High-nickel ternary positive electrode material coated with lithium aluminum titanium phosphate and preparation method thereof

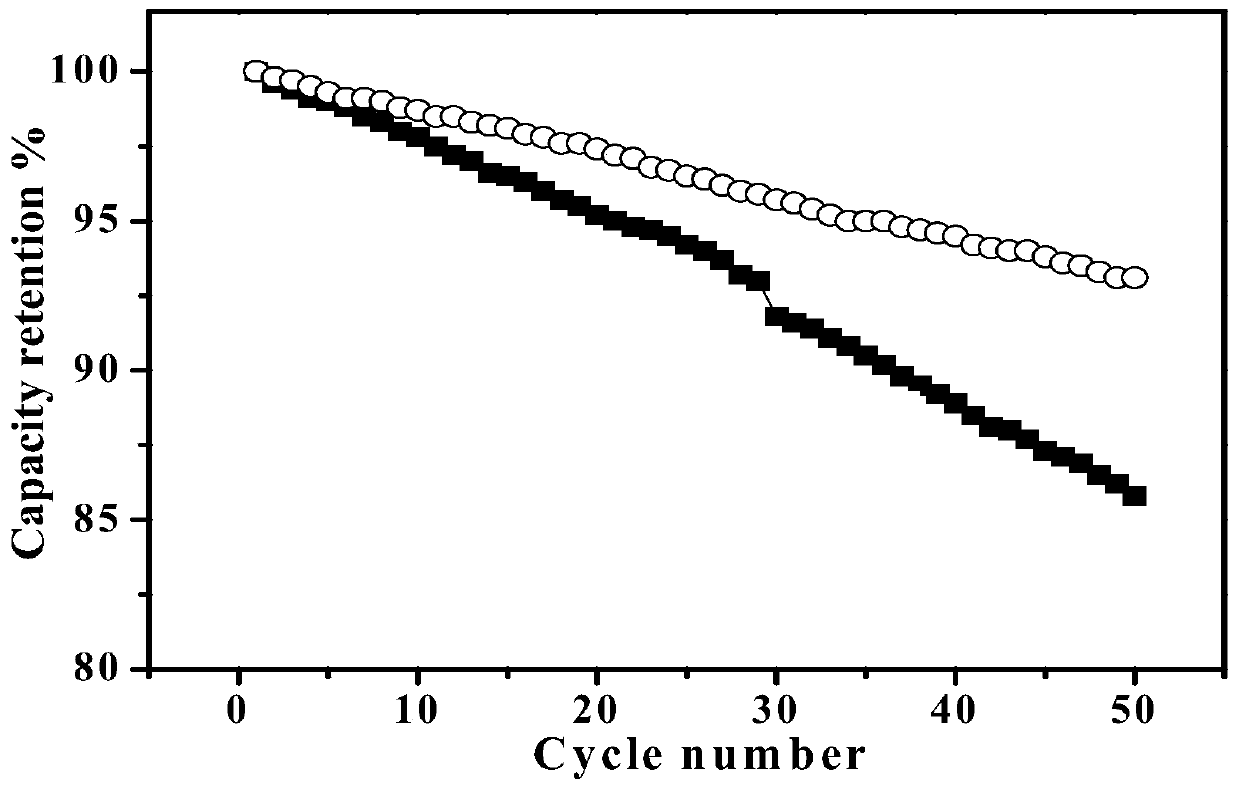

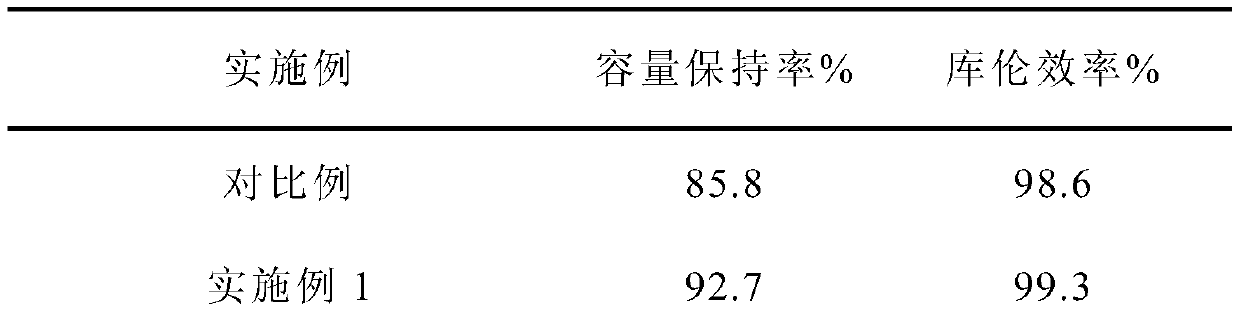

A technology of lithium aluminum titanate phosphate and cathode material, applied in the direction of positive electrodes, electrical components, battery electrodes, etc., can solve the problem that the battery cycle performance cannot be effectively improved, so as to improve the capacity retention rate, inhibit micro-cracks, and inhibit the capacity. the effect of decay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A preparation method of a high-nickel ternary positive electrode material coated with titanium aluminum phosphate, comprising the steps of:

[0022] (1) Preparation of Li 1.3 Al 0.3 Ti 1.7 (PO 4 ) 3 Coating solution: Weigh 0.013mol LiNO according to the number of moles 3 , 0.003mol Al(NO 3 ) 3 9H 2 O, 0.017mol tetrabutyl titanate and 0.03mol tributyl phosphate; the above LiNO 3 , Al(NO 3 ) 3 9H 2O. Tetrabutyl titanate and tributyl phosphate were added to 30 mL of ethanol and mixed evenly, heated at 80° C. and stirred for 30 min to obtain the first mixed solution; 0.016 mol ethylenediamine tetraacetic acid and 0.0224 mol citric acid were weighed by moles, and EDTA and citric acid were added to 10ml ethanol and mixed uniformly to obtain a second mixed solution; the second mixed solution was poured into the first mixed solution and stirred to obtain 52.6gLi 1.3 Al 0.3 Ti 1.7 (PO 4 ) 3 Coating solution, where Li 1.3 Al 0.3 Ti 1.7 (PO 4 ) 3 The number of...

Embodiment 2

[0026] A preparation method of a high-nickel ternary positive electrode material coated with titanium aluminum phosphate, comprising the steps of:

