Method for preparing zinc phosphate conversion coating on surface of titanium

A technology of zinc phosphate and conversion coating, which is applied in the field of biomedical metal materials to achieve the effects of high crystallinity, excellent surface structure and mechanical properties, and excellent electrochemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

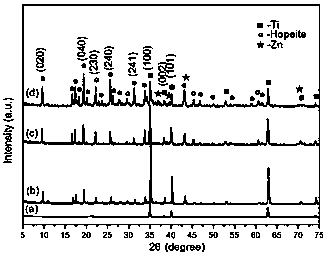

Image

Examples

Embodiment 1

[0022] A method for preparing a zinc phosphate conversion coating on a titanium surface is provided, comprising the steps of:

[0023] (1) First, pour 1 / 3 volume of water into the acid-resistant beaker, and add H at one time 3 PO 4 , then pour the powdered ZnO slowly, stir for 10~20min to fully react, then add Zn(NO 3 ) 2 ·6H 2 O and Ca(NO 3 ) 2 4H 2 O. The contents of the basic chemical raw materials used are H 3 PO 4 : 30g / L, ZnO: 9g / L, Zn(NO 3 ) 2 ·6H 2 O: 23g / L, Ca(NO 3 ) 2 4H 2 O: 23g / L, keep the molar ratio Zn:P:Ca=0.6:1:0.3, and finally add different types of accelerators 3 g / L. After stirring for a sufficient time, add H 3 PO 4 and ZnO to adjust the pH to 2.6.

[0024] (2) Immerse the polished pure titanium sample in an alkaline degreasing solution (NaOH: 15g, NaOH: 15g, Na 2 CO 3 :30g, Na 3 PO 4 : 70g, Na 2 SiO 3 : 10 g) for 20 min, and rinse thoroughly with tap water and deionized water respectively. Put the rinsed sample into 2% HF solution ...

Embodiment 2

[0028] A method for preparing a zinc phosphate conversion coating on a titanium surface is provided, comprising the steps of:

[0029] 30g / L H 3 PO 4 , 9g / L ZnO, 23g / L Zn(NO 3 ) 2 ·6H 2 O, 23g / L Ca(NO 3 ) 2 4H 2 Mix O and 3g / L accelerator, stir well, add H 3 PO 4 and ZnO to adjust the pH value to 2.6, and prepare a chemical conversion basic solution; add a current field to the chemical conversion basic solution, use an inert electrode Pt as the anode, and use 2% HF to activate pure Ti after surface adjustment of colloidal titanium phosphate as the cathode. The current density used was 40 mA / cm 2, the temperature is 60° C., and the reaction treatment time is 30 minutes.

Embodiment 3

[0031] A method for preparing a zinc phosphate conversion coating on a titanium surface is provided, comprising the steps of:

[0032] 40g / L H 3 PO 4 , 12g / L ZnO, 30g / L Zn(NO 3 ) 2 ·6H 2 O, 30g / L Ca(NO 3 ) 2 4H 2 Mix O and 4g / L accelerator, stir well, add H 3 PO 4 and ZnO to adjust the pH value to 2.6, and prepare a chemical conversion basic solution; add a current field to the chemical conversion basic solution, use an inert electrode Pt as the anode, and use 2% HF to activate pure Ti after surface adjustment of colloidal titanium phosphate as the cathode. The current density used was 20 mA / cm 2 , the temperature is 60° C., and the reaction treatment time is 30 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com