Patents

Literature

61results about "Metal cyanides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

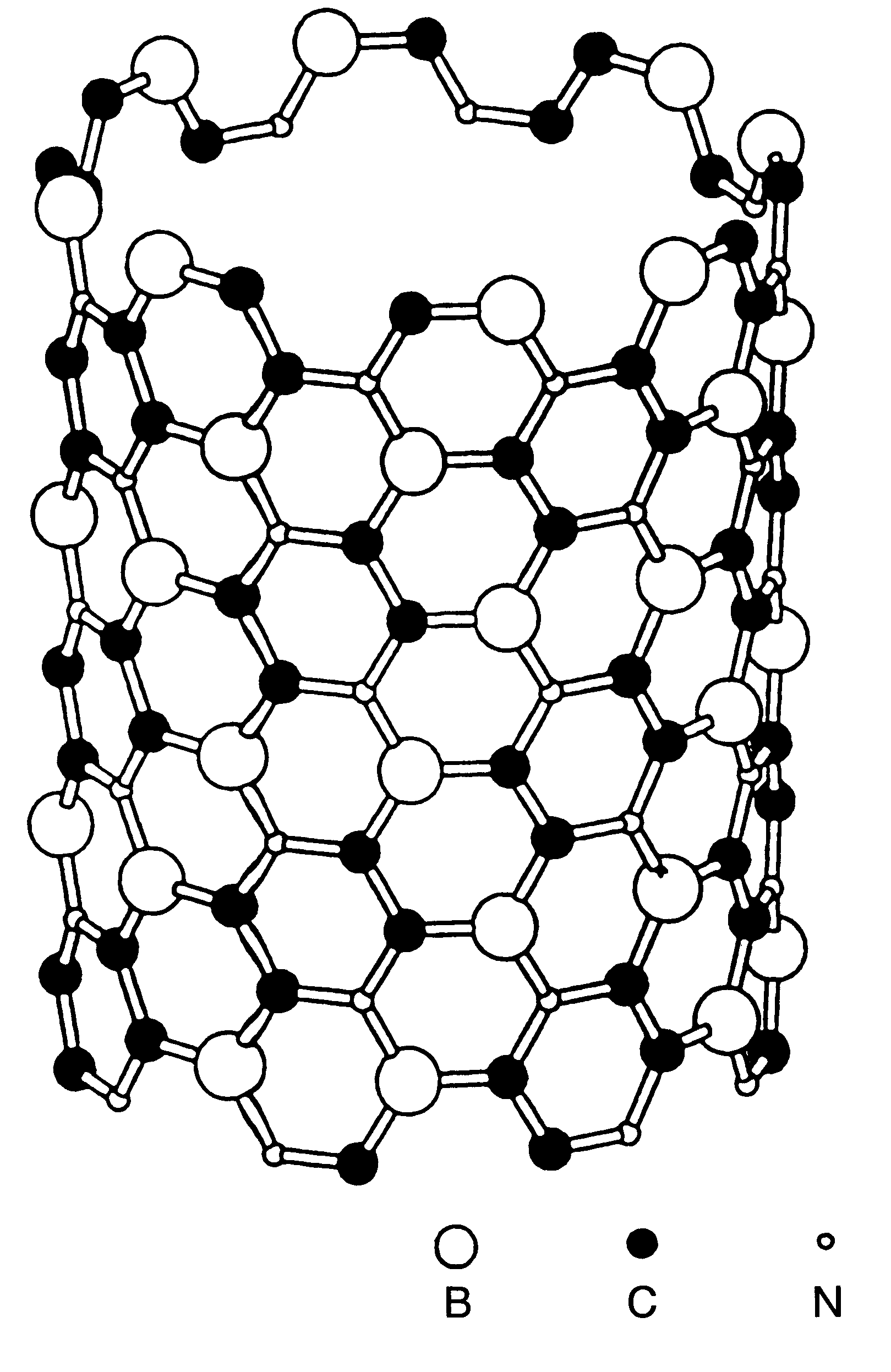

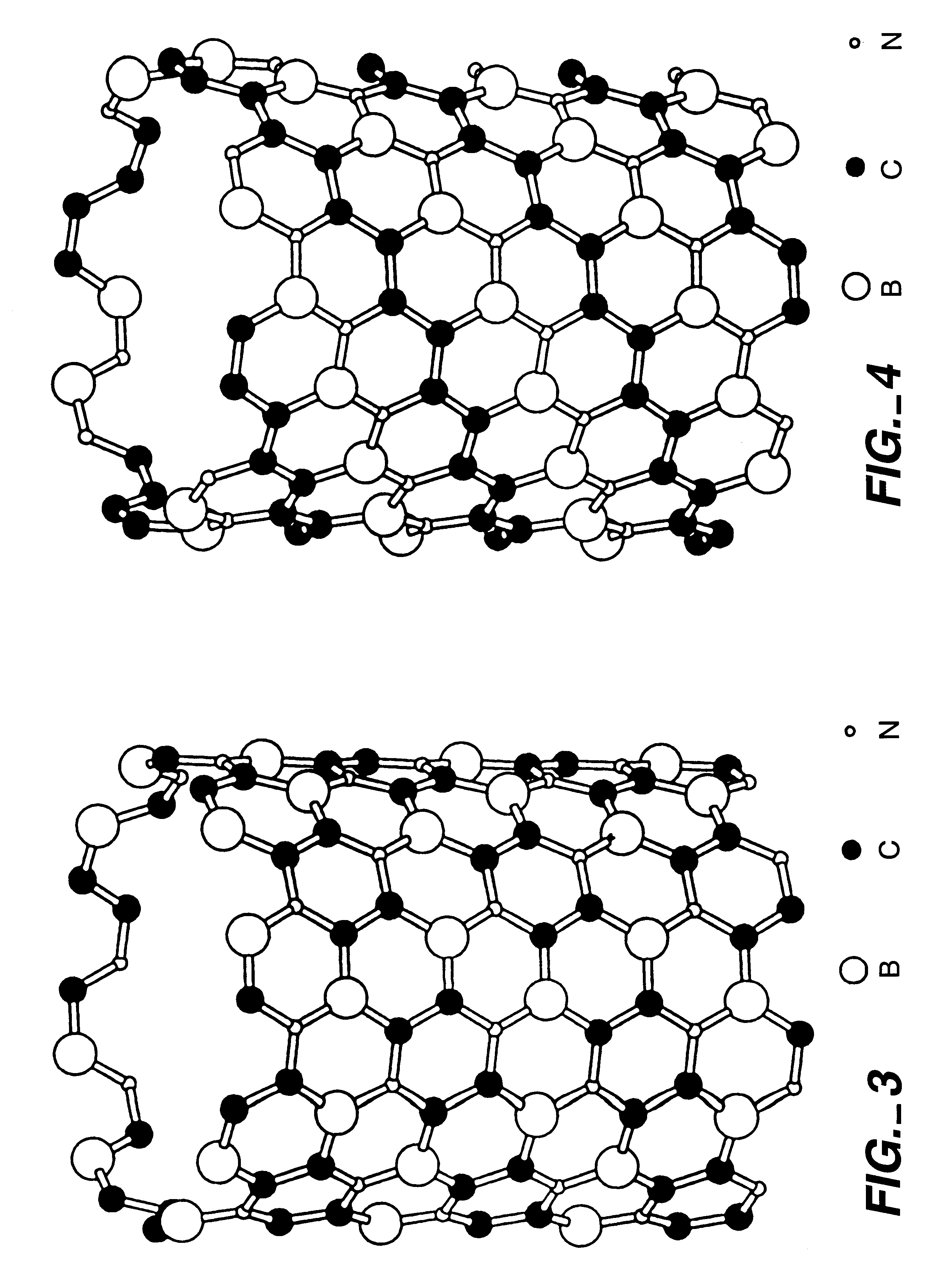

BX CY NZ nanotubes and nanoparticles

Owner:RGT UNIV OF CALIFORNIA

Delayed-Setting Calcium Phosphate Pastes

ActiveUS20080028992A1Easy injectionReduce the ratioBiocideData processing applicationsCalcium biphosphateDelivery vehicle

