber FDY (Fully Drawn Yarn) and a preparation method thereof. A spinning melt contains saturated fatty acid metal salt and modified polyester, wherein the mass ratio of saturated fatty acid metal salt to modified polyester is (0.0005-0.002) to 1; saturated fatty acid metal salt is fatty acid metal salt, the carbon atomic number is 12-22, the melting point is 100-180 DEG C, and the kinetic viscosity is less than or equal to 1Pa.s; a molecular chain of modified polyester comprises a terephthalic acid chain segment, a glycol chain segment and a rigid structure chain segment, and the molar ratio of the rigid structure chain segment to the terephthalic acid chain segment is (0.02-0.05) to 1; and the die swell ratio of the spinning melt is 1.23-1.33, and the after-filtration pressure during the spinning is 85-125kg / cm<2>. The prepared 8-shaped hollow polyester fiber FDY has relatively high degree of hollowness and relatively good shape-preserving effect.

Owner:JIANGSU HENGKE ADVANCED MATERIALS CO LTD

Extraction process of coconut oil

Owner:海南建邦制药科技有限公司

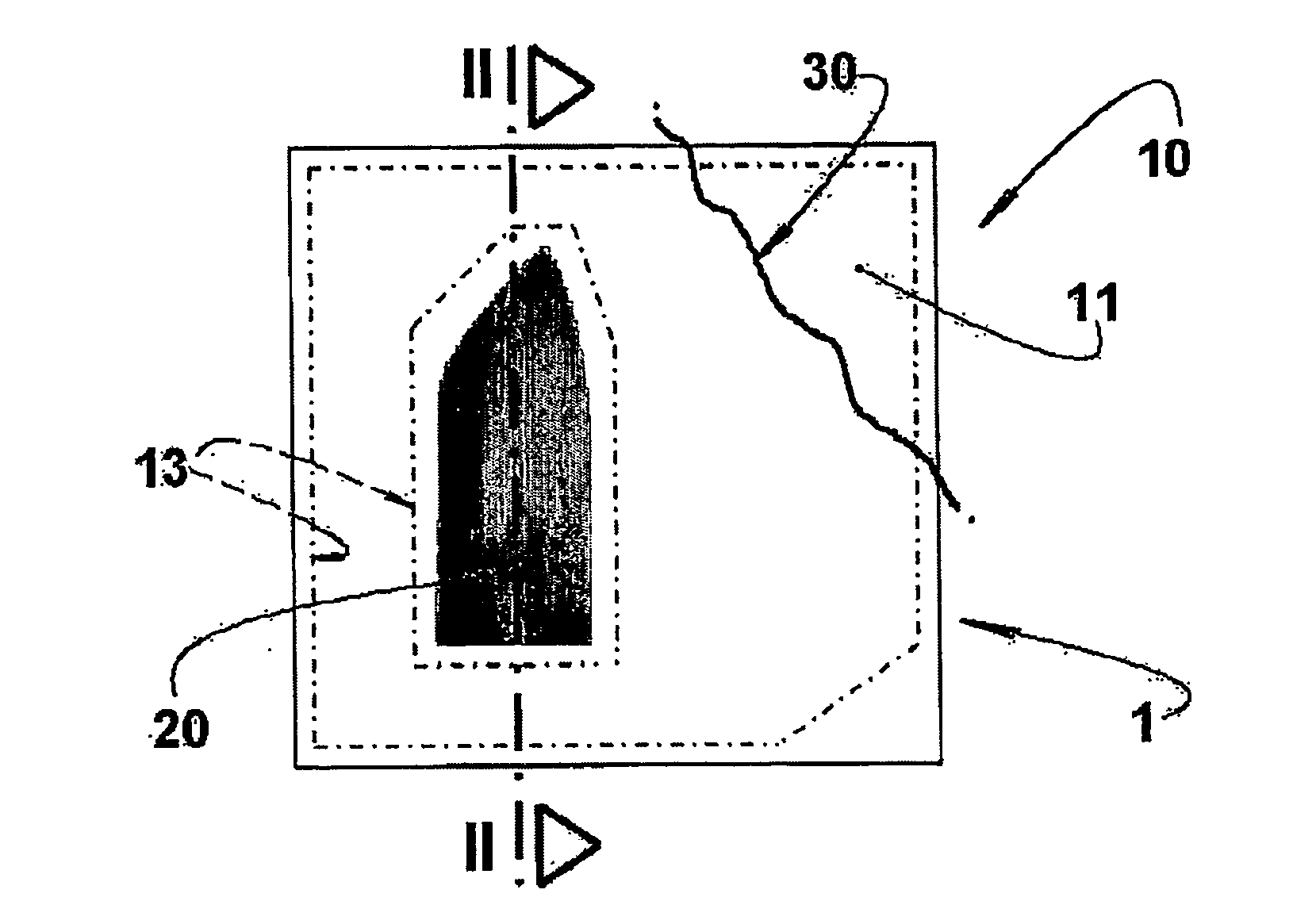

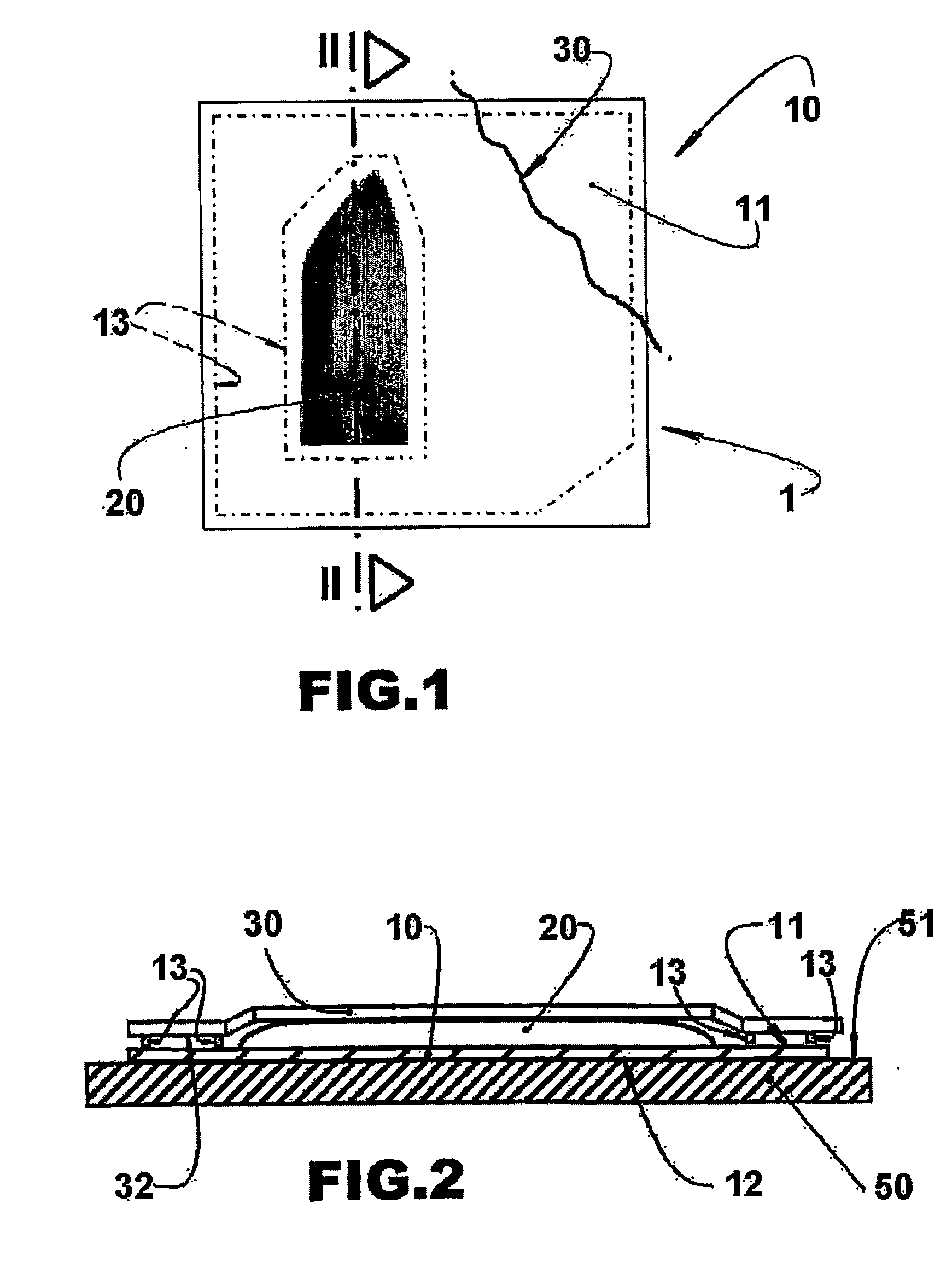

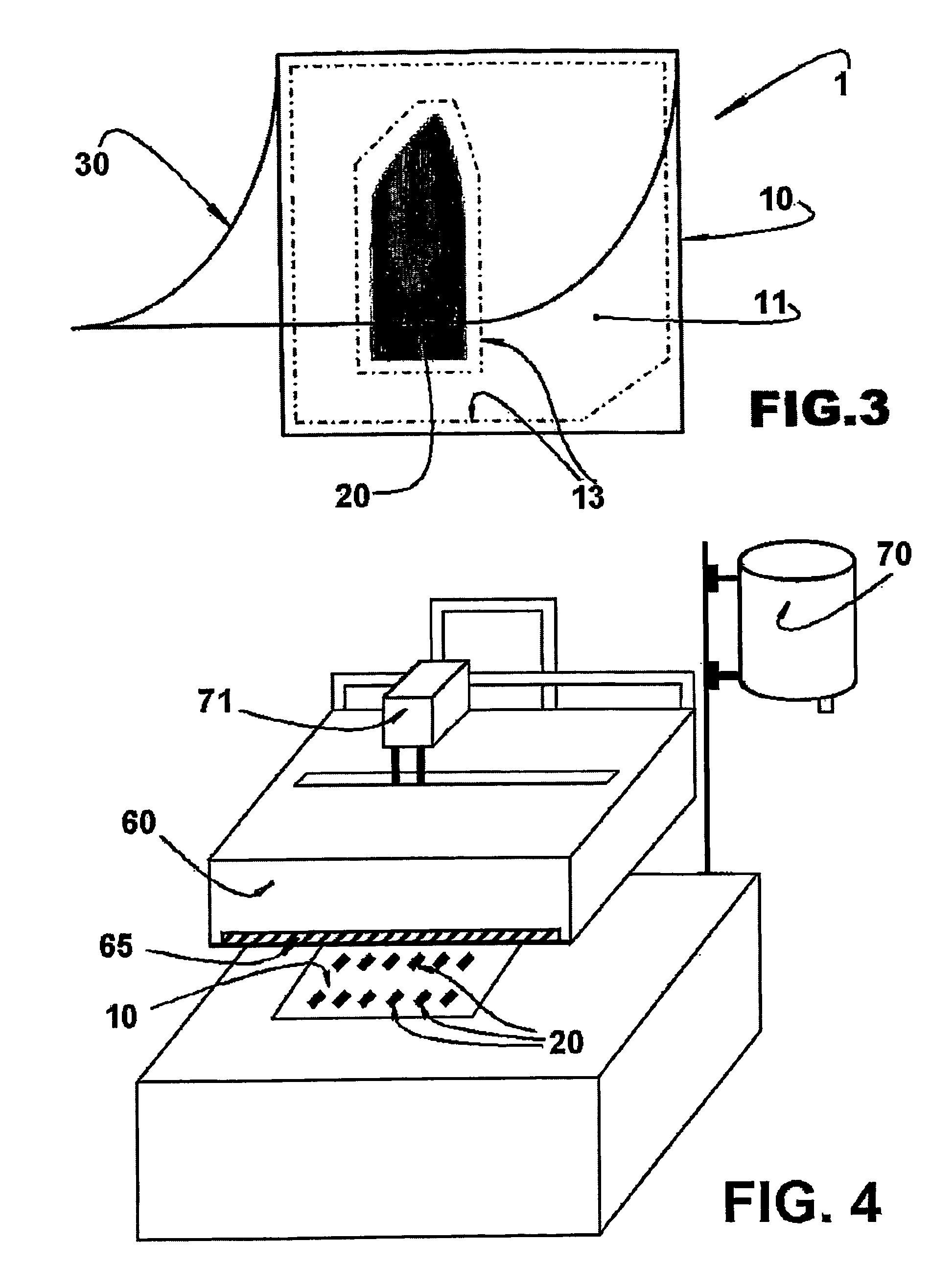

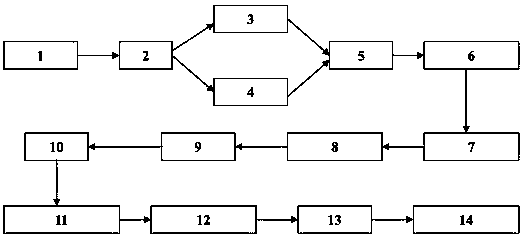

Cosmetic Sampler and Process to Manufacture the Same

InactiveUS20080011319A1Maintain qualityAvoid thermal decompositionLaminationLamination apparatusLower faceBiomedical engineering

COSMETIC SAMPLER AND PROCESS TO MANUFACTURE THE SAME, said cosmetic sampler comprising: a base film (10) presenting an oleophobic upper face (11); a cosmetic product portion (20) deposited an retained on the oleophobic upper face (11) of the base film (10); a covering film (30) having