Industrialized preparation method of using 2-bromothiazole for compounding thiazole-2-methanamide in a one-boiler mode

A technology of bromothiazole and formamide, which is applied in the field of industrial preparation, can solve the problems of high raw material cost, safety, and low yield, and achieve the effects of low preparation cost, easy reaction control, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

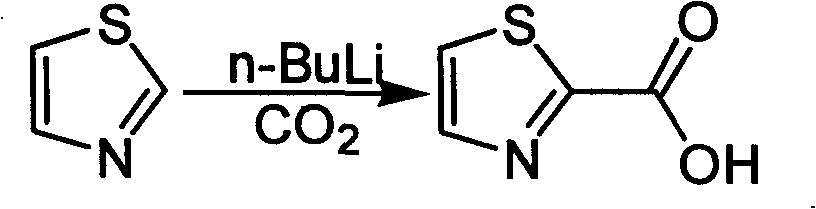

[0034] 1000 mL of methyl tert-butyl ether was added to a 3 L three-necked flask, stirred, cooled to -75° C., and 220 mL of n-butyllithium in n-hexane solution (2.5 mol / L) was added. A solution of 2-bromothiazole (82.01 g) in methyl tert-butyl ether (500 mL) was added dropwise, the temperature was controlled at -70°C to -75°C, and stirring was continued for 0.5 hours after the dropwise addition was completed.

[0035] Dry carbon dioxide gas was introduced into the above obtained mixture, and the temperature was controlled at -70°C to -75°C until the reaction was completed. The temperature was slowly raised to 25° C. and concentrated to dryness to obtain 76 g of solid, namely lithium thiazole-2-carboxylate, the weight content of which was 65.2%, and the yield was 73.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com