Owner:ETEX

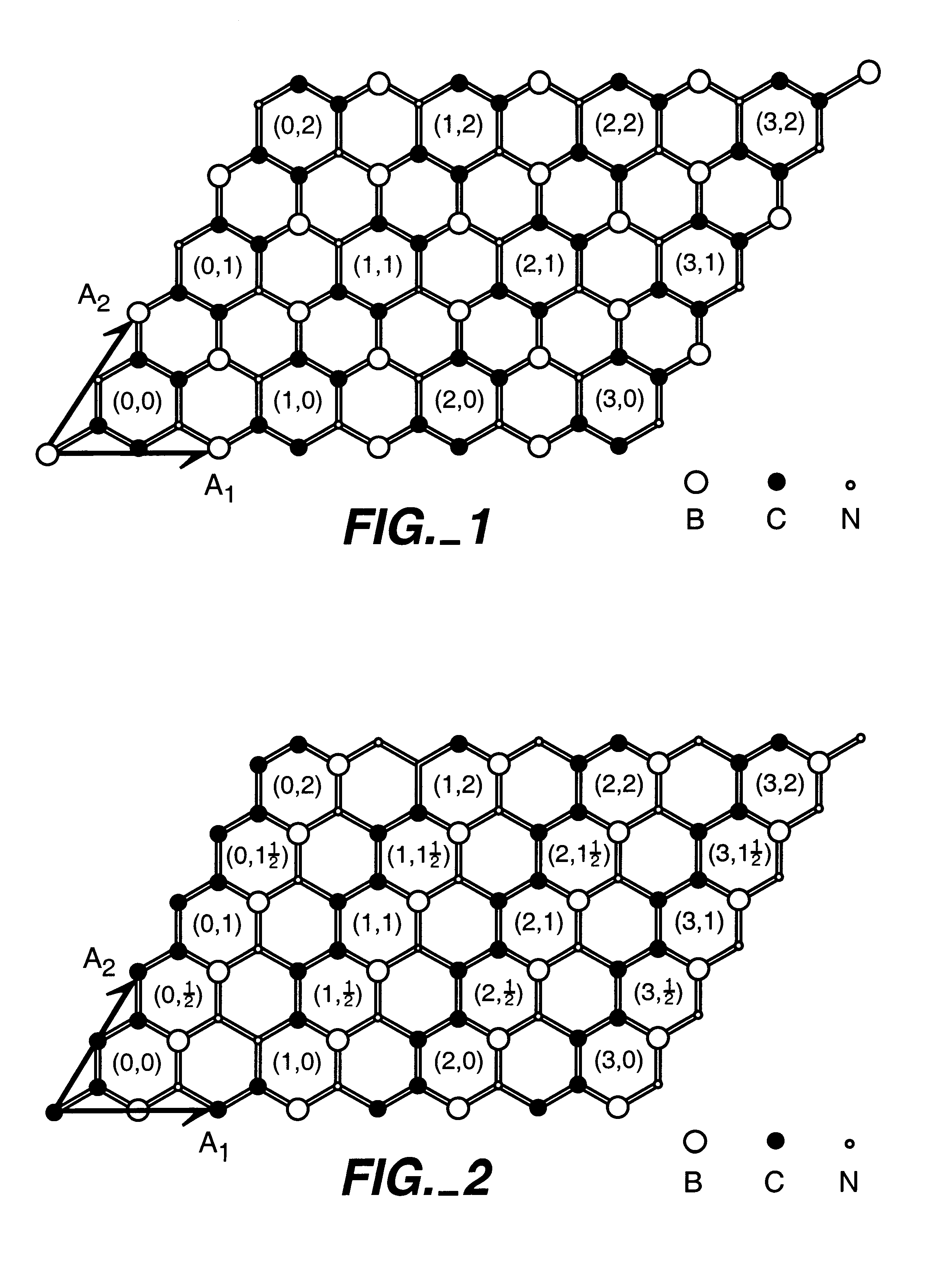

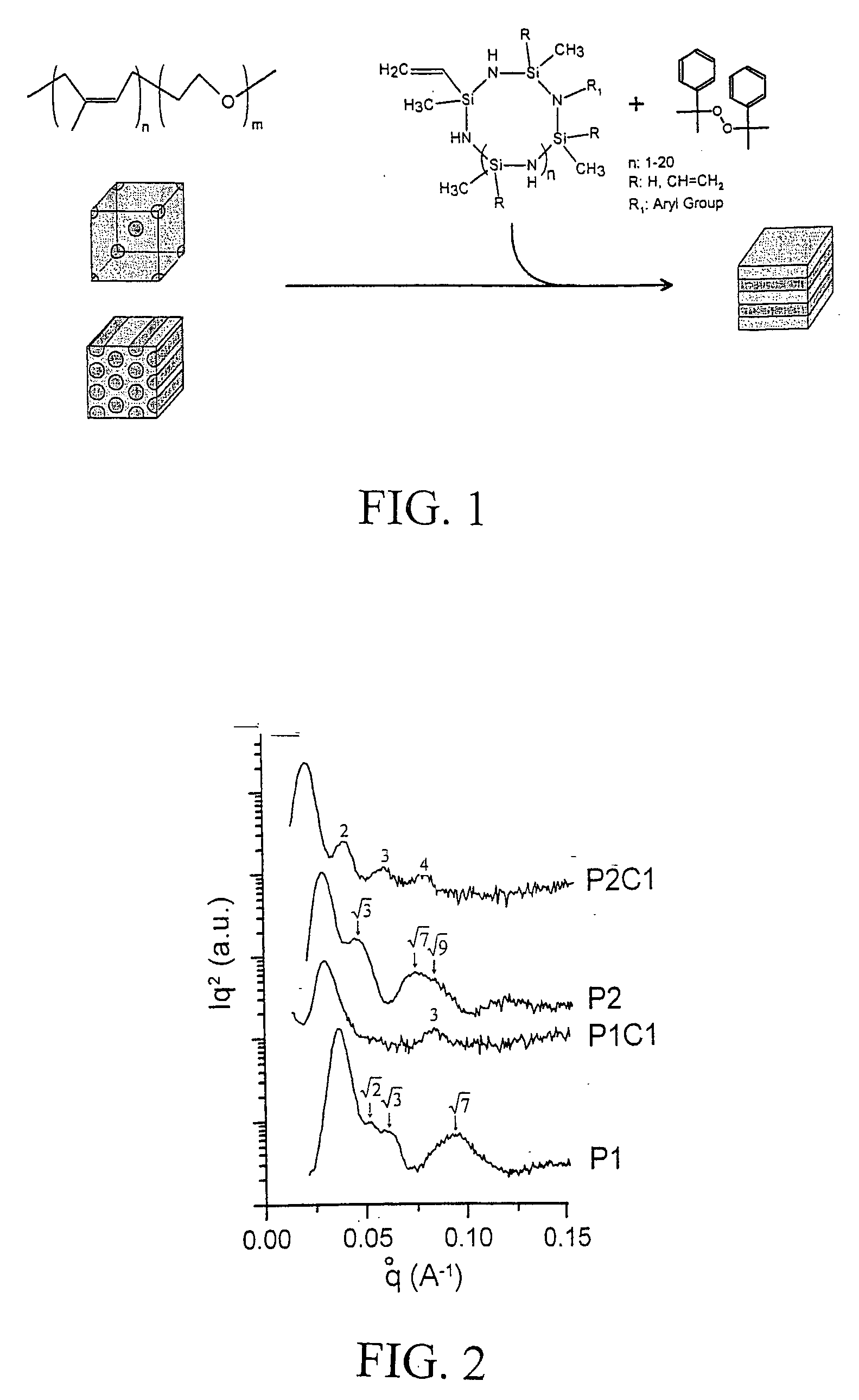

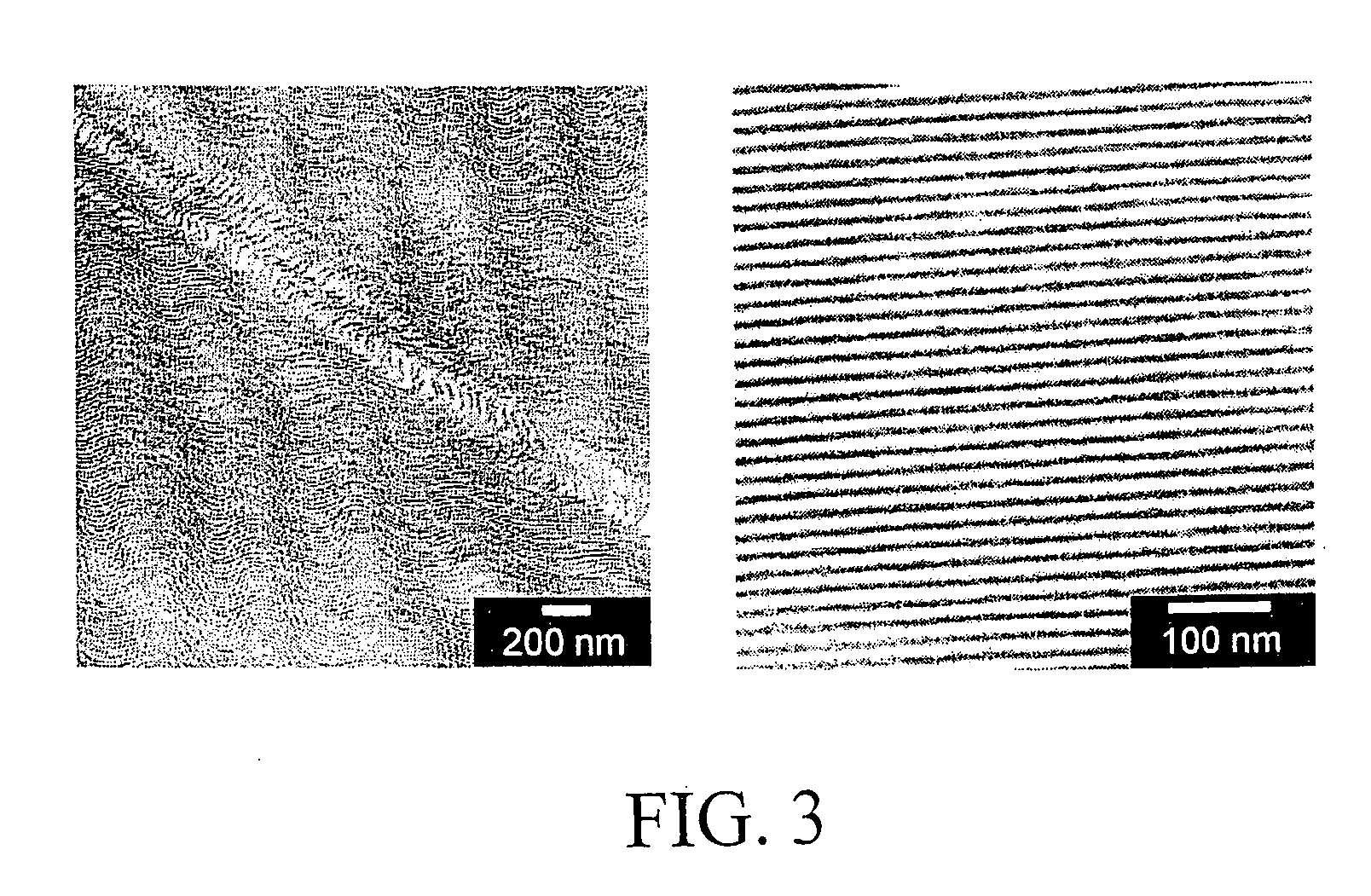

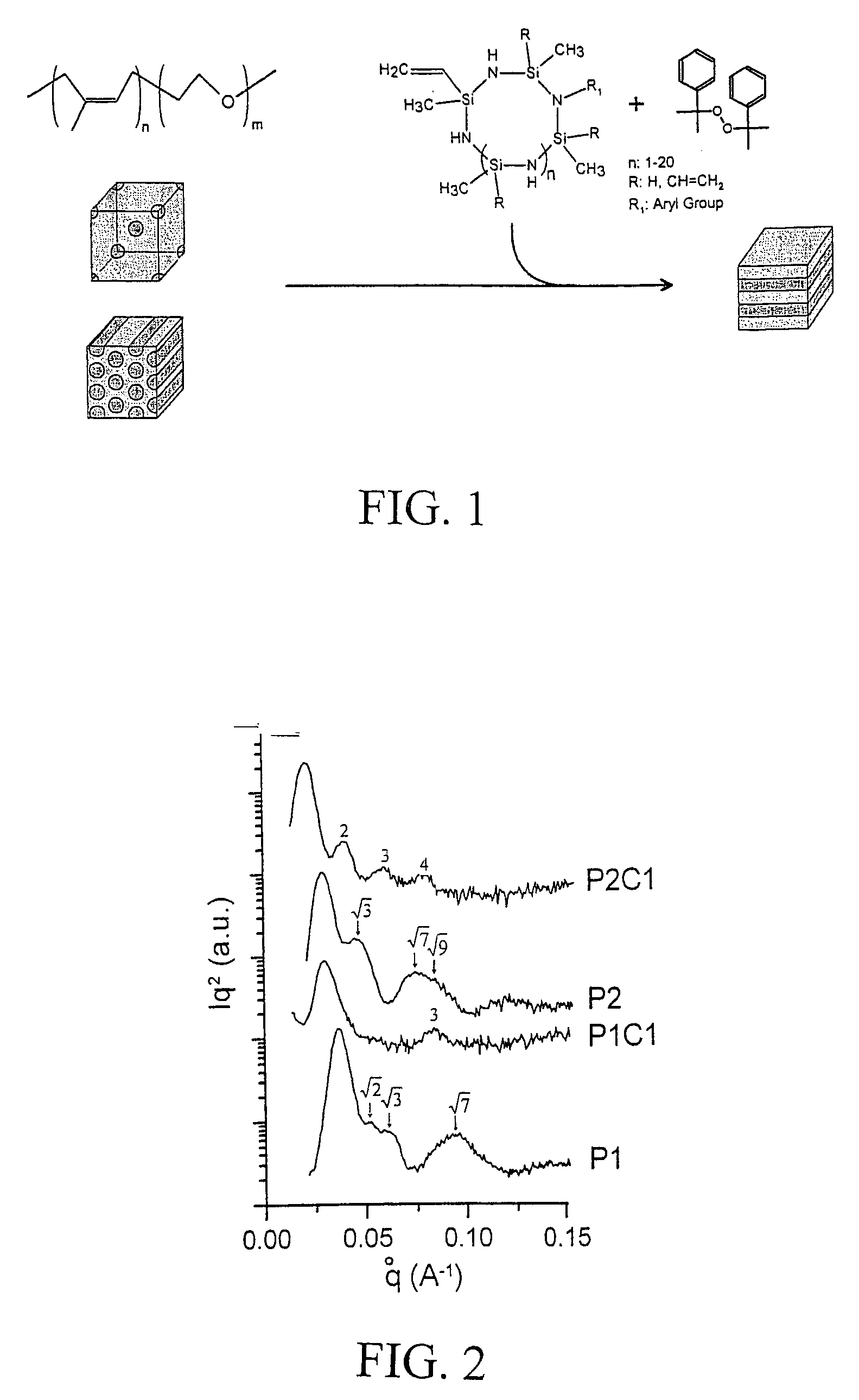

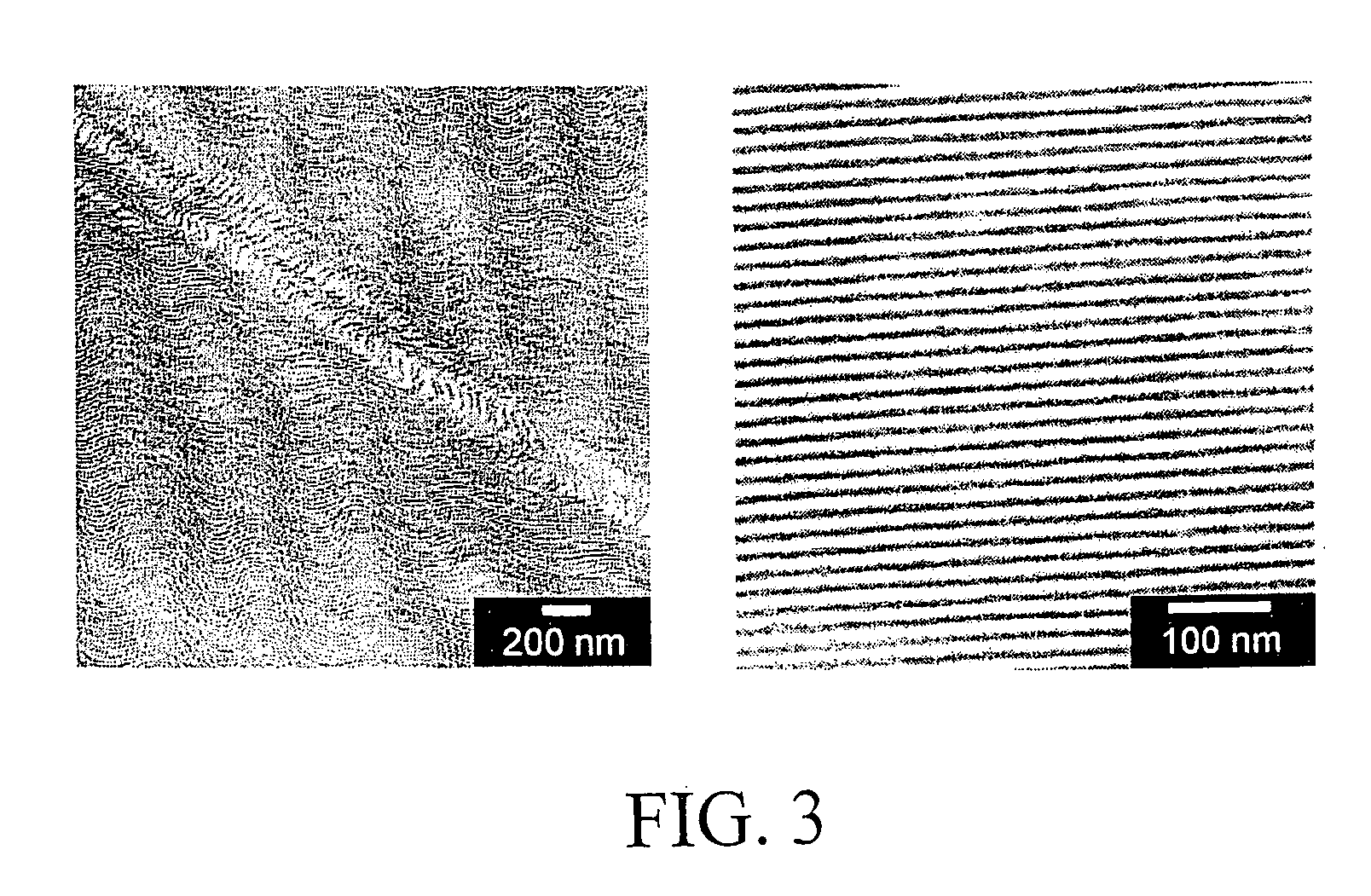

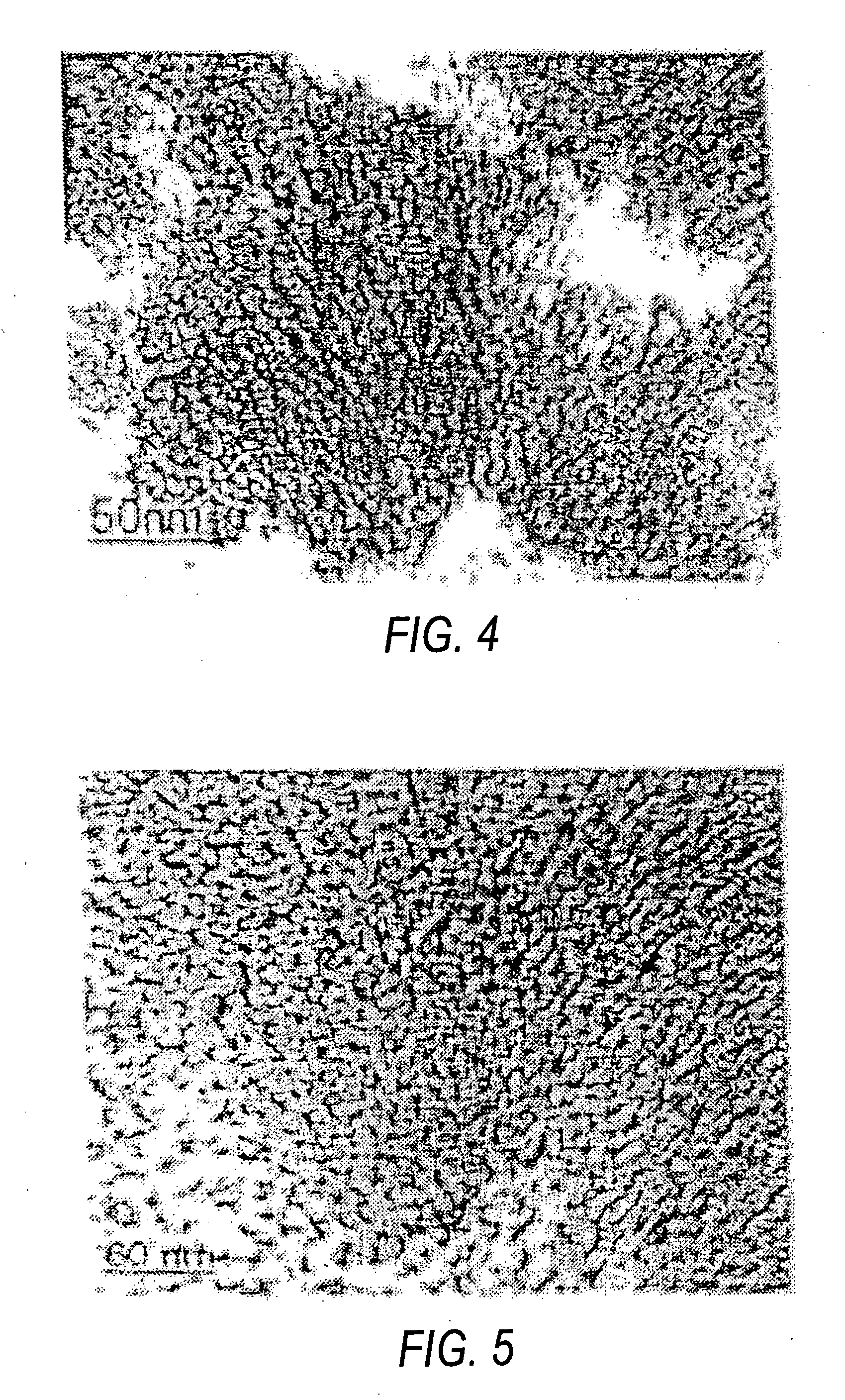

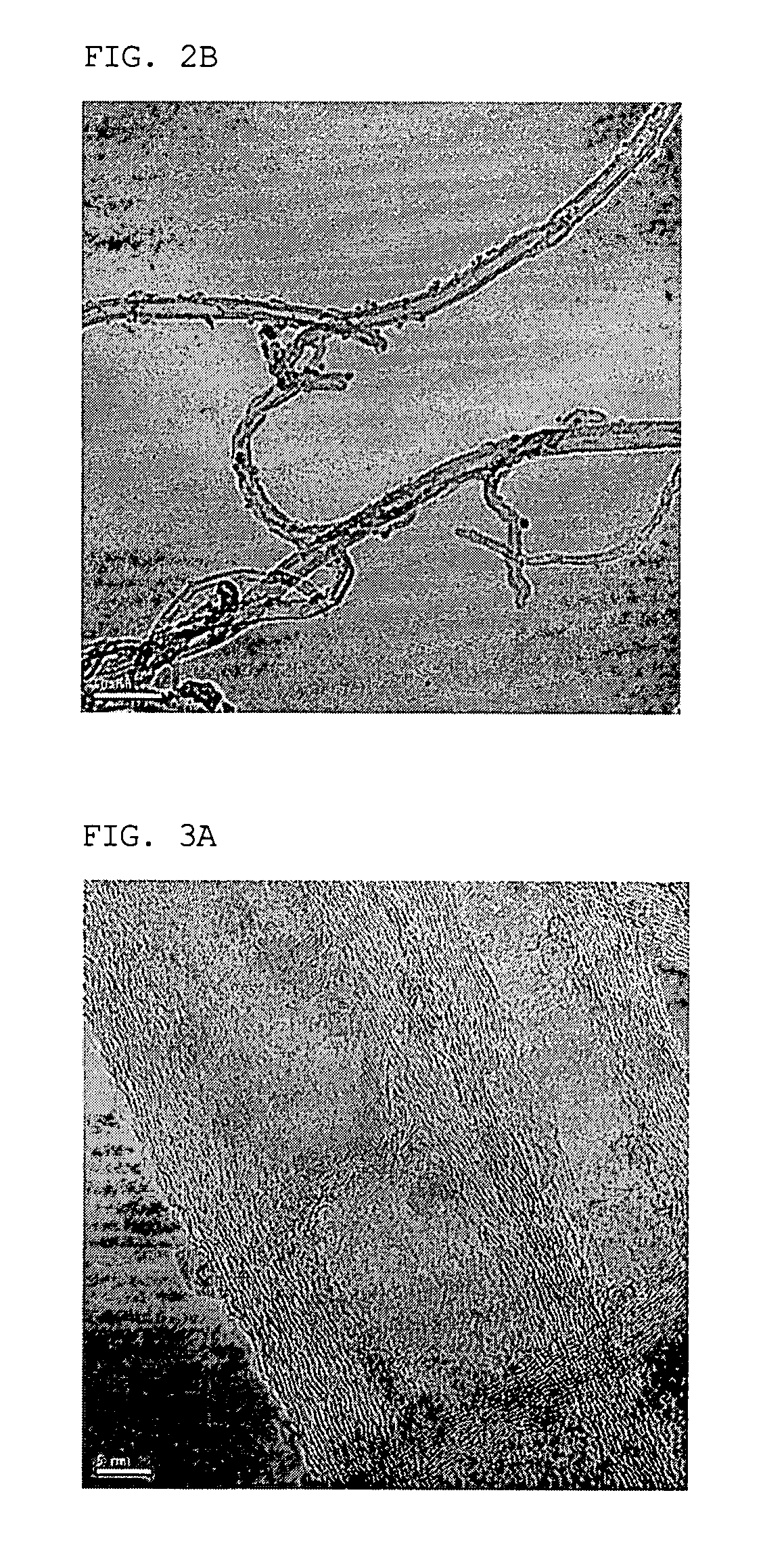

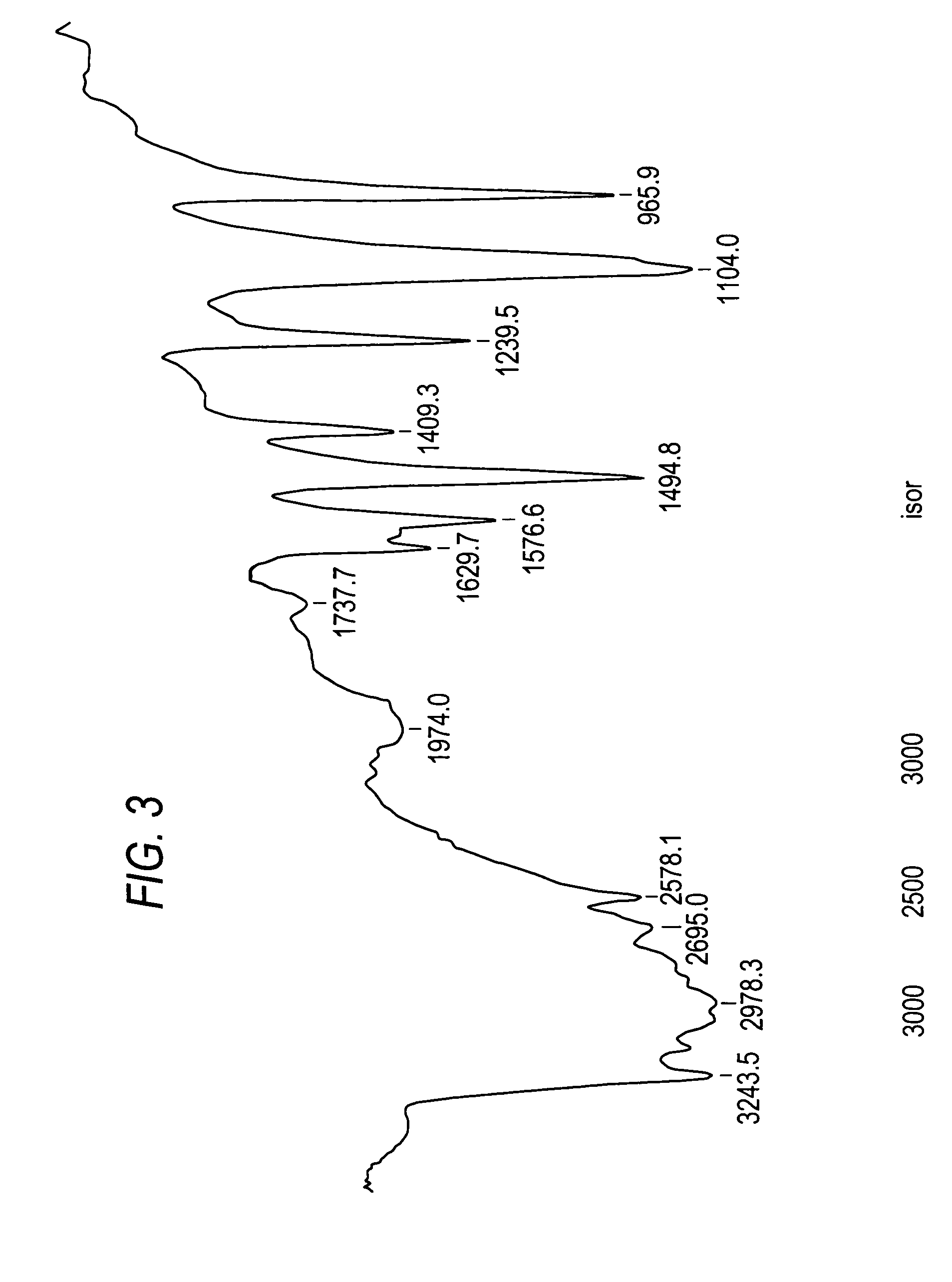

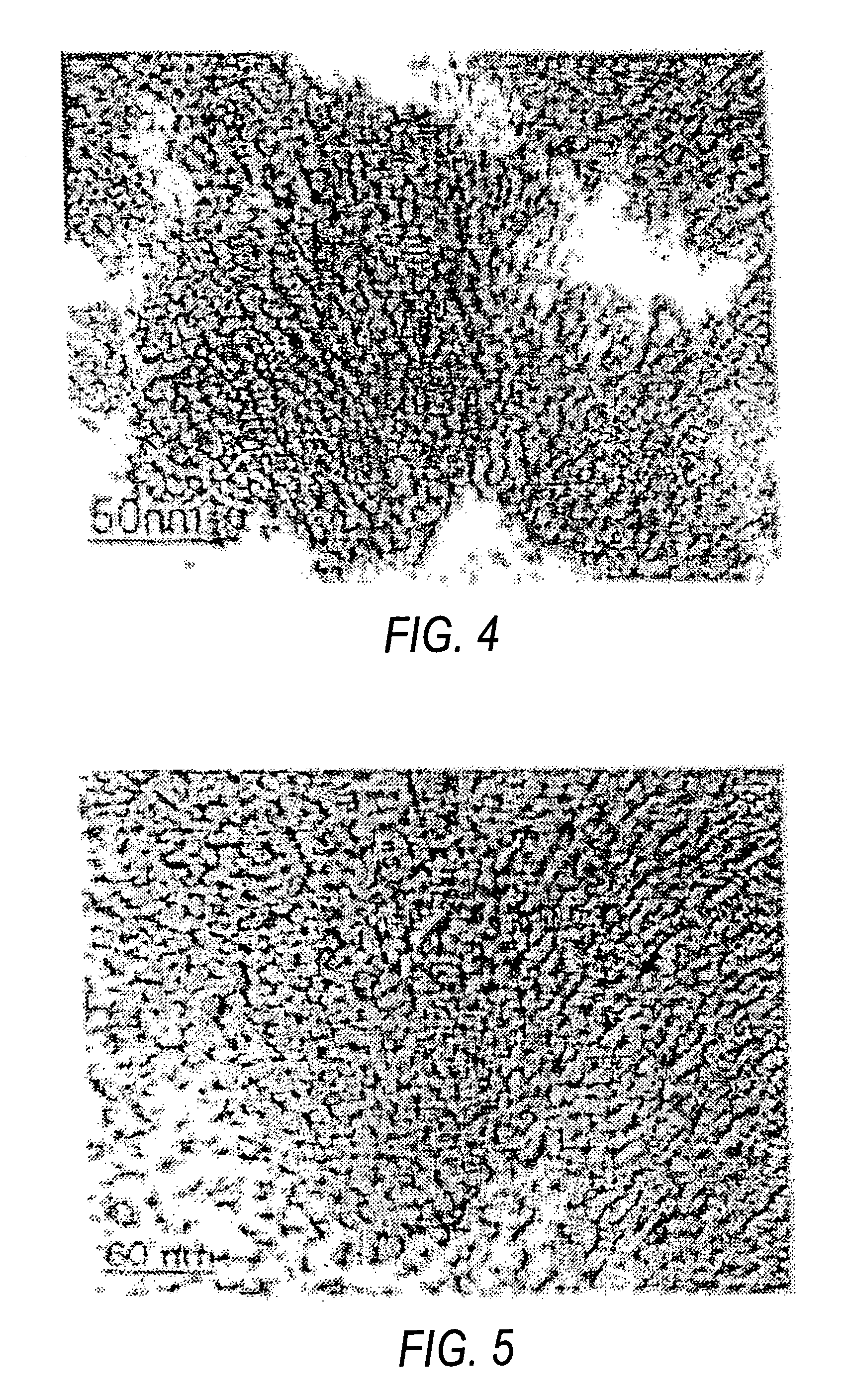

High temperature SiCN and SiC-type nanostructured ceramic material from block copolymer mesophases

InactiveUS20050036931A1Simple and easily controlled pathwayCarbon compoundsNitrogen and non-metal compoundsNon oxide ceramicsPolymer science

A block copolymer, preferably a block copolymer such as poly(isoprene-block-ethylene oxide), PI-b-PEO, is used as a structure directing agent for a polymer derived ceramic (PDC) precursor, preferably a silazane, most preferably a silazane commercially known as Ceraset. The PDC precursor is preferably polymerized after mixing with the block copolymer to form a nanostructured composite material. Through further heating steps, the nanostructured composite material can be transformed into a nanostructured non-oxide ceramic material, preferably a high temperature SiCN or SiC material.

Owner:CORNELL RES FOUNDATION INC

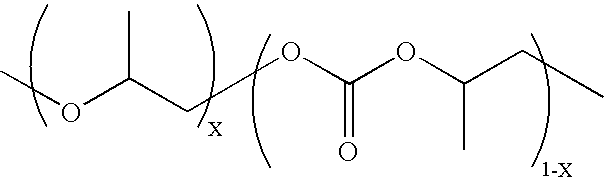

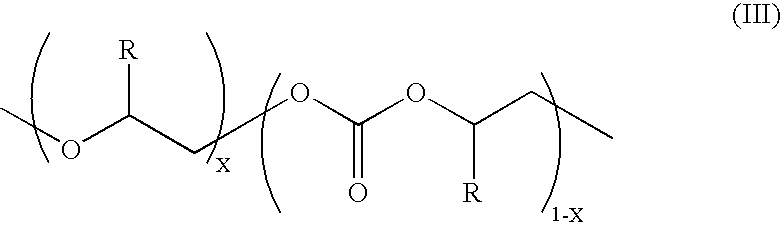

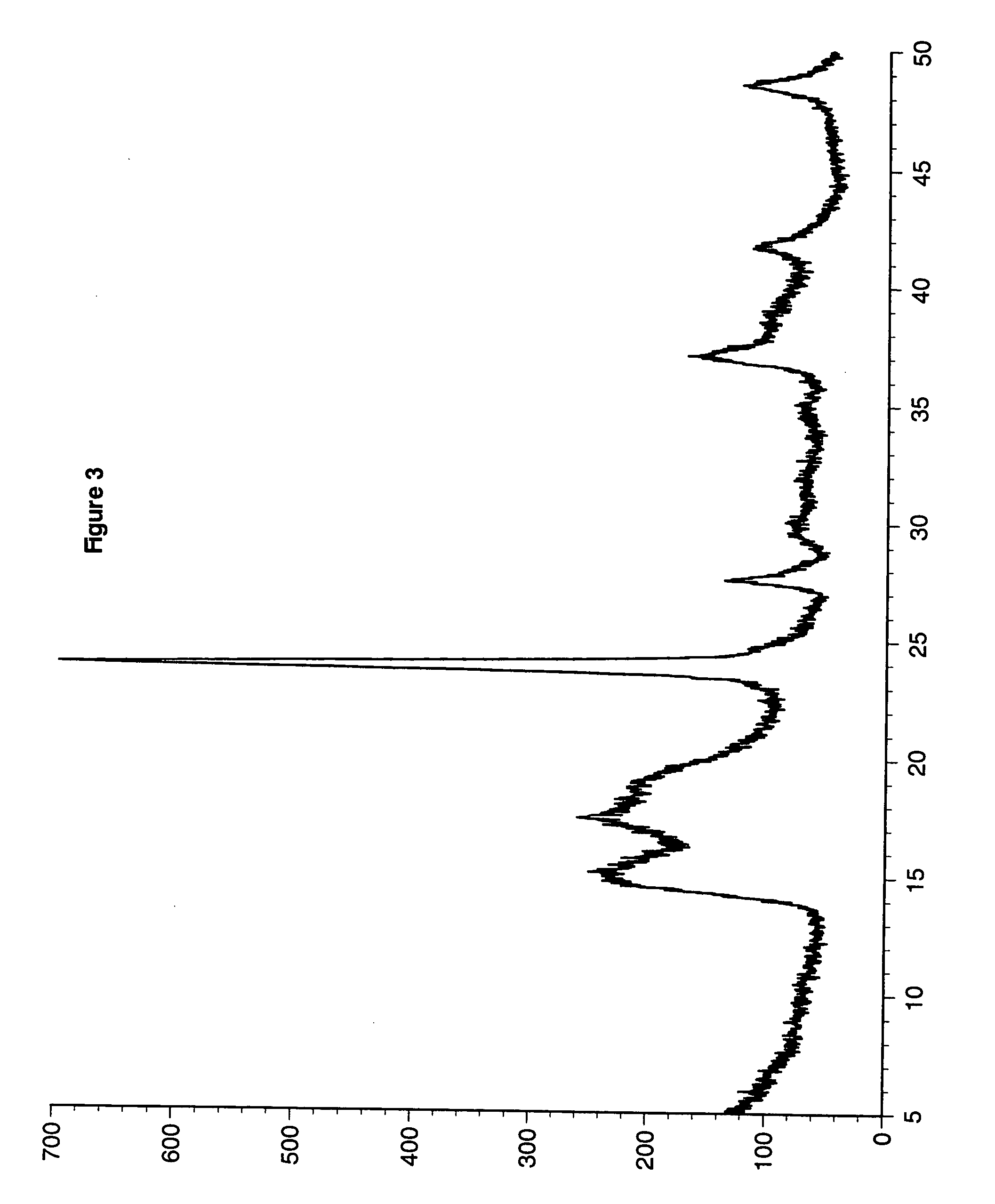

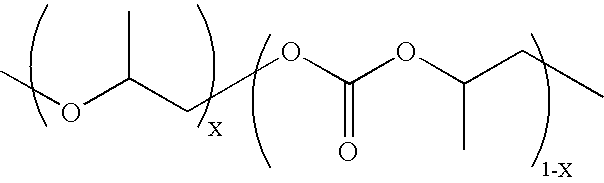

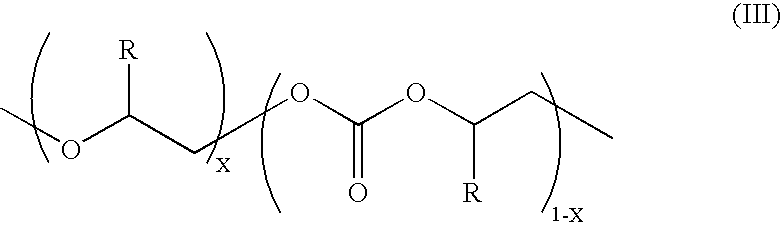

Copolymerization of propylene oxide and carbon dioxide and homopolymerization of propylene oxide

Copolymers of propylene oxide and carbon dioxide and homopolymers of propylene oxide are made using two dimensional double metal cyanide complexes having the formula Co[M(CN)4] or hydrated or partially dehydrated form thereof. There is no propylene carbonate by product in the copolymerization.

Owner:CORNELL RES FOUNDATION INC

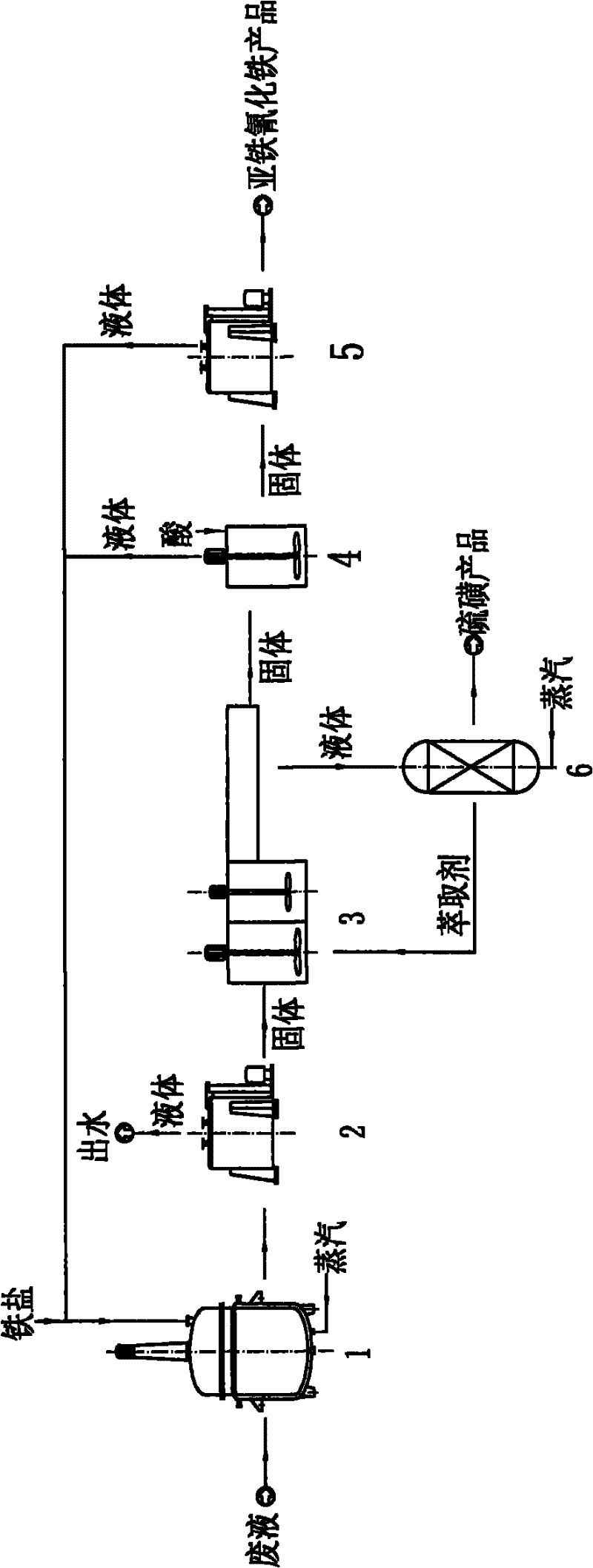

A method for recycling coke oven gas desulfurization and decyanation waste liquid by vacuum potassium carbonate method

ActiveCN102267769AMeet the requirements of biochemical treatmentMultistage water/sewage treatmentMetal cyanidesHigh concentrationProcess equipment

The invention discloses a vacuum potassium carbonate method for utilizing coke oven coal gas desulphurization and decyanation waste liquid recycling as a resource. The method is also suitable to be used in other waste liquids containing high concentration cyanide and sulfide. According to the method, cyanide and sulfide are simultaneously precipitated; the precipitate is separated by centrifugation; the waste liquid processed from desulphurization and decyanation is processed through pH regulation and coagulant dosing; the processed waste liquid is discharged into a carbonization wastewater biochemical treatment system, and is treated; ferrocyanide precipitate is subject to a reaction with added lye in a high temperature, and is converted into potassium ferrocyanide; potassium ferrocyanide is disoluted, and is separated by centrifugation, such that potassium ferrocyanide mother liquor is obtained; potassium ferrocyanide mother liquor is cooled and crystallized, such that potassium ferrocyanide product is obtained. The method has advantages of simple equipment and convenient operation. With the method, simultaneous desulphurization and decyanation can be realized, requirements of subsequent treatments are satisfied, the wastes are utilized as resources, and economic benefits are brought in.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

