Patents

Literature

2415 results about "Carboxylic ester" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In chemistry, an ester is a chemical compound derived from an acid (organic or inorganic) in which at least one –OH (hydroxyl) group is replaced by an –O–alkyl (alkoxy) group. Usually, esters are derived from a carboxylic acid and an alcohol.

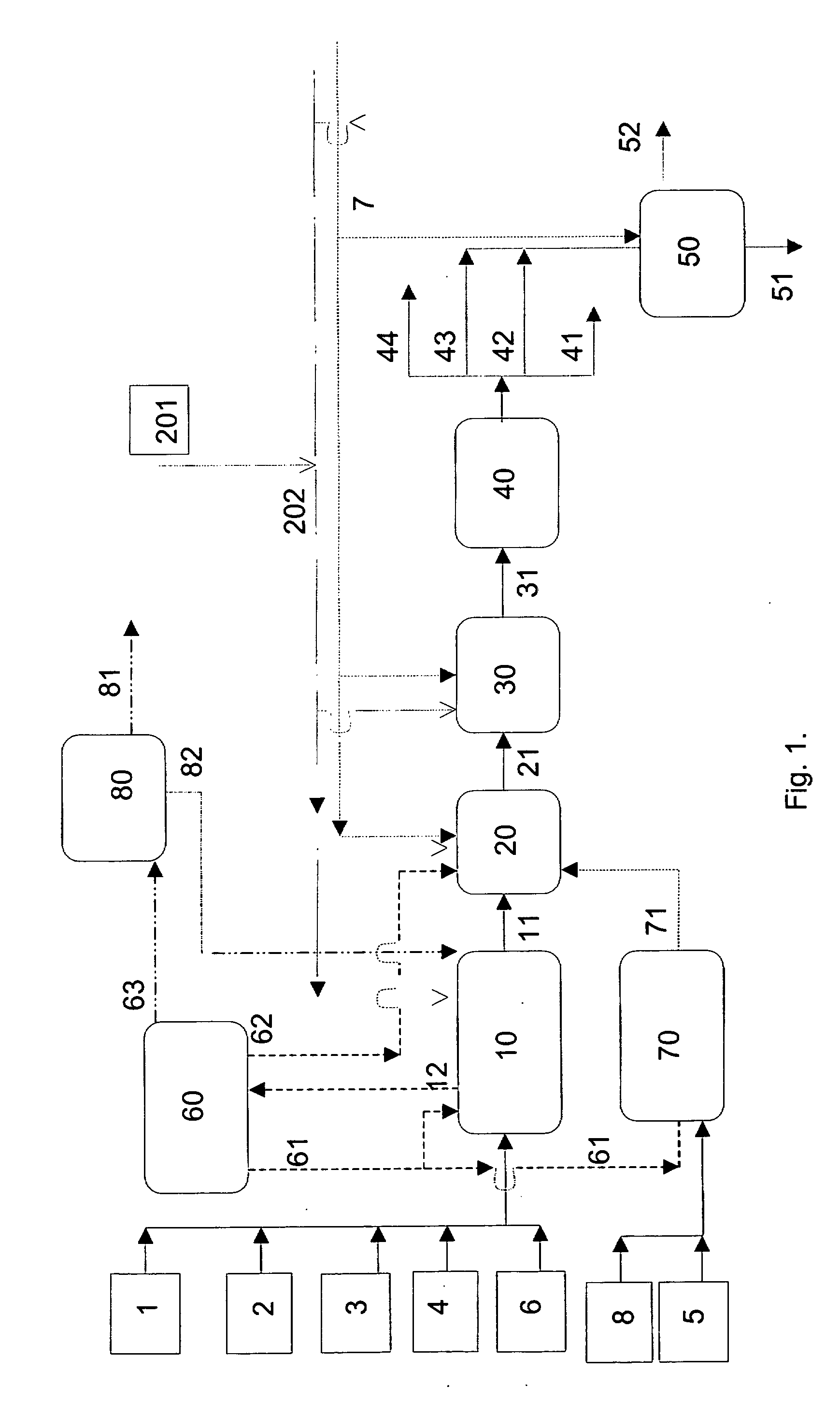

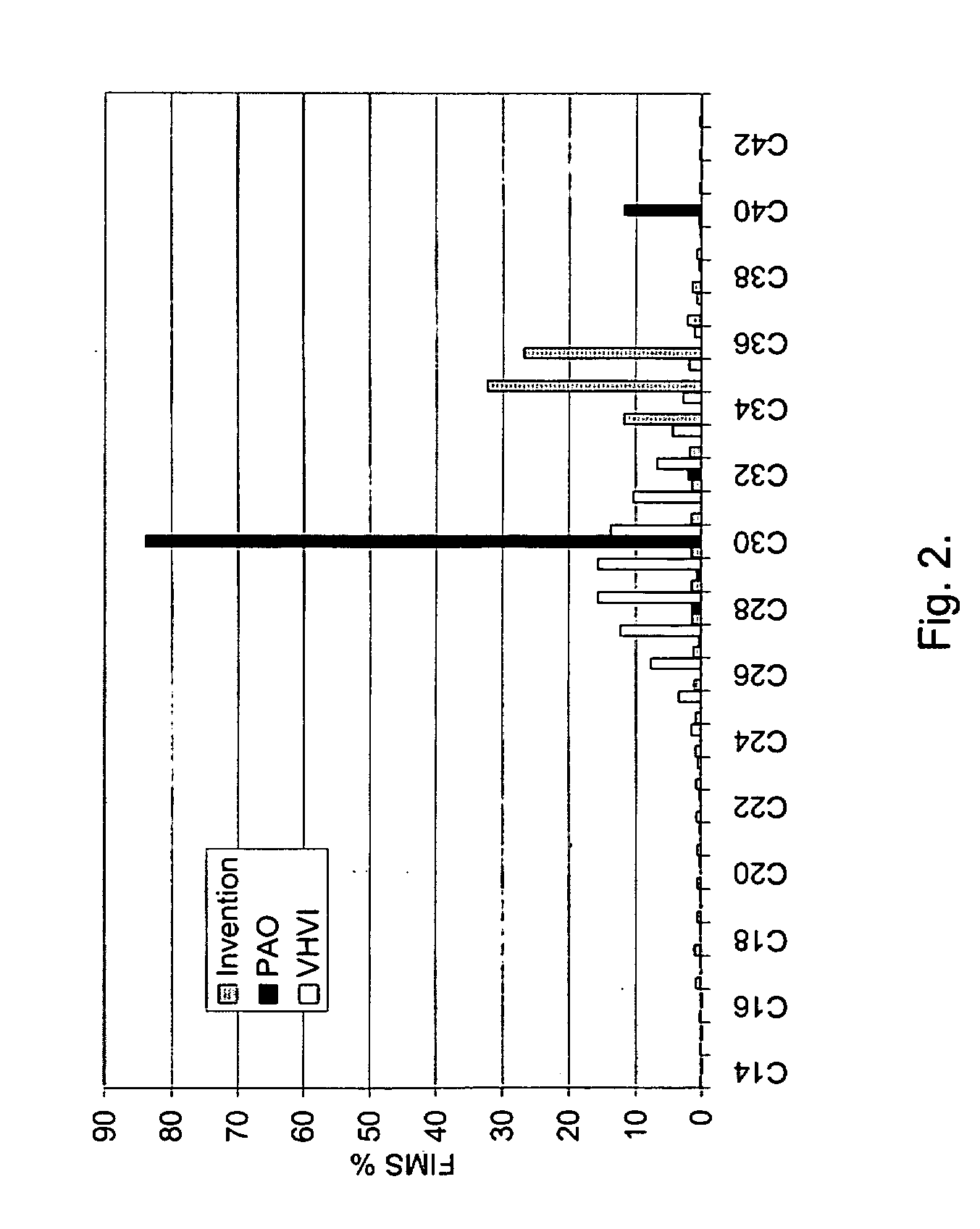

Process for producing a saturated hydrocarbon component

ActiveUS20070131579A1Reduce carbon dioxide emissionsIncrease carbon dioxide loadProductsReagentsCarboxylic acidBase oil

The invention relates to a process for producing high-quality saturated base oil or a base oil component based on hydrocarbons. The process of the invention comprises two main steps, the oligomerization and deoxygenation. A biological starting material containing unsaturated carboxylic acids and / or esters of carboxylic acids is preferably used as the feedstock.

Owner:NESTE OIL OY

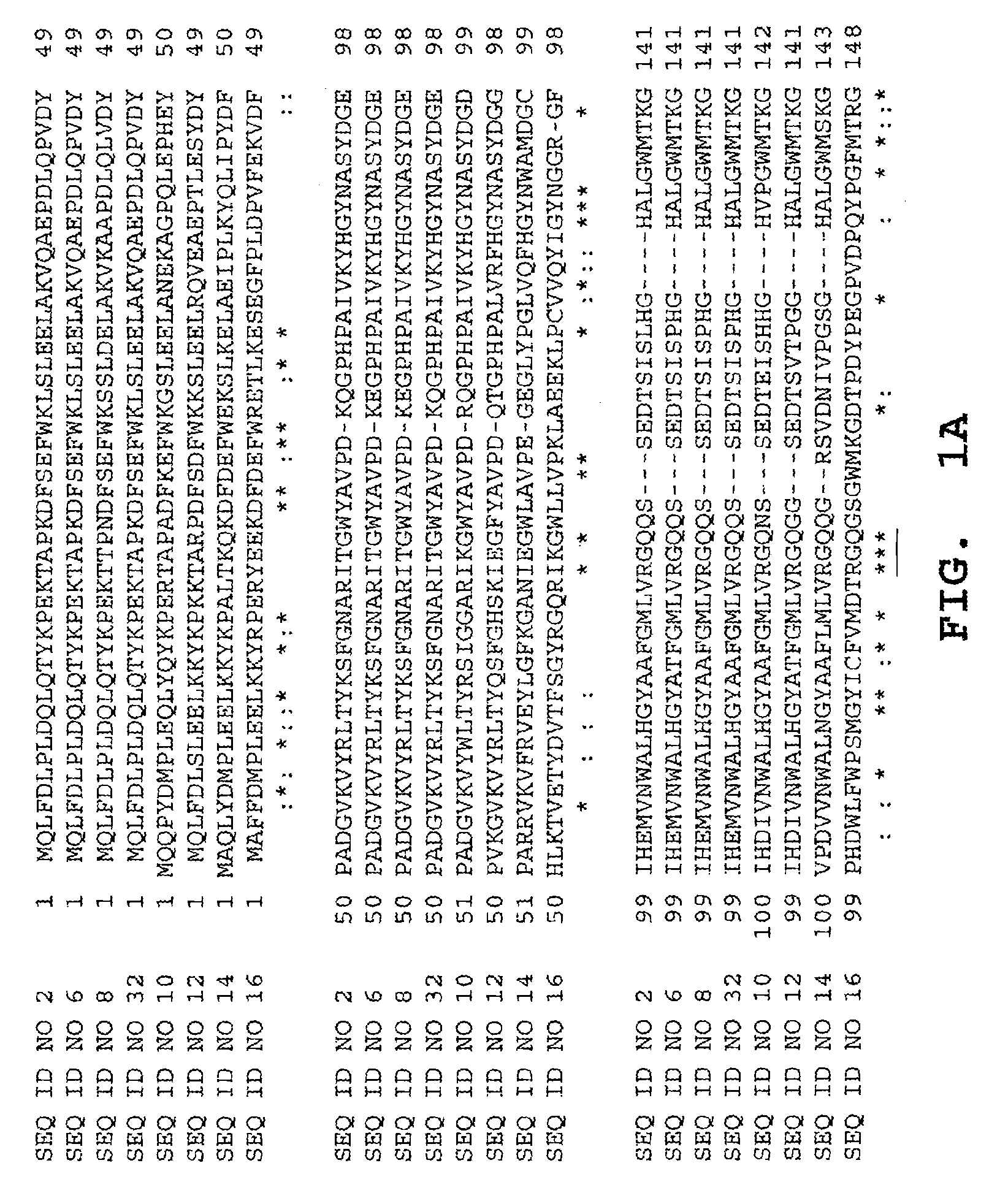

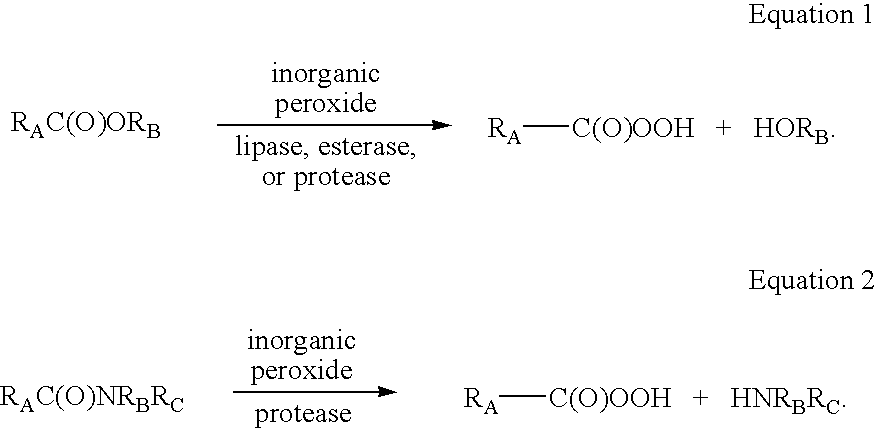

Production of Peracids Using An Enzyme Having Perhydrolysis Activity

ActiveUS20080176783A1Efficient implementationReduce concentrationBiocideHydrolasesMedicinal chemistryPeroxide

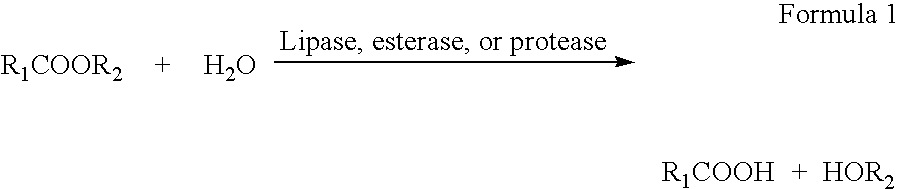

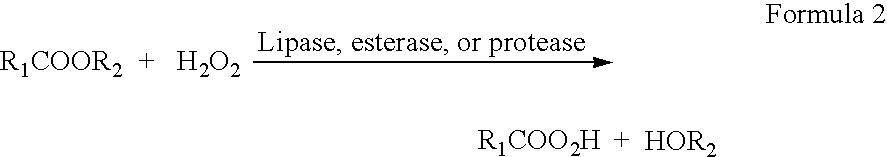

A process is provided for producing peroxycarboxylic acids from carboxylic acid esters. More specifically, carboxylic acid esters are reacted with an inorganic peroxide, such as hydrogen peroxide, in the presence of an enzyme catalyst having perhydrolysis activity. The present perhydrolase catalysts are classified as members of the carbohydrate esterase family 7 (CE-7) based on the conserved structural features. Further, disinfectant formulations comprising the peracids produced by the processes described herein are provided.

Owner:DUPONT US HLDG LLC

Catalyst component for olefinic polymerization and its catalyst

This invention provides a catalys conponent and catalyst. Said catalyst comprises titanium, magnesium and at least three electron donor compounds a, b and c, in which is selected from mono-aliphatic-carboxylate or mono-aromatic-carboxylate compounds, b is selected from a special diatomic alkoxide compound, and c is selected from binary binary-aliphatic-carboxylate or binary-aromatic-carboxylate or b is ether compound. Advantages: high polymerization activity and stereospecificity when used for olefin polymerization, in particular for propylene polymerization, wide molecular weight distribution of obtained polymer and good shape of polymer granulars.