an oleophobic lower face (32) hermetically and removably fixed onto the oleophobic upper face (11) of the base film (10), in order to cover the cosmetic product portion (20). The process to manufacture the cosmetic sampler comprises the steps of: depositing on said oleophobic upper face (11) of the base film (10) a cosmetic product portion (20) maintained at a determined temperature range and according to a predetermined contour, and removably fixing the covering film (30) against said oleophobic upper face (11) of the base film (10), in order to retain said cosmetic product portion (20) according to said previously determined contour.

Owner:PABLO EUGENIO RIPOLI

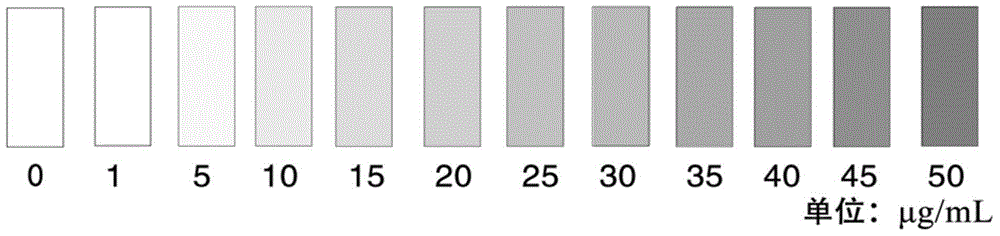

Test paper for rapidly testing nitrite and standard colourimetric card and application of test paper

InactiveCN104535712AUniform infiltrationExcellent gas barrier propertiesAnalysis using chemical indicatorsMaterial analysis by observing effect on chemical indicatorPolyvinyl alcoholN-(1-Naphthyl)ethylenediamine

The invention belongs to the field of chemical detection and particularly relates to test paper for rapidly detecting nitrite and a preparation method and application of the test paper. According preparation method, the test paper for rapidly detecting the nitrite is prepared by taking a filter paper body as a carrier, a p-aminobenzene sulfonic acid solution and an N-1-naphthyl ethylenediamine hydrochloride as color developing agents, as well as an ethanol water solution of polyvinyl alcohol as a surface protectant and can be used for detecting the content of the nitrite. The test paper is low in cost, convenient and rapid to use and has long-term stability.

