Patents

Literature

290results about How to "Improve surface structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

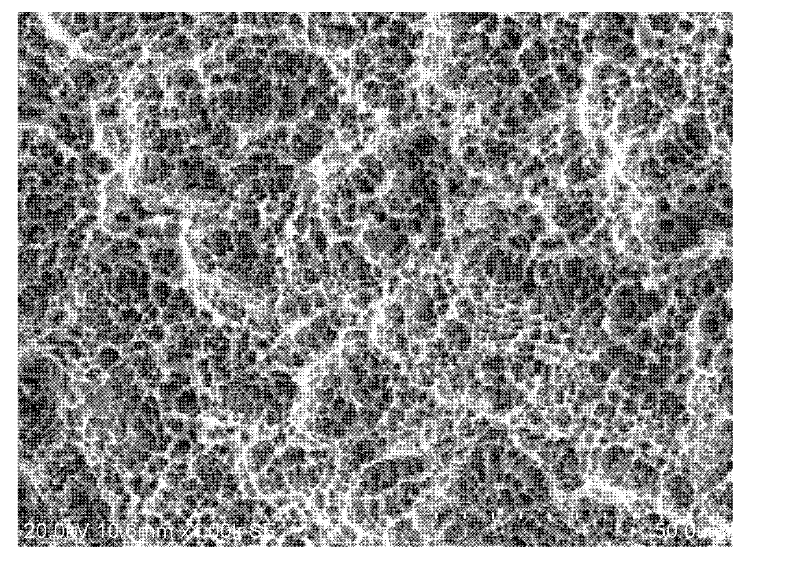

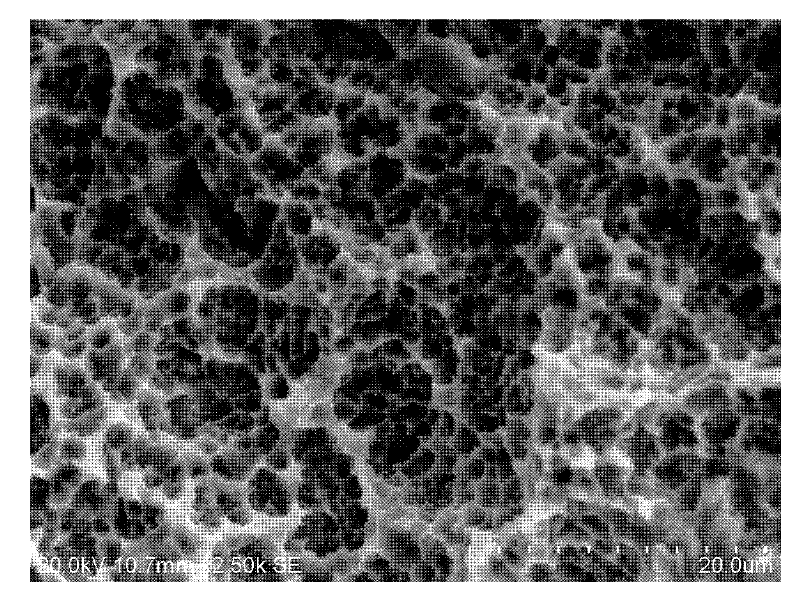

Superhydrophobic surface and method for forming same

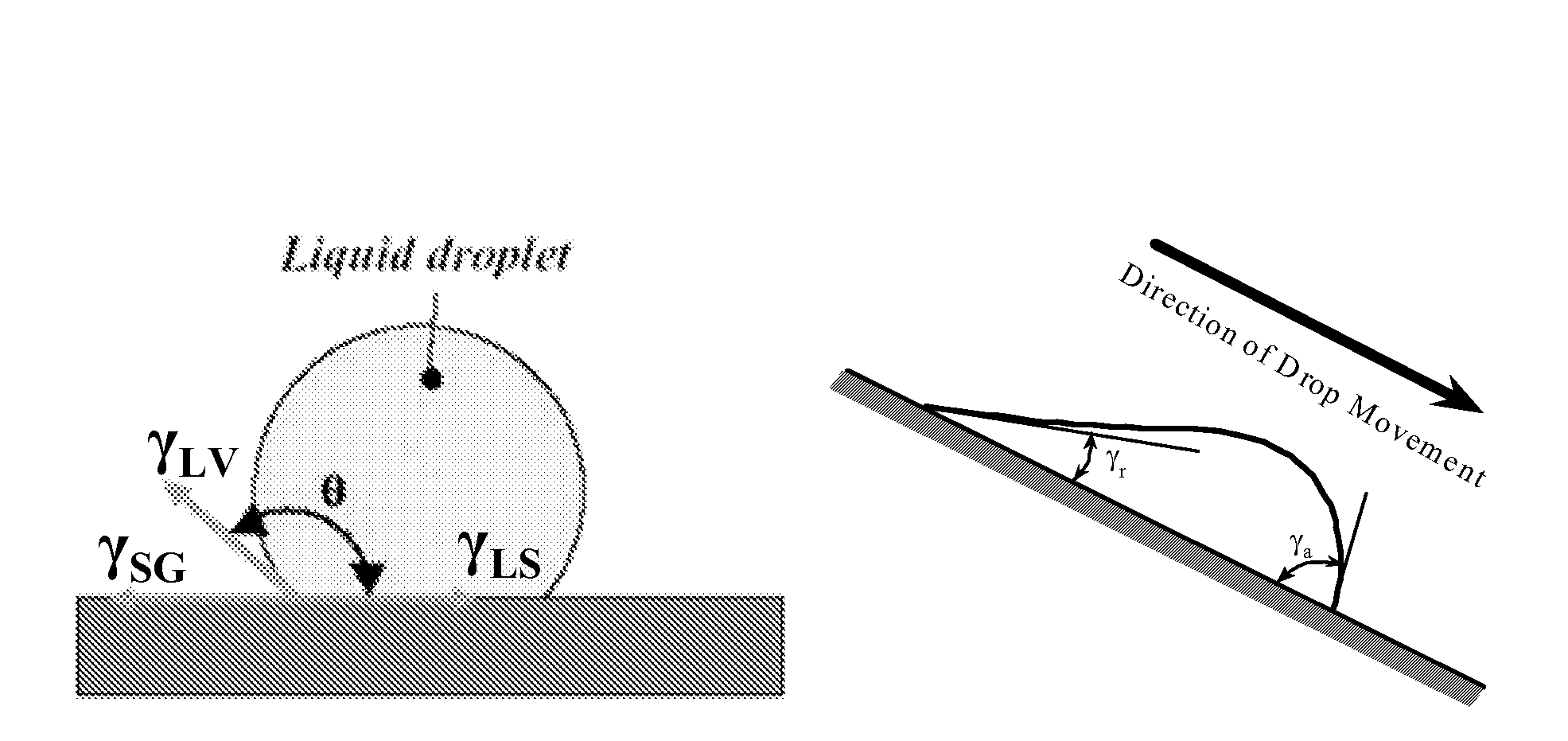

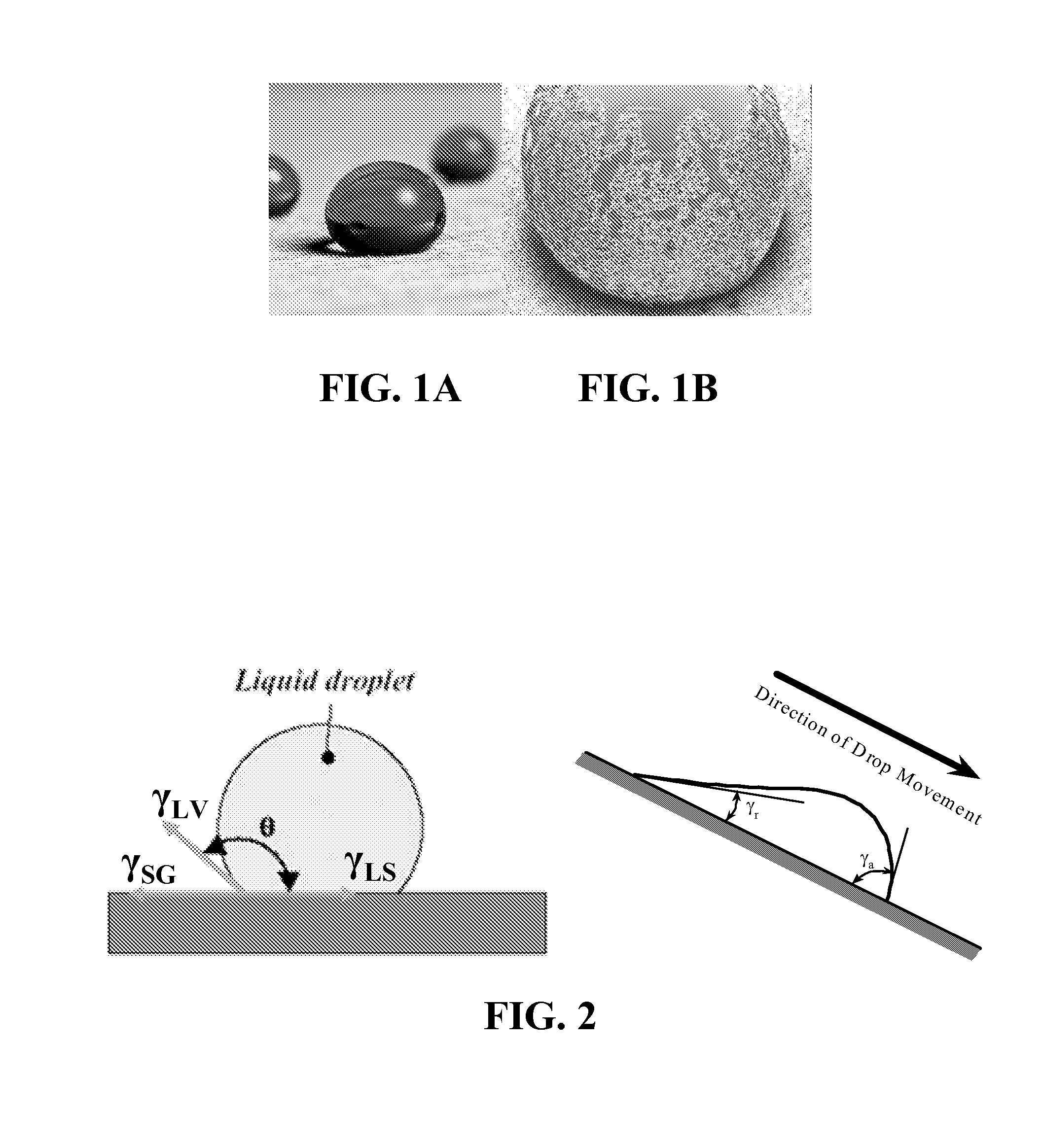

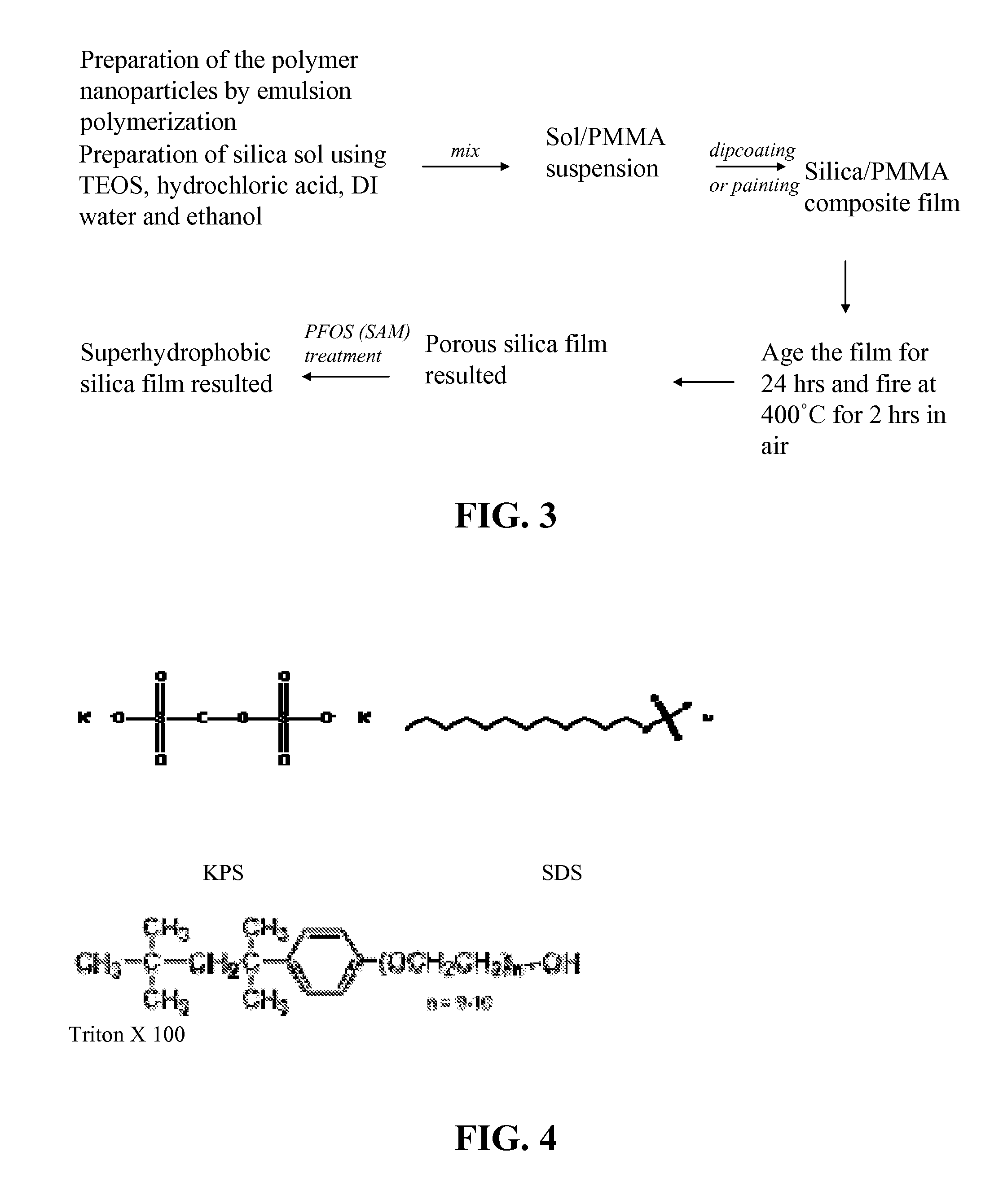

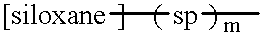

InactiveUS20090011222A1Excellent superhydrophobicityIncrease contact angleLayered productsPretreated surfacesLotus effectHydrophobic surfaces

Owner:GEORGIA TECH RES CORP

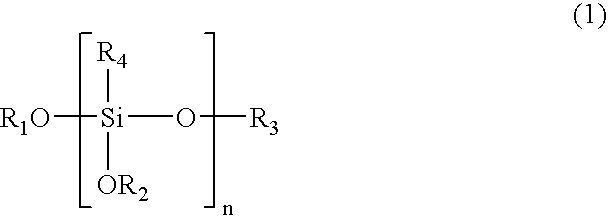

Polypeptide-polysiloxane copolymers

InactiveUS6358501B1Simple processWithout usingCosmetic preparationsHair cosmeticsOrganic chemistryCopolymer

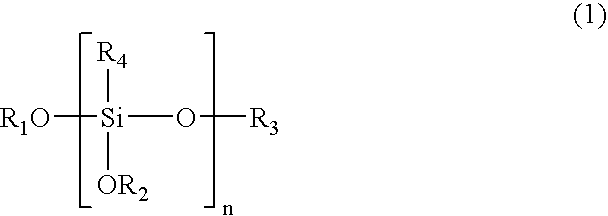

The present invention relates to polypeptide-polysiloxane copolymers, to their preparation by thermal copolymerization of amino acids with organofunctional polysiloxanes, and to their use as interface-active substances. The polypeptide-polysiloxane copolymers consist of at least one polysiloxane unitand of at least one polypeptide unit

Owner:GOLDSCHMIDT GMBH

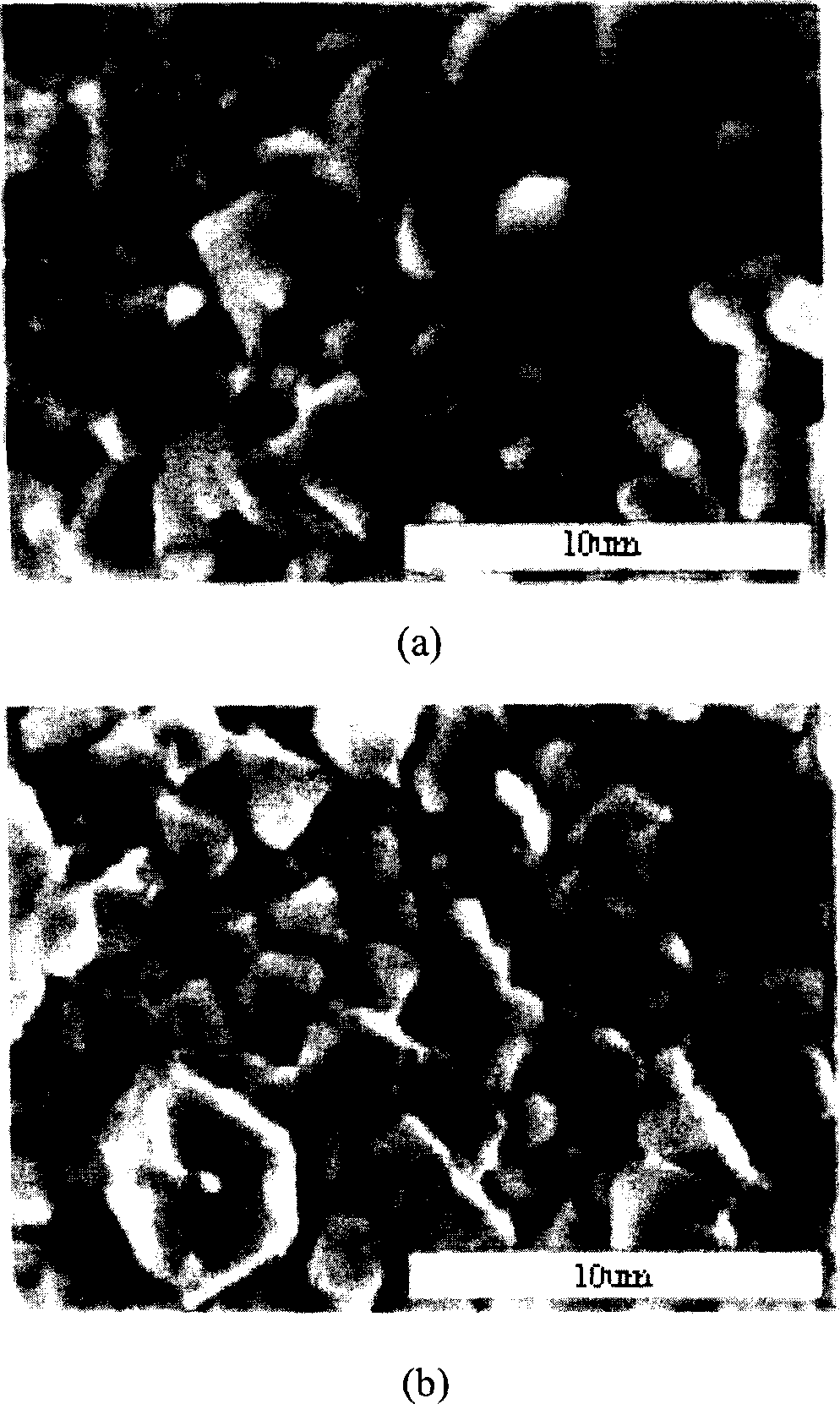

Catalyst used for olefine polymerization or copolymerization, its preparation method and application

A catalyst for the polymerization or copdymerization of olefin is composed of Ti-contained solid component A, organoaluminium compound B and organosilicon compound C. Said A is prepared through dissolving magnesium halide in the mixture of organic epoxy compound, organophosphorus compound and inertial diluent, adding educing agent and magnesium halide or its derivatives to educe out Mg / Ti contained deposit, and carrying a surface modifier, a titanium halide or derivative and an electronic doner. It can be used for the polymerization of propene or copolymerization of propene-ethene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Manganese-included multi-element metal oxide, lithium ion secondary battery anode material and its preparing method

ActiveCN1770513AImprove cycle performanceUniform particle sizeCell electrodesSecondary cellsNickel saltLithium hydroxide

This invention relates to one multi-element metal oxidation and discloses The process method, which comprises the following steps: a, in nitrogen or inertance gas depositing the mixture of cobalt salt, nickel salt and maganism salt to generate Ni-Co-Mn compound hydrogen oxidation to process front drive after drying and grinding; b, adding lithium hydrate into the front drive grinding and processing mixture to remove absorbed water and structure water; c, processing products under degrees of 650 to 850 degrees; d, using high polymer as assistant agent to process surface covering on product; e, processing the product to remove solvent to process multi-metal oxidation.

