Patents

Literature

97results about "Other rubber coatings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Copolymer surfactants

InactiveUS20090076211A1Improved flow and levelingSpeed up the flowOther rubber coatingsTransportation and packagingSURFACTANT BLENDPolymer chemistry

Owner:COLUMBIA INSURANCE CO

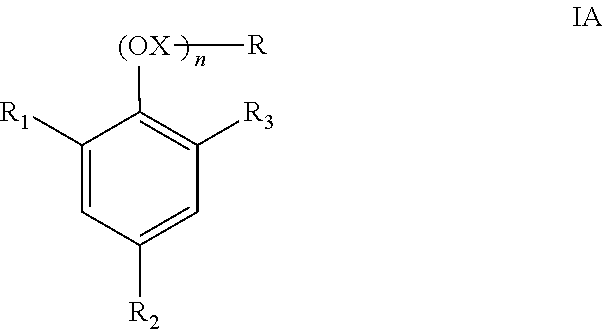

New reactive surfactants for freeze-thaw stable emulsion polymers and coatings thereof

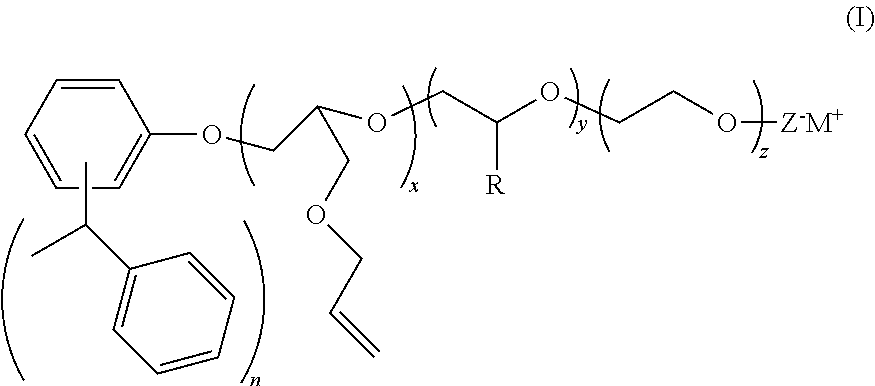

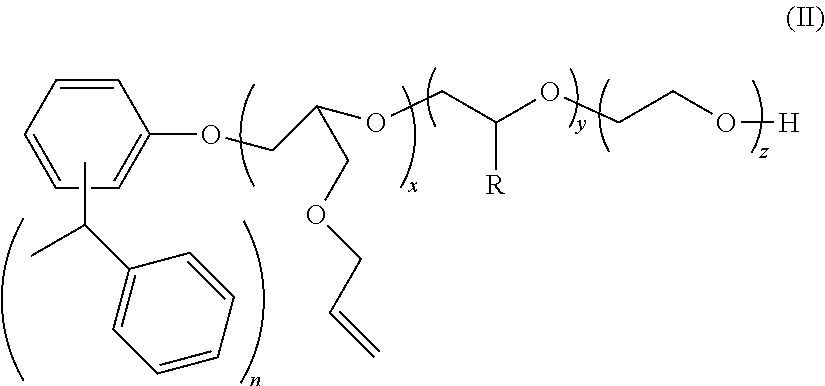

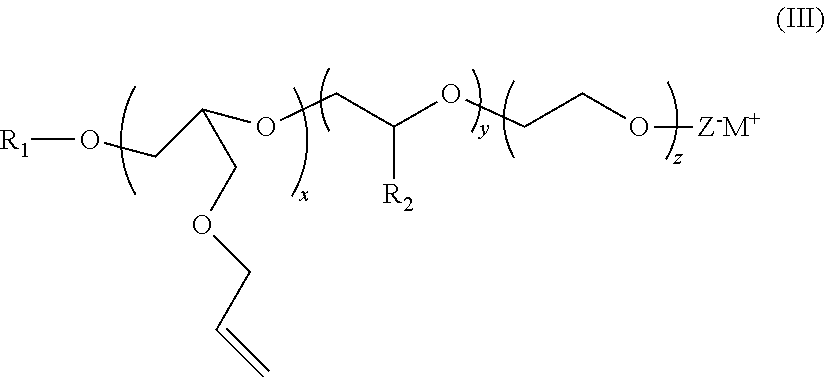

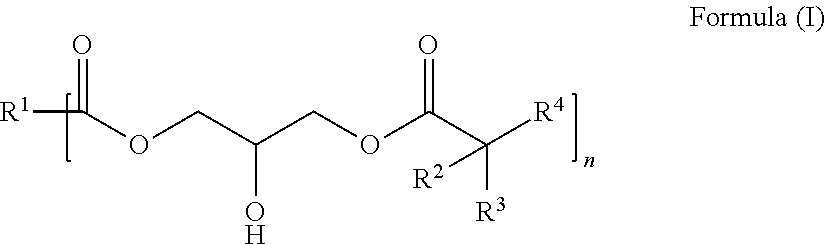

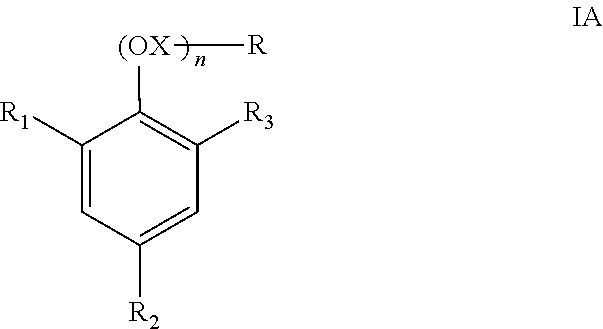

ActiveUS20140114006A1Reduce the amount requiredConvenient coatingOther rubber coatingsPolyether coatingsArylPolymer science

The invention provides aqueous coating composition having freeze thaw stability, comprising: (a) at least one latex polymer derived from at least one monomer and at least one reactive surfactant of the formulaR1O—(CH2CHR2O)x—(CH2CH2O)y—(CH2CHR3O)z—R4 where R1 is either alkyl, aryl, alkylaryl, or aralkylaryl of 8-30 carbon atoms, R2 is —CH2OCH2CH═CH2 (AGE); R3 is either H, CH3, or CH2CH3; R4 is H or —SO3M or —PO3M where M is H or K, Na, NH4, NR4, alkanolamine, or other cationic species and x=2-100; y=4-200 and z=0-50.

