Patents

Literature

30results about How to "Meet the requirements of biochemical treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

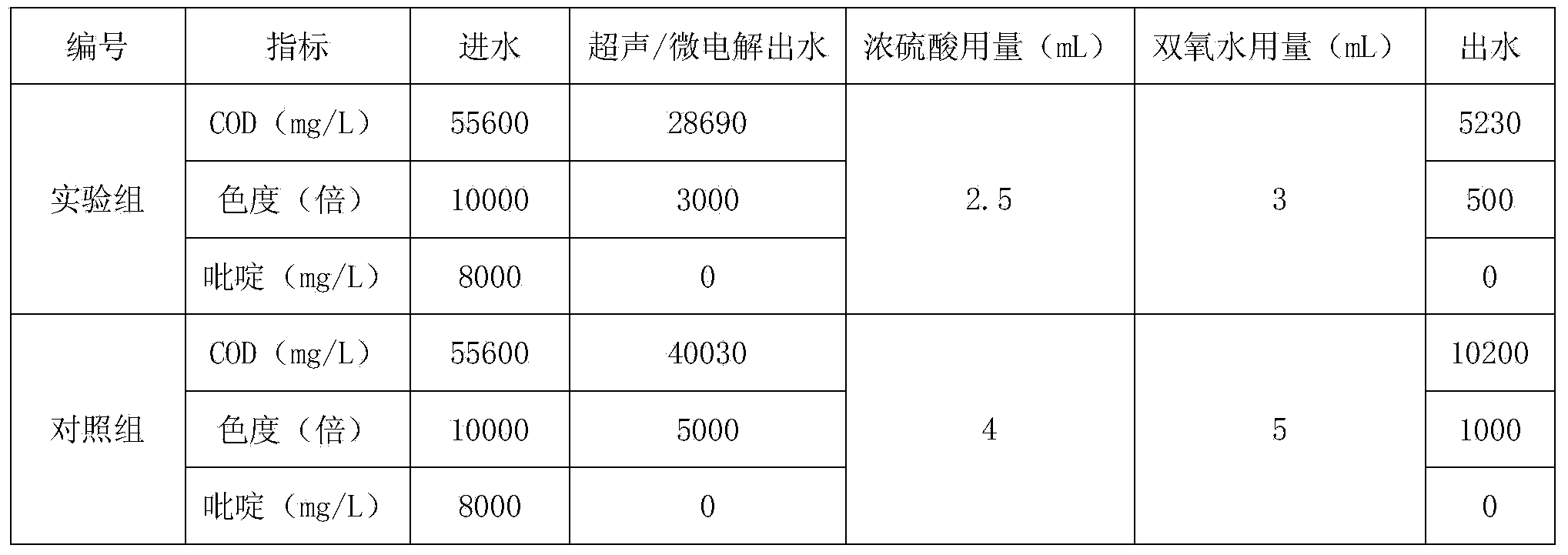

A method for recycling coke oven gas desulfurization and decyanation waste liquid by vacuum potassium carbonate method

ActiveCN102267769AMeet the requirements of biochemical treatmentMultistage water/sewage treatmentMetal cyanidesHigh concentrationProcess equipment

The invention discloses a vacuum potassium carbonate method for utilizing coke oven coal gas desulphurization and decyanation waste liquid recycling as a resource. The method is also suitable to be used in other waste liquids containing high concentration cyanide and sulfide. According to the method, cyanide and sulfide are simultaneously precipitated; the precipitate is separated by centrifugation; the waste liquid processed from desulphurization and decyanation is processed through pH regulation and coagulant dosing; the processed waste liquid is discharged into a carbonization wastewater biochemical treatment system, and is treated; ferrocyanide precipitate is subject to a reaction with added lye in a high temperature, and is converted into potassium ferrocyanide; potassium ferrocyanide is disoluted, and is separated by centrifugation, such that potassium ferrocyanide mother liquor is obtained; potassium ferrocyanide mother liquor is cooled and crystallized, such that potassium ferrocyanide product is obtained. The method has advantages of simple equipment and convenient operation. With the method, simultaneous desulphurization and decyanation can be realized, requirements of subsequent treatments are satisfied, the wastes are utilized as resources, and economic benefits are brought in.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

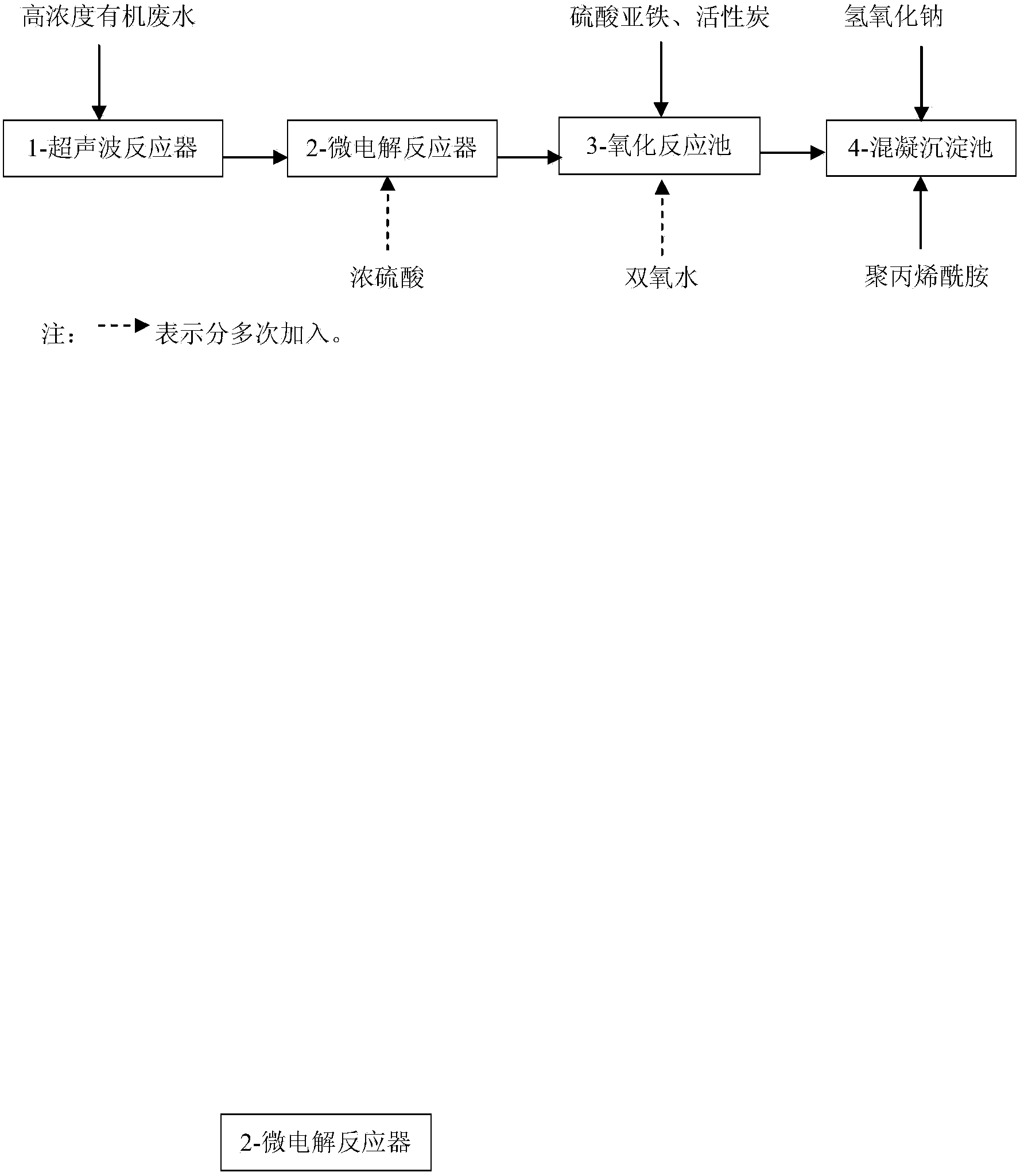

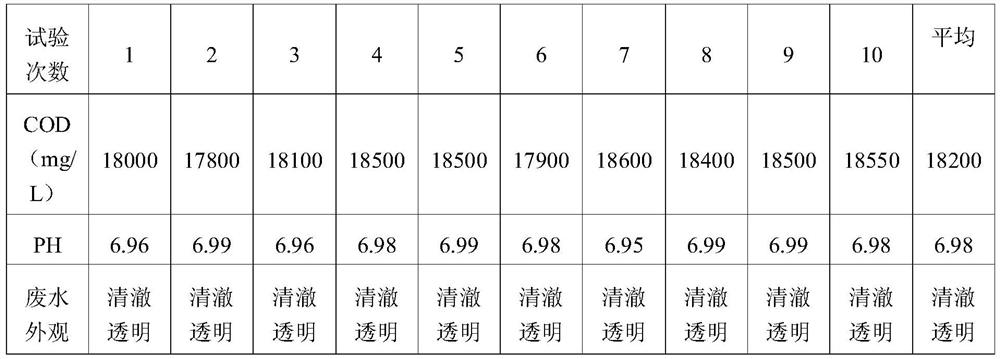

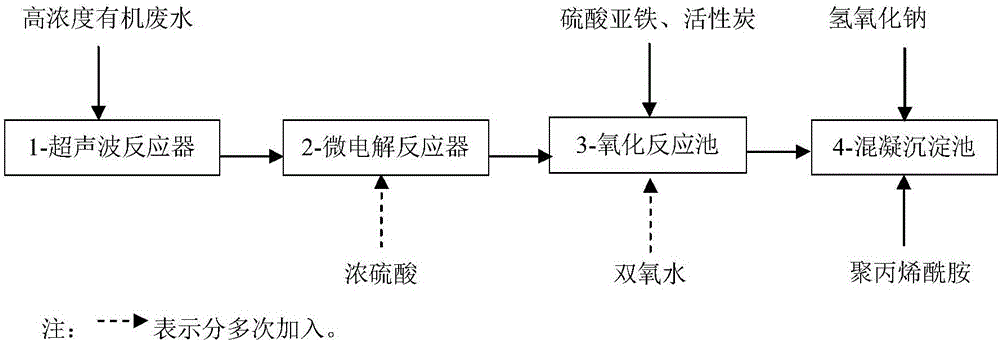

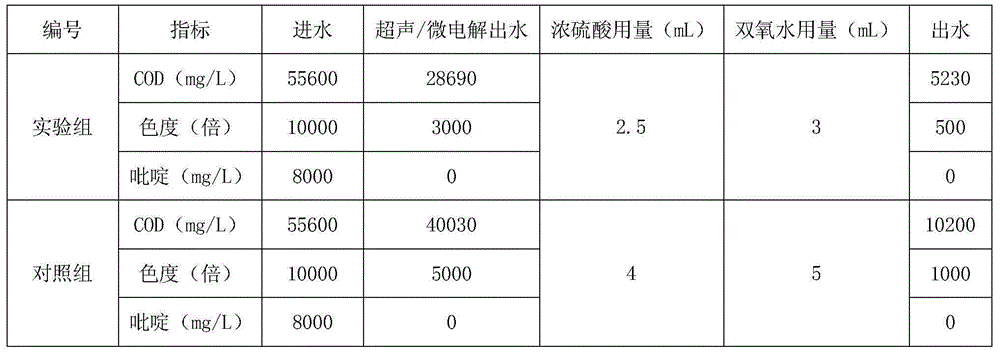

Treatment method of high-concentration organic wastewater

InactiveCN103864250AImprove decomposition efficiencyReduce lossMultistage water/sewage treatmentHigh concentrationChemical oxygen demand

The invention discloses a treatment method of high-concentration organic wastewater. The method has a favorable treatment effect on high-concentration organic wastewater of which the COD (Chemical Oxygen Demand) concentration is larger than 50000mg / L and the chromaticity is larger than 10000 times. The hardly degradable substances in the treated wastewater can be degraded, so that the biodegradability of the treated wastewater is improved and the treated wastewater reaches the biochemical treatment requirement. The treatment method smartly combines ultrasonic splitting, micro-electrolytic decomposition and high-grade oxidation, and the problem that the high-concentration organic wastewater which has high COD and large toxicity and is difficulty biochemically degraded is solved.

