Treatment method of high concentration undegradable nitrile containing organic waste water

A technology of organic wastewater and treatment method, applied in water/sewage treatment, water/sewage multi-stage treatment, neutralized water/sewage treatment, etc., can solve the problems of poor biodegradability, high toxicity and unacceptable engineering investment of wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

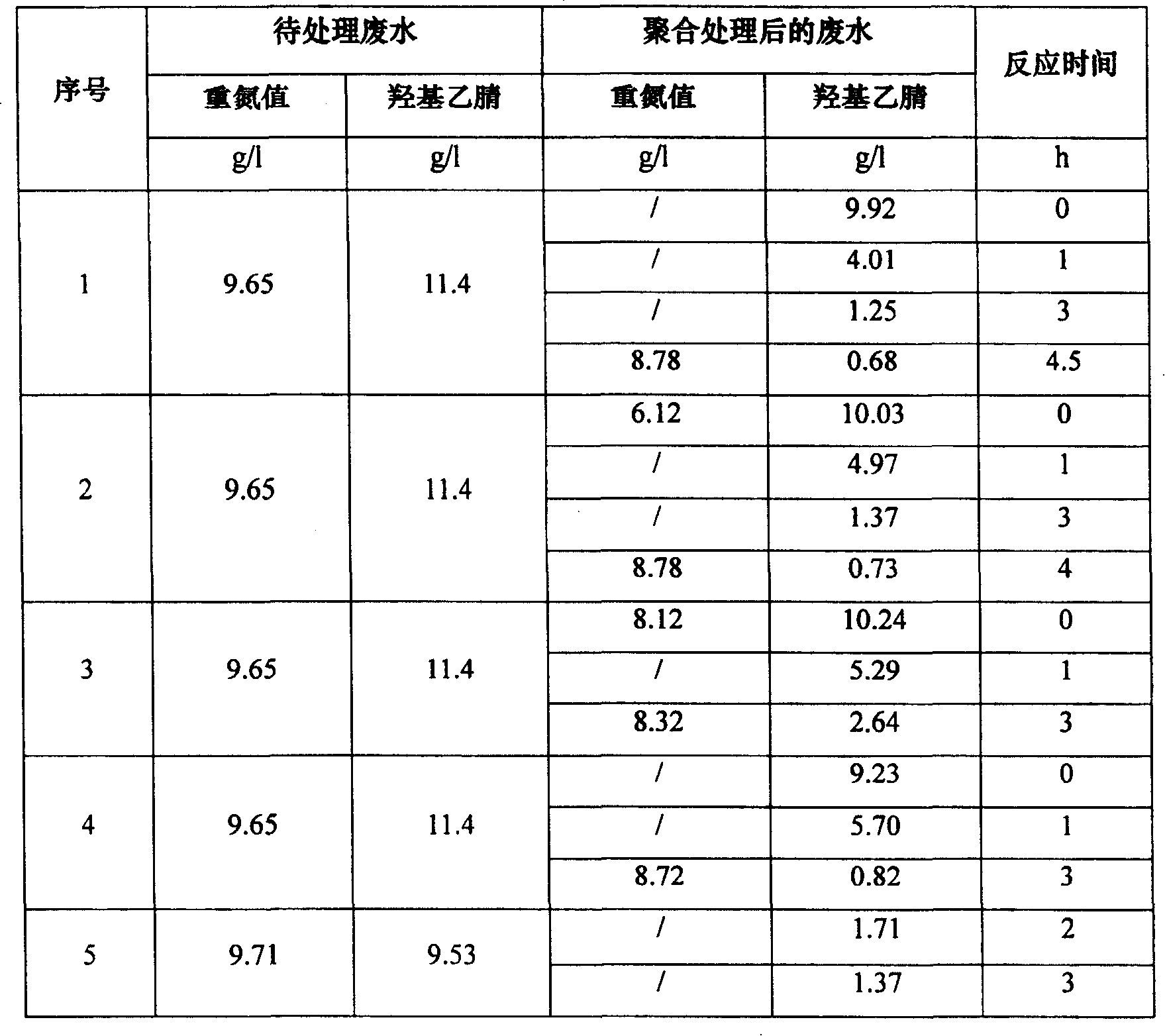

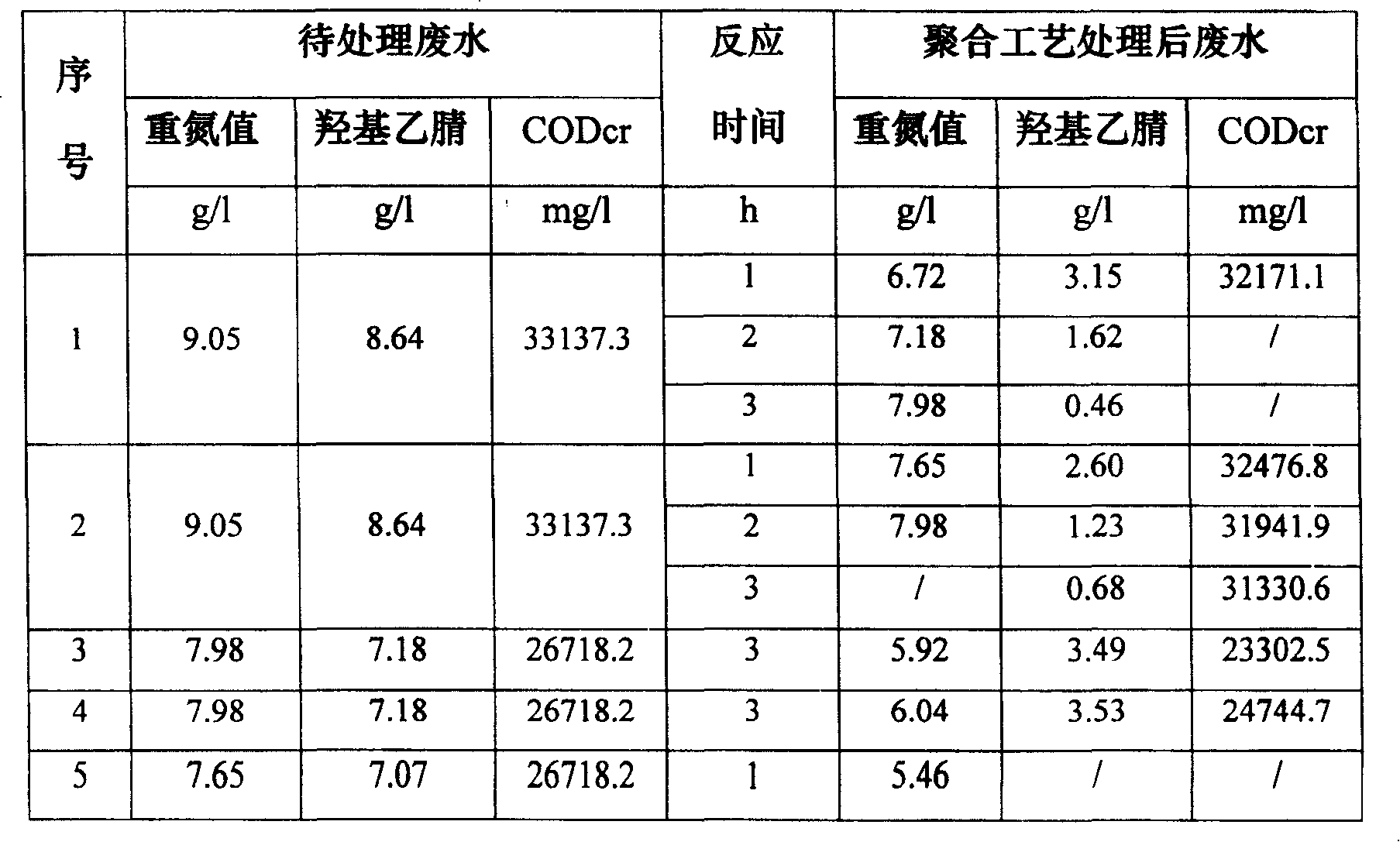

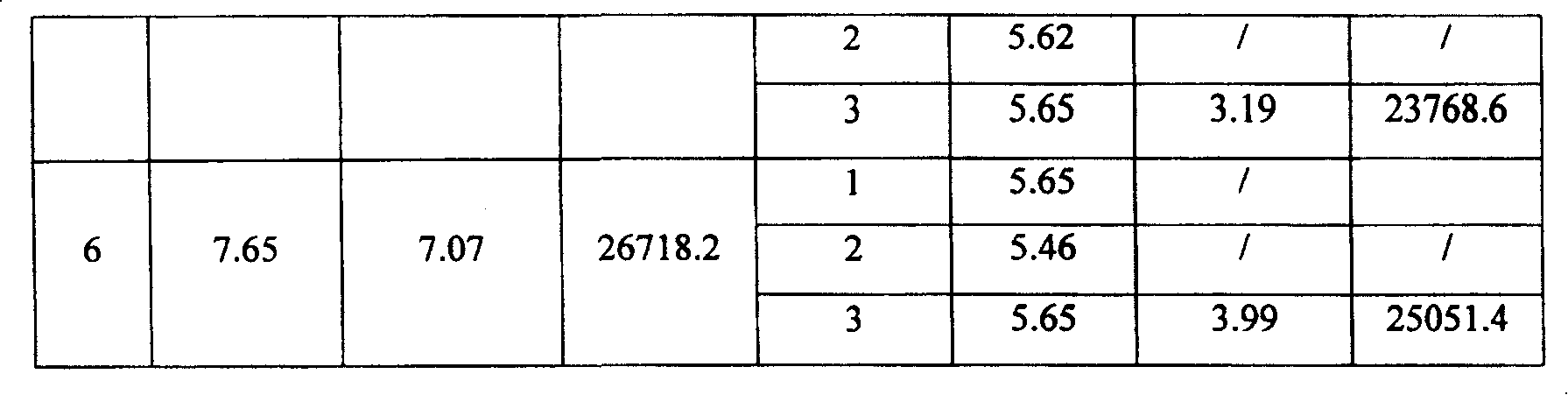

[0044] Embodiment 1: a kind of treatment method of high concentration, refractory organic waste water containing nitrile:

[0045]In 2500 milliliters of this high-concentration, refractory nitrile-containing organic waste water (CODcr content is 32500 mg / l), add 5 grams of potassium oxide, stir 10~20 min, be that the sodium hydroxide aqueous solution of 30% by weight percentage concentration is used to regulate above-mentioned waste water The pH value is 10, and the waste water is heated to control the reaction temperature at 40-60° C., stirred at a slow speed for about 30-40 minutes, and filtered after the polymerization reaction is complete.

