Patents

Literature

266 results about "Titanium phosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Titanium phosphide can be prepared by the reaction of TiCl4 and PH3. There are other titanium phosphide phases, including Ti3P, Ti2P, Ti7P4, Ti5P3, and Ti4P3. Titanium phosphide should not be confused with titanium phosphate or titanium isopropoxide, both of which are sometimes known by the acronym TIP.

Photo-catalytic coating

The invention discloses a photocatalyst paint, consisting of the following raw materials according to weight percentage: 0.5-1.5 percent of nanometer titanium dioxide, 0.05-0.15 percent of nanometer titanium phosphate, 0.05-0.15 percent of nanometer silicon dioxide, 0.5-1.5 percent of nanometer negative ion powder, 5-15 percent of emulsion used for construction coatings, 0.001-0.004 percent of defoaming agent, 0.001-0.004 percent of coupling agent, 0.001-0.004 percent of dispersant, 0.01-0.04 percent of thickener and the rest of water. The paint can purify air in a rapid, efficient and lasting manner, completely remove interior odor and harmful gases such as formaldehyde, TVOC, benzene, ammonia and the like, and inhibit or kill microorganism; furthermore, the preparation equipment and technology are simple, the production cost is low, the product is harmless and odorless, safe, environment-friendly and applicable to various interior environments such as newly decorated rooms, office places, hotels, stores, and the like.

Owner:张文磊

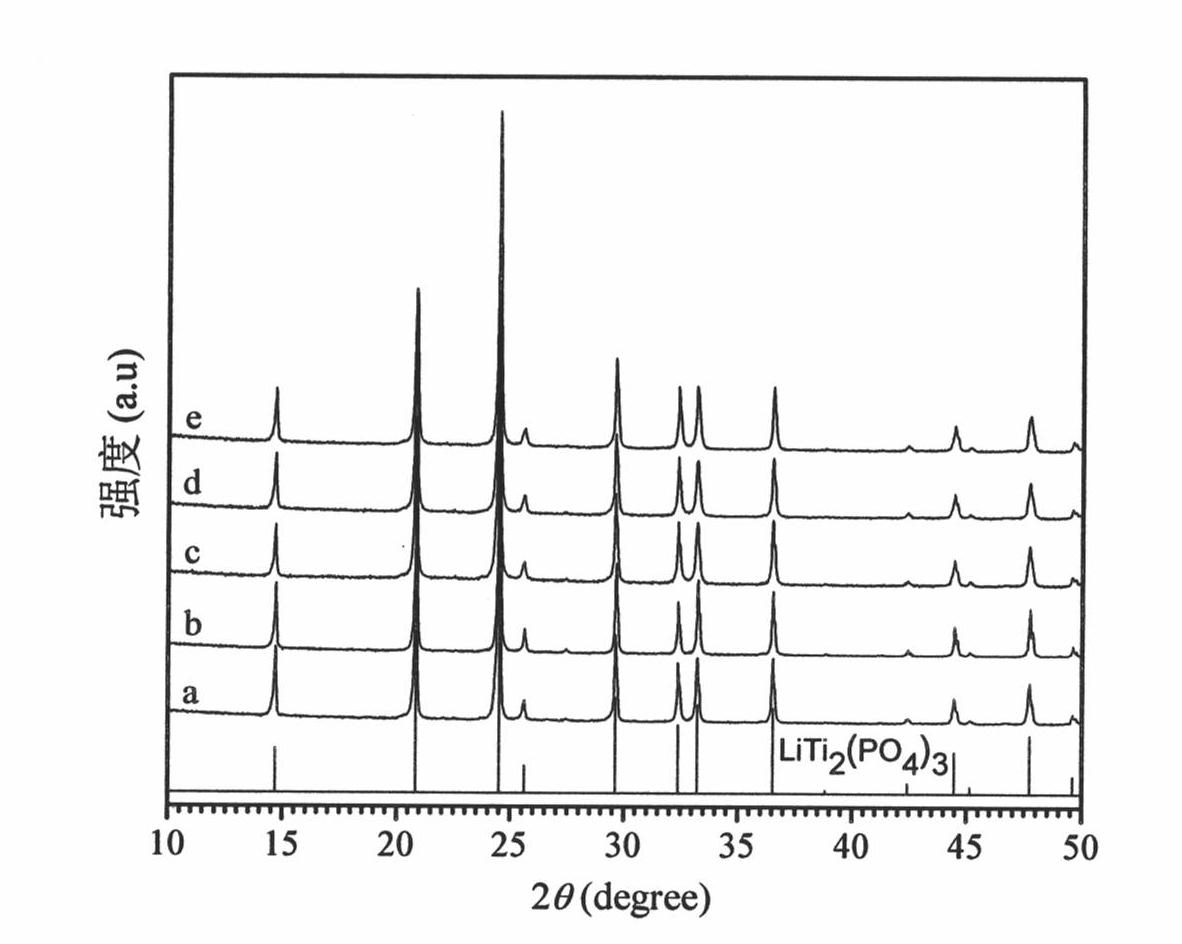

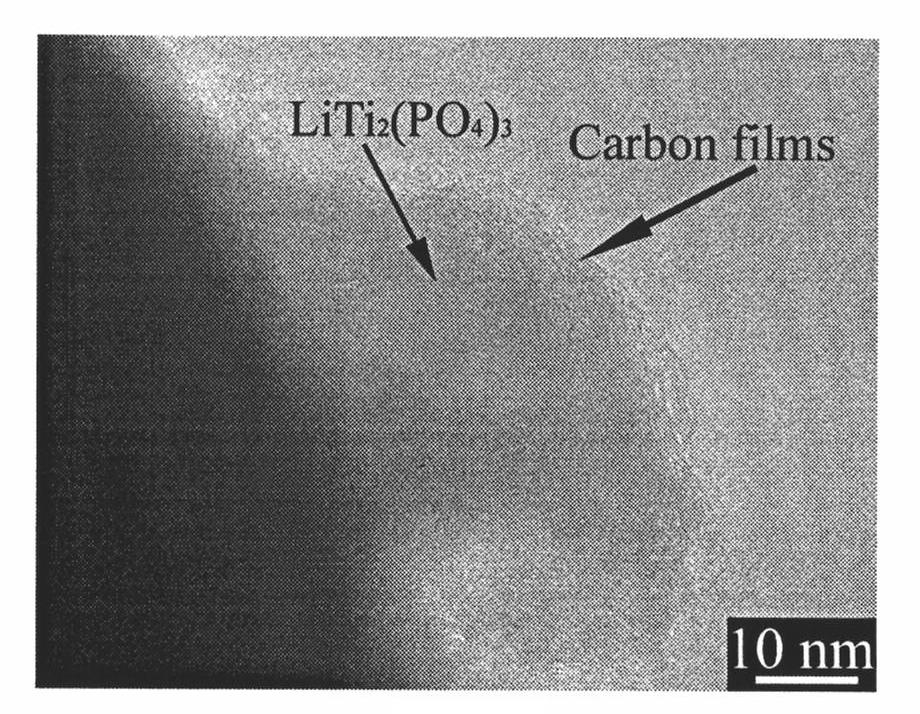

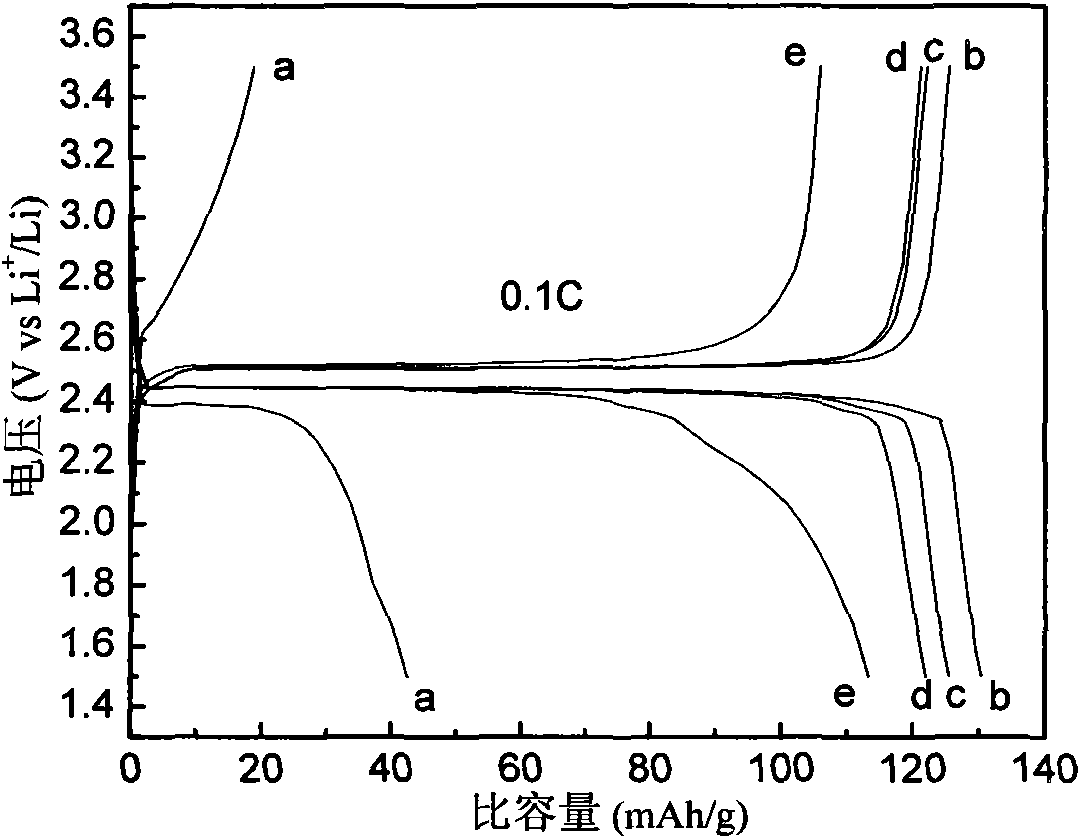

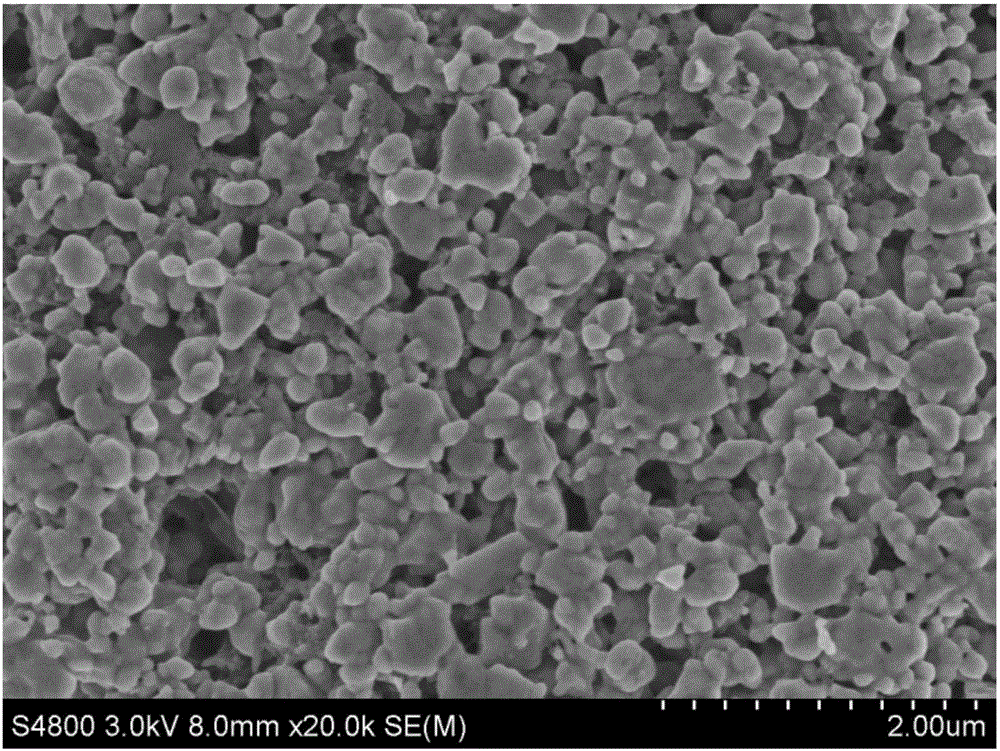

Titanium phosphate lithium material used for cathode of lithium ion battery and preparation method thereof

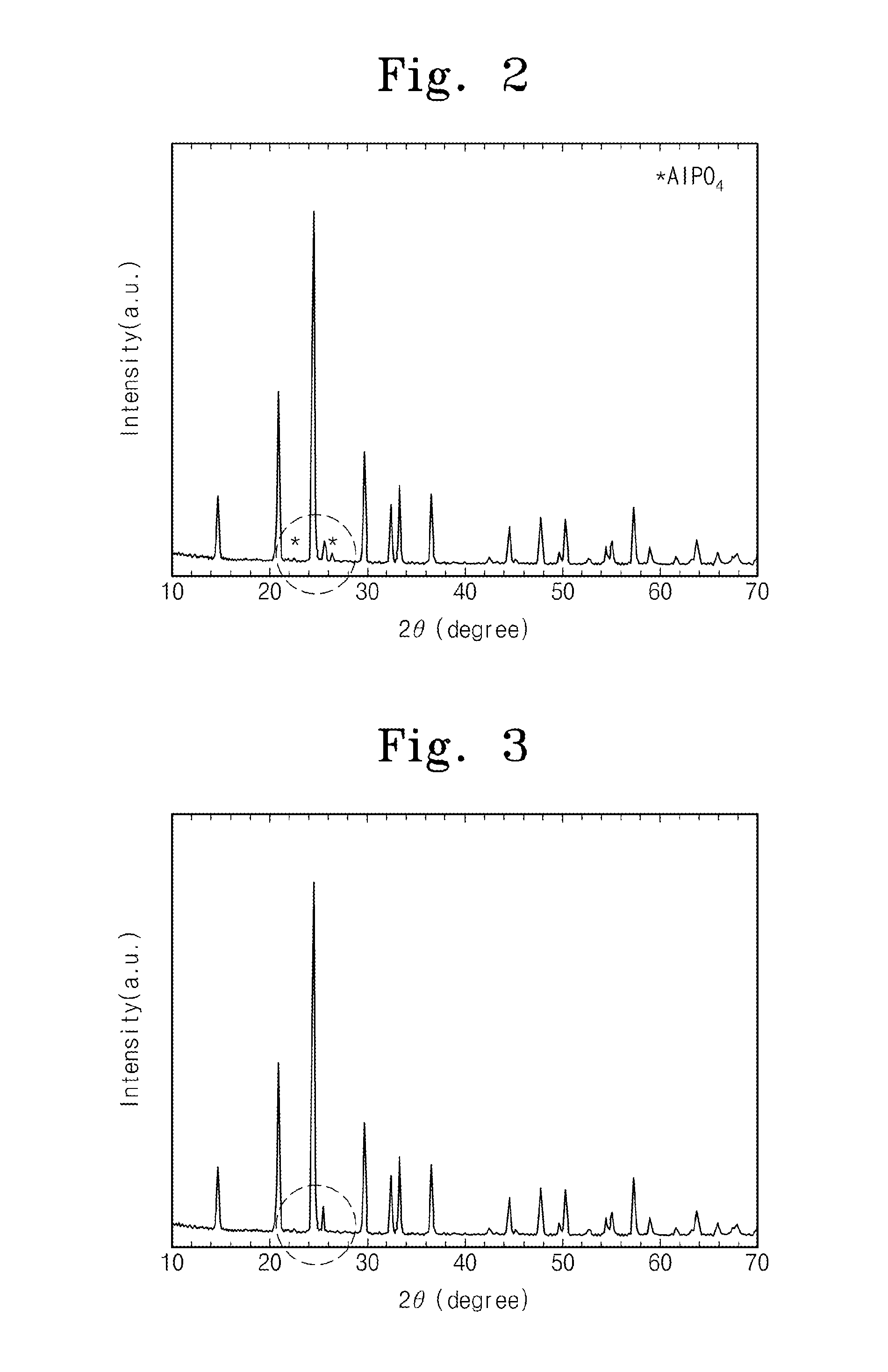

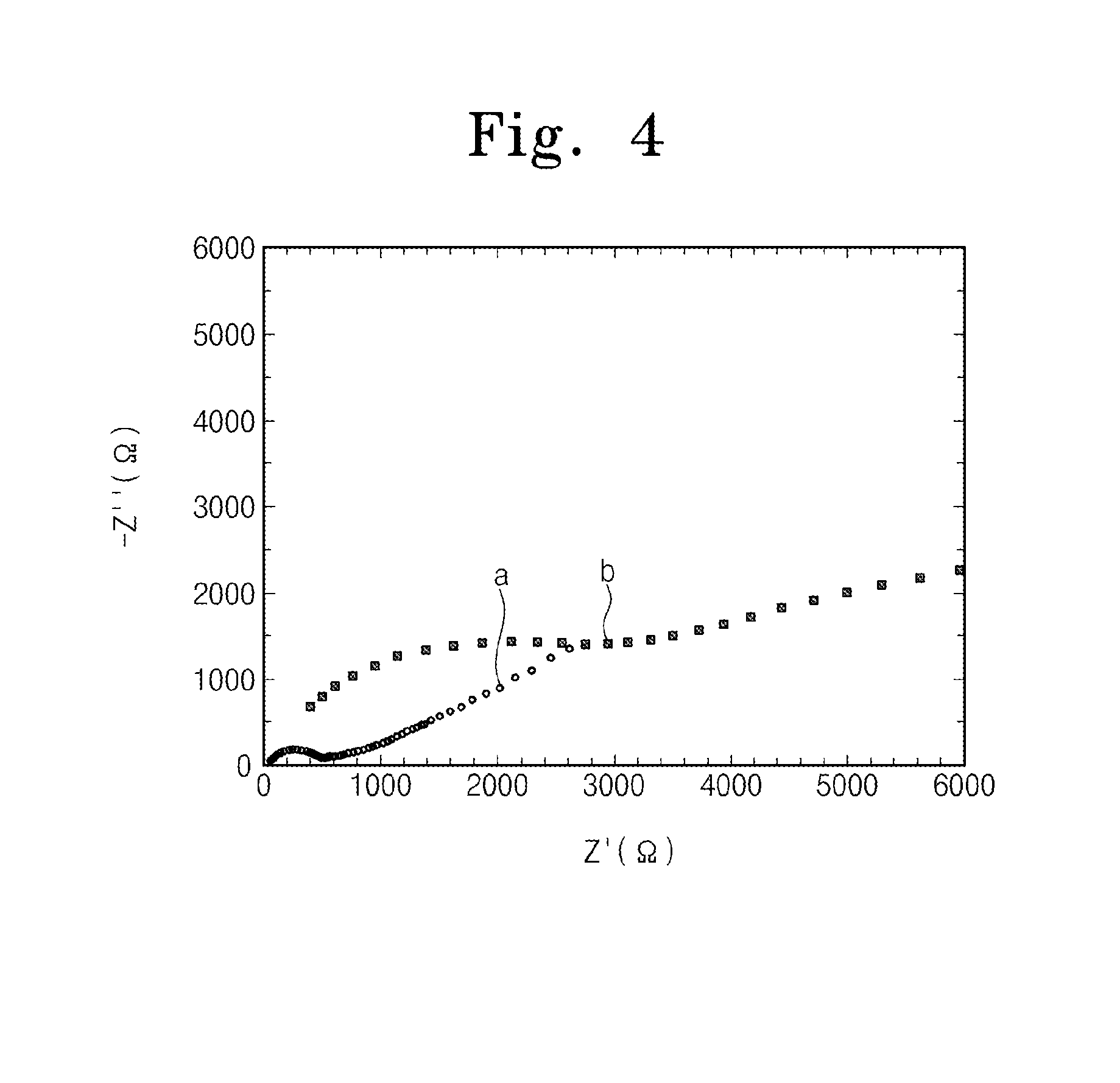

InactiveCN101807696AStable structureImprove securityCell electrodesPhosphorus compoundsAir atmosphereAluminium-ion battery

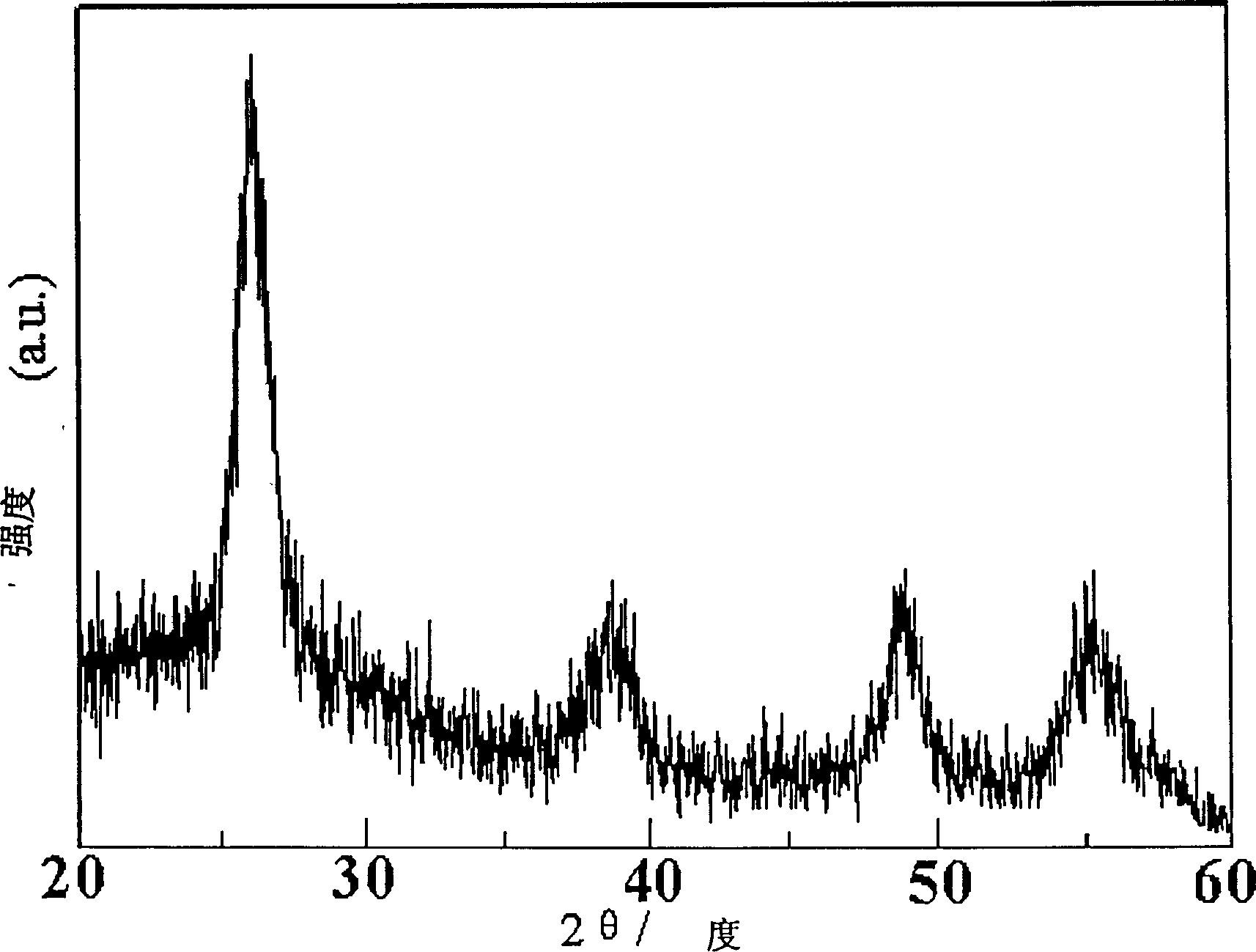

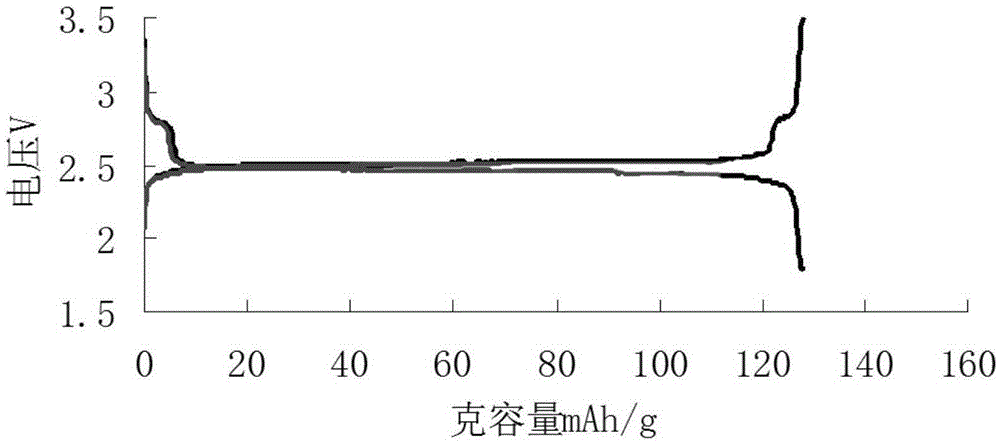

The invention relates to a titanium phosphate lithium material used for the cathode of a lithium ion battery and a preparation method thereof. The crystal structure of the titanium phosphate lithium material is an NASICON structure, and the composition is LixTi2(PO4)3, wherein x is 1 to 1.05. The preparation method of the material comprises the following steps: firstly, evenly mixing lithium-contained, titanium-contained and phosphorus-contained inorganic matter raw materials, and carrying out one-step roasting in an air atmosphere with the temperature of 800 to 1000 DEG C to prepare high-purity titanium phosphate lithium; then mixing the prepared titanium phosphate lithium with organic matter of glucose and the like in a certain proportion; milling and evenly mixing by a planet ball mill; then roasting in an inert atmosphere to obtain the carbon-cladding titanium phosphate lithium material. The preparation method is simple and has low cost, and the obtained titanium phosphate lithium cathode material has high purity, complete structure, high electrical conductivity and good electrochemical properties.