Owner:TIANJIN GUOAN MGL NEW MATERIALS TECH CO LTD

Catalyst, preparation method and application for olefin polymerization or copolymerization

This invention relates to a catalyst system which is used for alkenes polymerizing or copolymerization, it includes solid catalyst composition A that contains titanium and organic Aluminum compound B, silicoorganic compound C, in the composing process of catalyst composition A, use aldyl ester of aryl group mon-carboxylic acid and aldyl ester of fatty series or multielement carboxylic acid of aryl group for reasonable combination, among them aldyl ester of aryl group mon-carboxylic can play a role of assisting separating agent, it is useful to separate catalyst particle; Meanwhile it is used as electron donor, it also can load on the surface of catalytic agent together with compound of multielement carboxylic esters, improve the surface structure of catalytic agent, thus improve the catalyzing function of catalytic agent. This catalytic agent that is used for propylene polymerizing has high catalytic activity and anti- impurity function, particle appearance of catalytic agent is good, particles distribute narrowly, hydro-adjusting function of catalytic agent is good, it is useful for many polymerizing technology such as seriflux method, noumenon method and gas method, molecular weight distribution of polymer is narrow, particle appearance of polymer is good, fine grits is little; Its fine anti-impurity function can effectively reduce production cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

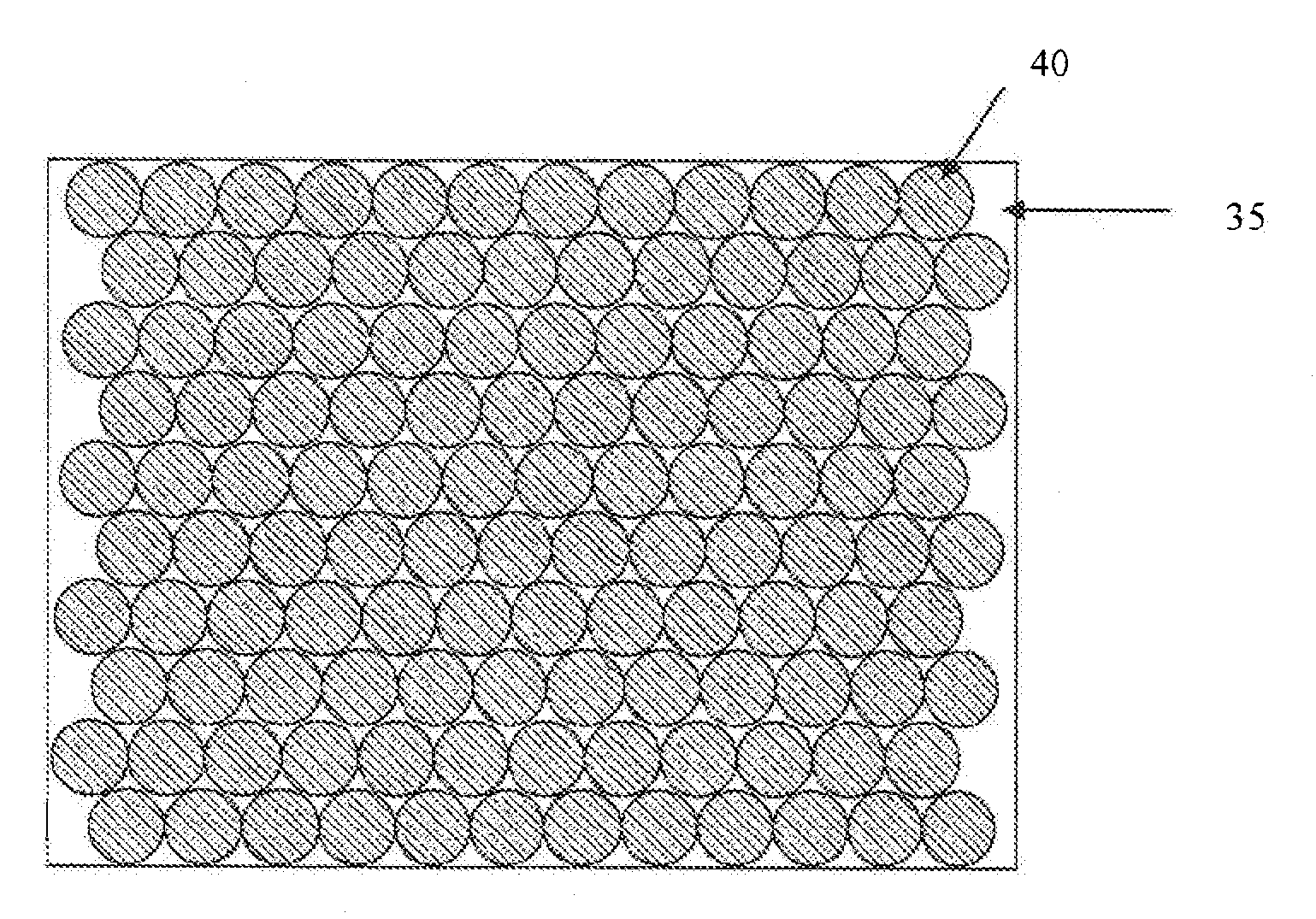

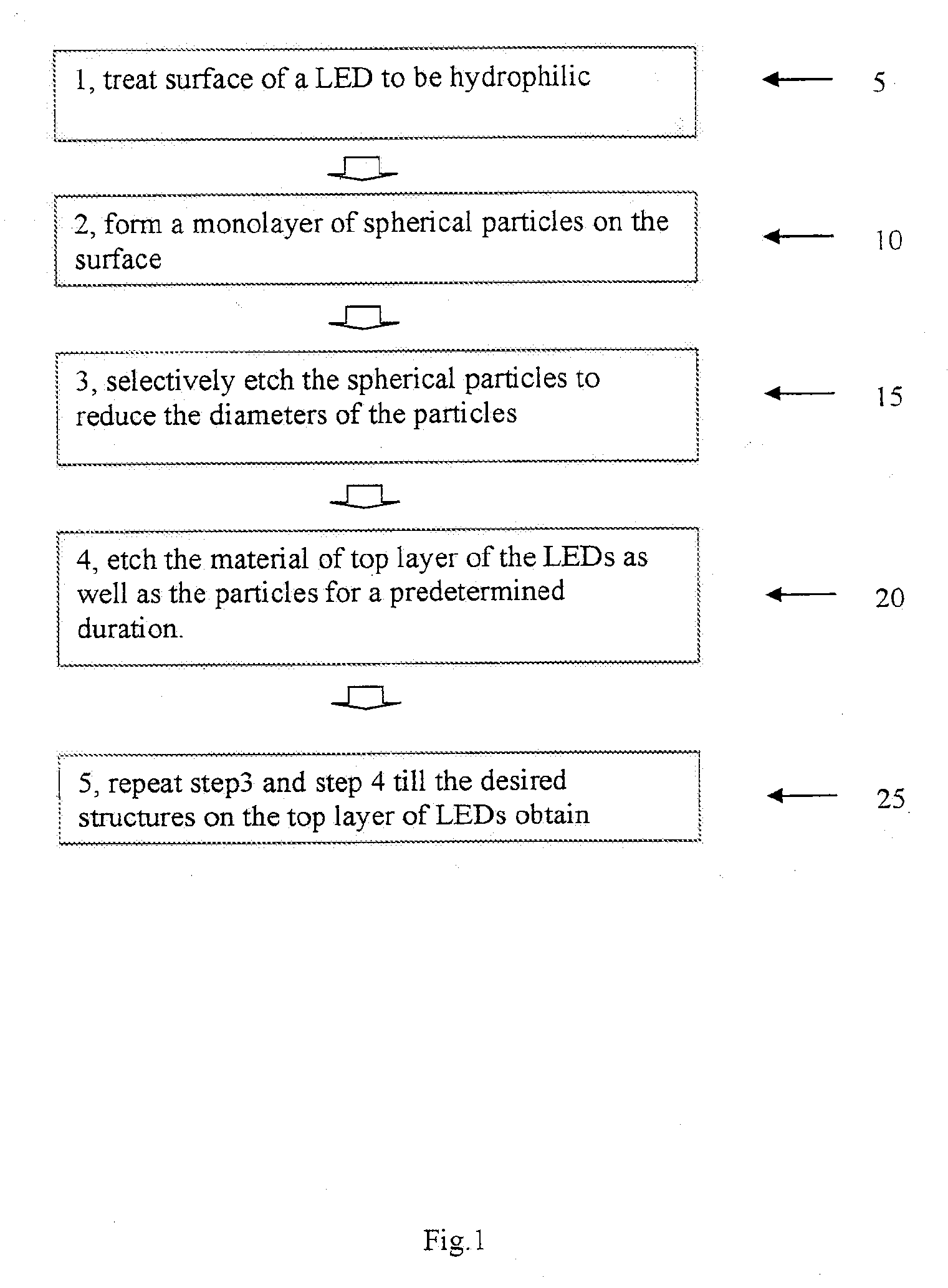

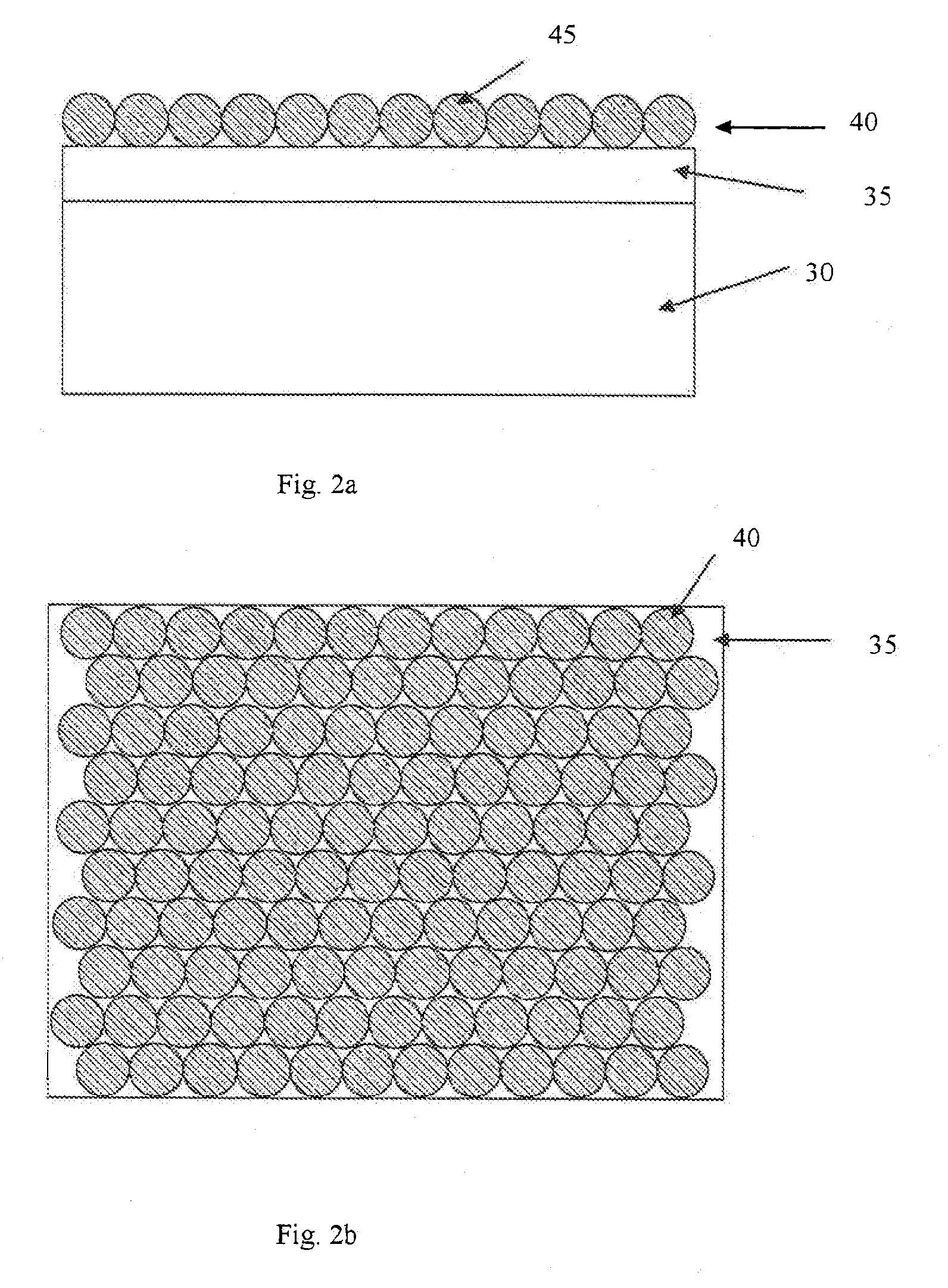

Method for fabricating micro and NANO structures

InactiveUS20080047929A1Small particle sizeLight extraction efficiencyMaterial nanotechnologyOptical articlesMicro nanoMaterials science

A method of forming an array of selectively shaped optical elements on a substrate, the method including the steps of providing the substrate, the substrate having an optical layer placed thereon; placing a layer of particles on the optical layer; performing an etching cycle. The cycle includes the steps of: etching the layer of particles, using a first etching process so as to reduce the size of the particles within the layer, then; simultaneously etching the optical layer and the layer of particles, using a second etching process, the further reducing particles forming a mask over areas of the optical layer to create discrete optical elements from the optical layer.

Owner:AGENCY FOR SCI TECH & RES

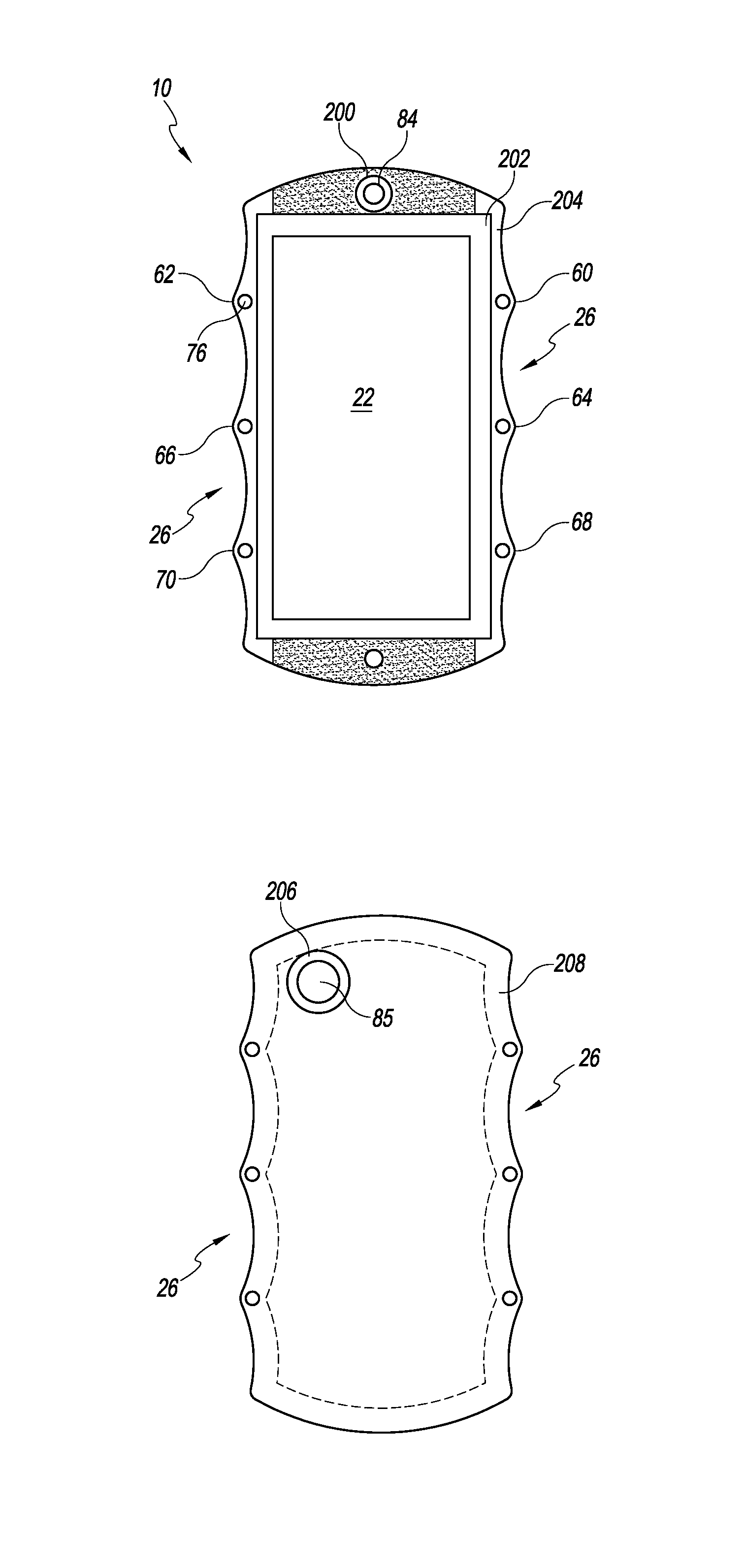

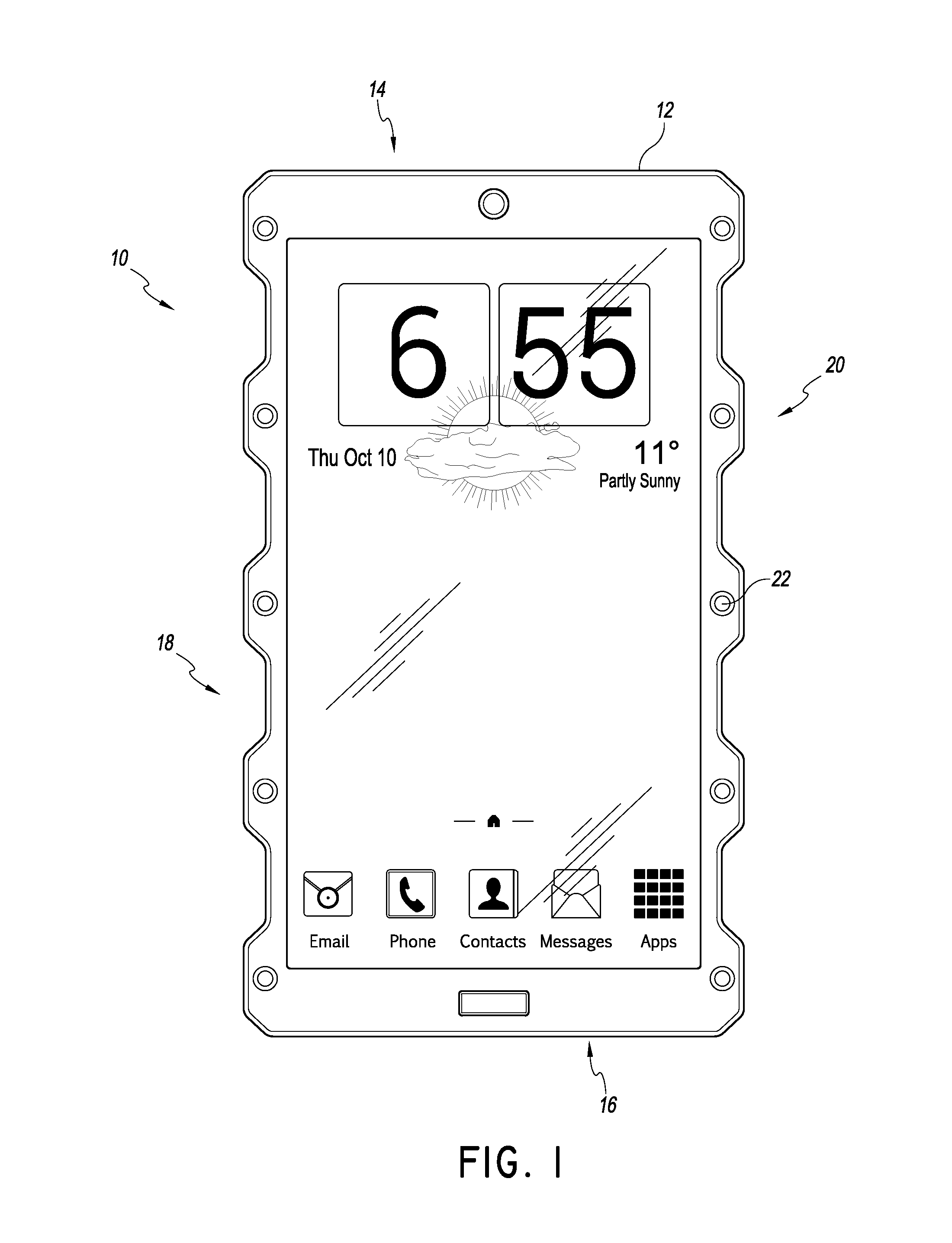

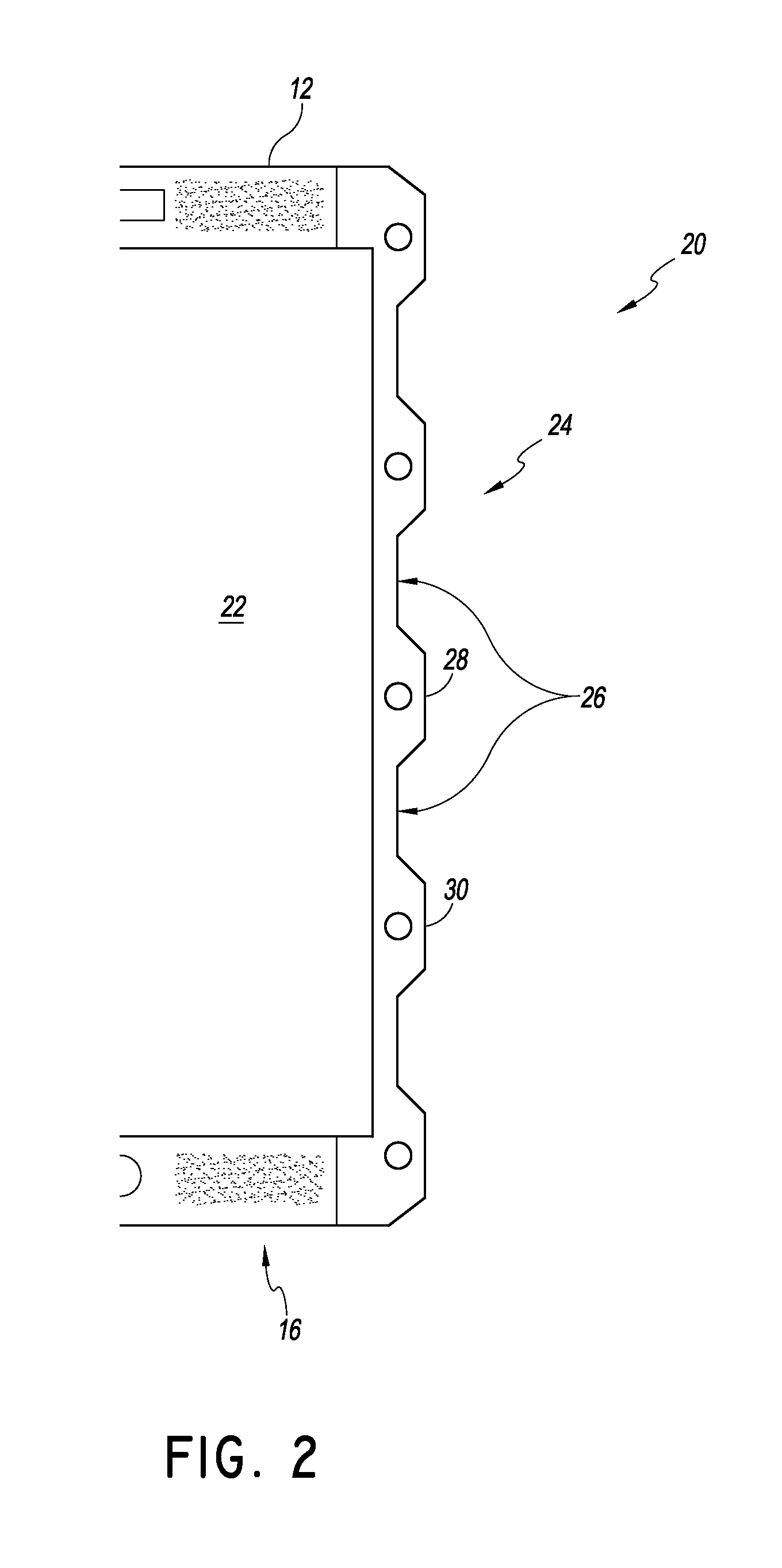

Cellphone with contoured surfaces

ActiveUS20150256655A1Great tractionResist slippingDigital data processing detailsTransmissionEngineeringSurface structure

