Process for preparing biodiesel by using low-acid-value waste oil

A technology of biodiesel and low acid value, which is applied in the fields of biofuel, petroleum industry, fat oil/fat refining, etc. It can solve the problems of affecting the production efficiency and production cost of biodiesel, the inability to connect the production process of biodiesel, and the high production cost. Achieving high social significance and economic value, alleviating diesel shortage, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is specifically described below by the embodiment, only for further illustrating the present invention, can not be interpreted as the limitation of protection scope of the present invention, the technical engineer of this field can make some non-essential improvements and improvements to the present invention according to the content of the above-mentioned invention Adjustment.

[0017] The collected low-acid value waste oil is obtained through the following steps to obtain biodiesel.

[0018] (1) Dehydration treatment, the collected waste oil with low acid value is dehydrated so that the water content is less than 0.1%; the dehydration treatment described in this step is to dehydrate the collected waste oil with low acid value through a rising film evaporator .

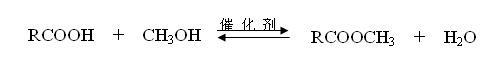

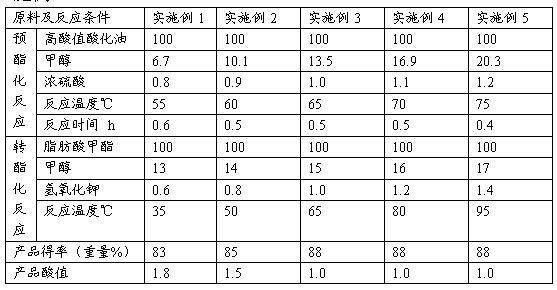

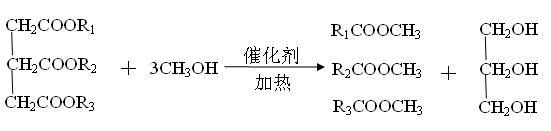

[0019] (2) Pre-esterification reaction, adding dehydrated waste oil with low acid value, methanol and concentrated sulfuric acid into the esterification reaction kettle, controlling the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com