Owner:ETHOX CHEM LLC

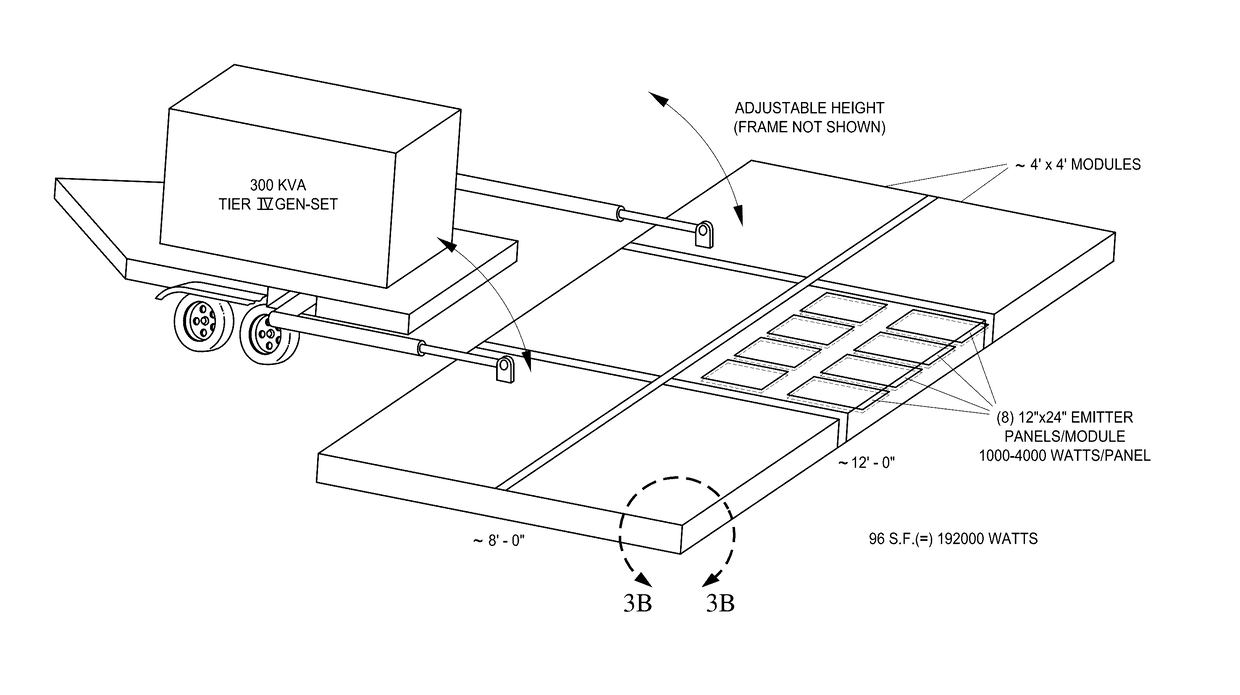

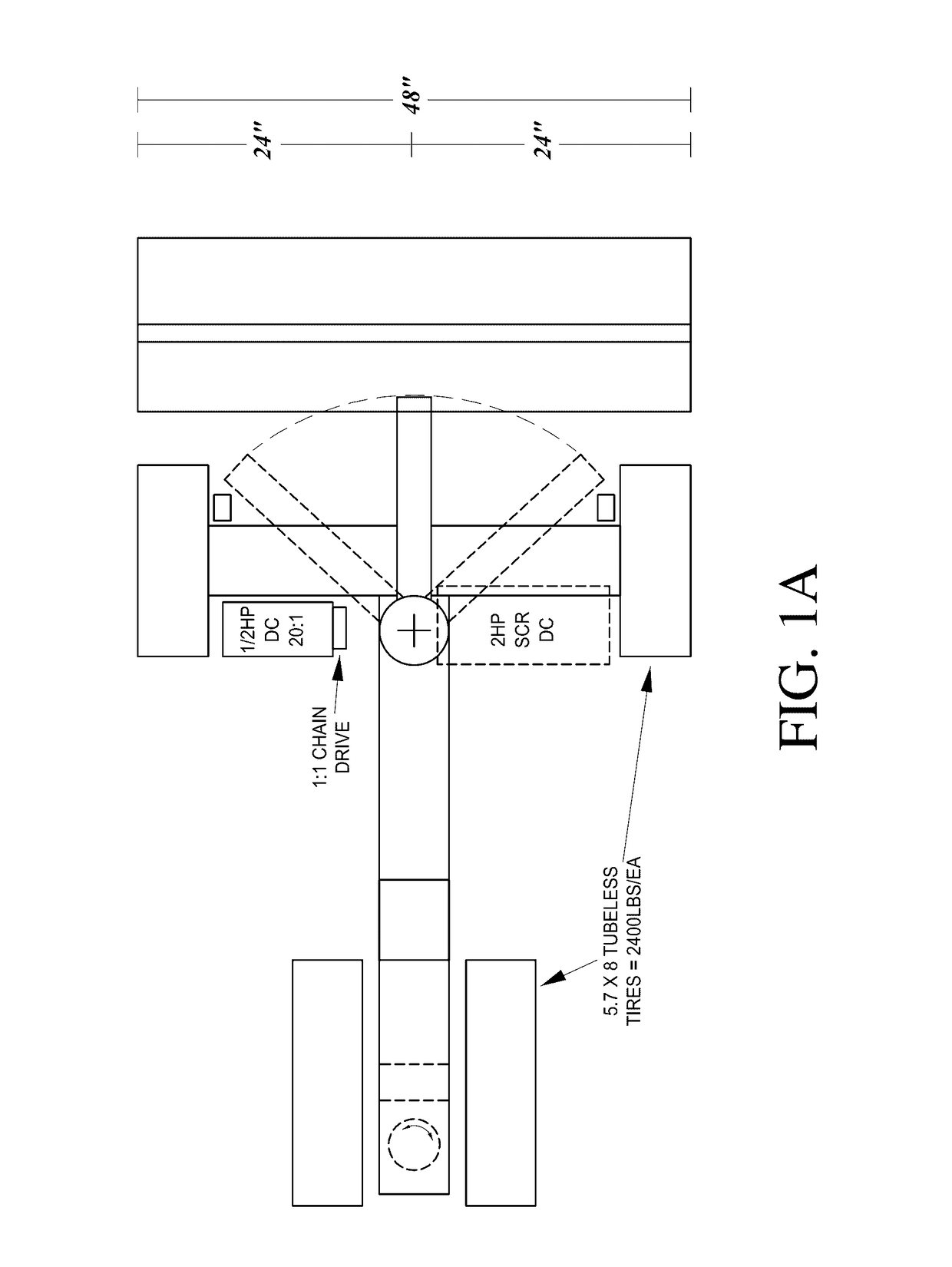

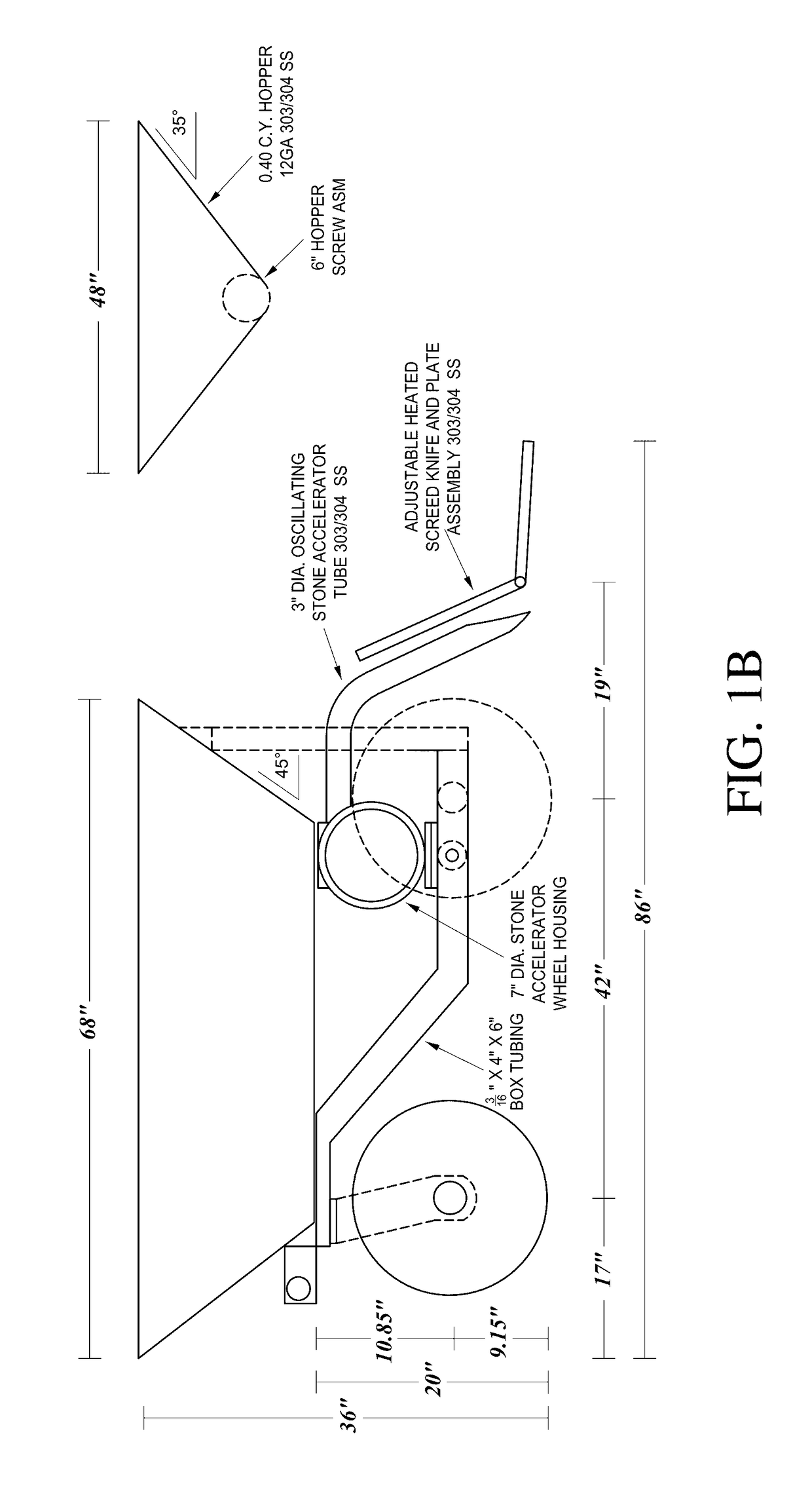

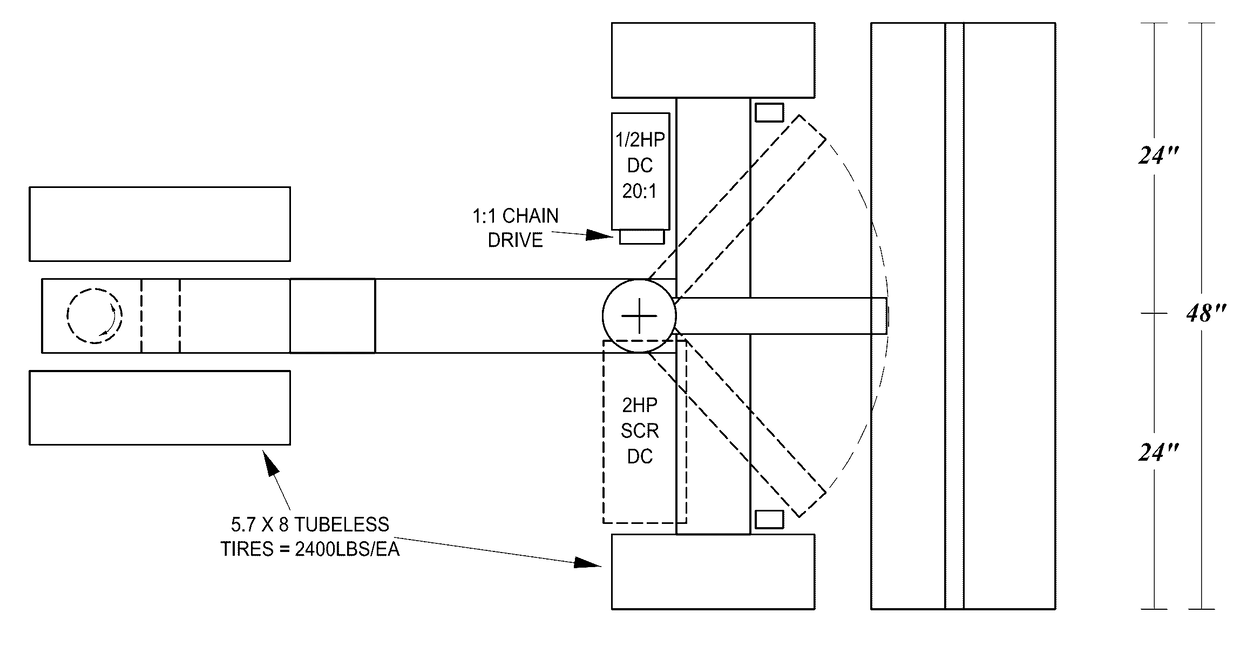

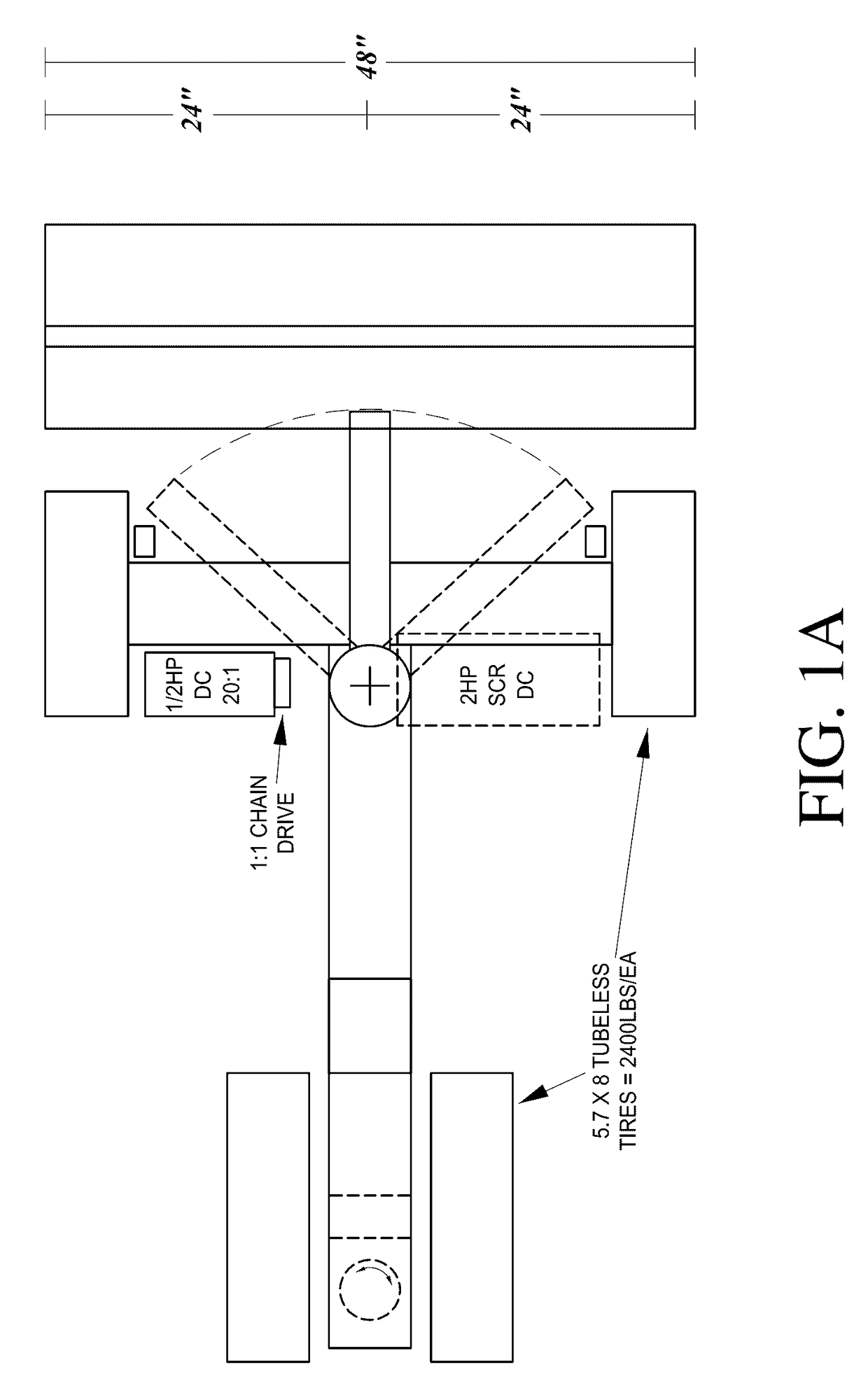

Pavement repair system

ActiveUS9637870B1Paving propertyLong and longer useful lifeProtective foundationPaving detailsRoad surfaceAsphalt pavement

A pavement repair system utilizing solid phase auto regenerative cohesion and homogenization by liquid asphalt oligopolymerization technologies. The system is suitable for use in repairing asphalt pavement, including pavement exhibiting a high degree of deterioration (as manifested in the presence of potholes, cracks, ruts, or the like) as well as pavement that has been subject to previous repair and may comprise a substantial amount of dirt and other debris (e.g., chipped road paint or other damaged or disturbed surfacing materials). A system utilizing homogenization by liquid asphalt oligopolymerization is suitable for rejuvenating or repairing aged asphalt, thereby improving properties of the paving material.

