Patents

Literature

380results about How to "Tight bond" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium-ion battery separator subjected to composite coating treatment and preparation method thereof

ActiveCN106252565ATight bondIncrease volumetric energy densityFireproof paintsCell component detailsLithium-ion batteryAramid

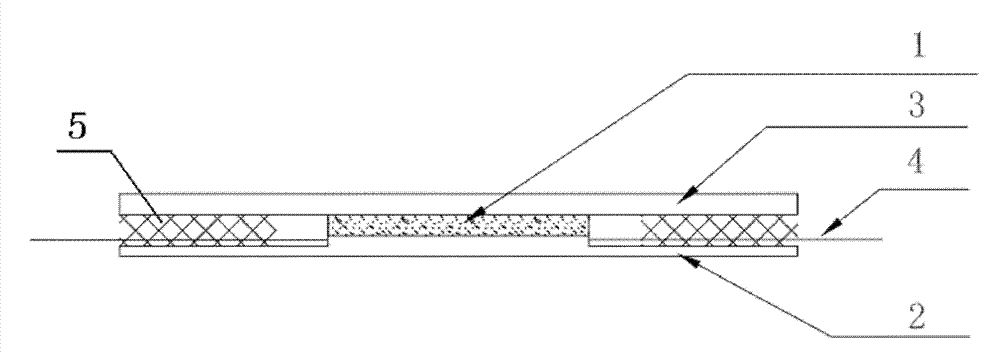

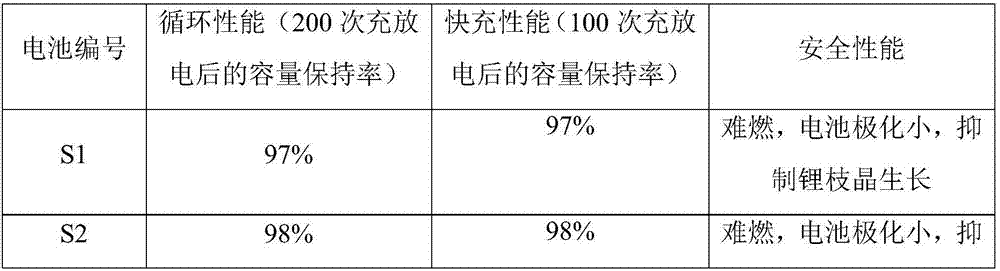

The invention discloses a lithium-ion battery separator subjected to composite coating treatment and a preparation method thereof. The lithium-ion battery separator comprises a basement membrane, a polymer coating coated at one side of the basement membrane, and an inorganic particle coating coated at the other side of the basement membrane; the polymer coating is composed of an aramid coating coated on the basement membrane and a polyvinylidene fluoride coating coated on the aramid coating, and the thickness of the polymer coating is 0.3 to 5 [mu] m; and the inorganic particle coating is composed of inorganic particles of different particle sizes and a binding agent, and the thickness of the inorganic particle coating is s 0.5 to 5 [mu] m. The lithium-ion battery separator provided by the invention has the characteristics of being excellent in mechanical property and heat resistant property, having good wettability and solution preserving property to electrolyte, and excellent in cycle performance and high in safety performance.

Owner:深圳市鼎泰祥新能源科技有限公司

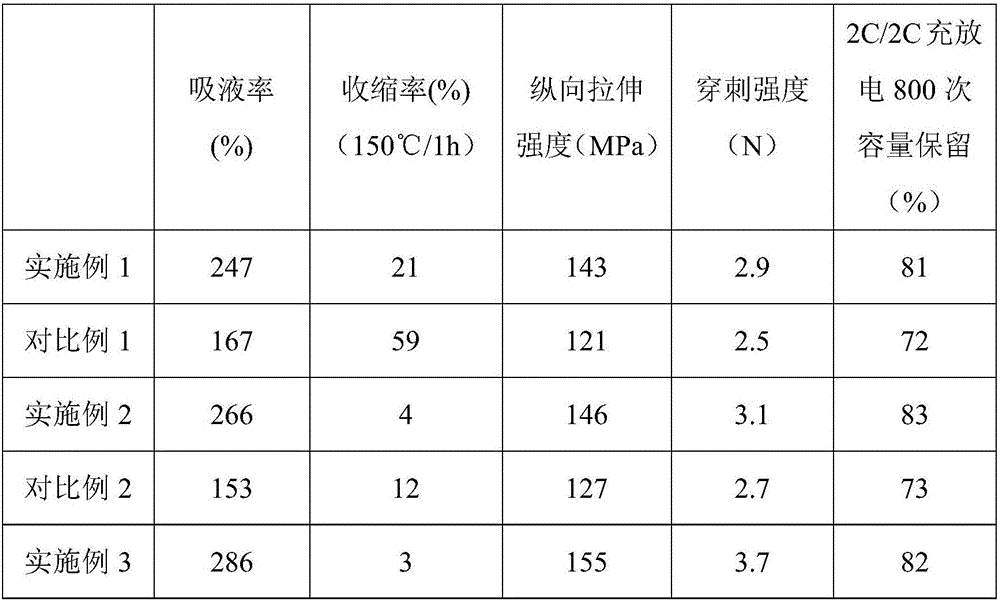

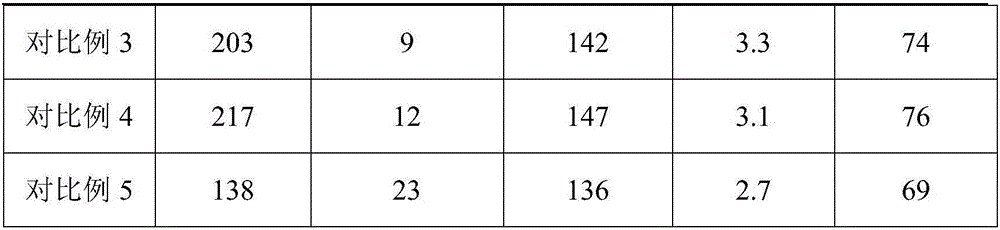

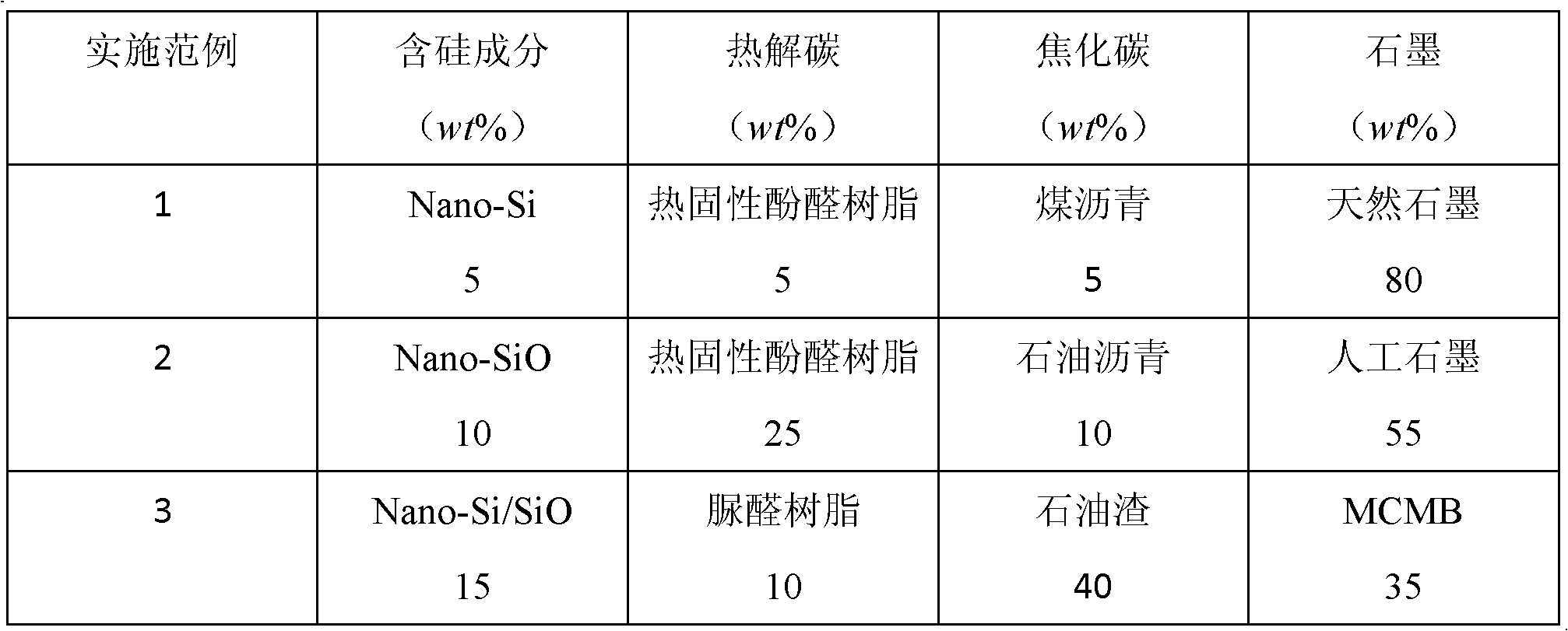

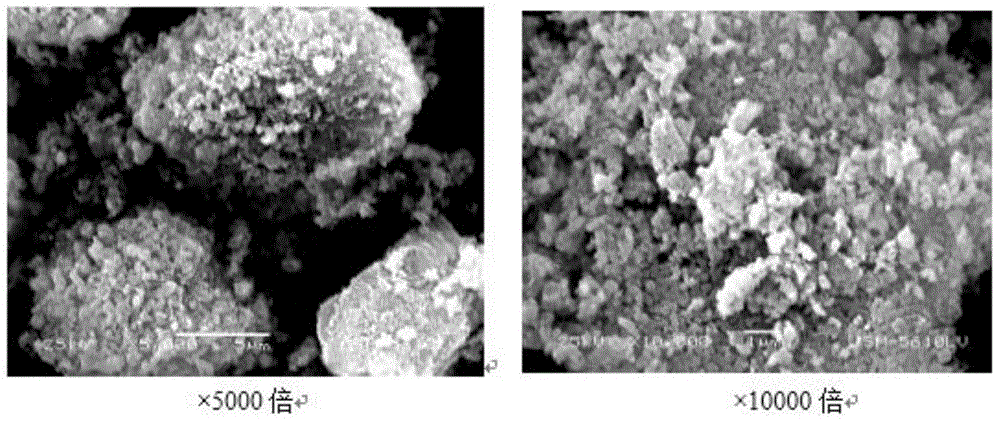

Preparation method for composite cathode material of lithium ion battery

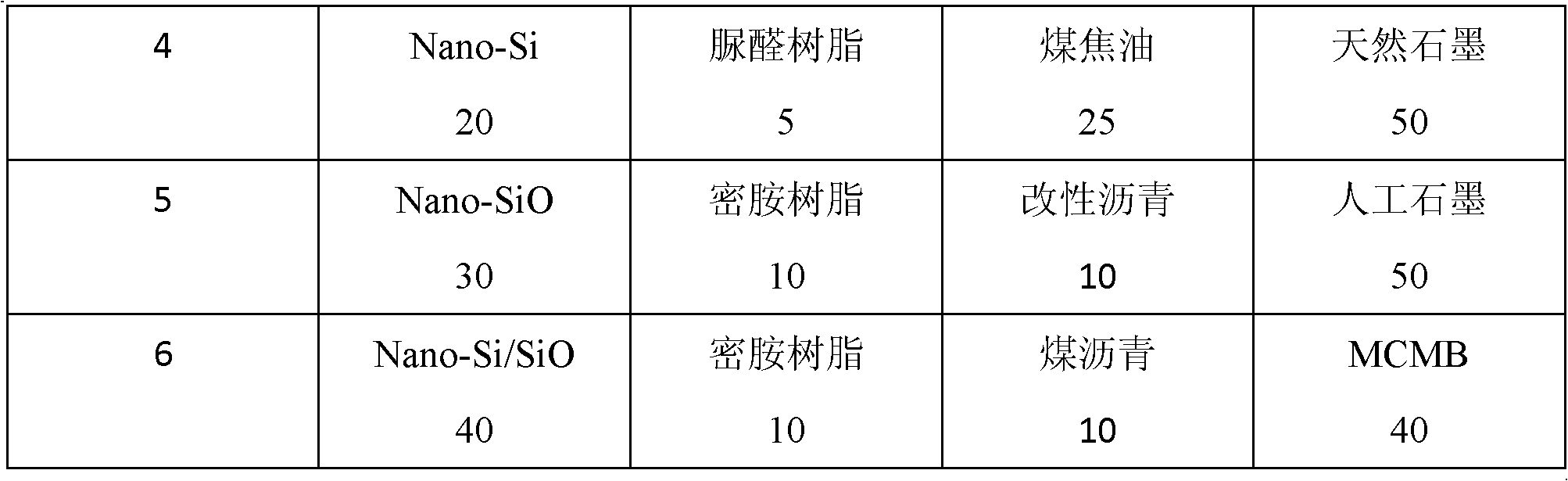

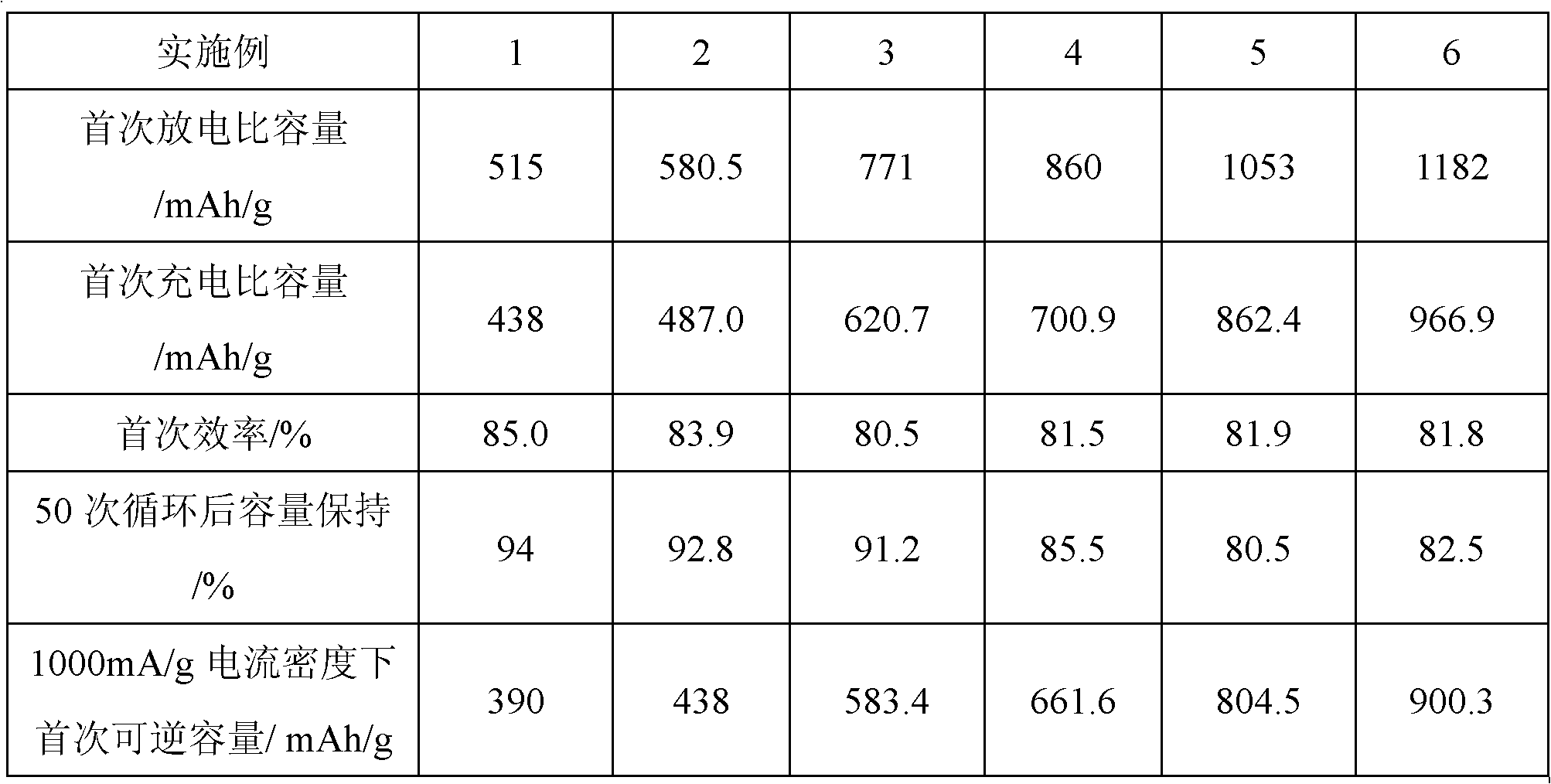

The invention discloses a preparation method for a composite cathode material of a lithium ion battery by means of spray drying pyrolysis treatment. The preparation method includes the steps: dissolving a first type of binder organic carbon source into solvent of a proper quantity, adding a silicon source, a second type of binder and a dispersing agent, dispersing uniformly, adding graphite, dispersing for a certain time, subjecting uniformly dispersed suspension to spray drying, and using the first type of binder organic carbon source to bond the silicon source, the graphite and the second type of binder particles into spherical or spherical-like forms to obtain a composite precursor; and transferring the precursor into a shielding atmosphere for sintering, heating the second type of binder to a certain temperature to be melted into a liquid crystal state, bonding the particle silicon source and the graphite into cores, subjecting the organic carbon source to pyrolysis at the high temperature to form a coating, and furnace cooling to obtain the carbon-silicon composite cathode material of the lithium ion battery. The preparation method is simple, easy in implementation and high in practicality. The carbon-silicon composite prepared by the method has the advantages of high reversible capacity, designable capacity, high circulating performance and high-current discharging performance, high tap density and the like.

