Garbage treatment device for environment-friendly machine

The technology of a garbage disposal device and machinery, which is applied in the directions of garbage drying, dryer, press, etc., can solve the problems affecting the garbage compression effect, etc., and achieve the effect of improving the effect, improving the adequacy, and increasing the compression area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

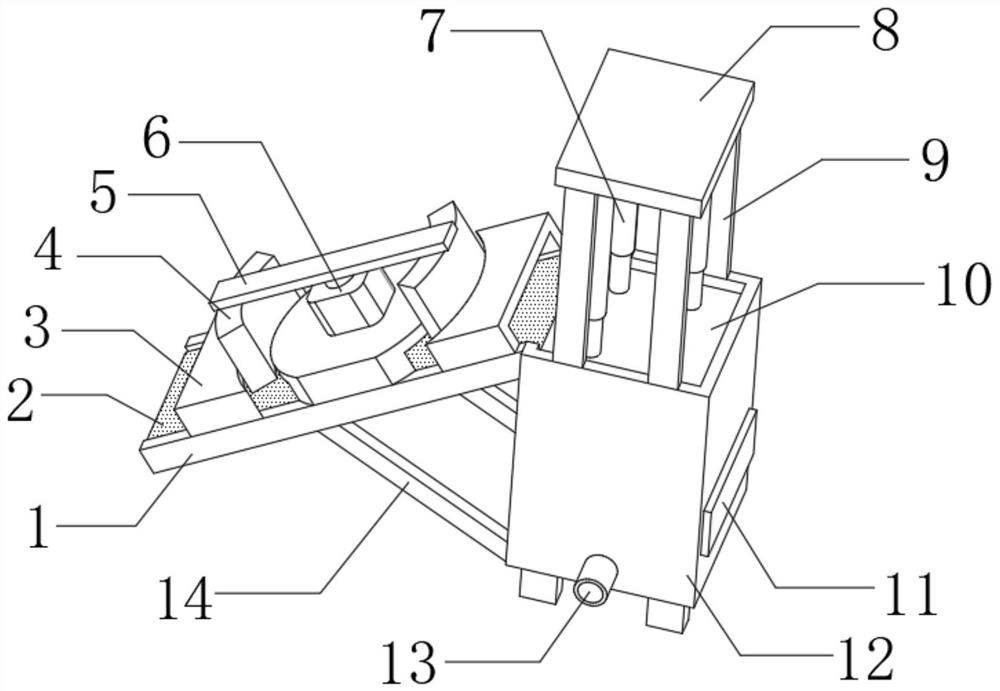

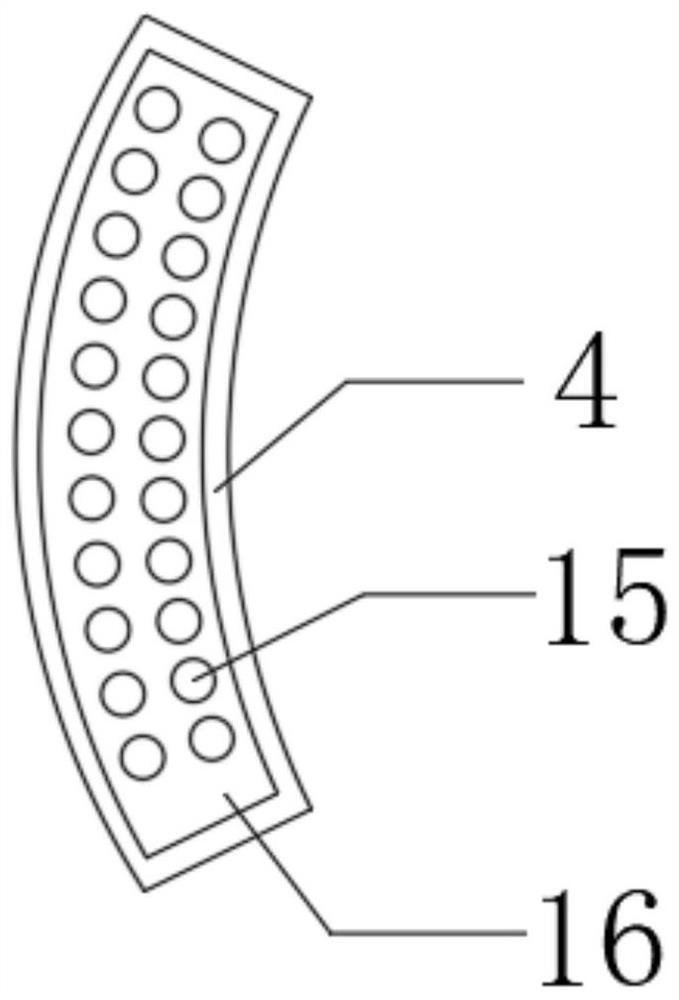

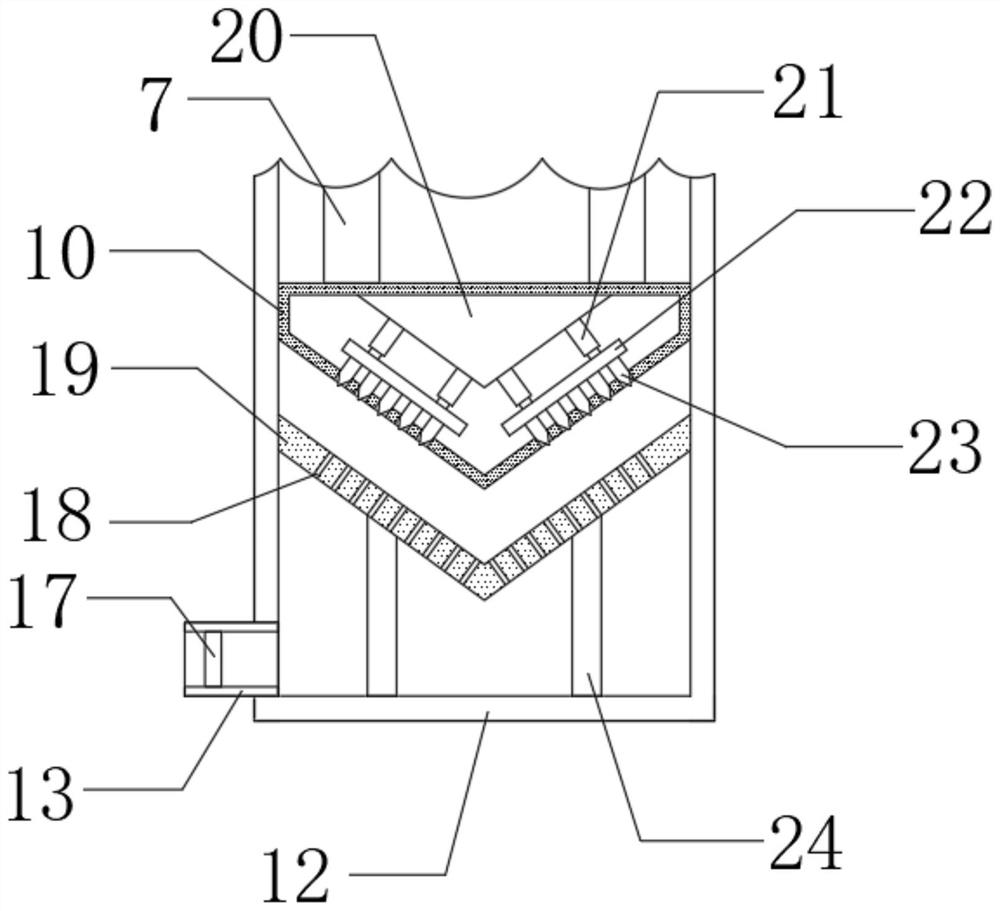

[0031] A garbage disposal device for environmental protection machinery, such as Figure 1-4 As shown, including the storage housing 12, the outer walls at the four corners of the bottom of the storage housing 12 are connected with support legs by bolts, and the outer walls at both ends of the bottom of one side of the storage housing 12 are connected with second support rods 14 by bolts. And the outer walls on one side of the two second support rods 14 are all connected with splints 1 by bolts, and the outer walls on one side of the two splints 1 are respectively connected to the outer walls at both ends of the top of one side of the storage housing 12 by bolts, and the two splints 1 The same conveyor belt 2 is connected by bolts, and the top outer wall of the conveyor belt 2 is connected with a protective shell 3 by bolts, and the top central outer wall of the protective shell 3 is connected with a rotating motor 6 by bolts, and the output shaft of the rotating motor 6 passes...

Embodiment 2

[0041] A garbage disposal device for environmental protection machinery, such as Figure 1-5 As shown, it also includes an air distribution pipe 27 installed on the bottom outer wall of the other end of the material storage housing 12 by bolts, and the outer wall at one end of the air distribution pipe 27 is connected with an exhaust pipe 26 equidistantly inclined by bolts, and the air distribution pipe The outer wall of the other end of 27 is connected with air duct 28 by bolts.

[0042] When this embodiment is in use, a hot air blower is externally connected to the air guide pipe 28, and the hot air is blown to the exhaust pipe 26 by the hot air blower, and then the garbage inside the storage housing 12 is dried by the hot air, which further improves the Garbage collection effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com