Patents

Literature

335results about "Garbage drying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

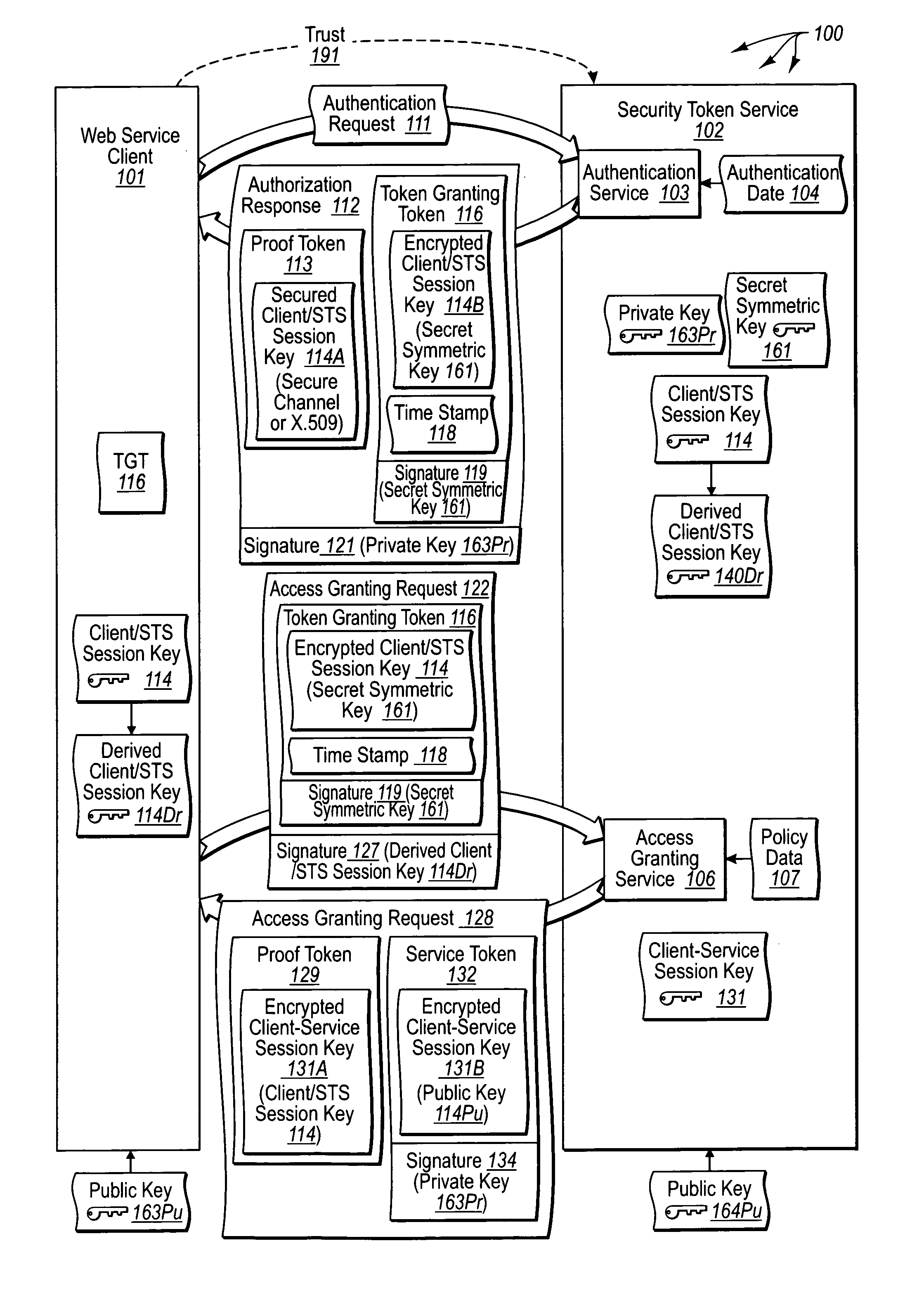

Trusted third party authentication for web services

InactiveUS20060206932A1Communication securityDigital data processing detailsUser identity/authority verificationWeb serviceInternet privacy

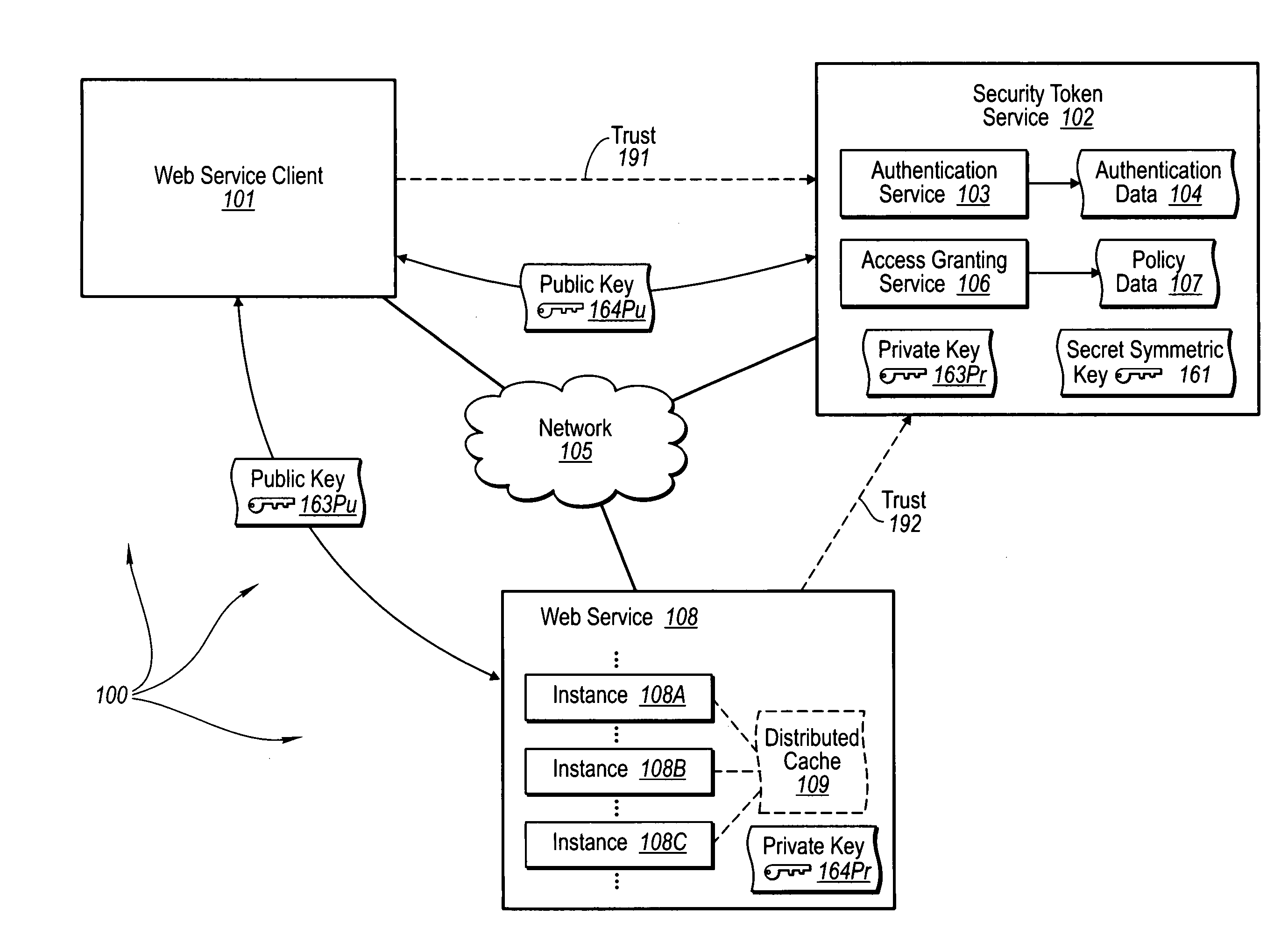

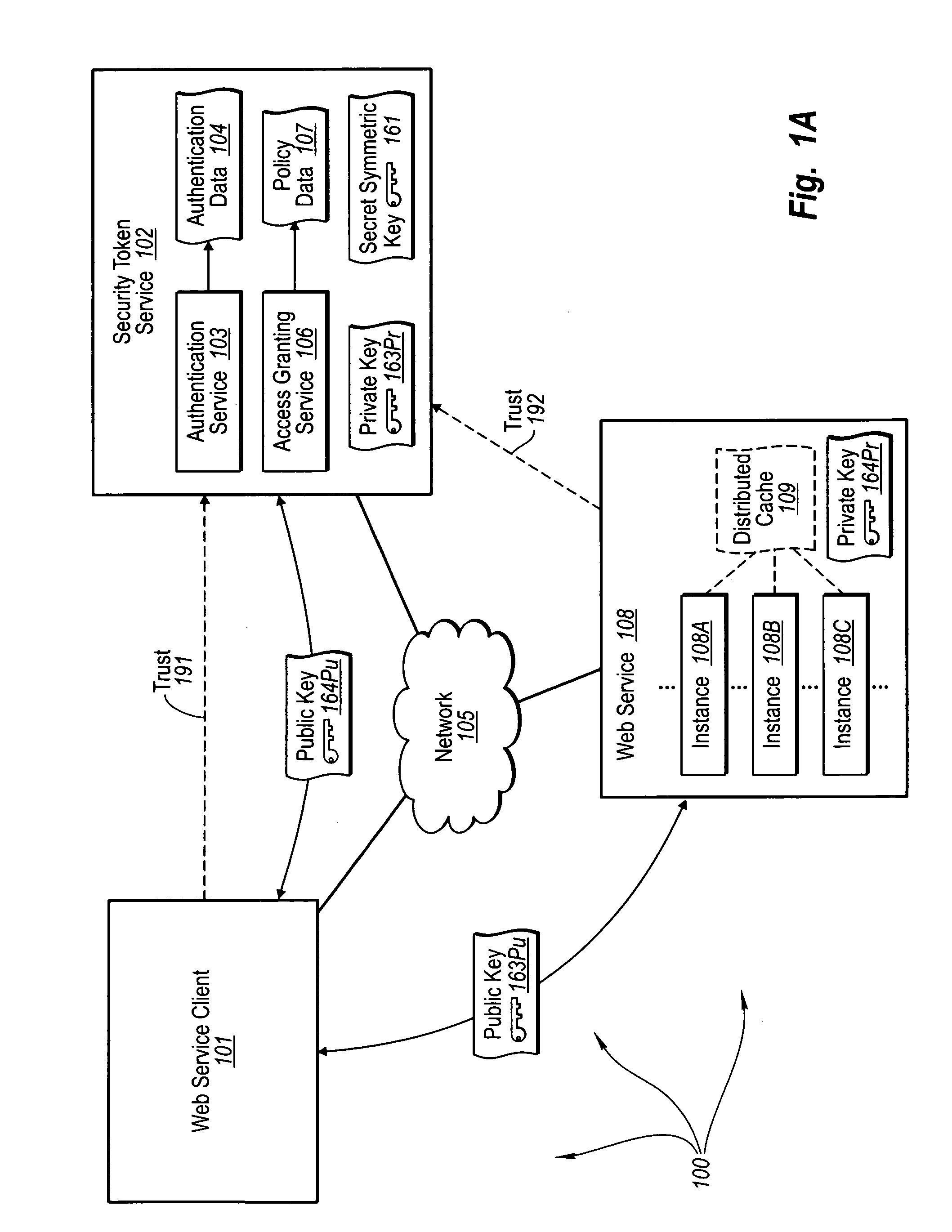

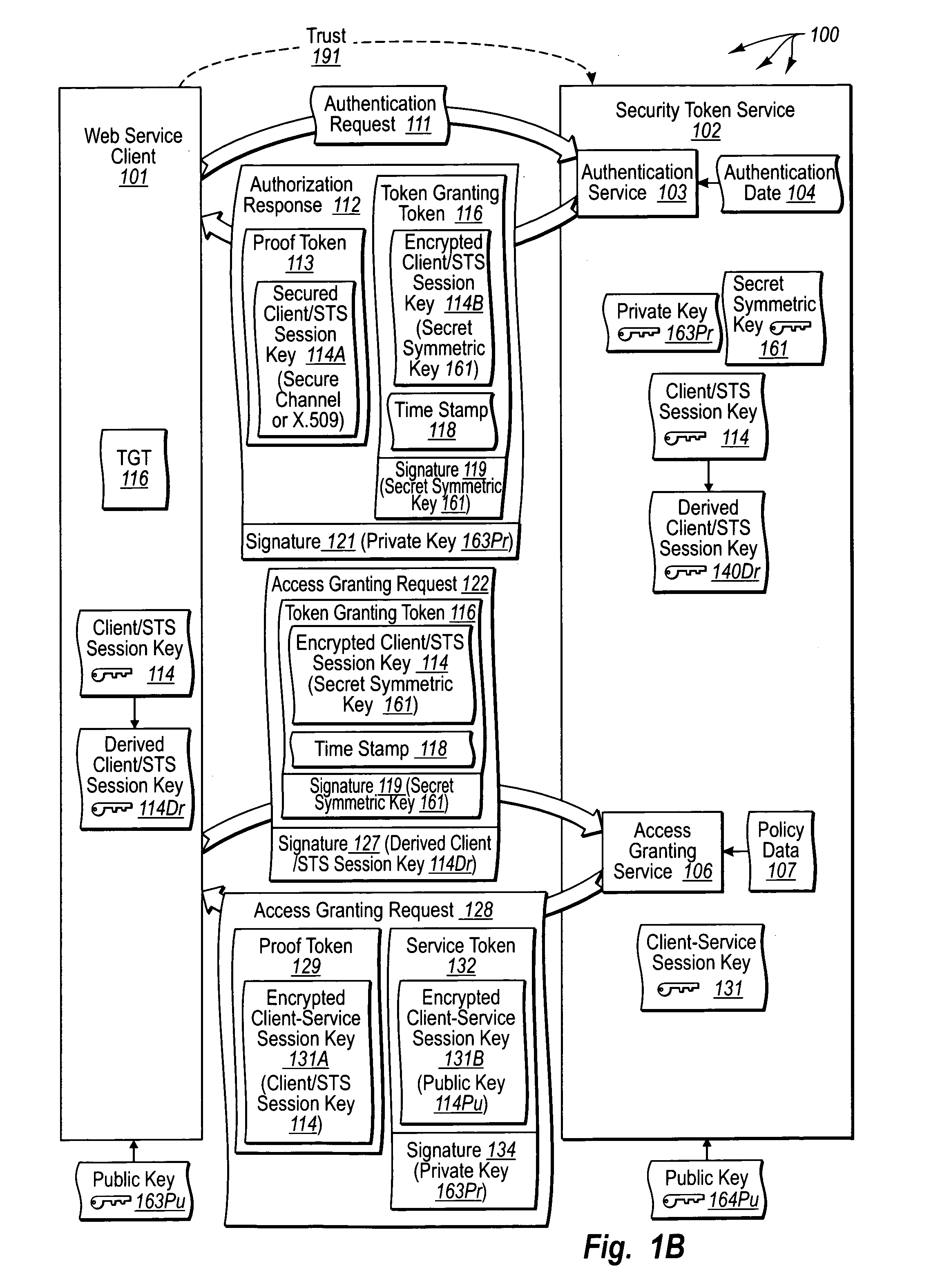

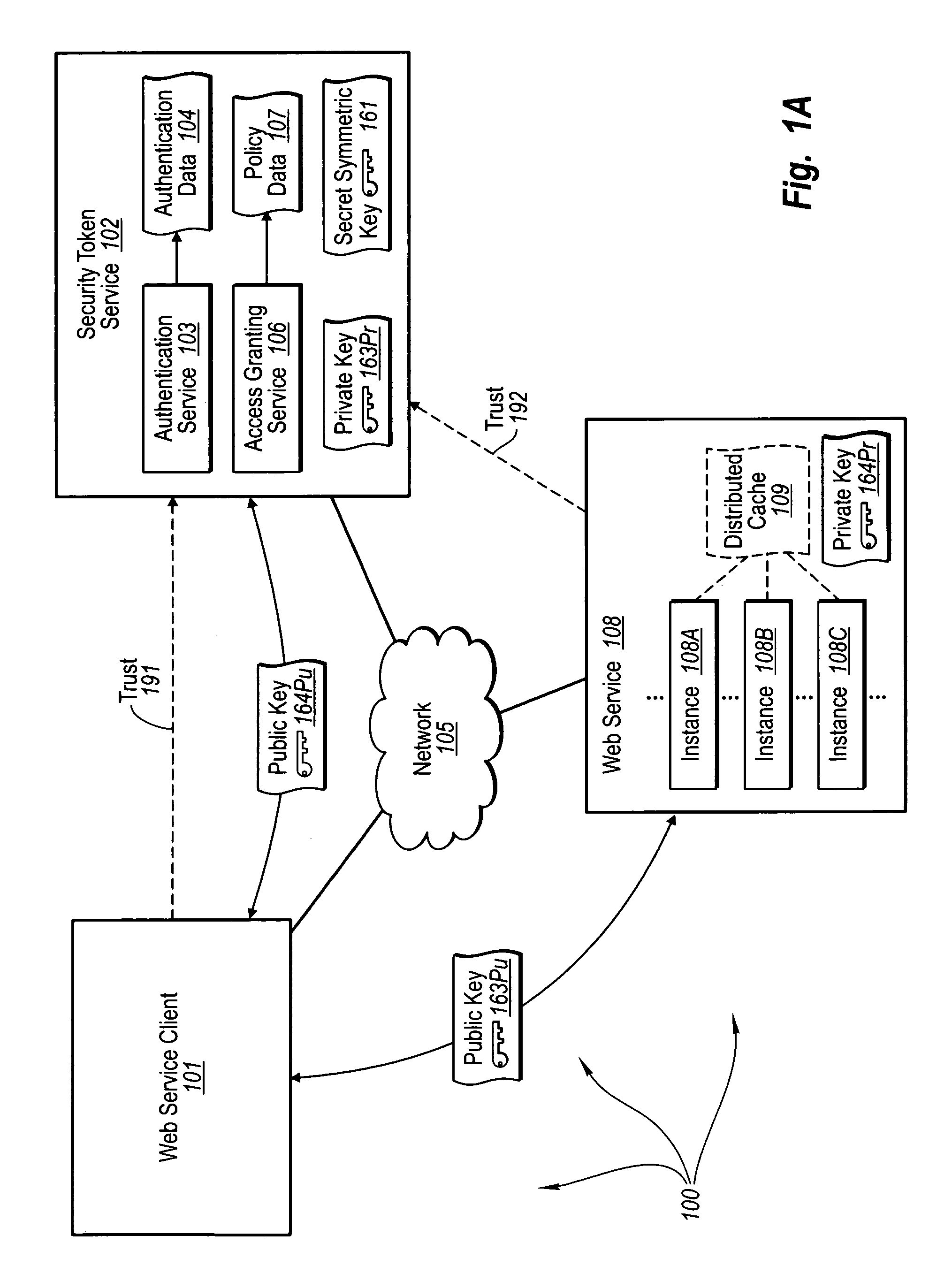

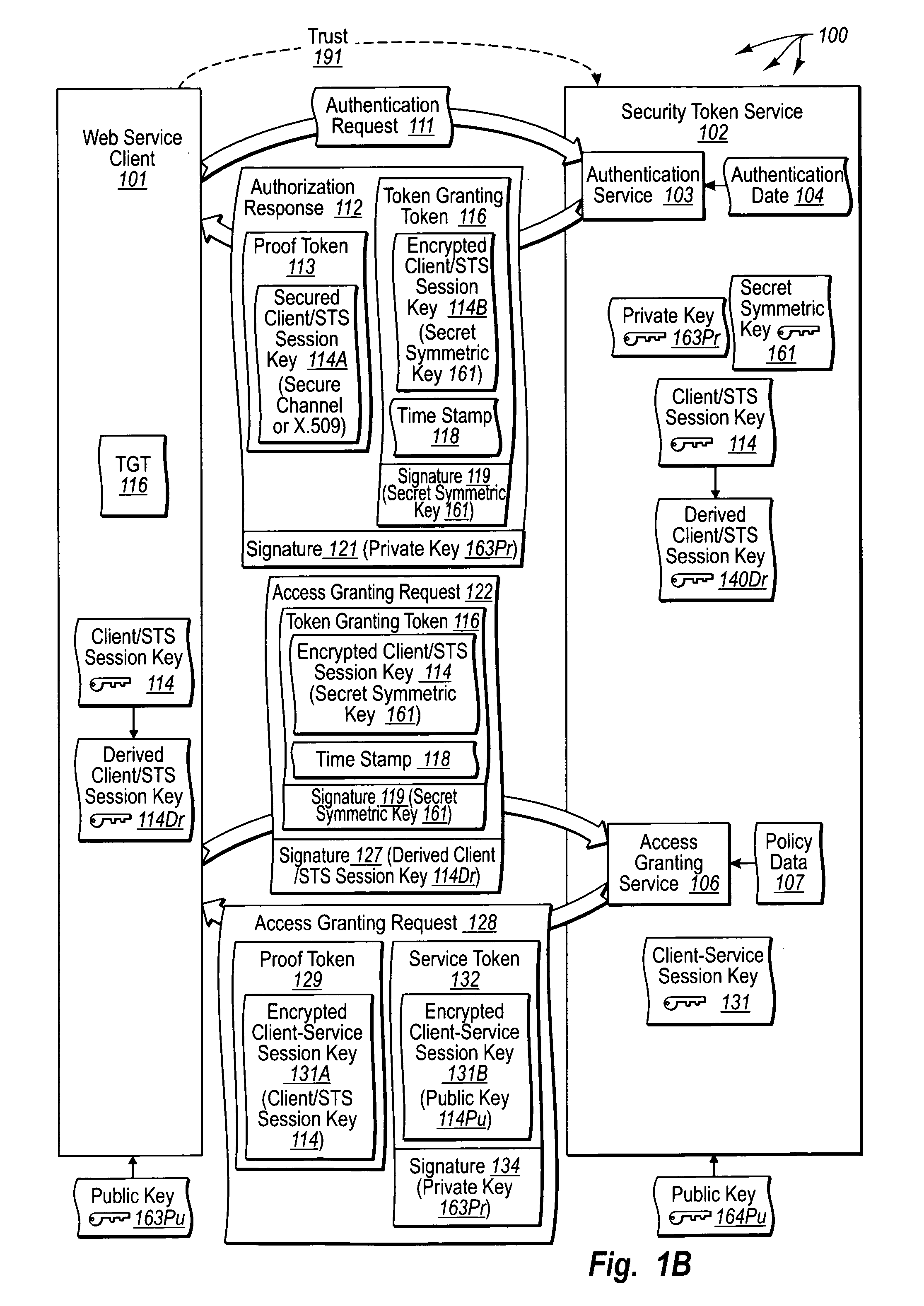

The present invention extends to trusted third party authentication for Web services. Web services trust and delegate user authentication responsibility to a trusted third party that acts as an identity provider for the trusting Web services. The trusted third party authenticates users through common authentication mechanisms, such as, for example, username / password and X.509 certificates and uses initial user authentication to bootstrap subsequent secure sessions with Web services. Web services construct user identity context using a service session token issued by the trusted third party and reconstruct security states without having to use a service-side distributed cache.

