Environmental-protection efficient PVC stabilizer system and its use

A technology of polyvinyl chloride and stabilizer, which is applied in the field of plastic product production, can solve problems such as affecting the normal performance of intelligence, and achieve the effects of avoiding thermal decomposition, good compatibility, and improving physical and mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

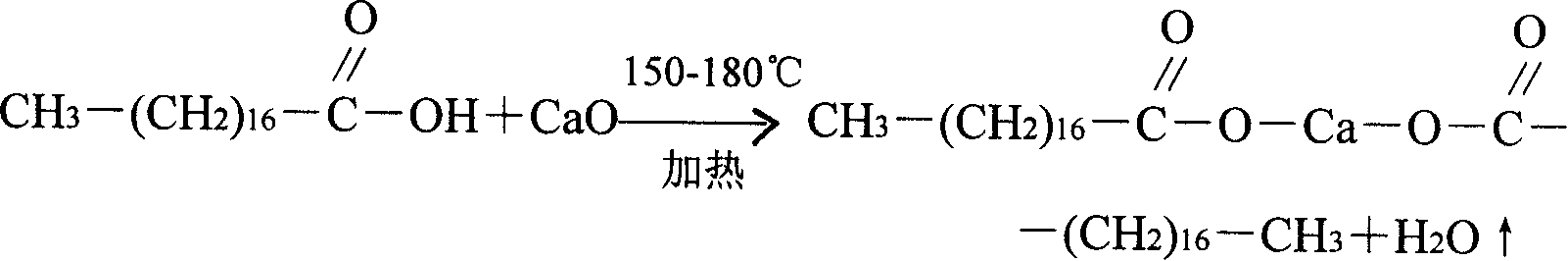

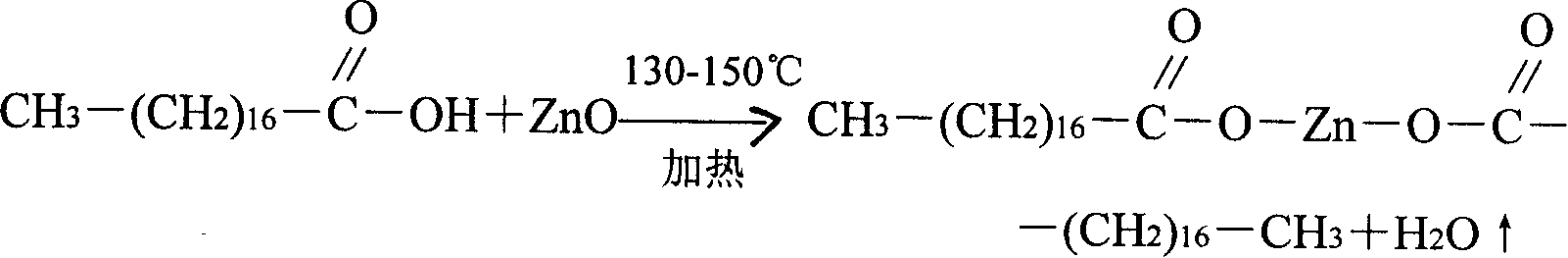

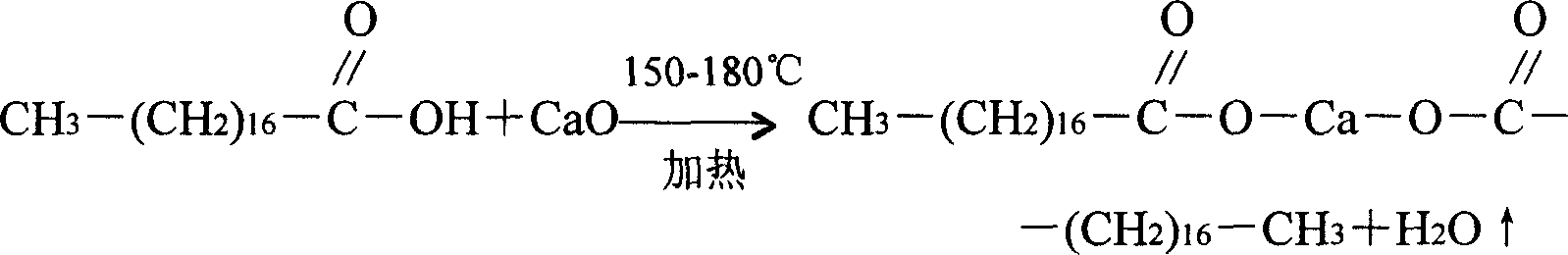

Method used

Image

Examples

Embodiment Construction

[0029] Below is the application of the present invention in PVC plastics production:

[0030] 1. Formula of PVC-U water supply and drainage pipe (by weight):

[0031] 1. Water supply pipe:

[0032] PVC resin (type five) 100

[0033] Lihui Calcium Zinc 060# 3-4

[0034] Chlorinated polyethylene 4-6

[0035] Polyethylene wax 0.1

[0036] ACR (processing aid) 1.5-2.5

[0037] Titanium dioxide 0.5

[0038] Phthalocyanine 0.2

[0039] Paraffin 0.4

[0040] Ground calcium carbonate 30-50

[0041] 2. Drain pipe:

[0042] PVC resin (type five) 100

[0043] Lihui Calcium Zinc 060# 5-6

[0044] Chlorinated polyethylene 6-8

[0045] Polyethylene wax 0.2

[0046] ACR (processing aid) 3

[0047] Titanium dioxide 2

[0048] Paraffin 0.6

[0049] Ground calcium carbonate 80-150

[0050] DT (brightener) 3 grams

[0051] Features: good thermal and light stability, high quality and low price, environmental protection, can reduce the processing temperature by about 10 ℃.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com