Patents

Literature

178results about How to "Reduce pollution pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

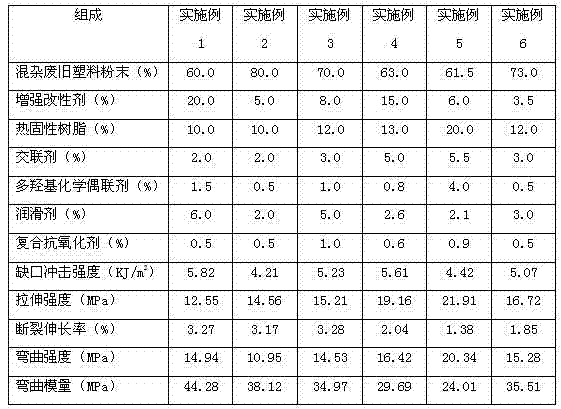

Composite board based on mixed waste polymers and preparation method thereof

The present invention discloses a composite board based on mixed waste polymers and a preparation method thereof. The preparation method of the composite board based on the mixed waste polymers is characterized by comprising the following steps of: (1) weighing the raw materials according to a certain proportion, adding the raw materials to a high-speed mixer, mixing at the temperature of 40-60 DEG C and the rotation speed of 800-2000 rpm for 20-30 minutes, cooling to room temperature and discharging; and (2) adding the mixed material to a mold, vulcanizing at the temperature of 150-180 DEG C and the pressure of 10-15 MPa for 10-20 minutes, cooling and relieving pressure. The composite board based on the mixed waste polymers provided by the invention does not need to consider the complex compatibility and plasticizing problems of multiple polymers, effectively solves the problems that the existing mixed waste polymers can not be classified and are discarded, and can be used as the substitute for wood to be applied in the tray manufacturing field and other fields. The production process provided by the invention is simple, uses existing equipment and is suitable for mass production.

Owner:佛山市南海承骏科技有限公司 +1

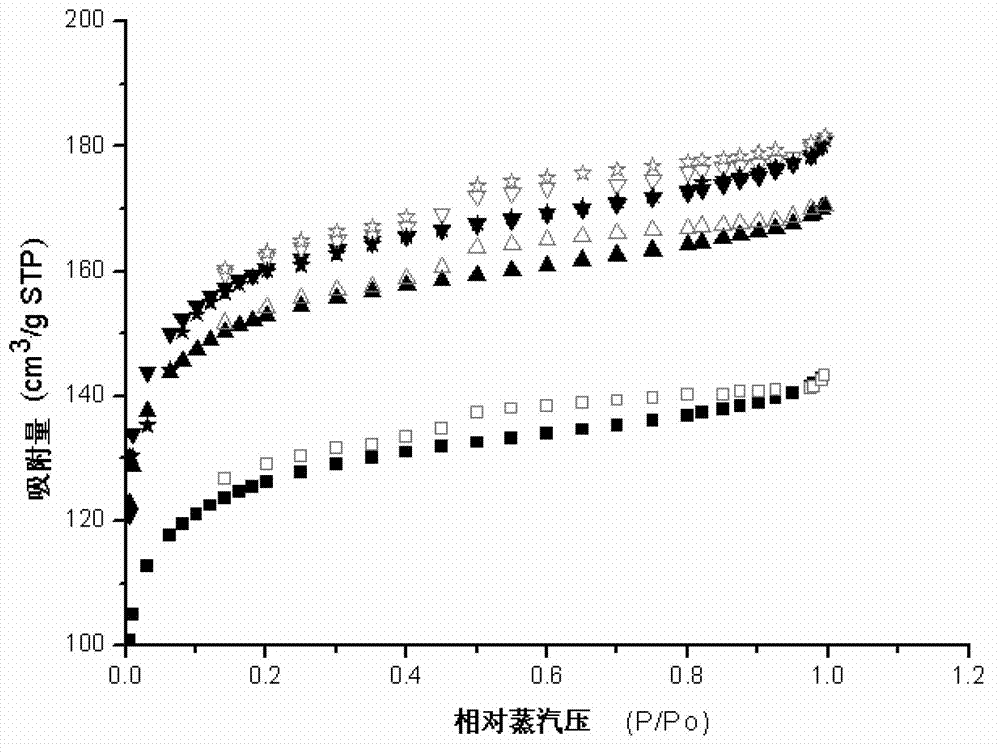

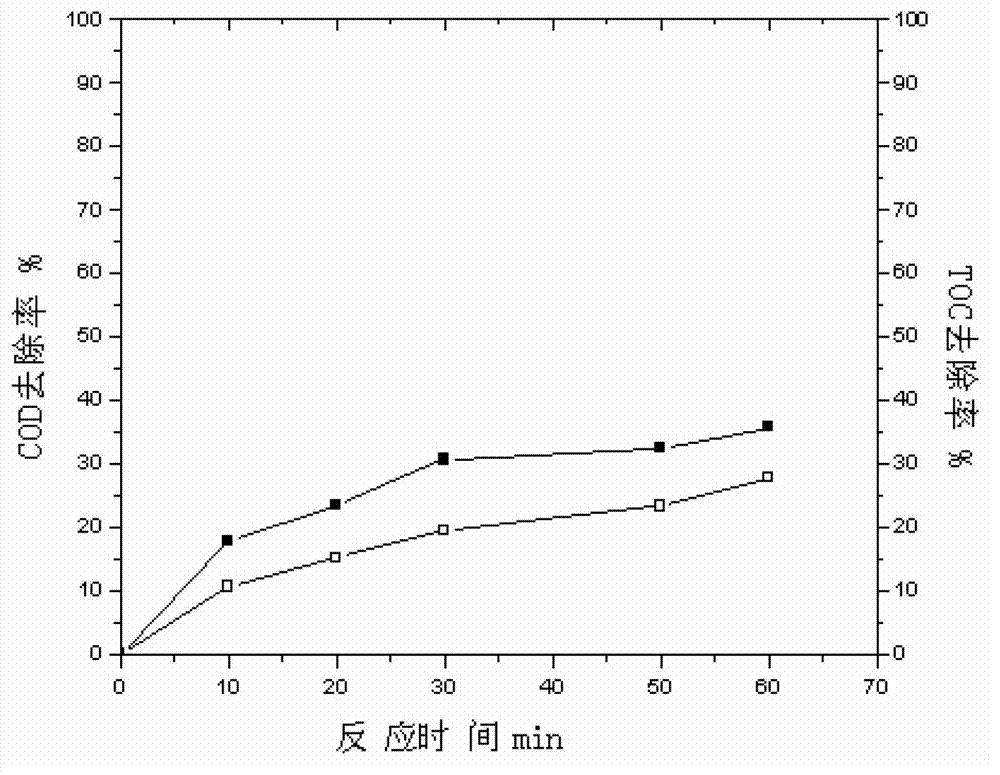

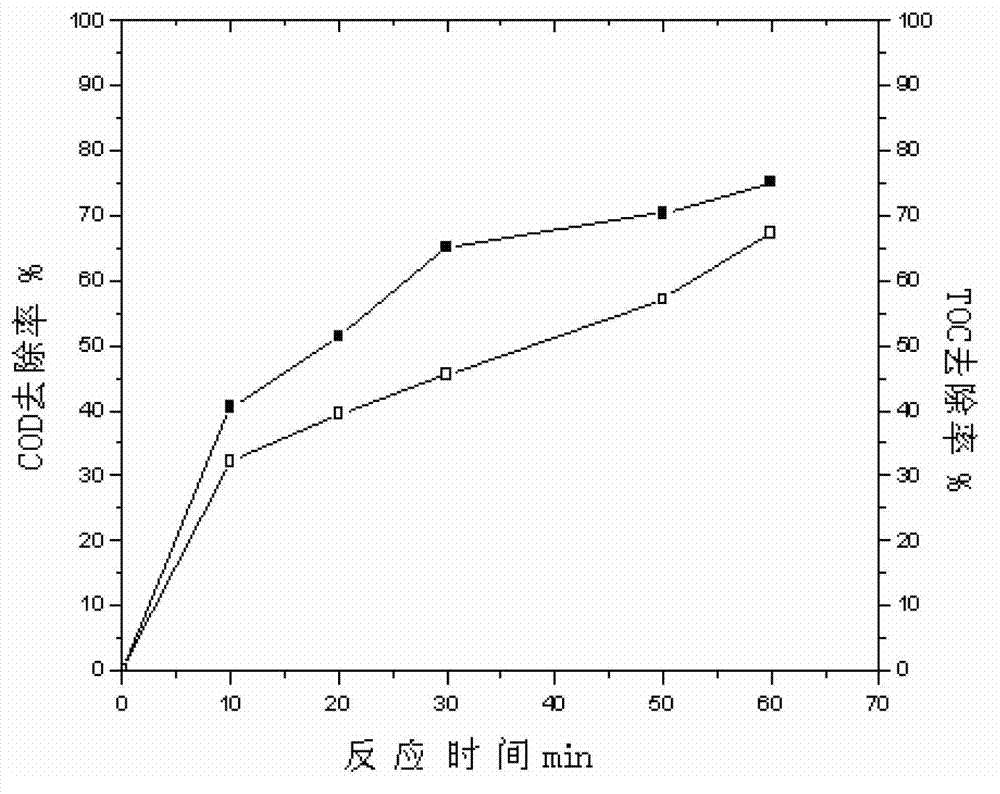

Preparation method of catalyst for catalyzing ozonation for advanced treatment of coal chemical wastewater

InactiveCN103111290AReduce pollution pressureLarge specific surface areaCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsSolubilityHazardous substance

The invention discloses a preparation method of a catalyst for catalyzing ozonation for advanced treatment of coal chemical wastewater and relates to a preparation method for the catalyst. The preparation method is used for solving the technical problems that the existing ozonation method is poor in ozone water solubility and low in degradation rate, successfully applied to the advanced treatment of the coal chemical wastewater, and capable of removing the degradation-resistant hazardous substances in water, improving the biodegradability of the wastewater and enabling the quality of the outlet water to reach the first-grade national emission standards. The preparation method comprises the following steps of: firstly, washing active carbon particles; secondly, soaking the active carbon in a metal nitrate solution, shaking for mixing and reacting, and taking out the active carbon 12 hours later; and thirdly, drying the active carbon and putting the dried active carbon to a muffle furnace, heating the muffle furnace to 200 DEG C by adopting nitrogen gas as the protective gas, roasting for one hour, continuing heating the muffle furnace to 600 DEG C and roasting for 3 hours at 600 DEG C to obtain the catalyst for treating the coal chemical wastewater. By using the catalyst prepared by the preparation method disclosed by the invention, the utilization rate of ozone is greatly improved, and the catalyst is very suitable for the field of coal chemical wastewater treatment.

Owner:HARBIN INST OF TECH

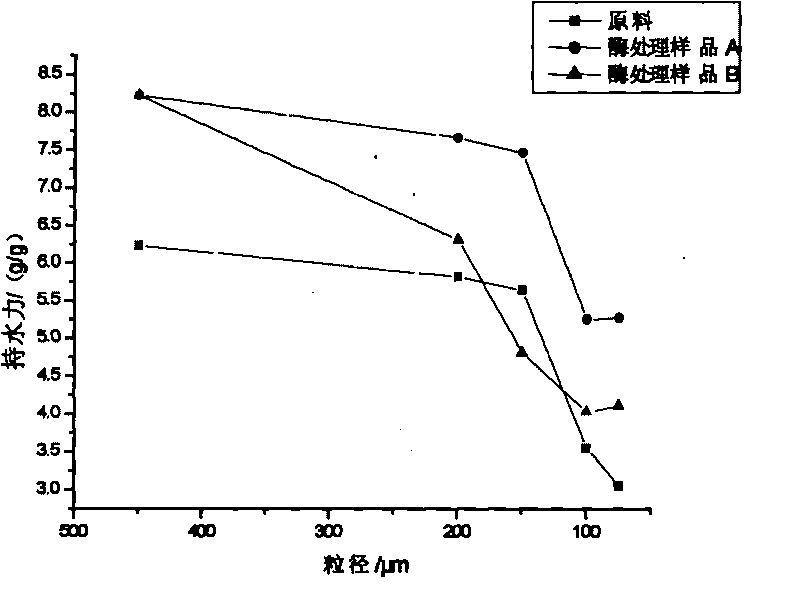

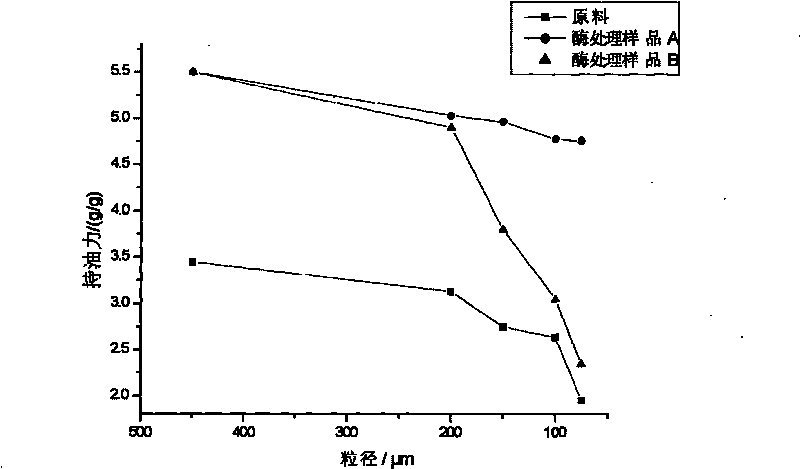

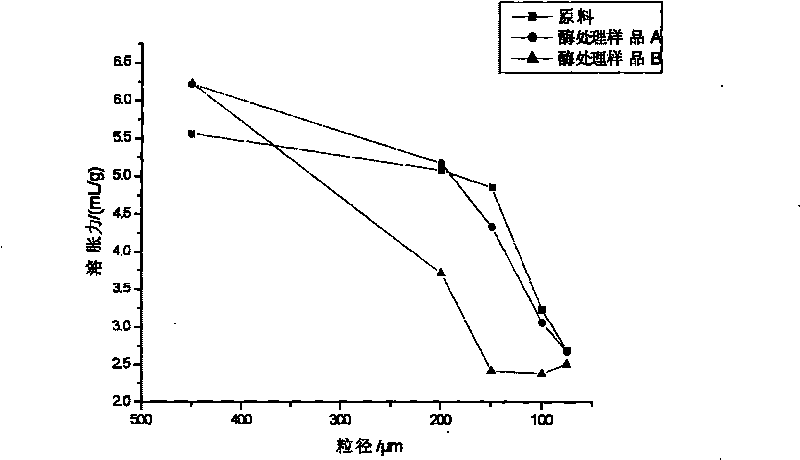

Method for extracting dietary fiber from potato residues

InactiveCN101715946AReduce pollutionSolve processing problemsFood preparationNeutral proteinaseSolanum tuberosum

The invention discloses a method for extracting a dietary fiber from potato residues, which comprises the following steps of: drying potato residues, pulverizing and screening to prepare potato residue powder; adding water into the potato residue powder, uniformly mixing to form a potato residue pulp, carrying out enzymolysis processing by using mixed enzyme, boiling and cooling; adding neutral proteinase to carry out enzymolysis processing, boiling and cooling, wherein the activity of the neutral proteinase is 1,600AU; filtering to form filter liquid and filter residues; and drying, pulverizing and screening the filter residues to obtain the dietary fiber. The invention improves the water-holding capacity and the oil-holding capacity of the potato dietary fiber by bio-enzyme processing and obtains a production process of the dietary fiber with optimal grain diameter simultaneously.