Owner:CHINA PETROLEUM & CHEM CORP +1

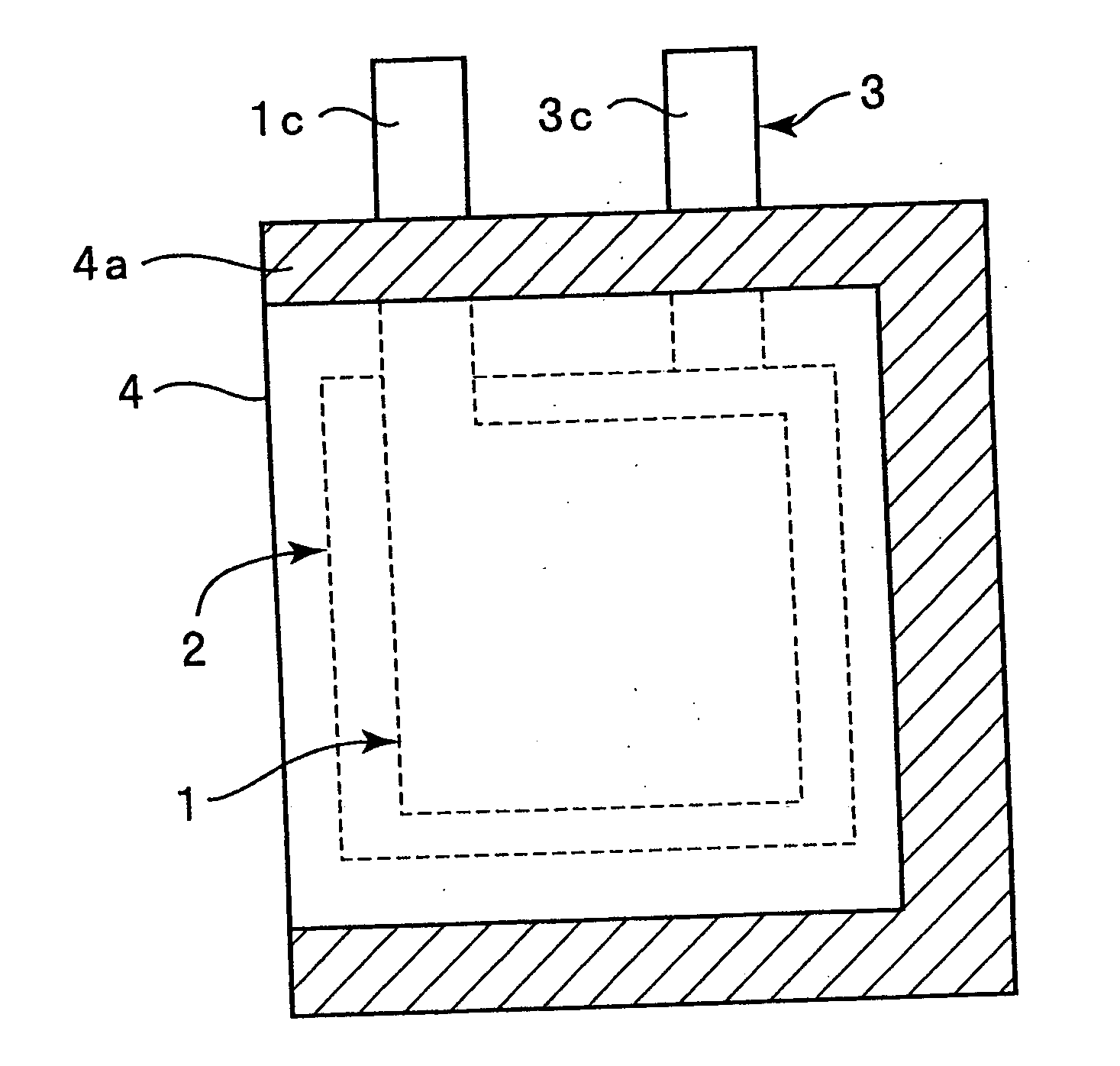

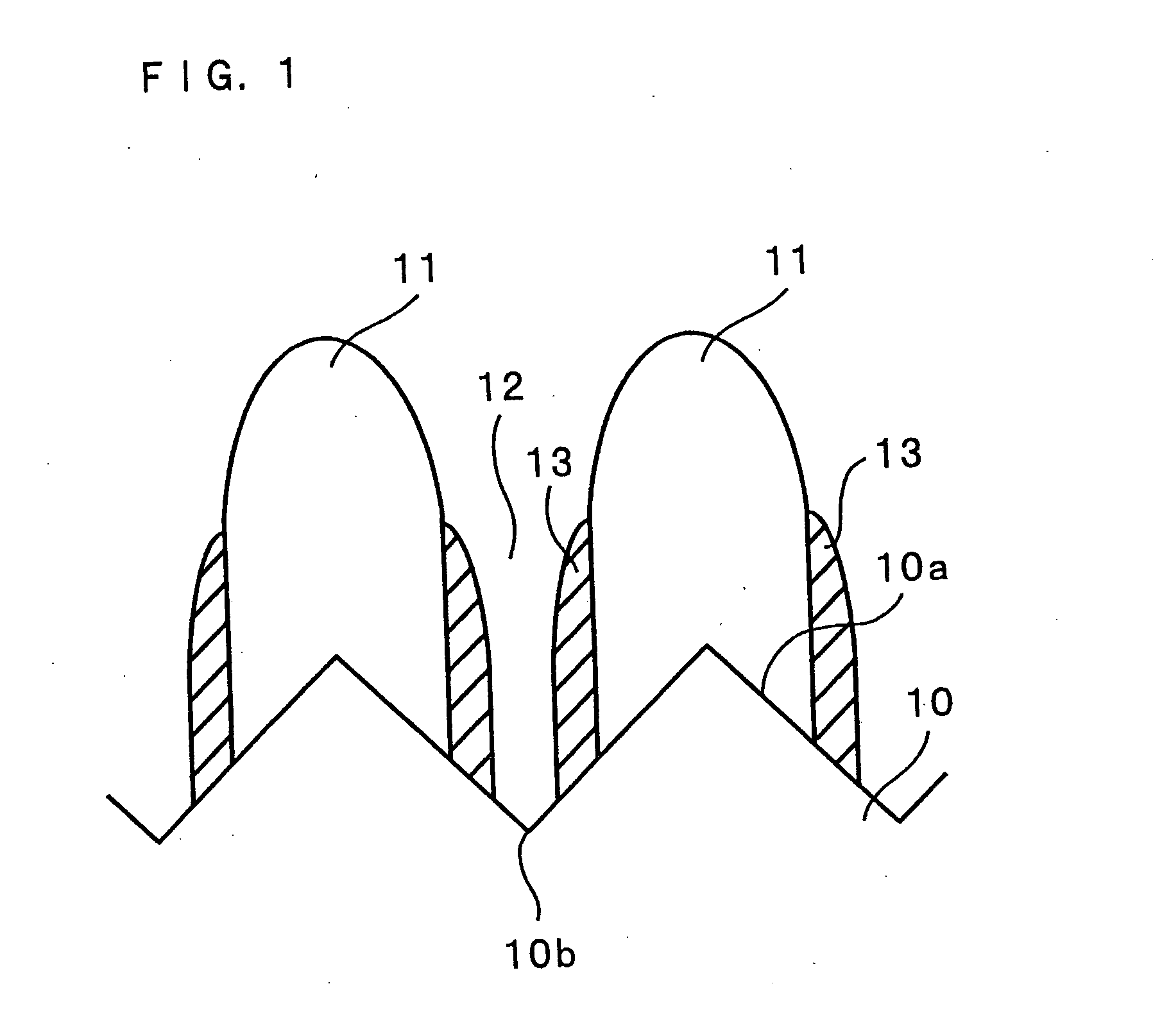

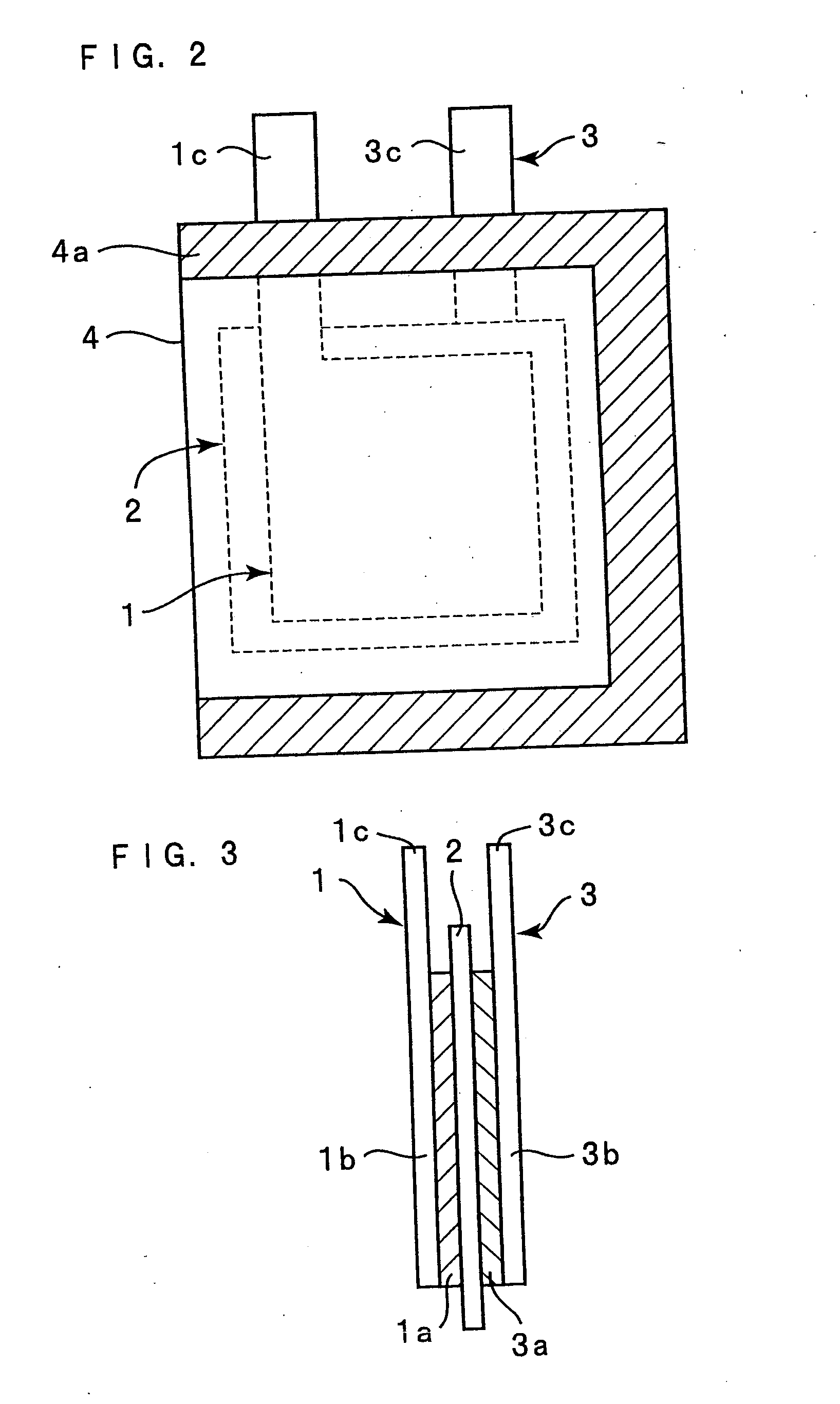

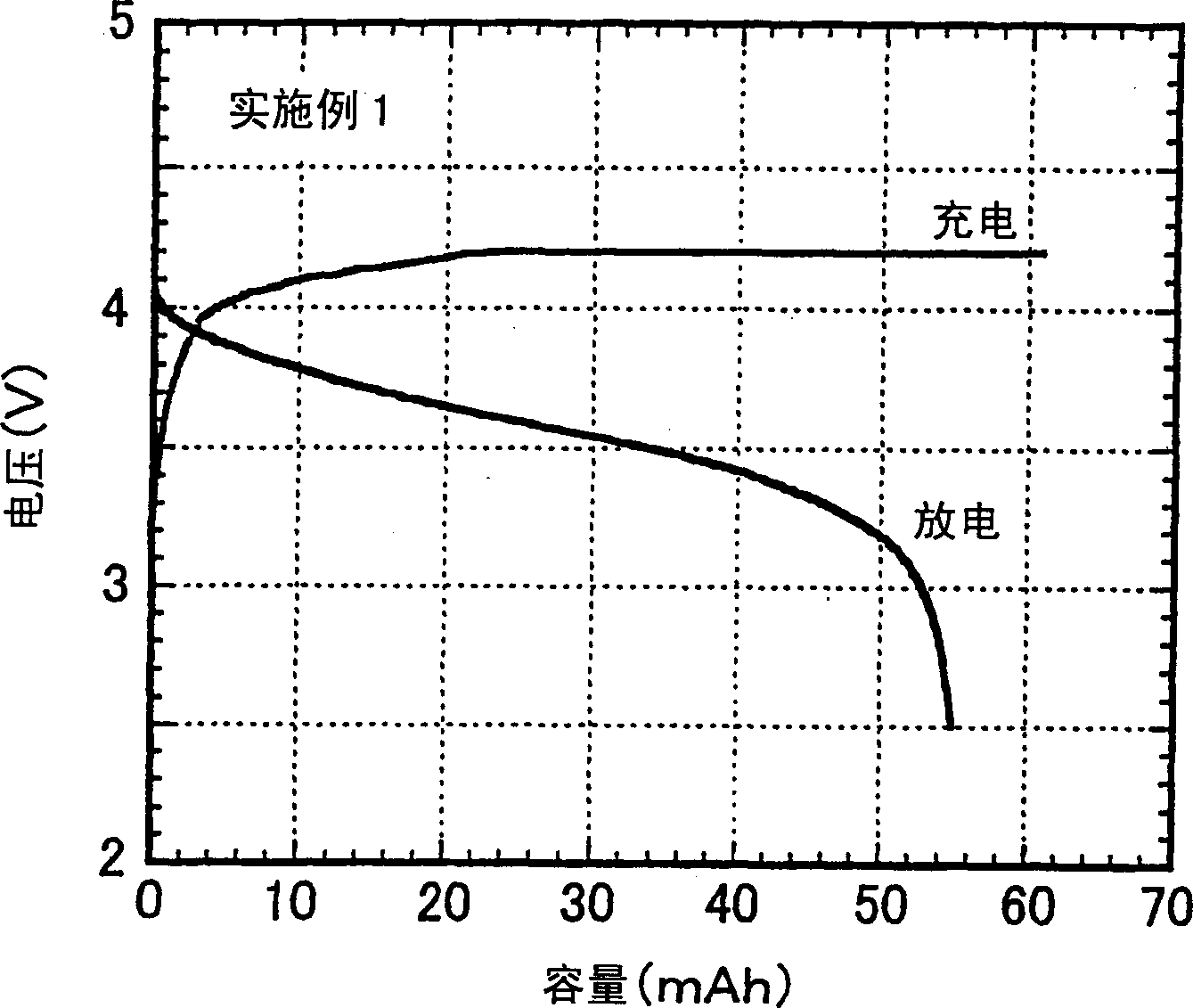

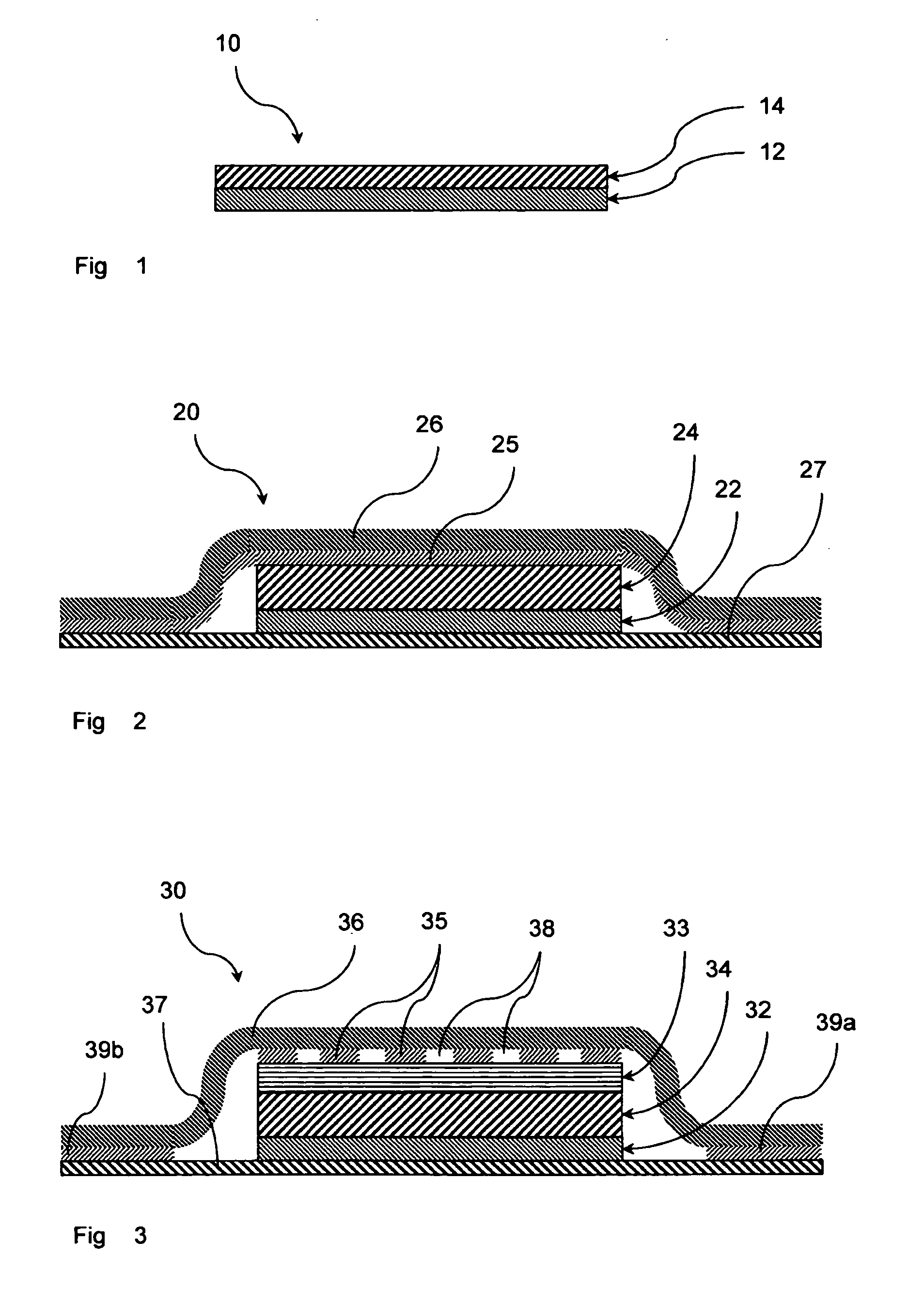

Lithium secondary battery

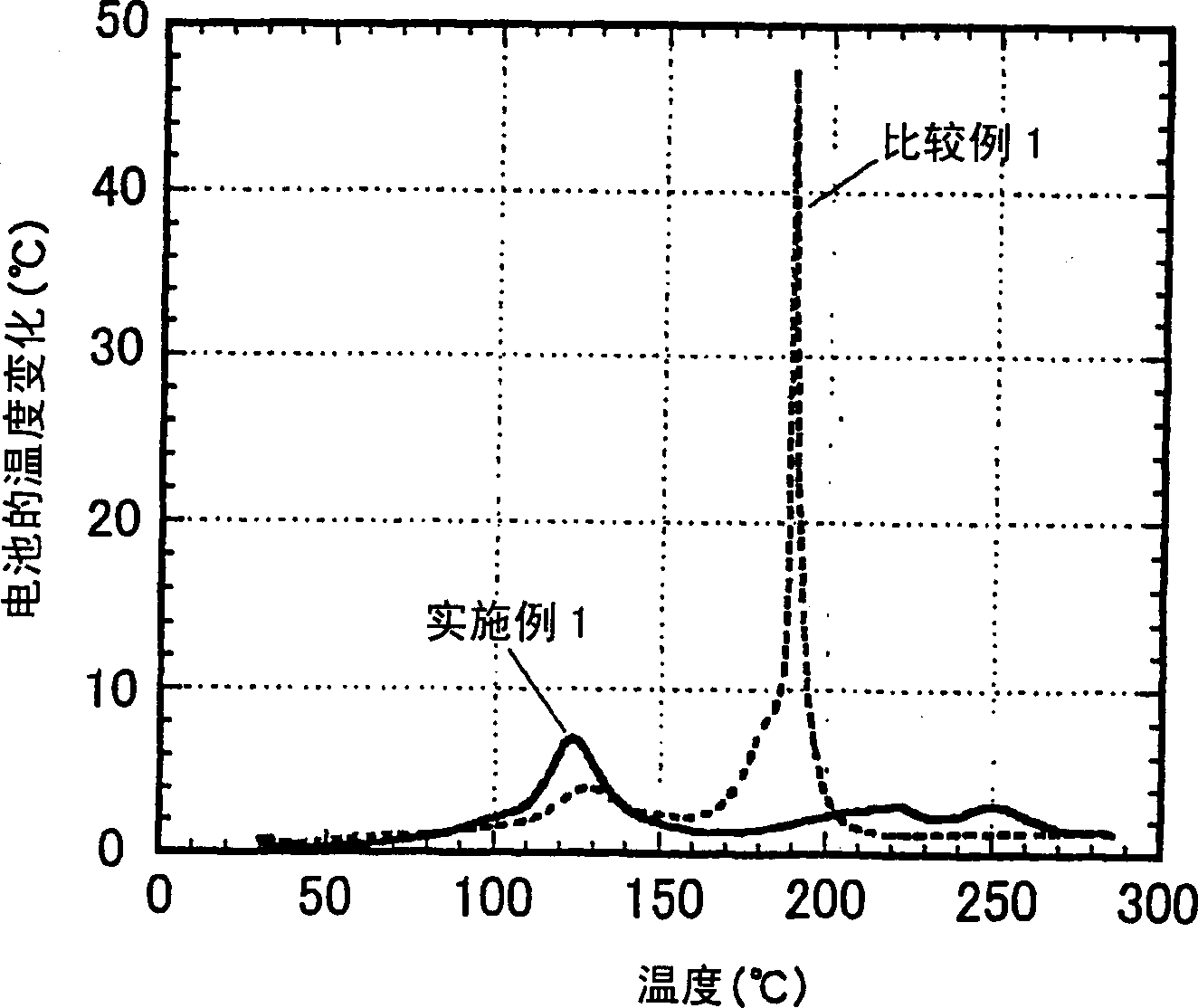

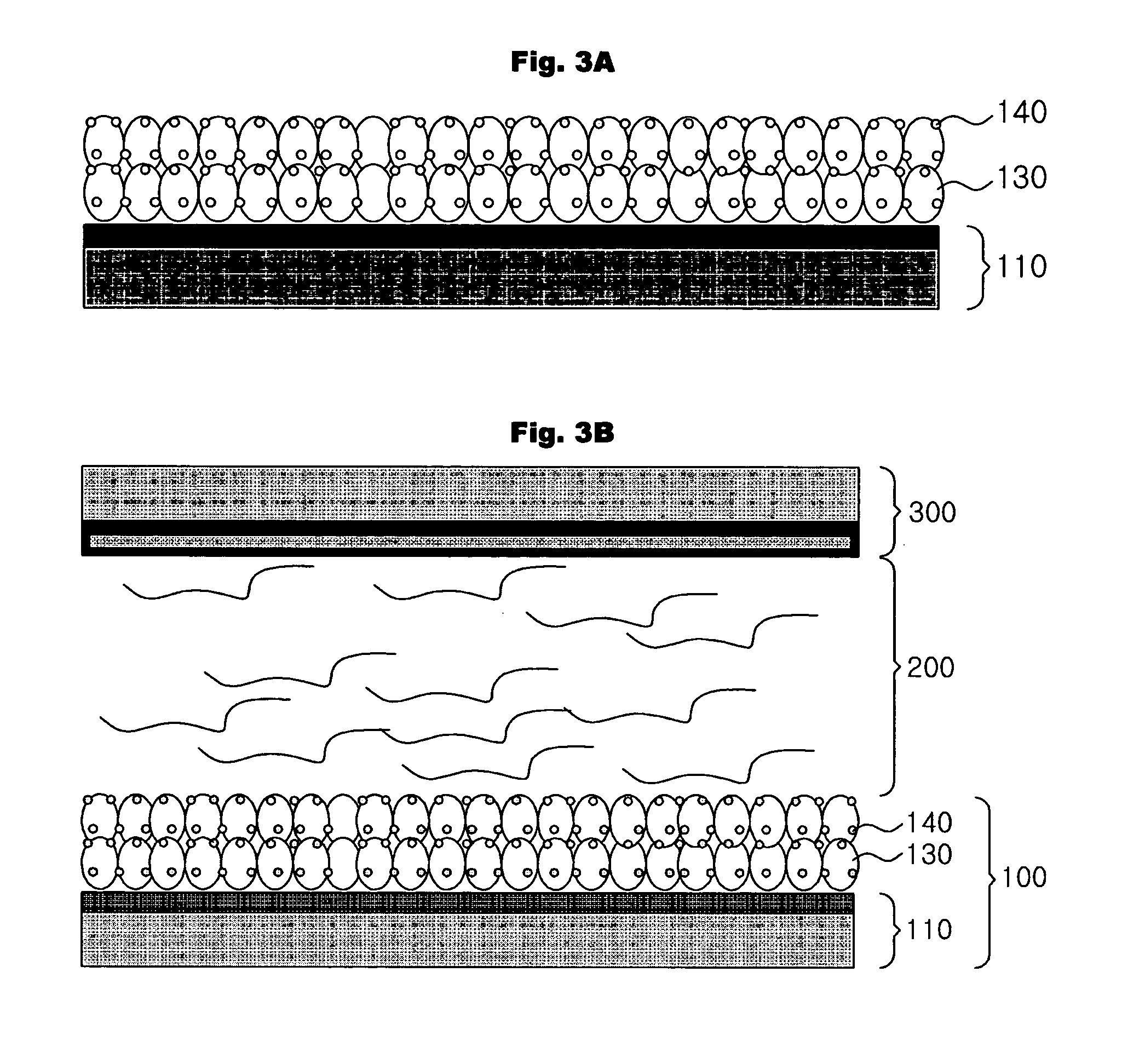

InactiveUS20050008939A1Improve featuresElectrochemical processing of electrodesFinal product manufactureLithiumPhosphate

A lithium secondary battery comprising a positive electrode, a negative electrode, and a nonaqueous electrolyte, wherein the positive electrode or the negative electrode is an electrode obtained by depositing a thin film of active material capable of lithium storage and release on a current collector, the thin film is divided into columns by gaps formed therein in a manner to extend in its thickness direction and the columnar portions are adhered at their bottoms to the current collector, and the nonaqueous electrolyte contains at least one selected from phosphate ester, phosphite ester, borate ester and carboxylic ester having a fluoroalkyl group.

Owner:SANYO ELECTRIC CO LTD

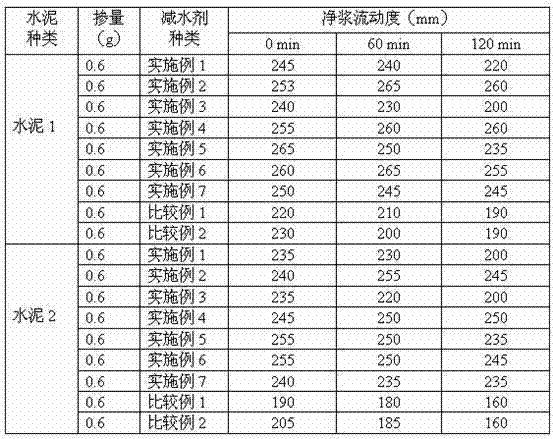

High-performance water reducer of polycarboxylic acid, and preparation method thereof