Owner:CENT SOUTH UNIV

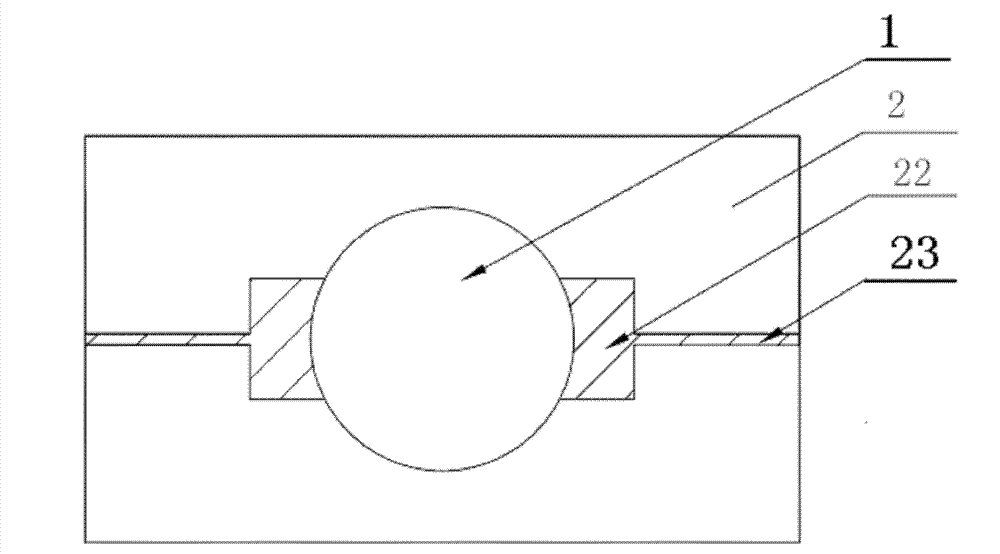

Visualized microscopic model of real core and manufacturing method of visualized microscopic model of real core

ActiveCN102768812AMaintain physical and chemical propertiesAvoid breakingEducational modelsPorous mediumMicrosphere

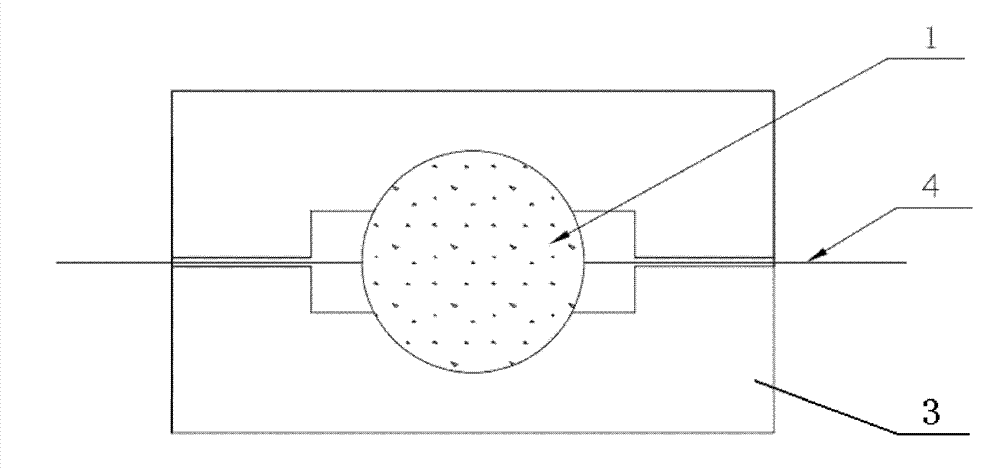

The invention relates to a visualized microscopic model of a real core and a manufacturing method of the visualized microscopic model of the real core. The model comprises a real core sheet, an organic glass cover plate, an organic glass slide and a needle and is formed via the pressure at high temperatures; the real core sheet is milled to be visualized and is then clamped between two pieces of the organic glass; the needle is firstly fixed well, and the organic glass cover plate is then arranged; at a high temperature and at a high pressure, the organic glass is softened to be adhered more tightly with the core sheet; and the model is formed by cooling. According to the visualized microscopic model and the manufacturing method provided by the invention, the physico-chemical properties of the real core are kept, and the distribution and flowing condition of the multi-phase fluid in the porous medium pores are observed, so that the visualized microscopic model and the manufacturing method play an important role in studying the percolation mechanism and enhancing the yield of the polymer microspheres.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Aluminium nitride ceramic copper-clad substrate and preparation method thereof

ActiveCN102208371APrecise thickness controlReduce thermal resistanceSemiconductor/solid-state device detailsSolid-state devicesCopper foilCeramic

The invention provides an aluminium nitride ceramic copper-clad substrate which comprises an aluminium nitride ceramic chip, and a copper foil coated on at least one surface of the aluminium nitride ceramic chip, wherein a metal modification layer is formed between the ceramic chip and the copper foil, and the metal modification layer comprises Cu2O, CuAlO2 and a set of compound selected from the following two set of compounds: (1) TixNy and TiO2 wherein x / y is 0.25 to 1; (2) MnO2. In addition, the invention also provides a preparation method of aluminium nitride ceramic copper-clad substrate. In the invention, with a magnetron sputtering method, a metal mixture coating is formed on the surface of the dense sintering of the aluminium nitride ceramic chip, as the dense sintering of the metal mixture coating through high temperature sintering, the formed metal modification layer can improve the surface of the aluminium nitride ceramics chip and forms a good bonding with the copper foil.

Owner:亨新电子工业(常熟)有限公司

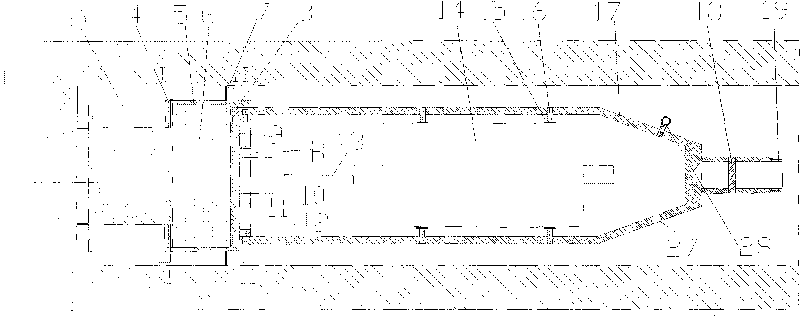

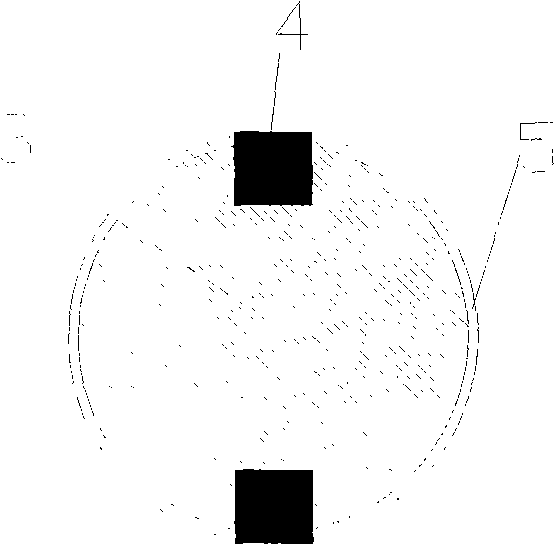

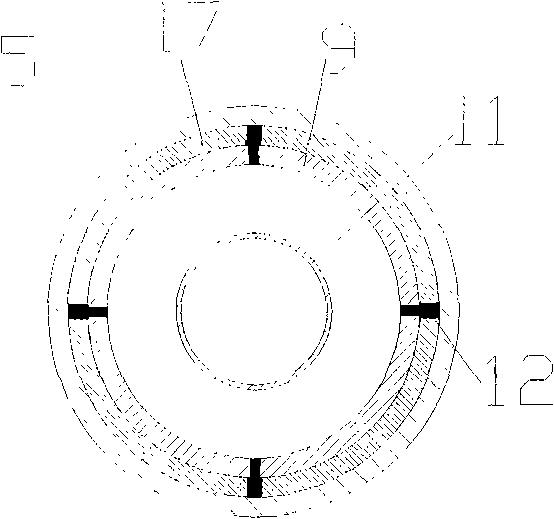

Protecting, fixing and retracting integration device of an acoustic emission deep hole monitoring sensor

InactiveCN101726544AImprove protectionAvoid damageMaterial analysis using acoustic emission techniquesRock engineeringCoupling

The invention discloses a protecting, fixing and retracting integration device of an acoustic emission deep hole monitoring sensor. The device consists of a sensor protecting sleeve, a fixing device of the sensor protecting sleeve, a guider, a mounting rod, a directional ring and a rotary disc. The front end of the sensor protecting sleeve is connected with the fixing device of the sensor protecting sleeve by counterclockwise screws. The tail part of the sensor protecting sleeve is connected with the guider by clockwise screws, and is connected with the mounting rod through a pin and a unidirectional clamping groove. The directional ring is fixed at the front end of the mounting rod. The rotary disc is mounted on the tail part of the mounting rod. During retracting, the rotary disc facilitates the mounting rod to screw the sensor protecting sleeve off the fixing device of the sensor protecting sleeve. The device can better overcome the defects of insufficient protection, simple mounting angle and large absence or deflection of the monitored data due to untight coupling of the sensor and the rock existing in the traditional sensor, solves the problem of difficult retracting of the sensor in deep hole mounting, can be widely applied to rock engineering of tunnels, underground chambers, mine underground stopes, roadways and the like, and has great economical benefit.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

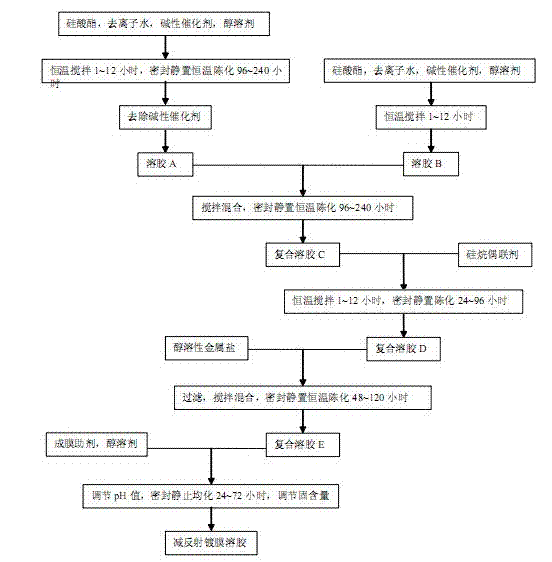

Composite sol for anti-reflection coating and anti-reflection coated photovoltaic glass

InactiveCN102850894AHigh mechanical strengthImprove smoothnessCoatingsColloidal chemistry detailsWeather resistanceSolar cell

The invention relates to the field of manufacture of packaging glass for solar cells, and especially relates to a multi-step catalyzed composite sol for anti-reflection coating, and anti-reflection coated photovoltaic glass manufactured by the composite sol. The composite sol for anti-reflection coating is prepared from the following raw materials by the following method which comprises steps of: preparing sol A, preparing sol B, preparing composite sol C, preparing composite sol D, preparing composite sol E, and preparing the composite sol for anti-reflection coating. An anti-reflection film coated by the sol only needs coating once; therefore the production cost is low, and the process is high-efficient and easily-controlled; the composite sol of the invention is suitable for large-area coating production of photovoltaic glass; the coated product can pass related examinations, such as film hardness, adhesion, and weatherability.

Owner:杭州美格玻璃有限公司

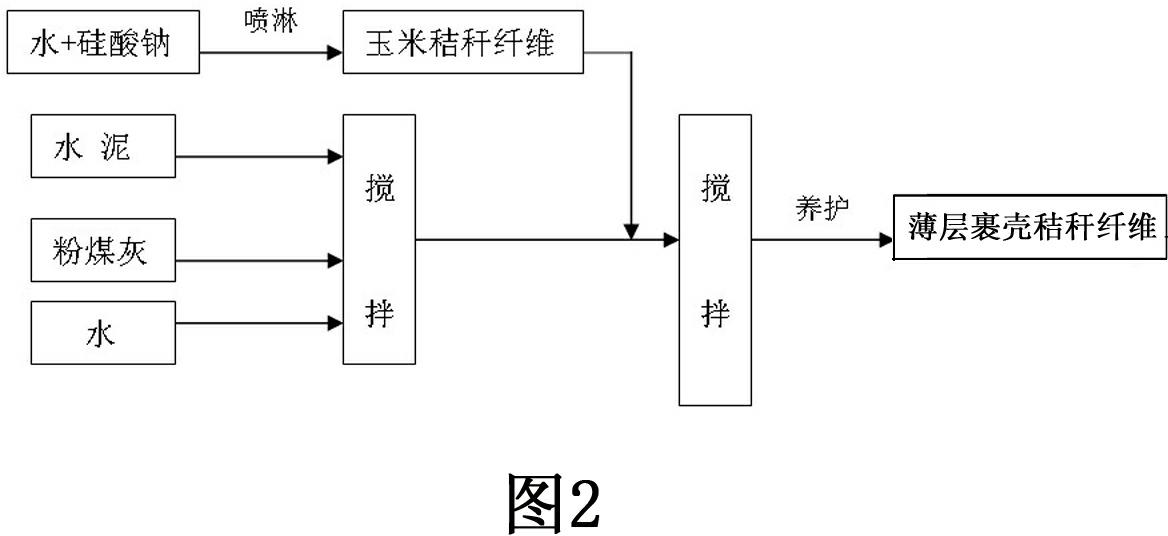

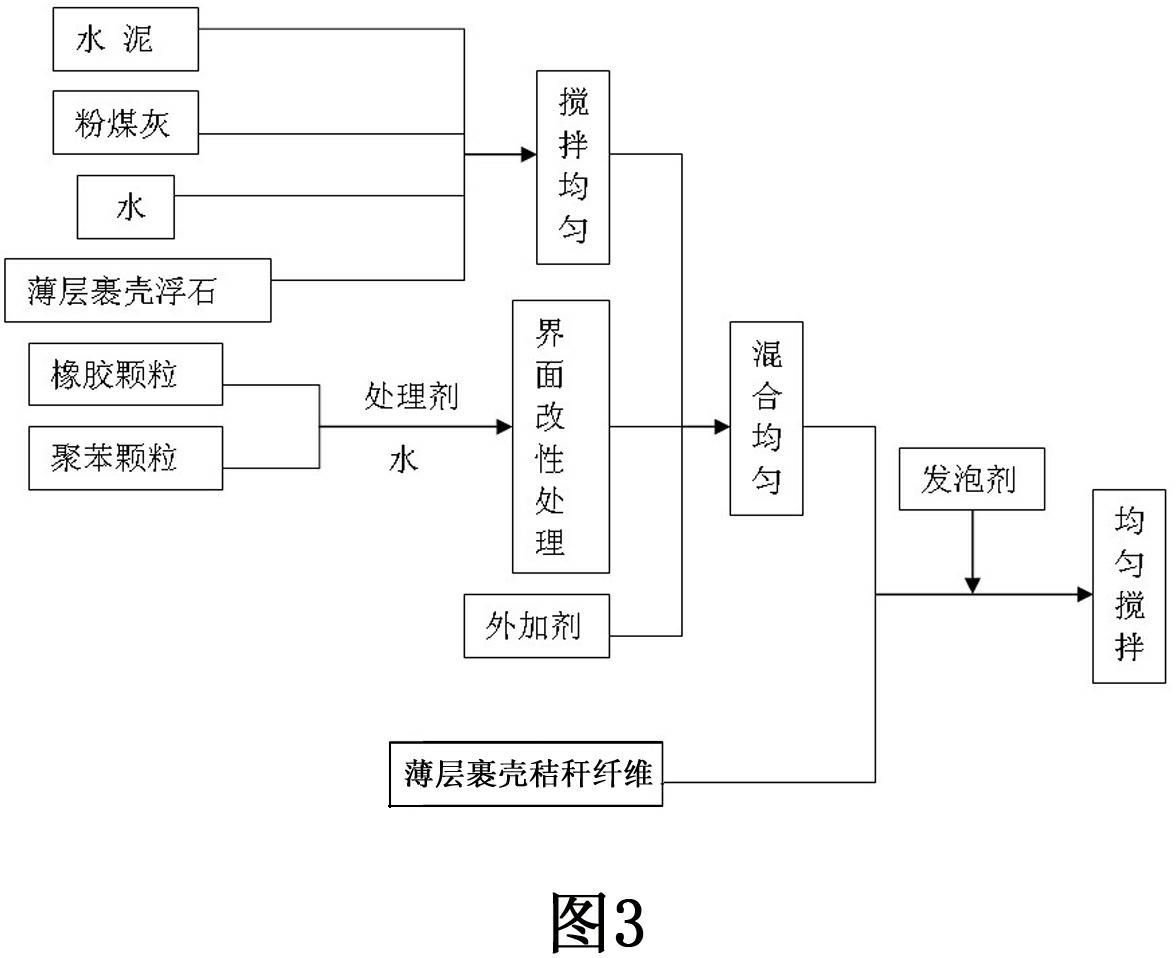

Multi-phase combined lightweight aggregate concrete and preparation method thereof