[0027] (1) Preparation of Li 1.3 Al 0.3 Ti 1.7 (PO 4 ) 3 Coating solution: Weigh 0.013mol LiNO according to the number of moles 3 , 0.003mol Al(NO 3 ) 3 9H 2 O, 0.017mol tetrabutyl titanate and 0.03mol tributyl phosphate; the above LiNO 3 , Al(NO 3 ) 3 9H 2 O. Tetrabutyl titanate and tributyl phosphate were added to 30 mL of ethanol and mixed evenly, heated at 80° C. and stirred for 30 min to obtain the first mixed solution; 0.016 mol ethylenediamine tetraacetic acid and 0.0224 mol citric acid were weighed by moles, and EDTA and citric acid were added to 10ml of ethanol and mixed uniformly to obtain a second mixed solution; the second mixed solution was poured into the first mixed solution and stirred to obtain 53.1g Li 1.3 Al 0.3 Ti 1.7 (PO 4 ) 3 Coating fluid.

[0028] (2) Preparation of Li[Ni 0.90 co 0.05 mn ...

Embodiment 3

[0031] A preparation method of a high-nickel ternary positive electrode material coated with titanium aluminum phosphate, comprising the steps of:

[0032] (1) Preparation of Li 1.3 Al 0.3 Ti 1.7 (PO 4 ) 3 Coating solution: Weigh 0.013mol LiNO according to the number of moles 3 , 0.003mol Al(NO 3 ) 3 9H 2 O, 0.017mol tetrabutyl titanate and 0.03mol tributyl phosphate; the above LiNO 3 , Al(NO 3 ) 3 9H 2 O. Tetrabutyl titanate and tributyl phosphate were added to 30 mL of ethanol and mixed evenly, heated at 80° C. and stirred for 30 min to obtain the first mixed solution; 0.016 mol ethylenediamine tetraacetic acid and 0.0224 mol citric acid were weighed by moles, and EDTA and citric acid were added to 10ml ethanol and mixed uniformly to obtain a second mixed solution; the second mixed solution was poured into the first mixed solution and stirred to obtain 55.2gLi 1.3 Al 0.3 Ti 1.7 (PO 4 ) 3 Coating fluid.

[0033] (2) Preparation of Li[Ni 0.90 co 0.05 mn 0.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com