Patents

Literature

193results about How to "Guaranteed production cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

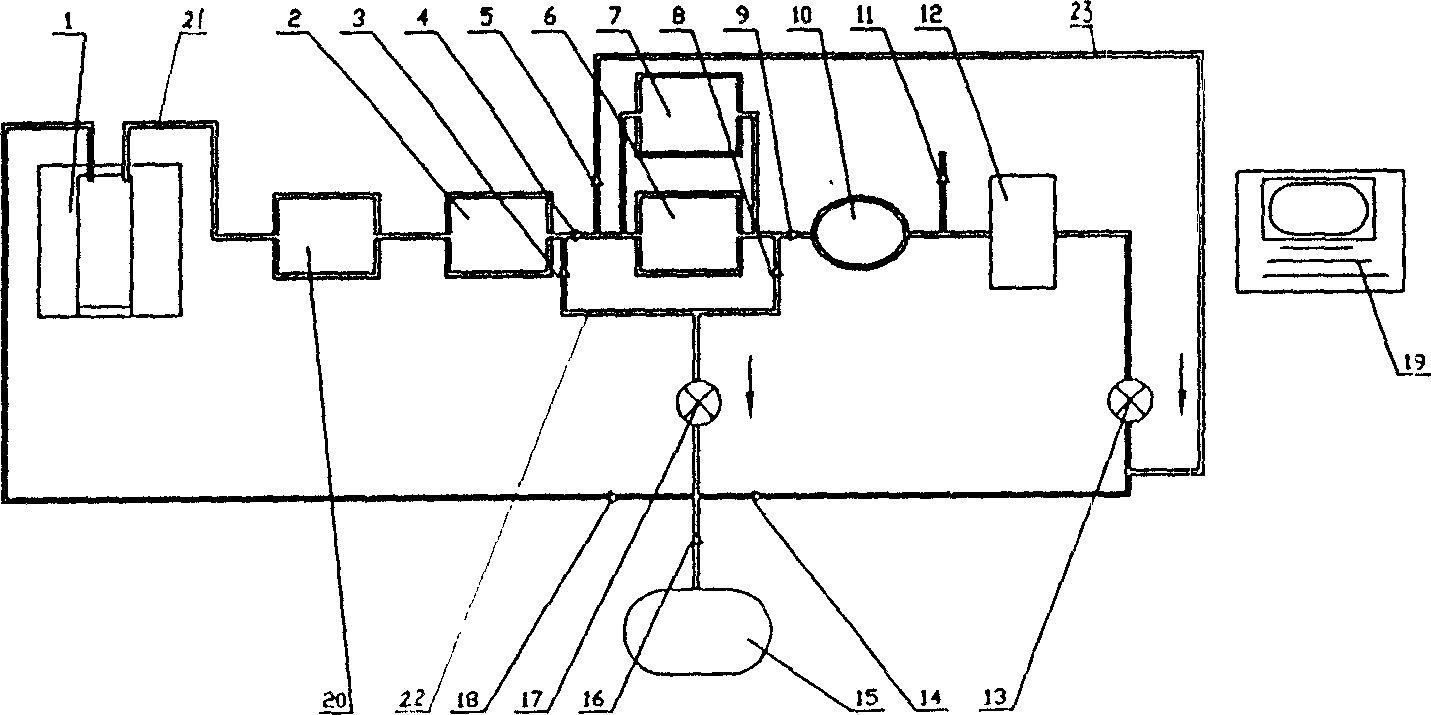

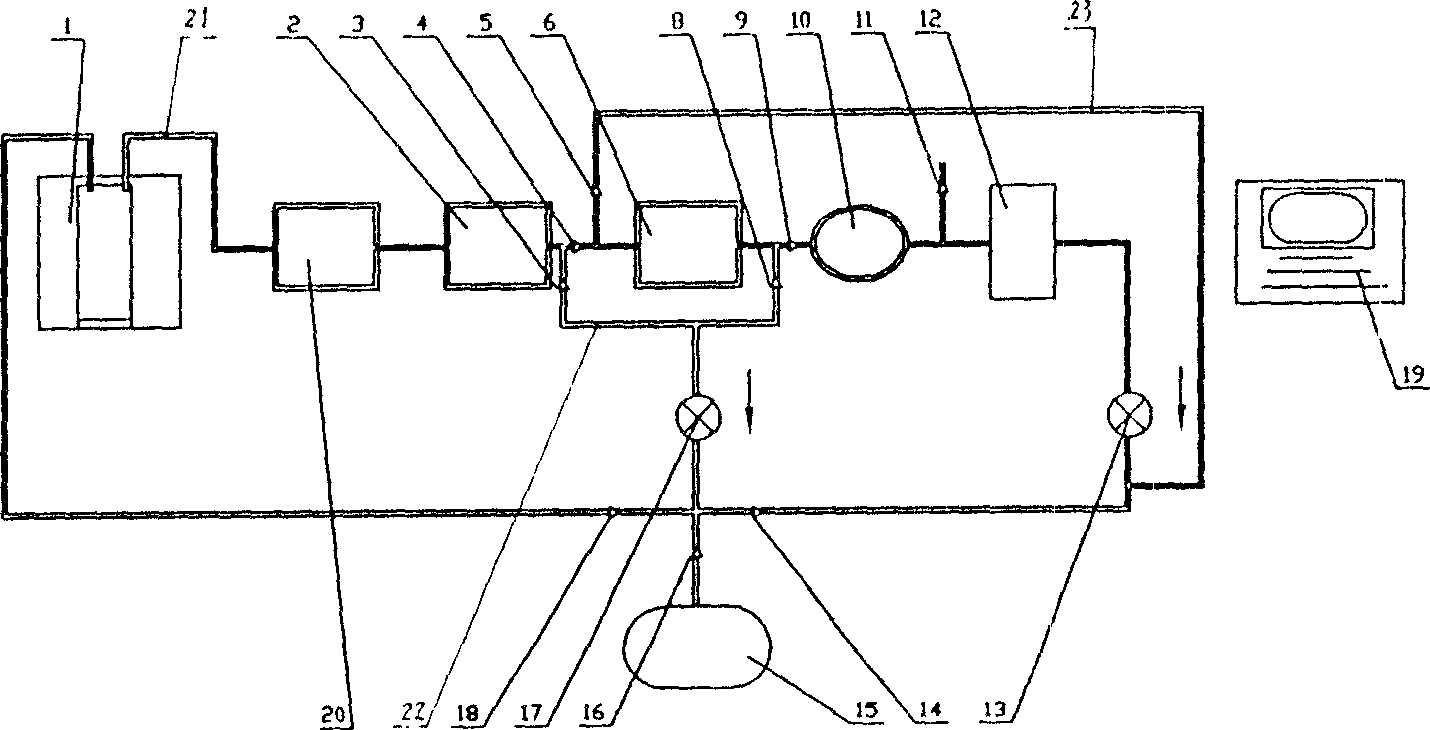

Equipment and method for extracting biologically active ingredients from subcritical fluid

InactiveCN101905091AKeep intactGuaranteed production costExtraction purification/separationSolid solvent extractionAutomatic controlSeparation technology

The invention discloses equipment and a method for extracting biologically active ingredients from subcritical fluid, aims to solve the problems of low extraction efficiency and the like existing in the aspects of biologically active ingredient separation technology in the prior art and provides a set of subcritical equipment which comprises an extracting agent supply system, an entrainer supply system, an extraction system, a separation system, a solvent recycling system, a desolvation system, a heat supply system, a computer control system and the like, has high automatic control degree and is used for extracting the biologically active ingredients. Simultaneously, the invention also provides a new technological method for extracting the biologically active ingredients by adopting a subcritical extraction process. The method has the advantage of relatively low cost on the conventional extraction of an organic solvent, and the equipment has the characteristics of no solvent residue, no pollution, high bioactivity and the like in a product obtained by supercritical CO2 extraction technology and has the advantages of low investment on production equipment, high production efficiency within unit time, low energy consumption, flexible operation, high degree of automation and the like.