ActiveCN102206096ALow densityImprove toughnessSolid waste managementCeramicwareFiberThermal insulation

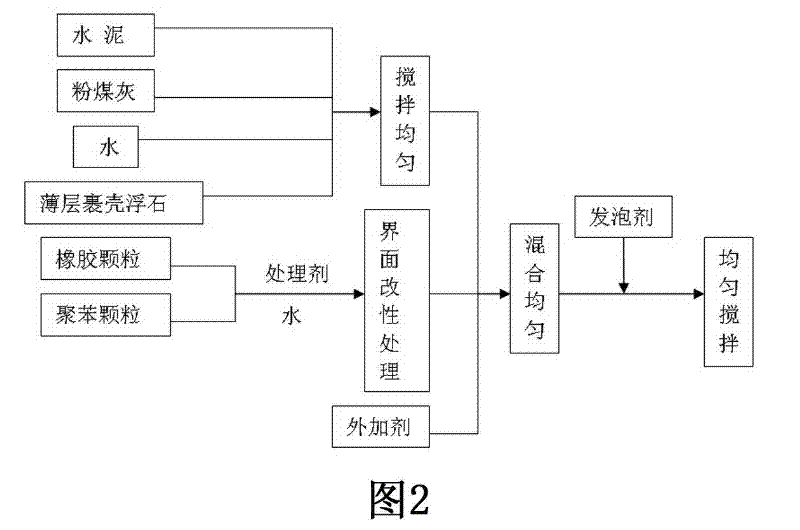

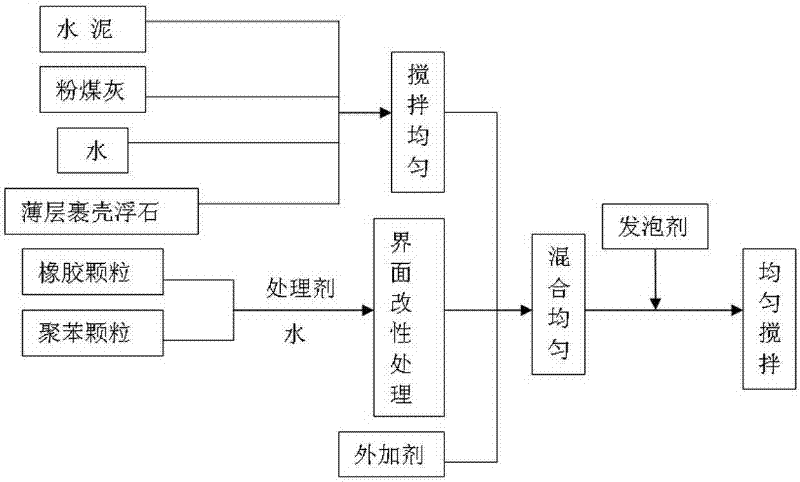

The invention discloses multi-phase combined lightweight aggregate concrete and a preparation method thereof. The multi-phase combined lightweight aggregate concrete is prepared from the following raw materials in part by weight: 1 part of cement, 0.40 to 0.50 part of fly ash, 1.836 to 2.219 parts of pumice sand, 0.028 to 0.043 part of corn straw fibers, 0.006 to 0.008 part of polyphenyl particles, 0.23 to 0.33 parts of rubber particles, 0.010 to 0.015 part of additive, 0.005 to 0.007 part of foaming agent, and 0.50 to 0.55 parts of water. The preparation method comprises the following steps:1, preparing thin-coating pumice sand and thin-coating straw fibers; 2, performing interference treatment of polyphenyl particles and rubber particles; 3, uniformly stirring the cement, fly ash, water, additive and thin-coating pumice sand; and 4, adding the polyphenyl particles, rubber particles and thin-coating straw fibers in turn, and continuing to stir. When the method is used, the mechanical performance of the lightweight aggregate concrete can be improved effectively, the thermal-insulation and heat-preservation performance is enhanced, and production cost is lowered.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

Inorganic/organic composite thin film solid-state electrolyte for lithium metal battery and preparation method of inorganic/organic composite thin film solid-state electrolyte

ActiveCN107394261AImprove ionic conductivityImprove flexibilityLi-accumulatorsLithium electrodeInorganic electrolyte

The invention belongs to the technical field of a lithium metal battery, and particularly relates to an inorganic / organic composite thin film solid-state electrolyte for the lithium metal battery. The inorganic / organic composite thin film solid-state electrolyte comprises a ceramic nanowire network framework, an inorganic electrolyte and a polymer electrolyte, wherein the inorganic electrolyte is combined with the ceramic nanowire network framework by a magnetron sputtering method, and the polymer electrolyte is combined with the inorganic electrolyte and the ceramic nanowire network framework in an in-situ way. Compared with the prior art, the ceramic nanowire network framework with a unique structure is used, and the multi-layer network-structure inorganic / organic composite thin film solid-state electrolyte is prepared on the basis; and moreover, by optimizing and improving the interface compatibility and stability of the inorganic / organic composite thin film solid-state electrolyte and a metal lithium electrode, rapid ion transmission is achieved, the growth of lithium dendrites is suppressed, the penetrating of the lithium dendrites is prevented, and the cycle stability and the safety of the lithium metal battery are improved.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV +1

Foaming-free fast-curing high-strength leak-stopping waterproof polyurethane grouting material

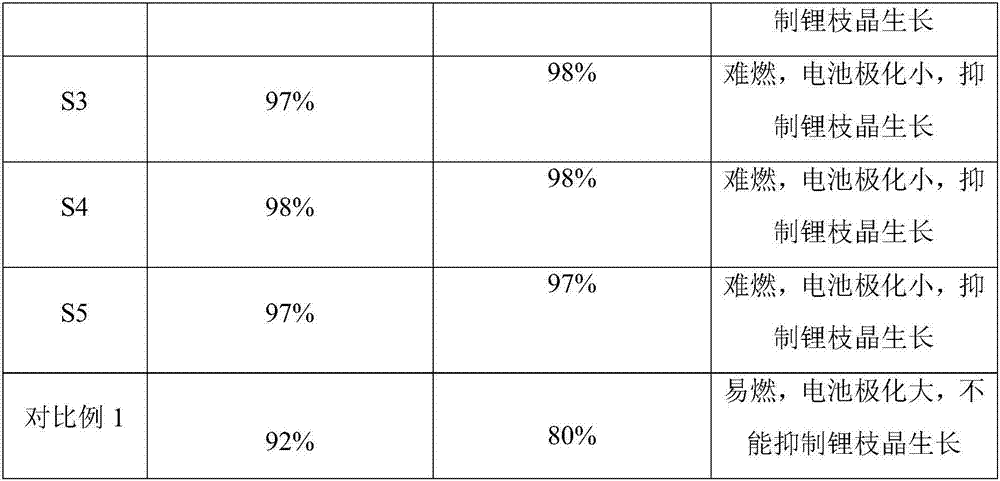

The invention provides a foaming-free fast-curing high-strength leak-stopping waterproof polyurethane grouting material. The material is composed of a component A and a component B, wherein the component A comprises isocyanate monomer, isocyanate prepolymer and highly-hydrophobic environment-friendly plasticizer, the component B comprises high-activity polyether polyol, chain-extending cross-linking agent, highly-hydrophobic environment-friendly plasticizer and antioxidant, and a volume ratio of the component A to the component B is 1: 1. The leak-stopping waterproof polyurethane grouting material has low viscosity, is convenient to grout, has the characteristics of no foaming and fast curing and the advantages of good leak-stopping effect, high mechanical strength and wet bonding strength and excellent aging resistance, and is applicable to rapid leak stopping, water prevention and reinforcement of distress in concrete of an underground construction.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +1