Owner:SOUTH CHINA NORMAL UNIVERSITY

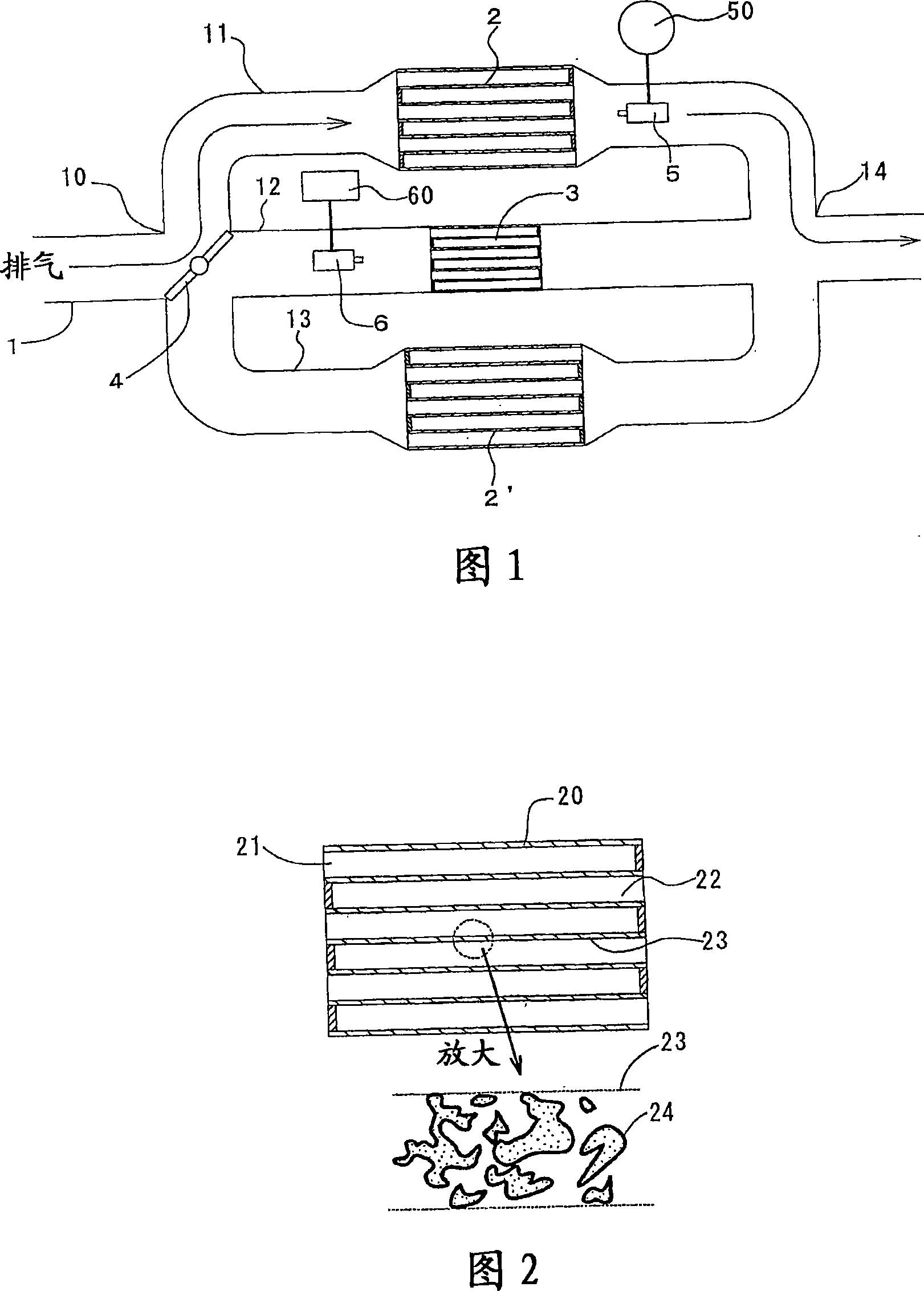

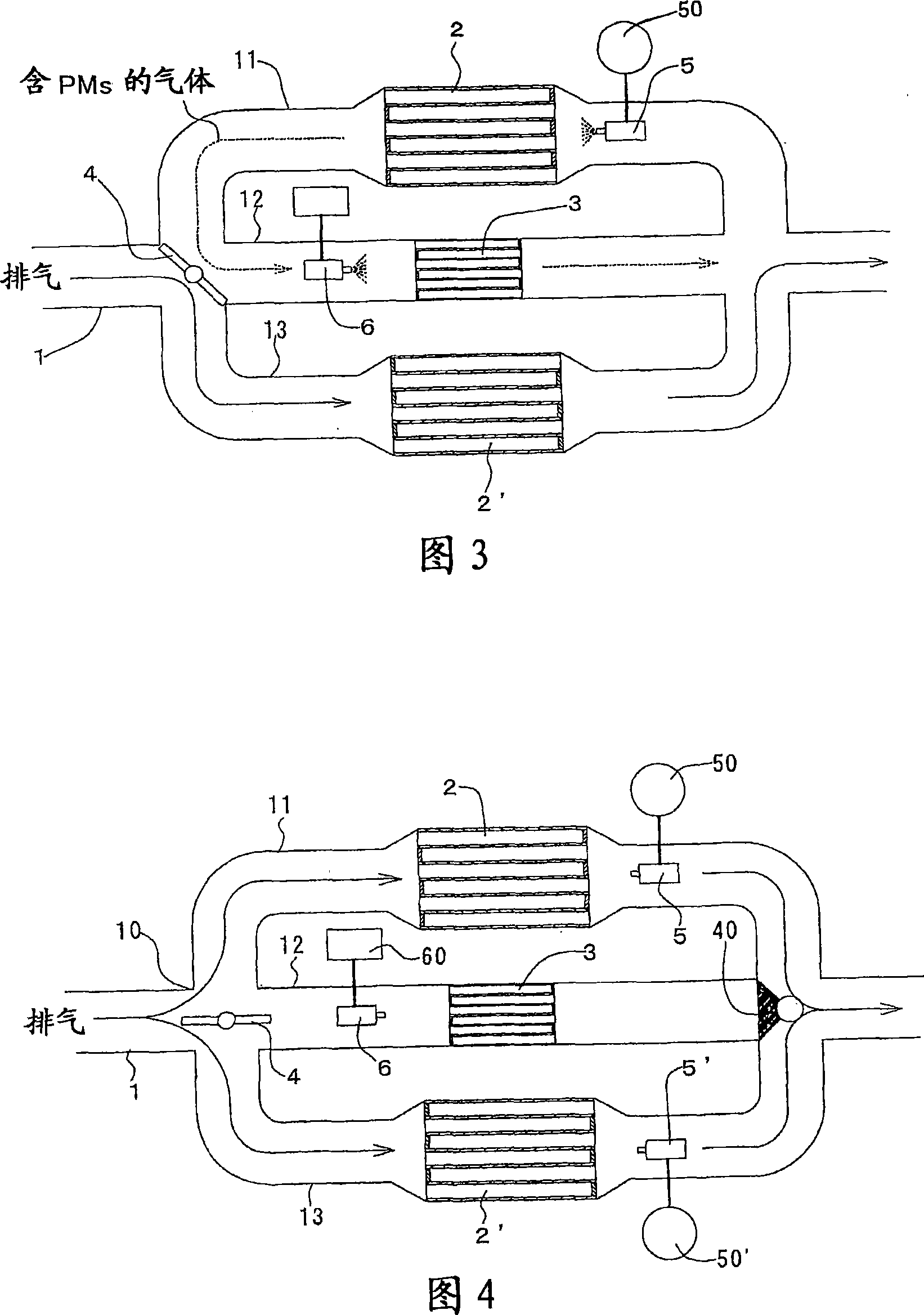

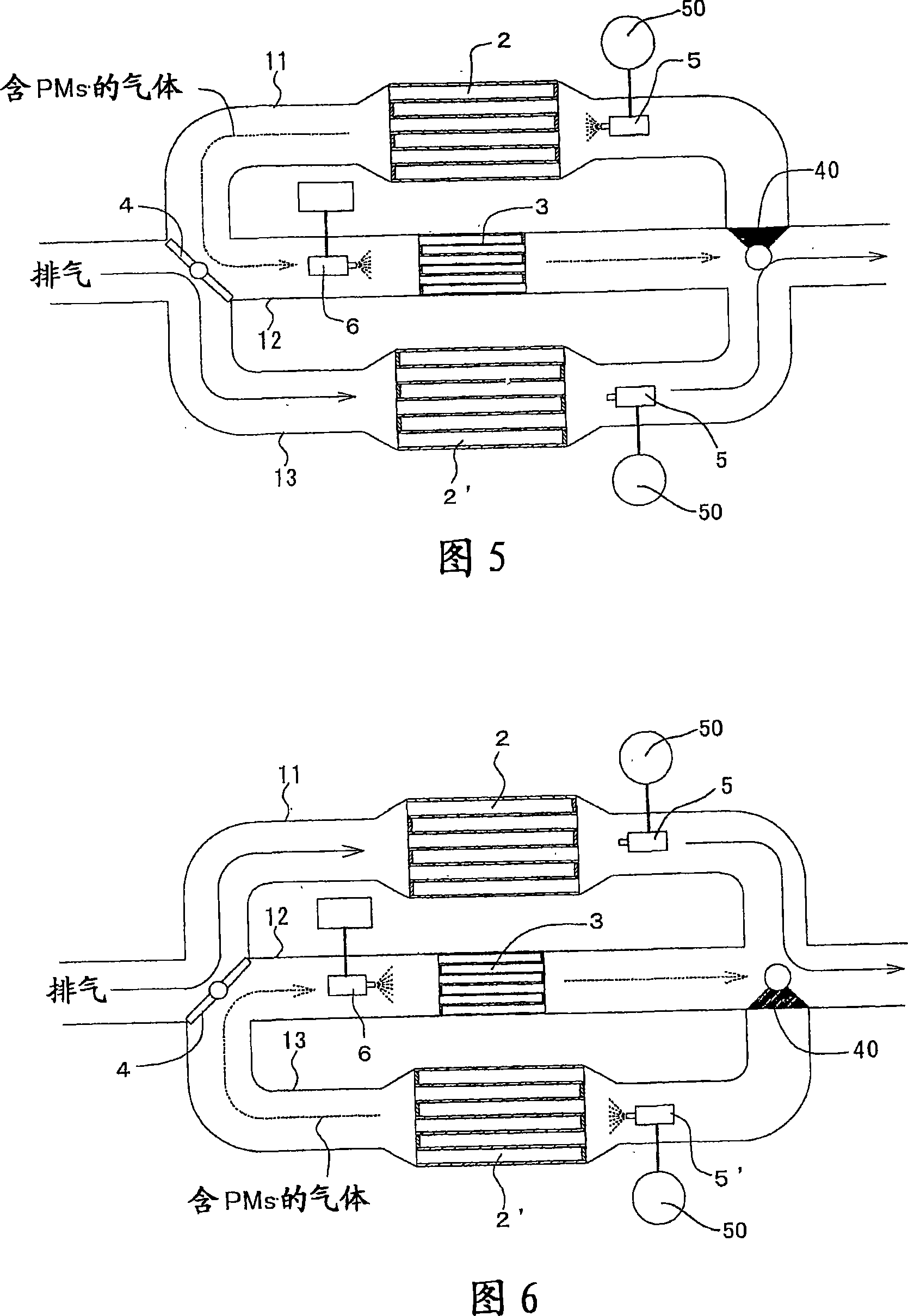

Process for purifying exhaust gases and apparatus for purifying exhaust gases

InactiveCN101166568APromote regenerationEfficient removalGas treatmentDispersed particle filtrationEnvironmental engineeringOxidizing agent

The present invention relates to a process for purifying exhaust gases and an exhaust-gas purifying apparatus utilizing the exhaust-gas purifying process. A process for purifying exhaust gases includes the steps of collecting PMs, forcibly exhausting PMs, and purifying PMs. In the step of purifying PMs, PMs in exhaust gases are collected with a filter. In the step of forcibly exhausting PMs, PMs, which are collected on the filter, are exhausted by blowing a pressurized gas onto the filter, thereby forming PMs-containing gases. In the step of purifying PMs, PMs, which are contained in the PMs-containing gases, are purified by contacting an oxidizing agent with the PMs-containing gases, thereby removing the PMs from the PMs-containing gases by means of oxidation.

Owner:TOYOTA JIDOSHA KK

Method for continuous counter-current ultrasonic extraction of high-purity astragalus polysaccharide

The invention discloses a method for continuous counter-current ultrasonic extraction of high-purity astragalus polysaccharide. The method comprises the following processing steps: crushing astragalus membranaceus and soaking into distilled water; centrifuging and taking supernate after continuous counter-current ultrasonic extraction; decoloring by active carbon, so as to obtain an astragalus polysaccharide water extract solution; then concentrating and adding ethanol to stir; centrifuging and diluting sediments by the distilled water; carrying out alcohol precipitation after filtering diluents by a membrane, wherein the sediment is astragalus polysaccharide solid. By adopting the method, the dissolution rate of the astragalus polysaccharide can be improved; the extraction time is shortened; the dosage of a solvent is reduced. Therefore, the method has the characteristics of high selectivity, simple process, low energy consumption, high yield, high product purity and the like.

Owner:NANJING TONGZE AGRI SCI & TECH

Thermal spray powder and process for producing the same as well as method for spraying the same

InactiveUS20070166478A1Avoid thermal decompositionLiquid surface applicatorsMolten spray coatingThermal sprayingMolybdenum disulfide

A thermal spray powder of the present invention includes particles composed of molybdenum disulfide, and a coating layer provided on the surface of each of the particles. The coating layer is composed of a metal that is softened or melted at a temperature lower than the heat decomposition temperature of the molybdenum disulfide. The coating layer is preferably composed of copper. The thermal spray powder suppresses heat decomposition of the molybdenum disulfide contained in the thermal spray powder during thermal spraying.

