Color pavement formed by spraying on porous polymer concrete facing and construction method therefor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] An example below:

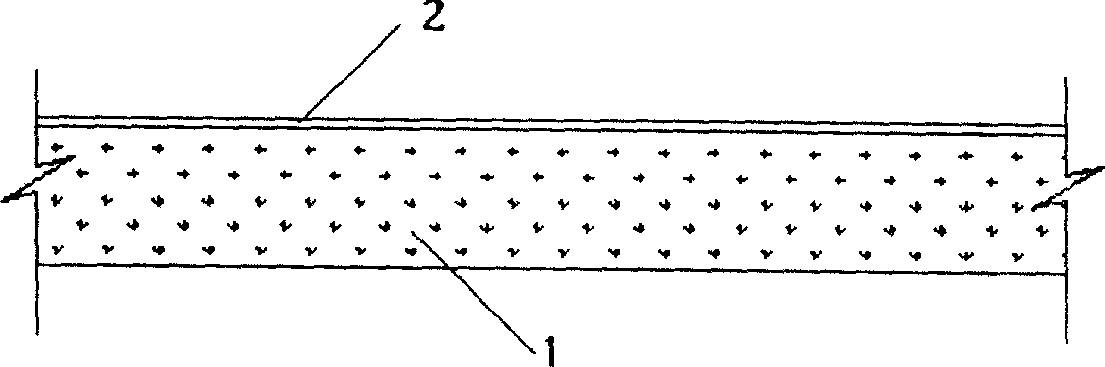

[0048] Its structure is: a porous polymer concrete surface layer 1 and a colored surface layer 2, and the porous polymer concrete surface layer 1 has a colored surface layer 2 on it.

[0049] Firstly, the ratio by weight is (per cubic meter of concrete)—polymer styrene-acrylic emulsion (water content 0.1, additive defoamer 0.01): gravel (granite, particle size range of 5-10mm) single gradation : Cement (P.O 42.5 Ordinary Portland Cement) = 160kg: 1700kg: 300kg, uniformly mixed with a concrete mixer to form a polymer concrete rich in pores. The asphalt paver with vibration function is used to pave the porous polymer concrete surface layer 1, and the self-vibration function of the paver is used to ensure that the compaction degree of the porous polymer concrete surface layer is not less than the design value, and no road roller is used for rolling. After the film is cured for 3 days, remove the film, and clean the sundries and floating ash on the surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com