Owner:SOUTH CHINA UNIV OF TECH

Trace element premixing feed for suckling piglet

InactiveCN101744120AContent balancePromote growthAnimal feeding stuffPotassium iodineFERROUS BISGLYCINATE

The invention discloses trace element premixing feed for a suckling piglet. 100-250g of ferrous bisglycinate chelate, 100-200g of zinc glycinate, 100-350g of copper glycine, 50-150g of manganese sulfate, 0.25-0.75g of potassium iodide and 35-100g of yeast selenium and the balance of premixing feed carrier are contained in the premixing feed per kilogram; In the premixing feed, contents of various trace elements are more balanced through reasonably and completely preparing the various trace elements, thereby effectively promoting the growth of the suckling piglet, improving the utilization ratio and the health state of the feed and simultaneously and remarkably reducing the pressure of heavy metal to environmental pollution.

Owner:HEBEI AGRICULTURAL UNIV.

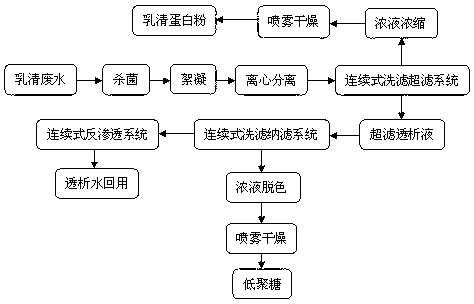

Method for recycling of soybean whey wastewater by membrane separation technology

InactiveCN103012580APrevent rancidityAvoid fouling of ultrafiltration membranesAlbumin peptidesPeptide preparation methodsFiltration membraneUltrafiltration

The invention discloses a method for recycling of soybean whey wastewater by a membrane separation technology. The method includes: sterilization pretreatment; flocculation and centrifugal separation for impurity removal; whey protein recovery by ultrafiltration membrane continuous separation; whey protein powder recovery; oligosaccharide syrup recovery by nanofiltration membrane continuous concentration; oligosaccharide recovery; and dialysis water recovery by reverse osmosis membrane continuous concentration. The method provided in the invention can avoid whey wastewater rancidity and ultrafiltration membrane pollution and plugging, and improves the product quality. Employment of the continuous separation concentration mode reduces stay of intercepted objects or protein, impurity concentrated liquors in a membrane assembly to the utmost, and back-and-forth circulation between a membrane liquid inlet tank and a membrane system no longer exists. Meanwhile, the membrane surface flow speed is controlled, so that the problems of membrane pollution and low separation efficiency are solved. An osmosis filtration membrane washing process is adopted, and water is added automatically for filter wash, so that the membrane pollution and plugging problems are solved, and the product quality is improved. The selection of high temperature resistant hydrophilic membrane materials guarantee a high water flux and help to reduce membrane pollution.

Owner:上海诚洲科技中心(有限合伙)

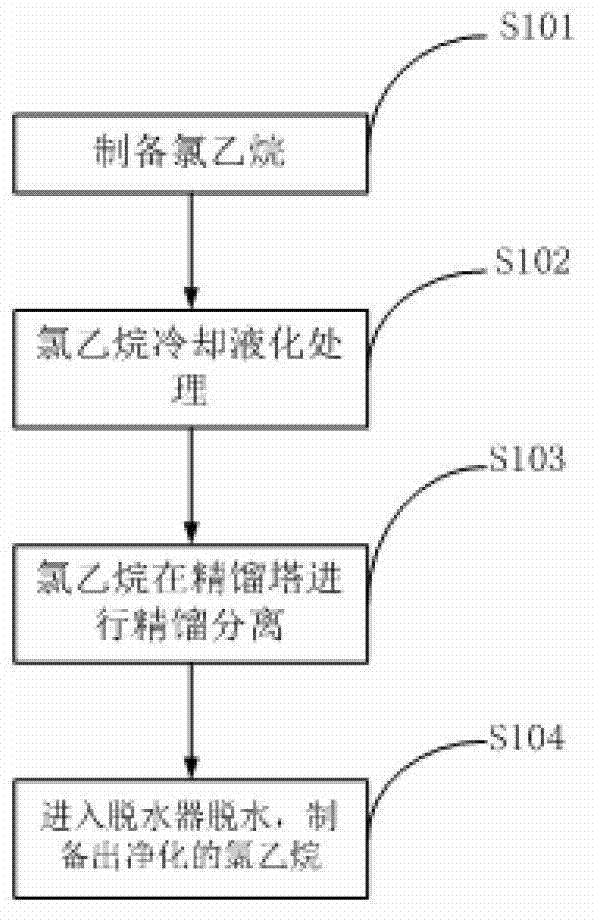

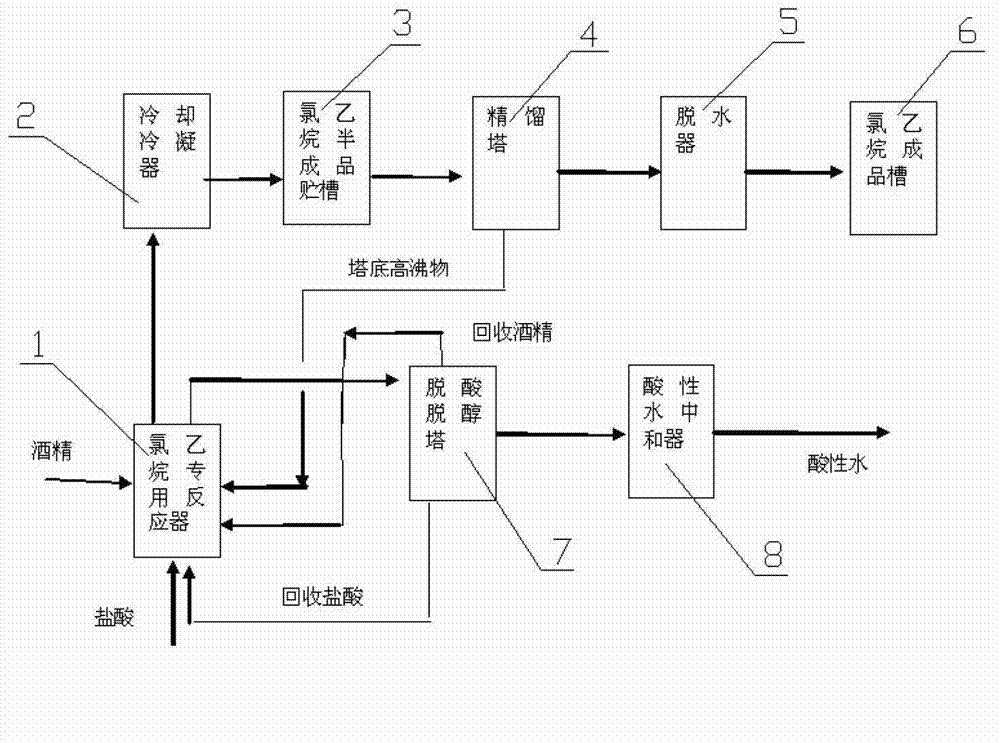

Halide alkylation technique and halide alkylation system for preparation of chloroethane

InactiveCN103044188AOperating temperature optimizationReduce pollution pressureHalogenated hydrocarbon separation/purificationAutomatic controlChemistry

The invention discloses a halide alkylation technique and a halide alkylation system for preparation of chloroethane. A special chloroethane reactor is used for replacing a plurality of reaction kettles to realize facility upsizing and automatic control and increase the transformation rate of raw materials. According to the difference of gaseous phase partial pressure of ethanol water solution at different temperatures and the difference of gaseous phase partial pressure of hydrochloric acid at different temperatures, most of the ethanol and hydrochloric acid in the reactant mixed gas is distilled and separated and then returned to the chloroethane reactor for reuse; according to the property that organic solvents such as chloroethane and ethanol have different boiling points at different concentrations, a rectification technique is adopted for rectifying and separating chloroethane of which the content satisfies the quality requirement; and according to the property that water has different solubilities in chloroethane at different temperatures, the temperature of chloroethane is reasonably controlled to realize dehydration of chloroethane, and most of the unreacted hydrochloric acid and alcohol in production is recycled and returned to a special reactor for reuse, so that the production cost is lowered, the total amount of pollutant is reduced and good application value is achieved.

Owner:JIANGSU YINZHU CHEM GROUP

Method for manufacturing soybean protein modified adhesive formaldehyde-free medium-density fiberboard

ActiveCN104059598AResolve dependenciesReduce dependenceNon-macromolecular adhesive additivesProtein adhesivesFiberPolymer science

The invention provides a method for manufacturing a soybean protein modified adhesive formaldehyde-free medium-density fiberboard, and belongs to the technical field of density fiberboard manufacture. The method comprises the following steps: heating, stirring and mixing raw materials (soybean pulp, a denaturing agent, a crosslinking agent, a defoaming agent, a preservative and water) to react; preparing the soybean protein formaldehyde-free adhesive by virtue of a colloid mill and a homogenizer; adding a water-proofing agent, a curing agent and a buffering agent into the soybean protein formaldehyde-free adhesive, stirring and mixing at room temperature, and uniformly mixing with wood fibers; performing drying, paving and hot-pressing to prepare the soybean protein modified adhesive formaldehyde-free medium-density fiberboard. The method is environment-friendly and non-pollution; the soybean protein modified adhesive formaldehyde-free medium-density fiberboard is high in adhesion strength, good in water proofing, low in price, low in viscosity and easy to treat and process, can be subjected to hot-pressing and cold-pressing in application, and is not easy to crack. The soybean protein modified adhesive formaldehyde-free medium-density fiberboard can be adhered to fibers and the like, and the processing process can be controlled, and an environment-friendly fiberboard can be manufactured.

Owner:DONGYING ARTIFICIAL BOARD FACTORY

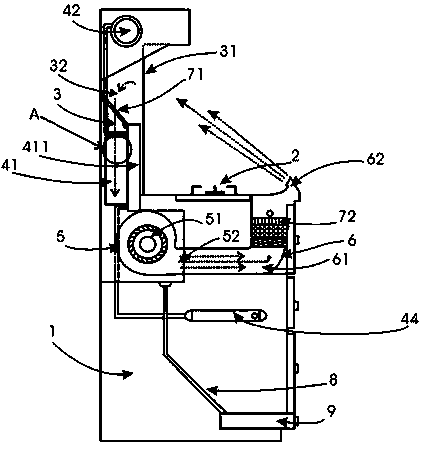

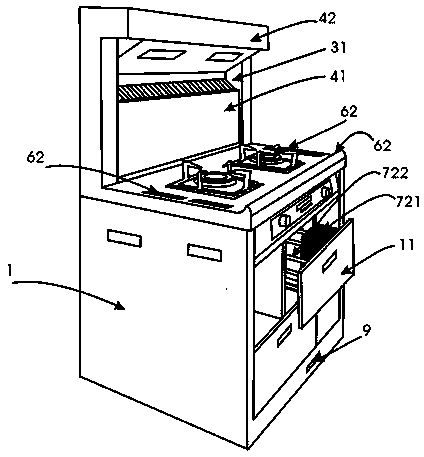

Water-cooled circulating integrated stove

ActiveCN103353134AReduce pollution pressureThorough purificationLighting and heating apparatusWater heating stoves/rangesEngineeringProduct gas

The invention discloses a water-cooled circulating integrated stove which comprises an integrated stove housing, a cooker arranged on the table board of the integrated stove housing, a gas inlet device in the integrated stove housing, a cooling device, a blower device, an air outlet device and an oil fume separating and purifying device, wherein the cooling device comprises a heat absorption water heater, a heat storage water tank and a drain valve; the heat absorption water heater is provided with a flat heat absorption water tank; the heat storage water tank is communicated with the flat heat absorption water tank; the drain valve is communicated with the heat storage water tank; the blower device is provided with an air suction hole and a blower hole; the air outlet device comprises an air outlet passage and an air outlet communicated with the air outlet passage; the oil fume separating and purifying device comprises a mechanical grease separator and a media smog processor; the mechanical grease separator and the gas inlet device are combined into a whole; the media smog processor and the air outlet device are combined into a whole. Through the arrangement of the oil fume separating and purifying device, zero outdoor emission of kitchen oil fume is realized, which not only reduces pollution pressure of social environment, but also completely purifies indoor oil fume, thereby improving living environment.