Owner:ZHEJIANG UNIV

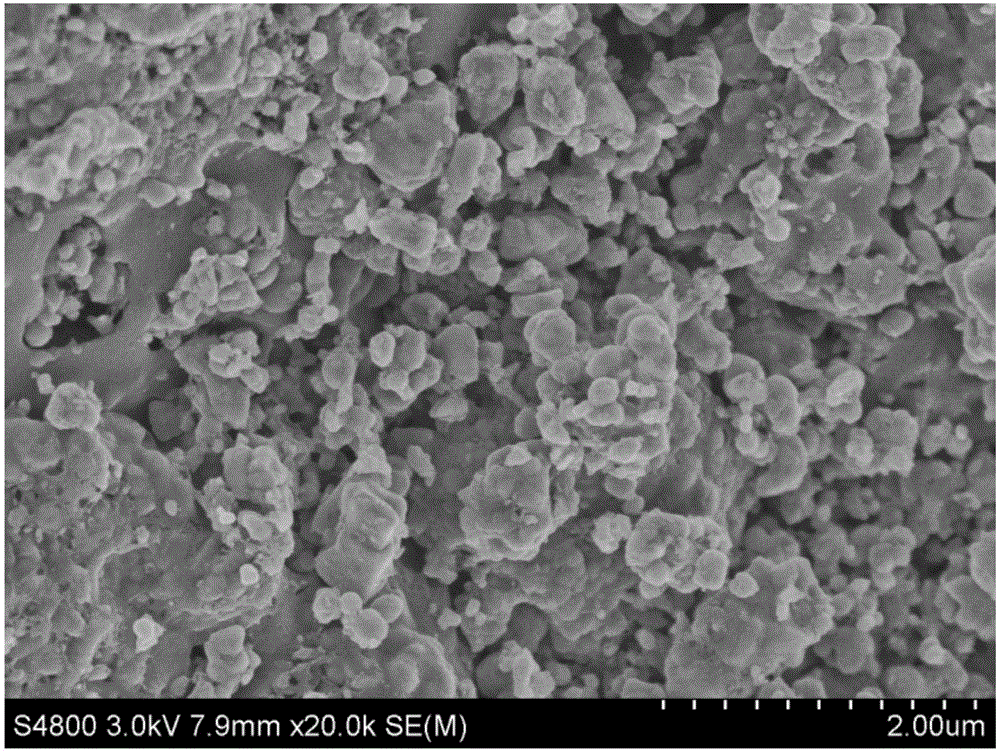

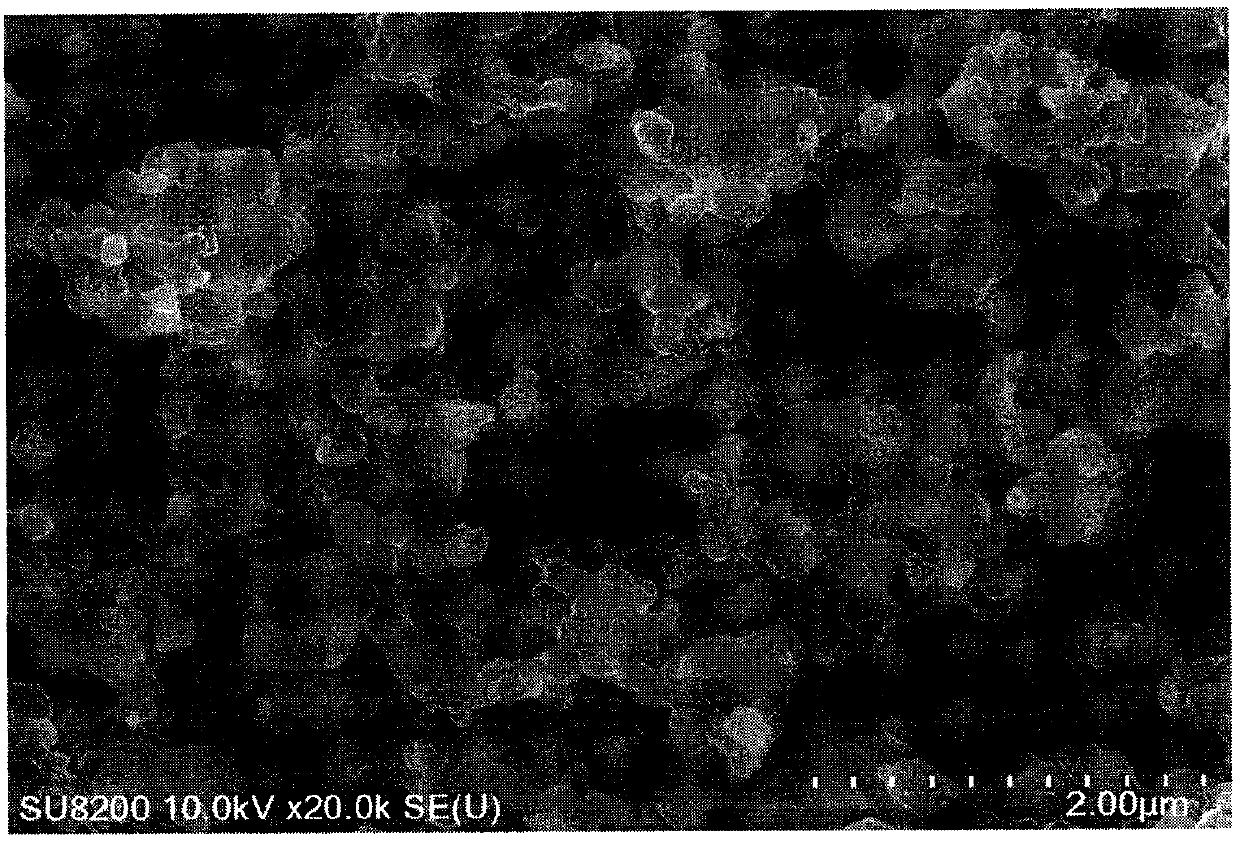

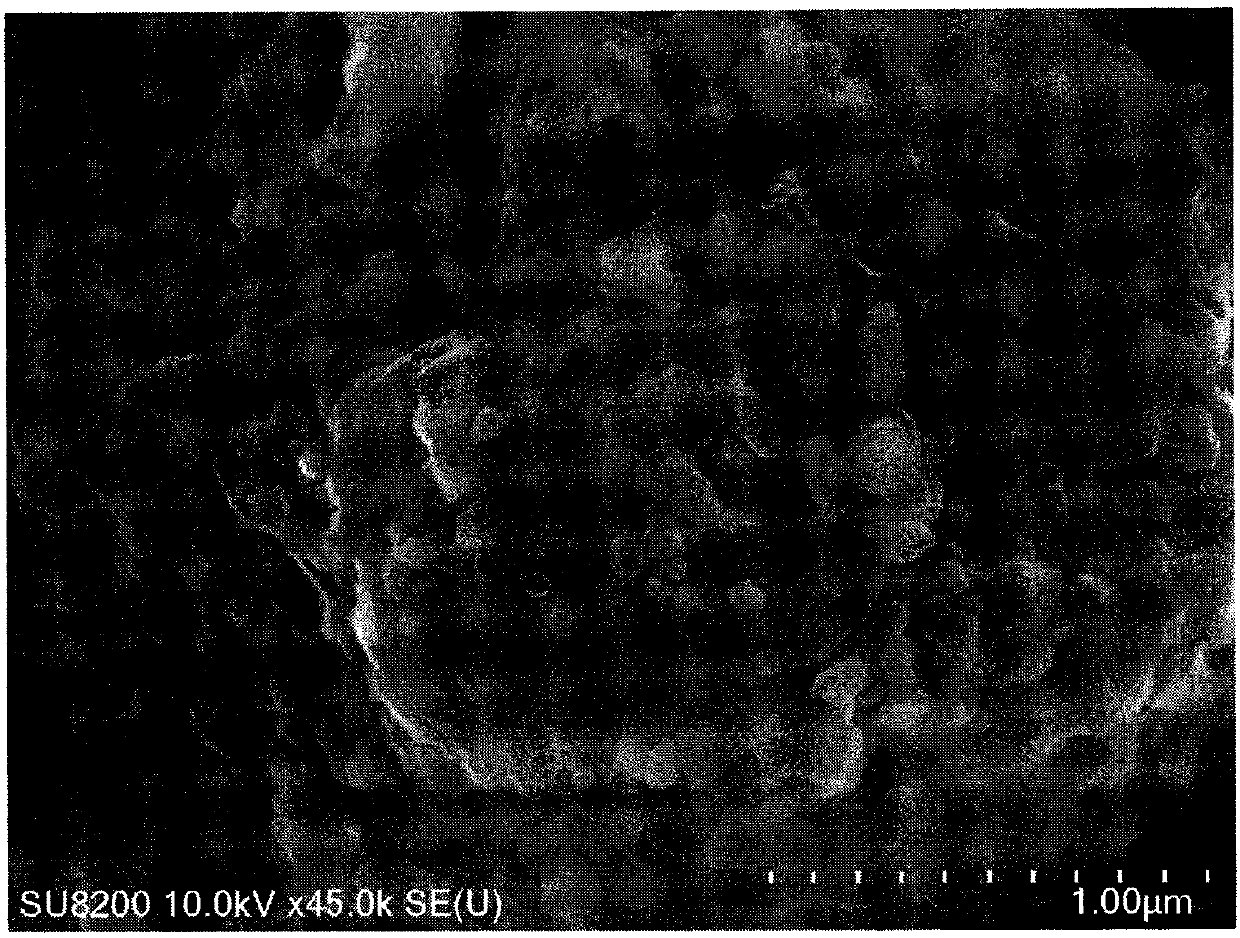

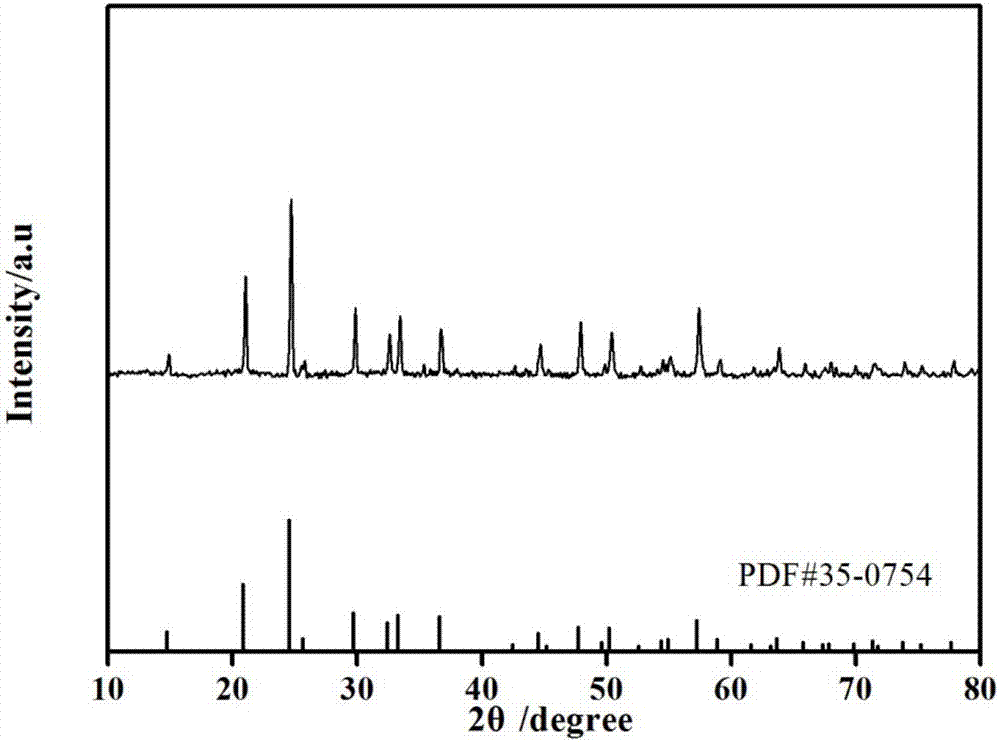

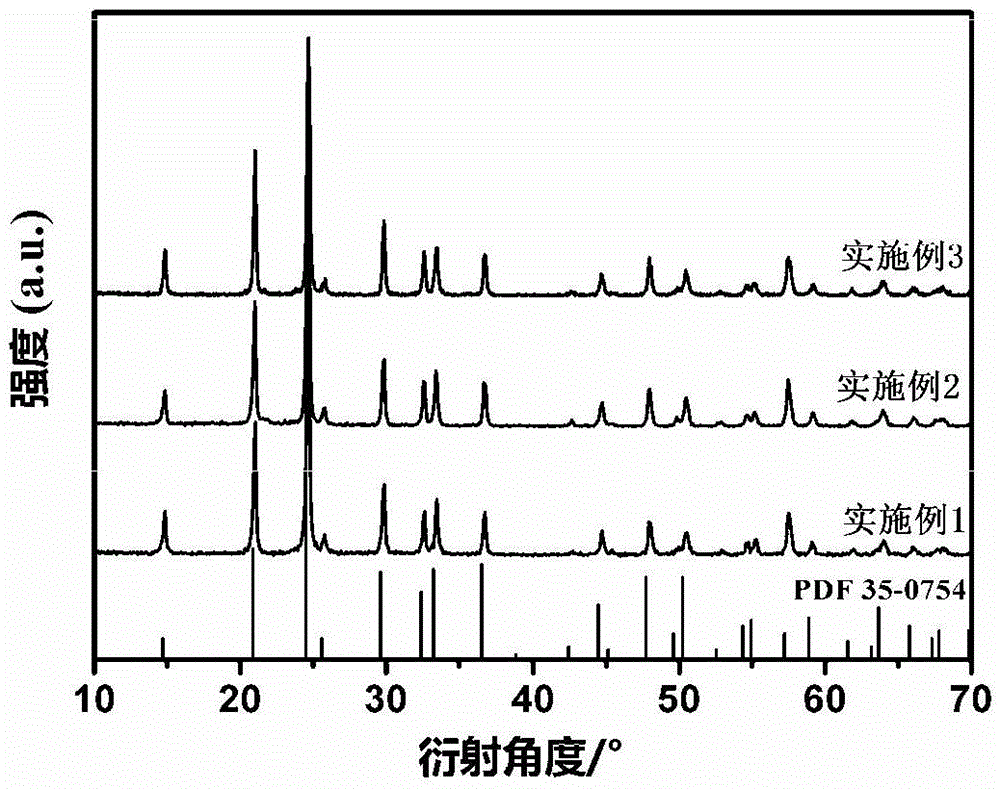

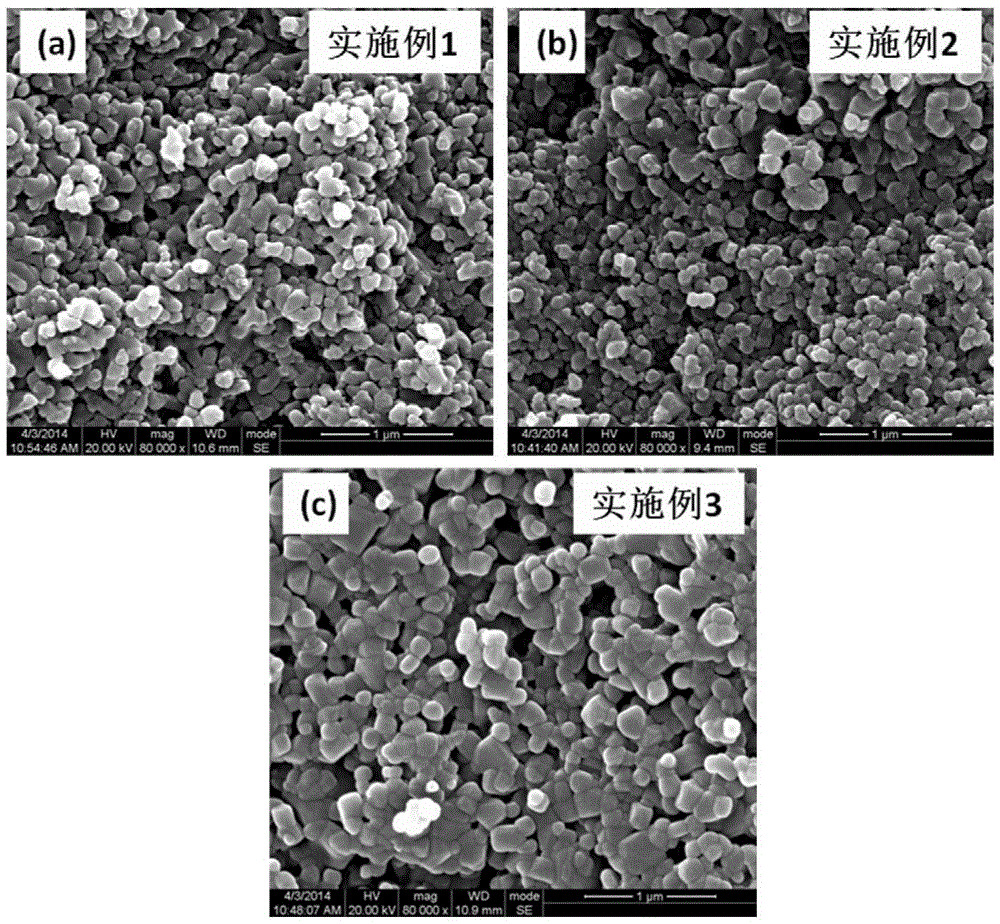

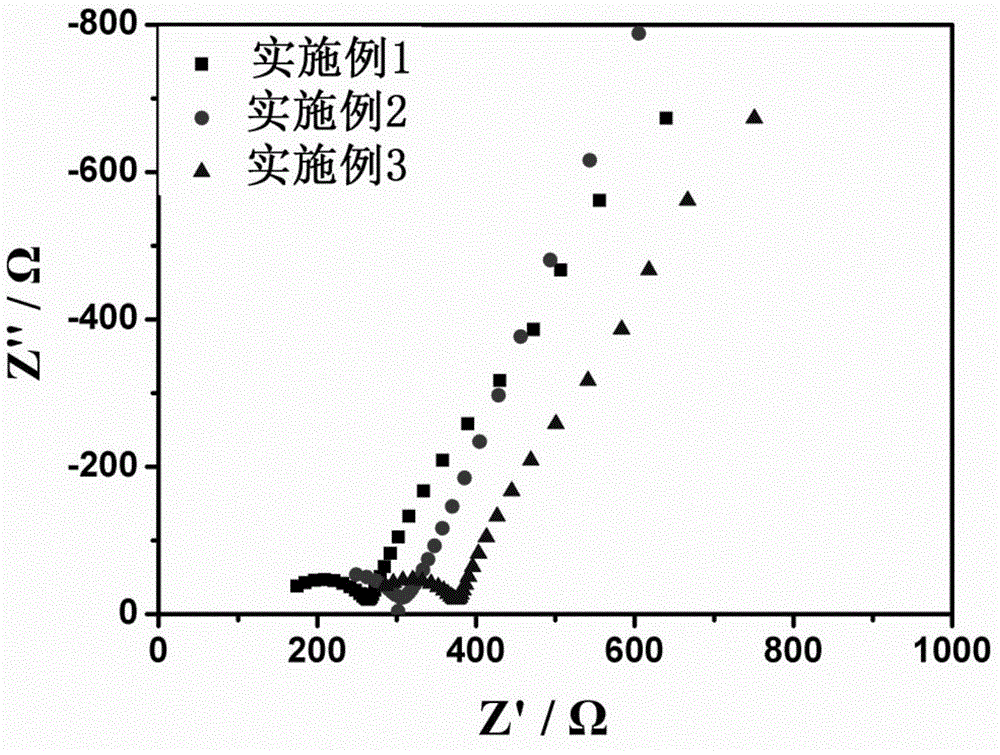

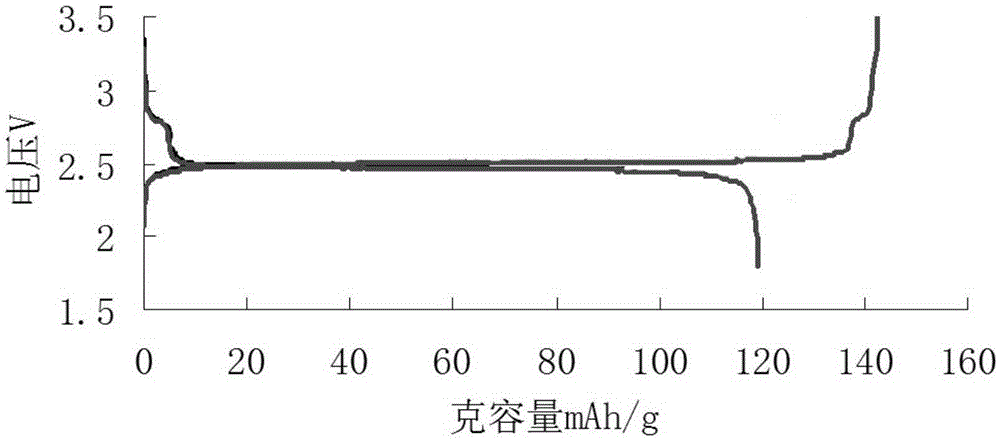

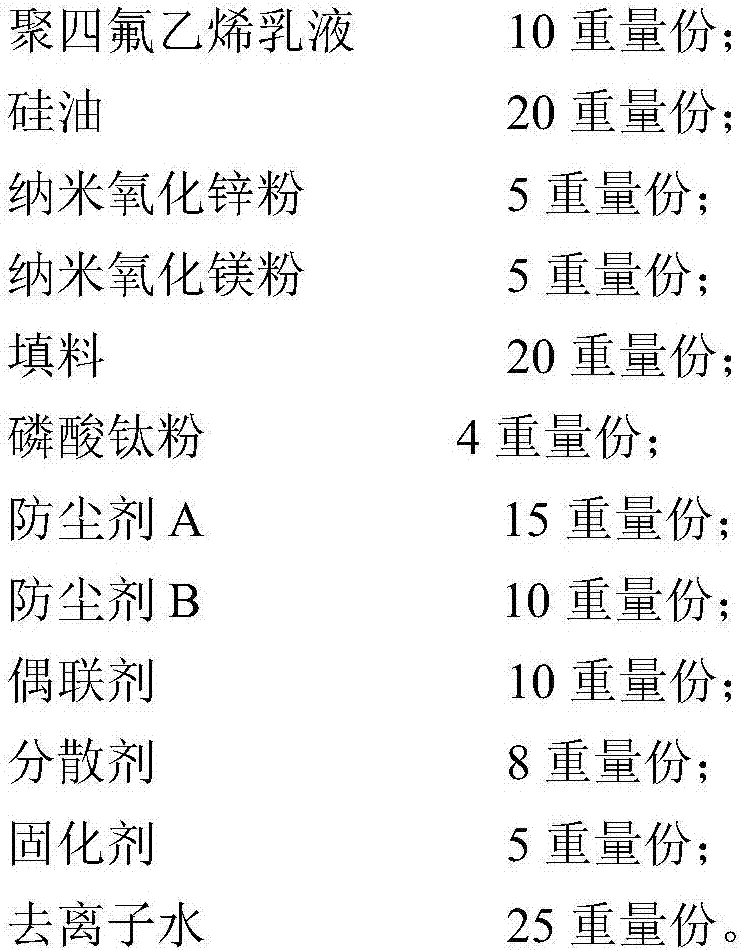

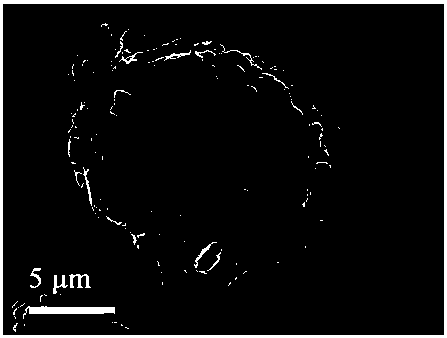

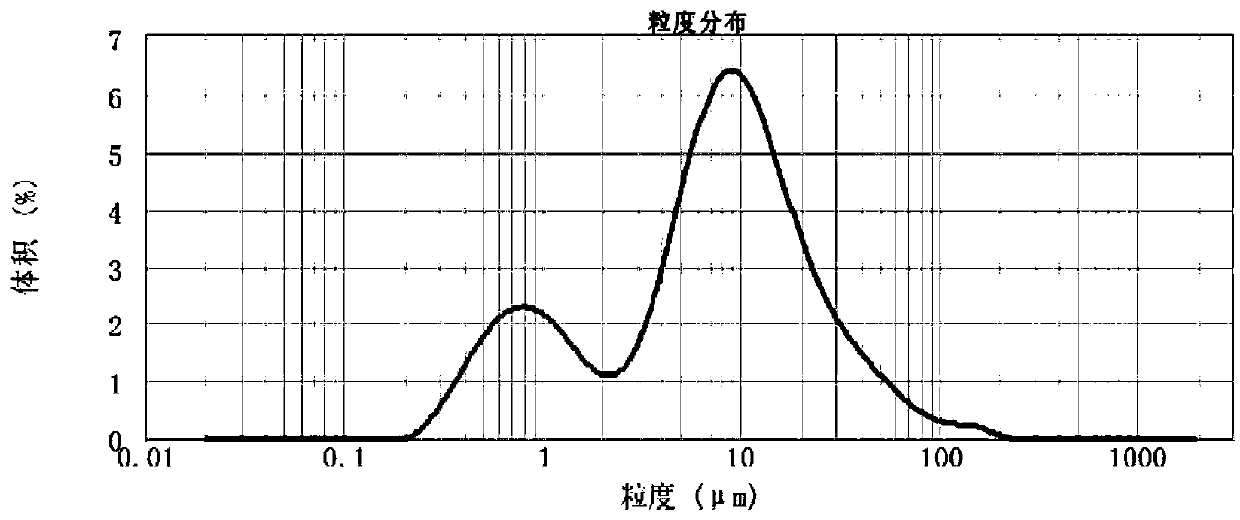

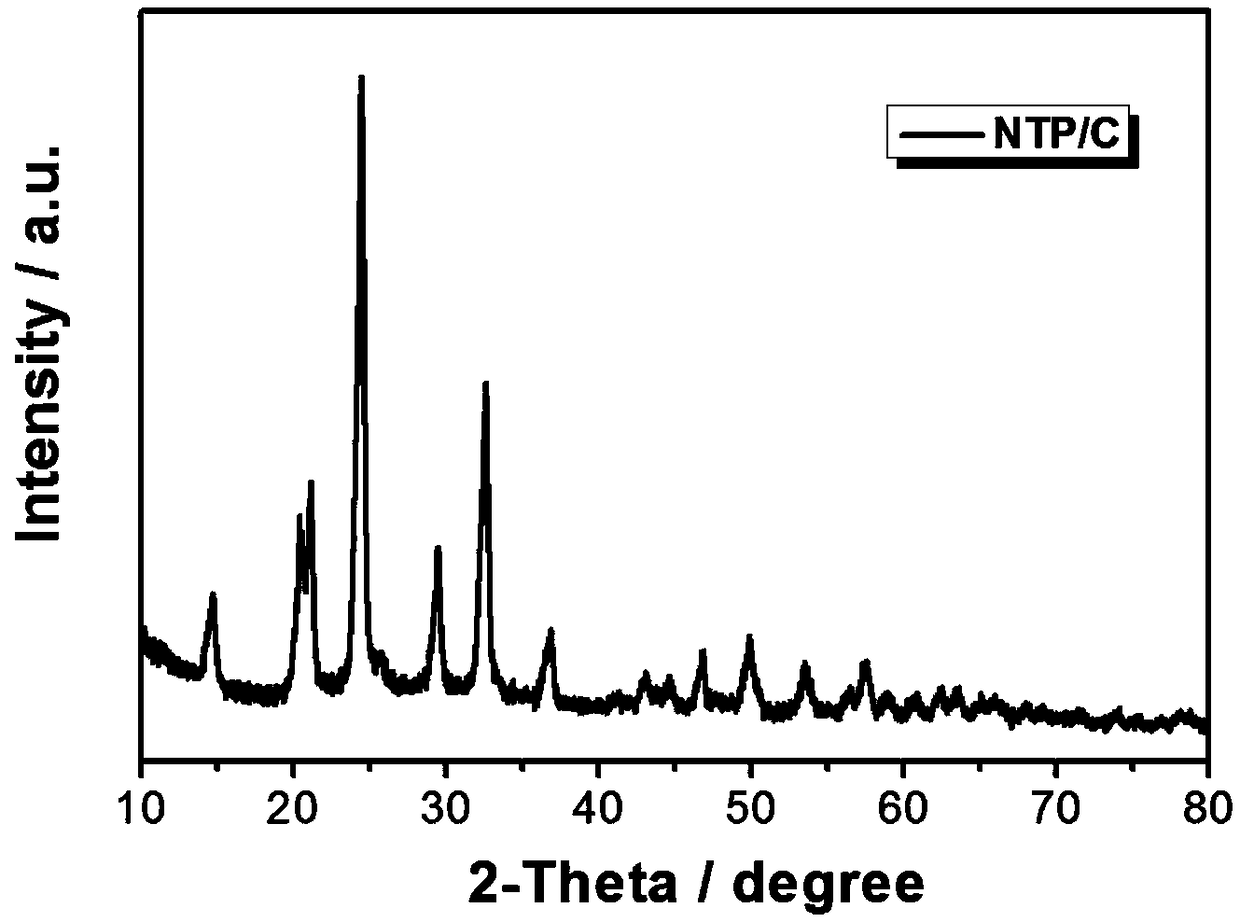

Sodium-titanium phosphate/carbon composite material and preparation method and use thereof

InactiveCN106784696AUneven solutionImprove uniformityCell electrodesSecondary cellsCarbon layerCarbon coating

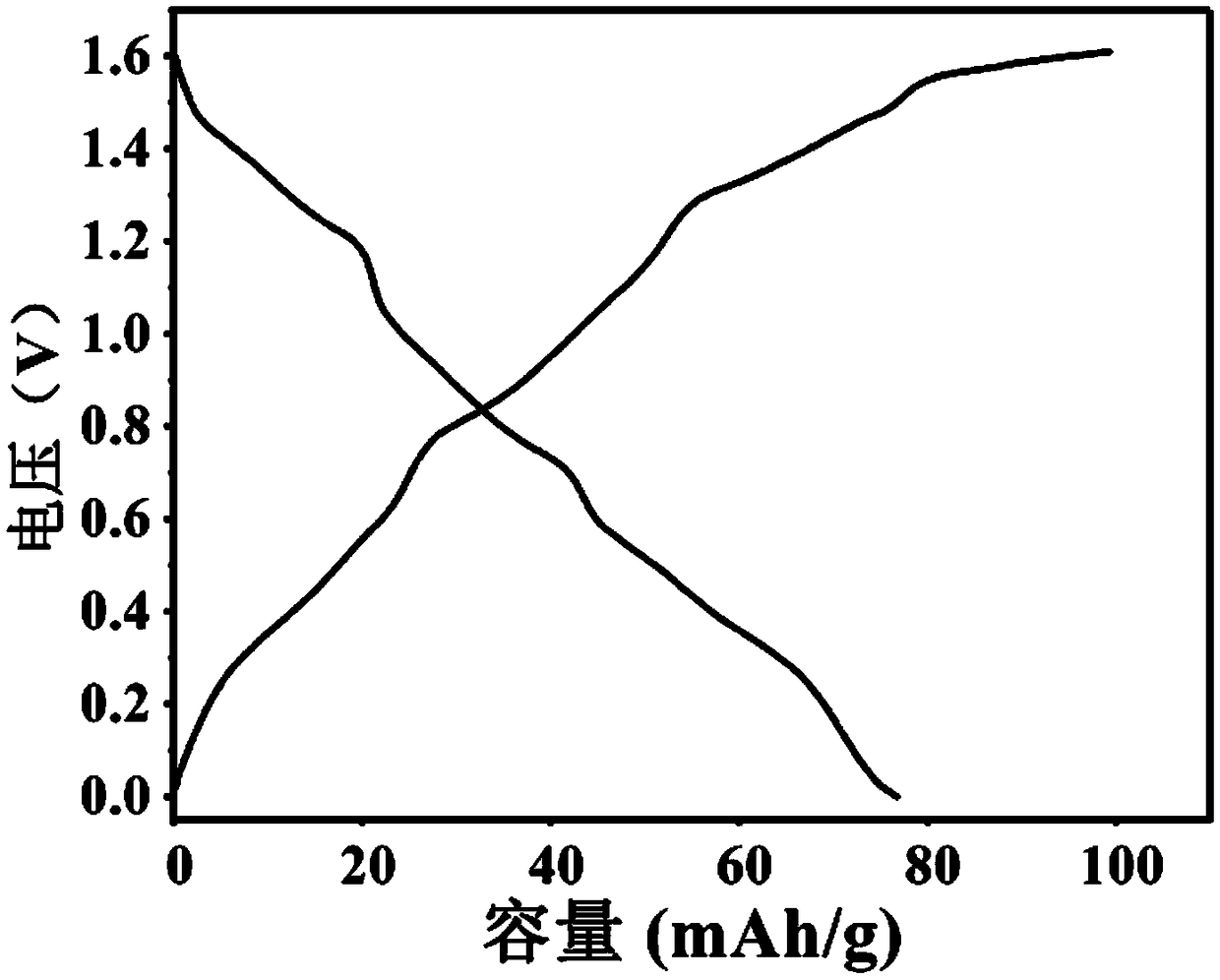

The invention belongs to the field of electrode material synthesis, and relates to a sodium-titanium phosphate / carbon composite material and a preparation method and use thereof. The sodium-titanium phosphate / carbon composite material comprises secondary particles formed by clustering primary particles, the primary particles comprise sodium-titanium phosphate particles and carbon layers coated on the surfaces of the sodium-titanium phosphate particles, and the carbon layers are prepared through two times of carbon coating. According to the sodium-titanium phosphate / carbon composite material and the preparation method and use thereof, by means of preparing a precursor of the sodium-titanium phosphate and then adopting a spray drying method to carry out primary carbon coating and secondary carbon coating, the sodium-titanium phosphate / carbon composite material having a uniform and compact coating carbon layer is prepared, and the problem that the coating carbon layer obtained by the primary carbon coating is not uniform is solved. The composite material is good in stability, electrodes prepared from the sodium-titanium phosphate / carbon composite material and assembled batteries have excellent electrochemical properties, the discharge capacity is above 115mAh / g, and the capacity retention ratio is above 95% after 500 weeks of circulation.

