Water-based sodium ion total battery based on nickel prussian blue positive electrode material and preparation method and application thereof

A Prussian blue and cathode material technology, applied in the field of aqueous sodium-ion full batteries and their preparation, can solve the problems of limited lithium resource reserves, environmental pollution, and inability to support the application requirements of large-scale power storage systems, and achieve excellent electrochemical performance, The effect of wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

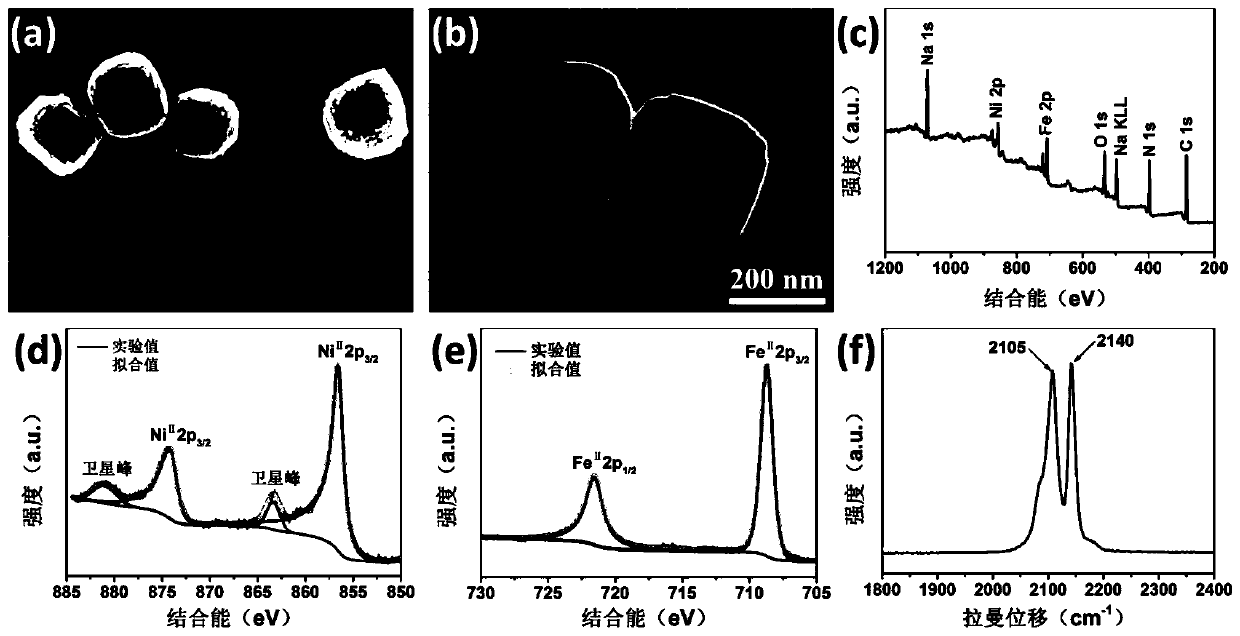

[0051] Synthesis of nickel Prussian blue positive electrode material: 5mmol nickel chloride hexahydrate and 25mmol sodium citrate dihydrate were dissolved in 50mL deionized water to form solution A; 5mmol sodium ferrocyanide decahydrate was dissolved in 50mL deionized water to Solution B was formed; solution C was formed by dissolving 5 g of polyvinylpyrrolidone and 10 g of sodium chloride in 100 mL of deionized water. Then, solutions A and B were slowly added dropwise to solution C simultaneously. After continuously stirring for 5 hours at room temperature and aging for 24 hours, the precipitate was centrifuged, washed with deionized water and ethanol three times each, and finally dried in a vacuum oven to obtain the obtained product.