Owner:RED COM LLC +1

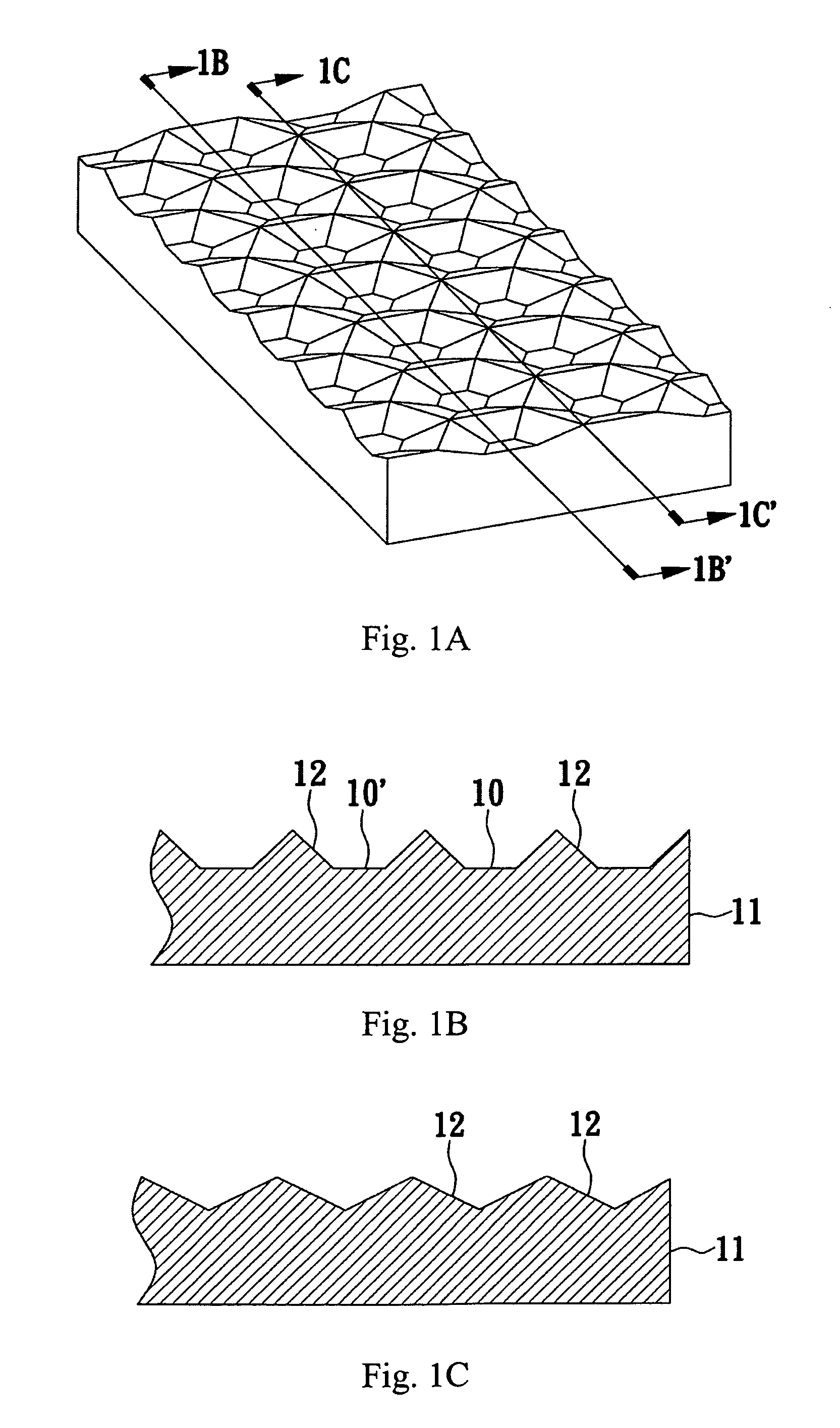

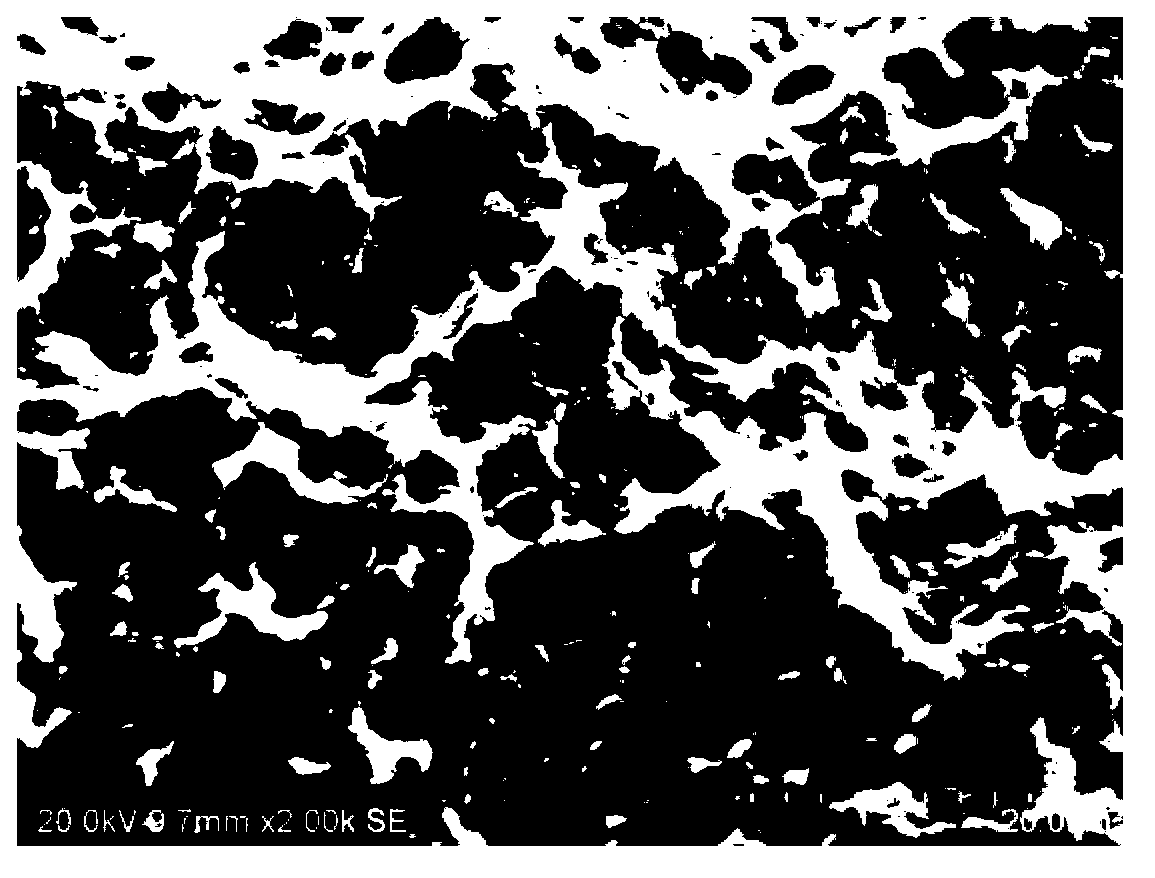

Surface processing technology for dental implant

InactiveCN102232876AGood surface morphologyGood rough surfaceArtificial teethCleaning using liquidsAcid etchingTitanium

The invention discloses a surface processing technology for a pure-titanium dental implant. The technology comprises the following steps: A, removing oil from the dental implant by ultrasonic cleaning; B, sandblasting the dental implant by white corundum to make the surface of the implant to be uniform gray in color and allow a three-dimensional porous structure to be formed on the surface of the dental implant; C, carrying out acid etching on the surface of the sandblasted dental implant with a mixed liquid with a certain concentration and a certain ratio of sulfuric acid to hydrochloric acid to allow gradually decreased multilevel scallops to be formed on the surface of the dental implant; and D, flushing and neutralizing the acid etched dental implant, and removing oil. According to the surface processing technology for the dental implant designed by the invention, the multilevel porous structure with biological activity is formed on the surface of the pure-titanium implant, so the biological activity of the pure-titanium implant is improved, the stability of the implant is improved, the bone combination speed of the dental implant is accelerated, the bone interfacial combination strength of the implant is enhanced, thereby the technology has the advantages of simple and high efficient technology, and low cost.

Owner:JIANGSU TRAUSIM MEDICAL INSTR

Nanocrystal-containing filtration media

InactiveUS20010042719A1Shorten the counting processSame efficiencyLoose filtering material filtersDisinfectionFiltrationNanocrystal

Owner:KINETICO

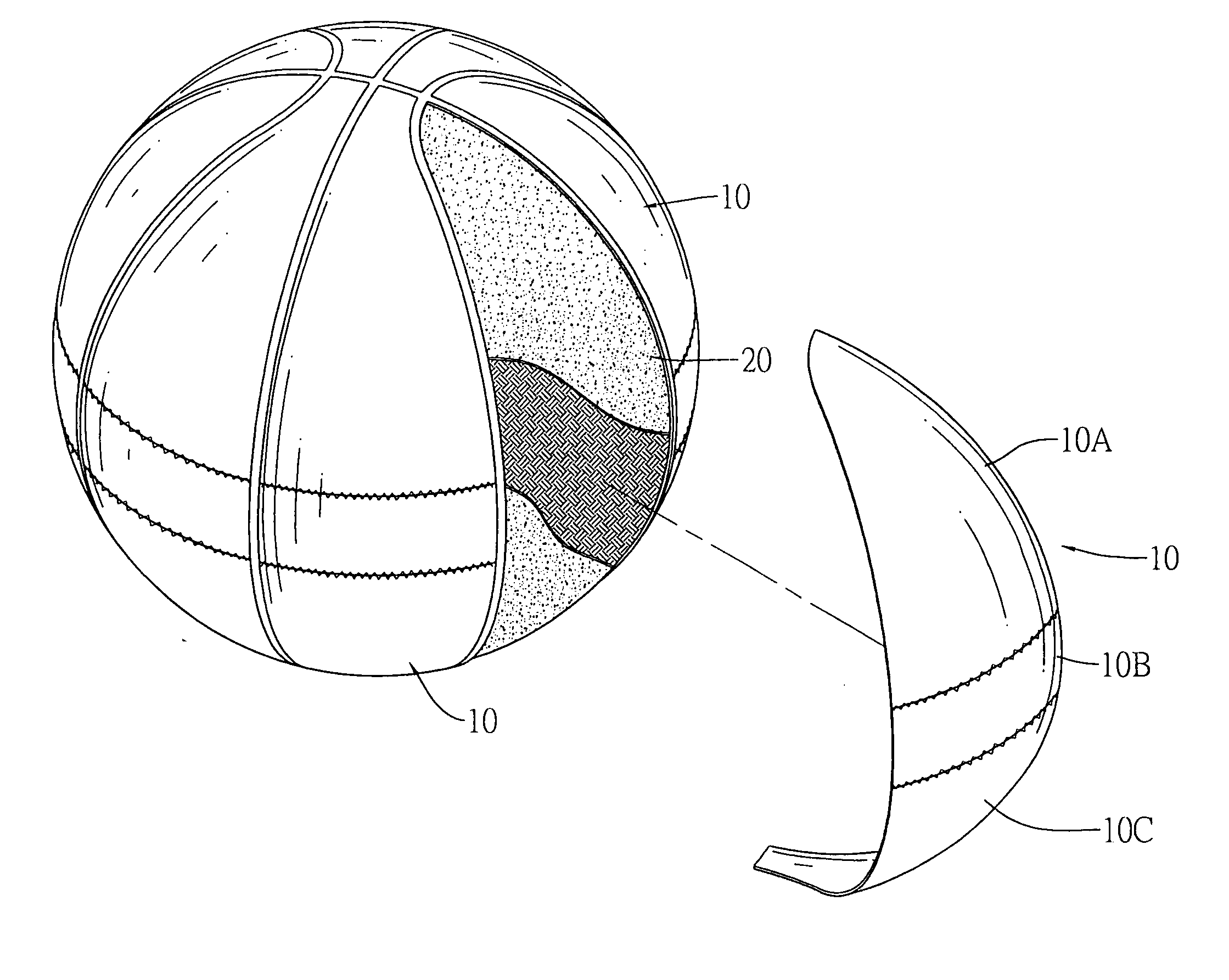

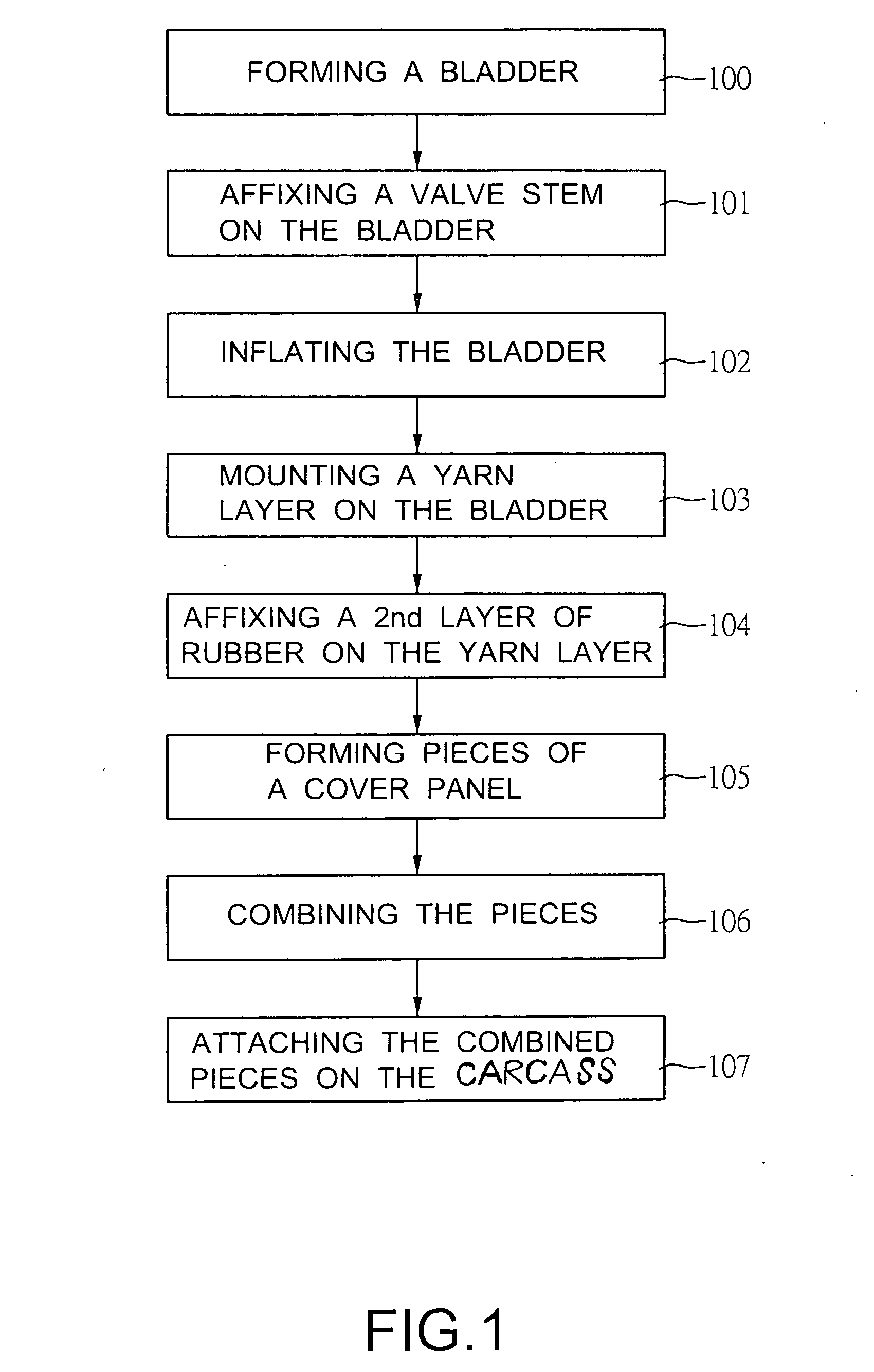

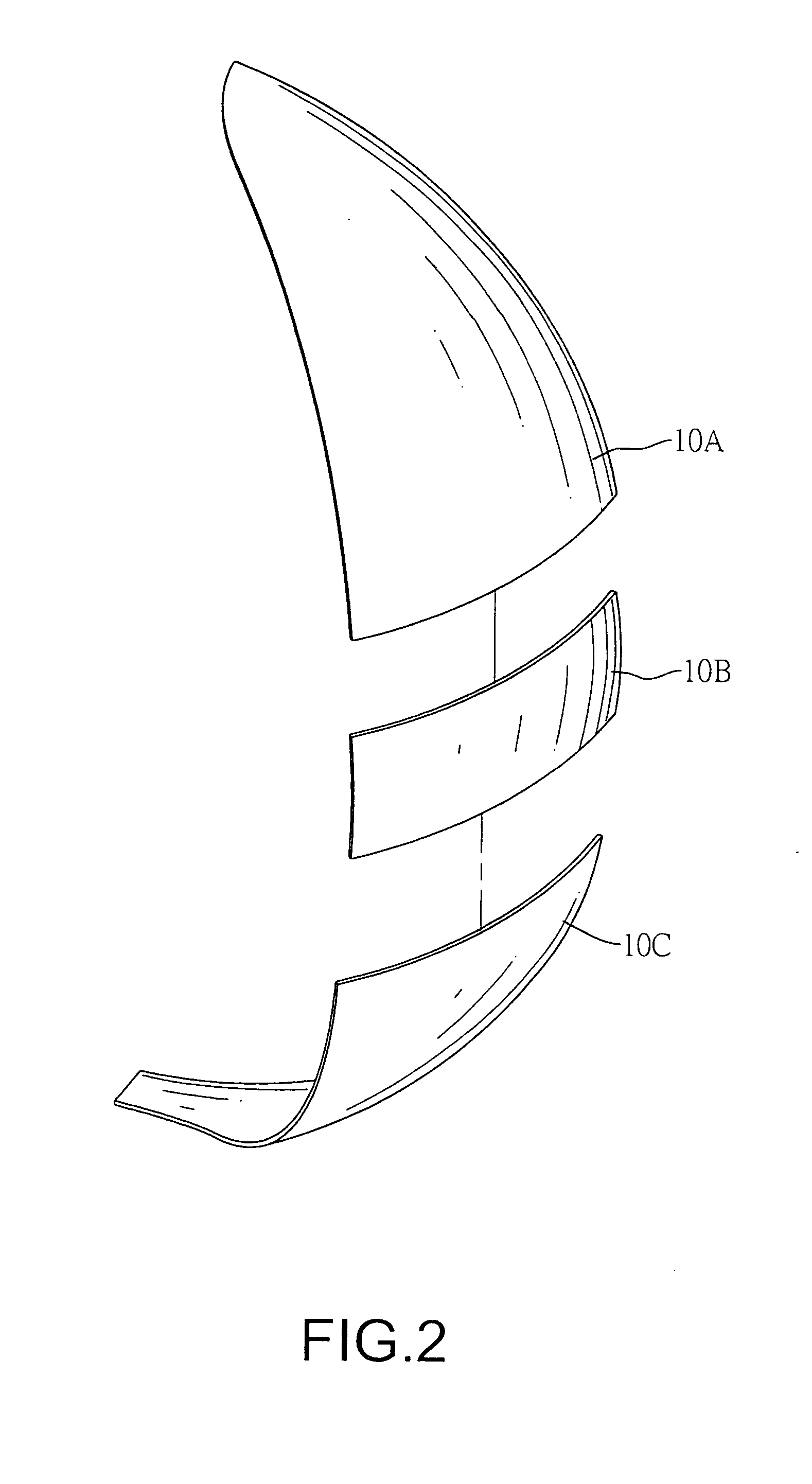

Cover panel structure of a ball surface

InactiveUS20070010360A1Improved ball surface structureReduce wasteHollow inflatable ballsHollow non-inflatable ballsEngineeringMechanical engineering

