Pre-treatment technology of 3-chloro-2-hydrazinopyridine production waste water

A technology of hydrazinopyridine and production wastewater, which is applied in the field of pretreatment technology of classified collection and quality separation treatment, can solve the problems of large dilution ratio of biochemical influent water, difficult to discharge standard treatment, harsh reaction conditions, etc., and achieves low cost and operation. Simple, targeted results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

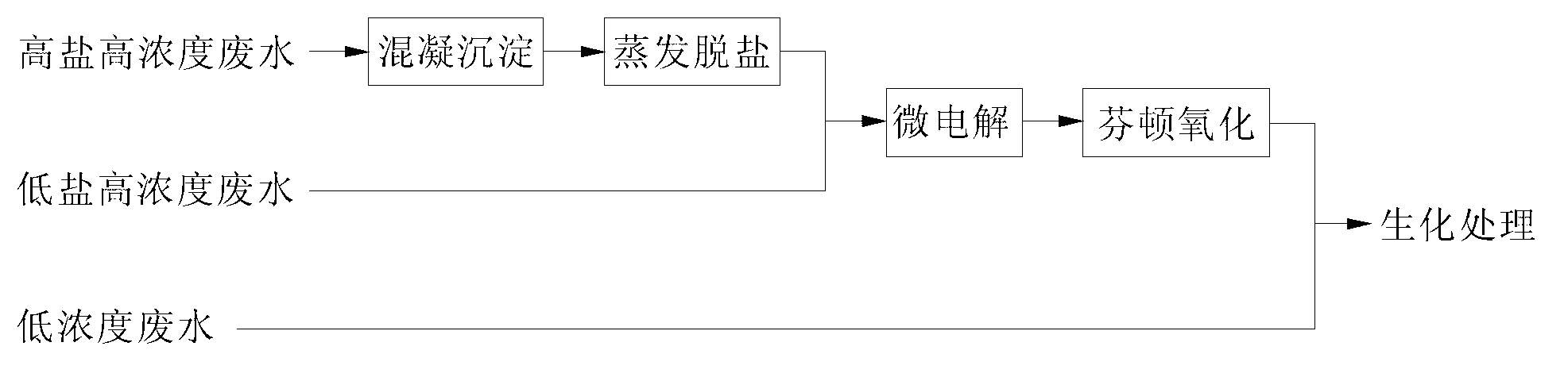

Method used

Image

Examples

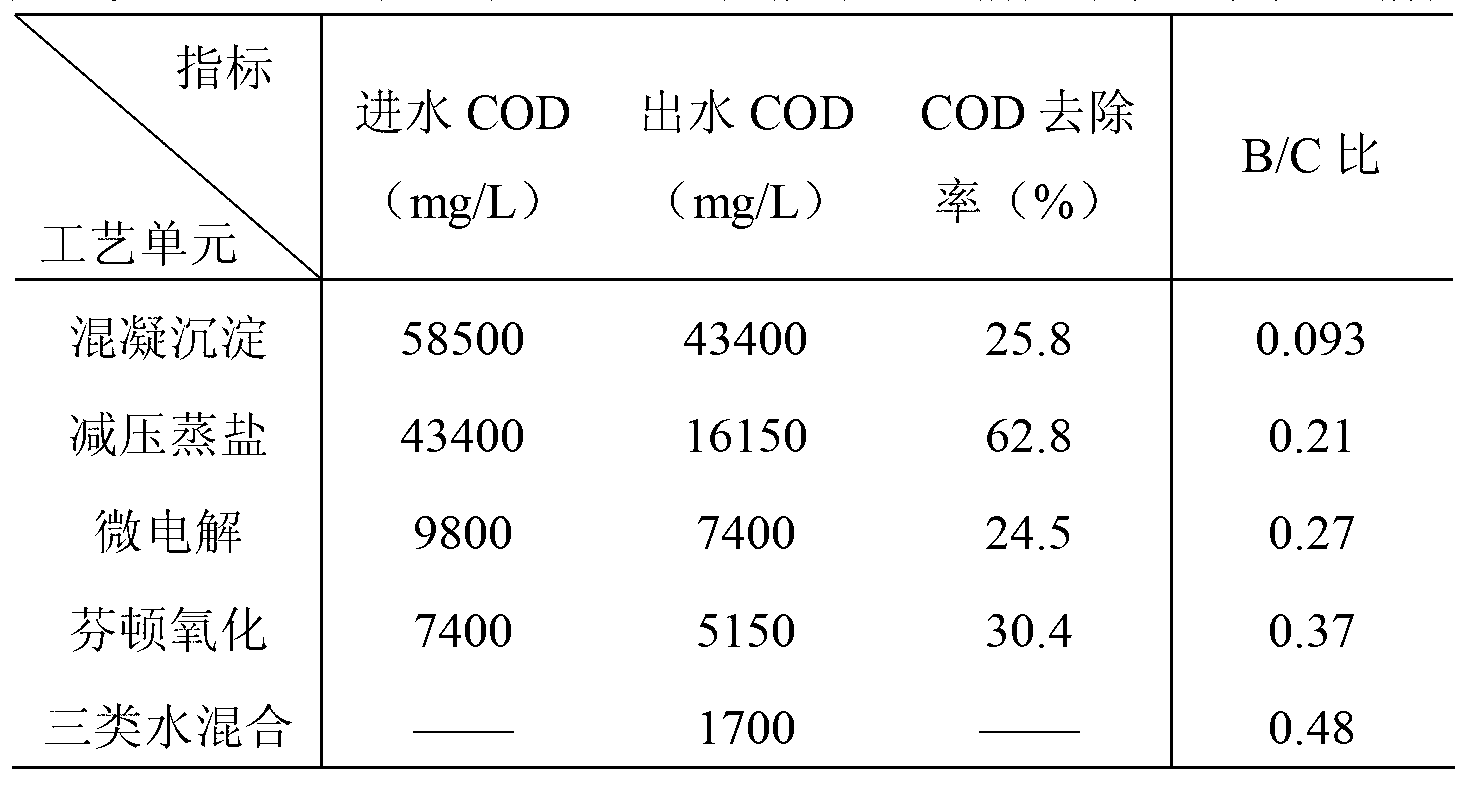

Embodiment 1

[0031] (1) Divide 3-chloro-2-hydrazinopyridine production wastewater into three categories for collection according to water quality, namely high-salt and high-concentration wastewater, low-salt and high-concentration wastewater, and low-concentration wastewater. Add hydrochloric acid dropwise to high-salt and high-concentration wastewater to bring the pH value to 8, add 10% (mass fraction) polyferric sulfate solution 10mL / L and stir, then add 2‰ (mass fraction) anionic polyacrylamide solution 5mL / L Afterwards, stir quickly and then slowly, and obtain the supernatant after standing still.

[0032] (2) Take the supernatant liquid obtained in (1), adjust the pH value to 5 with hydrochloric acid, and increase the vacuum pump pressure to 0.06 MPa, perform decompression evaporation and desalination, and obtain a distillate. Through the treatment of coagulation sedimentation-vacuum evaporation desalination process, the salt content of high-salt and high-concentration wastewater was ...