Owner:MICROSOFT TECH LICENSING LLC

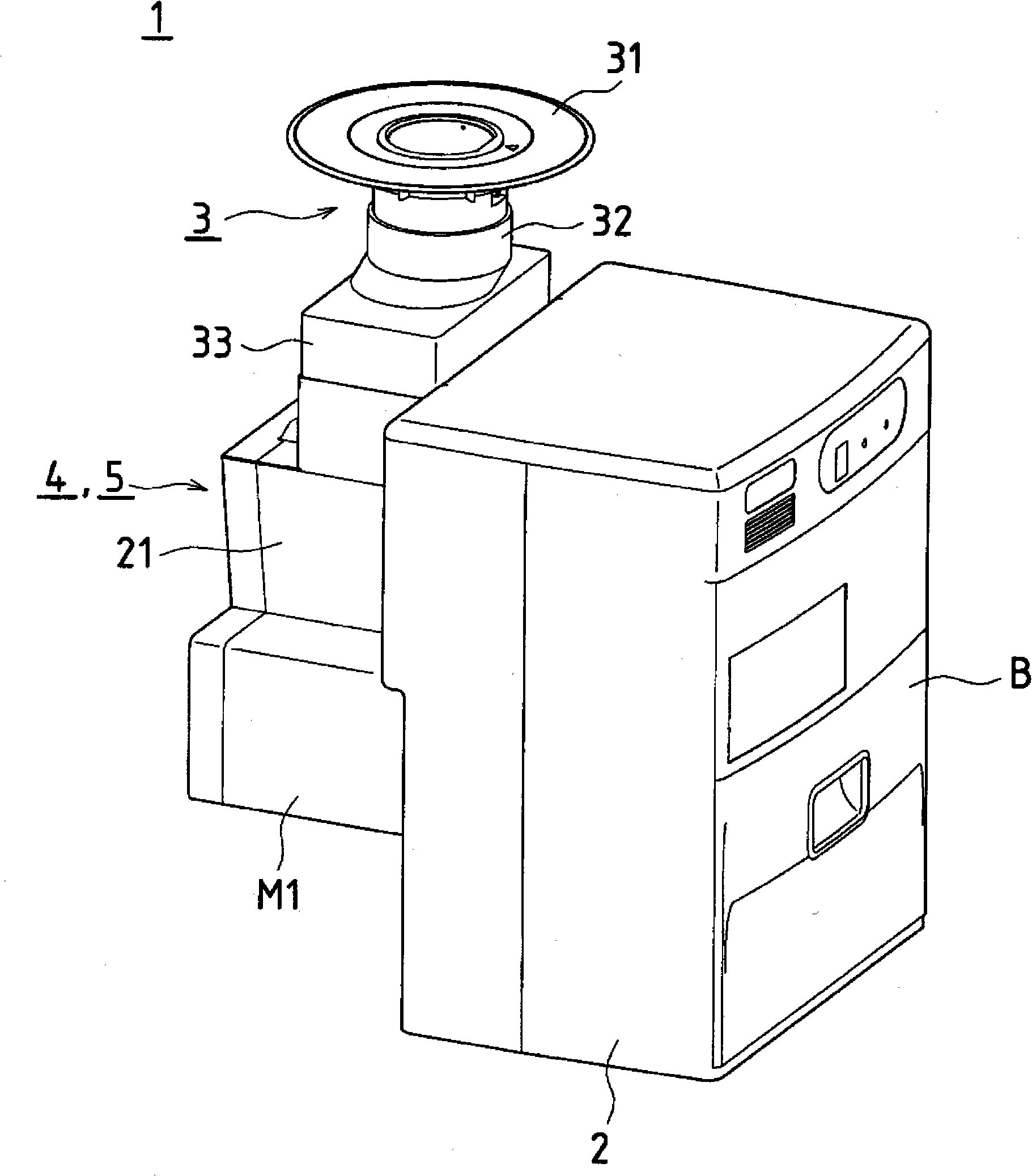

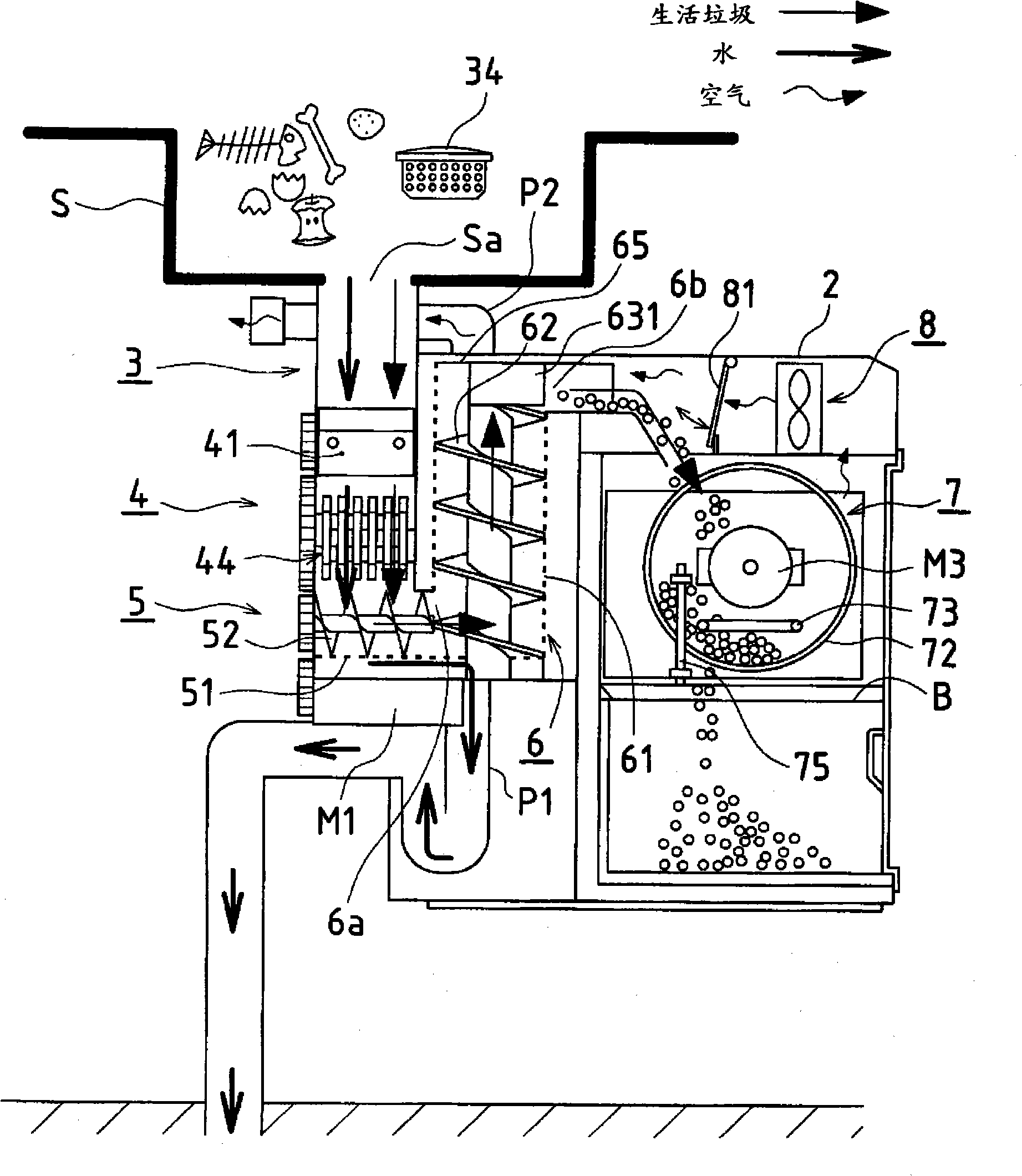

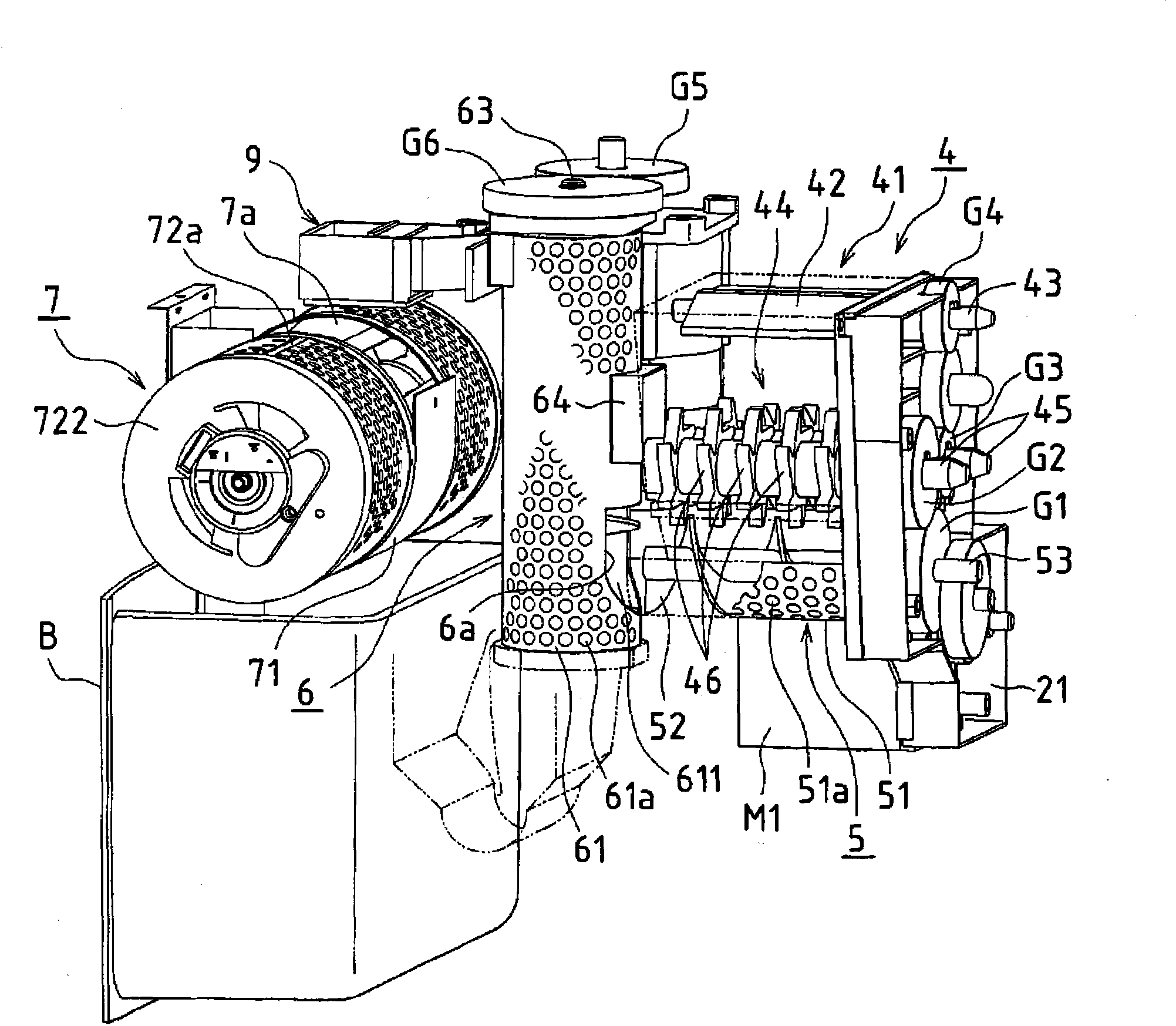

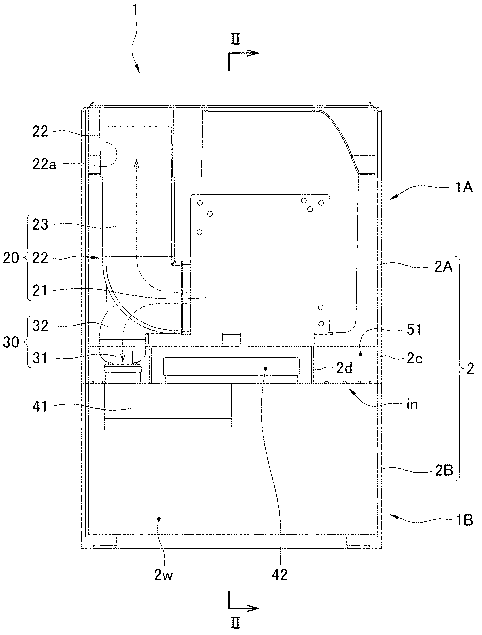

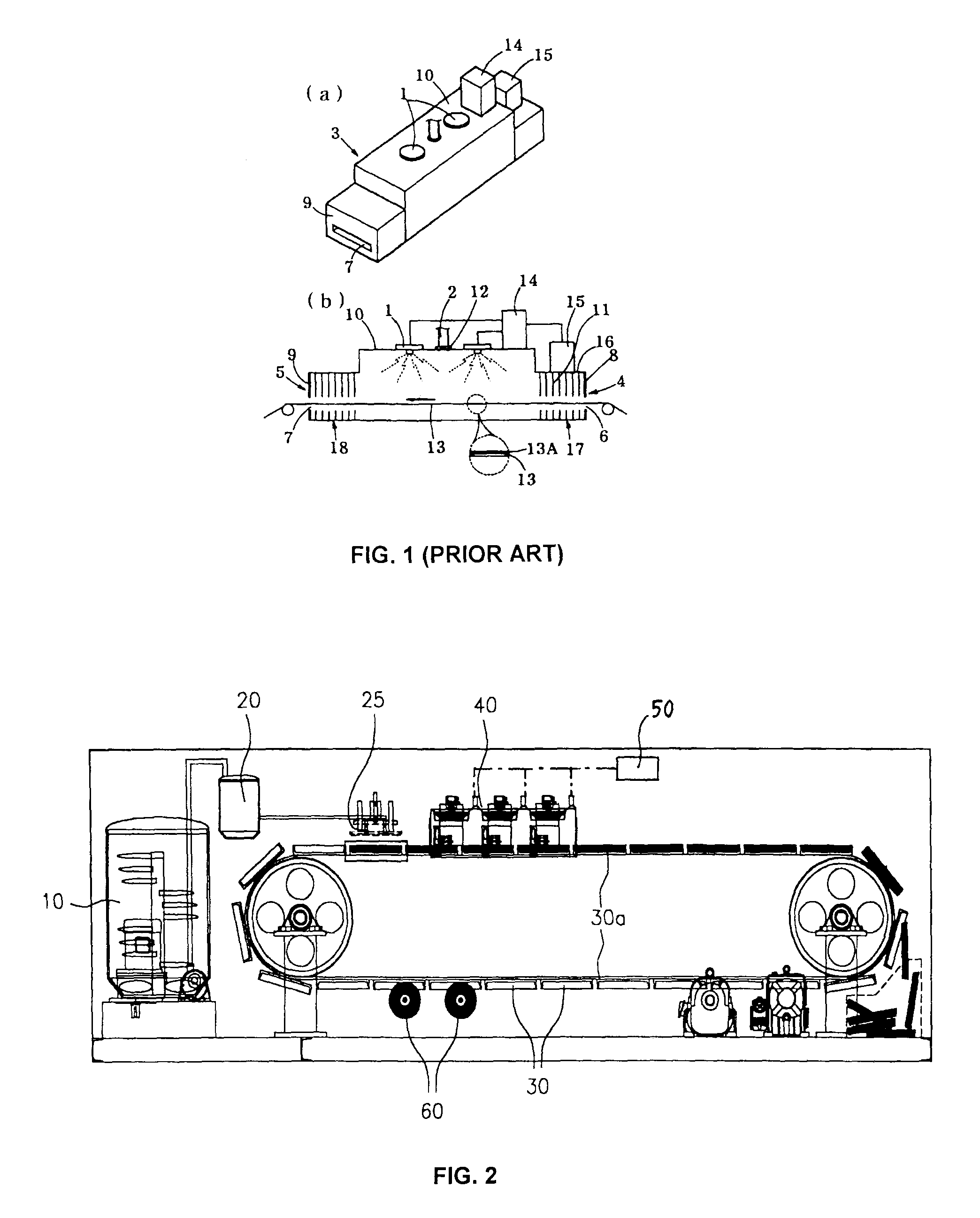

Garbage disposer

A garbage disposer (1), in one embodiment, is composed of a crushing means (4) which crushes garbage supplied through a plughole (Sa) and connection member (3) of a sink (S), a transverse conveyance means (5) which transversely conveys the garbage crushed by the crushing means (4), a dewatering means(6) which internally introduces the crushed garbage conveyed via the transverse conveyance means (5) and dewaters the crushed garbage while conveyed upward, a drying means (7) which internally supplies via a shute (9) the crushed garbage discharged via the dewatering means(6) and dries the crushedgarbage while rotated, and a garbage container (B) which is drawably disposed under the drying means (7). The crushed garbage dried to be reduced in volume by the drying means (7) is dropped therefrom down into the garbage container.

Owner:新矢 浩一

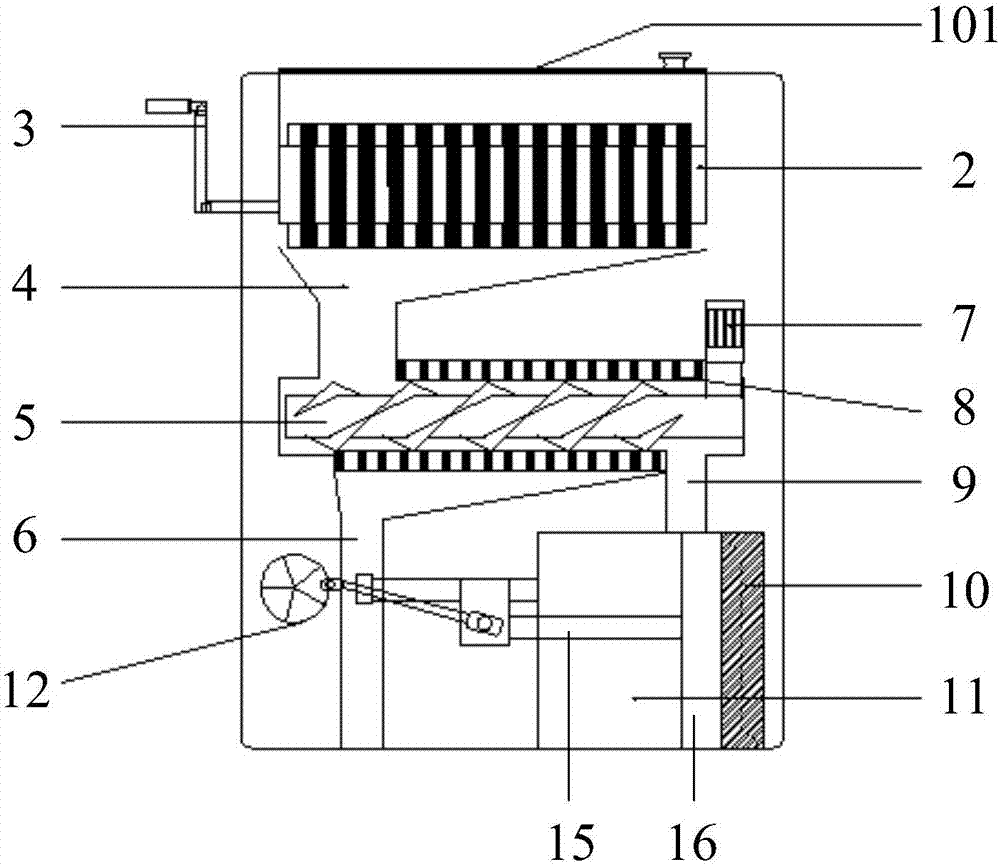

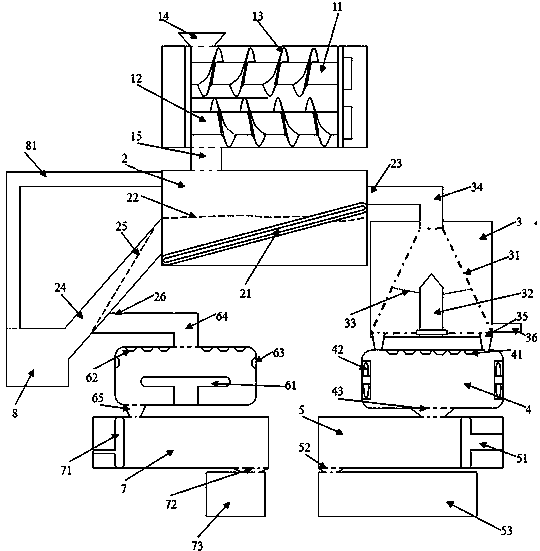

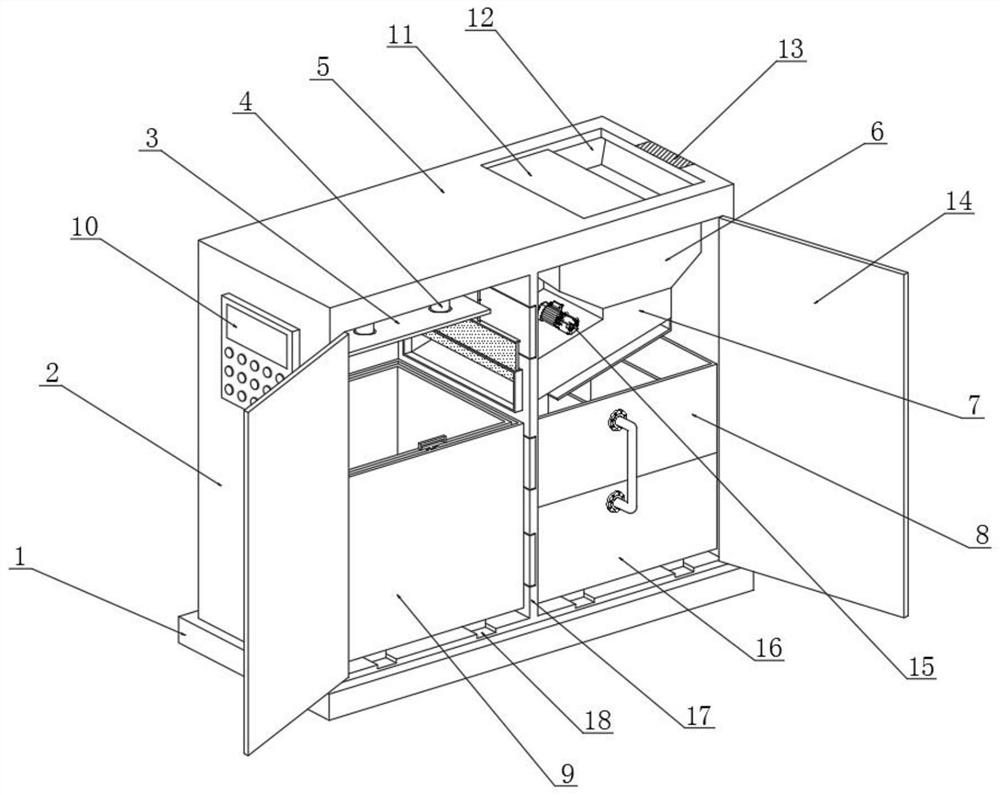

Household kitchen waste disposal device

PendingCN107321768AImprove processing efficiencyReduce wasteTransportation and packagingSolid waste disposalLitterPollution

The invention discloses a household kitchen waste disposal device. The device comprises a casing, a crushing assembly which is arranged in the casing and is used for crushing waste into preliminary residues, a dehydration assembly used for dehydrating the crushed waste to form dehydrated residues and waste liquids, a drying assembly used for drying the residues as well as a compression assembly used for compressing the residues; and the crushing assembly, the dehydration assembly, the drying assembly and the compression assembly are connected sequentially. With the household kitchen waste disposal device, the crushing assembly, the dehydration assembly, the drying assembly and the compression assembly are arranged, and crushing, dehydration, drying and compression operations can be performed on the waste sequentially, so that repeated pollution is no longer caused during centralized disposal of the waste, and the kitchen waste disposed by the disposal device is small in size, low in water content and convenient to transport and recycle.