Owner:COE WILLIAM B

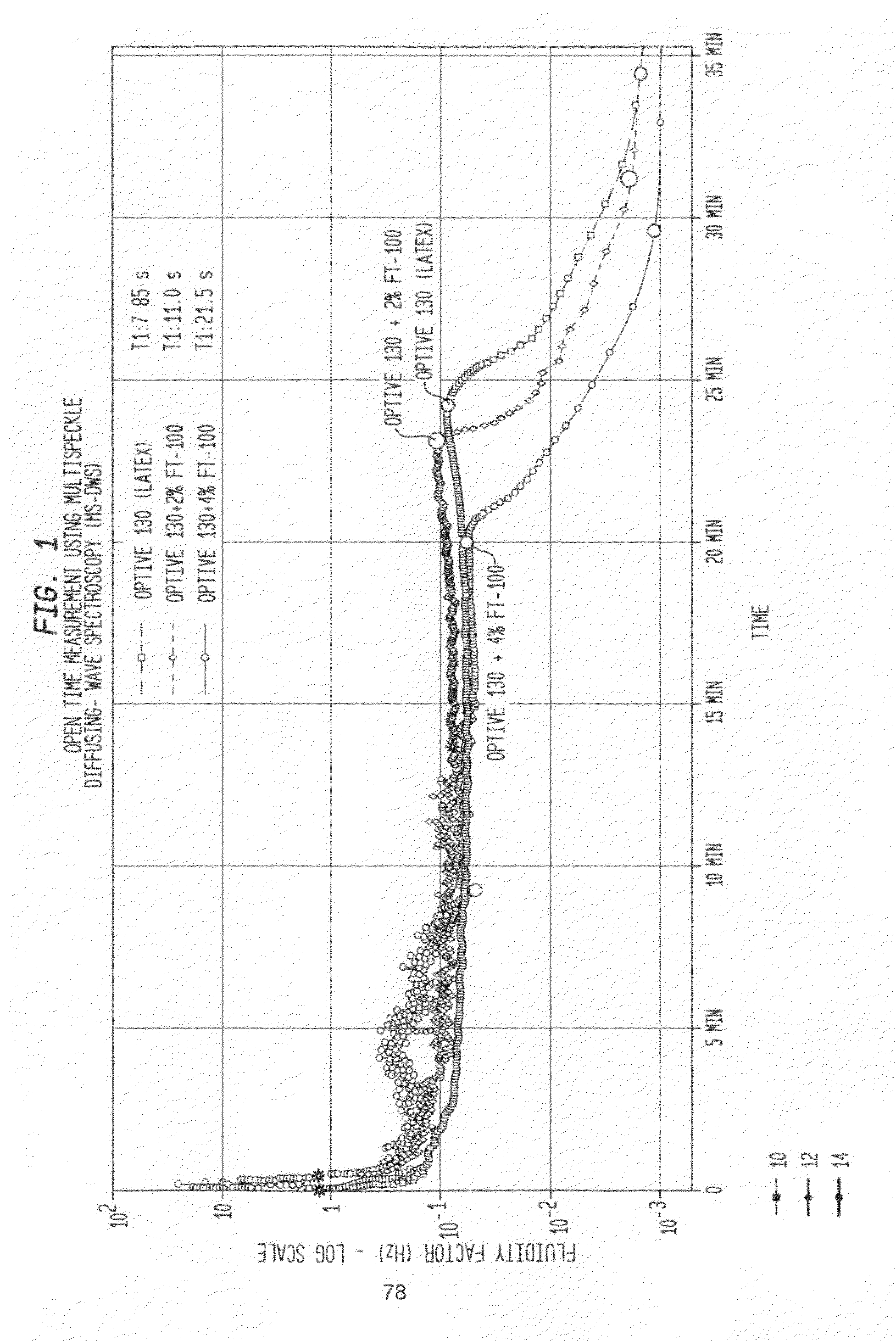

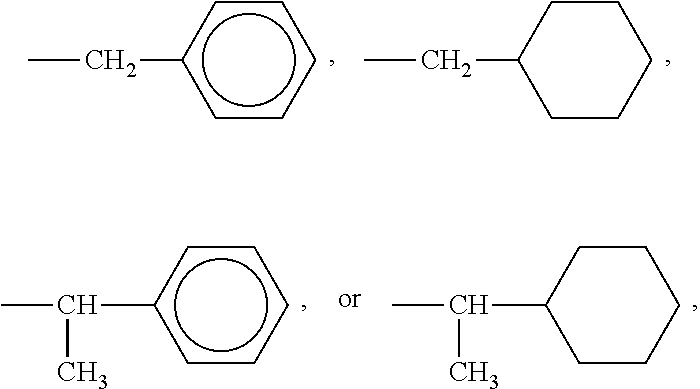

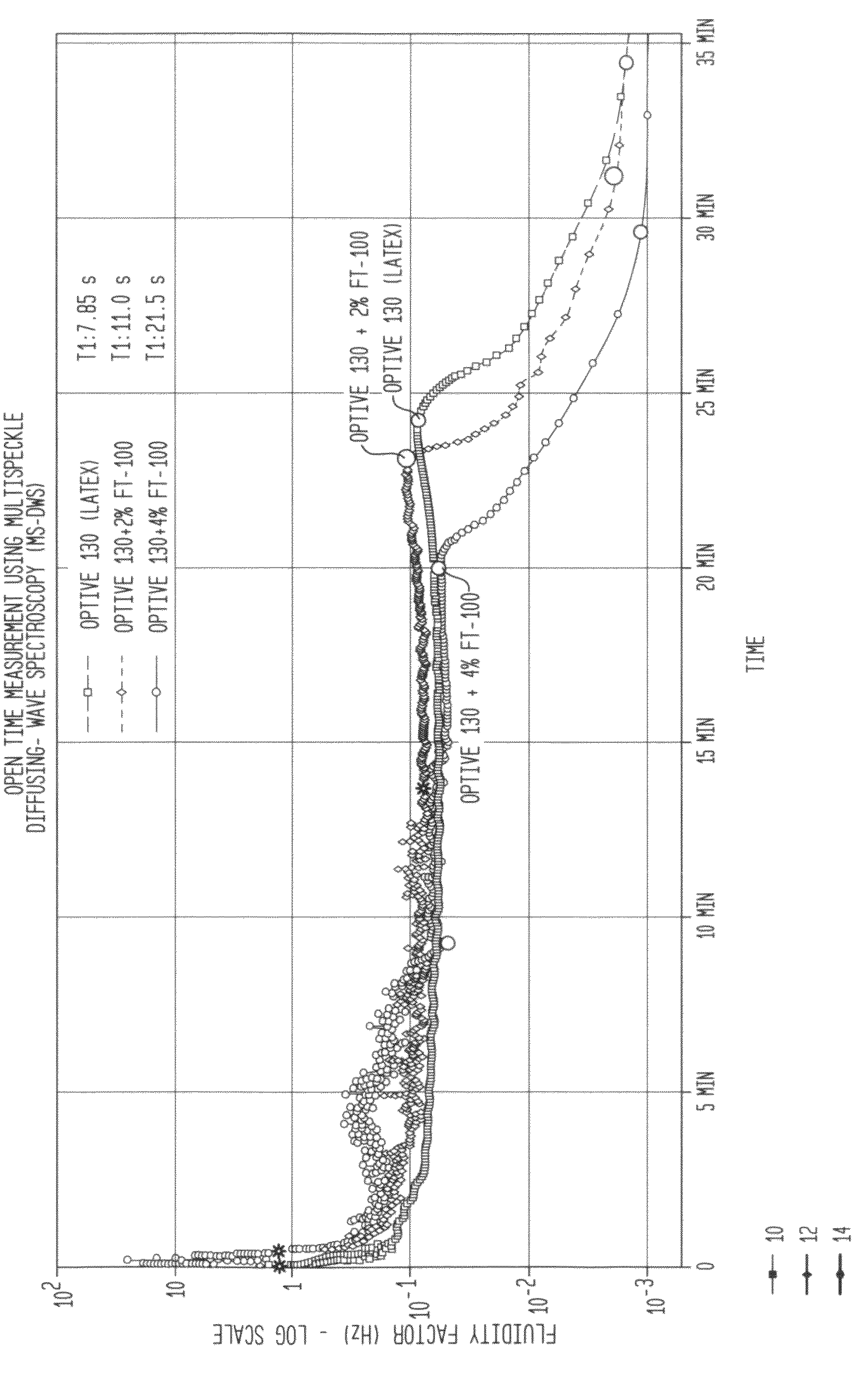

Methods and systems for improving open time and drying time of latex binders and aqueous coatings

ActiveUS20110144248A1Improving open time characteristicExtended opening timeOrganic chemistryOther rubber coatingsTime profileDrying time

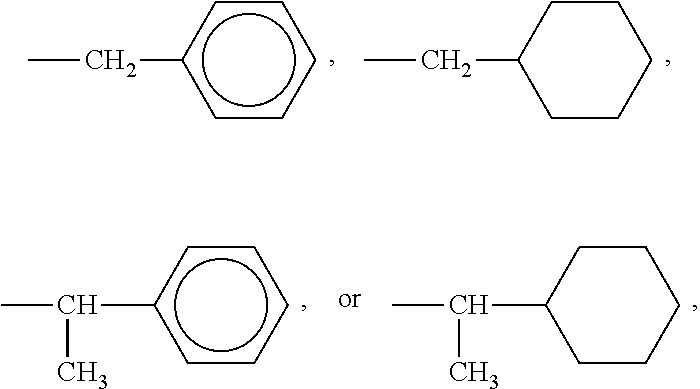

Disclosed are low Tg latex polymers and low VOC aqueous coating compositions having an improved open time profile, as well as drying time, stain resistance, wet edge time, low temperature film formation, block resistance, adhesion, water sensitivity and low-VOC content. The latex polymers and aqueous coating compositions include at least one latex polymer derived from at least one monomer copolymerized or alkoxylated compounds or blended with an alkoxylated compound, for example an alkoxylated tristyrylphenol or an alkoxylated tributylphenol. Also provided is an aqueous coating or adhesive composition including at least one latex polymer, water and one or a blend of two or more open time additives or drying time additives. The blend can comprise nonionic and anionic open time additives. Typically, the open time and / or drying time additive is present in an amount greater than about 1.3% by weight of the polymer or composition, typically in an amount greater than about 2% by weight of the polymer or composition, in an amount greater than about 4% by weight of the polymer or composition, in an amount greater than about 7.5% by weight of the polymer or composition, in an amount greater than about 10% by weight of the polymer or composition or in an amount greater than about 20% by weight of the polymer or composition.

Owner:RHODIA OPERATIONS SAS

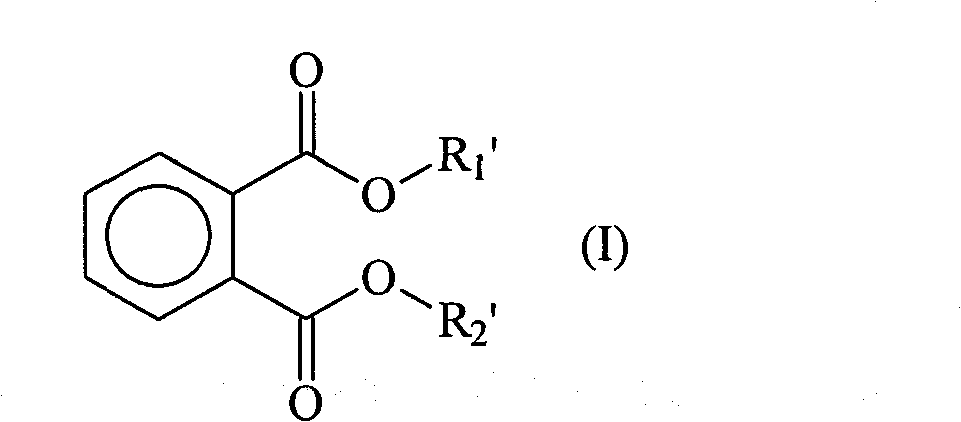

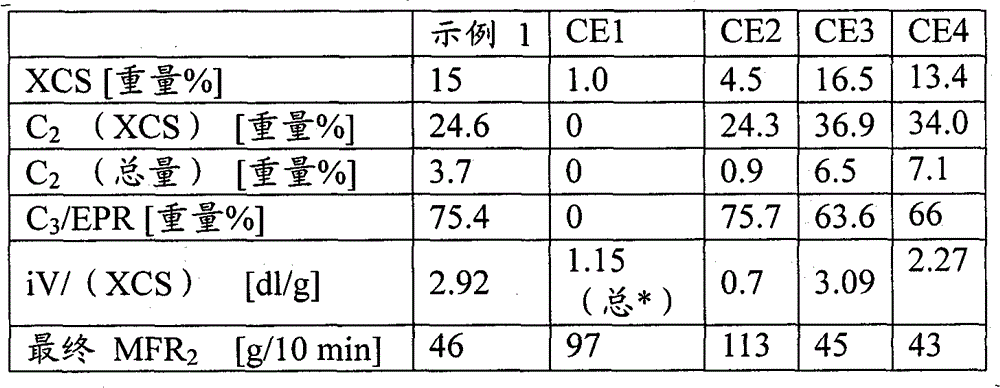

Propylene polymer composition having superior hexane extractables/impact balance

Heterophasic polypropylene copolymers having an MFR (2.16 kg, 230 DEG C) of 15 to 200 g / 10 min, determined according to ISO 1133 comprising a propylene homo- or copolymer matrix with an MFR (2.16 kg, 230 DEG C) of 80 to 500 g / 10 min, determined according to ISO 1133 (A) and an ethylene or C4-C10-alpha-olefin propylene rubber phase (B) dispersed within the matrix, wherein the heterophasic polypropylene resin has a fraction soluble in p-xylene at 25 DEG C (XCS), having an intrinsic viscosity of 2.85 to 4.00 dl / g, determined according to DIN EN ISO 1628-1 and -3 and being composed of propylene monomer units in an amount of 70 wt% to 90 wt%, with optimum balance of impact resistance and low amount of hexane extractables; a process for their preparation and their use.