Owner:SHANGHAI DUOHUAN OIL SMOKE PURIFICATION EQUIP CO LTD

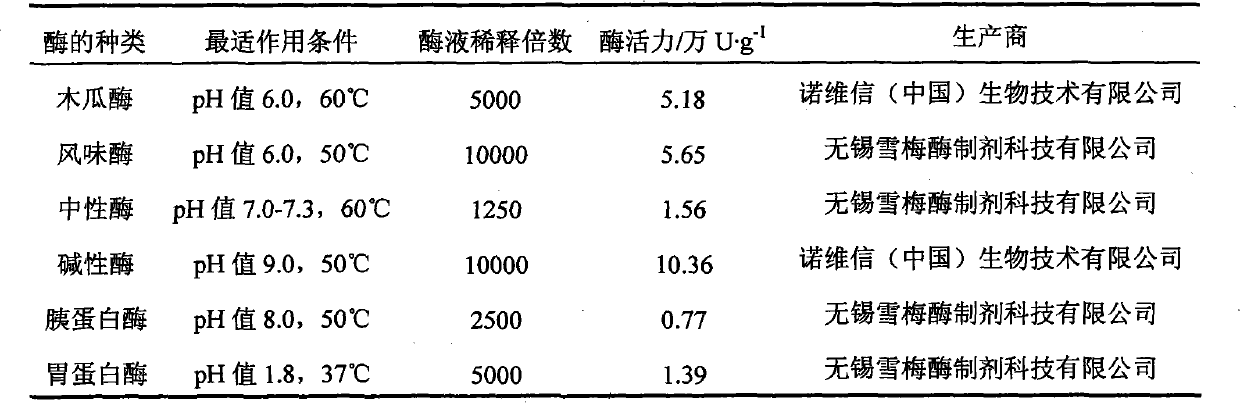

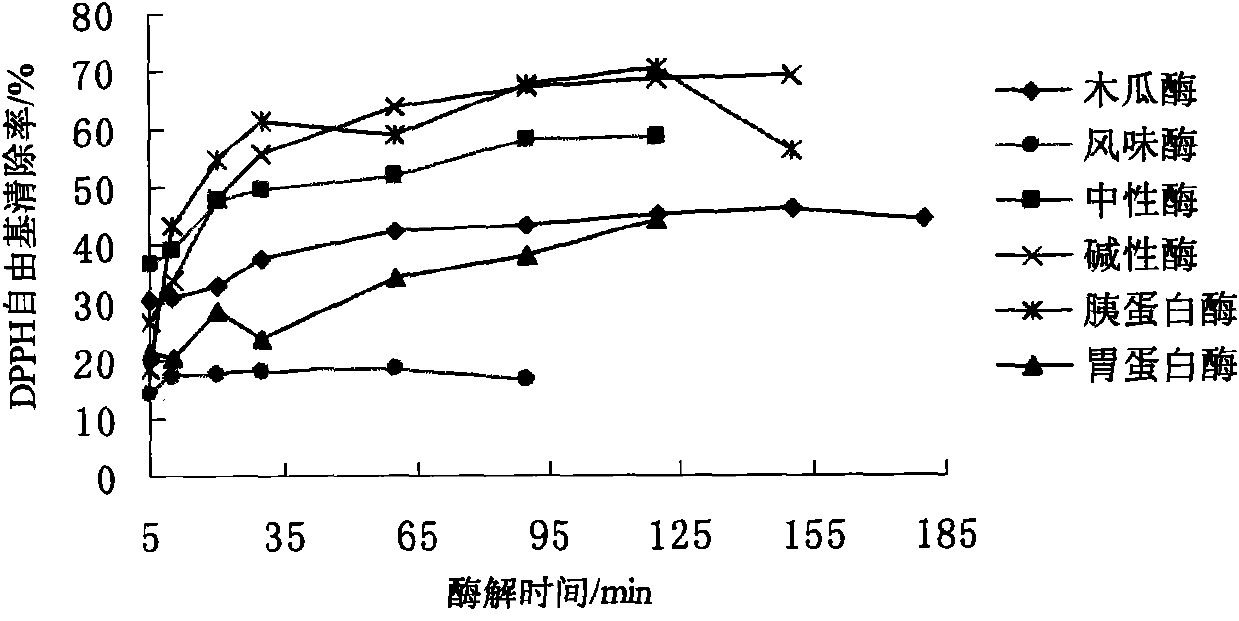

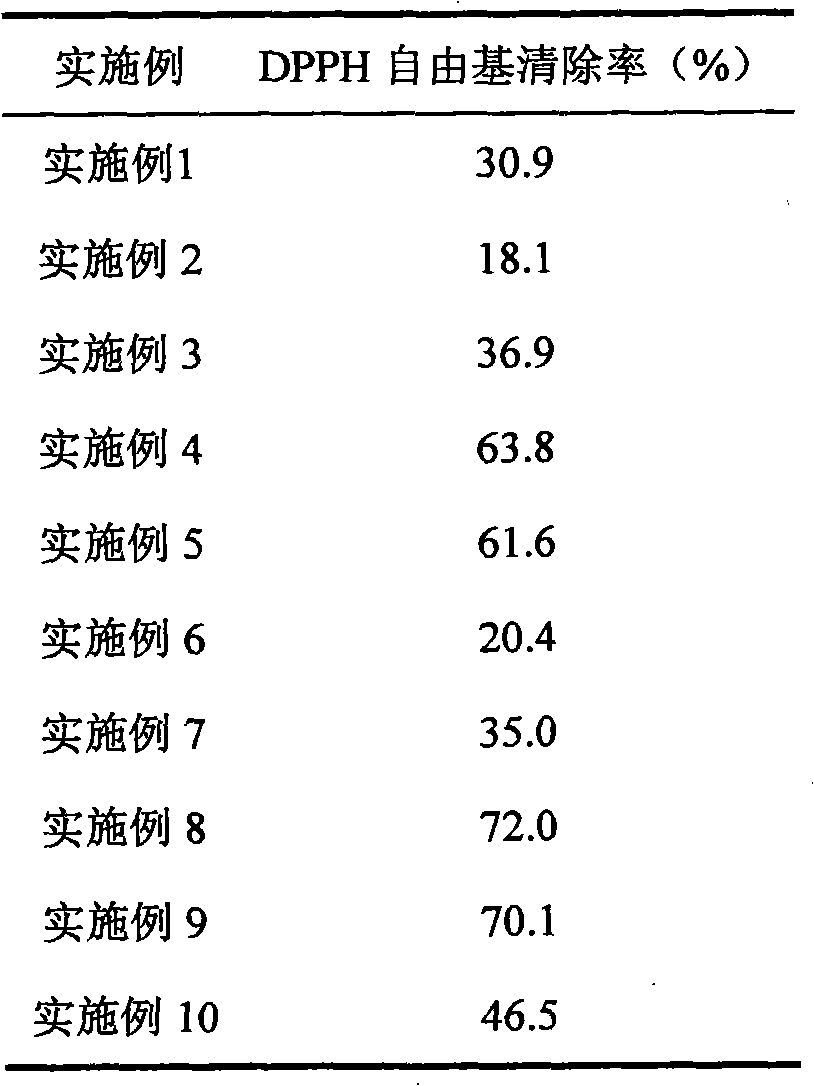

New method for development and utilization of potato residue resource

ActiveCN101948895AReduce the pressure of environmental pollutionReduce pollution pressureFermentationFood preparationPeptideChemistry

The invention relates to a new method for the development and utilization of potato residue resource, comprising the following steps: (1) adding water to the potato residue pulp or potato residue powder, wherein the mass-volume ratio of the potato residue dry substance to water is 1:12.5-1:50; (2) adding protease to process, carrying out reaction for 5-150 min, and then boiling the mixture for 10min, cooling the mixture to 20-30 DEG C and adjusting the pH value of feed liquid to 7.0-7.3; (3) centrifuging the potato residue enzymolysis liquid processed in step (2), collecting supernate to obtain polypeptide liquid, drying the polypeptide liquid to obtain polypeptide powder; and (4) applying the sediment obtained in step (3) to extract potato residue dietary fiber. The preferable enzyme istrypsin, the technique has the following conditions: substrate concentration: 4%, pH value: 8.0, temperature: 50 DEG C, enzyme addition quantity: 7% and enzymolysis time: 90 min. In the invention, the enzyme processing separation method is adopted to prepare the potato residue antioxidant peptide and dietary fiber and develop and utilize the potato residue resource, the production conditions are mild and the additional value of the product is high.

Owner:JIANGSU UNIV

Novel method for enriching metal rhenium in high-temperature alloy waste recovery technology

ActiveCN103173615AStrong water absorptionStrong permeabilityProcess efficiency improvementIon exchangeWaste recovery

The invention relates to a method for enriching metal rhenium in a high-temperature alloy waste recovery technology. The method is characterized by comprising the following steps of: adopting kieselguhr for replacing strong basic resin adopted in wet-process metallurgy, treating filtrate containing metal rhenium ions, enriching the metal rhenium ions in the filtrate by using the characteristics such as large porosity, strong adsorbability and stable chemical property of the kieselguhr, and soon afterwards, purifying the rhenium. The method has the remarkable advantages that the strong adsorption capacity and selectivity of the kieselguhr on the metal rhenium ions are used for enriching the metal rhenium ions in the filtrate; compared with ion exchange adsorption, the kieselguhr has high adsorption efficiency on the metal rhenium ions, increases the direct yield of the metal rhenium and is easy to desorb; lots of inorganic acids do not need to be consumed; the technological process is greatly shortened; the production working procedure is simplified; the environmental friendliness pressure is reduced; and simultaneously, high economic benefits are achieved. The method is a comprehensive recovery technology which is concise, short in technological process, small in specific volume and low in cost and has little pollution; and reports related to the method are not found at home and abroad.

Owner:昆明铂生金属材料加工有限公司

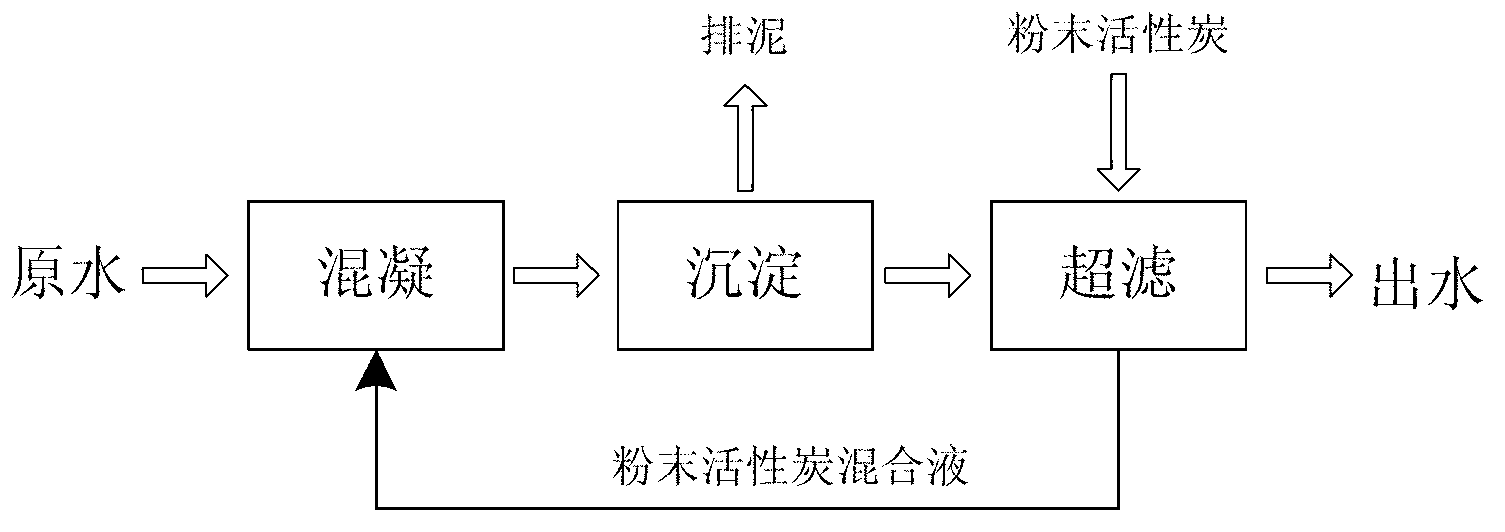

Powdered activated carbon reflux/ultrafiltration combined technology for water treatment plant

InactiveCN103214117AReduce pollution pressureReduce operational complexityMultistage water/sewage treatmentActivated carbonFlocculation

The invention relates to a powdered activated carbon reflux / ultrafiltration combined technology for a water treatment plant. The technology is characterized in that powdered activated carbon are fed into an ultrafiltration membrane tank, and the powdered activated carbon which are kept in the ultrafiltration membrane tank for a proper time are refluxed to a pre-treatment coagulation period at a proper reflux ratio through utilizing a reflux pump, wherein the addition amount of the powdered activated carbon is 5-20mg / L, the reflux ratio is 1%-5% of a system flow, and the retention time of the powdered activated carbon is 2-24 hours. The organic pollutant content of raw water is reduced through fully utilizing the adsorptive capability of the powdered activated carbon in a mixed liquid of the technology, powdered activated carbon particles serve as flocculation cores so as to enhance coagulation, and a treatment effect of a coagulation period is improved; and moreover, the operation stability of a system is improved, and the water production rate is increased. The technology can be widely applied to an ultrafiltration combined technology for the water treatment plant.