Owner:ITSUKAICHI TSUYOSHI +2

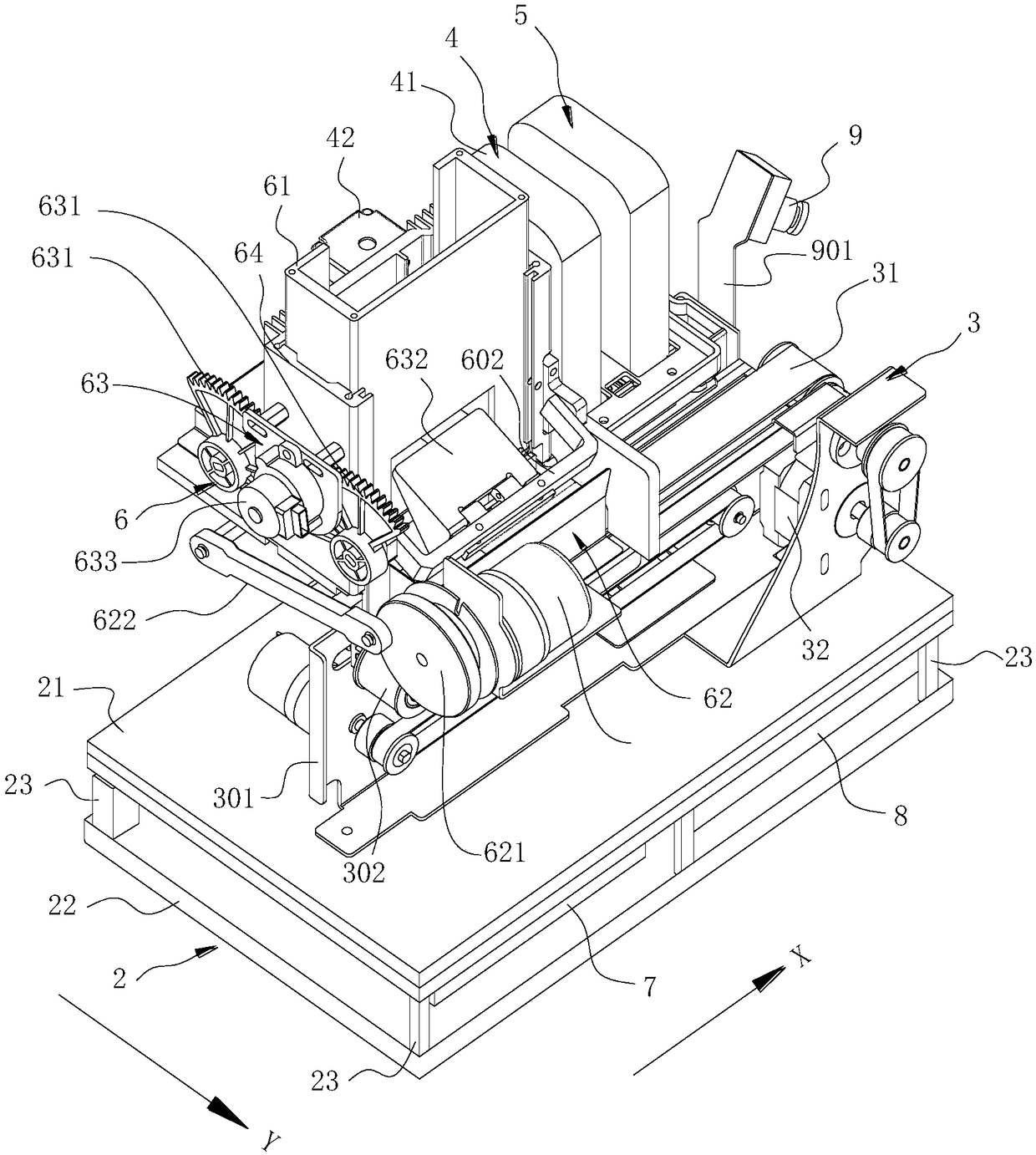

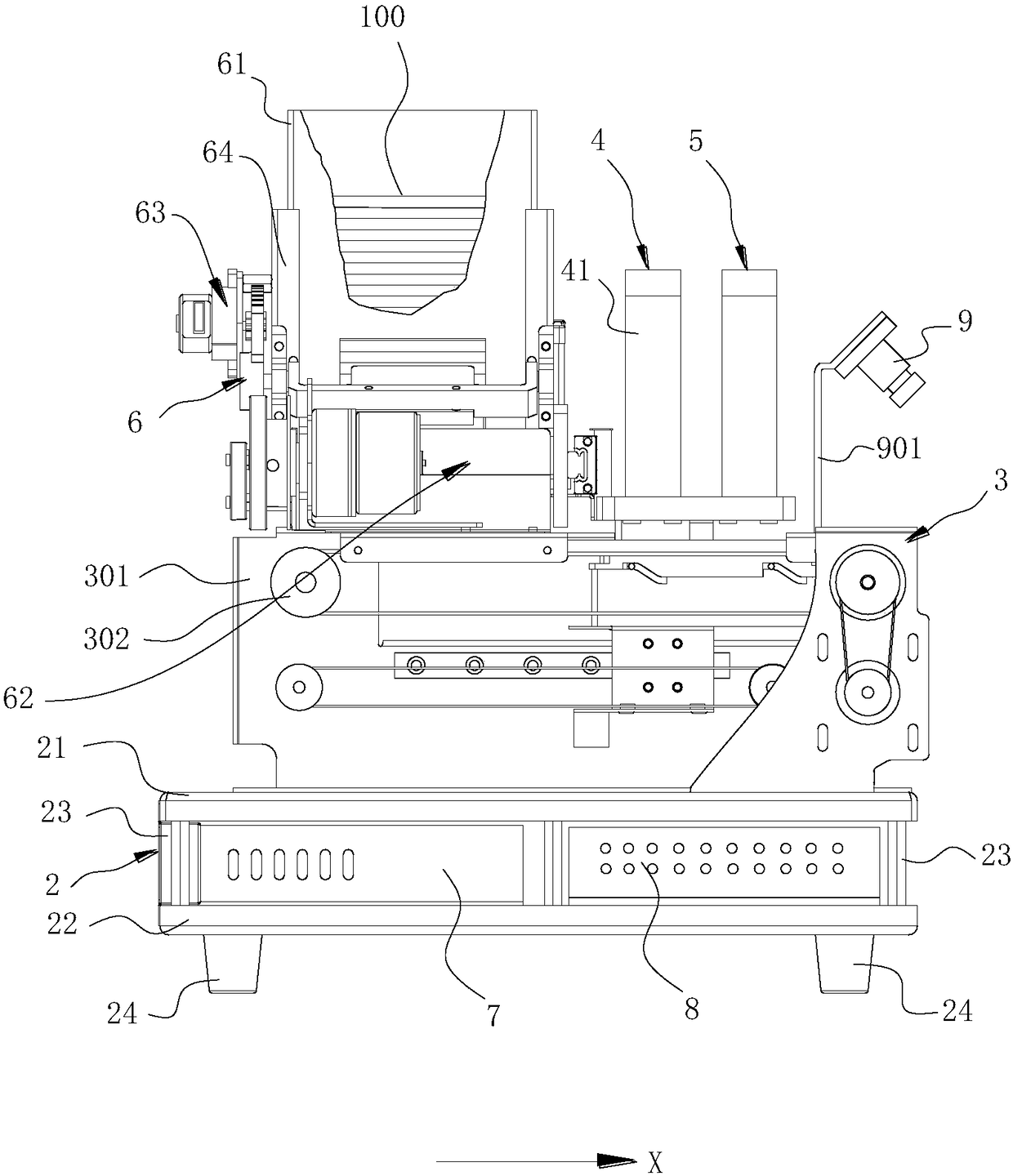

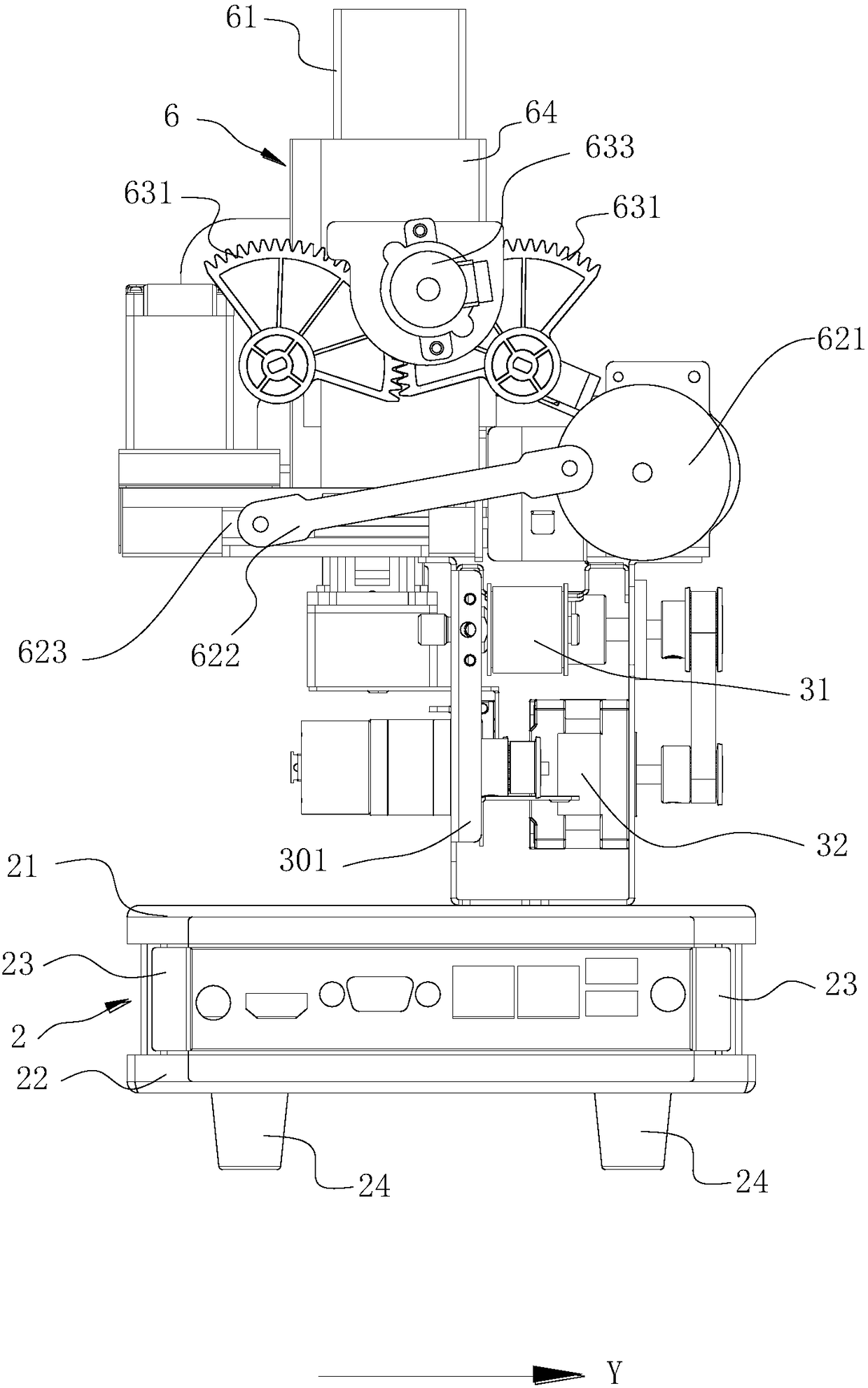

Glass slide printing machine

The invention provides a glass slide printing machine which comprises a conveying device, an ink jetting device and a curing device. The conveying device has a conveying path, and a to-be-printed glass slide moves along the conveying path. The ink jetting device is arranged above the conveying path and used for carrying out ink-jetting printing on a mark area of the glass slide on the conveying path. The curing device is arranged above the conveying path and located on the downstream of the ink-jetting device, and the curing device can cure printing ink drops jetted to the glass slide and forming characters or a two-dimension code in a heating mode or in a curing solution jetting mode. According to the glass slide printing machine, the thermal curing temperature of the curing device is low, a paint coating of the glass slide is prevented from being thermally decomposed, and dust harmful to human beings is not generated; and a curing solution adopted for the curing device can carry outcuring at the room temperature, and gas harmful to the human beings is not generated.