The invention relates to a high-performance water reducer of polycarboxylic acid, and a preparation method thereof, belonging to the technical field of concrete admixtures in construction industry. The water reducer is prepared by 55-90% of polyoxyethylene ether or ester containing unsaturated double bonds, 8-30% of unsaturated carboxylic acid and derivative thereof, 0-25% of unsaturated sulfonic acid and salt thereof, 0-15% of unsaturated carboxylic esters, and 0.5-5% of redox initiator. The high-performance water reducer of polycarboxylic acid prepared by the invention has the advantages of high water-reducing rate and collapse protectiveness, and has good adaptability for base materials. The water reducer provided by the invention is featured with simple technology, easy material getting, no pollution and low cost, and is industrially produced easily.

Owner:山西科腾环保新材料股份有限公司

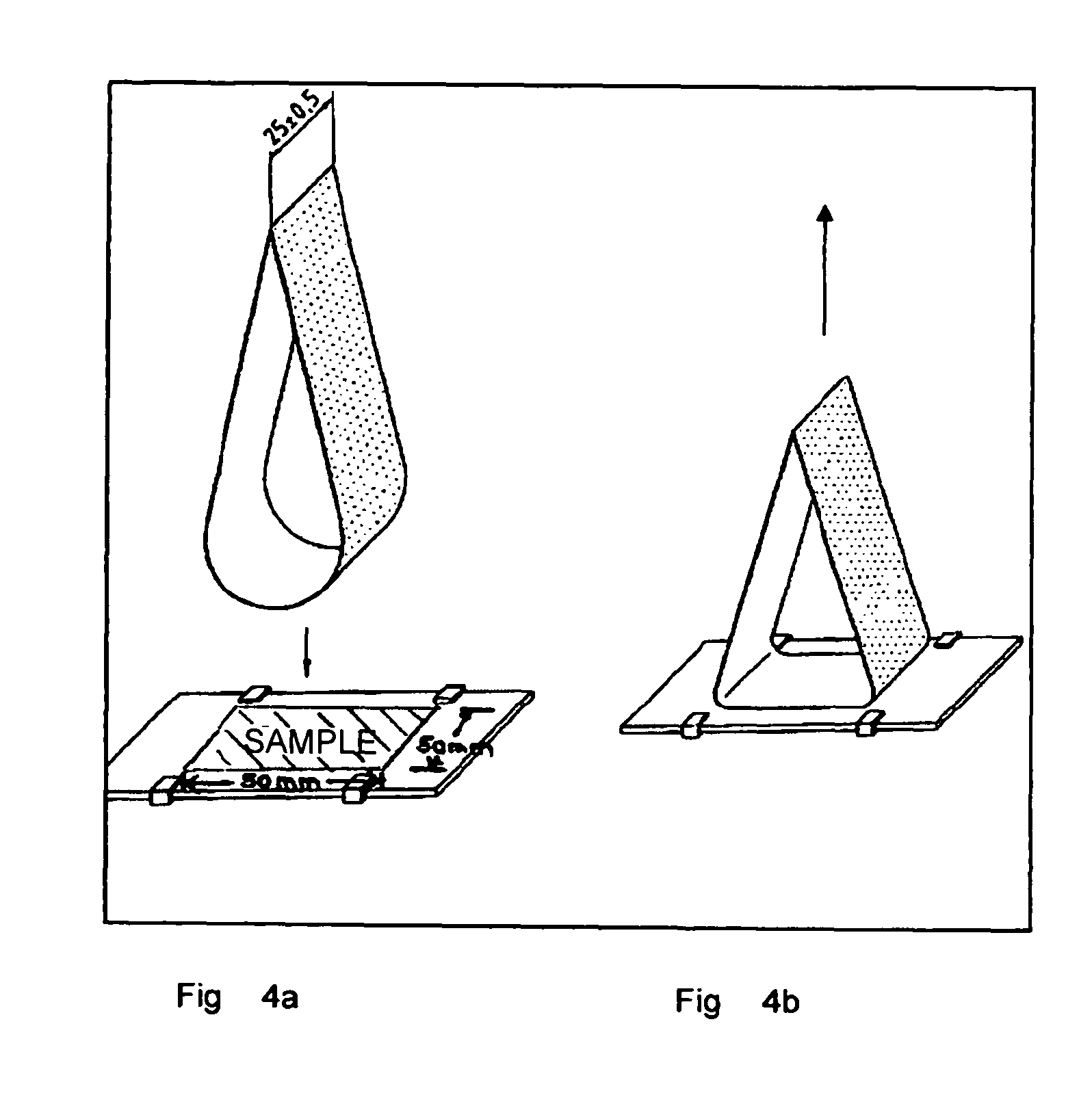

Process for producing composite semipermeable membrane

InactiveUS6521130B1Increase volumePromote hydrolysis reactionReverse osmosisWater/sewage treatment bu osmosis/dialysisPolymer sciencePolyamide

When forming a separating functional layer containing crosslinked polyamide, by carrying this out in the presence of 1) carboxylic acid ester with a total of 8 or more carbons, or 2) carboxylic acid, it is possible to provide a composite semipermeable membrane which, while still maintaining a high rejection rate, is more outstanding in its water permeability than hitherto.