Owner:SHENZHEN CITY BATTERY NANOMETER TECH

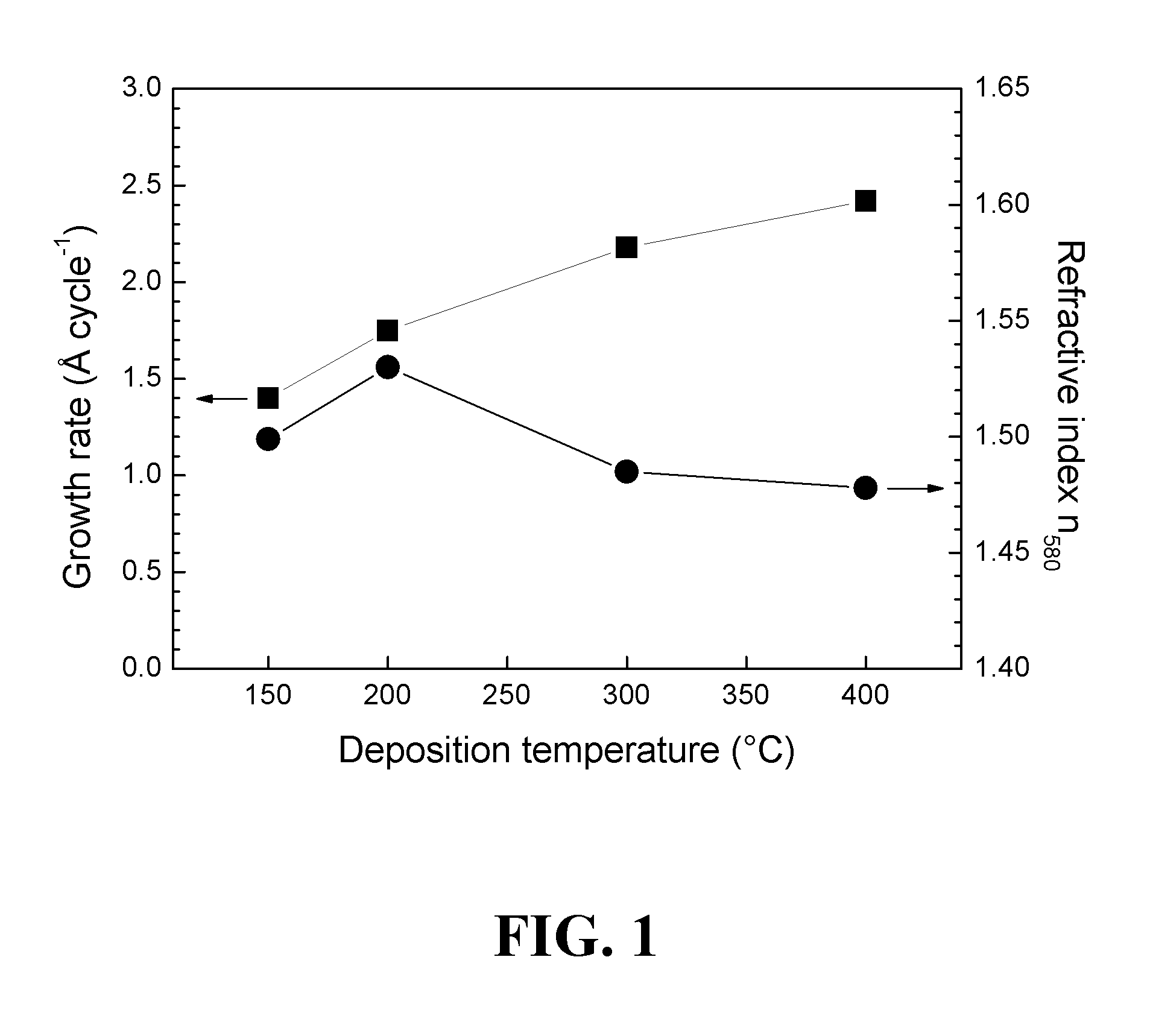

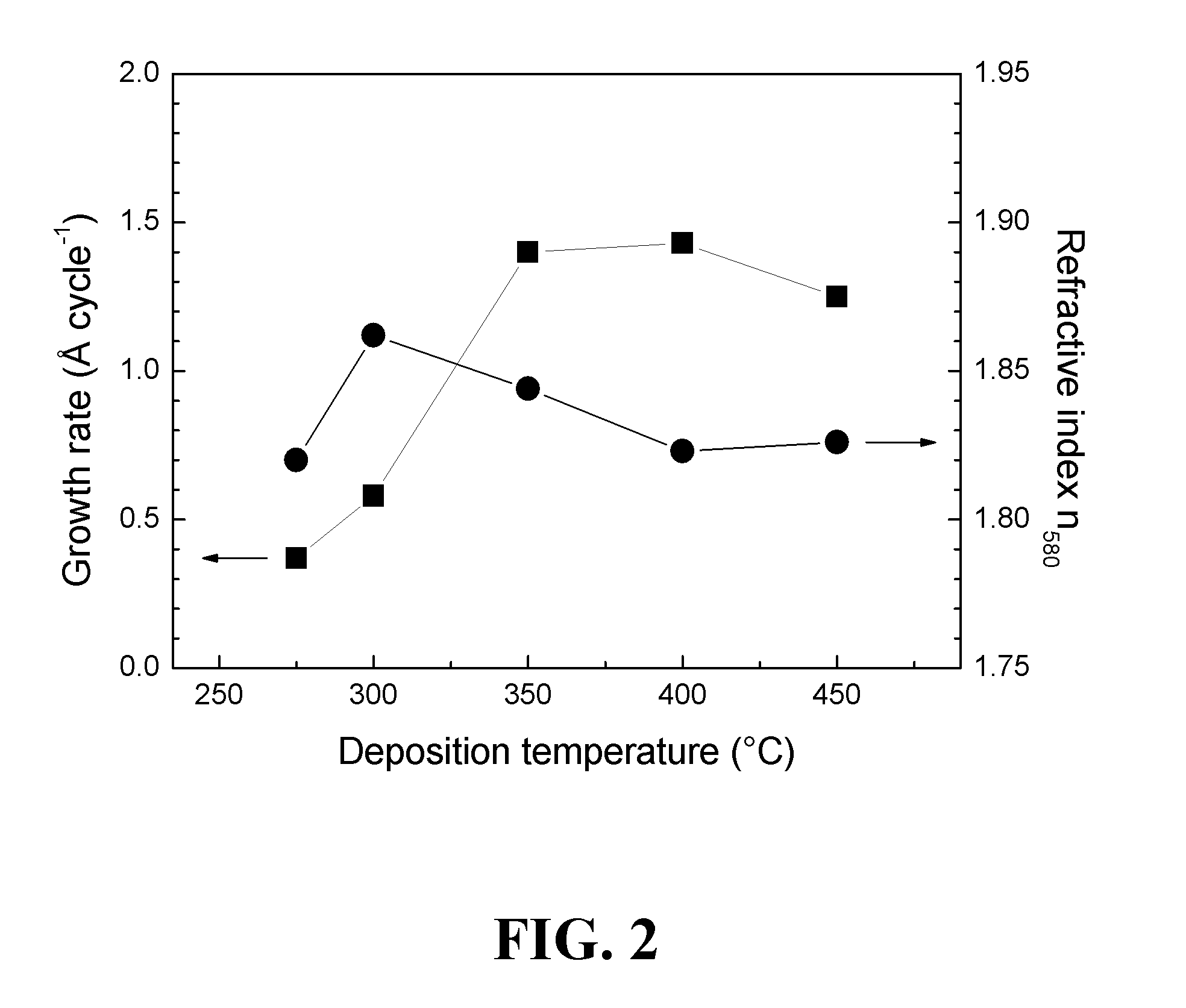

Atomic layer deposition of metal phosphates and lithium silicates

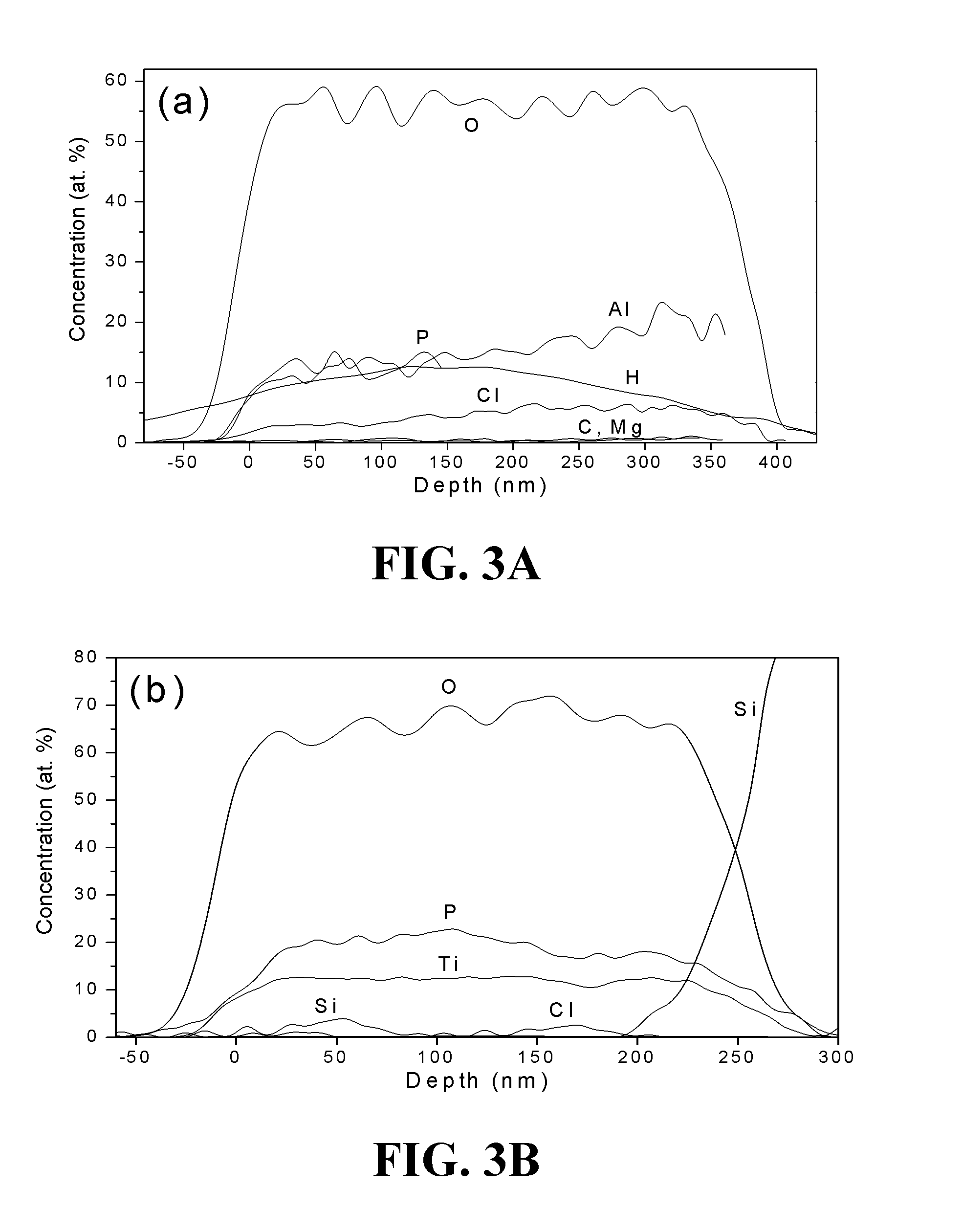

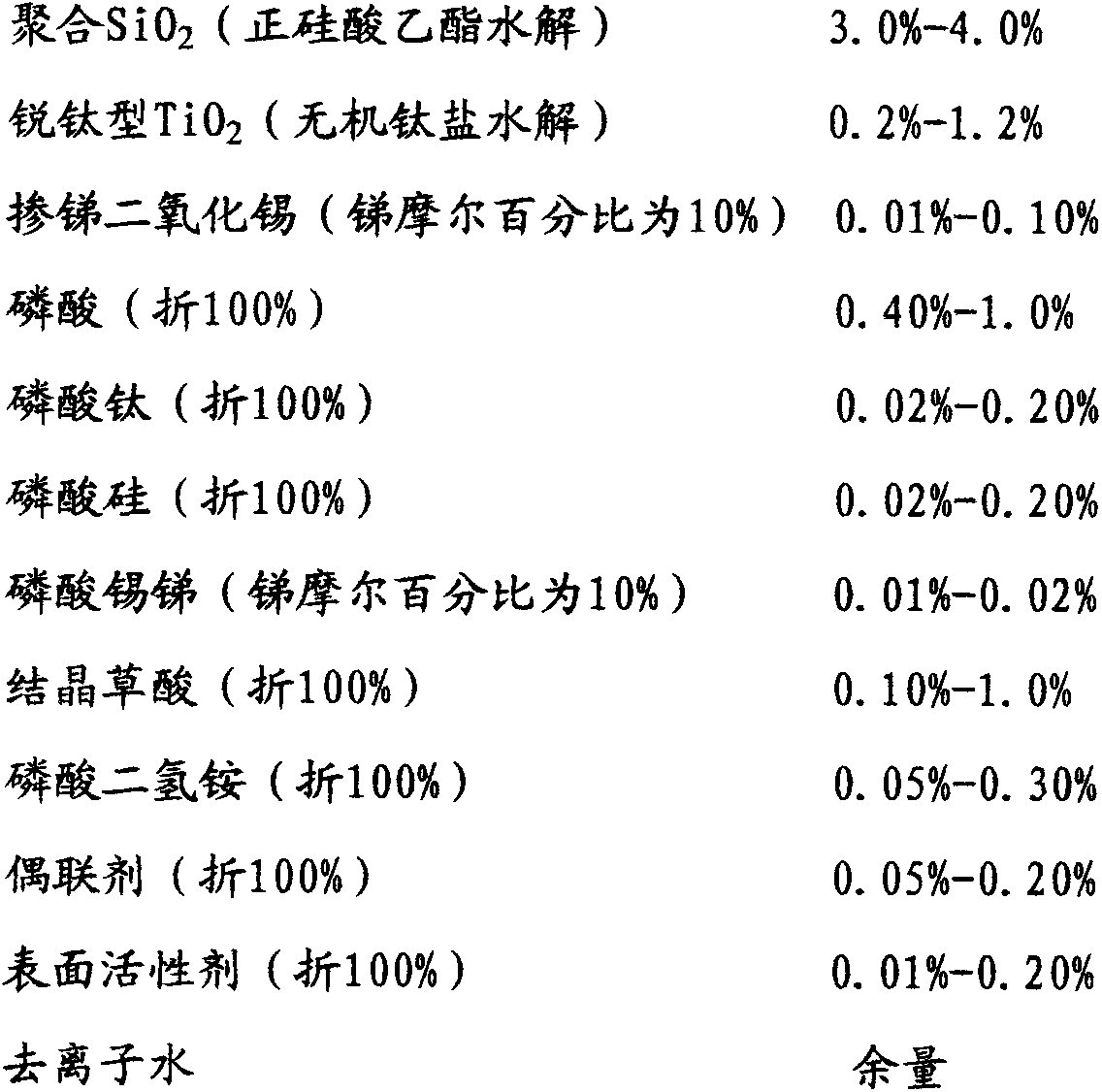

ActiveUS20120276305A1Increase amount of lithiumSpecial surfacesChemical vapor deposition coatingTitanium phosphateALUMINUM PHOSPHATE

The present application relates to atomic layer deposition (ALD) processes for producing metal phosphates such as titanium phosphate, aluminum phosphate and lithium phosphate, as well as to ALD processes for depositing lithium silicates.

Owner:ASM IP HLDG BV

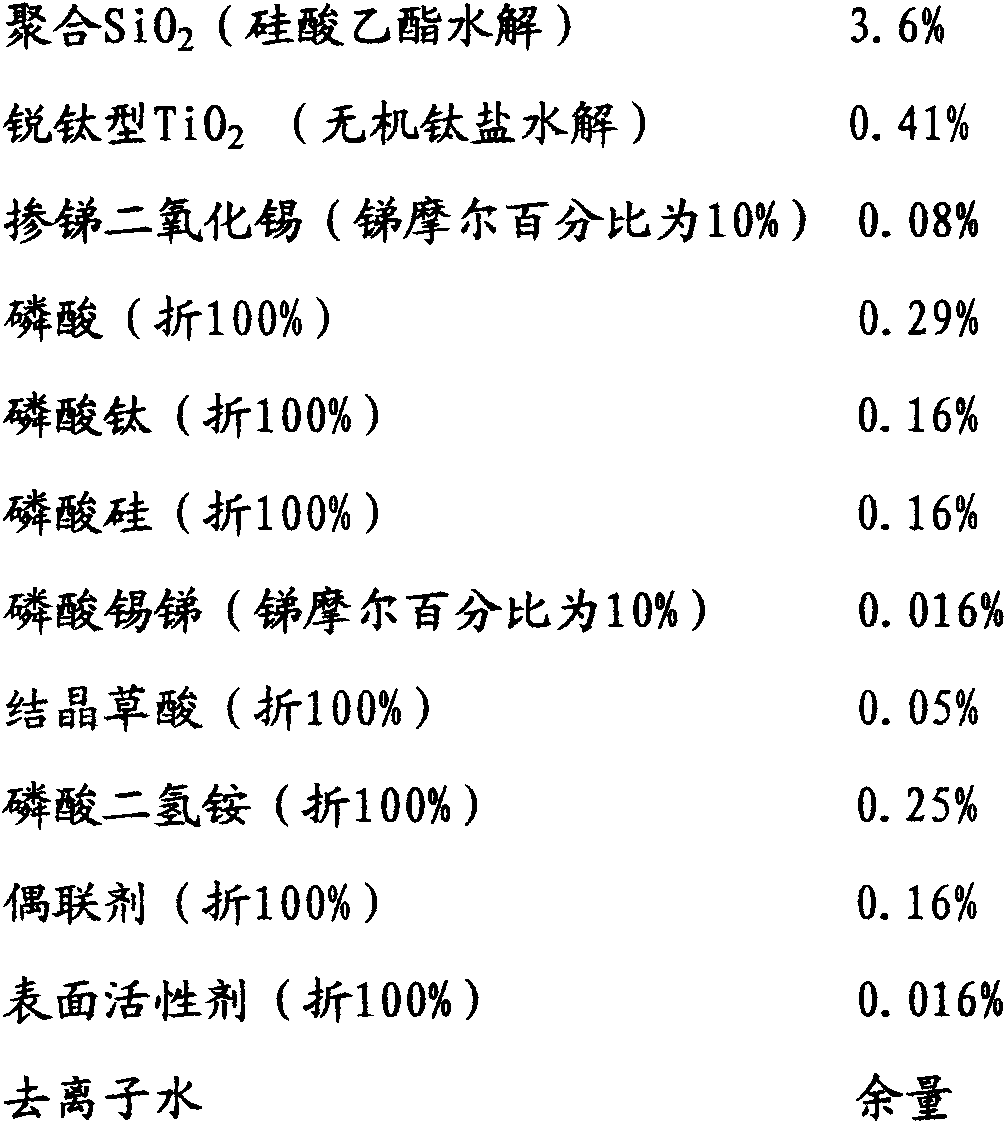

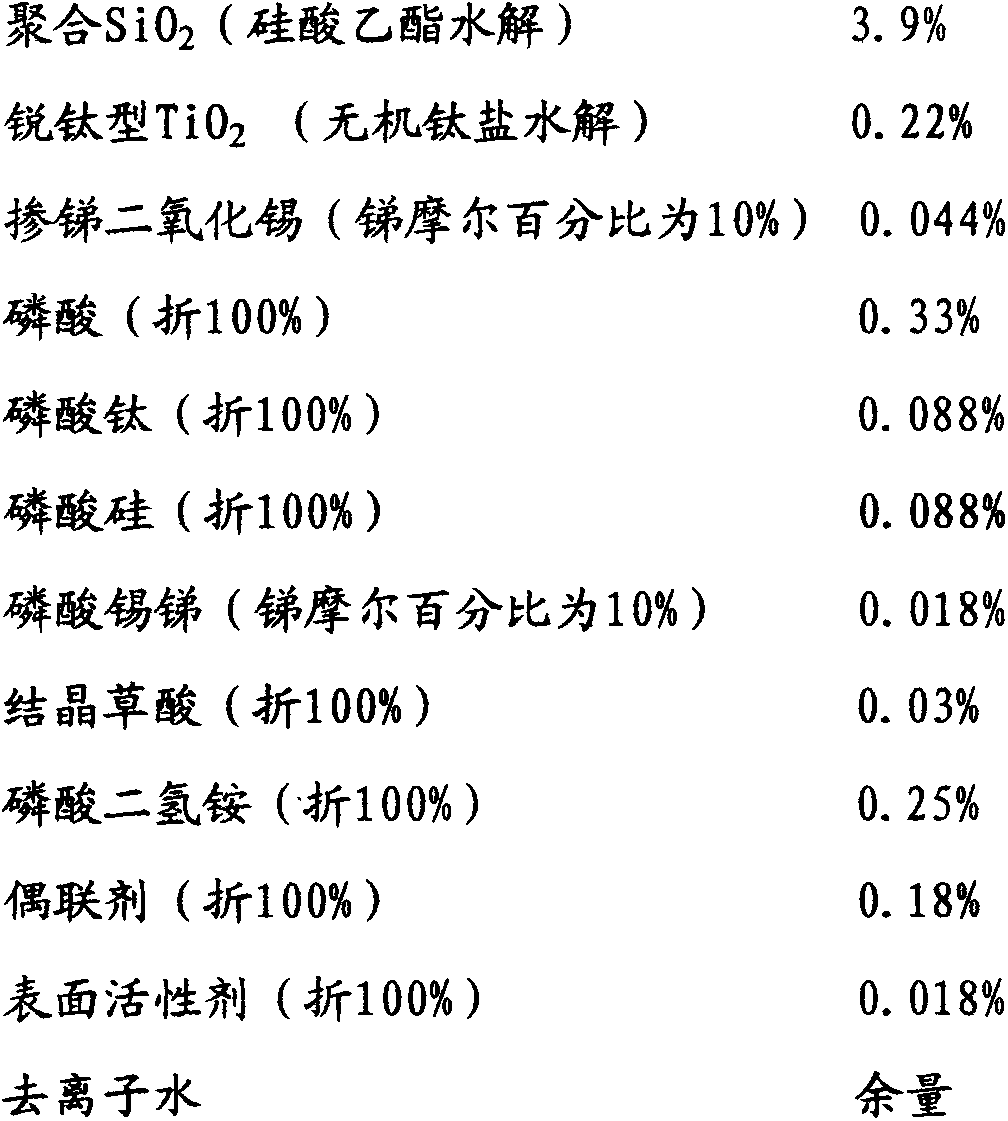

Solar glass self-cleaning antireflection paint and production method thereof

The invention discloses solar glass self-cleaning antireflection paint and a production method thereof. In the solar glass self-cleaning antireflection paint, poly silicon dioxide is used as a main antireflection component, low reflection titanium dioxide is used as an auxiliary antireflection component and a photocatalyst, antimony doped tin oxide, titanium phosphate, silicon phosphate, phosphoric acid and antimony doped tin phosphate are used as a self-cleaning synergist, an antistat and an antireflection membrane enhancer, and deionized water is used as a solvent. The production method comprises the step: a porous silicon dioxide shell generated through ethyl silicate hydrolysis is covered with the anatase titanium dioxide photocatalyst, the antimony doped stannic oxide antistat and other synergist components. The problem that antireflection performance and the self-cleaning performance of conventional solar glass self-cleaning antireflection paint can offset each other is solved, the power generating efficiency of a solar cell can be improved and stabilized greatly, and the maintenance management cost of the solar cell can be reduced.

Owner:TIANJIN VOCATIONAL INST

Surface conditioning composition and surface conditioning method

ActiveUS20080041498A1Good stabilityImprove stabilityOther chemical processesSolid state diffusion coatingOrganic acidConversion coating

A surface conditioning composition is provided in which a titanium phosphate compound can be stored in the state of a dispersion liquid for a long period of time while being stably present in the dispersion liquid, with favorable stability also in the bath, and with the composition being capable of forming a conversion coating film in a sufficient amount of the film even in the case of application to conversion resistant metal materials such as high-tensile steel sheets. A conversion coating film in a sufficient amount of the coating film can be formed with favorable dispersibility by blending an amine compound having a specified structure, an aromatic organic acid, a phenolic compound, a phenolic resin and the like in a surface conditioning composition, which contains the titanium phosphate compound and has a specified pH.

Owner:CHEMETALLGMBH

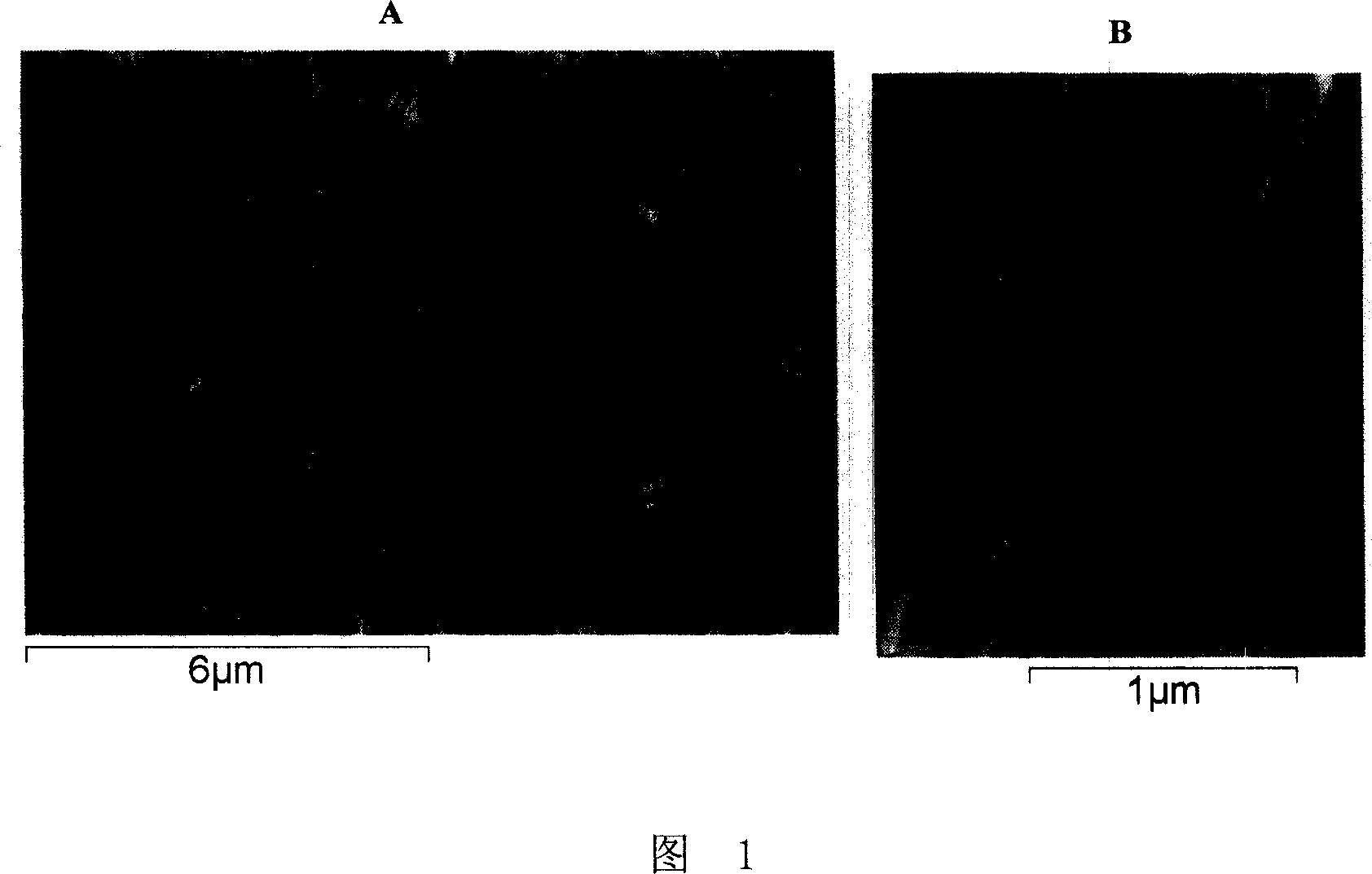

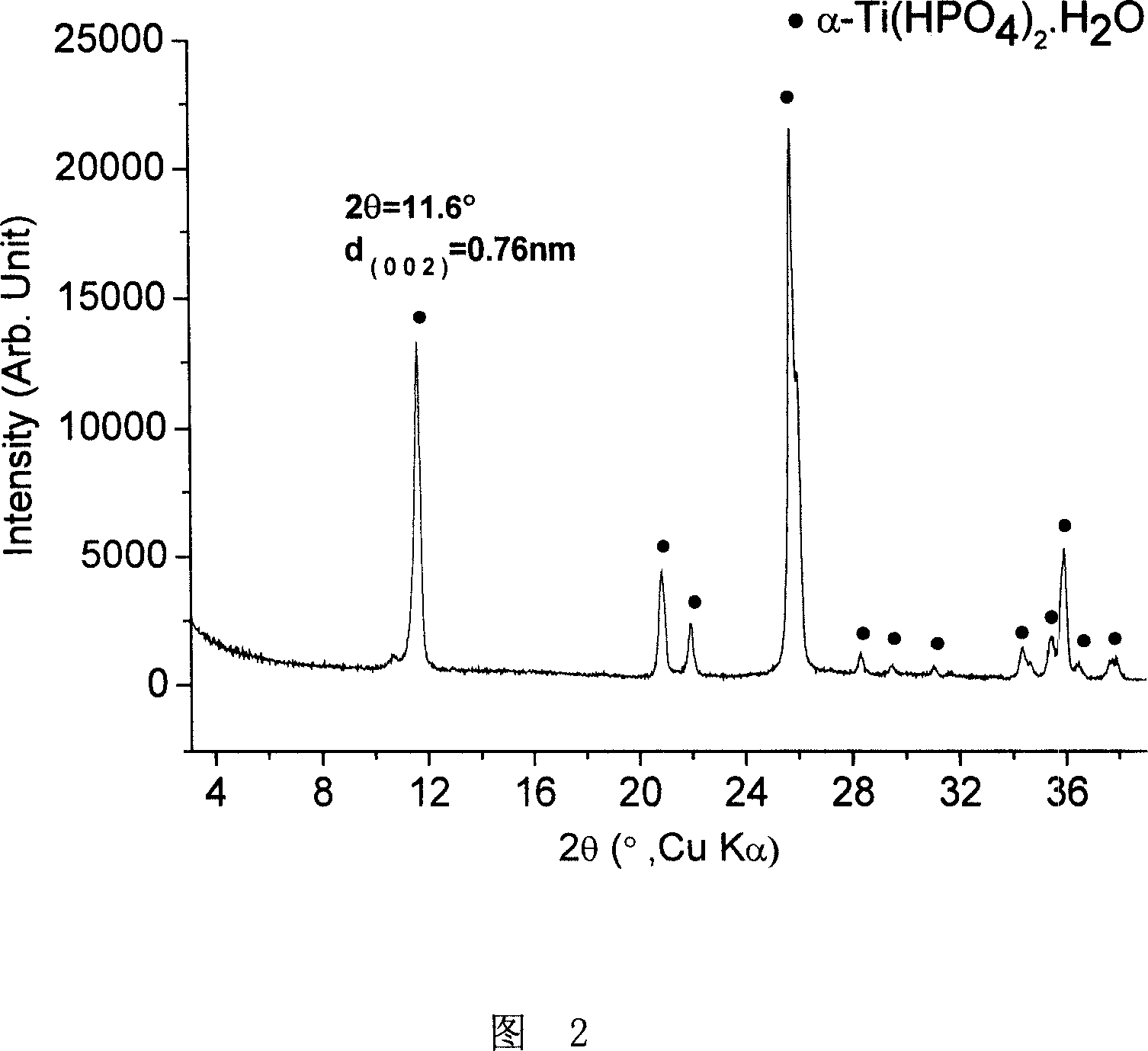

Method of preparing layered alpha-titanium phosphate

InactiveCN101033062AHigh crystallinityUniform shapePhosphatesTitanium compoundsTitanium phosphatePhosphoric acid

This invention discloses a method for preparing laminated alpha-Ti3(PO4)2, which mixes Ti salt with deionized water in the proportion of 1 :4-10 to get deposit after being hydrolyzed fully to be cleaned and mixed in the proportion of 1 : 20-30 : 3-15, then the concentration of H3PO4 in the mixed solution is 4-12mol / L, then transfers the mixed solution into a high pressure kettle and reacts for 4-24 h under 150-200deg.C to be cooled to room temperature t obe cleaned to 3-7 pH value to be dried to get laminated alpha-Ti3(PO4)2.