Owner:BEIJING UNIV OF TECH

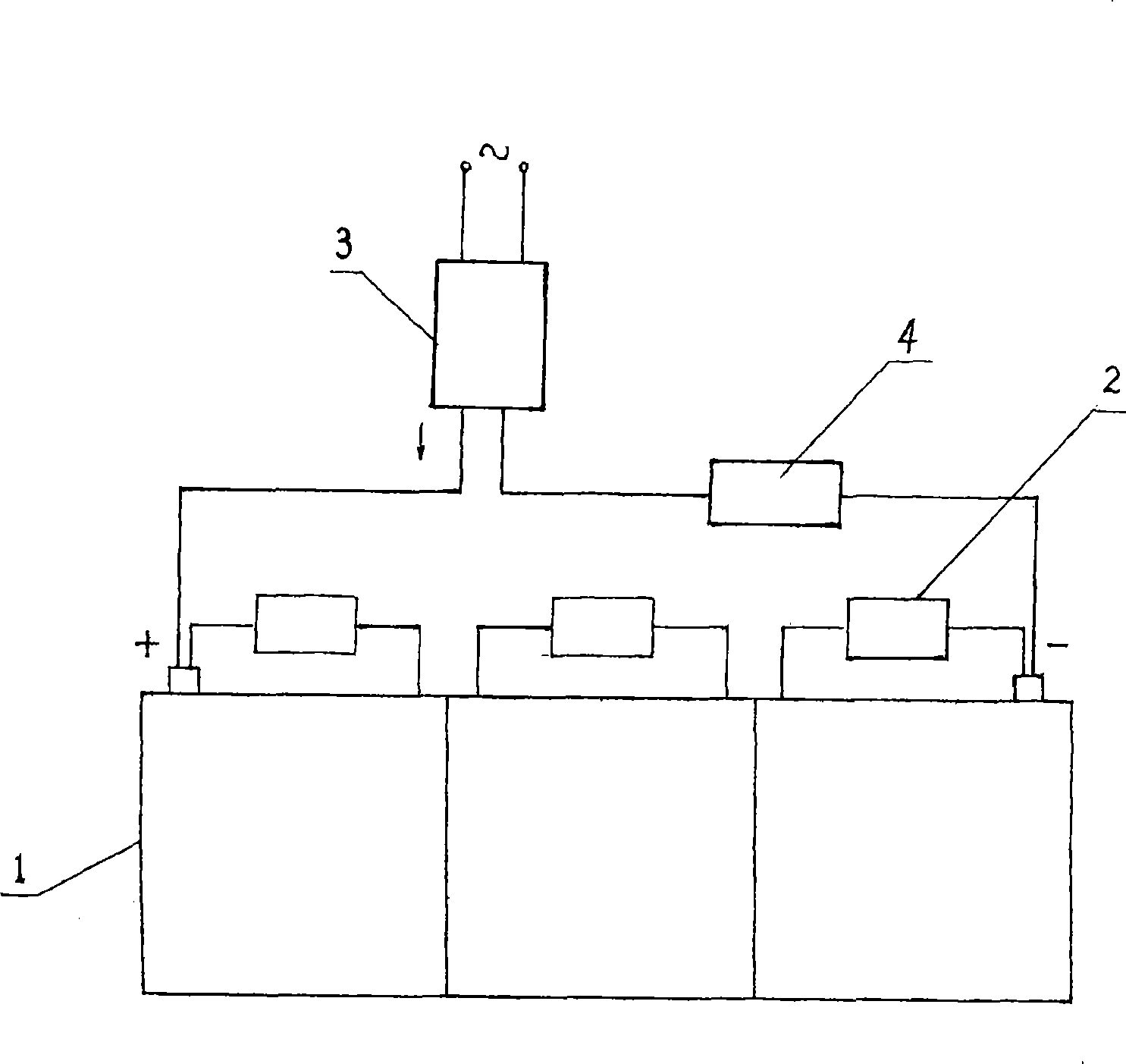

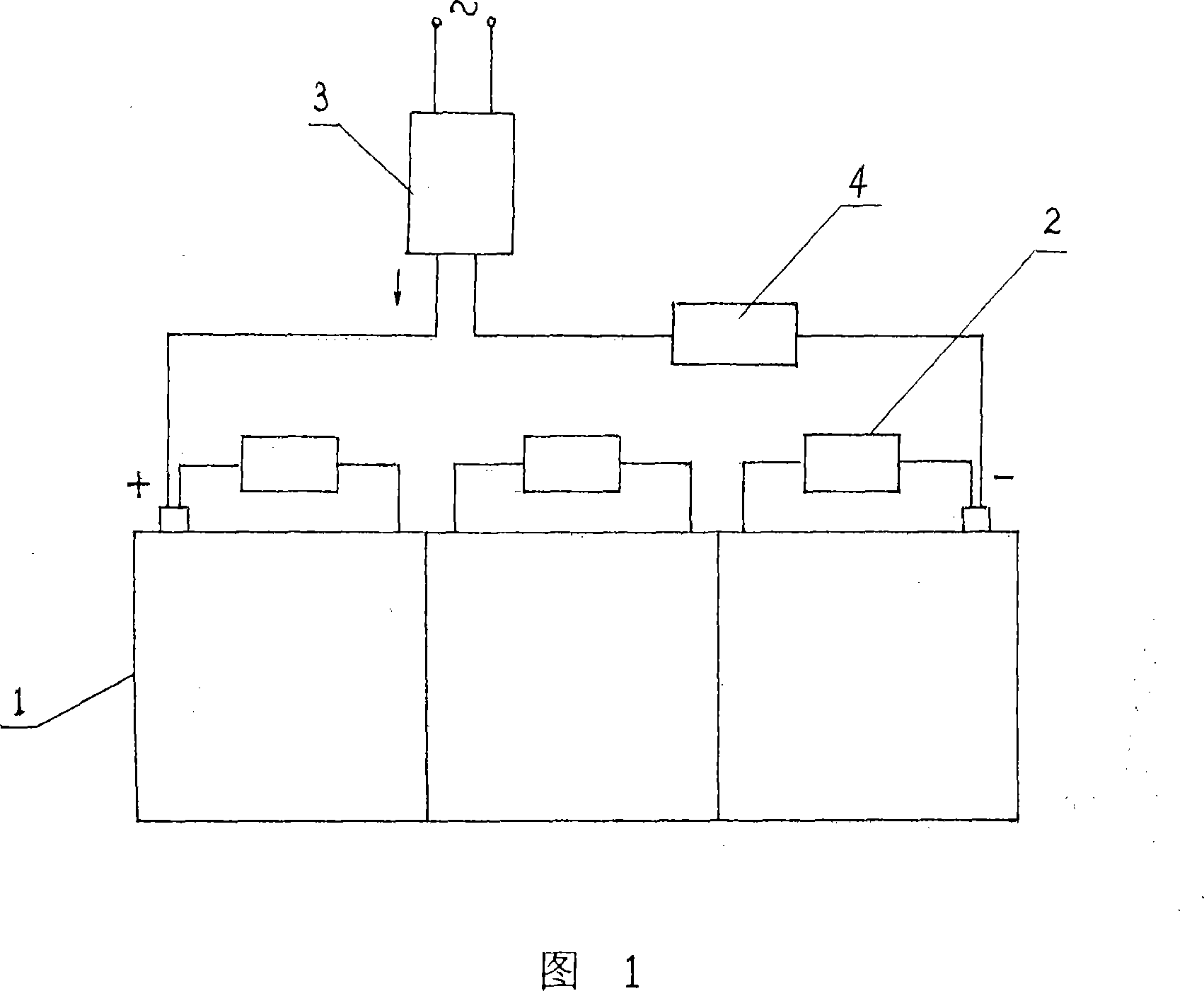

Lead acid accumulator renovation system and method thereof

InactiveCN101431170ASmall self-dischargeReduce pollutionCharge equalisation circuitLead-acid accumulatorsSocial benefitsElectrical battery

The invention relates to a lead-acid battery repair system which is designed against the difficult problem of irreversible vulcanization of a lead-acid battery and formed by combining a battery balancer and a devulcanized charger; and a developed repair agent is used for repair. Or a repair instrument is matched with the repair agent for direct repair. The repair technology can repair and use a waste vulcanized battery. The invention realizes the purpose of rapid elimination of the vulcanization by the self-repair and the principle of combing the physics and the chemistry to eliminate the vulcanization. The invention can prolong the service life of various lead-acid batteries to more than two times, lengthen the driving distance of various vehicles and repair various waste lead-acid batteries. The technology has simple operation, low cost, easy promotion, wide range of application and remarkable economic and social benefits.

Owner:邢纪国

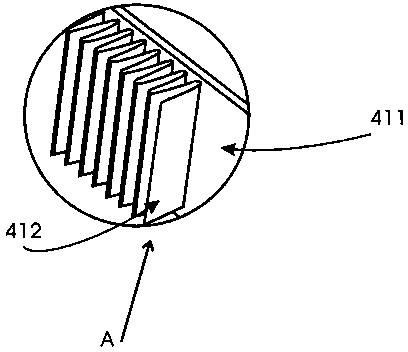

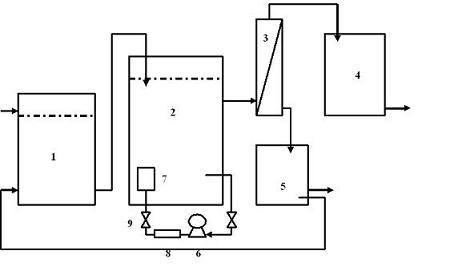

Method and device for using small-aperture spiral wound ultrafiltration membranes to treat papermaking wastewater

InactiveCN102515395AReduce pollution pressureEffective pollution controlMultistage water/sewage treatmentWaste water treatment from plant processingFiberChemical oxygen demand

The invention discloses a method and a device for using small-aperture spiral wound ultrafiltration membranes to treat papermaking wastewater. The main process includes coagulation efficient air floatation and small-aperture ultrafiltration system which comprises a water collection tank (1), an efficient air floating system (2), a small-aperture ultrafiltration system (3), a water recycling tank (4) and a concentrated water tank (5). The efficient air floating system comprises a coagulation portion and an air floatation portion. The method and the device for using small-aperture spiral wound ultrafiltration membranes to treat papermaking wastewater has the advantages that most CODCr (chemical oxygen demand), suspended matters and fibers can be removed by means of the coagulation efficient air floatation, the small-aperture spiral wound ultrafiltration membrane system using a linear water inlet runner net can effectively control membrane contamination, and the membrane molecular weight cutoff is 3000-10000Da. Quality of discharged water of the whole system is high and stable, turbidity of the discharged water is smaller than or equal to 3NTU (number of transfer units), the suspended matters can be removed completely, the discharged water is odorless in long-time standing, concentrated solution can be used as slurry to be reused after further treatment, and permeate liquid can be directly used as production circulating water for reuse. The method and the device for using small-aperture spiral wound ultrafiltration membranes to treat papermaking wastewater are used for treatment and recycling of papermaking wastewater, and worthy of wide popularization and application to the market.

Owner:北京清大国华膜科技有限公司

Coprinus comatus culture medium and preparation method thereof

ActiveCN103848700AAvoid wastingBroaden source channelsFertilizer mixturesCamellia oleiferaCulture mediums

The invention discloses a coprinus comatus culture medium. The coprinus comatus culture medium is prepared by mixing the following components in parts by weight: 10-30 parts of camellia oleifera shells, 20-40 parts of bagasse, 20-40 parts of mulberry sawdust, 10 parts of biogas residue, 4 parts of corn flour, 2 parts of wheat bran, 2 parts of rice bran, 1 part of lime powder and 1 part of gypsum powder. The pH value of the prepared culture medium is natural, and the water content of the culture medium is 60-70%. According to the coprinus comatus culture medium, the utilization range of the camellia oleifera shells is enlarged, the industrial chain is prolonged, the circular economy can be developed, and the sources of coprinus comatus production raw materials are increased. The coprinus comatus culture medium disclosed by the invention is low in pollution rate and fast in spawn running, the grown coprinus comatus sticks are good in quality, and hyphae are white, robust, thick, strong in growing power, uniform in growing speed and good in disease control performance. The stems of coprinus comatus obtained by using the culture medium are thick and large, and the bodies of the coprinus comatus are white, tender, dense, fresh and delicious.

Owner:GUANGXI FORESTRY RES INST

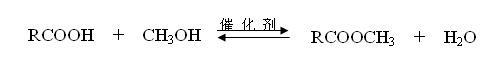

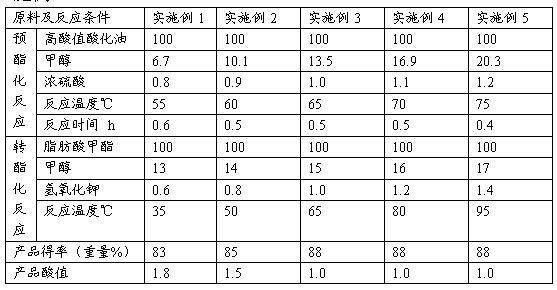

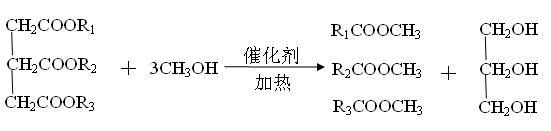

Process for preparing biodiesel by using low-acid-value waste oil

InactiveCN101935592ARealize the effect of reuseAlleviate shortagesFatty acid esterificationBiofuelsBiodieselCombustion

The invention discloses a process for preparing biodiesel by using low-acid-value waste oil. The procedures of dehydration, pre-esterification reaction, esterification reaction, slurry sedimentation, glycerin separation, and the like are carried out on the collected low-acid-value waste oil by introducing a plug flow reactor to obtain the biodiesel. By collecting low-acid-value waste oil generated in daily life of people and converting and synthesizing the collected low-acid-value waste oil into the biodiesel, the invention realizes waste recycling effect and is helpful to relieving the current predicament of diesel fuel shortage and atmospheric pollution pressure for diesel fuel combustion at the same time.

Owner:温州中科新能源科技有限公司

Lead acid batteries restoring system and method

InactiveCN101252211ACapacity balanceLarge capacityCharge equalisation circuitLead-acid accumulatorsSocial benefitsEngineering

The invention relates to a repairing system for lead-acid storage cells, which is formed by the combination of a cell equalizer and a desulfuration charger, aiming at the problem of the irreversible sulfuration of lead-acid storage cells, wherein the invention uses repair agent to repair, (or a series of repairing apparatuses to be matched with the repair agent for direct repair); the invention can refresh wasted vulcanized cells; the technology which is based on a principle of the self repairing or physical-chemical combination desulfuration realizes an aim of quickly eliminating the sulfuration. The invention has the advantages of more than doubling service lives of all lead-acid storage cells, prolonging driving distance of all vehicles and repairing all wasted lead-acid storage cells; moreover, the technology of the invention also has the advantages of simple operation, low cost, easy popularization, wide application range and obvious economic and social benefits.