Owner:TORAY IND INC

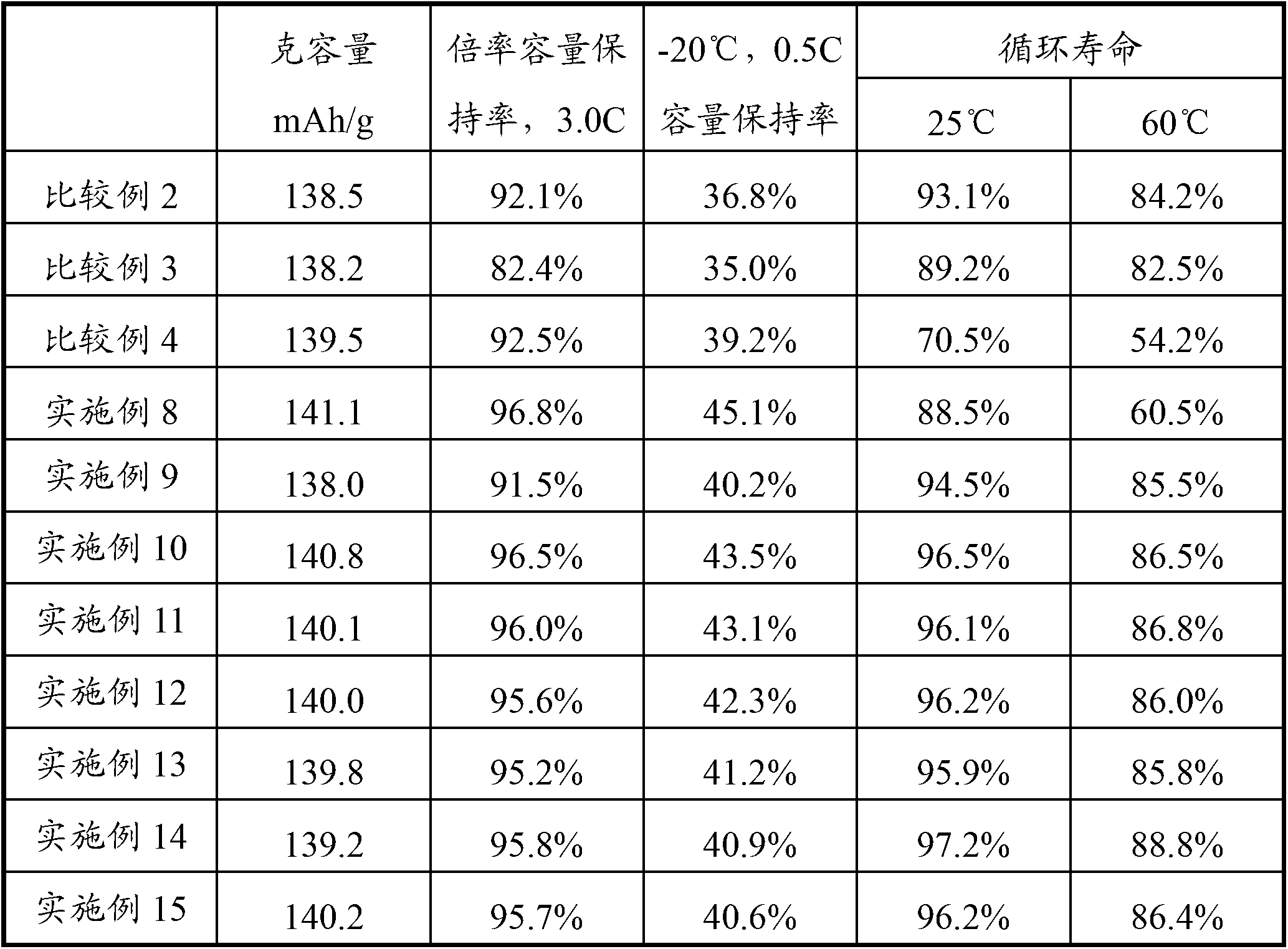

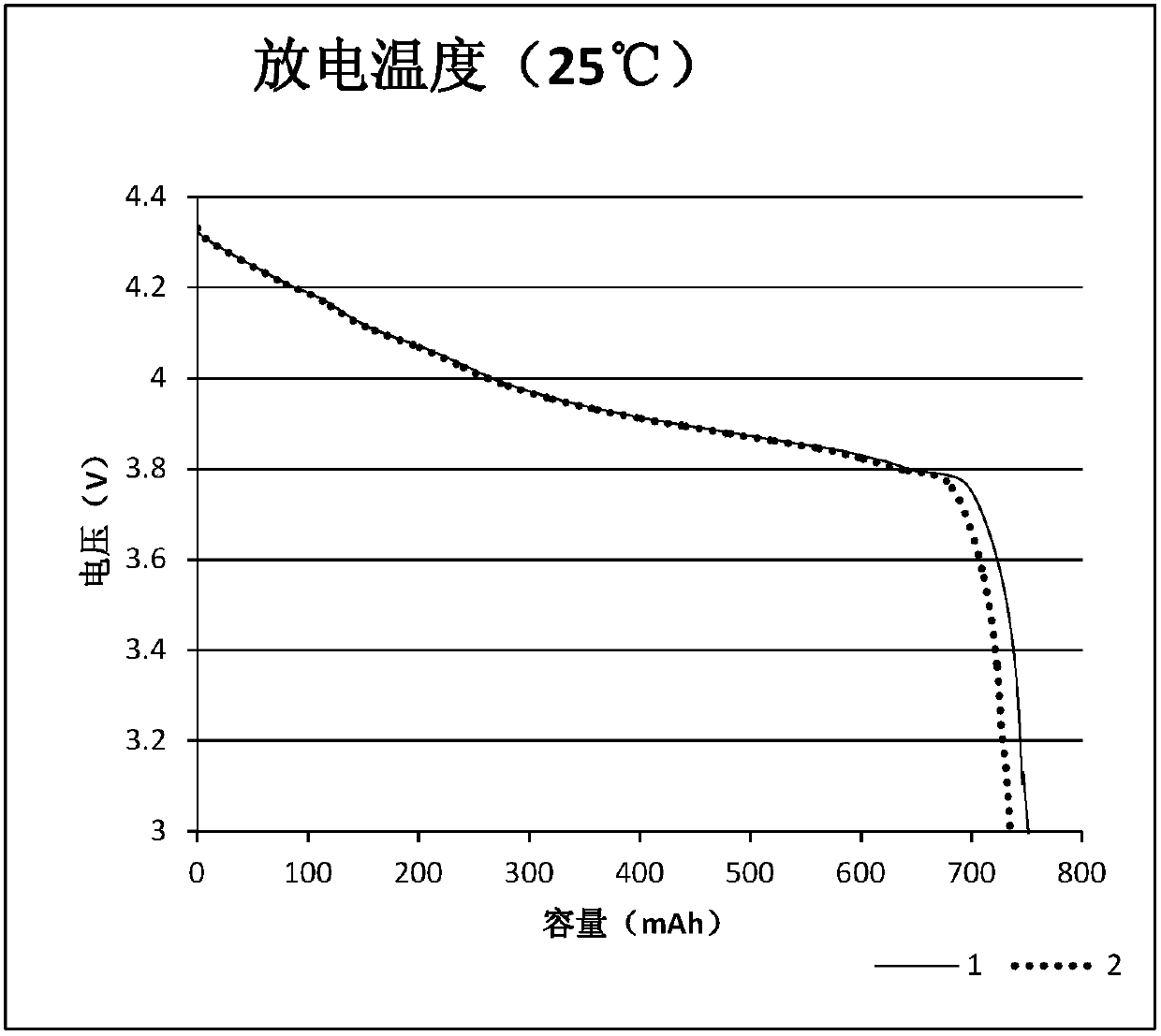

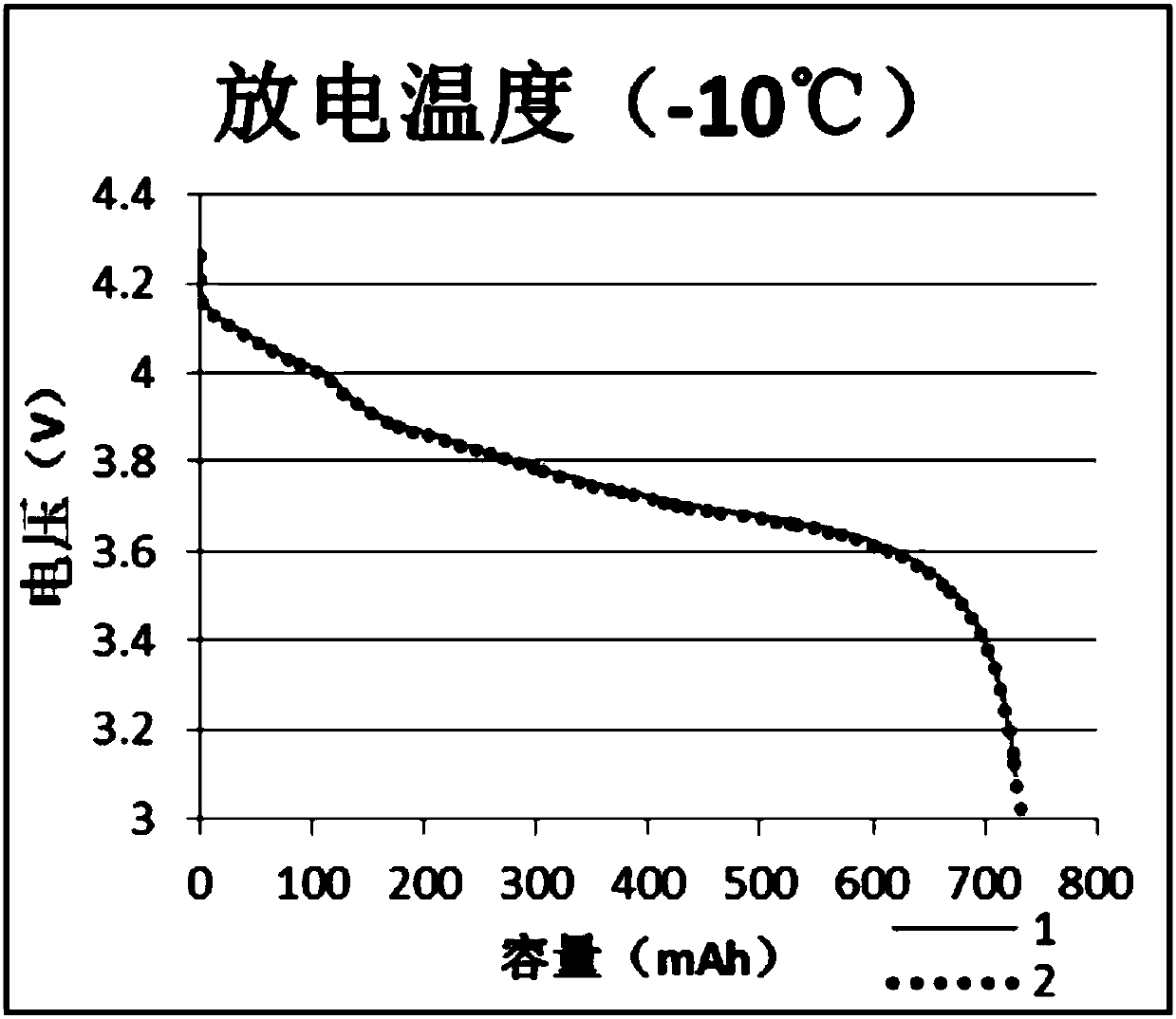

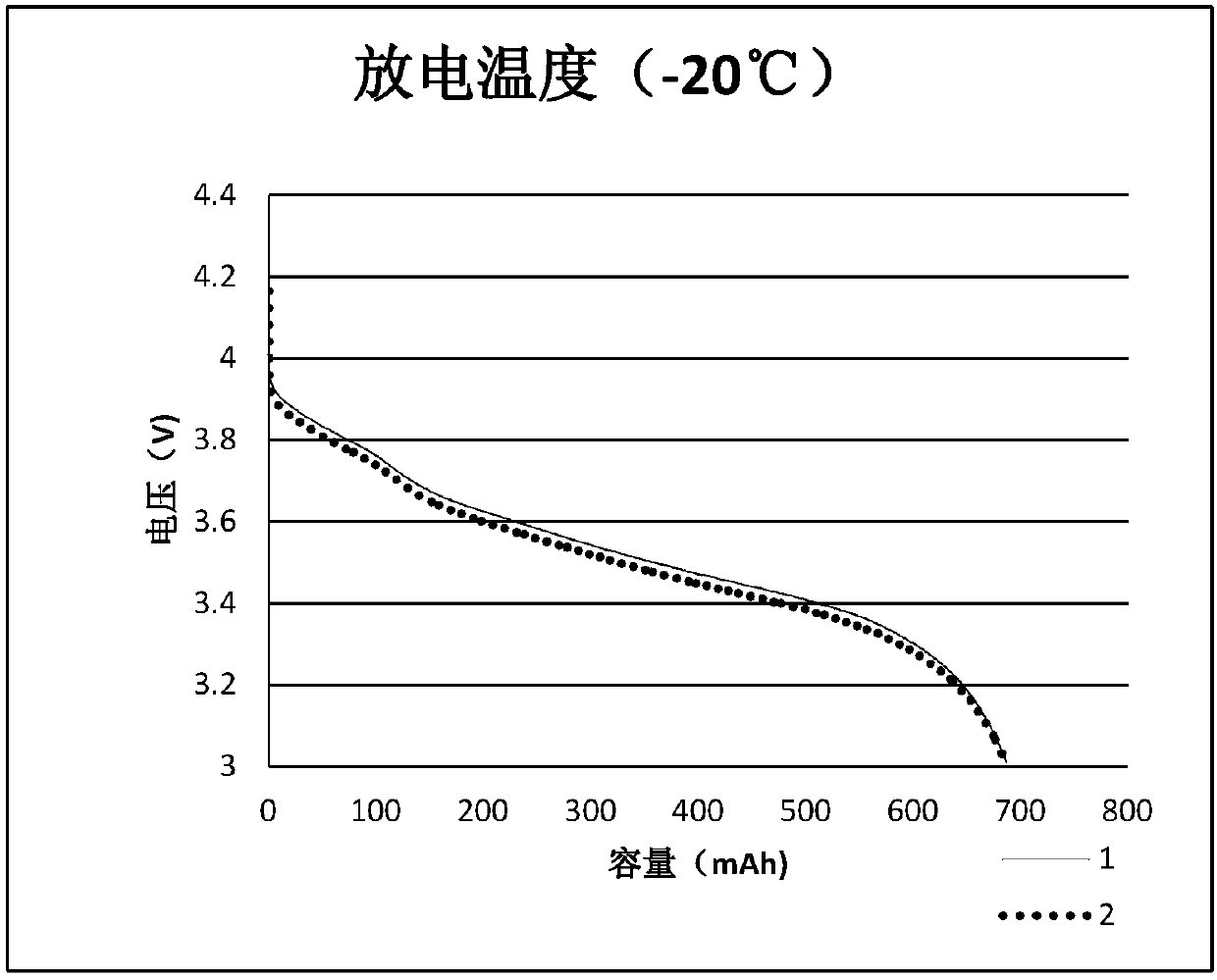

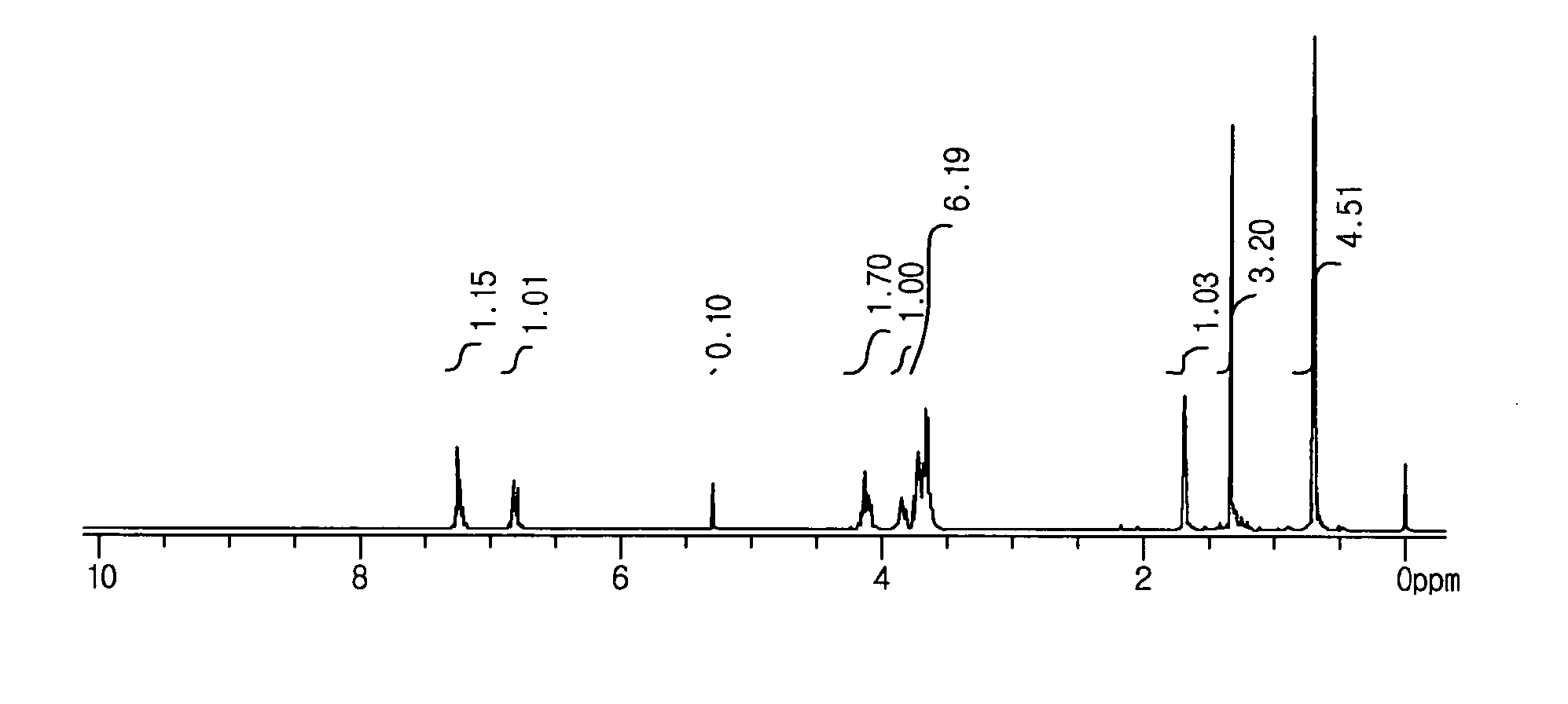

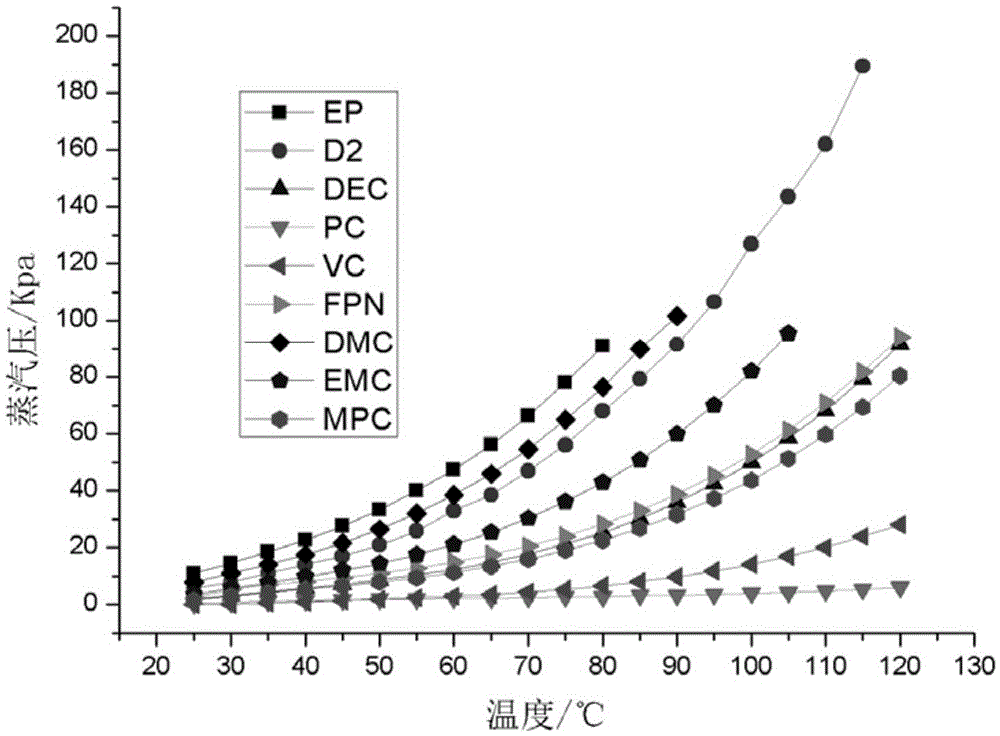

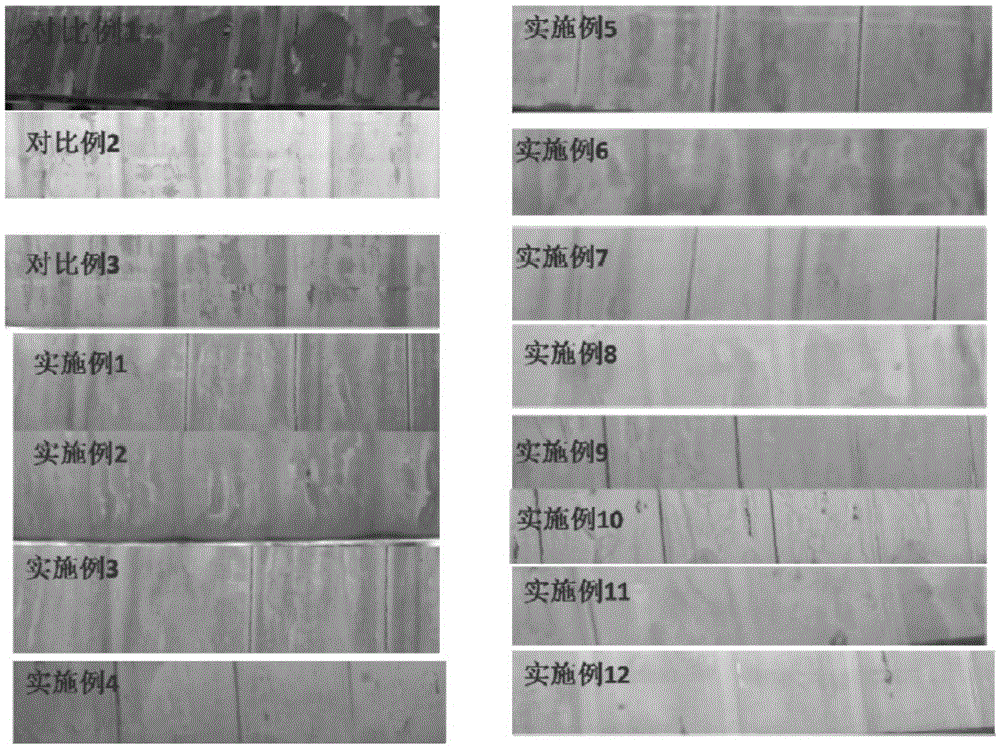

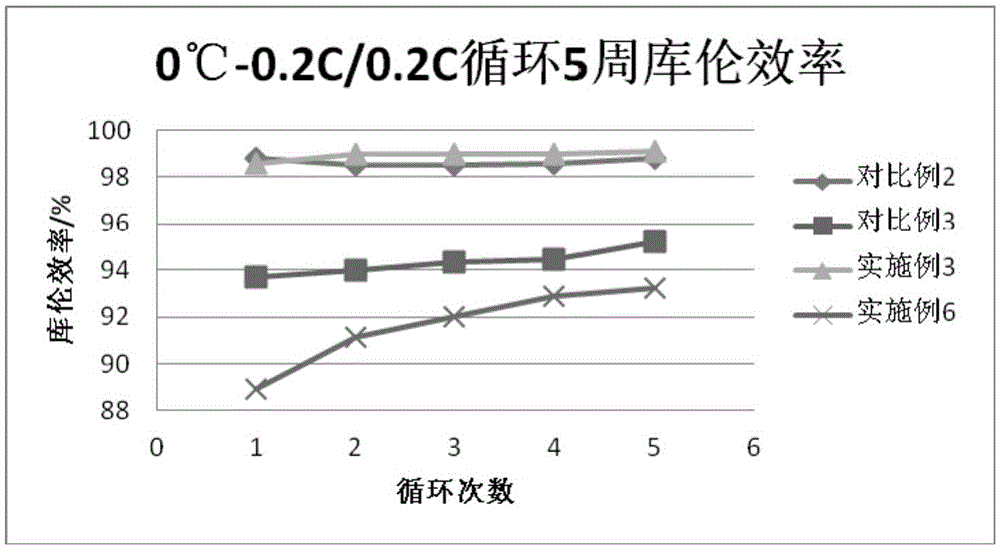

Lithium-ion secondary battery and electrolyte thereof

InactiveCN103078141AFacilitated DiffusionImproved magnification performanceSecondary cellsNon-aqueous electrolyte accumulator electrodesMethyl carbonateCarbonate

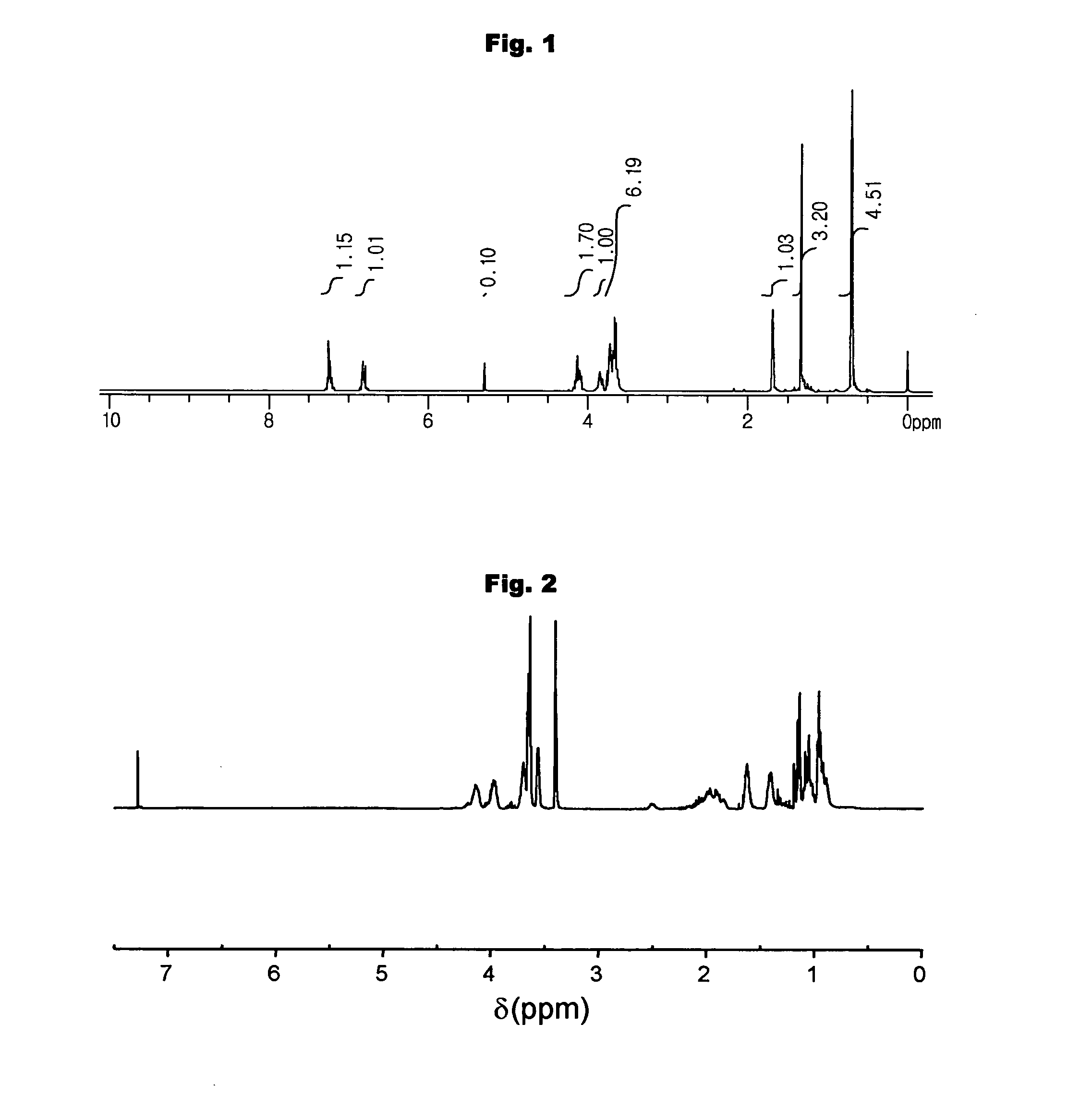

The invention discloses a lithium-ion secondary battery and an electrolyte thereof. The electrolyte comprises a solvent, lithium salt and a film forming additive, wherein the solvent comprises a first solvent and a second solvent; the first solvent comprises linear carboxylic ester and ethylene carbonate; the second solvent is one or more of ethyl methyl carbonate, diethyl carbonate, dimethyl carbonate and propylene carbonate; and the film forming additive is one or more of fluoroethylene carbonate, vinylene carbonate, 1,3-propane suhone, succinonitrile, adiponitrile, lithium bis(oxalato)borate, and lithium oxalyldifluoroborate. Due to the collocation of linear carboxylic ester and ethylene carbonate, a solvent system with a higher dielectric constant and low viscosity is obtained; the film forming additive improves poor compatibility between linear carboxylic ester and graphite; and finally the lithium-ion secondary battery adopting the electrolyte presents high-power discharge capacity, excellent high-temperature cycling stability and low-temperature charge and discharge properties.