Owner:BOREALIS AG

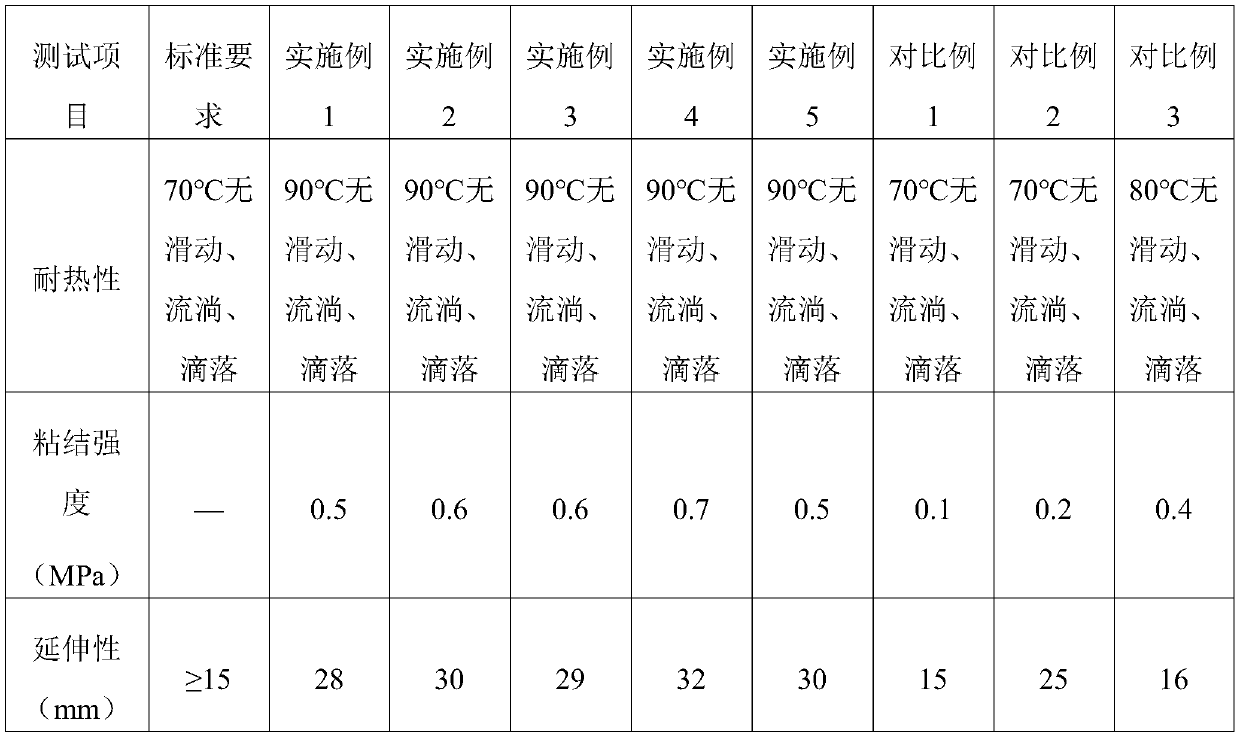

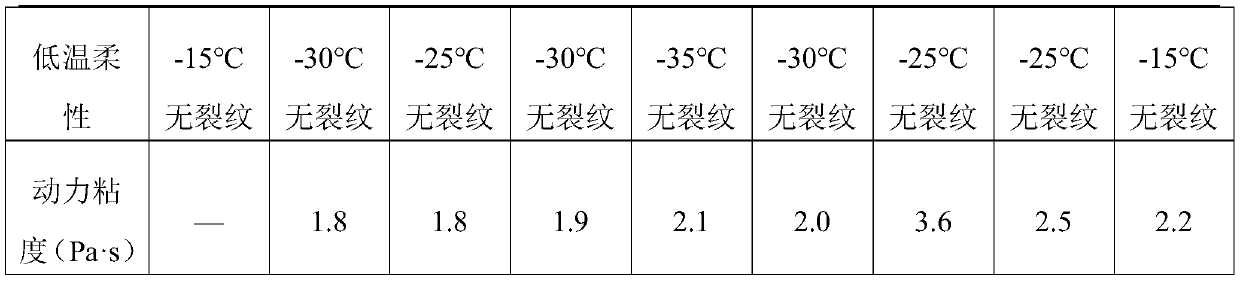

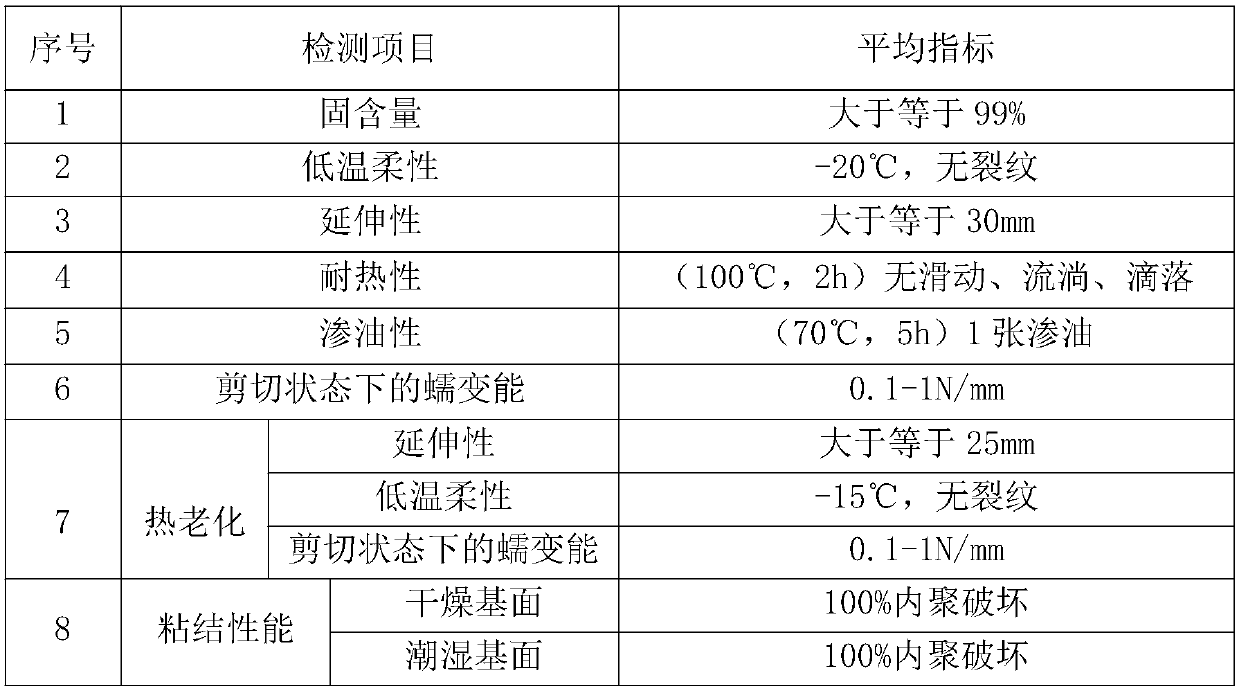

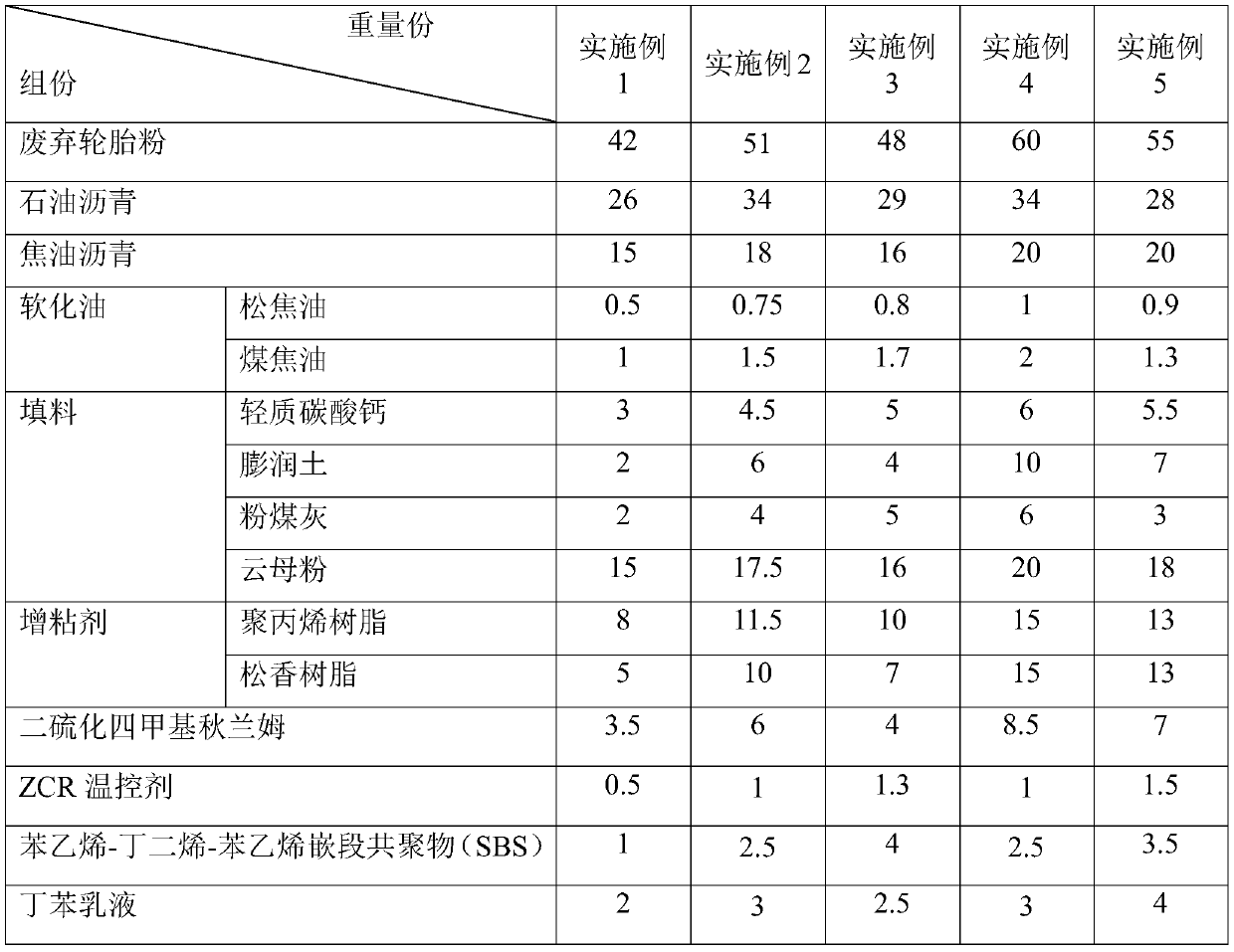

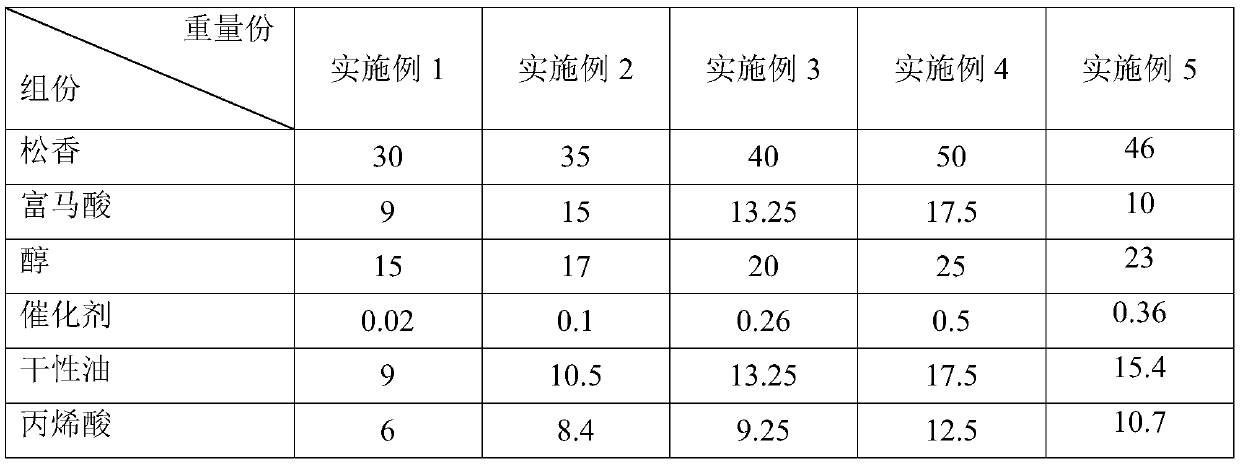

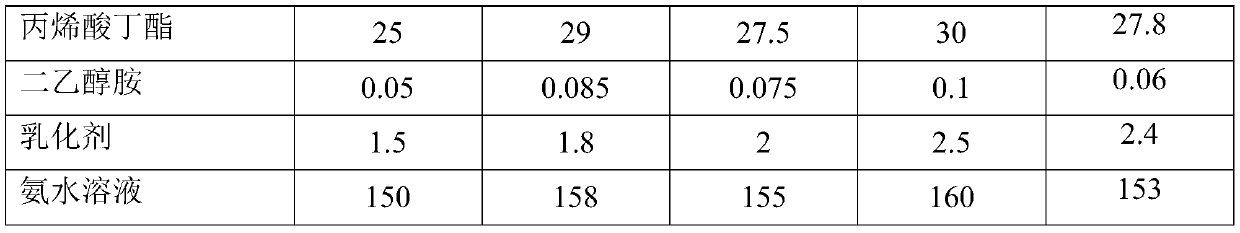

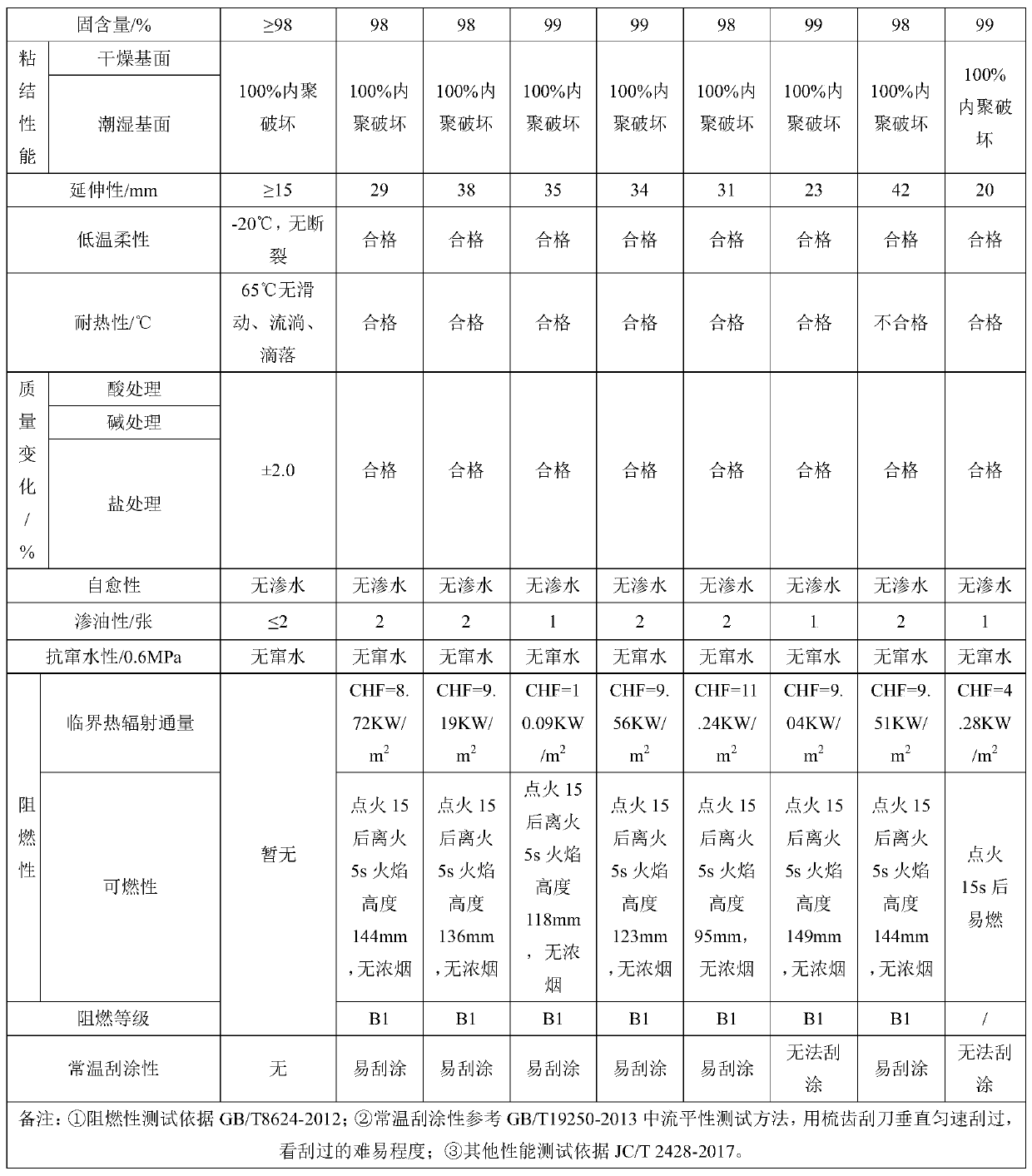

Novel high-temperature-resistant non-curing waterproof coating and preparation method thereof

InactiveCN110016291AImprove high temperature resistanceImprove adhesionFireproof paintsOther rubber coatingsPolymer sciencePolyamide

The invention belongs to the technical field of building materials, and provides a novel high-temperature-resistant non-curing waterproof coating. The coating is composed of the following components in percentage by weight: 25-35% of asphalt, 15-30% of rubber oil, 10-20% of waste tire rubber powder, 5-10% of styrene-butadiene rubber, 1-3% of styrene-butadiene-styrene (SBS), 4-10% of tackifying resin, 10-20% of fly ash, 2-5% of a high-temperature modifier and 2-5% of a viscosity reducer, wherein the high-temperature modifier is a BL modifier or polyamide wax. The preparation method is carried out by adopting a three-section-type feeding method and comprises the following steps: adding asphalt and rubber oil, carrying out heating to 150 DEG C, then adding the SBS, the styrene-butadiene rubber, the tackifying resin and the viscosity reducer, carrying out heating to 180 DEG C, then adding the fly ash and a high-temperature modifier, mixing the components at 180 DEG C to form a uniform liquid, and carrying out cooling and discharging to obtain the novel high-temperature-resistant non-curing waterproof coating. The invention solves the problem that a non-curing rubber asphalt waterproofcoating is poor in heat resistance.

Owner:河南驼峰防水科技有限公司

Epoxy non-cured rubber asphalt waterproof coating and preparation method thereof

InactiveCN107739575ASolve the problem of heating to constructionEnsure safetyFireproof paintsOther rubber coatingsSelf-healingEpoxy

The invention discloses an epoxy non-cured rubber asphalt waterproof coating and a preparation method thereof and belongs to the field of coatings. The coating comprises a component A and a componentB, wherein the component A is prepared from asphalt, plasticizers, polymer modifiers and epoxy resin; the component B is prepared from epoxy curing agents. The problem that the non-cured rubber asphalt waterproof coating can be constructed after the coating is heated can be solved; the coating is energy-saving and environmentally friendly; the safety of constructors is ensured; the construction operation is simplified; the application range of the product is expanded; the coating is excellent in construction performance, does not need to be heated in the whole construction process, is excellent in high-temperature performance, can achieve obstacle-free construction under high temperature and low temperature, and is high in flexibility, high in elongation rate, excellent in creep property,high in self-healing capability, high in water channeling resistance and high in adhesion performance.