Owner:XINJIANG UNIVERSITY +1

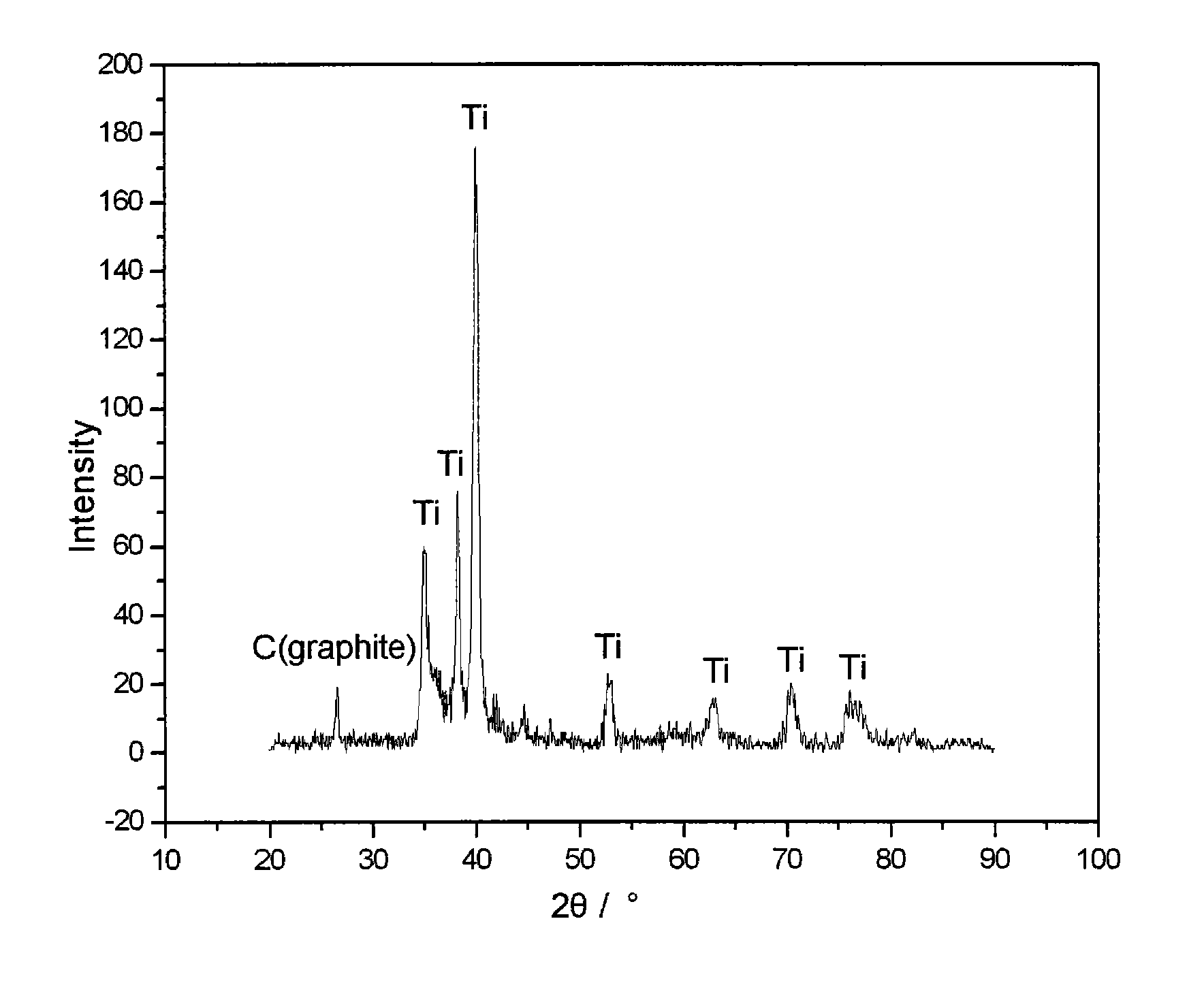

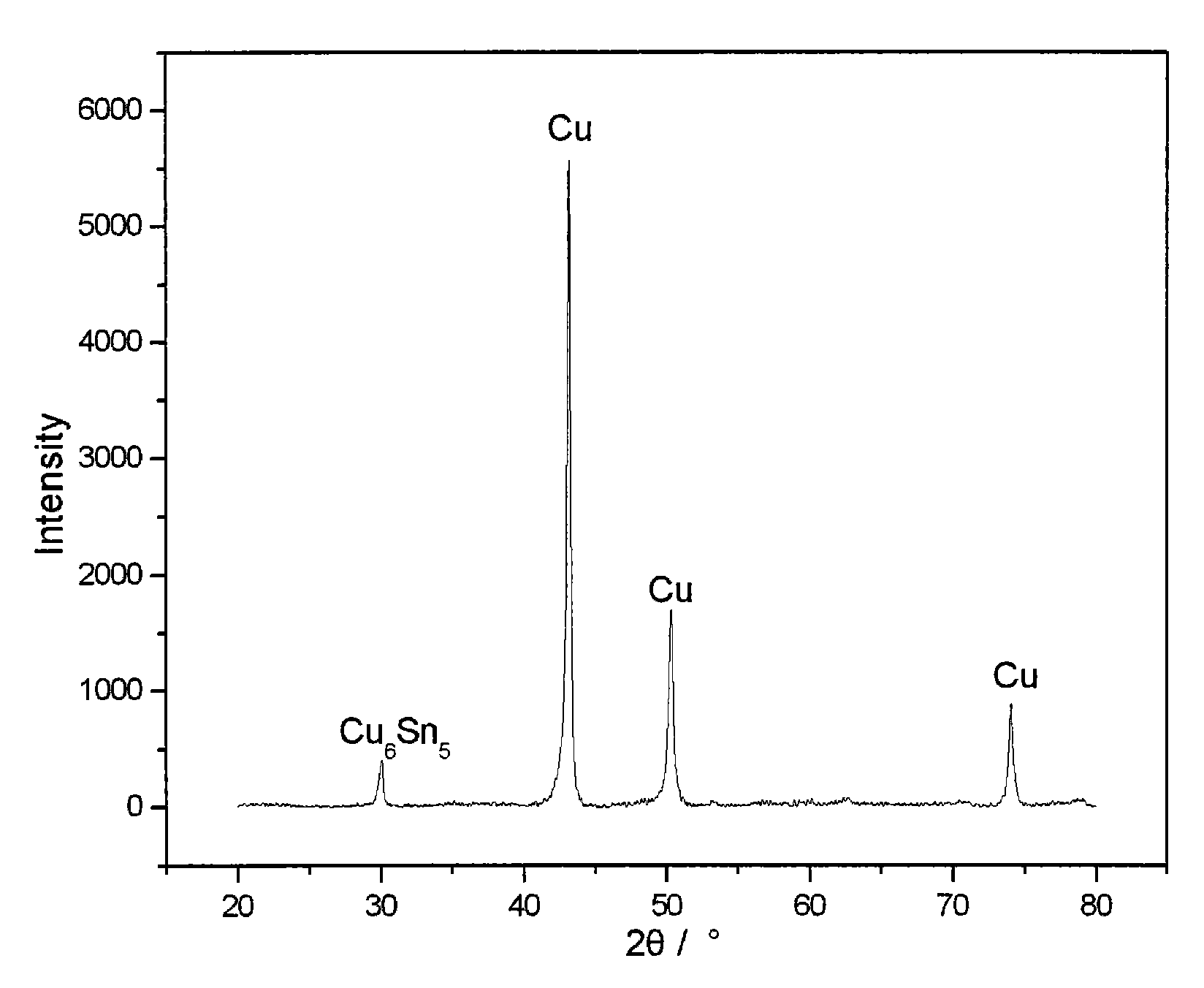

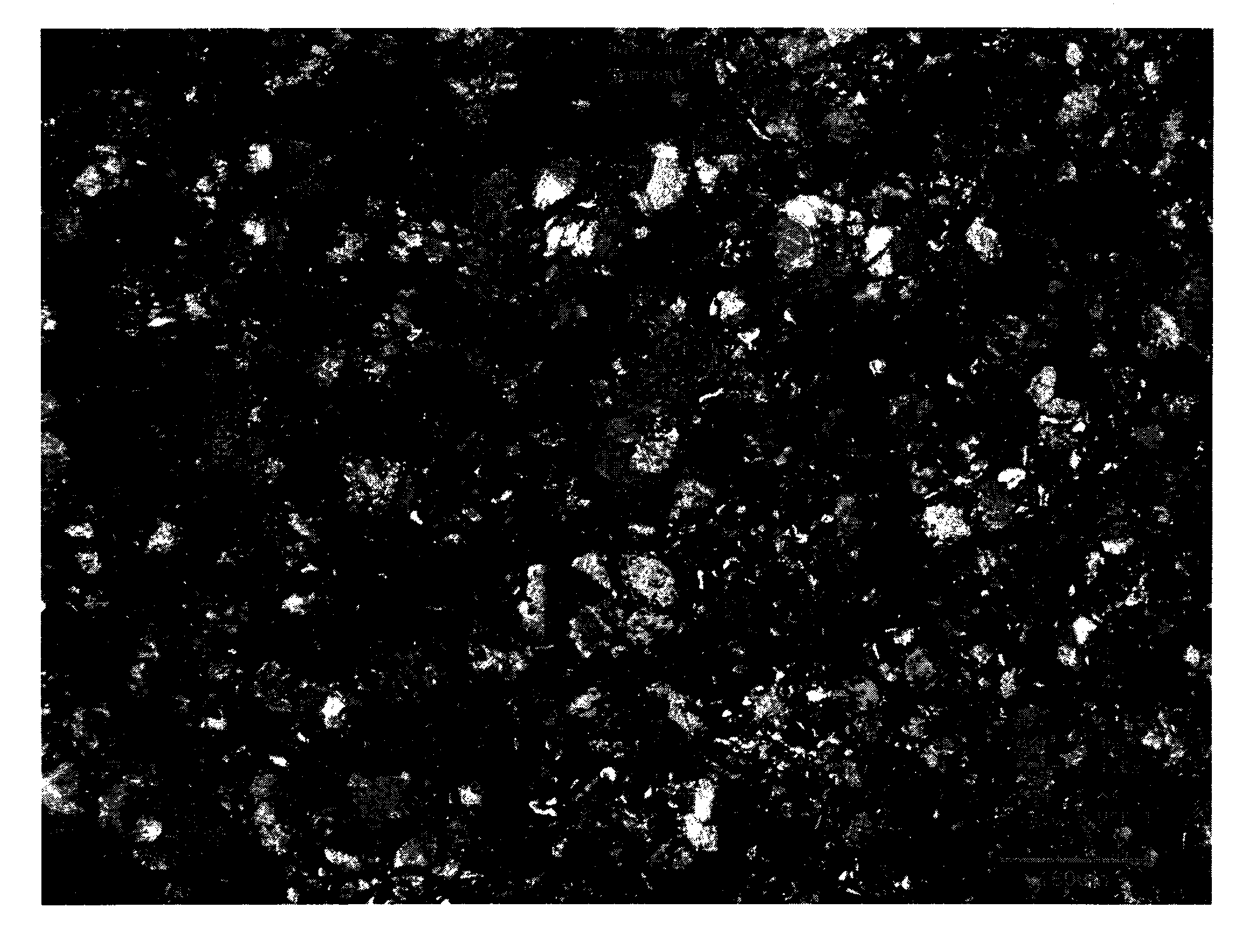

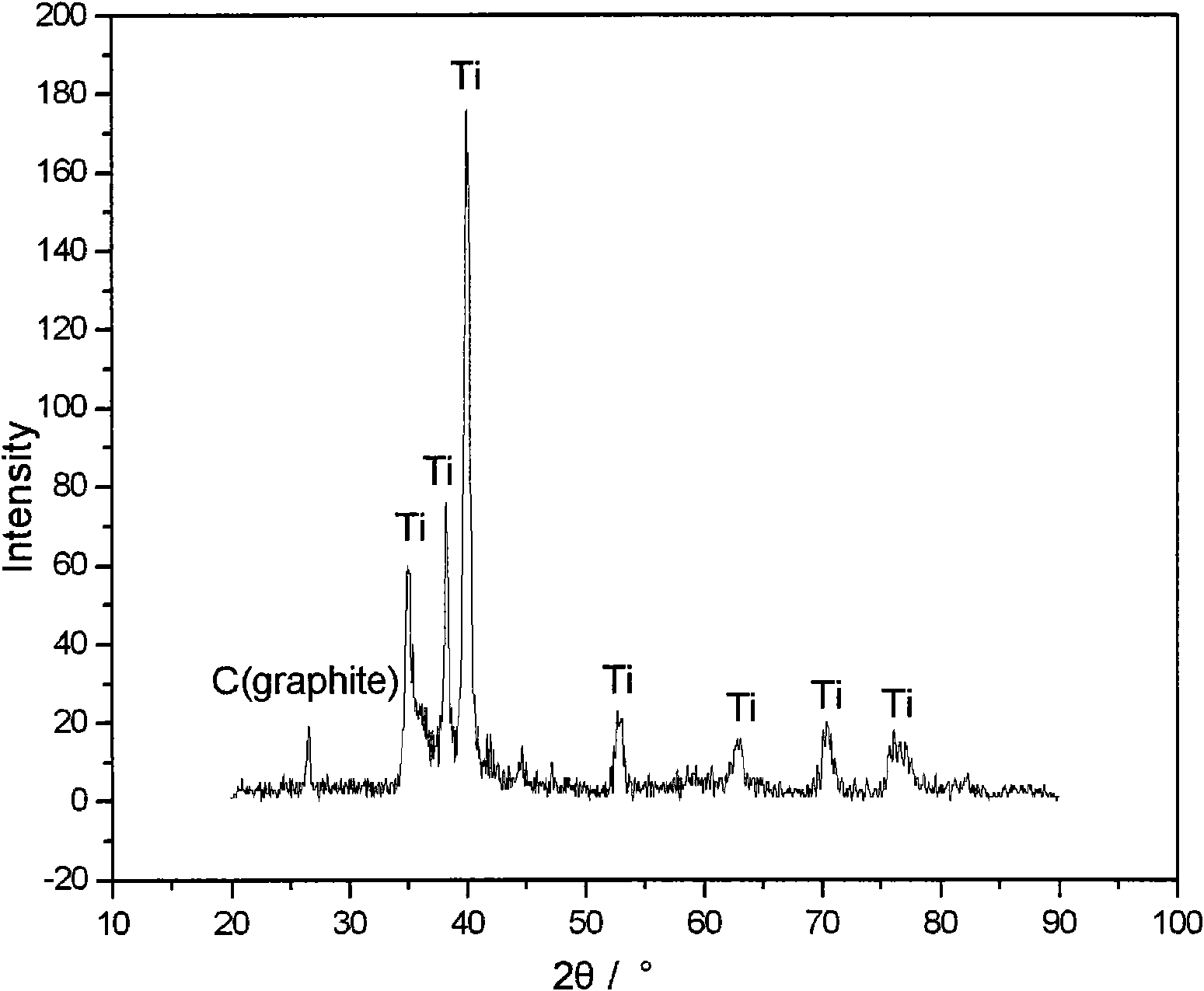

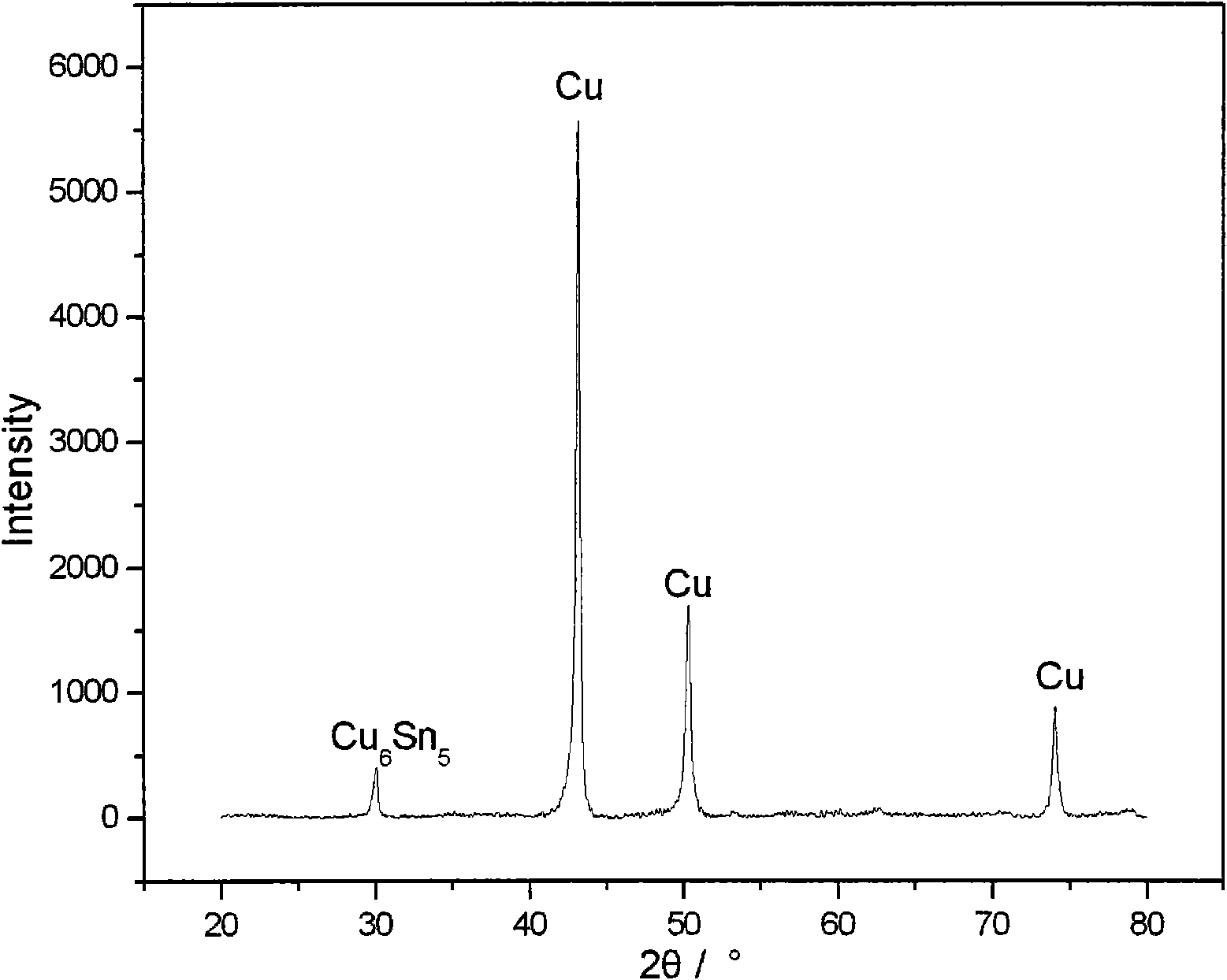

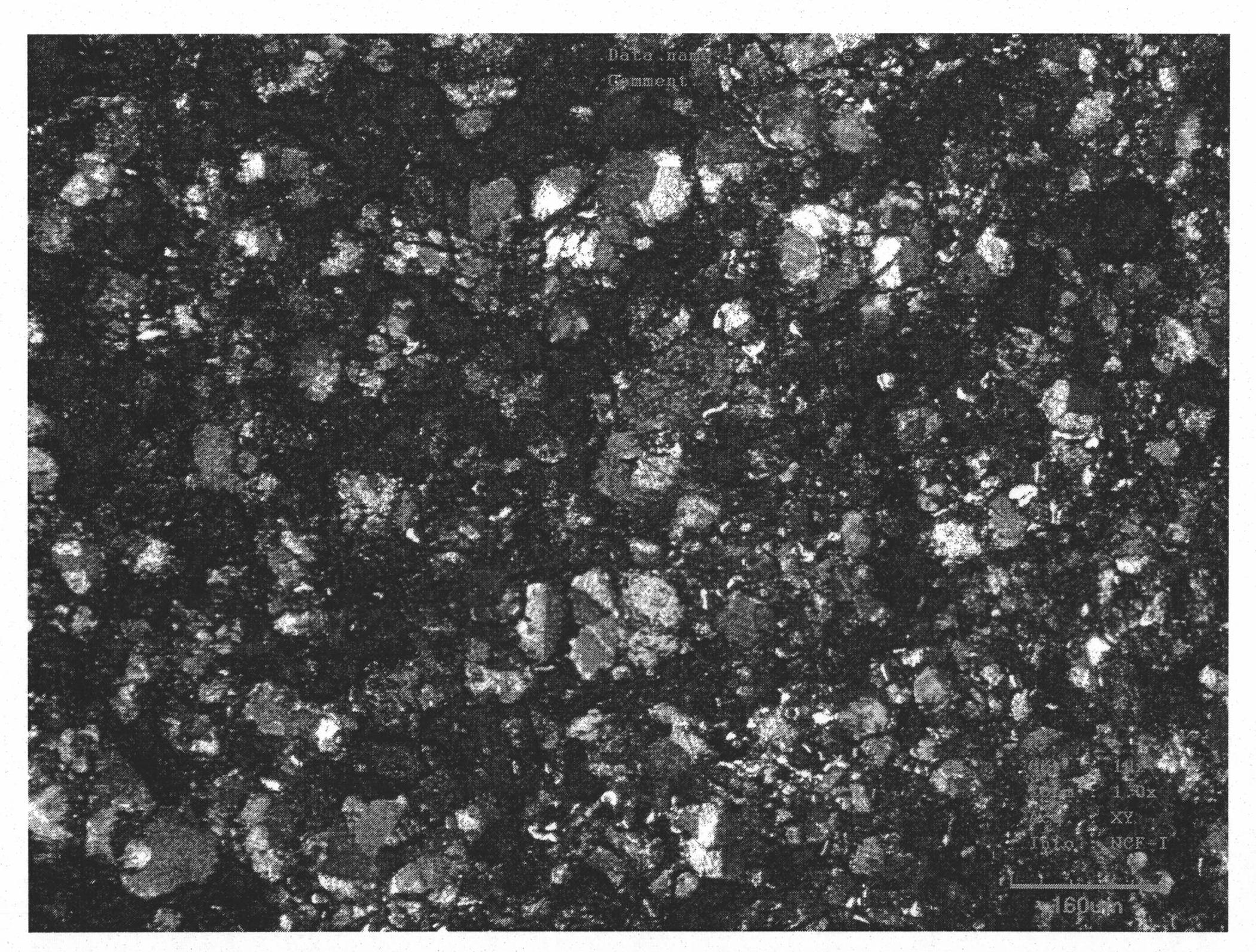

Metal-based powder metallurgy brake lining material and preparation methods thereof

InactiveCN101602105AExcellent material performanceSimple material compositionFriction liningPowder metallurgyCeramic particle

The invention discloses a metal-based powder metallurgy brake lining material and preparation methods thereof. The invention aims to solve the problems that the strength of a material is reduced along with the adding of ceramic particles when the powder metallurgy brake lining material is produced by the prior art and the like. The material comprises the following components in percentage by weight: 10 to 80 percent of Cu-Sn mechanical alloy powder, 1.25 to 15 percent of Ti-C mechanical activated powder, 2 to 65 percent of Fe powder, 0 to 10 percent of Ni powder, 0 to 12 percent of Cr powder, 2 to 8 percent of Al2O3 powder, and 7.75 to 23 percent of graphite, wherein the Cu-Sn mechanical alloy powder is prepared from Sn powder and Cu powder which contains 6 to 10 percent of Sn powder by mechanical alloying beforehand; and the Ti-C mechanical activated powder is prepared from Ti powder and C powder according to the ratio of 2:1-8:1 through mechanical activation beforehand, and forms TiC during the sintering. The invention also provides two preparation methods which combine the mechanical activation and the mechanical alloying with the prior powder metallurgy or discharge plasma sintering method.