Owner:苏州森荣环保处置有限公司

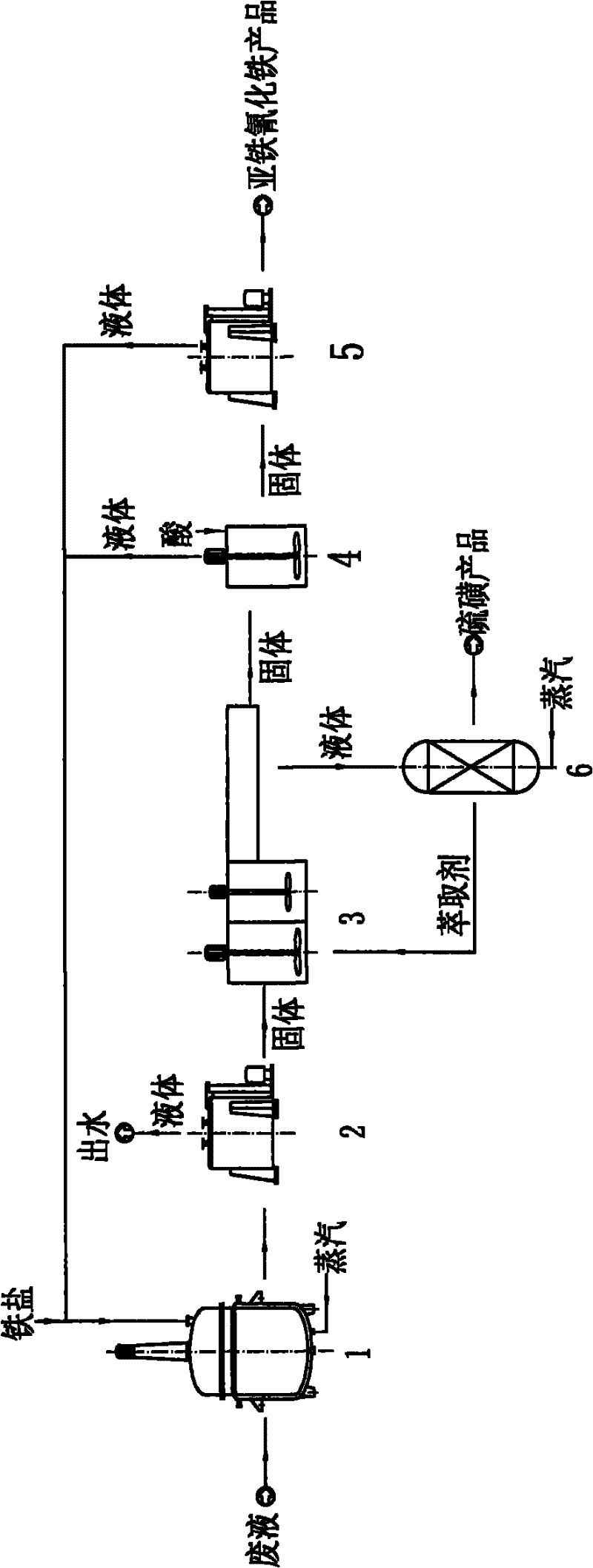

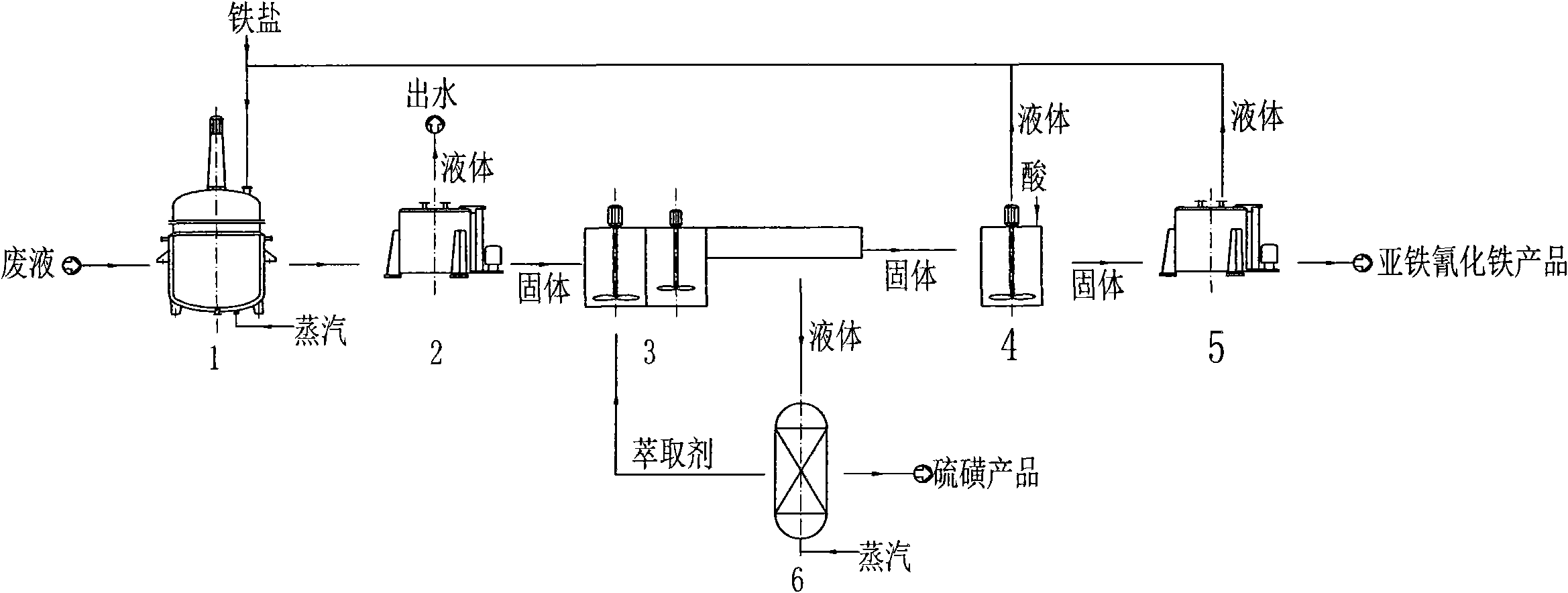

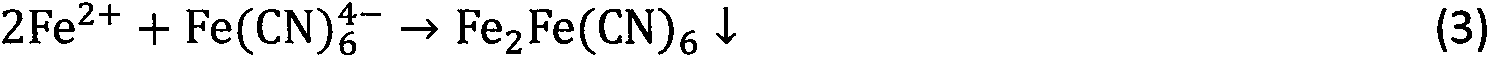

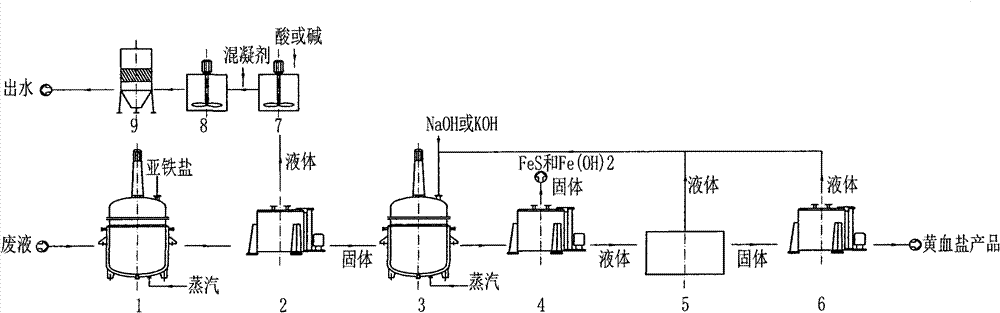

A resource recovery method for coke oven gas desulfurization and decyanation waste liquid

ActiveCN102267778AMeet the requirements of biochemical treatmentReduce toxic substancesSulfur preparation/purificationMultistage water/sewage treatmentChemistrySulfide

The invention provides a resource method of a waste liquid from coke oven gas desulphurization and decyanation. The method is also suitable for other waste liquids containing high-concentration cyanide and sulfide. Ferric salt is employed to oxidize sulfide in the waste liquid to elemental sulfur, meanwhile Fe<2+> is generated to react with cyanide to generate precipitates. After decyanation and desulphurization, the waste liquid is charged to a coking waste water biochemical treatment system for processing. The precipitates are washed and added with an extractant to extract the elemental sulfur and recover an elemental sulfur product; remaining ferrocyanide solid is treated with pickling, centrifuged and prepared into a ferrocyanide product. Equipment of the technology is simple and convenient for operation. Not only can simultaneous desulphurization and decyanation be realized to meet requirements of subsequent processing, but also resource of waste can be realized; therefore, the method has important environmental and economic significance.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

