Preparation method of medium modulus polyvinyl alcohol fiber

A fiber and modulus technology, applied in the field of preparation of polyvinyl alcohol fibers, can solve the problems of high operation risk, long washing time, and no advantages, and achieves low cost, improved physical and mechanical properties, and improved uniformity and quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

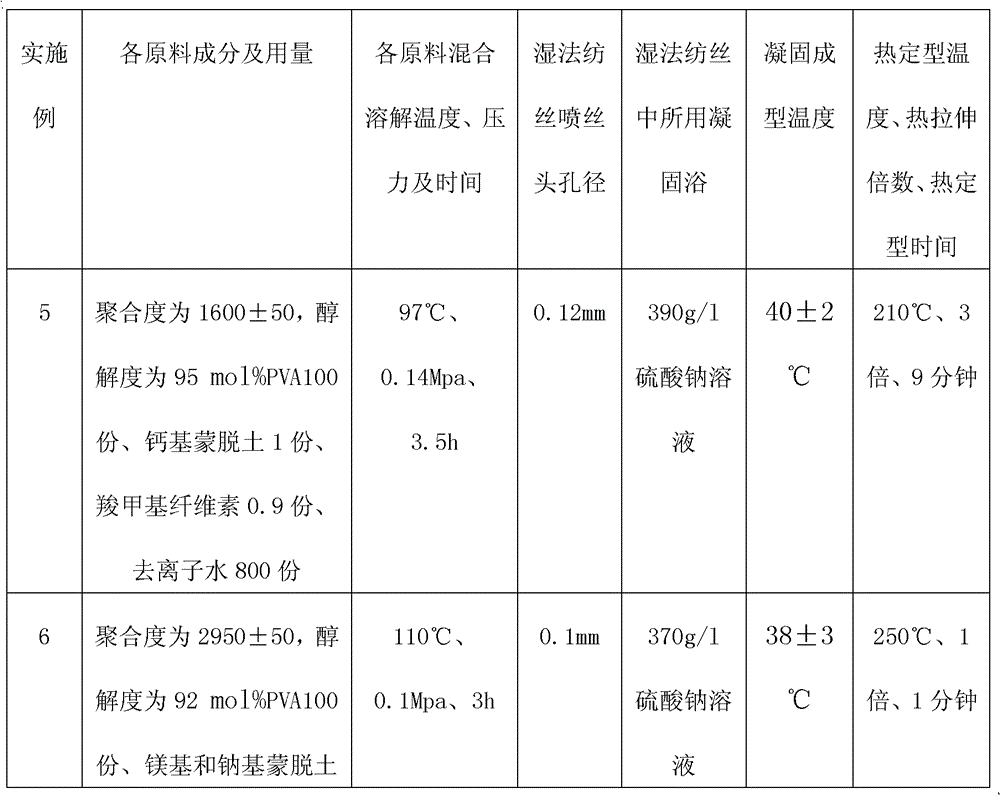

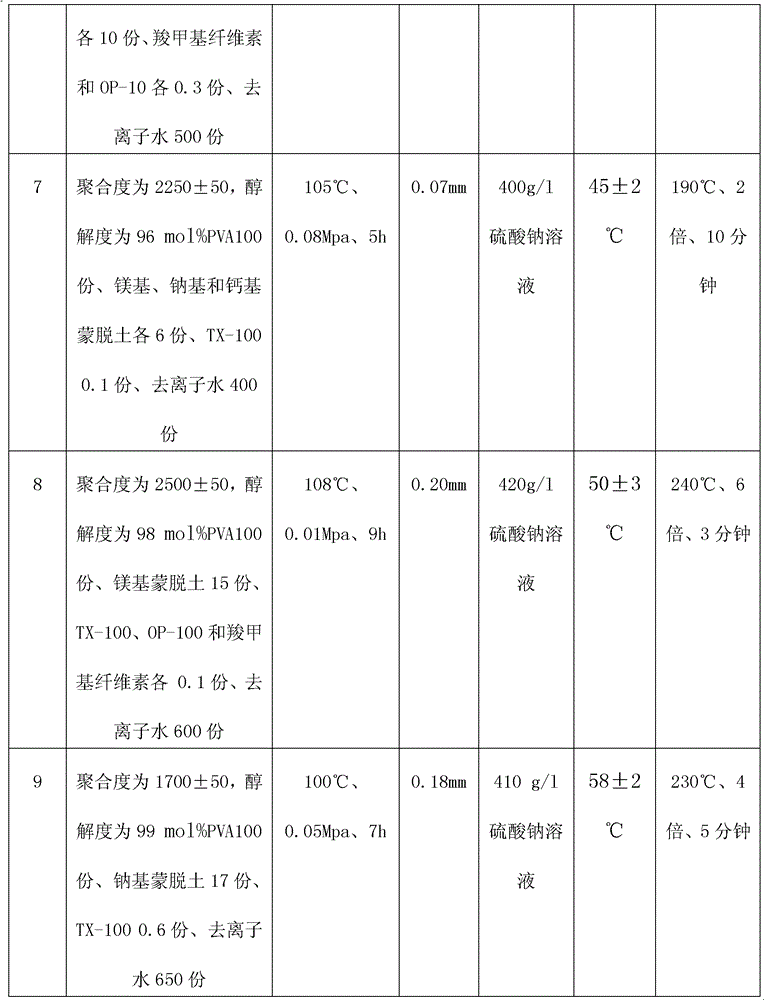

Examples

Embodiment 1

[0029] Add 15 kg of PVA with a degree of polymerization of 1750±50 and a degree of alcoholysis of 95 mol%, 0.3 kg of 1500 mesh calcium-based montmorillonite, 0.1 kg of OP-10 additive, and 84 kg of water into the dissolving kettle. 98±2℃, pressure 0.01MPa, 4 hours after dissolving, filter by pump, defoaming under normal pressure for 18 hours, defoaming temperature of 97℃, the temperature of spinning dope is 97℃, measured by metering pump, the pore diameter is Spinneret spinneret of 0.10mm, 6000 holes, coagulated and formed in Glauber's salt coagulation bath, and the spinneret stretched -0.5 times. The spun nascent fiber was wet-heated, dried, stretched, and heat-set, the total stretched 6 times, The obtained fiber has a linear density of 3.1 dtex and a Young's modulus of 118 cN / dtex.

Embodiment 2