Owner:SICHUAN SHUYANG WATERPROOF MATERIAL

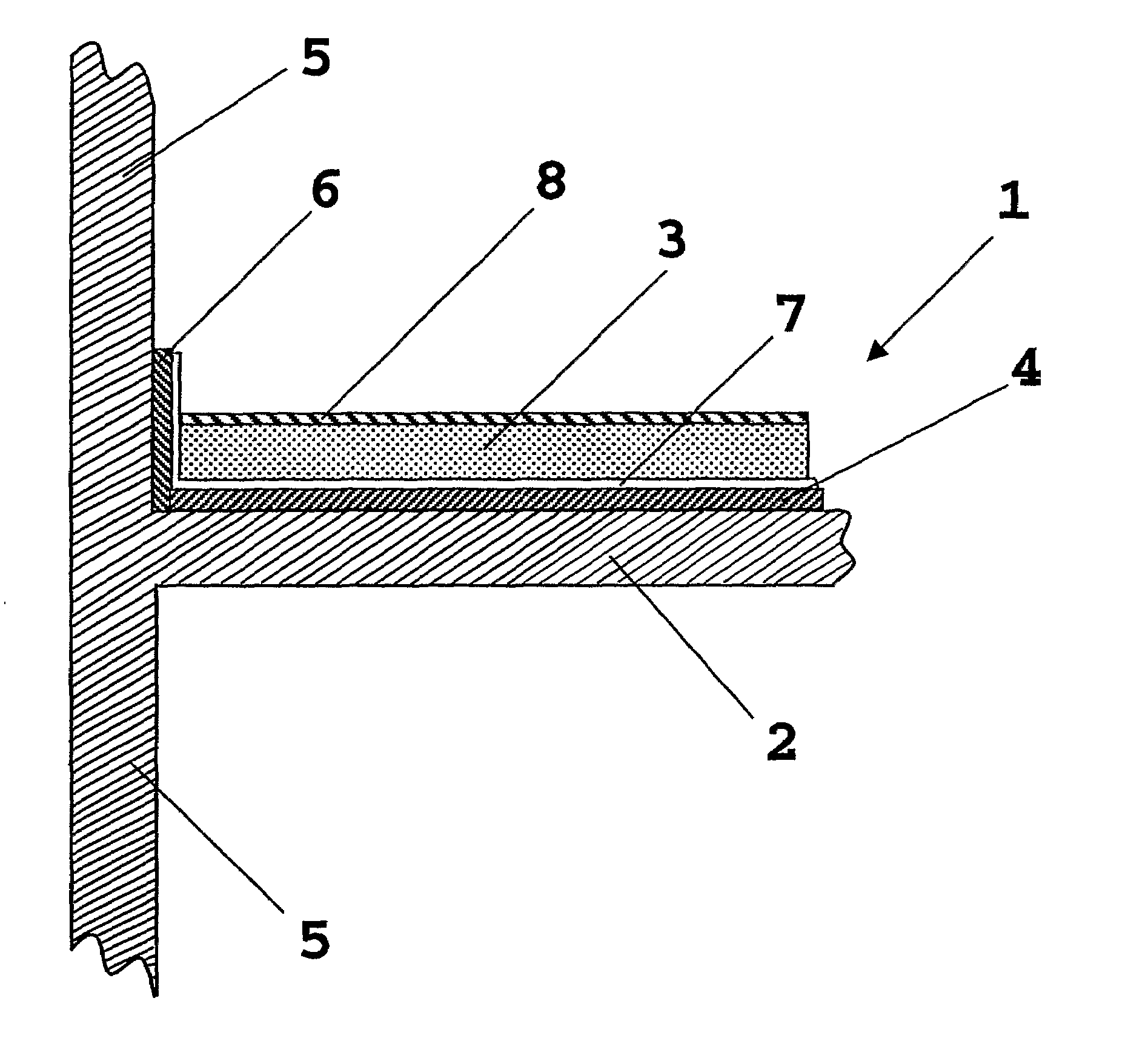

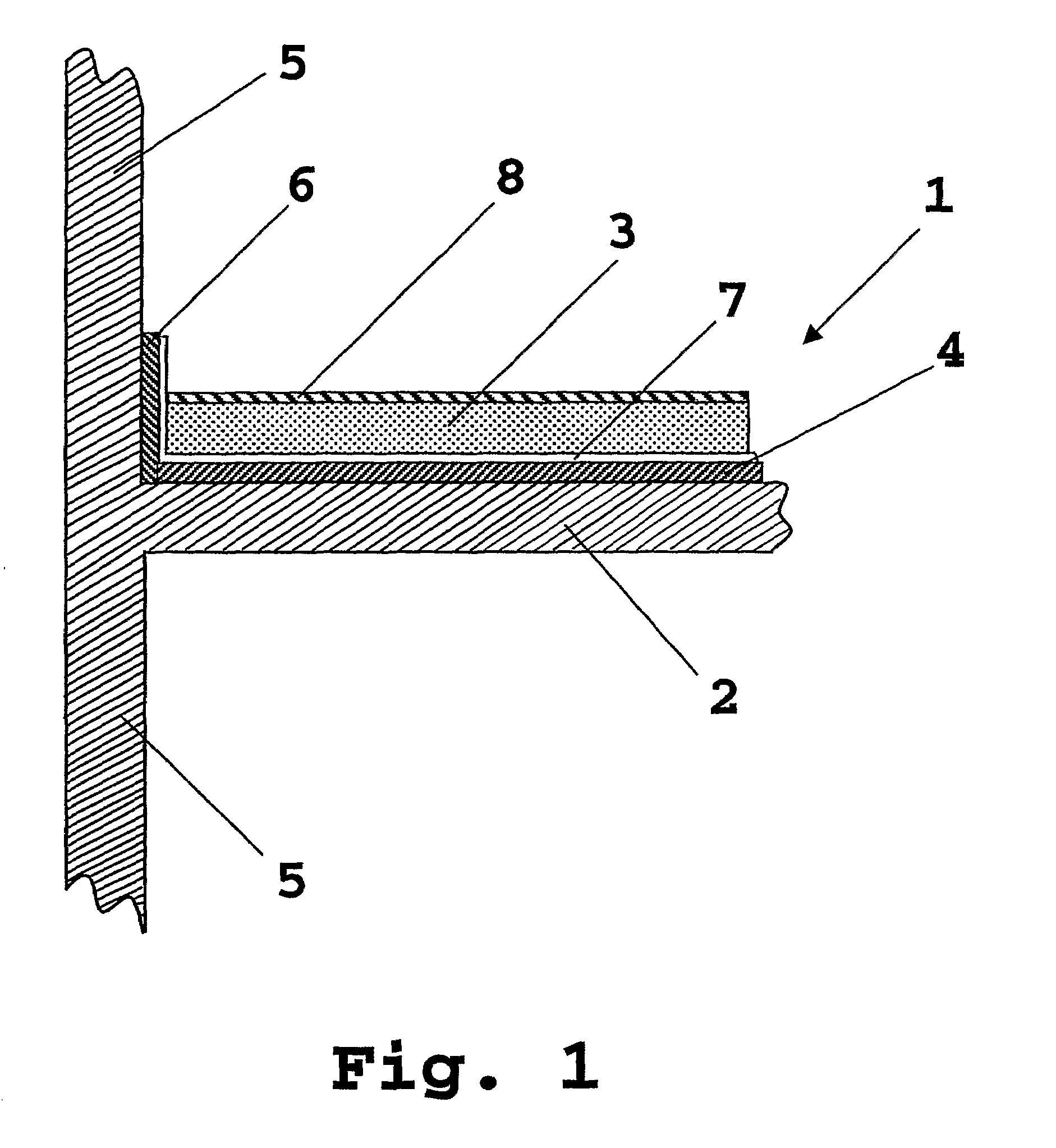

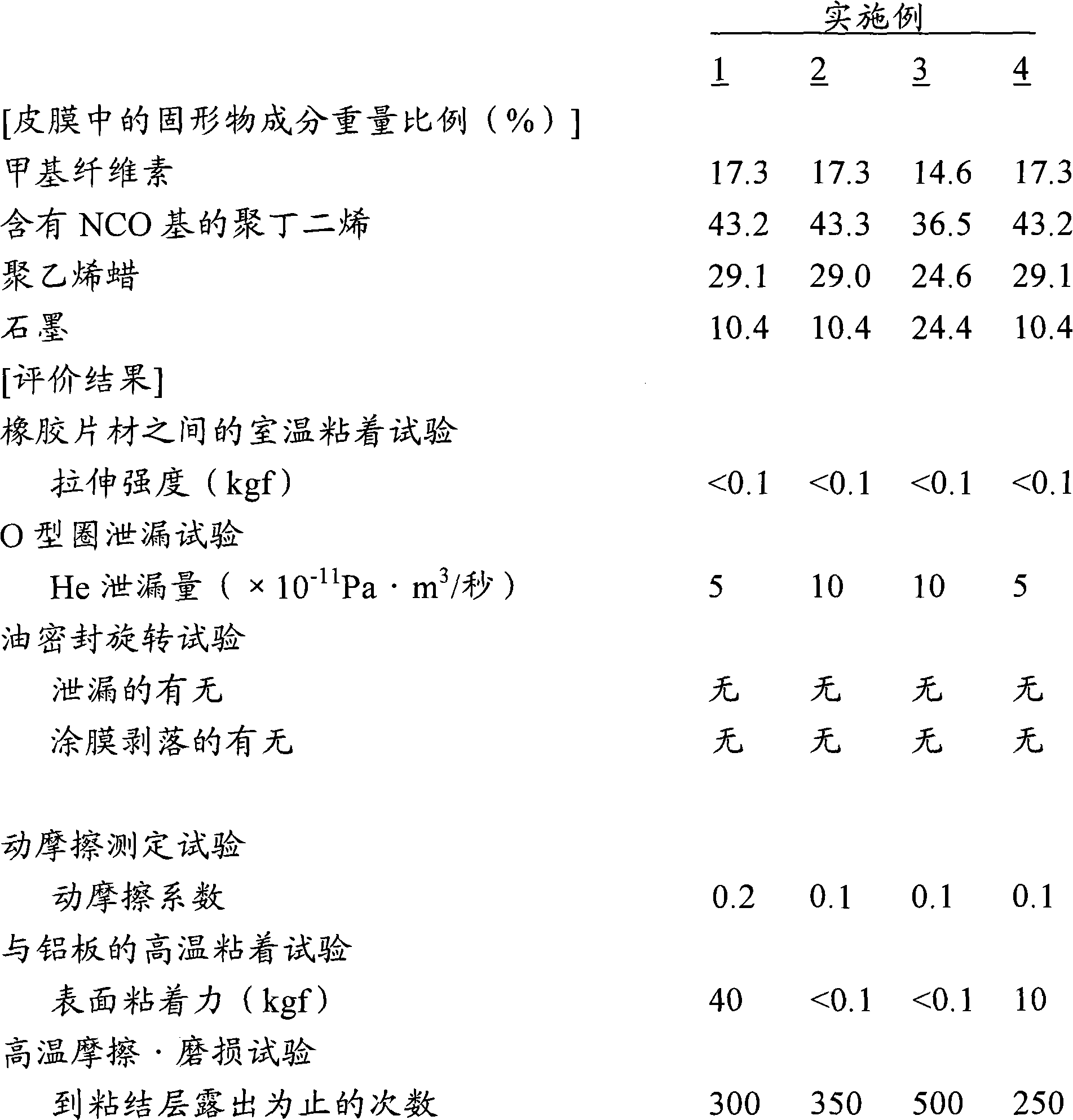

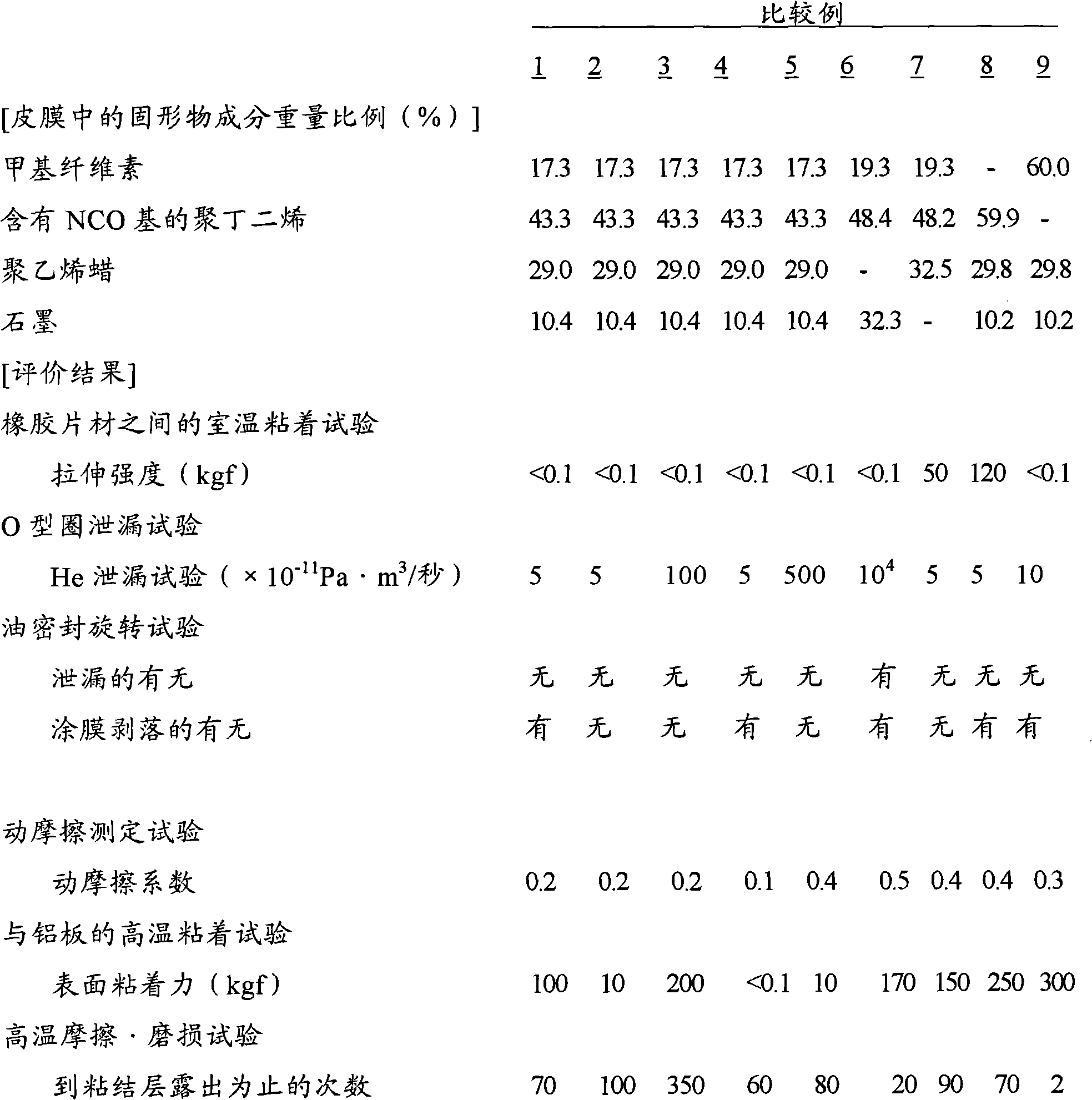

Coating agent

A coating agent, which comprises a cellulose derivative, an isocyanate group-containing 1,2-polybutadiene, a synthetic wax having a softening point of 100°-150° C., a fatty acid amide having a softening point of 60°-170° C., and graphite, can satisfy desired performances, when applied to rubbery elastomers, etc. such as prevention of sticking, adhesion and blocking, and improvement of abrasion resistance, and also can serve as a surface-treating agent for vulcanized rubber without peeling of coating films due to adhesion under high-temperature compression or friction-abrasion under high specific pressure.