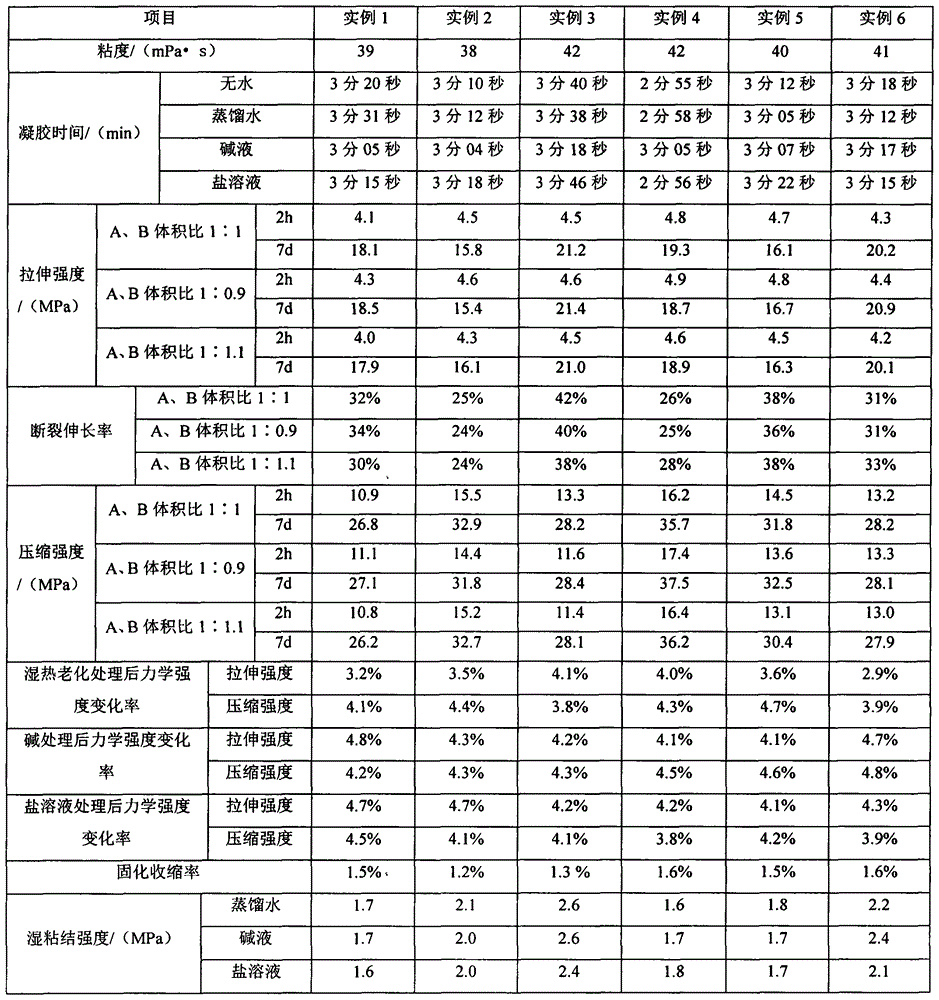

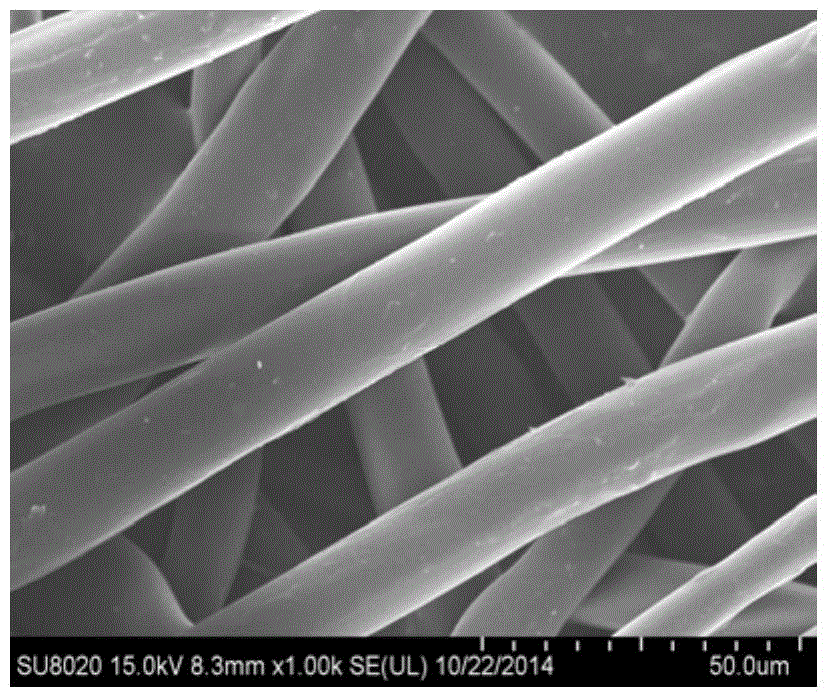

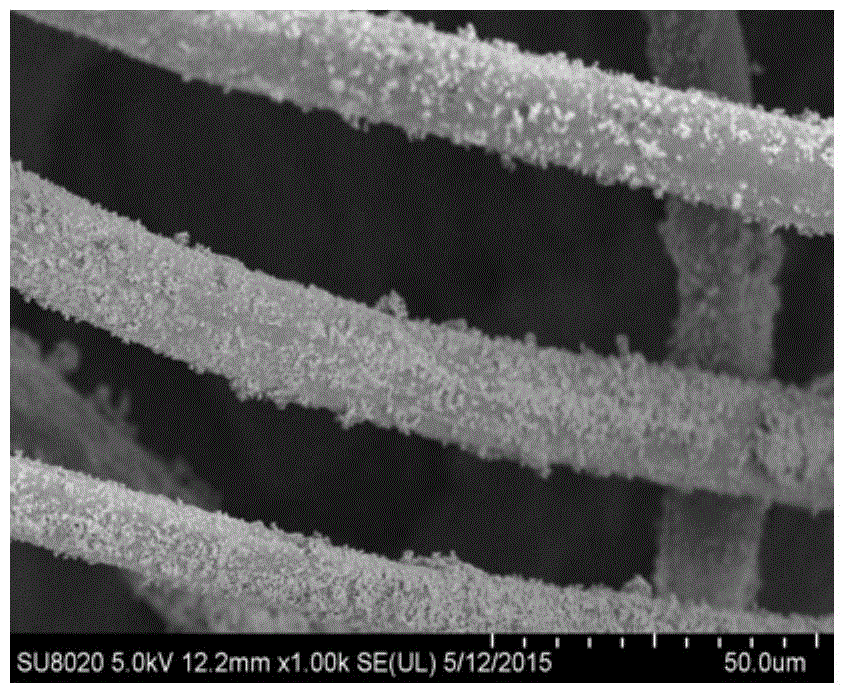

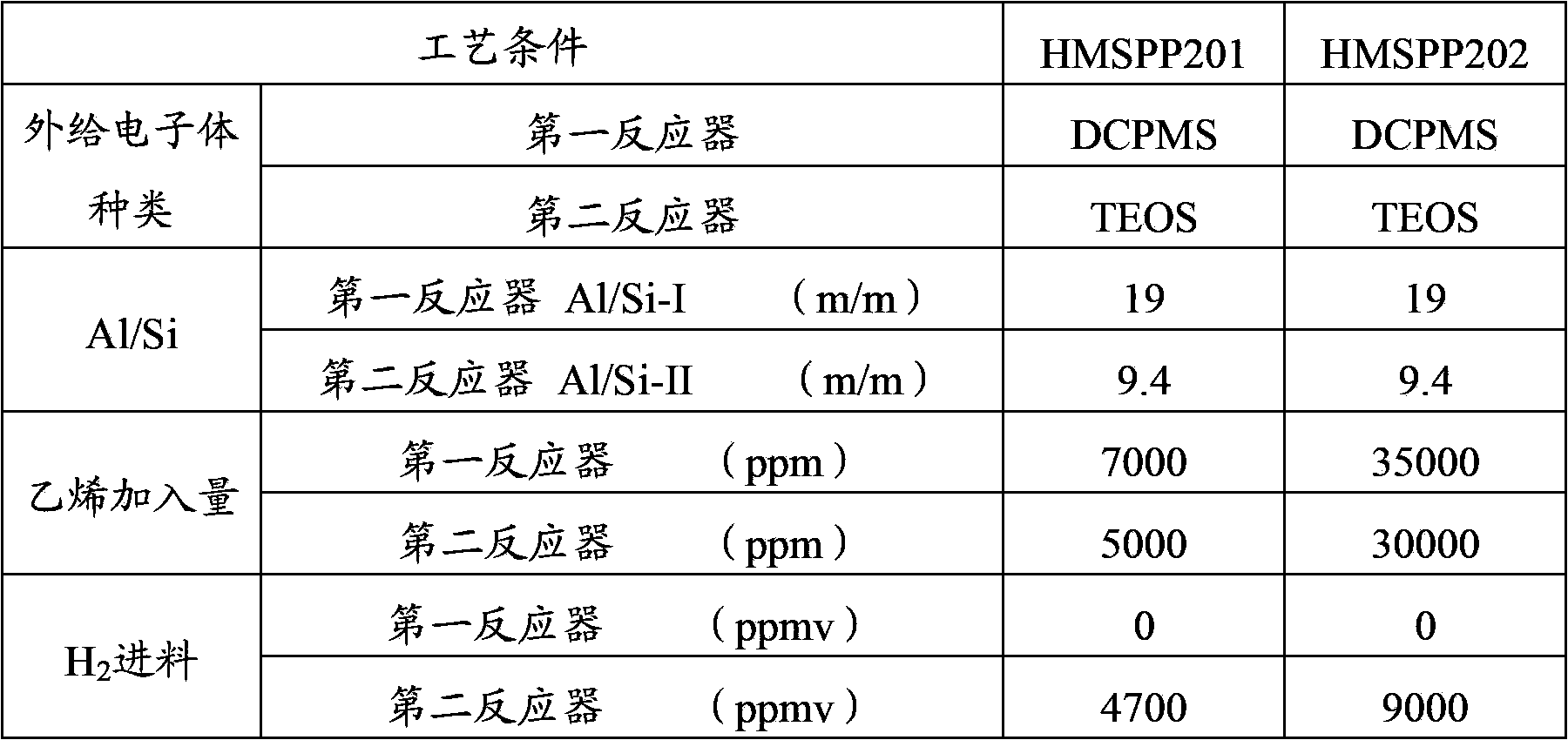

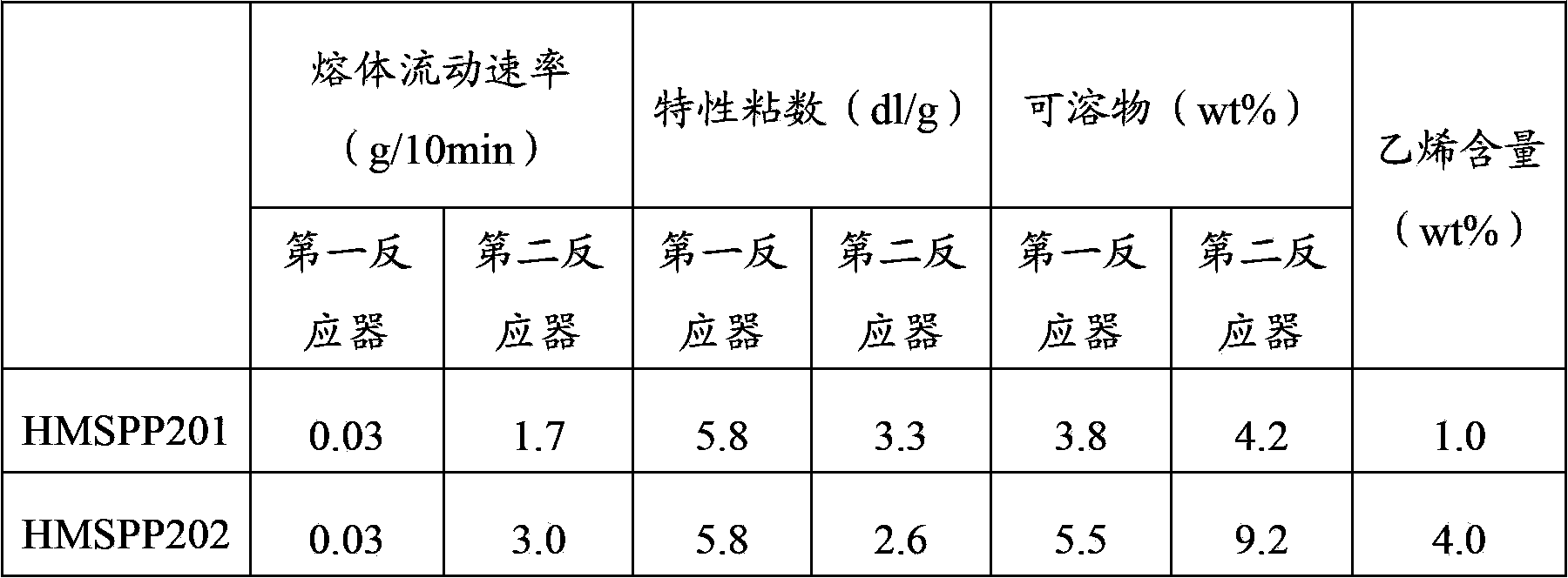

Method for preparing manganese-base dedusting and denitration integration function filter material

ActiveCN104941319AImprove denitrification activityTight bondDispersed particle filtrationFiltration separationPolyurethane adhesiveOperability

The invention discloses a method for preparing a manganese-base dedusting and denitration integration function filter material. The method is characterized by comprising first soaking a dedusting filter material in an organic silicone modified polyurethane adhesive solution to obtain a sticky filter material; adopting a potassium permanganate solution and a manganese nitrate solution to perform the liquid phase oxidation-reduction reaction, and preparing obtained nanoscale manganese oxide powder into a manganese oxide suspension; finally performing ultrasonic auxiliary soaking of the sticky filter material in the manganese oxide suspension, and performing drying and curing to obtain a target product. A preparation process is simple, the device requirements are low, the operability is high, the close integration of denitration active ingredients and the filter material can be effectively achieved, and the novel thinking and method are provided for achieving a denitration function of the filter material.

Owner:HEFEI UNIV OF TECH

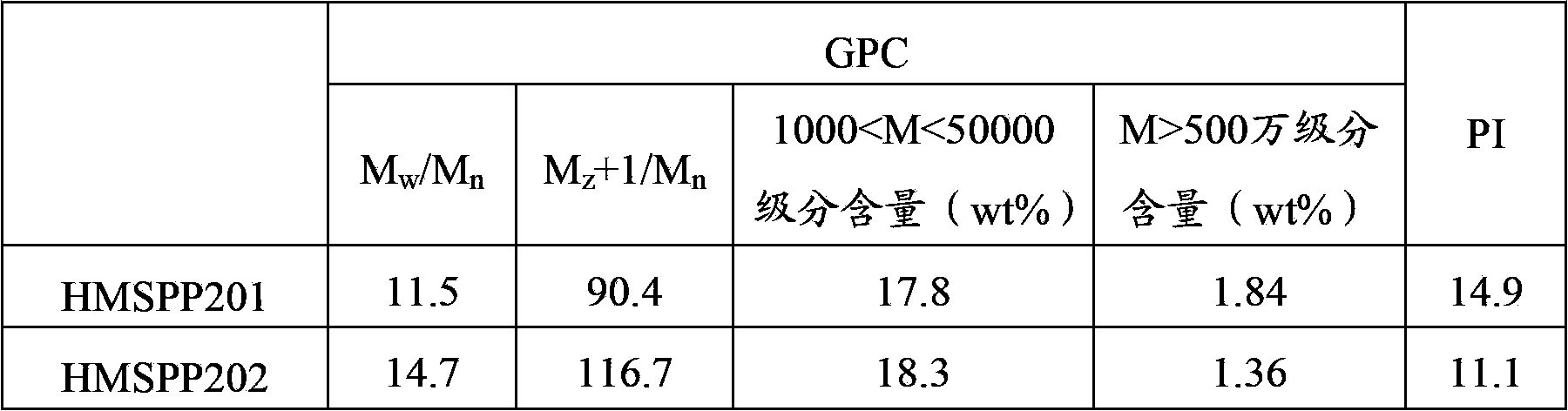

Polypropylene foaming bead formed body and preparation method thereof

The invention provides a polypropylene foaming bead formed body and a preparation method thereof. The preparation method comprises the following steps: mixing polypropylene foaming beads having different foaming rates and prepared by using wide-molecular-weight-distribution high-melt-strength polypropylene as a raw material in proportion, and carrying out thermal molding of the above obtained mixed foaming beads to obtain the foamed body with good surface flatness and tight adhesion. The formed body can be widely applied to the heat insulation tableware field, the automobile interior decorative part field, the finishing material interlayer field, the product damping packaging field and the like. Additionally, the molded body can be recycled, causes no secondary pollution, and accords with circular economy requirements.

Owner:CHINA PETROLEUM & CHEM CORP +1

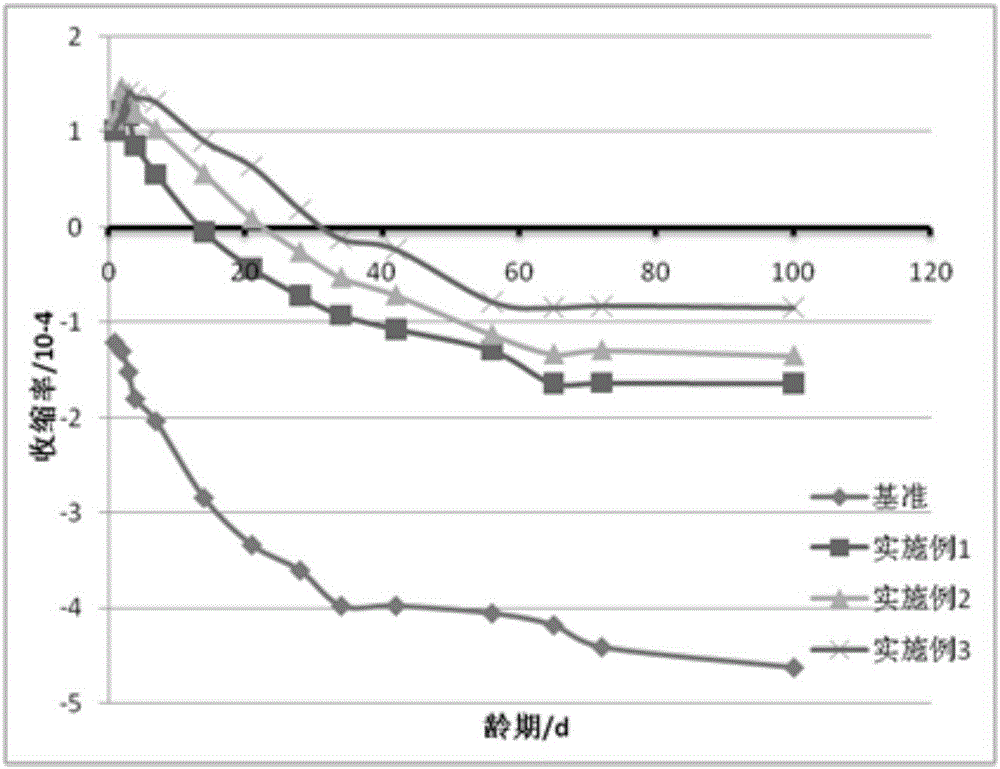

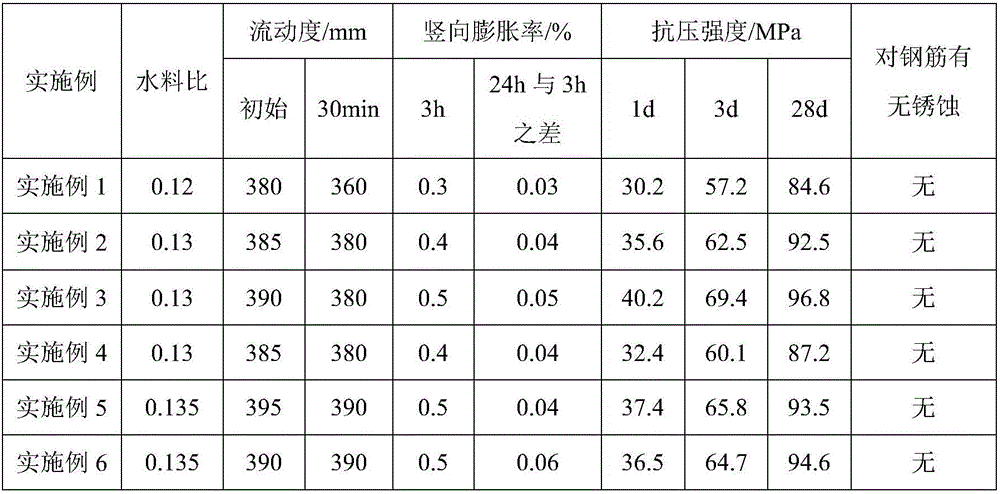

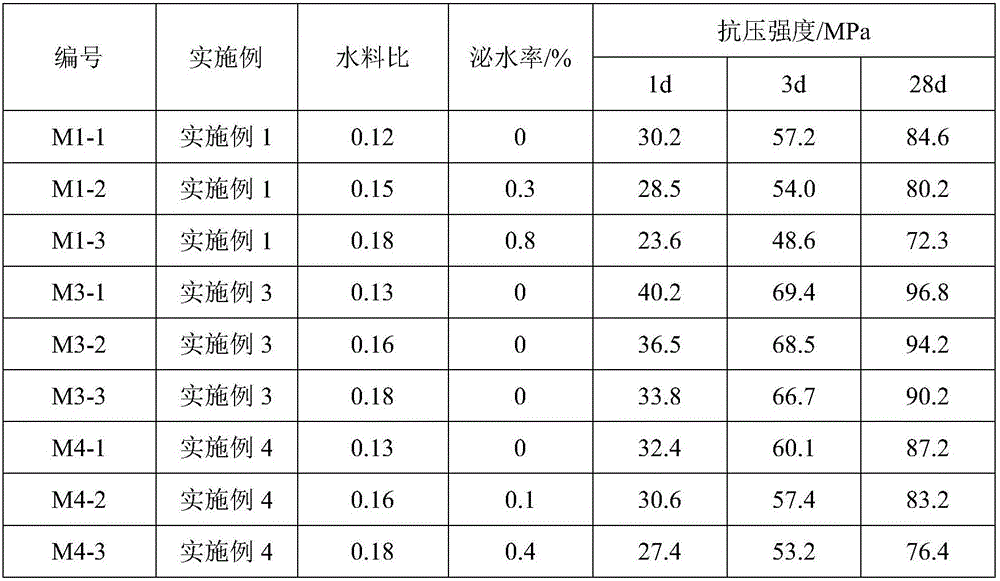

High-flow-state and high-strength non-shrinkage grouting material and preparation method thereof

ActiveCN106747128AImprove liquidityHigh mechanical strengthSolid waste managementMoisture distributionSuperplasticizer

The invention belongs to the field of buildings, and particularly relates to a high-flow-state and high-strength non-shrinkage grouting material and a preparation method thereof. The grouting material is prepared from the following components in percentage by mass: 30-45% of cement, 5-20% of a mineral admixture, 3-10% of dolomite composite powder, 2-8% of a composite expansion agent, 40-55% of aggregates, 0.2-1.0% of a polycarboxylate superplasticizer and 0.2-1.5% of a synergistic additive. Through a powder system and a close packing technology of the aggregates, the fluidity and the strength are improved; through introduction of the synergistic additive, moisture distribution is adjusted through thickening of a composite anti-segregation agent and water absorption and water release effects, so that the problems of high-flow-state grouting material segregation and bleeding and sensitive water consumption are solved; and adjustment of the expansion properties at different stages is carried out through introducing a plastic expansion agent and the composite expansion agent, so that the problems of shrinkage and sedimentation of the grouting material are solved.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD

Antibacterial scratch-resistant thermoplastic elastomer composition and preparation method thereof

InactiveCN104045960AImprove antibacterial propertiesExcellent surface scratch resistancePolyolefinThermoplastic elastomer

The invention relates to an antibacterial scratch-resistant thermoplastic elastomer composition which is prepared from the following raw materials by weight percent: 15-25% of styrene thermoplastic elastomer, 25-40% of plasticizer, 6-10% of polypropylene, 0.5-2% of polyolefin thermoplastic elastomer, 30-40% of inorganic mineral, 0.6-0.9% of compatilizer, 0.06-0.2% of antibacterial agent, and 0.01-0.2% of additive. The invention also provides a preparation method for the antibacterial scratch-resistant thermoplastic elastomer composition. The thermoplastic elastomer composition has excellent antibacterial performance and surface scratch resistance as well as strong adhesive force, is kept attractive for long, and can be tightly bonded on the matrix in secondary forming, and the product made of the thermoplastic elastomer composition has a function of resisting bacteria and mould. The thermoplastic elastomer composition can be used for secondary forming (such as, rubber coating of tooth brushes, tool handles and the like), or can be used for forming alone (such as manufacturing bottle plugs).