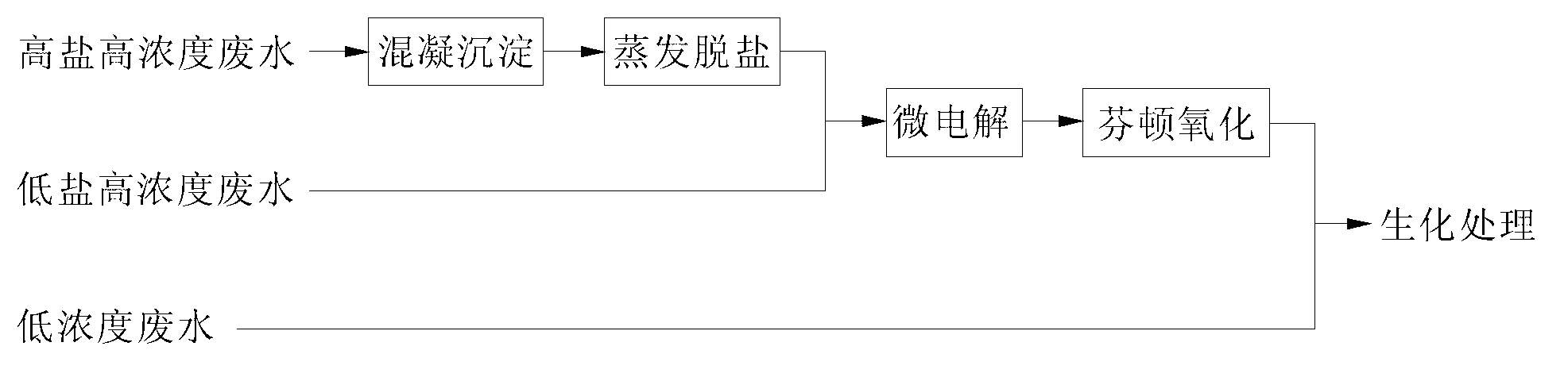

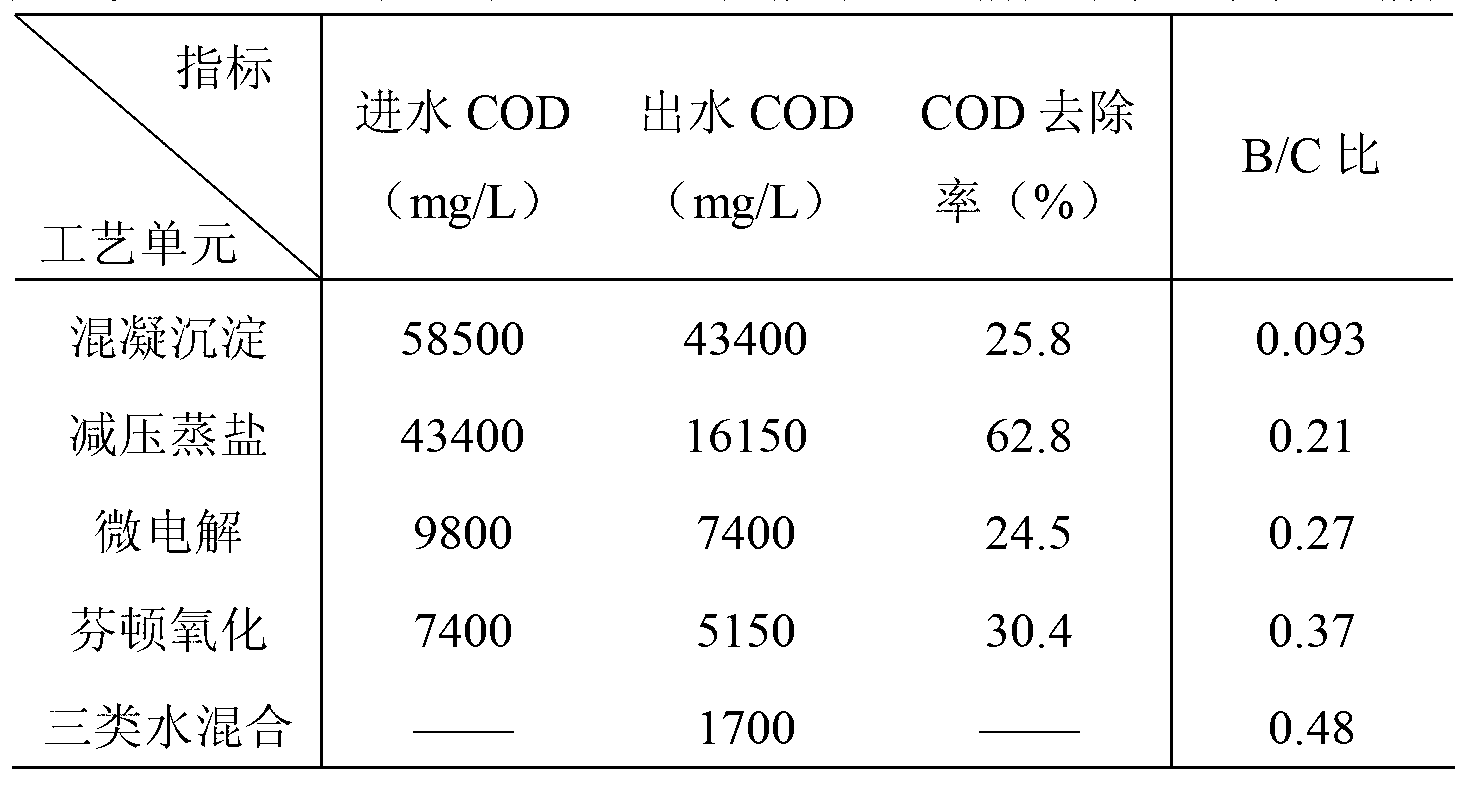

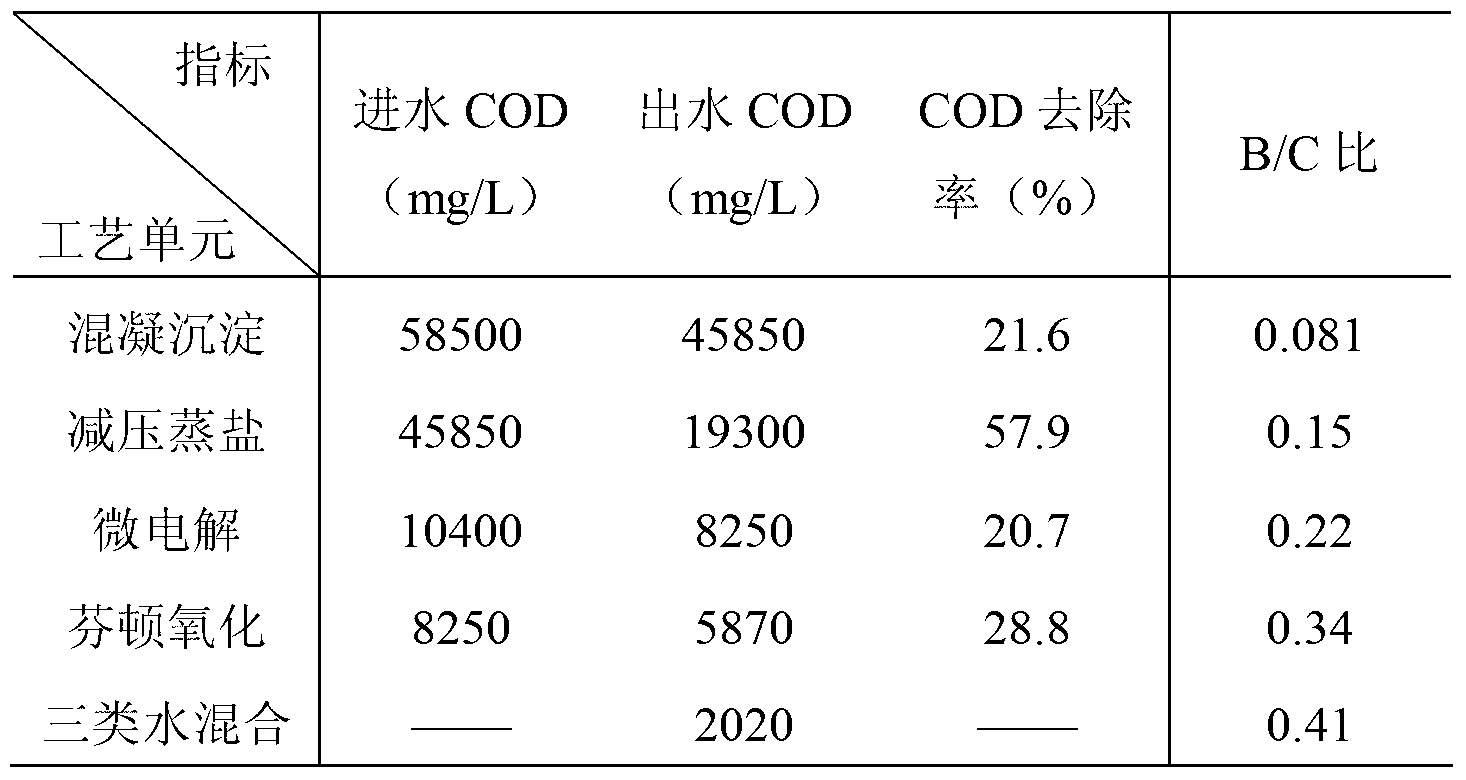

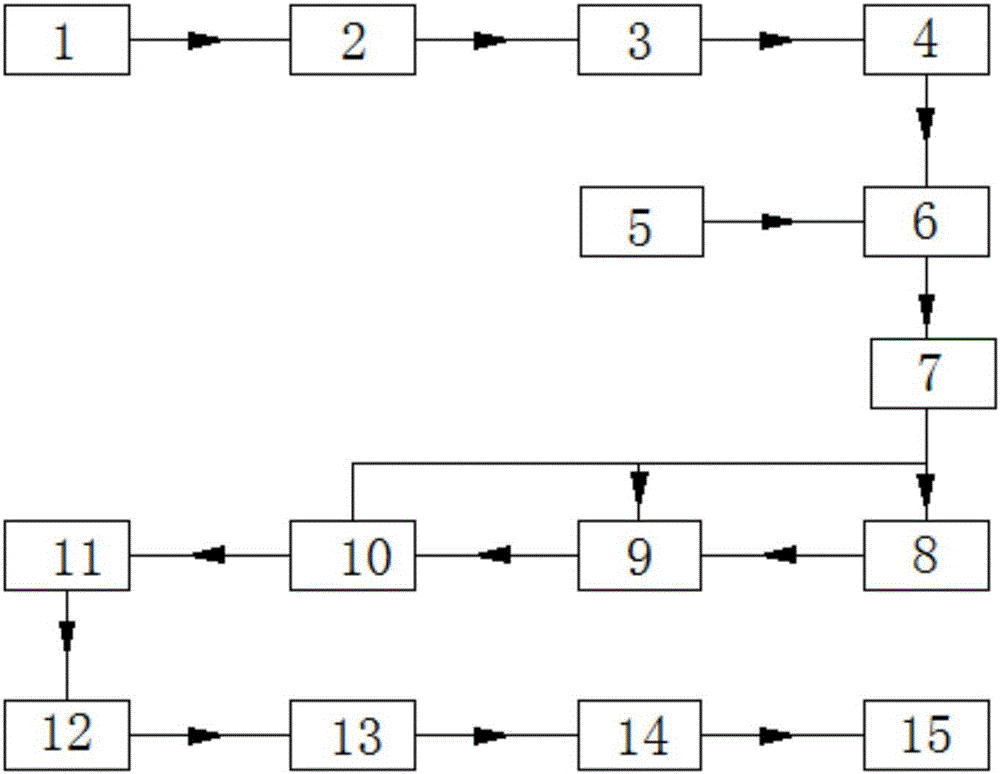

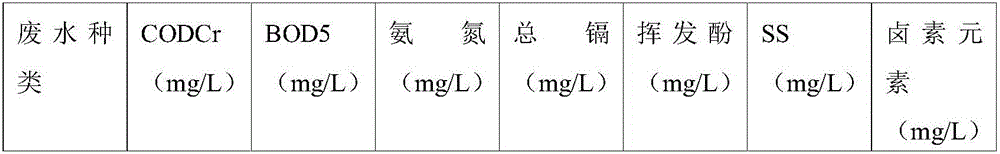

Pre-treatment technology of 3-chloro-2-hydrazinopyridine production waste water

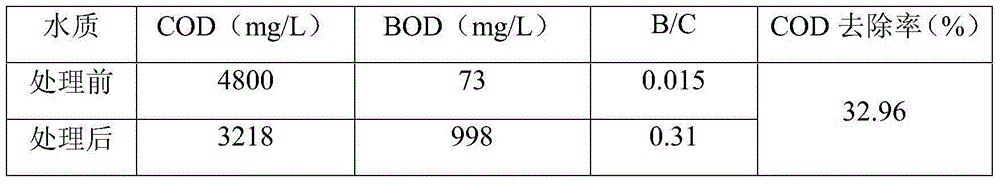

InactiveCN103253829ATargetedGood processing effectMultistage water/sewage treatmentNature of treatment waterPre treatmentToxicity

The invention relates to a pre-treatment technology of 3-chloro-2-hydrazinopyridine production waste water. The pre-treatment technique is characterized by comprising the steps of separating and collecting 3-chloro-2-hydrazinopyridine production waste water, and carrying out separation treatment aiming at the water quality characteristics of all types of waste water. According to the pre-treatment technology of 3-chloro-2-hydrazinopyridine production waste water, the defects that an existing pyridine organic matter production waste water pretreatment technology is high in cost, the reaction conditions are harsh, biochemical inflowing water dilution ratio is large, the treatment is difficult to achieve the standard, and the like can be overcome, the separation collection and separation treatment to the 3-chloro-2-hydrazinopyridine production waste water can be realized, the pretreatment technology is strong in pertinence, strong in practicability, remarkable in effect, lower in cost, and convenient to operate, the biological toxicity of the waste water can be greatly reduced, and the biodegradability of the waste water can be enhanced.

Owner:NANJING UNIV OF TECH

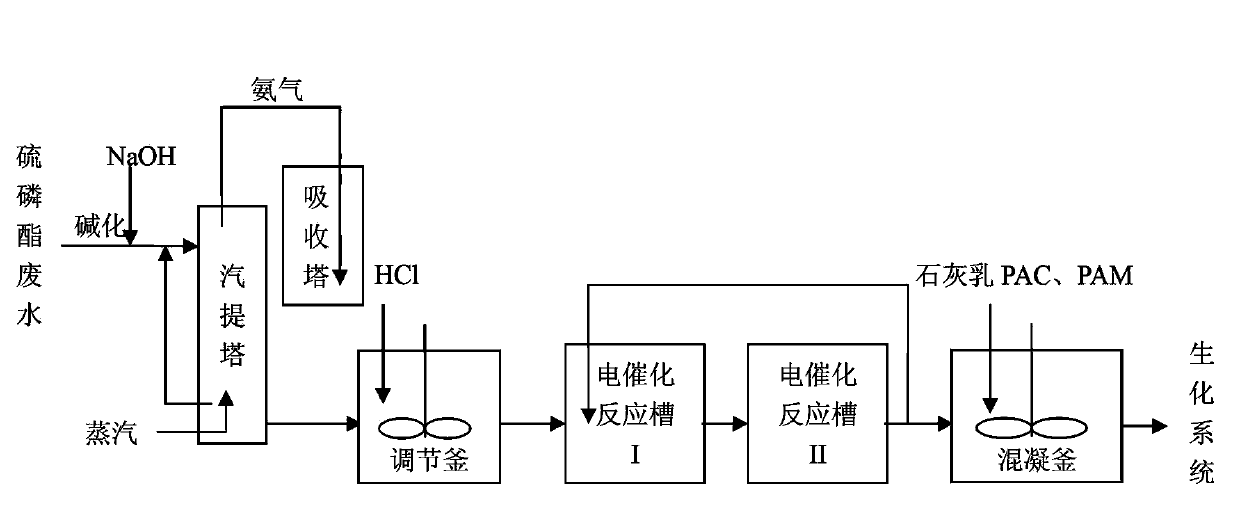

Dithiophosphate wastewater pretreatment method

InactiveCN103755089AMeet deodorantSatisfy DecolorizationMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationLoad resistanceElectrolysis

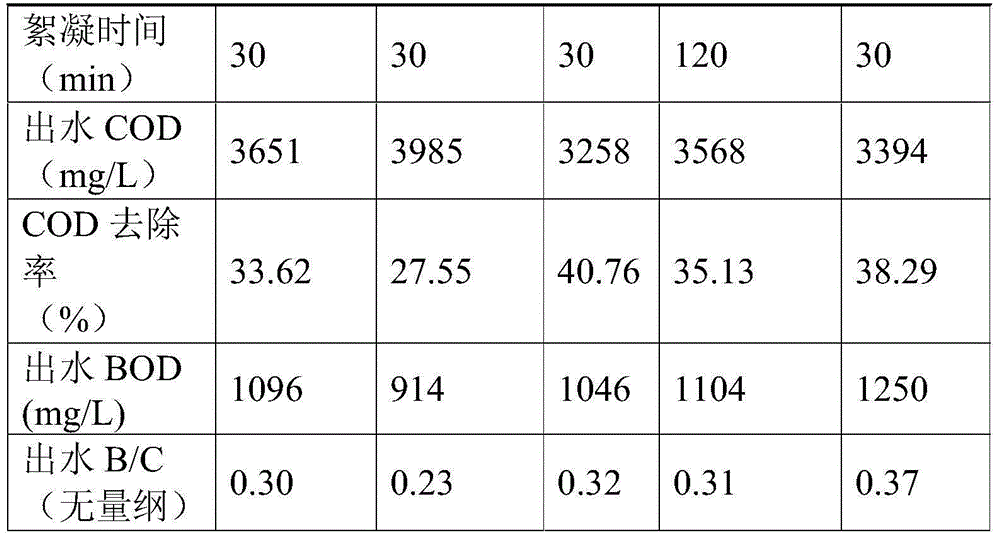

The invention discloses a dithiophosphate wastewater pretreatment method. Dithiophosphate wastewater is pretreated by the three steps of stream stripping, electro-catalytic reaction and coagulation to remove ammonia nitrogen from the wastewater, and is supplied to a biochemical system for treatment after reaching biochemical treatment requirements when effluent is colorless and odorless, the CODcr is reduced to be lower than 10,000 mg / L, the biodegradability B / C of the wastewater is more than 0.3, the chromaticity is less than 50 and the ammonia nitrogen is reduced to be lower than 15 mg / L. According to the method, the three treatment steps of stream stripping, electrolysis and coagulation are combined, so that the problems of high ammonia nitrogen, high COD and stink in the dithiophosphate wastewater are solved, and the ammonia nitrogen in the wastewater is effectively recycled for production; the method has the characteristics of high impact load resistance, good treatment effects and lower running cost, certain economic benefits can also be created, and the stink of the dithiophosphate wastewater can be completely prevented to meet the biochemical treatment requirements after the dithiophosphate wastewater is treated.

Owner:HUNAN HAILI CHEM IND

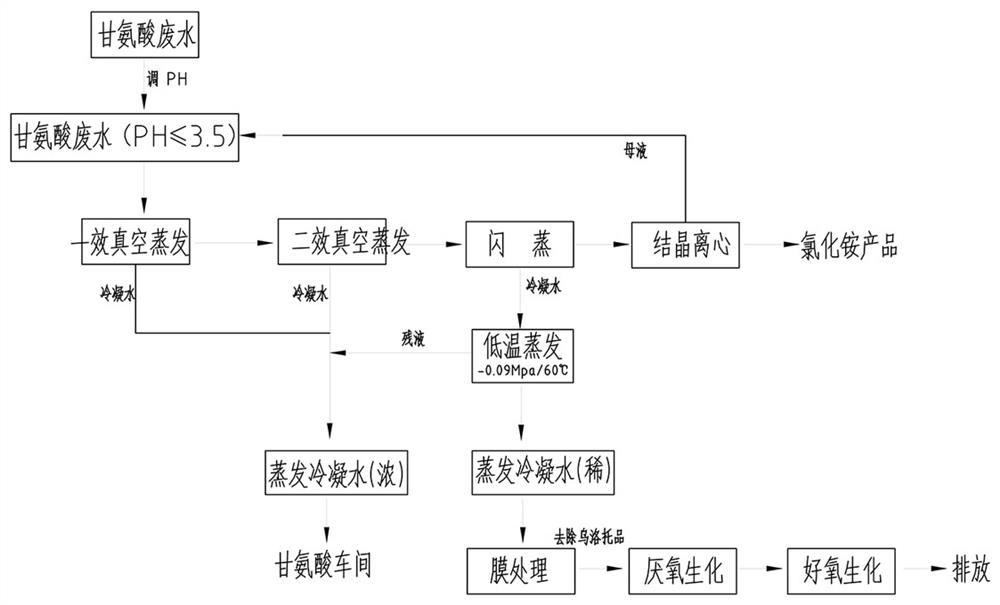

Cleaning treatment method of glycine production wastewater

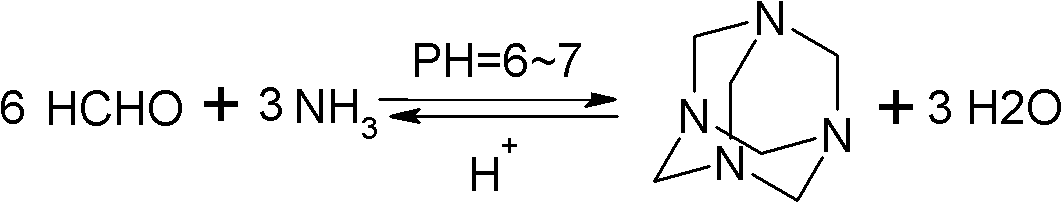

ActiveCN108658374AEmission complianceDoes not affect the centrifugation processWater treatment parameter controlWater contaminantsComposite filmHexamethylenetetramine