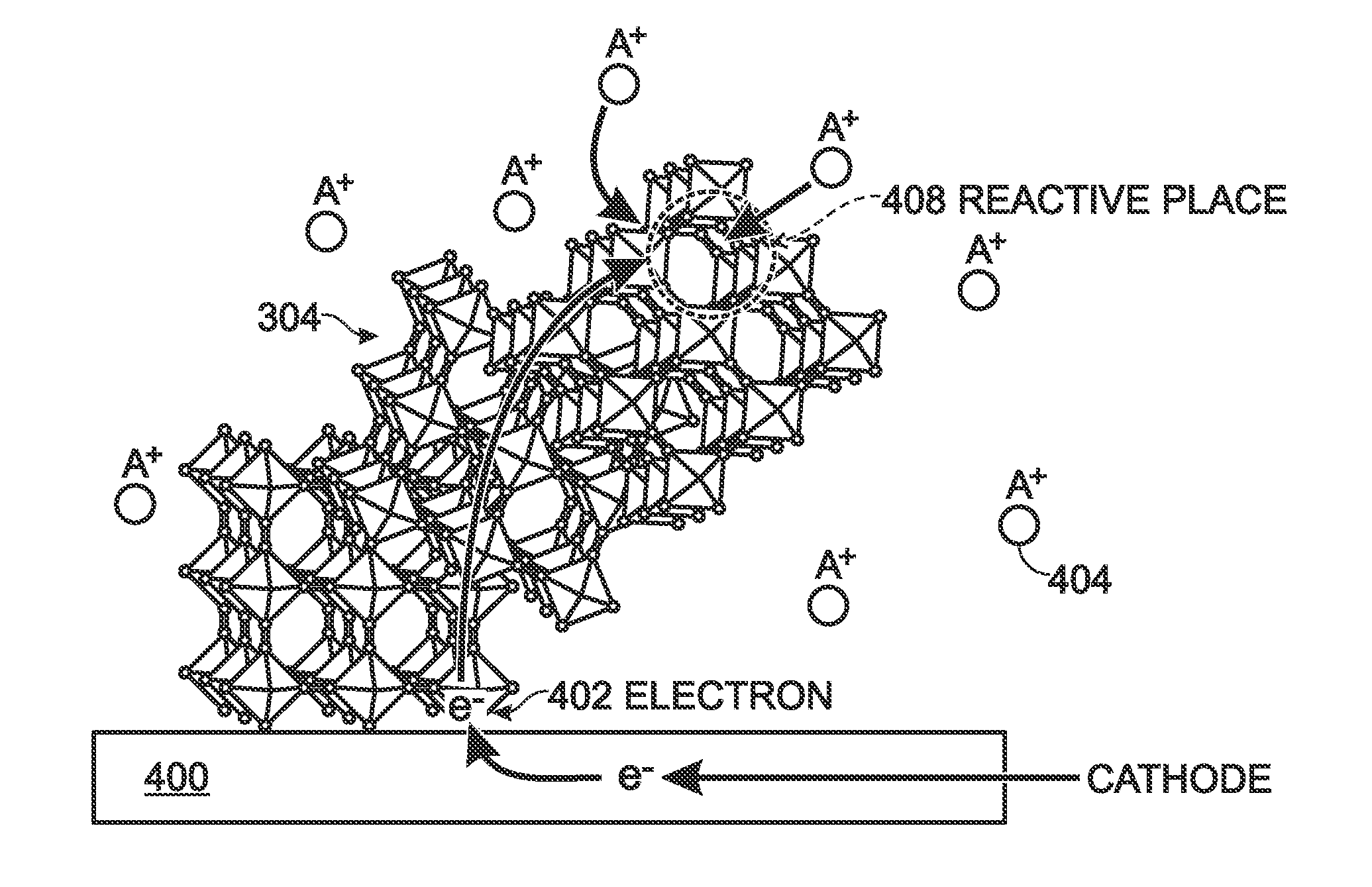

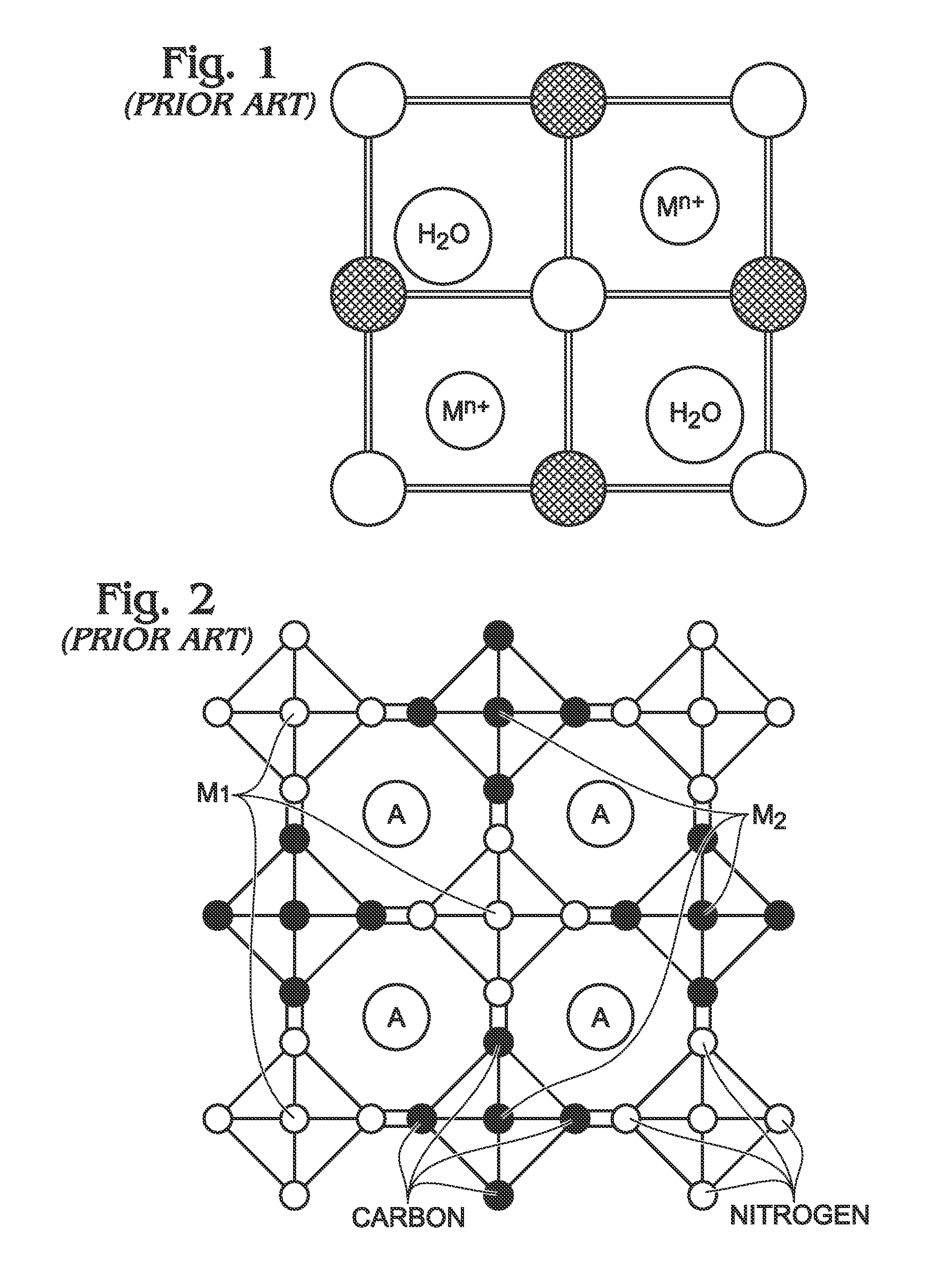

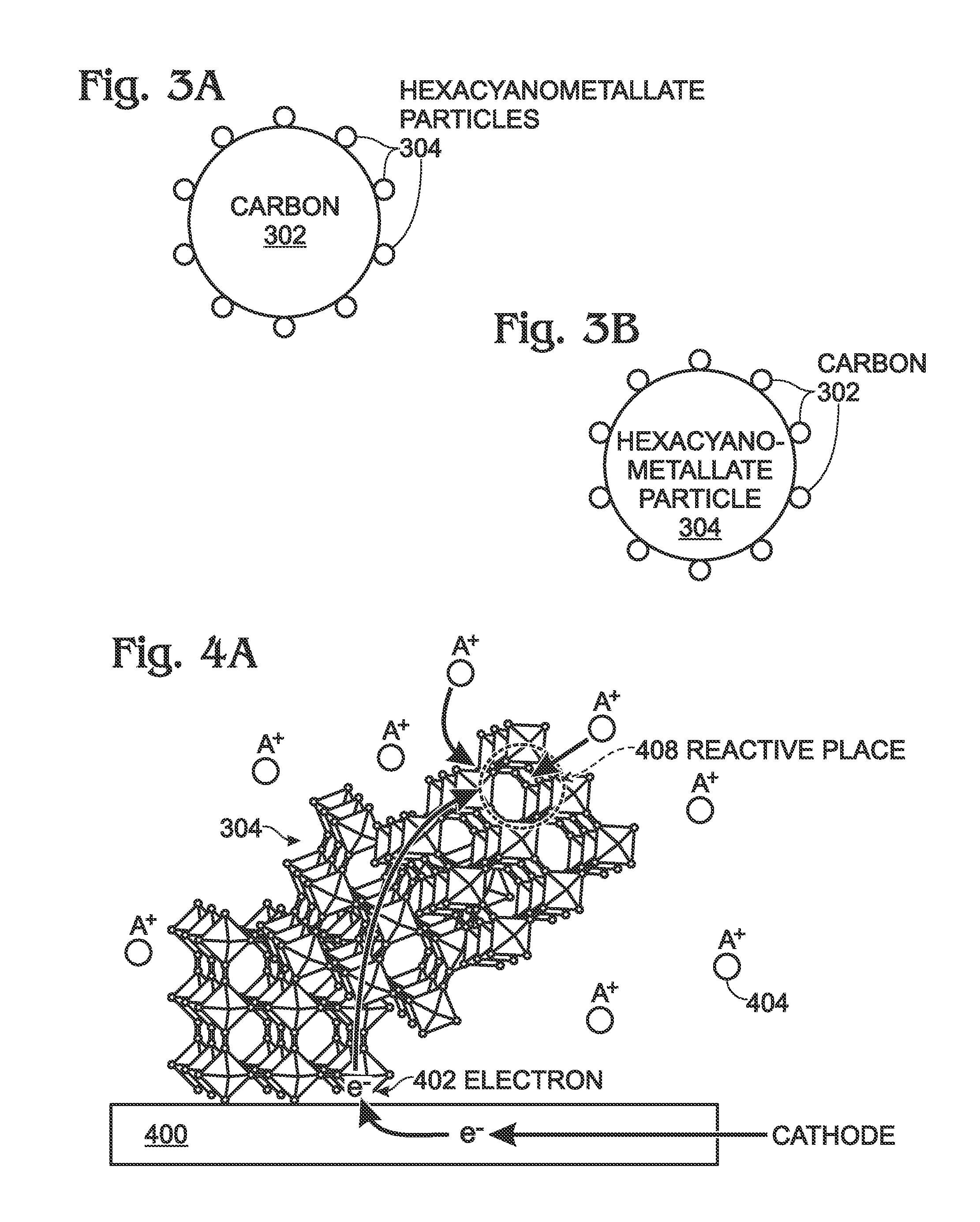

Electron Transport in Hexacyanometallate Electrode for Electrochemical Applications

ActiveUS20130260021A1Reduce electron transport pathImprove performanceMaterial nanotechnologyNon-metal conductorsElectrochemistryElectron

A structure of intimately contacting carbon-hexacyanometallate is provided for forming a metal-ion battery electrode. Several methods are provided for forming the carbon-hexacyanometallate intimate contact. These methods include (1) adding conducting carbon during the synthesis of hexacyanometallate and forming the carbon-hexacyanometallate powder prior to forming the paste for electrode printing; (2) coating with conducting carbon after hexacyanometallate powder formation and prior to forming the paste for electrode printing; and (3) coating a layer of conducting carbon over the hexacyanometallate electrode.

Owner:SHARP KK

High temperature SiCN and SiC-type nanostructured ceramic material from block copolymer mesophases

InactiveUS7087656B2Simple and easily controlled pathwayCarbon compoundsNitrogen and non-metal compoundsNon oxide ceramicsPolymer science

A block copolymer, preferably a block copolymer such as poly(isoprene-block-ethylene oxide), PI-b-PEO, is used as a structure directing agent for a polymer derived ceramic (PDC) precursor, preferably a silazane, most preferably a silazane commercially known as Ceraset. The PDC precursor is preferably polymerized after mixing with the block copolymer to form a nanostructured composite material. Through further heating steps, the nanostructured composite material can be transformed into a nanostructured non-oxide ceramic material, preferably a high temperature SiCN or SiC material.

Owner:CORNELL RES FOUNDATION INC

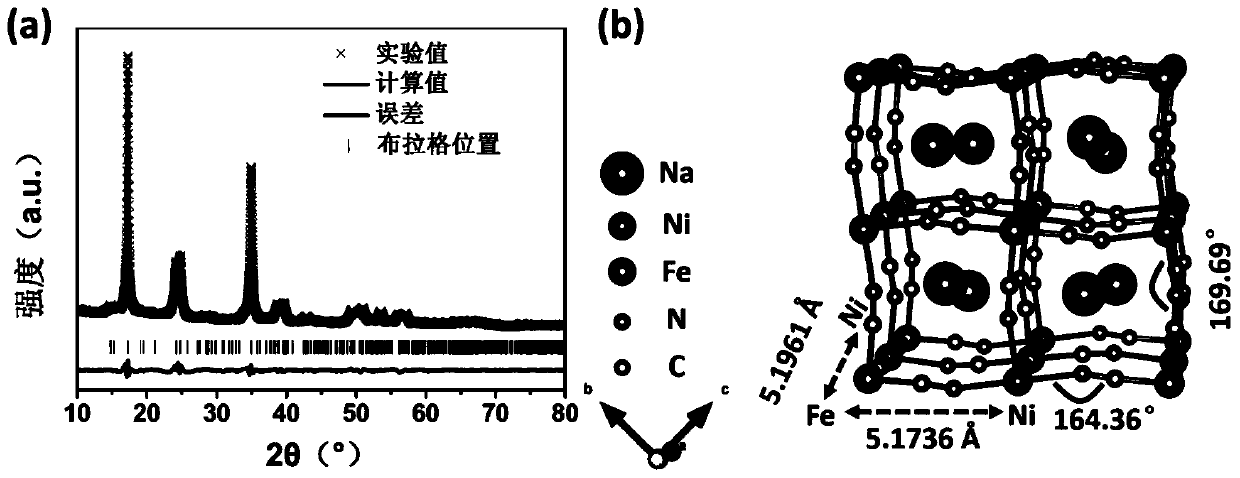

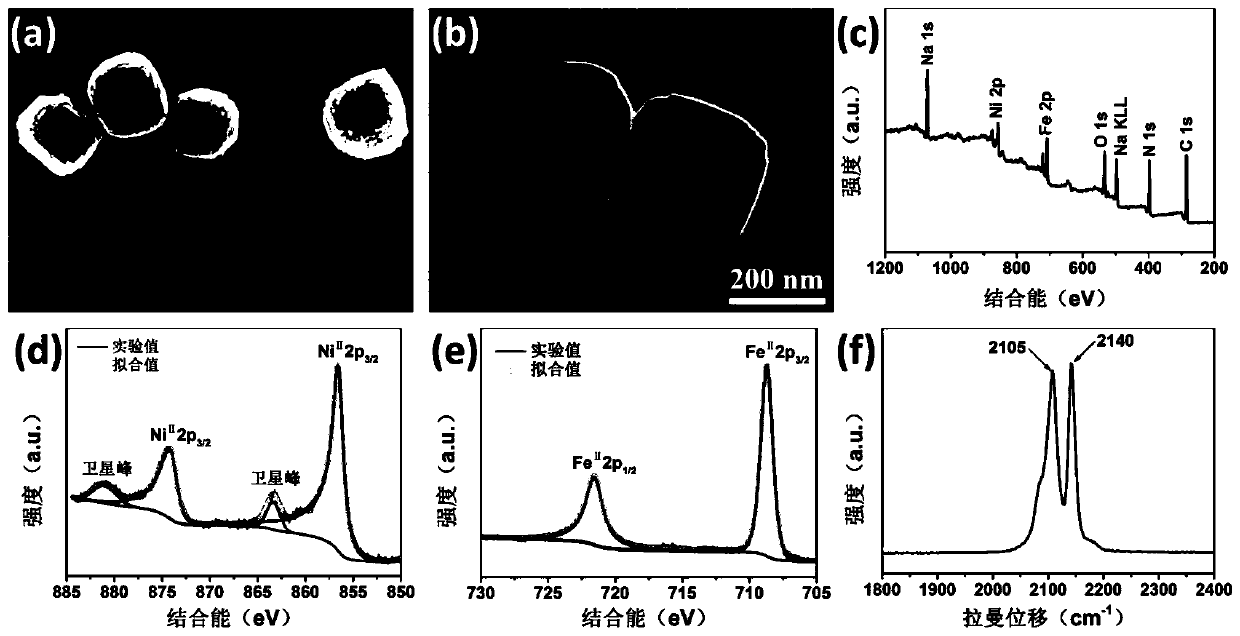

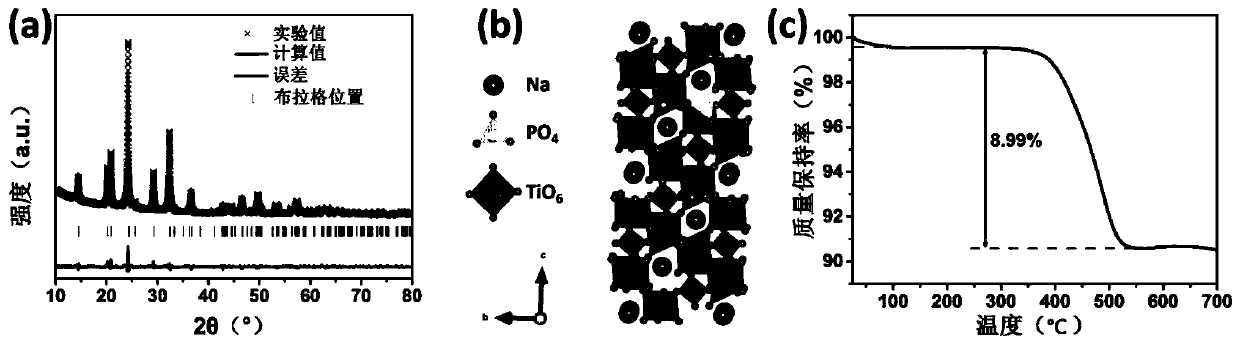

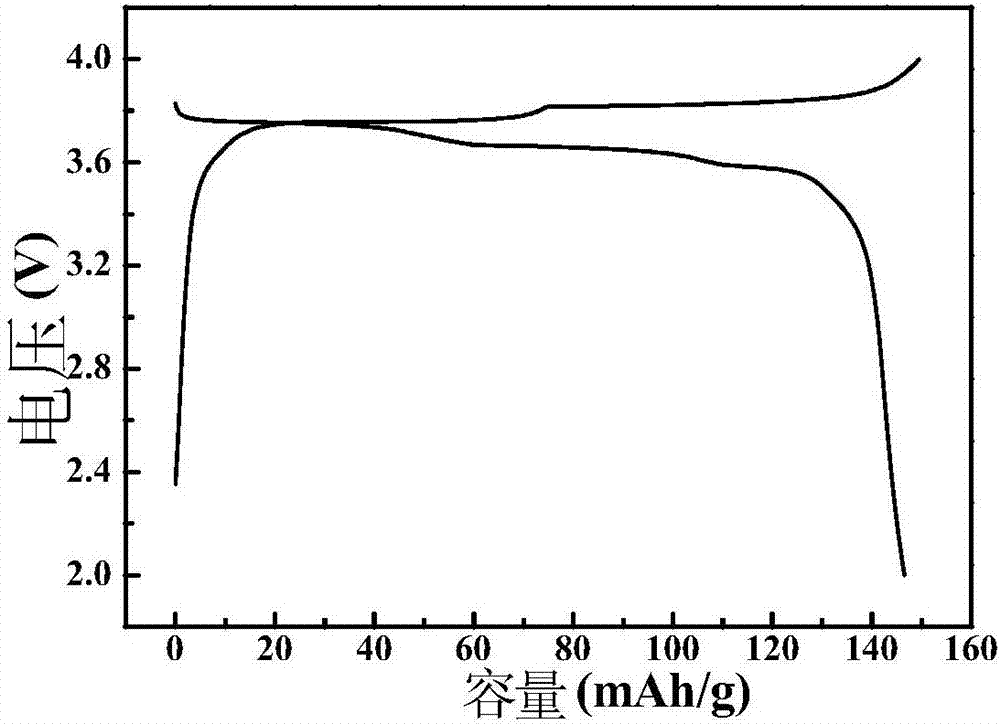

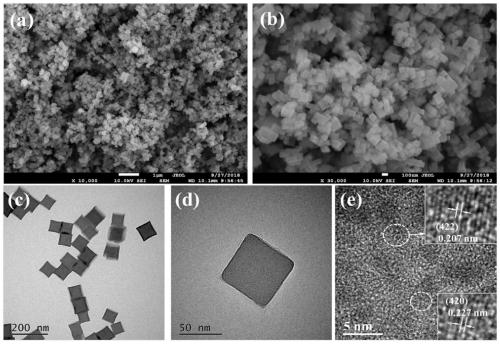

Water-based sodium ion total battery based on nickel prussian blue positive electrode material and preparation method and application thereof

InactiveCN111525129AControl crystal formControl shapeEnergy inputSecondary cellsElectrolytic agentNew energy

The invention discloses a water-based sodium ion total battery based on a nickel prussian blue positive electrode material and a preparation method and application thereof, and belongs to the field oflarge-scale energy storage. According to the invention, sodium citrate is added as a chelating agent and polyvinylpyrrolidone is added as a surfactant to control the growth process of the Prussian blue material in the process of preparing the Prussian blue positive electrode material by a coprecipitation method, and finally, the monoclinic phase nickel Prussian blue nanocube is synthesized. The carbon-coated sodium titanium phosphate negative electrode material, a carbon-coated sodium titanium phosphate negative electrode material and a water-soluble sodium salt electrolyte are assembled intoa low-cost and high-performance water-based sodium ion battery by taking the carbon-coated sodium titanium phosphate negative electrode material as a positive electrode material. The method is expected to be applied to a large-scale energy storage system to promote the development of new energy and renewable energy industries.

Owner:DALIAN UNIV OF TECH

Process for simultaneous preparation of nanocystalline anatase titanium dioxide powder and hydrazine monohydrochloride

InactiveUS20050106095A1Inhibition of agglomerationMaterial nanotechnologyTitanium dioxideHydrazine compoundHydrazine monohydrate

The present invention relates to an environmentally benign process for the simultaneous preparation of nanocrystalline anatase titanium dioxide and hydrazine mohydrochloride, in substantial amounts from the acidic aqueous titanium tetrachloride solution by reacting with hydrazine monohydrate at ambient conditions of temperature and pressure. The process of the present invention is simple, easy to operate, pollution free, high in product purity and homogeneous in product particle.

