Cover panel structure of a ball surface

a technology of ball surface and cover panel, which is applied in the direction of hollow balls, non-inflatable balls, sports equipment, etc., can solve the problems of economic and environmental protection of the conventional method of making balls, and achieve the effect of improving the surface structure and reducing the waste of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

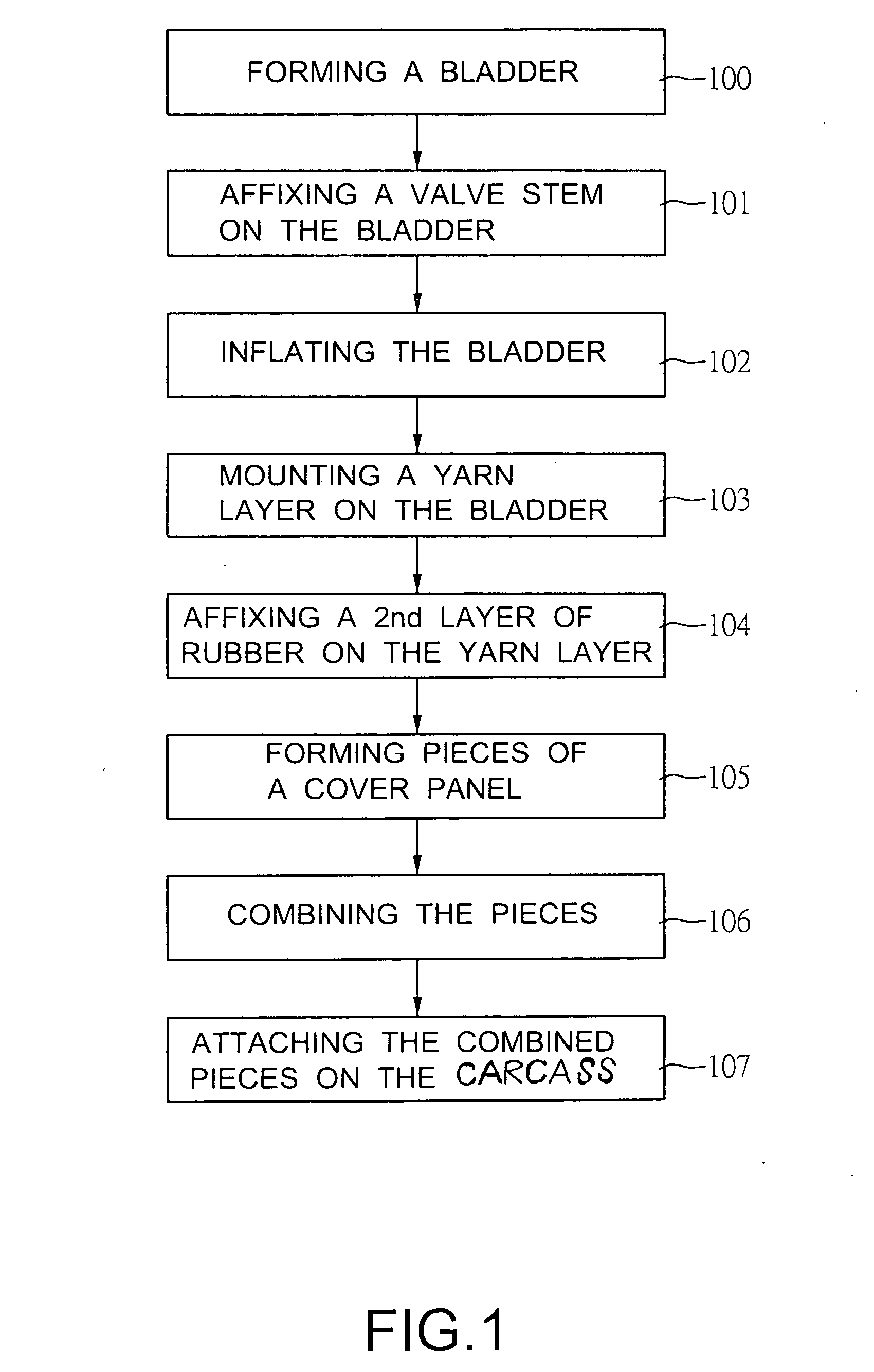

[0018] With reference to FIG. 1, it is noted that the process for making a ball in accordance with the present invention includes the steps of forming a bladder (100), affixing a valve stem on a surface of the bladder (101), inflating the bladder (102), mounting a yarn layer onto the bladder (103), affixing a second layer of rubber on the yarn layer (104) to form a carcass, forming pieces of a cover panel (105), combining the pieces of the cover panel (106) and attaching the combined cover panels onto the carcass (107).