Owner:NINGDE AMPEREX TECH

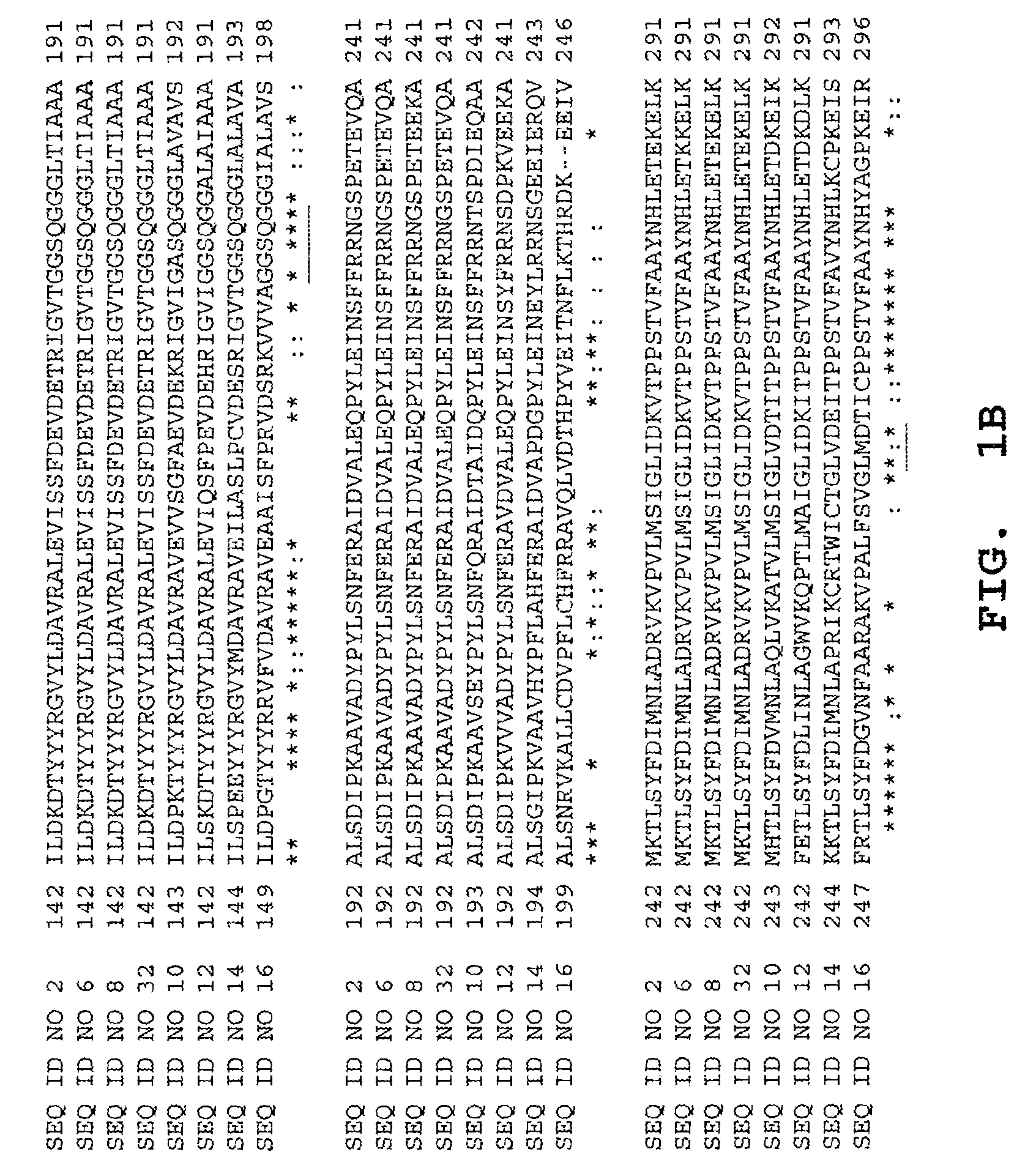

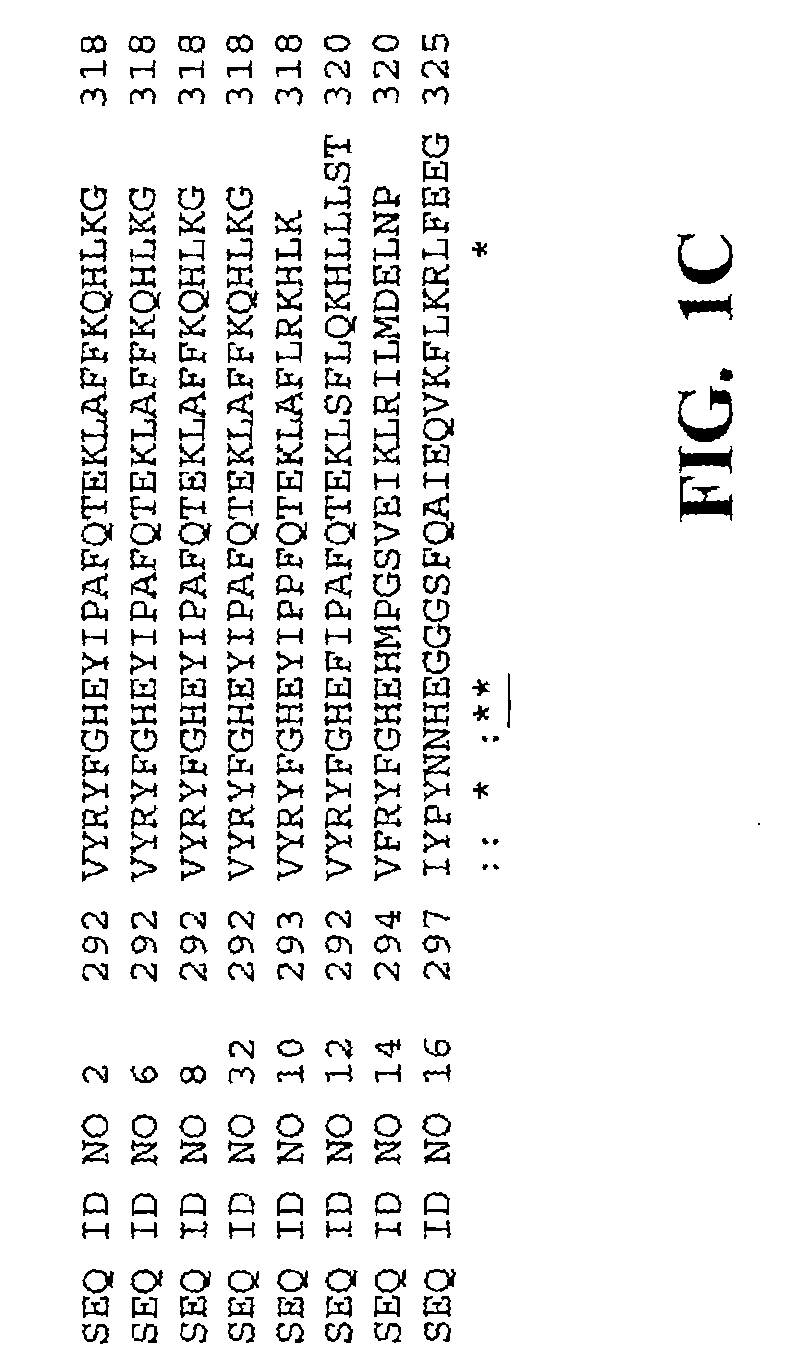

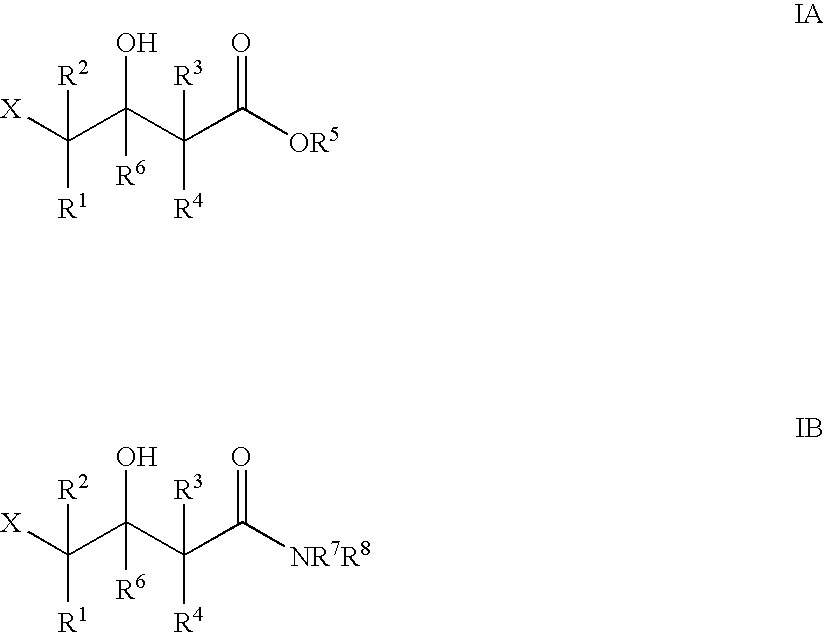

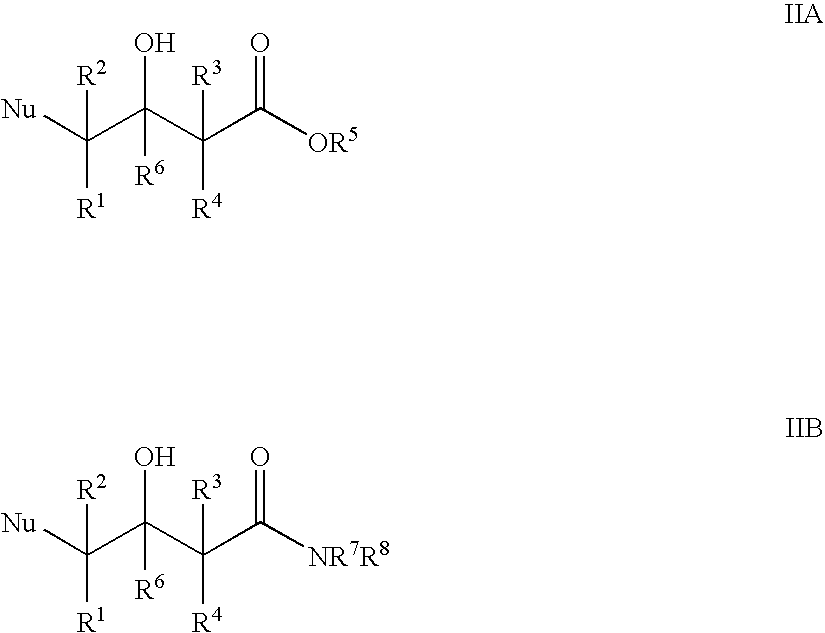

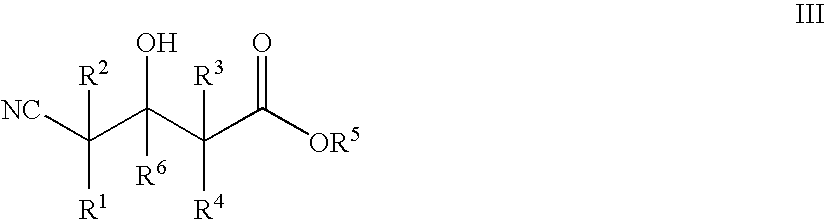

Enzymatic processes for the production of 4-substituted 3-hydroxybutyric acid derivatives and vicinal cyano, hydroxy substituted carboxylic acid esters

The present invention provides methods and compositions for preparing 4-substituted 3-hydroxybutyric acid derivatives by halohydrin dehalogenase-catalyzed conversion of 4-halo-3-hydroxybutyric acid derivatives. The present invention further provides methods and compositions for preparing 4-halo-3-hydroxybutyric acid derivatives by ketoreductase-catalyzed conversion of 4-halo-3-ketobutyric acid derivatives The present invention also provides methods and compositions for preparing vicinal cyano, hydroxyl substituted carboxylic acid esters.

Owner:CODEXIS INC

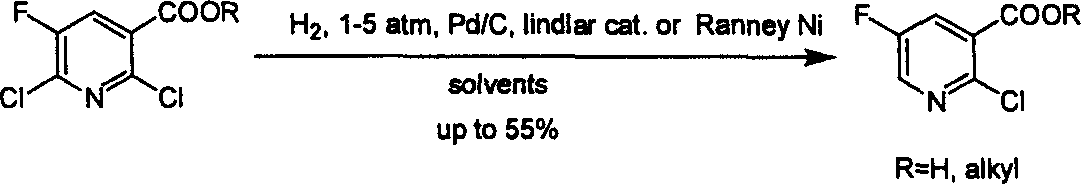

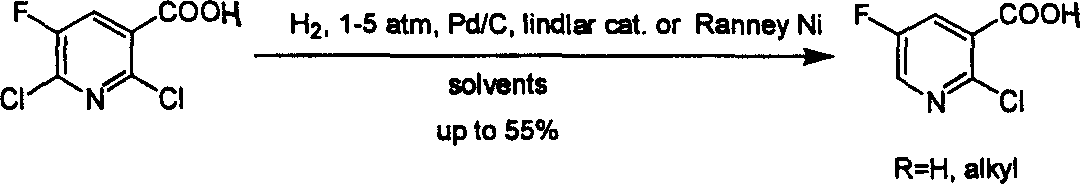

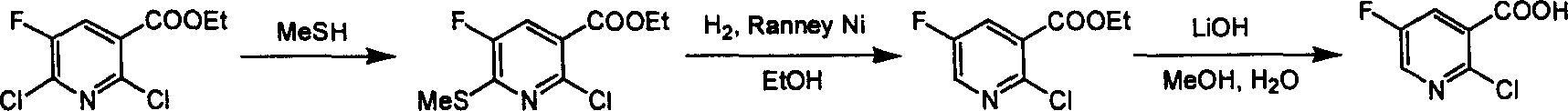

Preparation of 2-Cl-5-F-nicotinate and nicotonic acid

InactiveCN1613849AReasonable choice of reaction processShorten the synthesis processOrganic chemistryNiacinAcid production

Production of 2-chlorine-5-fluorine-nicotinate and acid is carried out by 2-chlorine-5-fluorine-nicotinate and related carboxylic acid selective dechlorinating, and 2-chlorine-5-fluorine-nicotinate hydrolyzing 2-chlorine-5-fluorine-niacin under the exist of alkaline substances. It can be used for 2-chlorine-5-fluorine-nicotinate and 2-chlorine-5-fluorine-niacin medicine intermediate.

Owner:上海药明康德新药开发有限公司

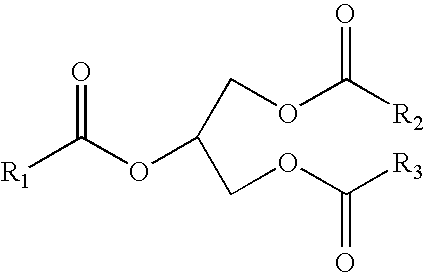

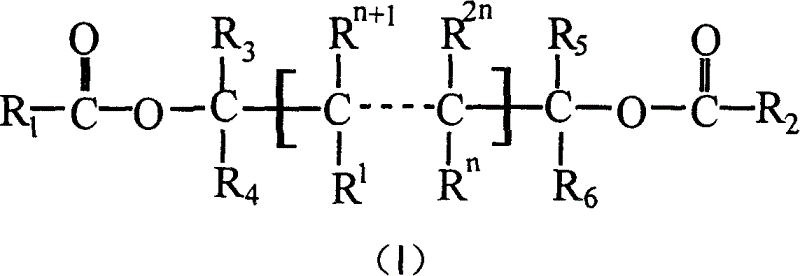

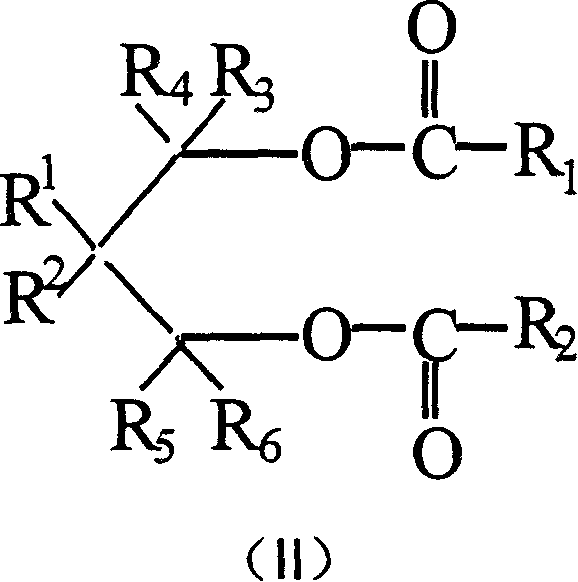

Lubricant compositions containing hydroxy carboxylic acid and hydroxy polycarboxylic acid esters

InactiveUS7696136B2Reduce the amount requiredLower performance requirementsOrganic chemistryLiquid carbonaceous fuelsCarboxylic acidMedicinal chemistry

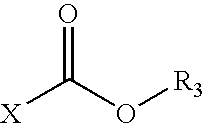

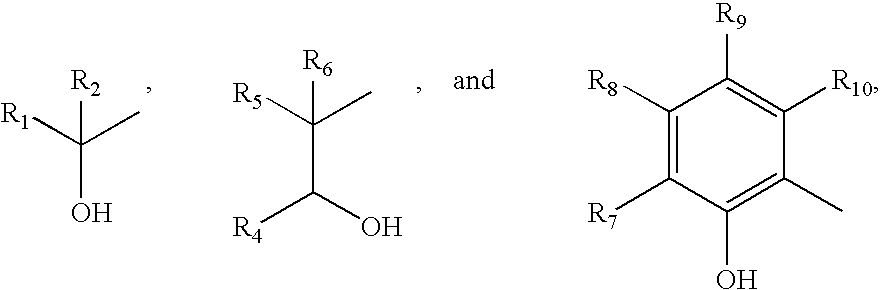

Disclosed herein is a composition comprising:(A) a lubricant or a hydrocarbon fuel;(B) at least one hydroxy carboxylic acid ester or hydroxy polycarboxylic acid ester having the generic formula defined herein; and(C) at least one phosphorus-containing additive.