Owner:COUNCIL OF SCI & IND RES

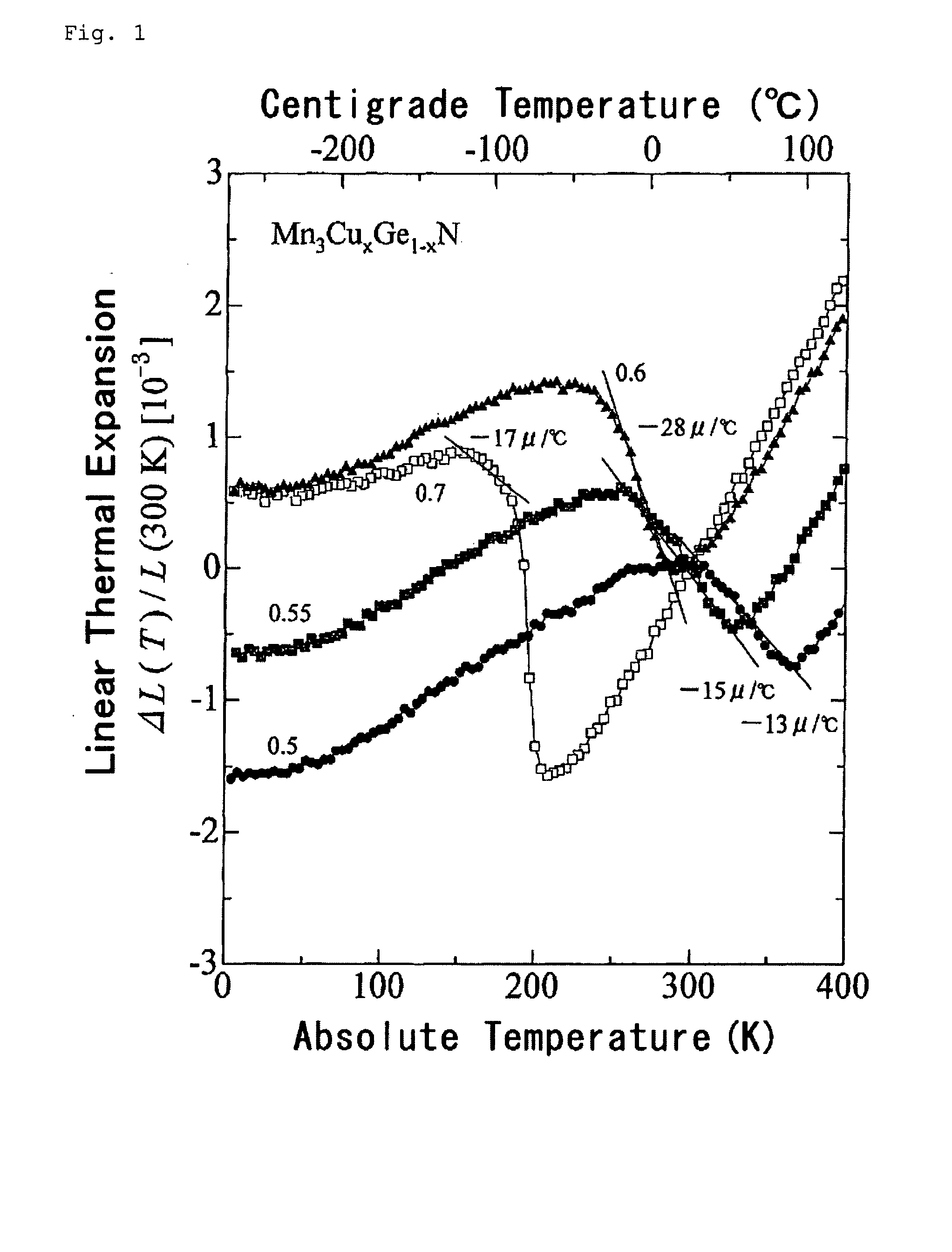

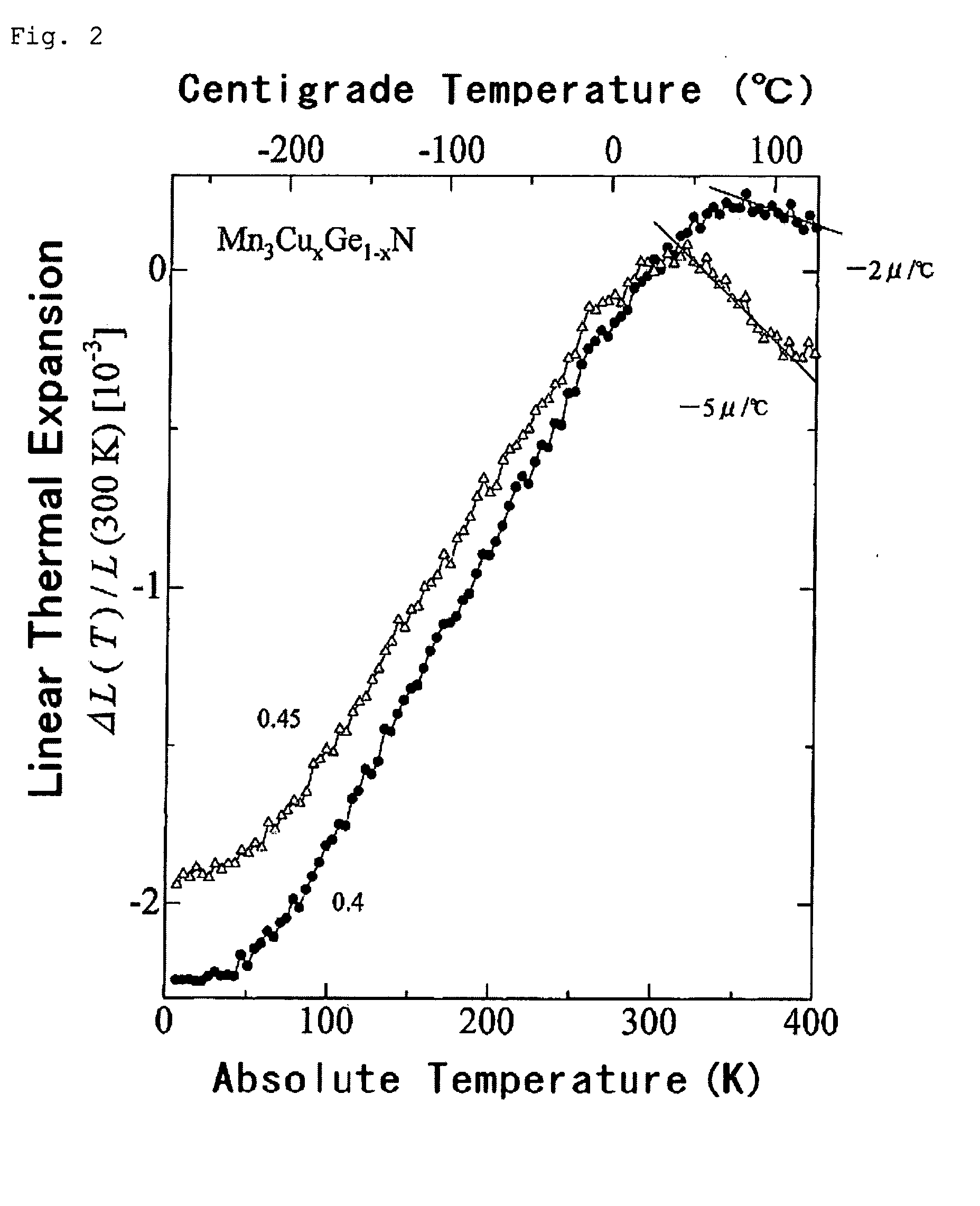

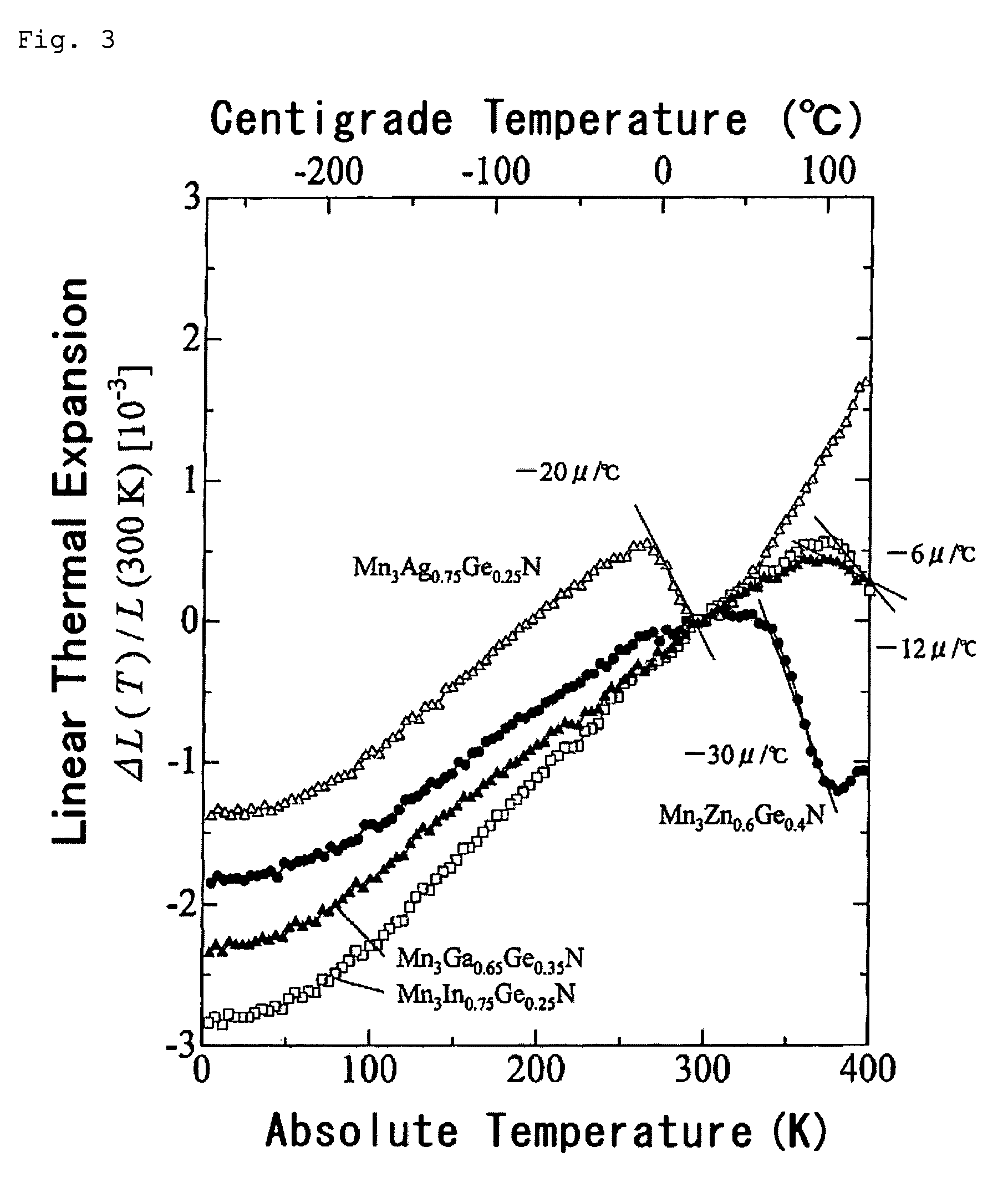

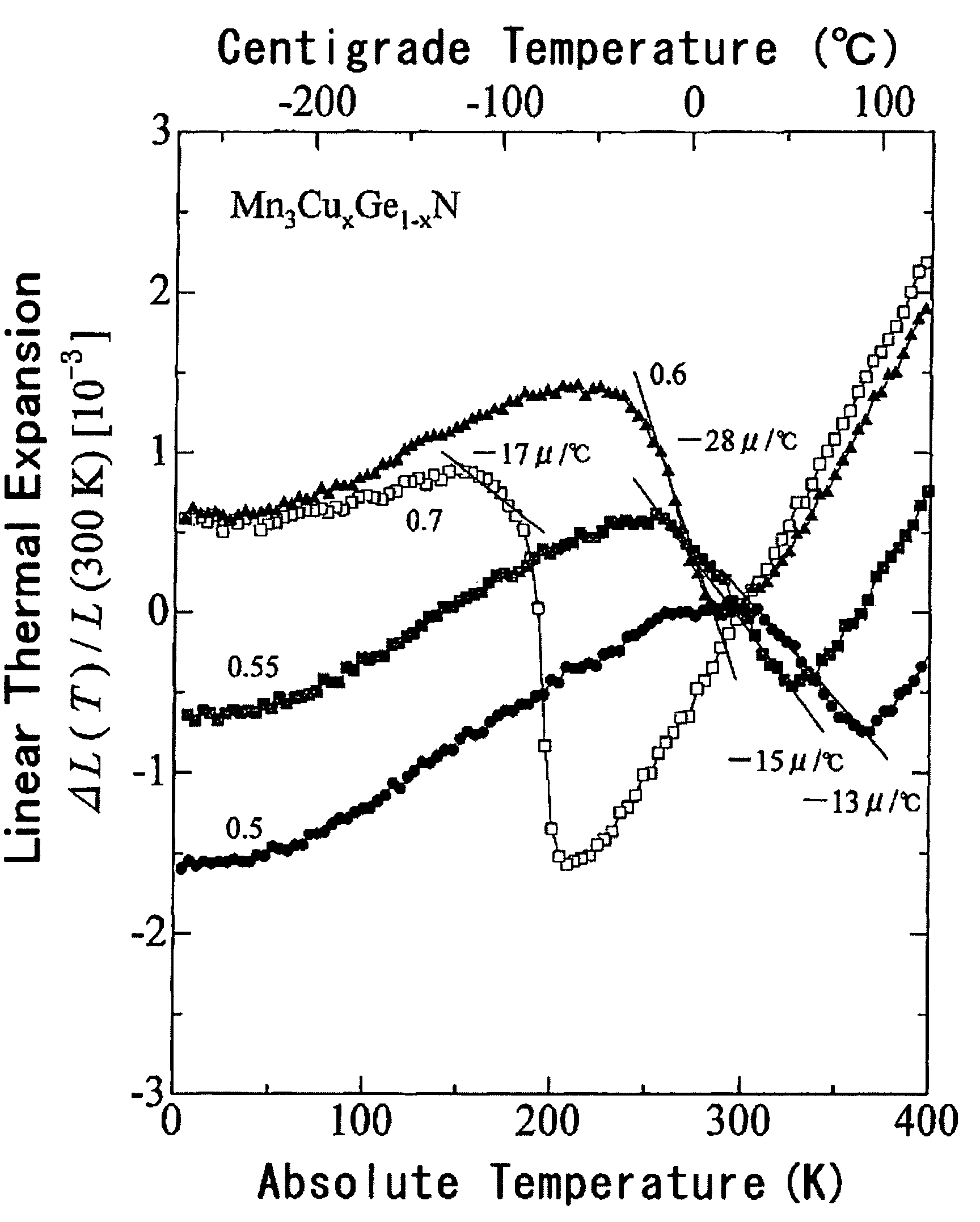

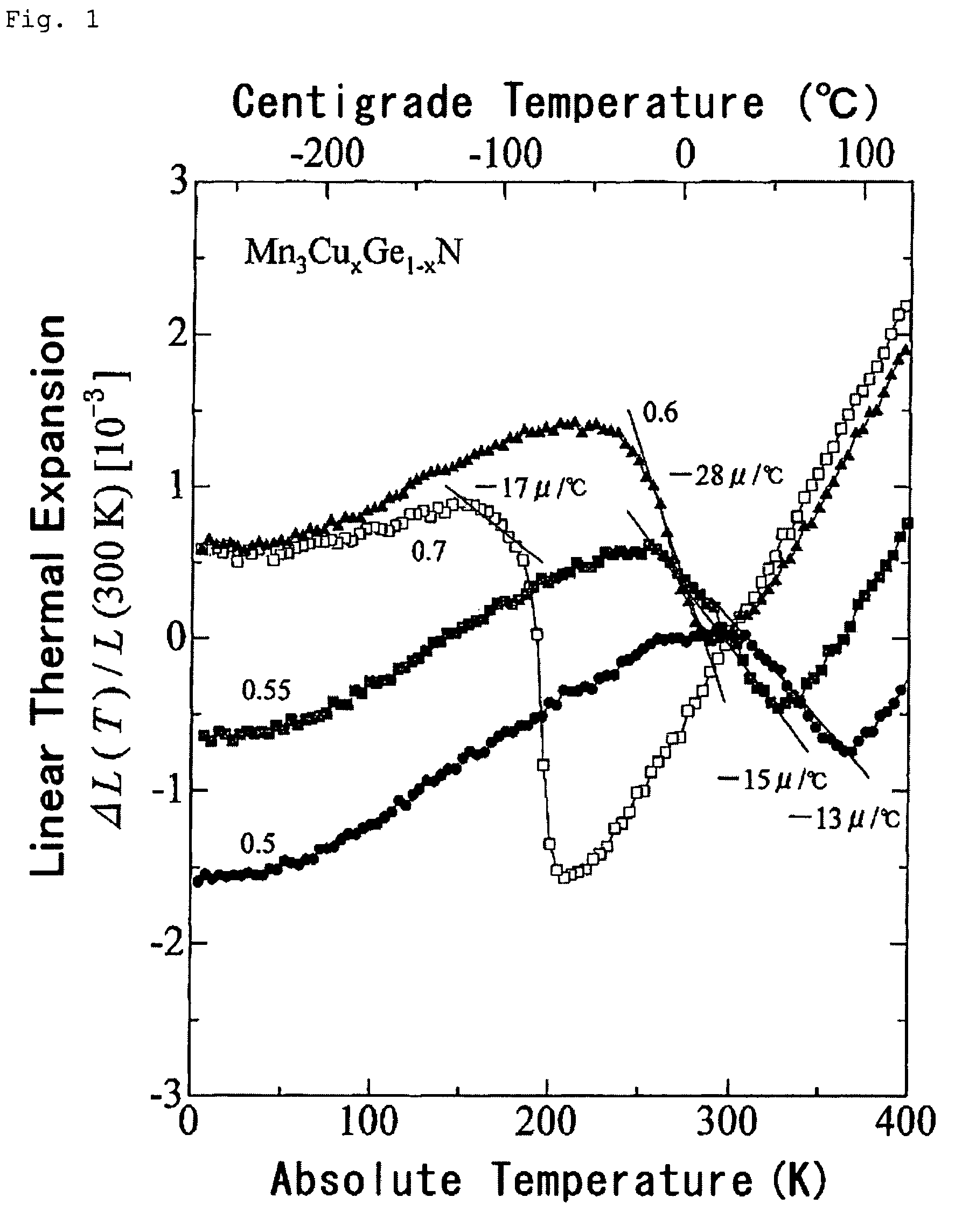

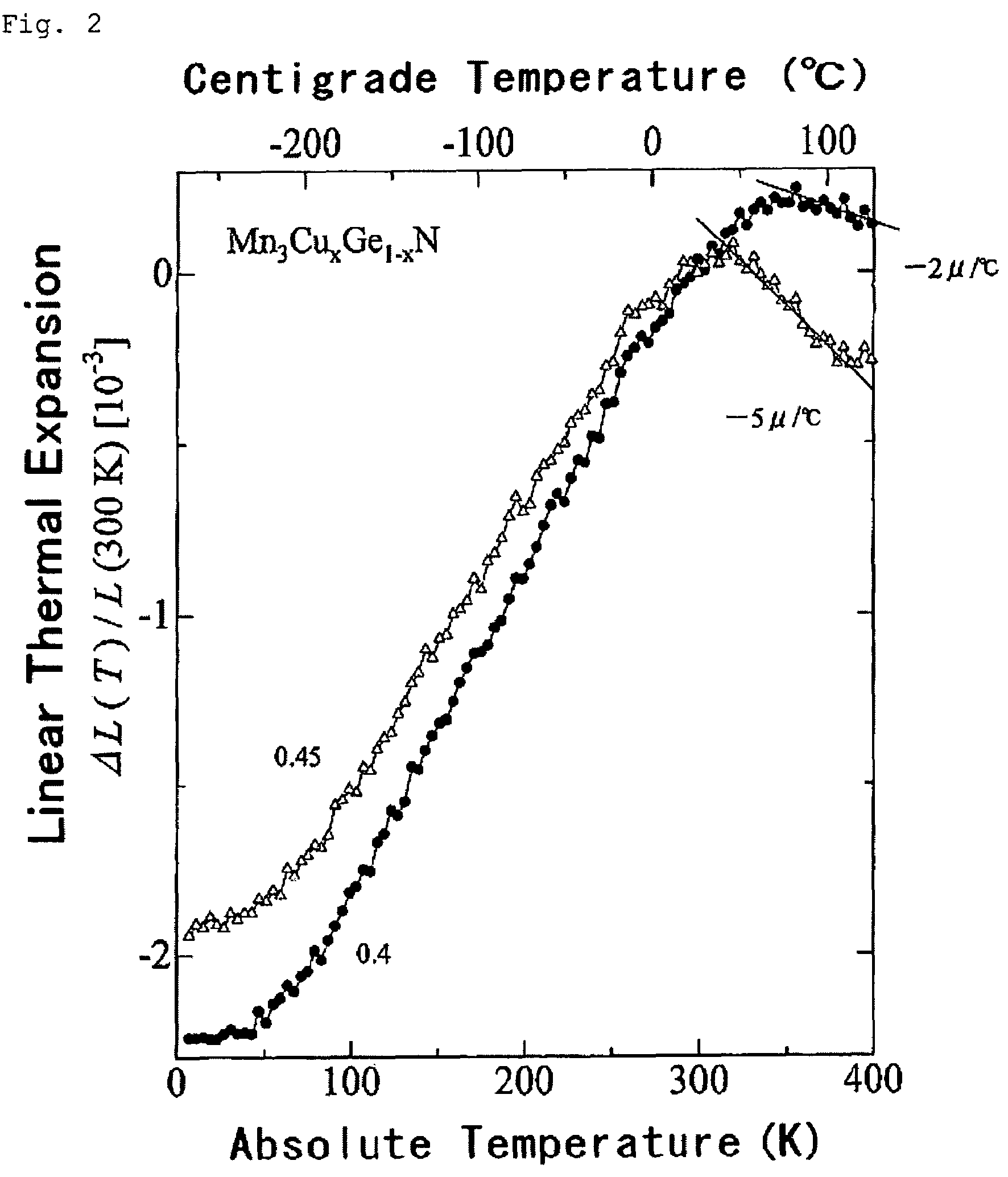

Thermal Expansion Inhibitor, Zero Thermal Expansion Material, Negative Thermal Expansion Material, Method for Inhibiting Thermal Expansion, and Method for Producing Thermal Expansion Inhibitor

InactiveUS20090004087A1Broaden magnetic transition temperature rangeKeep thermal expansionOther chemical processesNitrogen-metal/silicon/boron binary compoundsNitrideMaterials science

Provided is a thermal expansion inhibitor which has a much broader application range and which can be used with ease.Used is a thermal expansion inhibitor comprising a manganese nitride crystal.

Owner:RIKEN

Process for production and use of carbonitride mixture particles or oxycarbonitride mixture particles

InactiveUS20110183234A1Uniform particle size distributionMaintain good propertiesMaterial nanotechnologyCatalyst protectionLaser lightNitrogen oxide

The invention has an object of providing catalysts that are not corroded in acidic electrolytes or at high potential, have excellent durability and show high oxygen reducing ability. An aspect of the invention is directed to a process wherein metal carbonitride mixture particles or metal oxycarbonitride mixture particles are produced from an organometallic compound of a Group IV or V transition metal, a metal salt of a Group IV or V transition metal, or a mixture of these compounds using laser light as a light source.

Owner:SHOWA DENKO KK

Method for producing cyanogen-halide, cyanate ester compound and method for producing the same, and resin composition

ActiveUS20150299110A1Inhibit side effectsEfficient productionOrganic chemistryDecorative surface effectsCyanogen halideCyanide

A method for efficiently producing a cyanogen halide with suppressed side effects, and a method for producing a high-purity cyanate ester compound at a high yield includes contacting a halogen molecule with an aqueous solution containing hydrogen cyanide and / or a metal cyanide, so that the hydrogen cyanide and / or the metal cyanide is allowed to react with the halogen molecule in the reaction solution to obtain the cyanogen halide, wherein more than 1 mole of the hydrogen cyanide or the metal cyanide is used based on 1 mole of the halogen molecule, and when an amount of substance of an unreacted hydrogen cyanide or an unreacted metal cyanide is defined as mole (A) and an amount of substance of the generated cyanogen halide is defined as mole (B), the reaction is terminated in a state in which (A):(A)+(B) is between 0.00009:1 and 0.2:1.

Owner:MITSUBISHI GAS CHEM CO INC

Auric potassium cyanide and method for preparing same

InactiveCN101289746AReduce capacityIncreased chance of reactionElectrolysis componentsMetal cyanidesElectrolysisPotassium cyanide

The invention discloses a method for making potassium auric cyanide, which uses potassuim cyanide and metallic gold as raw materials and matches the gold per kilogram with 1020-1030 grams of the potassuim cyanide. The method comprises the following: 1) a step of pressing gold, which is to roll the gold into a thin gold sheet as an electrode; 2) a step of electrolyzing, which is to carry out electrolysis reaction in a diaphragm electrolyzer with the thin gold sheet as an anode, a stainless steel sheet as a cathode and a potassuim cyanide solution as electrolyte, so as to gradually dissolve the thin gold sheet as the anode into Au(CN)2<->; 3) a step of purifying, which is to purify potassium auric cyanide generated in electrolysis through a low-temperature cooling crystallization method after the thin gold sheet is completely dissolved; 4) a step of condensing; 5) a step of purifying repeatedly; 6) a step of condensing; 7) a step of drying, which is to bake potassium auric cyanide crystals in vacuum so as to get a finished product. The adoption of the method shortens electrolysis time, reduces purifying times, and improves the quality and yield of potassium auric cyanide.

Owner:吴朝勤

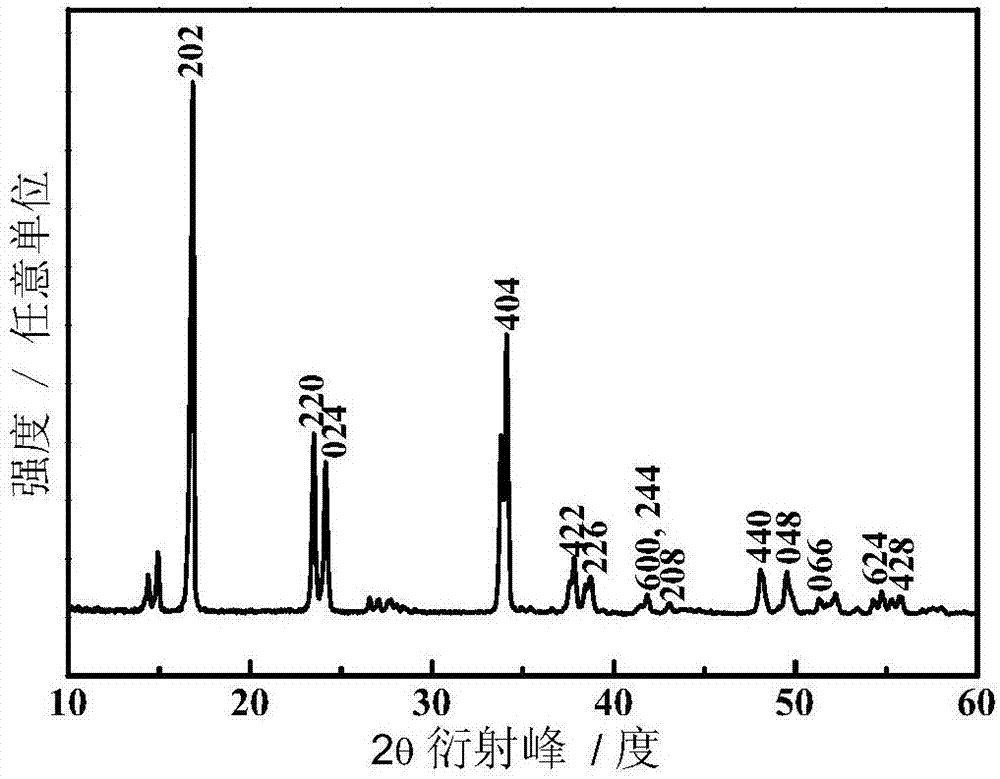

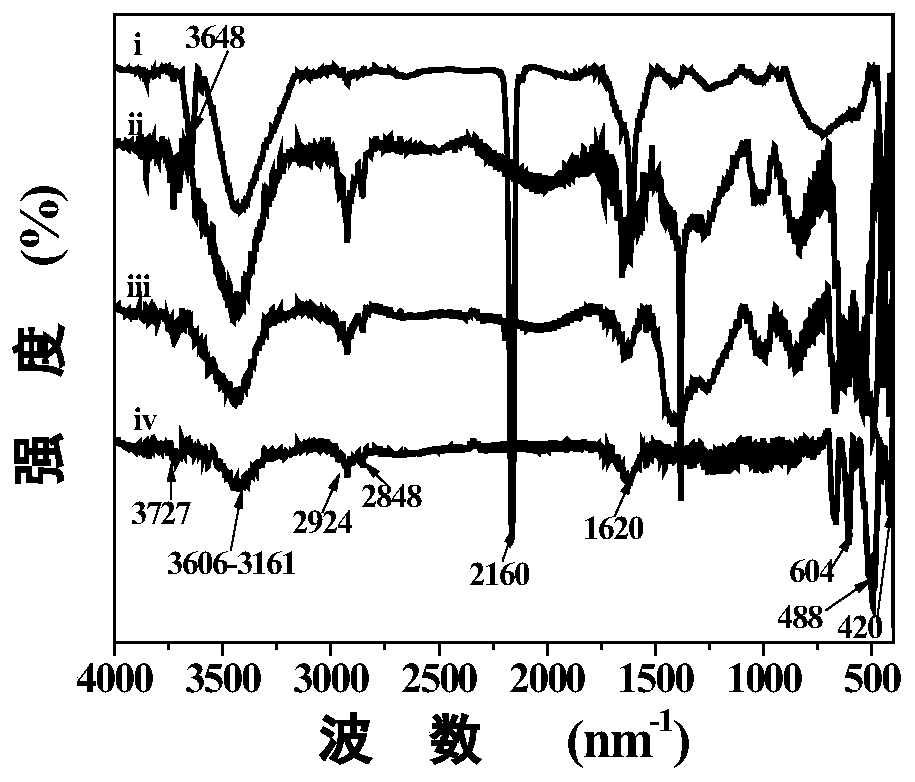

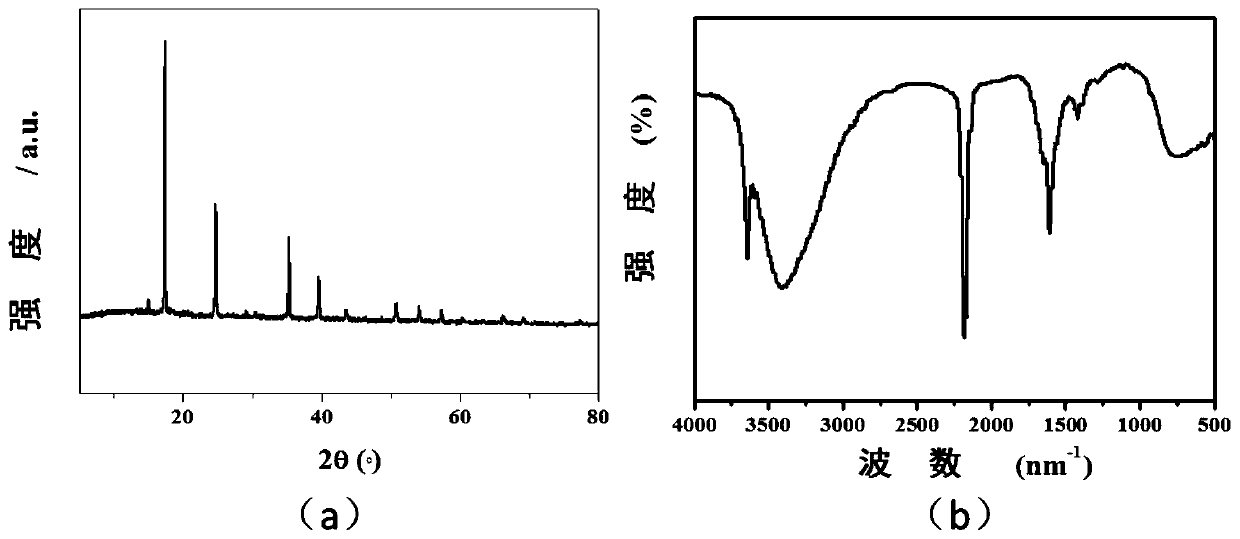

Cyano cathode material as well as preparation method and application thereof

ActiveCN107331864AHigh sodium and ferrocyanide contentHigh crystallinityCell electrodesSecondary cellsSodium-ion batteryCrystallinity

The invention discloses a preparation method of a cyano cathode material. The preparation method comprises specific steps as follows: mixing sodium ferrocyanide with deionized water to obtain a solution A, mixing transition metal M with the deionized water to obtain a dispersion solution B, mixing the solution A with the dispersion solution B, and then adding dilute acid, and obtaining the cyano cathode material through a hydrothermal reaction. According to the preparation method of the cyano cathode material, the morphology and the lattice structure of a target product can be regulated; the prepared cyano cathode material has good crystallinity, and can remarkably improve electrochemical performance of sodium ion batteries after being applied to electrodes of the sodium ion batteries.