Owner:邢纪国

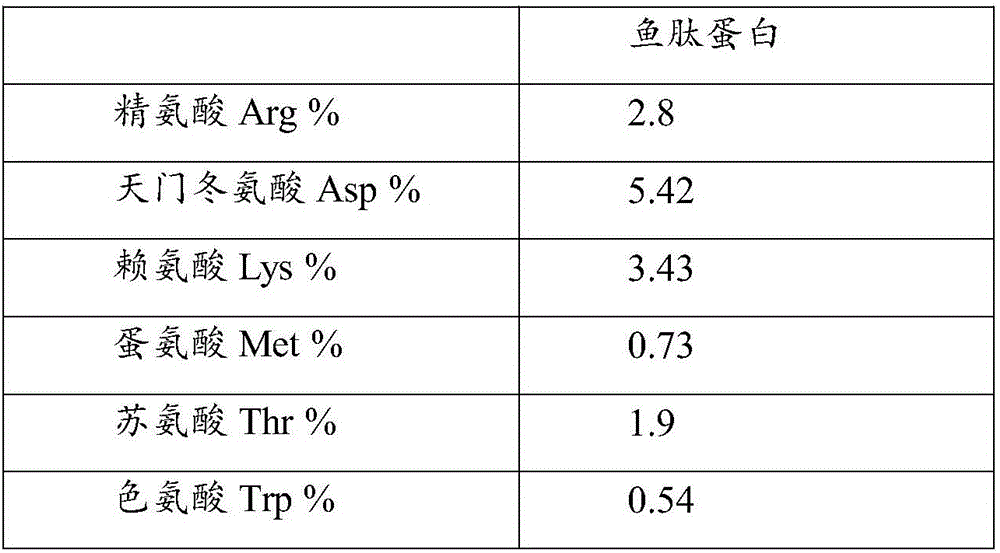

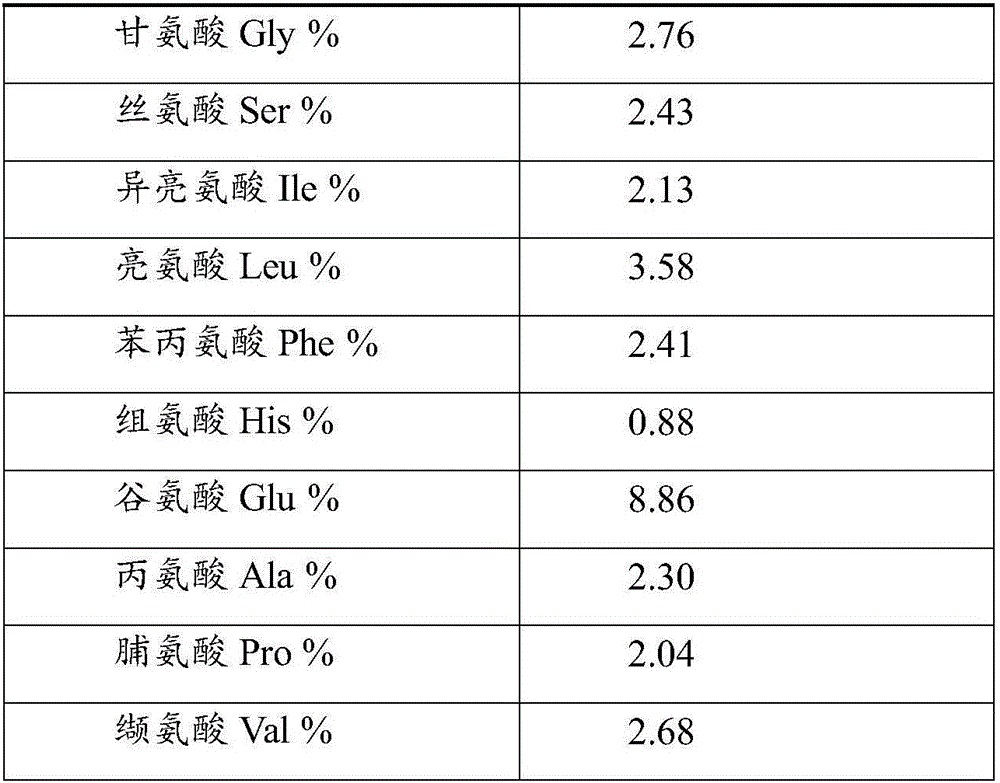

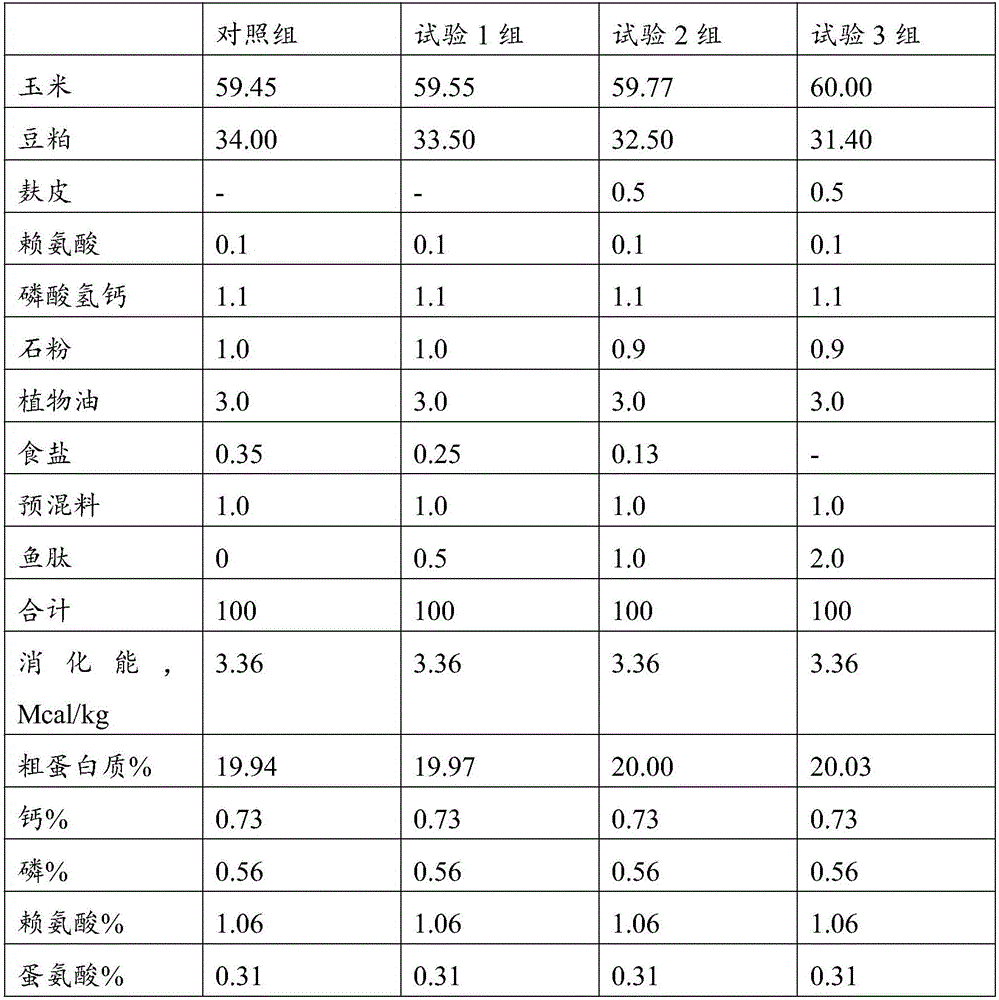

Compound fish peptide protein for feed and preparation process thereof

InactiveCN106173259AHigh nutritional valueLow costFood processingAnimal feeding stuffBiotechnologySmall peptide

The invention provides a compound fish peptide protein for feed and a preparation process thereof. The compound fish peptide protein for the feed comprises 6-8 parts by weight of fermented soybean meal and 2-4 parts by weight of fish soluble, wherein crude protein content of the fermented soybean meal is more than or equal to 50%, and DM of the fish soluble is more than or equal to 90%. High-quality peptide and protein raw materials are adopted, small peptide content is more than or equal to 12%, nutritional value is high, cost is low, and part of fish meal and blood plasma can be replaced.

Owner:陈雨

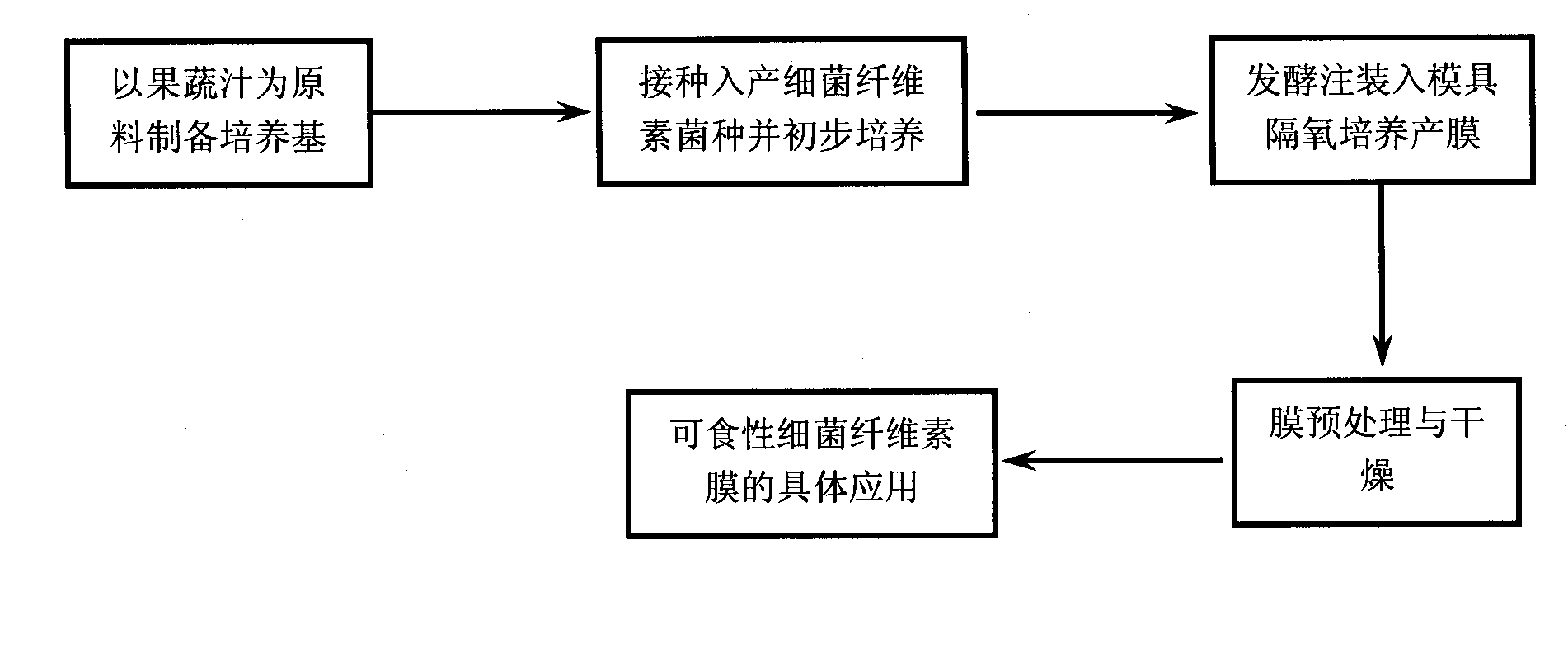

Bacterial cellulose edible packaging product and production method thereof

The invention relates to a bacterial cellulose edible packaging product and a production method thereof, mainly aims to provide an edible food packing material and a preparation method thereof, and belongs to the technical field of biotechnology and food packaging materials. In the method, a bacterial cellulose film is produced by taking fruit and vegetable juice such as coconut milk, chayote juice, white gourd juice and the like as raw materials and acetobacter xylinum or acetobacter pasteurianus as strains through fermentation; and then the bacterial cellulose film is treated by alkali and hydrogen peroxide sequentially and then dried to form the edible food packaging product.

Owner:GUANGDONG IND TECHN COLLEGE

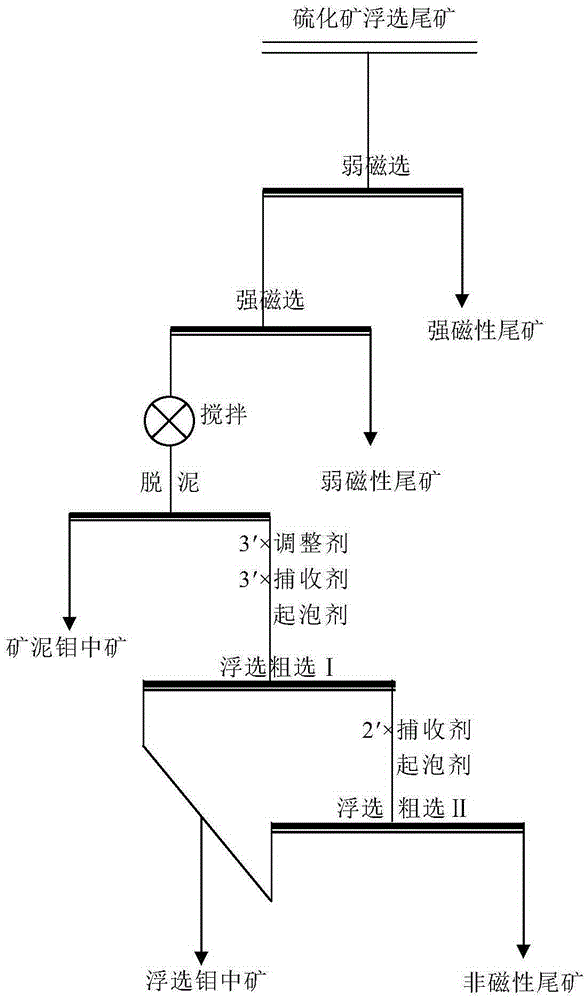

Mineral separation and enrichment method for molybdenum oxide ores

InactiveCN105381870AReduce processingImprove sorting efficiencySolid separationMechanical material recoveryEnrichment methodsHydrometallurgy

The invention provides a mineral separation and enrichment method for molybdenum oxide ores. The method includes the several steps of low intensity magnetic separation and high intensity magnetic separation for sulphide ore flotation tailing ore pulp, non-magnetic ore pulp material desliming, flotation and the like, and finally molybdenum middlings with high grade are obtained. The molybdenum middlings can serve as raw materials for extraction of ammonium molybdate products through hydrometallurgy, and low-grade hard-to-separate molybdenum oxide ore resources in copper and molybdenum polymetallic mixed associated ores are effectively and comprehensively recycled. The mineral separation and enrichment method for the molybdenum oxide ores can be widely applied to the field of recycling of the low-grade hard-to-separate molybdenum oxide ore resources in similar tailings.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

Method for planting alfalfa in saline-alkali soil

InactiveCN108651205AYi Jianzhi succeedsEstablished successfullyFabaceae cultivationSoil-working methodsAlkali soilNormal growth

The invention discloses a method for planting alfalfa in saline-alkali soil. The method comprises the following steps: deep application of a base fertilizer, a sowing process, irrigation, field management, a clipping process and greenness returning management. According to the invention, the soil structure is improved and the salt content of soil is reduced through soil preparation and deep application of the humic acid organic fertilizer. At the same time, a low-salinity environment is created in the germination period of alfalfa seeds by utilizing a drip irrigation mode, so that the seed germination and the seedling growth are promoted. Winter water for irrigation penetrates through a cultivation layer, so that the icing caused by water accumulation on the ground is avoided, and topdressing is carried out with the combination of irrigation by greenness returning water. In addition, a saline-alkaline-resistant alfalfa variety is selected as a recommendation variety, and the planting success rate is further improved. According to the method provided by the invention, the organic matter content of soil is increased before the alfalfa is planted, the disadvantages to the alfalfa germination and seedling growth caused by increased the salinity of dry soil in spring are overcome through the utilization of the drip irrigation method, conditions are created for normal growth of the alfalfa in the later stage, and the technical support for the production of high-quality alfalfa and the development of animal husbandry in saline-alkali areas is provided.