Owner:GUANGDONG KINGREAT HITECH

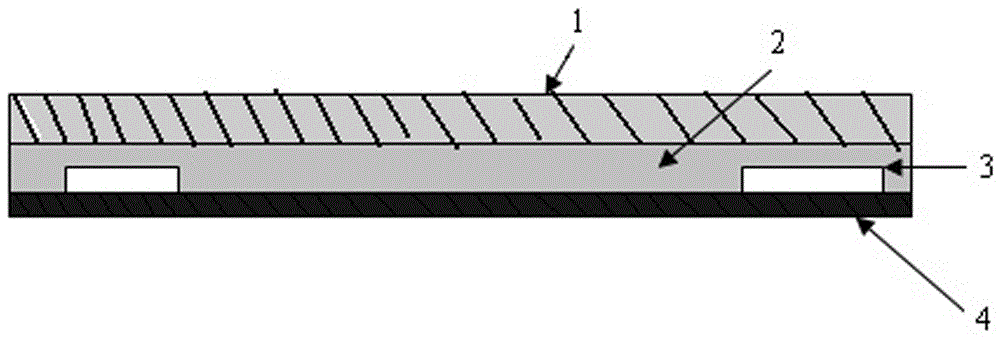

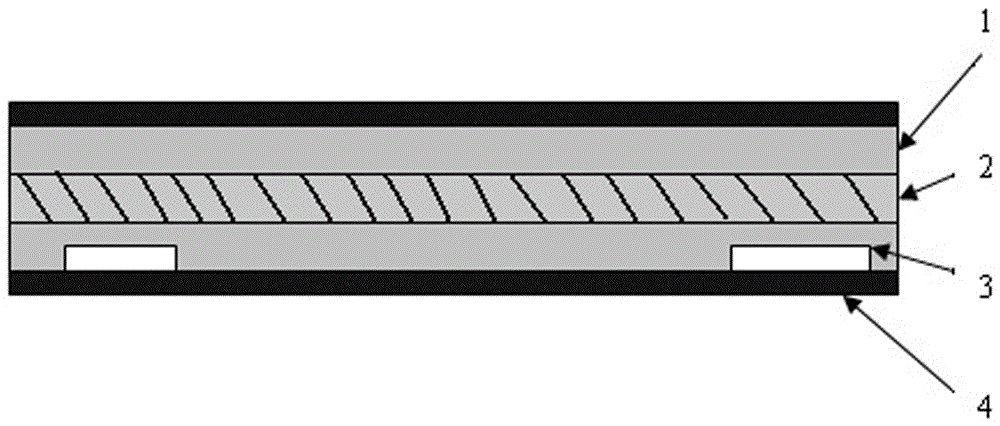

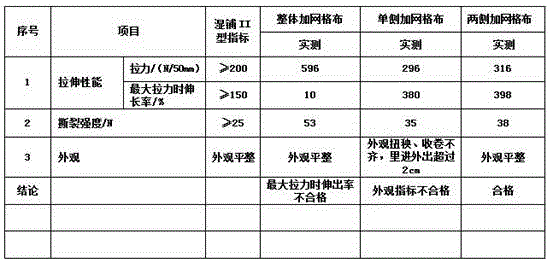

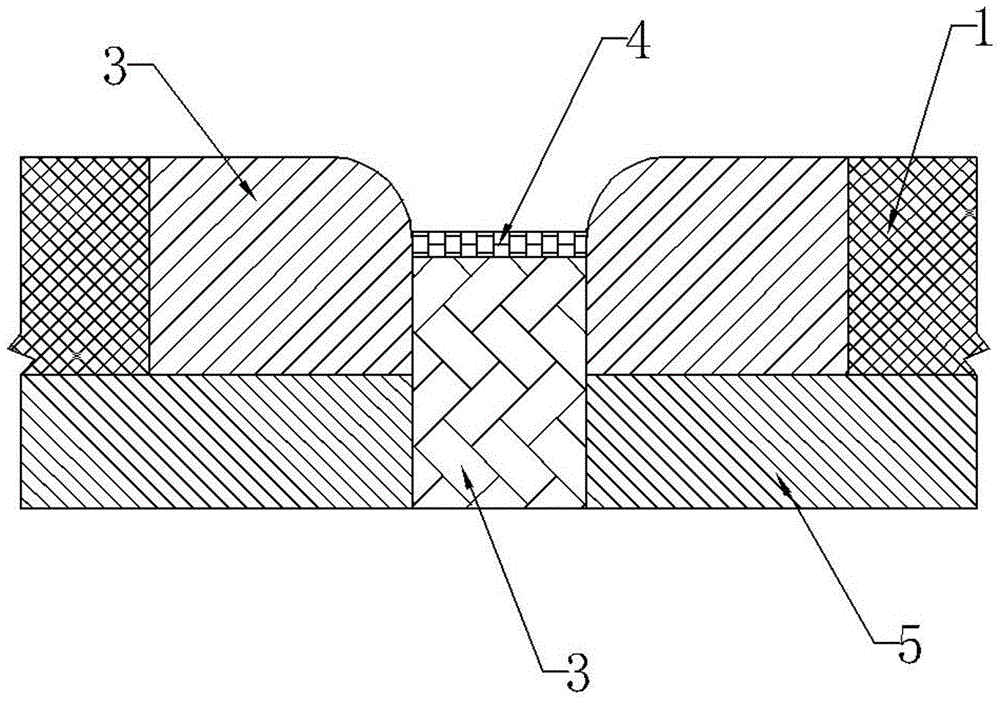

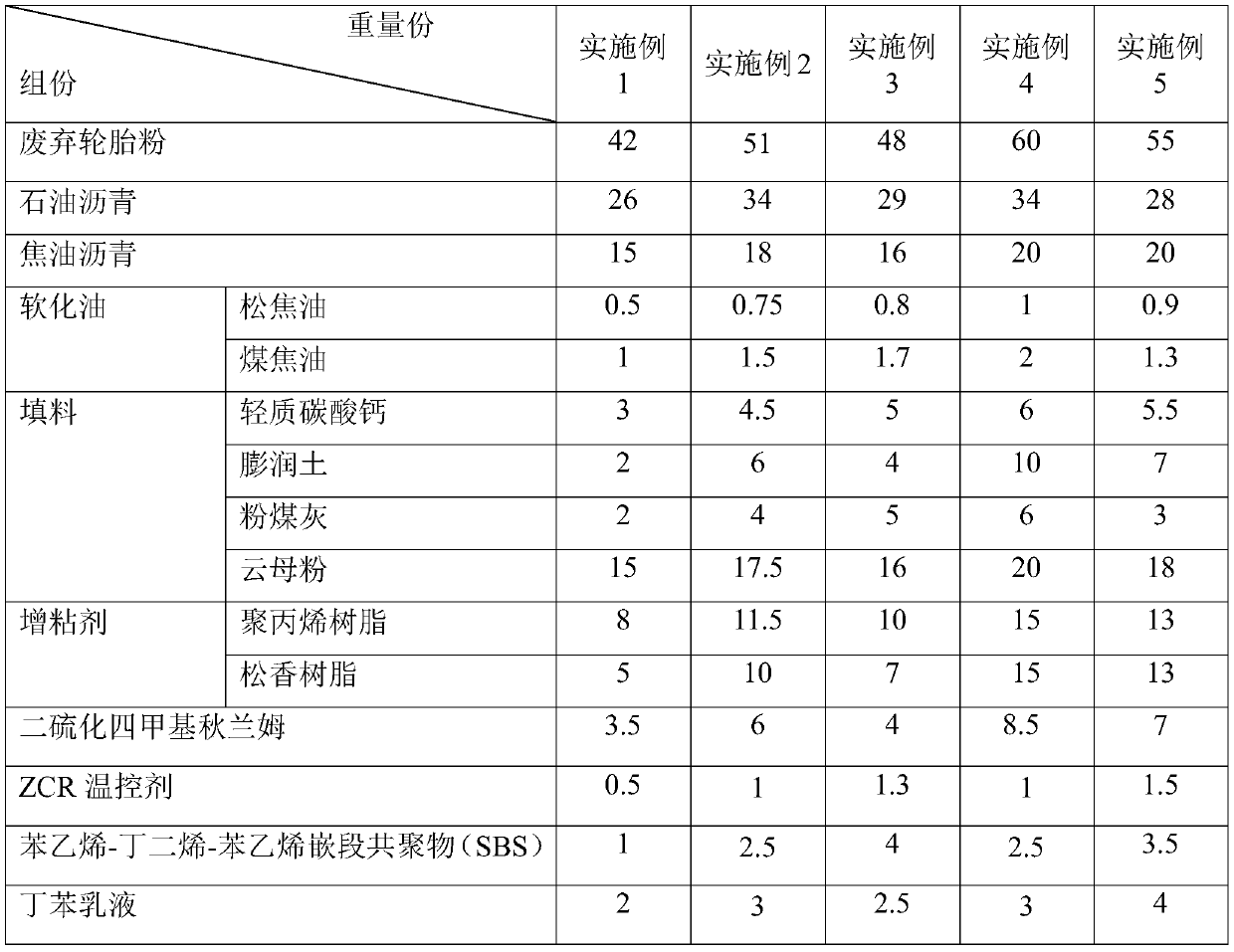

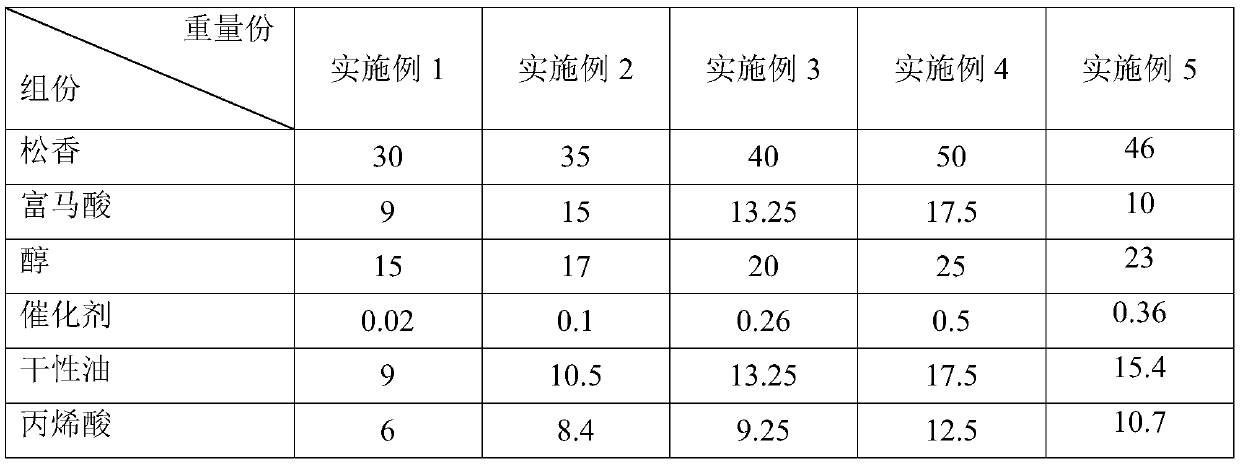

Modified asphalt waterproof coiled material with reinforced overlap edges and production method of modified asphalt waterproof coiled material

InactiveCN107175870AQuality improvementImprove mechanical propertiesRoof covering using flexible materialsSynthetic resin layered productsFiberBituminous waterproofing

The invention relates to a modified asphalt waterproof coiled material with reinforced overlap edges and a production method of the modified asphalt waterproof coiled material. The modified asphalt waterproof coiled material comprises a main body material layer, a modified asphalt layer and an isolating membrane, wherein two strips of fiber cloth are respectively embedded between the parts, which are respectively 0.1-1cm away from the edges of the two sides along the longitudinal direction of the modified asphalt layer, and the isolating membrane, so that the overlap edges are formed. After the method is adopted, the mechanical properties of the overlap edges are obviously improved after the modified asphalt waterproof coiled material is molded, so that the water resistance of the modified asphalt waterproof coiled material is more reliable; the production method provided by the invention solves the problems that in the traditional production process, due to mechanical mismatch of the left side and the right side of the coiled material, the coiled material is neat when being coiled and is twisted when being unfolded, and the like, and improves the quality of the waterproof coiled material.

Owner:XI NIU PI WATERPROOFING TECH CO LTD

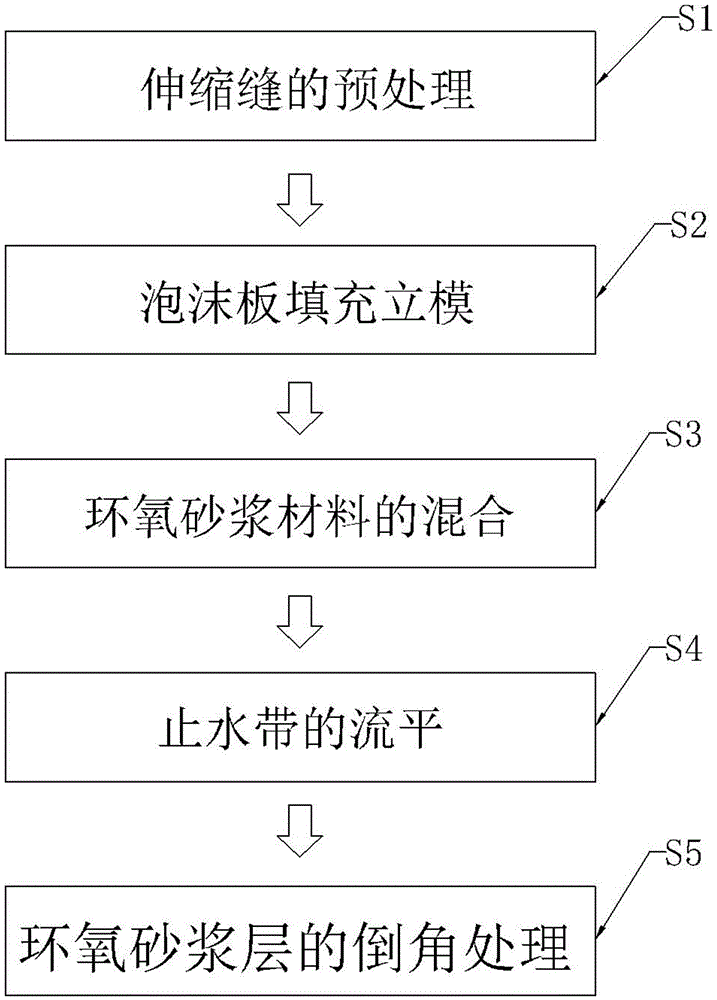

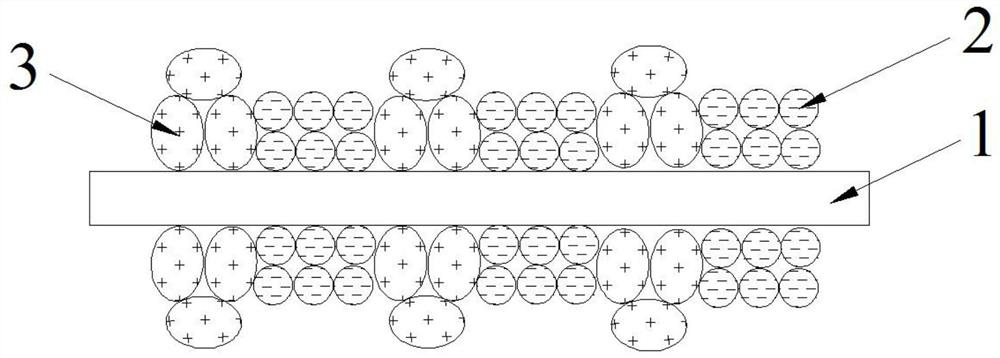

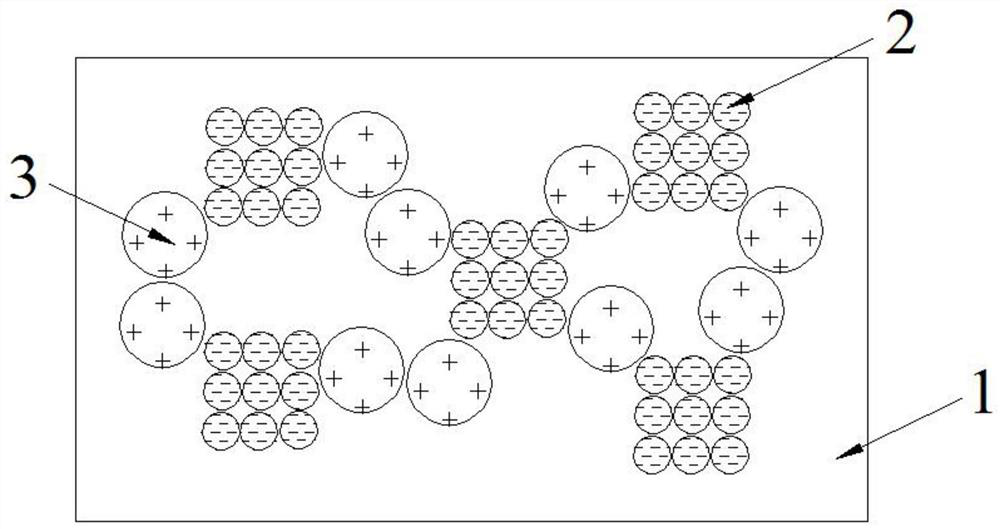

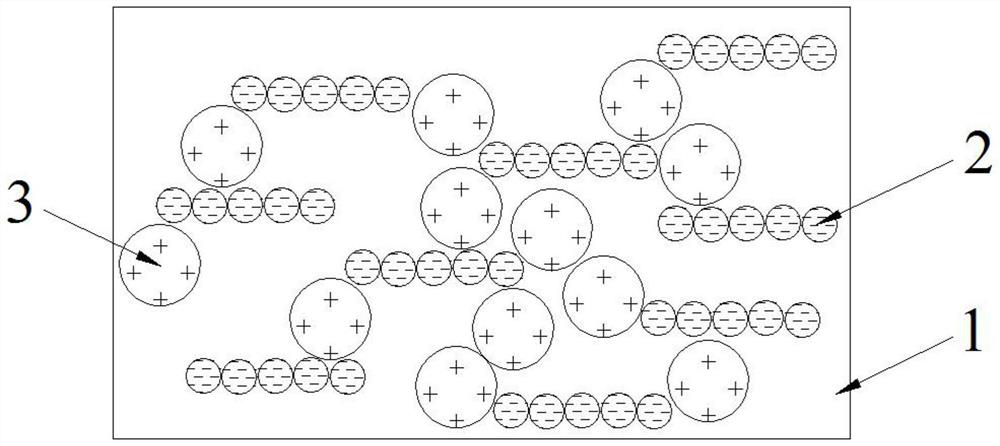

Epoxy mortar for bridge expansion joints and construction method thereof

InactiveCN105541180ALow viscosityHigh viscositySolid waste managementBridge structural detailsFirming agentArchitectural engineering

The invention relates to an epoxy mortar for bridge expansion joints and construction method thereof, and belongs to the technical field of building materials. The epoxy mortar material consists of a liquid A, a liquid B and a filler; and diamines D2000 and D230 are mixed as an epoxy curing agent. The curing agent has low viscosity, good compatibility with the epoxy resin, long working life, high bonding strength, good flexibility and thermal shock resistance, and can be applied to the epoxy mortar material capable of absorbing the stress. The epoxy mortar material mixed from the liquid A, liquid B and filler for construction of bridge expansion joints changes the condition that rigid concrete, which can to be easily damaged under impact stress, needs profile steel for protection in the traditional bridge expansion joint; epoxy mortar material substitutes the rigid concrete in traditional expansion joints, avoids a steel structure, and has good waterproof and seal performance; the expansion joints have color consistent with the color of the adjacent concrete or asphalt, so that the bridge is more beautiful; the expansion joints cannot cause vibration of vehicles when the vehicles pass by the expansion joints; and the noise generated by the vehicles is lower.