Owner:CHANG YEN LI

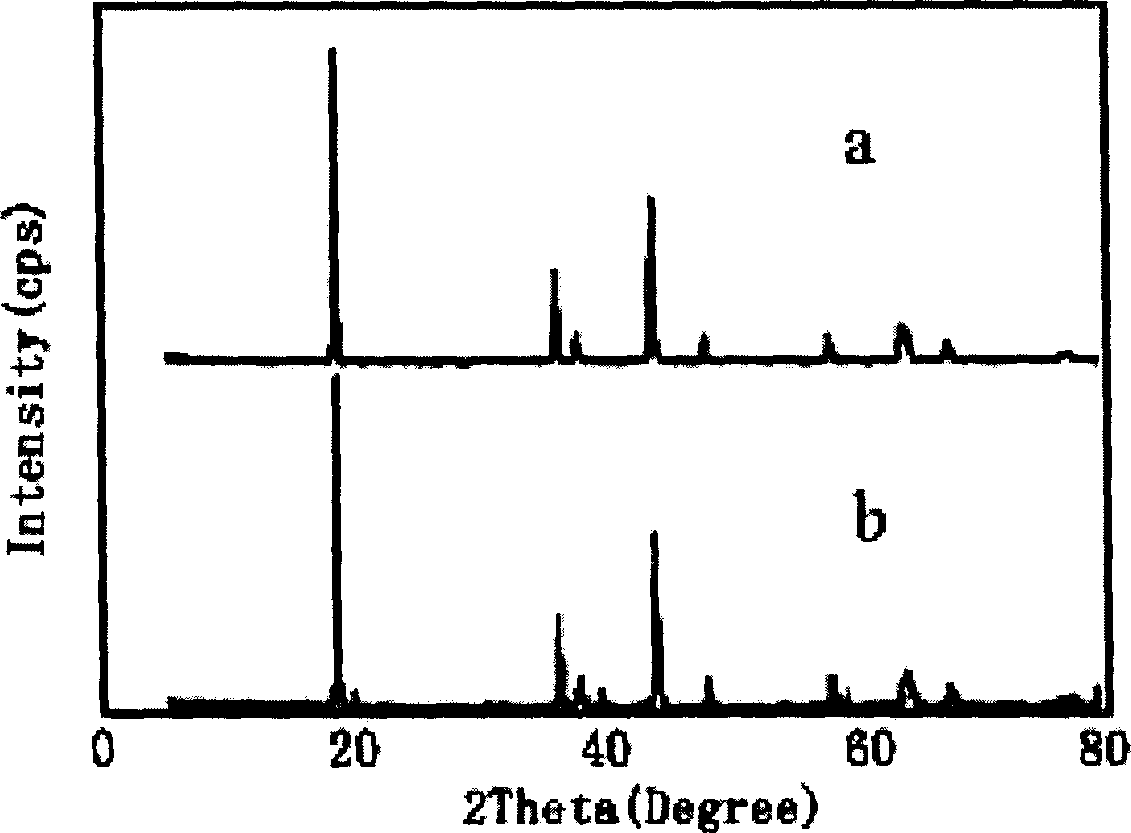

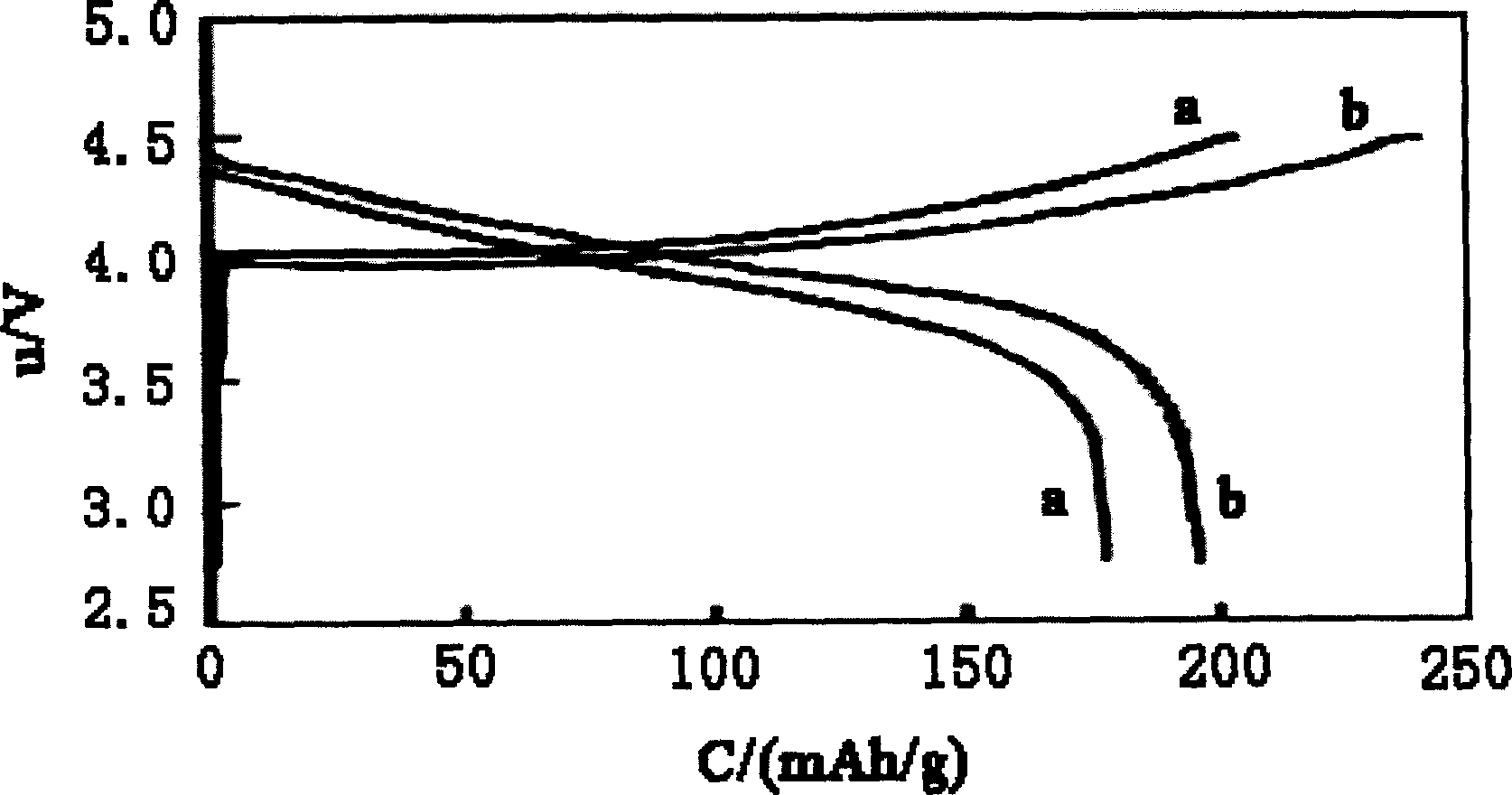

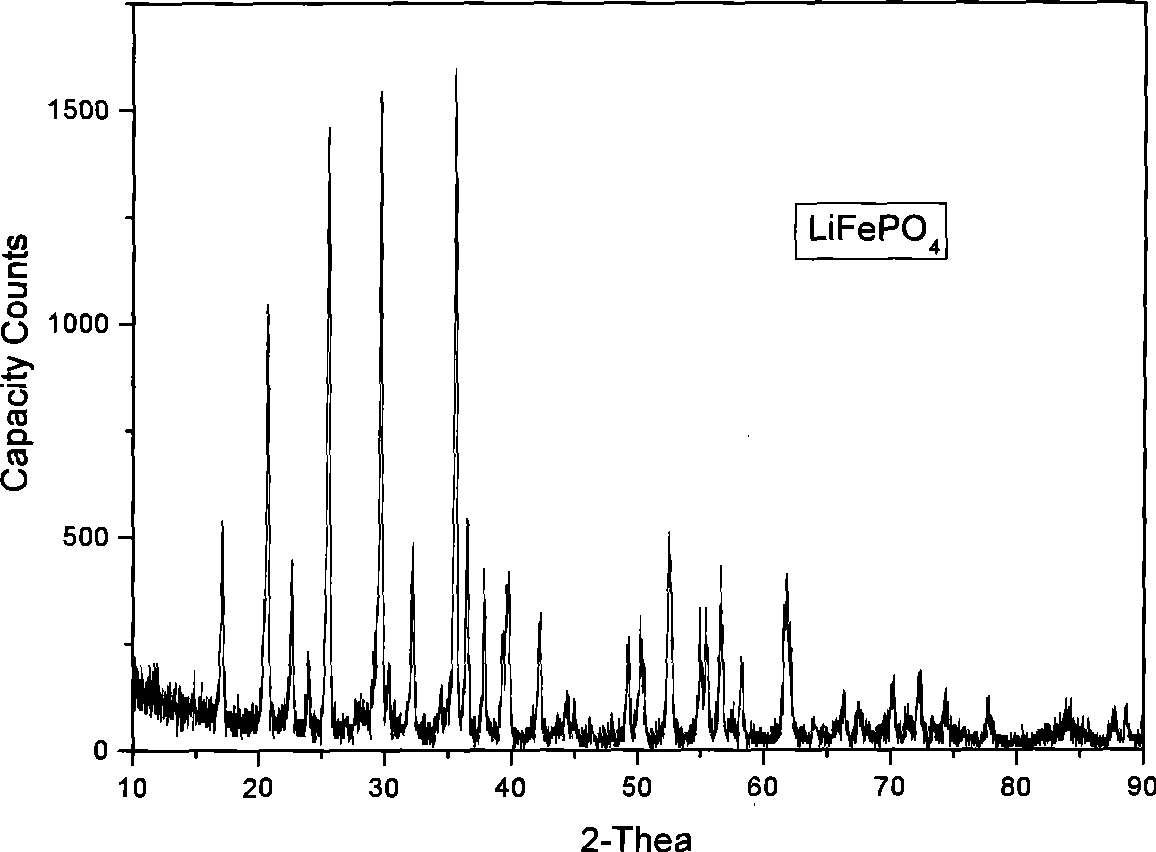

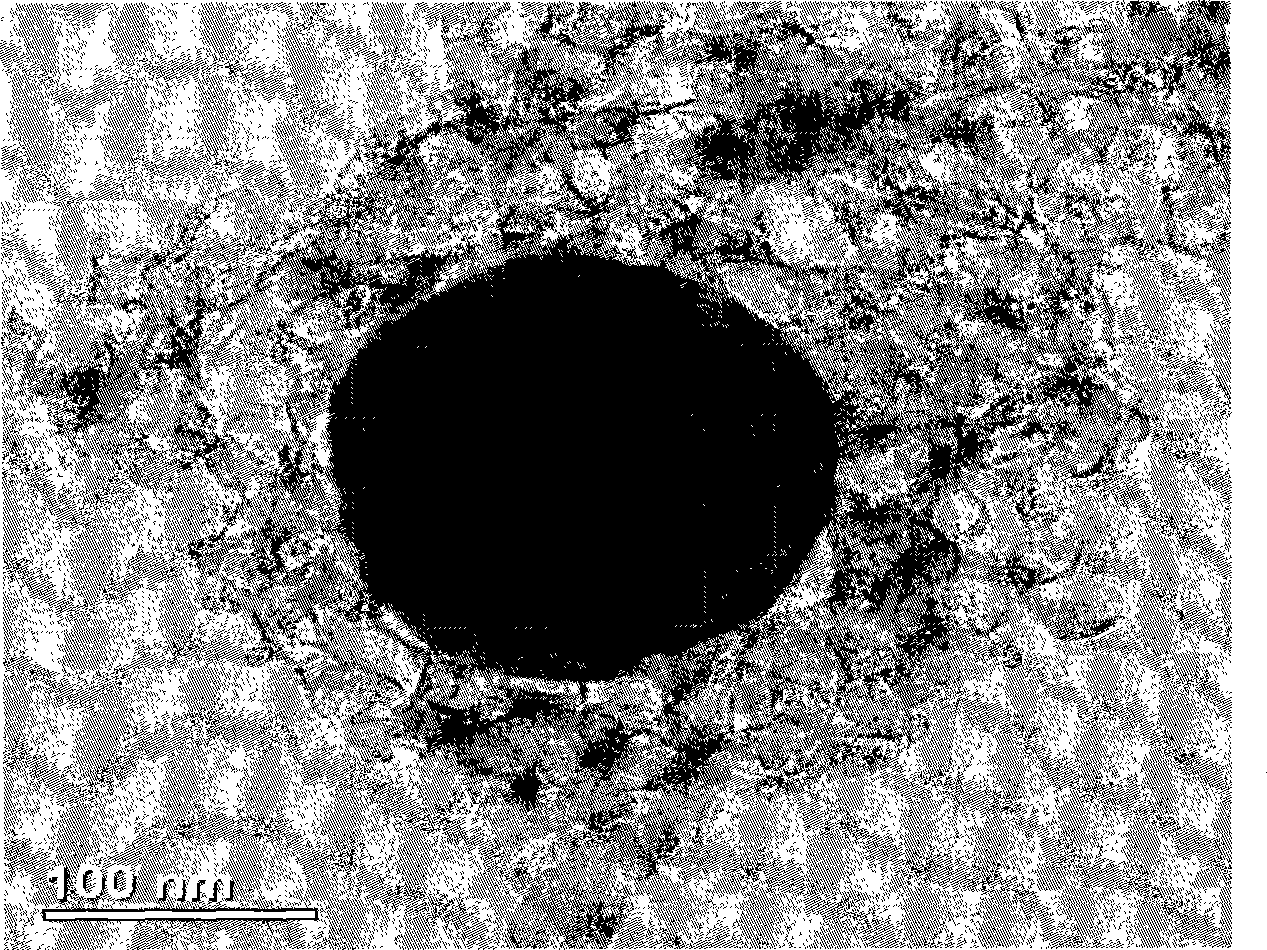

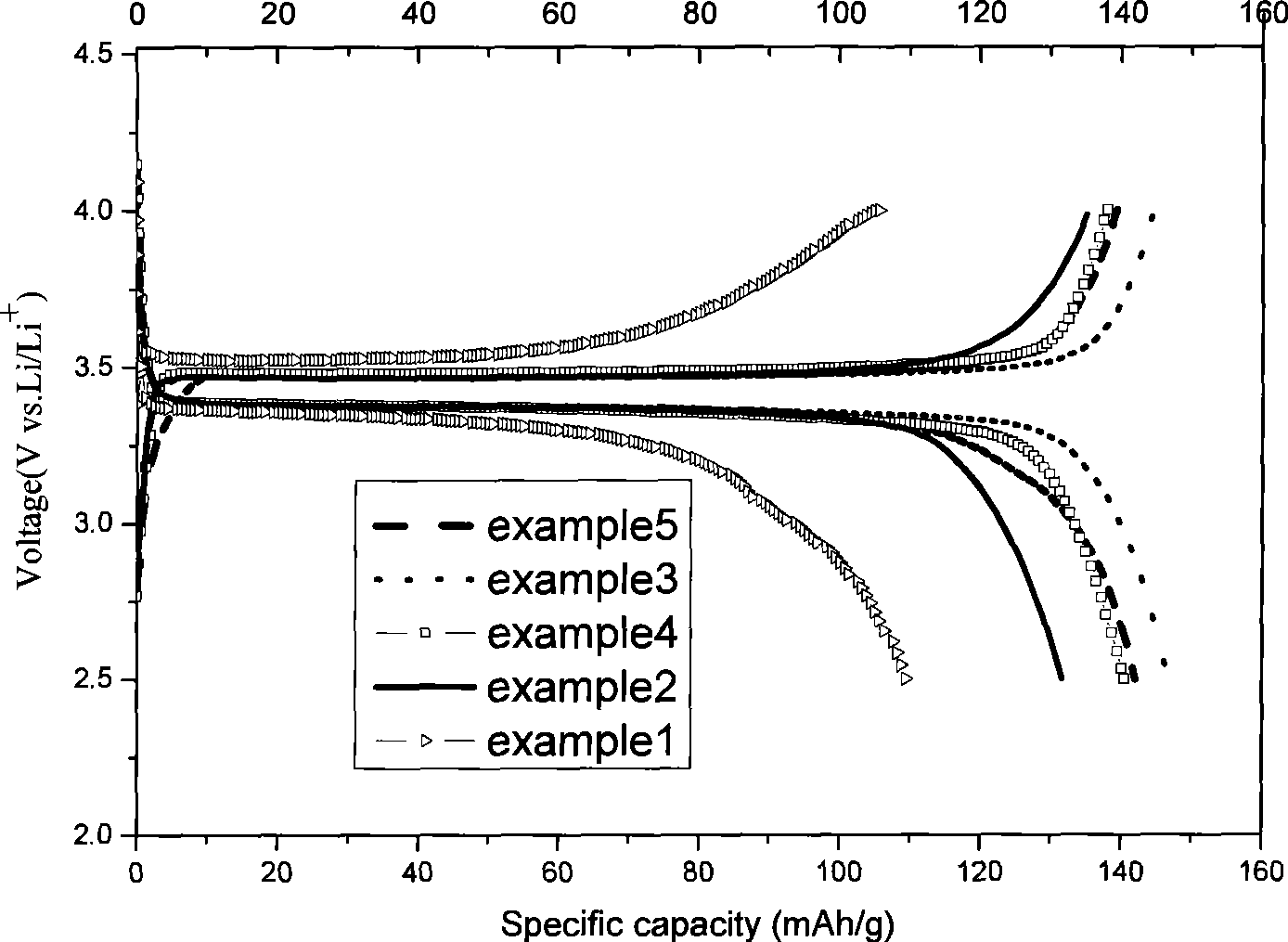

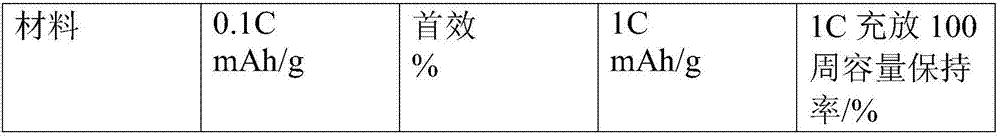

Method for preparing carbon-coating ferric phosphate lithium

ActiveCN101442117AImprove surface structureImprove electrochemical performanceElectrode manufacturing processesPhosphateNon oxidative

The invention discloses a method for preparing carbon-coated lithium iron phosphate (LiFePO4 / C). The method comprises the following steps: a, LiOH.H2O, reduced Fe powder and H3PO4 are weighed according to the molar ratio of 1:1:1 and are stirred in an aqueous solution so as to react for 2 to 10 hours under nitrogen protection; a carbon source is added to a reaction system, and an obtained suspension as a reaction product is subjected to spray drying through a high-speed centrifugal spray drying machine, so as to obtain a LiFePO4 / C precursor; and b, the LiFePO4 / C precursor is transferred to a tubular furnace in inert or non-oxidative atmosphere and treated for 6 to 24 hours at a temperature of between 200 and 750 DEG C, so as to obtain the LiFePO4 / C. As the method adopts the Fe powder as a raw material, the specific discharge capacity of a LiFePO4 / C anode material prepared by a coprecipitation method under the multiplying power between 0.1 and 2C is obviously improved.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER +1

Lithium ion battery cathode material and preparation method thereof

ActiveCN107394160AImprove surface structureReduce surface residual alkali contentMaterial nanotechnologyCell electrodesTwo stepLithium-ion battery

Belonging to the technical field of lithium ion batteries, the invention discloses a lithium ion battery cathode material and a preparation method thereof. The chemical molecular formula of the cathode material is Lix(NiaCobMnc)1-yMyO2, wherein x is greater than or equal to 0.96 and smaller than or equal to 1.04, y is greater than or equal to 0.01 and smaller than or equal to 0.06, a is greater than or equal to 0.8 and smaller than or equal to 0.9, and a+b+c=1, M has a general formula of BzM'1-z, M' is composed of one or several of the following elements: Al, Mg, Ti and Zr, and z is greater than or equal to 0.1 and smaller than or equal to 0.5. The cathode material is coated by a layer of compound containing L, B, Ni, Co and Mn, the content of B in the outermost surface of the coating layer is at least two times that of the B in the innermost layer of the coating layer. According to the invention, the high capacity cathode material is acquired from a high nickel content ternary system, additionally multielement doping is employed to stabilize the crystal structure of the material, and then by means of washing, boron element surface modification and two-step sintering process, the material surface structure can be improved, and the surface residual alkali content can be reduced to improve the interface stability. The whole technological process of the invention is simple, and is easy for large scale production.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

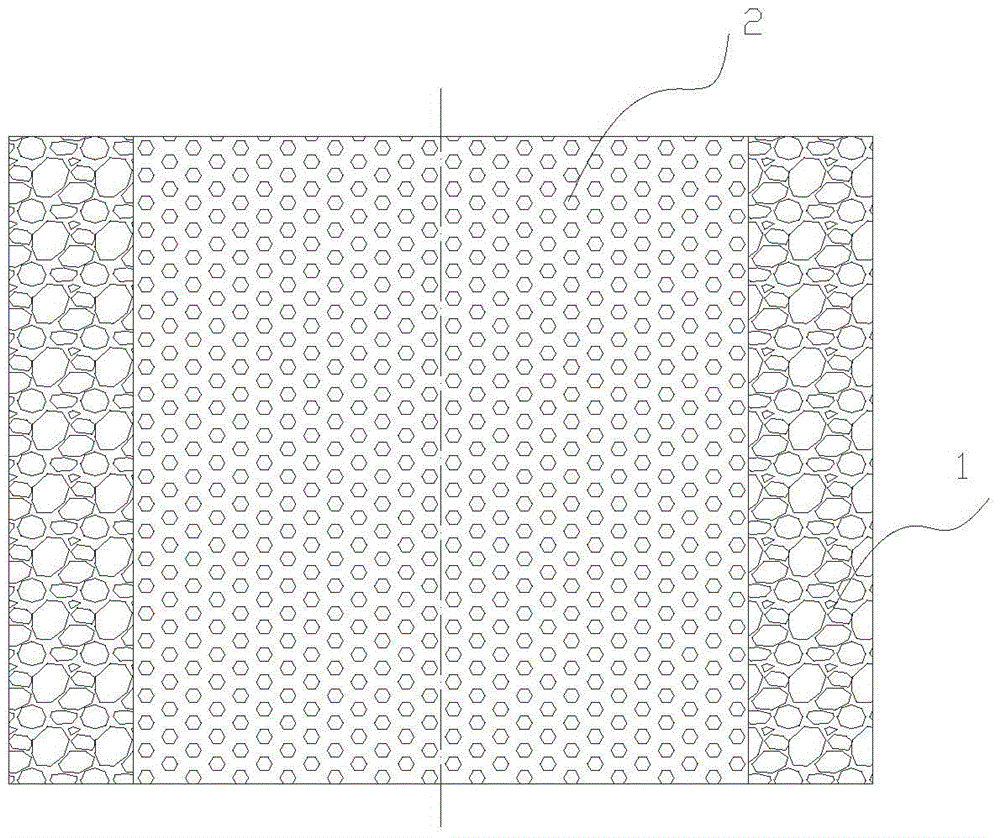

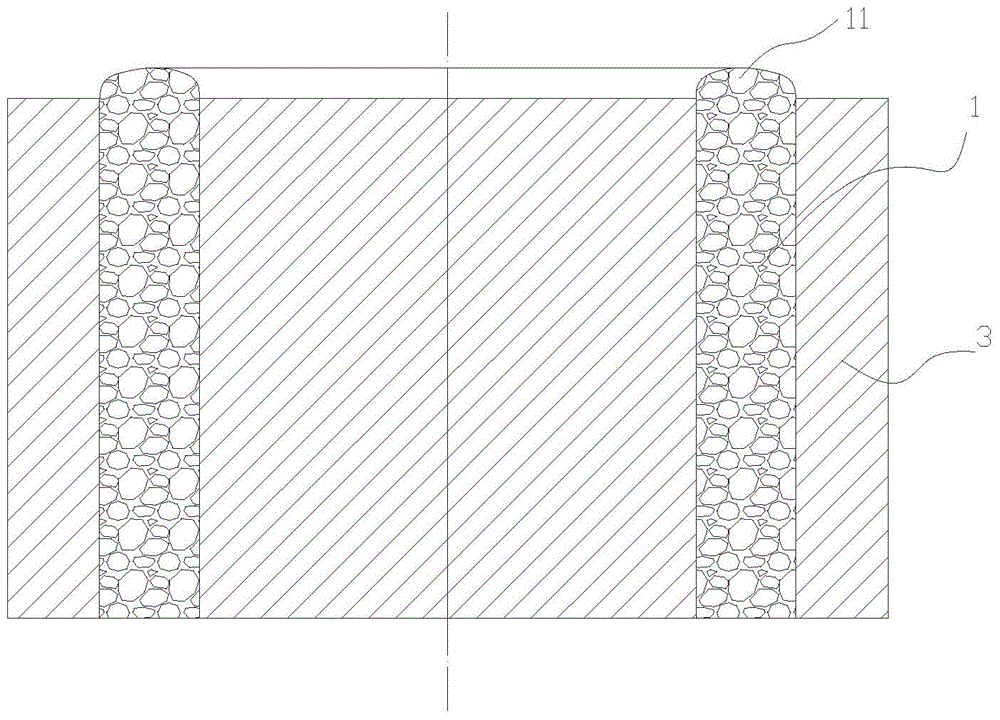

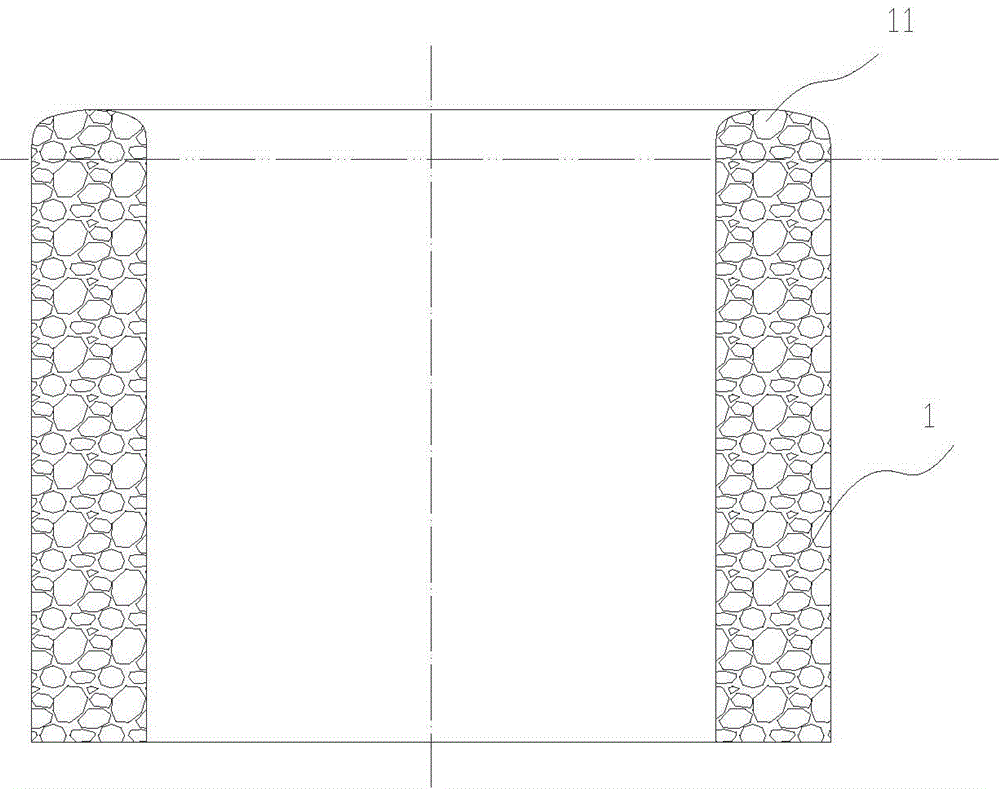

Processing method for building waste foamed concrete composite heat preservation building blocks

InactiveCN104153512AImprove surface structureHigh bonding strengthConstruction materialSolid waste managementFoam concreteMixed materials

The invention discloses a processing method for building waste foamed concrete composite heat preservation building blocks. The invention provides a processing method for the building waste foamed concrete composite heat preservation building blocks. By virtue of the processing method, the performance of a recycled material can be optimized to the maximum extent, so that the compression strength, the shear strength and the heat preservation performance of a finished product can be guaranteed. Each building block comprises a base body and a heat preservation core body. A building block preparation process comprises base body forming, core body preparation, maintaining and drying working procedures; each base body comprises cement, an active mixed material, a modifier and a recycled aggregate. A processing method for the recycled aggregate comprises the steps of (1) classifying and initially sorting building waste; (2) roughly crushing building waste to prepare granular recycled coarse aggregates of which the dimension is smaller than 10mm; (3) performing mechanical enhancement on the recycled coarse aggregates, adding natural sand into the recycled coarse aggregates according to a weight ratio of 1:(0.2 to 1), and taking fine sand, which has the particle size of 0.25-0.5 mm, in the mechanically enhanced aggregates for later use. According to the method, the building blocks are high in bonding strength and uniform, the water absorption property of a single unit is reduced, the production cost is lowered, and the production technology is simple and feasible.