Owner:CHEMTURA CORP

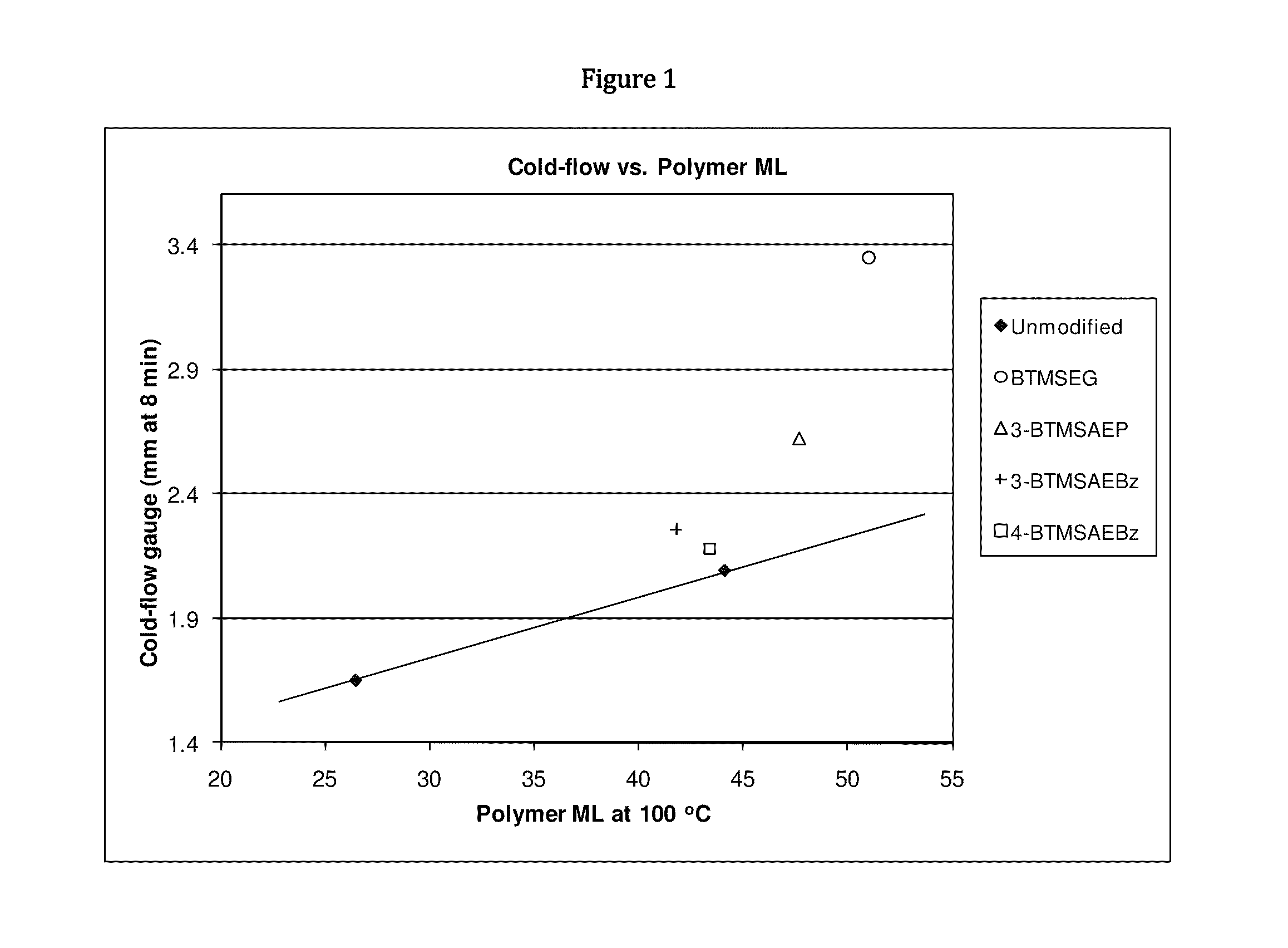

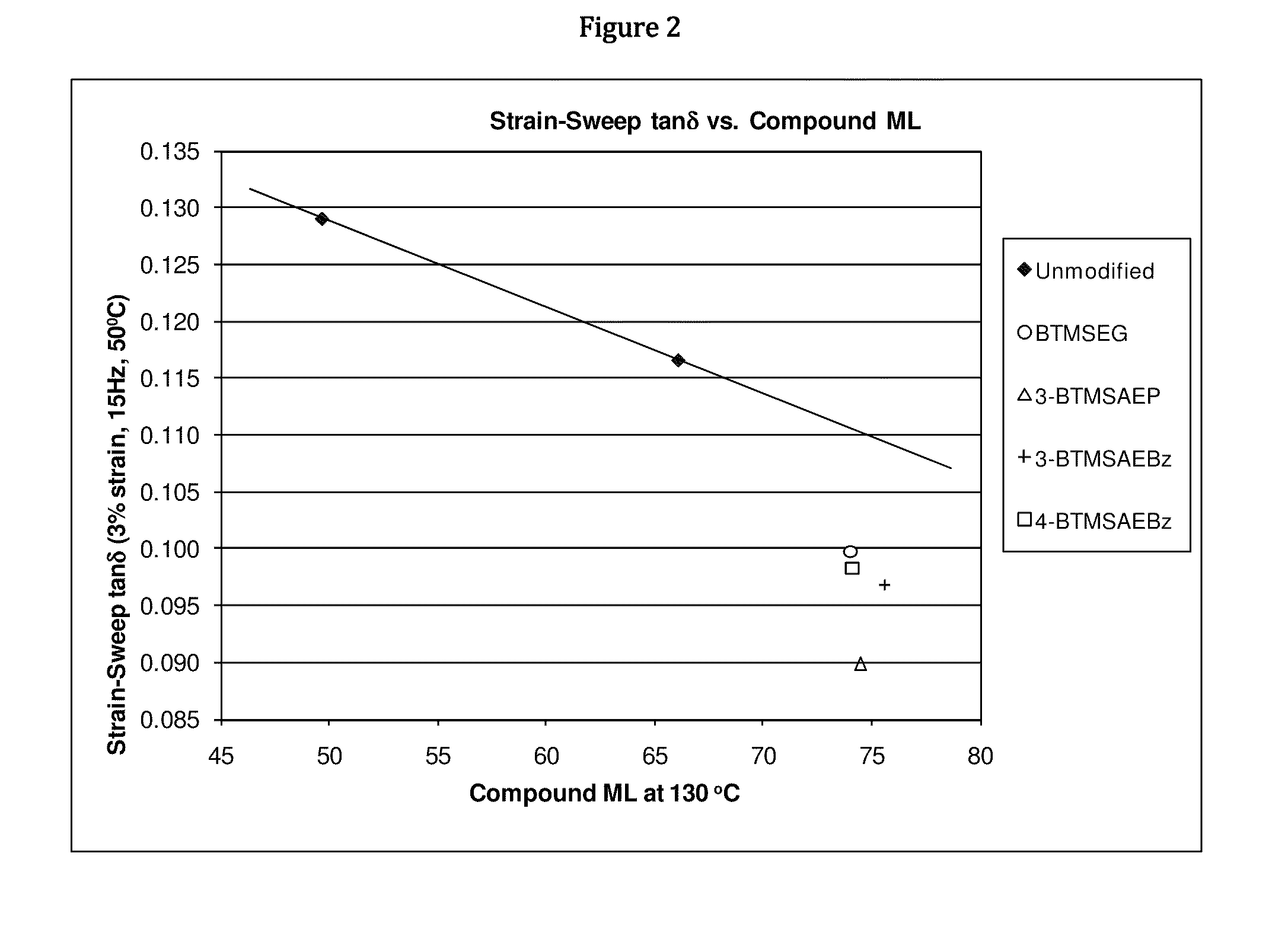

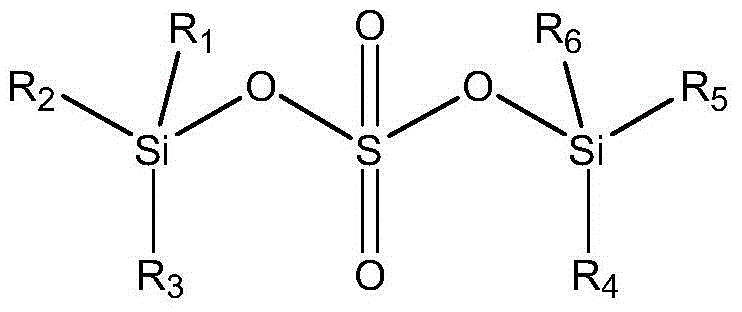

Functionalized polymers and methods for their manufacture

A method for preparing a functionalized polymer, the method comprising the steps of (i) polymerizing monomer with a coordination catalyst to form a reactive polymer; and (ii) reacting the reactive polymer with a carboxylic or thiocarboxylic ester containing a silylated amino group.

Owner:BRIDGESTONE CORP

Power battery and lithium ion electrolyte thereof

InactiveCN104600362AImprove low temperature discharge performancePromote circulationSecondary cellsSilanesKetone solvents

The invention provides a power battery and a lithium ion electrolyte thereof. The lithium ion electrolyte comprises a non-aqueous organic solvent, lithium salt and an additive, wherein the additive comprises a first additive and a second additive, and the first additive comprises silane sulfate; the first additive accounts for 0.05 to 10% of the total weight of the electrolyte, and the second additive is an auxiliary additive and comprises one or more of vinylene carbonate, propane sultone, fluoroethylene carbonate, vinyl ethylene carbonate, ethylene sulfite, adiponitrile, and succinic anhydride in any proportion; the second additive accounts for 0.1-5wt% of the total weight of the electrolyte, and the non-aqueous organic solvent is a carbonic ester solvent, a carboxylic ester solvent, an ether solvent or a ketone solvent; and the lithium salt comprises primary lithium salt and secondary lithium salt.