Owner:GUANGDONG UNIV OF TECH

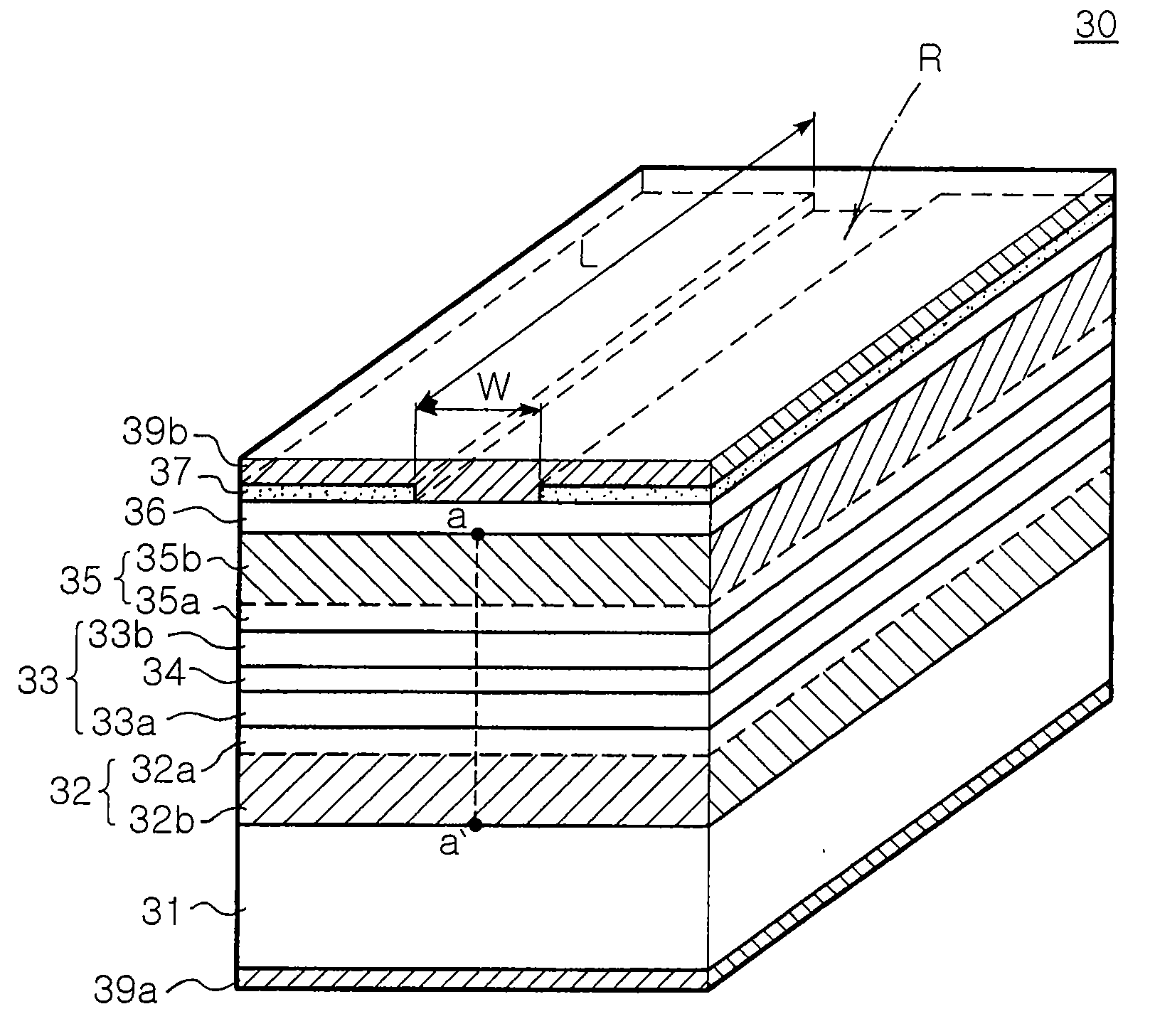

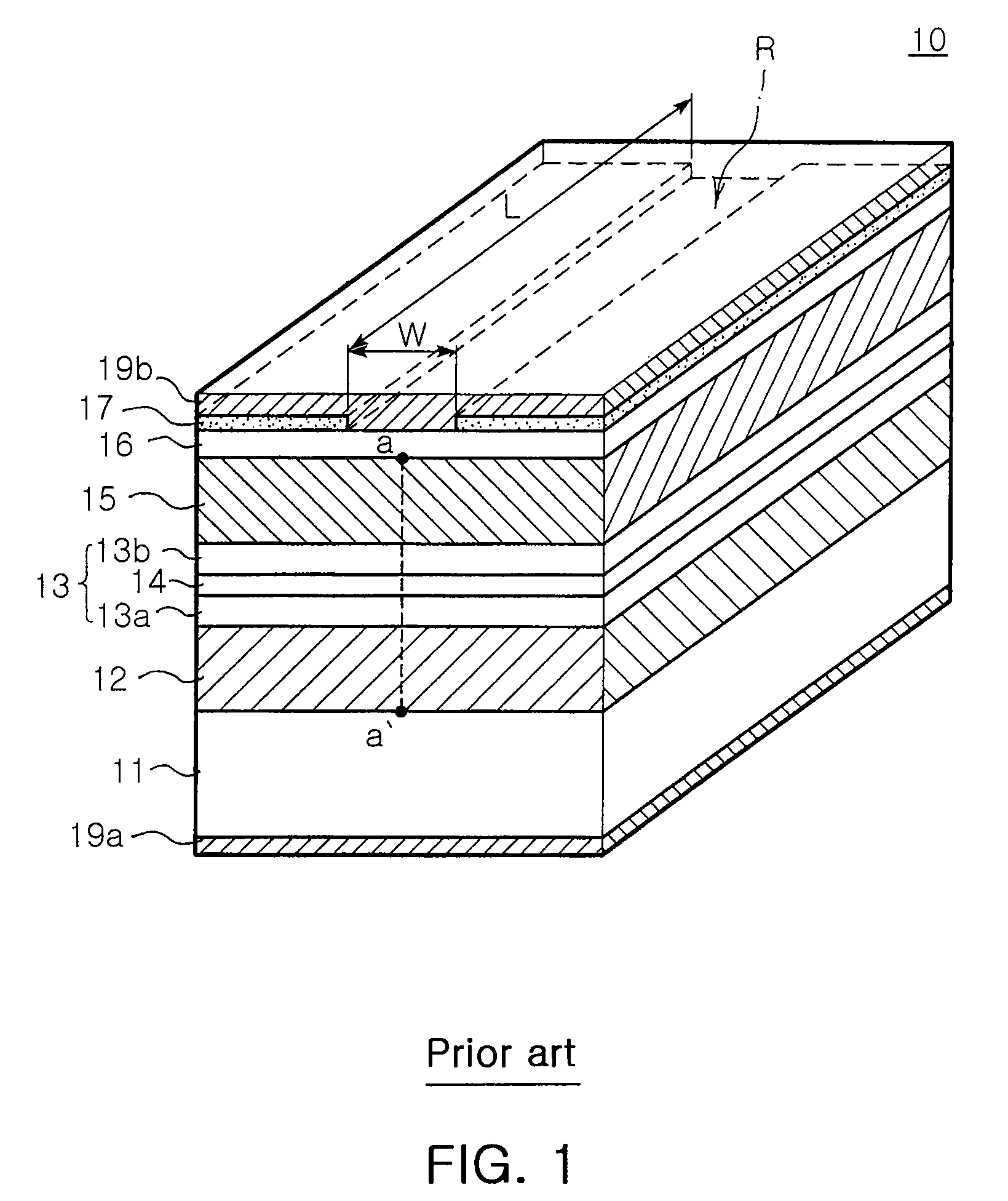

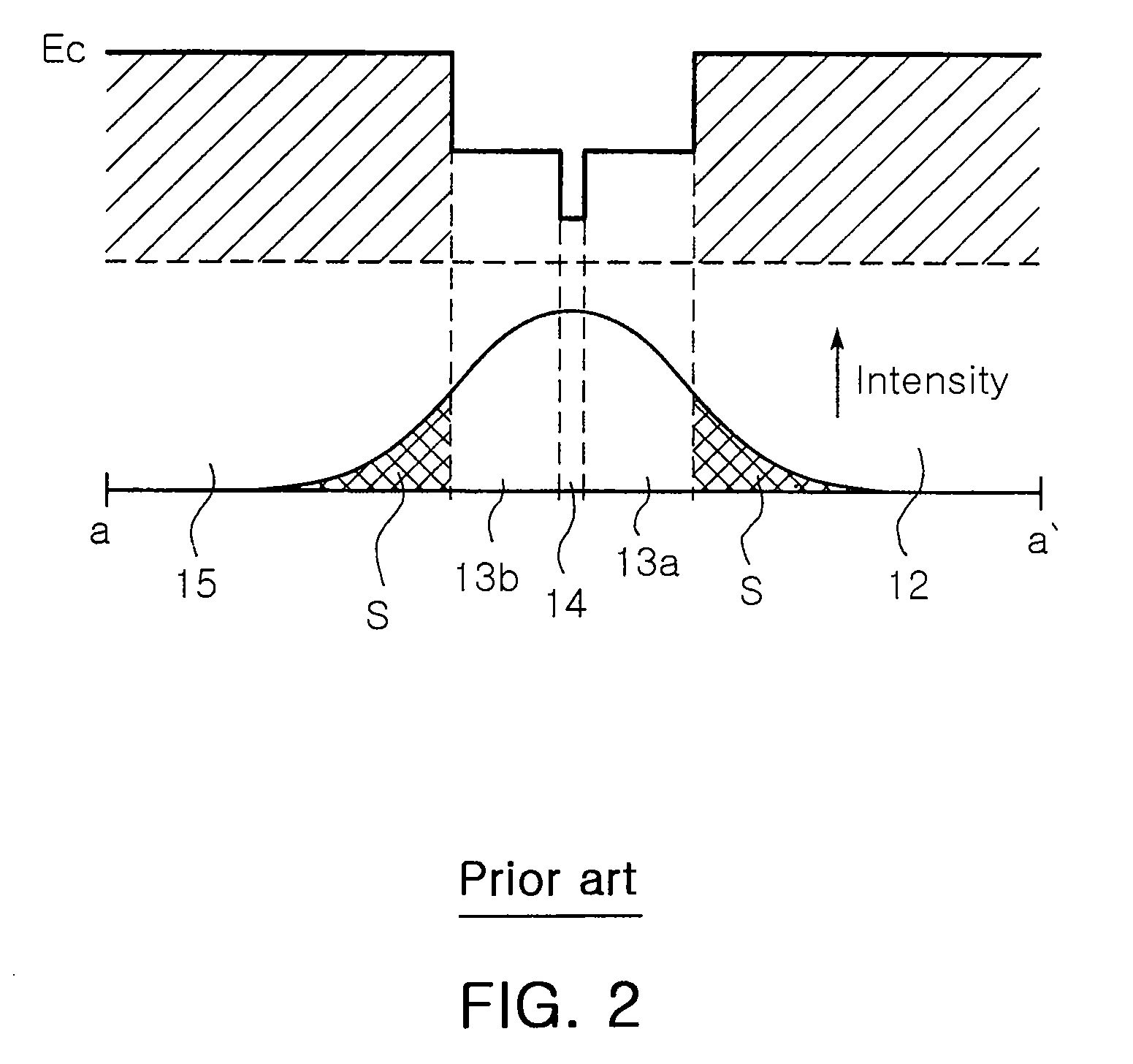

High power semiconductor laser device

ActiveUS20070195844A1Convenient lengthHigh occurrenceOptical wave guidanceLaser detailsOptoelectronicsActive layer

In a high power semiconductor laser device, first and second conductivity type clad layers are provided. An active layer is interposed between the first and second conductivity type clad layers. A first optical guide layer is disposed between the first conductivity type clad layer and the active layer. A second optical guide layer is disposed between the second conductivity clad layer and the active layer. Also, an intentionally undoped optical loss confinement region is formed in a portion of at least one of the first and second conductivity type clad layers overlapping laser beam distribution.

Owner:SAMSUNG ELECTRONICS CO LTD

Trusted third party authentication for web services

InactiveUS7900247B2Digital data processing detailsUser identity/authority verificationThird partyInternet privacy

Owner:MICROSOFT TECH LICENSING LLC

Intelligent kitchen waste disposal machine and using method thereof

PendingCN107671105AEasy to operateSolid waste disposalTransportation and packagingEffective treatmentWaste disposal

The invention discloses an intelligent kitchen waste disposal machine and a using method thereof. The intelligent kitchen waste disposal machine comprises a crushing device, a solid-liquid separationdevice and a drying treatment device adopting heated air circulation, wherein a cyclic heating draught fan is the main heat source for drying treatment and heating; and through the arrangement of an air inlet and an air outlet through which air is discharged in the inclined downward direction, the cyclic air intake and discharge of hot air are realized, the heating efficiency is high, and the energy consumption is reduced. The using method comprises the following steps: the kitchen waste is firstly subjected to crushing treatment through the crushing device, the crushed kitchen waste is then subjected to solid-liquid separation through the solid-liquid separation device to separate out the liquid, the kitchen waste after solid-liquid separation is further subjected to drying treatment through the cyclic heating draught fan, and the kitchen waste after drying treatment is finally subjected to fermentation to form an organic fertilizer. According to the intelligent kitchen waste disposalmachine and the using method thereof, through the cooperative work of all the components, the kitchen waste is subjected to effective treatment to be turned into waste oil, waste water and an organicfertilizer, the operation is simple, and the processes are convenient.

Owner:常州波纳斯风力发电设备科技有限公司

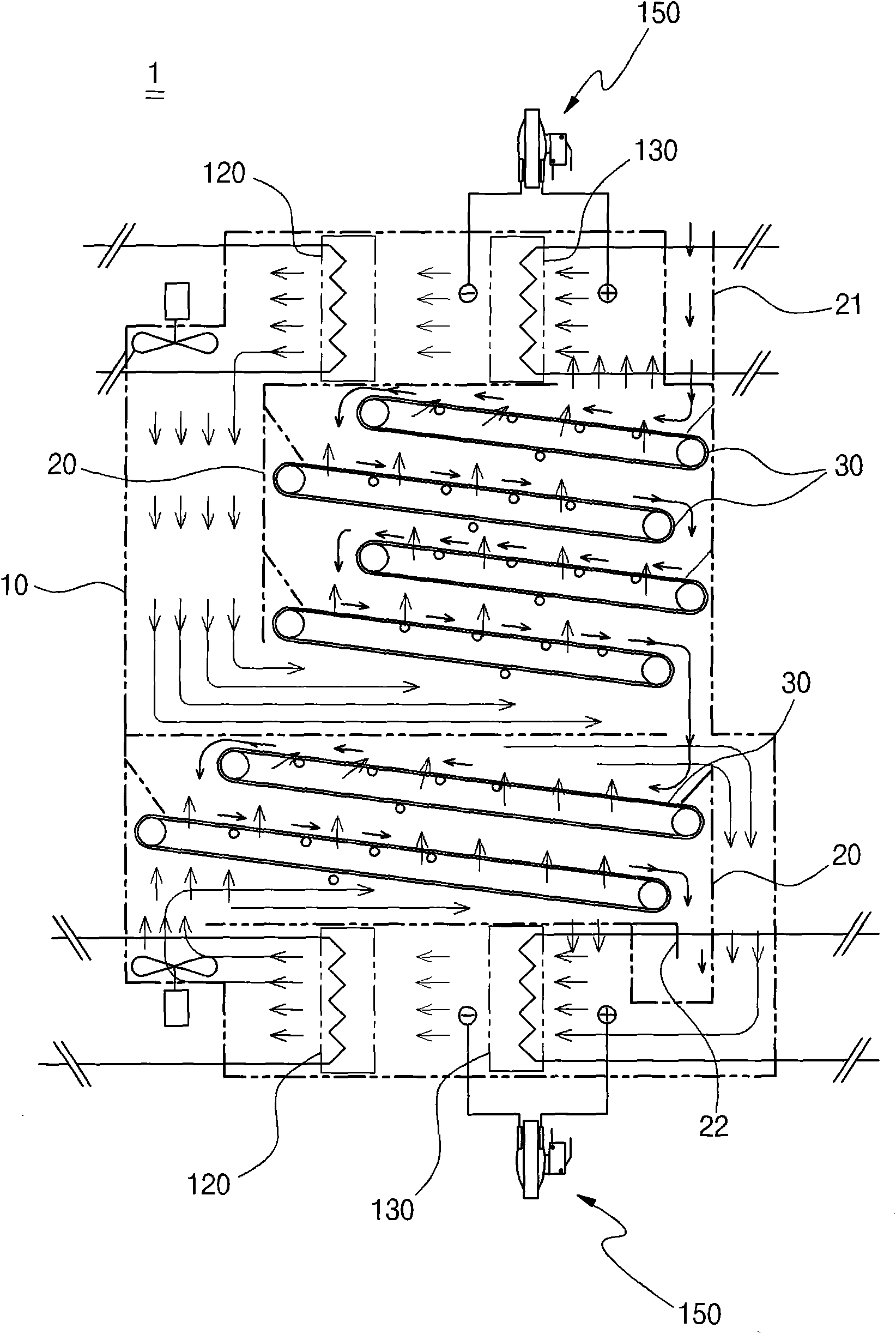

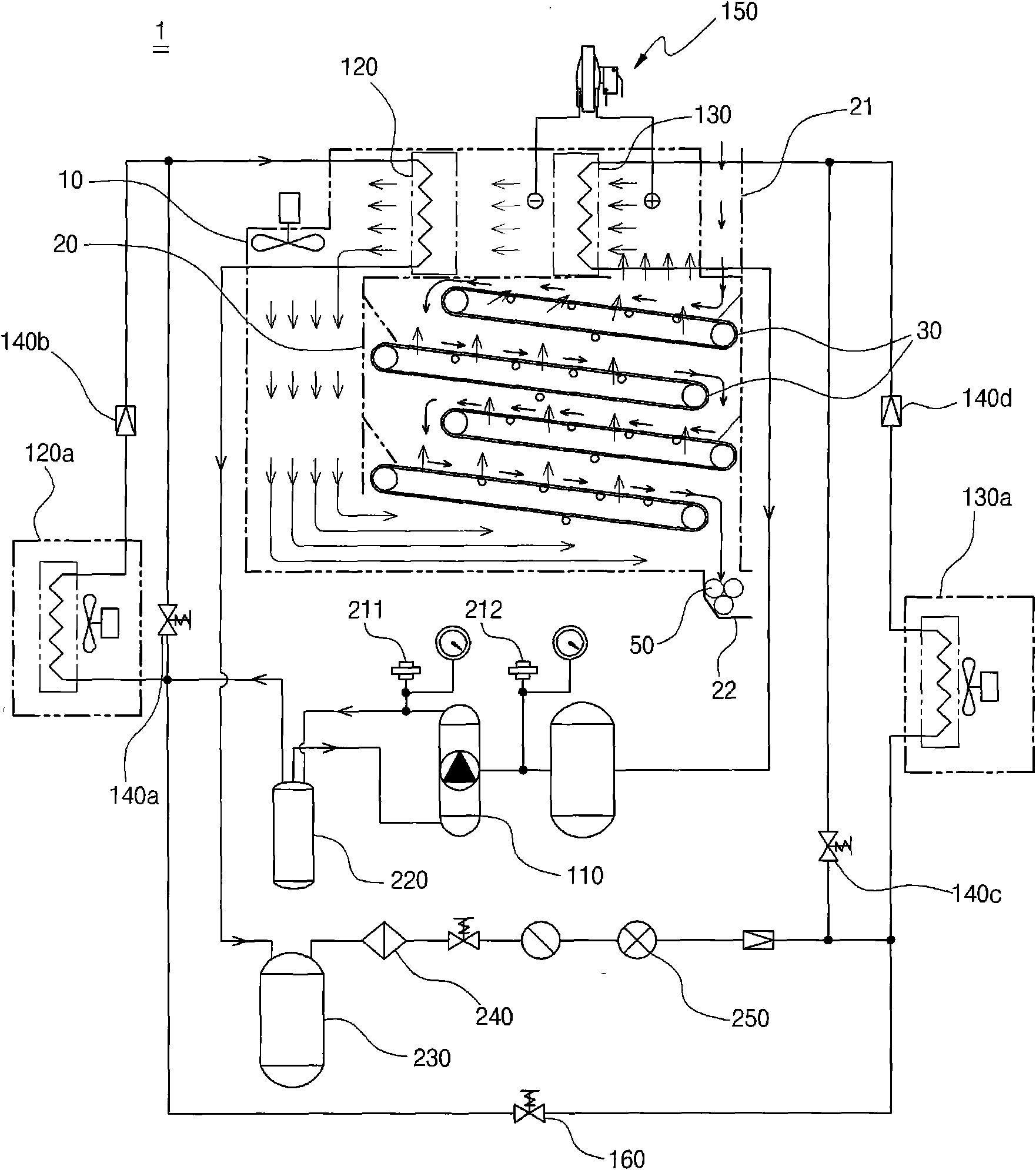

Multipurpose drying apparatus using heat pump system

InactiveCN101782315AIncrease temperatureDry properlyHeat pumpsDrying solid materials with heatProcess engineeringRefrigerant

The invention provides a multipurpose drying apparatus using heat pump system. According to one side of the invention, the multipurpose drying apparatus is characterized in that the drying is performed through a heat pump system, the heat pump system circulates the refrigerant by means of a compressor, a main condenser and a main evaporator, the multipurpose drying apparatus using heat pump system includes a drying apparatus body, wherein a main condenser and a main evaporator are provided to perform heat exchange; and a drying chamber formed inside the drying apparatus, to perform drying to drying objects. The heat pump system includes an auxiliary condenser, provided at the external of the drying apparatus body, and is configured to selectively link between the compressor and the main condenser, so as to reduce the temperature inside the drying apparatus body.