Owner:CHINA BUILDING MATERIALS ACAD

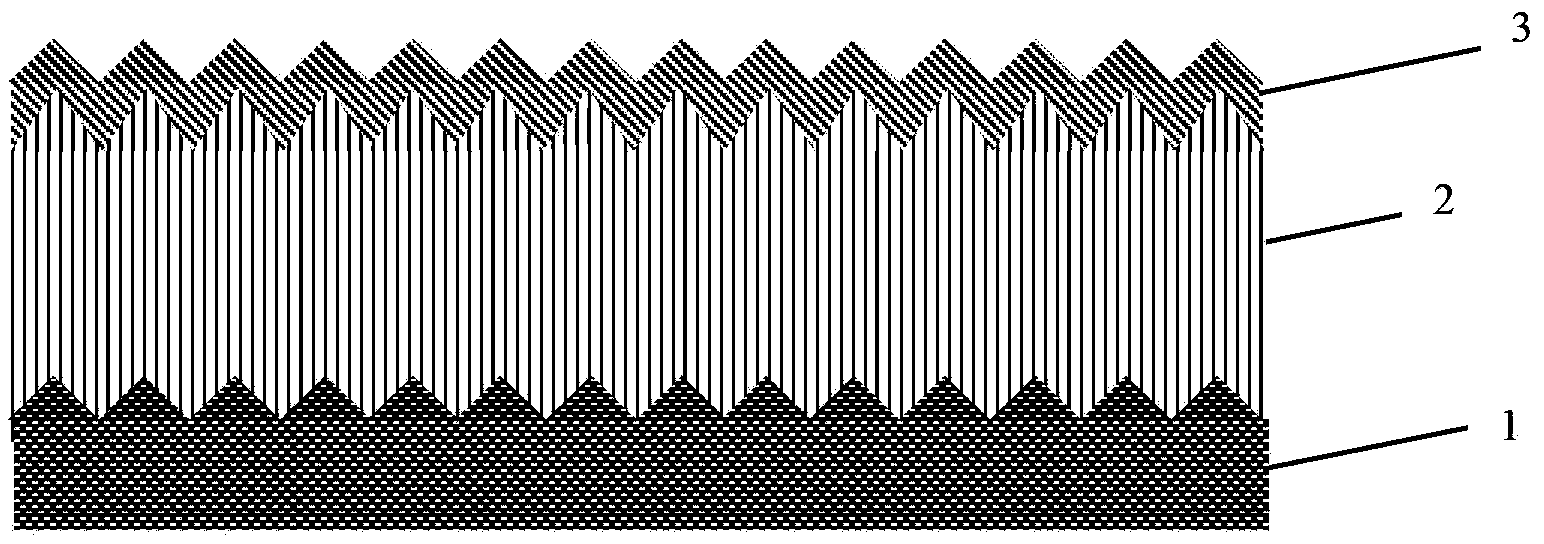

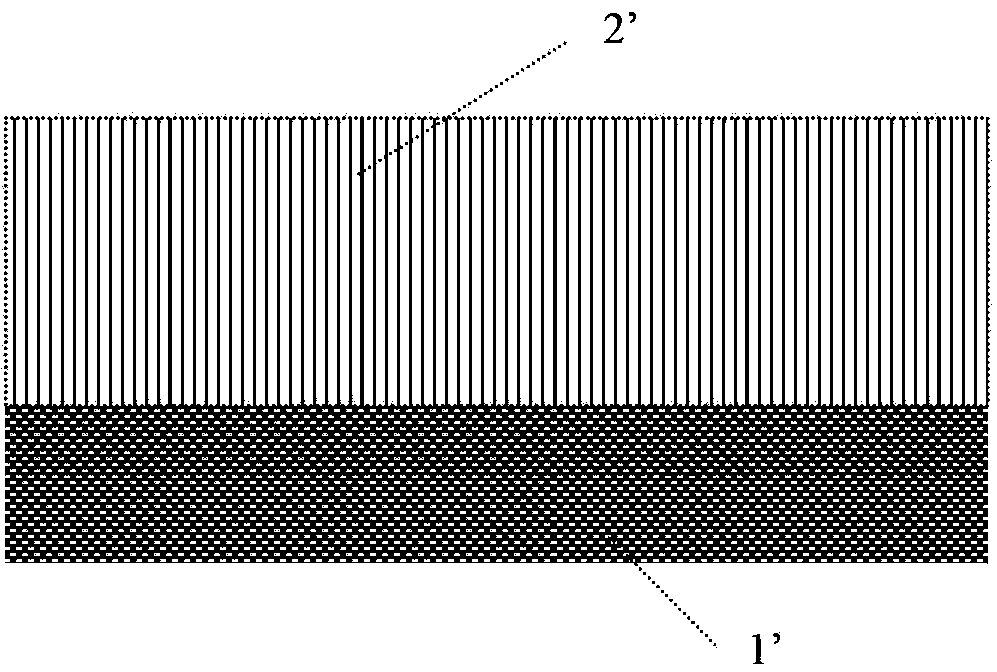

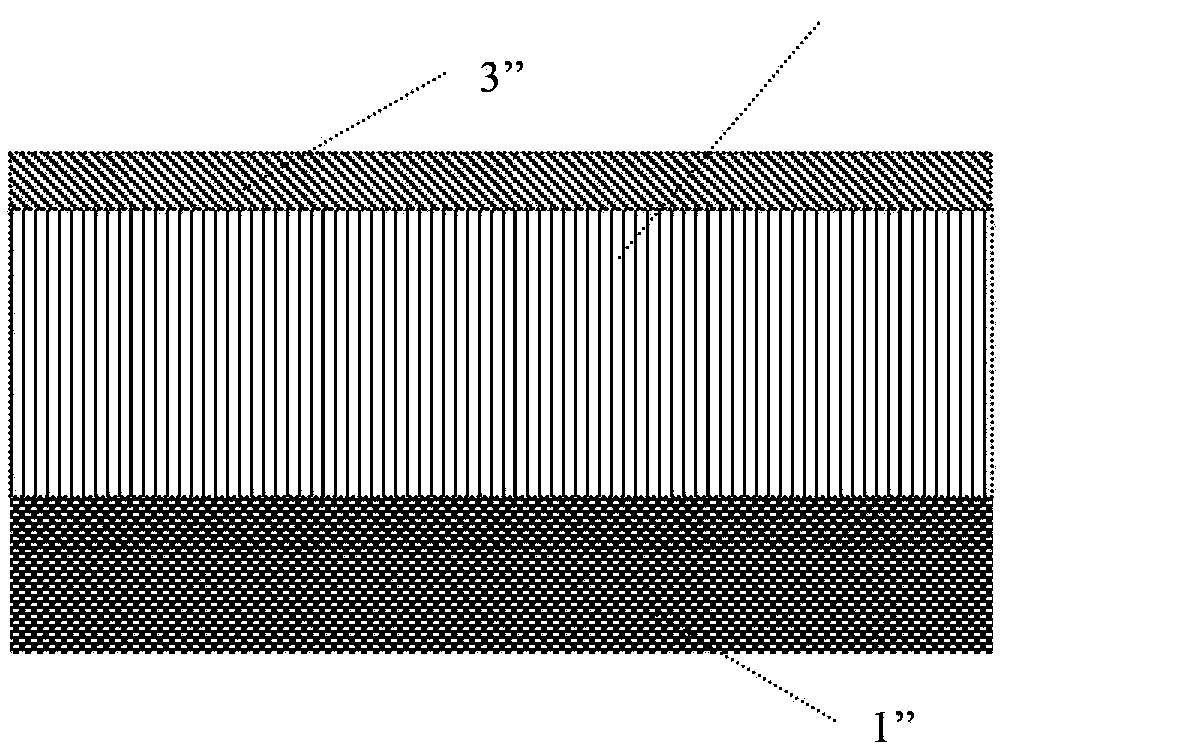

Zr-Co-Re thin film getter provided with protection layer, and preparation method thereof

InactiveCN103849835AIncrease speedIncrease inspiratory capacityVacuum evaporation coatingSputtering coatingRare-earth elementHydrogen

The invention relates to a Zr-Co-Re thin film getter provided with a protection layer, and a preparation method thereof. The Zr-Co-Re thin film getter is composed of a getter layer and the protection layer; main components of the getter layer are Zr, Co, and one or more selected form rare earth elements La, Ce, Pr, and Nd; and main component of the protection layer is Ni. Pulsed laser deposition film plating is adopted, and deposition of the double-layer structured thin film getter containing the protection layer and the getter layer on texture monocrystalline silicon is carried out. The texture substrate is capable of increasing effective area of the getter thin film, and so that inspiratory flow rate and inspiratory capacity are increased. The surface of the getter layer is plated with a Ni protection layer; Ni is capable of realizing dissociation of hydrogen, and increasing absorption amount of hydrogen; and the Ni protection layer is capable of inhibiting absorption of oxygen and reducing activation temperature. Activation of the Zr-Co-Re thin film getter can be realized in roasting processes at a temperature of 180 to 350 DEG C; after roasting, the Zr-Co-Re thin film getter possesses excellent inspiration performance at room temperature, can be used for internal gas residue removing of high vacuum microelectronic devices.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

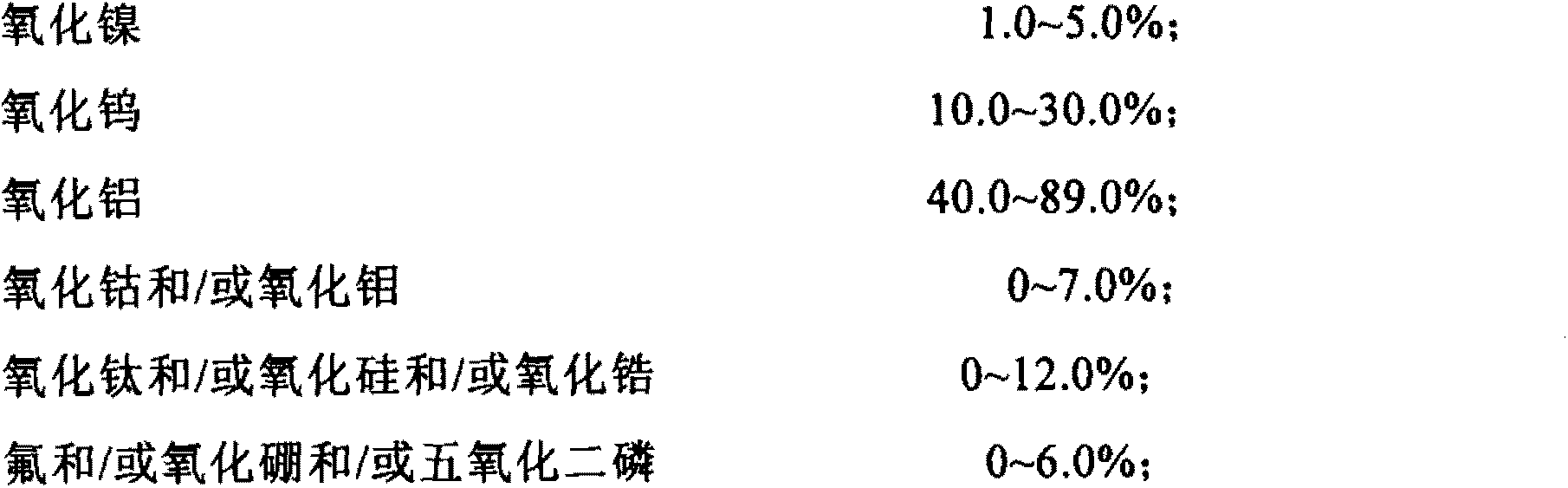

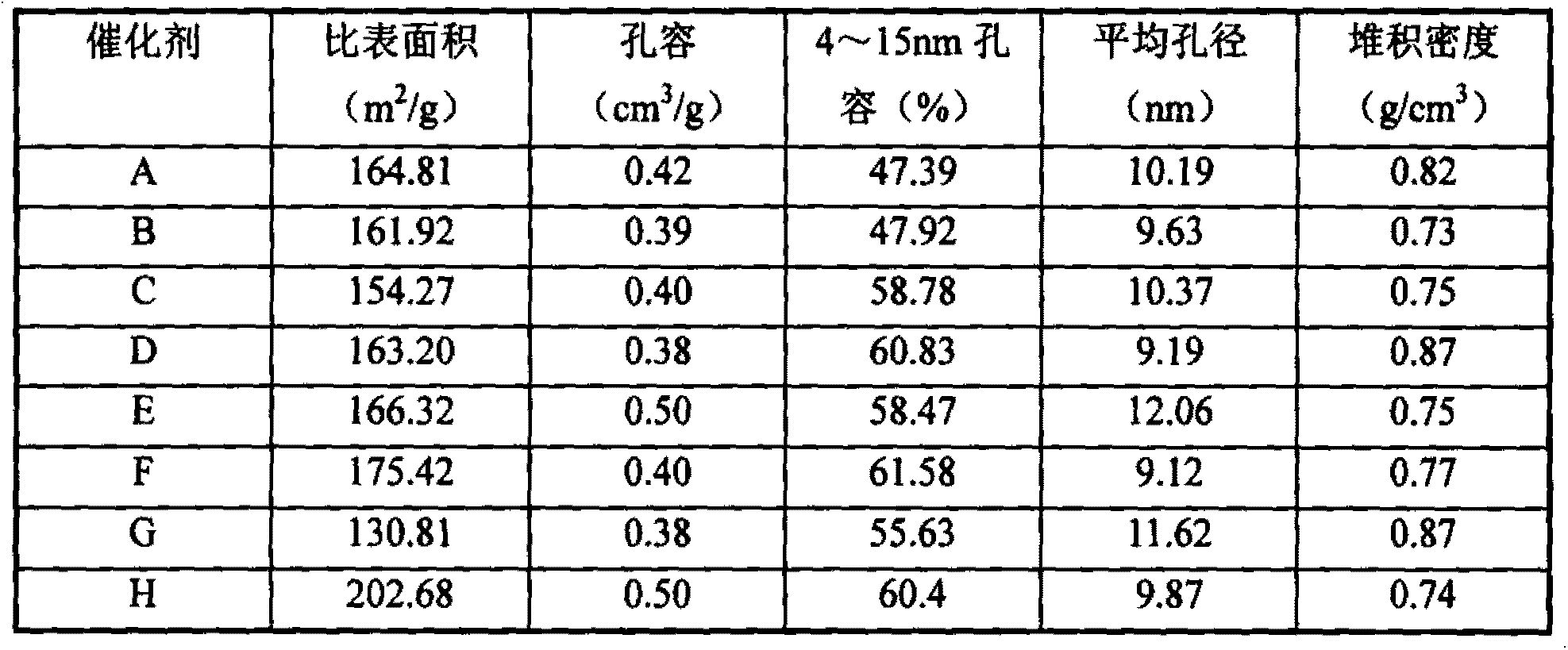

Catalyst for hydrogenation refining of Fischer-Tropsch synthetic oil, as well as preparation method and application thereof

InactiveCN103191754AImprove thermal stabilityImprove pore structureMetal/metal-oxides/metal-hydroxide catalystsRefining by selective hydrogenationSilicon oxideOxygen

The invention relates to a catalyst for hydrogenation refining of Fischer-Tropsch synthetic oil, as well as a preparation method and application thereof. Aluminum oxide is taken as a carrier, nickel and tungsten are taken as hydrogenation active components, and one or more of auxiliaries, such as titanium oxide, silicon oxide, zirconium oxide, fluorine, boron, phosphorus and the like are used. The preparation method of the catalyst comprises the following steps of: preparing the aluminum oxide carrier, modifying the carrier, and loading the metal active components. The prepared catalyst is used for hydrogenation refining of the Fischer-Tropsch synthetic oil. The catalyst disclosed by the invention is suitable for hydrogenation refining of oil products which have high content of olefins and further contain certain quantities of oxygen-containing compounds, in particular to hydrogen refining of low-temperature Fischer-Tropsch synthetic oil, and has the advantages of high hydrogenation activity of olefins, high removal rate of oxygen-containing compounds, good stability of the catalyst and the like.