Owner:HEERON TECH (WUHAN) NEW MATERIALS CO LTD

Ceramic particle with far infrared and photocatalysis functions and manufacturing method thereof

The invention discloses a ceramic particle with far infrared and photocatalysis functions, confected by the following raw materials by weight percentage content: minus 15-65% of far infrared powder, minus 5-59% of photocatalyst, minus 3-15% of rare earth oxide and minus 5-35% of binding agent. The invention also discloses a manufacturing method of the ceramic particle with far infrared and photocatalysis functions. The invention has extremely strong far infrared radiation capability and excellent photocatalysis activity and can be widely applied to the fields of running water mineralization activation treatment, biological health care, clothing tableware cleaning and air purification, so as to realize the functions of purification, health care, washing and activation.

Owner:深圳市成为生物科技有限公司

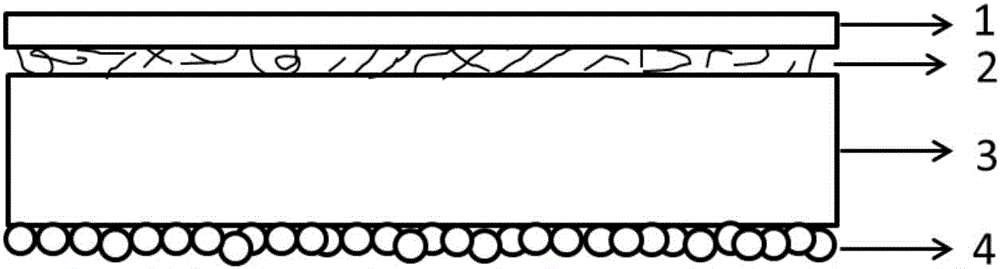

Preparation method of composite diaphragm, composite diaphragm and lithium ion battery

ActiveCN111653717AImprove bonding effectRealize regular arrangementSecondary cellsCell component detailsBond coatingLithium electrode

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a preparation method of a composite diaphragm. The preparation method comprises the following steps:putting inorganic particles into a first solvent to obtain inorganic slurry, coating at least one surface of a base membrane with the inorganic slurry at intervals, and drying to obtain an inorganic heat-stable coating; putting organic particles into a second solvent to obtain organic slurry, and coating the surface of the base film between the inorganic heat-stable coatings with the organic slurry at intervals to obtain an organic bonding coating, wherein the thickness of the organic bonding coating is greater than that of the inorganic heat-stable coating; and drying to obtain the compositediaphragm. According to the invention, the problems that inorganic particles and organic particles cannot be regularly arranged, the organic particles can be buried by the inorganic particles, and thebonding effect of the organic particles, a base film and a pole piece is poor are solved.

Owner:东莞市魔方新能源科技有限公司

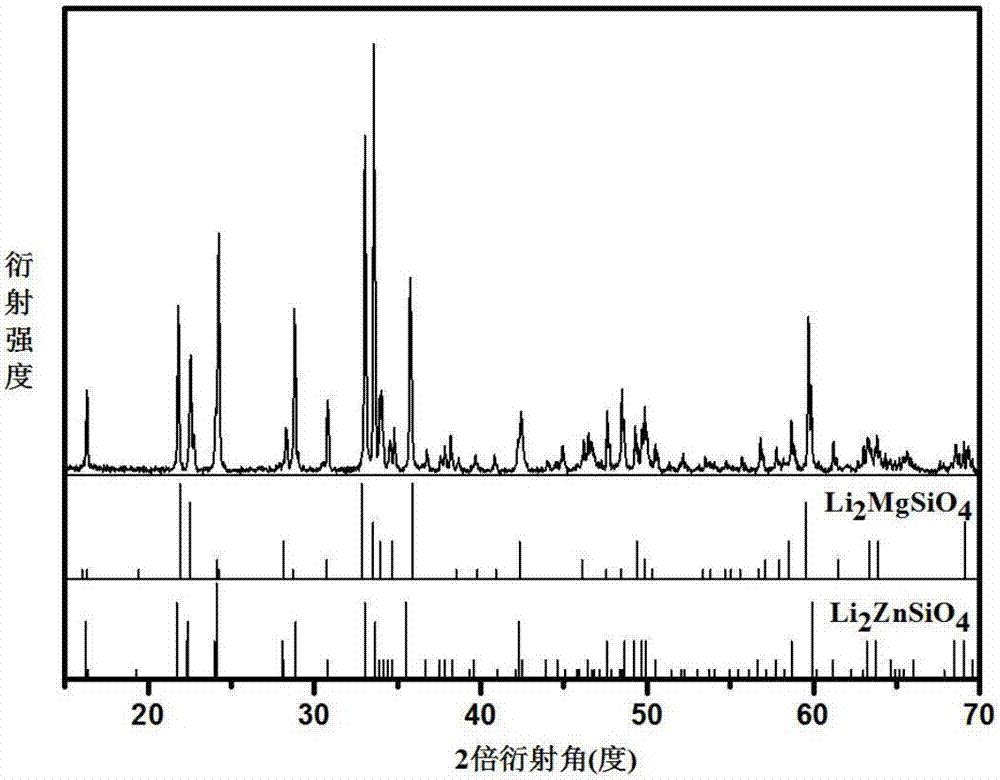

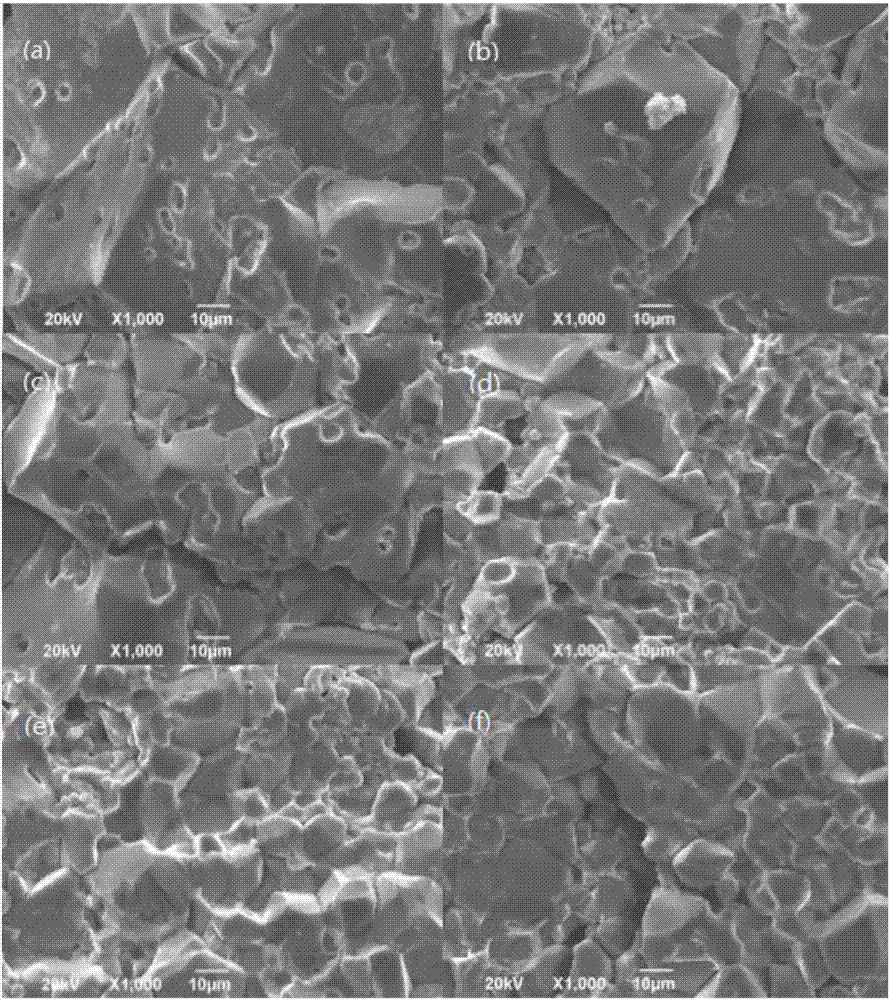

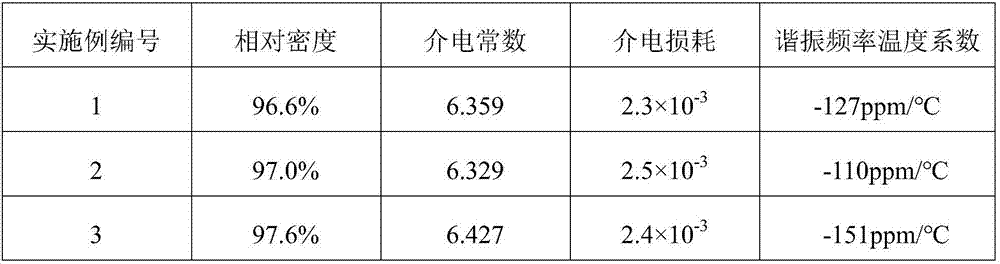

Low-temperature preparation method of low-dielectric microwave medium ceramic

The invention discloses a low-temperature preparation method of low-dielectric microwave medium ceramic, and belongs to the technical field of microwave medium ceramic. According to a chemical formula Li2(Mg1-xZnx)SiO4, burdening, ball mixing, drying and presintering are carried out to form a crystal phase, and then, compound sintering aids are added into presintered powder to carry out secondary ball mixing, drying and low-temperature sintering, so as to finally obtain the microwave medium ceramic material. Zn<2+> is used for replacing Mg<2+> so as to preliminarily lower the densifying temperature of the microwave medium ceramic and improve the dielectric property of the microwave medium ceramic; the compound sintering aids form a liquid phase in a subsequent sintering process, so that the sintering temperature is further lowered to 900DEG C, and in addition, the compactness of a microwave medium ceramic material is improved. Preparation with the method provided by the invention is favorable for application of Li2MgSiO4-based microwave medium ceramic with a low dielectric constant and a high quality factor into LTCC (Low Temperature Co-Fired Ceramic), and the requirements of the microwave communication industry are met.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA +1

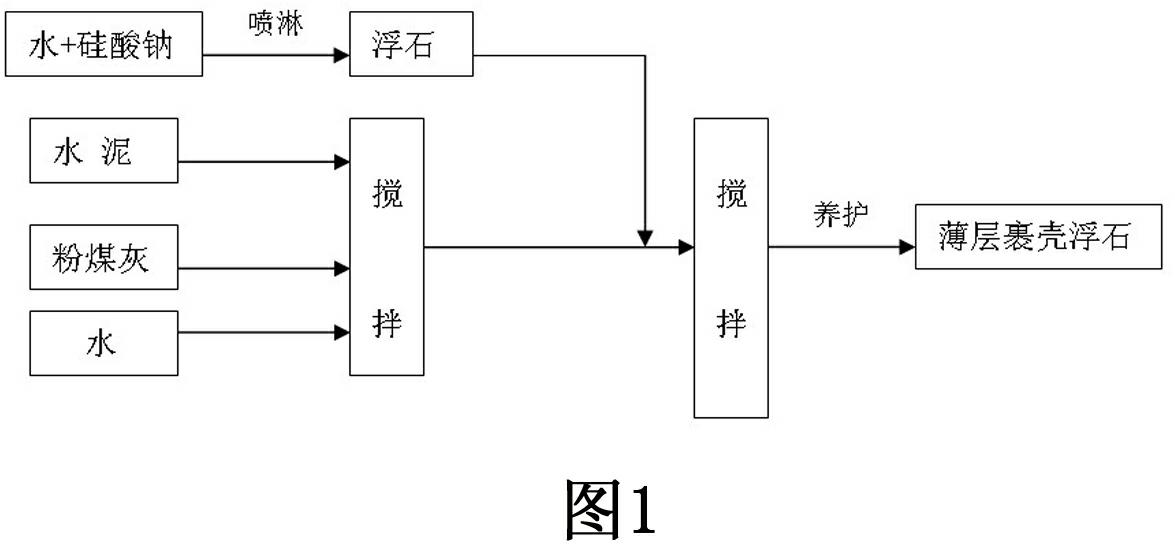

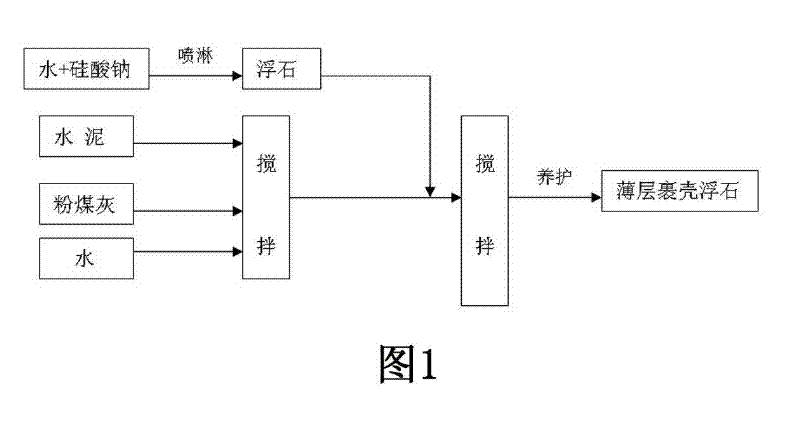

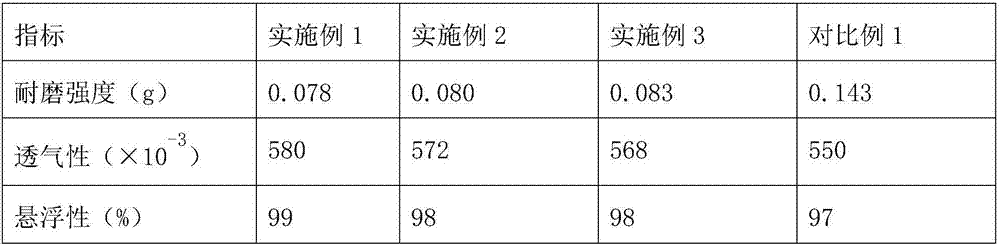

Polystyrene particle-rubber particle-pumice stone composite lightweight aggregate concrete and preparation method thereof

ActiveCN102219451AImprove impact resistanceImprove seismic performanceSolid waste managementCeramicwarePumice dustFoaming agent

The invention discloses a method for preparing polystyrene particle-rubber particle-pumice stone composite lightweight aggregate concrete. The polystyrene particle-rubber particle-pumice stone composite lightweight aggregate concrete comprises the following raw materials in parts by weight: 1 part of cement, 0.40-0.50 part of coal ash, 0.80-1.20 parts of thin-layer cladded pumice sand, polystyrene particles and rubber particles, 0.010-0.015 part of admixture, 0.005-0.007 part of foaming agent, and 0.50-0.55 part of water. The preparation method comprises the following steps of: 1, preparing the thin-layer cladded pumice sand; 2, carrying out interface treatment on the polystyrene particles and the rubber particles; 3, adding the cement, the coal ash, the water, the admixture and the thin-layer cladded pumice sand to a stirring machine to be stirred according to proportions; 4, adding the polystyrene particles and the rubber particles subjected to the interface treatment in the stirring machine to be stirred continuously; and 5, after frothing, pouring the forthed foaming agent into the stirred mixture and uniformly stirring. According to the method disclosed by the invention, the mechanical property of the lightweight aggregate concrete is effectively improved; the thermal insulation performance is improved; and the production cost is reduced.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

Color pavement formed by spraying on porous polymer concrete facing and construction method therefor

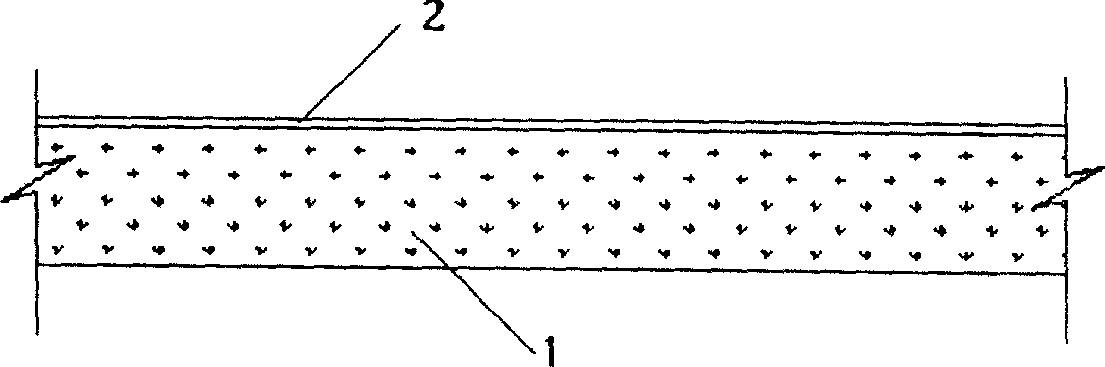

A colorful road plated with porous polymer concrete face and relative construction first mix polymer, broken stone and stuff uniformly to form polymer porous concrete material, lay to form polymer porous concrete face 1, mix uniformly the colorful face, and plate colorful face on the face of porous polymer concrete face layer 1 to form a colorful face layer 2, while the colorful face layer 2 is adhered with the porous polymer concrete face layer 1, to form a colorful road. The inventive road has high strength, better deformation property, abrasion resistance or the like, while the color can adjust via different fields.