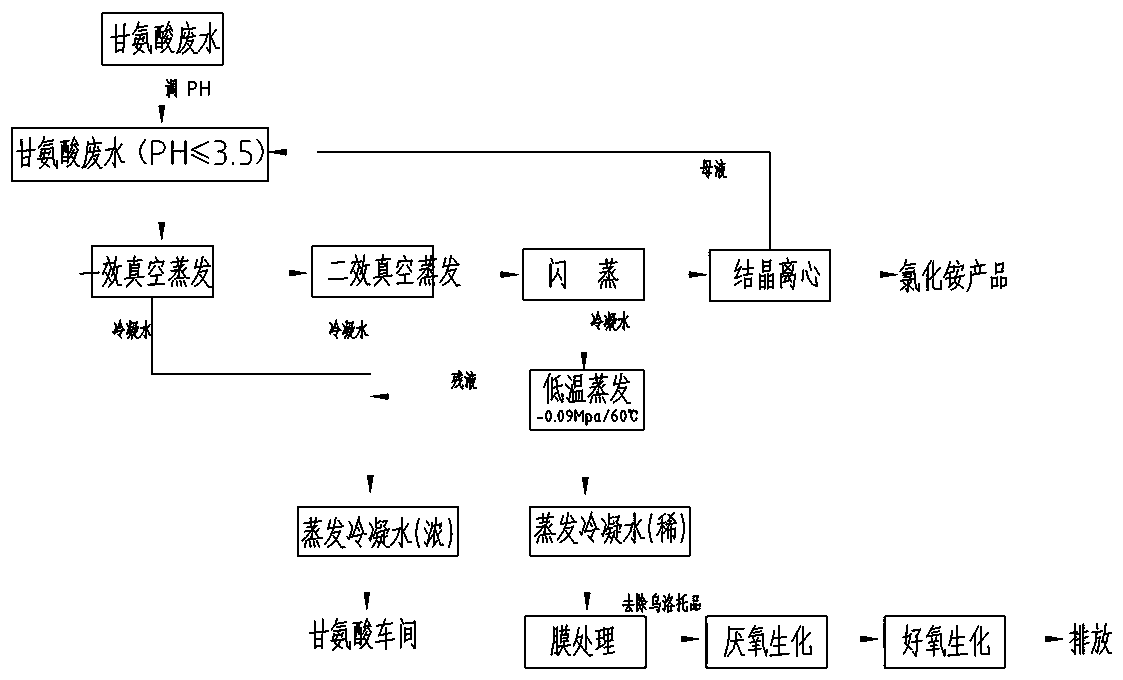

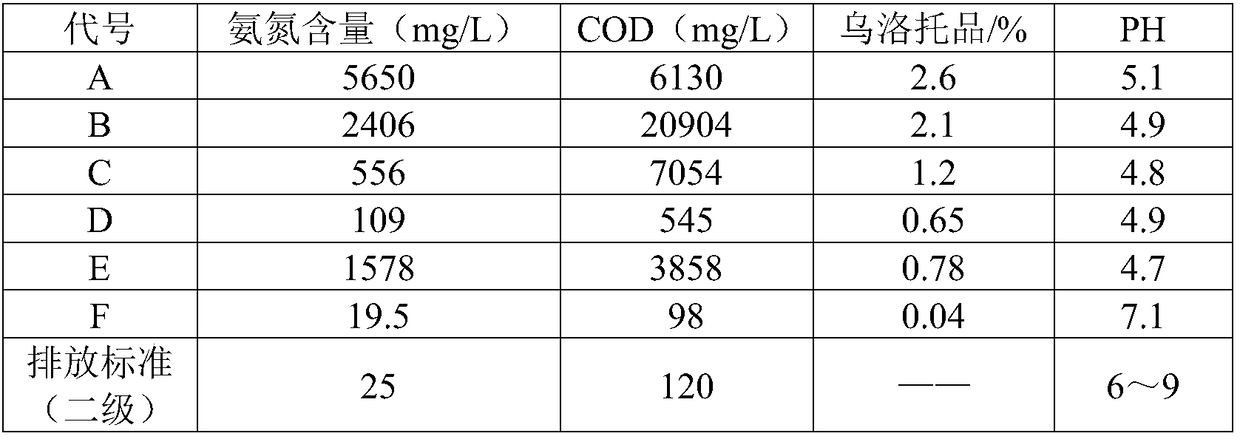

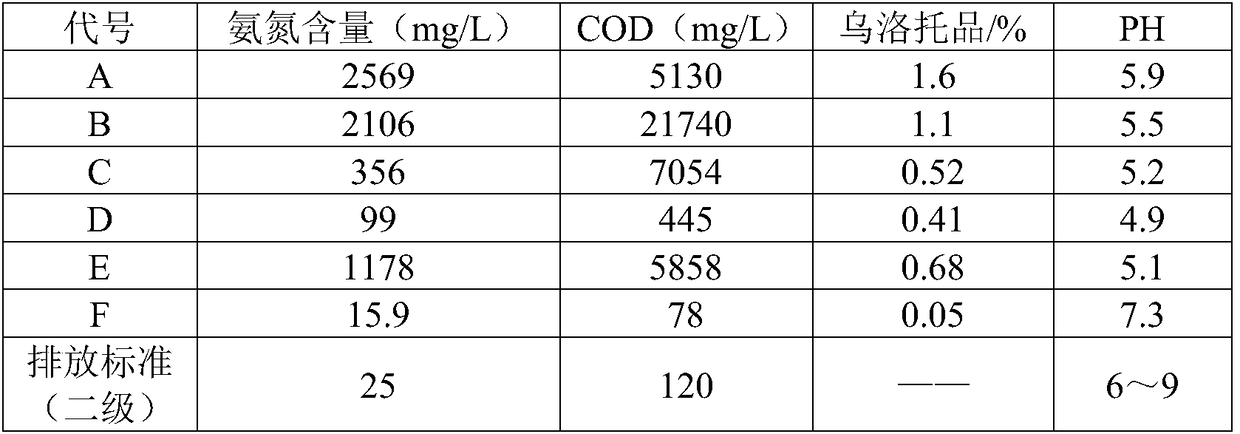

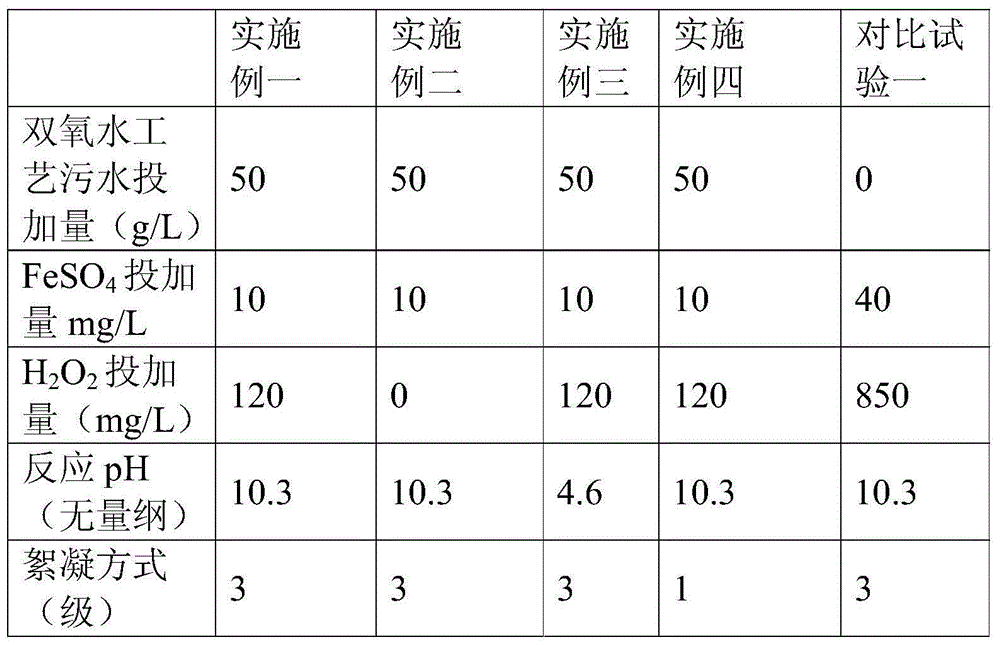

The invention relates to a cleaning treatment method of glycine production wastewater. The method comprises the following specific steps: firstly adjusting the pH of glycine wastewater to be within arange of 2 to 3.5 through hydrochloric acid, so as to inhibit the decomposition of ammonium chloride; then obtaining condensed water with high ammonia nitrogen and COD contents through an I-effect evaporation system and an II-effect evaporation system, and ensuring that the condensed water directly returns a glycine production system to be recycled, so as to reduce dosages of urotropine and methanol; performing concentration through a vacuum flash evaporation system, so as to obtain condensed water with medium ammonia nitrogen and COD contents; treating the condensed water through a special high-vacuum low-temperature evaporation system; performing low-temperature evaporation, so as to obtain condensed water with low ammonia nitrogen and COD contents, ensuring that the condensed water canmeet an II-grade discharge standard through further organic composite film treatment and biochemical treatment, and ensuring that residual liquid with high ammonia nitrogen and COD contents still returns the glycine system to be recycled. The method is small in equipment investment, realizes harmless mother liquor treatment, is energy-saving and environmentally friendly, ensures that the glycine wastewater can realize close circulation, and is suitable for being widely applied in the glycine industry.