Owner:YANKUANG ENERGY R&D CO LTD

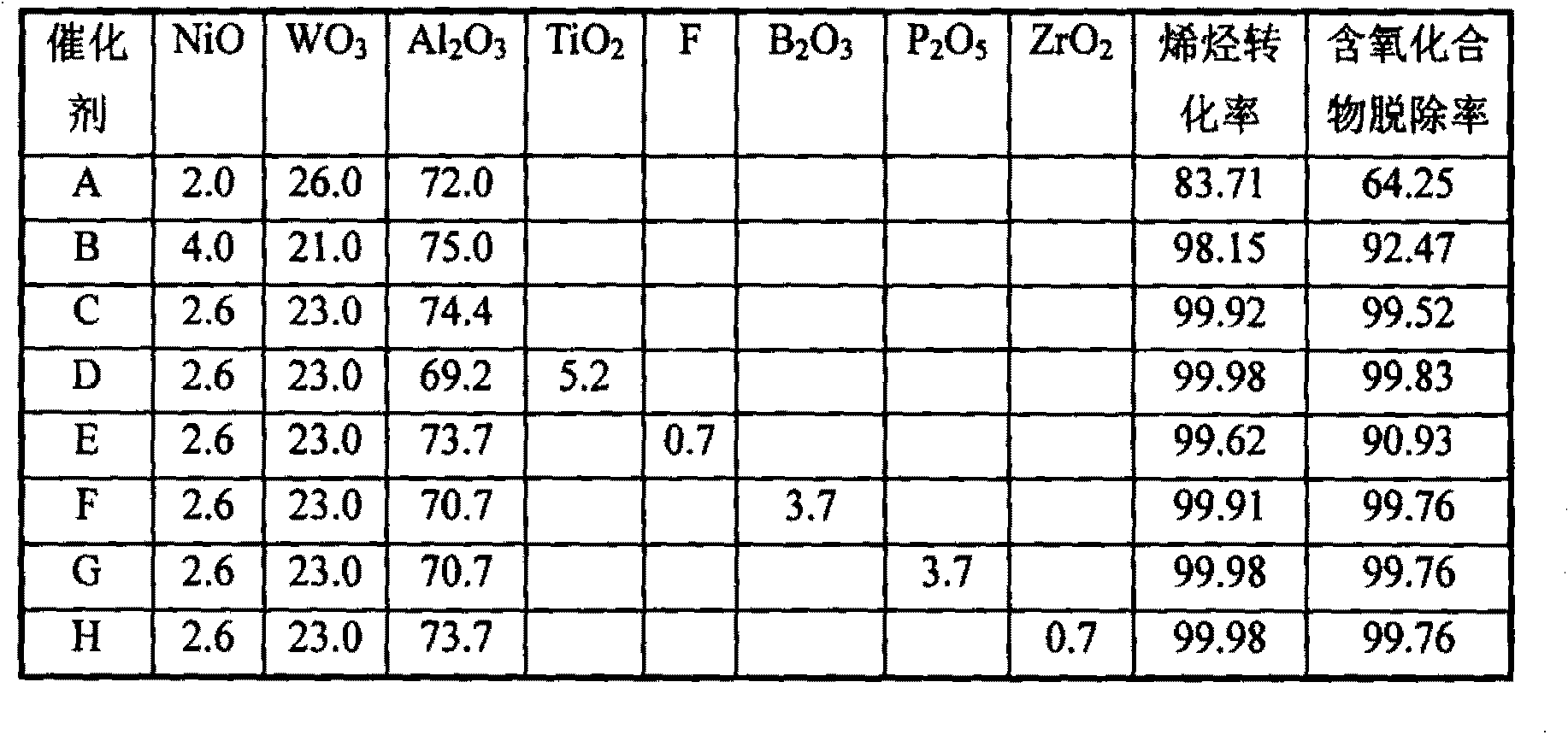

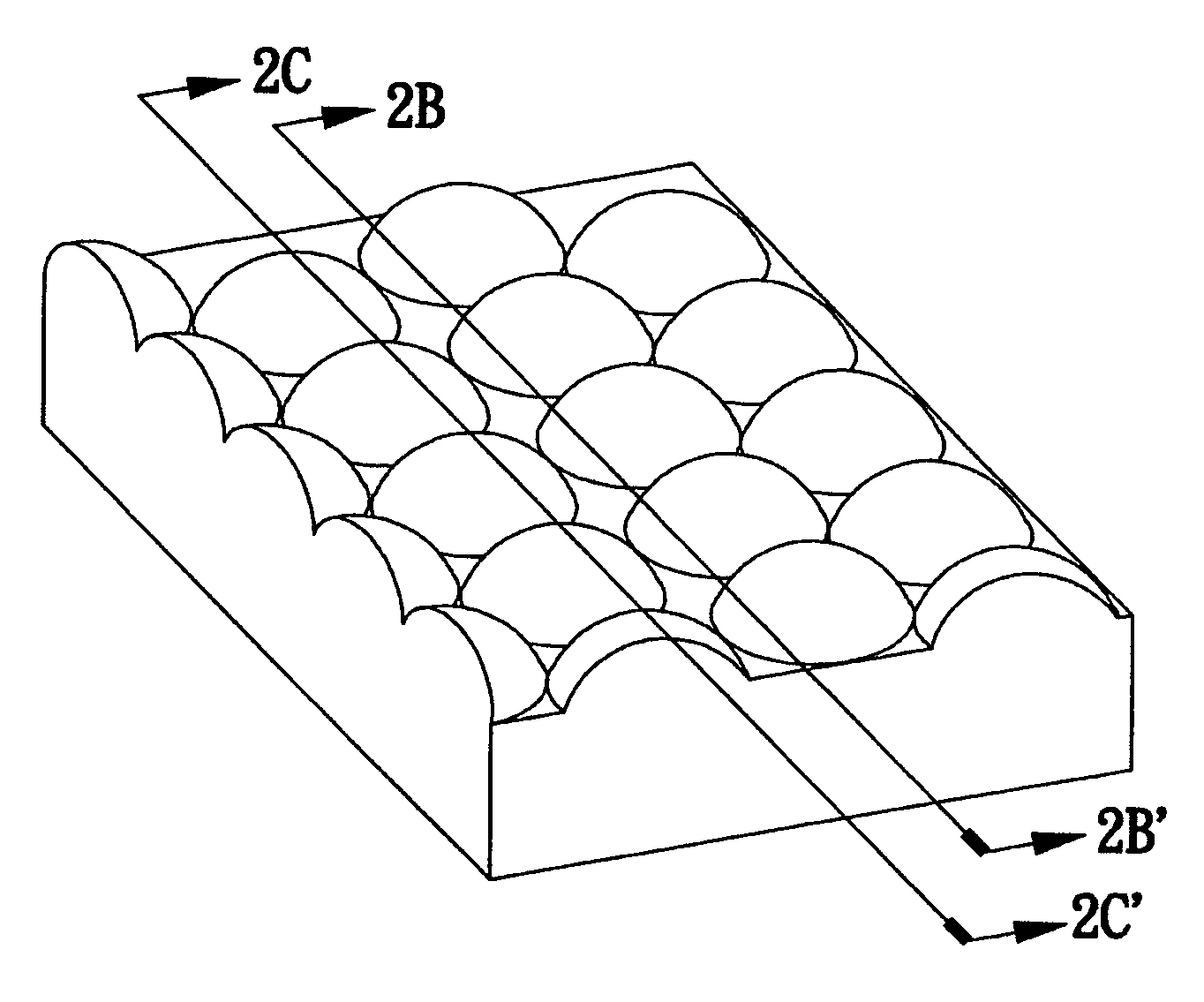

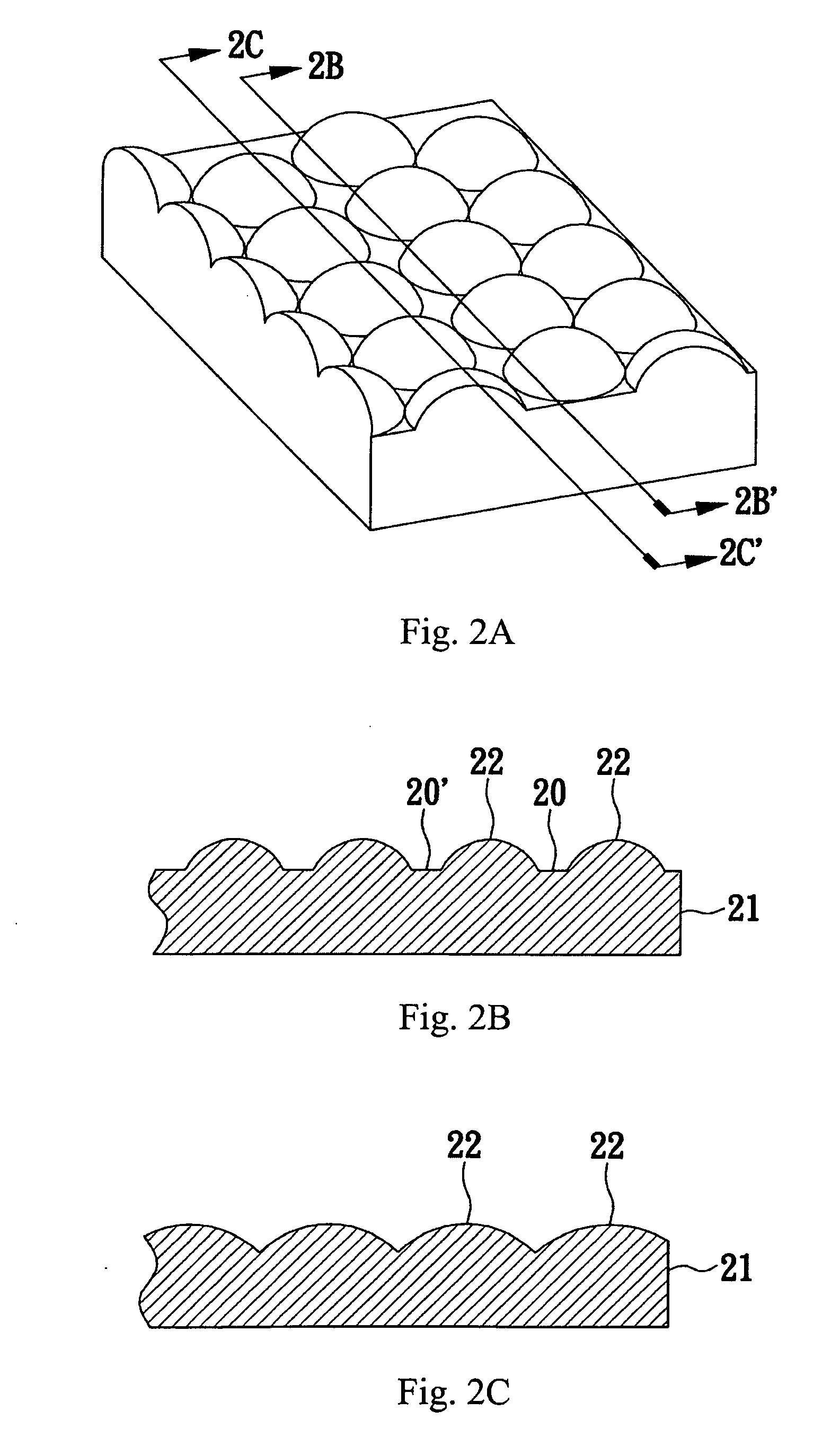

Substrate for fabricating light emitting device and light emitting device fabricated therefrom

InactiveUS20100006862A1Improve surface structureIncrease the effective surface areaLayered productsSolid-state devicesQuantum efficiencyLight emitting device

The invention provides a substrate for fabricating a light emitting device and the light emitting device fabricated therefrom. The substrate includes at least one platform region having a first facet direction for epitaxial growth; and a plurality of continuous protruded portions surrounding the at least one platform region to isolate the at least one platform region from another platform region, wherein the first facet direction is substantially excluded from facet directions of the plurality of continuous protruded portions. Since facet directions of the plurality of continuous protruded portions substantially do not include the first facet direction, during formation of the light emitting device, epitaxial growth is mainly conducted on the at least one platform region, which may prevent epitaxial defects from generating and enhance external quantum efficiency of the light emitting device.

Owner:EPISTAR CORP

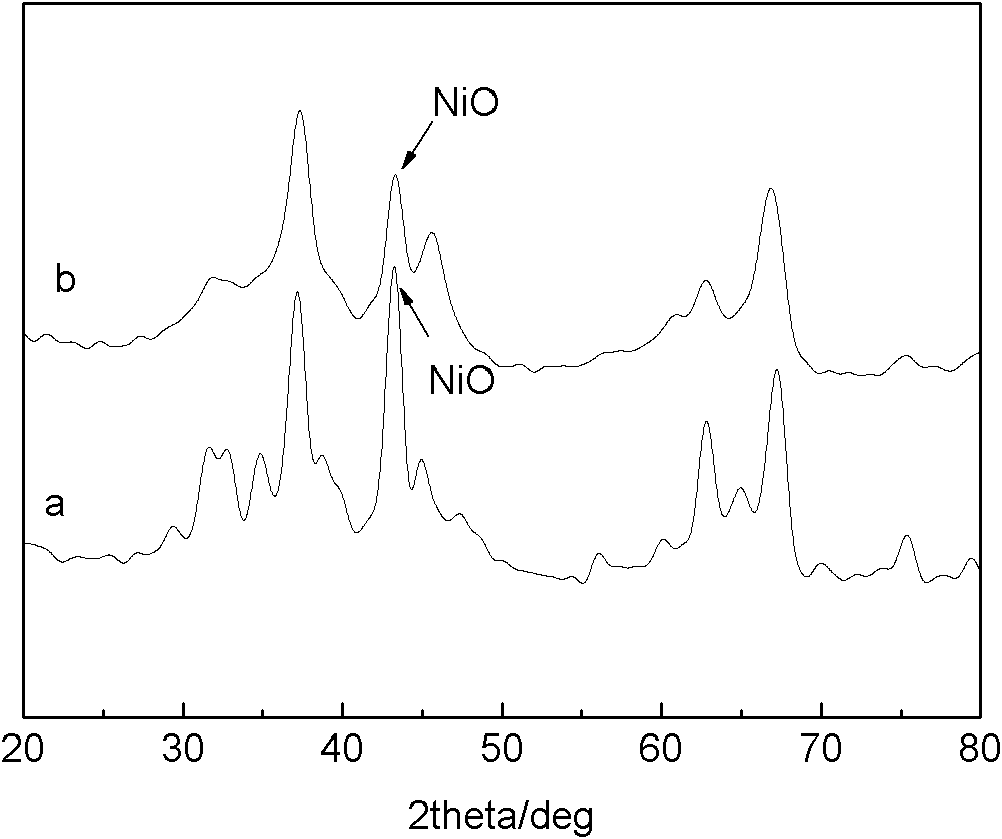

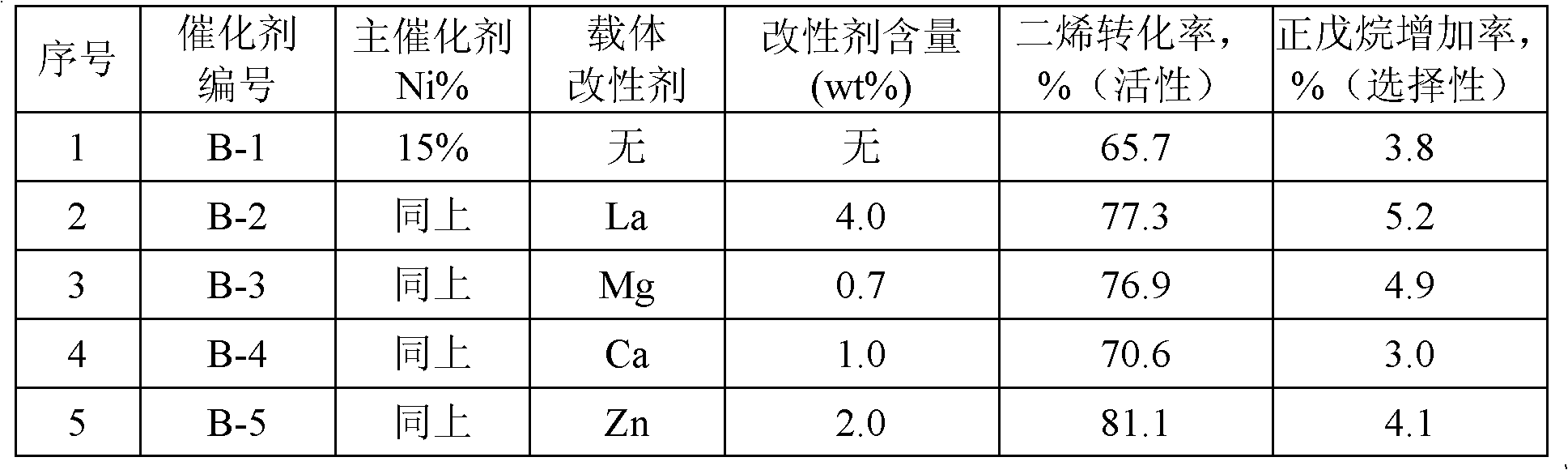

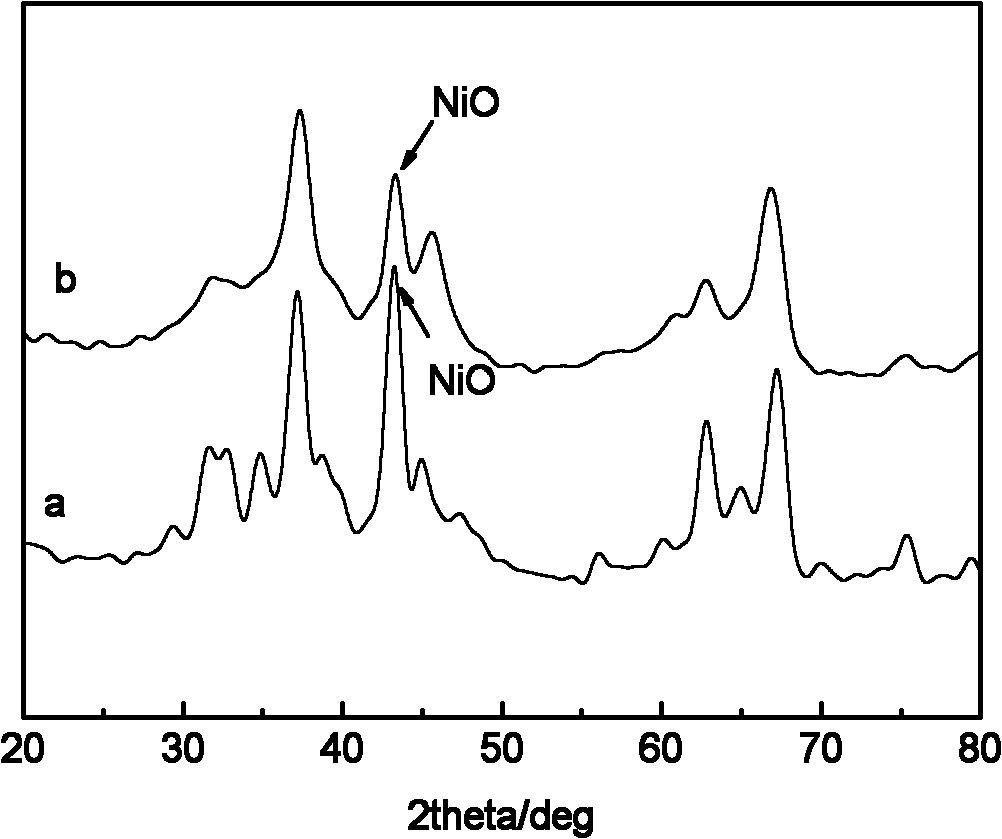

Modified Al2O3 carrier and preparation method thereof

InactiveCN102125878AInhibitory responseHigh activityCatalyst carriersCatalyst activation/preparationPtru catalystPhysical chemistry

The invention relates to a modified Al2O3 carrier and a preparation method thereof. The invention first provides the modified Al2O3 carrier, Al2O3 is used as a matrix in the carrier, and the surface of the carrier is provided with a layer of spinel compound formed by modifying the Al2O3 with a modifying element M, wherein the modifying element M is one of La, Ce, Pr, Mg, Ca, Sr, Ba and Zn. The invention also provides the preparation method for the modified Al2O3 carrier. By selecting the proper modifying element for modifying the surface of the Al2O3 matrix, the modifying element and the Al2O3 form the spinel compound on the surface of the matrix, so the acidity of the carrier surface can be greatly reduced, the reaction between the active metal on the surface of the catalyst and the carrier is inhibited, the surface structure of the carrier is improved, and a catalyst obtained by using the surface modified carrier as a carrier can keep high activity and stability in long-time operation.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

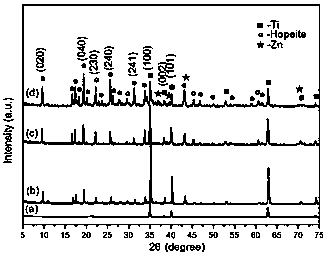

Method for preparing zinc phosphate conversion coating on surface of titanium

InactiveCN103952745AHigh crystallinityExcellent electrochemical performancePhosphatisationChemistryConversion coating

The invention discloses a method for preparing a zinc phosphate conversion coating on the surface of titanium. The method comprises the following steps: mixing a phosphorous compound, a zinc-containing compound, a calcium-containing compound and an accelerant together to form a chemical conversion basic liquid; performing activating treatment and surface adjustment on a pure titanium substrate; putting the treated pure titanium substrate in the chemical conversion basic liquid and applying an electric current field, wherein the pure titanium substrate is taken as a cathode, while platinum is taken as an anode; and obtaining the zinc phosphate conversion coating on the surface of titanium after chemical conversion. In such a manner, the reaction of the method for preparing the zinc phosphate conversion coating on the surface of titanium can be finished at a relatively low temperature, and the obtained product is high in degree of crystallinity and good in electrochemical performance; the method is low in pollution, low in cost and simple in process, and thus suitable for large-scale production and application; the zinc phosphate conversion coatings more excellent in mechanical properties can be obtained by use of the methods of solution optimization, current intensity change, time control and the like.

Owner:SUZHOU RES INST SHANDONG UNIV

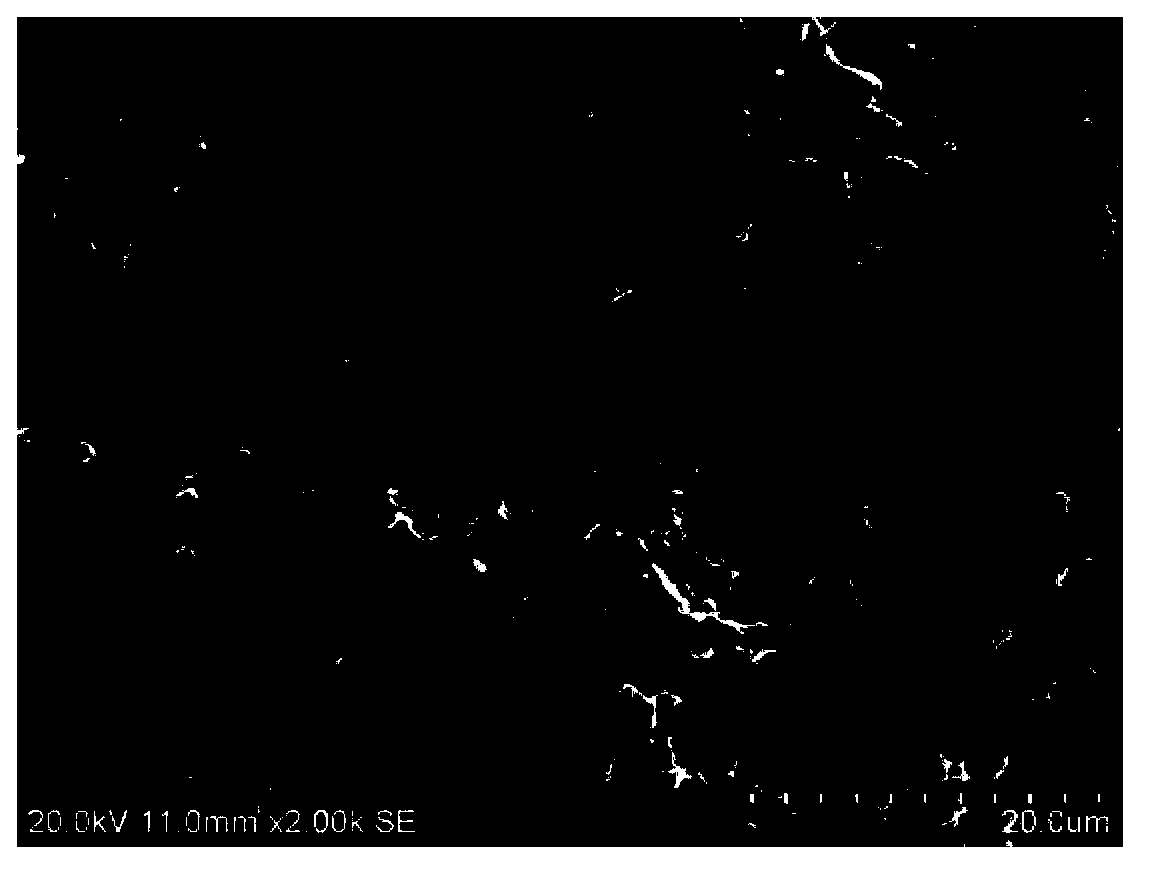

Surface treatment process of bioactive metallic titanium implant having multistage micro-pit structure

InactiveCN103451602ANot easy to fall offInhibit sheddingVacuum evaporation coatingSputtering coatingAcid etchingDrug biological activity

The invention relates to a surface treatment process of a bioactive metallic titanium implant having a multistage micro-pit structure, and the surface treatment process comprises the following steps: pretreatment, sandblasting treatment, acid etching treatment, sputtering treatment and glow discharge treatment; according to the surface treatment process, a multistage micro-pit three-dimensional structure having a bioactive tantalum coating is formed on the surface of the metallic titanium implant, so that the binding strength between the tantalum coating and the metallic titanium implant is very good, the tantalum coating is not easy to shed, shedding of the tantalum coating during or after an implantation process is avoided, the biological activity of the metal titanium implant can be improved, bone deposition of the surface of the metal titanium implant is accelerated, the tissue healing time is shortened, and through the formation of synostosis between the metal titanium implant and a surrounding bone tissue, the effect of improvement of the stability of the metal titanium implant can be achieved.