Owner:TSINGHUA UNIV

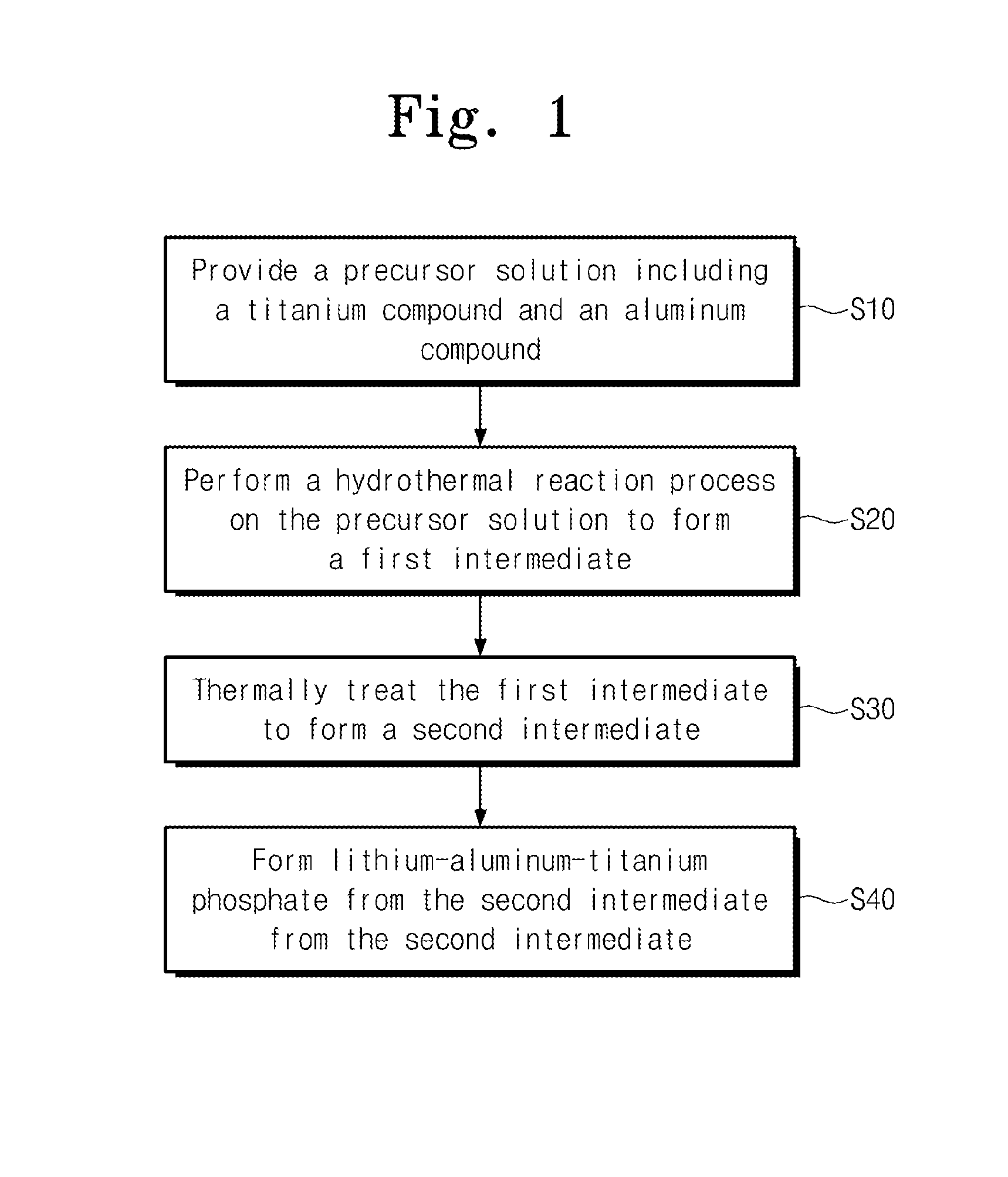

Method of forming lithium-aluminum-titanium phosphate

InactiveUS20140162136A1High purityHigh ion conductanceNon-metal conductorsSolid electrolytesTitanium phosphateLithium compound

Disclosed are methods of forming lithium-aluminum-titanium phosphate. The method includes providing a precursor solution including a titanium compound and an aluminum compound, forming an intermediate using a hydrothermal reaction process performed on the precursor solution, adding a lithium compound and a phosphate compound to the intermediate, and firing a mixture of the lithium compound, the phosphate compound, and the intermediate.

Owner:ELECTRONICS & TELECOMM RES INST

High-nickel ternary positive electrode material coated with lithium aluminum titanium phosphate and preparation method thereof

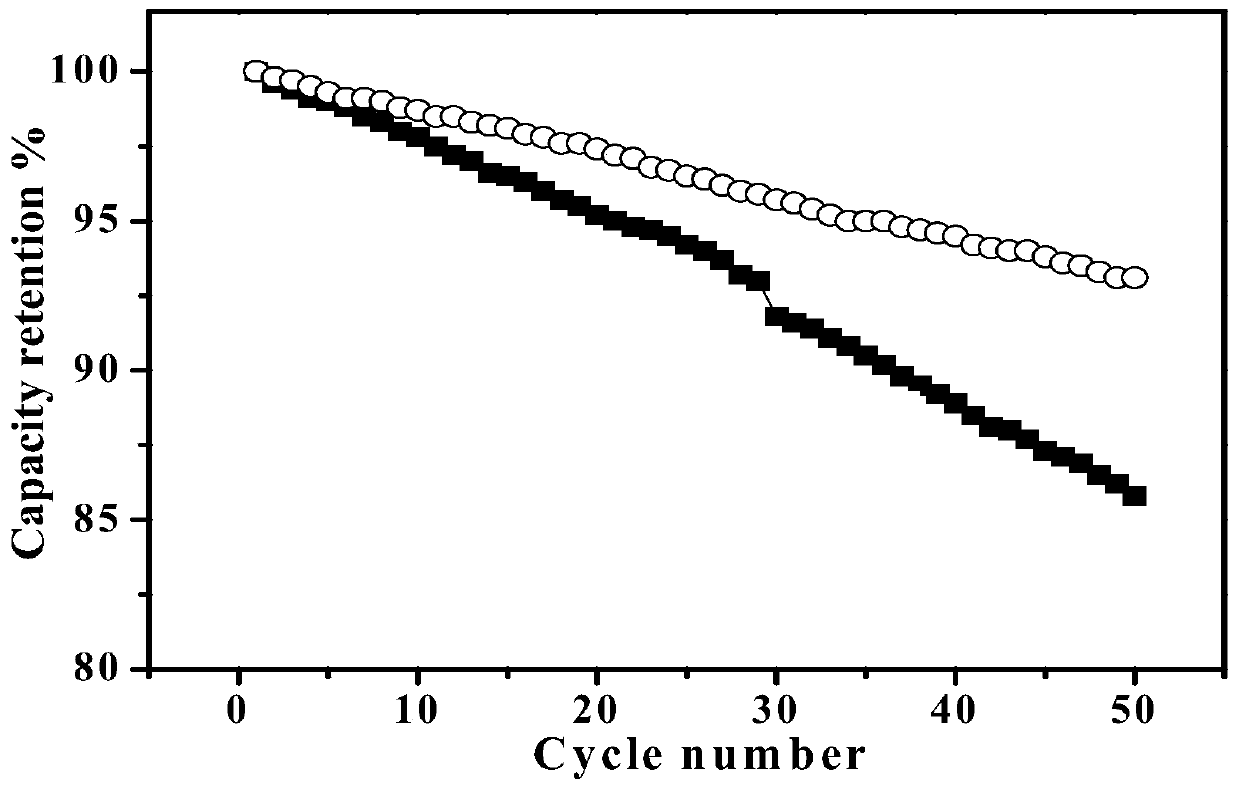

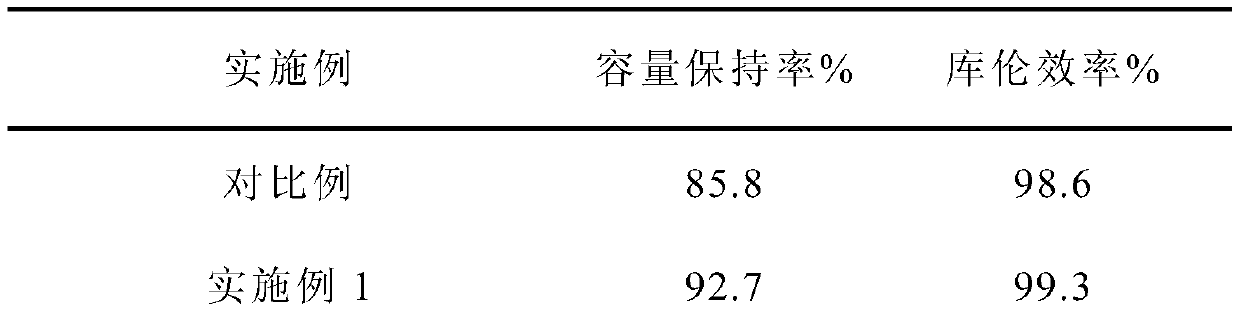

InactiveCN110112383AImprove cycle performanceSecondary cellsPositive electrodesEthylenediaminePhosphoric acid

The invention relates to the field of positive electrode materials for lithium-ion batteries and particularly relates to a high-nickel ternary positive electrode material coated with lithium aluminumtitanium phosphate and a preparation method thereof. The method comprises the steps of (1) preparing a lithium aluminum titanium phosphate coating solution including the steps of uniformly mixing LiNO3, Al(NO3)3-9H2O, tetrabutyl titanate and tributyl phosphate in ethanol, then slowly adding ethylenediaminetetraacetic acid and citric acid, and uniformly stirring to obtain the lithium aluminum titanium phosphate coating solution, and (2) coating including the steps of adding the high-nickel ternary positive electrode material into the lithium aluminum titanium phosphate coating solution, uniformly stirring, and orderly performing drying and calcination steps to obtain the high-nickel ternary positive electrode material coated with the lithium aluminum titanium phosphate. The high-nickel ternary positive electrode material is coated with a lithium aluminum titanium phosphate material with high structural stability, since the high structural stability of the lithium aluminum titanium phosphate facilitates the suppression of the side reaction of a high nickel material, therefore, the occurrence of micro cracks is suppressed, the attenuation of the capacity is suppressed, and the capacity retention rate is improved.

Owner:湖北锂诺新能源科技有限公司

An alkaline aqueous sodium ion battery

InactiveCN109119610AImprove charging capacitySave raw materialsCell electrodesFinal product manufactureSodium-ion batteryIon

The invention discloses an alkaline aqueous solution sodium ion battery and a preparation method thereof, the alkaline aqueous solution sodium ion battery is mainly characterized in that the cathode material adopted is NaxMnyNzO2, N is a doping element, and can be one or more of metal elements Ca, Ti, V, Cr, Mn, Fe, Co, Ni, Cu, Zn, Al, Zr and Ru. The cathode material is activated carbon, sodium titanium phosphate and other electrode materials capable of stable deintercalation of sodium ions in an aqueous solution and a zinc electrode which can be stable in an alkaline aqueous solution. The electrolyte is an alkaline aqueous solution. The cathode material adopted by the invention has high first-cycle charging capacity, low cost of raw materials, simple preparation process and the like. Compared with a neutral electrolyte, an alkaline electrolyte has higher conductivity and stability, requirements for current collector and other metal accessories are lowered, and a selection range is widened, so the alkaline aqueous solution sodium ion battery has good commercial prospects.

Owner:SHENZHEN JANAENERGY TECH CO LTD

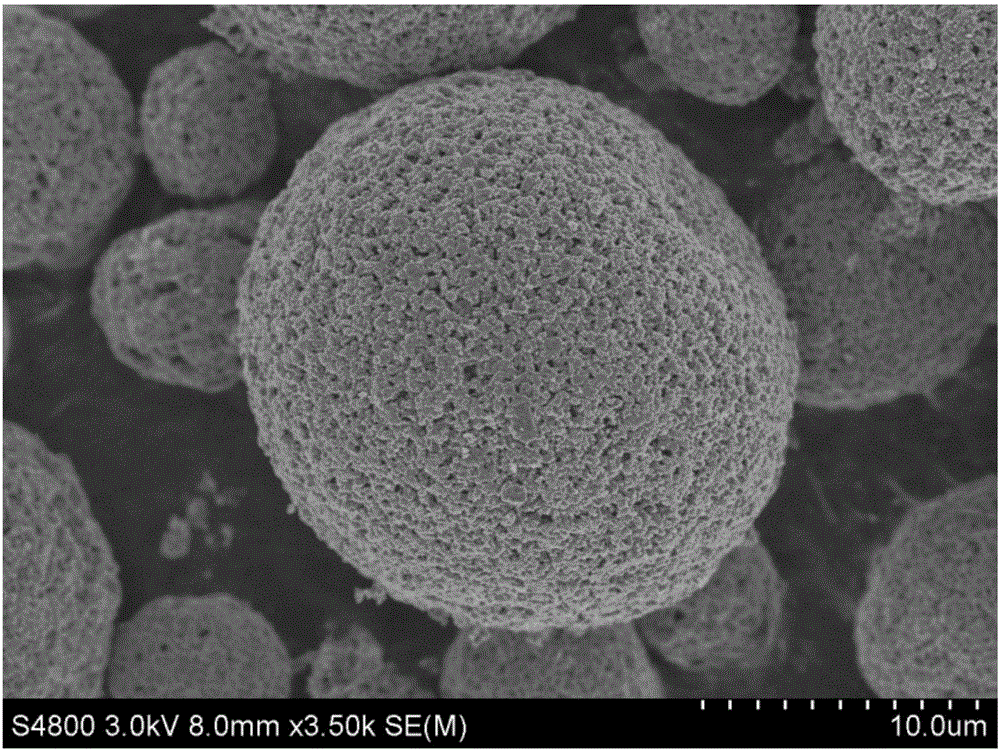

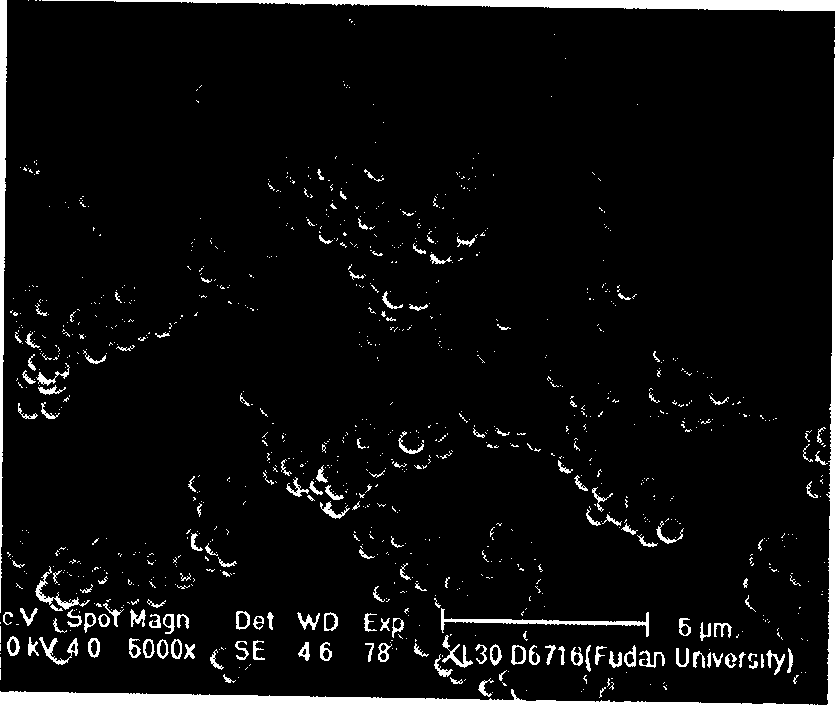

Synthetic method of mesopore metallic oxide, mixed metallic oxide and metallic phosphate serial microballons using mesopore carbon microballons as form

InactiveCN1448371ALarge specific surface areaGood lookingPhysical/chemical process catalystsCeramicwareMicrosphereTitanium zirconium

The present invention the method of forming mesoporous metal oxide, mixed metal oxide and metal phosphate microballoon through synthesizing small mesoporous carbon ball with mesoporous silicon microballoon as mother body, perfusing the mixture of metal alkoxide, metal chloride and phaophate, drying and roasting. The mesoporous metal oxide, phosphate, etc. have important uses in catalysis, adsorption and other fields owing to their high specific surface area, nanometer level pores, great amount of active components on the pore wall and other features. Through said process, serial mesoporous microballoons including titania, zirconia, alumina, mixed titanium-zirconium oxide, mixed titanium-silicon oxide, zirconium phosphate, titanium phosphate, aluminum phosphate, tin phosphate and ferric phosphate may be synthesized.

Owner:FUDAN UNIV

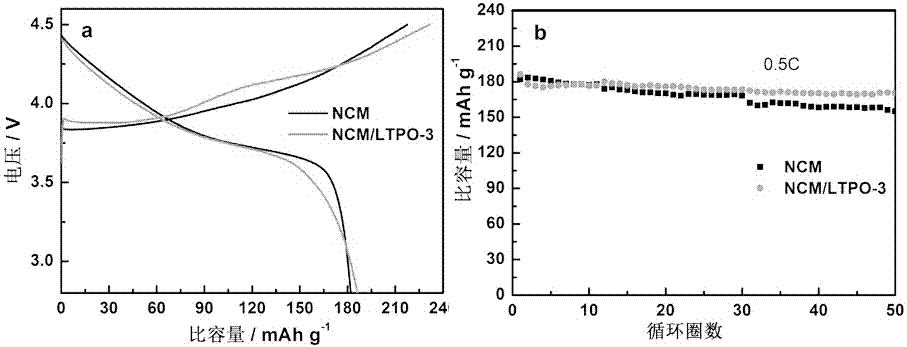

Lithium titanium phosphate-coated LiNi<1/3>Co<1/3>Mn<1/3>O<2> positive electrode material and preparation method therefor

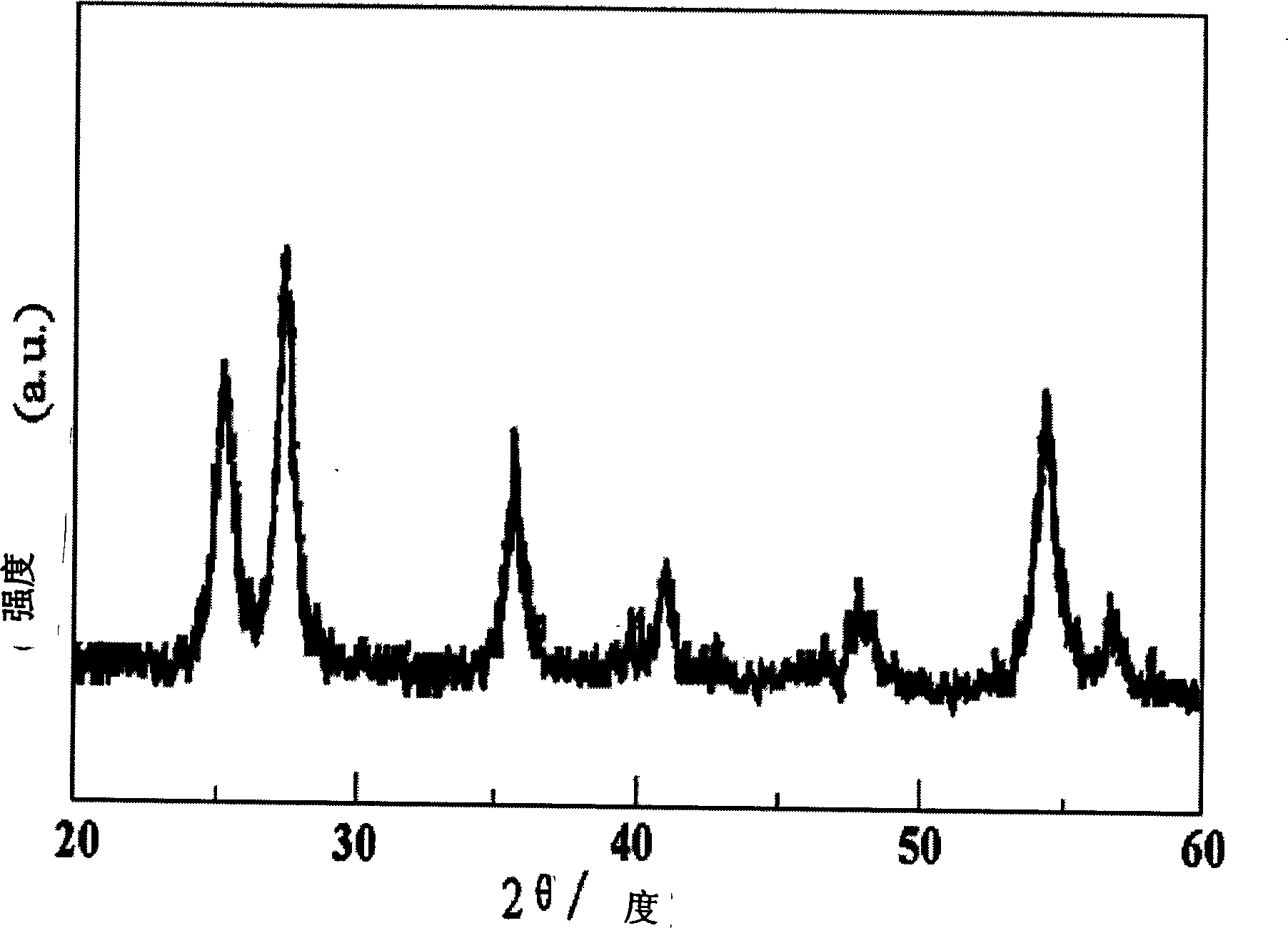

InactiveCN107492643AImprove cycle performanceImprove structural stabilitySecondary cellsElectrode collector coatingLithium hydroxideManganese

The invention provides a lithium titanium phosphate-coated lithium nickel cobalt manganate LiNi<1 / 3>Co<1 / 3>Mn<1 / 3>O<2> positive electrode material and a preparation method therefor. The preparation method comprises the steps of performing ball milling on a hydroxyl nickel cobalt manganese Ni<1 / 3>Co<1 / 3>Mn<1 / 3>(OH)<2> precursor prepared by a co-deposition method and lithium carbonate Li<2>CO<3> in an absolute ethyl alcohol medium, and then performing calcining on the obtained powder after drying in a muffle furnace, and next, performing cooling and screening to obtain a lithium nickel cobalt manganate LiNi<1 / 3>Co<1 / 3>Mn<1 / 3>O<2> positive electrode material; performing uniform ultrasonic dispersion of the LiNi<1 / 3>Co<1 / 3>Mn<1 / 3>O<2> in the mixed solution of absolute ethyl alcohol and acetone, then adding tetrabutyl titanate C<16>H<36>O<4>Ti and stirring for 60min, next, slowly dropwise adding 10ml of deionized water and stirring for 60min, and finally adding ammonium di-hydrogen phosphate NH<4>H<2>PO<4> and lithium hydroxide LiOH.H<2>O and stirring for 9h; and performing filtering, washing and drying to obtain powder and performing sintering on the obtained powder in the muffle furnace, and next, performing cooling and screening to obtain the lithium titanium phosphate LiTi<2>(PO<4>)<3>-coated LiNi<1 / 3>Co<1 / 3>Mn<1 / 3>O<2> ternary positive electrode material.