[0046] Add 25 grams of lime to the filtrate after the above polymerization reaction, stir, then heat the waste water at 80-95° C. for 4 hours, and finally filter. The CODcr content in the filtrate dropped to 18185mg / l, and the CODcr removal rate was 44.05%.

Embodiment 2

[0047] Embodiment 2: in a kind of high concentration, in 2500 milliliters of refractory nitrile-containing organic waste water (CODcr content is 34923mg / l), add 8 grams of sodium oxide, stir 5~10min, be 42% sodium hydroxide with weight percent concentration The aqueous solution adjusts the pH value of the wastewater to 9, heats the wastewater to control the reaction temperature at 30-50° C., stirs at a slow speed for about 20-30 minutes, and filters after the polymerization reaction is complete.

[0048] Add 30 grams of lime to the filtrate after the above polymerization reaction, stir, then heat the waste water at 75-90° C. for 6 hours, and finally filter. The CODcr content in the filtrate dropped to 21900mg / l, and the CODcr removal rate was 37.29%.

Embodiment 3

[0049] Embodiment 3: in 2500 milliliters (CODcr content is 28565mg / l) of high concentration, refractory nitrile-containing organic waste water, add 10 grams of calcium oxide, stir 5~10min, be 40% sodium hydroxide aqueous solution adjustment with weight percent concentration The pH value of the above wastewater is 11, and the wastewater is heated to control the reaction temperature at 30-40° C., stirred at a slow speed for about 30-40 minutes, and filtered after the polymerization reaction is complete.

[0050] Add 20 grams of lime to the filtrate after the above polymerization reaction, stir, then heat the waste water at 90-100° C. for 3 hours, and finally filter. The CODcr content in the filtrate dropped to 17213mg / l, and the CODcr removal rate was 39.74%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen consumption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com