Owner:JILIN UNIV

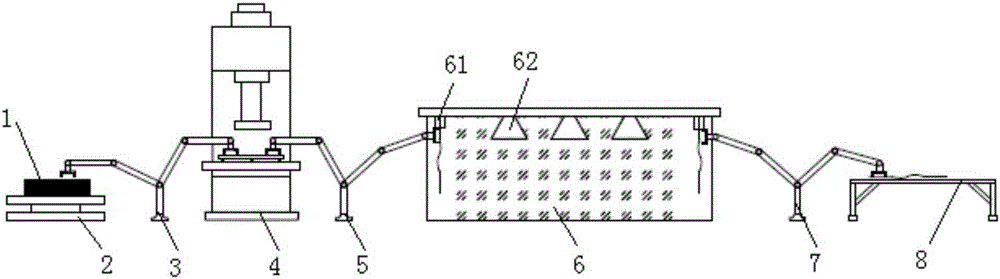

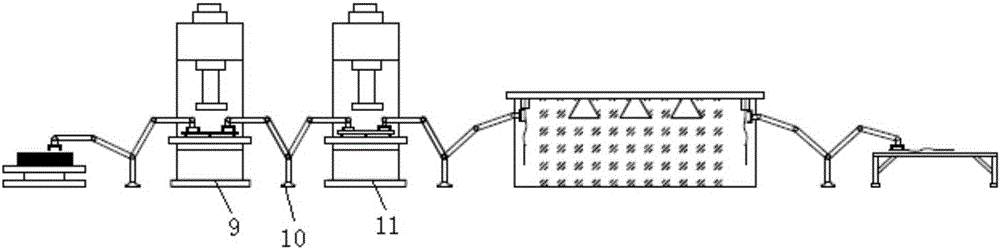

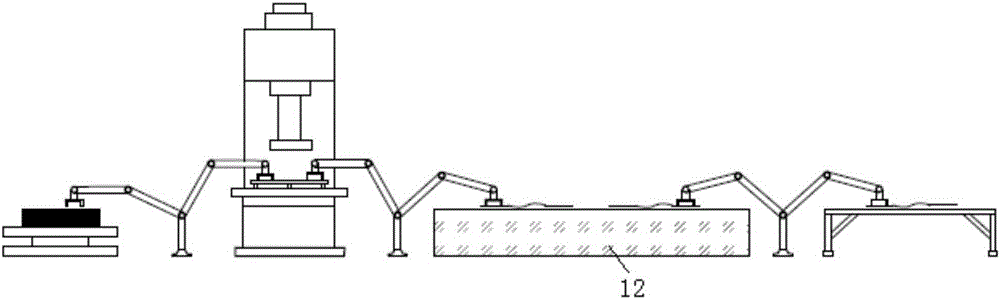

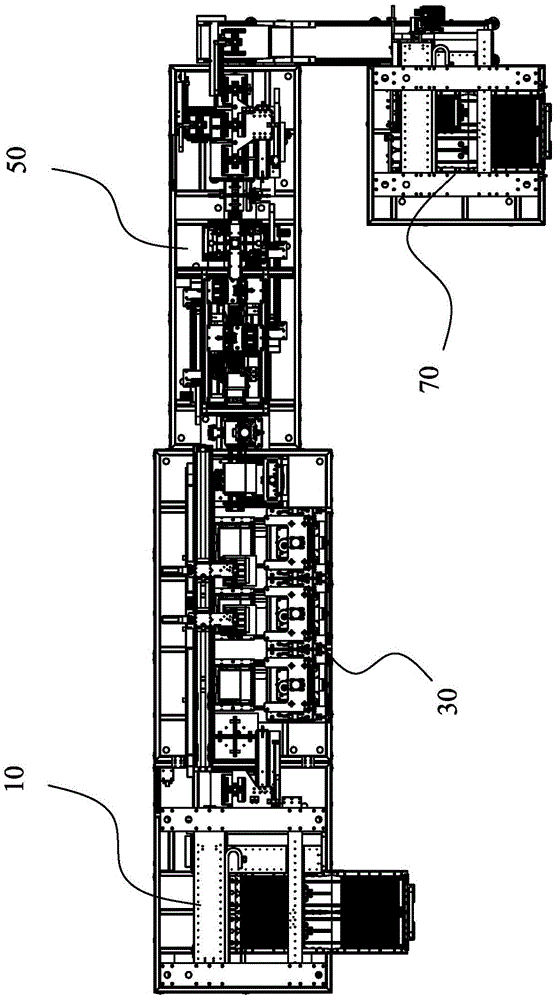

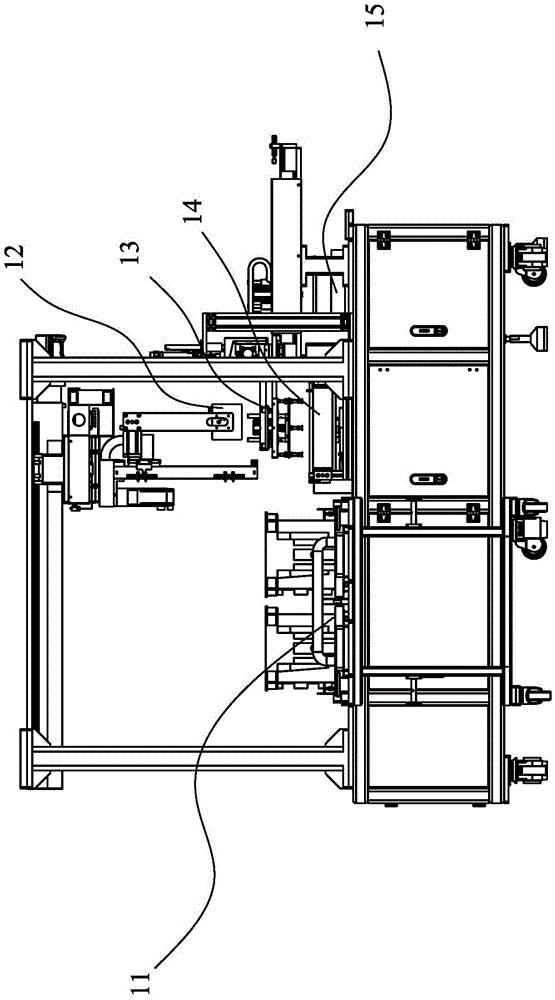

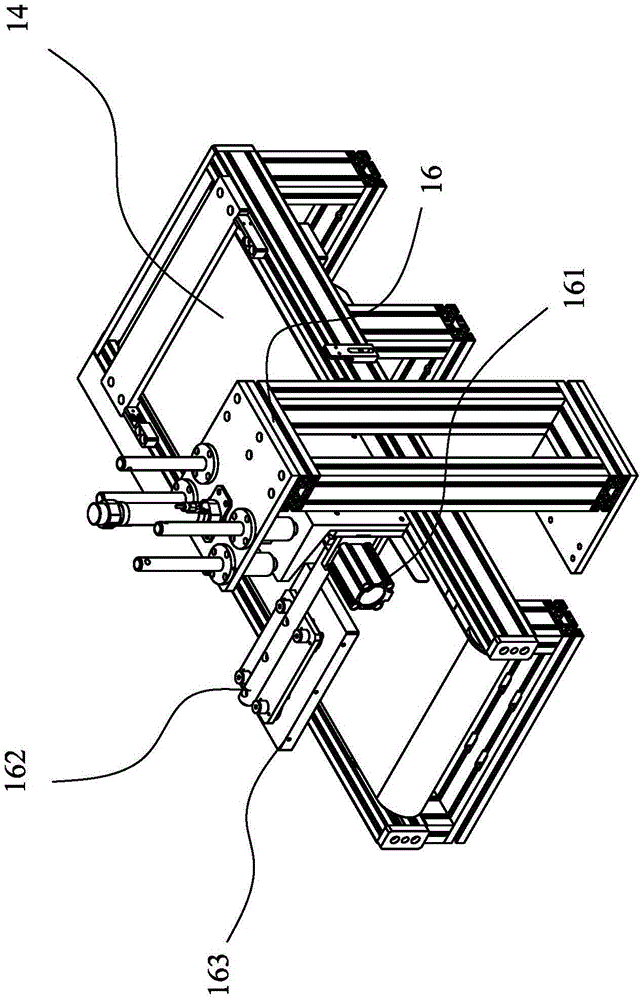

Multi-station continuous hot stamping production line and method

ActiveCN105215160AGuaranteed surface qualityReduce lossesShaping toolsMetal-working feeding devicesHot stampingProduction line

The invention discloses a multi-station continuous hot stamping production line and method. The production line comprises a material loading table, a feeding robot, a press unit, a material conveying robot, a quenching device, a material unloading robot and a conveyor belt which are arranged in sequence. The press unit comprises a heating device, a mould device and at least one press used for installation of the mould device; the heating device is used for wholly or locally heating a prefabricated blank to obtain a hot blank, and the mould device is used for conducting stamping forming, pressure maintaining setting and trimming and punching on the hot blank to obtain a hot stamped part. The rapid heating, stamping forming, pressure maintaining setting, trimming and punching and quenching can be continuously completed, so that the heating efficiency is improved, and the transportation process before punching of the hot blank is also avoided. For steel plates, stamped parts are blanked at a high temperature, increasing of cutting difficulty caused by generation of a martensitic structure at normal temperature is avoided, the blanking force is reduced, and the optimal blanked edge can be obtained.

Owner:WUHAN UNIV OF TECH

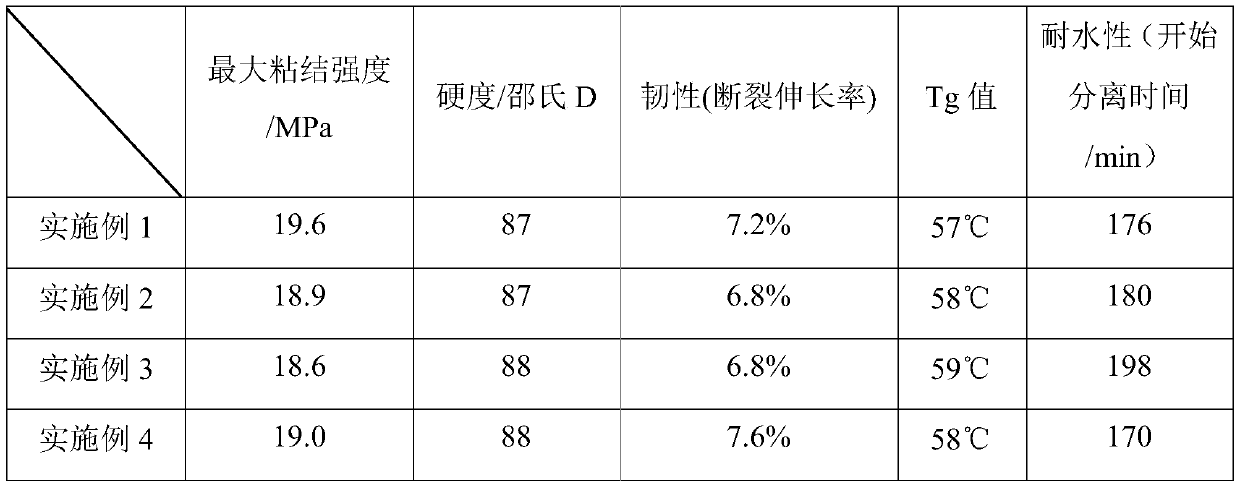

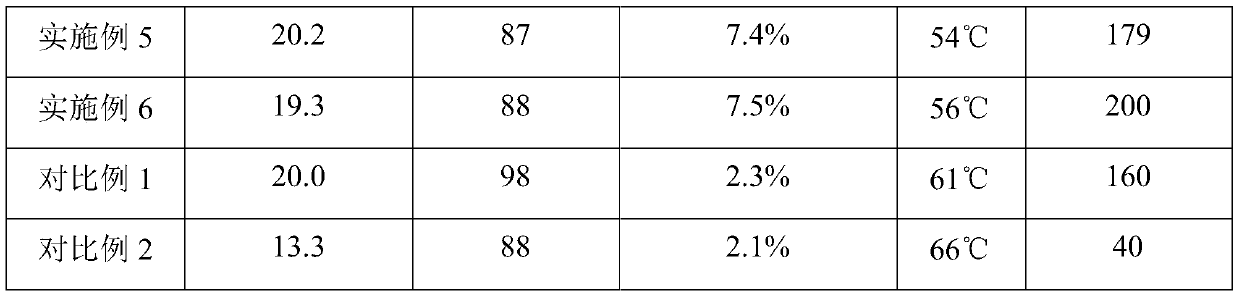

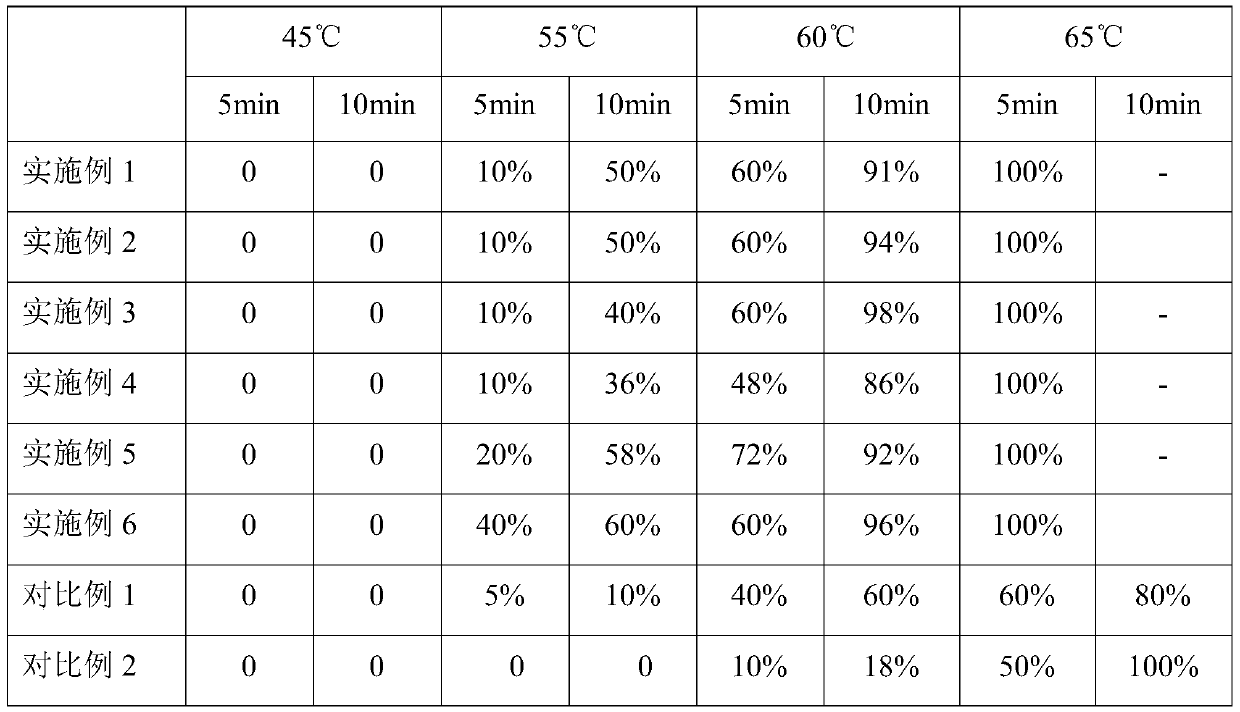

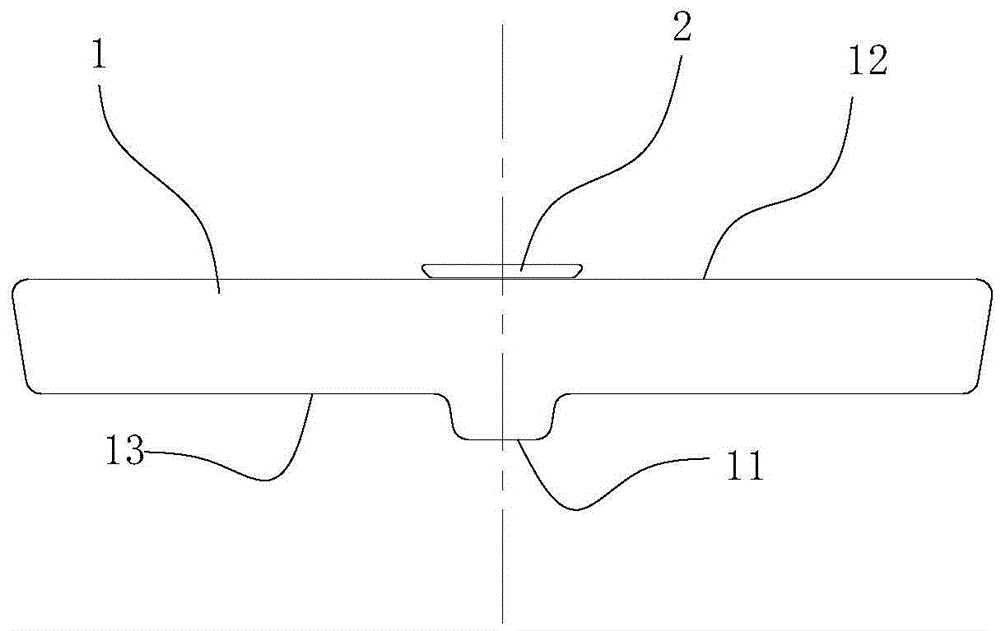

Sticking glue for diamond wire silicon slice and preparation method

InactiveCN109880567ALower Tg valueImprove conductivityNon-macromolecular adhesive additivesEpoxy resin adhesivesGlycidyl ethersWater circulation

The invention discloses a sticking glue for a diamond wire silicon slice and a preparation method. The sticking glue comprises a component A and a component B; the component A includes glycidyl estertype epoxy resin, general bisphenol A epoxy resin, glycidyl ether, filler, defoaming agent, anti-settling agent and coupling reagent; the component B includes modified polythiol, self-prepared m-xylylenediamine prepolymer, accelerant, filler, defoaming agent and anti-settling agent. On the basis of the prior art, the invention modifies the last generation sticking glue and provides the sticking glue for the diamond wire silicon slice and the preparation method thereof. Boiling degumming without acid can be completed without adding degumming factors; the boiling degumming temperature is 10 DEGC lower than the present one; electrical conductivity of solution in cooling water or degumming water is reduced; normal working of cooling water circulation system is guaranteed; the service life ofmachine is prolonged; production efficiency of factory is guaranteed and potential safety hazard of easiness in causing machine failure is solved.

Owner:广西珀源新材料有限公司

Steel plates for 355MPa-level easy-to-weld ocean platform and production process of steel plates

The invention belongs to the technical field of constructional steel for ships and ocean engineering and in particular relates to steel plates for a 355MPa-level easy-to-weld ocean platform and a production process of the steel plates. Two steel plates of which the thickness specifications are [6-40]mm and [40-60]mm are comprised, wherein the steel plate with the thickness specification of [6-40]mm comprises the following chemical components in percentage by mass: 0.10-0.15 percent of C, 0.20-0.50 percent of Si, 1.20-1.50 percent of Mn, not more than 0.015 percent of P, not more than 0.005 percent of S, 0.020-0.050 percent of Nb, 0.010-0.050 percent of V, 0.008-0.020 percent of Ti, 0.015-0.055 percent of Als, not more than 0.43 percent of Ceq, not more than 0.23 percent of Pcm and the balance of Fe and inevitable impurities; and the steel plate with the thickness specification of [40-60]mm comprises the following chemical components in percentage by mass: 0.10-0.15 percent of C, 0.20-0.50 percent of Si, 1.30-1.60 percent of Mn, not more than 0.015 percent of P, not more than 0.005 percent of S, 0.030-0.060 percent of Nb, 0.020-0.060 percent of V, 0.008-0.020 percent of Ti, 0.015-0.055 percent of Als, not more than 0.12 percent of Nb+V+Ti, not more than 0.43 percent of Ceq, not more than 0.23 percent of Pcm and the balance of Fe and inevitable impurities. According to the production method, the steel plates for the easy-to-weld ocean platform are produced by adopting low Ceq, low Pcm, Nb as well as V and Ti microalloy components and a normalizing heat treatment process and are lower in production cost, even in mechanical property and favorable in welding property.