Owner:CHINA THREE GORGES UNIV +1

Application of titanium phosphate for preparing facial beautifiers

InactiveCN102641214AWith whiteningMoisturizingCosmetic preparationsBody powdersTitanium phosphatePhosphoric acid

The invention discloses application of titanium phosphate for preparing facial beautifiers. The titanium phosphate is a white powder material, has good biocompatibility, is not easy to absorb through skin, has certain whitening performance, moisturizing performance, smoothness and photocatalytic activity when used in the facial beautifiers, and is a soft pigment for the facial beautifiers.

Owner:SHANTOU XUEQI COSMETICS

Preparation method of nitrogen-doped carbon-coated dual-core shell lithium titanium phosphate or sodium titanium phosphate

InactiveCN107910514AImprove the wrapping effectGuaranteed electronic conductivityPhosphatesCell electrodesCarbon coatingDual core

The invention relates to a preparation method of nitrogen-doped carbon-coated dual-core shell lithium titanium phosphate or sodium titanium phosphate, and belongs to the field of electrode material synthesis. According to the preparation method, secondary uniform and compact coating is achieved by the process of oxidization polymerization and attachment of dopamine onto surfaces of solid particleson the basis of combination of primary conductive carbon and lithium titanium phosphate / sodium titanium phosphate and initial carbon coating, and a nitrogen-doped carbon-coated dual-core shell lithium titanium phosphate or sodium titanium phosphate material is obtained after high-temperature carbonization. By the preparation method, the problems of low electron conductivity of lithium titanium phosphate or sodium titanium phosphate and non-uniformity and untightness of the carbon coating layer are effectively solved, and the prepared lithium titanium phosphate or sodium titanium phosphate electrode is excellent and stable in performance. A titanium source with high yield and low cost is employed, the preparation method is simple and easy to operation, and promotion and application are convenient.

Owner:NO 63971 TROOPS PLA

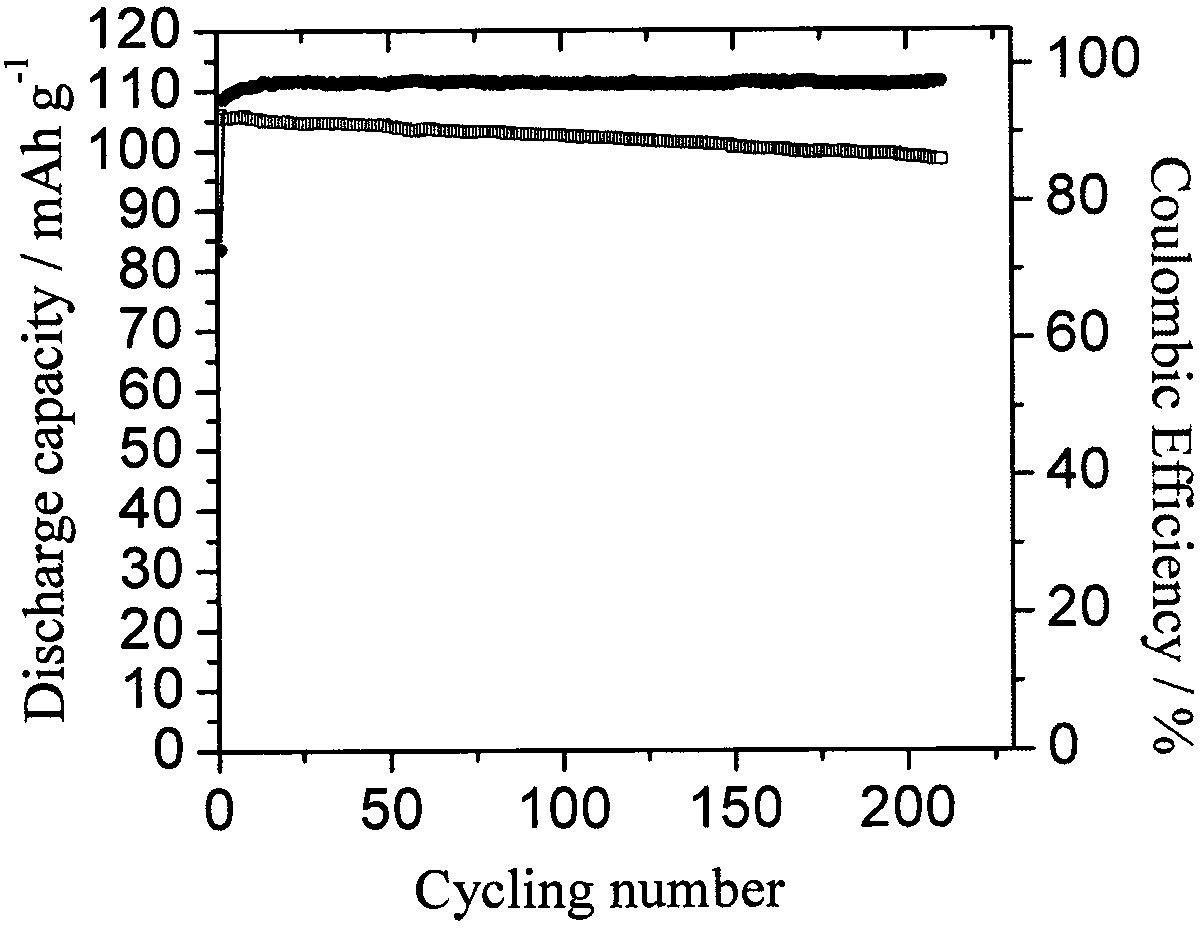

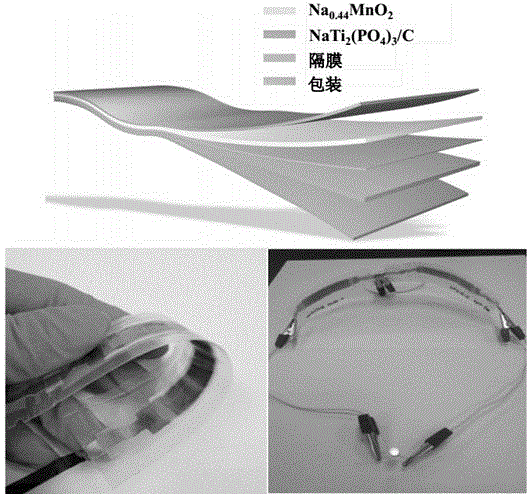

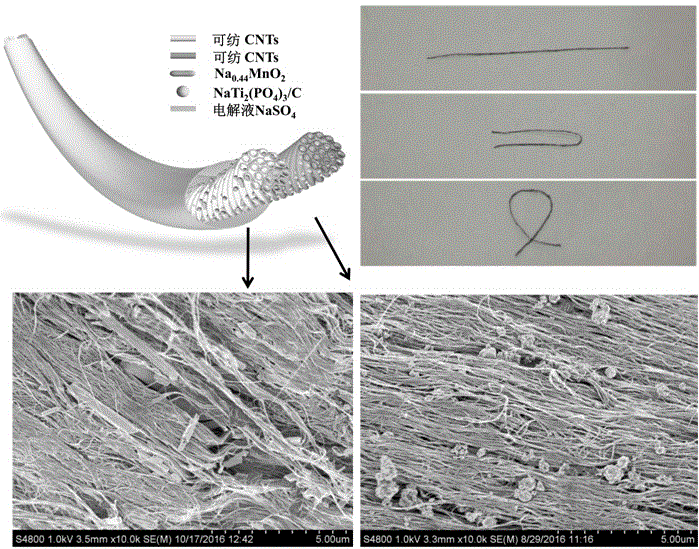

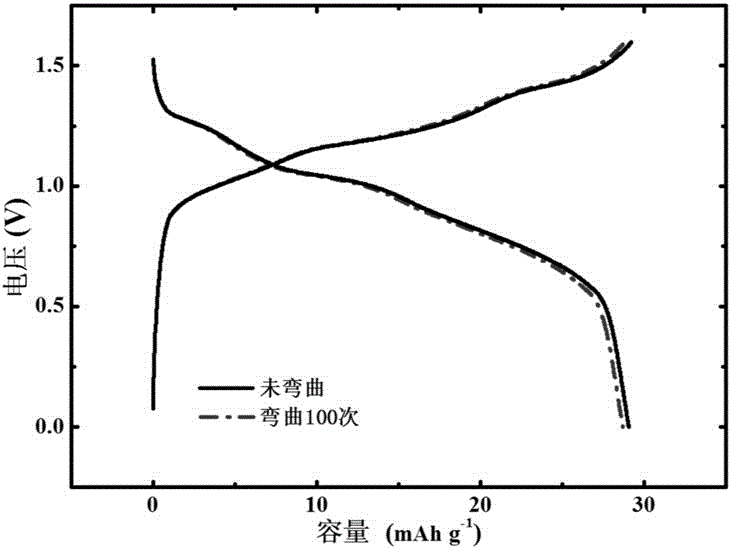

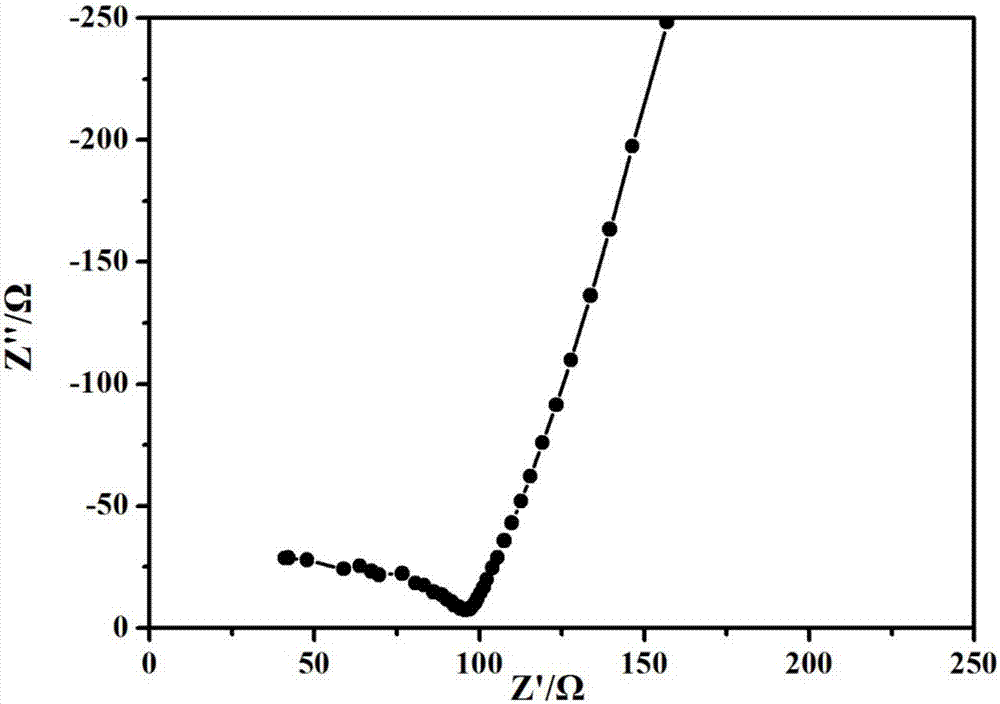

Flexible water-based sodium-ion batteries and preparation method thereof

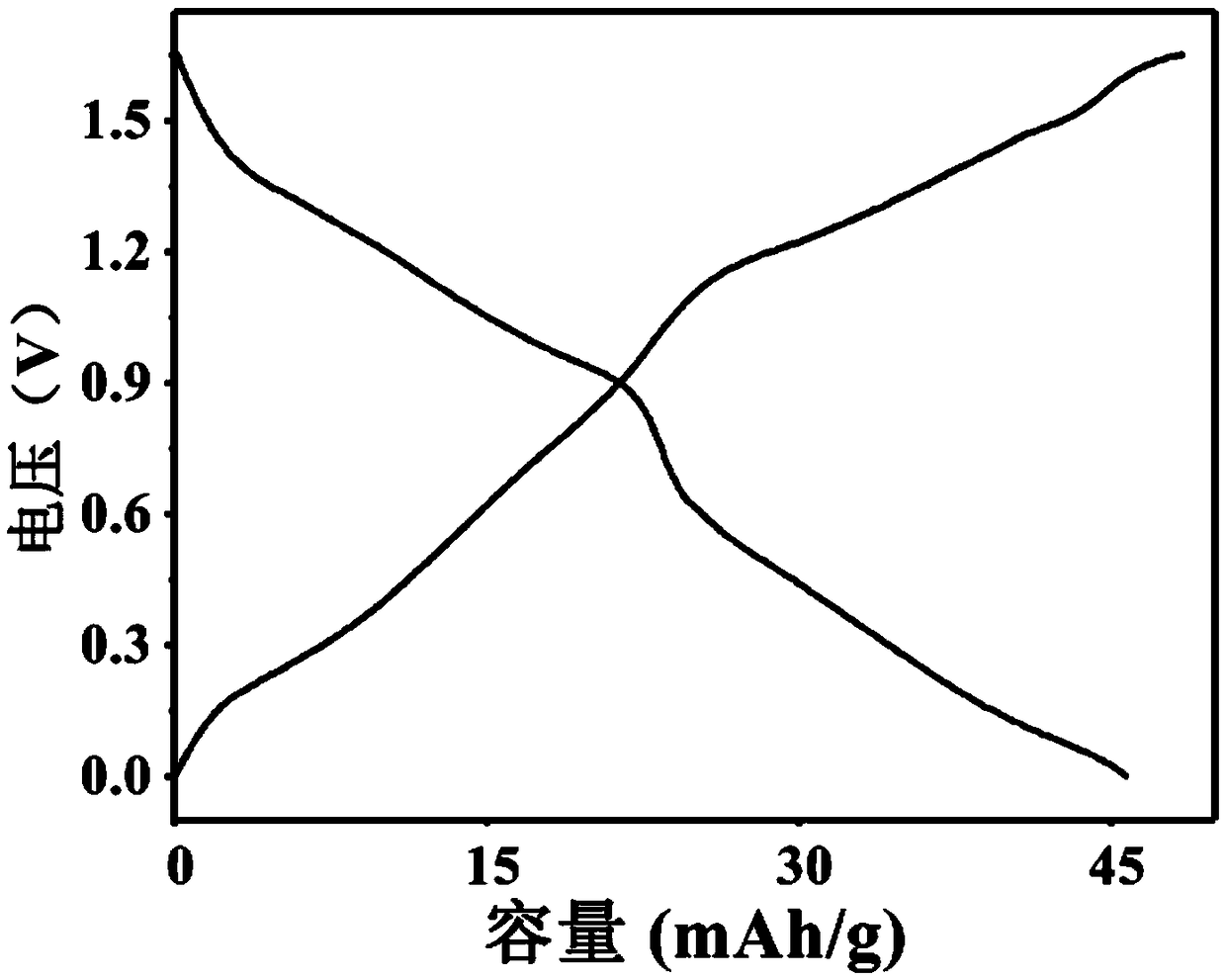

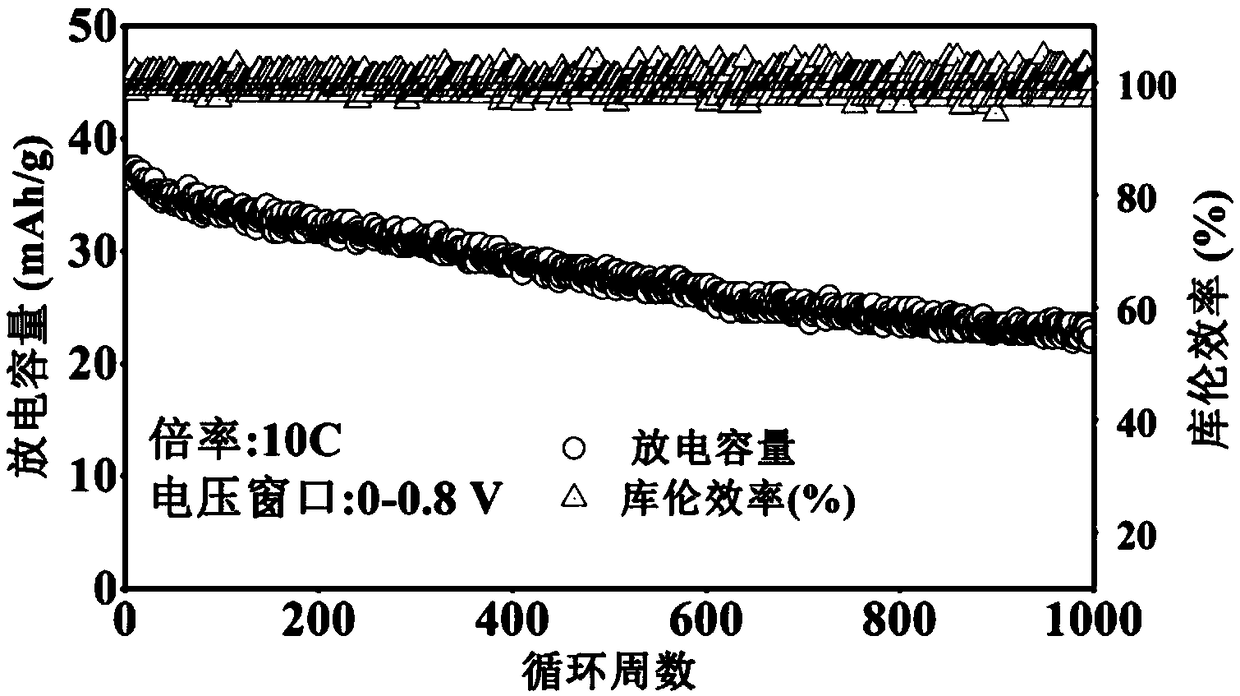

InactiveCN106374147AImproved magnification performanceImprove cycle stabilityFinal product manufactureSecondary cellsWater basedFiber

The invention belongs to the technical field of energy storage devices, and in particular relates to flexible water-based sodium-ion batteries and a preparation method thereof. The flexible water-based sodium-ion batteries take sodium manganate as a positive active material and carbon-coated sodium-titanium phosphate as a negative active material; the flexible water-based sodium-ion batteries with excellent electrochemical performance are prepared from the sodium manganate and the carbon-coated sodium-titanium phosphate according to an appropriate mass ratio; the two types of flexible water-based sodium-ion batteries are a two-dimension band-shaped flexible water-based sodium-ion battery and a one-dimensional thread-shaped flexible water-based sodium-ion battery. The band-shaped flexible water-based sodium-ion battery takes soft stainless steel as a current collector; the thread-shaped water-based sodium-ion battery enables the active materials to be rolled into an orientation carbon nano tube (CNT) to prepare composite fibers, and the CNT is used as a current collector and a conductive additive at the same time, so that the mass and volume of the battery are reduced, the flexibility of the battery is improved, and the thread-shaped water-based sodium-ion battery is easy to weave and integrate. The two-dimension band-shaped flexible water-based sodium-ion battery and the one-dimensional thread-shaped flexible water-based sodium-ion battery have excellent electrochemical performance, and have the advantages of being light in mass, low in cost, high in flexibility and safety, environmental-friendly, and the like, thus providing possibility for the application in the field of wearable electronic devices. The thread-shaped flexible water-based sodium-ion battery can even be implanted in a human body for assisting health monitoring and treatment of diseases.

Owner:FUDAN UNIV

Preparation method of titanium phosphate/germanium-aluminum-lithium solid electrolyte

InactiveCN107265430AImprove conductivityImprove product qualitySolid electrolytesSecondary cellsMolten stateLithium

The invention relates to a preparation method of a titanium phosphate / germanium-aluminum-lithium solid electrolyte, and belongs to the technical field of solid electrolytes. The preparation method of the titanium phosphate / germanium-aluminum-lithium solid electrolyte is characterized by adopting a molten salt assisted solid phase method, enabling fused salt to become a molten state so as to provide a liquid state environment beneficial to fully mixing a precursor, and obtaining a solid electrolyte material with the characteristics that Li1+xAlxM2-x(PO4)3x is equal to 0 to 0.7 and M is equal to Ti and Ge. The preparation method of the titanium phosphate / germanium-aluminum-lithium solid electrolyte provided by the invention has the advantages of simple production process, convenience in industrial production, high ionic conductivity of the product solid electrolyte material at the room temperature, stable product quality and the like.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

Nanometer lithium aluminium titanium phosphate solid electrolyte material and preparation method therefor

ActiveCN105680090AMild conditionsThe process is simple and easy to controlMaterial nanotechnologyFinal product manufactureAll solid stateTitanium phosphate

The invention belongs to the preparation technical field of a lithium ion battery solid electrolyte, and specifically relates to a nanometer titanium aluminium lithium phosphate solid electrolyte material and a preparation method therefor. The invention provides the preparation method for a nanometer solid electrolyte material; the chemical formula of the material is Li<1+x>Al<x>Ti<2-x>(PO4)3, wherein x is 0.3-0.5; and the average grain diameter is 70-100nm. The preparation method provided by the invention has the advantages of mild conditions, simple and easily-controlled process, short time consumption and high yield, and industrial production of the solid electrolyte material can be realized; the nanometer LATP (titanium aluminium lithium phosphate) solid electrolyte material provided by the invention has uniform and controllable grain diameters, relatively high conductivity, and can be used for preparation of the all-solid-state lithium ion battery.

Owner:SICHUAN UNIV

Preparation method of lithium titanium phosphate anode material

ActiveCN106299267AAvoid wall stickingImprove conductivityCell electrodesSecondary cellsAqueous electrolyteSlurry

The invention belongs to the technical field of green energy source material, and more specifically relates to a preparation method of a lithium titanium phosphate anode material of lithium ion batteries taking an aqueous solution as the electrolyte. According to the preparation method, a primary carbon source with a relatively high glass transition temperature is added into a slurry so as to avoid adhering on the wall in spray drying process caused by adding of an organic carbon source completely; carbon sources are added in two times, a secondary carbon source is added in a second time after an initial precursor is formed, and the secondary carbon source is mixed with the initial precursor at a high speed, adoption of composite carbon sources is capable of achieving excellent carbon coating effect on the surface of lithium titanium phosphate; electrical conductivity among the LiTi2(PO4)3 particles is increased via coating by the secondary carbon source, the electrical conductivity of LiTi2(PO4)3 is increased obviously, and carbon coated LiTi2(PO4)3 possesses excellent cycling stability in aqueous electrolyte. The production process is continuous; product characteristics are uniform; quality is stable; the preparation method is simple and convenient, and is suitable for industrialized production.

Owner:江西省金锂科技股份有限公司

Interior wall paint capable of absorbing and decomposing formaldehyde

ActiveCN103555110ADoes not affect general performanceSatisfied with the adsorption effectCoatingsActivated carbonSodium Bentonite

The invention discloses interior wall paint capable of absorbing and decomposing formaldehyde. The interior wall paint is characterized by comprising the following active ingredients in percentage by weight: 30-45% of film forming base stock, 10-30% of filler, 1-4% of activated carbon powder, 3-5% of Na2SO3 doped modified bentonite, 3-8% of nanometer titanium dioxide, 2-5% of nanometer titanium phosphate, 11-20% of pigment and auxiliaries and the balance of water, wherein Na2SO3 accounts for 16-30% of the Na2SO3 doped modified bentonite.