Owner:NOK CORP

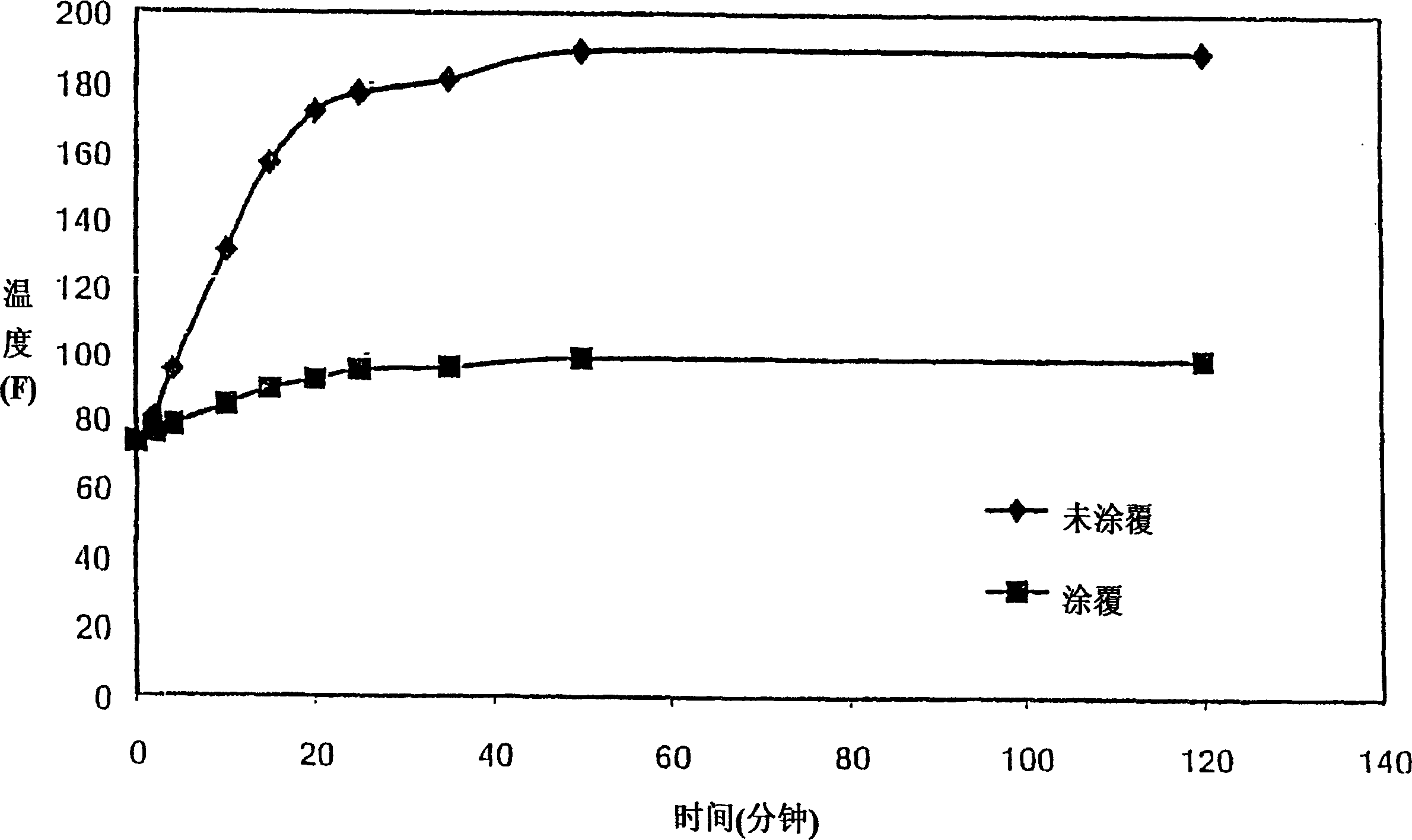

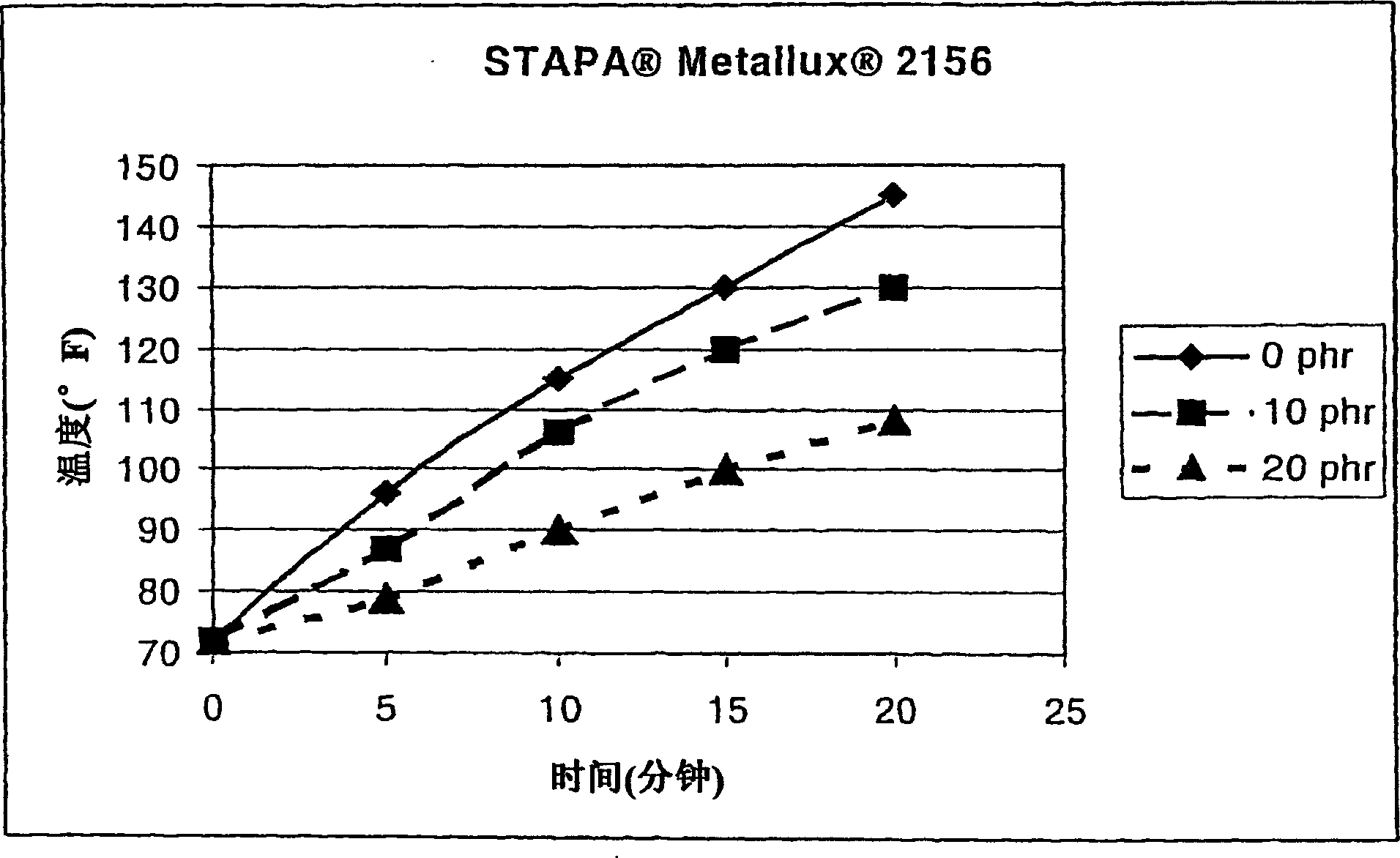

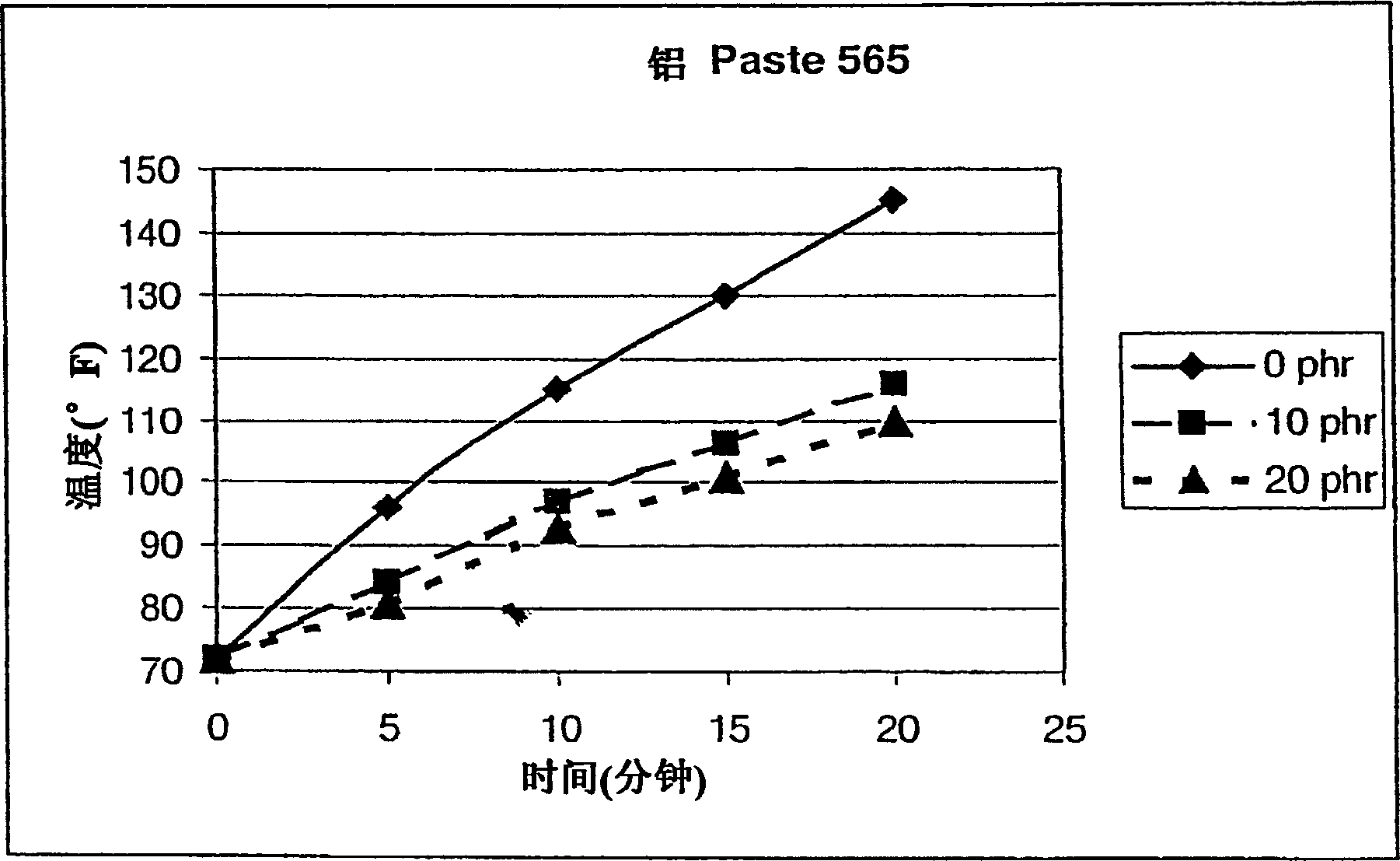

Flexible coatings for elastomer substrates

The present invention discloses a radiation coating for flexible substrates, preferably for elastomers or elastomers bonded to metals. The coating composition is formed by mixing component (a) and component (b), wherein component (a) includes an organic solution or aqueous dispersion of a polymer or copolymer containing a functional group, and a thermally conductive filler; Part (b) includes liquid curing components such as polyisocyanates, carbodiimides or amino resins. The coating compound can be applied to the substrate before or after the substrate is vulcanized. The coating cures at ambient temperatures and dissipates heat during long-term use at elevated temperatures.

Owner:LORD CORP

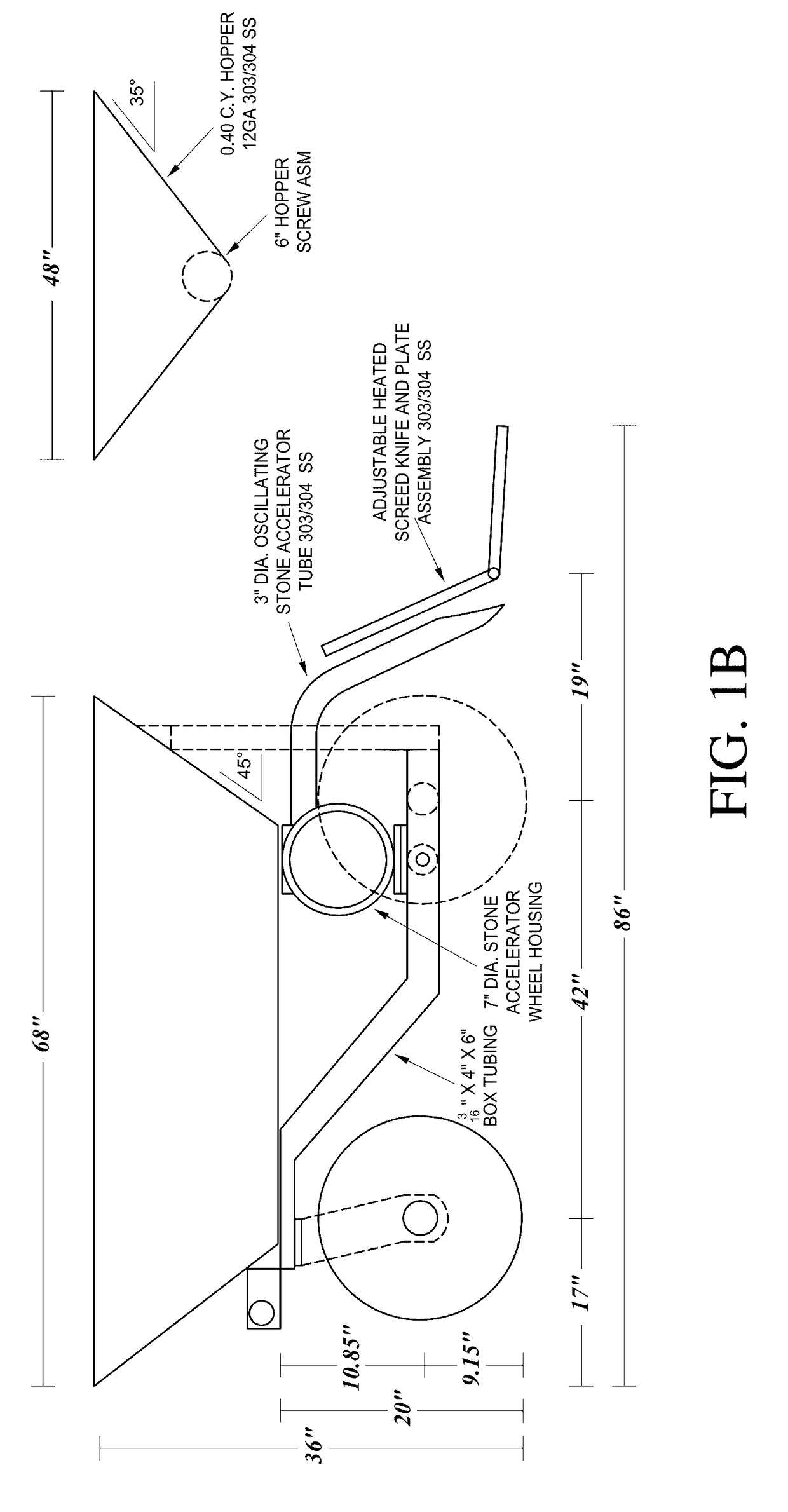

Method for making a sound-insulating load-bearing floor

InactiveUS7861477B2Speed up dryingLow dynamic stiffnessOther rubber coatingsBuilding repairsPolymer scienceWater dispersible

A method for making a sound-insulating load-bearing floor, includes the following steps: providing a load-bearing floor; applying a sound-insulating material onto the load-bearing floor so as to form a substantially continuous coating layer; allowing the substantially continuous coating layer to dry; wherein the sound-insulating material includes: 40% by weight to 95% by weight, preferably 60% by weight to 90% by weight, with respect to the total weight of the sound-insulating material, of at least one rubber in a subdivided form; 5% by weight to 60% by weight, preferably 10% by weight to 40% by weight, with respect to the total weight of the sound-insulating material, of at least one binding agent including at least one water-dispersible polymer having a glass transition temperature (Tg) of −50° C. to +50° C., preferably of −40° C. to +10° C.