Owner:SHENZHEN DFST TECH CO LTD

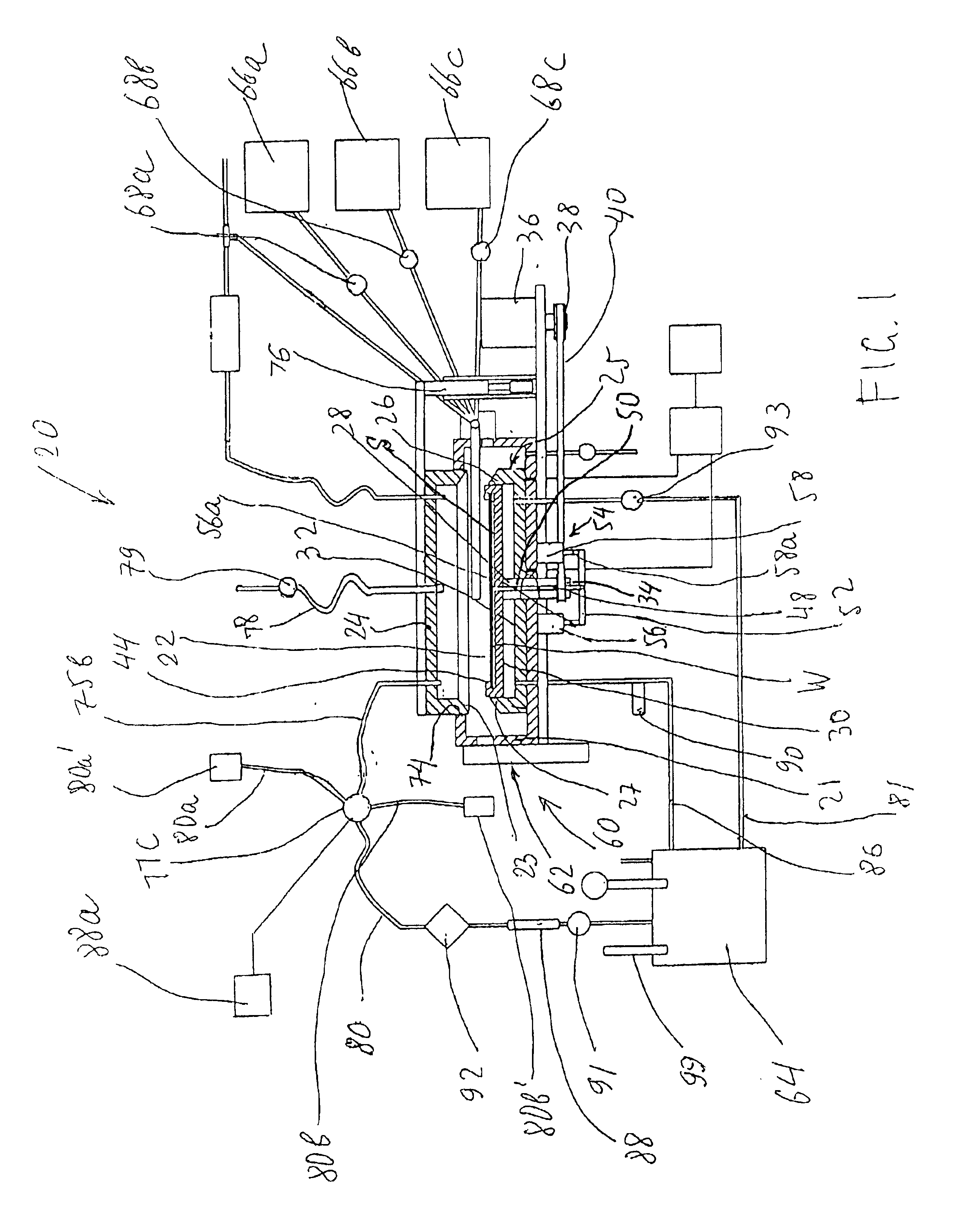

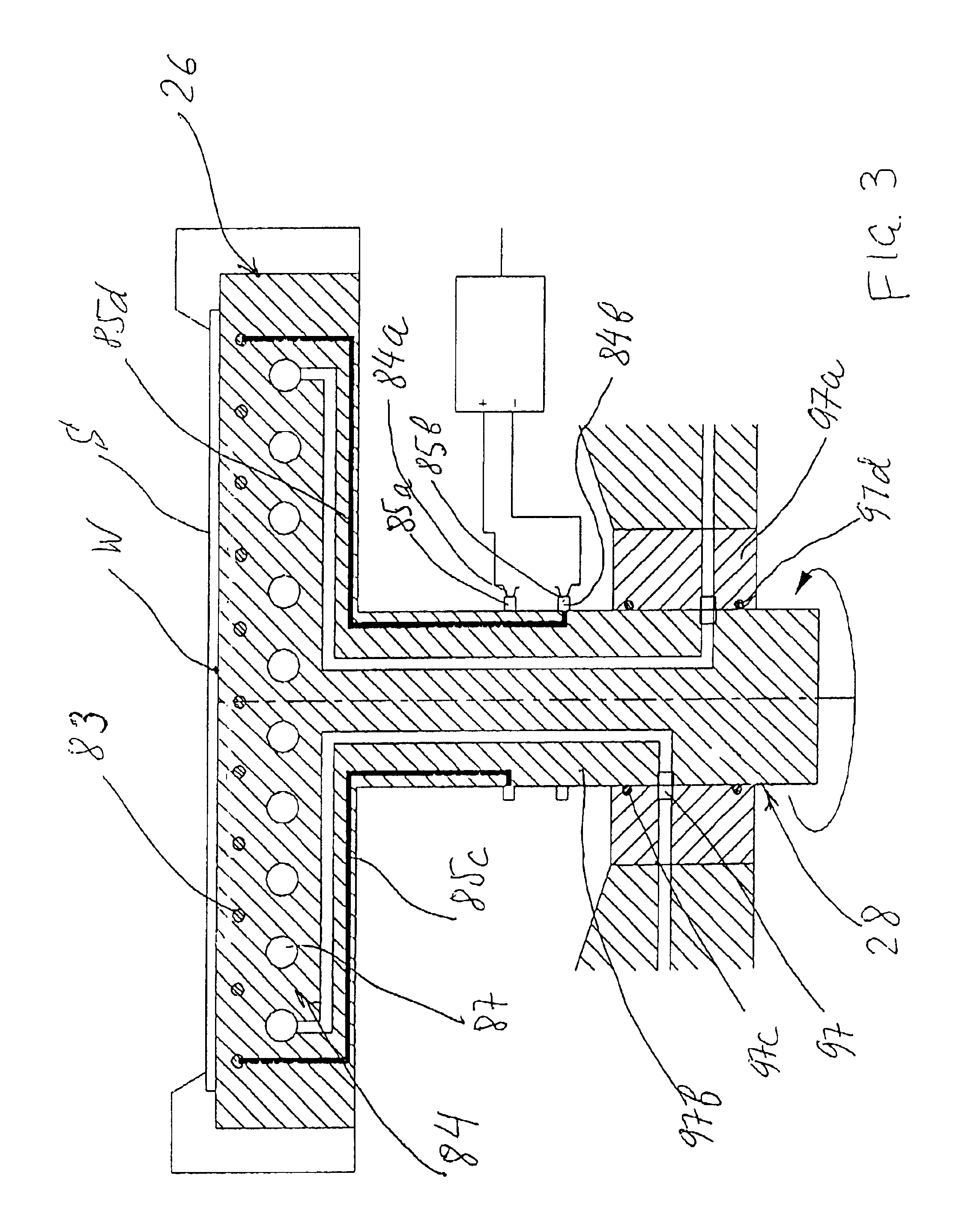

Method and apparatus for electroless deposition with temperature-controlled chuck

InactiveUS6846519B2Reduce formationAvoid thermal decompositionLiquid surface applicatorsSemiconductor/solid-state device manufacturingTemperature controlElectroless deposition

The method for electroless deposition of a coating material, which may be a metal, semiconductor, or dielectric, that is carried out at a relatively low temperature of the working solution compensated by an increased temperature on the substrate which is controlled by a heater built into the substrate chuck. A decrease in the temperature of the working solution prevents thermal decomposition of the solution and reduces formation of gas bubbles, normally generated at increased temperatures. Accumulation of bubbles on the surface of the substrate is further prevented due to upwardly-facing orientation of the treated surface of the substrate. The substrate holder is equipped with a substrate heater and a substrate cooler, that can be used alternatingly for quick heating or cooling of the substrate surface.

Owner:LAM RES CORP

Regenerating process technology for producing high-quality low-pour-point lubricant base oil by full hydrogen method of waste lubricant oil

ActiveCN107254330AHigh degree of separationAvoid thermal decompositionTreatment with hydrotreatment processesLubricant compositionHydrogenNaphtha

The invention relates to a regenerating process technology for producing high quality low-pour-point lubricant base oil by the full hydrogen method of waste lubricant oil. The process technology comprises the following steps: firstly, performing predistillation and atmospheric flashing on the waste lubricant oil to remove water and pulling out light oil, and then performing propane refining to remove the vast majority of impurities and additives in the oil; performing a hydrogenating reaction on the lubricant oil fraction without water and impurities and hydrogen under the action of a catalyst after being mixed, and performing gas liquid separation to obtain a liquid which enters a stripping tower to divide, thereby obtaining naphtha and light diesel oil from the top of the stripping tower; and feeding the pre-heated product in the bottom of the stripping tower into an isomeric pour point depression reactor and a compensating refining reactor, and separating light oil and the lubricant base oil from the reaction product through a fractioning device. The regenerating process technology provided by the invention is environment-friendly and pollution-free; the regenerating recovery of waste oil reaches up to 99% or above; the oxidizing stability and light stability of the base oil are remarkably improved; the product is good in quality and high in additional value; and therefore, the regenerating process technology has a very good market application prospect.