Owner:苏州市东挺河智能科技发展有限公司

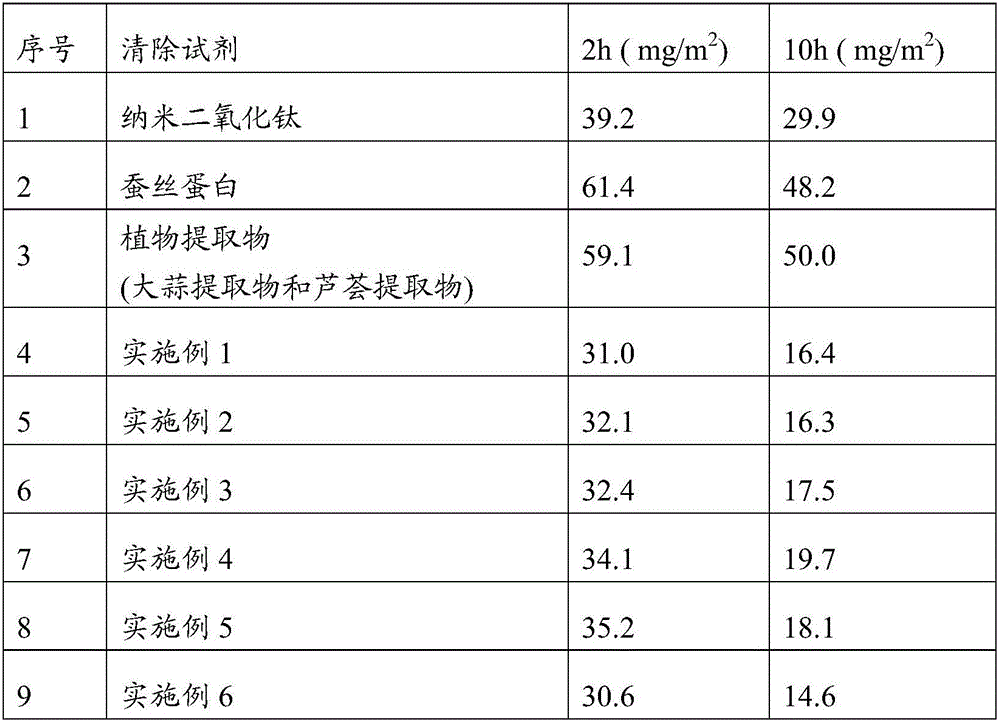

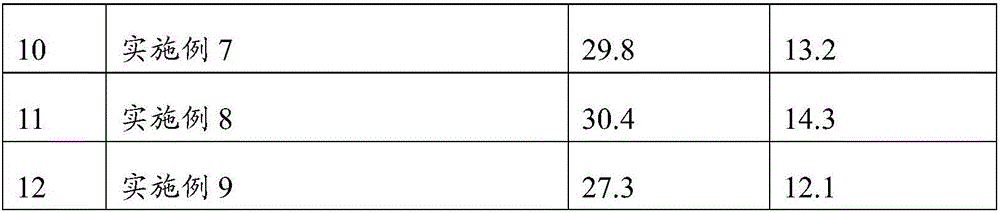

Environment-friendly formaldehyde removing spray

InactiveCN106731766AImprove formaldehyde removal efficiencyRemove completelyGas treatmentDispersed particle separationBenzeneHazardous substance

The invention relates to environment-friendly formaldehyde removing spray. The environment-friendly formaldehyde removing spray is characterized in that the environment-friendly formaldehyde removing spray is prepared from the following components according to mass percent: 1 to 5% of nanometer titania, 0.5 to 5% of nanometer titanium phosphate, 0.5 to 5% of nanometer silicon dioxide, 0.5 to 5% of plant extracts, 0.1 to 0.5% of fibroin, 0.01 to 0.1% of dispersant and the balance of water. According to the environment-friendly formaldehyde removing spray, components and biological enzymes in the plant extracts interact with substances such as the nanometer titania, the fibroin, and the nanometer titanium phosphate, so that the formaldehyde removing efficiency of the formaldehyde removing spray prepared by combining the components according to a certain proportion is improved, indoor formaldehyde can be completely removed under natural conditions, and in addition, a plurality of common harmful substances such as benzene, and ammonia which are generated by home decoration can be removed.

Owner:无锡枫擎食品有限公司

Dustproof coating for inner wall of shell of dust collector

InactiveCN106987200AImprove protectionImprove self-cleaning abilityAntifouling/underwater paintsPaints with biocidesEmulsionTitanium phosphate

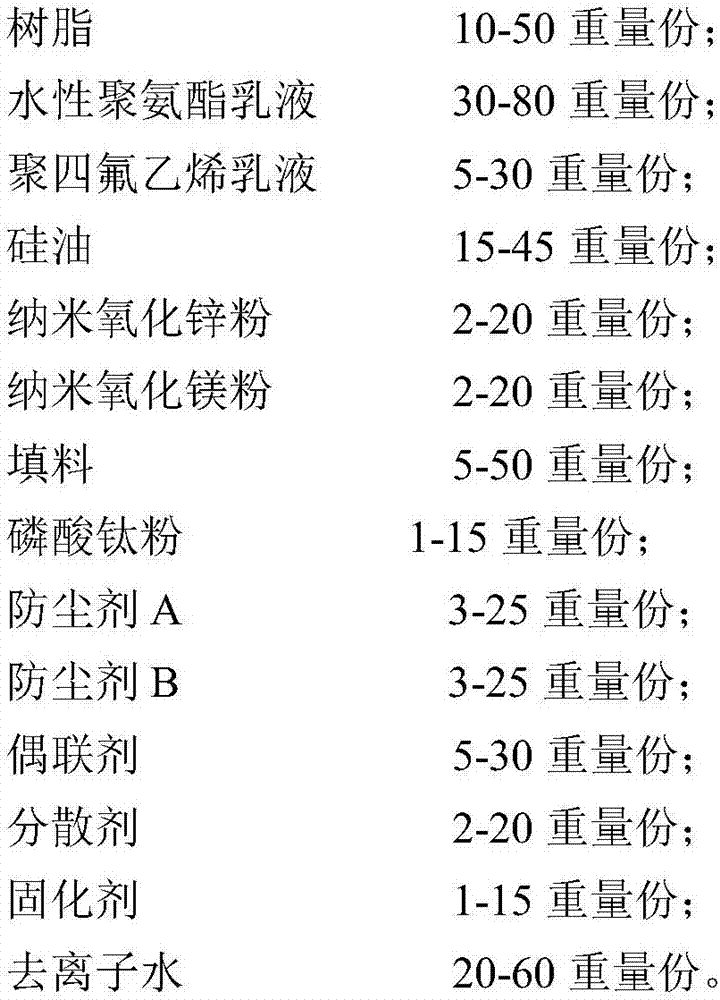

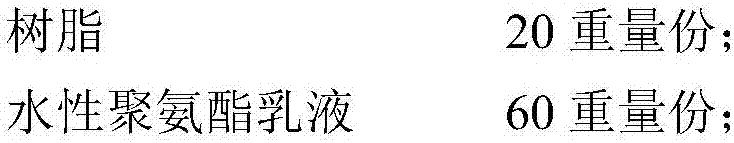

The invention discloses a dustproof coating for an inner wall of a shell of a dust collector. The dustproof coating for the inner wall of the shell of the dust collector comprises the following raw materials in parts by weight: 10-50 parts of resin, 30-80 parts of aqueous polyurethane emulsion, 5-30 parts of polytetrafluoroethylene emulsion, 15-45 parts of silicone oil, 2-20 parts of nano zinc oxide powder, 2-20 parts of nano magnesium oxide powder, 5-50 parts of a filler, 1-15 parts of titanium phosphate powder, 3-25 parts of a dust-proof agent A, 3-25 parts of a dust-proof agent B, 5-30 parts of a coupling agent, 2-20 parts of a dispersing agent, 1-15 parts of a curing agent and 20-60 parts of deionized water. The dustproof coating for the inner wall of the shell of the dust collector is uniform and stable, and is high in adhesive force; and a coating layer which is formed by coating the inner wall of the shell of the dust collector with the dustproof coating has quite high dustproof property and quite high wear resistance, and can protect the inner wall of the shell of the dust collector well.

Owner:SUZHOU HAIGE ELECTRICAL TECH CO LTD

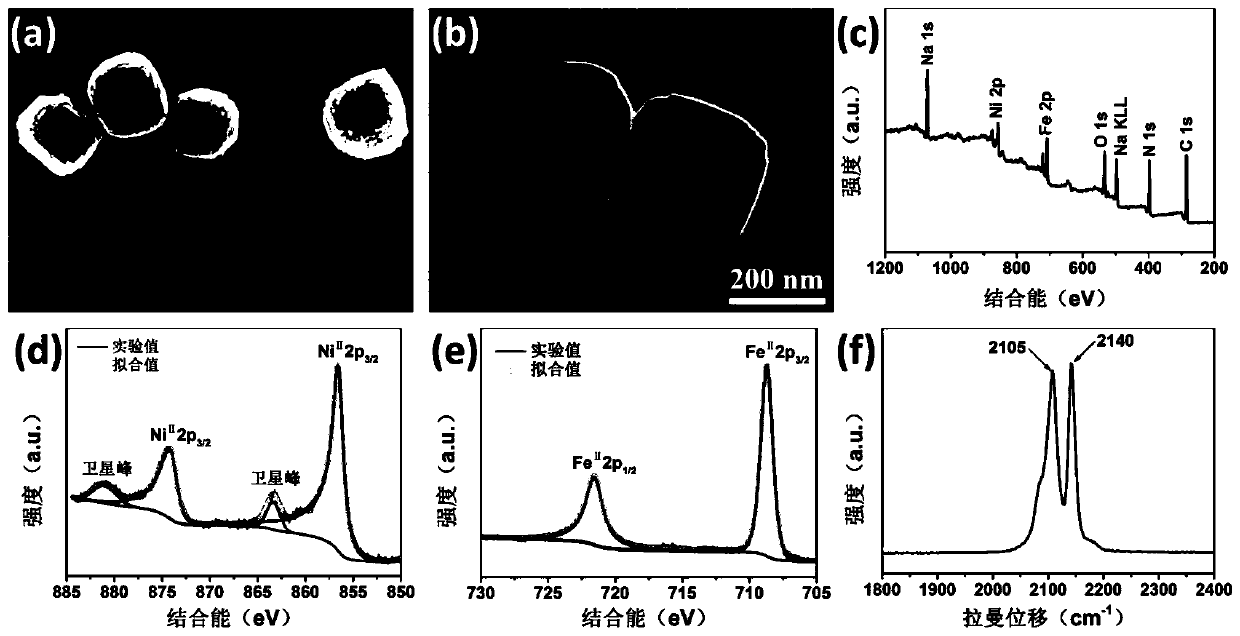

Water-based sodium ion total battery based on nickel prussian blue positive electrode material and preparation method and application thereof

InactiveCN111525129AControl crystal formControl shapeEnergy inputSecondary cellsElectrolytic agentNew energy

The invention discloses a water-based sodium ion total battery based on a nickel prussian blue positive electrode material and a preparation method and application thereof, and belongs to the field oflarge-scale energy storage. According to the invention, sodium citrate is added as a chelating agent and polyvinylpyrrolidone is added as a surfactant to control the growth process of the Prussian blue material in the process of preparing the Prussian blue positive electrode material by a coprecipitation method, and finally, the monoclinic phase nickel Prussian blue nanocube is synthesized. The carbon-coated sodium titanium phosphate negative electrode material, a carbon-coated sodium titanium phosphate negative electrode material and a water-soluble sodium salt electrolyte are assembled intoa low-cost and high-performance water-based sodium ion battery by taking the carbon-coated sodium titanium phosphate negative electrode material as a positive electrode material. The method is expected to be applied to a large-scale energy storage system to promote the development of new energy and renewable energy industries.

Owner:DALIAN UNIV OF TECH

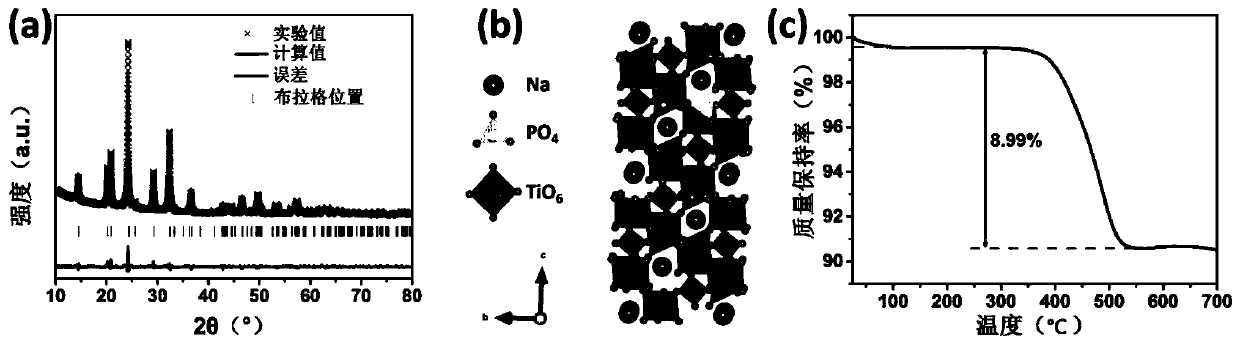

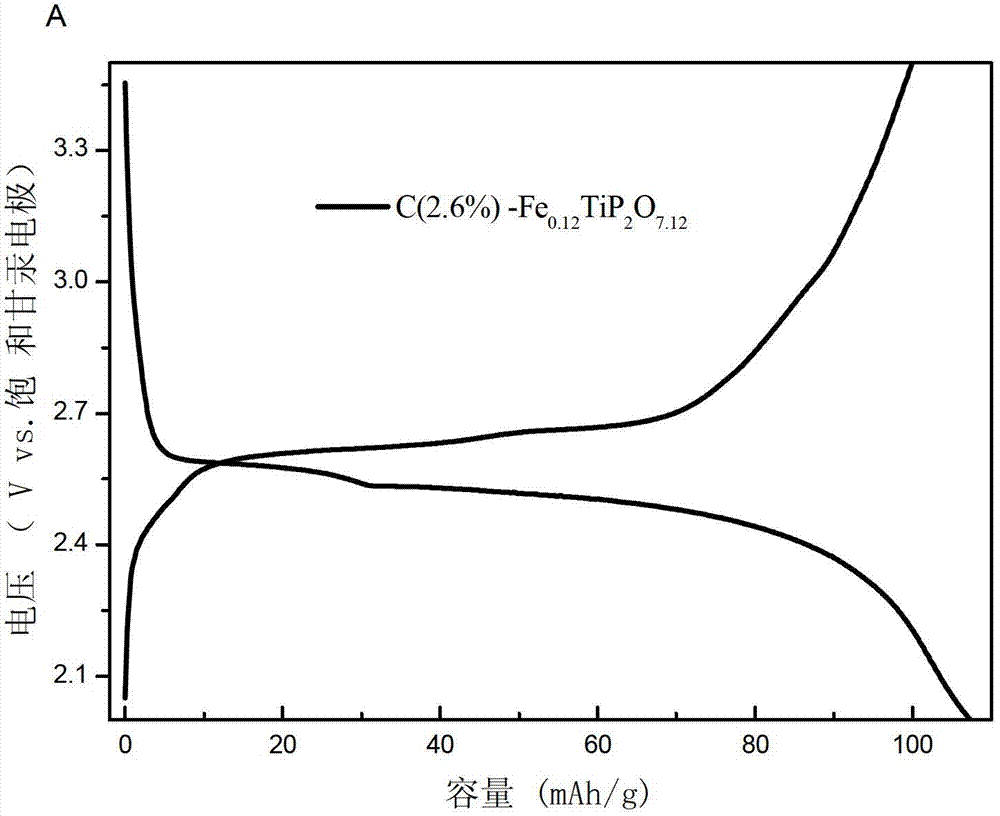

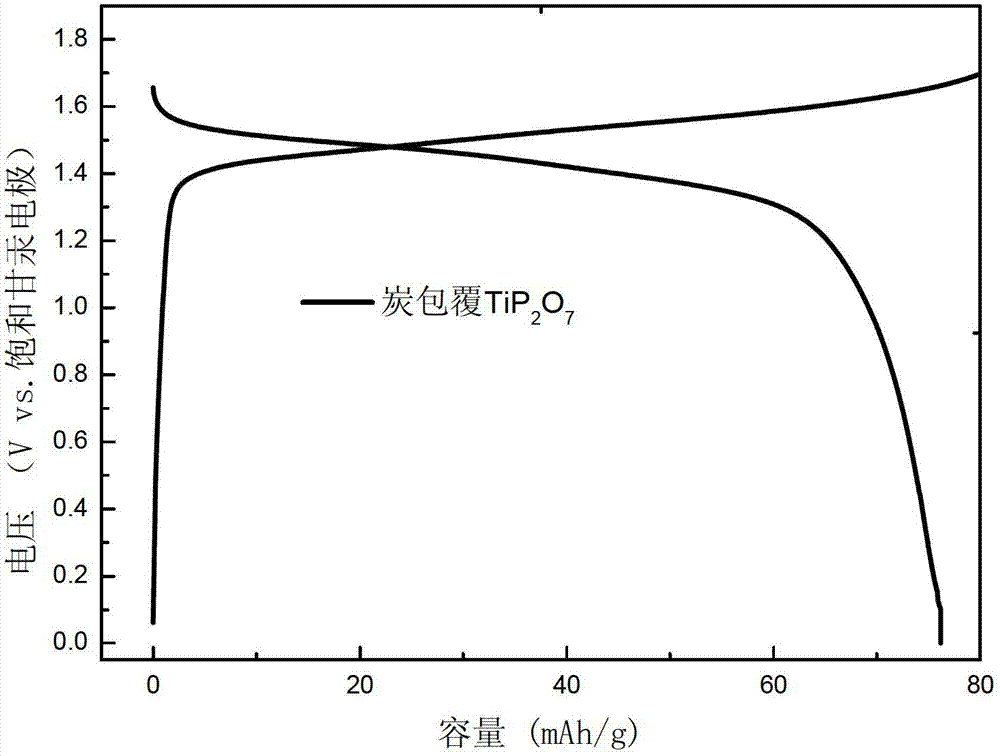

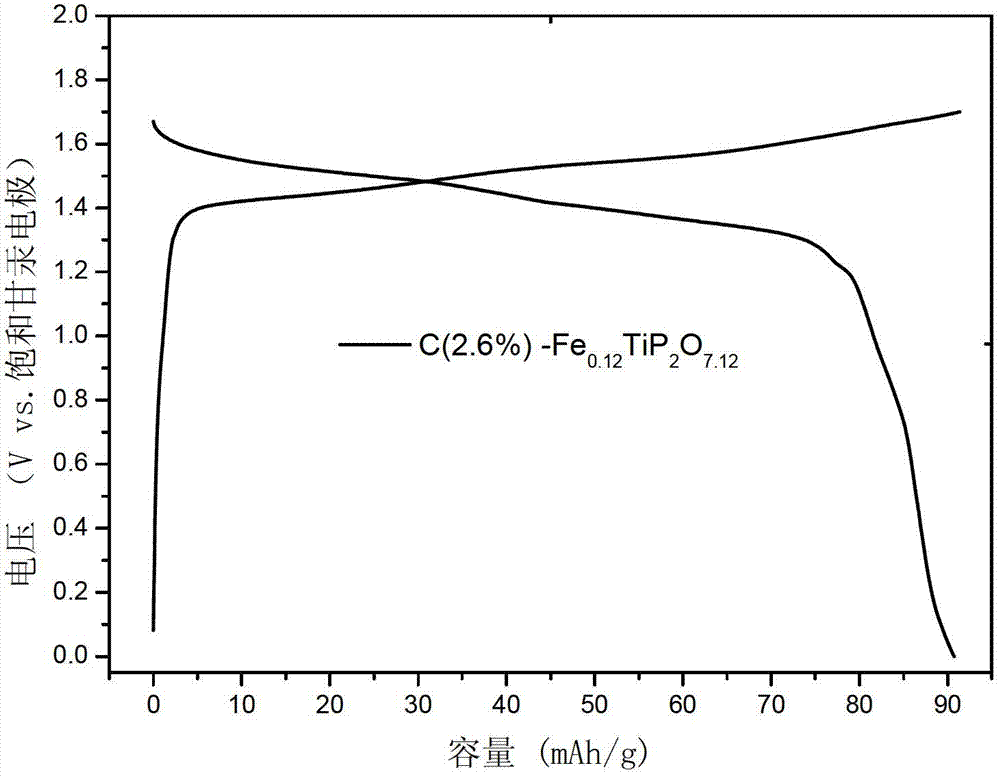

High-performance lithium ion battery electrode material and preparation method

ActiveCN103199245AIncreased rate capacityImproved magnification performanceCell electrodesElectrical conductorPhosphoric acid

The object of the present invention is to provide a novel titanium phosphate electrode material having good lithium ion battery characteristics, and is to solve the problem that the cycle life of a titanium pyrophosphate electrode material is poor in the prior art. The electrode material is intercalation compound carbon-coated C-Fe[x]TiP[2]O[7+x], and is a fast ion conductor electrode material of a three-dimensional structure. A preparation method comprises: (1) mixing and grinding TiO2 and NH4H2PO4, adding distilled water, stirring until the mixture is dried, finally placing the mixture in air for calcination to obtain TiP2O7; and (2) taking TiP2O7 obtained in Step (1) as a raw material, weighing TiP2O7 and an iron source material, mixing evenly, then adding a carbon source aqueous solution, stirring continuously at 40 DEG C until the mixture is dried, and finally calcining the mixture in a nitrogen atmosphere to obtain carbon-coated C-Fe[x]TiP[2]O[7+x].

Owner:常州孚达新能源科技有限公司

A method for preparing a lithium-rich manganese-based cathode material coated with lithium titanium phosphate

ActiveCN109119624ARelieve ruptureEase phase transitionSecondary cellsPositive electrodesAir atmosphereManganese

A method for preparing a lithium-rich manganese-based cathode material coated with lithium titanium phosphate comprises the following steps: (1) mixing and grinding a lithium-rich manganese-based precursor with a lithium source, calcining in an air atmosphere, and cooling; 2, dispersing the lithium-rich manganese-based cathode material in an anhydrous organic solvent I and uniformly stirring; thenadding a titanium source, uniformly stirring to obtain a black suspension a; 3, weighing a lithium source and phosphorus source, adding the lithium source and phosphorus source into an anhydrous organic solvent II, uniformly stirring to obtain a mixed suspension b; 4) adding the mixed suspension b into the black suspension a for reaction, evaporating in an oil bath to obtain dry gel powder; 5, calcining the dry gel powder under a reducing atmosphere to obtain the material. As the surface coating layer, the lithium titanium phosphate of the invention can not only alleviate the cracking and lamellar-snipel phase change of the secondary particles, but also can improve the positive pole-electrolyte interface kinetics, and thus the lithium-rich manganese-based cathode material composite coatedwith lithium titanium phosphate have excellent cycle stability.