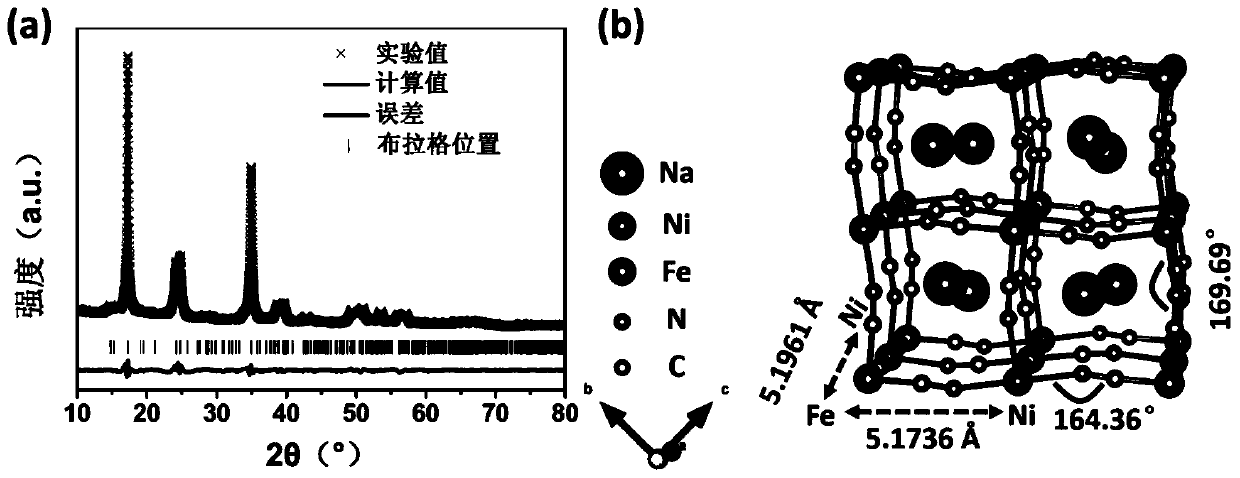

[0052] The phase characterization of the prepared nickel Prussian blue cathode material was carried out, and the results were as follows: figure 1 As shown in a, the XRD pattern of the nickel Prussian blue cathode material splits at 24.5°, 39...

Embodiment 2

[0056] Synthesis of carbon-coated sodium titanium phosphate negative electrode material: first slowly add 4mmol tetrabutyl titanate into 40mL ethylene glycol and vigorously stir to form solution A. 2mmol sodium dihydrogen phosphate, 4mmol phosphoric acid and 2mmol glucose were dissolved in 40mL deionized water to form solution B, which was poured into solution A and stirred continuously for 1h. Then the above mixed solution was transferred to a 100 mL autoclave for 12 h at 180 °C. After the reaction was completed, the solution was evaporated to dryness at 120° C. in a blast drying oven. Finally, the evaporated residue was preheated at 350° C. for 2 h in an argon atmosphere, and annealed at 700° C. for 4 h to obtain the obtained product.

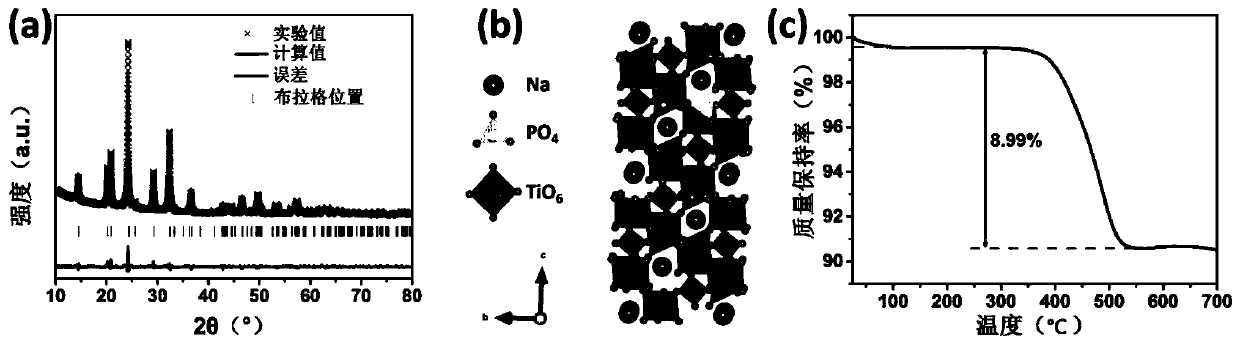

[0057] The phase characterization of the prepared carbon-coated sodium titanium phosphate anode material was carried out, and the results were as follows: image 3 As shown in a, the XRD pattern shows that all diffraction peaks point to the...

Embodiment 3

[0061] The nickel Prussian blue positive electrode material prepared in Example 1 was mixed with a conductive agent (Ketjen black powder) and a binder (60% polyperfluoroethylene dispersion) in a mass ratio of 7:2:1 to make a slurry, Add ethanol solvent to grind and mix to obtain a mixed solution, and use a roller press to load the mixed solution on a stainless steel current collector to make a positive electrode sheet; follow the same method to replace the nickel Prussian blue positive electrode material prepared in Example 2 with carbon-coated titanium phosphate Negative sheet was prepared after sodium negative electrode material.

[0062] The electrochemical performance of the electrode sheet was tested in a three-electrode system. The electrode sheet was used as the working electrode, the activated carbon electrode sheet was used as the auxiliary electrode, and the Ag / AgCl electrode was used as the reference electrode. -1 NaClO 4 The solution was tested using an electroche...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com