Owner:JIGANG GRP

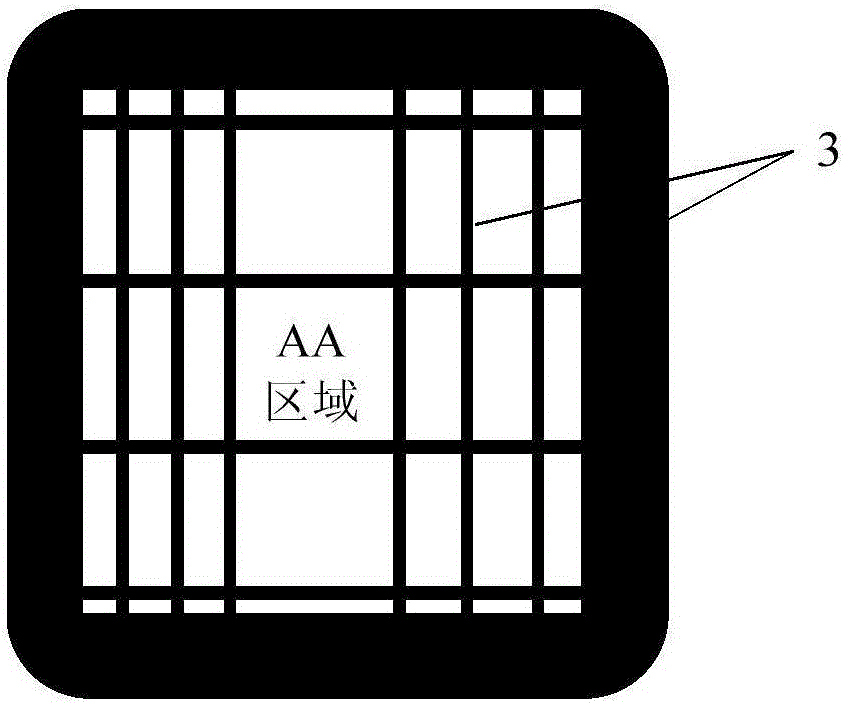

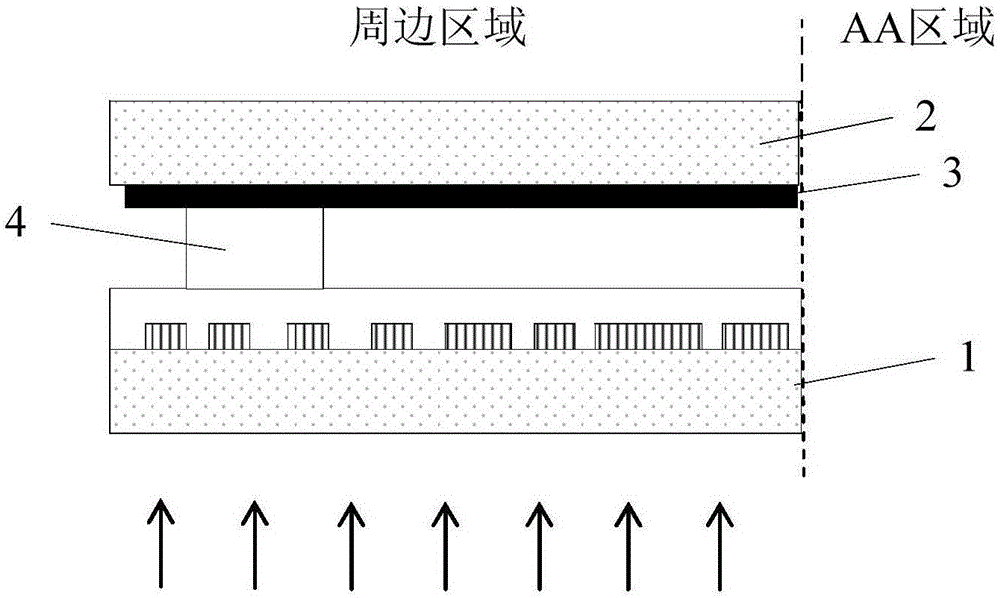

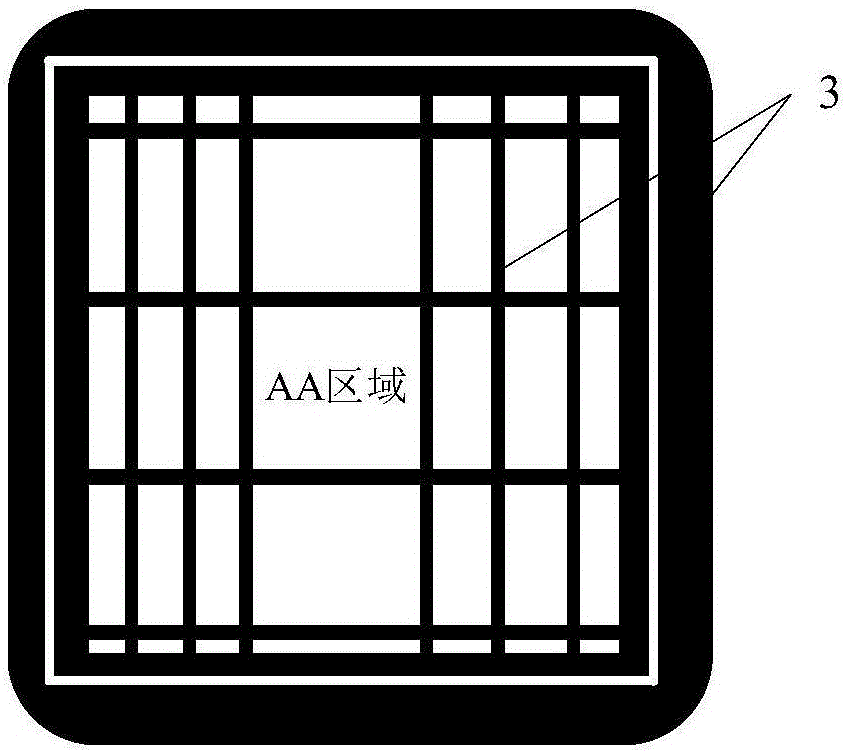

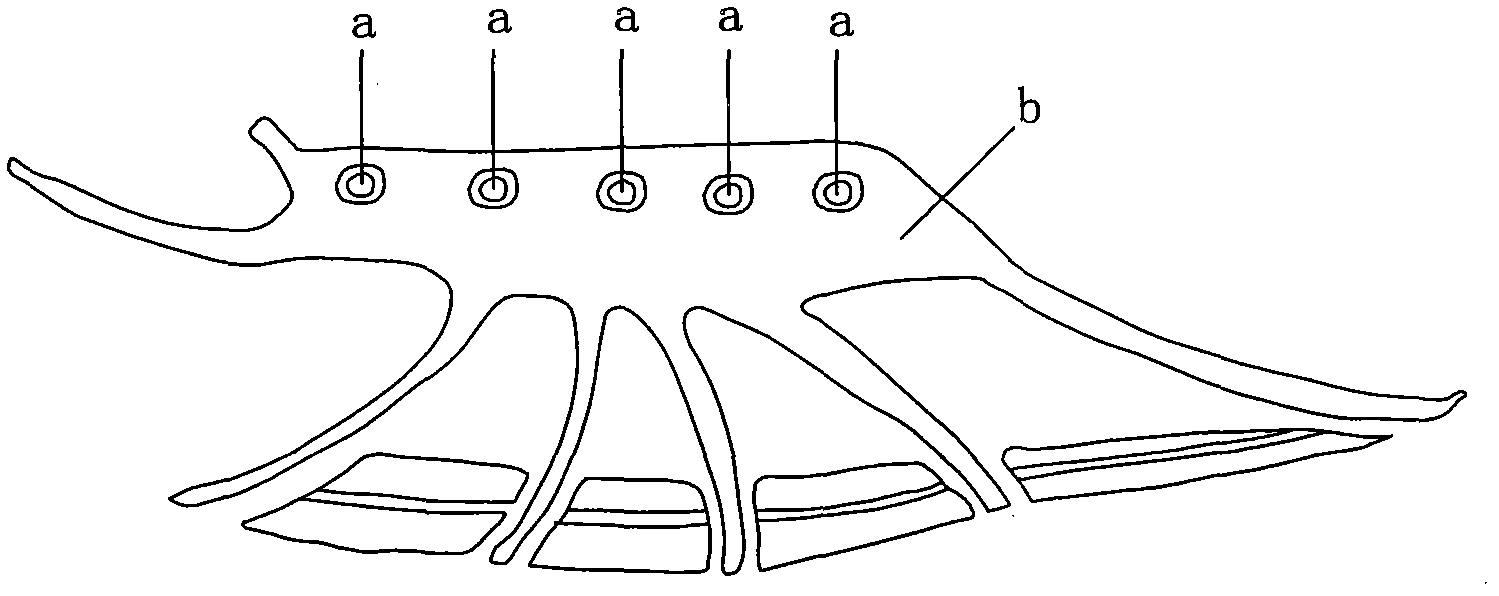

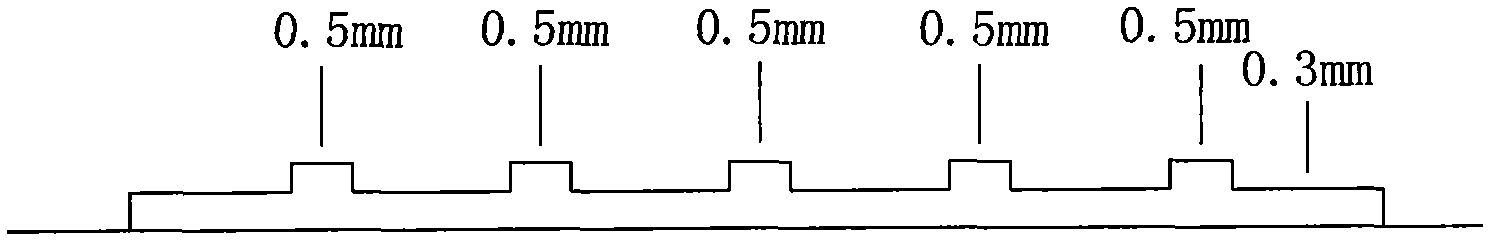

Color film substrate, display panel and display device

InactiveCN106842678AImprove the ability to resist signal crosstalkTaking into account the anti-interferenceNon-linear opticsDisplay deviceColor film

The invention provides a color film substrate, a display panel and a display device. A black matrix in a non-display area of the color film substrate is provided with an opening, the edge of the opening along a substrate is closed, and the opening penetrates the black matrix in the direction perpendicular to the substrate, so the black matrix in the non-display area and a black matrix in a display area are isolated completely. When an outside electric field has interference, an influence is generated only on an induced voltage passing the black matrix inside the non-display area adjacent to the edge of the color film substrate, no influence is generated on the induced voltage passing the black matrix inside the display area, and normal display of the display panel is not affected. Thus, the black matrix does not need to be made of an anti-inference material, signal crosstalk resistance of the black matrix can be improved, and thus the production cost and anti-interference performance of the black matrix are both considered. The production cost can be reduced by 50% on the premise of guaranteeing anti-interference performance of the black matrix.

Owner:BOE TECH GRP CO LTD +1

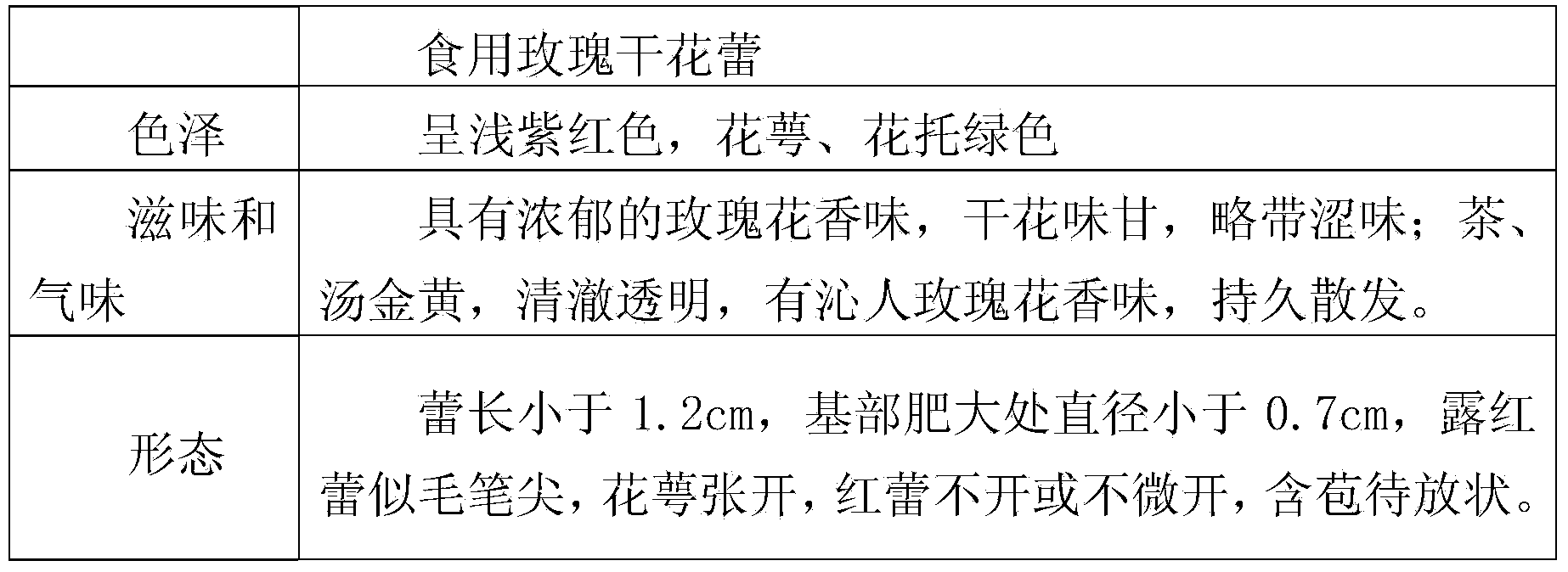

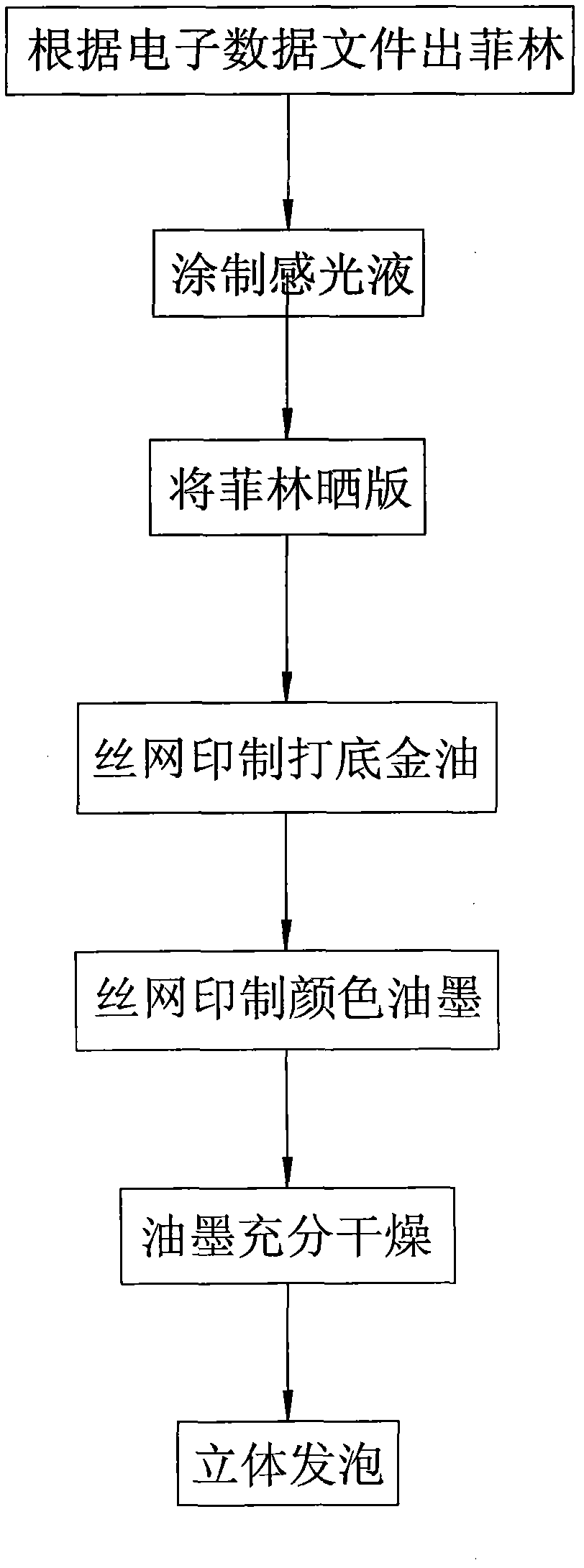

Comprehensive method for drying rosebuds through microwave vacuum and heated air circulation

ActiveCN103504448AEasy to useHumidity removalFood thermal treatmentFloral handlingEngineeringMicrowave

The invention discloses a method for drying rosebuds and belongs to the technical field of rosebud drying through microwave vacuum and heated air circulation. A comprehensive method for drying rosebuds through microwave vacuum and heated air circulation comprises the following steps: (1) feeding the rosebuds to a heated air circulation dryer for drying; (2) feeding the rosebuds obtained in the step (1) to a microwave vacuum drier for drying. According to the comprehensive method, the temperatures are low during the drying processes, the drying time is short, the product quality is high, meanwhile energy consumption is lowered, and the production efficiency is improved. Besides, microwaves can effectively sterilize the rosebuds and kill worms' eggs attached to the rosebuds, and are beneficial for prolonging product shelf lives.

Owner:银谷芳香科技有限公司

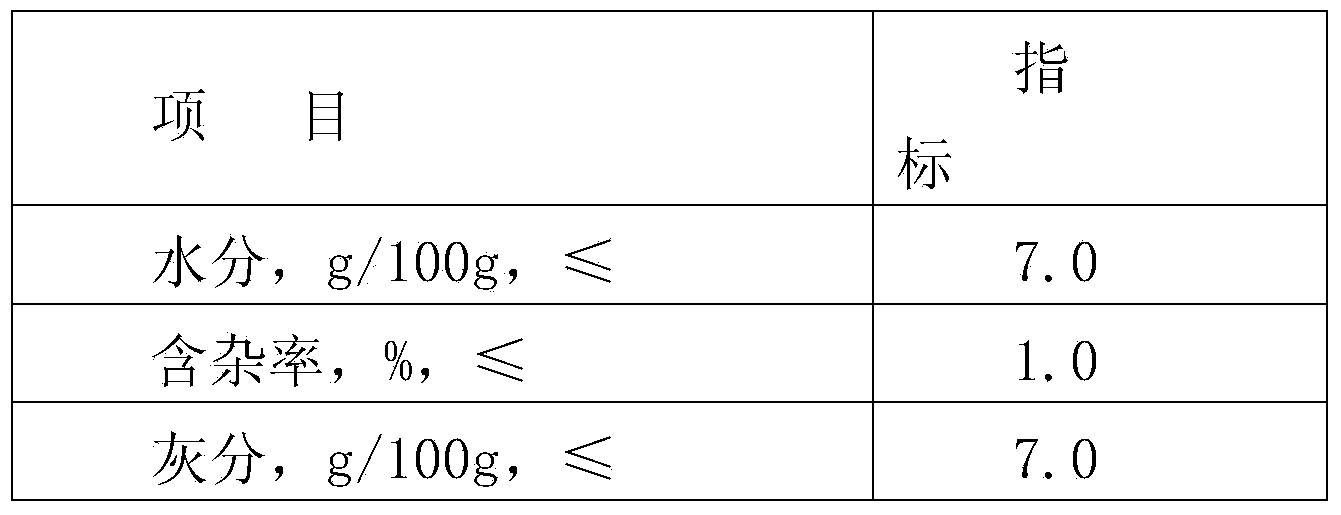

High-performance reactor with quantitative feeding mechanism

InactiveCN106040156ASave human resourcesIncrease productivityRotary stirring mixersTransportation and packagingEngineeringRaw material

The invention discloses a high-performance reactor with a quantitative feeding mechanism, comprising a body. The top end of the left outer wall of the body is provided with a particles feeding port, the upper left and right of the body are provided with a particles feeding device and a powder feeding device respectively, the particles feeding device comprises a particles storage bucket, a stirring device mounted in the particles storage bucket, a particles discharge tank and an intelligent meter. The high-performance reactor with a quantitative feeding mechanism can automatically finish a feeding process and enables raw materials to be automatically and intelligently rationed and weighed, production efficiency is effectively improved, production cost is reduced, material in the body is stirred by using three stirring mechanisms arranged from top to bottom, stirring efficiency is greatly improved, and stirring effect is guaranteed; a collection pit and a screen arranged at the bottom of the body can separate the material and impurities, the quality of the material is guaranteed, and in addition, a heat transfer coefficient of a reactor stirrer can be promoted.

Owner:李明波

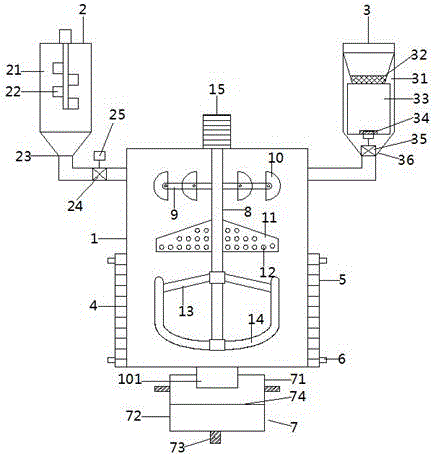

Three-dimensional foaming printing method

InactiveCN102848765AThree-dimensionalGood flexibilityPattern printingOther printing apparatusScreen printingEngineering

The invention discloses a three-dimensional foaming printing method which comprises the steps of producing films according to electronic data files; coating the films with light sensitive liquids; selecting suitable gauze and subjecting the films to printing down; printing bottoming gold oil on silk screens; printing color ink on the silk screens to obtain picture bases with a stereoscopic sense; fully drying the bottoming gold oil and the color ink to obtain pattern materials; and subjecting the pattern materials to three-dimensional foaming with a foaming machine. The pattern materials obtained finally through the method have the advantages that patterns have a stereoscopic sense and good softness, the definition and the accuracy are high, and defects that screen printing techniques in the prior art are only applied to print plane products are overcome.

