Process for extracting the soyabean oligosaccharides by air-float purification and film integration

A soybean oligosaccharide, membrane integration technology, applied in application, food preparation, food science and other directions, can solve the problems of membrane pore blockage, membrane flux attenuation, environmental pollution and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

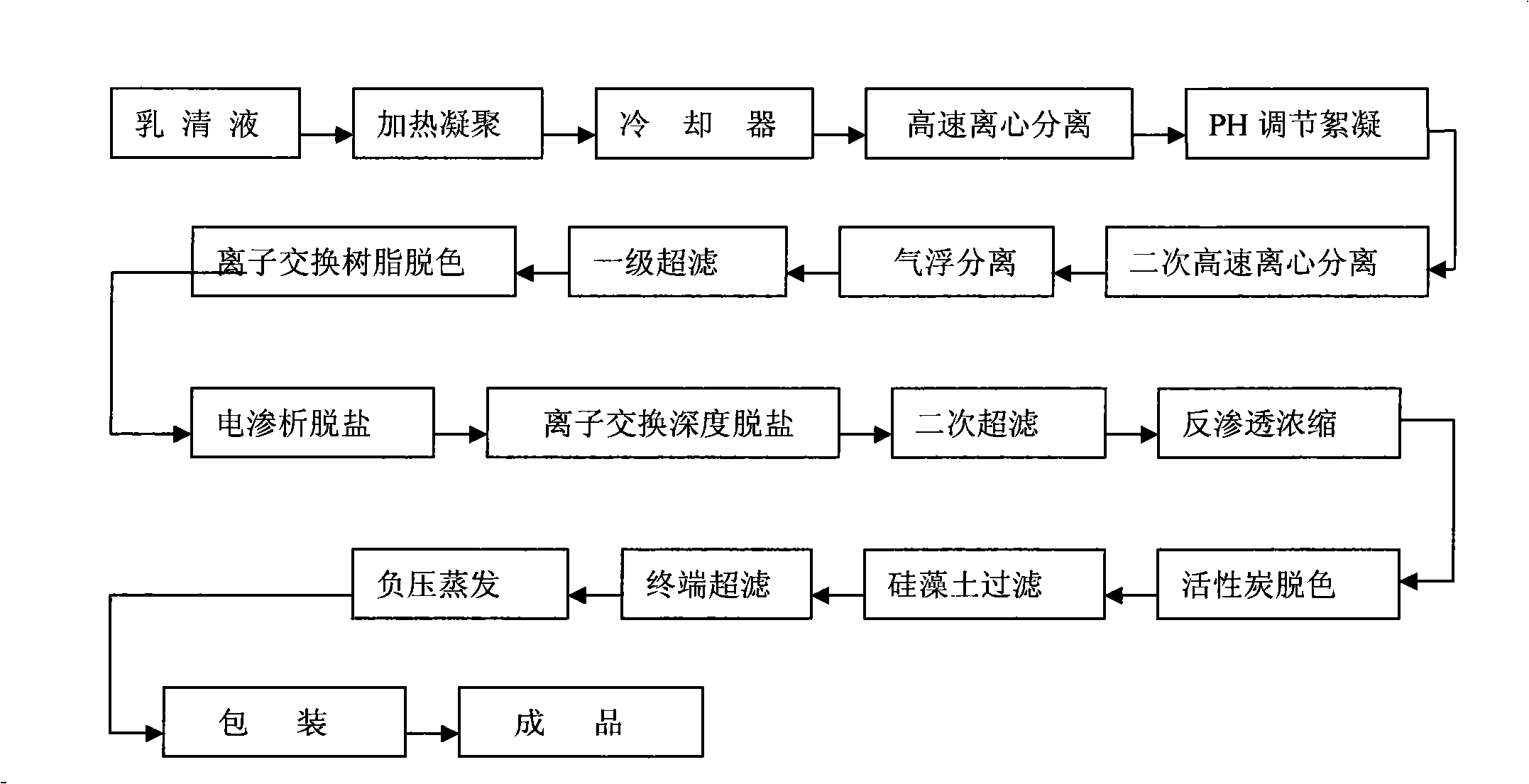

Image

Examples

Embodiment 1

[0043] Example 1: (1) Coagulation by heating. Firstly, the soybean whey liquid is heated to 95° C. under the condition of pH value=4.5, and kept for 20 minutes to denature the whey protein in the whey liquid and coagulate and precipitate.

[0044] (2) Cooling, sending the heated condensed whey liquid into a cooler, and indirect heat exchange with cooling water, so that its temperature drops to 35°C.

[0045] (3) High-speed centrifugation, the cooled whey liquid is sent to a high-speed centrifuge for solid-liquid separation. The solid phase is discharged, and the liquid phase is sent to the flocculation tank for pH adjustment.

[0046] (4) PH value adjustment flocculation, high-speed centrifuge is separated liquid phase, sends into pH value adjustment flocculation tank, under stirring condition of 30 revs / min, add the sodium hydroxide solution of 10% concentration, adjust PH=7 to make milk Albumin flocculation and precipitation.

[0047] (5) Secondary high-speed centrifugatio...

Embodiment 2

[0059] Example 2: (1) Coagulation by heating. Firstly, when the soybean whey liquid is heated to 100° C. under the condition of pH value=4.7, keep it for 30 minutes to denature the whey protein in the whey liquid and coagulate and precipitate.

[0060] (2) Cooling, sending the heated condensed whey liquid into a cooler, and indirect heat exchange with cooling water, so that its temperature drops to 42°C.

[0061] (3) High-speed centrifugation, the cooled whey liquid is sent to a high-speed centrifuge for solid-liquid separation. The solid phase is discharged, and the liquid phase is sent to the flocculation tank for pH adjustment.

[0062] (4) PH value adjustment flocculation, high-speed centrifuge is separated liquid phase, sends into pH value adjustment flocculation tank, under stirring condition of 30 revs / min, add the sodium hydroxide solution of 30% concentration, adjust PH=9 to make milk Albumin flocculation and precipitation.

[0063] (5) Secondary high-speed centrifu...

Embodiment 3

[0075] Example 3: (1) Coagulation by heating. Firstly, when the soybean whey liquid is heated to 98° C. under the condition of pH value=4.0, keep it for 25 minutes to denature the whey protein in the whey liquid and coagulate and precipitate.

[0076] (2) Cooling, sending the heated condensed whey liquid into a cooler, and indirect heat exchange with cooling water, so that its temperature drops to 40°C.

[0077] (3) High-speed centrifugation, the cooled whey liquid is sent to a high-speed centrifuge for solid-liquid separation. The solid phase is discharged, and the liquid phase is sent to the flocculation tank for pH adjustment.

[0078] (4) PH value adjustment flocculation, high-speed centrifuge is separated liquid phase, sends into pH value adjustment flocculation tank, under 30 rev / min stirring conditions, add the sodium hydroxide solution of 25% concentration, adjust PH=8 to make milk Albumin flocculation and precipitation.

[0079] (5) Secondary high-speed centrifugati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com