Owner:HUBEI TAISHENG CHEM

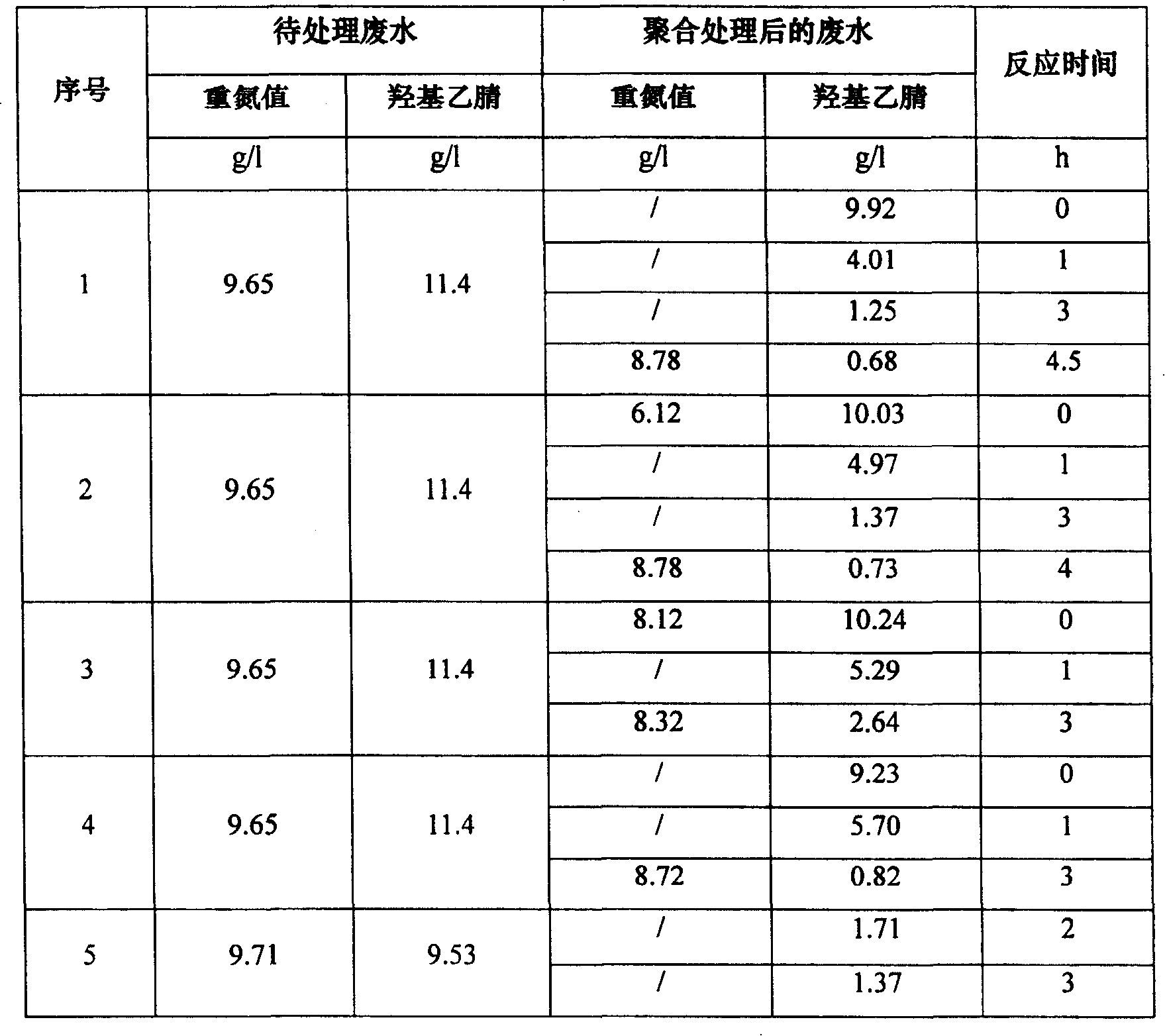

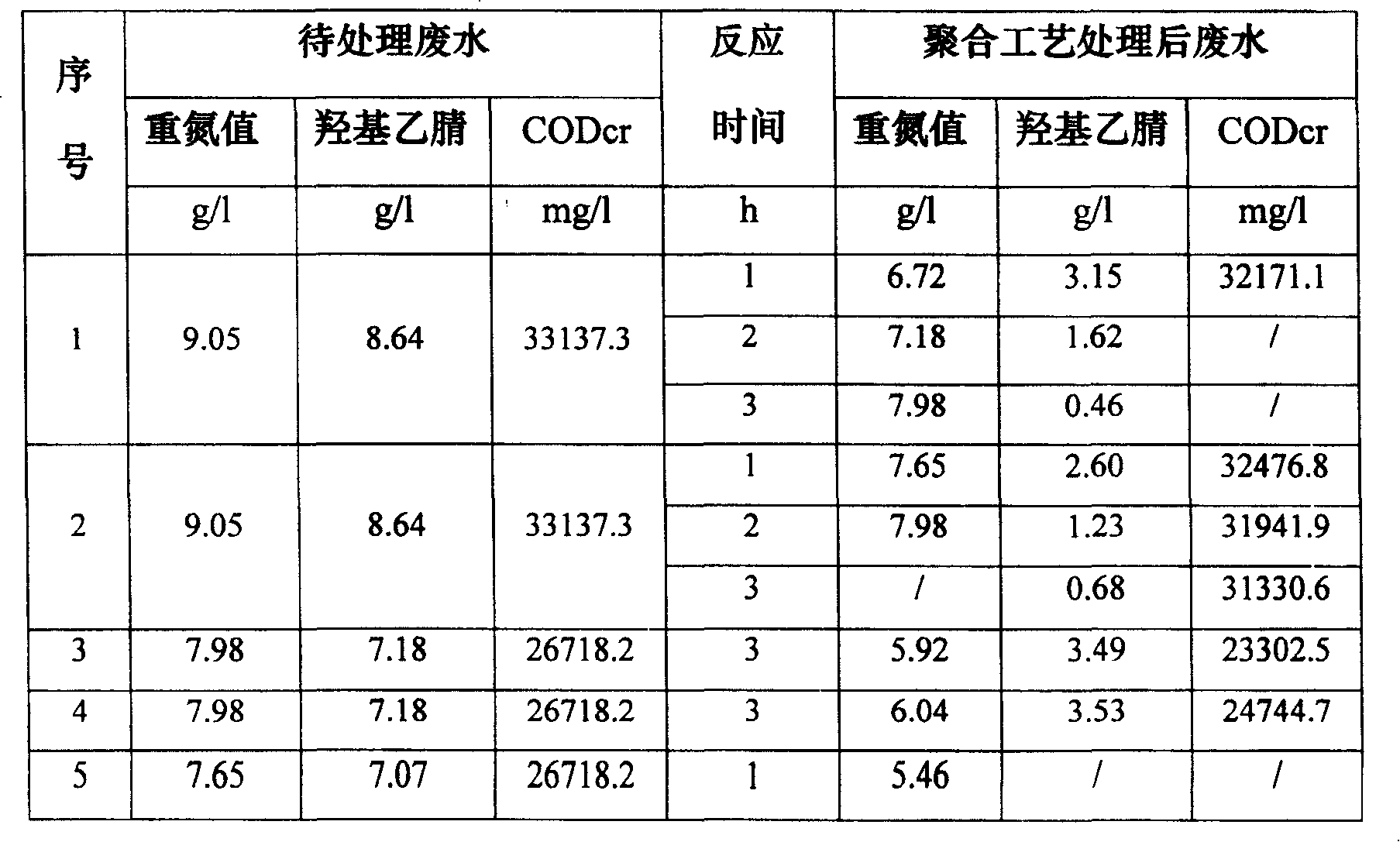

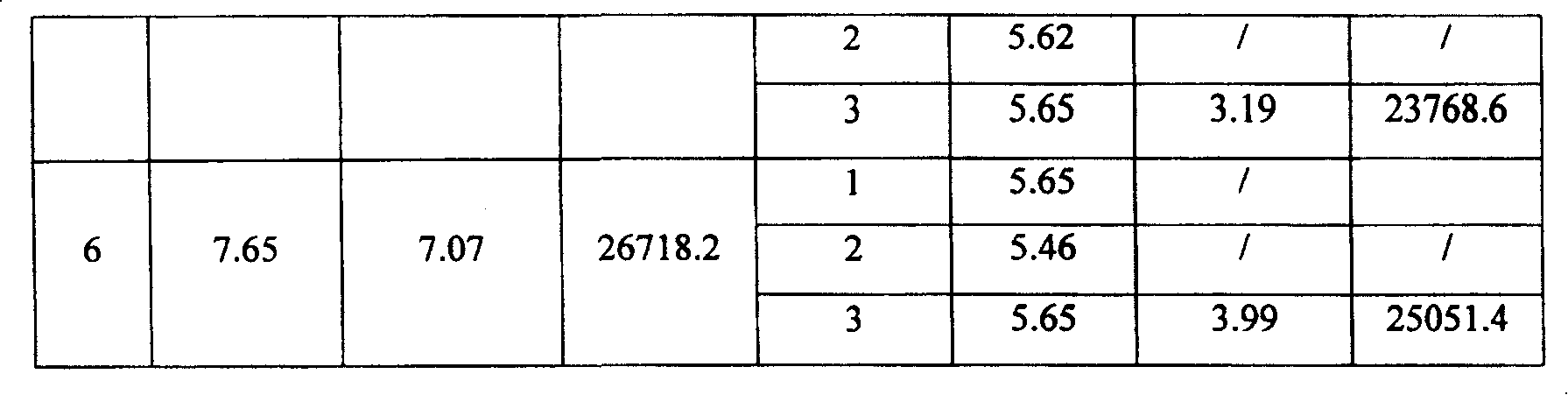

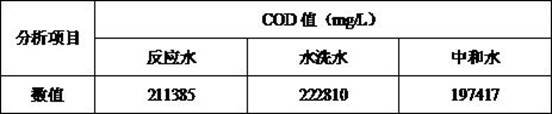

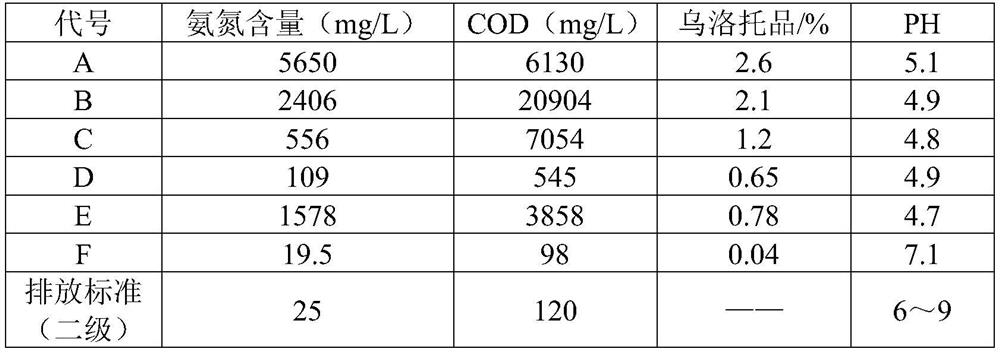

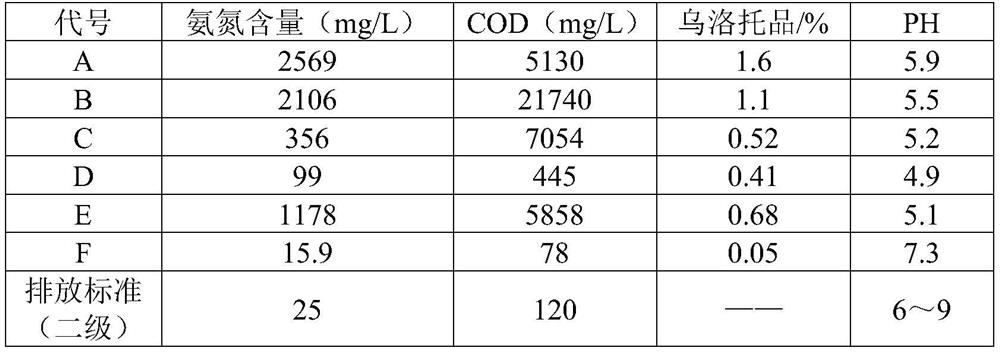

Treatment method of high concentration undegradable nitrile containing organic waste water

ActiveCN1911837AImprove biodegradabilityMeet the requirements of biochemical treatmentMultistage water/sewage treatmentWater/sewage treatment by neutralisationHigh concentrationWastewater

The present invention relates to process of treating waste water containing nitrile and other non-degradable organic matter in high concentration. The waste water is first polymerizing treated under alkaline condition, and the filtrate is then added with lime for hydrolysis treating. According to the feature of nitrile compounds, which are easy to self polymerize under alkaline condition, alkali is added into the waste water to regulate pH value while heating, so as to produce polymerizing reaction to destroy nitrile structure and lower the content of NH3-N and CODcr greatly simultaneously.

Owner:NINGXIA UNISPLENDOUR TIANHUA METHIONINE CO LTD

Method for treating fiber ethanol production wastewater

ActiveCN106746162AEfficient removalEasy to handleWater contaminantsMultistage water/sewage treatmentFiberChemical oxygen demand

The invention relates to a method for treating fiber ethanol production wastewater. The method comprises the following steps: (1) adjusting the concentration of a sulfate radical in fiber ethanol production wastewater with epoxy chloropropane production wastewater so as to control the content of the sulfate radical in mixed wastewater to be within 3000 mg / L, and removing precipitates; (2) adjusting the pH value of the mixed wastewater to be 7.6-9.0, and keeping the temperature of the mixed wastewater to be higher than 60 DEG C; (3) after the reaction is completed, removing the precipitates, and performing anaerobic biochemical treatment on effluent; and (4) performing aerobiotic biochemical treatment on anaerobic effluent, thereby enabling treated wastewater to meet emission requirements. According to the method, the concentration of the sulfate radical in the fiber ethanol production wastewater is adjusted with the epoxy chloropropane production wastewater, and the mixed wastewater is treated by using anaerobic-aerobiotic processes, so that efficient removal of the sulfate radical and COD (Chemical Oxygen Demand) in the wastewater can be achieved, and the method has the characteristics of being simple in treatment process, good in treatment effect and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Treatment method for sewage produced in caprolactam ammoximation process

InactiveCN104556344AAvoid repeated adjustmentsSimple and efficient operationMultistage water/sewage treatmentNature of treatment waterChemistryPollutant

The invention provides a treatment method for sewage produced in a caprolactam ammoximation process. The treatment method is characterized in that sewage produced by a hydrogen peroxide production process is utilized as a main oxidizing agent, under the combined action of a small quantity of other auxiliary oxidizing agents and a catalyst, or only the action of the main oxidizing agent, organic pollutants capable of causing biochemical system impact in sewage can be oxidized and degraded through an advanced oxidation reaction. According to the treatment method provided by the invention, the sewage produced in the hydrogen peroxide process in a caprolactam device is effectively and comprehensively utilized to realize the treatment of wastes with the wastes and the consumption of the oxidizing agents and the catalysts required by the advanced oxidation pretreatment of the sewage produced in the ammoximation process is greatly reduced; meanwhile, the method does not comprise the step of adjusting pH repeatedly, so that the running cost is greatly reduced, the environmental pollution is reduced, the operation is simple and easy to realize, and good economic and environmental benefits are realized.

Owner:CHINA TIANCHEN ENG +2

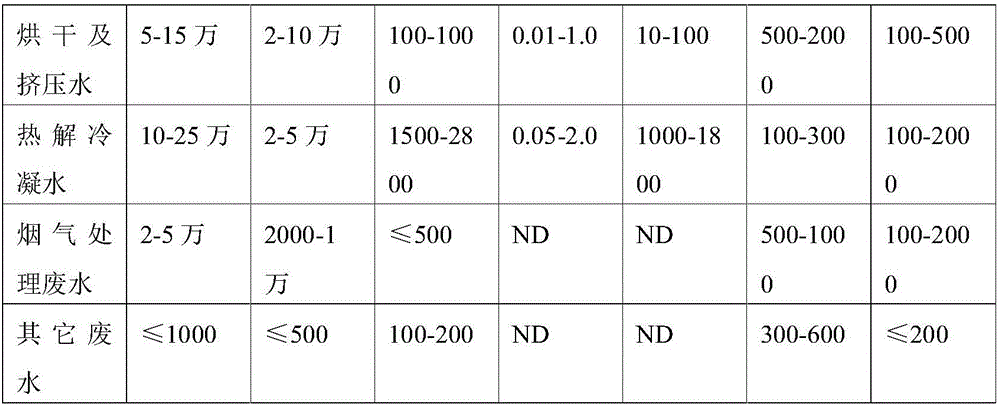

Disposal method of pyrolysis comprehensive wastewater of solid waste

InactiveCN106565063ALow investment costLow running costWater contaminantsMultistage water/sewage treatmentOil separationShock resistance

The invention relates to the field of wastewater treatment, and particularly relates to a disposal method of pyrolysis comprehensive wastewater of solid waste. The disposal method comprises the following steps of first carrying out oil separation and precipitation treatment, gas-liquid blowing off treatment, advanced oxidation treatment and coagulation and precipitation treatment on high-pollutant-concentration pyrolysis condensation water which contains many aromatic compounds in sequence then mixing the high-pollutant-concentration pyrolysis condensation water with oven-drying and squeezing water, fume treatment wastewater, sanitary sewage and ground flushing water, which are subjected to primary precipitation treatment, finally, carrying out anaerobic treatment, facultative aerobic treatment, aerobic treatment, secondary precipitation treatment, the advanced oxidation treatment and secondary coagulation and precipitation treatment on formed comprehensive wastewater in sequence, and making the comprehensive wastewater meet a discharge requirement. By using the disposal method of the pyrolysis comprehensive wastewater of the solid waste, which is provided by the invention, the investment cost and the running cost of the wastewater can be effectively decreased; meanwhile, the integral shock-resistance ability is improved; moreover, the disposal method comprises multiple technical chains; requirements on yielding water of different grades and different standards can be met; the applicability is higher.

Owner:HUNAN VARY TECH

Epichlorohydrin production wastewater treatment method

ActiveCN106746156AAvoid cloggingReduce or eliminate inhibitionMultistage water/sewage treatmentNature of treatment waterAnaerobic aerobicFiber

The invention relates to an epichlorohydrin production wastewater treatment method, which comprises the following steps: (1) concentration of calcium ion in the epichlorohydrin production wastewater is adjusted by the use of cellulosic bioethanol production wastewater until the concentration of calcium ion in the mixed wastewater is lower than 2100 mg / L and concentration of sulfate ion is not higher than 3000 mg / L, and generated precipitates are removed; (2) pH value of the mixed wastewater is adjusted to 7.6-9.0, and temperature is maintained to be greater than 60 DEG C; (3) after a reaction, generated precipitates are removed, and an effluent undergoes anaerobic biotreatment; (4) an anaerobic effluent and epichlorohydrin production wastewater are mixed until concentration of calcium ion is not higher than 4000 mg / L after the mixing, and generated precipitates are removed; and (5) the effluent undergoes aerobic biochemical treatment, and the treated wastewater meets the emission requirement. By adjusting the concentration of calcium ion in the epichlorohydrin production wastewater by the use of cellulosic bioethanol production wastewater and carrying out anaerobic-aerobic treatment on the mixed wastewater, calcium ion and CDD in the epichlorohydrin production wastewater can be efficiently removed. The method of the invention has characteristics of simple treatment technology, good treatment effect and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