Owner:SHANDONG AGRI SUSTAINABLE DEV INST

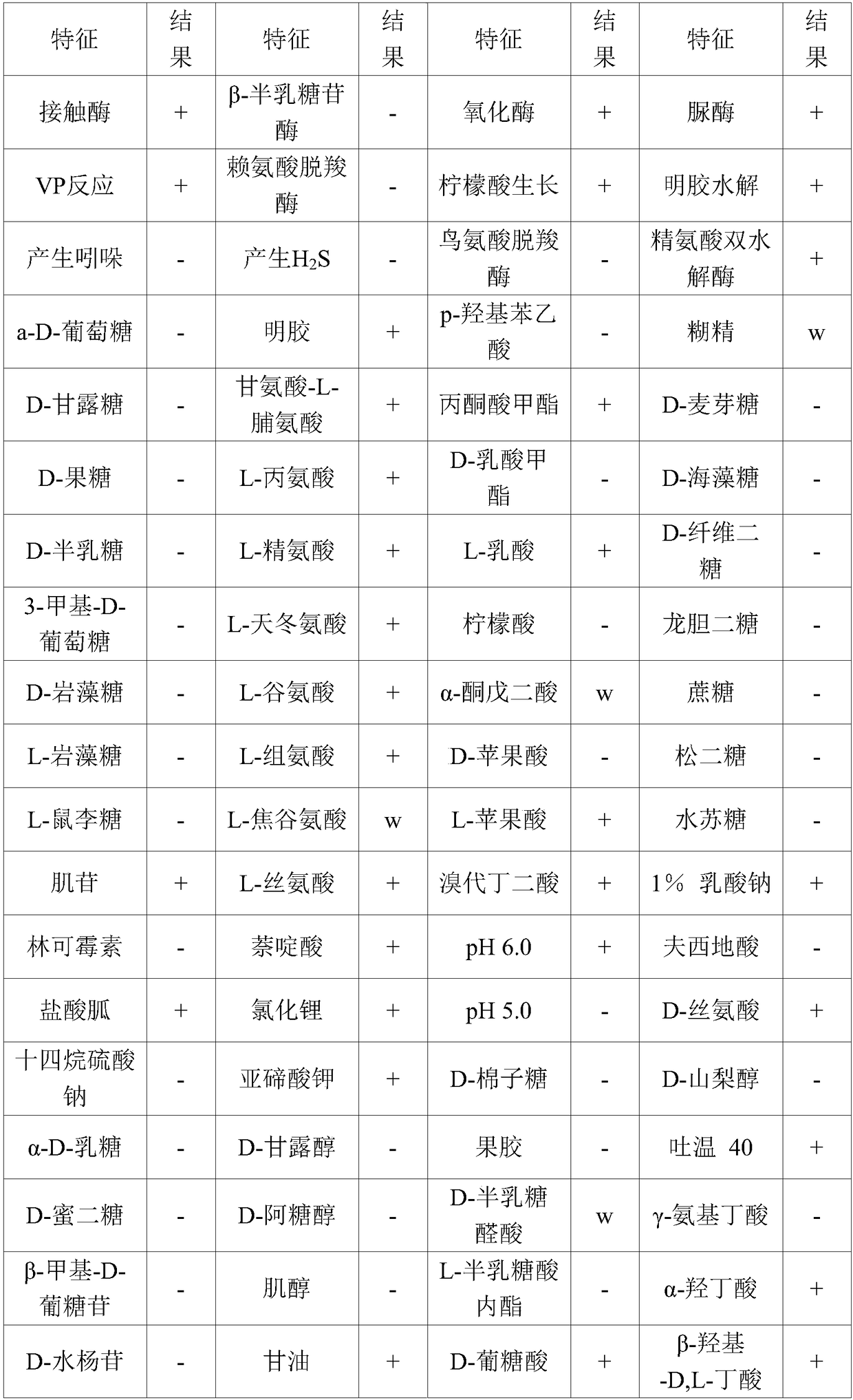

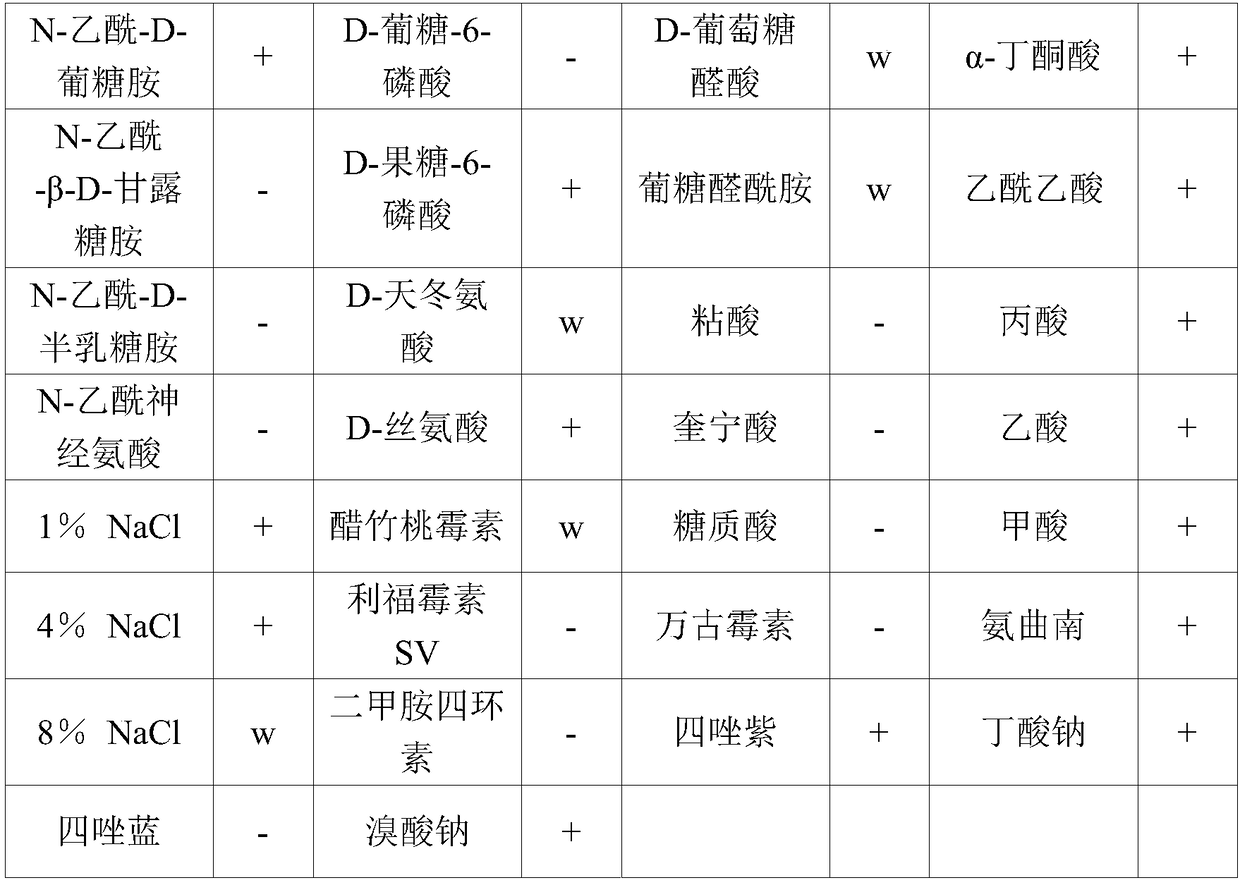

Composite microbial inoculum of lysinibacillus and bacillus subtilis and preparation method thereof

ActiveCN109504622ASignificant phosphorus and potassium dissolving effectImprove fertilityBiocidePlant growth regulatorsPlant diseaseRoot rot

The invention discloses a composite microbial inoculum of lysinibacillus and bacillus subtilis and a preparation method thereof, and belongs to the technical field of agricultural microbes. The composite microbial inoculum is prepared by blending and confecting bacillus subtilis R31 fermentation broth and lysinibacillus fusiformis LW-3 fermentation broth, wherein the collection number of the lysinibacillus fusiformis LW-3 is CGMCC (China General Microbiological Culture Collection Center) No. 16228; and the mixing proportion of the bacillus subtilis R31 fermentation broth to the lysinibacillusfusiformis LW-3 fermentation broth is (1 to 10) to (10 to 1). The composite microbial inoculum provided by the invention has obvious growth-promotion, antibacterial and disease-prevention effects on aplant, can obviously inhibit the occurrences of diseases of bacterial wilt, blight and root rot and the like, improves a yield and quality, has the characteristics of being safe, efficient, nontoxicand pollution-free, can effectively reduce the use of a chemical fertilizer and a pesticide, relieves environmental pollution pressure, and assists agricultural sustainable development.

Owner:GUANGDONG GEOLONG BIOTECH

Micro-energy network system and collaborative optimization operation control method thereof

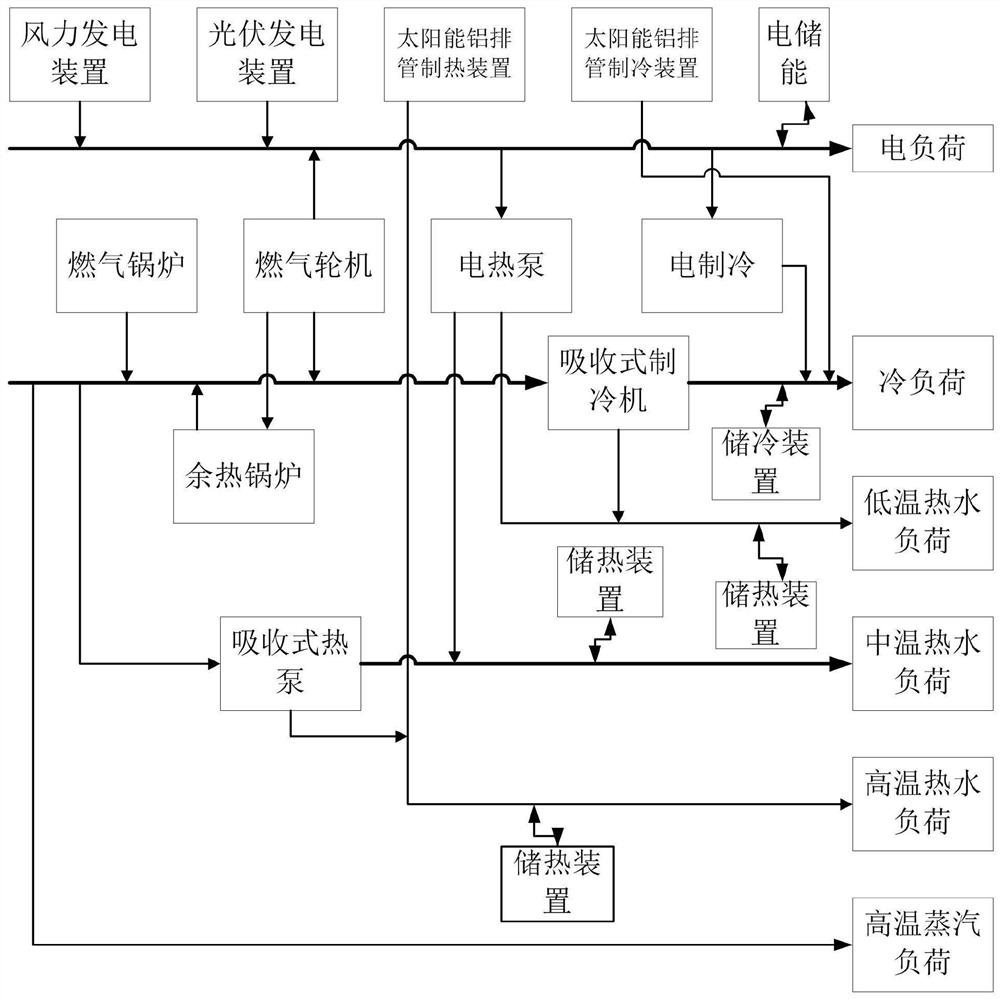

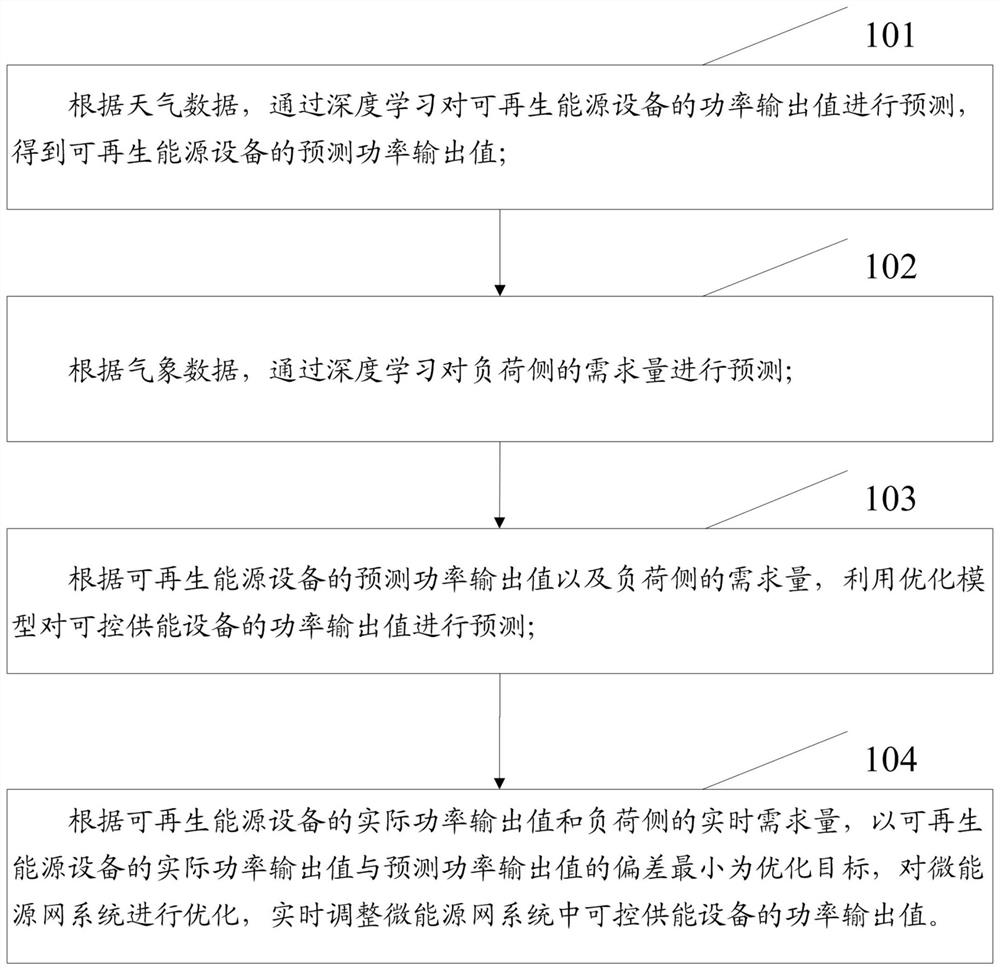

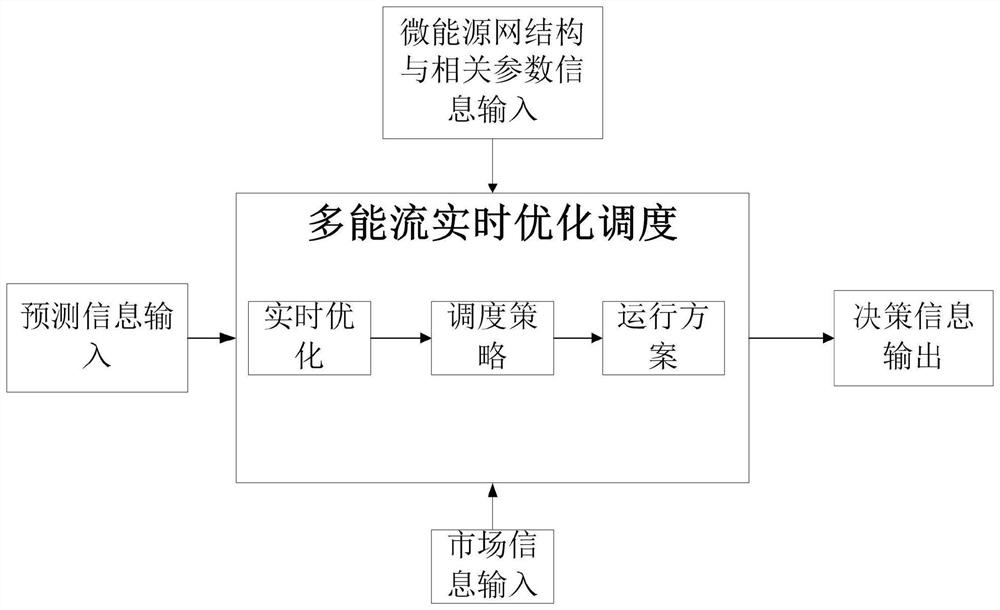

ActiveCN111969603ARealize ladder utilizationChange the way of useSolar heating energyHeat pumpsNew energyControl engineering

