Liquid sound insulation coating

A sound insulation coating and liquid technology, applied in asphalt coatings, other rubber coatings, coatings, etc., can solve the problems of limited clear space height and sound insulation effect of compressed floors, poor ground sound insulation effect, complicated construction, etc., and achieve good cement compatibility. High performance, good viscosity, convenient and fast construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

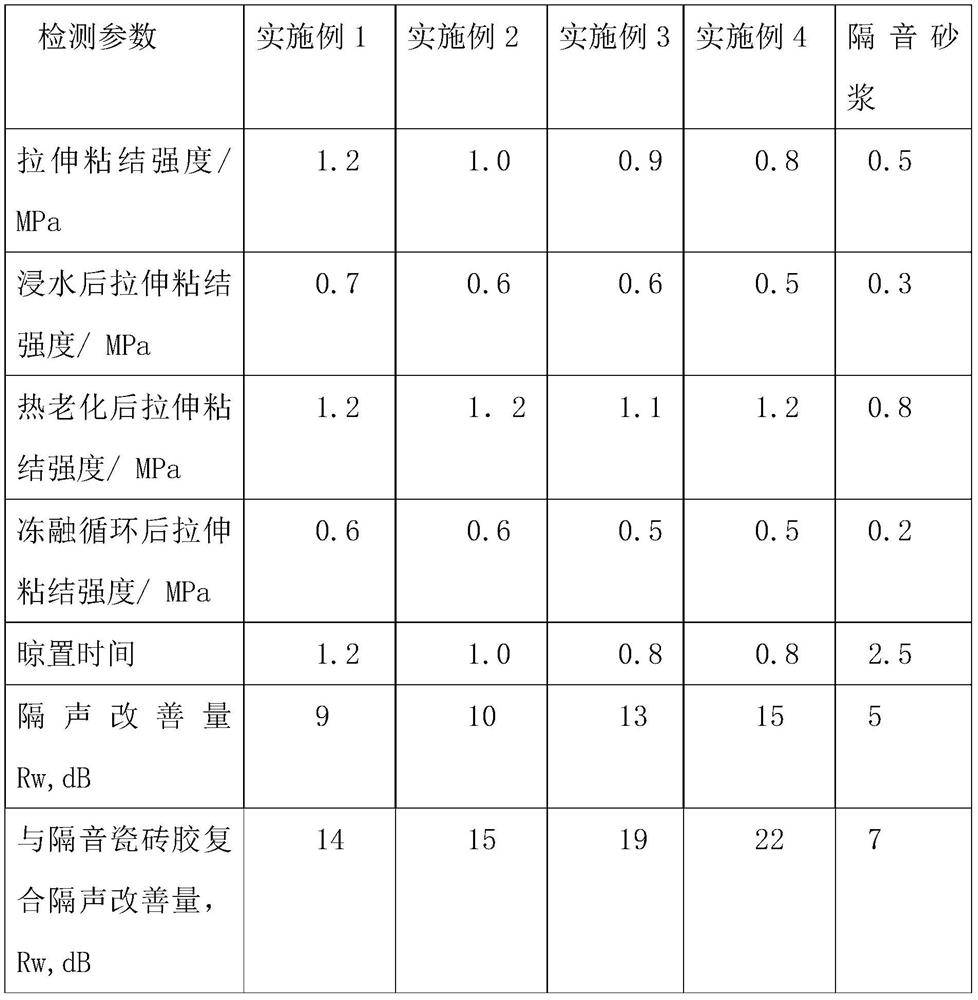

Examples

Embodiment Construction

[0018] The following will clearly and completely describe the technical solution in the embodiment of the invention in combination with this embodiment.

[0019] The applicant improved the processing technology and equipment, and obtained a liquid sound-insulating coating of the present invention after thousands of experiments and tests, which comprises: acrylic acid emulsion: 10-20%, emulsified asphalt: 10-20%, rubber powder 20 mesh: 30---50%, polystyrene particles: 5--15%, thickener: 0.1-0.5%, cross-linking agent: 0.1-0.3%, water: 2-20%, the acrylic emulsion It is an emulsion with a solid content of 50%, Tg: -20 degrees, that is, the transition temperature from the glass state to the high elastic state is minus 20 degrees Celsius, and has good water resistance and cement compatibility; the emulsified asphalt is an anionic and non-ionic The emulsified asphalt with ion as emulsifier has good compatibility with the acrylic emulsion.

[0020] The present invention adopts specia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com