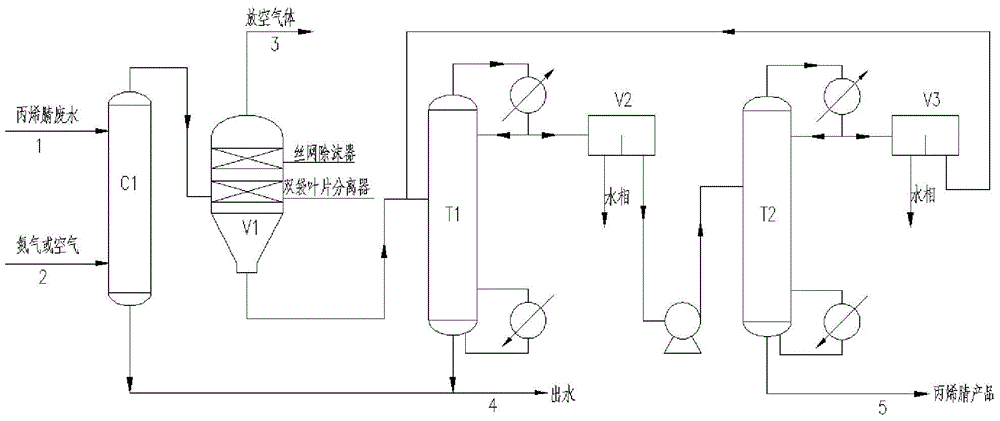

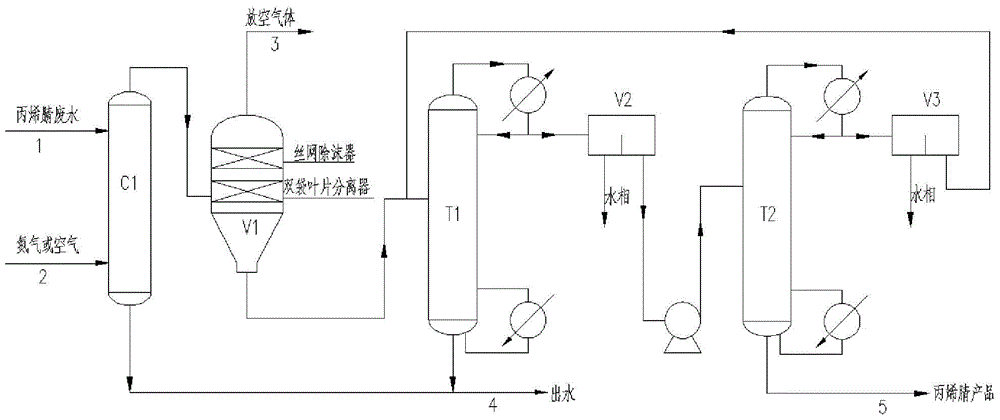

High-concentration acrylonitrile wastewater treatment method

ActiveCN104556527AReduce riskMeet the requirements of biochemical treatmentCombination devicesWater contaminantsHigh concentrationAcrylonitrile

The invention provides a high-concentration acrylonitrile wastewater treatment method. The method comprises the following steps: blowing off high-concentration acrylonitrile wastewater to obtain wastewater with the acrylonitrile concentration of below 1mg / L, and directly carrying out biochemical treatment; carrying out gas-liquid separation on the obtained blown mist gas to obtain a separated gas with the acrylonitrile concentration of 0.1mg / Nm<3> and reaching emission requirements; and carrying out azeotropic rectification and rectification treatment on the obtained separated liquid to obtain an acrylonitrile product with the purity of above 99%. The method allows acrylonitrile in the wastewater to be thoroughly separated and recovered, reduces harms of the acrylonitrile wastewater to the environment, and realizes a remarkable economic benefit.

Owner:CHINA PETROLEUM & CHEM CORP +1

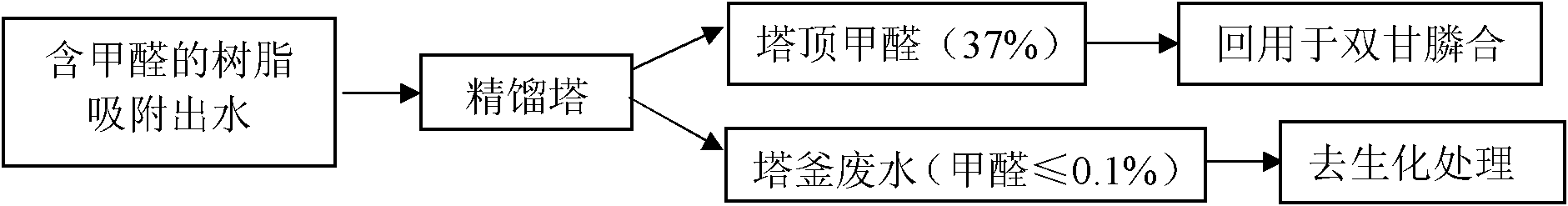

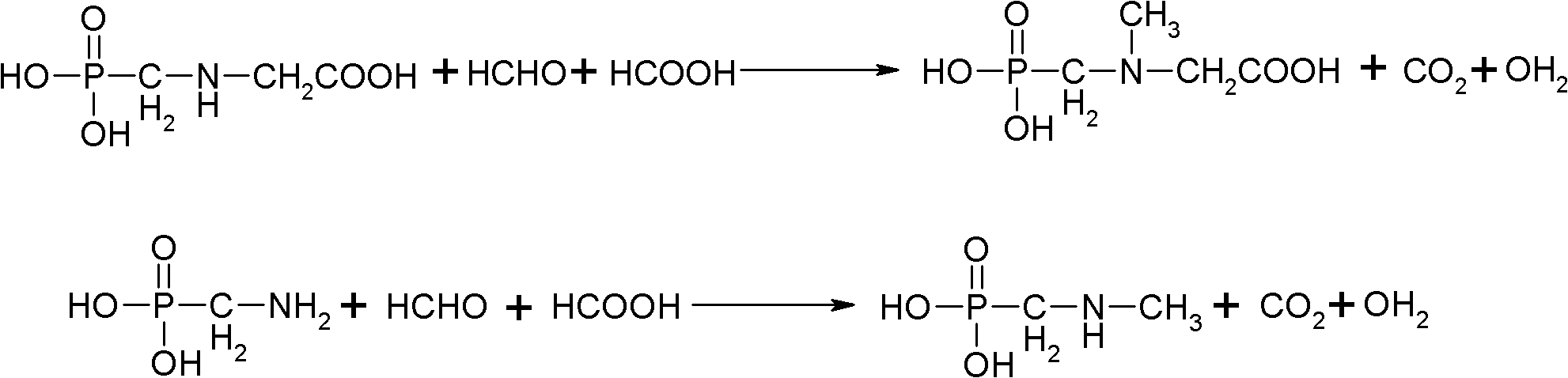

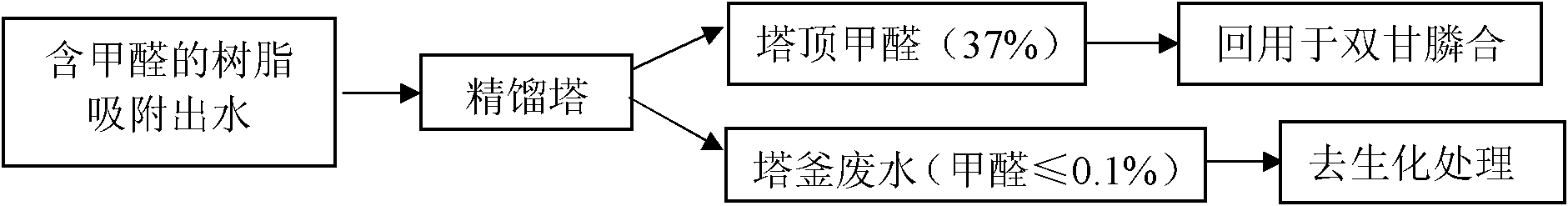

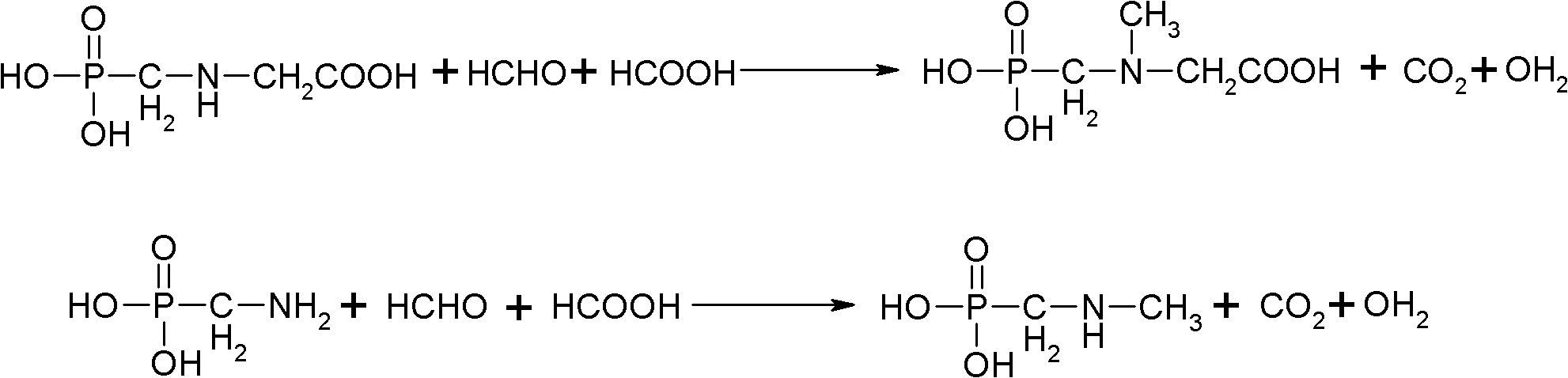

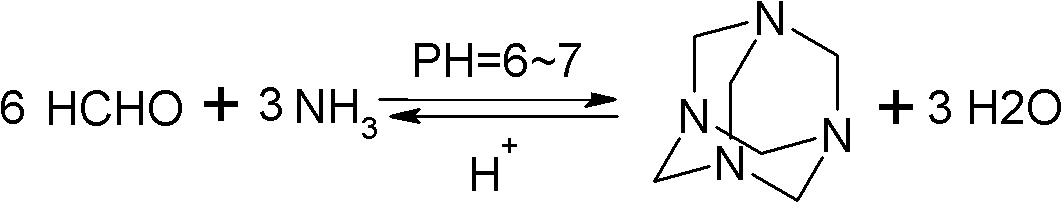

Comprehensive treatment technique for recycling glyphosate mother liquor

ActiveCN102153584BMeet the requirements of biochemical treatmentImprove resource recoveryGroup 5/15 element organic compoundsMultistage water/sewage treatmentGlyphosateDesorption

The invention provides a treatment method of glyphosate mother liquor. The glyphosate mother liquor is from the glyphosate preparation process by an IDA (incremental dynamic analysis) route air oxidation method. The treatment method comprises the steps of resin adsorption, resin desorption and formaldehyde recovery. The method provided by the invention achieves the goal of recycling waste materials, implements circulation and economy, and has the advantages of energy consumption saving, environmental friendliness, lower production cost and the like.

