Method for treating wastewater containing molasses alcohol

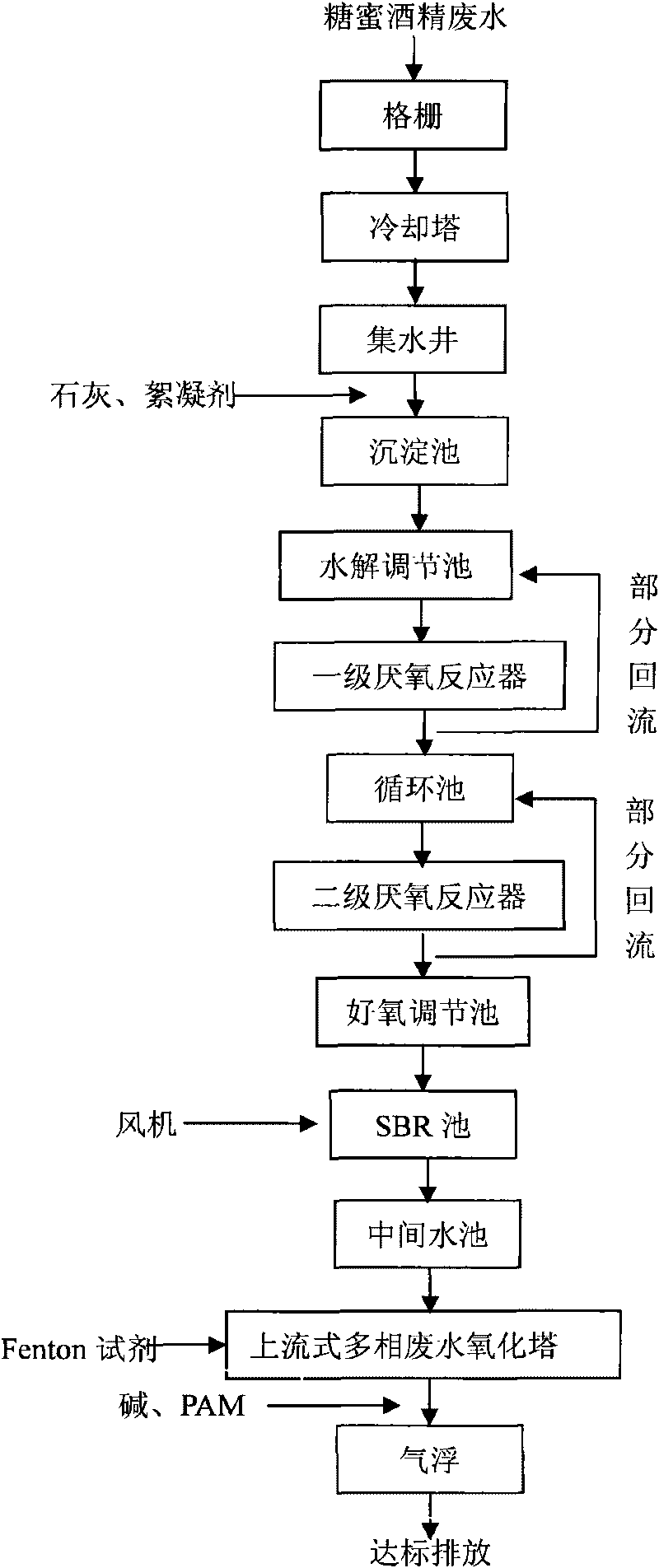

A technology of molasses alcohol wastewater and its treatment method, which is applied in the field of molasses alcohol wastewater treatment, can solve the problems such as ineffective chroma removal effect of molasses alcohol wastewater, slow initial start-up process of reactor, and long anaerobic treatment time, etc. Biochemical properties, low processing costs, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A molasses alcohol factory in Guangxi adopts the method of the present invention to treat the waste water of the factory. The raw water COD is about 100000mg / L, and the designed treatment capacity is 2000m 3 / d, the surface load of the sedimentation tank is 0.7m 3 / m 2 h, the hydraulic retention time is 2.5h, the hydraulic retention time of the hydrolysis regulating tank is 8h, and the volume load of the primary anaerobic reactor is 4kgCOD / m 3 d, the volume load of the secondary anaerobic reactor is 12kgCOD / m 3 d. The ascending flow rate is 6m / h, and the volume load of the SBR tank is 0.6kgBOD / m 3 d, dissolved oxygen 2mg / L, sludge concentration 3500mg / L, aerobic effluent COD average 400mg / L, H 2 o 2 The mass ratio of dosing amount to aerobic effluent COD is 2:1; Fe 2+ with H 2 o 2 The molar ratio is 1:18, and the hydraulic retention time in the upflow multiphase wastewater oxidation tower is 0.5h. After air flotation treatment, the average COD of the effluent is ...

Embodiment 2

[0054] A molasses alcohol factory in Guangxi adopts the method of the present invention to treat the waste water of the factory. The raw water COD is about 120000mg / L, and the designed treatment capacity is 1500m 3 / d, the surface load of the sedimentation tank is 0.8m 3 / m 2 h, the hydraulic retention time is 3h, the hydraulic retention time of the hydrolysis regulating tank is 10h, and the volume load of the primary anaerobic reactor is 5kgCOD / m 3 d, the volume load of the secondary anaerobic reactor is 15kgCOD / m 3 d. The ascending flow rate is 8m / h, and the volume load of the SBR pool is 0.8kgBOD / m 3 d, dissolved oxygen 2.5mg / L, sludge concentration 4000mg / L, aerobic effluent COD average 380mg / L, H 2 o 2 The mass ratio of dosing amount to aerobic effluent COD is 3:1; Fe 2+ with H 2 o 2 The molar ratio is 1:20, and the hydraulic retention time in the upflow multi-phase wastewater oxidation tower is 1h. After air flotation treatment, the average COD of the effluent is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface load factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com