Propylene polymer composition having superior hexane extractables/impact balance

A technology of propylene copolymer and composition, applied in the field of preparing said copolymer, can solve the problem of high content of hexane extractables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

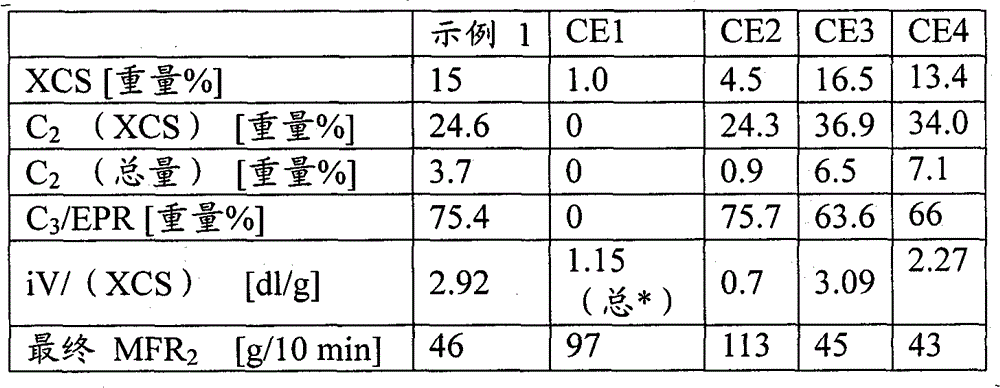

[0171] Example 1 (invention) and comparative examples CE1, CE2, CE3, and CE4:

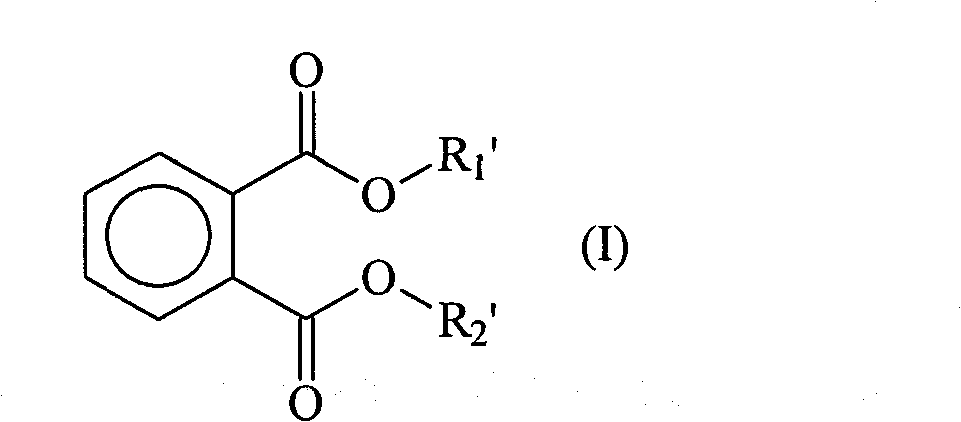

[0172] The base resin was prepared in a 211 autoclave. The catalyst used for polymerization is prepared according to WO 92 / 19653 with DOP as dialkyl phthalate of formula (I) with ethanol as alcohol, cocatalyst is triethylaluminum (TEA), using cyclohexylmethyl- Dimethoxysilane as external donor (D).

[0173] After the first prepolymerization step, the reactor was heated to 85 °C and filled with the required amount of C 3 and H 2 to initiate the bulk reaction conditions. by feed C 3 The pressure of the reactor was kept constant. After a specified bulk residence time, the reactor is flashed and the preparation of the homopolymer matrix continues using gas phase conditions. After a specified GP1 residence time, the reactor was flashed again. In the third stage, the elastomeric rubber dispersed phase is prepared by copolymerizing propylene and ethylene comonomers using specific gas phase conditio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural modulus | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com