Owner:JIANGSU YOUTH CHEM +1

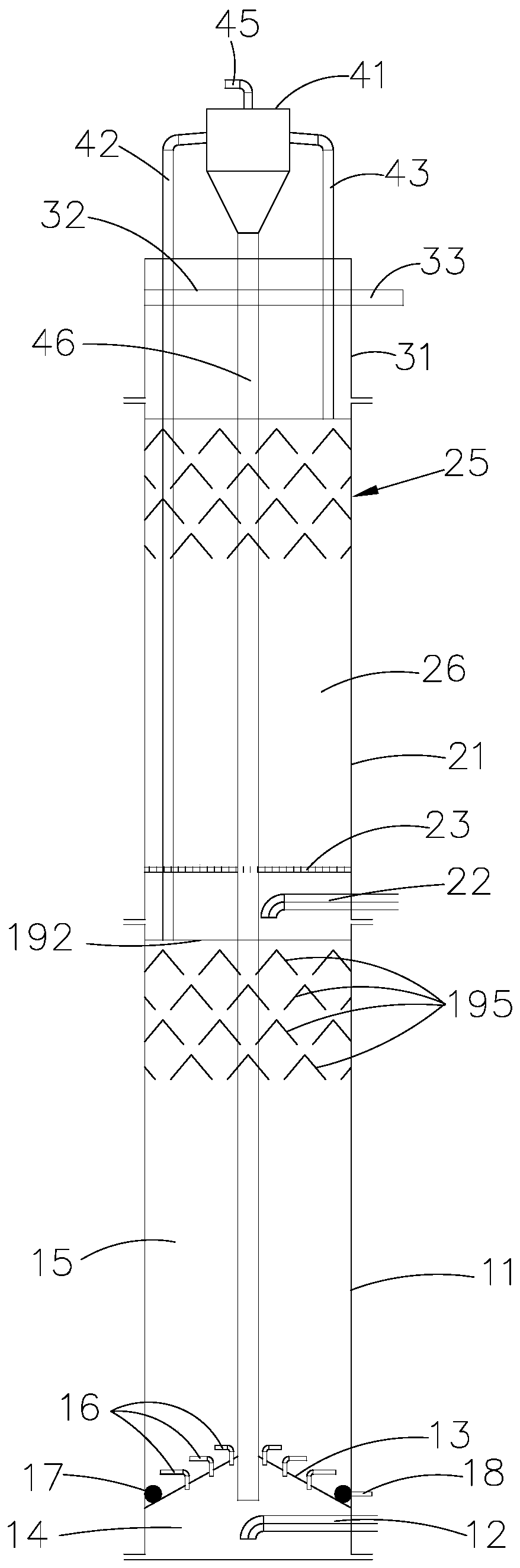

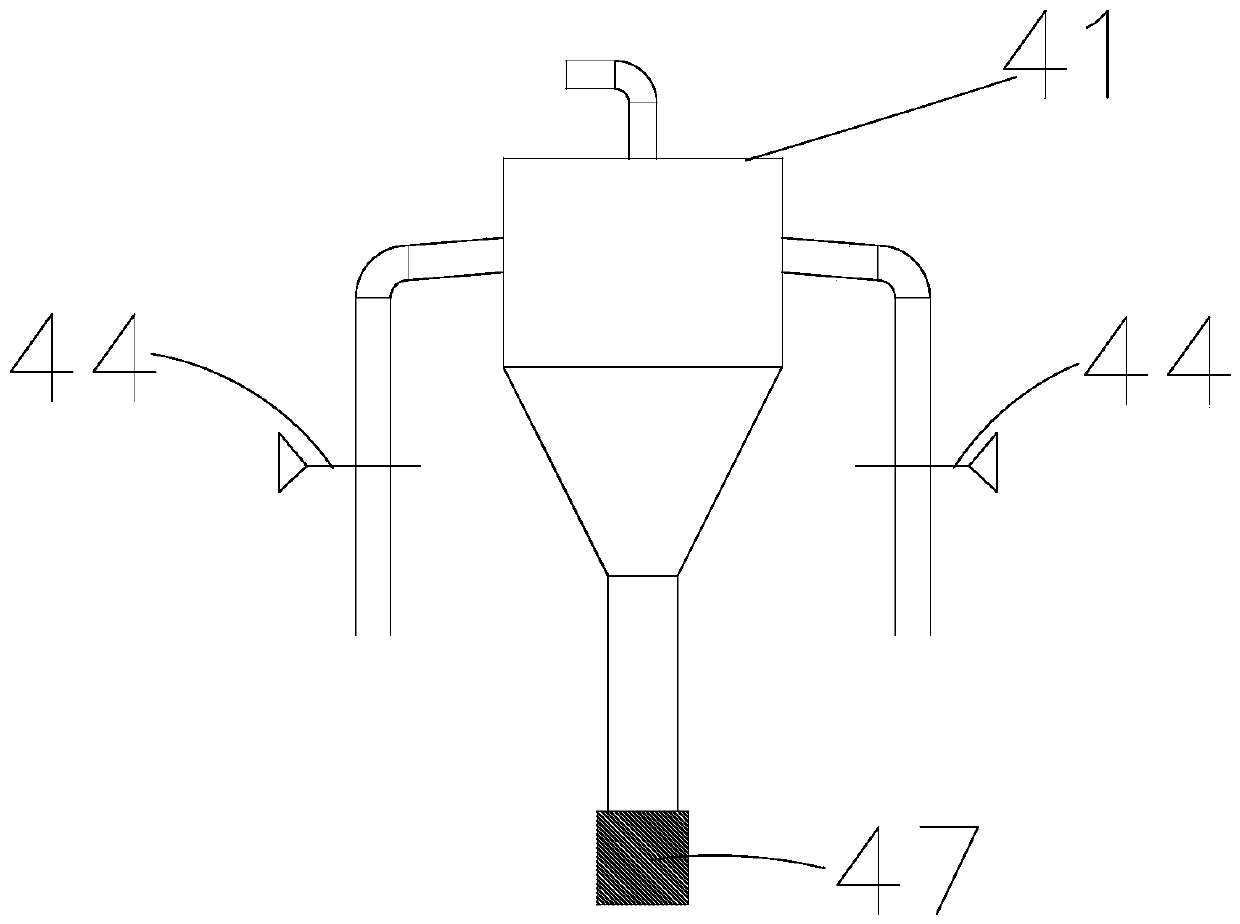

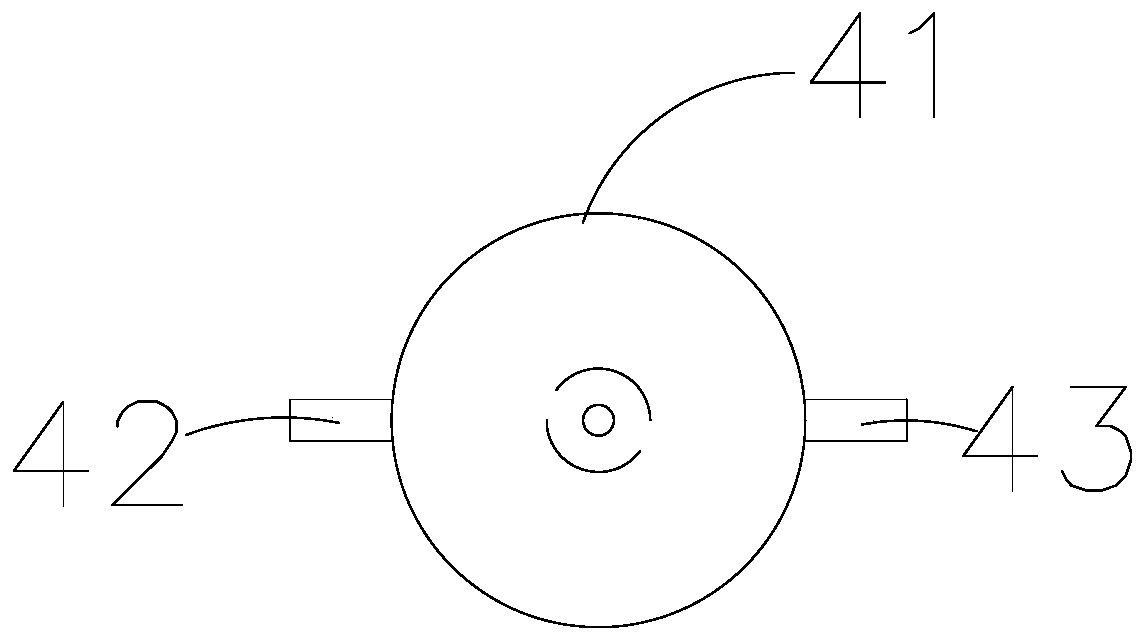

Integrated sewage treatment device

ActiveCN110902946AAvoid extraMeet the requirements of biochemical treatmentTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentVapor–liquid separatorAutotrophic organism

The invention relates to an integrated sewage treatment device which comprises a first reactor module, a second reactor module, a settling module and a gas-liquid separation module; the first reactormodule comprises a first reactor, an anoxic reaction zone, an aerobic reaction zone, a first gas collecting and pressurizing layer, a first water inlet pipe and an aeration device; the second reactormodule comprises a second reactor, a second water inlet pipe, an anaerobic reaction zone and a second gas collecting and pressurizing layer; the settling module comprises a third reactor and a water outlet pipe; the gas-liquid separation module comprises a gas-liquid separator, an exhaust pipe, a first riser pipe, a second riser pipe and a backflow pipe. The device provided by the invention can give full play to the advantages of an autotrophic biological denitrification process, meets the biochemical treatment requirements of sewage with a low C / N ratio, and has the advantages of high denitrification efficiency, low treatment energy consumption, avoidance of addition of chemicals, high space utilization rate, simplicity in maintenance and the like.

Owner:SUZHOU UNIV OF SCI & TECH

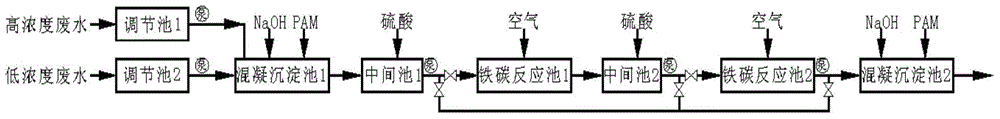

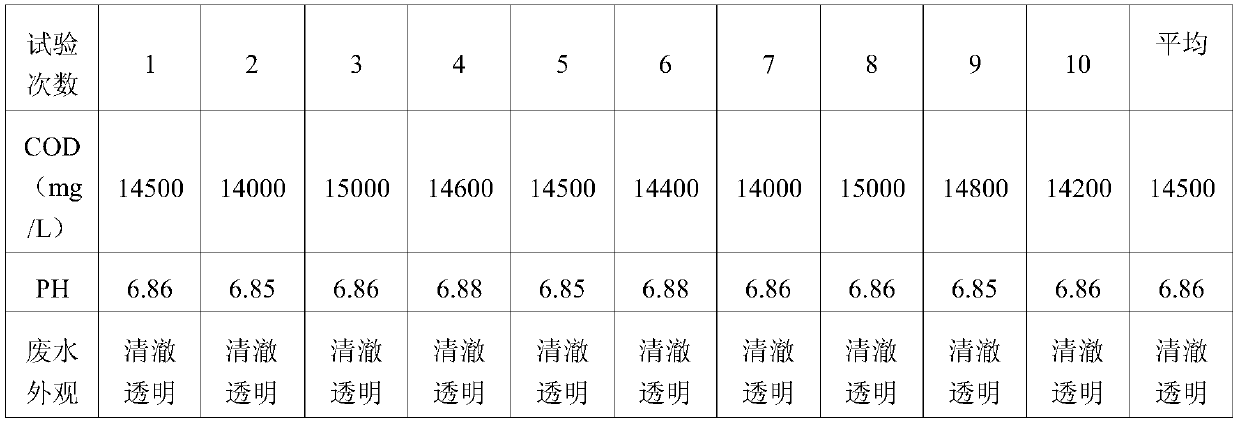

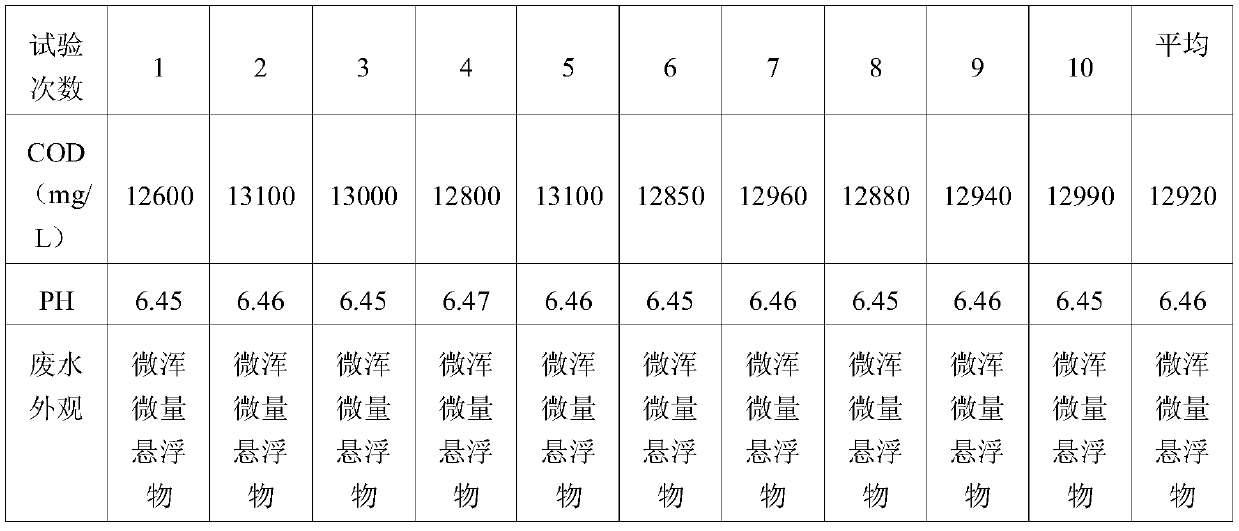

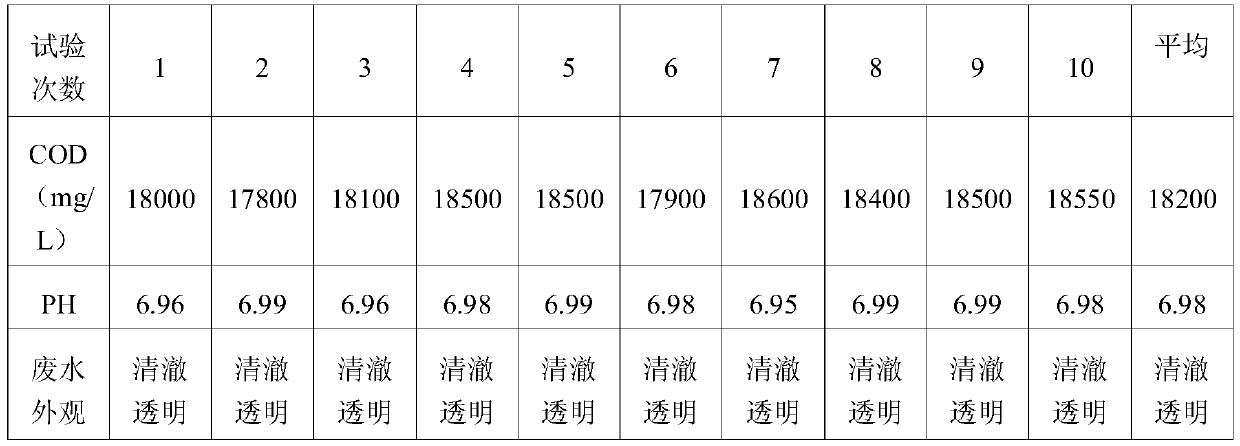

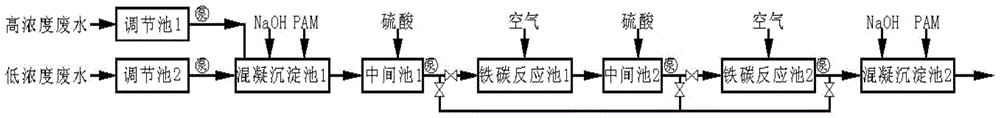

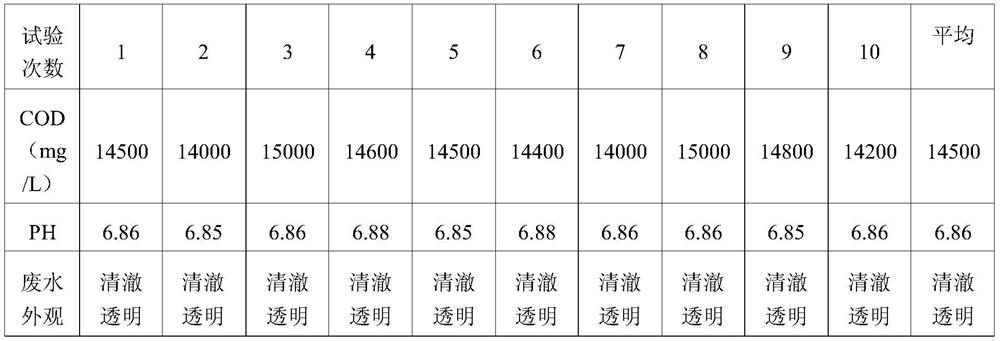

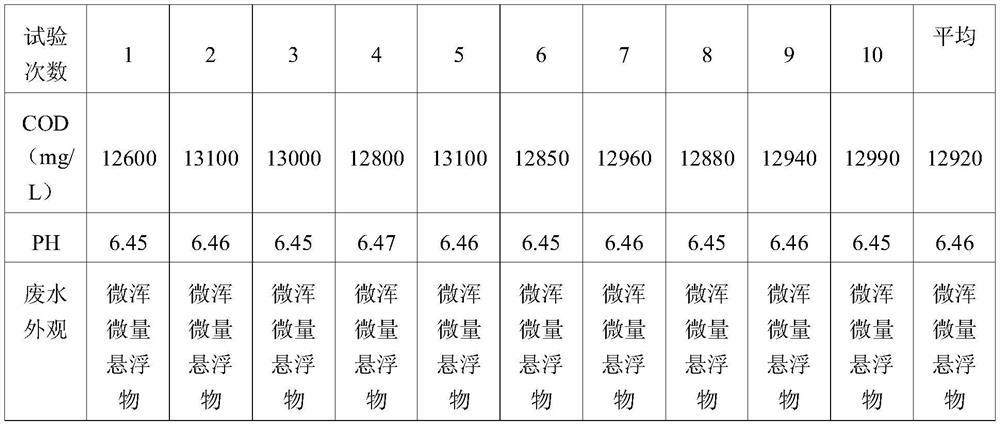

Pretreatment device and method for colored crystal synthesis wastewater

ActiveCN104556500AEasy to handleDoes not affect productionWater contaminantsMultistage water/sewage treatmentHigh concentrationPretreatment method

The invention relates to a pretreatment device and method for colored crystal synthesis wastewater, and belongs to the field of wastewater treatment. The pretreatment device comprises two regulating tanks, two coagulating precipitation tanks, two intermediate tanks and two ferric carbon reaction tanks. The pretreatment method comprises the following steps: firstly, homogenizing and averaging high-concentration and low-concentration wastewater through the two regulating tanks; secondly, carrying out coagulating precipitation, acid modulation treatment and internal electrolysis treatment; thirdly, carrying out acid modulation treatment and internal electrolysis treatment again; finally, carrying out coagulating precipitation again. The wastewater pretreated by the device and the method can meet the biochemical treatment requirements.