Owner:成 明济 +2

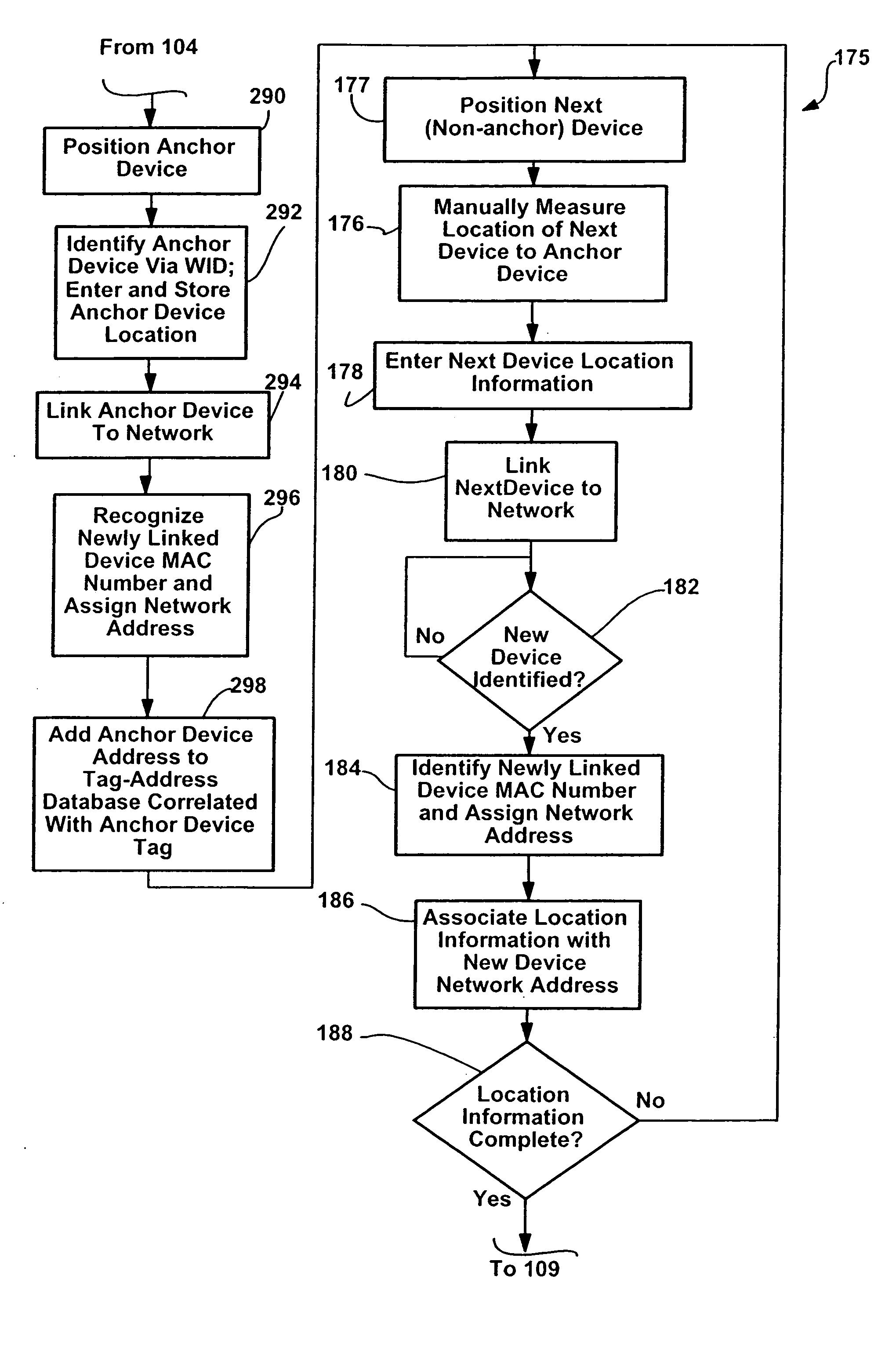

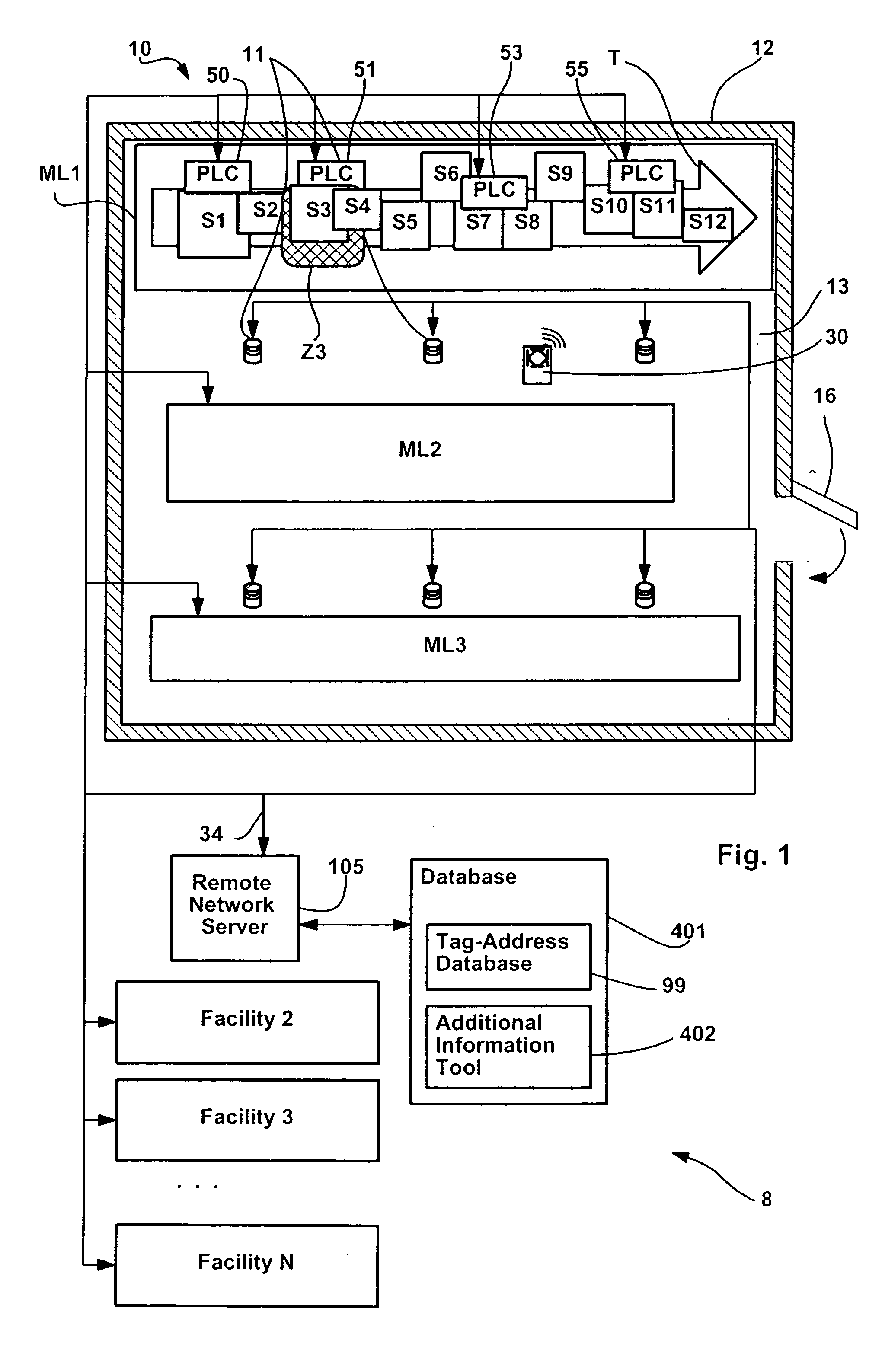

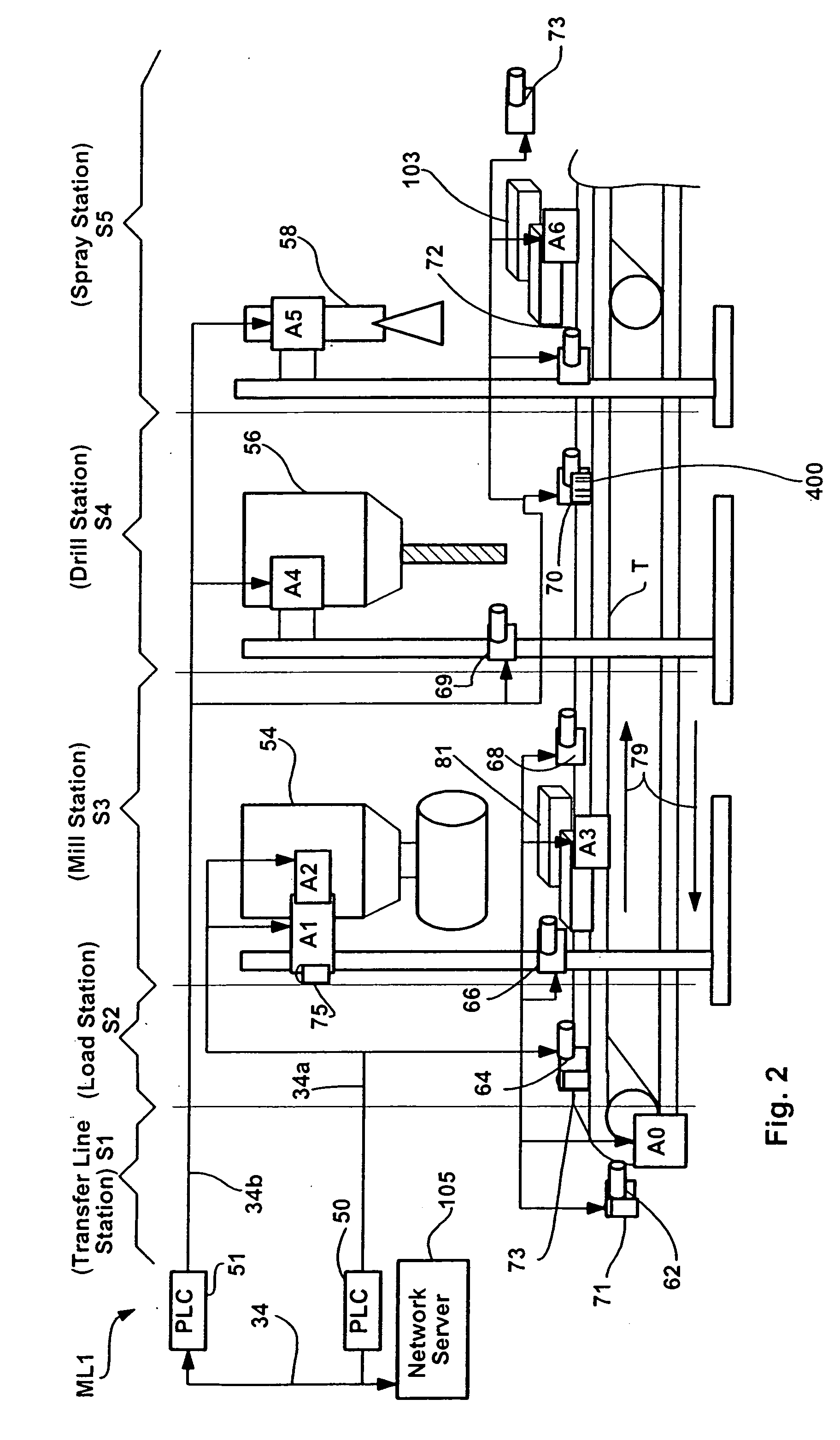

Juxtaposition based machine addressing

Owner:ROCKWELL AUTOMATION TECH

Medical waste disposal device

InactiveCN107913896AMaximize recyclingHigh degree of killingDrying solid materials with heatSolid waste disposalMedical wasteMedical treatment

The invention relates to a medical waste disposal device. The medical waste disposal device comprises a crushing chamber, a soaking chamber, a water removal cavity, a first drying chamber, a first compression chamber, a first storage box, a second drying chamber, a second compression chamber, a second storage box and a disinfectant fluid collecting chamber. Due to the fact that medical waste contains a number of harmful microorganisms, the soaking chamber is arranged to conduct disinfection treatment on the medical waste. Meanwhile, the soaking chamber is arranged to enable the medical waste to be classified, two sets of drying components and two sets of compression components are arranged to dispose and store different kinds of medical waste, and therefore refined classification disposalof the medical waste is achieved.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

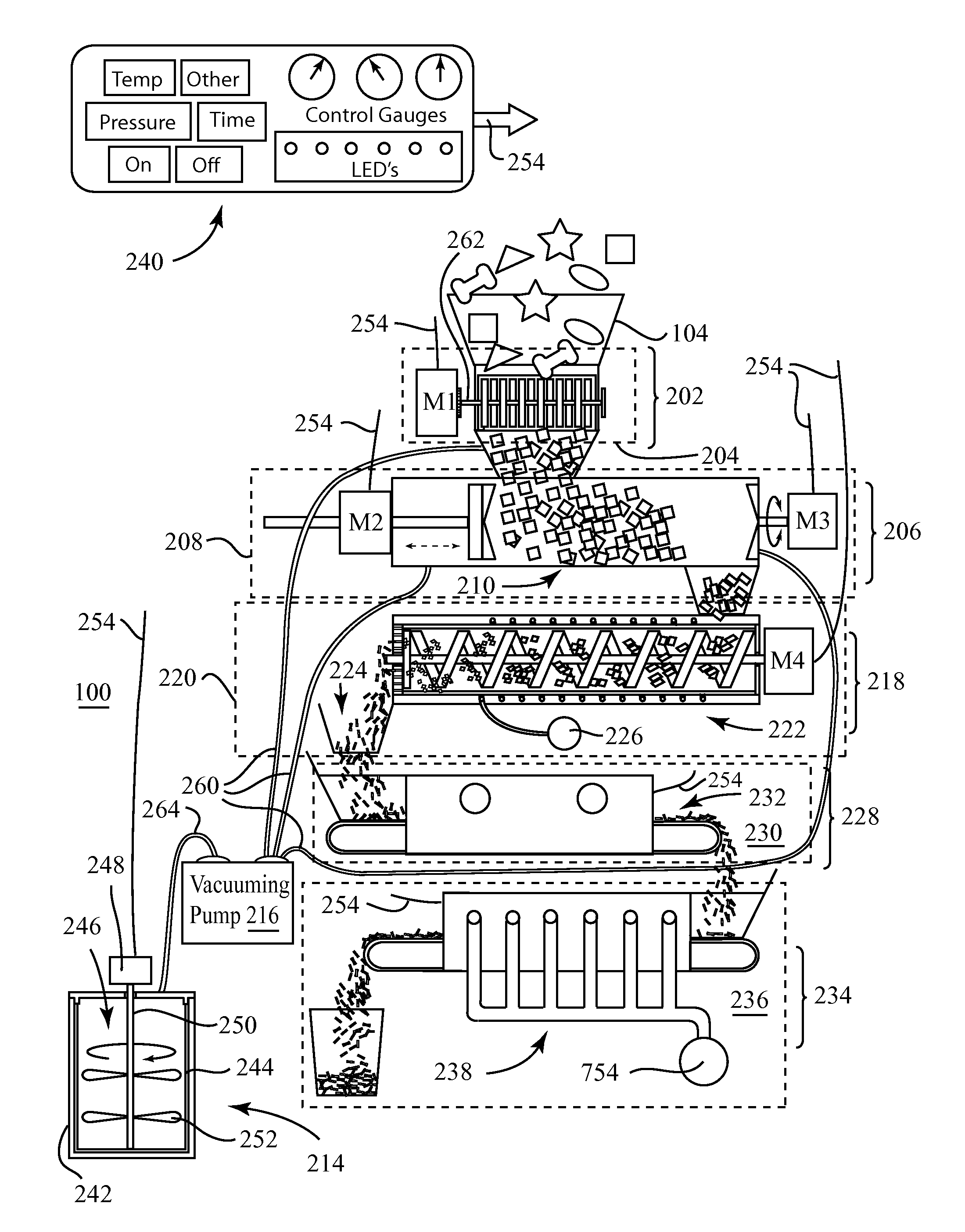

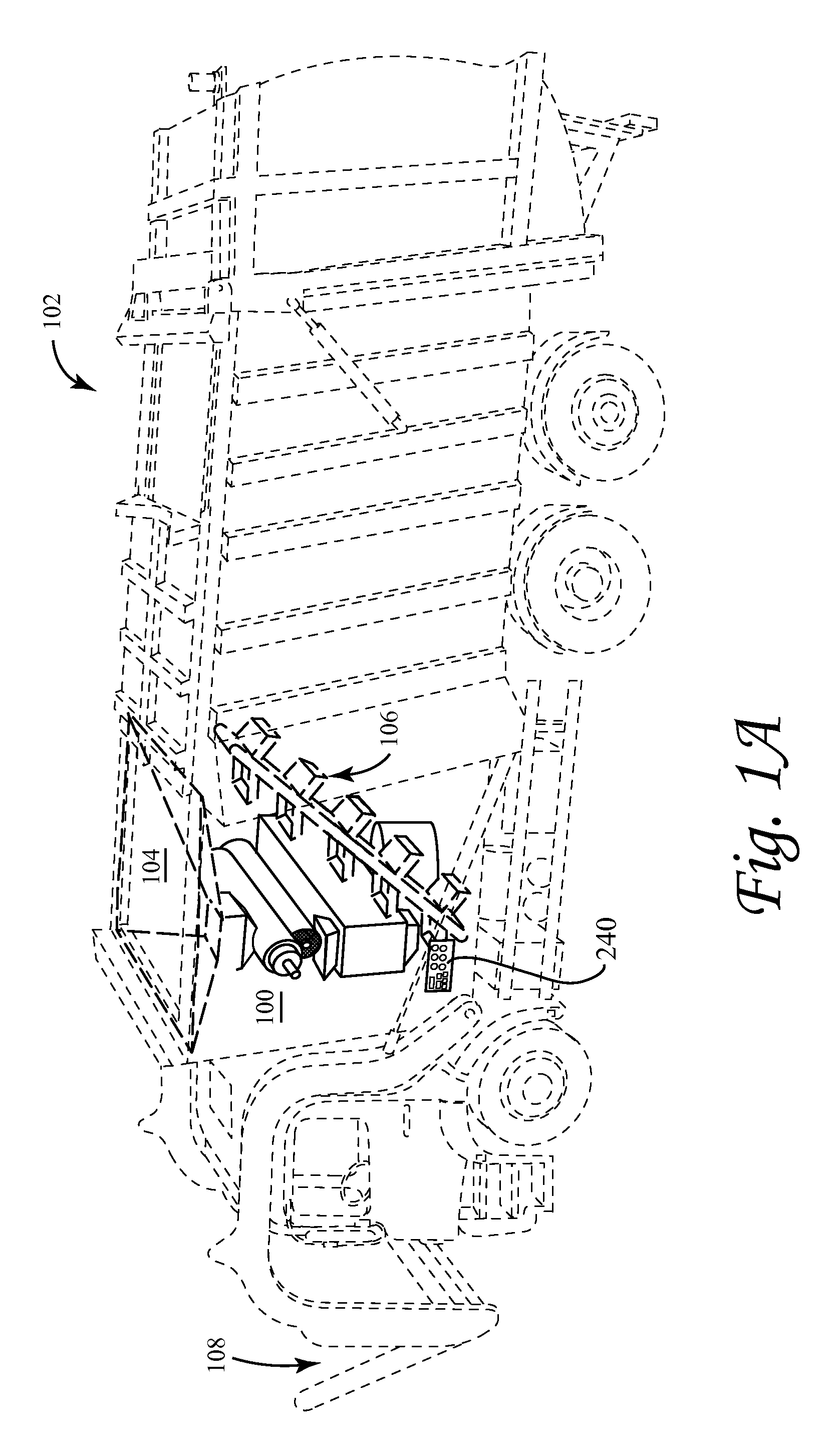

Device for conversion of waste to sources of energy or fertilizer and a method thereof

ActiveUS20130205613A1Efficient conversationEasy to handleDrying using combination processesDrying solid materials with heatEnvironmental engineeringWaste treatment