[0019] After the cover panels are securely attached to the carcass, the ball is completed.

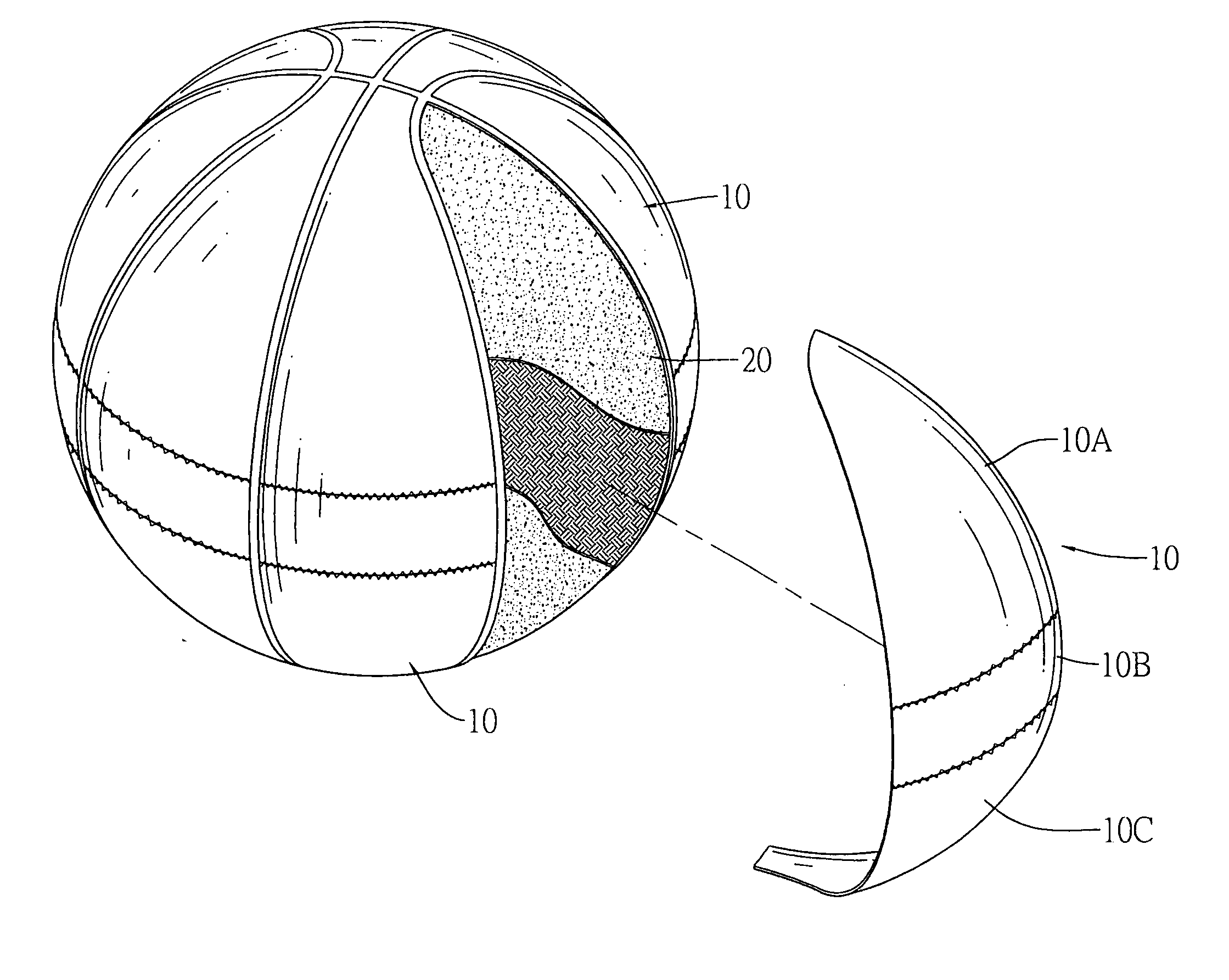

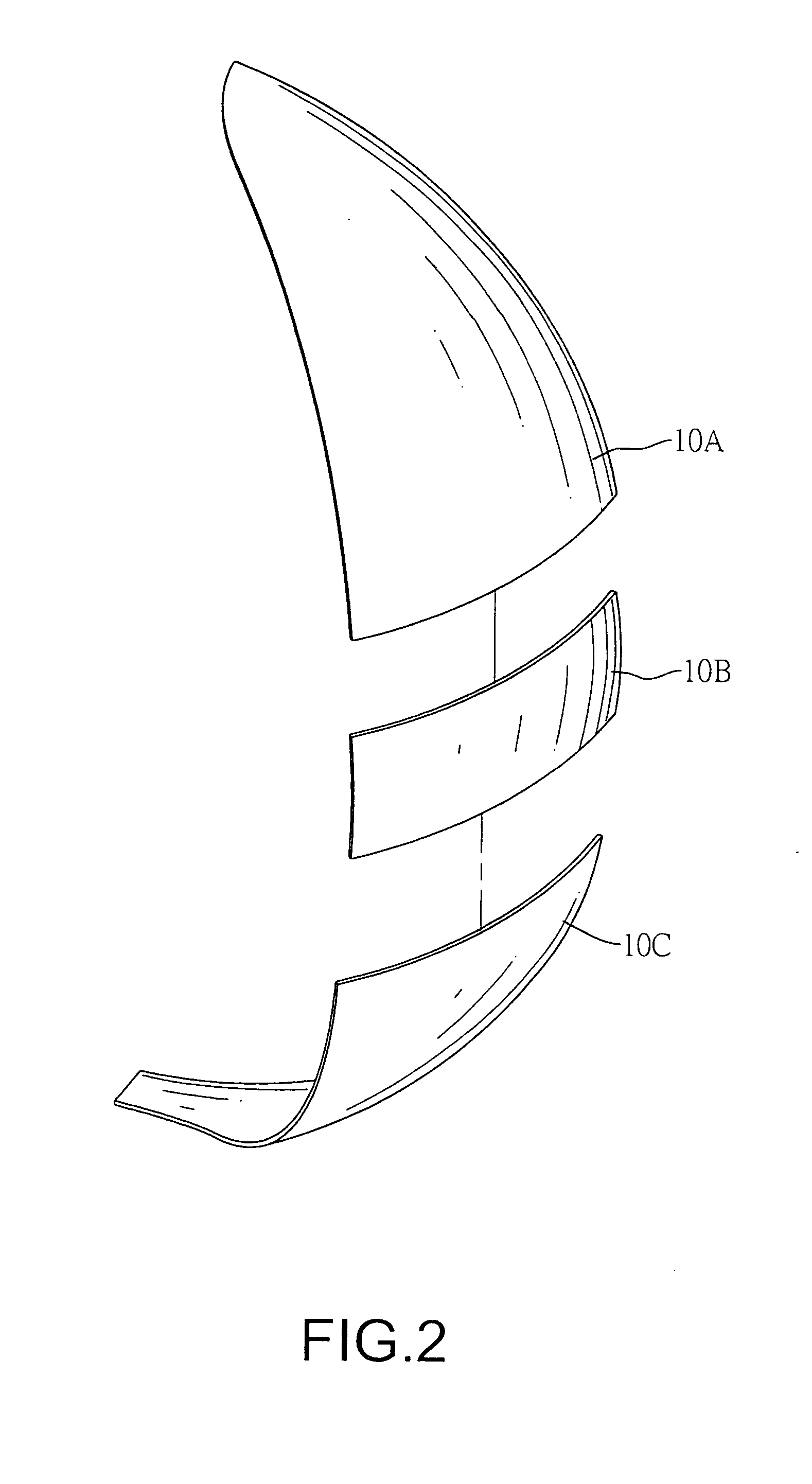

[0020] With reference to FIGS. 2, 3, and 4, it is noted that in order to accomplish the goal of reducing material waste, each of cover panels (10) forming a partial outer periphery of a ball is composed of secondary pieces of different shapes and dimensions, i.e. a top piece (10A), a mediate piece (10B) and a bottom piece (10C).

[0021] From this preferred embodiment of the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com