Owner:SHENZHEN 3SUN ELECTRONICS

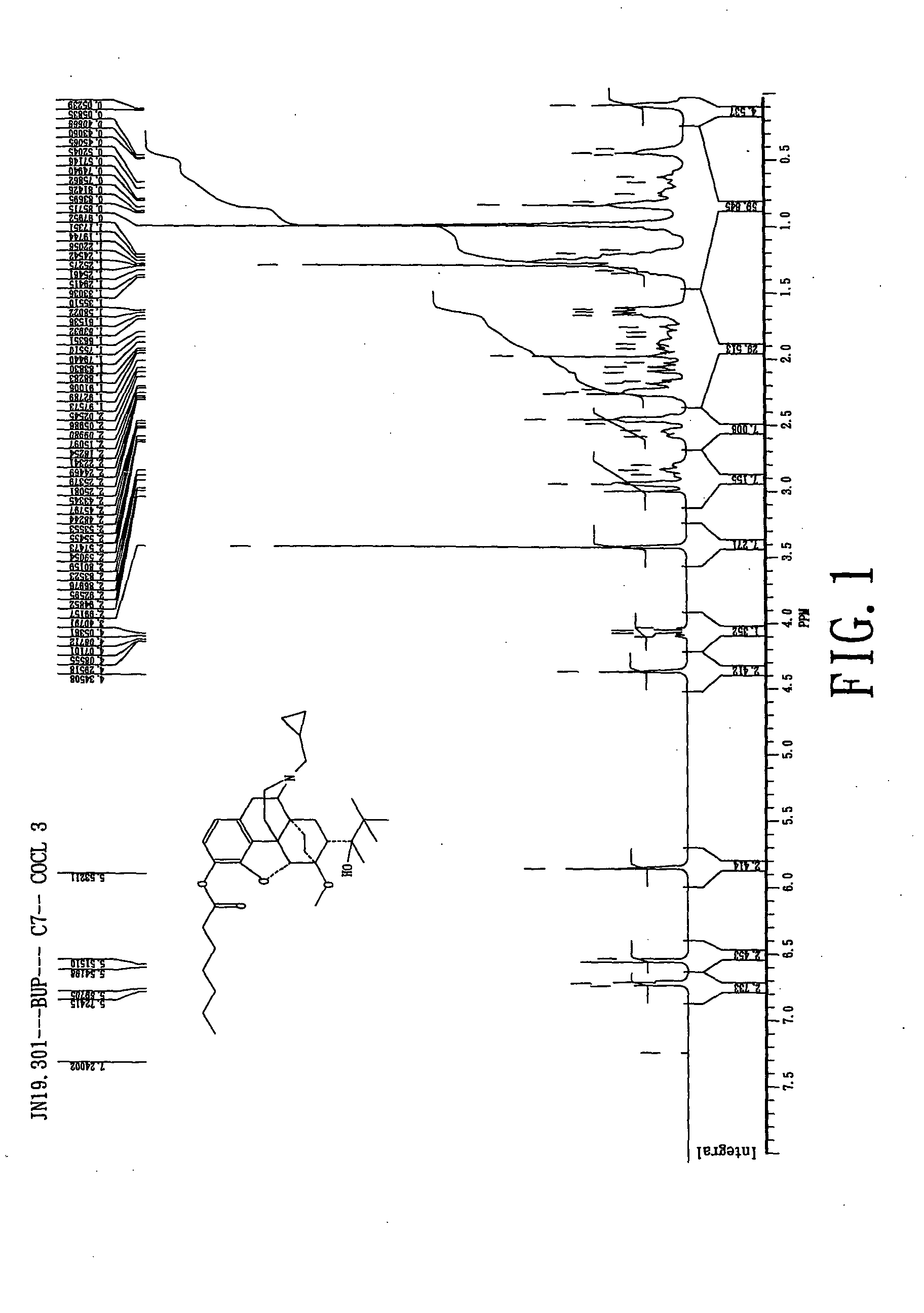

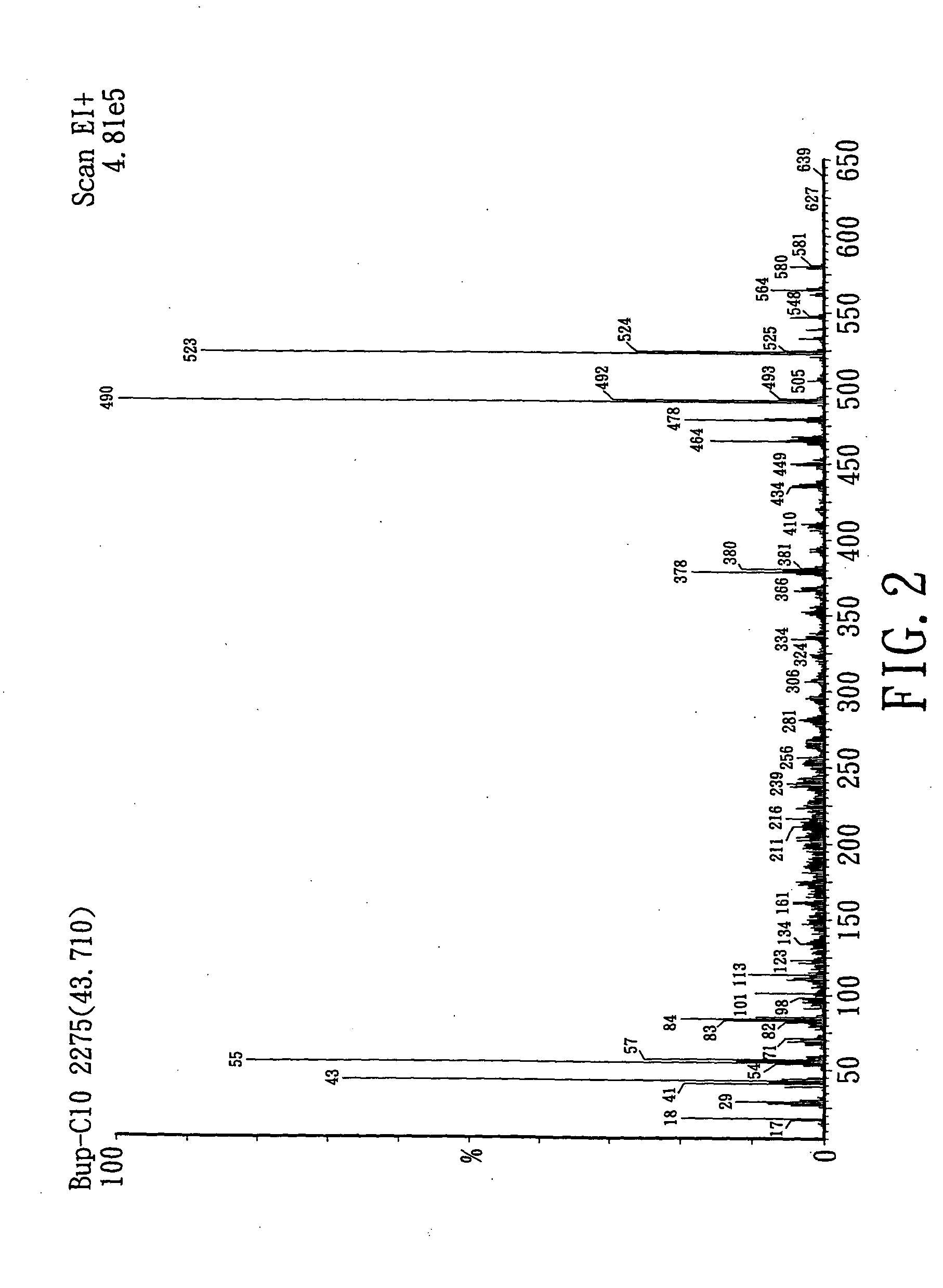

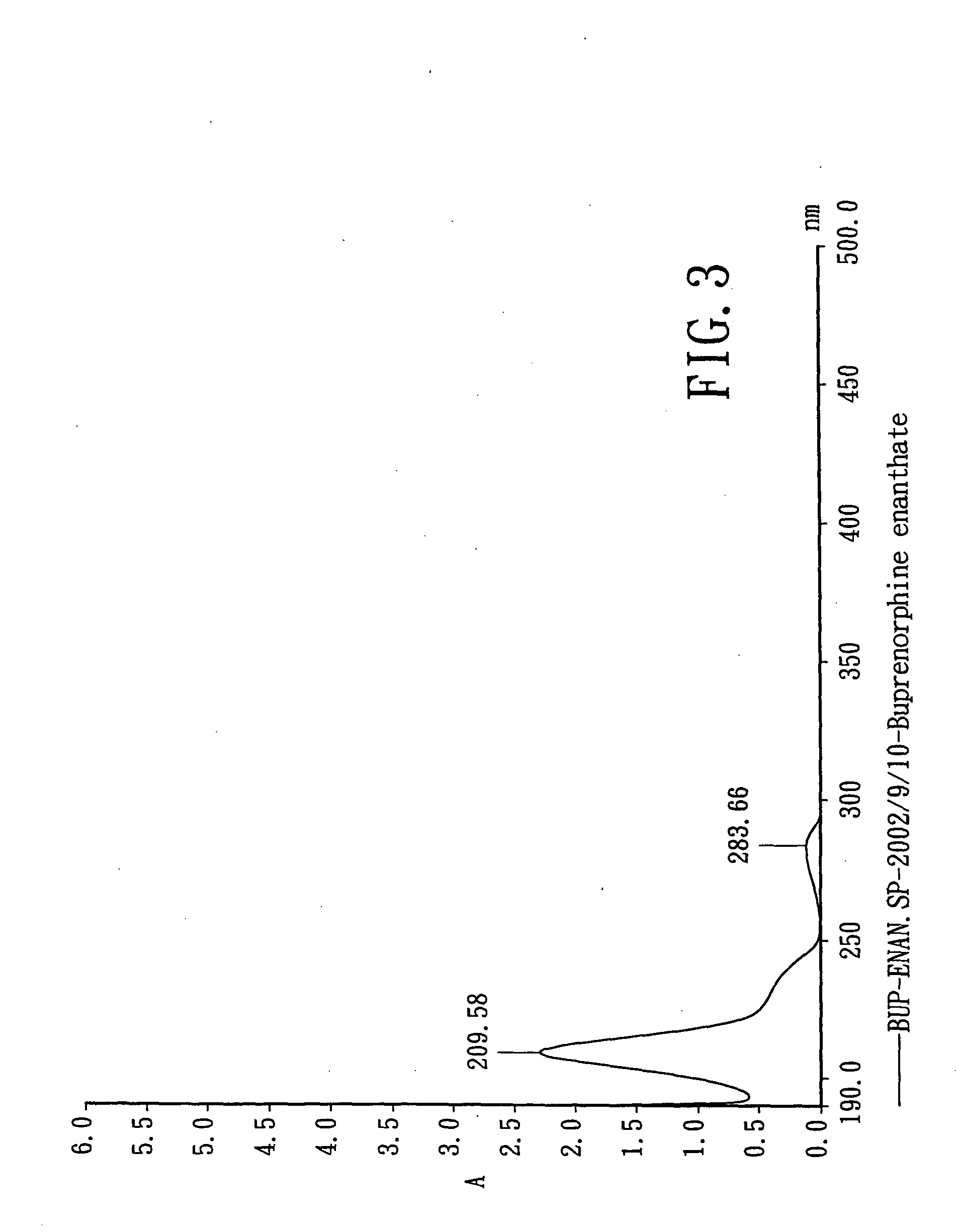

Novel ester derivatives of buprenorphine and their preparation processes, and long acting analgestic pharmaceutical compositions

Disclosed herein are novel buprenorphine monocarboxylic ester derivatives and dibuprenorphine dicarboxylic ester derivatives which exert a longer analgesic effect as compared to buprenorphine hydrochloride. Also disclosed are the processes for synthesizing the novel ester derivatives of buprenorphine, and long-acting analgesic pharmaceutical compositions containing a compound selected from buprenorphine base and the novel ester derivatives of buprenorphine.

Owner:CHI MEI MEDICAL CENT

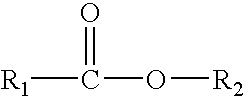

Plasticizer Blends and Use Thereof

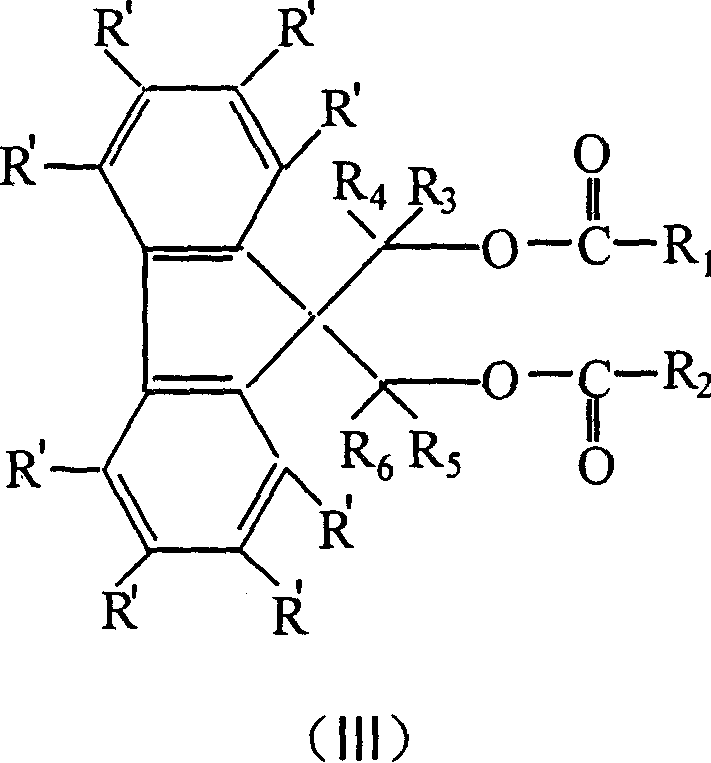

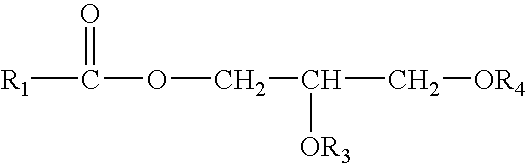

Provided are mixtures of 1) compounds of the formula:wherein R1 is a saturated or unsaturated cyclic hydrocarbon optionally substituted with an alkyl and / or an OXO-ester, and R2 is a C4 to C14 hydrocarbyl; and 2) one or more second plasticizers selected from the group consisting of alkyl terephthalates, alkyl phthalates, alkyl benzoate esters, di-benzoate esters, esters of cyclohexane polycarboxylic acids, and dialkyl adipates. Also provided are plasticized polymer compositions containing said mixtures.

Owner:EXXONMOBIL CHEM PAT INC

Nonaqueous electrolytic liquid and lithium secondary battery employing same

InactiveCN1411619AExcellent charge and discharge characteristicsImprove conductivityOrganic electrolyte cellsNegative electrodesPhosphoric Acid EstersCarbamate

Nonaqueous electrolytic liquids for lithium secondary batteries which have flame retardancy (self-extinguishing characteristics) or incombustibility (no flash point), have a high conductivity, and are electrochemically stable. One of the nonaqueous electrolytic liquids comprises a nonaqueous solvent comprising as an essential ingredient at least one phosphate (a) selected among chain phosphoric esters (a1) and cyclic phosphoric esters (a2). The nonaqueous solvent may further contain a cyclic carboxylic ester (b1) and a cyclic carbonic ester (b2). Another nonaqueous electrolytic liquid comprises the nonaqueous solvent and incorporated therein at least either a vinylene carbonate compound (c1) or a vinylethylene carbonate compound (c2) and one or more compounds selected from the group consisting of cyclic amide compounds (d1), cyclic carbamate compounds (d2), and cyclic hetero-compounds (d3).

Owner:MITSUBISHI RAYON CO LTD

Enzymatic production of peracids using perhydrolytic enzymes

A process is provided to produce a concentrated aqueous peracid solution in situ using at least one enzyme having perhydrolase activity in the presence of hydrogen peroxide (at a concentration of at least 500 mM) under neutral to acidic reaction conditions from suitable carboxylic acid esters (including glycerides) and / or amides substrates. The concentrated peracid solution produced is sufficient for use in a variety of disinfection and / or bleaching applications.

Owner:DUPONT US HLDG LLC

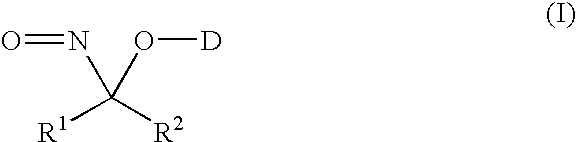

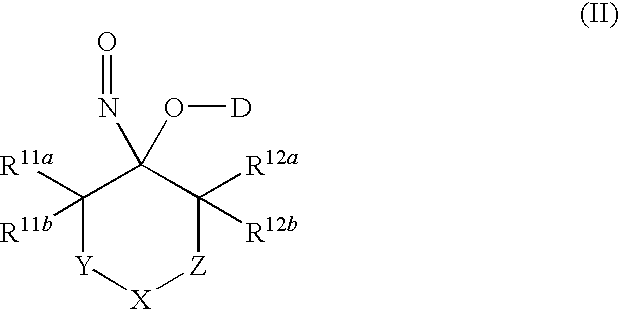

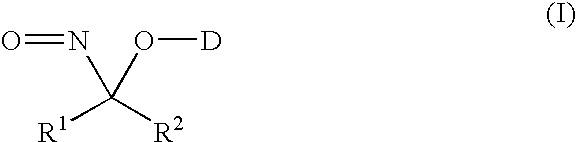

Nitroso compounds as nitroxyl donors and methods of use thereof

The invention relates to nitroso derivatives including carboxylic acid and phosphoric acid esters of hydroxy nitroso compounds that donate nitroxyl (HNO) under physiological conditions. The compounds and compositions of the invention are useful in treating and / or preventing the onset and / or development of diseases or conditions that are responsive to nitroxyl therapy, including heart failure, ischemia / reperfusion injury and cancer.

Owner:CARDIOXYL PHARMA

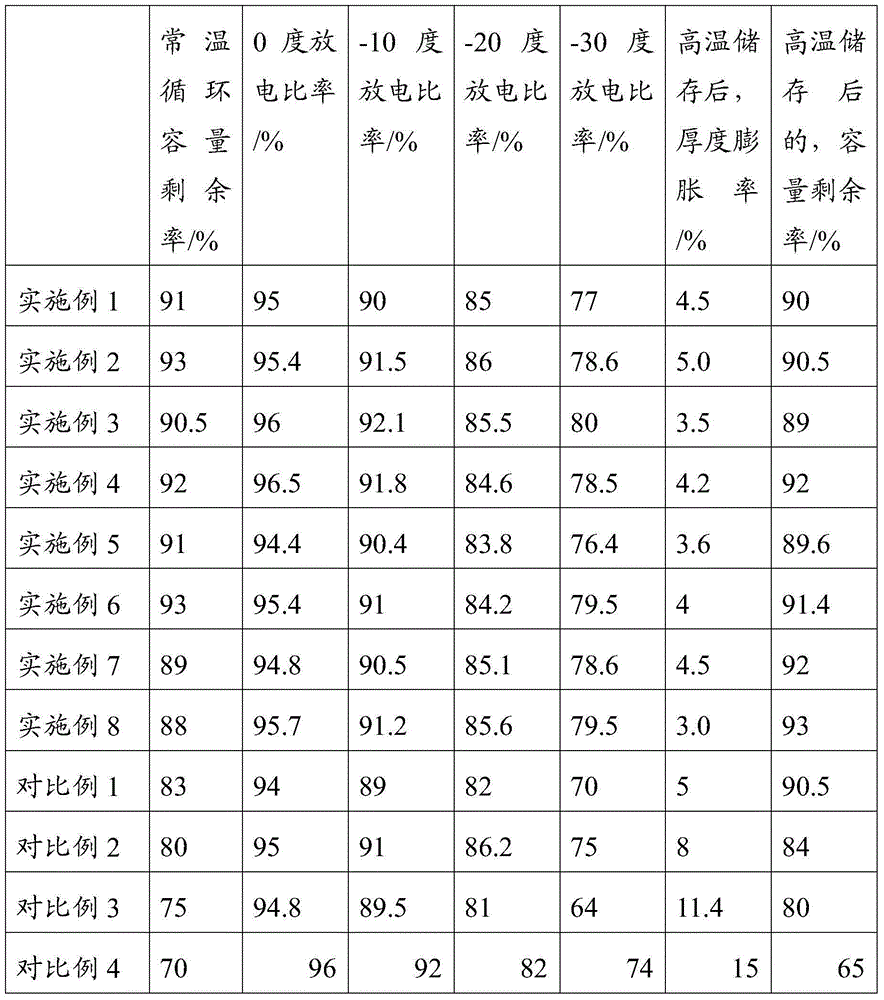

High-voltage rate electrolyte with high-and-low temperature performance and lithium ion battery using electrolyte

PendingCN107706455AAvoid decompositionImprove high temperature storage performanceSecondary cellsOrganic electrolytesHigh temperature storageLithium-ion battery

The invention discloses a high-voltage rate electrolyte with high-and-low temperature performance and a lithium ion battery using the electrolyte. The electrolyte comprises a non-aqueous solvent, a lithium salt dissolved in the non-aqueous solvent and additives, wherein the non-aqueous solvent comprises propylene carbonate (PC) and linear carboxylic ester; and the additives comprise citraconic anhydride, lithium difluorophosphate (LiPO<2>F<2>), fluoroethylene carbonate, ethylene sulfate and 1, 2-di(2-cyanoethoxyl)ethane. By applying the synergistic effect generated by the solvent system and the additive optimization combination to the lithium ion battery, excellent cycle life, low-temperature discharge characteristic and high-temperature storage characteristic of the battery still can be maintained at high-voltage rate.

Owner:EVE ENERGY CO LTD

Metal oxide paste composition and method of manufacturing semiconductor electrode using the same

InactiveUS20070102676A1Good dispersionOrganic chemistryElectrolytic capacitorsSemiconductor electrodeMetal oxide nanoparticles

Disclosed herein are a metal oxide paste composition comprising a carboxylic ester dispersant and / or a phosphate dispersant, and a method for manufacturing a semiconductor electrode for solar cells using the same. The disclosed metal oxide paste composition improves the dispersibility of metal oxide nanoparticles. Thus, if it is used to manufacture a semiconductor electrode for solar cells, it will allow the increased adsorption of a dye, thus improving the photoelectric efficiency of the resulting solar cell.

Owner:SAMSUNG SDI CO LTD

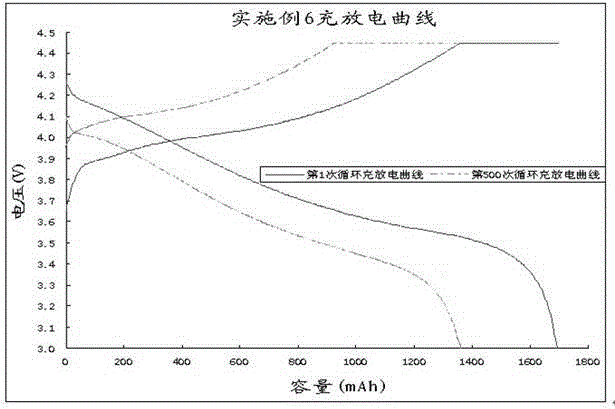

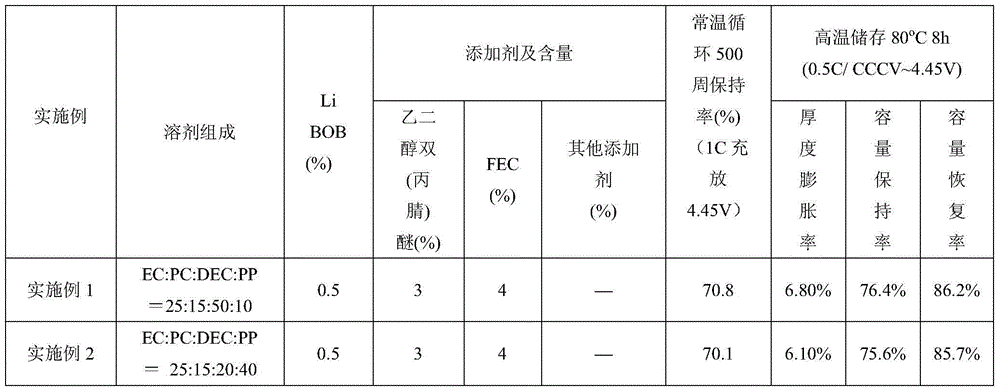

High-voltage electrolyte and lithium ion battery using electrolyte

InactiveCN104979589APromote circulationHigh decomposition voltageSecondary cellsHigh temperature storageEthylene glycol bis

The invention discloses high-voltage electrolyte and a lithium ion battery using the electrolyte. The invention is realized by the following technical scheme: the high-voltage electrolyte comprises a non-aqueous solvent, lithium salt and an additive, wherein the non-aqueous solvent is a carboxylic ester compound which accounts for 1-40% by mass of the high-voltage electrolyte; the additive is any one or more of lithium bis(oxalate)borate (Li BOB), fluoroethylene carbonate (FEC) and ethylene glycol bis(propionitrile) ether. The high-voltage electrolyte contains carboxylic ester solvents capable of improving an electrode / electrolyte interface, and through optimized combination of the carboxylic ester solvents, Li BOB, FEC, ethylene glycol bis(propionitrile) ether and other various additives, the good cycle performance of a high-voltage battery can be ensured, meanwhile, the high-temperature storage performance of the high-voltage battery can be effectively improved, and gas generation of the battery under high-voltage high-temperature storage condition can be obviously inhibited.

Owner:DONGUAN KAIXIN BATTERY MATERIAL

Lithium ion battery electrolyte with both high and low temperature performances

The invention relates to the technical field of lithium ion electrolytes, and in particular relates to a lithium-ion battery electrolyte with both high and low temperature performances. The electrolyte comprises lithium hexafluorophosphate, mixed organic solvents, filming additives, additives for improving the dielectric constant and the low temperature infiltration capability, and a lithium salt type additive, wherein the mixed organic solvents comprise a carbonic ester solvent and a linear carboxylic ester solvent; the linear carboxylic ester solvent in the mixed organic solvents is one or a mixture of more than two of ethyl propionate, propionic acid n-propyl ester, n-propyl acetate, acetic acid n-butyl ester and isobutyl acetate; and the additives for improving the dielectric constant and the low temperature infiltration capability are one or a mixture of more than two of fluoro ethylene carbonate, difluoro ethylene carbonate and 4-trifluoromethyl ethylene carbonate. A battery prepared from the lithium-ion battery electrolyte with both high and low temperature performances is long in service life, and both the good low temperature discharge performance of the battery is ensured, and the storage performance of the battery at the high temperature of 60 DEG C is effectively considered.

Owner:DONGGUAN SHANSHAN BATTERY MATERIALS

Automatic dishwashing composition containing a sulfonated copolymer

ActiveUS8389458B2Improve abilitiesInhibit coloringOrganic detergent compounding agentsSurface-active detergent compositionsSulfonatePolymer science

An ADW composition comprising a builder and a water-soluble copolymer which comprises: (a) from about 30 to 60 mol % of the copolymer having a structural unit originating from a monoethylenic unsaturated dicarboxylic acid (or dicarboxylate) monomer having 4 to 6 carbon atoms or its anhydride at; (b) from about 30 to 60 mol % of the copolymer having a structural unit originating from a monoethylenic unsaturated monocarboxylic acid (or monocarboxylate) monomer having 3 to 8 carbon atoms; and (c) from about 5 to 15 mol % of the polymer having a structural unit originating from a monoethylenic unsaturated monomer having a sulfonic (or sulfonate) group; wherein the water-soluble copolymer has a weight average molecular weight of from about 1,000 to about 50,000 wherein the copolymer is polymerized with hydrogen peroxide.

