Three-dimensional foaming printing method

A three-dimensional, screen printing technology, applied in printing, printing devices, printing processes, etc., can solve the problems of high labor costs, heavy manual work, and high production costs, and achieve simple plate making, convenient operation, and low cost. cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and specific embodiment the present invention will be further described:

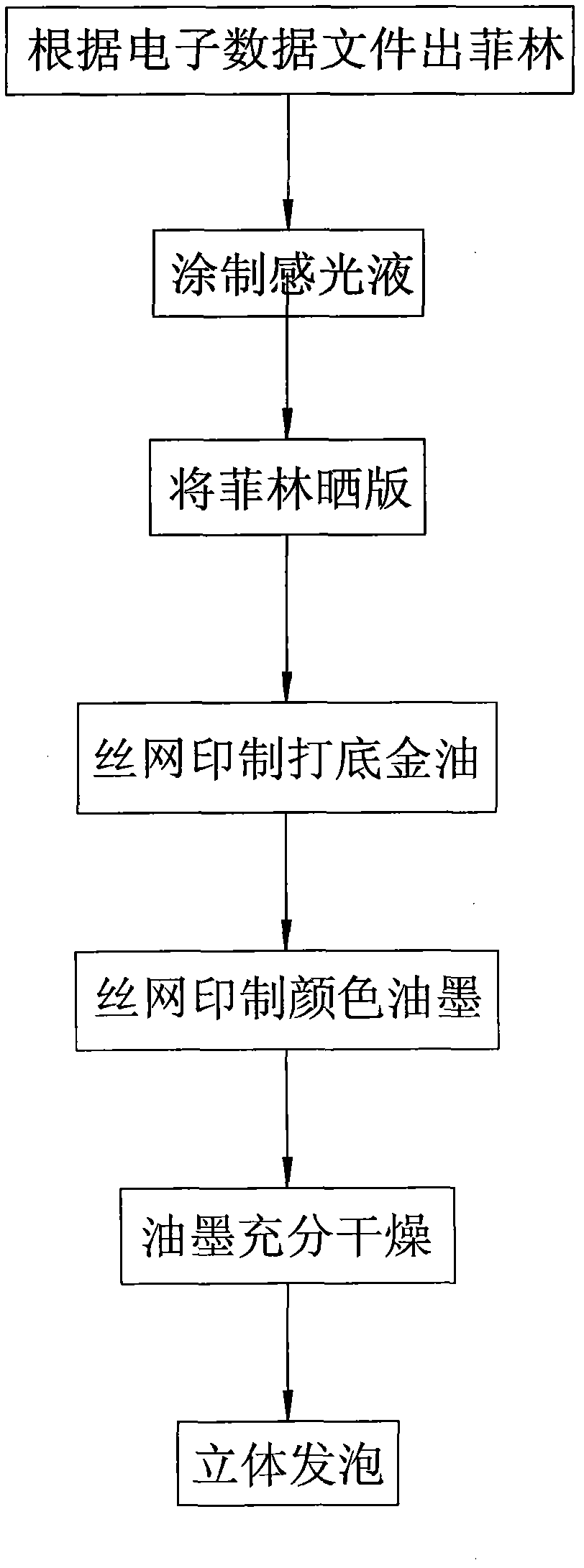

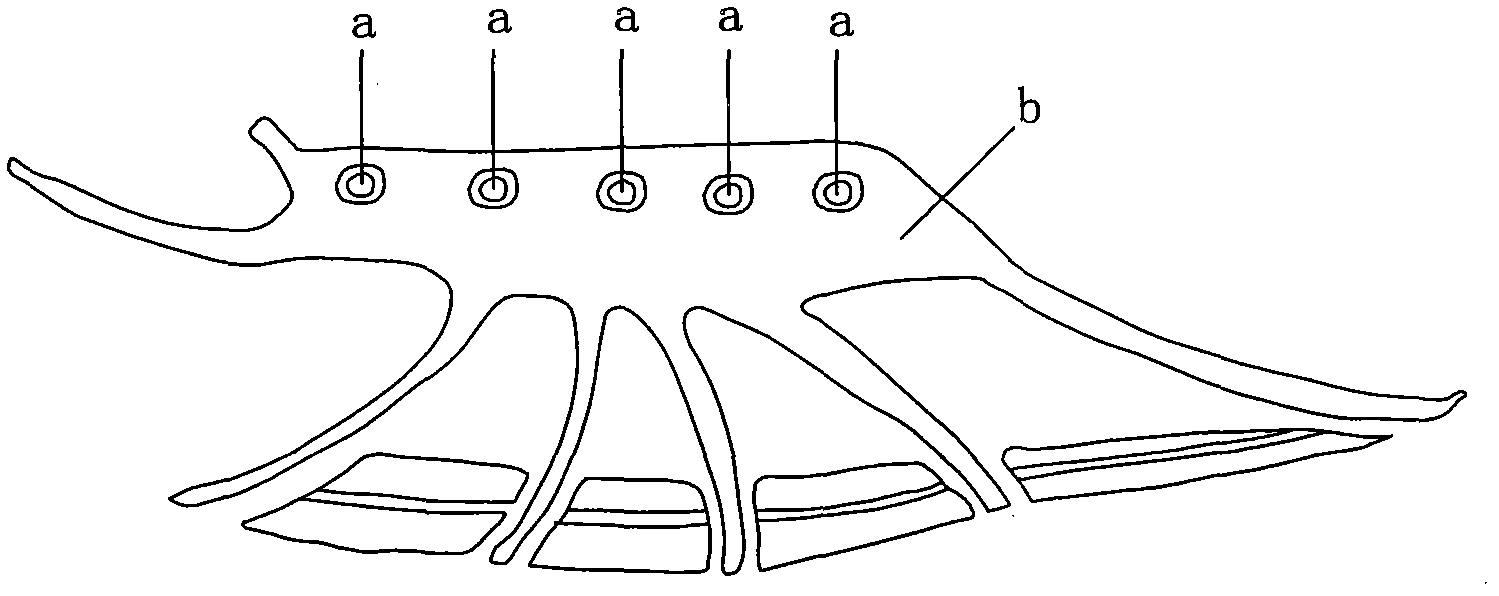

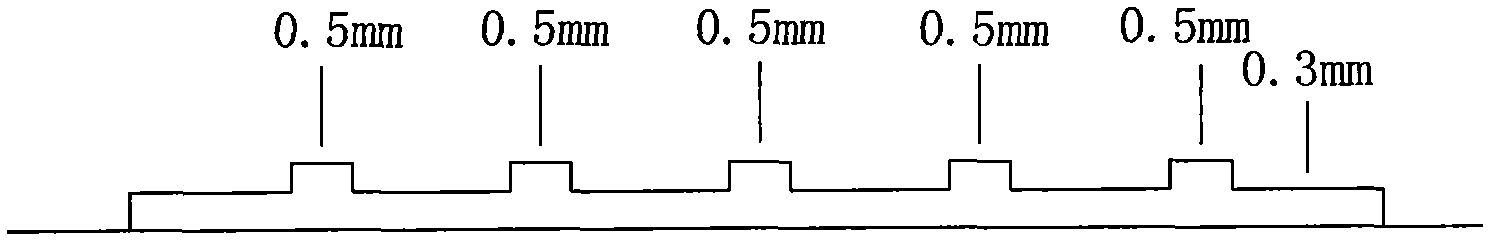

[0021] refer to Figure 1 to Figure 4 Shown, the three-dimensional foam printing method of the present invention, it comprises the following steps:

[0022] A. Produce the film according to the electronic data file; copy the electronic data file (image) after design modification to the film output device, and then output the electronic data file (image) on the film.

[0023] B. Apply photosensitive liquid to the film; the number of times to apply photosensitive liquid in this step depends on the degree of unevenness of the image, and can be applied once or multiple times.

[0024] C. Choose the appropriate mesh, and print the film; expose the image content on the film to the zinc oxide plate through the exposure machine, and then install the zinc oxide plate on the printing machine.

[0025] D. Screen printing primer gold oil.

[0026] E. Set the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com