Owner:CHINA NORTH ENERGY CONSERVATION & ENVIRONMENT PROTECTION

Method for treating wastewater of methyl methacrylate device

ActiveCN111559816AInhibition of polymerizationSolve the problem of easy aggregationWater contaminantsMultistage water/sewage treatmentWastewaterMethacrylate methyl

The invention provides a method for treating wastewater of a methyl methacrylate device. The treatment method comprises the following steps: adjusting the pH value of the wastewater of the methyl methacrylate device to 9.7-10.3 by adopting alkali; and introducing the methyl methacrylate device wastewater of which the pH value is adjusted into a rectifying tower for rectification so as to remove methyl methacrylate in the wastewater. Through the treatment method provided by the invention, the problem that methyl methacrylate contained in the wastewater is easy to polymerize in the heating process can be effectively solved, and the treated wastewater meets the biochemical treatment requirements.

Owner:PETROCHINA CO LTD

Treatment method of high concentration undegradable nitrile containing organic waste water

ActiveCN100404441CImprove biodegradabilityMeet the requirements of biochemical treatmentMultistage water/sewage treatmentWater/sewage treatment by neutralisationHigh concentrationWastewater

The present invention relates to process of treating waste water containing nitrile and other non-degradable organic matter in high concentration. The waste water is first polymerizing treated under alkaline condition, and the filtrate is then added with lime for hydrolysis treating. According to the feature of nitrile compounds, which are easy to self polymerize under alkaline condition, alkali is added into the waste water to regulate pH value while heating, so as to produce polymerizing reaction to destroy nitrile structure and lower the content of NH3-N and CODcr greatly simultaneously.

Owner:NINGXIA UNISPLENDOUR TIANHUA METHIONINE CO LTD

Method for treating wastewater in process for synthesizing N-phenylmaleimide by one-step method

PendingCN113371881AReduce COD valueMeet the requirements of biochemical treatmentWater treatment compoundsTreatment involving filtrationImideCatalytic oxidation

The invention relates to a method for treating wastewater in a process for synthesizing N-PMI by a one-step method. The method comprises the following steps: (1) catalytic oxidation; and (2) Fenton oxidation. The wastewater can be directly subjected to biochemical treatment. Compared with a direct Fenton oxidation method, the method has the advantages that the treatment process is simplified, and the treatment cost is obviously reduced. Compared with an existing method for treating the N-PMI wastewater in patent literature, the process is suitable for treating the wastewater with higher acid content, secondary pollution such as solid waste cannot be generated in the treatment process, and the process is more economical and environmentally friendly, so that the process has better application prospects.

Owner:SINOPEC NANJING RES INST OF CHEM IND CO LTD +2

A kind of treatment method of cellulosic ethanol production wastewater

ActiveCN106746162BAvoid cloggingReduce or eliminate inhibitionWater contaminantsMultistage water/sewage treatmentSulfate radicalsChemical oxygen demand

The invention relates to a method for treating fiber ethanol production wastewater. The method comprises the following steps: (1) adjusting the concentration of a sulfate radical in fiber ethanol production wastewater with epoxy chloropropane production wastewater so as to control the content of the sulfate radical in mixed wastewater to be within 3000 mg / L, and removing precipitates; (2) adjusting the pH value of the mixed wastewater to be 7.6-9.0, and keeping the temperature of the mixed wastewater to be higher than 60 DEG C; (3) after the reaction is completed, removing the precipitates, and performing anaerobic biochemical treatment on effluent; and (4) performing aerobiotic biochemical treatment on anaerobic effluent, thereby enabling treated wastewater to meet emission requirements. According to the method, the concentration of the sulfate radical in the fiber ethanol production wastewater is adjusted with the epoxy chloropropane production wastewater, and the mixed wastewater is treated by using anaerobic-aerobiotic processes, so that efficient removal of the sulfate radical and COD (Chemical Oxygen Demand) in the wastewater can be achieved, and the method has the characteristics of being simple in treatment process, good in treatment effect and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Comprehensive treatment technique for recycling glyphosate mother liquor

ActiveCN102153584AImprove resource recoveryEmission complianceGroup 5/15 element organic compoundsMultistage water/sewage treatmentGlyphosateDesorption

The invention provides a treatment method of glyphosate mother liquor. The glyphosate mother liquor is from the glyphosate preparation process by an IDA (incremental dynamic analysis) route air oxidation method. The treatment method comprises the steps of resin adsorption, resin desorption and formaldehyde recovery. The method provided by the invention achieves the goal of recycling waste materials, implements circulation and economy, and has the advantages of energy consumption saving, environmental friendliness, lower production cost and the like.

Owner:JIANGSU YOUTH CHEM +1

A kind of treatment method of epichlorohydrin production waste water

ActiveCN106746156BAvoid cloggingReduce or eliminate inhibitionMultistage water/sewage treatmentNature of treatment waterSulfate radicalsSULFATE ION

The invention relates to an epichlorohydrin production wastewater treatment method, which comprises the following steps: (1) concentration of calcium ion in the epichlorohydrin production wastewater is adjusted by the use of cellulosic bioethanol production wastewater until the concentration of calcium ion in the mixed wastewater is lower than 2100 mg / L and concentration of sulfate ion is not higher than 3000 mg / L, and generated precipitates are removed; (2) pH value of the mixed wastewater is adjusted to 7.6-9.0, and temperature is maintained to be greater than 60 DEG C; (3) after a reaction, generated precipitates are removed, and an effluent undergoes anaerobic biotreatment; (4) an anaerobic effluent and epichlorohydrin production wastewater are mixed until concentration of calcium ion is not higher than 4000 mg / L after the mixing, and generated precipitates are removed; and (5) the effluent undergoes aerobic biochemical treatment, and the treated wastewater meets the emission requirement. By adjusting the concentration of calcium ion in the epichlorohydrin production wastewater by the use of cellulosic bioethanol production wastewater and carrying out anaerobic-aerobic treatment on the mixed wastewater, calcium ion and CDD in the epichlorohydrin production wastewater can be efficiently removed. The method of the invention has characteristics of simple treatment technology, good treatment effect and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of cleaning treatment method of glycine production wastewater

ActiveCN108658374BAvoid decompositionReduce ammonia nitrogen contentWater treatment parameter controlWater contaminantsAmmoniacal nitrogenHexamethylenetetramine

The invention relates to a method for cleaning and treating waste water from glycine production. The specific steps are: first use hydrochloric acid to adjust the pH of glycine wastewater to the range of 2 to 3.5 to inhibit the decomposition of ammonium chloride; then through the I-effect evaporation and II-effect evaporation systems to obtain condensed water with high ammonia nitrogen and high COD content, the water can be directly Return to the glycine production system for reuse to reduce the consumption of urotropine and methanol; then condense through a decompression flash system to obtain condensed water with a medium content of ammonia nitrogen and COD; the water obtained from the flash system is treated by a special high-vacuum low-temperature evaporation system The condensed water with low ammonia nitrogen and COD content obtained by low-temperature evaporation can reach the secondary discharge standard after further organic composite membrane treatment and biochemical treatment, and the remaining raffinate with high ammonia nitrogen and COD is still returned to the glycine system for reuse. The method has low equipment investment, harmless mother liquor treatment, energy saving and environmental protection, and glycine wastewater can realize closed-circuit circulation, and is suitable for wide application in the glycine industry.

Owner:HUBEI TAISHENG CHEM

A kind of treatment method of high concentration acrylonitrile wastewater

ActiveCN104556527BReduce riskMeet the requirements of biochemical treatmentCombination devicesMultistage water/sewage treatmentHigh concentrationComing out

Owner:CHINA PETROLEUM & CHEM CORP +1

Vacuum potassium carbonate method for utilizing coke oven coal gas desulphurization and decyanation waste liquid as resource

ActiveCN102267769BMeet the requirements of biochemical treatmentMultistage water/sewage treatmentMetal cyanidesHigh concentrationLiquid waste

The invention discloses a vacuum potassium carbonate method for utilizing coke oven coal gas desulphurization and decyanation waste liquid recycling as a resource. The method is also suitable to be used in other waste liquids containing high concentration cyanide and sulfide. According to the method, cyanide and sulfide are simultaneously precipitated; the precipitate is separated by centrifugation; the waste liquid processed from desulphurization and decyanation is processed through pH regulation and coagulant dosing; the processed waste liquid is discharged into a carbonization wastewater biochemical treatment system, and is treated; ferrocyanide precipitate is subject to a reaction with added lye in a high temperature, and is converted into potassium ferrocyanide; potassium ferrocyanide is disoluted, and is separated by centrifugation, such that potassium ferrocyanide mother liquor is obtained; potassium ferrocyanide mother liquor is cooled and crystallized, such that potassium ferrocyanide product is obtained. The method has advantages of simple equipment and convenient operation. With the method, simultaneous desulphurization and decyanation can be realized, requirements of subsequent treatments are satisfied, the wastes are utilized as resources, and economic benefits are brought in.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

A pretreatment device and method for color crystal synthetic wastewater

ActiveCN104556500BImprove processing efficiencyHarmfulWater contaminantsMultistage water/sewage treatmentHigh concentrationPretreatment method

The invention relates to a pretreatment device and method for colored crystal synthesis wastewater, and belongs to the field of wastewater treatment. The pretreatment device comprises two regulating tanks, two coagulating precipitation tanks, two intermediate tanks and two ferric carbon reaction tanks. The pretreatment method comprises the following steps: firstly, homogenizing and averaging high-concentration and low-concentration wastewater through the two regulating tanks; secondly, carrying out coagulating precipitation, acid modulation treatment and internal electrolysis treatment; thirdly, carrying out acid modulation treatment and internal electrolysis treatment again; finally, carrying out coagulating precipitation again. The wastewater pretreated by the device and the method can meet the biochemical treatment requirements.

Owner:CHINA NORTH ENERGY CONSERVATION & ENVIRONMENT PROTECTION

Treatment method of wastewater from methyl methacrylate plant

ActiveCN111559816BInhibition of polymerizationSolve the problem of easy aggregationWater contaminantsMultistage water/sewage treatmentPulp and paper industryMethacrylate methyl

The invention provides a method for treating wastewater from a methyl methacrylate plant. The treatment method comprises the following steps: using alkali to adjust the pH value of the methyl methacrylate plant wastewater to 9.7-10.3; passing the pH-adjusted methyl methacrylate plant wastewater into a rectification tower for rectification to remove Methyl methacrylate in wastewater. The treatment method provided by the invention can effectively solve the problem that the methyl methacrylate contained in the waste water is easily polymerized during the heating process, and make the treated waste water meet the requirements of biochemical treatment.

Owner:PETROCHINA CO LTD

A treatment method for high-concentration organic wastewater

InactiveCN103864250BImprove decomposition efficiencyReduce lossMultistage water/sewage treatmentHigh concentrationChemical oxygen demand

The invention discloses a treatment method of high-concentration organic wastewater. The method has a favorable treatment effect on high-concentration organic wastewater of which the COD (Chemical Oxygen Demand) concentration is larger than 50000mg / L and the chromaticity is larger than 10000 times. The hardly degradable substances in the treated wastewater can be degraded, so that the biodegradability of the treated wastewater is improved and the treated wastewater reaches the biochemical treatment requirement. The treatment method smartly combines ultrasonic splitting, micro-electrolytic decomposition and high-grade oxidation, and the problem that the high-concentration organic wastewater which has high COD and large toxicity and is difficulty biochemically degraded is solved.

Owner:苏州森荣环保处置有限公司

Resource method of waste liquid from coke oven gas desulphurization and decyanation

InactiveCN102267778BMeet the requirements of biochemical treatmentReduce toxic substancesSulfur preparation/purificationMultistage water/sewage treatmentHigh concentrationCyanide

The invention provides a resource method of a waste liquid from coke oven gas desulphurization and decyanation. The method is also suitable for other waste liquids containing high-concentration cyanide and sulfide. Ferric salt is employed to oxidize sulfide in the waste liquid to elemental sulfur, meanwhile Fe<2+> is generated to react with cyanide to generate precipitates. After decyanation and desulphurization, the waste liquid is charged to a coking waste water biochemical treatment system for processing. The precipitates are washed and added with an extractant to extract the elemental sulfur and recover an elemental sulfur product; remaining ferrocyanide solid is treated with pickling, centrifuged and prepared into a ferrocyanide product. Equipment of the technology is simple and convenient for operation. Not only can simultaneous desulphurization and decyanation be realized to meet requirements of subsequent processing, but also resource of waste can be realized; therefore, the method has important environmental and economic significance.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

A comprehensive treatment method for epichlorohydrin production wastewater

ActiveCN106745927BAvoid cloggingReduce or eliminate inhibitionTreatment using aerobic processesWater contaminantsEpoxyIndustrial waste water

The invention relates to a comprehensive treatment method of wastewater of epoxy chloropropane production. The method comprises the following steps: (1) pre-treating the wastewater of molecular sieve catalyst production through sulfuric acid; (2) adjusting the concentration of calcium ion in the wastewater of the epoxy chloropropane production through the pre-treated molecular sieve catalyst until the concentration of the calcium ions in the mixed wastewater is less than 2000mg / L, and removing the generated precipitate; (3) diluting the wastewater obtained in step (2) through domestic sewage and / or industrial wastewater; adjusting the pH of the wastewater to be 7.5-9.0, and removing the generated precipitate; (4) performing aerobic biochemical treatment on the diluted wastewater. With the adoption of the method, the calcium ions, sulfate radical, total nitrogen and COD in the wastewater can be efficiently removed; the method has the characteristics of being simple in treatment processes, and good in treatment effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for treating wastewater of methyl methacrylate device

PendingCN113754163AMeet the requirements of biochemical treatmentSolve the problem of thermal polymerizationWater contaminantsMultistage water/sewage treatmentMethacrylate methylMethyl acrylate

The invention provides a method for treating wastewater of a methyl methacrylate device. The method comprises the following steps: extracting methyl methacrylate from wastewater by adopting multiple extraction agents to obtain a first raffinate phase; adjusting the pH value of the first raffinate phase to be neutral to obtain a second raffinate phase; and rectifying the second raffinate phase to obtain treated wastewater. According to the method, on one hand, the problem that methyl methacrylate is polymerized when heated in the wastewater organic matter removal process in the prior art is solved, and on the other hand, the COD value of the treated wastewater is lower than 15000 mg / L, and the PH value is close to neutral, so that the biochemical treatment requirement is met.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com