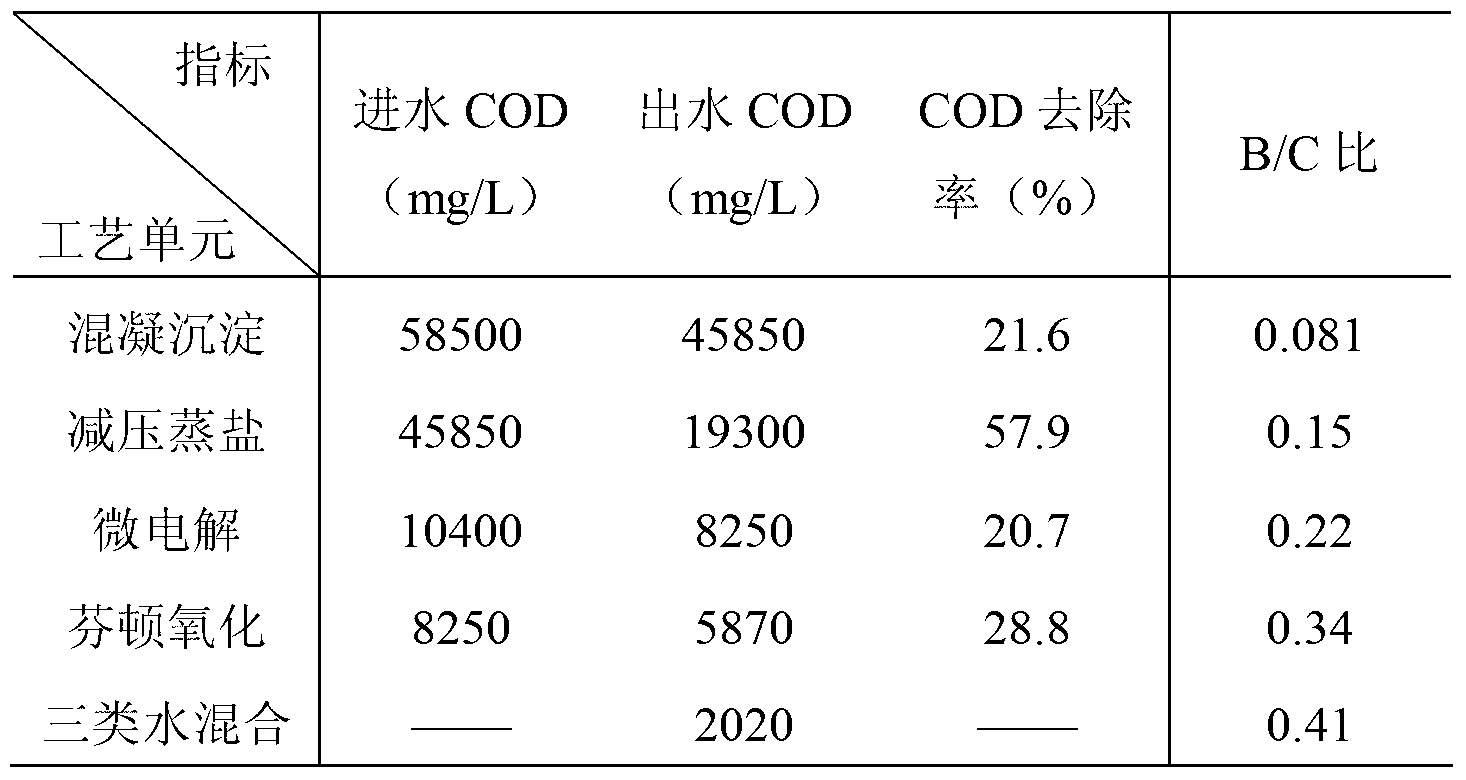

Embodiment 2

[0040](1) Divide 3-chloro-2-hydrazinopyridine production wastewater into three categories for collection according to water quality, namely high-salt and high-concentration wastewater, low-salt and high-concentration wastewater, and low-concentration wastewater. Add sulfuric acid dropwise to high-salt and high-concentration wastewater to bring the pH to 9, add 5% (mass fraction) polyaluminum chloride solution 5mL / L and stir, then add 1‰ (mass fraction) anionic polyacrylamide solution 2.5mL After / L, stir rapidly and then slowly, and obtain the supernatant after standing still.

[0041] (2) Take the supernatant liquid obtained in (1), adjust the pH value to 6 with sulfuric acid, and increase the vacuum pump pressure to 0.03 MPa, carry out desalination by decompression evaporation, and obtain distillate. Through the treatment of coagulation sedimentation-vacuum evaporation desalination process, the salt content of high-salt and high-concentration wastewater was reduced from 211g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com