The invention relates to a micro-energy network system and a collaborative optimization operation control method thereof. Specific equipment contained in an energy supply side and an energy conversiondevice is reasonably configured; the formed micro-energy network system has the advantages that the new energy access proportion is higher; configuration can be optimized through the energy storage device; the power grid, the heat supply network and the air network meet the energy requirements of users; basic balance between local energy production and user energy consumption load is achieved; the collaborative optimization operation control method is used for carrying out rolling optimization on the micro-energy network system, the power output value of controllable energy supply equipment in the micro-energy network system is continuously adjusted, the micro-energy network system is made to operate economically on the premise that the real-time balance of supply and demand is met, and therefore the purpose of saving energy is achieved. Energy consumption, energy supply and energy storage are uniformly and cooperatively dispatched, multi-energy supply complementation in a micro-energy network system is achieved, the comprehensive utilization efficiency and stepped utilization of multi-energy supply in a micro-energy network are improved, emission is reduced, and local consumptionof energy is achieved.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Novel method for processing fruit and vegetable by full brewing

ActiveCN102250717AInhibit bacteriaLong shelf lifeCosmetic preparationsToilet preparationsFruit wineFruits and vegetables

The invention relates to the field of deep processing of fruit and vegetable, and especially to the technology of using fruit and vegetable for wine brewing and preparation of edible powder and cosmetic products. The invention is characterized in that: according to the novel method, the whole of fruit and vegetable is brewed and residual wine dregs from brewage of vegetable and fruit wine are utilized to produce vegetable and fruit powder and cosmetic skin care ointment or liquid, so a novel technical combination for comprehensive utilization of fruit and vegetable resources is provided and aplurality of varieties of new products are produced, thereby substantially improving the utilization rate of fresh vegetable fruit of existing technologies of deep processing.

Owner:雷晓明

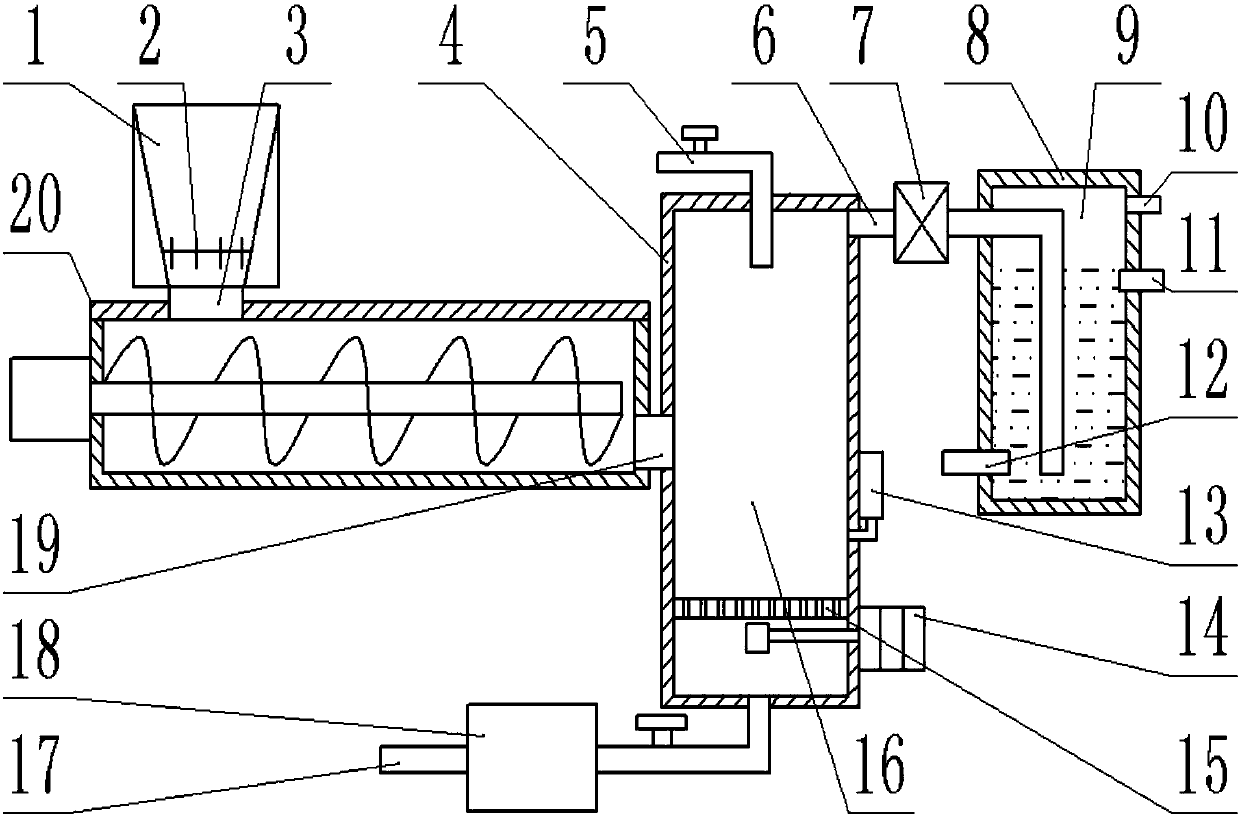

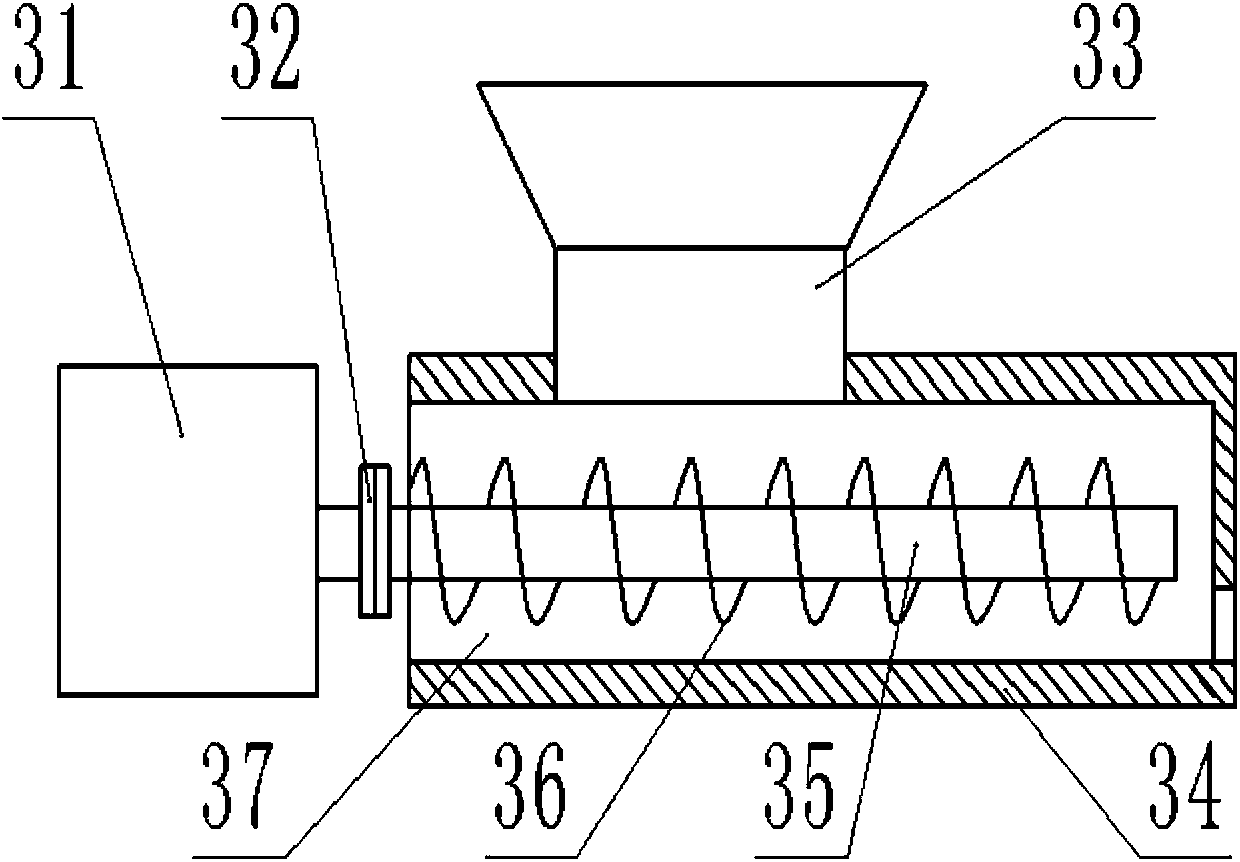

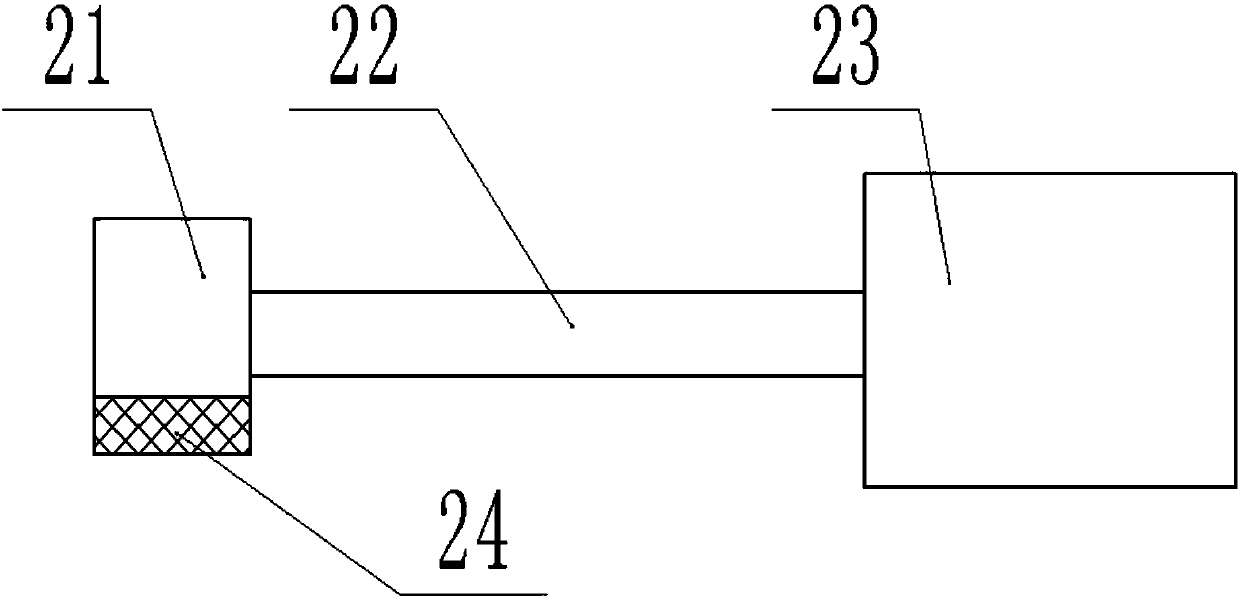

Novel medical plastic garbage incineration system

InactiveCN107631306AImprove processing efficiencyEasy to operateIncinerator apparatusCrusherIncineration

The invention provides a novel medical plastic garbage incineration system, which belongs to the field of plastic garbage treatment, and comprises an incineration device, a purification shell and a conveying device. The incineration device is vertically placed; a connecting pipe is arranged between the conveying device and the incineration device; the conveying device is in threaded connection tothe left end of the connecting pipe; the right end of the connecting pipe is fixedly connected with the incineration device; a feed hopper is arranged at the upper end of the conveying device; a crusher is arranged in the feed hopper; a conveyor is arranged at the lower end of the crusher and is fixedly connected with the conveying device; the incineration device comprises a water inlet pipe, an air outlet pipe, an oxygen tank, an ignition device, an incineration plate and a water outlet pipe; an incineration cavity is arranged in the incineration device; and the incineration plate fixedly connected onto the incineration device is arranged under the middle part of the incineration cavity. The invention provides the medical plastic garbage treatment device, which is high in treatment efficiency, simple to operate, reasonable in design, wide in application range, high in treatment efficiency and low in cost.

Owner:HUIAN WEIKE ELECTRONICS TECH CO LTD

Method for low-temperature fermentation of biogas from agricultural waste

InactiveCN105803004AReduce pollution pressureNormal gas production rateWaste based fuelFermentationBiotechnologyHusk

The invention specifically relates to a method for low-temperature fermentation of biogas from agricultural waste, which belongs to the technical field of biogas fermentation. The method provided by the invention employs straw materials, weeds, dry branches, fallen leaves, rice husk, wood chip, fruit and vegetable waste and excrement and urine waste for mixed fermentation of biogas, so cyclic utilization of energy and materials is realized. The objective of the invention is to overcome the problems that large-scale livestock and poultry culture and crop straw which is no longer used as major household fuel become main sources of rural environmental pollution, that production of biogas through anaerobic fermentation of manure of livestock and poultry in the prior art is greatly influenced by seasons and that traditional biogas slurry utilization technology is not mature enough.