Owner:湖北润驰环保科技有限公司

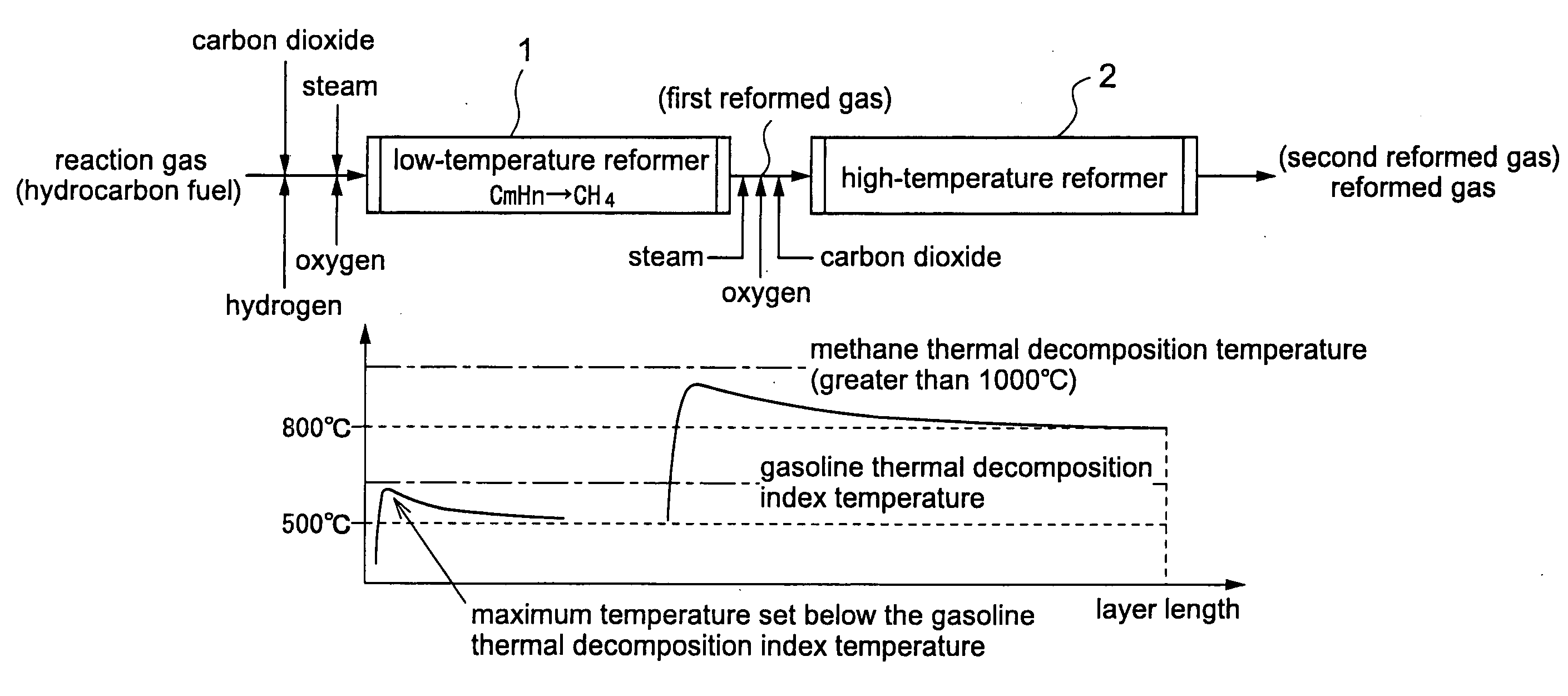

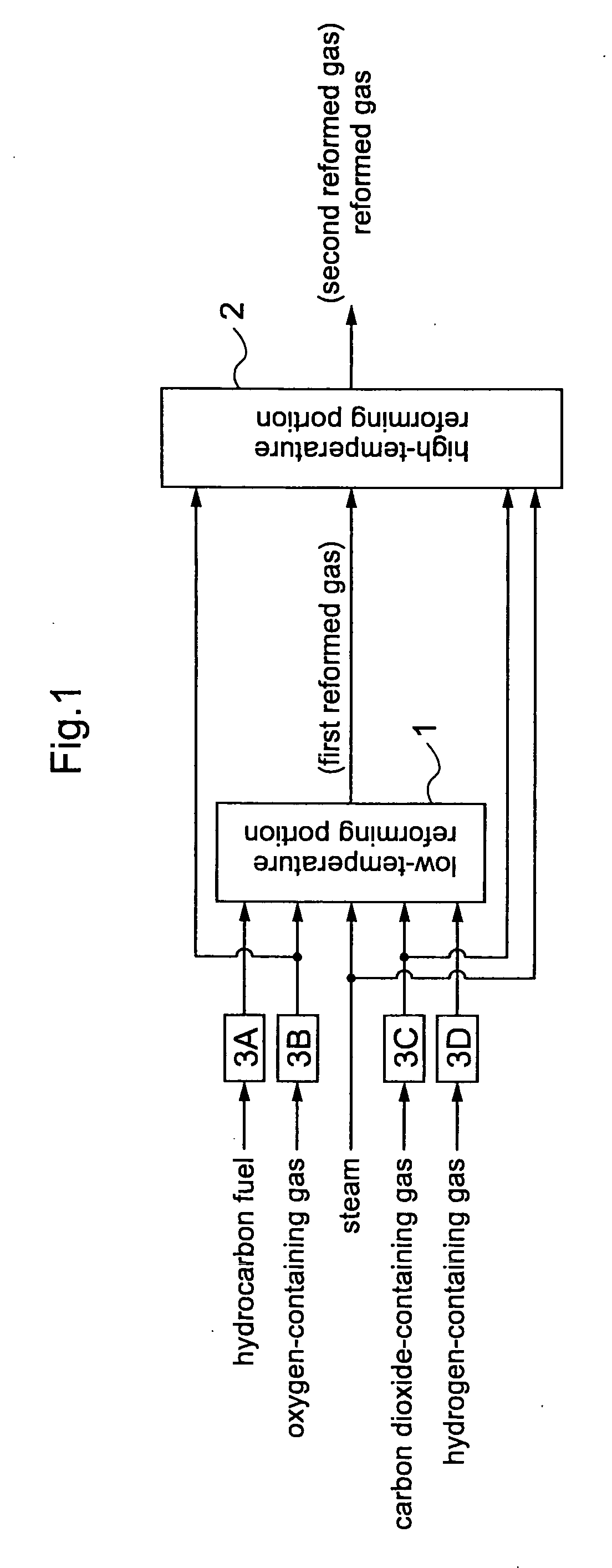

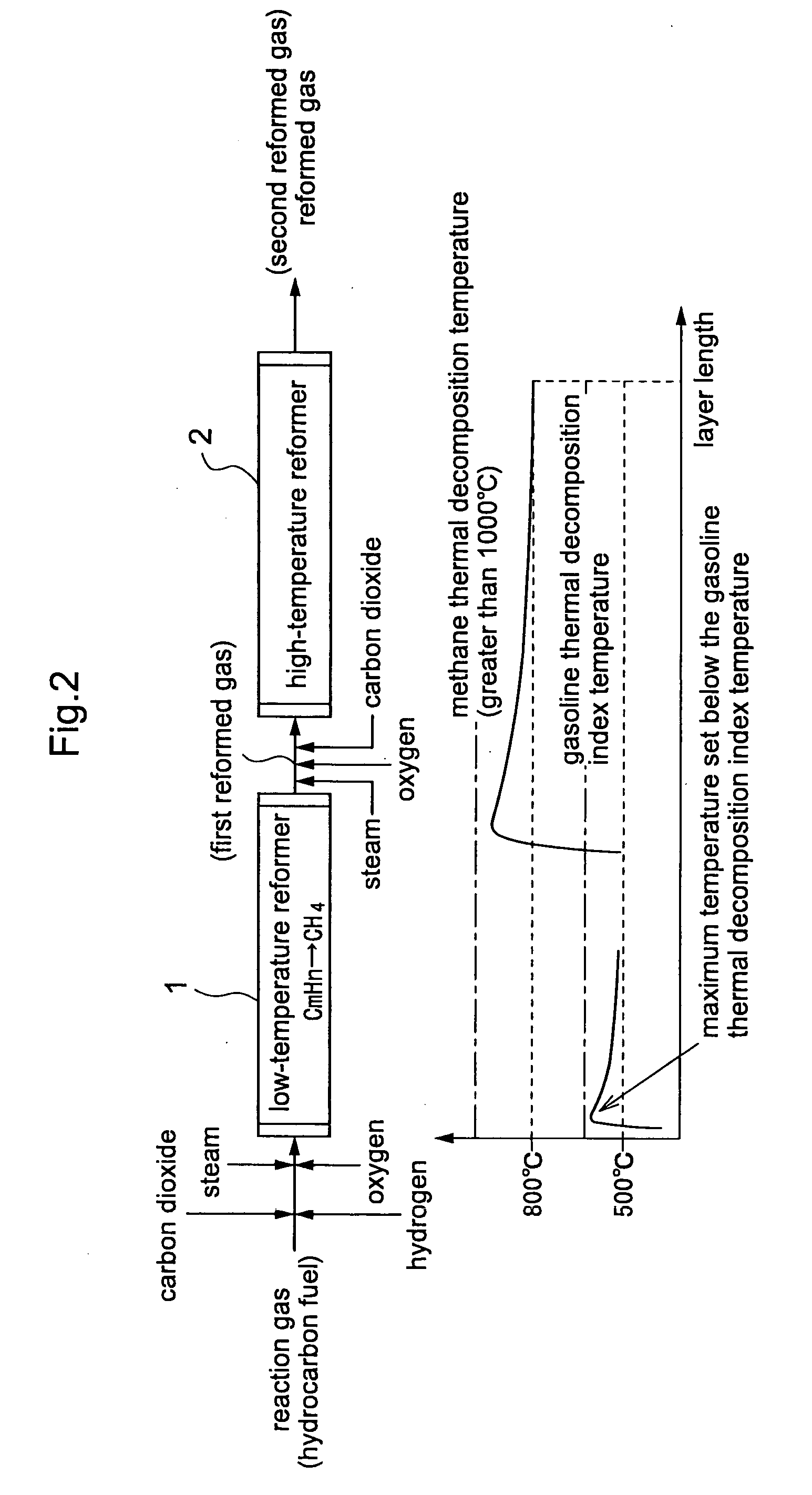

Reformed Gas Production Method and Reformed Gas Production Apparatus

InactiveUS20080263953A1Increase ratingsSuitable for useHydrogenFinal product manufactureHydrogenProduct gas

The invention provides a method for operating a reformed gas production apparatus with which it is possible to achieve a high reforming efficiency while preventing a drop in catalyst activity due to the deposition of carbon. The reformed gas production method uses a reforming catalyst to reform a fuel that contains a hydrocarbon having at least two carbon atoms to produce a reformed gas that includes methane, hydrogen, and carbon monoxide. With this method, a fluid that includes the fuel, at least one of steam and a carbon dioxide-containing gas, and an oxygen-containing gas, is supplied to a reforming reaction region, and with the thermal decomposition index temperature of the fuel, which is determined by the type and the concentration of the hydrocarbons having at least two carbon atoms that make up the fuel, serving as an upper limit temperature of the reforming reaction region, the fluid is brought into contact with the reforming catalyst to produce the reformed gas.

Owner:OSAKA GAS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com