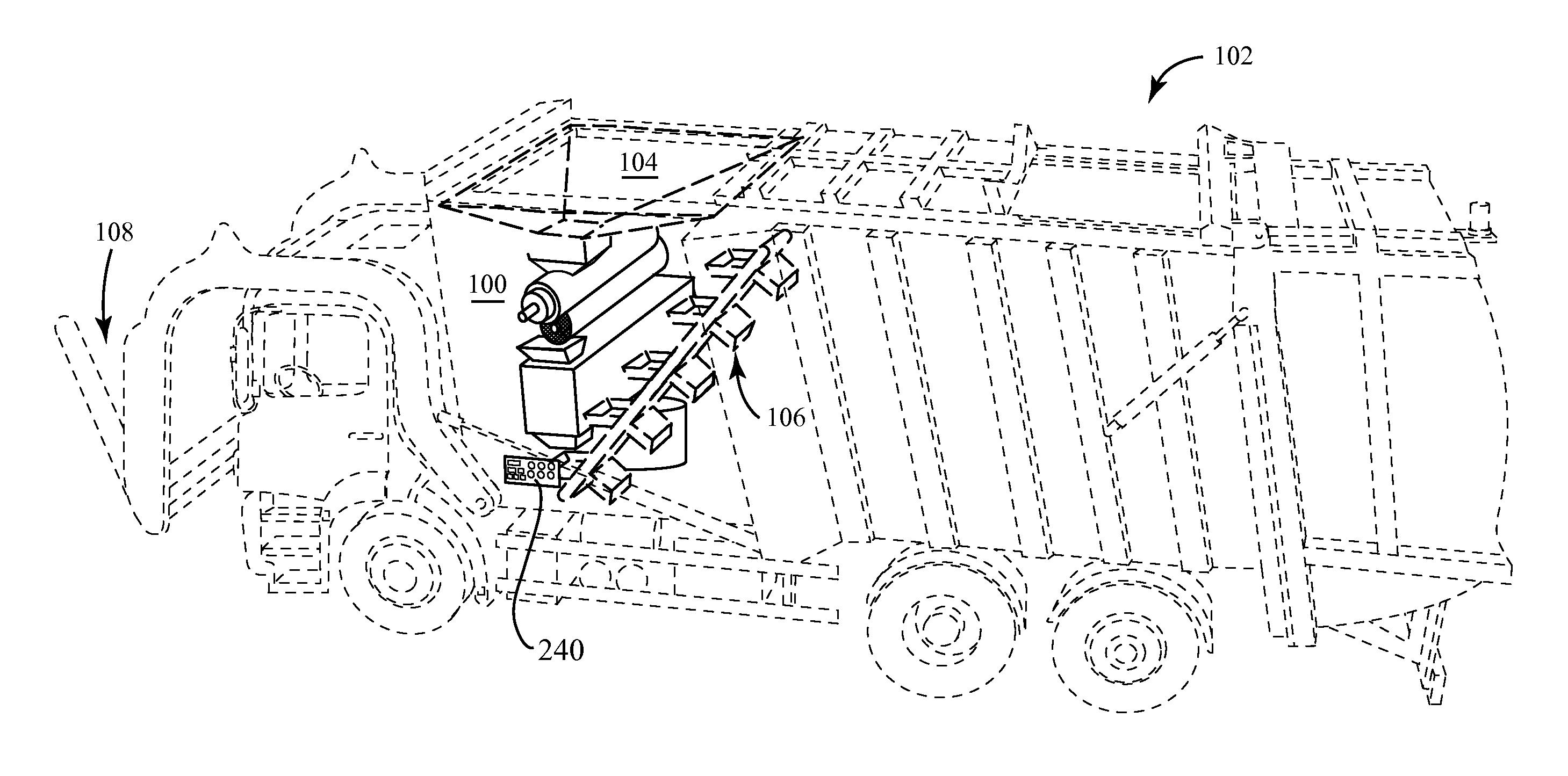

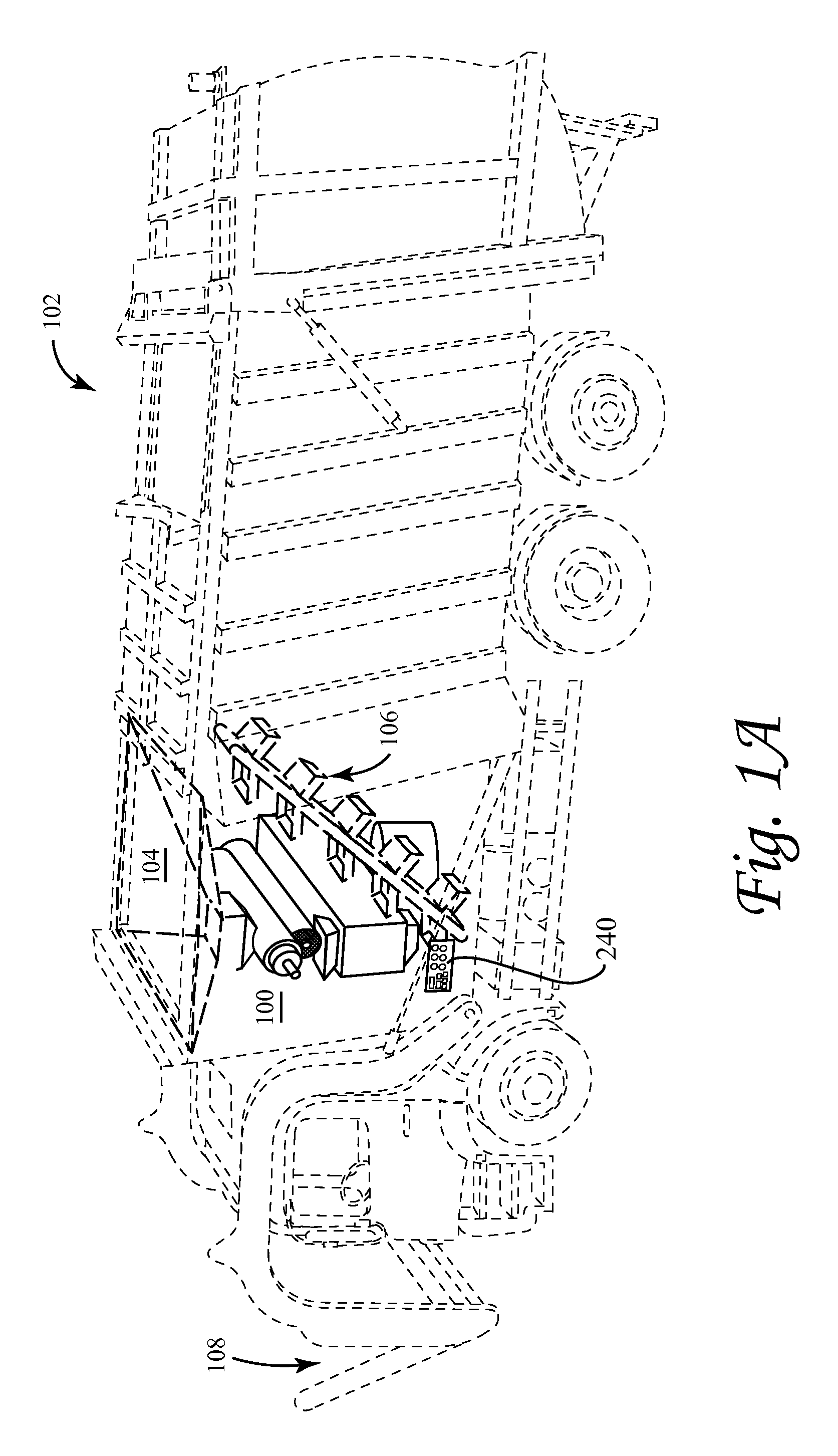

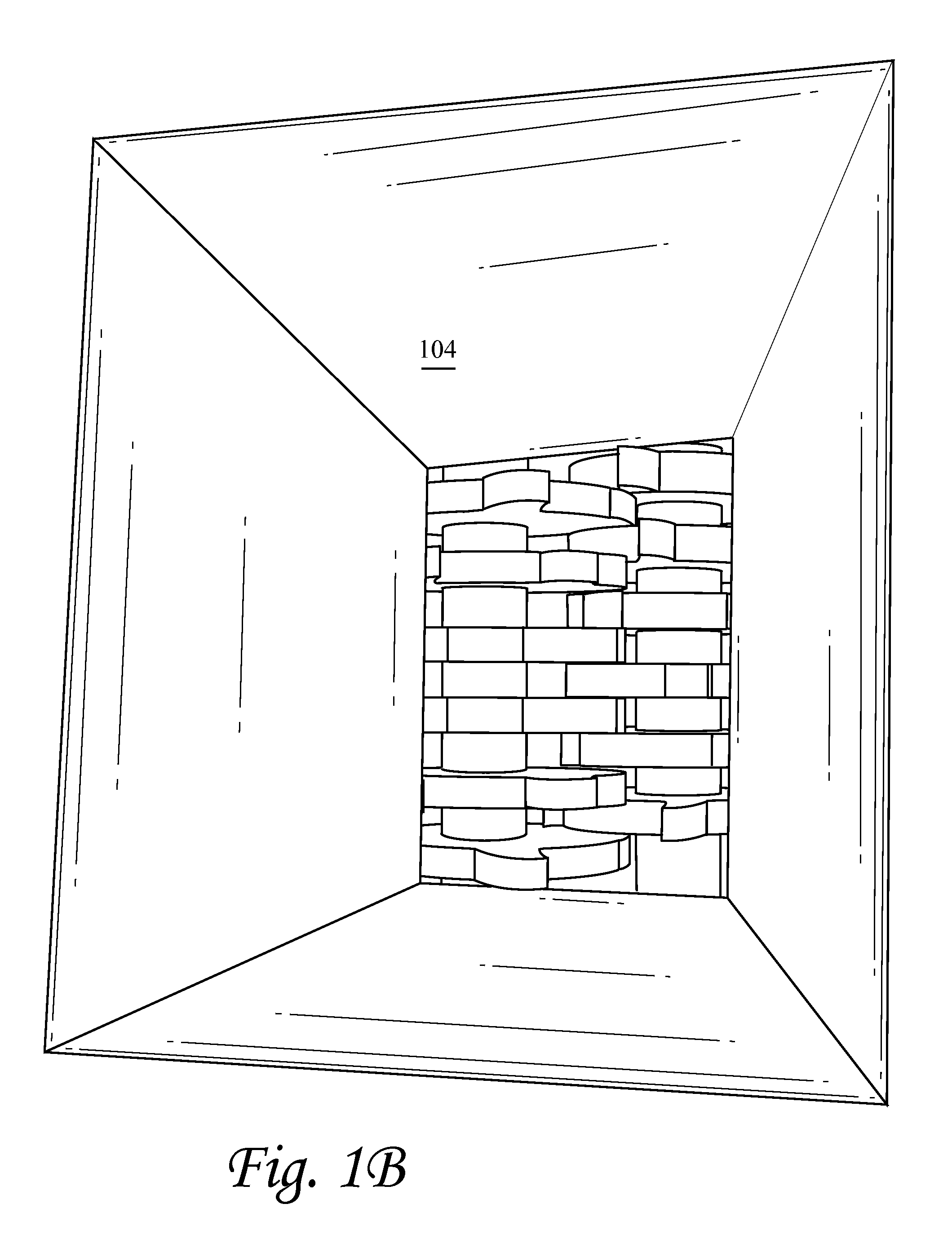

The present invention provides a compact device (that may be installed onto a mobile or stationary platform) for conversion of waste to sources of energy or fertilizer. The device includes multiple stages for efficient conversation and processing of waste into energy or fertilizer, including a first stage for reducing a size of received waste, a second stage for compressing the reduced sized waste into partially dehydrated waste, a third stage for grinding and further compression of received waste from second stage to pulverize the constituent parts into highly dense substantially dehydrated pellets or fertilizers, with a fourth stage for further drying of the received pellets or fertilizers and a final fifth stage for cooling the received pellets or fertilizers into highly dense pellets. The device of the present invention further includes a controller for controlling each operational stage.

Owner:REGREEN TECH INC

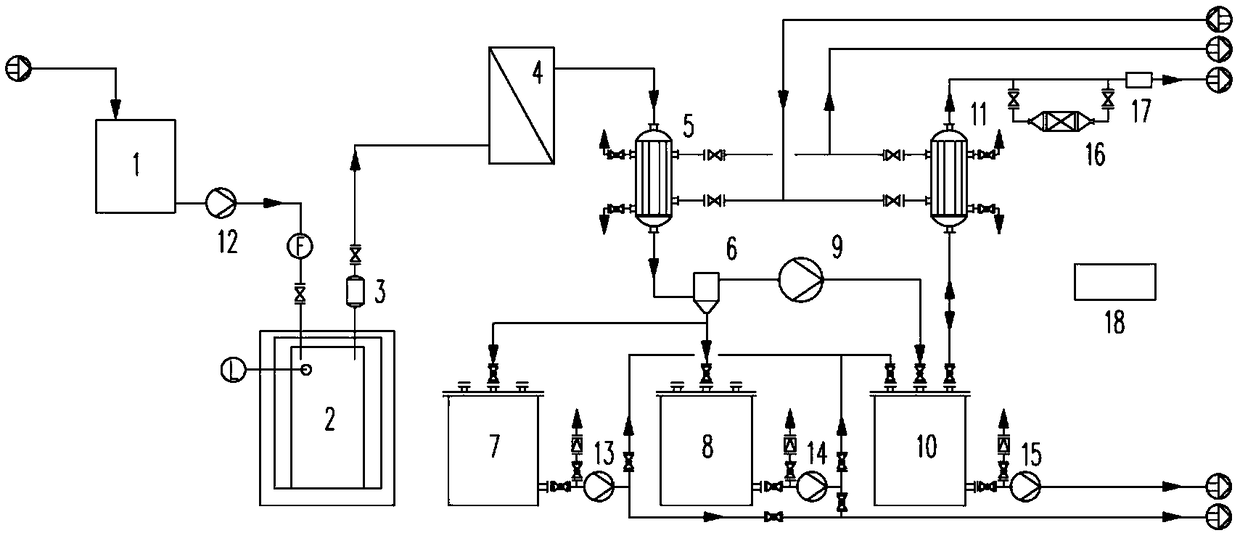

In-barrel vacuum microwave drying system and method for radioactive wet wastes

InactiveCN108630335ADry fastMeet staging criteriaDrying solid materials without heatSludge dryingMicrowaveAtmospheric air

The invention belongs to the technical field of radioactive waste treatment and relates to an in-barrel vacuum microwave drying system and method for radioactive wet wastes. The drying system comprises a drying barrel, a demister, a filter, a condenser, a steam-water separator, a vacuum pump, a tail gas continuous monitoring device and connecting pipelines; the drying barrel is used for drying thewastes by microwave heating; the demister, the filter, the condenser, the steam-water separator and the vacuum pump which are connected in sequence are respectively used for realizing demisting, filtration, condensation, steam-water separation and vacuumizing treatment of evaporated tail gases generated by drying; and the tail gas continuous monitoring device is connected with the condenser and is used for monitoring noncondensable gases in the evaporated tail gases and discharging qualified noncondensable gases into the air by the connecting pipeline connected with an outlet of the tail gascontinuous monitoring device. By using the drying system and method disclosed by the invention, the rapid drying of various radioactive wastes can be realized, new substances are not introduced in a drying process, and the tail gases discharged after being dried almost have no any harmful effects on the environment.

Owner:CHINA NUCLEAR POWER ENG CO LTD

Environment-friendly garbage processor

InactiveCN108325655AReduce pollutionImprove secondary utilizationDomestic plumbingMedical waste disposalElectricityImpeller

The invention discloses an environment-friendly garbage processor including a machine shell, a storage box, a feeding cylinder, a crushing and grinding device, a driving motor, a water supply device,a drainage device, a drying device, a controller and a switch; a sending cylinder is arranged at the center of the upper end of the machine shell, and a feeding cylinder is arranged above the sendingcylinder and is internally provided with an anti-splashing device; the crushing and grinding device jointly consists of a grinding cutterhead, a rotating shaft, a grinding gear ring, cutterhead grinding teeth, a cutting knife and a baffle knife; the water supply device jointly consists of a water supply pipe, a nozzle and a first solenoid valve; the drainage device jointly consists of a drainage plate, a drainage impeller and a drainage pipe; a drain pipe is connected at the bottom of the storage box, a filter plate, an electric heater and an ultraviolet sterilization lamp are arranged in thestorage box, and an exhaust pipe is connected at the top end of the storage box. The environment-friendly garbage processor has the beneficial effects of simple structure and high practicability.

Owner:阚建发

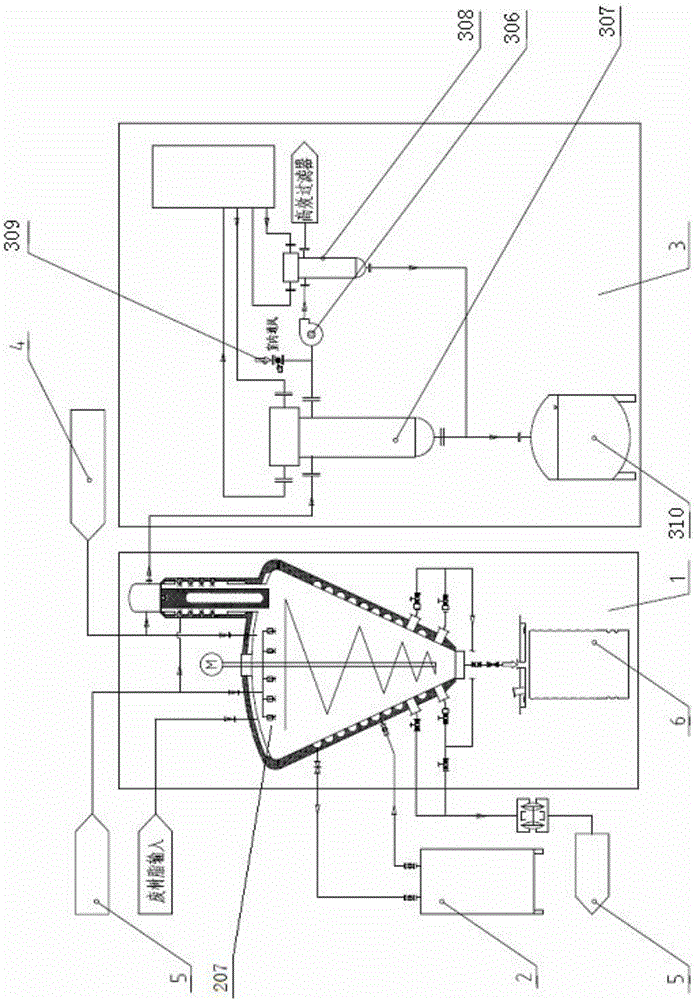

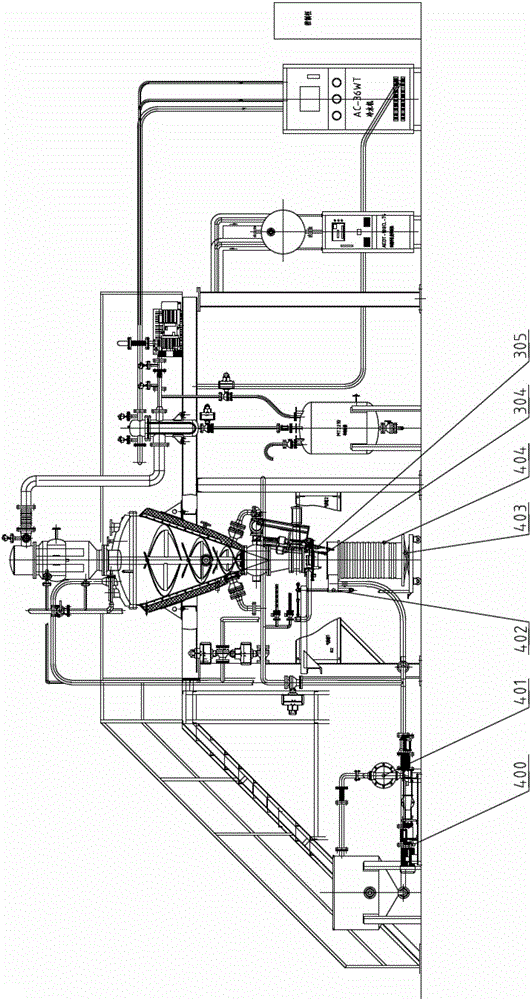

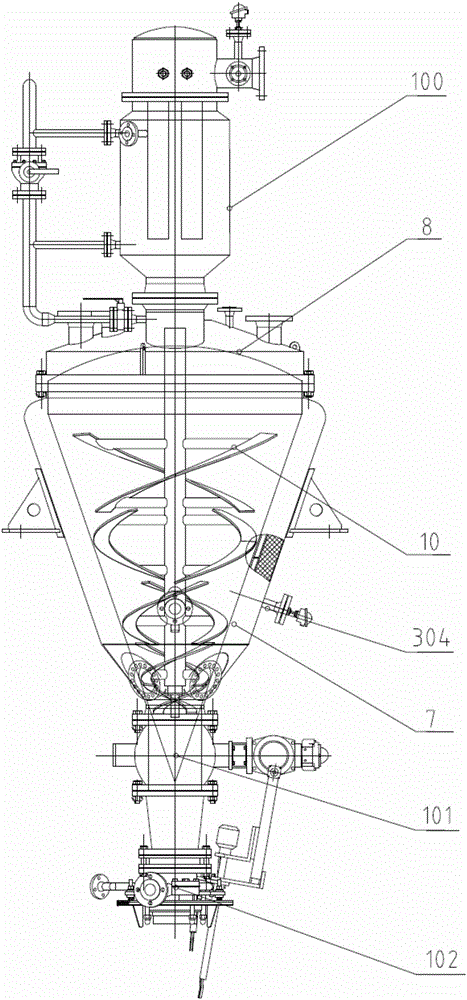

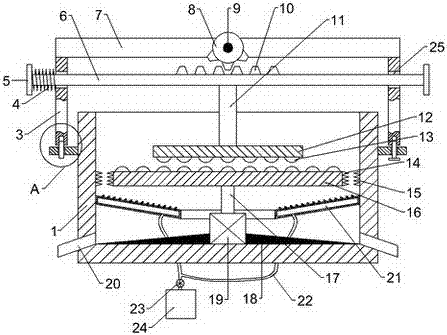

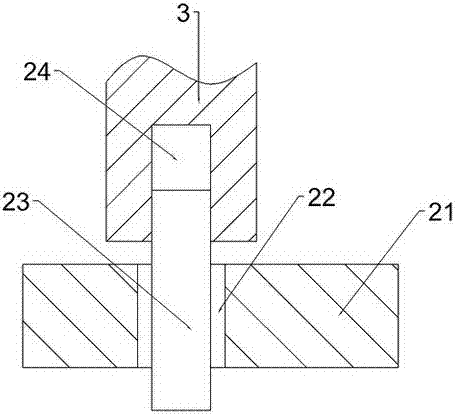

Conic nuclear power plant waste resin drying device

ActiveCN106558352AEvenly heatedReasonable structureDrying solid materials without heatDrying chambers/containersNitrogenEngineering

The invention discloses a conic nuclear power plant waste resin drying device. The conic nuclear power plant waste resin drying device comprises conic dryer body equipment used for waste resin vacuum drying, a hot oil unit used for heating and cooling a conic dryer, an air exhausting and condensation system used for maintaining the vacuum degree in a dryer body and condensing steam, a nitrogen purging system used for protecting the system and washing a washable filter, a washing and dewatering system used for dewatering waste resin and washing system pipelines, and a resin barreling system used for simulating a nuclear island SRTF station. The provided conic nuclear power plant waste resin drying device is safe, reliable, easy to operate and control, reasonable in structure configuration, high in drying efficiency and large in resin volume reduction ratio.

Owner:AEROSUN CORP +1

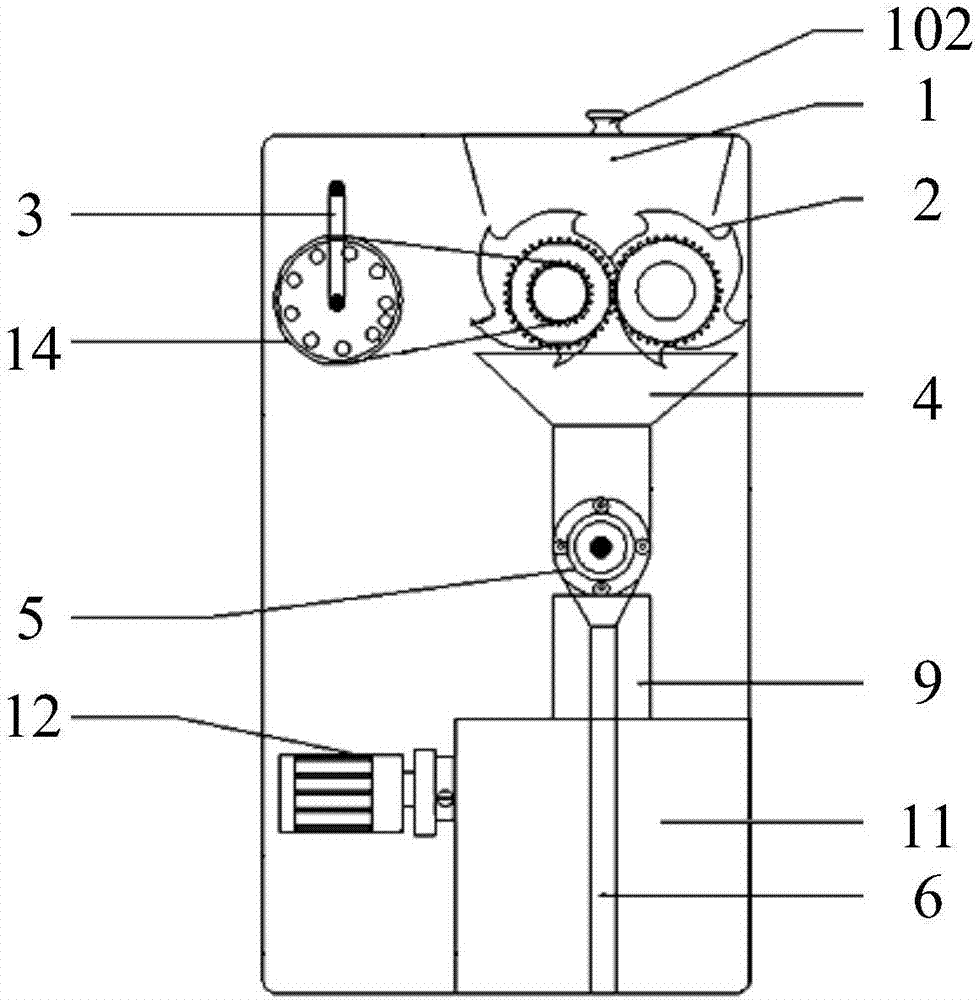

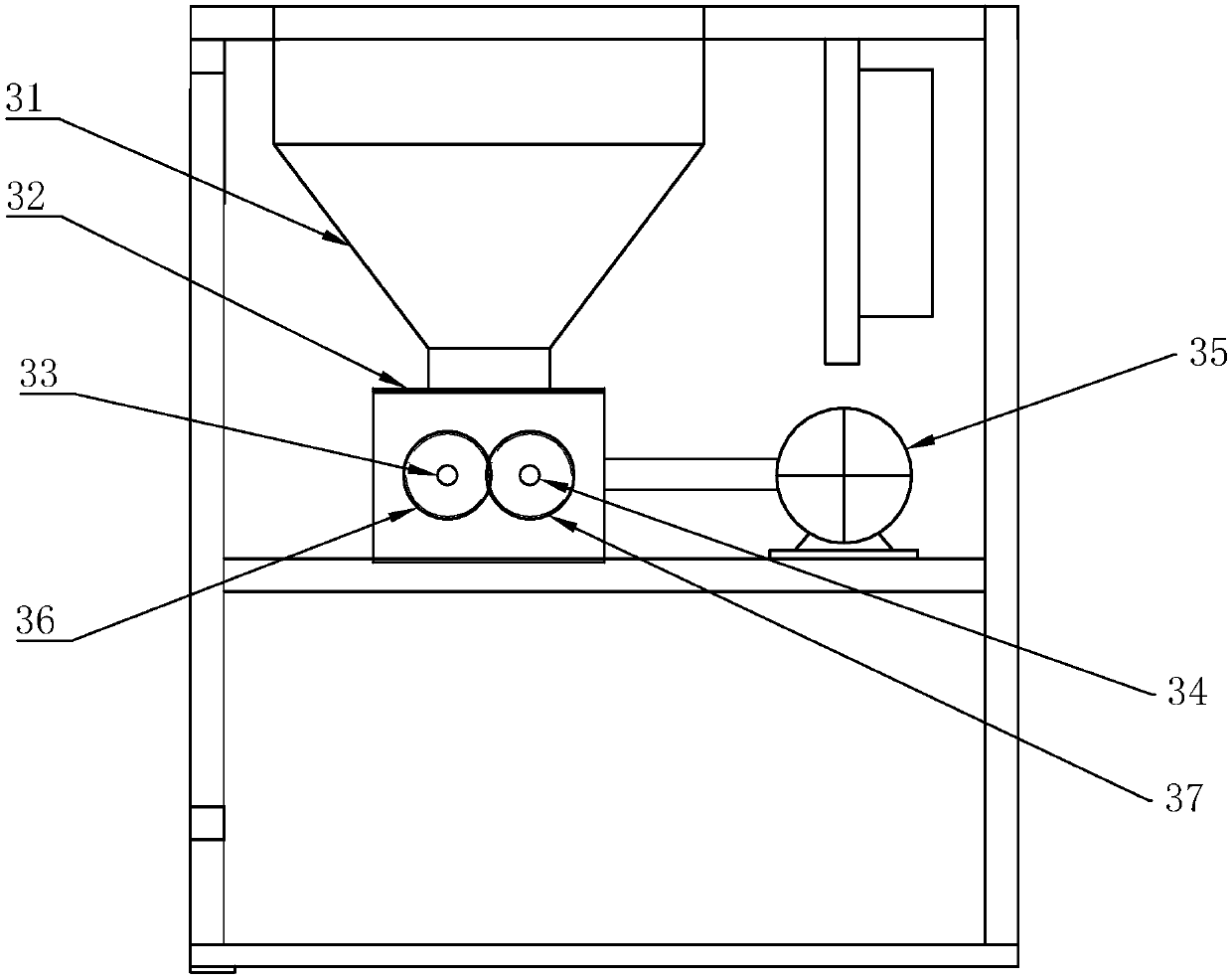

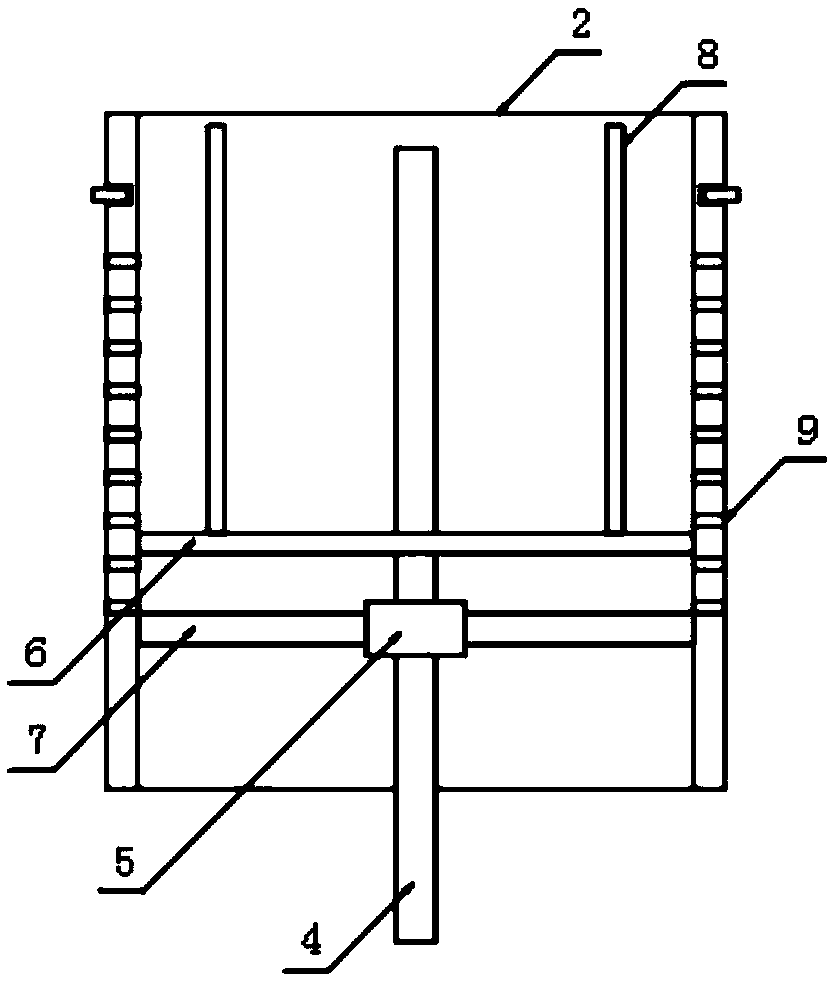

Energy-saving kitchen waste disposal device

InactiveCN107497579ASpacing adjustmentGrinding Particle Size ControlDrying gas arrangementsCocoaEngineeringGear tooth

The invention discloses an energy-saving kitchen waste disposal device. The energy-saving kitchen waste disposal device comprises a frame body; two mounting bases are symmetrically and fixedly connected to the two side walls of the frame body; vertical threaded through holes are formed in the mounting bases; threaded rods are connected in the vertical threaded through holes in a threaded manner; supporting plates are arranged on the upper sides of the mounting bases; threaded grooves with upward openings are formed in the lower portions of the supporting plates; the tops of the threaded rods are connected to the threaded grooves in a threaded manner; through holes are formed in the supporting plates; a rack is arranged in the two through holes together in a suspended manner; baffles are fixedly connected to the two ends of the rack; a reset spring is arranged on the position, between the left side baffle and the left side supporting plate, of the rack in a sleeving manner; a gear tooth section is arranged in the middle section of the rack; the upper sides of gear teeth mesh with a half-toothed gear; a first rotating shaft is fixedly connected to the half-toothed gear; and a fixing plate is fixedly connected to the top ends of the two supporting plates together. The energy-saving kitchen waste disposal device has the advantages of being reasonable in structural design and good in crushing effect, and has a certain popularization and application value.

