Preparation method of polypropylene with wide molecular weight distribution and polymer thereof

A wide molecular weight distribution, polypropylene technology, applied in the preparation method of polypropylene and its polymer field, can solve the problems of complex asymmetric hydrogenation step-by-step polymerization operation, large fluctuation of product performance indicators, etc., and achieve xylene soluble Low material, excellent physical properties and processing properties, and the effect of stable control of performance indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

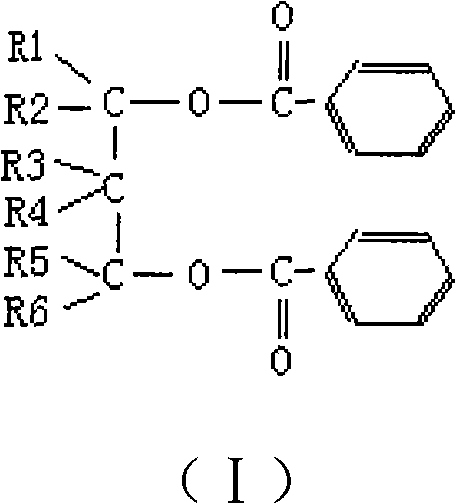

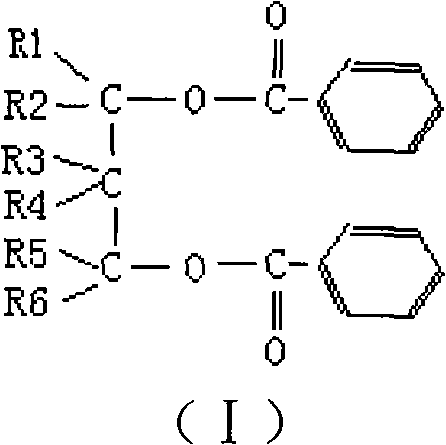

[0048] The preparation of catalyst component: in the glass reaction vial of 500ml, add 100ml titanium tetrachloride, add 8g spherical magnesium chloride alcoholate (MgCl 2 2.6C 2 h 5 OH), the temperature was raised to 120°C, 1.5ml of 2,4-pentanediol dibenzoate and 0.5ml of dibutyl phthalate were added during the temperature rise, and the temperature was maintained at 120°C for 1 hour, and the solution was filtered off. Add 100ml of titanium tetrachloride, stir at 120°C for 0.5 hour, and filter off the solution. The solid was washed with 100 ml of hexane and dried under vacuum to obtain a solid catalyst component. The content of 2,4-pentanediol dibenzoate in the catalyst component is 10.6wt%, and the content of dibutyl phthalate is 2.8wt%.

[0049] Propylene polymerization: in a 5L autoclave, purging with nitrogen gas flow, then introduce 5ml of triethylaluminum hexane solution (the concentration of triethylaluminum is 0.05mmol / ml), 1ml of triethylaluminum in nitrogen gas fl...

Embodiment 2

[0072] Preparation of catalyst components: at 3m 3 Add 1.5m 3 Titanium tetrachloride, add 180kg spherical magnesium chloride alcoholate (MgCl 2 2·6C 2 h 5 OH), the temperature was raised to 120°C, and 36kg of 2,4-pentanediol dibenzoate and 11.3kg of dibutyl phthalate were added during the heating process, and the temperature was maintained at 120°C for 1 hour, and the solution was filtered off. Join 1.5m 3 Titanium tetrachloride was stirred at 120°C for 0.5 hour, and the solution was filtered off. The solid was washed with 1.5 m3 of hexane and dried under vacuum to obtain a solid catalyst component. The content of 2,4-pentanediol dibenzoate in the catalyst component is 9.0wt%, and the content of dibutyl phthalate is 4.0wt%.

[0073] Propylene polymerization: In a 120,000-ton / year single-loop polymerization reactor, continuously add propylene and hydrogen, the above-prepared catalyst components (with a concentration of 230g / L paste) and triethylaluminum as external electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com