Owner:易志坚

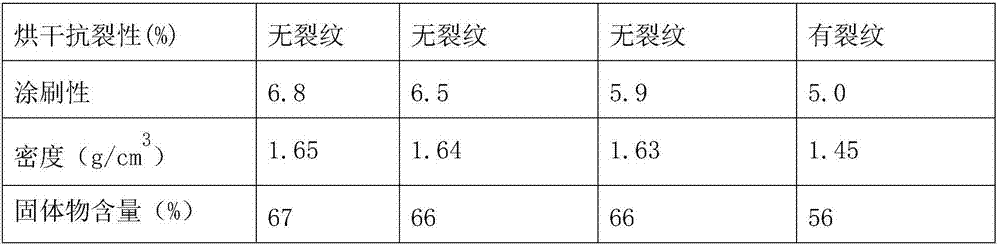

Full-mold casting paint and preparation method thereof

InactiveCN107052232ASolve the problem that cannot meet the production requirements of large castingsImprove wear resistanceFoundry mouldsFoundry coresPolyvinyl alcoholOlivine

The invention provides a full-shape casting coating and a preparation method thereof, relating to the field of casting. The full-shape casting coating includes the following raw materials in parts by weight: quartz powder, olivine powder, corundum powder, sodium bentonite, lignin sulfonic acid, and dextrin powder , sodium carboxymethyl cellulose, sodium benzoate, hollow glass microspheres, aluminum sulfate, polyvinyl alcohol, silica sol, iron oxide powder, n-octanol, graphite powder, zircon powder, attapulgite, water reducing agent and water The preparation method comprises the following steps: (1) weighing raw materials, (2) preparing each mixed solution in turn, and (3) adding to a reaction kettle and stirring in turn. The invention solves the problem that the existing solid casting coatings generally have strong wear resistance, high adhesion, excellent air permeability and quick drying under high temperature and low temperature environments, which makes them unable to meet the production requirements of large castings. question.

Owner:安徽华飞机械铸锻有限公司

Method for manufacturing organic supercapacitor electrode plate

The invention provides a method for manufacturing an organic supercapacitor electrode plate. The method comprises the following steps of: manufacturing an aluminum foil pretreatment coating, adding an adhesive into deionized water, and uniformly stirring at normal temperature; adding a conductive agent, absolute ethanol, a carbon nano tube and sodium carboxymethyl cellulose, stirring at a high speed and dispersing to obtain the coating; uniformly coating the manufactured pretreatment coating on an aluminum foil by employing a coating process, coating active substance slurry on the pretreated aluminum foil, and drying to manufacture the electrode plate. A corrosive aluminum foil is replaced by a common aluminum foil, the cost of raw materials is effectively reduced, and the production operability and stability are improved; meanwhile, after the aluminum foil is pretreated, internal resistance of the supercapacitor is greatly reduced, and high-power output performance of the product is improved.

Owner:JIANGSU FRONT NEW ENERGY

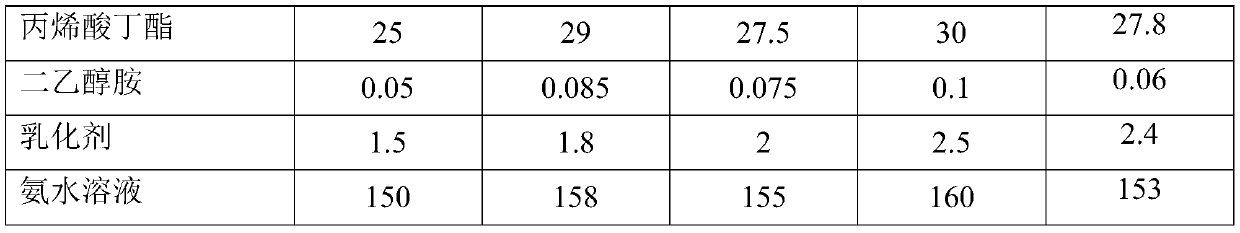

Waterproof concrete compacting agent and preparation method thereof

The invention discloses a waterproof concrete compacting agent and a preparation method thereof. The compacting agent consists of the following raw material components in percentage by weight: 10 to 13 percent of potassium hydroxide, 0.5 to 1 percent of volcanic ash, 0.5 to 1 percent of potassium oleate, 10 to 12 percent of sulfur, 0.5 to 1 percent of glycerol, 3 to 5 percent of triethanolamine, 0.5 to 1 percent of citric acid, 0.5 to 1.5 percent of ferric oxide, 0.5 to 1 percent of sodium fluosilicate, and the balance of water. Chemical crystal or colloid generated by chemical reaction of components in the compacting agent and silicon, calcium, sodium, magnesium and the like in cement can effectively prevent permeation of water molecules and effectively control cracking. The compacting agent contains extremely low harmful substances, particularly has extremely low chlorine ion content and ammonia content, reduces damage to steel bars and concrete, and is beneficial to environmental protection.

Owner:北京龙阳伟业科技股份有限公司

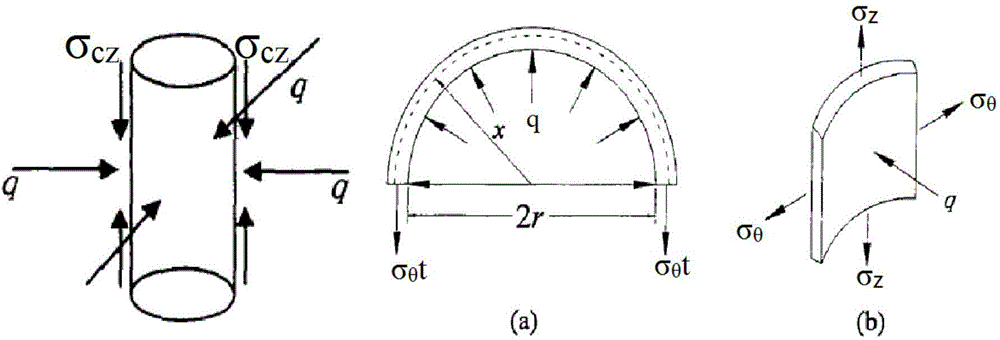

High efficiency composite expanding agent for high-strength self-stressing concrete filled steel tube and preparation method thereof

ActiveCN104909596AGood expansion performanceSwelling starts earlyHigh strength concreteUltimate tensile strength

The invention belongs to the building field, and concretely relates to a high efficiency composite expanding agent for a high-strength self-stressing concrete filled steel tube and a preparation method thereof. The high efficiency composite expanding agent comprises the following components by mass percentage: 22-40% of light calcined magnesia, 12-25% of active calcium oxide, 6-14% of calcined dolomite, 18-30% of sulphoaluminate cement clinker, 12-18% of natural gypsum and 2-6% of modified meerschaum powder. Through a design of hydration expansion characteristics of different components, expansion performance and high-strength concrete intensity are cooperated for development, expansion usefulness is high, water for hydration is little, expansion beginning time is early, and the expansion performance is stable, by introducing a maintenance material, problems of difficult maintenance of a steel pipe under enclosing condition and difficult supply of expanding agent and water for concrete hydration can be solved, and the high efficiency composite expanding agent is suitable for preparing the high-strength self-stressing concrete filled steel tube under enclosing condition of the steel pipe.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

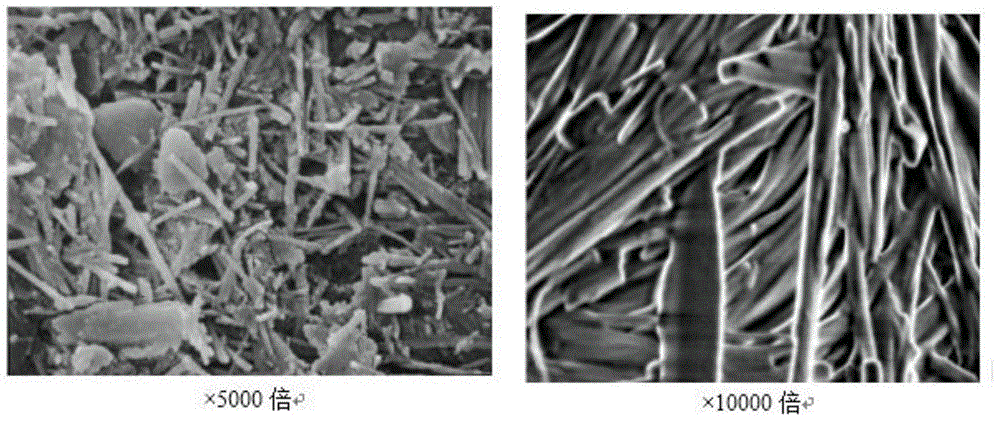

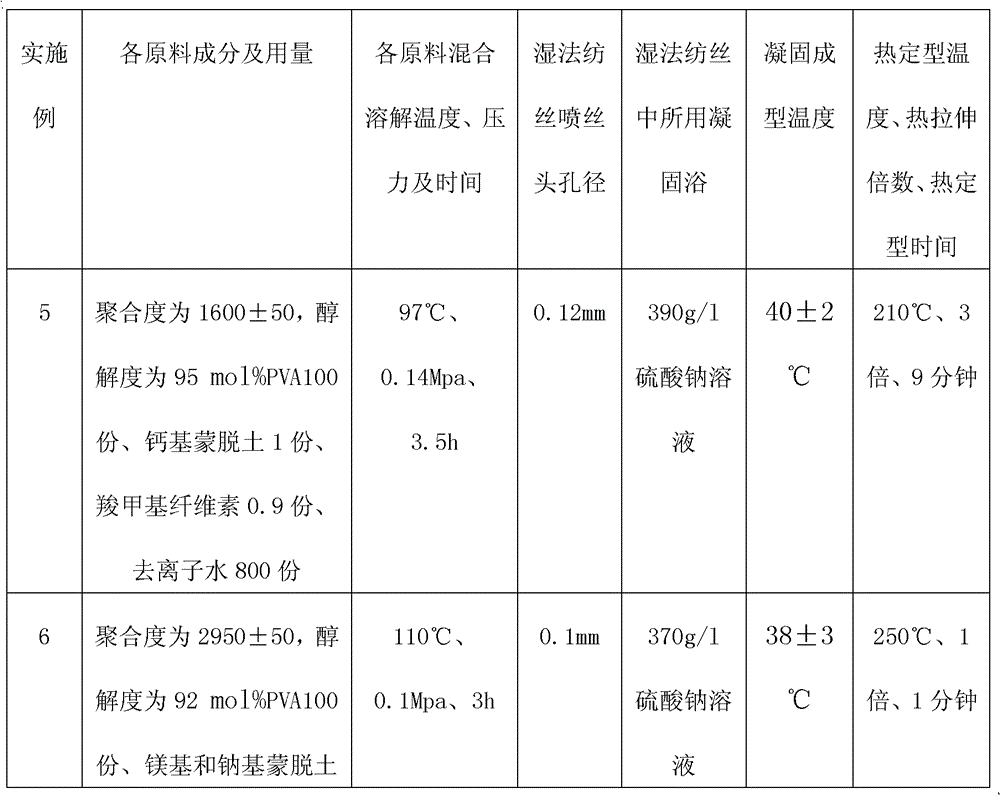

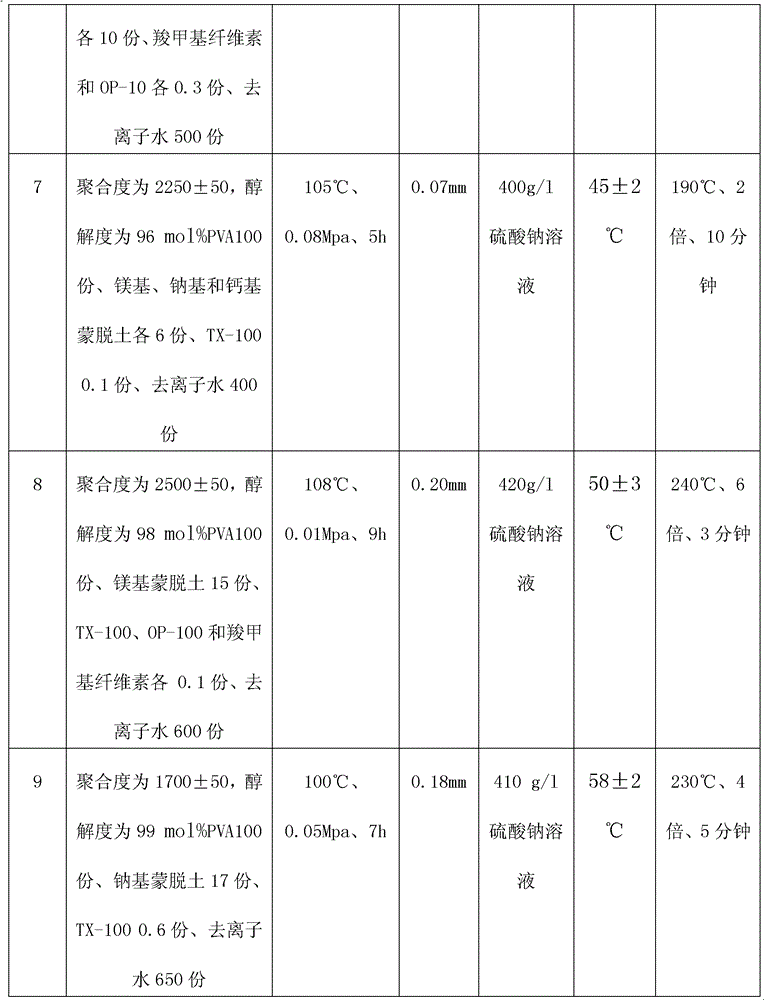

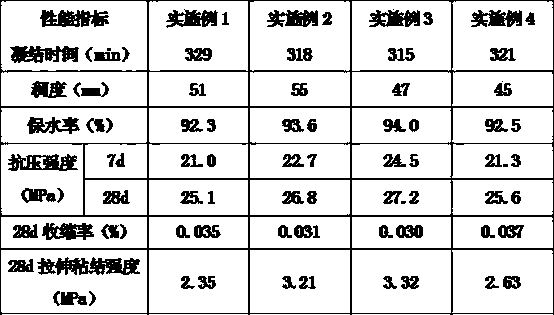

Preparation method of medium modulus polyvinyl alcohol fiber

ActiveCN103060940AGood physical and mechanical propertiesEvenly dispersedArtificial filament washing/dryingArtificial filament heat treatmentFiberBreaking strength

The invention relates to a preparation method of a medium modulus polyvinyl alcohol (PVA) fiber. The invention is characterized in that the fiber comprises the following raw materials: 100 parts of PVA, 1-20 parts of montmorillonite and 400-800 parts of water. Compared with the process of high strength and high modulus PVA fiber, the preparation method of the PVA fiber provided in the invention has the characteristics of simple operation, low cost and greater environmental friendliness, thus being especially suitable for large-scale industrial production. The PVA fiber prepared by the invention has a linear density of 1.0-10.0dtex, dry breaking strength of 6.0-10.0cN / dtex, breaking elongation of 6-20%, and a Young's modulus of 110-200cN / dtex, thus being very suitable for application in the construction field or industrial fabrics.