Owner:PIRELLI & C

Coating agent

Disclosed is a coating agent comprising a cellulose derivative, a 1,2-polybutadiene having an isocyanate group, a synthetic wax having a softening point of 100 to 150 DEG C, an aliphatic amide having a softening point of 60 to 170 DEG C and graphite. The coating agent has satisfactory levels of properties required for a coating agent for a rubbery elastic material, such as a sticking-preventing property, an adhesion-preventing property, a blocking-preventing property, and improved abrasion resistance. The coating agent can be used as a surface treatment agent for a vulcanized rubber, which does not cause adhesion upon compression at a high temperature or detachment of a coating film by friction / abrasion under a high surface pressure.

Owner:NOK CORP

Coating composition

An aqueous coating composition comprising a mixture of recycled rubber particles, and particles at least one of glass or plastic particles, graphite particles and fluorinated resin particles such as polytetrafluoroethytlene and a suspension agent or resin. Various embodiments are useful for coating suitable for highways and parking lots, roofs or swimming pools and metal surfaces and for “rubberizing” marine and other manufactured products.

Owner:SAVIN RONALD R

Soft-feel, chemical-resistant polyurethane coating compositions

Two-component waterborne coating compositions that form crosslinked polyurethane films exhibiting soft feel effect and high chemical resistance are disclosed. The two-component waterborne coating compositions include rubber particles and reaction products of hydroxy-functional polyacrylic polyol dispersions and water-dispersible polyisocyanates.

Owner:COVESTRO LLC

Smoke suppression low-odor modified asphalt coiled material coating material, preparation method thereof and modified asphalt coiled material

ActiveCN109705734AReduce generationEmission reductionOther rubber coatingsBituminous coatingsMetal-organic frameworkBULK ACTIVE INGREDIENT

The invention discloses a smoke suppression low-odor modified asphalt coiled material coating material, a preparation method thereof and a modified asphalt coiled material. The coating material comprises matrix asphalt, a softening agent, a free radical scavenger, a metal organic framework compound, an inorganic adsorption material, a reaction type odor inhibitor, a high polymer modifier, tackifying resin, rubber powder and a filler. According to the invention, the free radical scavenger is added, so that a small molecule volatile gas generated by free radical reaction is reduced; the metal organic framework compound can be used for efficiently selectively adsorbing polycyclic aromatic hydrocarbon sulfur-containing thiophene substances and reducing the emission of the polycyclic aromatic hydrocarbon sulfur-containing thiophene substances; the inorganic adsorption material is used for reinforcing the interaction between volatile organic matters and the asphalt matrix, so that the overall emission is reduced; the reaction type odor inhibitor reacts with mercaptan in the asphalt, and the emission of the mercaptan as one of peculiar smell sources and hydrogen sulfide is reduced. The test result shows that smoke-inhibiting and odor-removing active ingredients are added, the flue gas volatilization amount of the modified asphalt coating material is reduced by more than 80% at 180 DEGC, and pollutant emission and peculiar smell source emission are remarkably reduced.

Owner:苏州东方雨虹建筑材料有限公司

Non-cured rubber asphalt paint and self-adhesion coiled material composite construction method

InactiveCN110409513AImprove flatnessTight bondOther rubber coatingsUnderground chambersComposite constructionBond properties

The invention relates to the field of waterproof engineering construction methods, in particular to a non-cured rubber asphalt paint and self-adhesion coiled material composite construction method. The non-cured rubber asphalt paint and self-adhesion coiled material composite construction method comprises the following steps of S1, waterproof paint treatment; S2, base layer treatment; S3, joint reinforcing treatment; S4, self-adhesion coiled material pre-trial paving; S5, first bonding layer construction; S6, self-adhesion coiled material paving and lap joint; and S7, close-up seal. The methodhas the beneficial effects that a composite waterproof layer made through the construction method has the good anti-aging property, and even if the composite waterproof layer is used for a long time,the composite waterproof layer can still keep good structural strength and bonding property.

Owner:东莞市卓宝建筑工程有限公司

Pavement repair system

ActiveUS20170145640A1Long and longer useful lifePaving propertyProtective foundationPaving detailsRoad surfaceSolid phases

A pavement repair system is provided utilizing solid phase auto regenerative cohesion and homogenization by liquid asphalt oligopolymerization technologies. The system is suitable for use in repairing asphalt pavement, including pavement exhibiting a high degree of deterioration (as manifested in the presence of potholes, cracks, ruts, or the like) as well as pavement that has been subject to previous repair and may comprise a substantial amount of dirt and other debris (e.g., chipped road paint or other damaged or disturbed surfacing materials). A system utilizing homogenization by liquid asphalt oligopolymerization is suitable for rejuvenating or repairing aged asphalt, thereby improving properties of the paving material.

Owner:COE WILLIAM B

Liquid sound insulation coating

ActiveCN111621204AImprove stabilityFacilitated releaseOther rubber coatingsBituminous coatingsPolymer scienceBitumen emulsion

The invention discloses a liquid sound insulation coating. The liquid sound insulation coating comprises the following components in percentage by weight: 10-20% of an acrylic emulsion, 10-20% of emulsified asphalt, 30-50% of rubber powder with 20 meshes, 5-15% of polystyrene particles, 0.1-0.5% of a thickening agent, 0.1-0.3% of a cross-linking agent and 2-20% of water, wherein the acrylic emulsion is an emulsion with the solid content of 50%, the Tg is -20 degrees, good water resistance and good cement compatibility are achieved; wherein the emulsified asphalt is emulsified asphalt adoptinganions and non-ions as emulsifiers, and forms matching compatibility with the acrylic emulsion. The material components are easy to obtain, the cost is low, the construction is convenient, the flexible sound insulation pad with a plurality of tiny cavities can be formed, the impact force can be effectively reduced, and the sound insulation durability is good.

Owner:西卡(上海)管理有限公司

Coating compositions and methods, and articles coated with same

ActiveUS9884976B1Reduce generationReduce releaseOther rubber coatingsSynthetic resin layered productsPolybutadienePolymer

Described are sealing primer compositions that can be used to reduce paint defects such as pops or vapor boil on painted plastic substrates, as well as related methods for sealing plastic substrates, and sealed plastic substrates. Sealing primer compositions of the invention include a functionalized polydiene polymer such as a hydroxylated or other functional-group-containing polybutadiene polymer.

Owner:RED SPOT PAINT & VARNISH

Non-chrome passivation of steel

Chromate free treatments and compositions for applying a conversion or passivation coating to metal surfaces. Preferred compositions comprise a film forming latex polymer, fluoacid, phosphoric acid, and a polyoxyethylene / oxypropylene block copolymer. The requisite metal surfaces are contacted by the compositions and dried. Rinsing is optional.

Owner:CHEMETALL CORP

Methods and systems for improving open time and drying time of latex binders and aqueous coatings

ActiveUS8304479B2Extended opening timeIncrease the separation distanceOrganic chemistryOther rubber coatingsTime profileDrying time

Disclosed are low Tg latex polymers and low VOC aqueous coating compositions having an improved open time profile, as well as drying time, stain resistance, wet edge time, low temperature film formation, block resistance, adhesion, water sensitivity and low-VOC content. The latex polymers and aqueous coating compositions include at least one latex polymer derived from at least one monomer copolymerized or alkoxylated compounds or blended with an alkoxylated compound, for example an alkoxylated tristyrylphenol or an alkoxylated tributylphenol. Also provided is an aqueous coating or adhesive composition including at least one latex polymer, water and one or a blend of two or more open time additives or drying time additives. The blend can comprise nonionic and anionic open time additives. Typically, the open time and / or drying time additive is present in an amount greater than about 1.3% by weight of the polymer or composition, typically in an amount greater than about 2% by weight of the polymer or composition, in an amount greater than about 4% by weight of the polymer or composition, in an amount greater than about 7.5% by weight of the polymer or composition, in an amount greater than about 10% by weight of the polymer or composition or in an amount greater than about 20% by weight of the polymer or composition.

Owner:SPECIALTY OPERATIONS FRANCE

Coating type radiation-shielding material and radiation-shielding elastomer material

ActiveUS20160284430A1High radiation shielding rateReduce wasteOther rubber coatingsShieldingElastomerHigh concentration

An object of the invention is to provide a radiation-shielding material that has a high radiation-shielding capability and can be easily coated, molded and sheeted. Metals or the like having a radiation-shielding capability are blended with an elastomer precursor in a high concentration thereby providing a radiation-shielding material that has a higher radiation-shielding capability than ever before and can be easily coated, molded and sheeted in any desired configuration.

Owner:D&D CORP +1

Coating agent

A coating agent, which comprises a cellulose derivative, an isocyanate group-containing 1,2-polybutadiene, a synthetic wax having a softening point of 100°-150° C., a fatty acid amide having a softening point of 60°-170° C., and graphite, can satisfy desired performances, when applied to rubbery elastomers, etc. such as prevention of sticking, adhesion and blocking, and improvement of abrasion resistance, and also can serve as a surface-treating agent for vulcanized rubber without peeling of coating films due to adhesion under high-temperature compression or friction-abrasion under high specific pressure.

Owner:NOK CORP

Flame-retardant smoke-suppression non-cured rubber asphalt waterproof coating capable of being constructed at normal temperature

ActiveCN111117487AGood dispersionOptimizing the blending processFireproof paintsOther rubber coatingsRubberized asphaltPolymer chemistry

The invention provides a flame-retardant smoke-suppression non-cured rubber asphalt waterproof coating capable of being constructed at normal temperature. The flame-retardant smoke-suppression non-cured rubber asphalt waterproof coating is prepared from asphalt, softening oil, an activator, waste rubber powder, a modifier, a liquid flame retardant and a synergist. A preparation process of the waterproof coating comprises the following steps: uniformly mixing and stirring the mixed asphalt and the softening oil, heating to dehydrate, adding the activator, fully stirring to develop, adding the waste rubber powder, continuously adding the modifier to dissolve after complete development, adding the liquid flame retardant and the viscosity-reducing and flame-retarding synergist, cooling, and discharging. A sol method is adopted, the liquid flame retardant is used as a liquid filler to reduce viscosity and soften the rubber modifier, and the liquid flame retardant is also used as a main flame retardant to achieve a flame retardant effect. Asphalt is modified in multiple steps, and S-S bonds / S-C bonds of net-shaped macromolecular chain segments in the waste rubber powder are subjected tooxidative fracture through the desulfurization effect of the activator, so a large number of small molecular chain segments are produced and evenly dispersed in the asphalt in a suspended mode, and astable semi-solid continuous phase system is formed through a gel film. The process can reduce the shearing rate and energy consumption in the production process, so that normal-temperature construction and flame retardance and smoke suppression are realized, the construction energy consumption and environmental pollution are effectively reduced, macromolecular wastes such as waste rubber powder and the like are fully recycled, and the construction of the resource environment-friendly society is facilitated.