[0031] Add 15kg of PVA with a degree of polymerization of 1750±50 and a degree of alcoholysis of 99mol%, 0.3kg of 1800 mesh sodium-based montmorillonite, 0.2kg of TX-100 additive, and 84kg of water into the dissolving kettle. 98±2℃, pressure 0.02MPa, dissolve for 3 hours, filter by pump, defoam for 4 hours under normal pressure, defoam temperature 97℃, make spinning dope temperature 97℃, measure by metering pump, through pore size: Spinneret with a diameter of 0.10mm, 6000 holes, coagulated and formed in Glauber's salt coagulation bath, and the spinneret is stretched -0.2 times. The spun nascent fiber is wet-heated, dried, stretched, and heat-set, and the total stretch is 9 times. The obtained fiber has a linear density of 2.2 dtex and a Young's modulus of 160 cN / dtex.

Embodiment 3

[0033] Add 15kg of PVA with a degree of polymerization of 1850±50 and a degree of alcoholysis of 99mol%, 0.6kg of 3000 mesh sodium-based montmorillonite, 0.2kg of TX-100 additive, and 85kg of water into the dissolving kettle. 108±2℃, pressure 0.03MPa, dissolve for 6 hours, filter by pump, defoaming under normal pressure for 16 hours, defoaming temperature 97℃, the temperature of the spinning dope is 97℃, measured by the metering pump, the aperture is The spinneret of 0.08mm, 8000 holes spins, solidified and formed in Glauber's salt coagulation bath, the spinneret is stretched 0.1 times, and the spun nascent fiber is wet-heated, dried, stretched, and heat-set. The total stretch is 9 times. The resulting fiber has a linear density of 1.8 dtex and a Young's modulus of 198 cN / dtex.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com