Owner:ANHUI XINHONG ENVIRONMENTAL PROTECTION EQUIP TECH

Device for conversion of waste to sources of energy or fertilizer and a method thereof

ActiveUS9423178B2Efficient conversation processingHigh materialDrying using combination processesDrying solid materials with heatEnvironmental engineeringWaste treatment

The present invention provides a compact device (that may be installed onto a mobile or stationary platform) for conversion of waste to sources of energy or fertilizer. The device includes multiple stages for efficient conversation and processing of waste into energy or fertilizer, including a first stage for reducing a size of received waste, a second stage for compressing the reduced sized waste into partially dehydrated waste, a third stage for grinding and further compression of received waste from second stage to pulverize the constituent parts into highly dense substantially dehydrated pellets or fertilizers, with a fourth stage for further drying of the received pellets or fertilizers and a final fifth stage for cooling the received pellets or fertilizers into highly dense pellets. The device of the present invention further includes a controller for controlling each operational stage.

Owner:REGREEN TECH INC

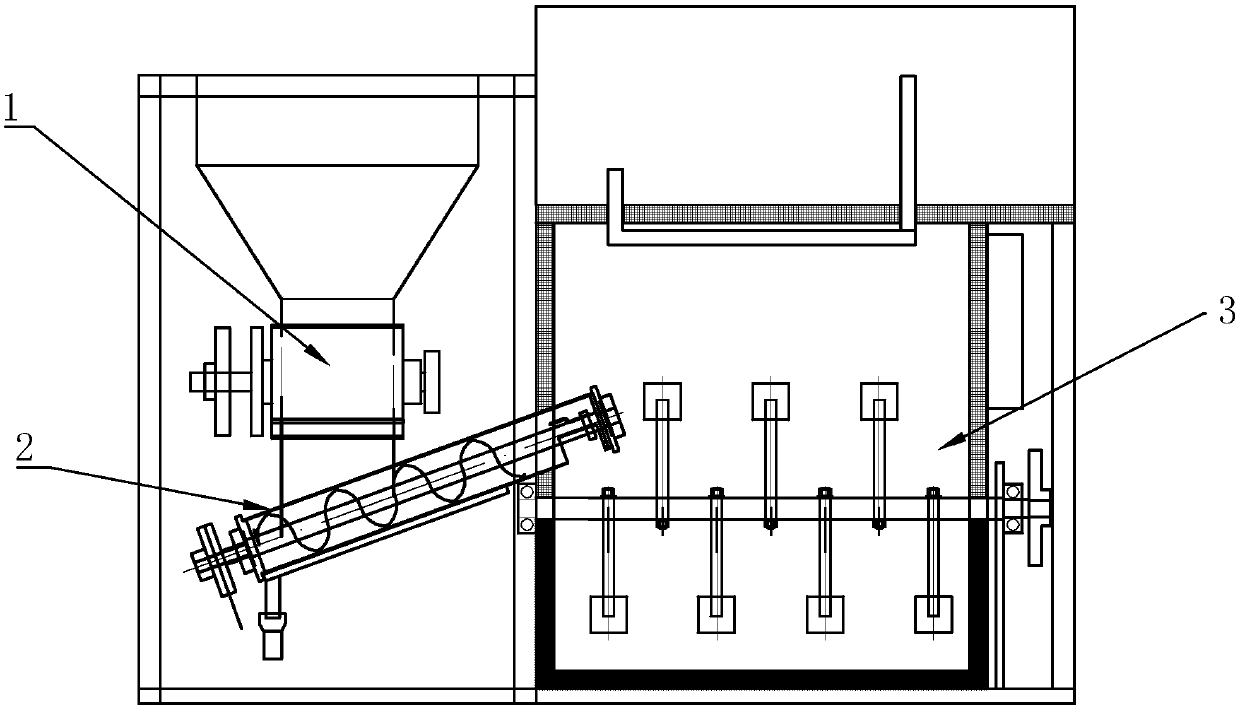

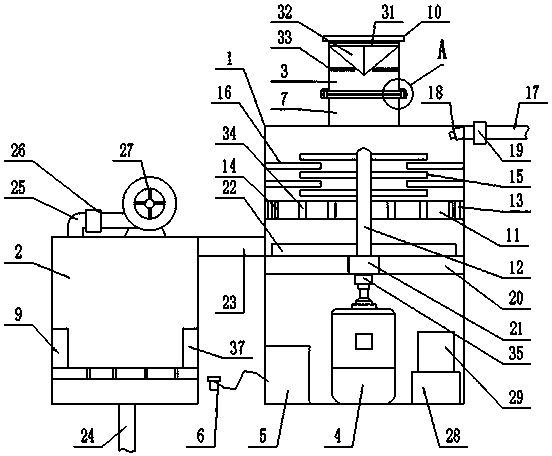

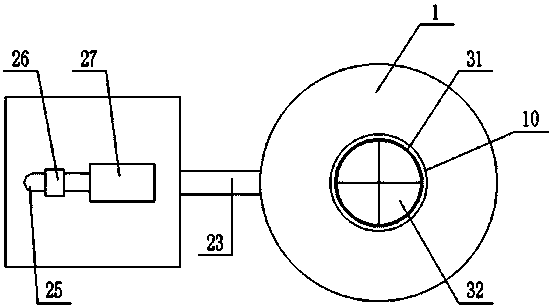

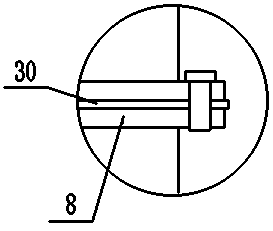

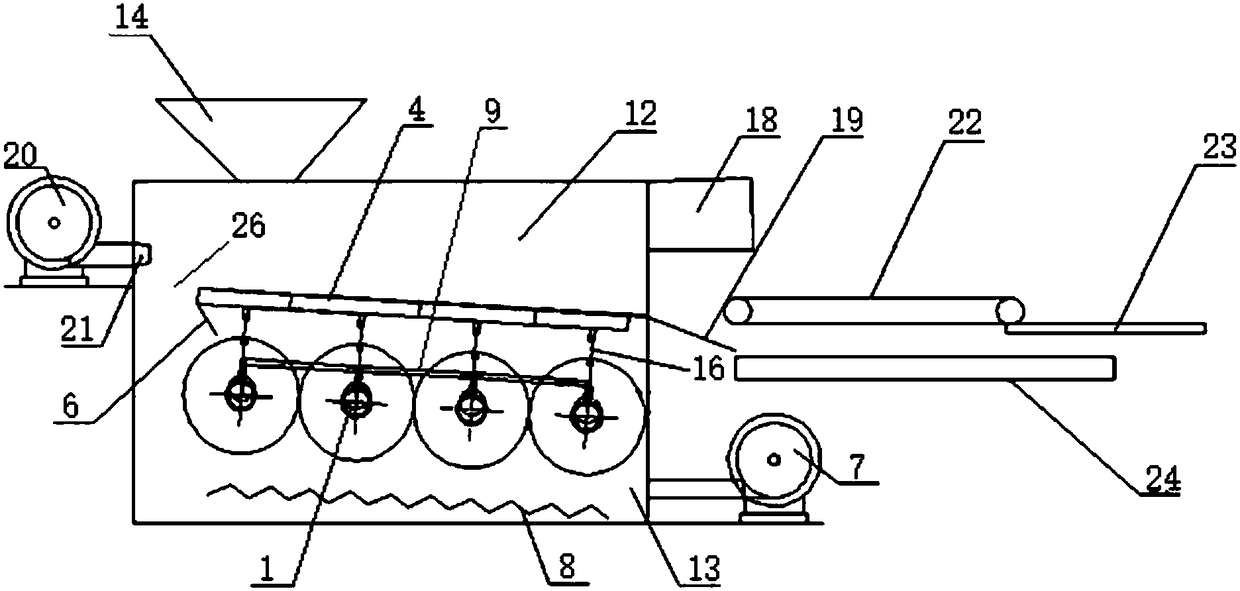

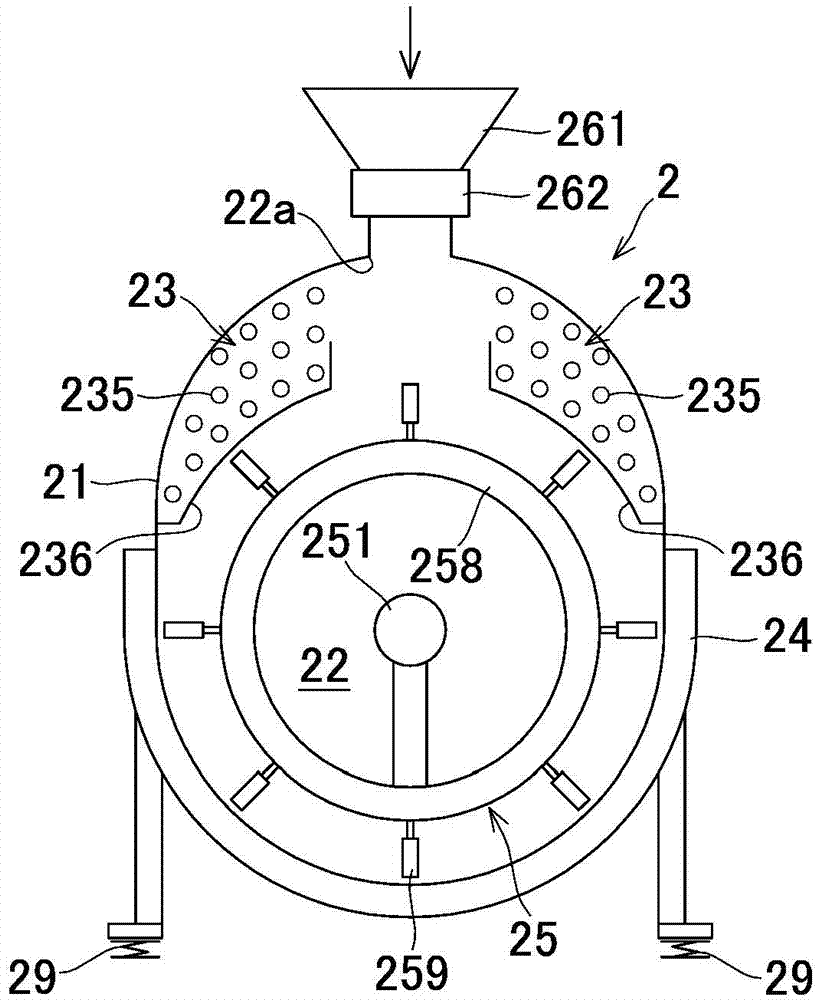

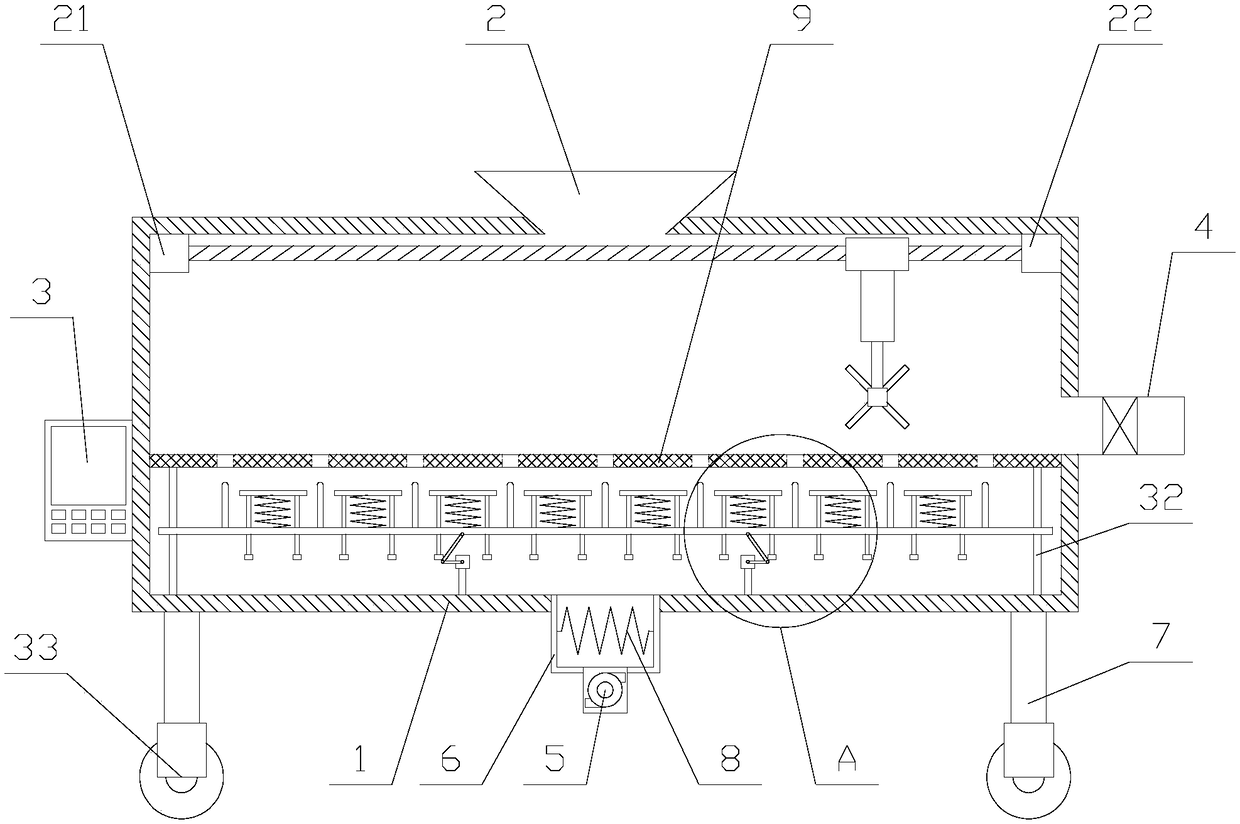

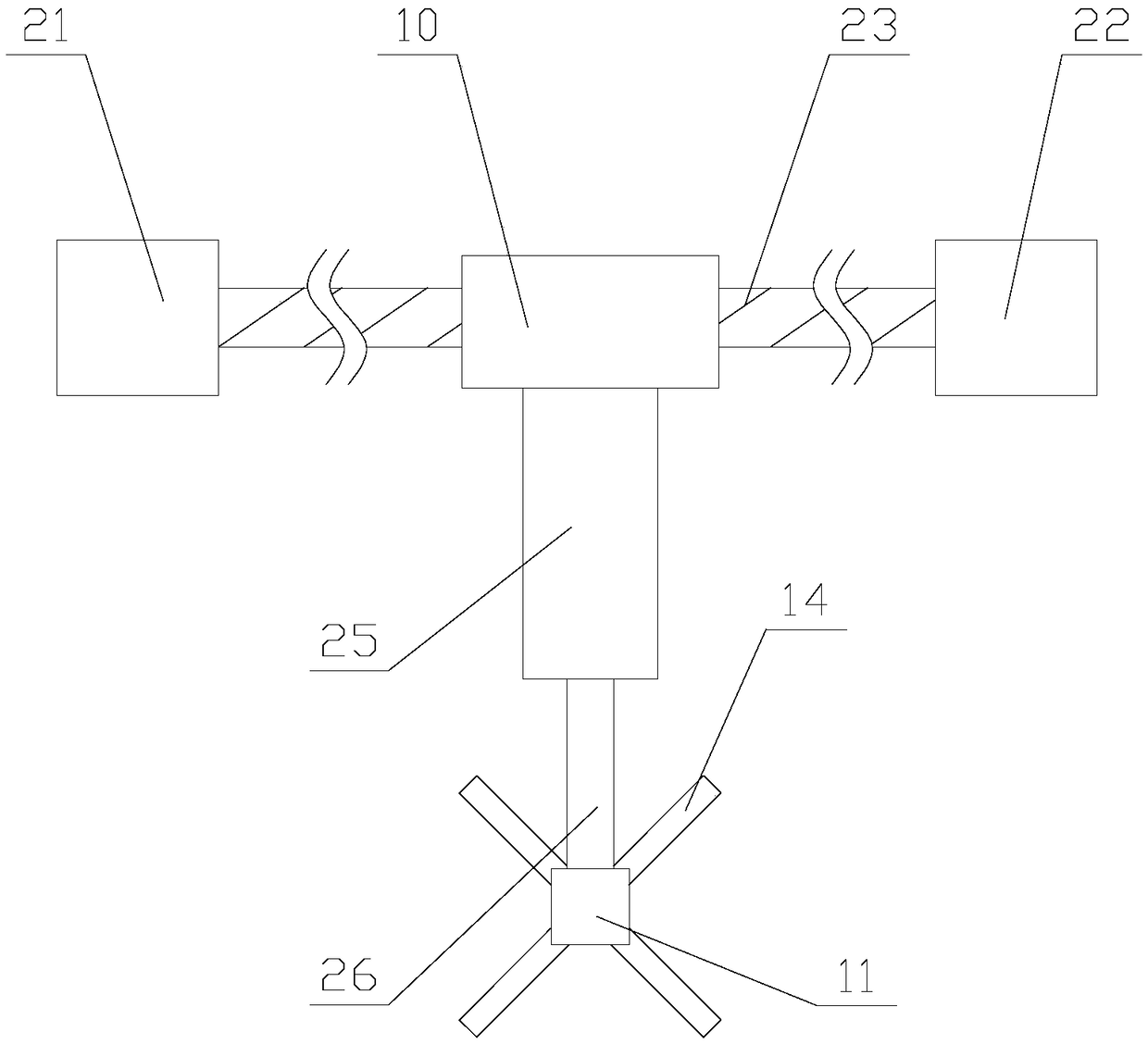

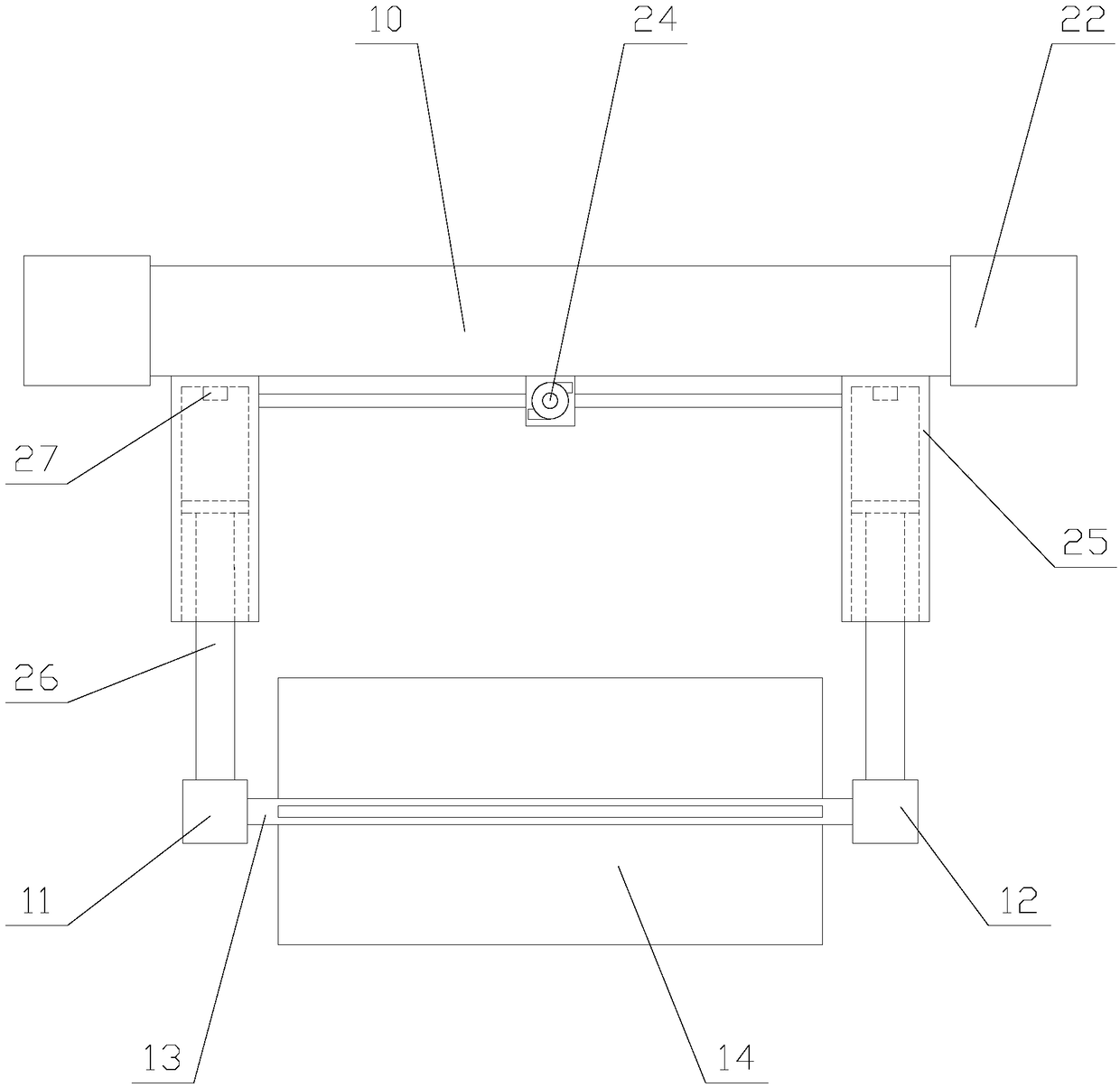

Rotting garbage drying and sorting integrated equipment

ActiveCN108311395AJitter up and down quicklyImprove sorting efficiencyGas current separationDrying gas arrangementsButt jointEngineering

The invention discloses rotting garbage drying and sorting integrated equipment which is internally provided with a conveying panel and a blower system; the conveying panel is obliquely arranged in the equipment and vertically divides the interior of the equipment into a falling material sorting cavity and a drying and heating cavity up and down; the high end of the conveying panel is located below a feed hopper in the equipment; the low end of the conveying panel is in butt joint with a heavy substance discharge port directly; the conveying panel comprises a plurality of unit panels which arearrayed and assembled longitudinally and horizontally; the bottom of each unit panel is connected with a reciprocating lifting driving module; a light substance discharge port is formed in one side,far away from the feed hopper, of the falling material sorting cavity; the blower system comprises an upper blower which is arranged on the other side, close to the feed hopper, in the blank sorting cavity; and the drying and heating cavity is internally provided with a heating component. A technological process of rotting garbage sorting can be shortened effectively, a floor area of the equipmentis reduced, the sorting efficiency of rotting garbage is improved, and the operational stability is improved.