Owner:ZHEJIANG UNIV

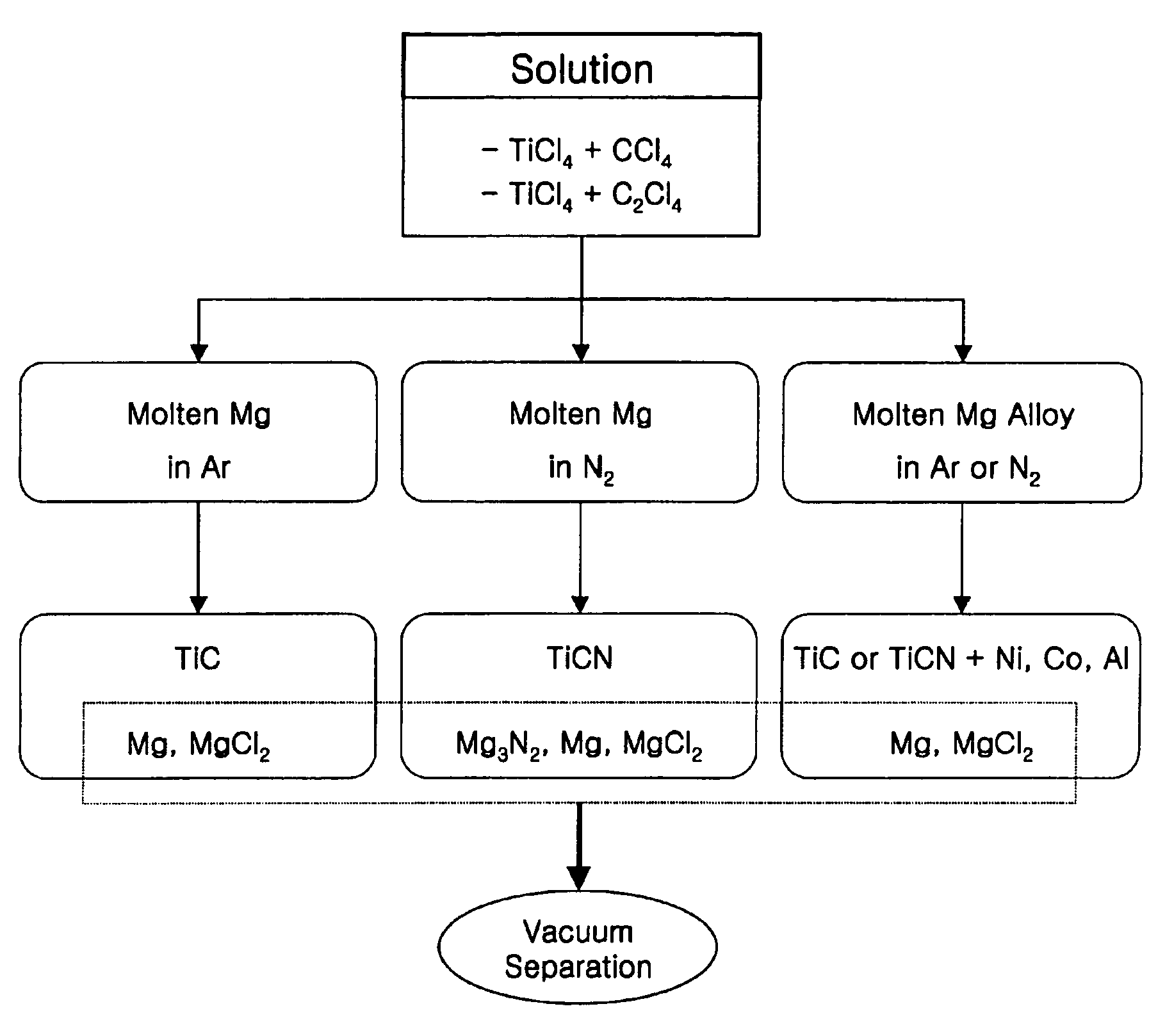

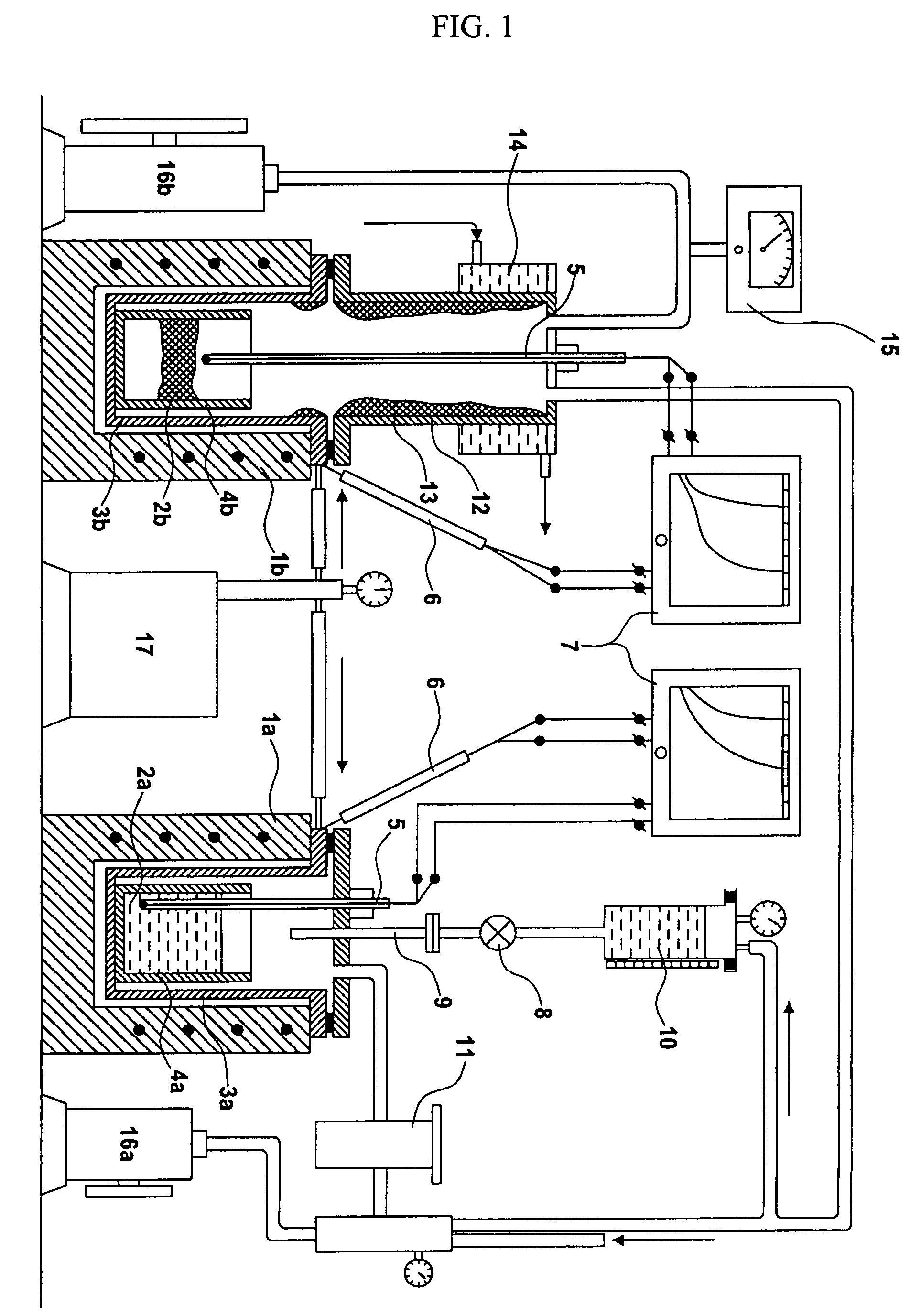

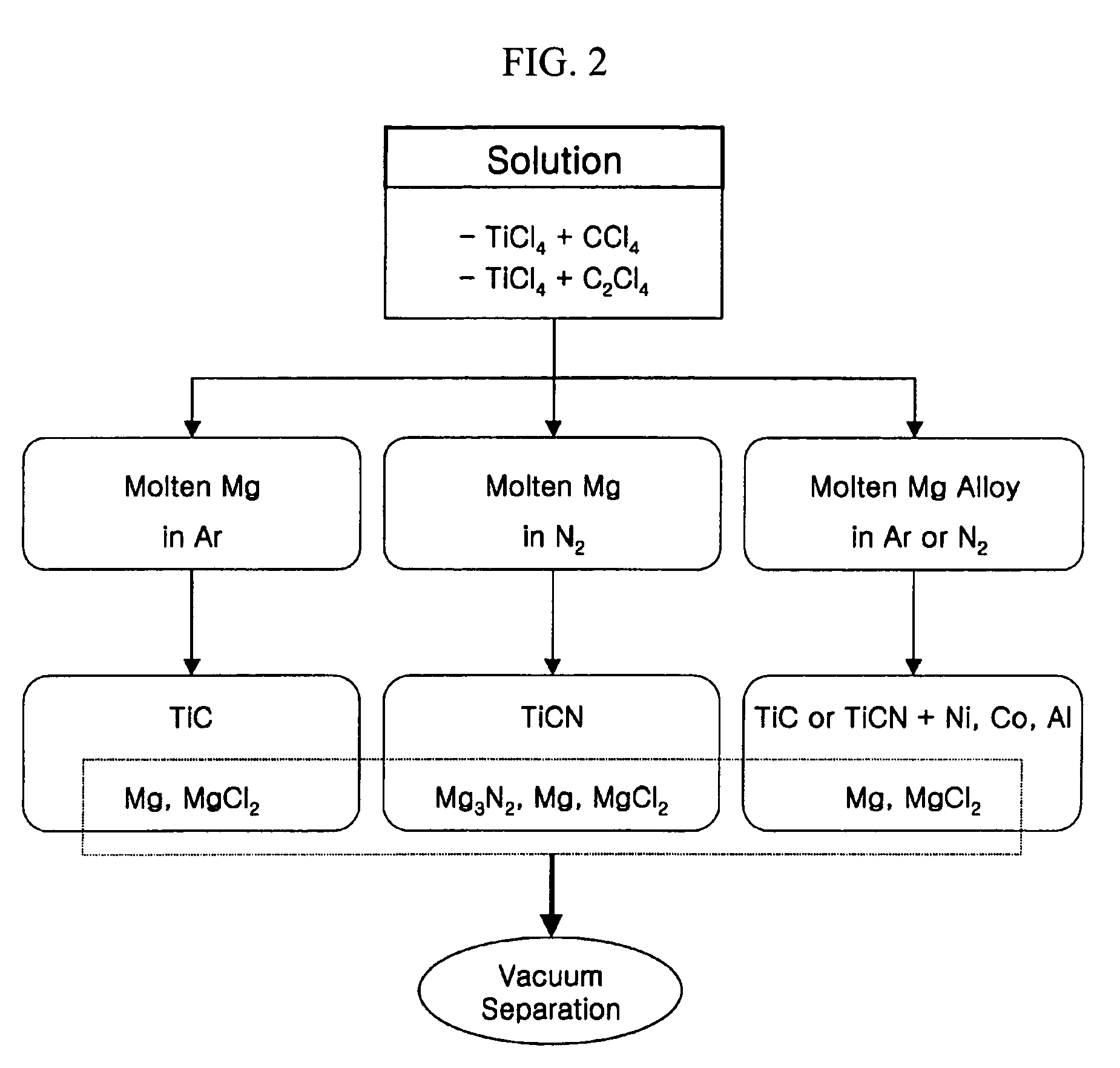

Method for manufacturing nanophase TiC-based composite powders by metallothermic reduction

Disclosed herein is a method for economically manufacturing high quality TiC powder, TiCN powder or ultrafine nanophase TiC+Ni (Co, Al) and TiCN+Ni (Co, Al) composite powders by means of metallothermic reduction. The method comprises the steps of preparing a starting solution of titanium tetrachloride (TiCl4) in a carbon chloride, feeding the starting solution into a closed container containing molten magnesium (Mg) under inert atmosphere, vacuum-separating unreacted liquid-phase Mg and magnesium chloride (MgCl2) remaining after reduction of magnesium from the closed container, and collecting a TiC compound from the closed container.TiC powder, TiCN powder or ultrafine nanophase TiC+Ni (Co, Al) and TiCN+Ni (Co, Al) composite powders having a particle size of a few tens nm can be manufactured in a simpler manner using economically advantageous starting materials such as titanium tetrachloride and carbon chlorides.

Owner:KOREA INST OF MACHINERY & MATERIALS

Saturable-absorber-based laser system

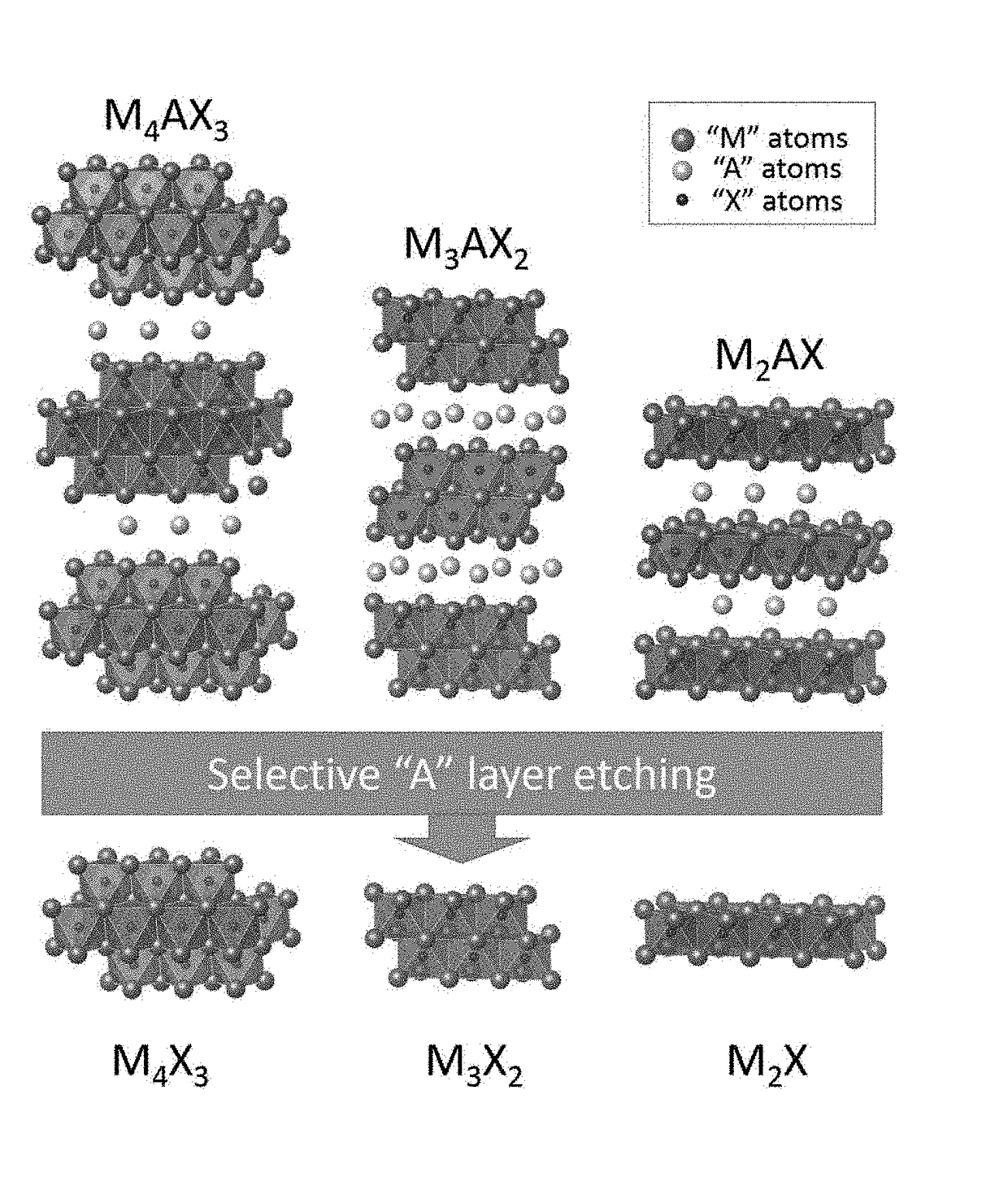

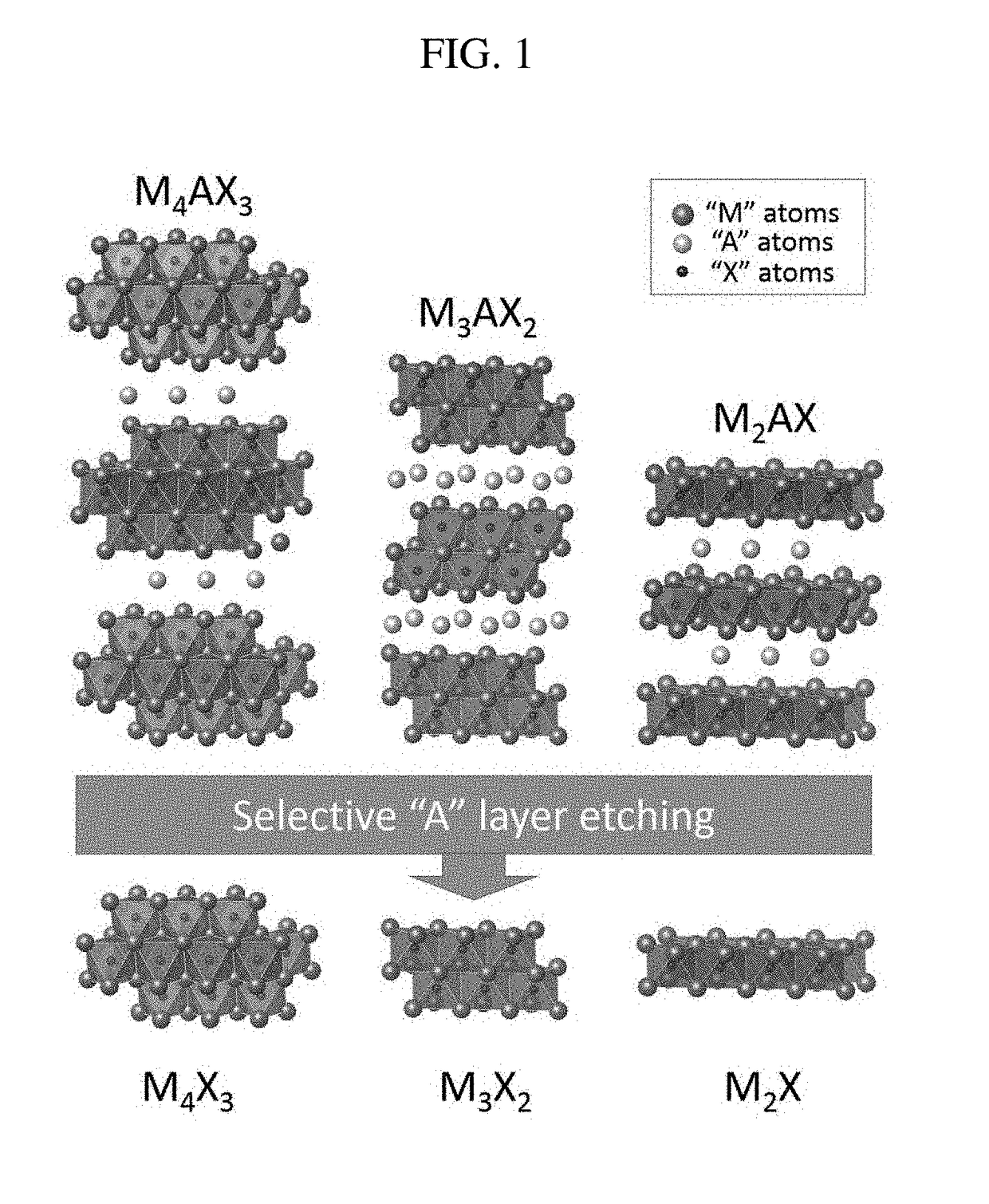

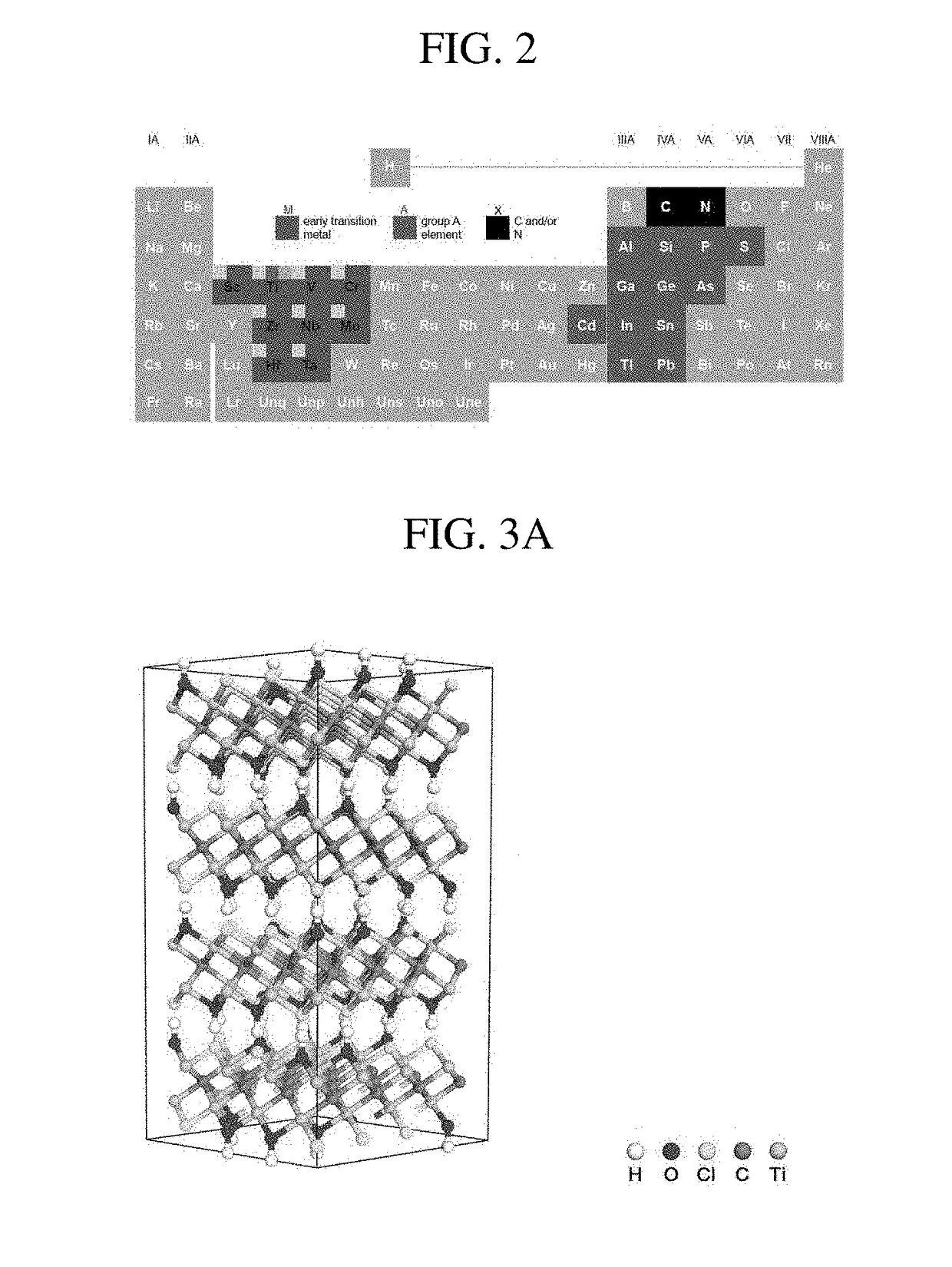

ActiveUS20180102624A1Good chemical stabilityAbsorption performanceMaterial nanotechnologyTitanium carbideOptoelectronicsQ-switching

Provided are a saturable absorber including at least one material selected from a group of MXenes, and a Q-switching and mode-locked pulsed laser system using the same.

Owner:KOREA INST OF SCI & TECH

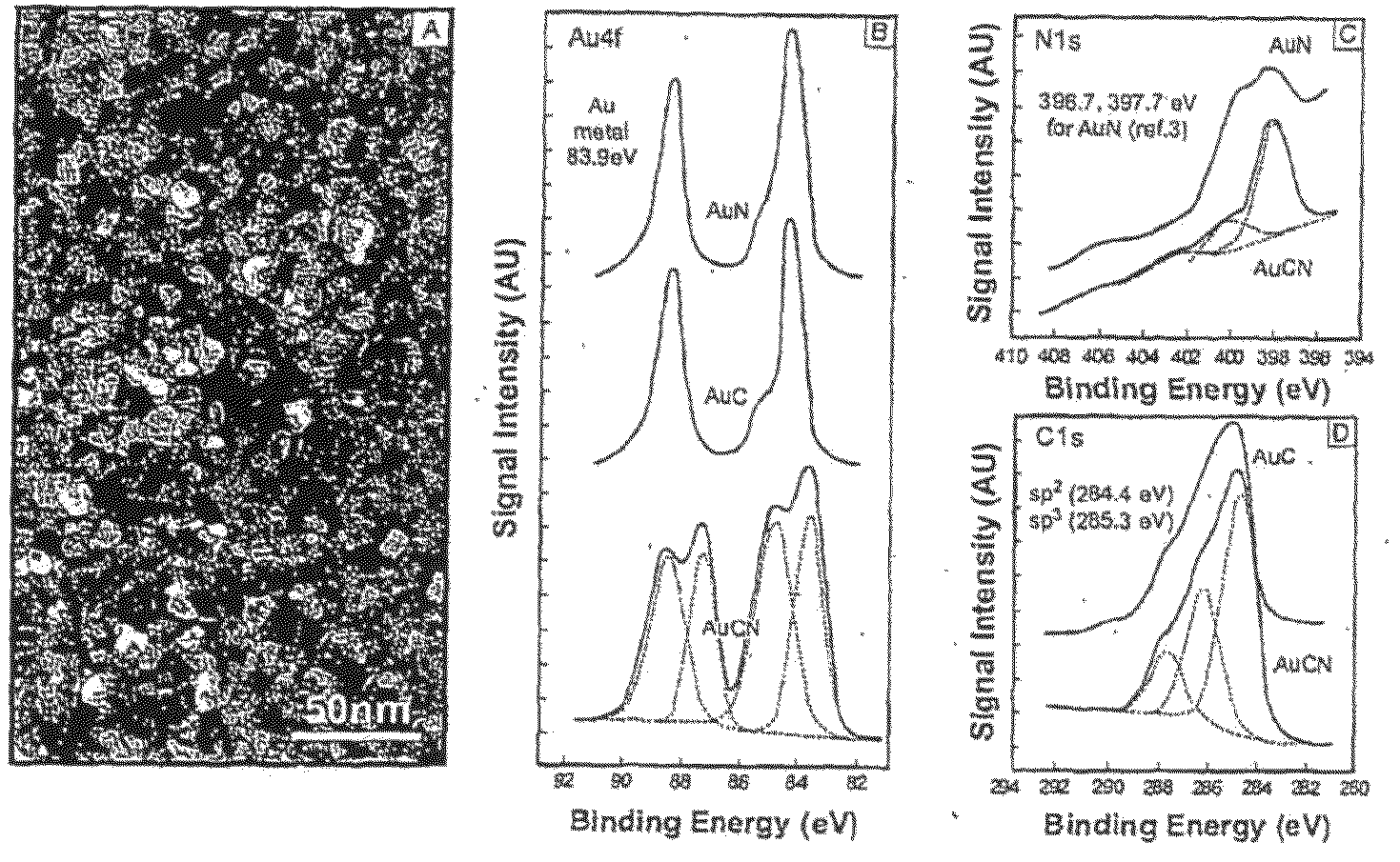

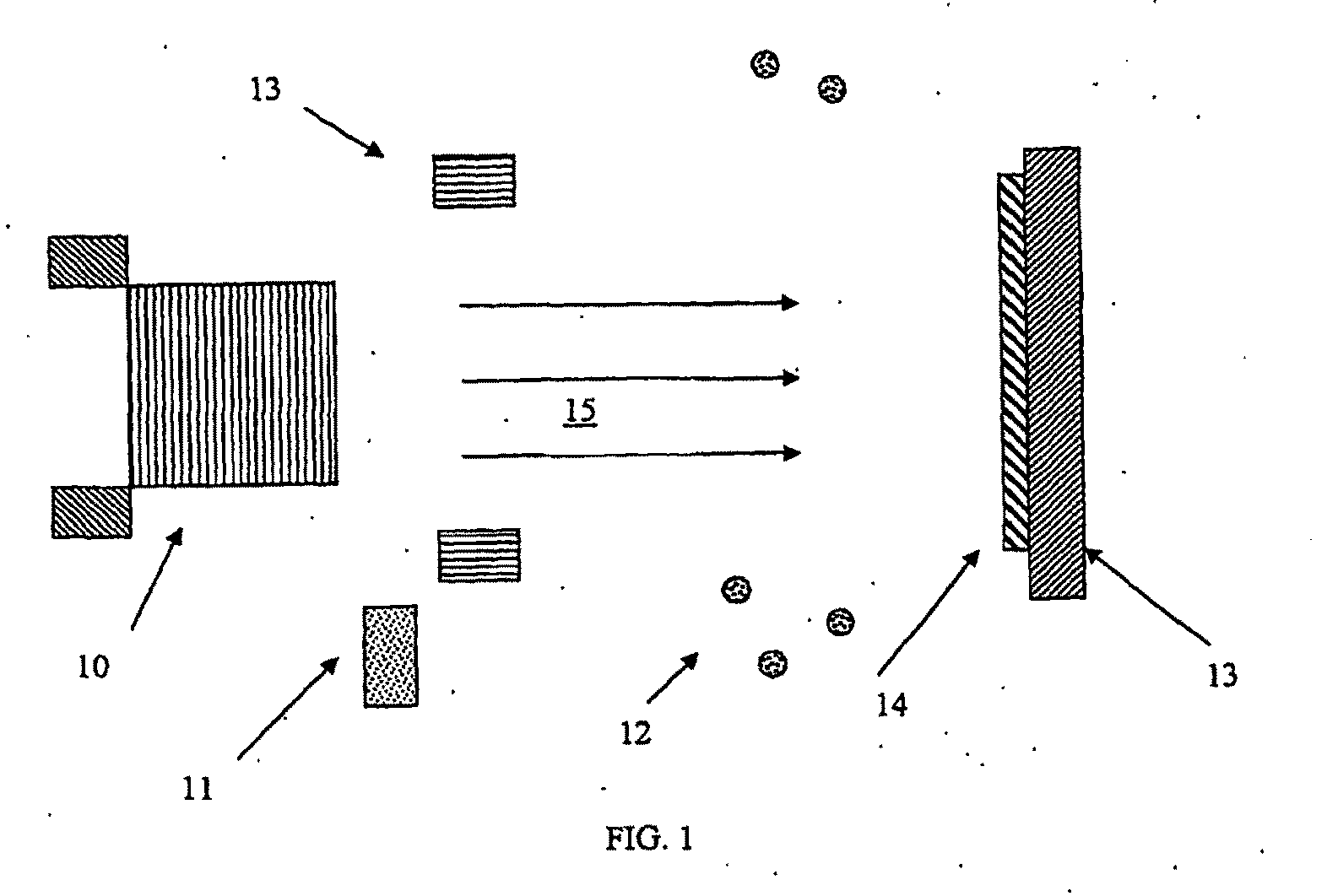

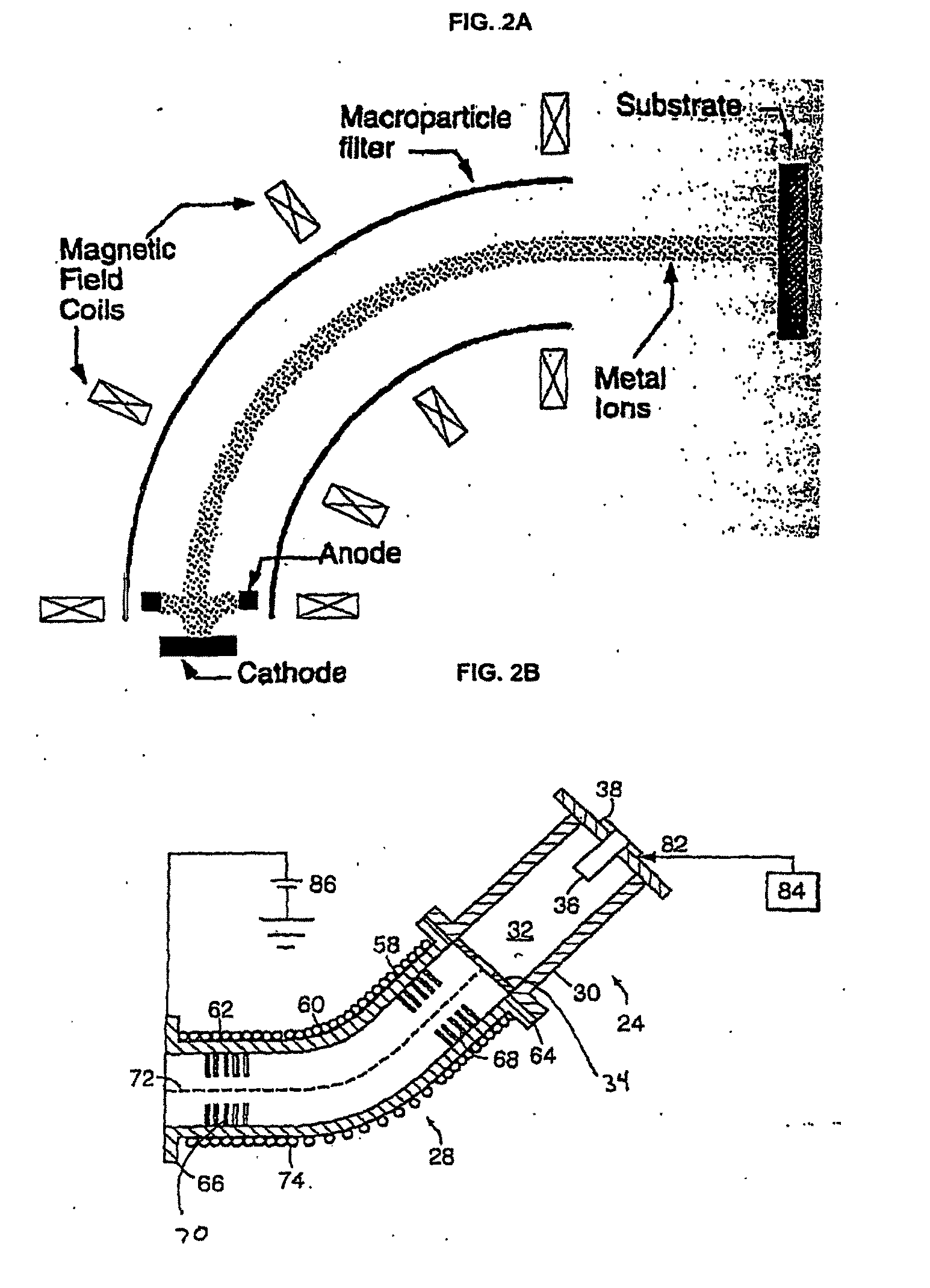

Metal binary and ternary compounds produced by cathodic arc deposition

InactiveUS20100143232A1Easy to produceElectric discharge tubesNitrogen-metal/silicon/boron binary compoundsCathodic arc depositionMedical device

The present invention allows the relatively easy production of binary and ternary compounds of metals, including noble metals. Embodiments of the invention allow, for the first time, the production of novel compositions of metal compounds, such as thick, stress-free single-phase binary and ternary compositions of metals, and porous compositions of such compounds. As such, the present invention allows for the production of metal compounds and / or compositions of matter thereof that have not before been possible, thereby providing for important new materials that find use in a multitude of different applications, including medical device and non-medical device applications.

