Preparation of 2-Cl-5-F-nicotinate and nicotonic acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

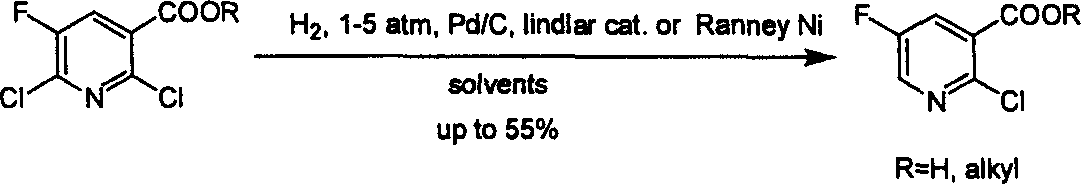

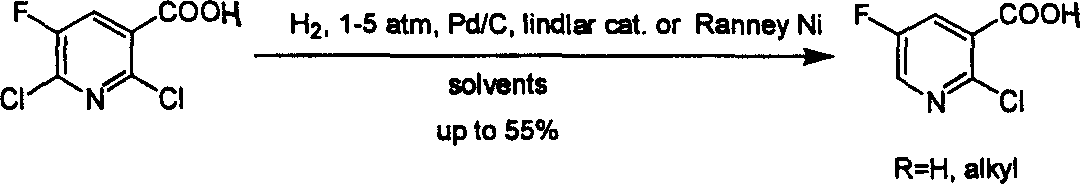

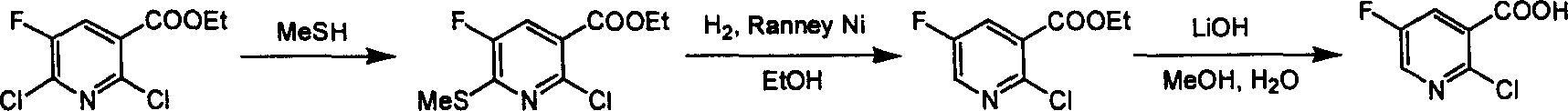

Method used

Image

Examples

Embodiment 1

[0018] The first step: the synthesis of 2-chloro-5-fluoro-nicotinic acid ethyl ester

[0019] Add triethylamine (32 g, 0.32 mol) and Lindlar catalyst (2.5 g) to ethyl acetate solution (1.2 L) of 2,6-dichloro-5-fluoro-nicotinic acid ethyl ester (50 g, 0.21 mol), Hydrogenation was carried out at 3 atmospheres at room temperature for 12 hours. The catalyst was removed by filtration, the reaction solution was concentrated and then column chromatographed to obtain 2-chloro-5-fluoro-nicotinic acid ethyl ester (24.1 g, 0.12 mol, yield: 55%) as a colorless oil. 1 H NMR (400MHz, CDCl 3 ): δ8.36(d, J=2.8Hz, 1H), 7.88(dd, J=8.0 & 2.8Hz, 1H), 4.40(q, J=7.2Hz, 2H), 1.39(t, J=7.2Hz ,2H); 13 C NMR (400MHz, CDCl 3 ): δ164.5(C), 160.5(C), 158.0(C), 146.0(d, J=10.8Hz, C), 141.3(d, J=99.6Hz, CH), 146.0(d, J=10.8 Hz, C), 129.2(d, J=13.6Hz, C), 128.5(d, J=85.4Hz, CH), 63.9(d, J=48.0Hz, CH 2 ), 15.4 (CH 3 ); Ms(M + +1204206).

[0020] The second step: the synthesis of 2-chloro-5-fluoro...

Embodiment 2

[0023] Synthesis of 2-amino-5-fluoro-nicotinic acid ethyl ester

[0024] Add triethylamine (32 g, 0.32 mol) and 5% Pd-C catalyst ( 1.0 g), hydrogenated at normal pressure and room temperature for 12 hours. The catalyst was removed by filtration, the reaction liquid was concentrated and then column chromatographed to obtain oily 2-chloro-5-fluoro-nicotinic acid ethyl ester (18.4 g, 0.09 mol, yield: 43%).

Embodiment 3

[0026] Synthesis of 2-chloro-5-fluoro-nicotinic acid ethyl ester

[0027] Add triethylamine (32g, 0.32mol) and 5% Raney nickel (1.0 g) Hydrogenation at normal pressure at 40°C for 12 hours. The catalyst was removed by filtration, the reaction solution was concentrated and then column chromatographed to obtain oily ethyl 2-chloro-5-fluoro-nicotinate (18.4 g, 0.09 mol, yield: 25%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com