Owner:PROCTER & GAMBLE CO

Catalyst, preparation method and application for olefin polymerization or copolymerization

This invention relates to a catalyst system which is used for alkenes polymerizing or copolymerization, it includes solid catalyst composition A that contains titanium and organic Aluminum compound B, silicoorganic compound C, in the composing process of catalyst composition A, use aldyl ester of aryl group mon-carboxylic acid and aldyl ester of fatty series or multielement carboxylic acid of aryl group for reasonable combination, among them aldyl ester of aryl group mon-carboxylic can play a role of assisting separating agent, it is useful to separate catalyst particle; Meanwhile it is used as electron donor, it also can load on the surface of catalytic agent together with compound of multielement carboxylic esters, improve the surface structure of catalytic agent, thus improve the catalyzing function of catalytic agent. This catalytic agent that is used for propylene polymerizing has high catalytic activity and anti- impurity function, particle appearance of catalytic agent is good, particles distribute narrowly, hydro-adjusting function of catalytic agent is good, it is useful for many polymerizing technology such as seriflux method, noumenon method and gas method, molecular weight distribution of polymer is narrow, particle appearance of polymer is good, fine grits is little; Its fine anti-impurity function can effectively reduce production cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Methods of removing filter cake from well producing zones

Methods are provided for removing filter cake containing a bridging agent soluble in a carboxylic acid salt from a formation fluids producing zone penetrated by a well bore. The methods basically comprise the steps of introducing in an aqueous carrier liquid a carboxylic acid ester and a base for slowly catalyzing the hydrolysis of the ester and forming a carboxylic acid salt therewith into the producing zone, and allowing the base to catalyze the hydrolysis of the carboxylic acid ester to form the carboxylic acid salt so that the carboxylic acid salt dissolves the bridging agent and the filter cake is removed.

Owner:HALLIBURTON ENERGY SERVICES INC

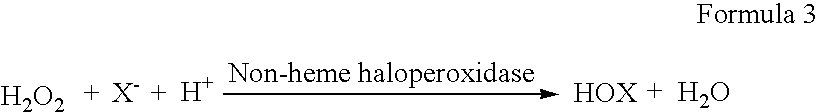

Enzymatic production of peracids from carboxylic acid ester substrates using non-heme haloperoxidases

A process is provided for producing peroxycarboxylic acids from carboxylic acid esters. More specifically, carboxylic acid esters are reacted in situ with an inorganic peroxide in the presence of a non-heme haloperoxidase having perhydrolysis activity to produce peroxycarboxylic acids.

Owner:EI DU PONT DE NEMOURS & CO

Lithium ion battery electrolyte for improving battery pole piece interface

InactiveCN105552440ALower impedanceHigh impedanceSecondary cellsOrganic electrolytesElectrical batteryPole piece

The invention relates to the technical field of a lithium ion battery, in particular to a lithium ion battery electrolyte for improving a battery pole piece interface. The lithium ion battery electrolyte comprises a non-aqueous organic solvent, a lithium salt and an additive, wherein the non-aqueous organic solvent comprises at least one of carboxylic ester, halogenated carbonic ester, aromatic hydrocarbon and halogenated aromatics thereof, and the additive comprises at least one of a lithium salt additive, fluoro carbonic ester, fluoro-ether, phosphonitrile and derivatives thereof. Compared with the prior art, the lithium ion battery electrolyte has the advantages that the solvent and the additive are used in a combination way to generate a synergic effect, the electrolyte has a favorable negative electrode interface in a low-temperature and rapid charging / discharging environments, no lithium is precipitated, thus, the requirements of low-temperature charging and discharging, rapid charging and discharging and high compaction density of a negative electrode pole plate can be simultaneously met, and meanwhile, the potential risk caused by lithium precipitation during the charging of the battery is reduced.

Owner:DONGGUAN SHANSHAN BATTERY MATERIALS

Polyurethane gel foams

ActiveUS8673992B2Improved permeation kineticsKind to skinBaby linensTamponsWound dressingPolymer science

Polyurethane gel foams are proposed as is their use in modern wound treatment. In particular, wound dressings comprise polyurethane gel foams for treating moderately to severely exuding wounds. The polyurethane gel foams are thereby produced from an isocyanate component A having a functionality f of fB≦3, a polymeric polyol component B having a functionality f of fB≦6, and a polysaccharide C, comprising at least one uronic acid or a salt thereof, wherein the ratio of the number of isocyanates groups of the isocyananate component A to the total number of hydroxyl groups, carboxy groups and carboxylate groups in the polymeric polyol component B and the polysaccharide C corresponds to the ratio 1:2 to 1:30.

Owner:PAUL HARTMANN AG

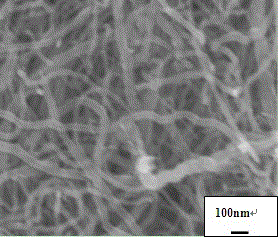

Surface modification method for carbon nano tube

InactiveCN102942810AGood for secondary modificationImprove thermal stabilityPigment treatment with organosilicon compoundsPigment treatment with non-polymer organic compoundsPtru catalystModified carbon

The invention provides a surface modification method for a carbon nano tube and belongs to the field of nanotechnology. The method includes step one, uniformly mixing a carbon nano tube which is subjected to acidification by a strong oxidizing acid with a silane coupling agent and deionized water, reacting under a certain condition, filtering, washing, and drying to obtain a primary modified carbon nano tube; step two, uniformly mixing the primary modified carbon nano tube with polyhydric alcohols and a concentrated sulfuric acid, reacting under a certain condition, filtering, washing to neutral, and drying to obtain a secondary modified carbon nano tube; uniformly mixing the secondary modified carbon nano tube with an organic carboxylic acid, an esterification reaction catalyst and N,N-dimethylformamide, reacting under a certain condition by the aid of the protection of inert gases, cooling to the room temperature, filtering, washing, and drying to obtain the surface modification carbon nano tube. When the prepared modified carbon nano tube which is provided with ester groups on the surface is mixed with a polyester resin, the interface-free mixing is achieved, and the heat stability and the mechanical property of the modified polyester resin can be improved.

Owner:TAIYUAN UNIV OF TECH

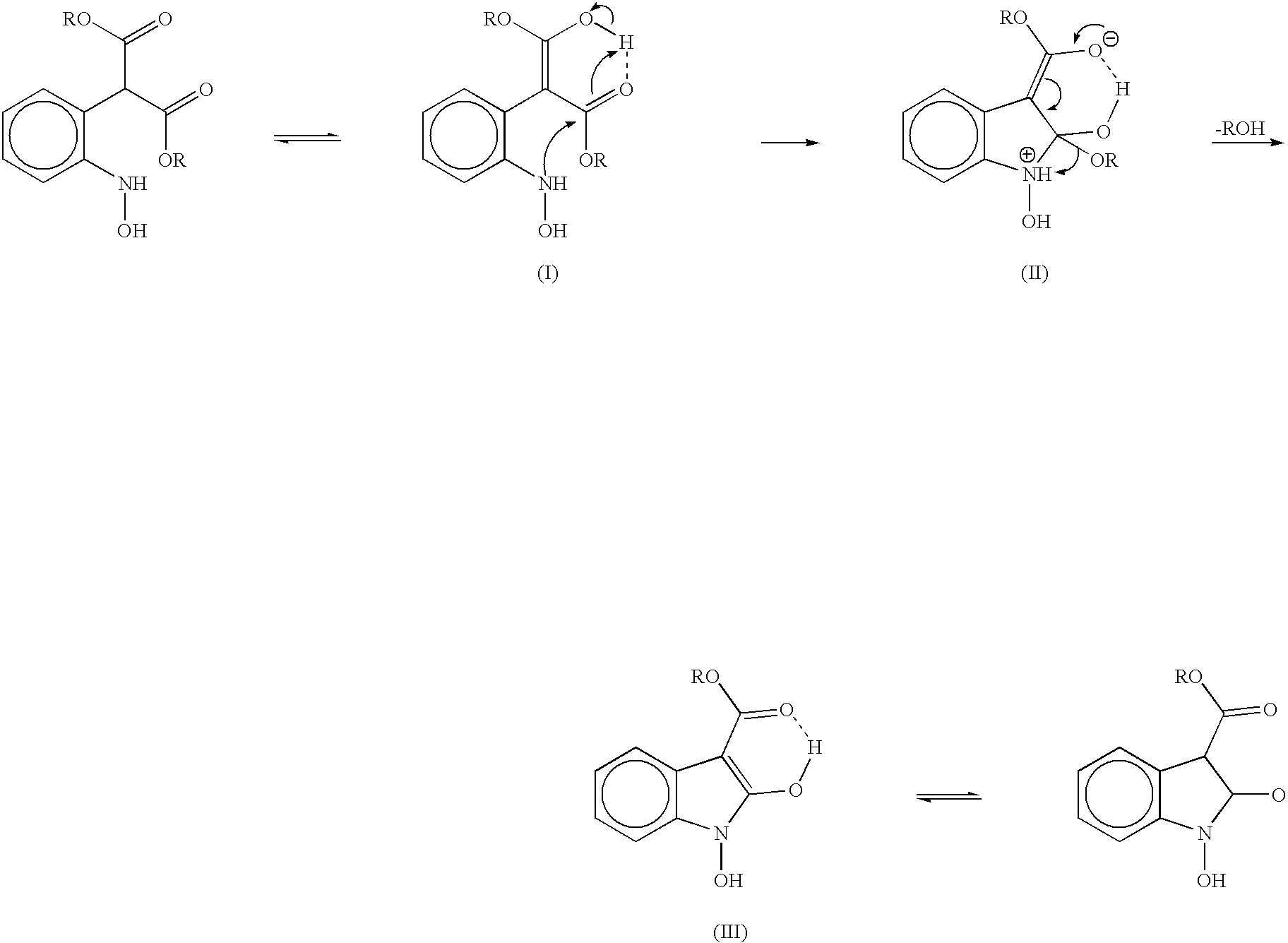

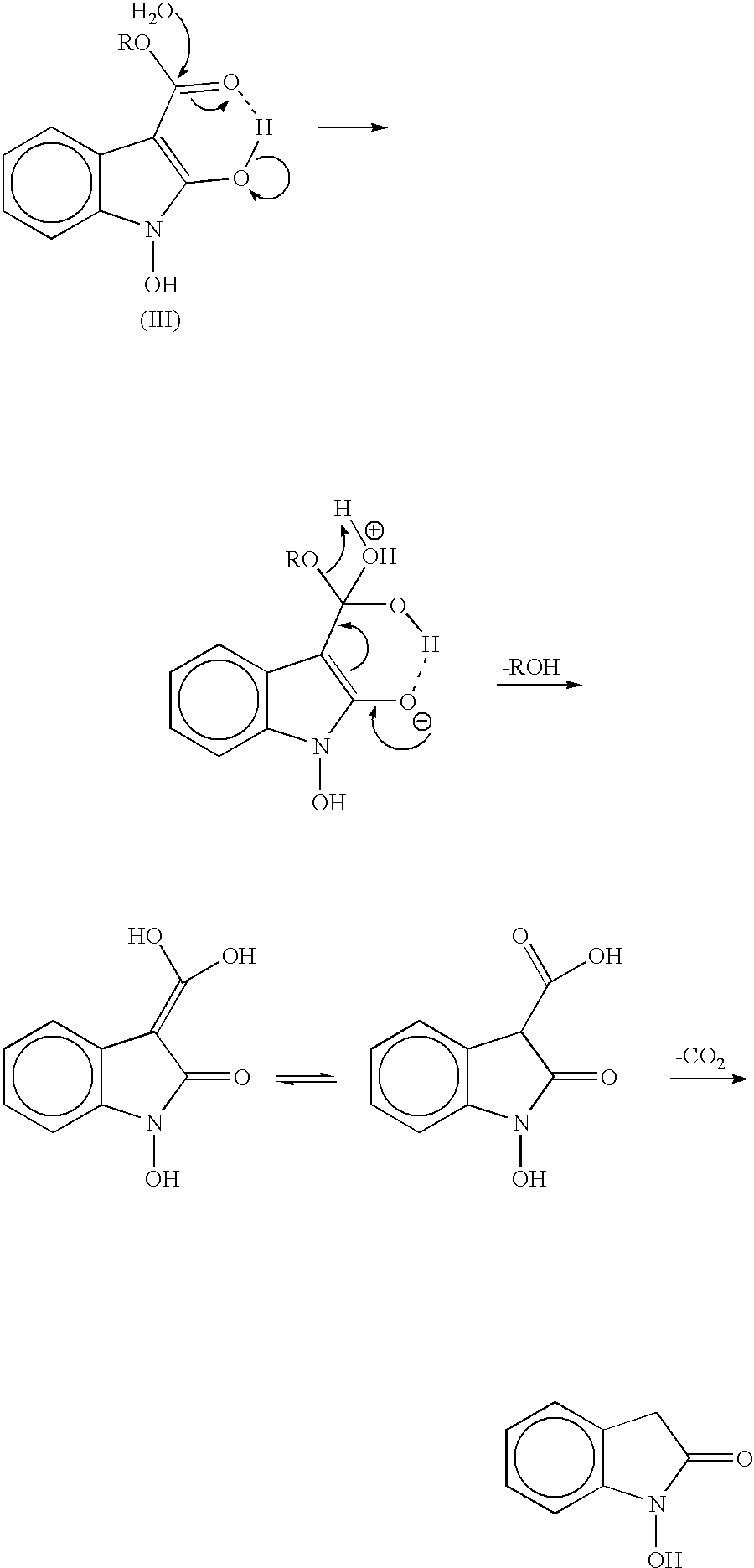

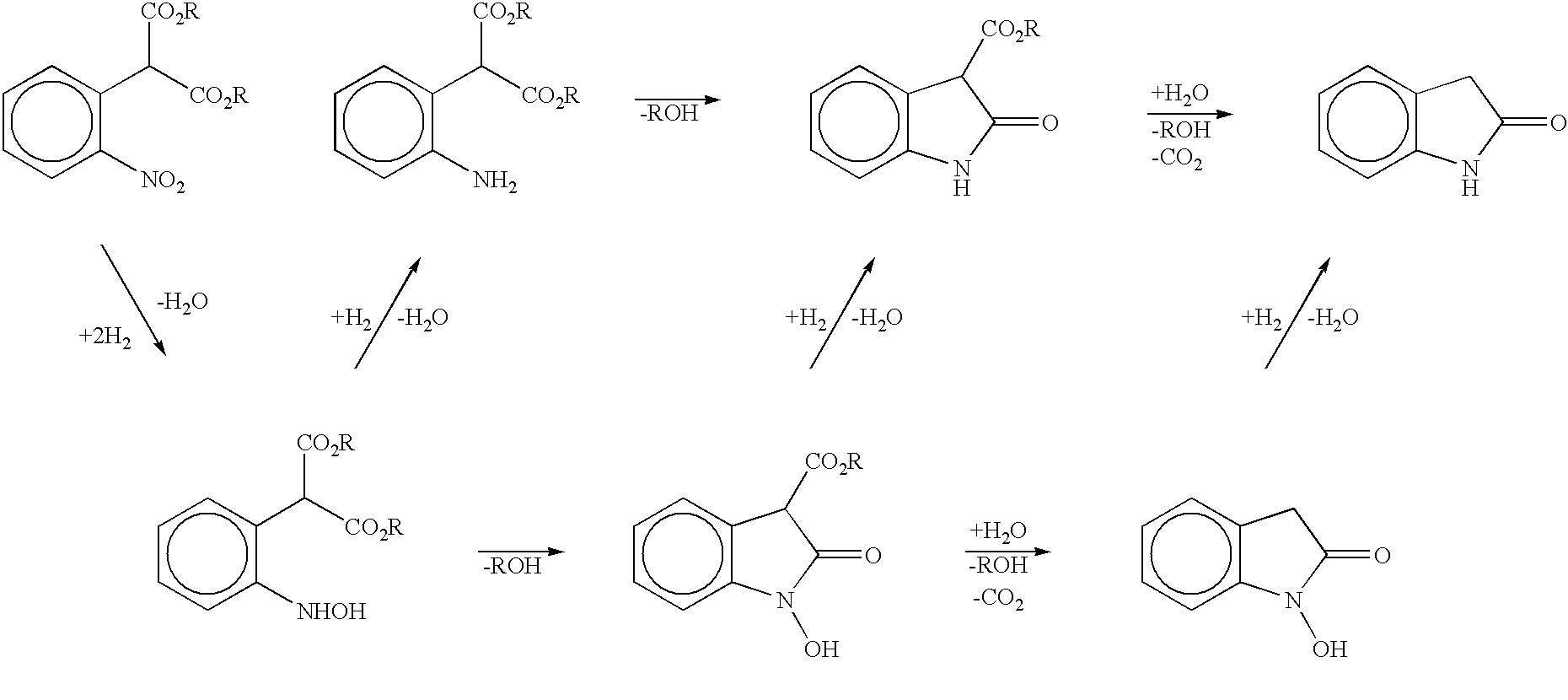

Process for preparing 2-oxindoles and N-hydroxy-2-oxindoles

InactiveUS6469181B1Avoid wastingImprove economyCarboxylic acid nitrile preparationOrganic compound preparationReaction intermediateCarboxylic salt

The present invention provides a processes, having practical utility, for preparing 2-oxindoles, N-hydroxy-2-oxindoles, or mixtures thereof comprising: catalytically hydrogenating a 2-nitroarylmalonate diester to produce a 2-(N-hydroxyamino)arylmalonate diester, a 2-aminoarylmalonate diester, or mixtures thereof as a first reaction intermediate; cyclizing, by intramolecular aminolysis of one ester group, the first reaction intermediate to produce a N-hydroxy-2-oxindole-3-carboxylate ester, 2-oxindole-3-carboxylate ester, or mixtures thereof as a second reaction intermediate; and hydrolyzing and decarboxylating the remaining ester group of the second reaction intermediate to produce the N-hydroxy-2-oxindole, the 2-oxindole, or mixtures thereof, wherein the cyclization reaction and the hydrolysis and decarboxylation reaction are conducted in situ with the catalytic hydrogenation reaction without isolation of said reaction intermediates.

Owner:CATALYTICA PHARMA

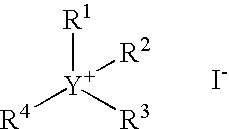

Carbonylation process

ActiveUS20070293695A1Organic compound preparationPreparation by carbon monoxide or formate reactionHydrogen halideCarboxylic acid

Disclosed is a carbonylation process for the production of carboxylic acids, carboxylic acid esters and / or carboxylic acid anhydrides wherein a carbonylation feedstock compound selected from one or more organic oxygenates such as alcohols, ethers, and esters is contacted with carbon monoxide in the presence of a carbonylation catalyst and one or more onium compounds. The carbonylation process differs from known carbonylation processes in that a halide compound such as a hydrogen halide, typically hydrogen iodide, and / or alkyl halide, typically methyl iodide, extraneous or exogenous to the carbonylation process is not fed or supplied separately to the process.

Owner:EASTMAN CHEM CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com