Owner:JIANGSU TRAUSIM MEDICAL INSTR

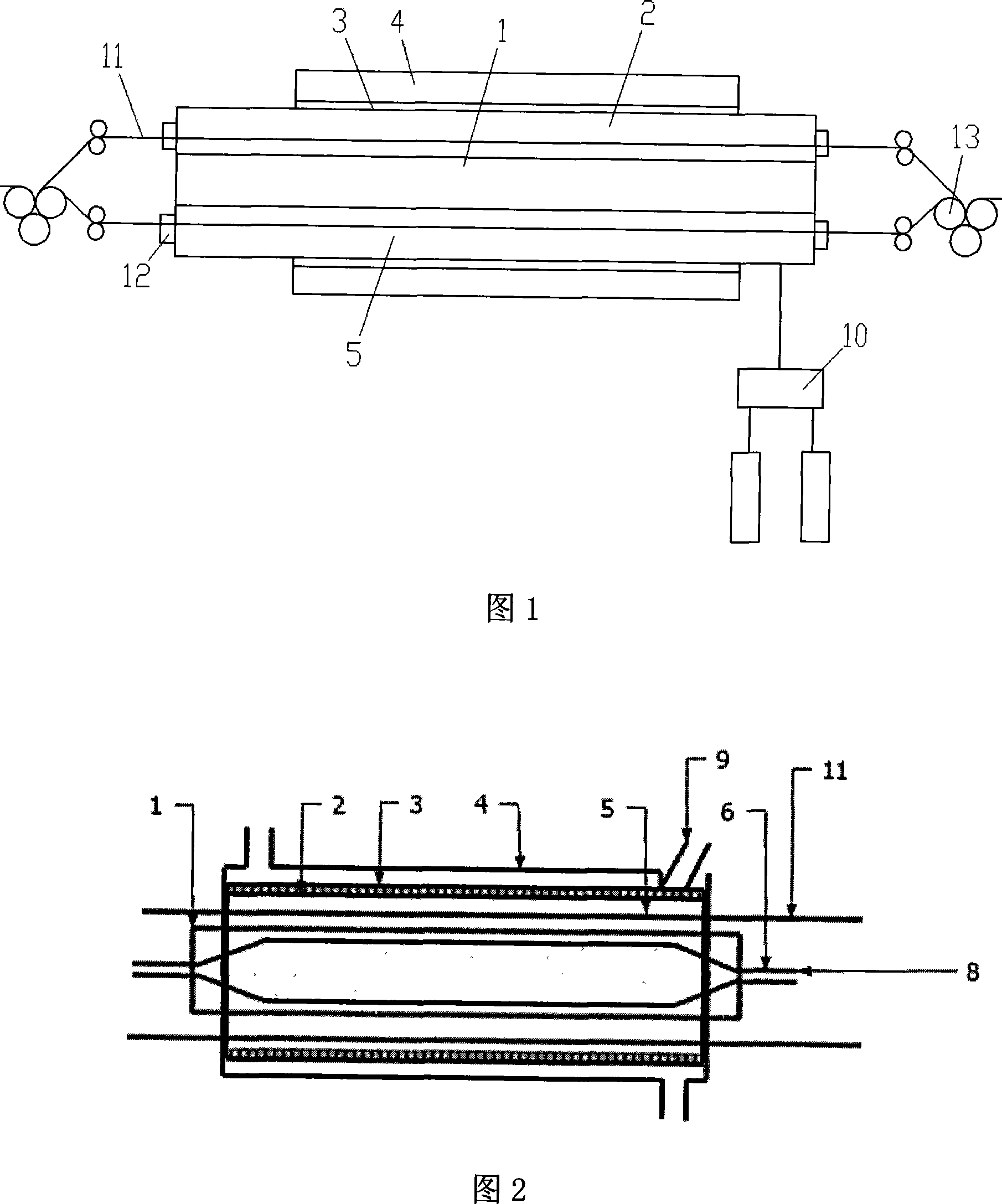

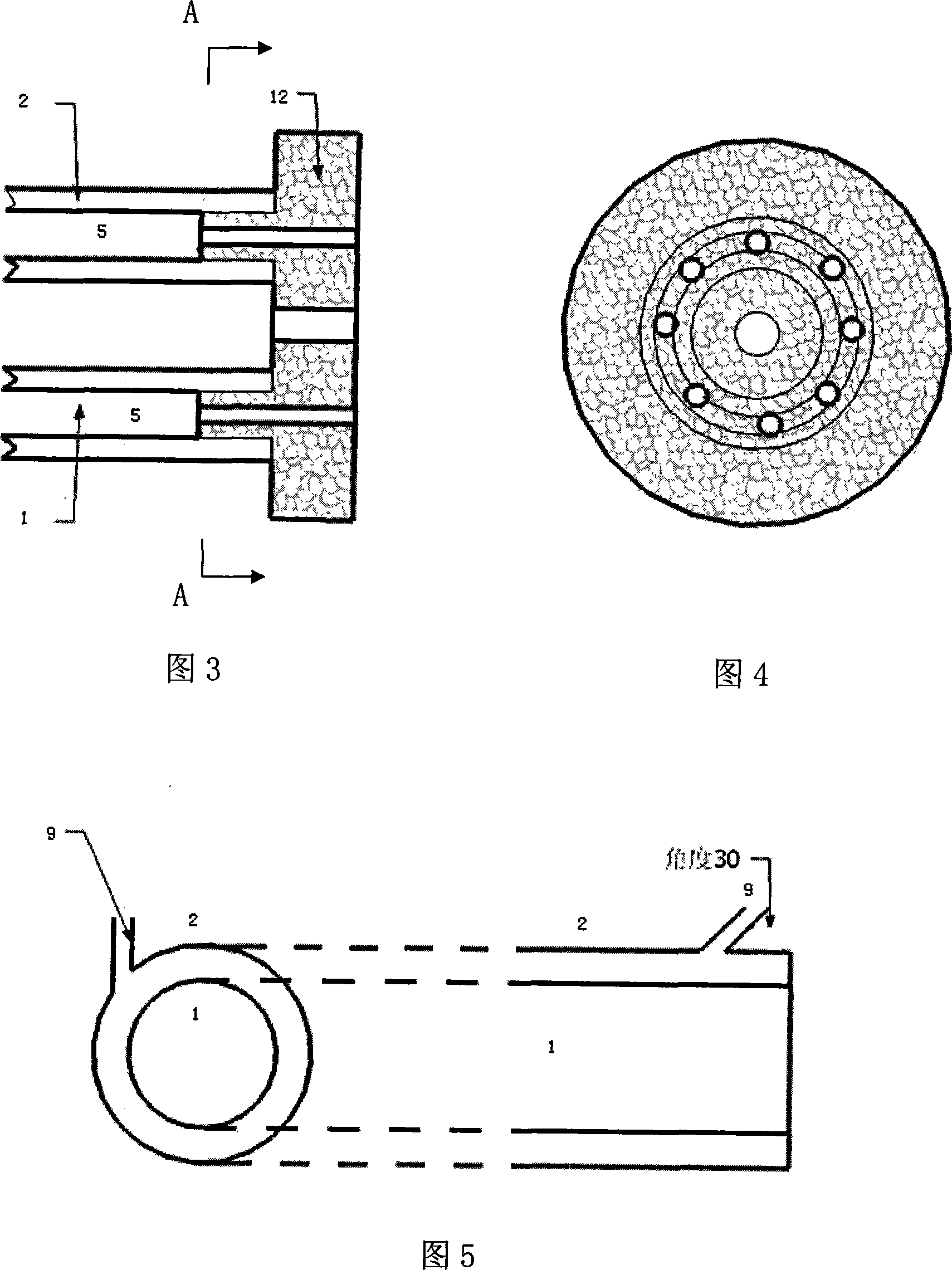

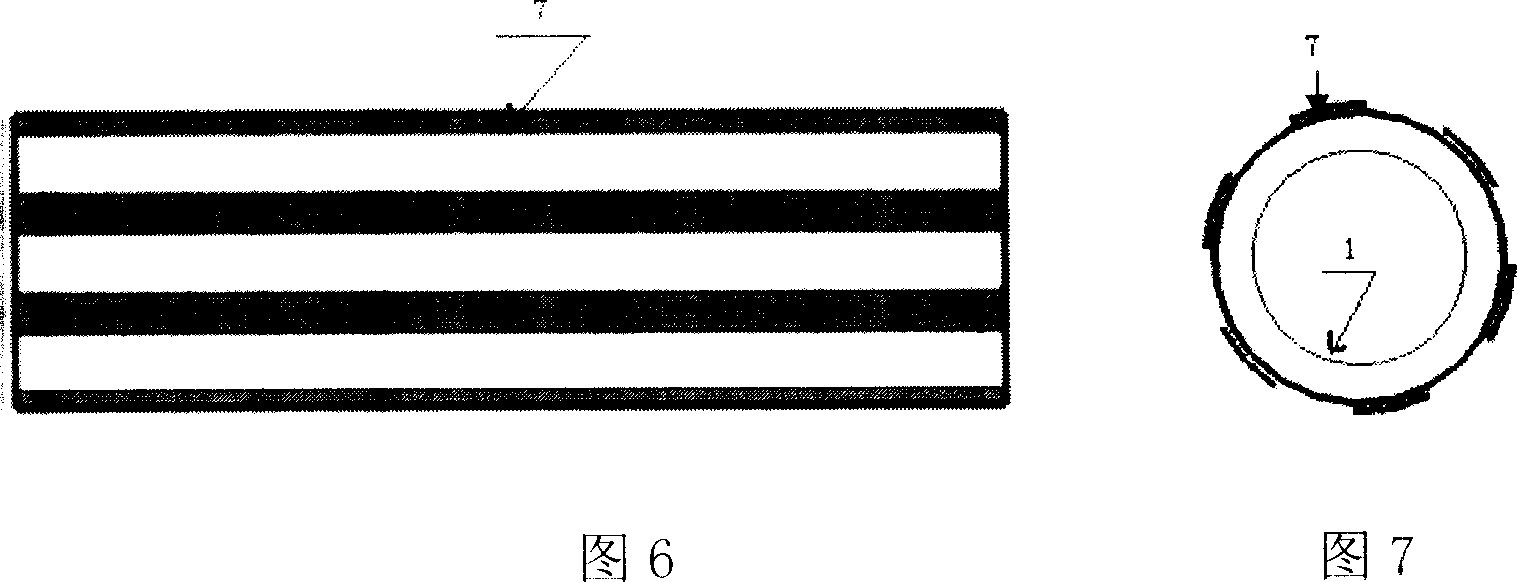

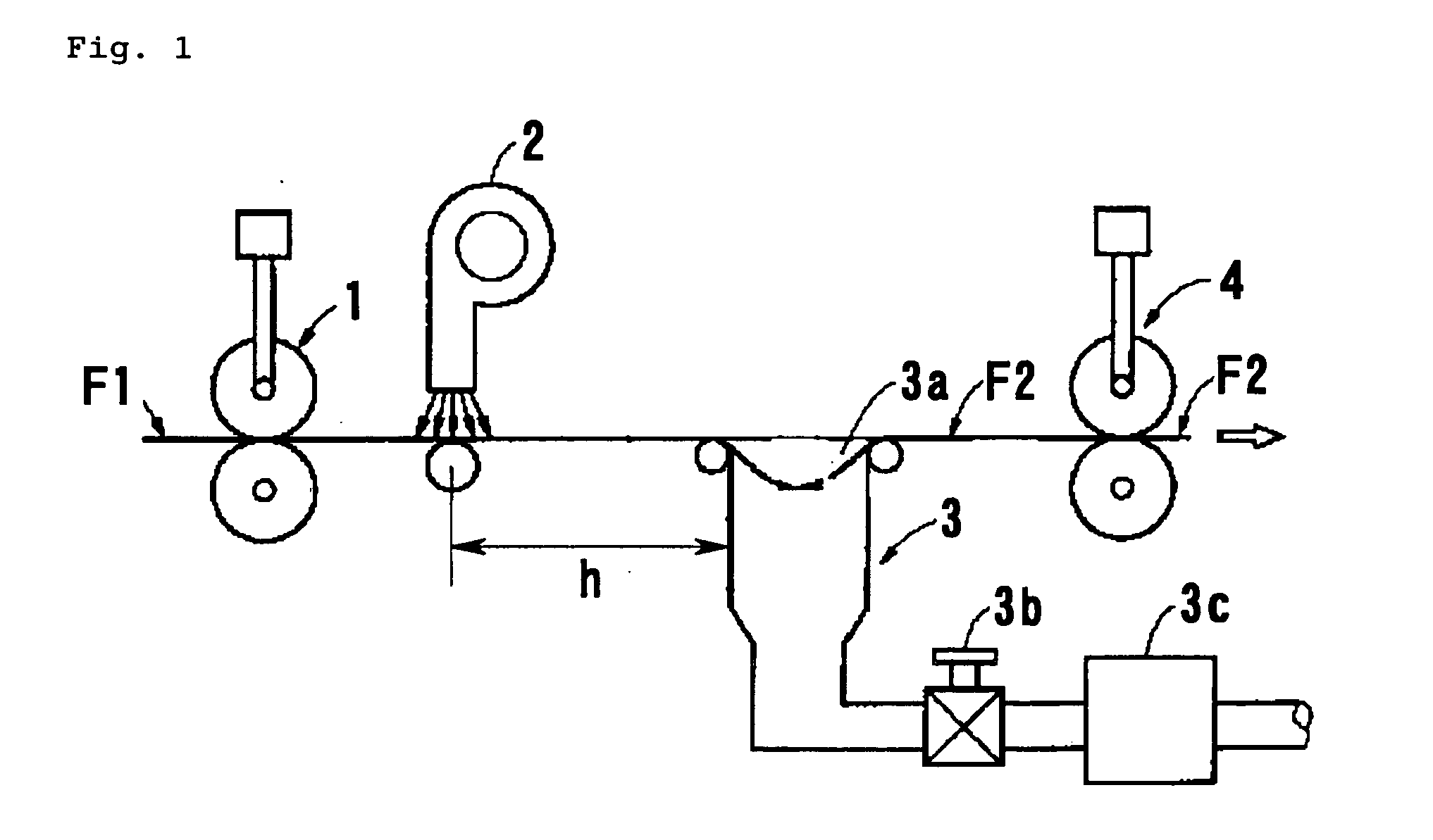

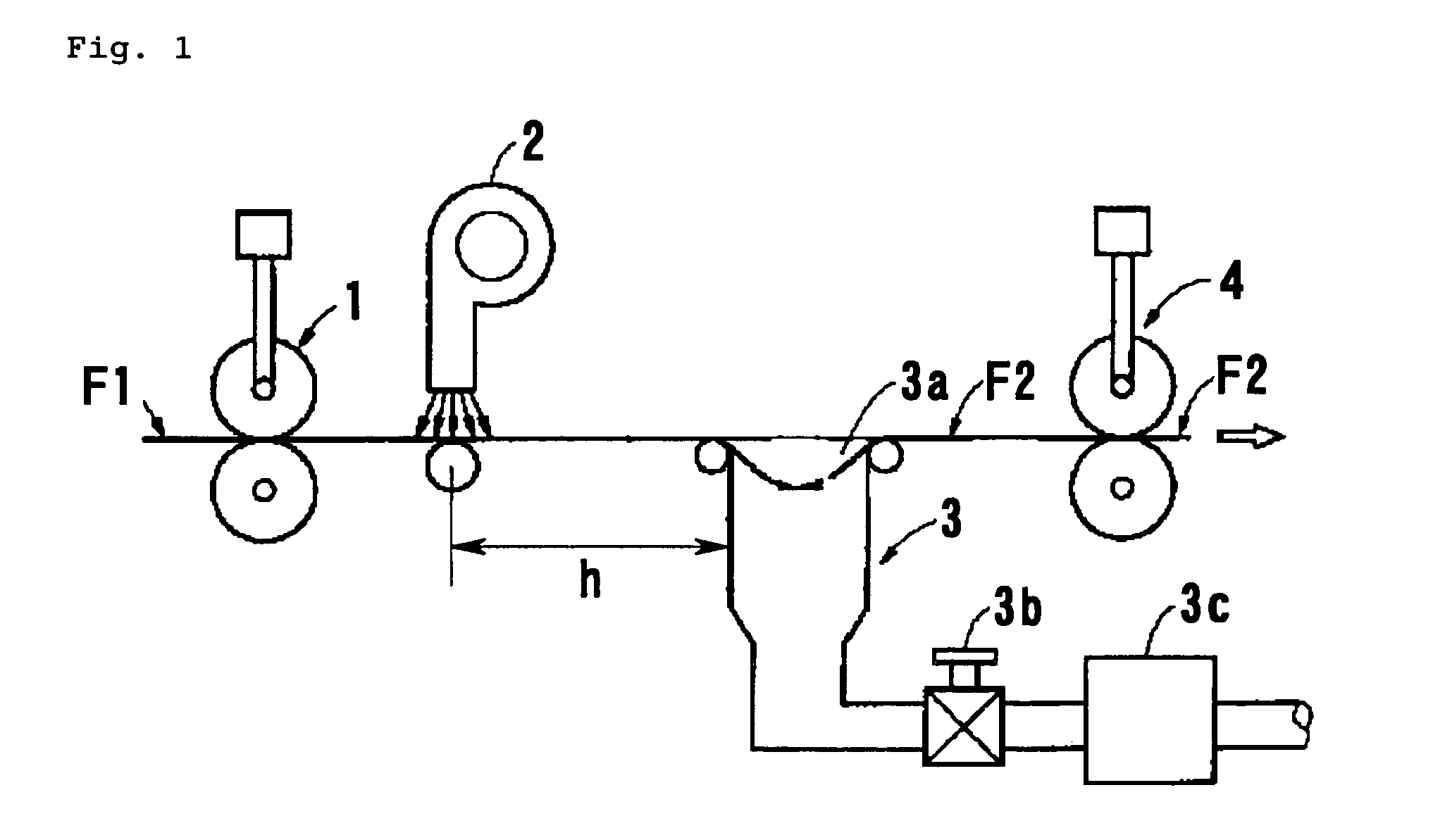

Atmosphere pressure plasma treatment fasciculus or fibre string surface device and method thereof

InactiveCN101096820AImprove surface structureImprove surface propertiesFibre typesUltrasonic/sonic fibre treatmentFiberPower parameter

The invention discloses an atmosphere pressure plasma dealing fiber tuft or fiber thread surface device and method, which is characterized by the following: arranging quartz liner pipe in coaxial cover; constructing gas discharging plasma zone with quartz outer tube; forming high pressure electrode with inner surface or outer surface of the quartz linear through vacuum deposition plated metallic film; cup-jointing stainless steel cloth and water coat sandwich on the outer surface of the quartz outer tube; constructing earth electrode; using coaxial quartz glass tube to construct asymmetric electrode structure of medium discharge resistance; keeping special laminar flow disperse for gas in sandwich; diminishing consumption of gas; decreasing treating temperature effectively. This invention can choose proper high pressure electrode form, gas component, power parameter and treating speed according to different fiber material, which can proceed highly effective, low consumption and environment protection treat for the surface of fiber tuft or fabric cord.

Owner:DONGHUA UNIV

Nanocrystal-containing filtration media

InactiveUS6662956B2Shorten the counting processSame efficiencyLoose filtering material filtersDisinfectionFiltrationNanocrystal

Owner:KINETICO

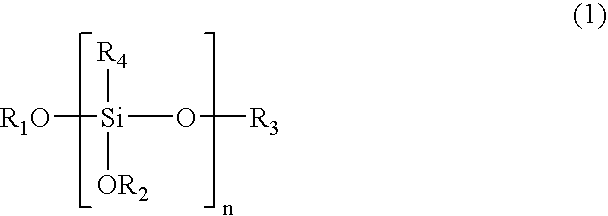

Composite comprising heat-resistant fiber and siloxane polymer

InactiveUS20050165154A1Improve heat resistanceImprove toughnessEngine sealsSynthetic resin layered productsPolymer scienceHeat resistance

The present invention provides a fiber-reinforced glass having excellent heat resistance and toughness, or a composite comprising a heat-resistant fiber and a siloxane polymer, which has a modified surface structure and is useful as a heat-resistant fiber.