Owner:CENT SOUTH UNIV

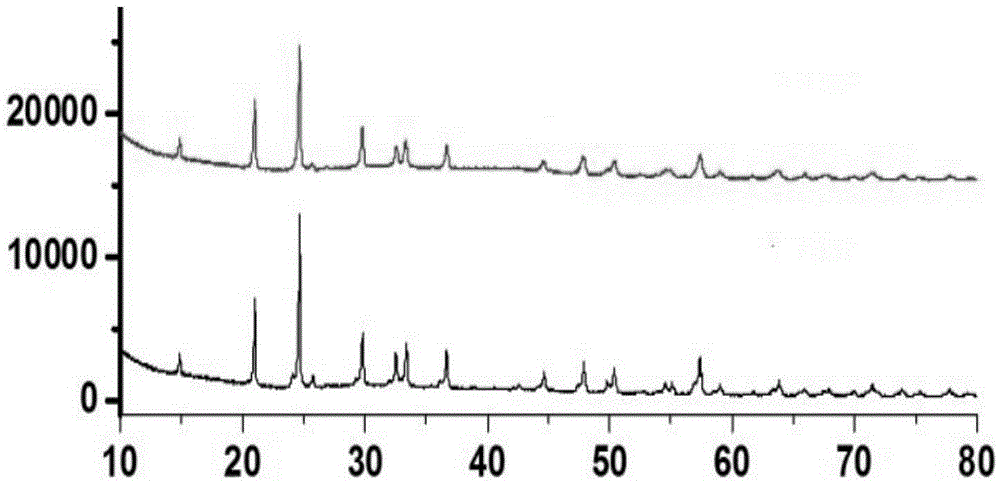

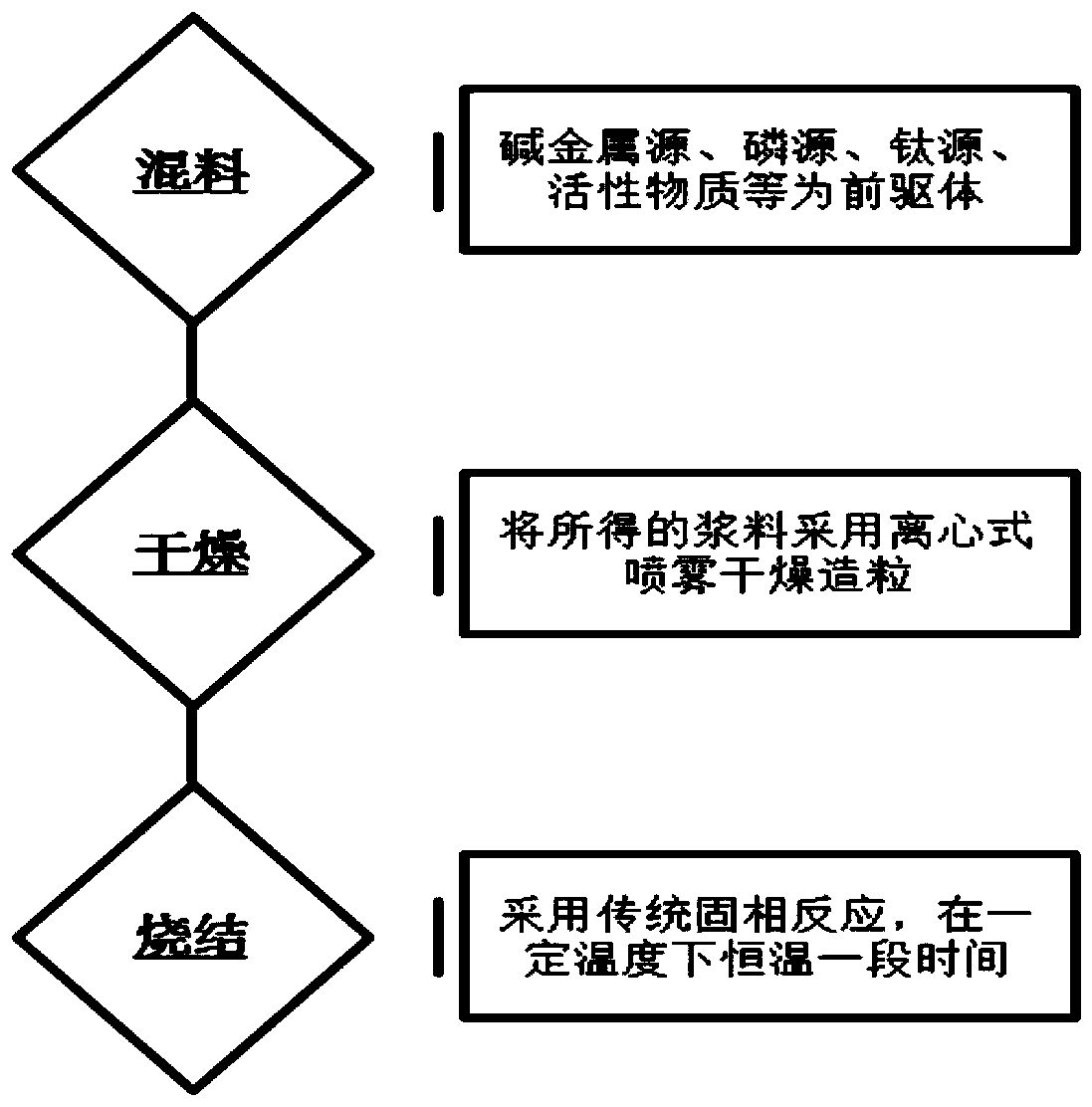

Batch preparation method for low-cost carbon-clad titanium phosphate compound

The invention relates to a batch preparation method for a low-cost carbon-clad titanium phosphate compound. The chemical formula of the titanium phosphate compound is MxTi2(PO4)3, wherein M is selected from at least one of alkali metals, and x is equal to 1-1.05. The method comprises the following steps: (1) carrying out wet-process ball milling on the raw materials of an alkali metal source, a phosphorus source, a titanium source and a carbon source in a stoichiometric ratio, so as to obtain slurry; (2) carrying out centrifugal spray drying on the slurry, so as to obtain carbon-clad titaniumphosphate compound precursor mixed powder; and (3) sintering the precursor mixed powder by virtue of a solid-phase synthesis method, so as to obtain titanium phosphate compound powder. According to the batch preparation method, the process is simple, the cost is low and the preparation method can be widely applied to the large-scale production of the titanium phosphate compounds.

Owner:BENAN ENERGY

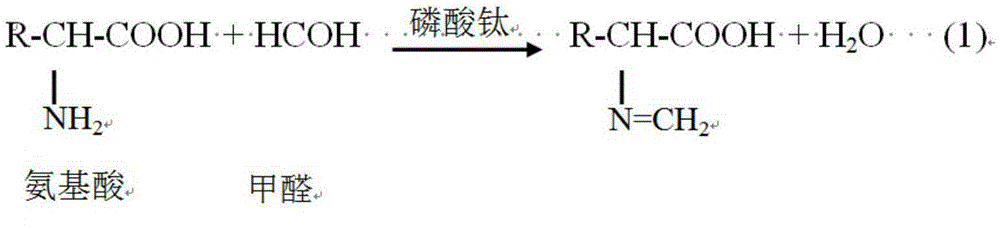

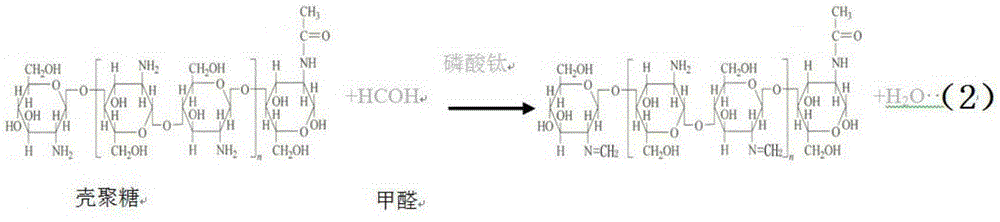

Formaldehyde purifying agent and application thereof in non-woven formaldehyde purifying wallpaper

InactiveCN105413454AImprove adsorption capacitySimple processGas treatmentPhysical/chemical process catalystsSocial benefitsAluminium sulfate

The invention discloses a formaldehyde purifying agent and application thereof in non-woven formaldehyde purifying wallpaper. The formaldehyde purifying agent is prepared from, by mass, 100 parts of an adsorbing agent, 1-100 parts of amino acid, 1-100 parts of chitosan and 1-100 parts of nano titanium phosphate. The adsorbing agent is prepared through a reaction of sepiolite and aluminum sulfate. The formaldehyde purifying agent can continuously and efficiently purify free formaldehyde in air. The purifying efficiency of the non-woven formaldehyde purifying wallpaper is larger than 97.5%. The non-woven formaldehyde purifying wallpaper can be widely applied to building interior decoration and has good economic benefits and social benefits.

Owner:沈阳领拓科技有限公司

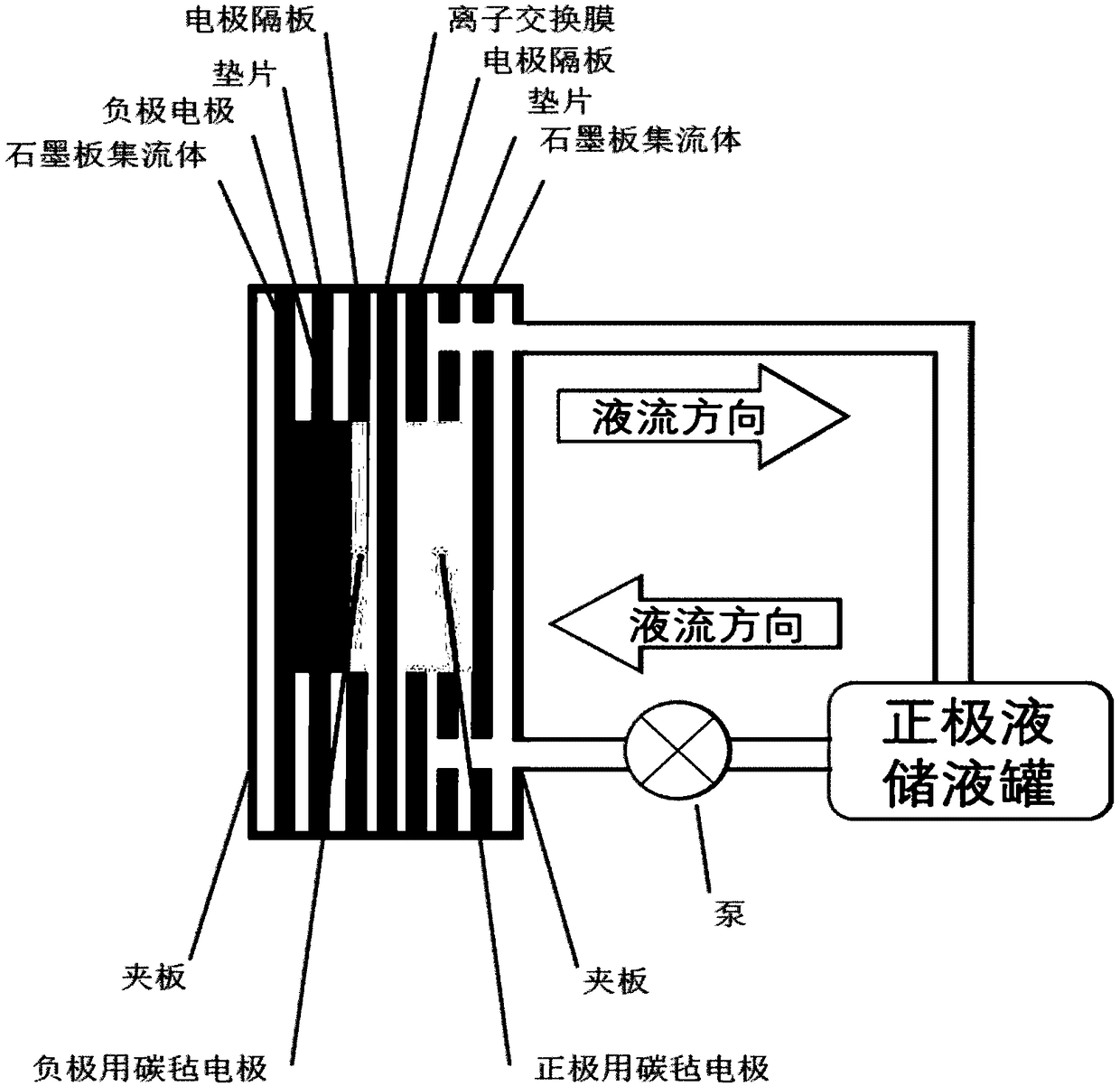

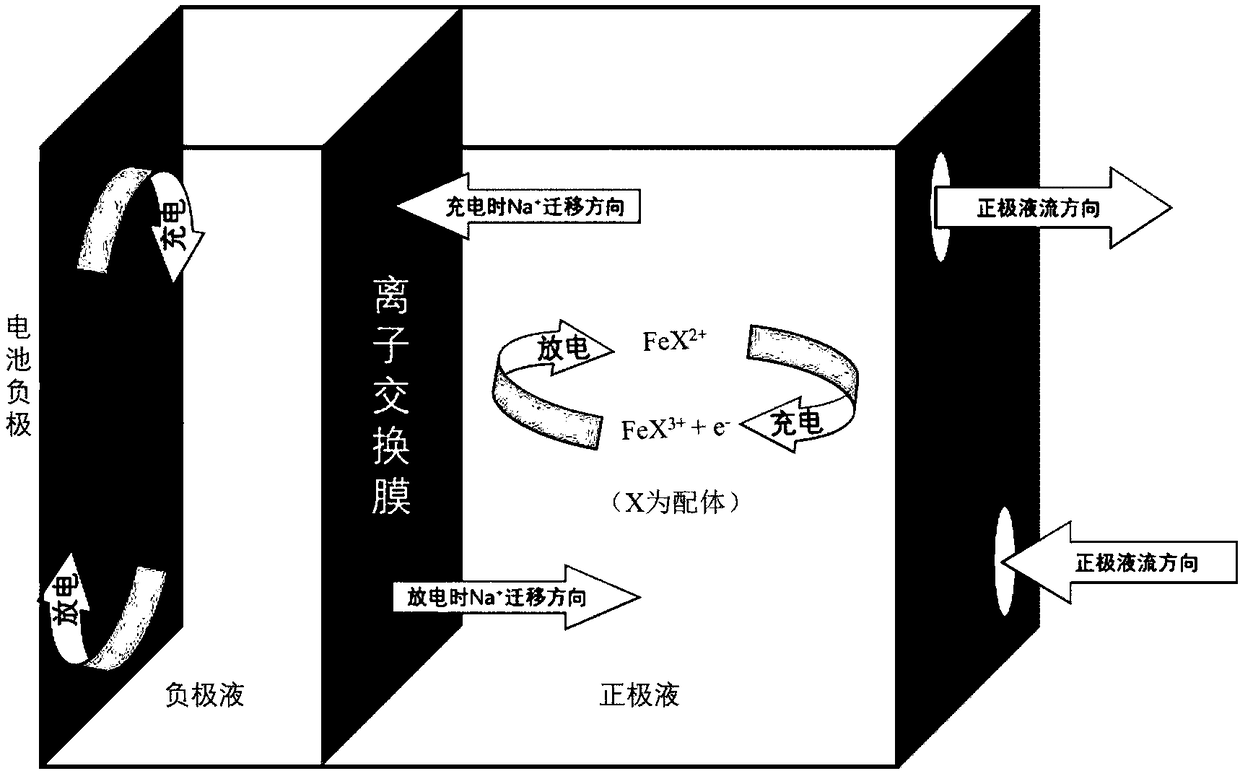

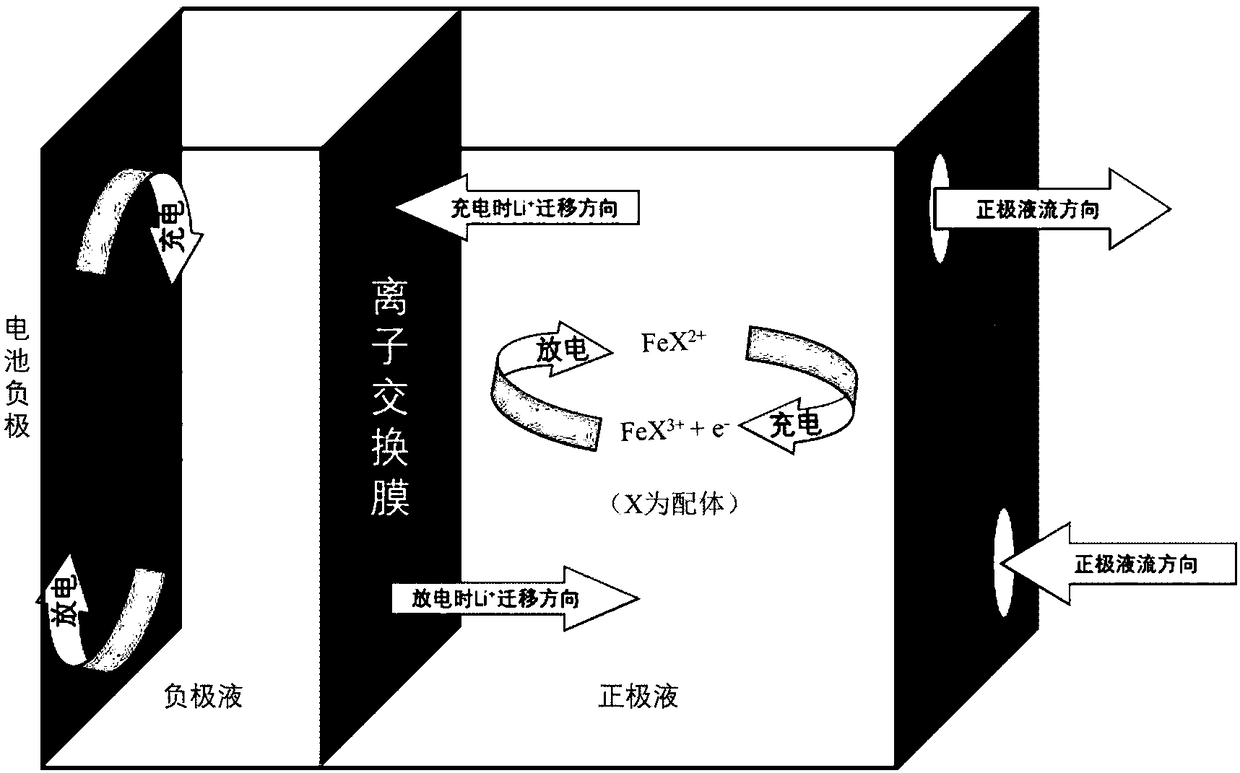

Semi-solid flow battery with ion-embedded solid negative electrode

InactiveCN108365246AImprove charge and discharge performanceExtended service lifeReactant parameters controlElectrolyte stream managementWater basedHigh energy

The invention belongs to the technical field of electrochemistry, and concretely relates to a semi-solid flow battery with an ion-embedded solid negative electrode. The system of the battery comprisesa sodium titanium phosphate or lithium titanium phosphate negative electrode, a negative electrode liquid composed of an aqueous solution containing one or two of a sodium ion and a lithium ion, an ion exchange membrane, and a positive electrode liquid formed by an aqueous solution containing an iron ion complex and one or two of the sodium ion and the lithium ion. The high-energy density solid-state water-based negative electrode material sodium titanium phosphate or lithium titanium phosphate is adopted to replace a liquid negative electrode in a traditional liquid flow battery, so the advantages of separate energy and power design, high safety and long cycle life of the liquid flow battery are kept; and the semi-solid flow battery is not limited by the concentration of a solute, so theenergy density of the negative side is greatly improved, and the impedance of the battery is greatly reduced, thereby the volumetric energy density, the mass energy density and the working efficiencyof a whole battery module are greatly improved.

Owner:FUDAN UNIV

Lithium-rich manganese-based material coated with lithium aluminum titanium phosphate and preparation method of lithium-rich manganese-based material

PendingCN107768631AImprove efficiencyImprove Coulombic efficiencyCell electrodesSecondary cellsNickel saltManganese

The invention discloses a lithium-rich manganese-based material coated with lithium aluminum titanium phosphate and a preparation method of the lithium-rich manganese-based material. The preparation method comprises the following steps: under the stirring condition, dropwise adding a mixed solution of ammonia water and sodium hydroxide into a mixed solution containing manganese salt, cobalt salt and nickel salt to obtain a hydroxyl precursor; then reacting the hydroxyl precursor with a proper amount of a lithium source to obtain a manganese-based lamellar lithium-rich oxide; adding one or moreof B2O3, BaCl2, PbCl2, CaCl2, KF, LiCl, Na2B4O7, Li2B4O7, LiBO2, Na2BO3, NaCl and KCl as fluxing agents in the sintering process; and finally, crushing the prepared manganese-based lamellar lithium-rich oxide. The lithium-rich manganese-based material coated with the titanium-aluminum phosphate, prepared by the prepared method disclosed by the invention, has the advantages of high specific capacity and excellent cyclic performance, in particular to the magnification performance and the charge-discharge coulomb efficiency of the lithium-rich manganese-based material; and in addition, the morphology of materials can be controlled by adjusting the sintering process and the use amount of the fluxing agents.

Owner:湖南桑瑞新材料有限公司

Preparation method and application of sodium titanium phosphate/carbon composition material

InactiveCN108461734AImprove electrochemical performanceCyclic stabilityMaterial nanotechnologyCell electrodesCarbon compositesSodium-ion battery

The invention relates to a preparation method of a sodium titanium phosphate / carbon composition material and application thereof in sodium ion batteries and belongs to the technical field of materials. The preparation method comprises the steps: firstly, preparing a sodium titanium phosphate precursor and polyvinyl pyrrolidone mixed solution according to a proportion; then electrostatically spinning the mixed solution to prepare a carbon coated sodium titanium phosphate fiber precursor and drying the carbon coated sodium titanium phosphate fiber precursor; finally, calcining for 2 to 8 hours under a constant temperature of 700 to 900 DEG C to prepare the sodium titanium phosphate / carbon composition material. The size of sodium titanium phosphate in the composition material prepared by thepreparation method disclosed by the invention is 15 to 25nm, the diameter of the carbon based fiber is 200 to 250nm, electrochemical performance is greatly improved by a porous nano fiber structure, and the composition material can stably circulate for 500 to 1000 turns under the 500mA / g current density and further has high specific capacity. The preparation method disclosed by the invention has the advantages of simpleness and easiness in operation, small energy consumption, low manufacturing cost, high industrial degree, high stability and suitability for large-scale industrial production.

Owner:HUAZHONG UNIV OF SCI & TECH

Preparation method of carbon-coated mesoporous lithium titanium phosphate

The invention relates to a preparation method of carbon-coated mesoporous lithium titanium phosphate. The preparation method includes the following steps that firstly, titanate is dissolved in a mixed solution of butyl alcohol and absolute ethyl alcohol, and mixed liquor A is obtained; secondly, metal lithium salt and phytic acid are dissolved in distilled water, and mixed liquor B is obtained; thirdly, the mixed liquor B is dripped into the mixed liquor A with stirring at room temperature, stirring continues to be preformed for 1-2 h, and mixed liquor C is obtained; fourthly, the mixed liquor C is subjected to solid-liquid separation, an obtained solid is dried, and solid powder D is obtained; fifthly, the powder D is subjected to heat treatment in inert gas, and carbon-coated lithium titanium phosphate is obtained. Obtained carbon-coated mesoporous lithium titanium phosphate has a large specific surface area and an obvious mesoporous feature, which is beneficial to improving the electrochemical performance of carbon-coated mesoporous lithium titanium phosphate used as a lithium battery electrode material.

Owner:济南智和弘盛光电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com