Owner:付顺林

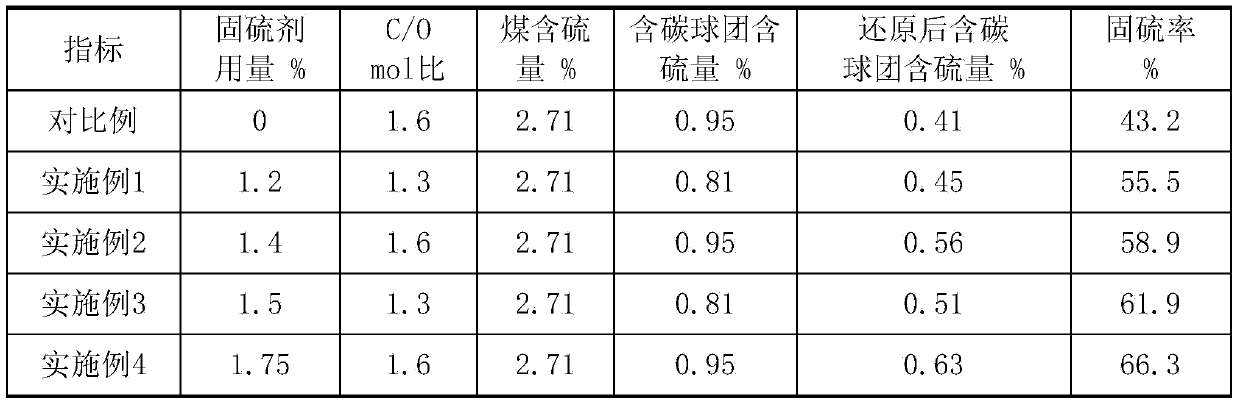

Sulfur-fixing agent for carbon-containing pellets and preparation method thereof

InactiveCN103468343AReduce manufacturing costLow priceDispersed particle separationSolid fuelsSulfurRed mud

The invention provides a sulfur-fixing agent for carbon-containing pellets and a preparation method thereof. The sulfur-fixing agent comprises the following components by mass percent: 25-35% of limestone, 1-5% of industrial manganese slag, 35-39% of red mud and 25-35% of dolomite. The preparation method comprises the following steps of mixing the industrial manganese slag and the red mud with limestone and dolomite in proportion, adding water and stirring the materials for 10-20 minutes and then drying the mixture until the water content is lower than 7%; re-breaking the dried sample, sieving the broken sample until the powder with grain size being less than 200 meshes and mass percent being more than 90% is obtained, thus preparing the finished product sulfur-fixing agent. The sulfur-fixing agent has the advantages that the sulfur-fixing agent can effectively reduce the emission of the harmful gas SO2 in the reduction processes of the carbon-containing pellets and reduce atmospheric pollution; the red mud and the industrial manganese slag are industrial wastes, thus being beneficial to secondary utilization of resources; the used raw materials are low in prices and are easier to obtain; the sulfur-fixing agent is small in usage amount, has obvious sulfur-fixing effects, is low in production cost and is suitable for industrial production and application.

Owner:ANGANG STEEL CO LTD

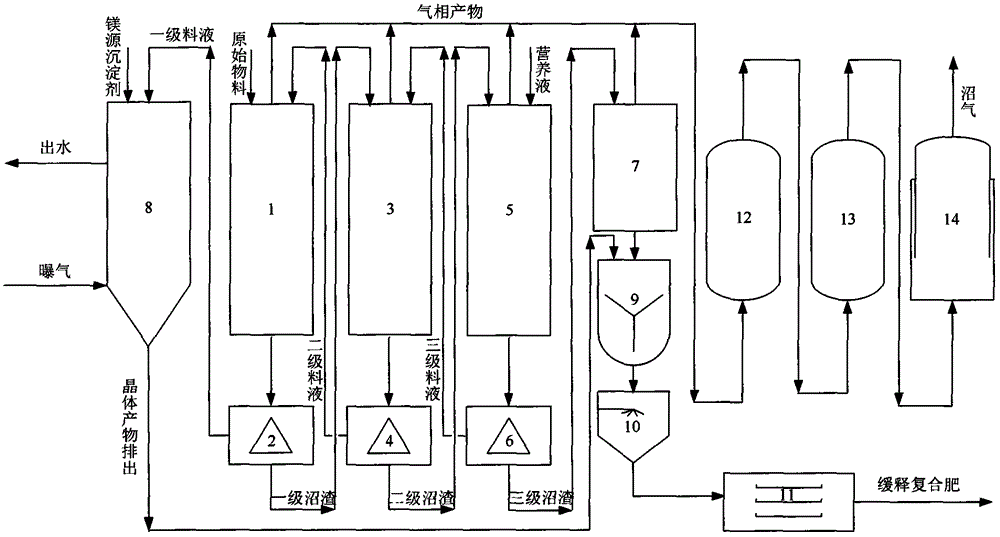

Technology for producing marsh gas and recycling phosphorus in anaerobic fermentation mode through chicken manure

InactiveCN104529115APromote degradationAchieve reductionProductsWaste processingThree levelHigh concentration

The invention discloses a technology for producing marsh gas and recycling phosphorus in an anaerobic fermentation mode through chicken manure, and belongs to the field of solid organism waste energy regeneration and resource recycling. The technology includes the working procedures of marsh gas production through anaerobic fermentation, solid-liquid separation, gas-water separation, desulfuration purification, phosphorus recycling, biogas residue high-temperature reacting and slow-release compound fertilizer preparing. According to the technology, fermentation marsh gas production and nitrogen and phosphorus gathering are carried out with a three-level reverse flow technology, separated fermentation material liquid and biogas residuals reversely flow among anaerobic tanks in various levels, the suppression effect of high-concentration ammonia nitrogen generated in the chicken manure fermentation process on anaerobic microorganism is reduced, and meanwhile the marsh gas yield and the nitrogen and phosphorus concentration in the anaerobic fermentation material liquid are improved. Nitrogen and phosphorus are recycled with a magnesium ammonium phosphate crystallizing method, formed crystal products are added into the high-temperature reacted biogas residuals, and slow-release compound fertilizers with magnesium ammonium phosphate as main effective ingredients are prepared. Products generated with the technology are the clean energy marsh gas and the efficient slow-release compound fertilizers, and the chicken manure energy regeneration aim and the resource recycling aim can be achieved at the same time.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Organic manure special for green nuisanceless farm products and preparation method thereof

InactiveCN1559990AWide variety of sourcesLarge reservesFertiliser formsFertilizer mixturesAdhesiveBran

The invention discloses a green harmless special organic fertilizer for farm produces, mixed of natural humic acid, peanut bran powder, bean cake, tea-leaf, adhesive, acid salt tolerance and regulating substance in weight ratios of 10-40 shares, 20-30 shares, 10-20 shares, 10-40 shares, 10-15 shares, and 3-8 shares, respectively; and its preparing method: crushing materials, adding in adhesive and premixing, and refining by the process 'secondary making particles, secondary drying' to make it. It has uniform and smooth particles, no phenomena of 'dirty, foul, wet, loose', etc, and no pollution to the environment, and is rich in nutrient substances of N, P, K, amino acid, S, Zn, Fe, Ca, Mg, etc, and has a pH value at 5.0-8.5; the content of heavy metals, harmful germs, hormones and drug residues is low, and it has no radiation. It can remarkably improve the quality of farm, produces, improve soil structure, and be suitable for the standard production of green harmless farm produces.

Owner:广东省农业科学院土壤肥料研究所

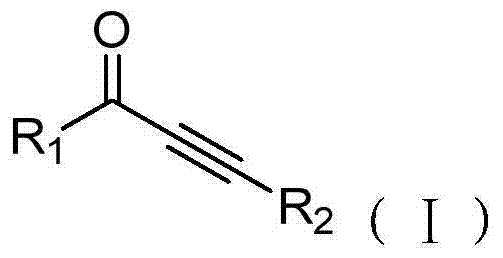

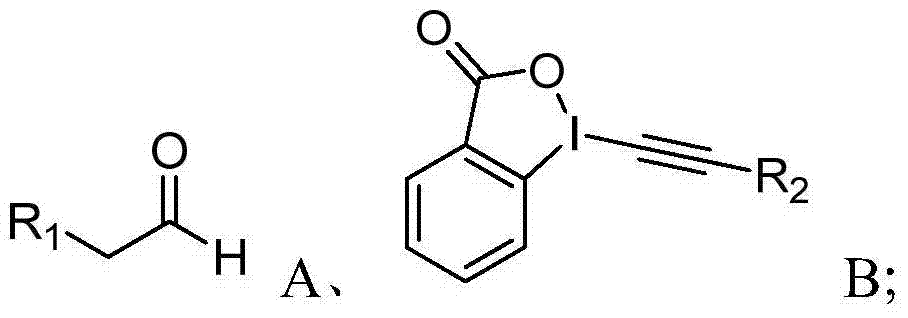

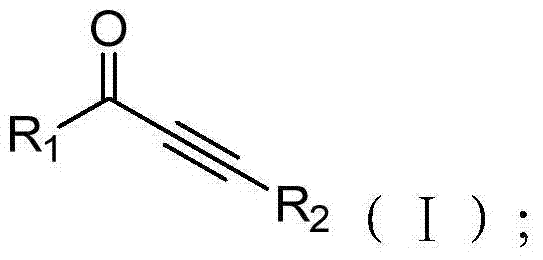

Acetylenic ketone compounds and preparing method thereof

InactiveCN104262375ALow toxicityThe reaction process is safe and controllableSilicon organic compoundsCompound aKetone

Acetylenic ketone compounds and a preparing method thereof are disclosed. The general formula of the acetylenic ketone compounds is shown as a formula (I) in the specification. The preparing method includes adding an aldehyde compound A and a high-valence iodoalkyne compound B into a reaction system comprising a copper / gold salt catalyst, a secondary amine catalyst, a ligand catalyst and an oxidant and reacting at a temperature ranging from -20 DEG C to 200 DEG C. The acetylenic ketone compounds have a typical acetylenic ketone structure, have similarity with other acetylenic ketone compounds, and can be used for development of medicine intermediates and preparation of functional materials. The preparing method is simple in process, low in reaction condition requirements, safe and controllable in reaction procedures, high in atom utilization rate, high in production efficiency, and low in environment pollution stress, and obviously reduces the production cost of the acetylenic ketone compounds provided by the invention.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

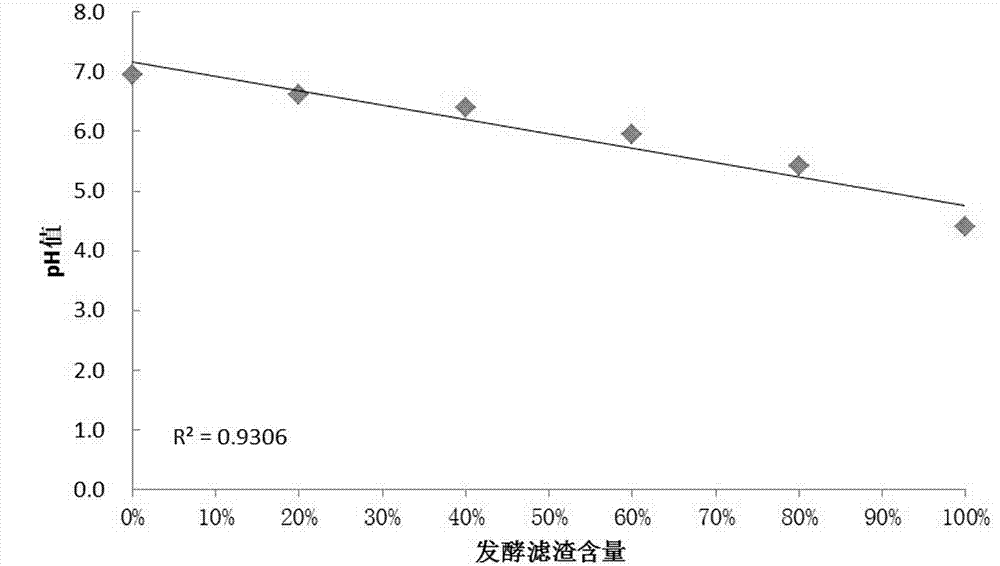

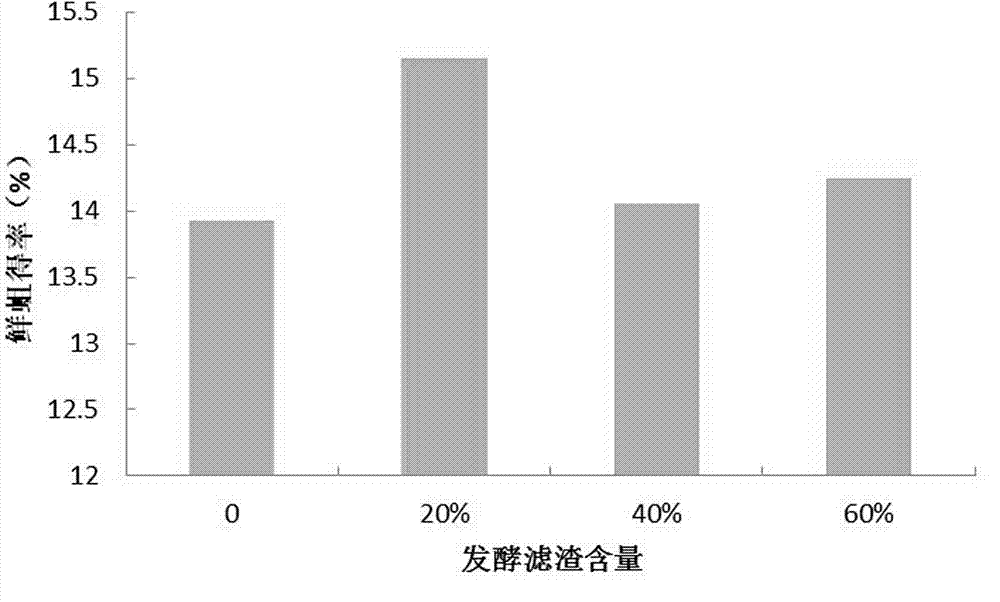

Method for treating fermentation filter residue and livestock and poultry manure mixture on large scale through fly maggots

ActiveCN104737989AReduce resource utilization costsRealize industrialized processingBio-organic fraction processingFood processingBiotechnologyMaggot

The invention provides a method for treating a fermentation filter residue and livestock and poultry manure mixture on a large scale through fly maggots. Livestock and poultry manure and gibberellin fermentation filter residues are mixed to control the pH value and used for large-scale fly maggot breeding. The method includes the following steps that firstly, a base material is prepared, wherein the livestock and poultry manure and the gibberellin fermentation filter residues are mixed to prepare the base material; secondly, the water content of the base material is adjusted; thirdly, fly maggot larvae are inoculated; fourthly, a breeding material is added; fifthly, the fly maggots are used for treating the fermentation filter residues and the livestock and poultry manure; sixthly, the fly maggots are separated; seventhly, organic manure is produced. The method is used for treating the fermentation filter residues and the livestock and poultry manure, the pressure of environment pollution can be relieved, resource utilization cost of the fermentation filter residues and the livestock and poultry manure can be reduced, the treatment difficulty can be lowered, collaborative industrialized treatment of the fermentation filter residues and the livestock and poultry manure is achieved, and economic benefits and social benefits are improved.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com