Owner:刘丽华

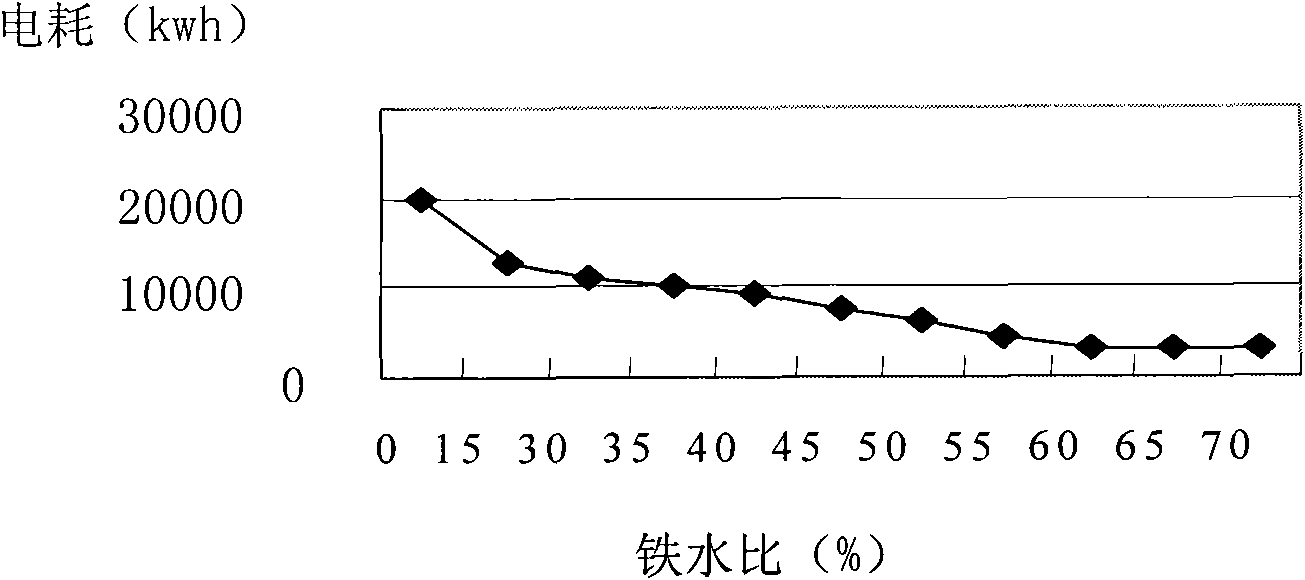

Electric furnace to converter steel making production process

InactiveCN1775959AImprove economyReduce risk of exposureElectric furnaceElectric arc furnaceEconomic benefits

The invention relates electric furnace converting steel-making process technology that contains 80-90% molten iron, waste steel, pig iron and other cold burden 10-20%. The temperature of the molten iron in electric furnace is controlled to the range of 1550-1580 degree centigrade. The invention supplies a method of using molten iron to take the place of waste steel. Thus, it has great economic benefits, reduces the smoke and improves the operation environment.

Owner:SGIS SONGSHAN CO LTD

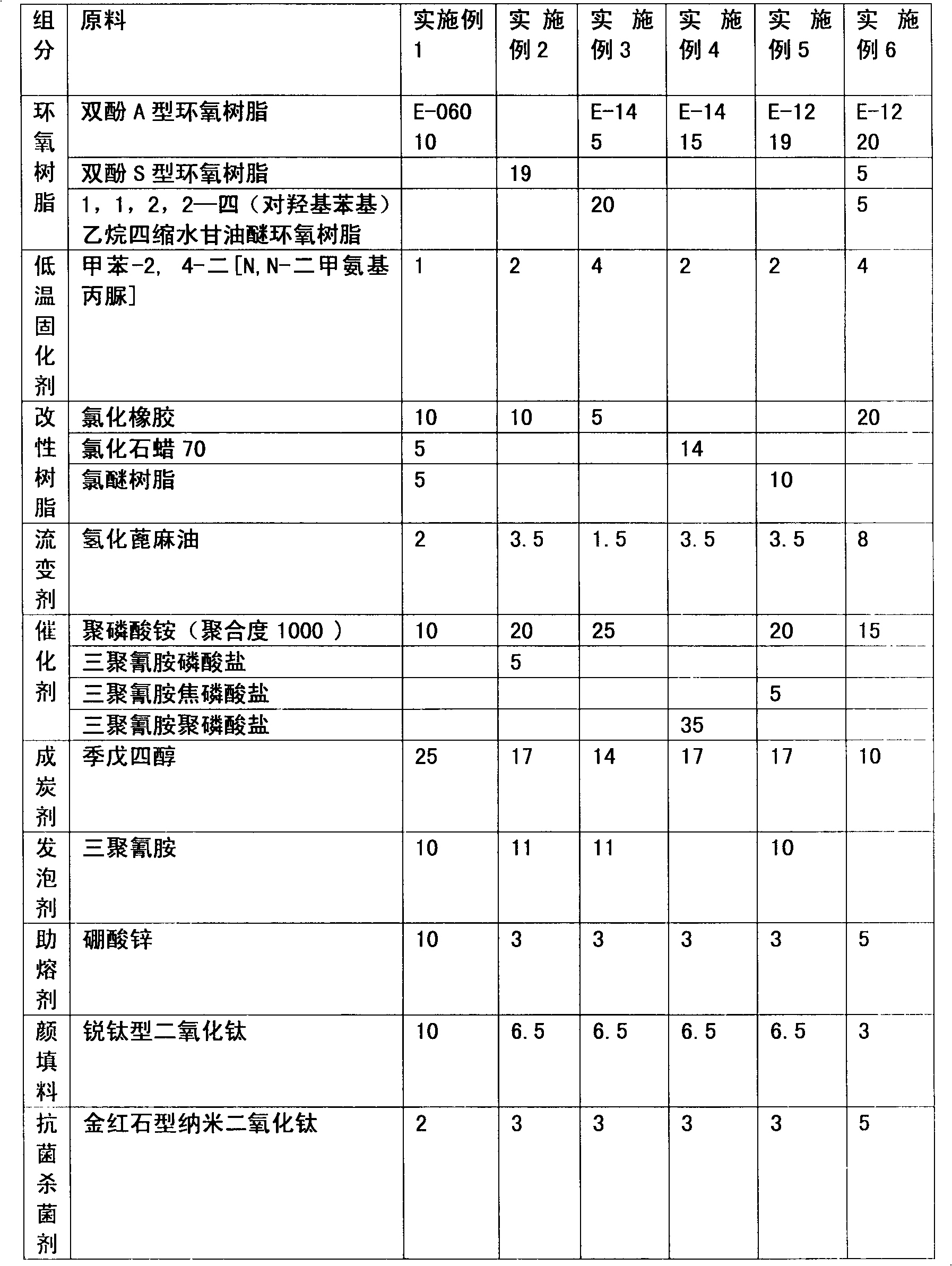

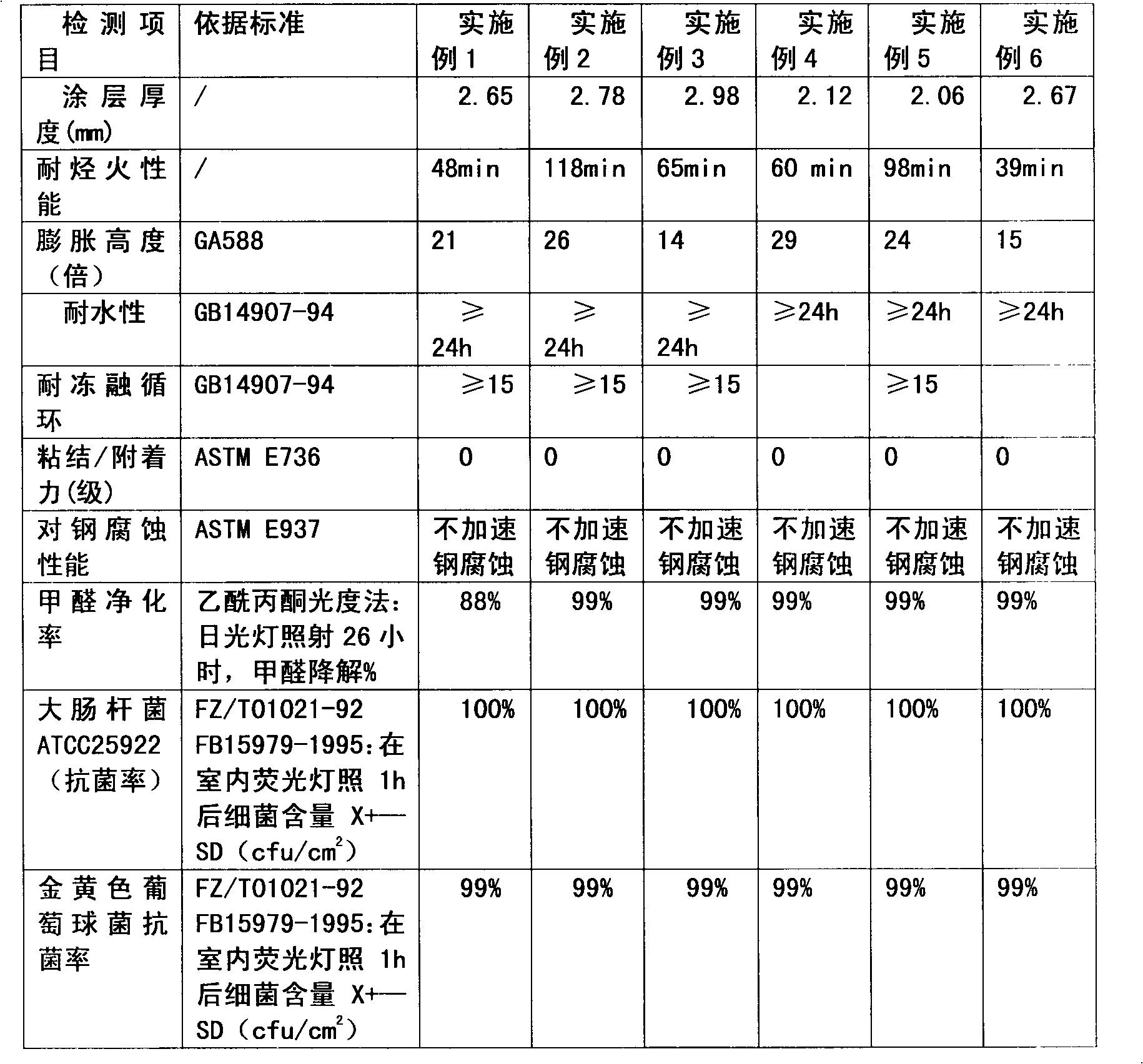

Hydrocarbon fire resistant ultrathin expanded fireproof coating and preparation method thereof

InactiveCN102020910ANot easy to fall offNo cross-linking reactionFireproof paintsRubber derivative coatingsEpoxyFire risk

The invention provides a hydrocarbon fire resistant ultrathin expanded fireproof coating and a preparation method thereof. The coating comprises the following components in part by weight: 10 to 30 parts of epoxy resin, 1 to 4 parts of modified curing agent, 5 to 20 parts of modified resin, 2 to 8 parts of rheological agent, 10 to 35 parts of catalyst, 10 to 25 parts of carbon forming agent, 0 to 11 parts of foaming agent, 5 to 10 parts of fluxing agent, 3 to 10 parts of pigment and filler, and 2 to 5 parts of antibacterial bactericide. The method comprises the following steps of: mixing the crushed resin and other components uniformly, extruding the mixture at the temperature of 95 DEG C at the rotational speed of 300 revolutions per minute, crushing the extruded product, and sieving the powder with a sieve of 40 meshes to obtain the coating. The coating has low curing temperature, high hydrocarbon fire resistant limit, good bonding force and high strength, can tolerate high and low-temperature circulating influence, has air purification and sterilization functions, and is convenient for construction; and the preparation method is simple, and has low energy consumption. The coating is particularly suitable for fire protection of steel, aluminum and other materials of the indoor and outdoor petrochemical industry with hydrocarbon fire risks.

Owner:应急管理部四川消防研究所

Electric furnace burden process with high efficiency and low cost

InactiveCN101660019ARaise the endpoint componentIncrease temperatureProcess efficiency improvementElectric furnaceElectric arc furnaceSmelting process

The invention relates to an electric furnace burden process with high efficiency and low cost. Main raw materials are molten iron accounting for 30-60 percent of metal adding amount, excellent scrap steel accounting for 5-10 percent of metal adding amount and low-lost scrap steel accounting for 30-35 percent of metal adding amount; auxiliary materials are lime and soft burning dolomite, wherein 3.0-3.5 percent of lime and 1.0-1.5 percent of soft burning dolomite are respectively added in each ton of molten steel; and through optimizing electric furnace slag discharge operation, using an oxygenlance and adopting power supply oxygen blowing control and other smelting processes, the electric furnace burden process greatly improves simultaneous hit rate of terminal point components and the temperature of an electric arc furnace, realizes the aims of improving the quality of the molten steel, shortening the smelting period and reducing the consumption and significantly reduces the full oxygen content of steel products at the same time. The electric furnace burden process has good application prospect for ensuring the quality of steel and reducing the production cost.

