Surface modification method for carbon nano tube

A carbon nanotube and surface modification technology, applied in fibrous fillers, dyed low-molecular-weight organic compound treatment, dyed organosilicon compound treatment, etc., can solve the problems of mechanical properties decline and structural defects of polyester resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

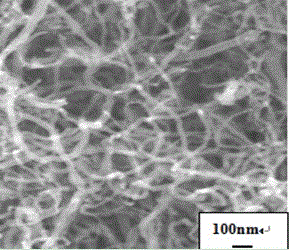

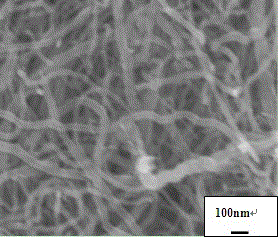

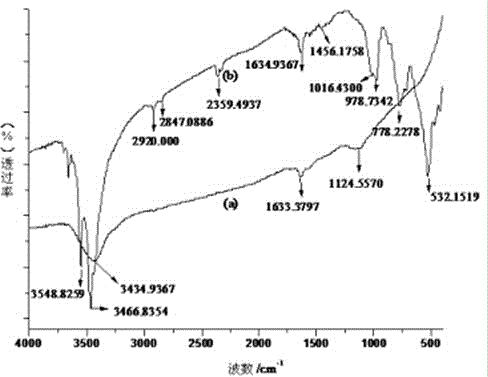

Image

Examples

Embodiment 1

[0045] (1) Add 3g of multi-walled carbon nanotubes acidified by sulfuric acid and 2.5ml of γ-aminopropyltriethoxysilane into 70ml of deionized water, stir and mix evenly at 70°C, after the reaction is completed, pass through 0.22 Filter through a μm vinylidene fluoride membrane, wash repeatedly with deionized water, and dry at 90°C for 12 hours to obtain primary modified multi-walled carbon nanotubes;

[0046] (2) Stir and mix 3 g of the primary modified multi-walled carbon nanotubes with 270 ml of ethylene glycol and 7.5 ml of concentrated sulfuric acid, and react at 130 ° C. After the reaction is completed, filter through a 0.22 μm vinylidene fluoride membrane, and washed with deionized water to neutrality, and dried at 120° C. for 4 hours to obtain secondary modified multi-walled carbon nanotubes;

[0047] (3) Mix 3 g of the secondary modified multi-walled carbon nanotubes with 9 ml of oxalic acid, 0.6 g of antimony trioxide, and 180 ml of N,N-dimethylformamide, and under n...

Embodiment 2

[0050] (1) Add 4g of multi-walled carbon nanotubes acidified with nitric acid and 4ml of anilinomethyltriethoxysilane into 92ml of deionized water, stir and mix evenly at 80°C, after the reaction is completed, pass through a 0.22μm bias Filtrate with vinyl fluoride membrane, wash repeatedly with deionized water, and dry at 80°C for 15 hours to obtain primary modified multi-walled carbon nanotubes;

[0051] (2) Stir and mix 4g of the primary modified multi-walled carbon nanotubes with 380ml of 1,4-butanediol and 10ml of concentrated sulfuric acid, and react at 135°C. Ethylene membrane filtration, and washing with deionized water to neutrality, after drying at a vacuum of 10 Pa and a temperature of 120°C for 5 hours, the secondary modified multi-walled carbon nanotubes were obtained;

[0052] (3) Stir and mix 4 g of the secondary modified multi-walled carbon nanotubes with 16 ml of oxalic acid, 0.8 g of antimony trioxide, and 280 ml of N,N-dimethylformamide, and mix them evenly ...

Embodiment 3

[0055] (1) Add 3g of multi-walled carbon nanotubes acidified by hydrogen peroxide and 6ml of γ-aminopropyltriethoxysilane into 90ml of deionized water, stir and mix evenly at 75°C, after the reaction is completed, pass through 0.22 Filter through a μm vinylidene fluoride membrane, wash repeatedly with deionized water, and dry at 90°C for 12 hours to obtain primary modified multi-walled carbon nanotubes;

[0056] (2) Stir and mix 3 g of the primary modified multi-walled carbon nanotubes with 375 ml of glycerin and 10.5 ml of concentrated sulfuric acid, and react at 140°C. After the reaction is completed, filter through a 0.22 μm vinylidene fluoride membrane, and washed with deionized water to neutrality, and dried for 5.5 hours at a vacuum degree of 10 Pa and a temperature of 115° C. to obtain secondary modified multi-walled carbon nanotubes;

[0057] (3) Stir and mix 3 g of the secondary modified multi-walled carbon nanotubes with 15 ml of terephthalic acid, 0.9 g of concentra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com