Owner:PROTEUS DIGITAL HEALTH INC

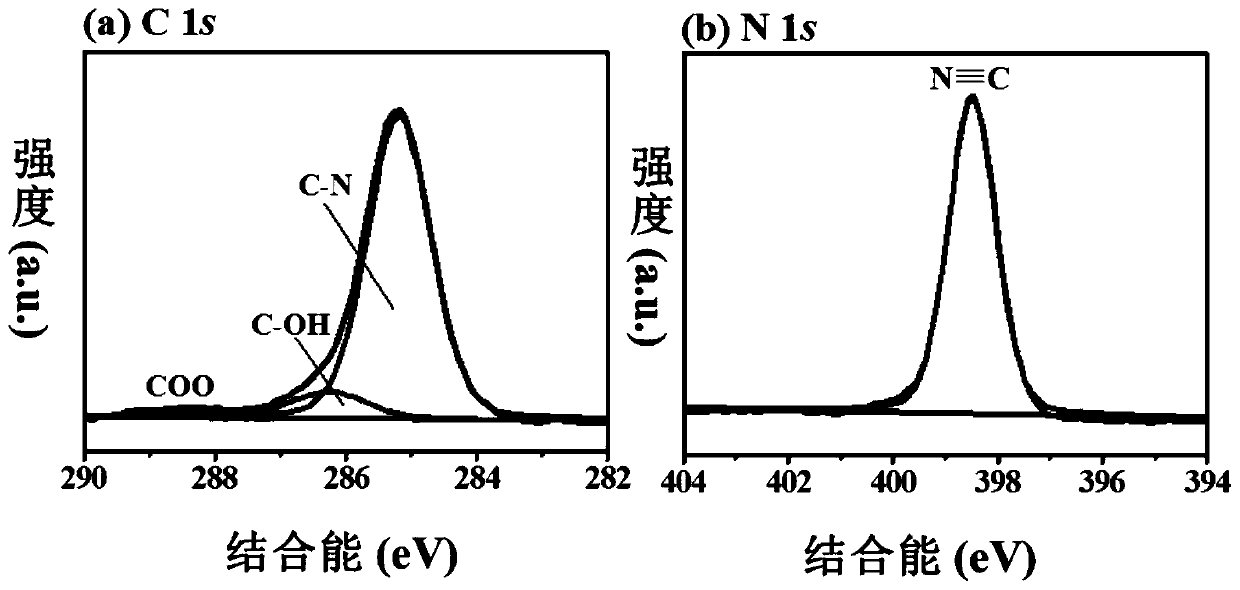

Electrode material for aptamer sensor, aptamer sensor and preparation method thereof

ActiveCN110330036AImprove electrochemical activityGood choiceMaterial electrochemical variablesMetal cyanidesManganeseOperability

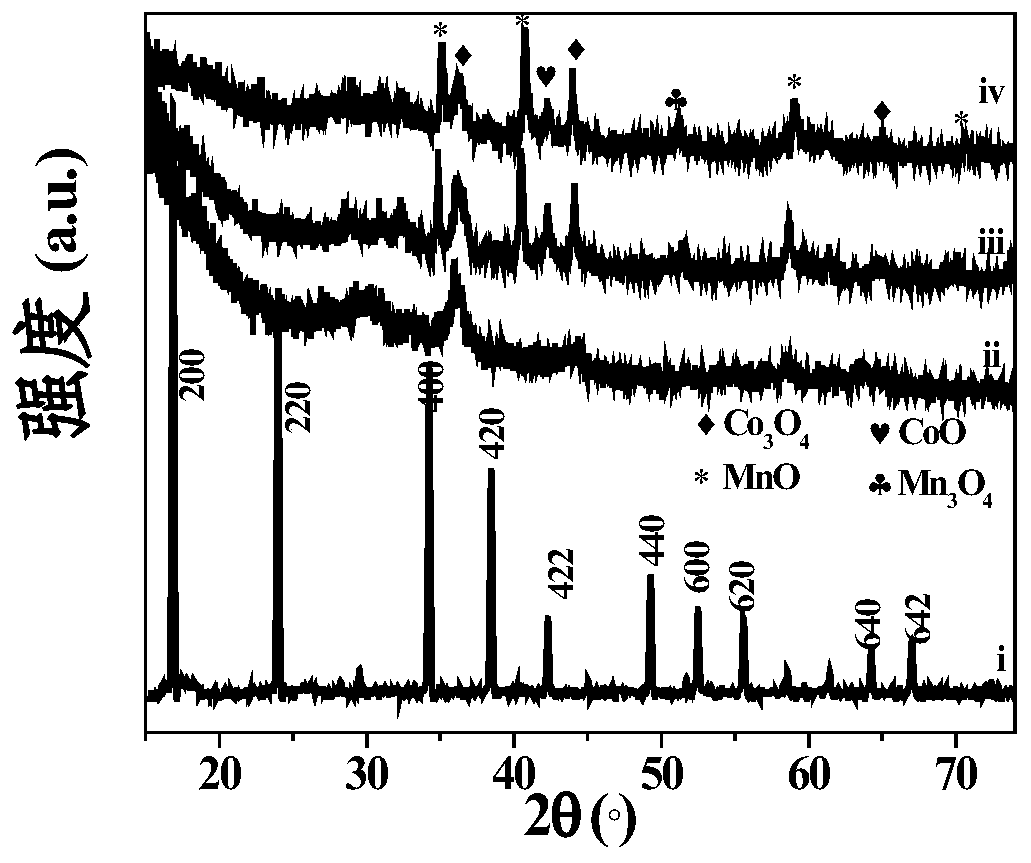

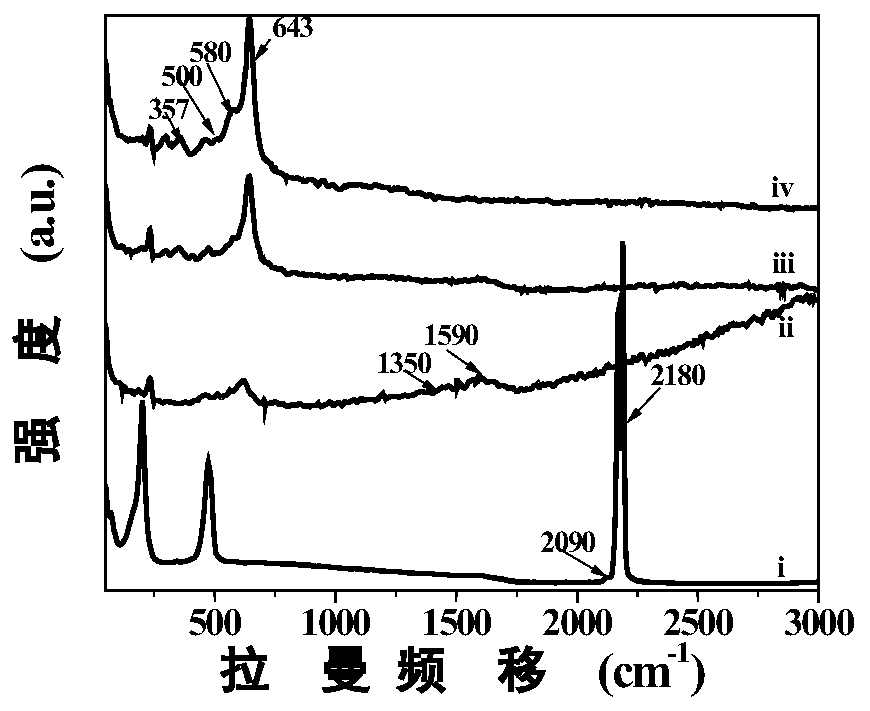

The invention relates to an electrode material for an aptamer sensor, the aptamer sensor and a preparation method, and belongs to the technical field of electromechanical sensors. The electrode material for the aptamer sensor is prepared according to a method comprising the following steps: (1) dissolving manganese salt, citrate and cobalt cyanide acid salt into a solvent; carrying out a reactionto obtain a manganese cobalt Prussian blue analogue; (2) roasting the obtained manganese cobalt Prussian blue analogue to obtain the electrode material for the aptamer sensor. The method is simple, high in operability, and low in cost; the prepared electrode material is high in electrochemical activity and high in combination effect with a nucleic acid aptamer material; the aptamer sensor preparedaccording to the method is high in selectivity, stability, repeatability, reproducibility and adaptability, and low in detection limit.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

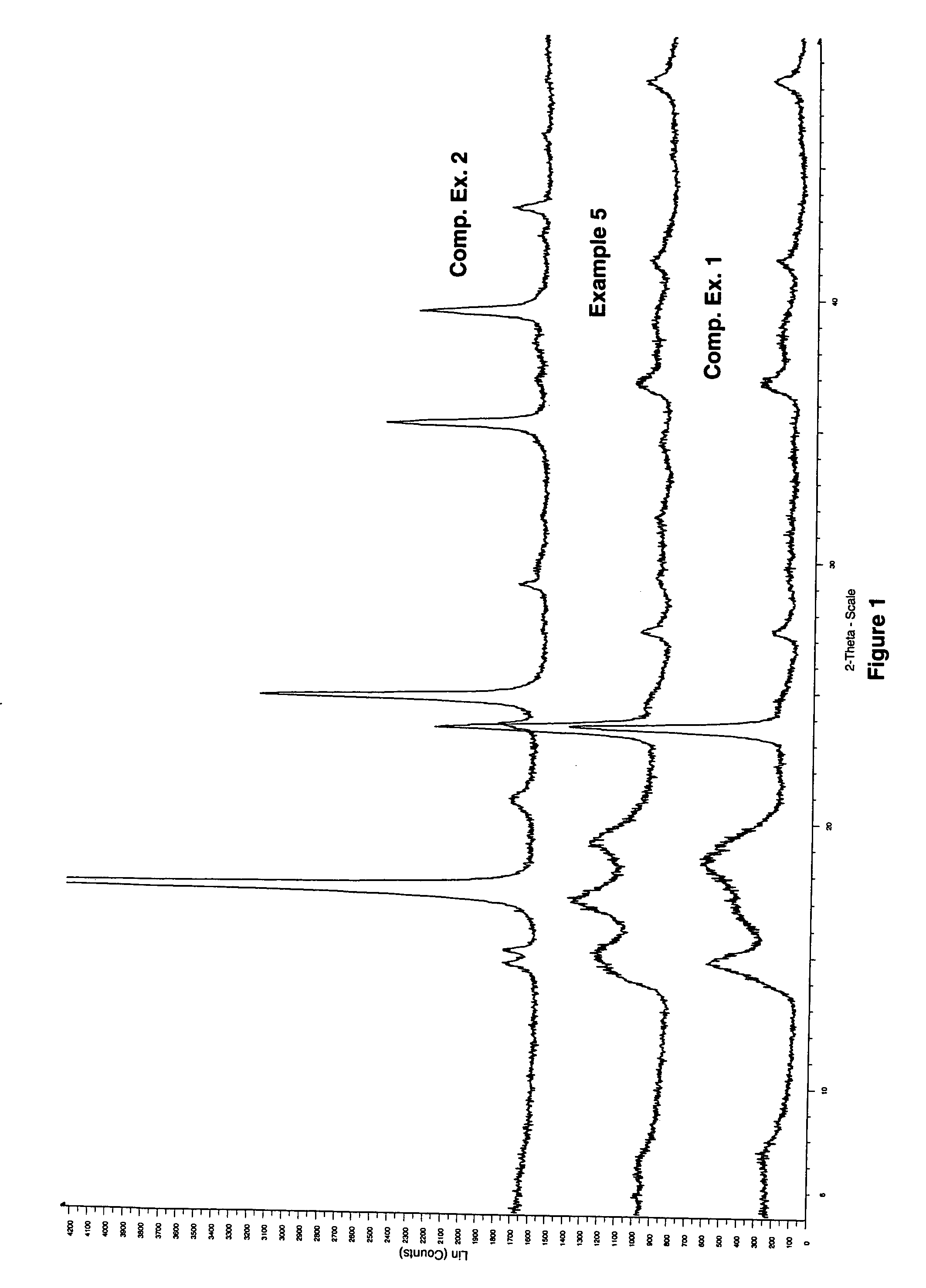

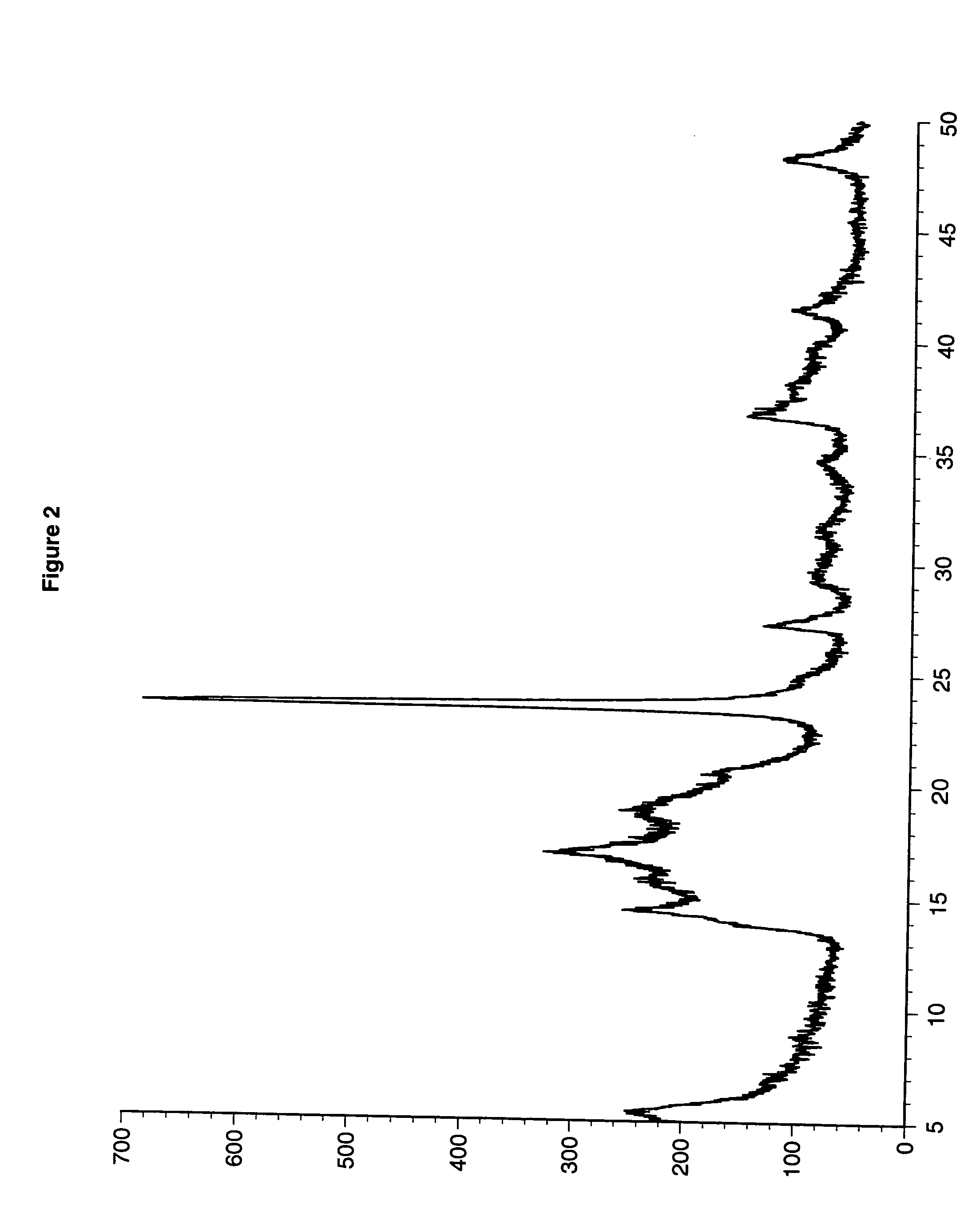

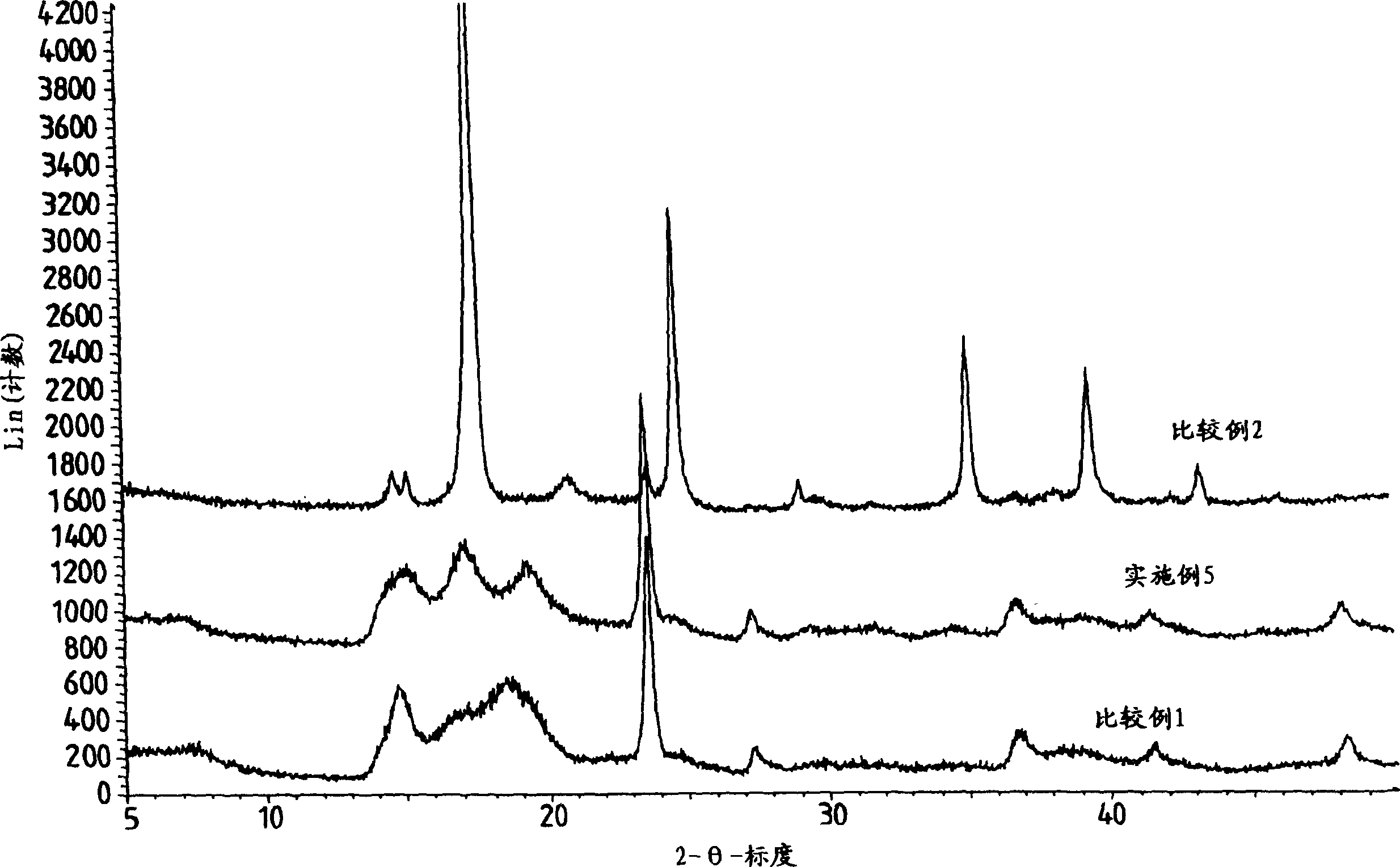

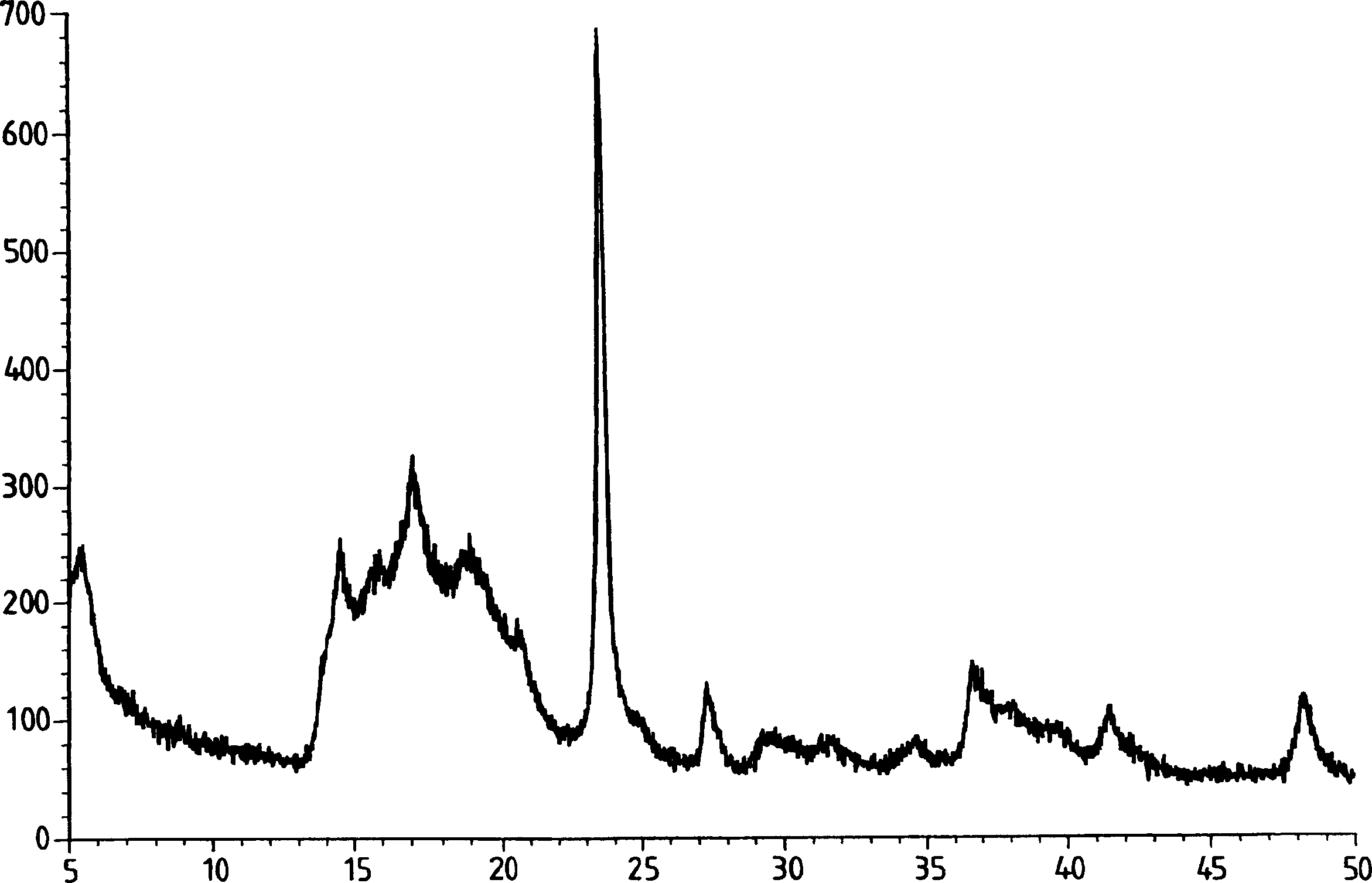

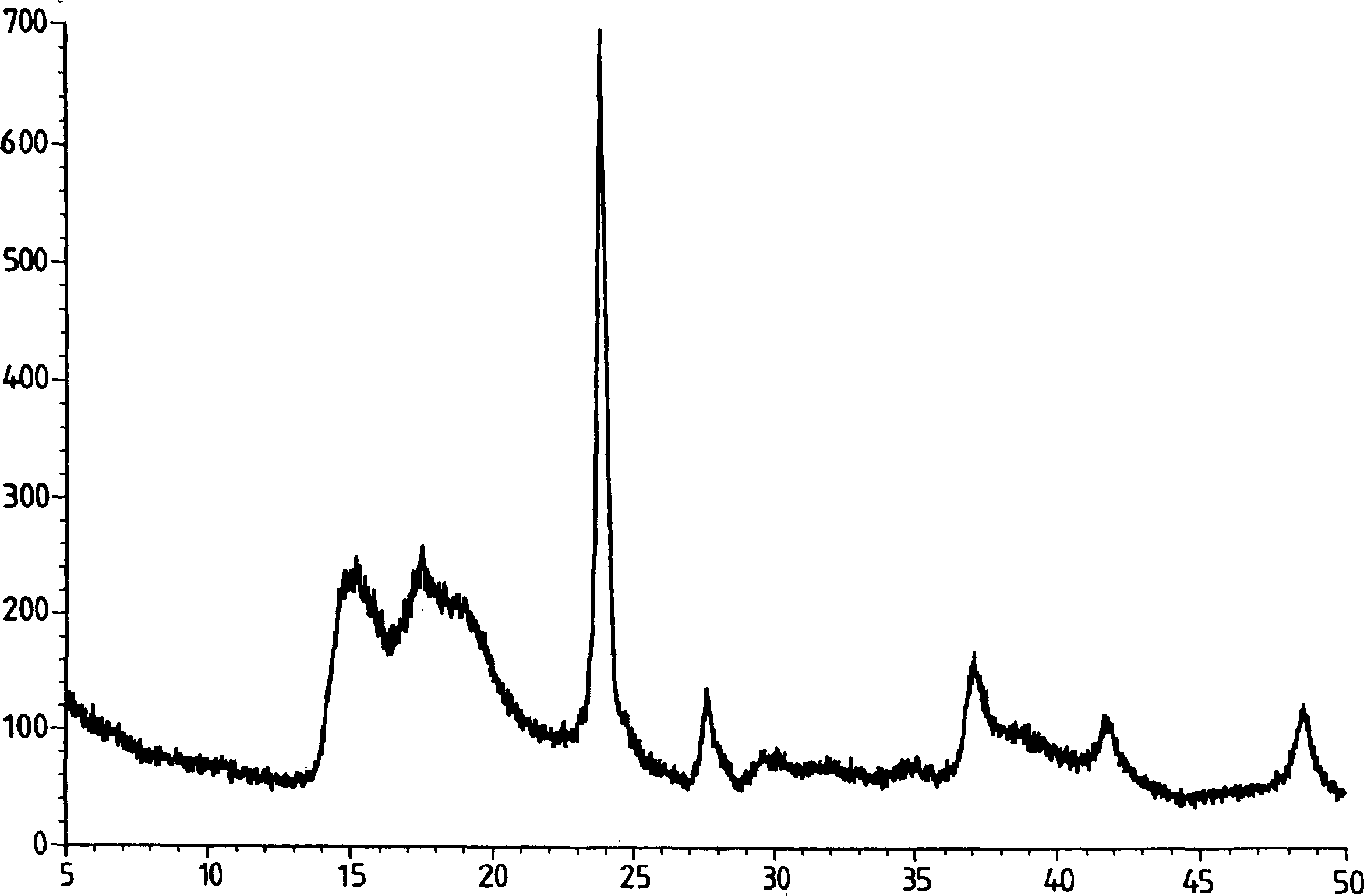

Processes for the preparation of double metal cyanide (DMC) catalysts

InactiveUS20060058182A1Low molar ratioOrganic-compounds/hydrides/coordination-complexes catalystsMetal cyanidesAlkalinityPolyol

The present invention provides processes for making double metal cyanide (DMC) catalysts, by simultaneously controlling the alkalinity of the transition metal salt, the molar ratio of water to total cations, the molar ratio of ligand to transition metal cation, the molar ratio of metal salt anion to metal cyanide anion, and the presence of a polymeric complexing ligand during the catalyst precipitation step. The substantially amorphous catalysts made by the present invention are highly active and may find use in the production of polyols.