Owner:KUNMING IRON & STEEL

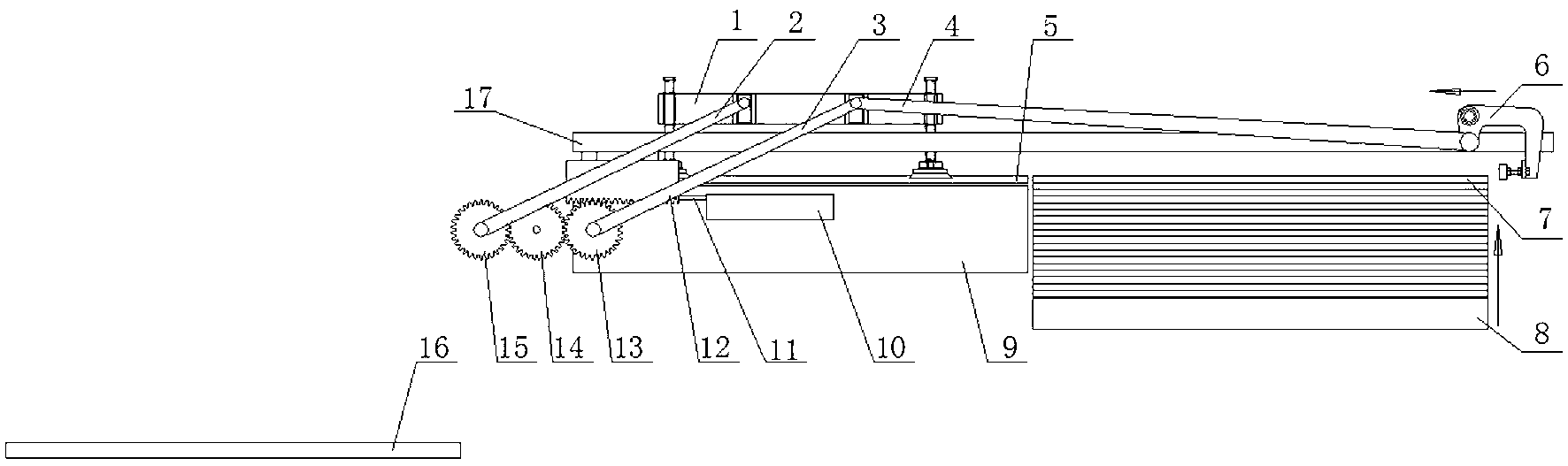

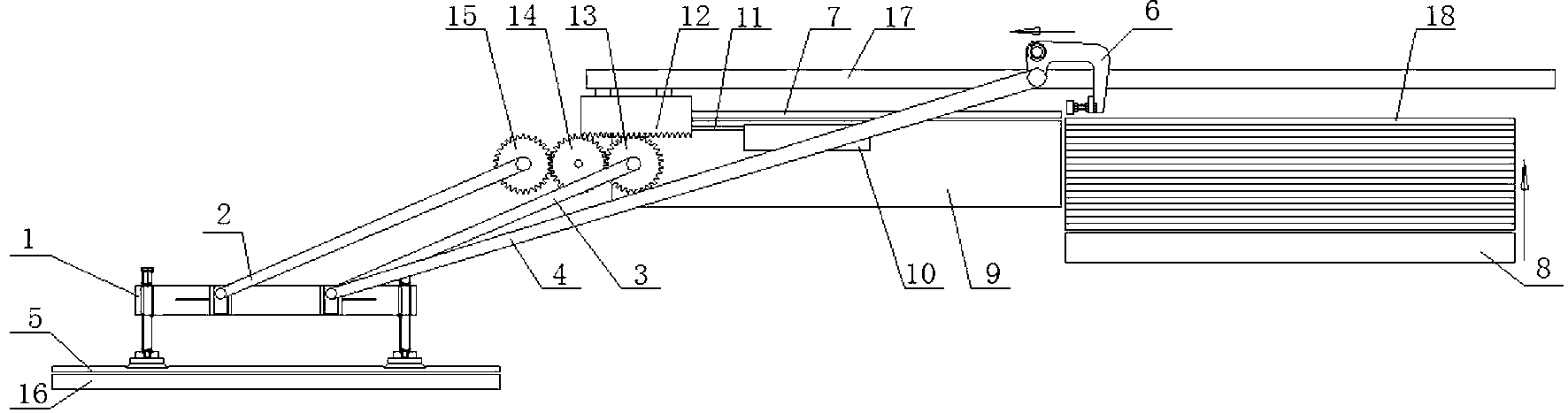

Plate transporter

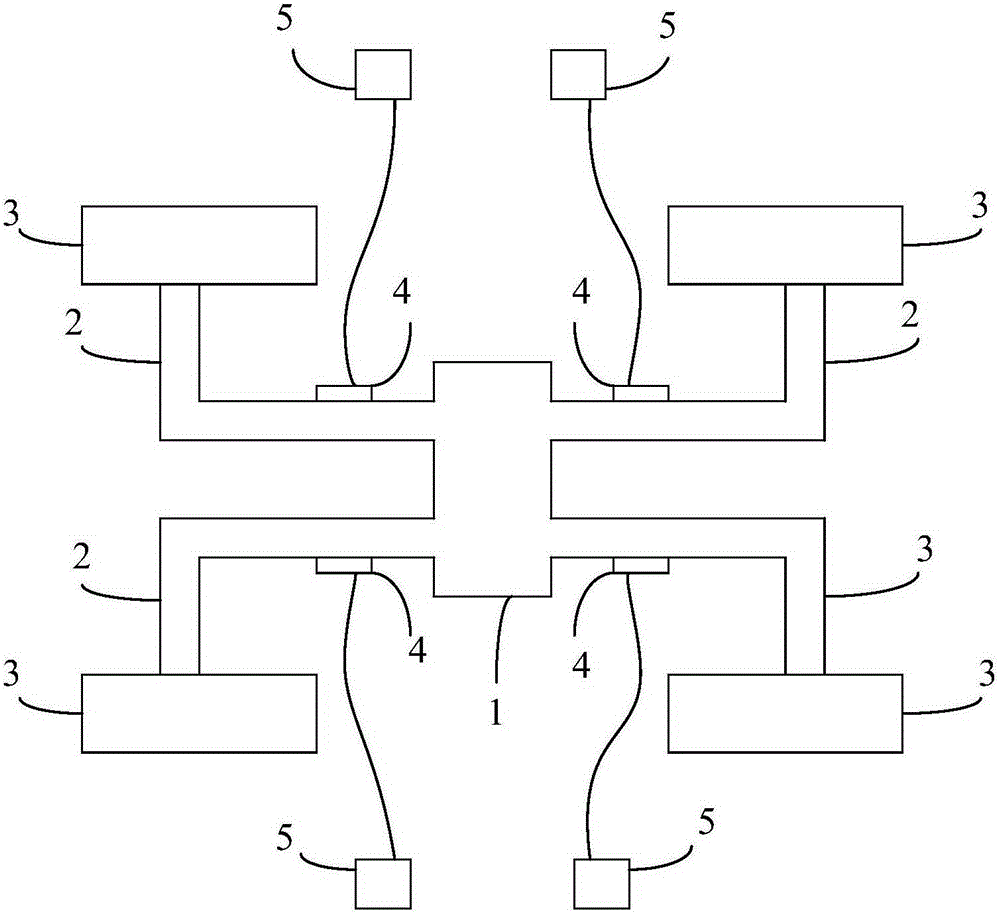

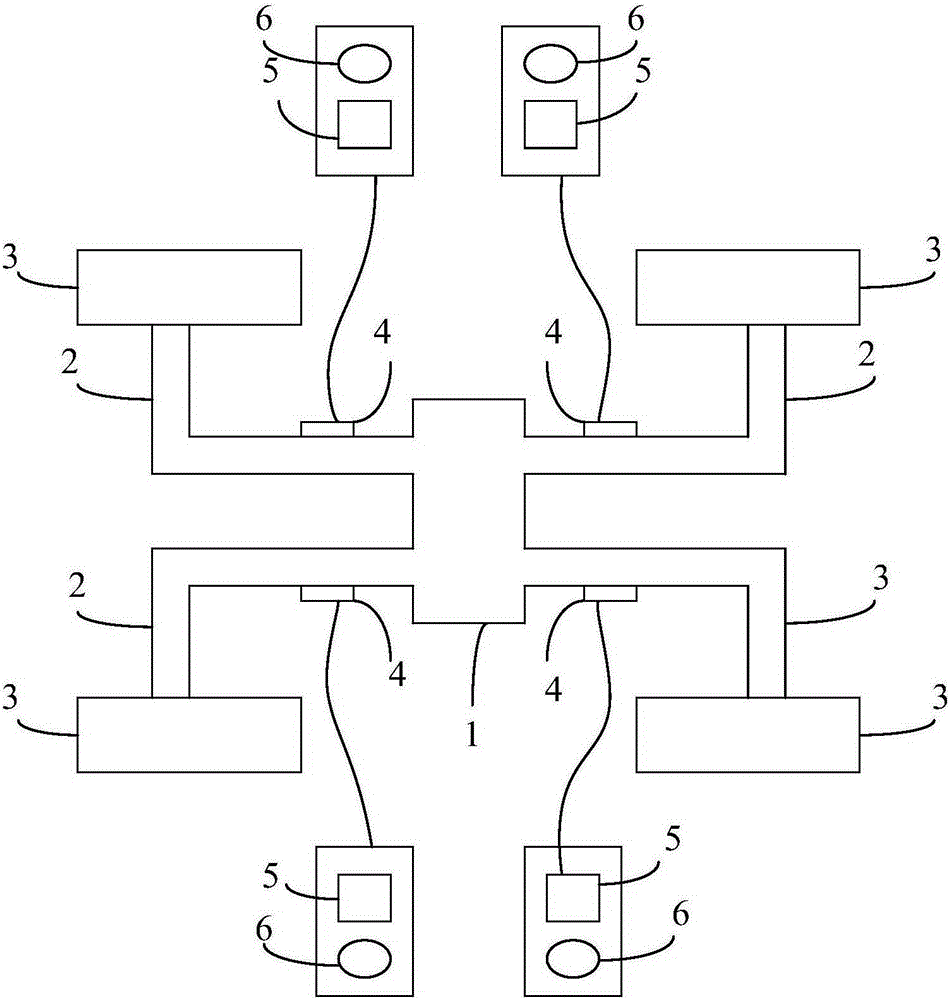

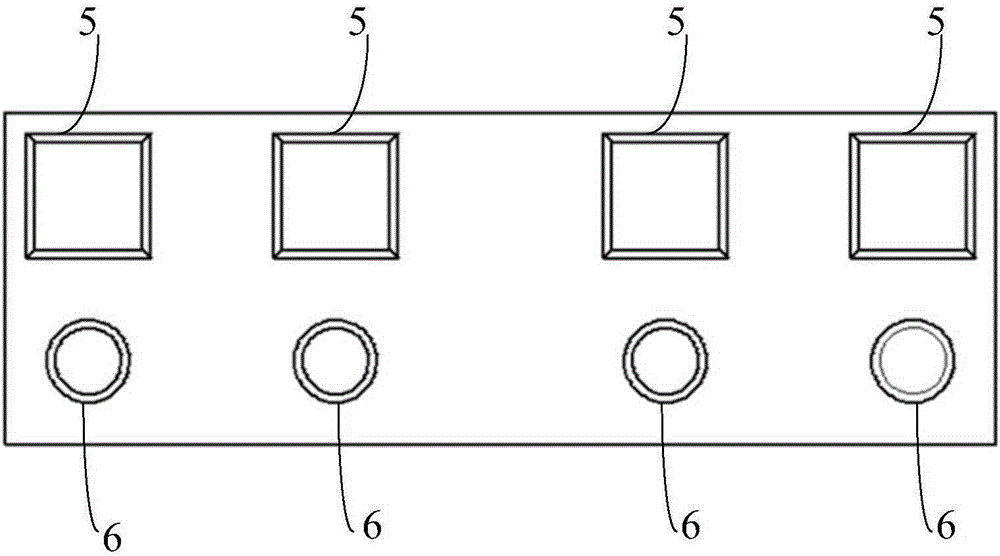

ActiveCN103287864ASmall footprintShort line lengthStacking articlesDe-stacking articlesCylinder blockManufacturing line

The invention relates to a plate transporter and solves the problems that the prior production line is large in length, large in floor area, high in production cost, complex in maintenance process, and inconvenient to use and operate. The plate transporter is technically characterized by comprising a transporting frame for picking and placing plates, a transition frame with a slide rail, a bench, and a driving mechanism for driving the transporting frame to transport plates between the transition frame and the bench. The driving mechanism comprises first gears, second gears, third gears, reciprocating cylinders, racks, second links, and first links, wherein the first gears, the second gears and the third gears are meshed in sequence, the racks driven by the reciprocating cylinders are meshed with the first gears, the second links fixed to the first gears are hinged to the transporting frame, and the first links fixed to the third gears are hinged to the transporting frame. The plate transporter further comprises a pusher and third links, wherein the pusher moves along the slide rail and the third links hinged to the first links, the second links or the transporting frame are hinged to the pusher. The plate transporter is simple in structure, easy to maintain, low in production cost and stable and safe in transporting process.

Owner:嘉兴笼列电子商务有限公司

Automatic secondary-packaging molding production line

ActiveCN105633478ARealize fully automatic productionIncrease productivityAssembling battery machinesFinal product manufactureProduction lineEconomic benefits

The invention discloses an automatic secondary-packaging molding production line. The production line comprises a feeding unit, a packaging unit, a molding unit and a discharging unit, wherein the feeding unit comprises a feeding pull band; the packaging unit comprises a primary-packaging station and a primary-cutting station; the primary-packaging station is arranged close to the primary-packaging correction station; an upper packaging cavity, a low packaging cavity and a movable cavity are formed in the primary-packaging station; the primary-cutting station is provided with a primary-cutting mechanism for cutting sealing edges of cells; the molding unit comprises a cell transfer mechanism, and a fine packaging mechanism, a rolling wheel edge-folding mechanism, an adhesive dispensing mechanism, a thermoprint edge-folding mechanism, and a second weighing station arranged on the two sides of the cell transfer mechanism in sequence; and the discharging unit comprises a discharging pull band. According to the automatic secondary-packaging molding production line, the feeding unit, the packaging unit, the molding unit and the discharging unit are integrated on one equipment, so that the fully automatic production of a softly-packaged lithium battery from feeding to discharging can be realized; and therefore, the production efficiency of the lithium battery is improved, the productivity is improved, the production cost is lowered, and the economic benefit is increased.

Owner:DONGGUAN HONBRO LI BATTERY EQUIP TECH

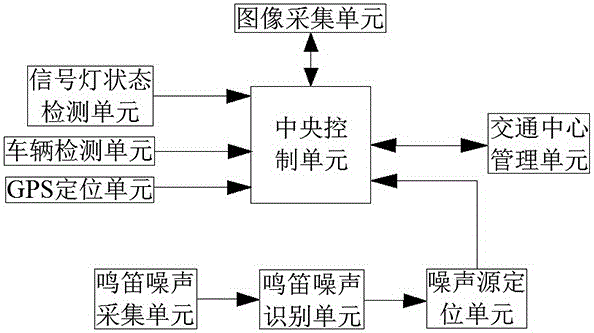

Automobile whistling and red light running snapshot system

InactiveCN105096606AIncrease transfer rateAvoid technical problemsRoad vehicles traffic controlSound sourcesEngineering

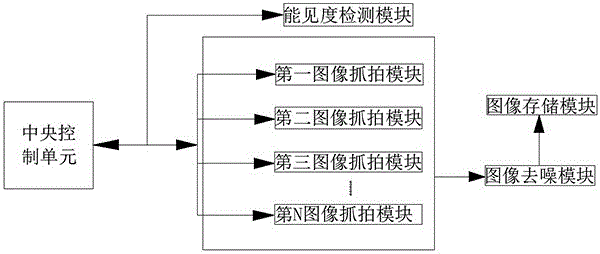

The invention discloses an automobile whistling and red light running snapshot system. The system comprises a signal lamp state detection unit, a vehicle detection unit, a GPS positioning unit, a whistling noise acquisition unit, a whistling noise identification unit, a sound source positioning unit, an image acquisition unit, a central control unit and a traffic center management unit. The signal lamp state detection unit, the vehicle detection unit, the GPS positioning unit and the image acquisition unit are connected with the central control unit. The whilsting noise acquisition unit, the whistling noise identification unit and the noise source positioning unit are successively connected and then are connected with the central control unit through the noise source positioning unit, and the central control unit is in communication connection with the traffic center management unit via a 4G wireless network. According to the invention, the system solves the problems of red light running and whistling capturing on a quite densely-populated street, can detect position and capture whistling and red light running vehicles, and facilitates management and improvement of traffic and residents' life by traffic management personnel.

Owner:CHENGDU ZHONGFU LIXIANG TECH

Composite conducting material and preparation method thereof

ActiveCN103077765AGuaranteed production costReduce manufacturing costNon-conductive material with dispersed conductive materialCable/conductor manufactureSimple Organic CompoundsActive agent

The invention provides a composite conducting material and a preparation method thereof. The composite conducting material comprises modified attapulgite powder and nanometer carbon powder. The nanometer carbon powder is absorbed to the surface of the modified attapulgite powder. After ion exchange reaction of the modified attapulgite powder with an organic compound through the attapulgite powder, a nonionic surfactant is further absorbed to the surface of the modified attapulgite powder. The nanometer carbon powder is 10-20% of the modified attapulgite powder by percentage by weight. The envelope-bulk to weight ratio of the total use level of the organic compound and the nonionic surfactant and the attapulgite powder is 5-10mL / 100g. The volume ratio of the organic compound and the nonionic surfactant is 1:1-1:2. The composite conducting material provided by the invention adequately utilizes the modified attapulgite powder to absorb the nanometer carbon powder, so that the dispersibility of the material is improved, the conducting performance of the material is ensured, and the production cost is saved.

Owner:江苏迪丞光电材料有限公司

Al-Mg-Zn aluminum alloy welding wire and preparation method thereof

PendingCN108396206AImprove mechanical propertiesIncreased intensityWelding/cutting media/materialsSoldering mediaWeld seamUltimate tensile strength

The invention relates to an Al-Mg-Zn aluminum alloy welding wire and a preparation method thereof, and belongs to the technical field of aluminum alloy welding wires. The Al-Mg-Zn aluminum alloy welding wire is prepared from the components in percentage by mass: 0.5 to 3.0 percent of Zn, 4.5 to 5.5 percent of Mg, 0.05 to 0.20 percent of Mn, less than or equal to 0.15 percent of Ti, less than or equal to 0.15 percent of Cr, less than or equal to 0.25 percent of Fe, less than or equal to 0.25 percent of Si, less than or equal to 0.15 percent of the total amount of other impurity elements, less than or equal to 0.05 percent of the content of single impurity element, and the balance Al. The preparation method comprises the steps of smelting, casting, heating to 440 DEG C to 470 DEG C, keepingwarm for 3h to 6h, carrying out hot extrusion, heating to 480 DEG C to 550 DEG C, keeping arm for 3h to 6h, rolling, intermediate annealing, scaling, and multi-pass drawing. According to the method, high-temperature long-time homogenization treatment is not needed, so that the energy is saved, and the welding wire production process is shortened; and excess crystal phase particles in the welding wire are fine in size and uniform in dispersion and distribution, so that wire breakage caused by drawing is reduced, the welding wire yield is improved, the production cost is reduced, and a welding performance and the weld seam metal strength of the welding wire can be improved.

Owner:NORTHEASTERN UNIV

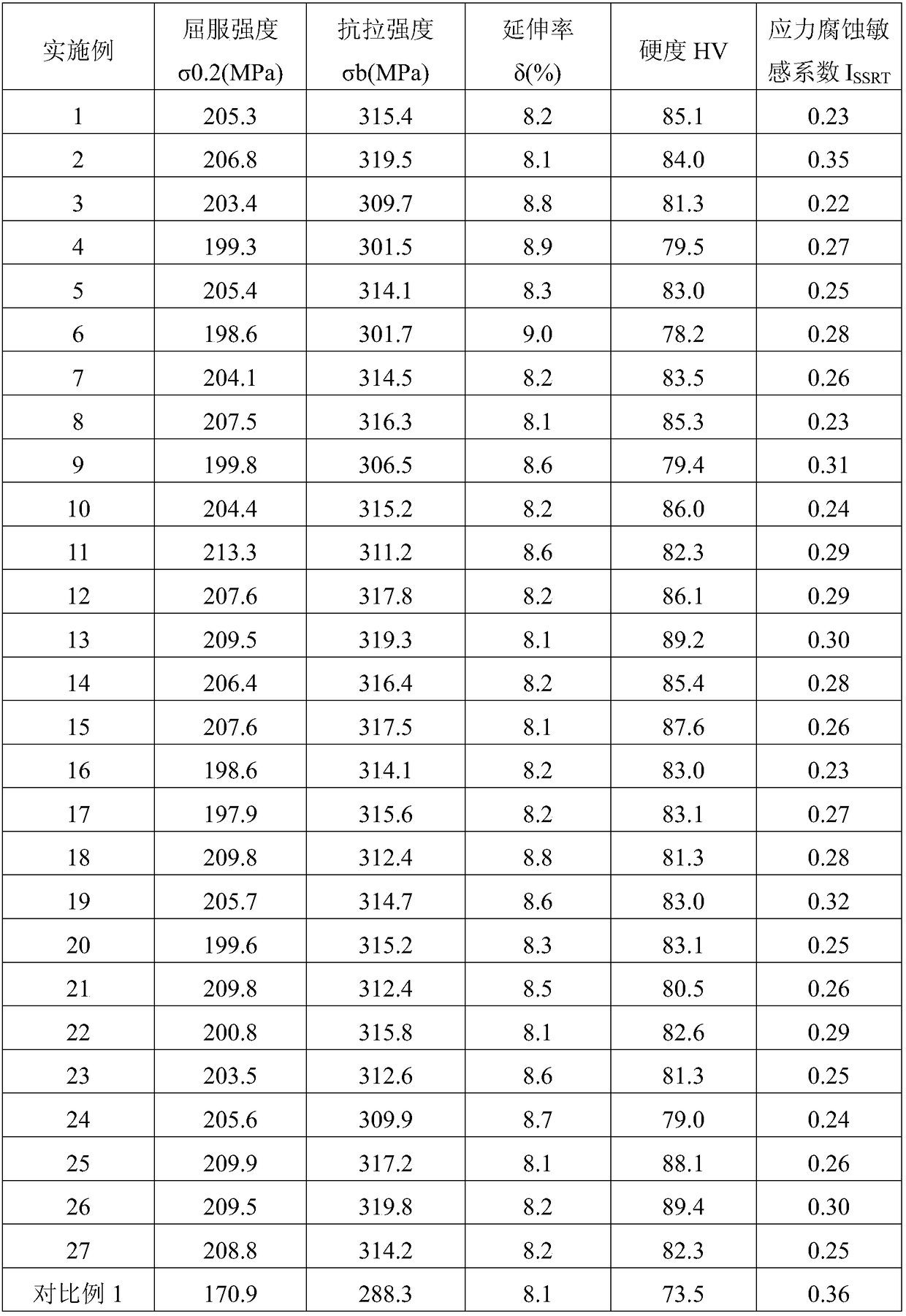

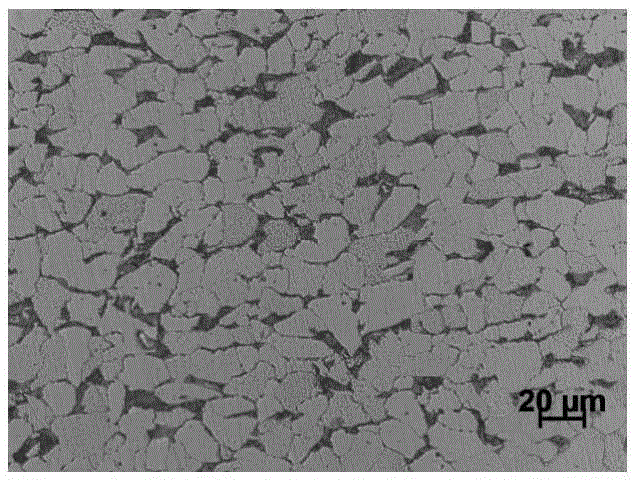

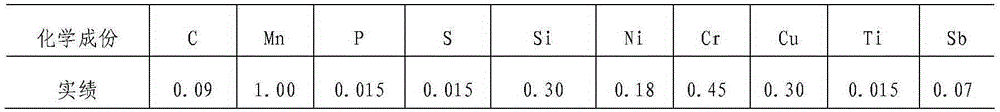

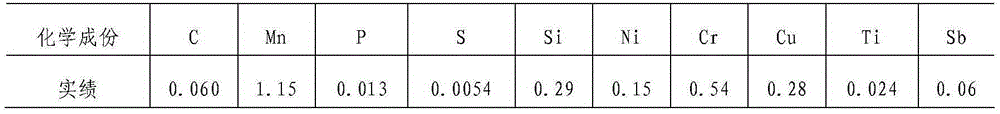

Low-cost Nb-free thin-gauge sulfuric acid dew point corrosion resisting steel and production method thereof