Owner:山东雨中情防水材料有限公司

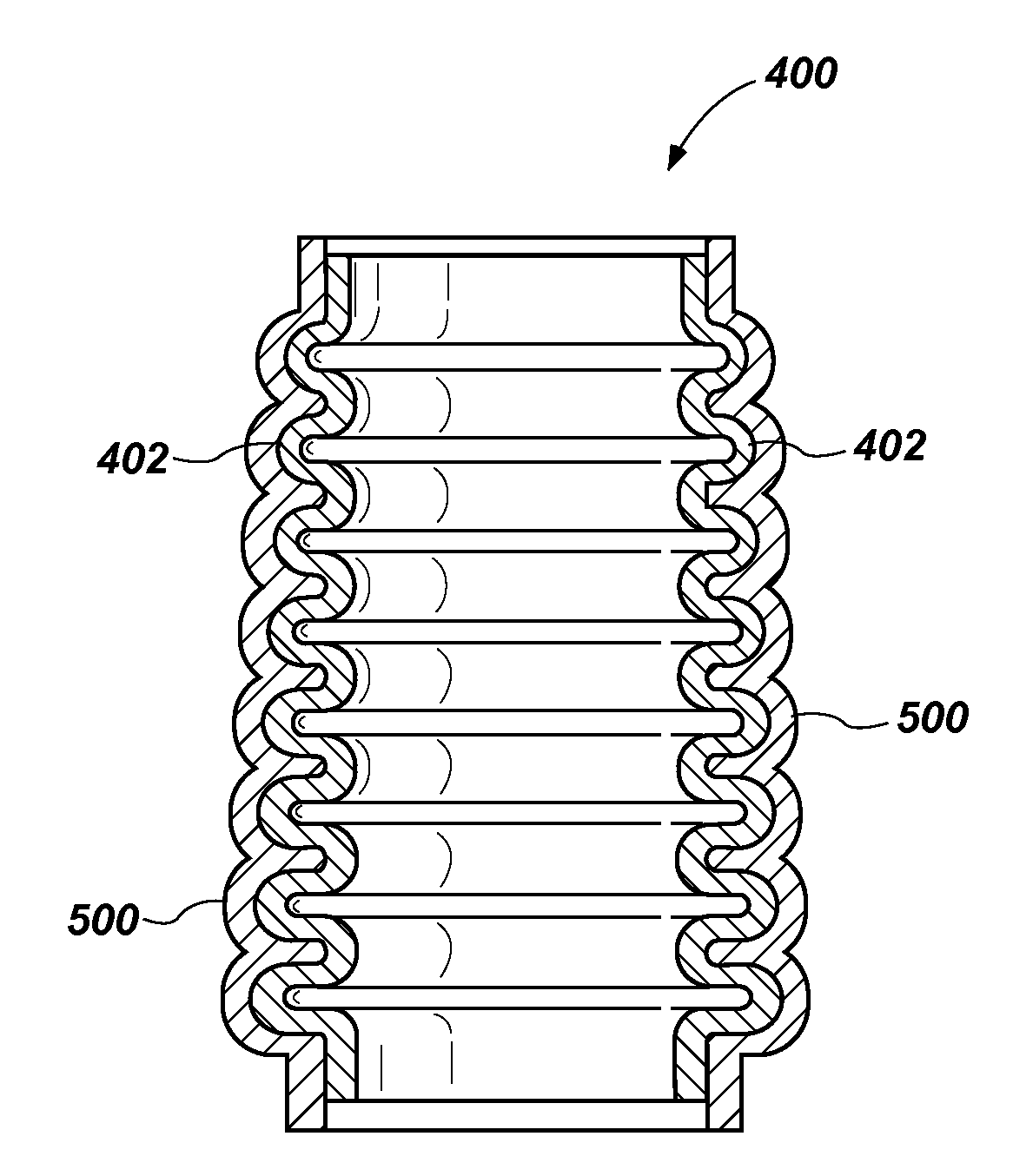

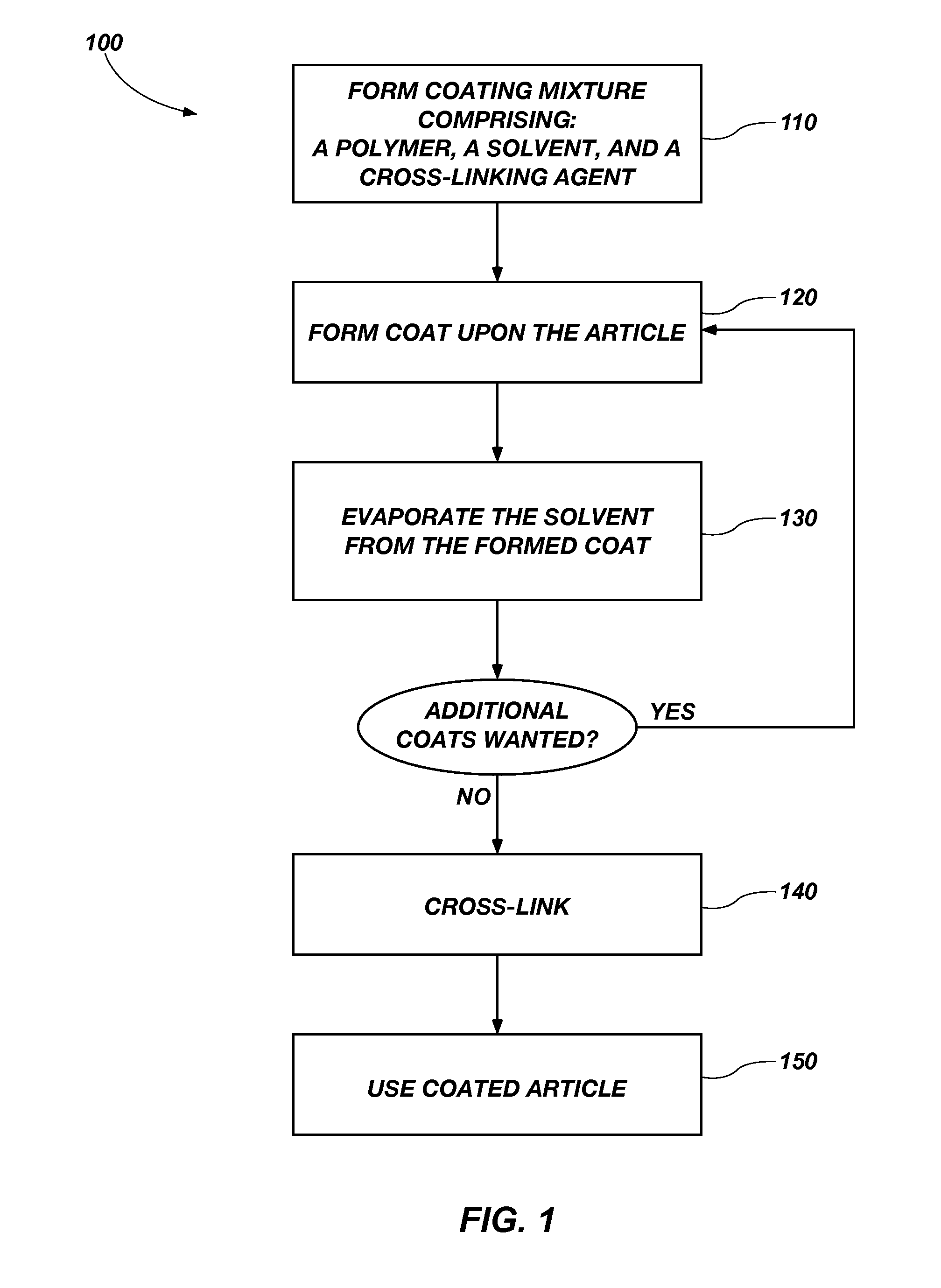

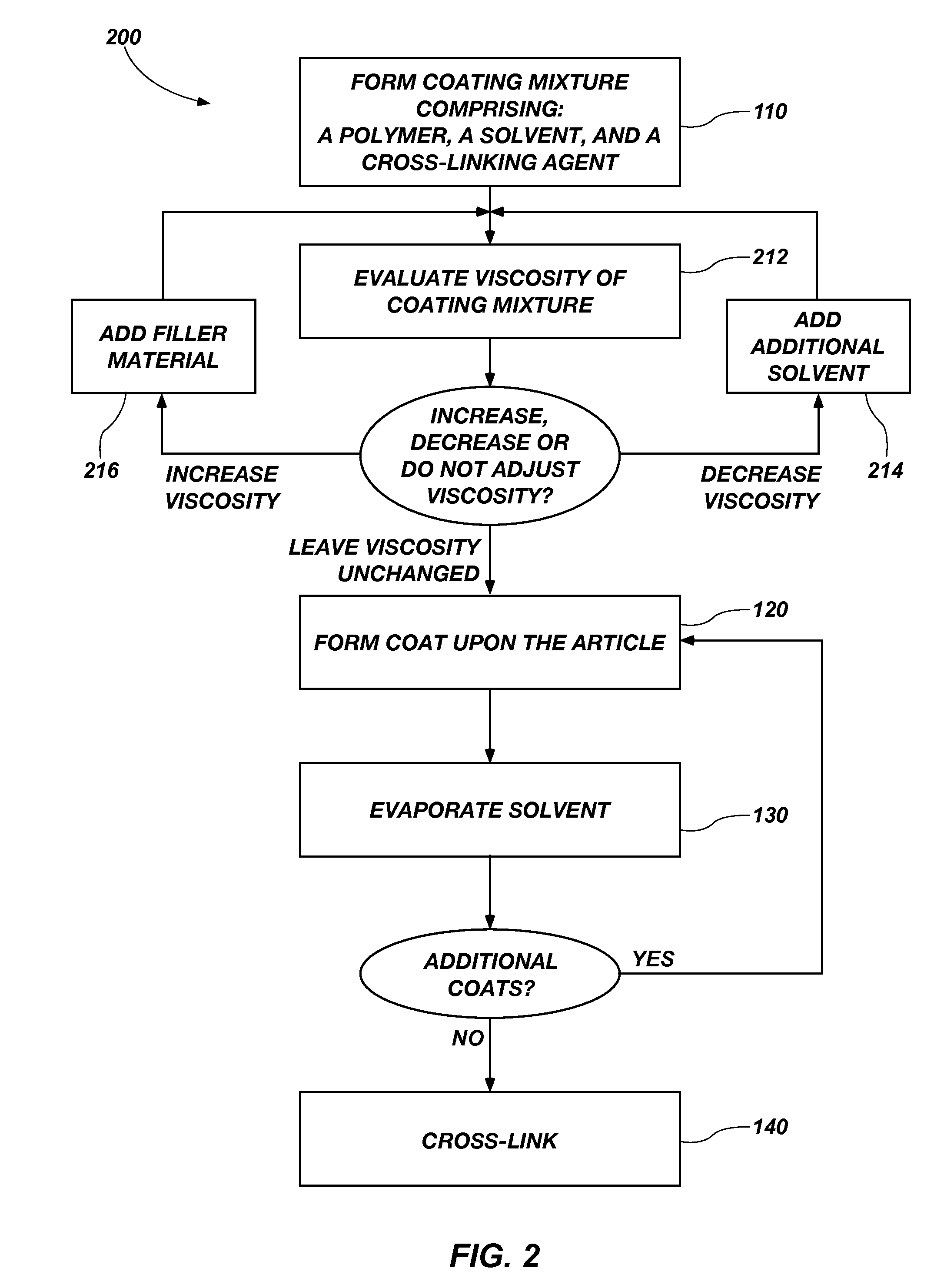

Methods of forming protecting coatings on substrate surfaces and devices including such protective coatings

A method for forming a protective coat upon an article includes forming a liquid coating mixture comprising a cross-linking agent and a polymer dissolved within a solvent; applying a first coat of the coating mixture upon the article; evaporating the solvent from the first coat; and cross-linking the article. Also disclosed is a device containing an exterior surface at least partially covered by a coating comprising a cross-linked polymer and a filler material that is selected from the group consisting of a fullerene, a micro-encapsulated material, and a combination of two or more thereof.

Owner:BAKER HUGHES INC

Root-resisting non-cured rubber asphalt waterproofing paint

InactiveCN107353823AWill not harmCompletely sealed and waterproofFireproof paintsOther rubber coatingsPolymer scienceBituminous waterproofing

The invention discloses root-resisting non-cured rubber asphalt waterproofing paint. A preparation technology for the root-resisting non-cured rubber asphalt waterproofing paint comprises the following steps: heating asphalt to be 140 DEG C and adding the asphalt into a stirring tank; adding a softening agent, resin powder and a high molecular polymer; carrying out stirring for 30min and raising the temperature to be 160 DEG C; conveying a mixture into a colloid mill and grinding two edges; raising the temperature to be 190 DEG C and adding a special additive; carrying out stirring for 1h; when cooling the temperature to be 160 DEG C to 170 DEG C, adding a root-resisting agent and carrying out stirring for 1h; adding filler and carrying out stirring for 1h; and discharging a material. By adopting the root-resisting non-cured rubber asphalt waterproofing paint disclosed by the invention, the problems that a waterproofing layer is broken and bending fatigue failure is caused, which are caused by the fact that base-course cracking stress is transmitted to the waterproofing layer, or the waterproofing layer is at a high-stress state and is aged in advance and the like are solved; meanwhile, capillary pores and cracks of a base course can be sealed very well due to the viscosity; and a water channeling difficulty of the waterproofing layer is solved and the waterproofing reliability is greatly improved.

Owner:北京新世纪京喜防水材料有限责任公司

Method of producing adherent coatings on resinous substrates

The present invention is directed to a method of producing an adherent coating over untreated thermoplastic and thermosetting resinous substrates from a coating composition that includes a crosslinkable component and a crosslinking component that are mixed prior to application and applied over the substrate. The crosslinkable component includes a polymeric mix containing at least one crosslinkable copolymer polymerized from a monomer mixture comprising one or more ethylenically unsaturated monomers having on average 1 to 10, preferably 1 to 4 and more preferably 1 to 2 hydroxyl groups and a saturated hydrocarbon polymer. The crosslinkable component includes one or more cycloaliphatic polyisocyanate of the formula:R1—(R2—NCO)n wherein R1 is a substituted or unsubstituted cycloaliphatic group, R2 is independently selected from a direct bond, a straight aliphatic group or branched aliphatic group, and wherein n ranges from 2 to 10. The method is well suited to produce adherent coatings on olefinic substrates such as those used in automotive and general commercial application without any pretreatment of the resinous substrates.

Owner:AXALTA COATING SYST IP CO LLC

Composition for the application of a protective layer to a substrate and method for the application thereof

InactiveUS20150112017A1Other rubber coatingsLiquid/solution decomposition chemical coatingSolventGlass transition

The present invention relates to a composition comprising: (a) about 5 wt. % to about 30 wt. % of an amorphous polymer, said amorphous polymer having a glass transition temperature of lower than about −20° C., (b) about 15 wt. % to about 60 wt. % of a filler, and (c) about 10 wt. % to about 80 wt. % of a solvent, wherein the amounts of (a), (b) and (c) are calculated on the total weight of the composition. The present invention also relates to a process for the application of a protective layer to a substrate, the process comprising application of a layer of the composition to the surface of the substrate or a part thereof. The present invention further relates to a container comprising the composition and a propellant.

Owner:FRANS NOOREN AFDICHTINGSSYSTN

Viscosity-reducing flame-retardant type non-cured rubber asphalt waterproof coating and preparation method thereof

InactiveCN110724454AViscosity reduction hasViscosity reduction flame retardant hasFireproof paintsOther rubber coatingsWaste rubberFire retardant

The invention belongs to the technical field of building waterproof materials, and particularly relates to a viscosity-reducing flame-retardant type non-cured rubber asphalt waterproof coating and a preparation method thereof. The waterproof coating is prepared from the raw materials in parts by weight: 30-60 parts of petroleum asphalt, 10-30 parts of a softener, 3-10 parts of a modifier SBS, 5-20parts of a tackifier, 5-20 parts of waste rubber powder, 5-25 parts of a filler, 3-10 parts of a flame retardant and 2-6 parts of a flowability-increasing agent. The waterproof coating provided by the invention has multiple characteristics such as water resistance, viscosity reduction, easy flowing, flame retardance and the like, the construction temperature and energy consumption are reduced, the non-cured rubber asphalt waterproof coating is prevented from fire in construction and application, and the safety of the non-cured rubber asphalt waterproof coating is enhanced. According to the preparation method provided by the invention, the dissolution difficulty of the modifier in the mixture is lowered, on one hand, the dissolution of the modifier is facilitated, and on the other hand, the preparation temperature of the non-cured rubber asphalt waterproof coating is lowered, and the energy is saved.

Owner:CHINA PETROLEUM & CHEM CORP

Non-curable rubber asphalt waterproof coating and preparation method thereof

InactiveCN109536025AGood high and low temperature performanceGood extensibilityOther rubber coatingsBituminous coatingsSelf-healingBituminous waterproofing

The invention belongs to the technical field of building waterproof materials, and in particular, relates to a non-curable rubber asphalt waterproof coating and a preparation method thereof. The non-curable rubber asphalt waterproof coating comprises the following raw materials in parts by weight: 35-65 parts of petroleum asphalt, 5-25 parts of a softener, 2-10 parts of styrene-butadiene block copolymer, 5-20 parts of tackifying resin, 5-25 parts of waste rubber powder, 5-20 parts of a filler and 0.5-3 parts of a surfactant. Cheap catalytic cracking oil slurry is introduced into the raw materials, fly ash collected from flue gas after coal combustion is used as a filler, and the prepared non-curable rubber asphalt waterproof coating can be guaranteed to have excellent high and low temperature performance, good extensibility, difficult curing, good cohesiveness, good flexibility, strong self-healing property and low cost. The invention also provides the preparation method, wherein the preparation method has the advantages of low cost, environmental protection, convenience, safety and reliability.

Owner:CHINA PETROLEUM & CHEM CORP

Anti-fouling and antibacterial skin feeling furniture decoration film and preparation method thereof

InactiveCN109094124AImproved photocorrosion resistanceImprove rigidityAntifouling/underwater paintsOther rubber coatingsEmulsionAgricultural engineering

The invention provides an anti-fouling and antibacterial skin feeling furniture decoration film. The anti-fouling and antibacterial skin feeling furniture decoration film comprises a base material, anantibacterial film and a printing facing film; the base material, the antibacterial film and the printing facing film are obtained by hot pressing and laminating; the anti-fouling and antibacterial skin feeling furniture decoration film further comprises a waterborne polyurethane composite coating; the waterborne polyurethane composite coating is formed after a mixed emulsion, which is obtained by mixing and stirring waterborne polyurethane, acrylate emulsion, modified silicon resin and vulcanized rubber, is coated on the printing facing film and dried. The anti-fouling and antibacterial skinfeeling furniture decoration film provided by the invention has the advantages of excellent photocorrosion resistance, excellent rigidity and excellent simulated skin feeling; and the super-smooth surface and soft hand feeling of the anti-fouling and antibacterial skin feeling furniture decoration film are realized.

Owner:JIANGSU HIMEI NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com