Owner:BAYER MATERIALSCIENCE AG

Delayed-setting calcium phosphate pastes

Owner:ETEX

Copolymerization of propylene oxide and carbon dioxide and homopolymerization of propylene oxide

Copolymers of propylene oxide and carbon dioxide and homopolymers of propylene oxide are made using two dimensional double metal cyanide complexes having the formula Co[M(CN)4] or hydrated or partially dehydrated form thereof. There is no propylene carbonate by product in the copolymerization.

Owner:CORNELL RES FOUNDATION INC

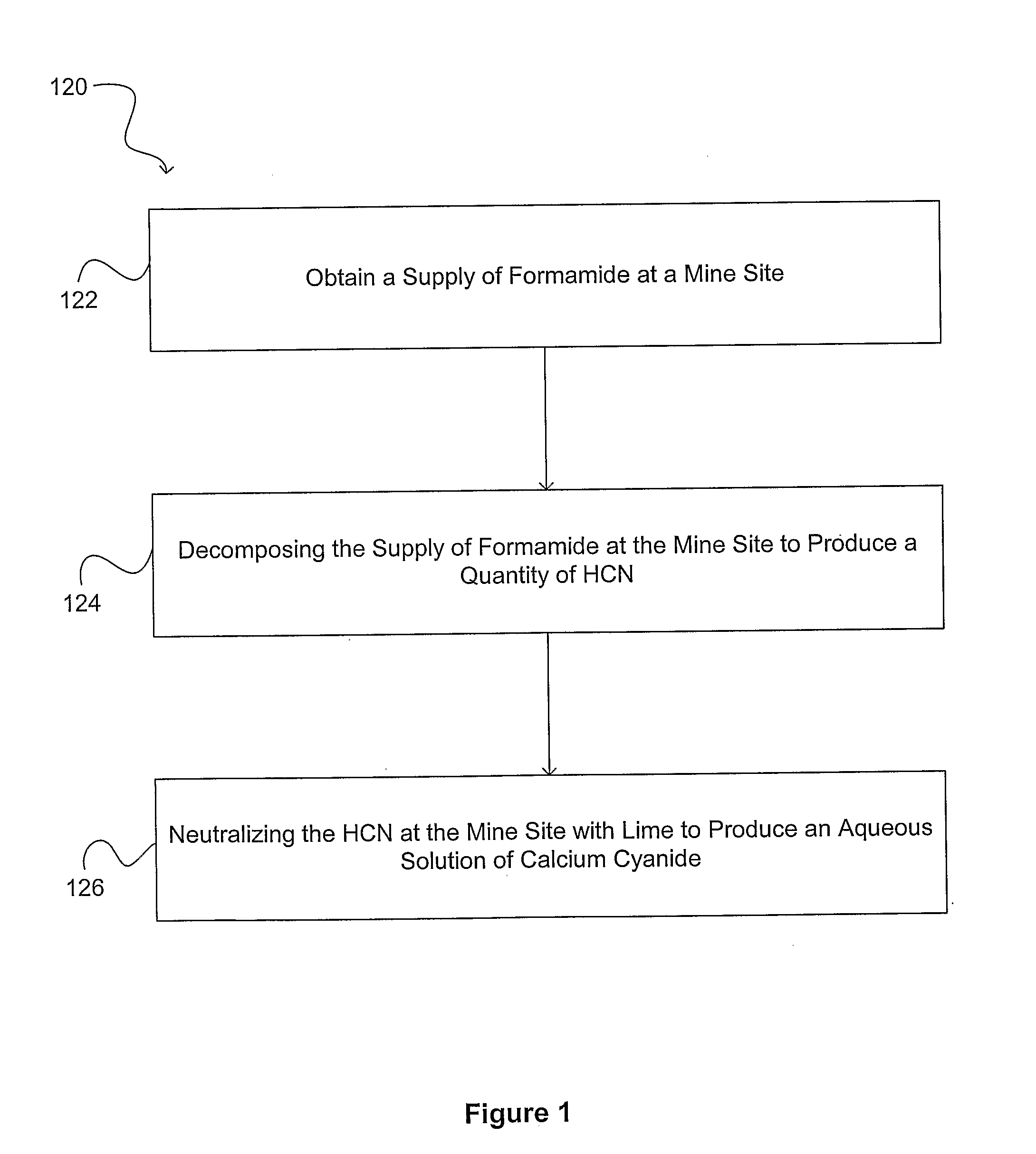

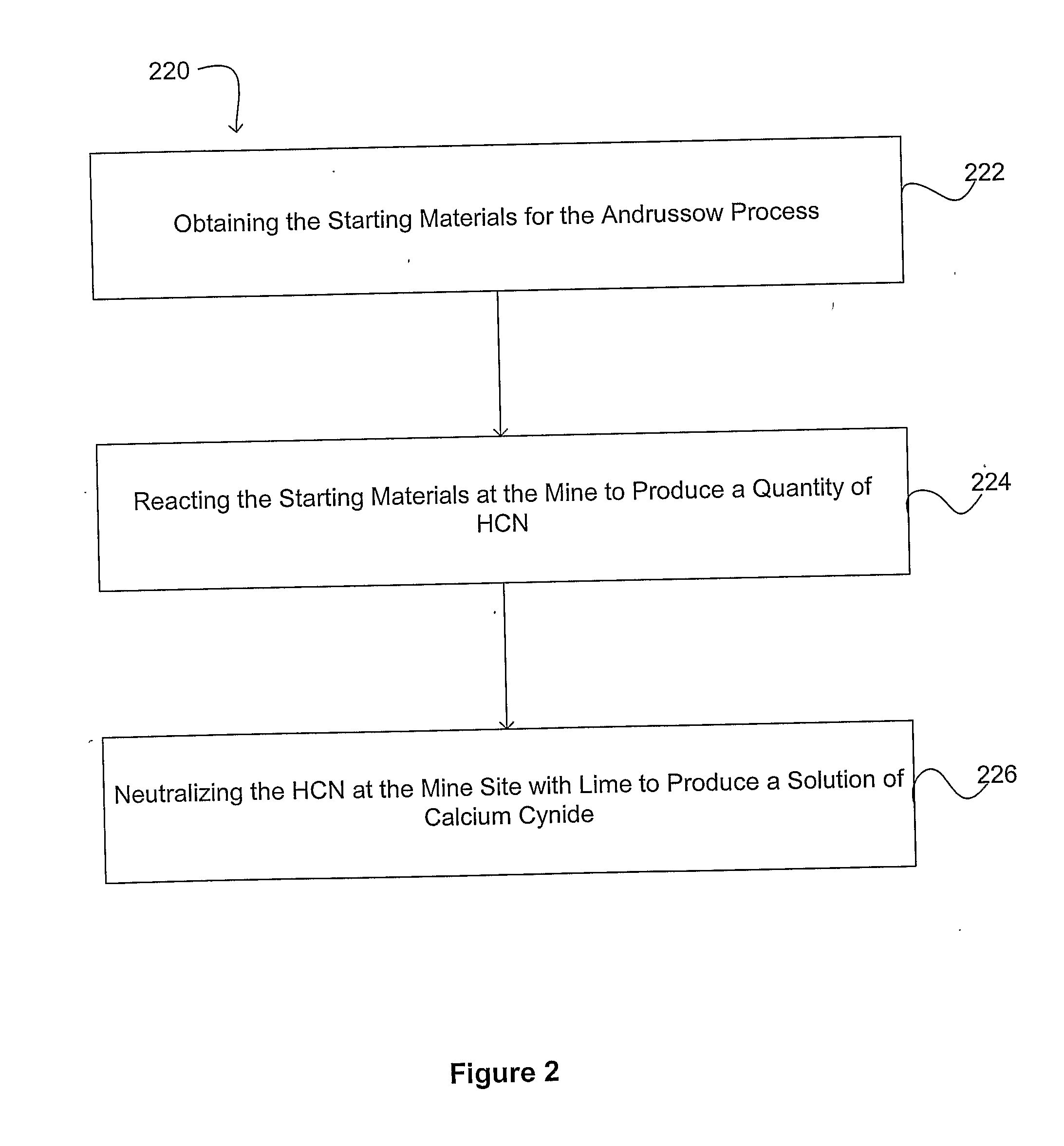

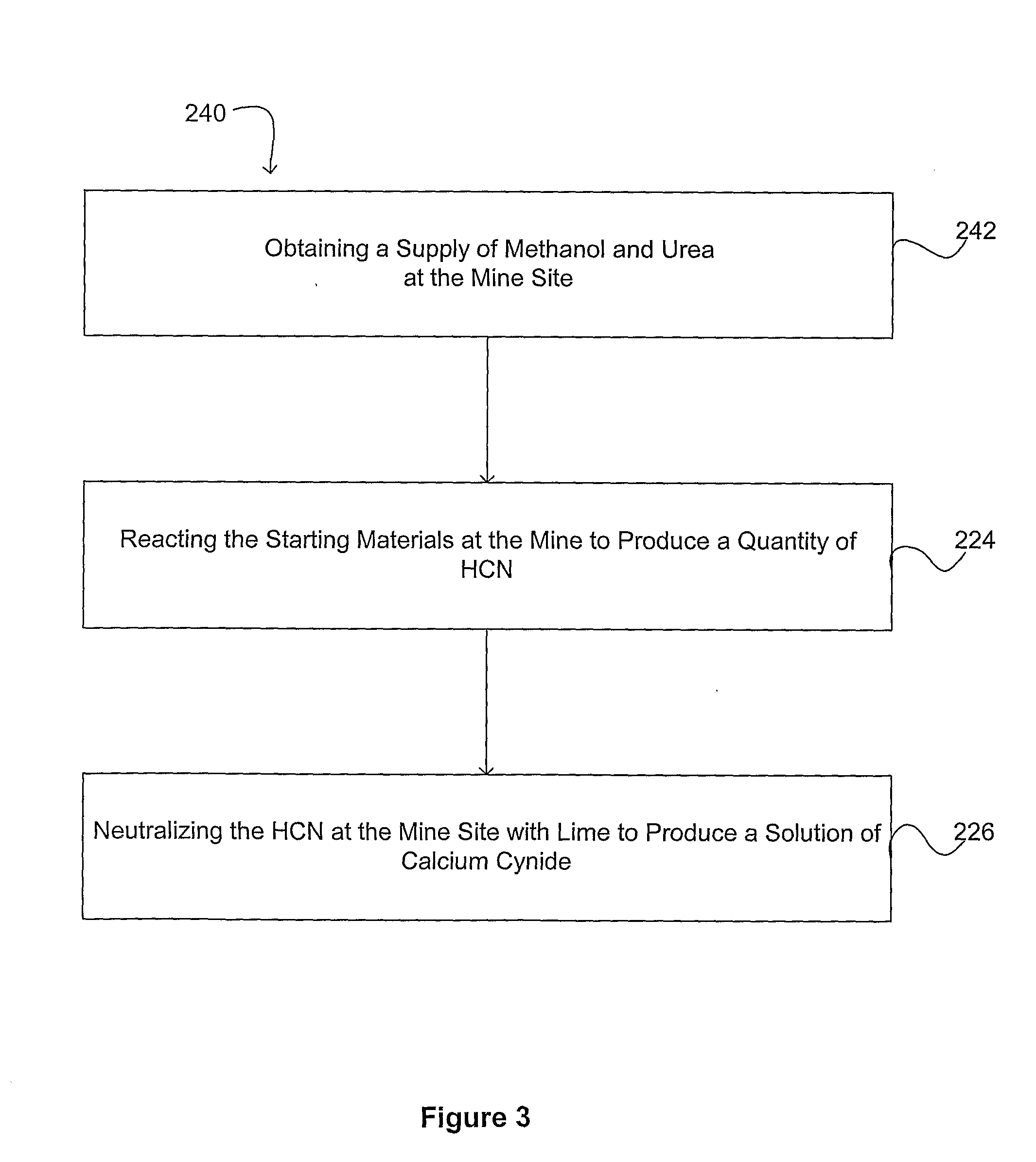

Producing Calcium Cyanide At A Mine Site Using Easily Transportable Starting Materials

InactiveUS20080203809A1Big investmentNo longer operatesUnderground miningFluid removalFormamideAlternative methods

Owner:CYANCO

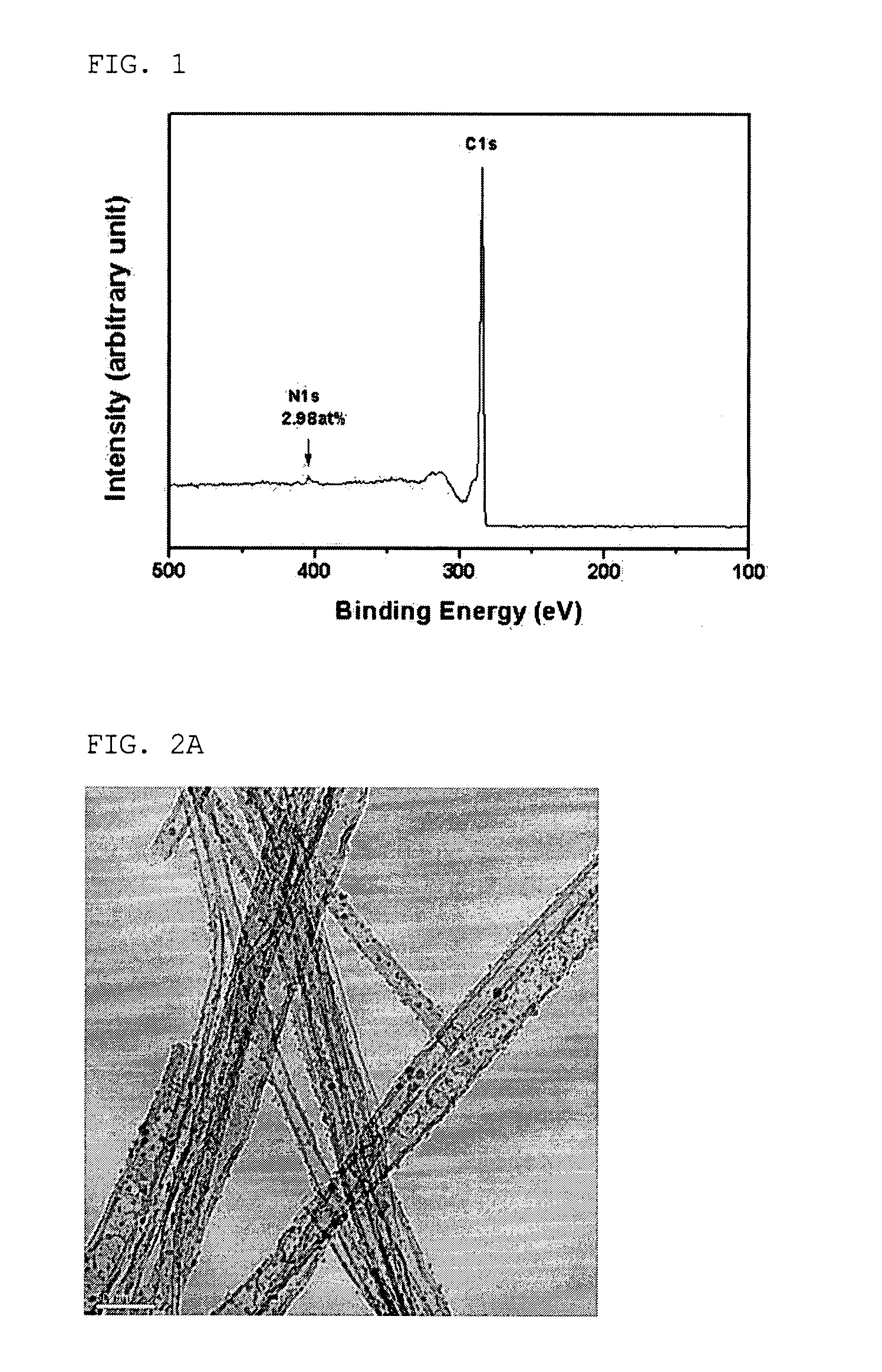

Nitrogen-mediated manufacturing method of transition metal-carbon nanotube hybrid materials

Owner:KOREA ADVANCED INST OF SCI & TECH

Aptamer sensor and preparation method thereof

ActiveCN110333277AStrong biocompatibilityGood biocompatibilityMaterial electrochemical variablesMetal cyanidesNickelElectrode material

The invention relates to an aptamer sensor and a preparation method thereof, and belongs to the technical field of electrochemical sensors. The invention provides the aptamer sensor comprising an electrode, an electrode material coated to the surface of the electrode and used for the aptamer sensor, and a nucleic acid aptamer attached to the electrode material used for the aptamer sensor, whereinthe electrode material used for the aptamer sensor is nickel-cobalt Prussian-blue analogue. The aptamer sensor exhibits good selectivity, stability, reproducibility, reactivity and applicability and low limit of detection. For example, the aptamer sensor obtained by a bare gold electrode, nickel-cobalt Prussian-blue analogue and carcino-embryonic antigen nucleic acid aptamer exhibits high sensitivity and selectivity on CEA (Earcino-Embryonic Antigen) detection in a range of 1.0fg.mL<-1>-5.0ng.mL<-1> (1.62fM), and the application of the nickel-cobalt Prussian-blue analogue is widened.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

Process for preparation of double metal cyanide (DMC) catalyst

Owner:BAYER MATERIALSCIENCE AG

Method for extracting copper-containing cyanided waste liquid by solvent to recycle copper

InactiveCN106350677APhotography auxillary processesProcess efficiency improvementLiquid wasteHigh concentration

The invention discloses a method for extracting copper-containing cyanided waste liquid by a solvent to recycle copper. The method is characterized in that quaternary ammonium salt is used as an extracting agent, and a sodium chloride solution is used as a back washing agent; by extraction and back washing, enrichment of the copper in waste water is realized, and the treatment volume of the waste water is reduced; the copper can be recycled from high-concentration copper-containing back washing liquid in various ways; the method does not have the extraction effect on cyanides existing in a free state, so that an extracting solution can be directly returned to a cyanidation leaching procedure to recycle the cyanides.

Owner:NORTHEASTERN UNIV

Process for simultaneous preparation of nanocrystalline anatase titanium dioxide powder and hydrazine monohydrochloride

InactiveUS7510694B2Inhibition of agglomerationMaterial nanotechnologyTitanium dioxideHydrazine compoundHydrazine monohydrate

The present invention relates to an environmentally benign process for the simultaneous preparation of nanocrystalline anatase titanium dioxide and hydrazine mohydrochloride, in substantial amounts from the acidic aqueous titanium tetrachloride solution by reacting with hydrazine monohydrate at ambient conditions of temperature and pressure. The process of the present invention is simple, easy to operate, pollution free, high in product purity and homogeneous in product particle.

Owner:COUNCIL OF SCI & IND RES

Thermal expansion inhibitor, zero thermal expansion material, negative thermal expansion material, method for inhibiting thermal expansion, and method for producing thermal expansion inhibitor

InactiveUS7632480B2Broaden magnetic transition temperature rangeKeep thermal expansionOther chemical processesNitrogen-metal/silicon/boron binary compoundsNitrideMaterials science