Owner:AEROSPACE KAITIAN ENVIRONMENTAL TECH CO LTD

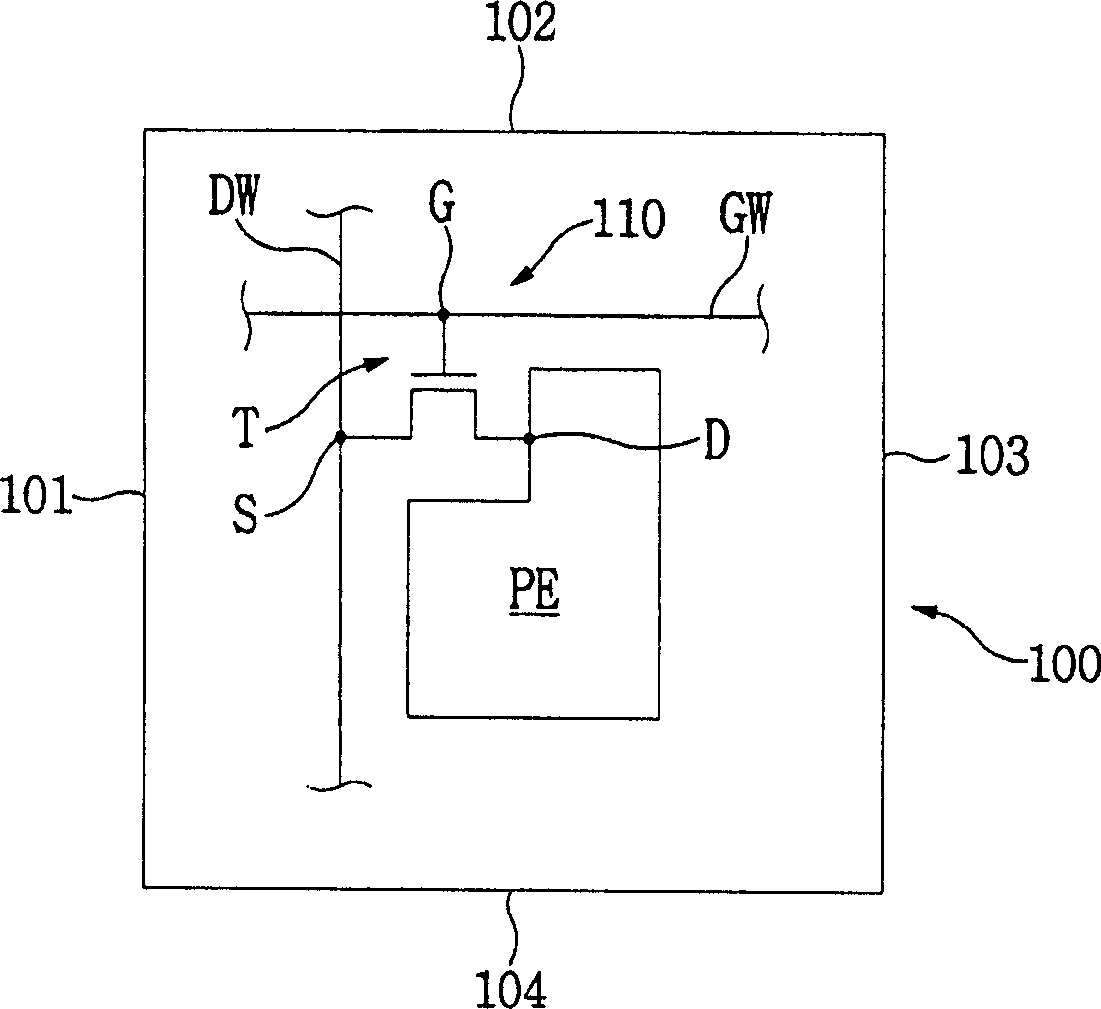

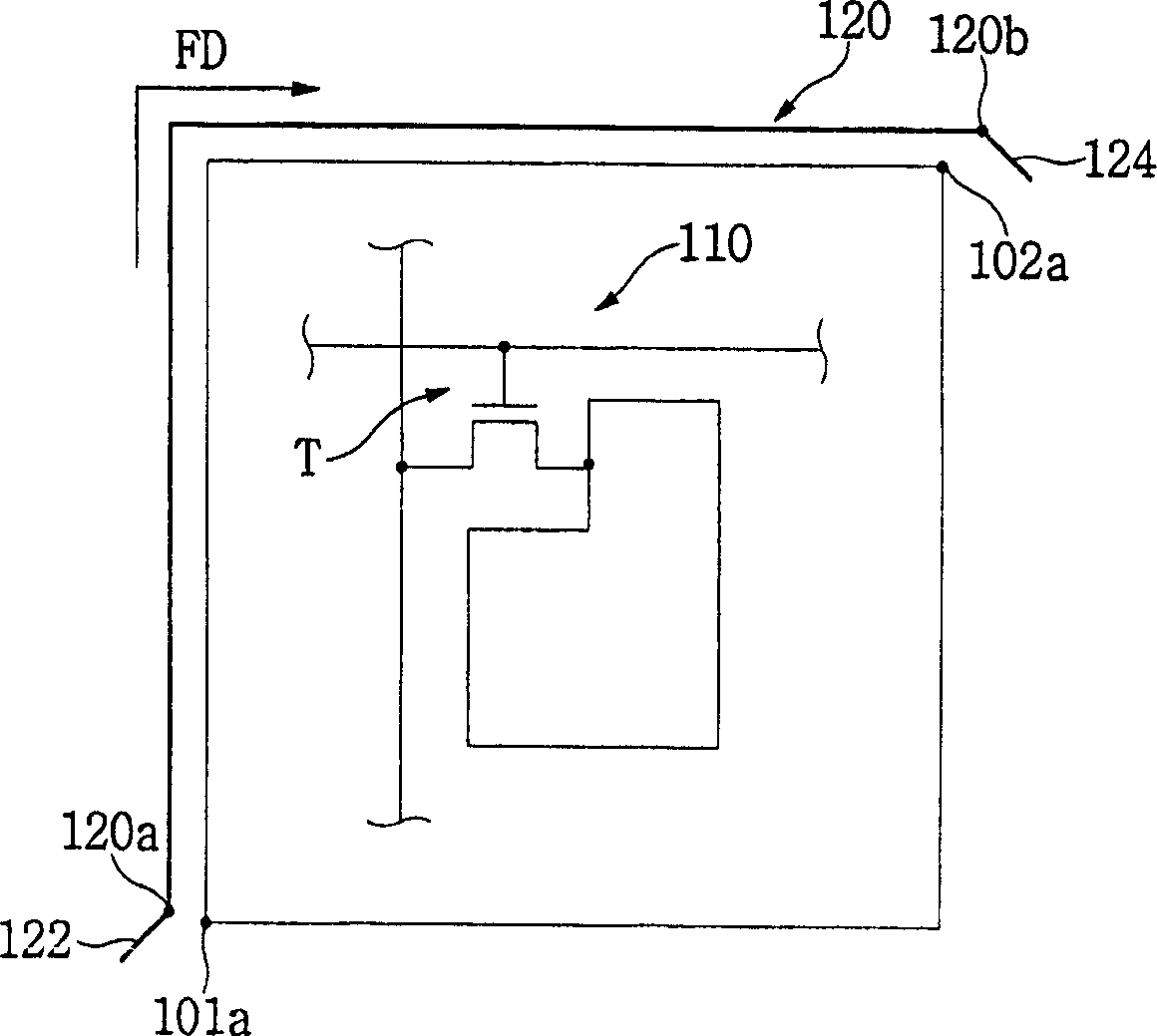

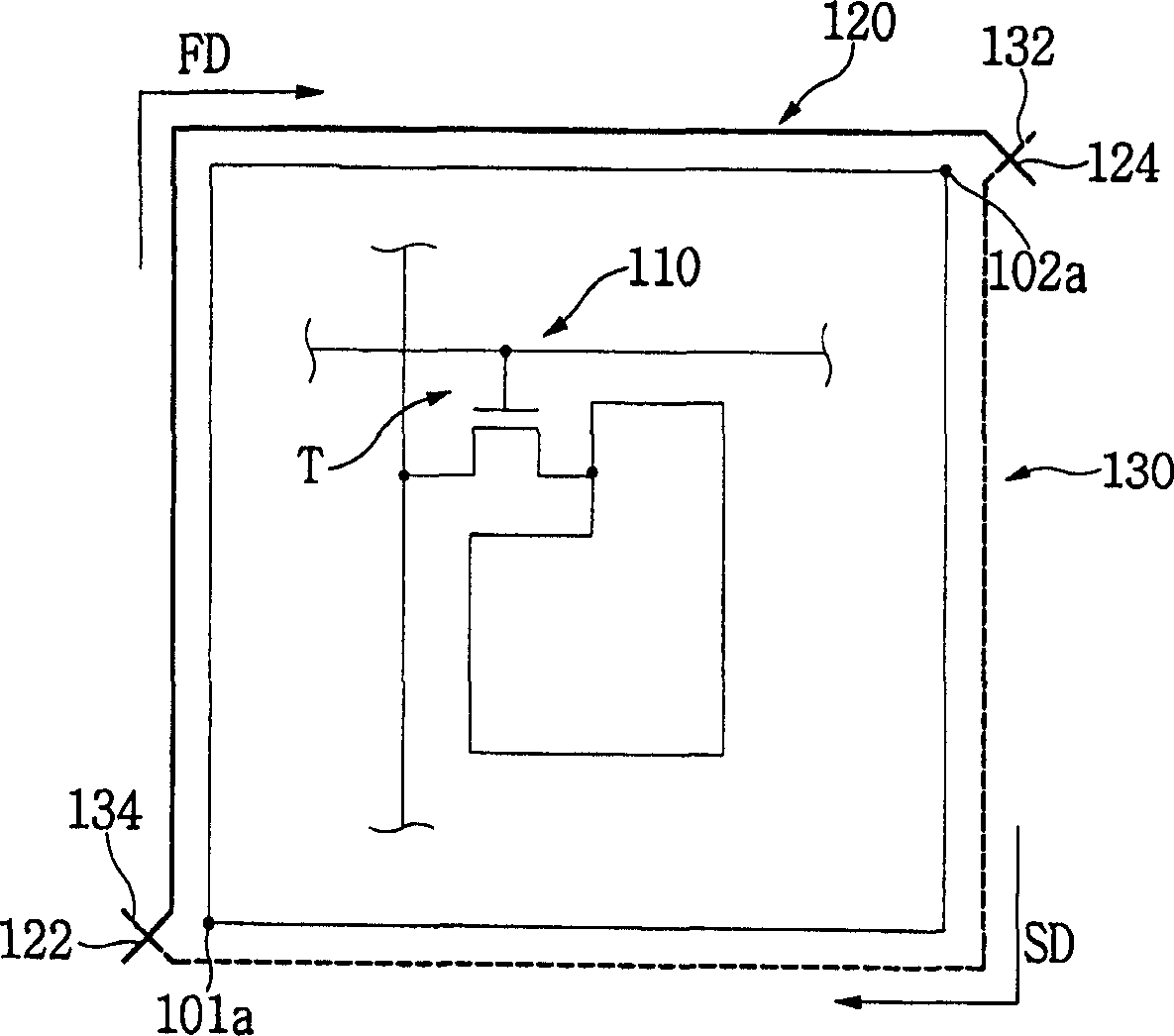

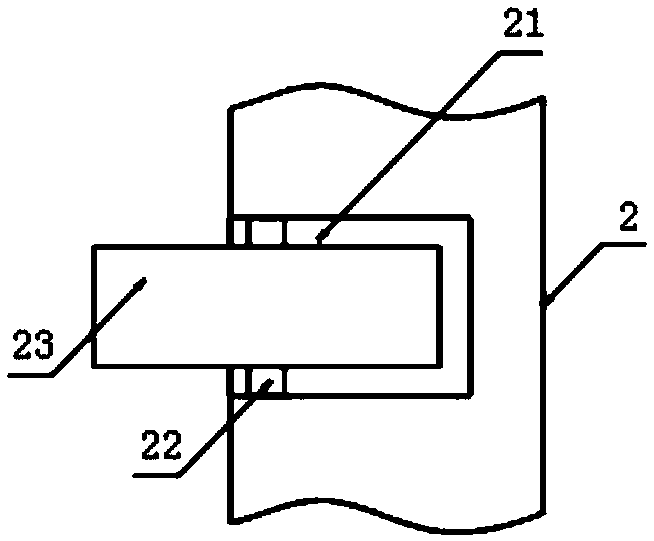

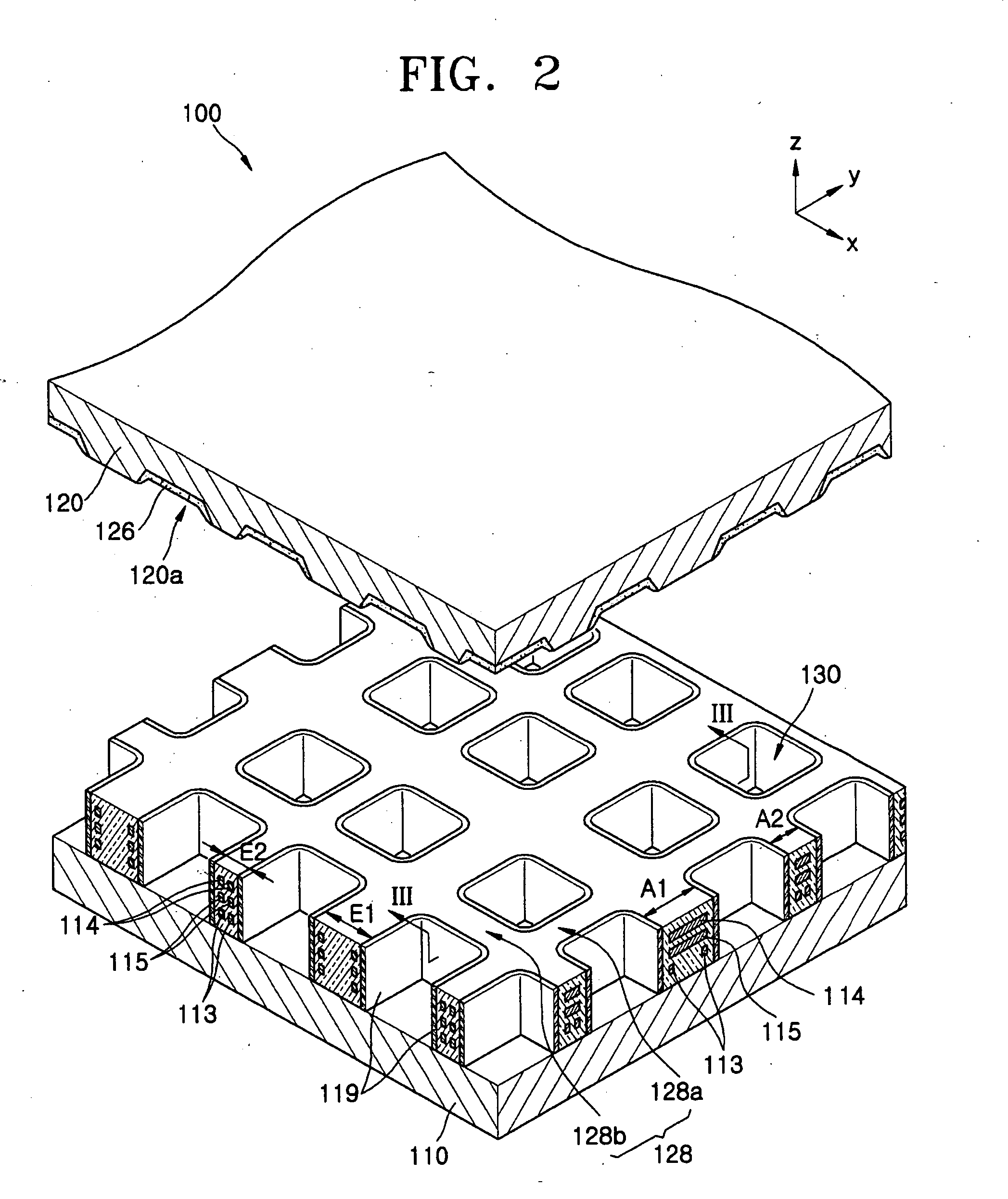

Method and apparatus for forming a sealing member for a display device

ActiveCN1673837ADrying solid materials with heatTransportation and packagingProduction rateDisplay device

A method and apparatus for forming a sealing member includes forming a first sealing part to surround one portion of a display area, the display area including a pixel, and forming a second sealing part to surround a remaining portion of the display area and to intersect ends defining the second sealing part with corresponding ends defining the first sealing part. Thus, a time needed to form the first and second sealing member may be reduced, thereby reducing an entire process time to manufacture the display apparatus. Further, an area needed to form the sealing member may be reduced, thereby enhancing productivity of the display apparatus.

Owner:SAMSUNG DISPLAY CO LTD

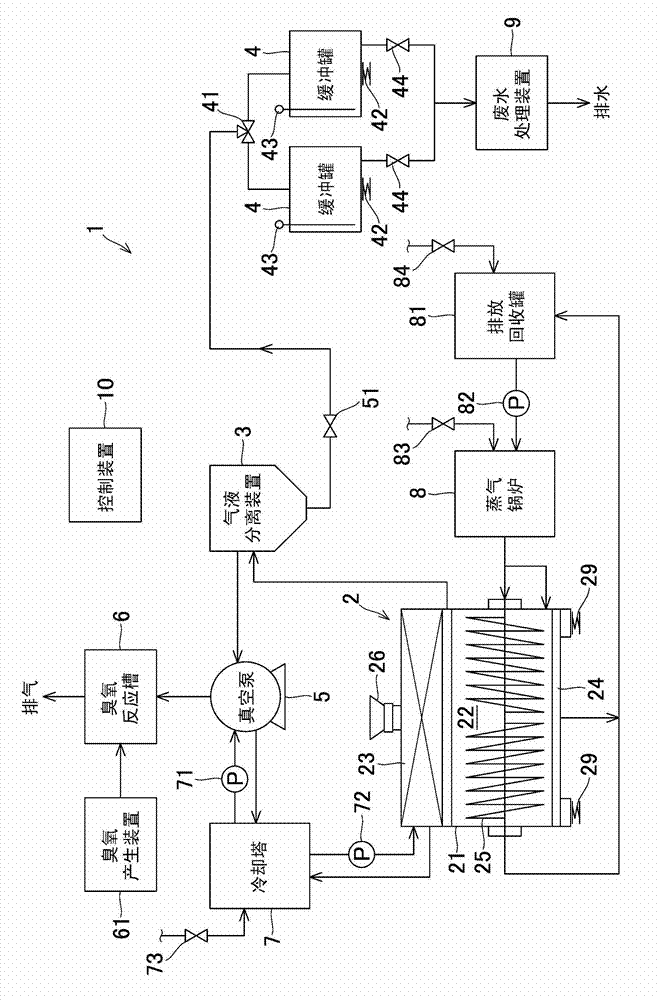

Reduced-pressure fermenting and drying apparatus

InactiveCN103030256AQuick and effective deodorizationQuick and effective dryingLiquid degasificationDrying solid materials with heatProcess engineeringWater vapor condensation

The invention provides a reduced-pressure fermenting and drying apparatus, which can effectively remove odor generated by processed materials, prevent odor from spreading outside and further prevent degradation caused by rotten parts of the processed materials. The reduced-pressure fermenting and drying apparatus comprises a drying machine having a processing chamber where organic processed materials with microorganisms are input; a heating sleeve pipe arranged on the drying machine and heating the processed materials; a heating stirring part configured inside the processing chamber of the drying machine in a way to be capable of rotating and applied for heating and stirring processed materials; a condensing part condensing moistures generated from organic wastes to generate condensed water; a gas-liquid separation device guiding the mixture of the condensed water in the condensing part and the air in the processing chamber and further separating the guided mixture into condensed water and air; and an absorption pump connected with the downstream side of the gas-liquid separation device and absorbing condensed water in the condensing part and the air in the processing chamber towards the gas-liquid separation device.