Owner:IWAMIYA YOKO

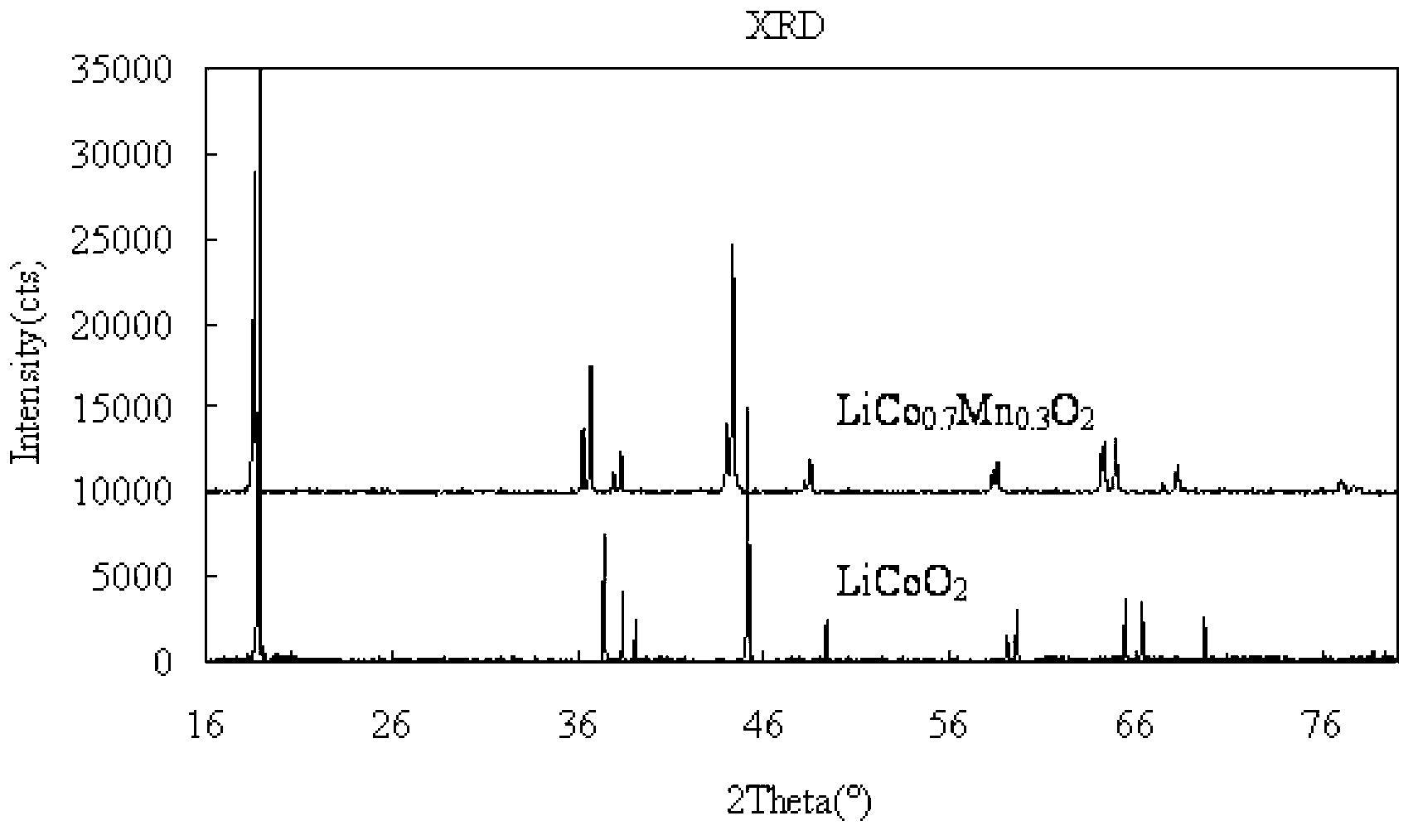

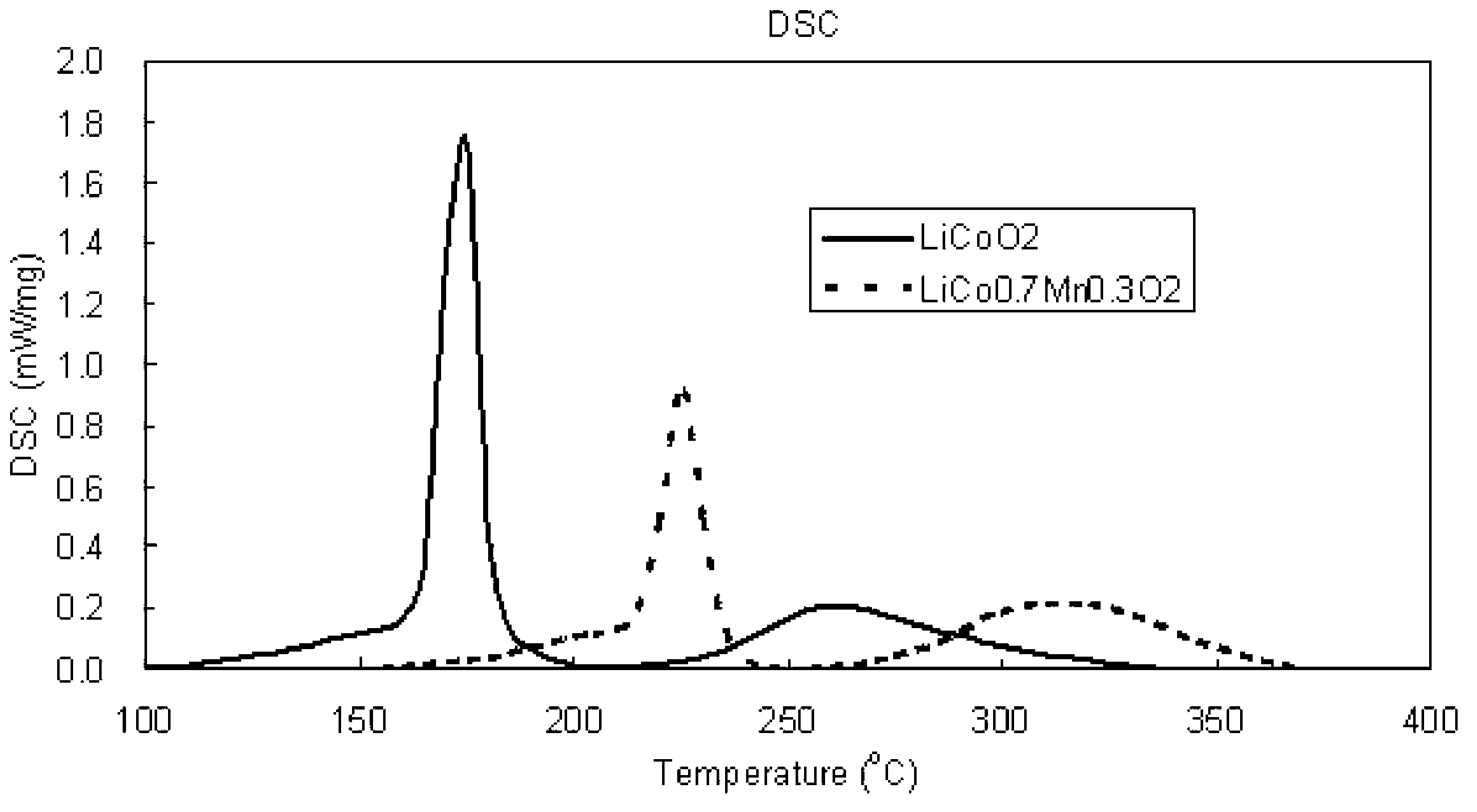

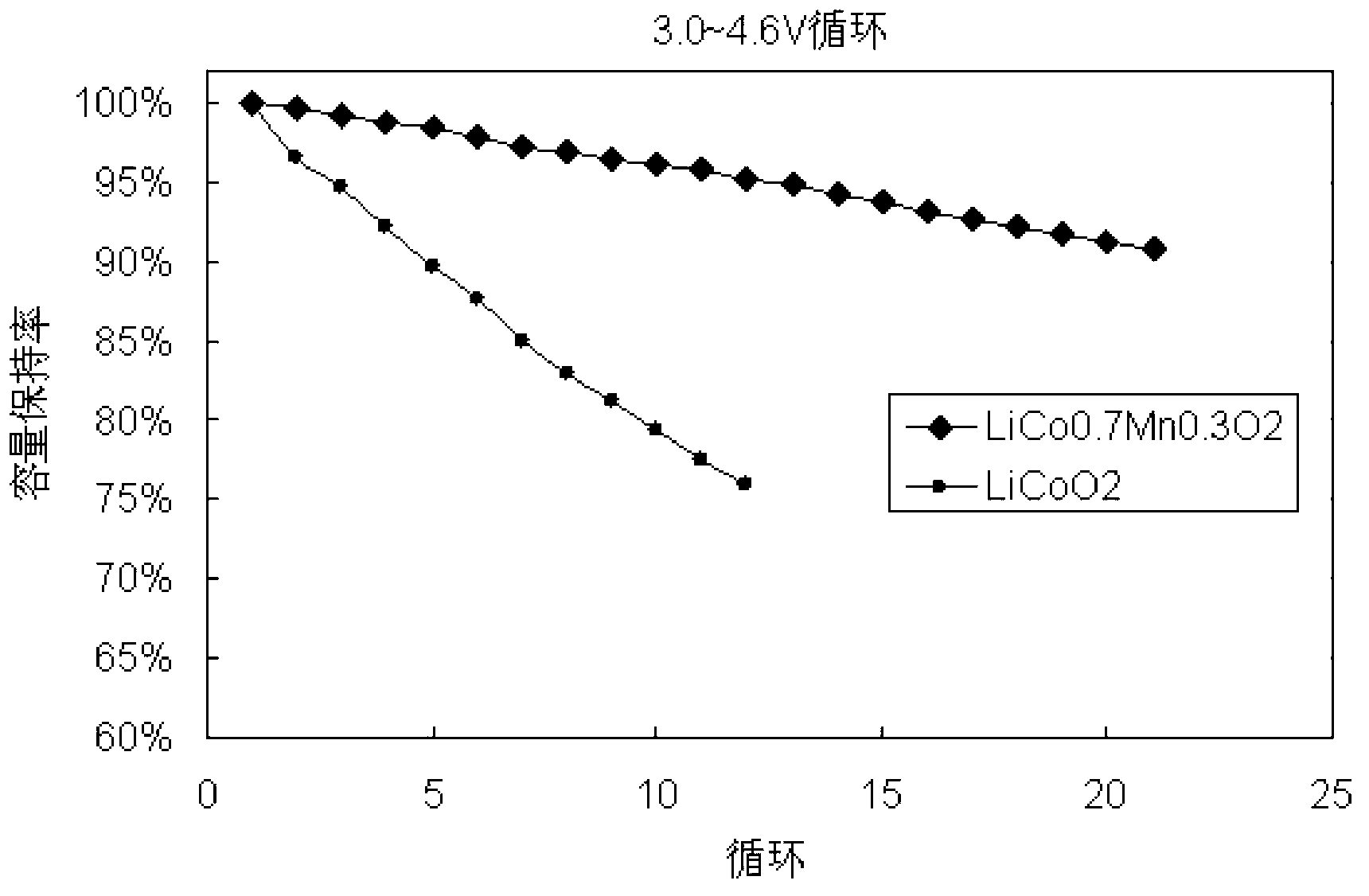

Polymorph positive electrode material for lithium ion battery and preparation method of material

ActiveCN103247796AImprove surface structureCell electrodesSecondary cellsThermal safetyStructural formula

The invention discloses a polymorph positive electrode material with a crystal lattice structure consisting of a layered hexagonal crystal lattice and a spinel-shaped cubic crystal lattice for a lithium ion battery. The structural formula of the polymorph positive electrode is LiCo<1-x-y-z>MnxNiyAlzO2, wherein x is more than zero and less than or equal to 0.3, y is more than or equal to 0 and less than or equal to 0.2, and Z is more than or equal to zero and less than or equal to 0.02. Compared with a single layered structure positive electrode material, the polymorph positive electrode material for the lithium ion battery has excellent structural stability and thermal stability and remarkable cycling property, thermal safety and multiplying property. In addition, the invention also discloses a preparation method of the polymorph positive electrode material for the lithium ion battery.

Owner:DONGGUAN AMPEREX TECH

Repairing reducing agent for lead-acid storage batteries

InactiveCN103311586AAvoid depositionGood dispersionSecondary cells servicing/maintenanceElectrolytic agentInternal resistance

The invention provides a repairing reducing agent for lead-acid storage batteries, which can dissolve lead sulfate crystals deposited on polar plates. Metal ions are not introduced in, so that the self discharge of the metal ions and the softening of the polar plates can be avoided. The physical structure of the batteries is not destroyed, the chemical environment of the batteries is not changed and an organic protective film can be formed on the surface of the polar plates of the batteries to restrain the deposition of newly-generated lead sulfate crystals and ensure the long-term action and the stability of repair effects. A nanometer graphene oxide material which is beneficial for increasing the specific surface area of electrodes, improving the surface structure of the electrodes, lowering the internal resistance and improving the transfer efficiency of interface electrons is introduced in. The electric conductance of electrolyte is enhanced, the internal resistance of the batteries is lowered, and the capacity restorability and the recharging receptivity after the overdischarge of the storage batteries are improved. The battery capacity can be restored to the maximum degree and the service life of the batteries is prolonged. The capability of the repaired storage batteries can be restored to more than 90% and the service life of the repaired storage batteries can be prolonged by double or more.

Owner:JILIN TIGER SAVING PROD TECH DEV

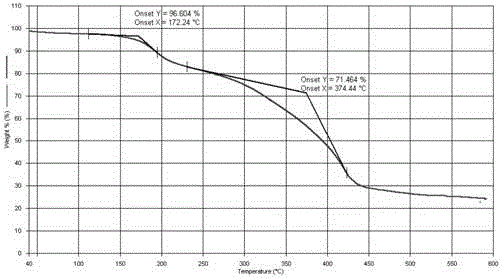

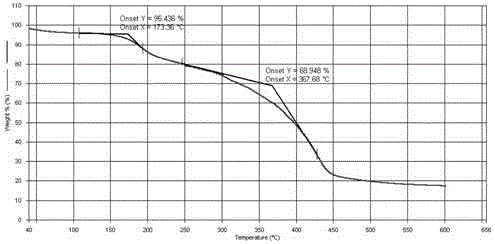

Preparation method of novel beta-carotene microcapsules

ActiveCN105876792AHigh encapsulation efficiencyImprove thermal stabilityFood shapingMaillard reactionBeta-Carotene

The invention discloses a preparation method of novel beta-carotene microcapsules. A Maillard reaction product of reducing sugar and whey protein is used as an oxidation resistance type wall material, and the beta-carotene microcapsules are prepared by a spray drying method. The method specifically comprises the following steps of firstly making the whey protein and the reducing sugar into a whey protein Maillard reaction product solution under certain conditions, wherein the whey protein Maillard reaction product solution is used as a wall material solution; then compounding beta-carotene into an oil solution of a certain concentration, wherein the oil solution is used as a core material, according to the proportion of the core material to the wall material, adding the core material and an emulsifying agent to the wall material solution, and performing high-speed homogenizing so as to obtain a microcapsule emulsifiable solution; and finally performing spray drying so as to obtain beta-carotene microcapsule products. Through the adoption of the preparation method disclosed by the invention, the beta-carotene microcapsules with good nature can be directly prepared, and the beta-carotene microcapsule can also be used as a nutrient enrichment agent to be directly added to foods.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Composite comprising heat-resistant fiber and siloxane polymer

InactiveUS7332196B2Increase resistanceImprove toughnessEngine sealsSynthetic resin layered productsPolymer scienceHeat resistance

The present invention provides a fiber-reinforced glass having excellent heat resistance and toughness, or a composite comprising a heat-resistant fiber and a siloxane polymer, which has a modified surface structure and is useful as a heat-resistant fiber.

Owner:IWAMIYA YOKO

A kind of preparation method of ion membrane electrode for pure water electrolysis

InactiveCN102260877ASimple preparation processEasy to useCellsElectrodesPtru catalystElectrolysed water

The invention relates to a preparation method of an ion membrane electrode for pure water electrolysis, belonging to the technical field of hydrogen production by water electrolysis. The preparation method comprises the following steps: separately preparing a cathode catalyst solution and an anode catalyst solution from a cathode catalyst, an anode catalyst, a Nafion solution, isopropyl alcohol, glycerol and distilled water; separately applying the cathode catalyst solution and the anode catalyst solution on two transfer-printing templates, and drying the templates at the temperature of 80-130 DEG C in vacuum; and fixing the two dried transfer-printing templates on both sides of an ion membrane, treating at the temperature of 130-190 DEG C and the pressure of 6 MPa for 2-5 minutes, cooling to room temperature while maintaining the pressure at 6 MPa, peeling off the transfer-printing templates, placing the templates in an oven and treating in vacuum at the temperature of 70-110 DEG C for 1 hour. By using the transfer-printing templates in the preparation method, under the premise of ensuring the combination firmness degree of the ion membrane and the catalyst layer, the direct damage to the ion membrane is reduced, thereby the service life of the membrane electrode is prolonged, the energy consumption is lowered, the electrolysis efficiency is improved, the preparation time is shortened and the production cost is reduced.

Owner:SHANDONG SAIKESAISI HYDROGEN ENERGY

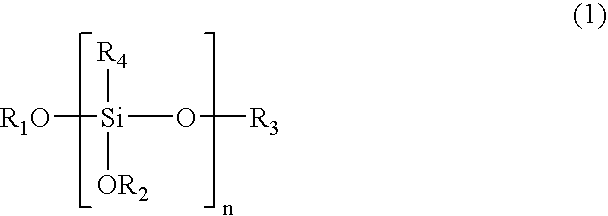

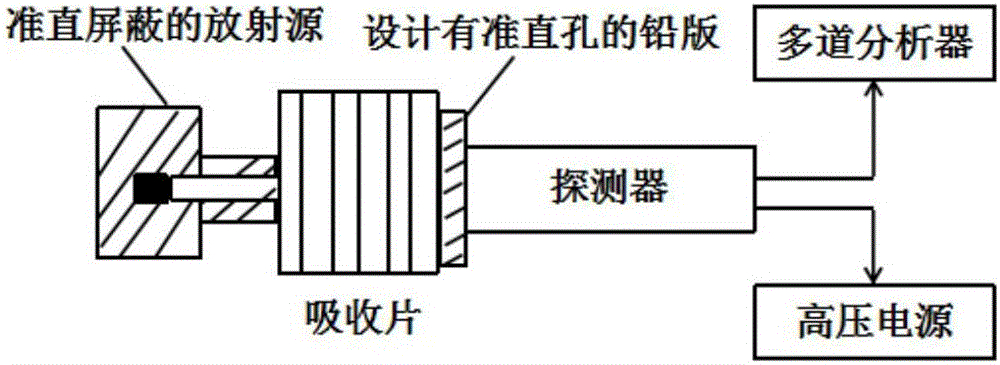

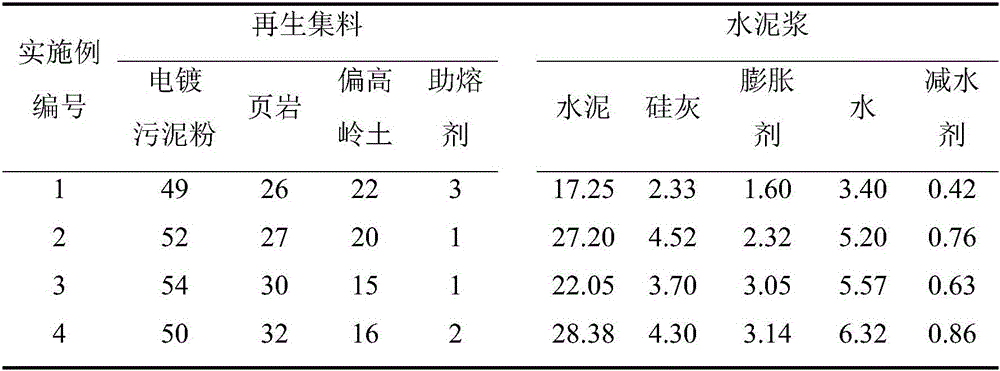

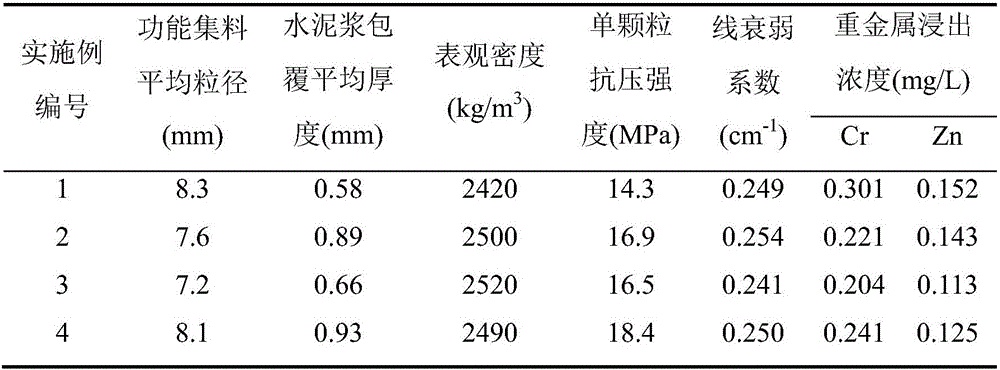

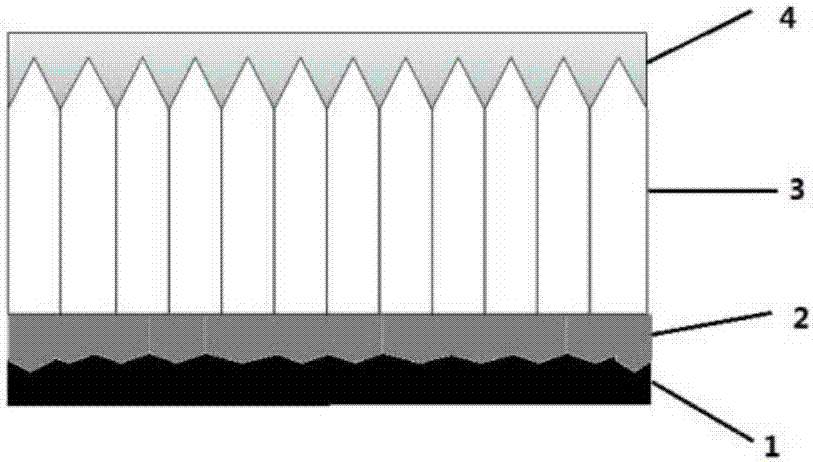

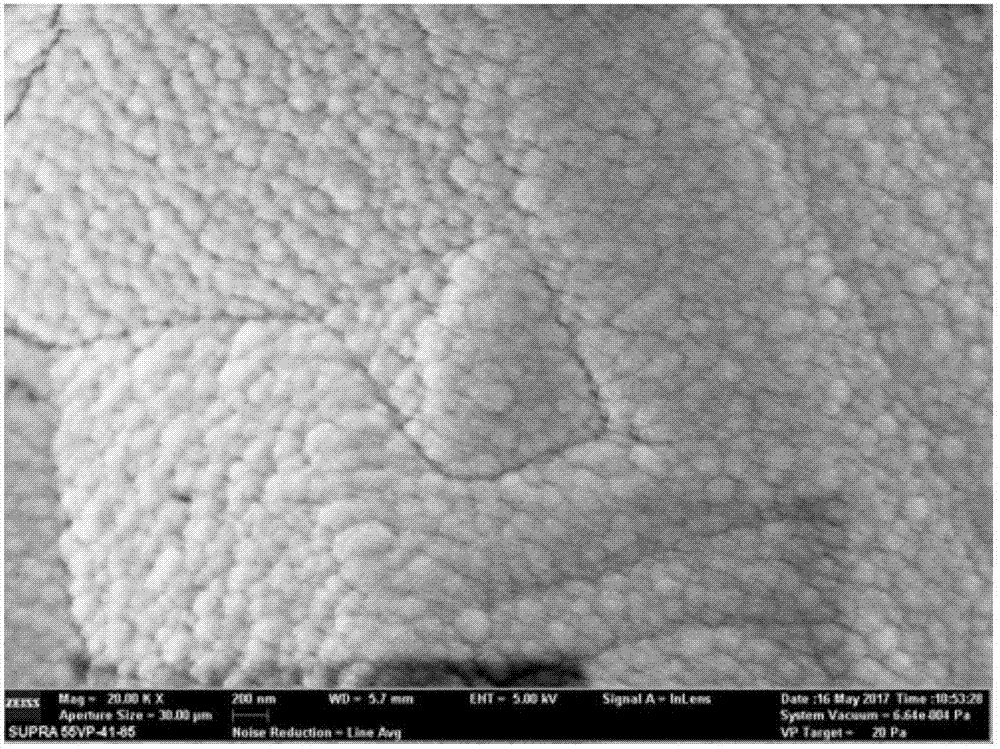

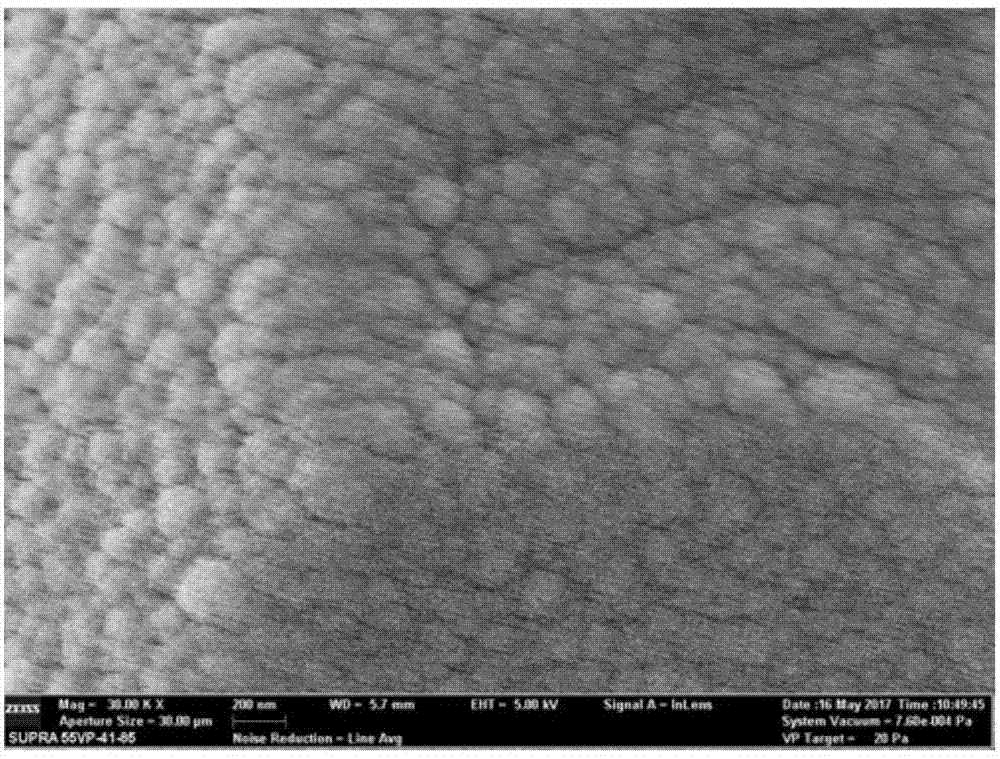

Anti-radiation functional aggregate prepared from Cr-containing and Zn-containing electroplating sludge

ActiveCN106588117AAvoid lostDissolution inhibitionMaterial analysis using wave/particle radiationCeramic materials productionHigh densitySludge

The invention discloses an anti-radiation functional aggregate prepared from Cr-containing and Zn-containing electroplating sludge. By means of heavy metal elements including Cr and Zn, the anti-radiation functional aggregate has the beneficial effect that the anti-radiation functional aggregate has good shielding performance for high-energy rays, and a regenerated aggregate can have good anti-radiation performance; pulp wrapping processing is conducted on the regenerated aggregate through a vacuum stirring technology, and the surface structure of the aggregate is optimized; ultrahigh performance processing is conducted on the aggregate, subjected to pulp wrapping, through autoclaved curing, and the chemical property, the shielding performance and the heavy metal ion solidification effect of the anti-radiation functional aggregate are improved. The anti-radiation functional aggregate solves the problem that the uniformity of natural high-density ore anti-radiation concrete is poor, meanwhile, a large amount of heavy-metal-containing industrial sludge can be consumed, and the important significance in preparation of anti-radiation concrete and processing of the industrial sludge is achieved.

Owner:WUHAN UNIV OF TECH

Non-evaporable low-temperature activated zirconium getter film and preparation method thereof

InactiveCN107400854AIncreased active surfaceImprove inhalation effectSemiconductor/solid-state device detailsVacuum evaporation coatingAdhesion forceChemical composition

The invention discloses a non-evaporable low-temperature activated zirconium getter film and a preparation method thereof. The non-evaporable low-temperature activated zirconium getter film comprises an adjusting layer, a gettering layer and a protecting layer which grow on a rough monocrystalline silicon wafer sequentially, wherein in terms of chemical composition, the gettering layer contains 75%-77% by mass of zirconium, 18%-22% by mass of cobalt, 2%-5% by mass of yttrium and the balance of other inevitable impurities; in terms of a microstructure, the gettering layer is formed by densely arranged columnar grains, and the height of columnar tissue is 100-300 nm. The prepared getter film has the advantages of being environment-friendly, high in gettering capacity, low in activation temperature, high in adhesion force, long in service life, easy to prepare, low in cost and the like and is applicable to packaging of mini vacuum devices in the industrial field of microelectronics.

Owner:YUNNAN NORMAL UNIV

Desulfurizing agent and preparation method thereof

InactiveCN102008873AImprove surface structureIncrease profitDispersed particle separationSewagePollution

The invention provides a calcium based desulfurizing agent loaded by coal ash and a preparation method thereof. Aiming at the problems of low absorbing agent utilization rate, large consumption and the like of the traditional dry method flue gas desulfurization process, the efficient calcium based desulfurizing agent loaded by the coal ash is prepared by using the coal ash, Ca(OH)2 and an activating agent as main raw materials through a solid phase reaction / hydrothermal combination reaction process. The coal ash waste of the traditional coal industries is fully utilized, and structurally modified to be used for treating SO2 waste gas, thus the invention has the advantages of simple preparation process and low cost; and the prepared desulfurizing agent has high desulfuration efficiency and no sewage during the desulfuration and does not produce the secondary pollution.

Owner:蒋历辉 +4

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com