InactiveCN105349911AGuaranteed Performance RequirementsGuaranteed production costHigh pressure waterHigh pressure

The invention provides low-cost Nb-free thin-gauge sulfuric acid dew point corrosion resisting steel. The steel is characterized by comprising the following elements in percentage by mass: smaller than or equal to 0.12% of C, smaller than or equal to 0.55% of Si, 0.75% to 1.20% of Mn, smaller than or equal to 0.020% of P, smaller than or equal to 0.025% of S, 0.50% to 1.2% of Cr, 0.20% to 0.50% of Cu, smaller than or equal to 0.25% of Ni, 0.05% to 0.15% of Sb, smaller than or equal to 0.025% of Ti, smaller than or equal to 0.010% of V, 0.020% to 0.050% of Alt and 0.0005% to 0.0035% of Ca. The tissues of the steel disclosed by the invention are ferrite and pearlite; the heating temperature is increased; generation of relatively thick iron oxide scale is facilitated; transient temperature reduction of the surface iron oxide scale is increased during descaling of high-pressure water, so that shrinkage of the surface iron oxide scale is intensified, the iron oxide scale is easier to remove from a base body, the descaling efficiency is improved, and iron oxide scale residues are fundamentally reduced.

Owner:NANJING IRON & STEEL CO LTD

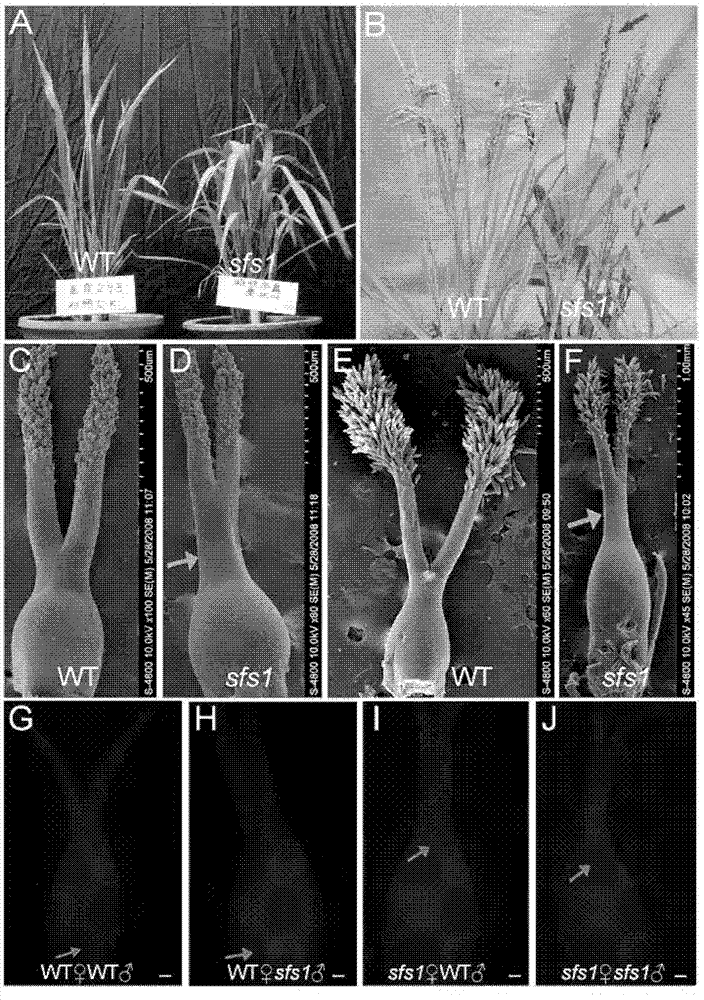

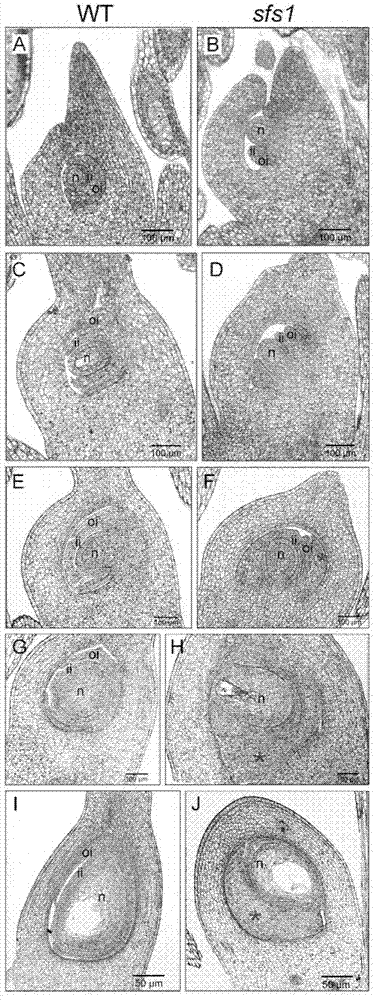

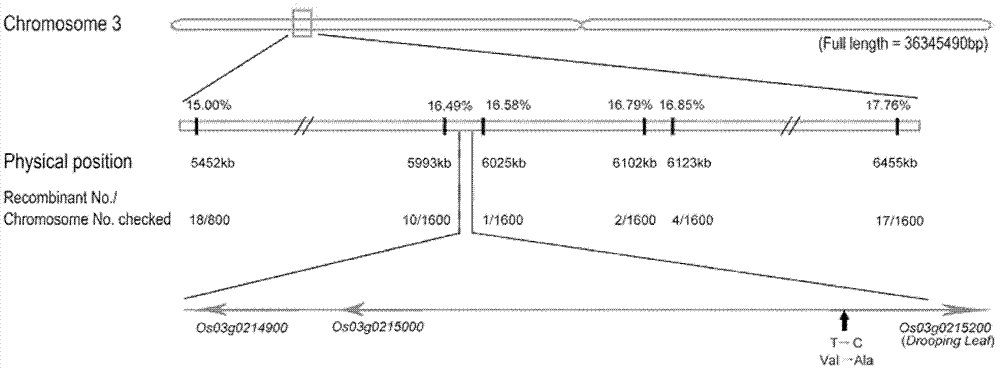

Paddy rice female sterility gene and application thereof in hybridized paddy rice seed production

InactiveCN102731635ALow costLight in massMicrobiological testing/measurementPlant peptidesHybrid seedAgricultural science

The invention discloses a paddy rice female sterility gene and an application thereof in hybridized paddy rice seed production. The 8th site nucleotide residue of the second exon of the paddy rice Os03g0215200 gene is mutated from T to C, such that a paddy rice mutant of female completely sterile phenotype with cernuous leaves is obtained, and is named sfs1. The female sterility is caused by that the exostome is blocked by outer integument abnormal proliferation of cells, and that fertilization can not be achieved. The paddy rice mutant is utilized as a male parent, and is hybridized with an existing restoring line. Rotational crossing and high-generation homozygous are carried out, such that a novel female completely sterile restoring line is obtained by screening. Mixed-sowing seed production is carried out based on the restoring line and a male sterile line female parent, such that seed production and seed reproduction yields can be improved, seed production cost can be reduced, purity of the hybridized seeds can be ensured, and mechanized production and light cultivation of the hybridized paddy rice seeds can be completely realized.

Owner:PEKING UNIV

Metal-based powder metallurgy brake lining material and preparation methods thereof

The invention discloses a metal-based powder metallurgy brake lining material and preparation methods thereof. The invention aims to solve the problems that the strength of a material is reduced along with the adding of ceramic particles when the powder metallurgy brake lining material is produced by the prior art and the like. The material comprises the following components in percentage by weight: 10 to 80 percent of Cu-Sn mechanical alloy powder, 1.25 to 15 percent of Ti-C mechanical activated powder, 2 to 65 percent of Fe powder, 0 to 10 percent of Ni powder, 0 to 12 percent of Cr powder,2 to 8 percent of Al2O3 powder, and 7.75 to 23 percent of graphite, wherein the Cu-Sn mechanical alloy powder is prepared from Sn powder and Cu powder which contains 6 to 10 percent of Sn powder by mechanical alloying beforehand; and the Ti-C mechanical activated powder is prepared from Ti powder and C powder according to the ratio of 2:1-8:1 through mechanical activation beforehand, and forms TiC during the sintering. The invention also provides two preparation methods which combine the mechanical activation and the mechanical alloying with the prior powder metallurgy or discharge plasma sintering method.

Owner:JILIN UNIV

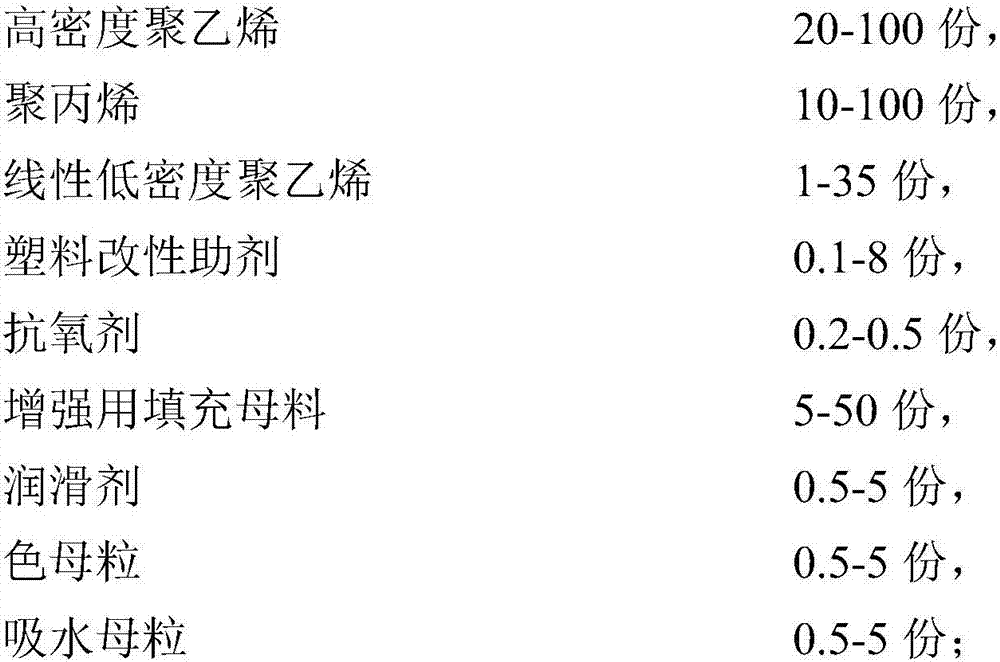

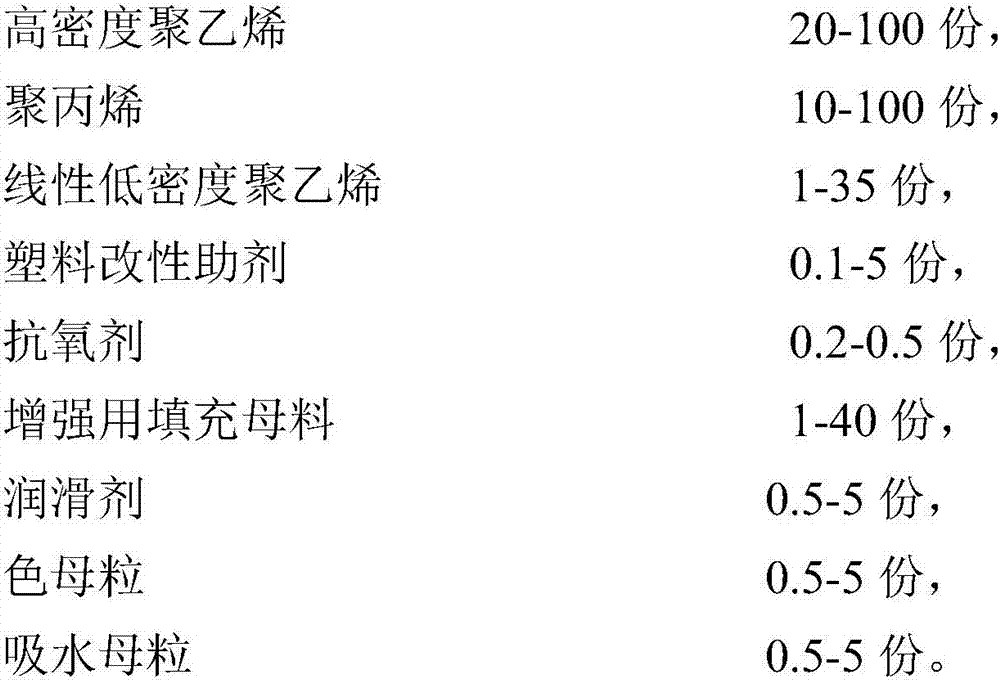

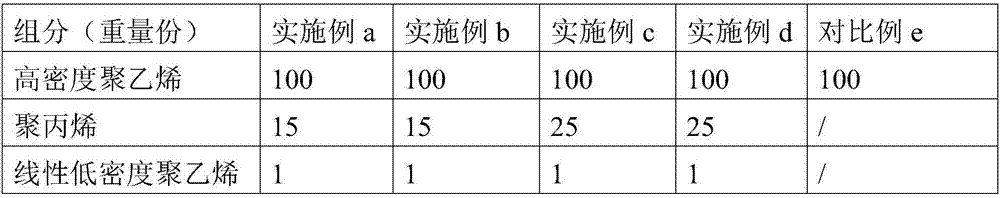

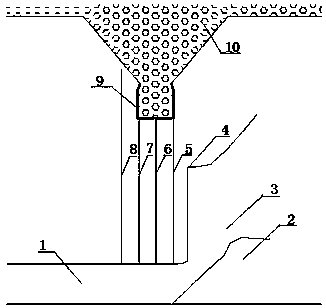

Enhanced composite polyethylene double wall twined pipe and production method thereof

InactiveCN107254087AAvoid disadvantagesImprove toughnessNon-macromolecular adhesive additivesMacromolecular adhesive additivesAdhesiveDouble wall

The invention relates to the technical field of a pipeline, and specifically relates to an enhanced composite polyethylene double wall (an alternate name of a hollow wall) twined pipe and a production method thereof. The enhanced composite polyethylene double wall twined pipe is formed by enhanced composite polyethylene hollow rectangular pipes through spiral winding and bound by the bonded adhesives. Through change of a raw material formula and the preparation method of the composite polyethylene double wall twined pipe, the disadvantages of the current polyethylene double wall twined pipe can be overcome, toughness and rigidity of the polyethylene double wall twined pipe can be obviously increased, the high temperature resistance and chemical stability of the product are increased, the shrinkage rate of the double wall twined pipe is reduced, the size stability of the increased; the degree of crystallization of the polypropylene having an enhancing effect is higher than that of polyethylene, a nucleating agent capable of increasing degree of crystallization and the crystallization speed is added as a modification auxiliary agent, during practical production, the cooling moulding speed of the product is obviously increased, the production efficiency is greatly increased, and the production cost is saved.

Owner:CHONGQING JINSHAN YANGSHENG PIPELINE CO LTD

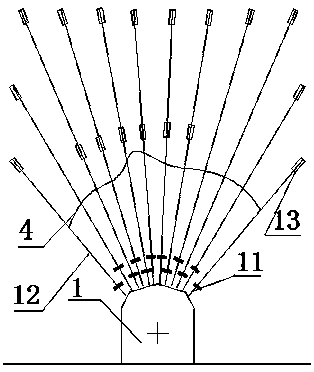

Blasting processing method for underground hanging arch

The invention discloses a blasting processing method for an underground hanging arch. After the hanging arch is generated, the position of the maximum distance away from the center of an access extraction roadway is determined, and the position, corresponding to the position, of a deep hole in the first row behind the hanging arch is a detonation point position; and the detonation point serves asa middle point, 3-4 middle-depth holes on each side are selected, a double-detonation-bomb charging mode with the same section is adopted, a hole bottom detonation bomb loading mode is adopted for theother remaining middle-deep holes in the same row, and the hanging arch is subjected to collapse treatment through the micro-differential explosion between the same row of holes. By the adoption of the method, normal blasting recovery of the middle-deep holes in the rear row is achieved, the middle-deep holes in the front row are not damaged, the equipment production cost is reduced, the influence of the hole repairing process of the rock drilling equipment and the influence of the hanging arch on the production arrangement is reduced, and the like, the normal recovery of a stope is guaranteed, and the safety of production and operation personnel is guaranteed.