Owner:CHINA PETROCHEMICAL CORP +1

Ceramic tile ready-mixed mortar and production method thereof

InactiveCN104230237AQuality assuranceQuality improvementSolid waste managementCelluloseCompressive resistance

The invention relates to ceramic tile ready-mixed mortar and a production method thereof. The ceramic tile ready-mixed mortar is characterized by comprising the following raw materials in parts by weight: 50-60 parts of artificial sand, 30-35 parts of cement, 10-12 parts of class II pulverized fuel ash, 0.5-1 part of a functional auxiliary agent and 0.1-0.5 part of additives, wherein the functional auxiliary agent comprises redispersible latex powder, cold cut polyvinyl alcohol powder and hydroxypropyl methyl cellulose ether. The ceramic tile ready-mixed mortar disclosed by the invention has tensile adhesive strength and compressive strength, can be used for significantly improving properties such as anti-permeability, crack resistance, water reduction performance and water-retention rate of the mortar, and also has excellent working performance and excellent construction properties such as easy pumping and easy compacting.

Owner:GUANGXI HENGXIAN HENGFENG BUILDING MATERIAL

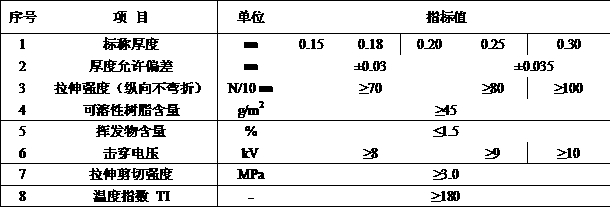

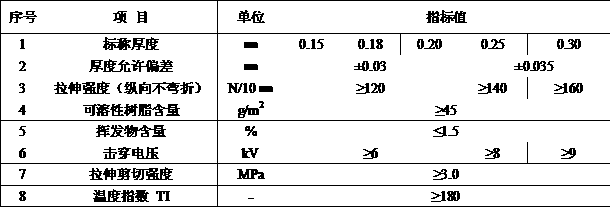

Coating type composite material for dry type transformer and preparation method thereof

ActiveCN103072352ATight bondGuaranteed insulation performanceLamination ancillary operationsSynthetic resin layered productsThin membraneAdhesive cement

The invention discloses a coating type composite material for a dry type transformer, which is characterized in that two layers of high temperature resistant epoxy resin are respectively coated on two surfaces of a five-layer composite material formed by compounding a thin film layer, adhesive layers and organic or inorganic fiber paper layers; the two surfaces of the thin film layer are adhered with the organic / inorganic fiber paper layers through the adhesive layers; and the organic / inorganic fiber paper layers can be soaked with the high temperature resistant epoxy resin. The invention further provides a preparation method of the coating type composite material for the dry type transformer. The preparation method comprises the following steps: compounding the thin film layer with the organic / inorganic fiber paper layers to form the five-layer composite material after soaking the thin film layer with adhesive, uniformly coating high temperature resistant epoxy resin coating liquid on the two surfaces of the prepared composite material, and cooling to the room temperature to obtain the product after heating and solidifying. The material is long in storage period at the room temperature, is ageing resistant, has an excellent electrical performance and is suitable for insulating between low-voltage coil copper (aluminum) foil taped coverings of the dry type transformer.

Owner:ZHUZHOU TIMES ELECTRIC INSULATION

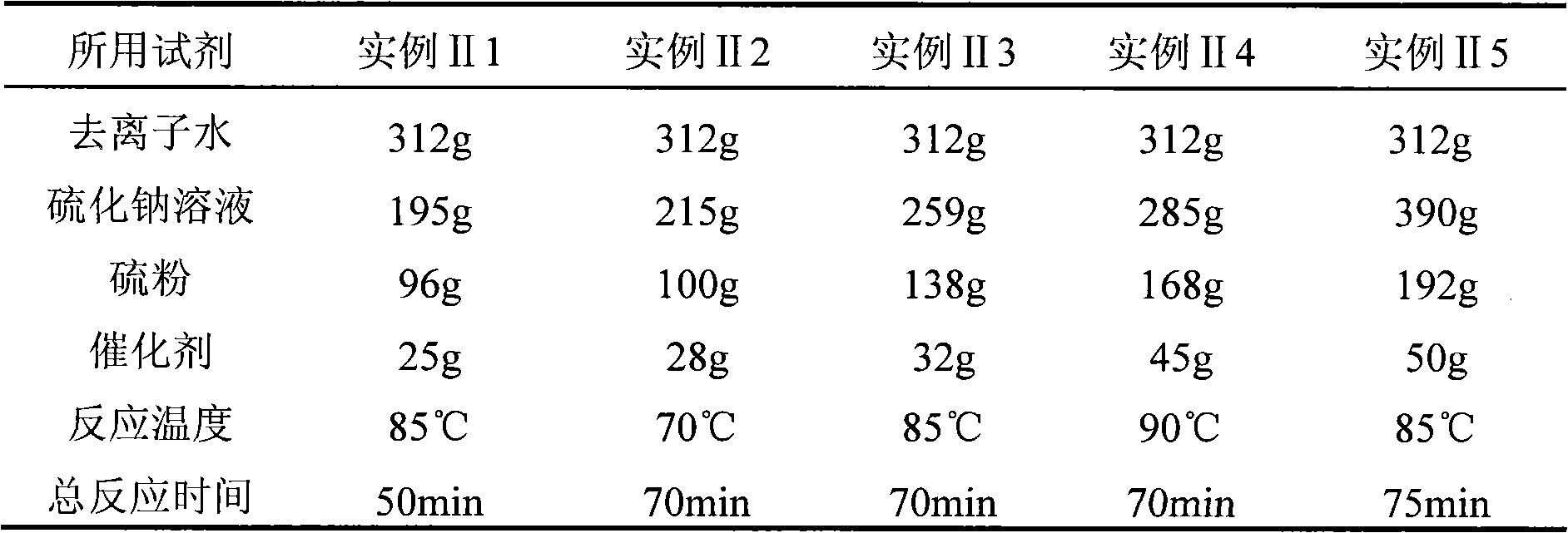

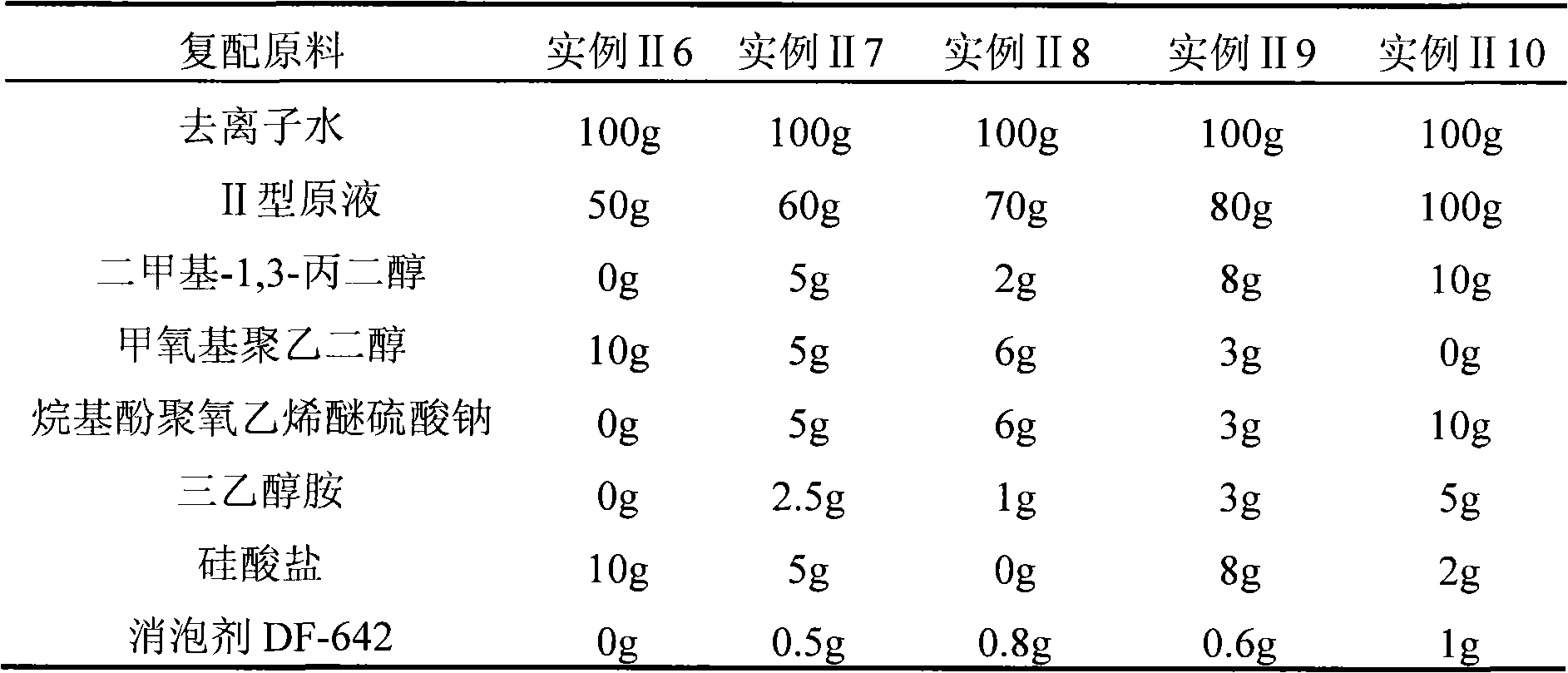

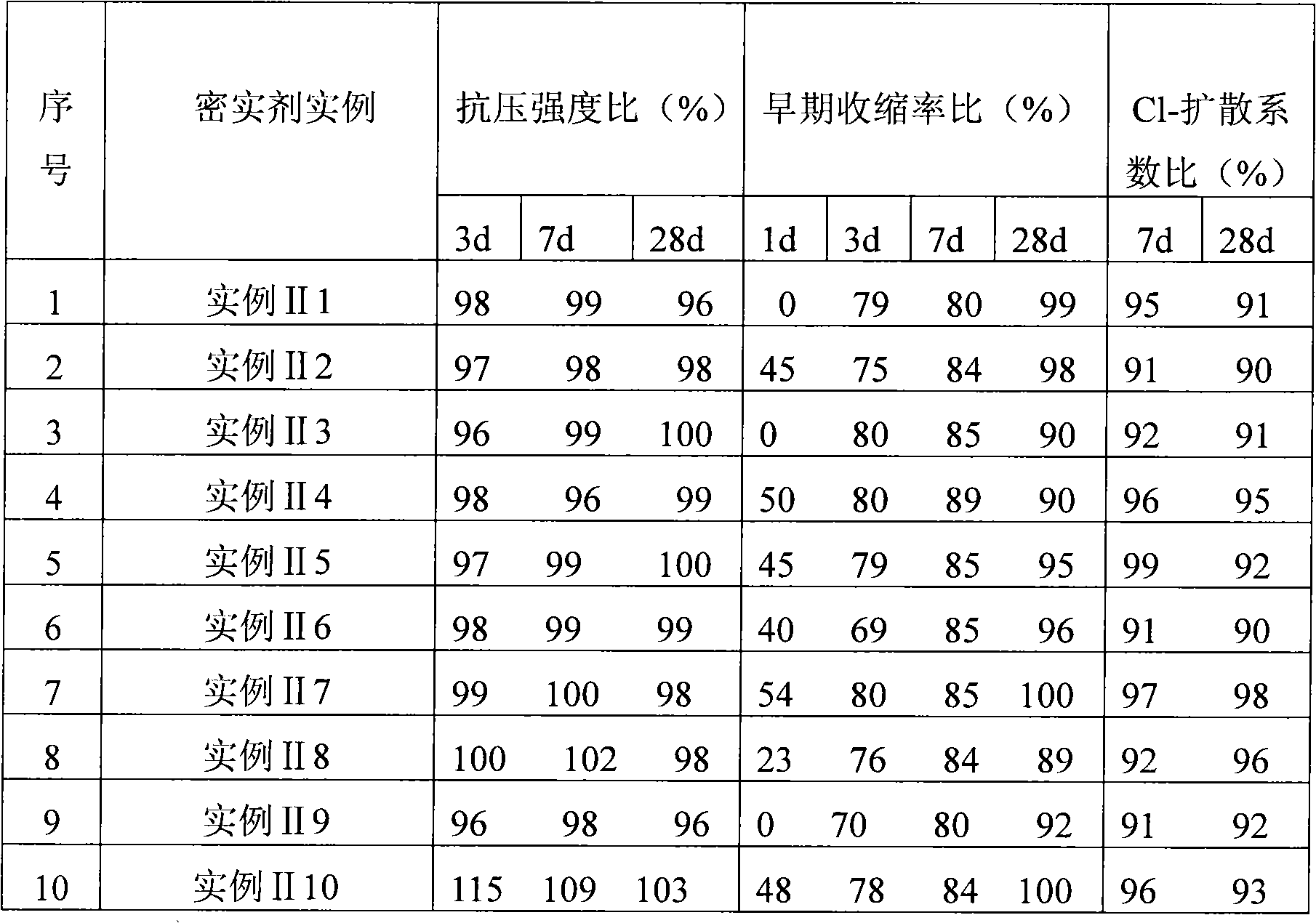

Novel special concrete contraction reducing type compacting agent

The invention discloses a novel special concrete contraction reducing type compacting agent, which relates to a novel special concrete contraction reducing type compacting agent, and belongs to the technical field of concrete admixture. The preparation method of the product comprises the following steps: preparing stock solution with deionized water, sodium sulfide solution, sulfur powder and a catalyst, wherein the catalyst is mixed solution of methoxypolyethylene glycol, dimethyl-1, 3-propylene glycol and alkylphenol ethoxylate sodium sulfide; and then preparing an inorganic waterproof contraction reducing type compacting agent for inorganic concrete with deionized water, the stock solution, triethanolamine, methoxypolyethylene glycol, dimethyl-1, 3-propylene glycol, alkylphenol ethoxylate sodium sulfide, silicate and a defoamer DF-642. The compacting agent is prepared under the low intermingled quantity, and experimental results show that when the intermingled quantity is 0.1-2 percent, the invention can effectively reduce the early contraction of the concrete, decrease the cracking risks, enhance the concrete compaction, improve the pore structure, and achieve the functions of preventing water and leakage, thereby enhancing the resistance of the concrete against physical and chemical erosion. However, the invention relates to an II type compacting agent, which has a significant effect on the reduction of the concrete contraction and is particularly applicable to the engineering field with strict requirements for concrete contraction and cracking.

Owner:TSINGHUA UNIV +1

Colorful pervious concrete and preparation method thereof

The invention relates to the technical field of pervious concrete preparation, in particular to colorful pervious concrete. Concrete in each stere is prepared from the following raw materials of, in parts by weight, 80-120 parts of coarse-diameter gravels, 9-15 parts of fine-diameter zeolite, 15-30 parts of cement, 6-8 parts of water, 4-6 parts of additives, 2-4 parts of painting and 0.5-1.5 partsof modified wood fibers. According to the technical scheme of the preparation method of the colorful pervious concrete, fine-diameter zeolite is added to increase the accumulation density of aggregates, the contact points among the aggregates are increased, accordingly the compressive strength of the prepared pervious concrete is improved, meanwhile, zeolite has a special porous structure, and thus the porosity of the pervious concrete is improved further. The modified wood fibers are added into the pervious concrete as well, so that adhesion among granules of the pervious concrete is tighter, the sedimentation rate of cement paste is lowered, meanwhile, the modified wood fibers can bear part of tensile stress, and accordingly the breaking strength of concrete is improved.

Owner:南通鸿基市政工程有限公司

Non-cured rubber asphalt paint and self-adhesion coiled material composite construction method

InactiveCN110409513AImprove flatnessTight bondOther rubber coatingsUnderground chambersComposite constructionBond properties

The invention relates to the field of waterproof engineering construction methods, in particular to a non-cured rubber asphalt paint and self-adhesion coiled material composite construction method. The non-cured rubber asphalt paint and self-adhesion coiled material composite construction method comprises the following steps of S1, waterproof paint treatment; S2, base layer treatment; S3, joint reinforcing treatment; S4, self-adhesion coiled material pre-trial paving; S5, first bonding layer construction; S6, self-adhesion coiled material paving and lap joint; and S7, close-up seal. The methodhas the beneficial effects that a composite waterproof layer made through the construction method has the good anti-aging property, and even if the composite waterproof layer is used for a long time,the composite waterproof layer can still keep good structural strength and bonding property.

Owner:东莞市卓宝建筑工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com