Owner:RIKEN

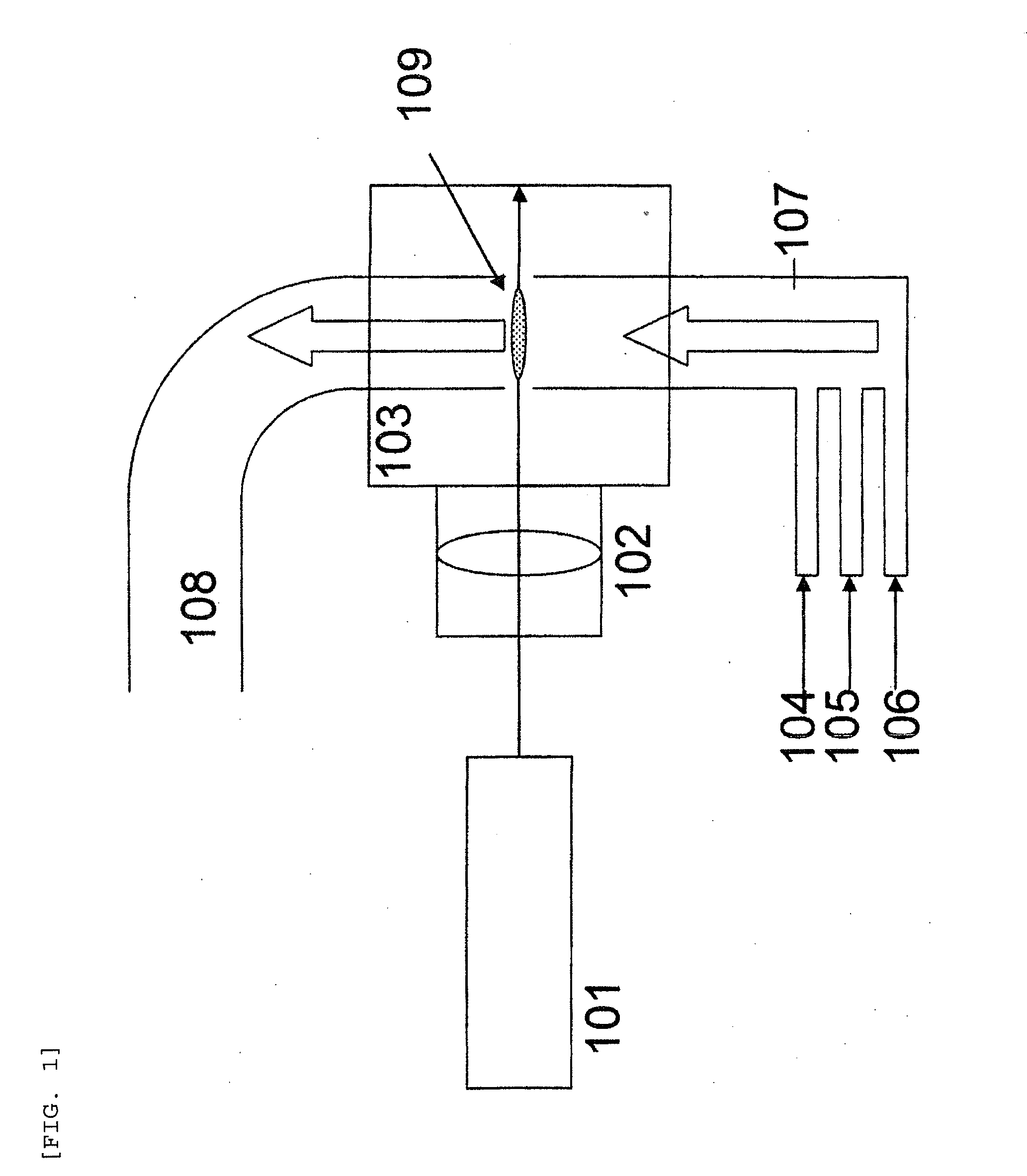

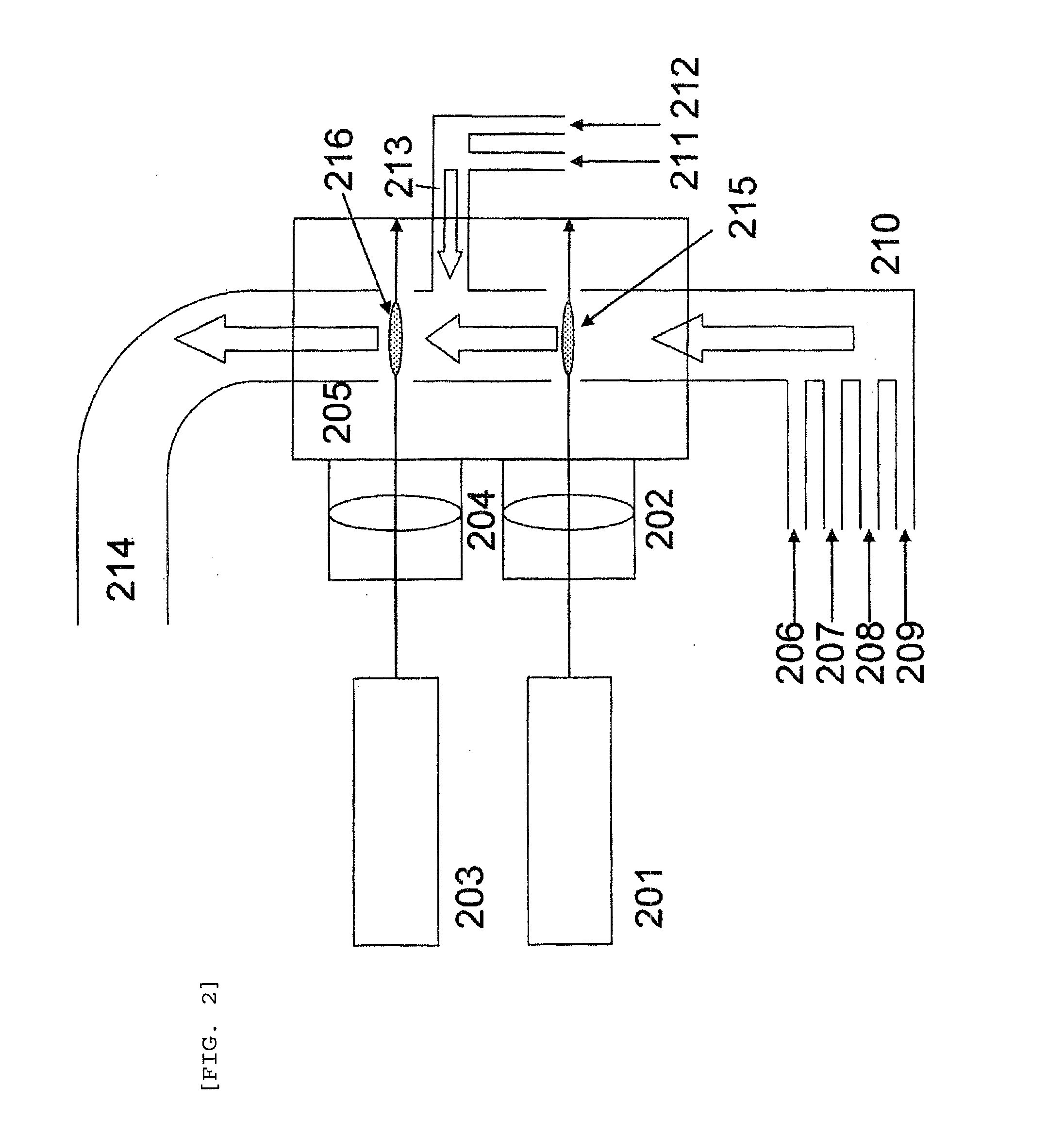

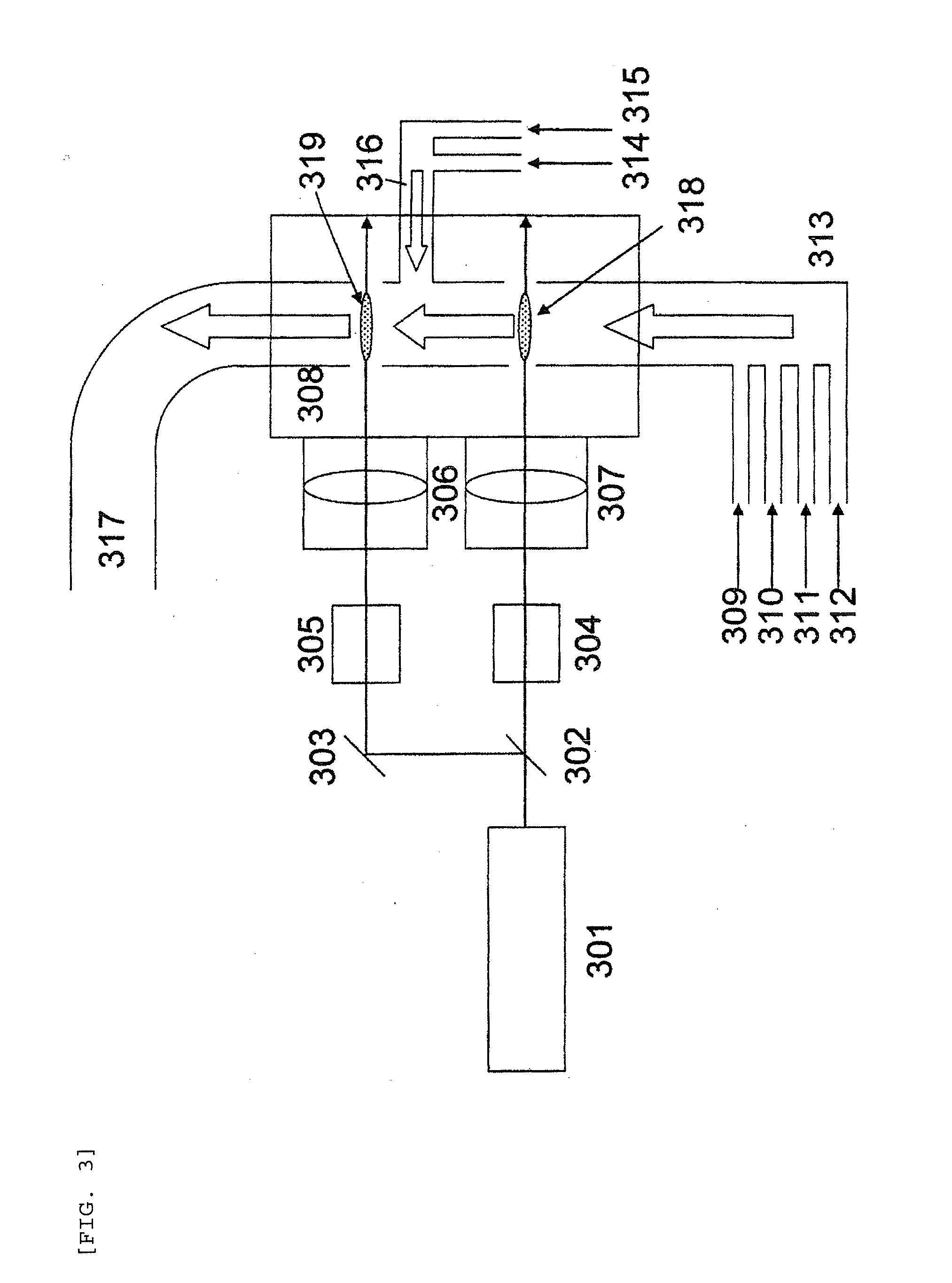

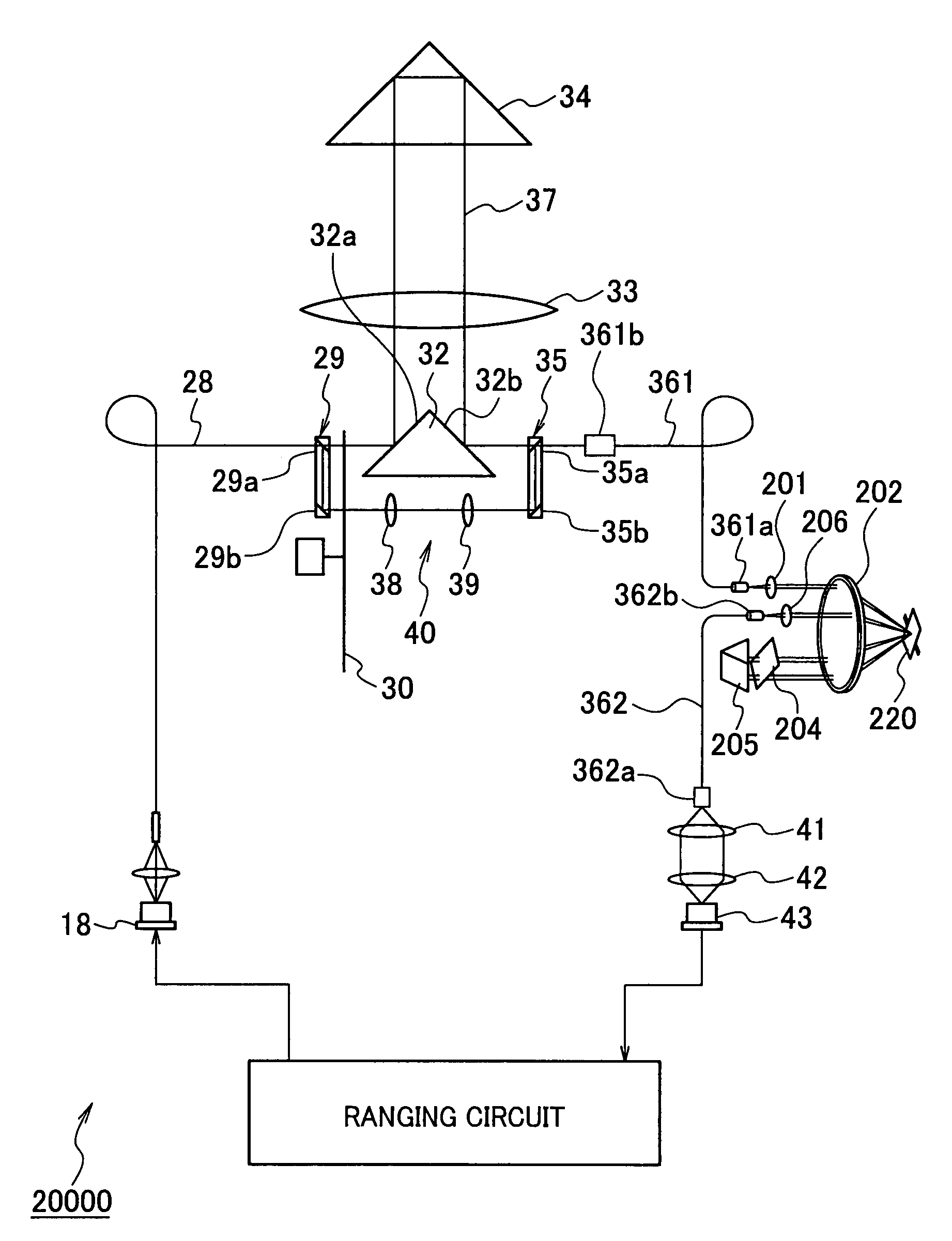

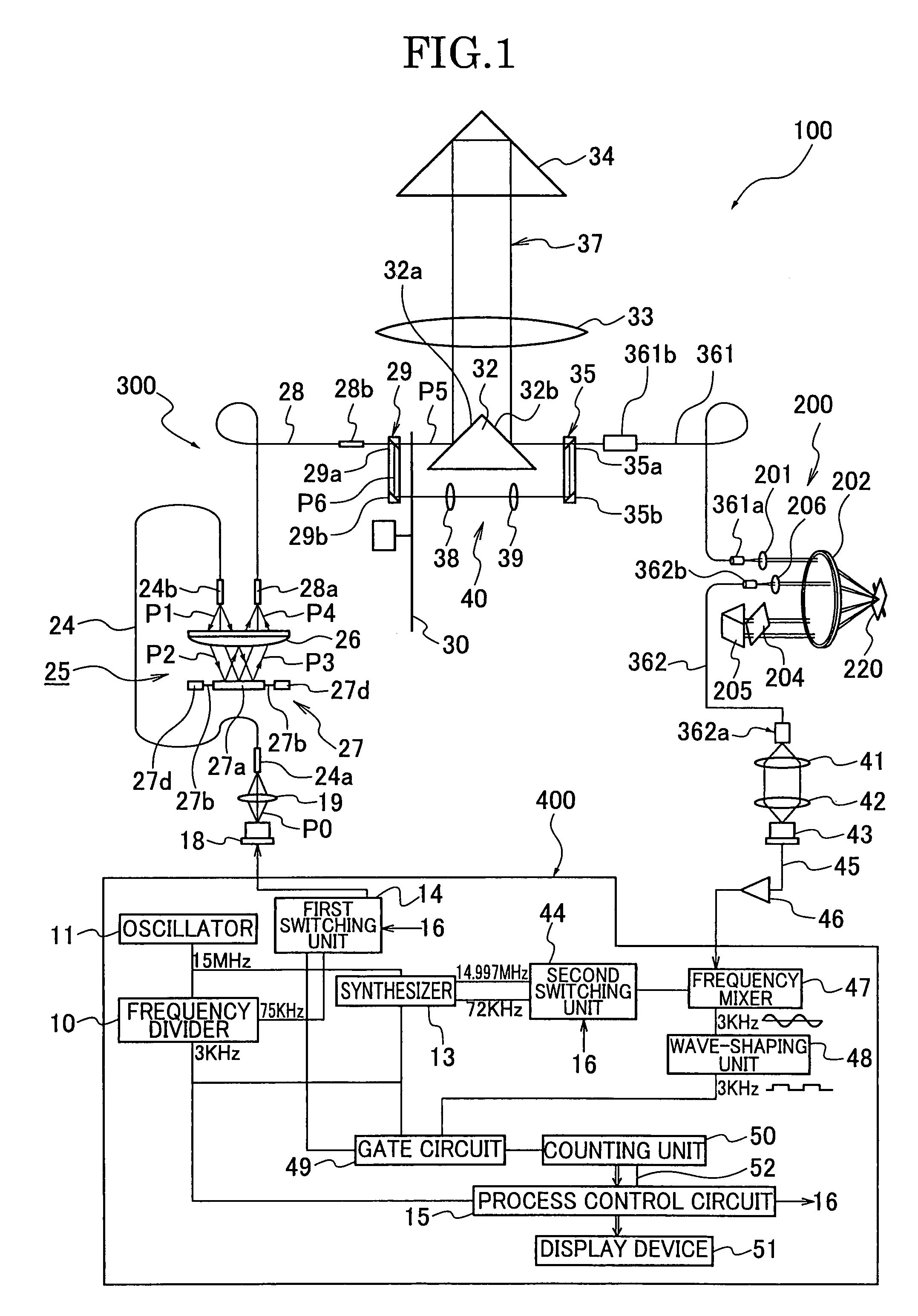

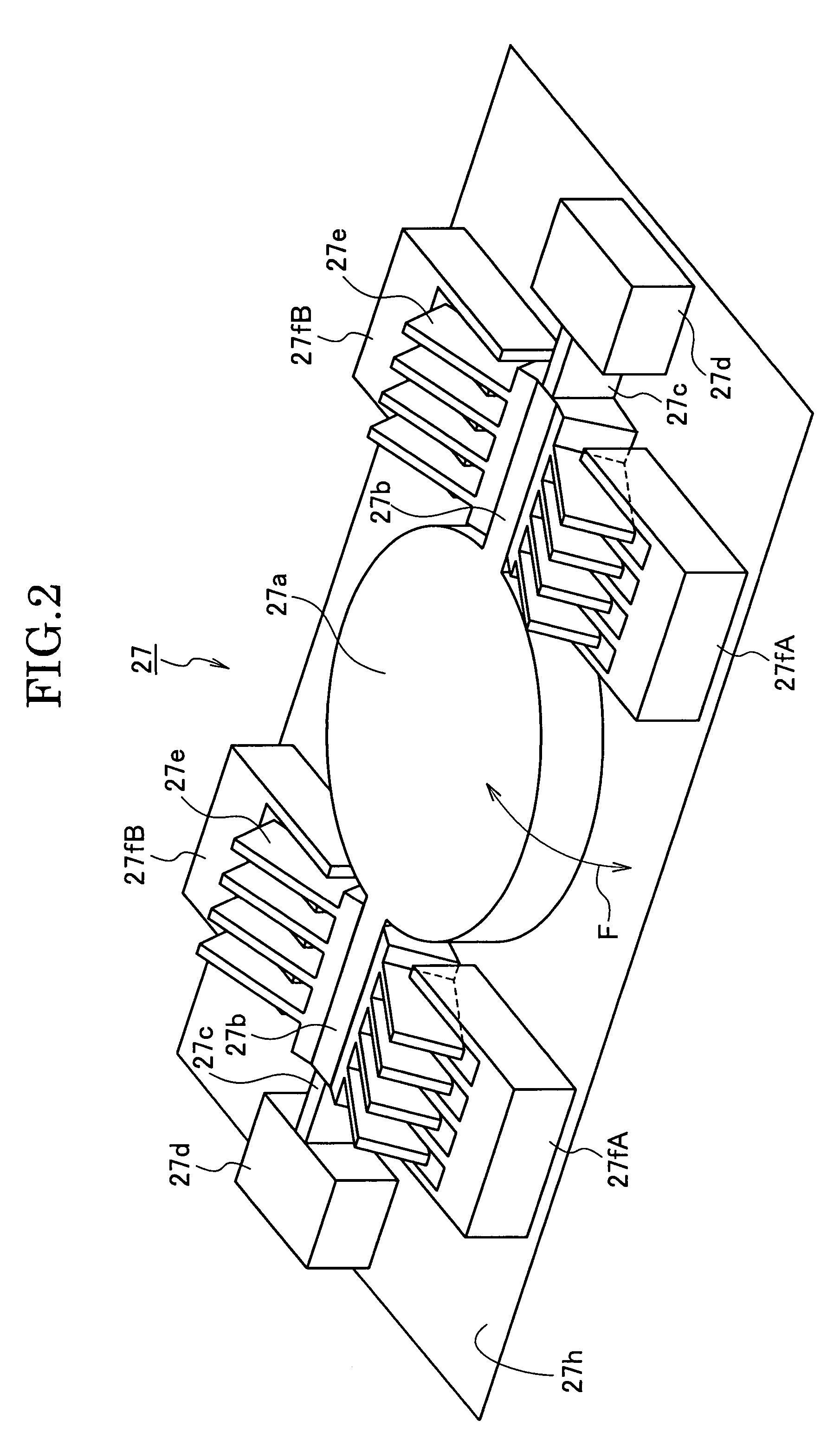

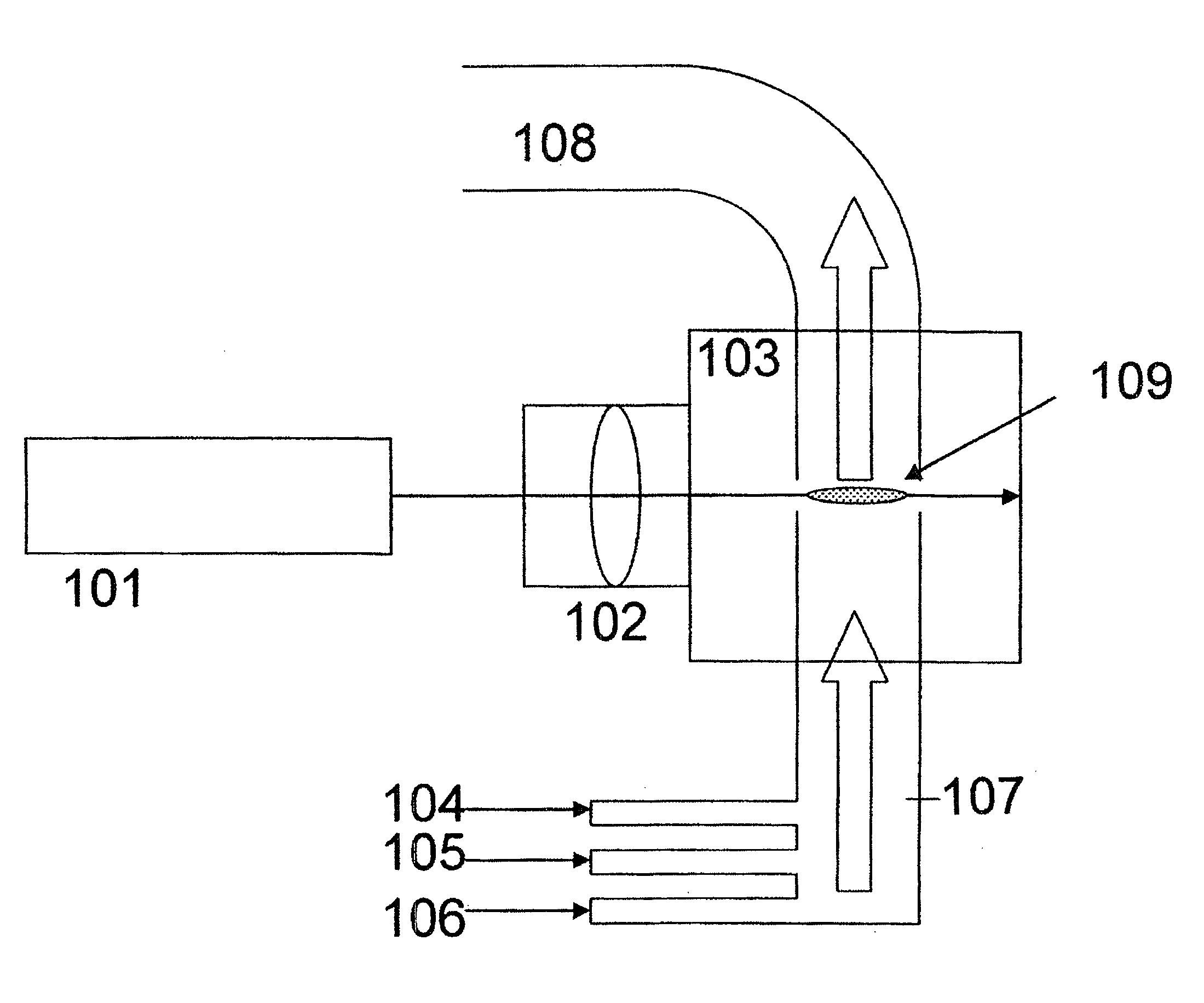

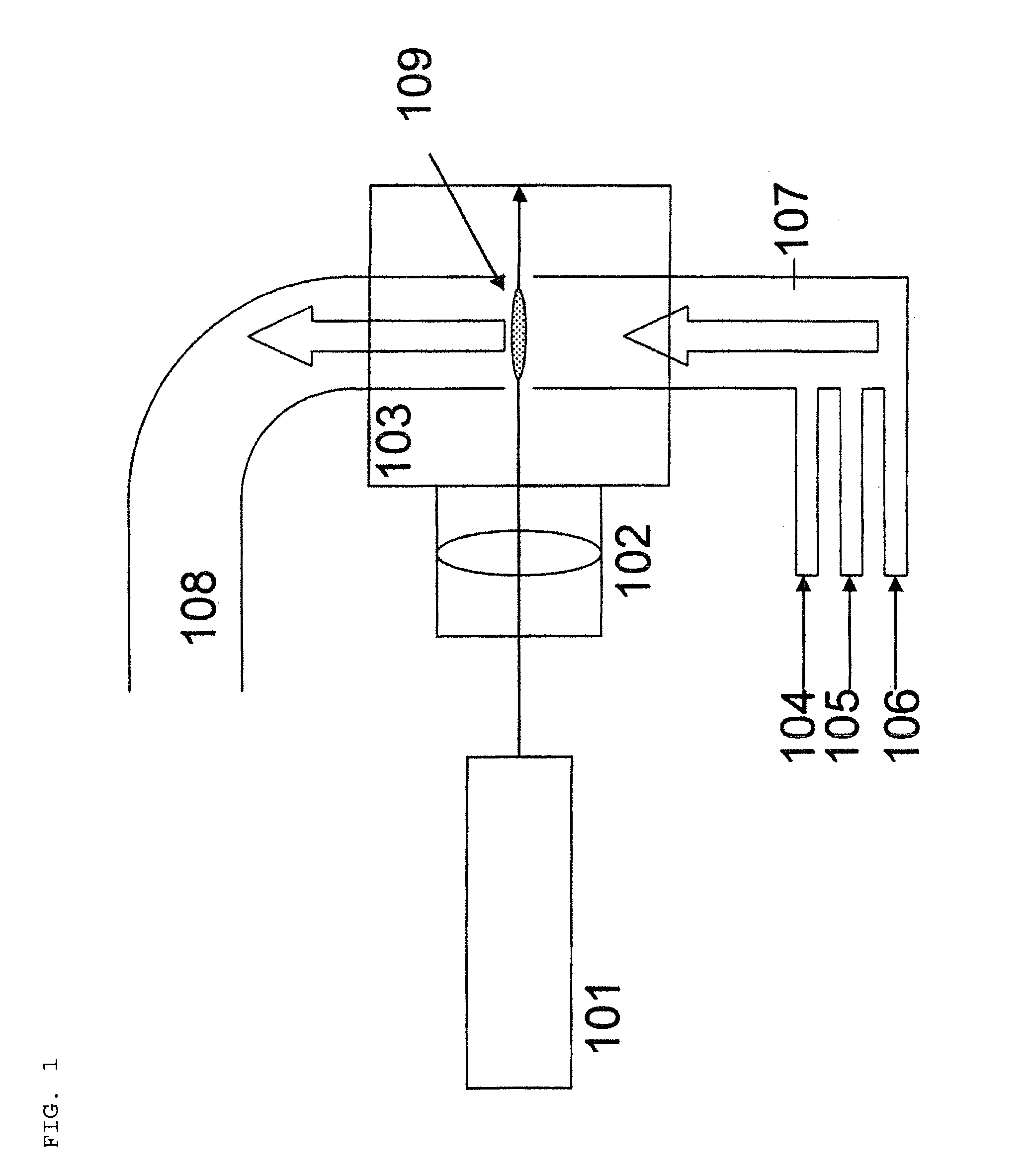

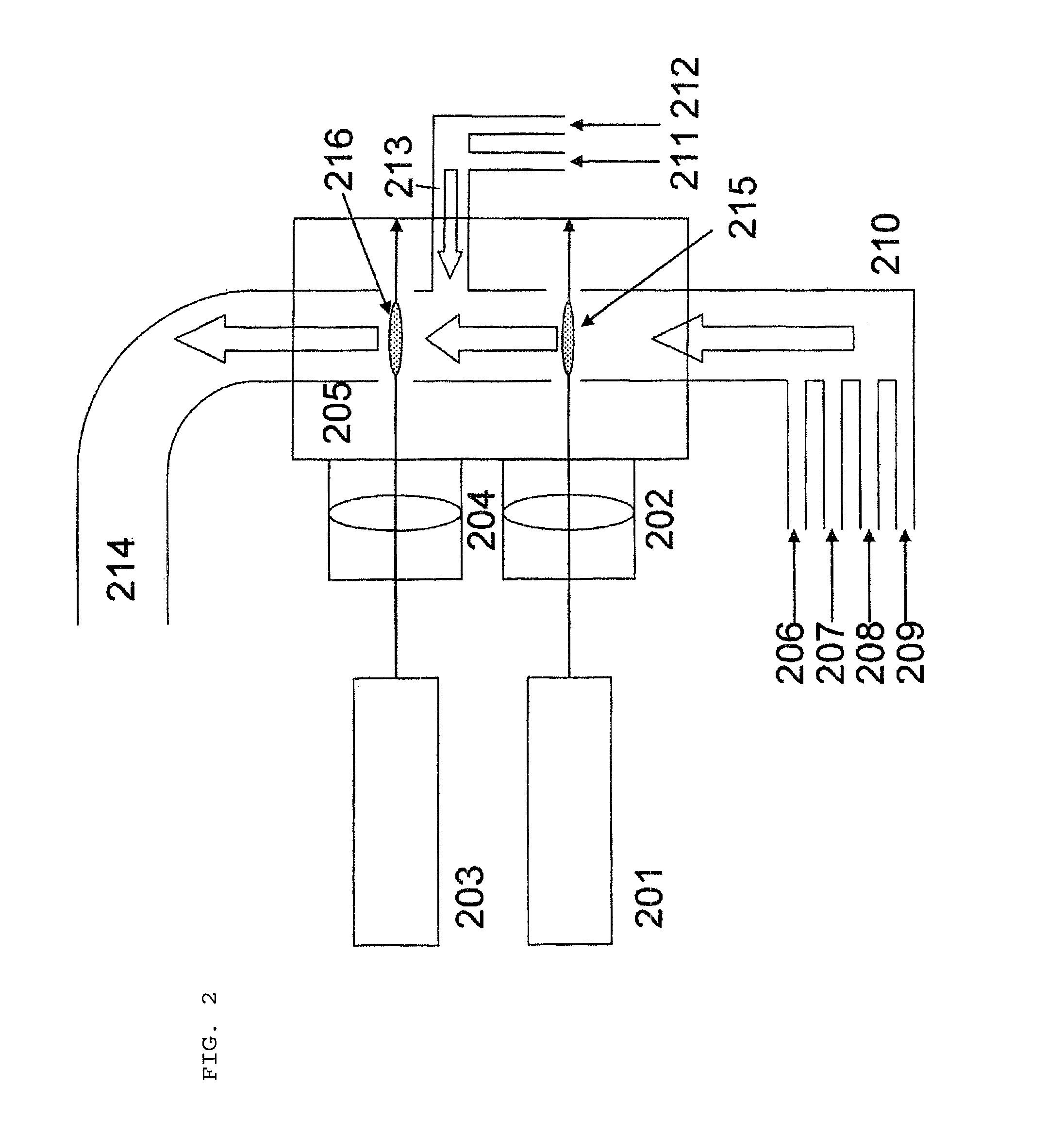

Variable optical attenuator and ranging apparatus using the same

A variable optical attenuator for adjusting a power of light which is output from an output end of a first optical fiber and is to be led to an input end of a second optical fiber, includes a reflection member which reflects the light output from the output end of the first optical fiber, a density filter which transmits the light reflected from the reflection member and controls the power of the light which is transmitted by the density filter depending on a light-transmitting position on the density filter, and an optical member which reflects the light transmitted by the density filter to lead the light to the reflection member. The reflection member is disposed tiltably, the power of the light transmitted by the density filter attenuates along a direction in which the light-transmitting position is changed, and the light-transmitting position of the light is changed by tilting the reflection member.

Owner:KK TOPCON

Process for production and use of carbonitride mixture particles or oxycarbonitride mixture particles

InactiveUS8703638B2Maintain good propertiesUniform particle size distributionMaterial nanotechnologyElectric discharge heatingLaser lightNitrogen oxide

The invention has an object of providing catalysts that are not corroded in acidic electrolytes or at high potential, have excellent durability and show high oxygen reducing ability. An aspect of the invention is directed to a process wherein metal carbonitride mixture particles or metal oxycarbonitride mixture particles are produced from an organometallic compound of a Group IV or V transition metal, a metal salt of a Group IV or V transition metal, or a mixture of these compounds using laser light as a light source.

Owner:SHOWA DENKO KK

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com