Owner:HEBEI IRON & STEEL GRP MINING

Vanadium-titanium nodular cast iron smelting method

The invention discloses a vanadium-titanium nodular cast iron smelting method which comprises the steps of weighing furnace burden, smelting, spheroidizing and inoculating, wherein the smelting step comprises the sub-steps: adding oxide scale of which the addition amount is 0.5-1.5 percent of the weight of the furnace burden, and adding the oxide scale at the bottom of the furnace burden during smelting and charging; in the smelting step, after the furnace burden is molten down, adding silicon iron into molten iron for regulating the components, so as to achieve the deoxidation effect. The method has the beneficial effects that the low-price oxide scale is added into the bottom of the furnace burden during charging, and the element Ti is oxidized preferentially, so that the titanium content is reduced, the inverse spheroidizing effect of titanium is weakened, nodularizing in vanadium-titanium ductile iron is guaranteed, and a good dephosphorization effect is achieved when the oxide scale is added during smelting; the oxide scale is wide in source and low in price, the oxide scale is reasonably utilized, the production cost can be reduced, and the environment-friendly energy-saving effects are achieved. According to the method, the process is simple, the operation is convenient and the cost is low, and the comprehensive performance of the vanadium-titanium nodular cast iron is guaranteed.

Owner:XIHUA UNIV

Low-cost low-acyl transparent type gellan gum extraction process

The invention relates to a low-cost low-acyl transparent type gellan gum extraction process which specifically comprises the following steps: (1) performing enzyme treatment; (2) performing centrifugal decontamination; (3) dissolving; (4) performing deacylation; (5) filtering; (6) chelating; (7) performing solid-liquid separation; (8) performing drying and crushing; and (9) treating wastes. The low-cost low-acyl transparent type gellan gum extraction process is gentle in process conditions, the pH value is relatively small in fluctuation in product treatment, no polyvalent metal ion is used in the process, and meanwhile due to a proper amount of chelating agent, a good dissolving property of a product is ensured; according to the process, no lower alcohol is adopted for washing gellan fiber, so that the production cost is greatly lowered, the treatment conditions are gentle, and the product quality is improved.

Owner:XINJIANG FUFENG BIOTECH

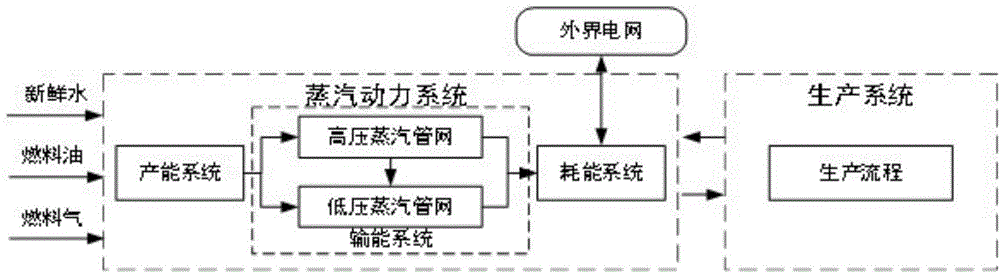

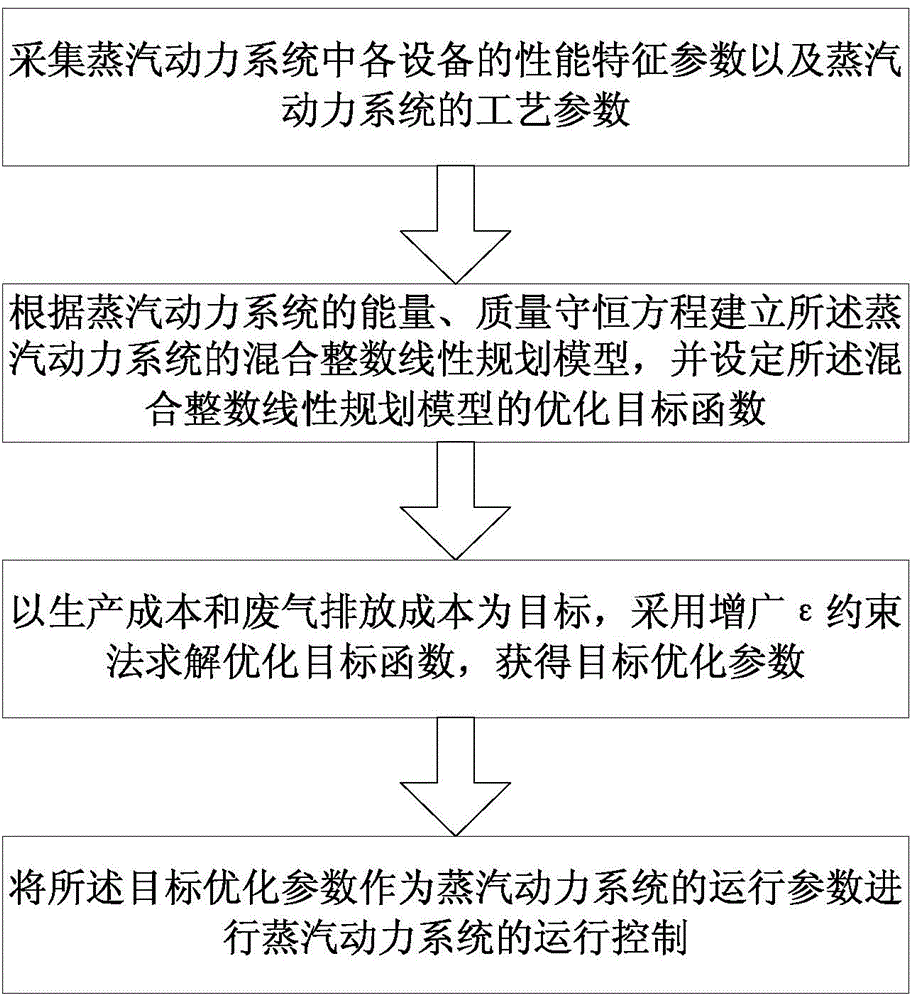

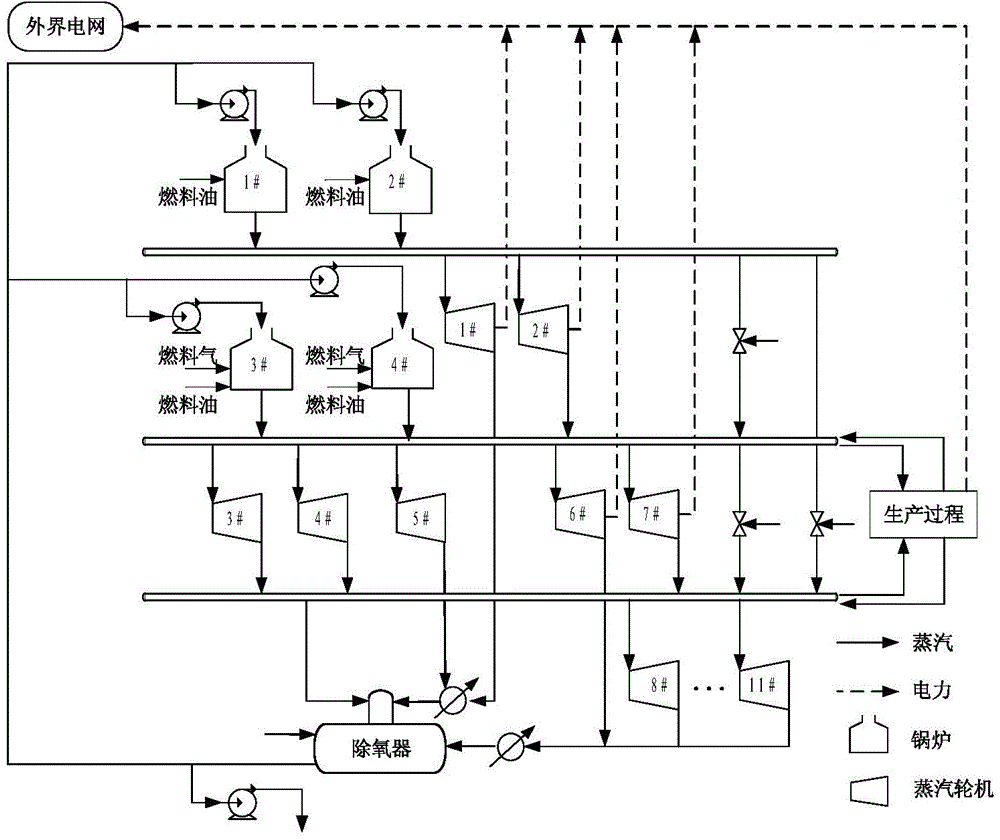

Running operation method of steam power system

InactiveCN104657789AGuaranteed production costAdapt to the trend of energy saving and environmental protection requirementsForecastingSteam powerEngineering

The invention discloses a running operation method of a steam power system. The method comprises the following steps: acquiring performance characteristic parameters of each device in the steam power system and technological parameters of the steam power system; according to an energy and mass conservation equation of the steam power system, establishing a mixed integral linear programming model of the steam power system, and setting an optimized target function for the mixed integral linear programming model; regarding a production cost and an exhaust emission cost as targets, adopting an epsilon augmented constraint method to solve the optimized target function to obtain target optimized parameters; using the target optimized parameters as operating parameters of the steam power system to carry out operation control on the steam power system. According to the running operation method disclosed by the invention, the production cost and the exhaust emission cost are regarded as targets, the optimized target function is solved by the epsilon augmented constraint method, and an optimizing strategies meeting the two targets of the production cost and the emission cost can be obtained, so that the production cost of an enterprise can be ensured, meanwhile the method is suitable for the energy-saving environment-protecting requirement tendency, and can be used for scientifically adjusting the production and operation strategy.

Owner:ZHEJIANG UNIV

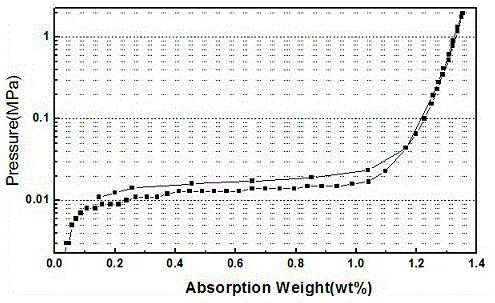

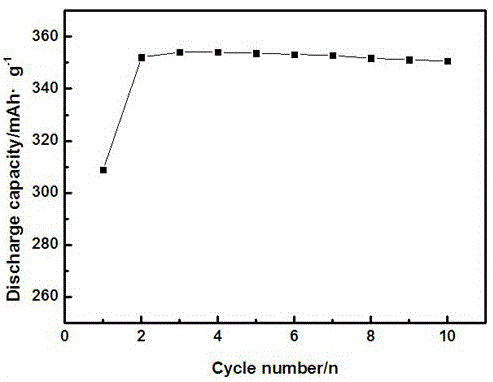

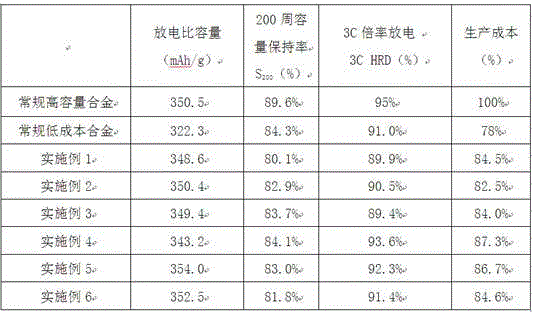

Hydrogen storage alloy for nickel-metal hydride battery and manufacturing method of hydrogen storage alloy

ActiveCN105463256AImprove performanceImprove discharge capacityCell electrodesImpurityNickel–metal hydride battery

The invention relates to hydrogen storage alloy for a nickel-metal hydride battery and a manufacturing method of the hydrogen storage alloy. The chemical formula of the hydrogen storage alloy is La1-x-yCexReyNi4.83-a-b-cCoaMnbAlcMd, x, y, a, b and c in the formula are atomic ratios, and the ranges of x, y, a, b and c satisfy the conditions that x=(0.175, 0.20, 0.30 and 0.35), y=(0.015, 0.02, 0.03 and 0.05), a=(0.15, 0.18, 0.20 and 0.25), b=(0.36, 0.42, 0.54 and 0.85), c=(0.15, 0.18 and 0.21), d=(0.25, 0.45 and 0.56), 0.19<=x+y<=0.4, and 0.9<=a+b+c+d<=1.4, wherein Re is one of Y, Zr and Gd, and M is at least one of Fe, Cr and Si. In the manufacturing process, gas and impurities in the alloy are removed in a film forming manner, raw materials are fully alloyed, annealing treatment is used as assistance, the composition segregation of the alloy can be remarkably reduced, and lattice imperfection and lattice stress are eliminated. The hydrogen storage alloy manufactured through the method has the beneficial effects of being high in discharge capacity and anti-pulverization capacity, low in production cost and the like, and the requirements of the Ni-MH battery for production cost and the performance can be met.

Owner:INNER MONGOLIA XIAOKE HYDROGEN STORAGE ALLOY CO LTD

Method for reducing residual stress of high-slenderness-ratio arc-shaped fillet opened aluminum alloy forge pieces

ActiveCN105537496AReduce residual stressIncrease production capacityHandling devicesSteel platesSheet steel

The invention discloses a method capable of avoiding buckling of forge pieces in the length direction and reducing residual stress of high-slenderness-ratio arc-shaped fillet opened aluminum alloy forge pieces. A cold compressing die is adopted for implementing the method and the method comprises the steps that A, the forge pieces are subjected to cold compression within four hours after solid solution heat treatment; B, the forge pieces are put into the cold compressing die; C, a steel plate is longitudinally arranged in the position, corresponding to a fillet, of the non-fillet face, and then cold compression deformation is conducted; D, a new steel plate is placed on each of the two sides of the part subjected to cold compression, the overlap amount of the steel plate and the indentation of former cold compression is 30%-50%, and then cold compression deformation is conducted again; E, the step D is repeated until cold compression deformation of all zones of the non-fillet face is completed; F, finally, the middle of the non-fillet face is subjected to cold compression again; and G, overall cold compression is conducted again after segmented cold compression is completed and the overall cold compression is controlled by tonnage. By adopting the method, the uniformity of the appearance of the forge pieces can be ensured and the evenness of the cold compression deformation amount of the forge pieces is improved.

Owner:中国第二重型机械集团德阳万航模锻有限责任公司

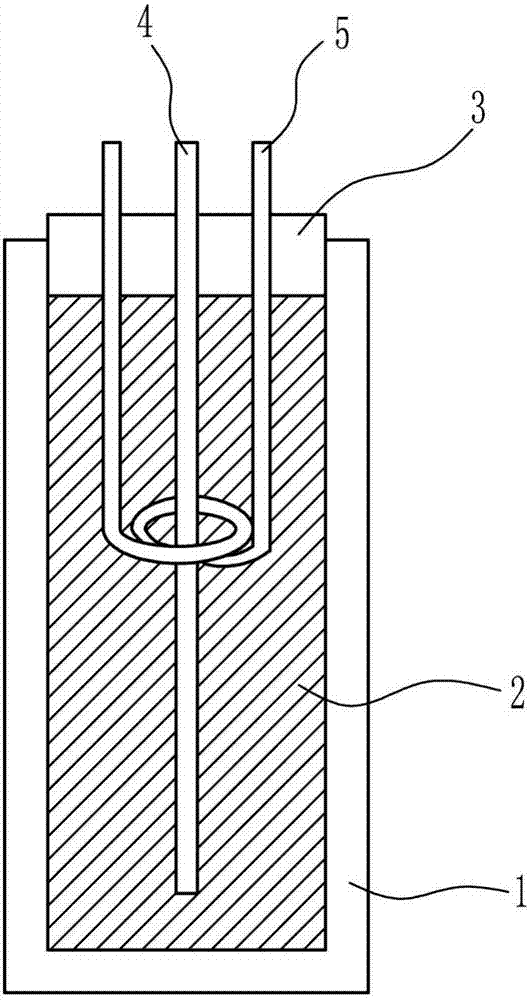

Composite cathode for conducting electrode reaction under rare earth metal fluorine-containing melt system

InactiveCN106978613AMeet performance requirementsGuaranteed temperatureElectrodesElectrical connectionRare earth

The invention discloses a composite cathode for electrode reaction in a rare earth metal fluorine-containing melting system. The composite cathode includes a U-shaped tungsten sleeve, a filler, an electrical connector, a thermocouple and a cooling pipe. The U-shaped tungsten sleeve is filled with filler The open end of the U-shaped tungsten sleeve is connected with an electrical connector, and the thermocouple extends through the electrical connector to the bottom of the filler. The thermocouple is wrapped with a cooling tube, and the cooling liquid is passed through the cooling tube. The material of the U-shaped tungsten sleeve is Tungsten, the filler material is copper alloy, and the hot electrode material of thermocouple is platinum-rhodium alloy. The composite cathode is light in use, high in strength, and has good thermal conductivity, and is not easy to be oxidized and gasified due to high temperature, which reduces the cost of use, and is also equipped with a temperature measurement function.

Owner:カン州晨光希土新材料有限公司

Capacity fixed and loop closed cyclic gas analyzing method and device for surlfur determiner for circular titration

InactiveCN1584580AUniform concentrationImprove adaptabilityChemical analysis using combustionMaterial analysis by electric/magnetic meansLoop closingClosed loop

An analysing device and method is featured as setting gas chamber, filter, measuring electrolytic pool and gas pump in sequence on piping connected to sample reactor to form a closed loop, setting another connecting pipe being controlled by control unit to open gas valve and pump for making gas circulate in each pipe and gas chamber; drawing off gas of fixed valume from closed loop and carrying on ratio conversion for finalizing sulphur content detection in sample.

Owner:SANDE IND CHANGSHA

Vehicle trapping extricating system and vehicle

ActiveCN105235666AAvoid getting deeperReduce manufacturing costFluid braking transmissionOutput deviceVehicle brake

The invention provides a vehicle trapping extricating system and a vehicle. The vehicle trapping extricating system comprises a pressure outputting device, valves, and first control devices, wherein the pressure outputting device is connected with a vehicle brake pedal and is used for outputting pressure according to a brake of each braking-direction wheel of the brake pedal to enable the brake to work; the pressure outputting device is connected with the brake of each wheel of the vehicle by a braking pipeline; the valves are arranged on the braking pipelines; the first control devices are used for controlling the valves to be in a switching on or off state, and when at least one wheel is trapped, the first control devices control the valve on the braking pipeline corresponding to the trapped wheel to be switched on, and when the pedal is started, the trapped wheel obtains power; and the other first control devices are used for controlling the valves on the braking pipelines corresponding to the other wheels, except for the trapped wheel, to be switched off, the corresponding braking pipelines are cut off by the valves, and when the pedal is started, the other wheels, except for the trapped wheel, have no power. The vehicle trapping extricating system provided by the invention is good in trapping extricating effect and low in production cost.

Owner:BAIC GRP ORV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com