Owner:MIIKE TEKKOSHA KK JP

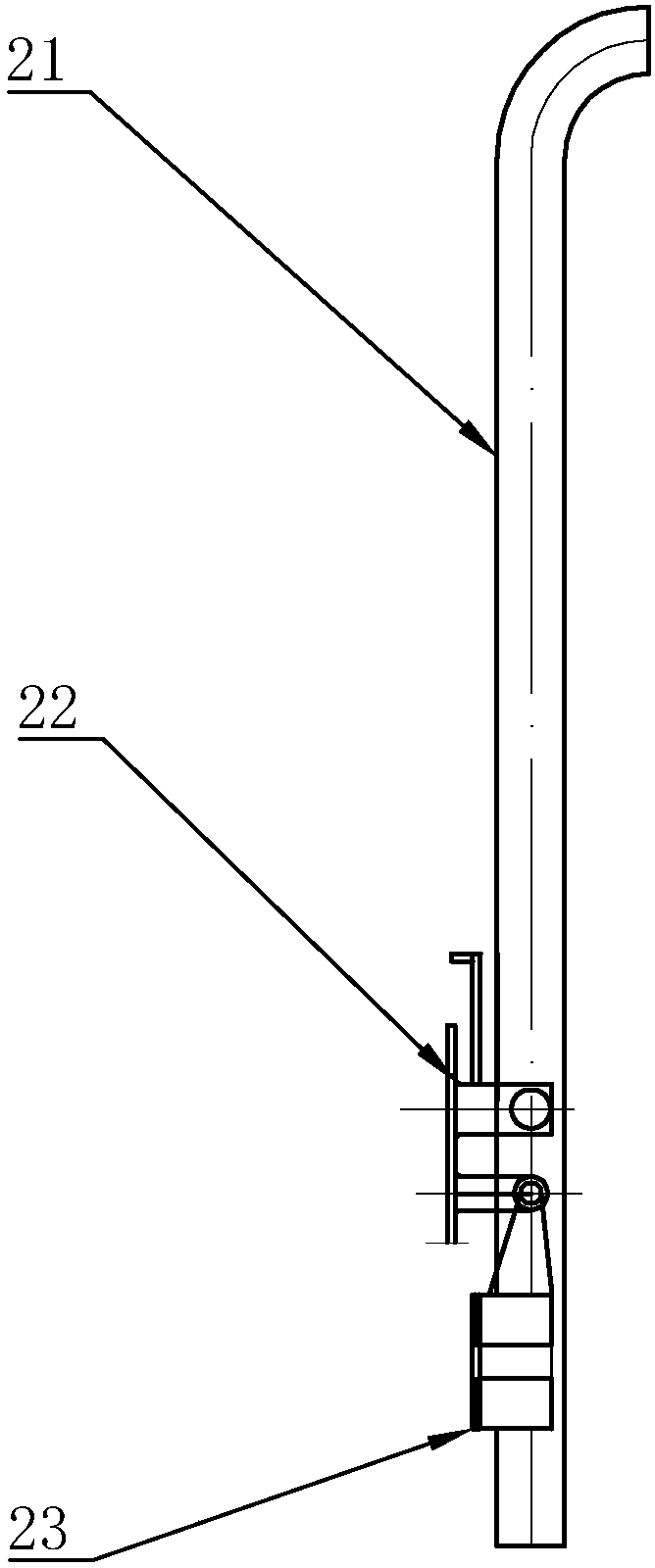

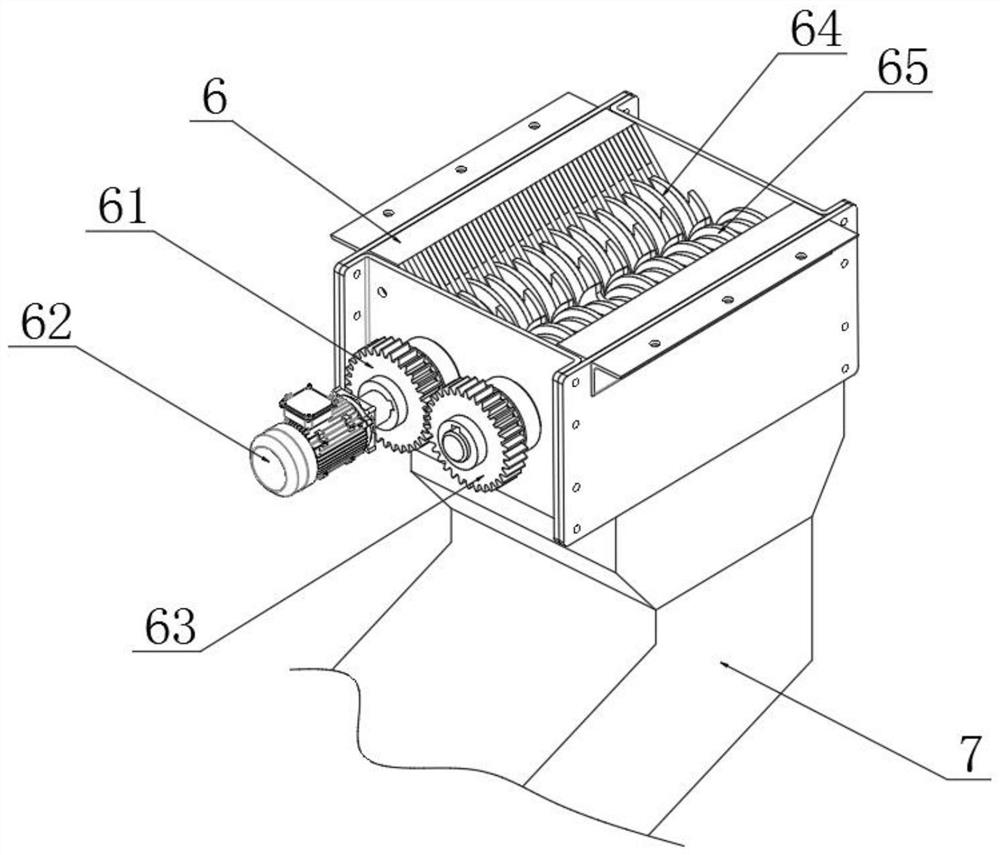

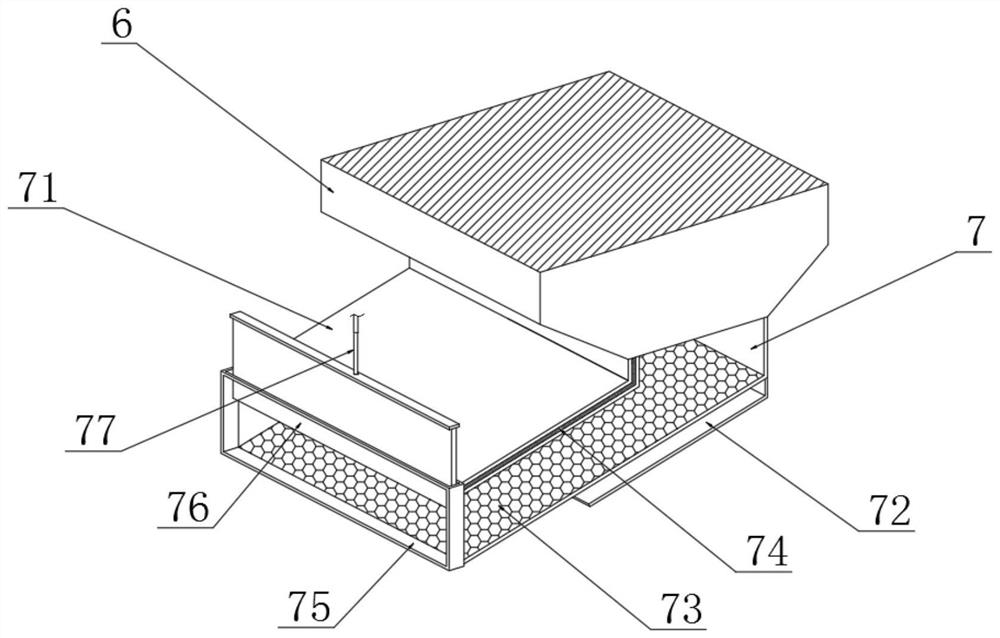

Kitchen waste pretreatment device

InactiveCN110524932ARealize extrusion dehydrationAchieve smashDrying solid materials without heatDrying gas arrangementsWater leakageSpiral blade

The invention discloses a kitchen waste pretreatment device. The kitchen waste pretreatment device comprises a shell, a dehydration barrel is arranged in the shell, and a water leakage net is embeddedat the lower portion of the dehydration barrel. A spiral blade roller is arranged in the dehydration barrel, an extrusion plate is arranged at the right side of the spiral blade roller and is connected with a reciprocating mechanism, the right side of the dehydration barrel communicates with a discharging pipe, and the discharging pipe communicates with a drying cylinder. Through the arrangementof the dehydration barrel, the water leakage net, the water collection cover and the extrusion plate connected with the reciprocating mechanism, the extrusion and dehydration of the kitchen waste is achieved, and the dehydration efficiency is improved. By arranging a hollow rotating shaft provided with the air spraying heads, the kitchen waste is rapidly and evenly dried, and the drying efficiencyis improved. By arranging the extrusion holes and the crushing cutters, the kitchen waste is further crushed, and the follow-up processing and transportation are facilitated.

Owner:唐红艳

Kitchen garbage treatment device with deodorization mechanism

InactiveCN111672872ARealize intelligent processingAvoid spillingTransportation and packagingSolid waste disposalEngineeringProcess engineering

The invention relates to the technical field of household waste treatment, and discloses a kitchen garbage treatment device with a deodorization mechanism. The kitchen garbage treatment device comprises a base and a box body arranged at the upper end of the base, and further comprises an automatic induction mechanism, a crushing mechanism, a solid-liquid separating mechanism, an oil-water separating mechanism, a solid garbage treatment mechanism and a deodorization board, wherein the middle part of the box body is perpendicularly provided with a partition plate. The kitchen garbage treatment device adopts an automatic induction type charge hole design, is quick in garbage adding, adopts an integrated design of a heating bin, a separating bin and a crushing bin, realizes solid-liquid separation, oil-liquid separation and crushing treatment of the kitchen garbage, also realizes primary drying treatment on solid garbage, can realize secondary drying treatment on the solid garbage throughthe effect of enabling the solid treatment bin with a pressure plate, and also can increase a space utilization rate of a solid storage bin. The design adopts multi-mechanism integrated design, realizes intelligent treatment on kitchen garbage, saves time and labor, and is high in treatment efficiency.

Owner:沃杰(北京)科技有限公司

Efficient centrifugal dehydrator and method

PendingCN109163527AFast and efficient dehydration treatmentAvoid spillingDrying solid materials without heatDrying machines with non-progressive movementsFiltrationEngineering

The invention discloses an efficient centrifugal dehydrator and a method. The dehydrator comprises a shell. An inner container is arranged inside the shell, and a top cover is arranged at the top of the shell. A lead screw is arranged inside the inner container. The outer side of the lead screw is sleeved with a connecting block and an extrusion disc. The connecting block is fixedly connected withthe lead screw. The extrusion disc is in threaded connection with the lead screw. Connecting rods are arranged on the outer side of the connecting block. One ends of the connecting rods are fixedly connected with the connecting block, and the other ends of the connecting rods are fixedly connected with the inner container. Limit rods are arranged at the top of the extrusion disc. Filtration poresare formed in the side wall of the inner container in a penetrating mode. A limit block is arranged at the bottom of the top cover. Limit grooves are formed in the bottom of the limit block. By meansof the efficient centrifugal dehydrator and the method, kitchen garbage can be fast and efficiently dehydrated, residual water in the kitchen garbage is prevented from being splashed out during subsequent dumping, the design is reasonable, application is convenient, and the practicability is high.

Owner:大连翼方科技有限公司

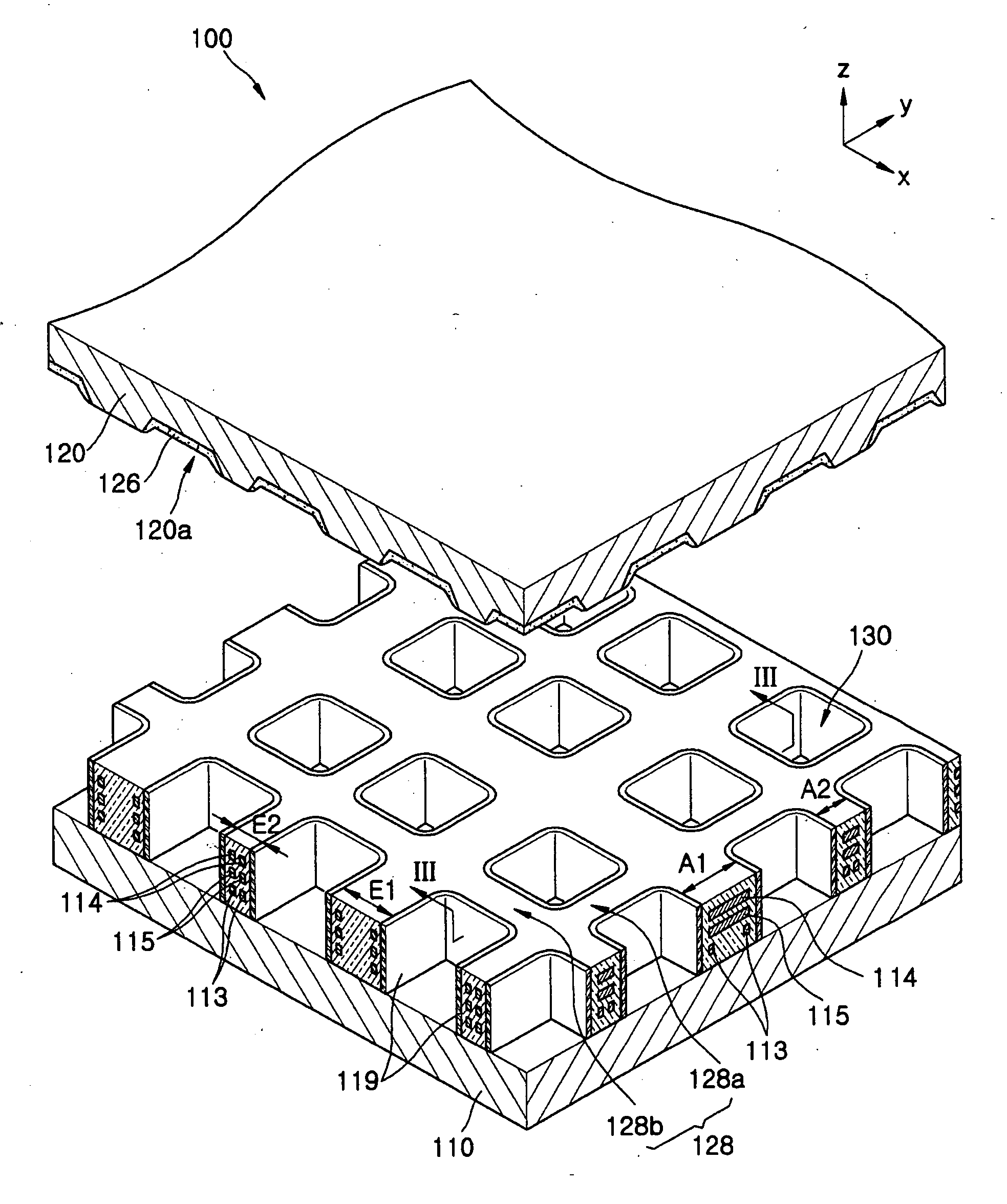

Plasma display panel

InactiveUS20060238123A1Simple designImprove luminous efficiencyAddress electrodesSustain/scan electrodesPhosphorEngineering

Provided is a plasma display panel including a rear substrate, a front substrate separated from the rear substrate, a plurality of barrier ribs arranged between the front substrate and the rear substrate and adapted to define a plurality of discharge cells corresponding to a plurality of sub-pixels, a plurality of sustain electrode pairs comprising a plurality of first discharge electrodes and a plurality of second discharge electrodes extending parallel to each other and surrounding ones of the plurality of discharge cells, the plurality of sustain electrode pairs being adapted to generate a discharge, a plurality of address electrodes extending and surrounding the plurality of discharge cells and arranged in a direction that crosses the plurality of sustain electrode pairs, a plurality of phosphor layers arranged within the plurality of discharge cells and a discharge gas arranged within the plurality of discharge cells, wherein a predetermined number of sub-pixels form a unit pixel, and unit pixels adjacent to each other in a direction are spaced apart from each other by a predetermined distance.

Owner:SAMSUNG SDI CO LTD

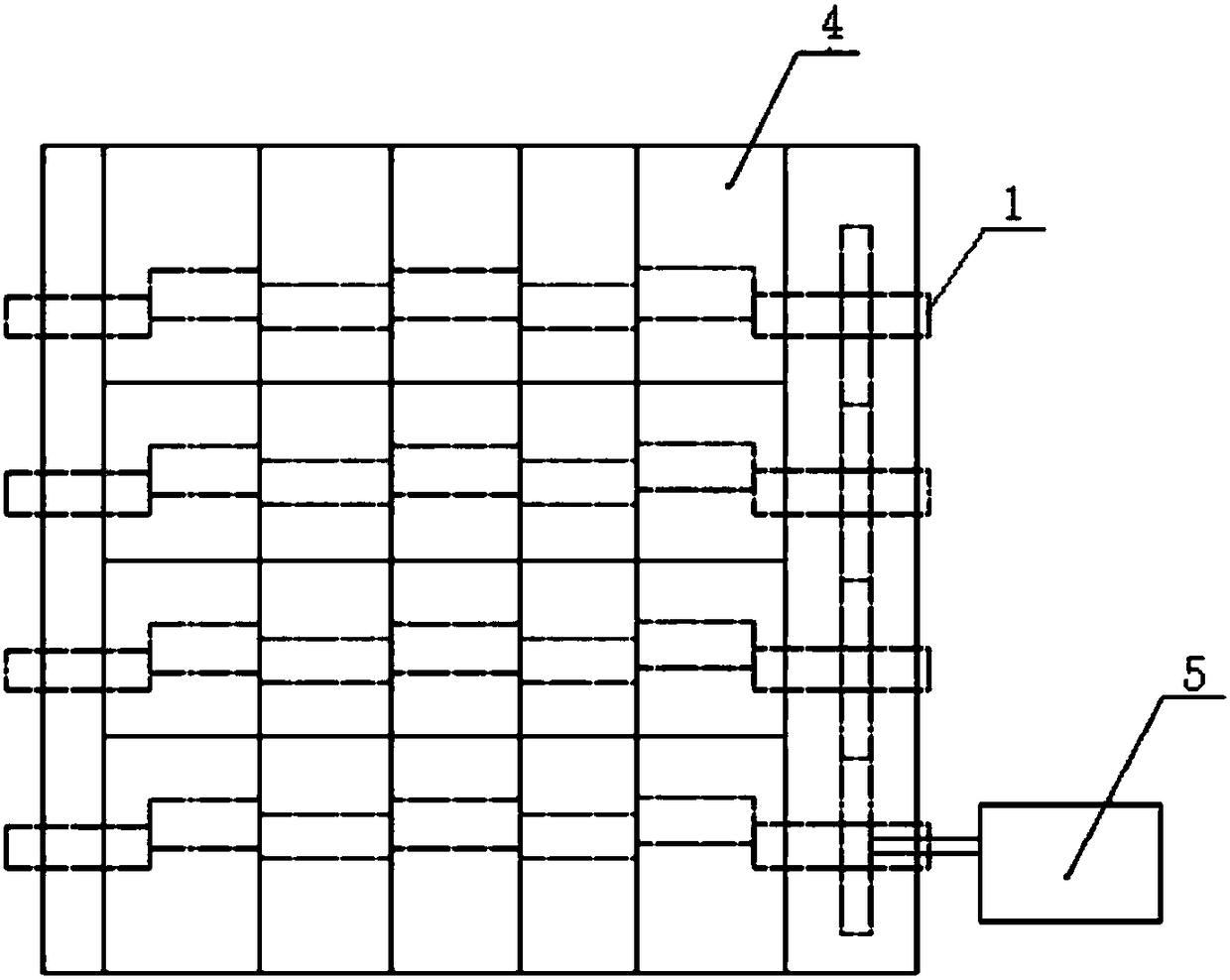

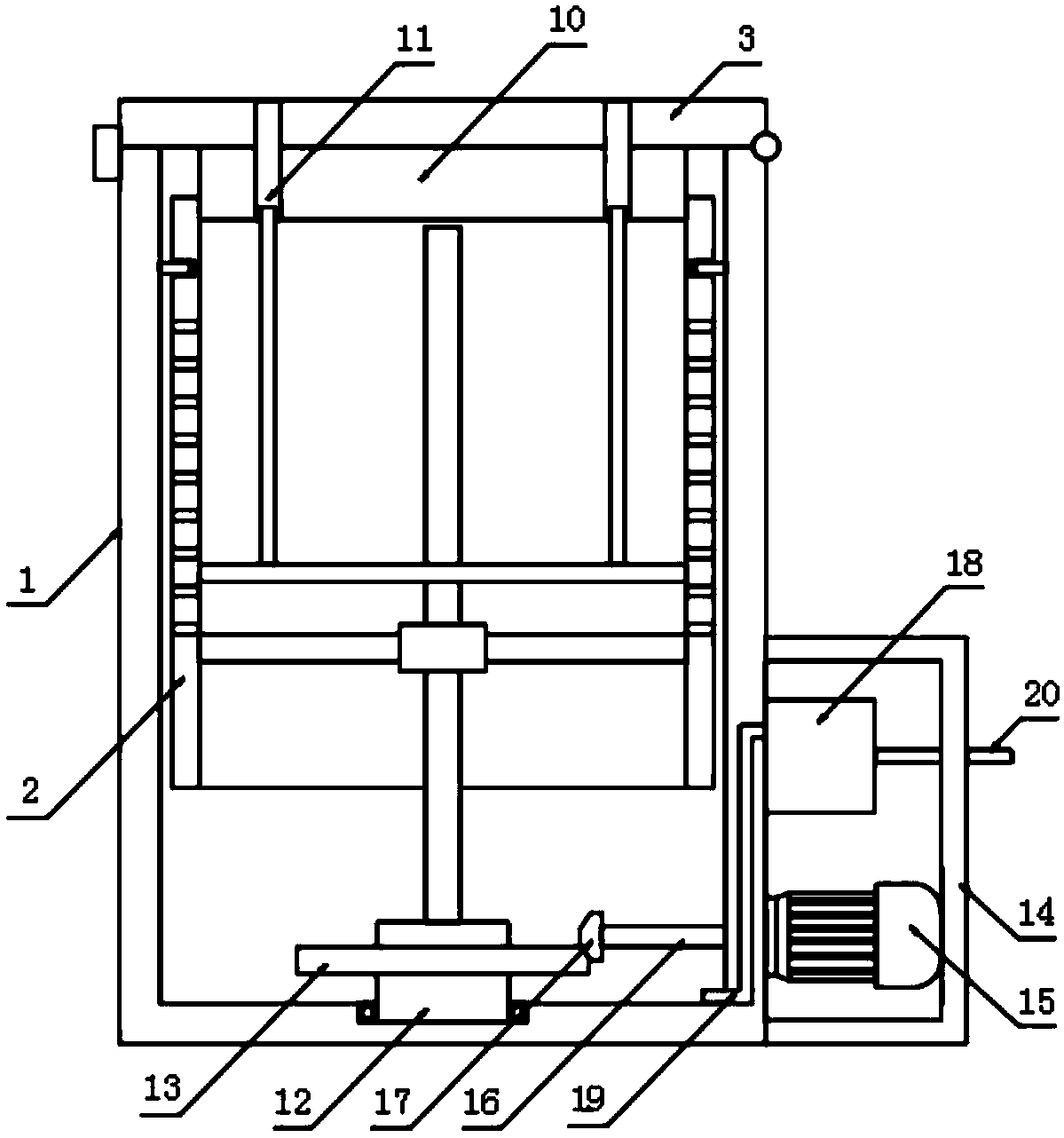

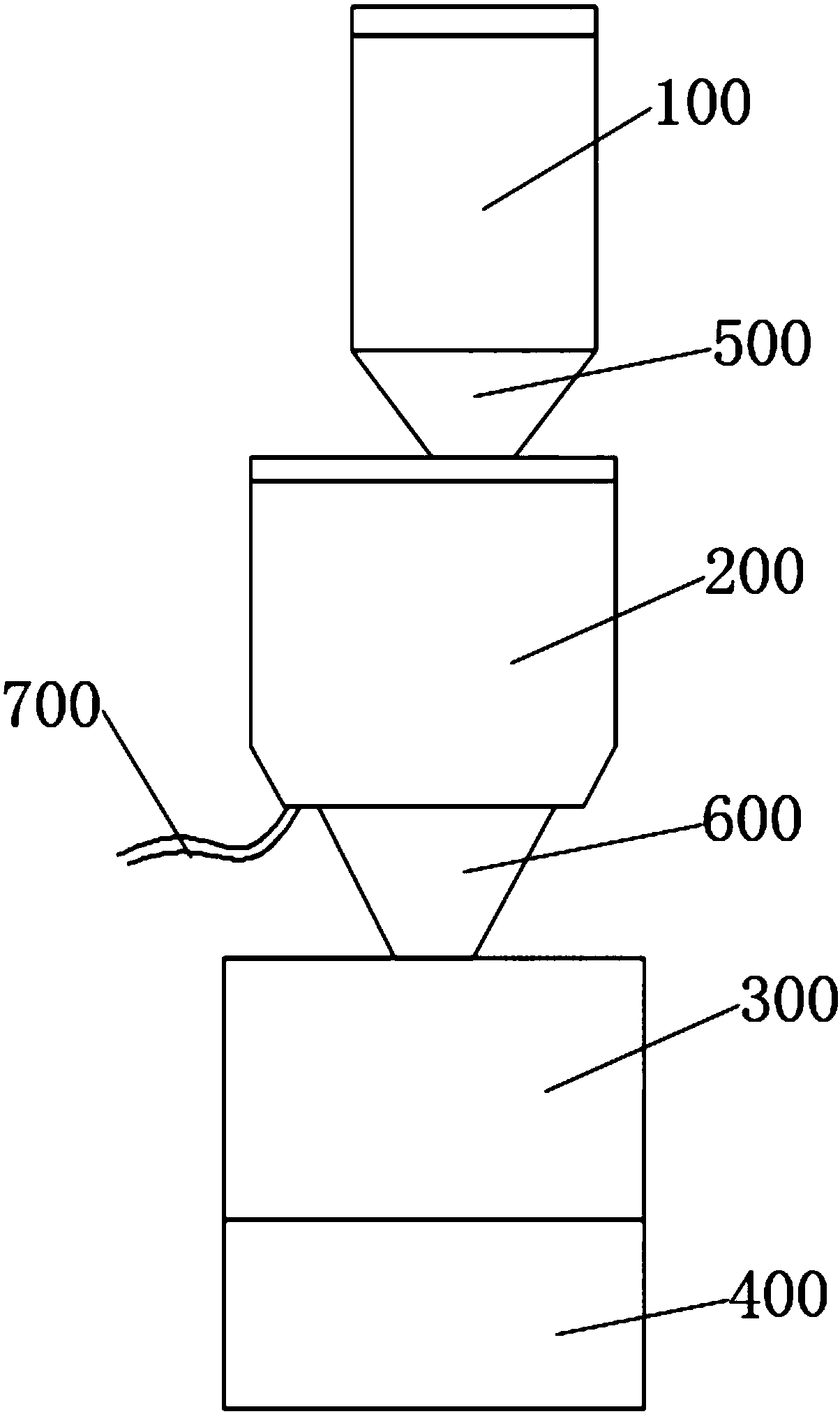

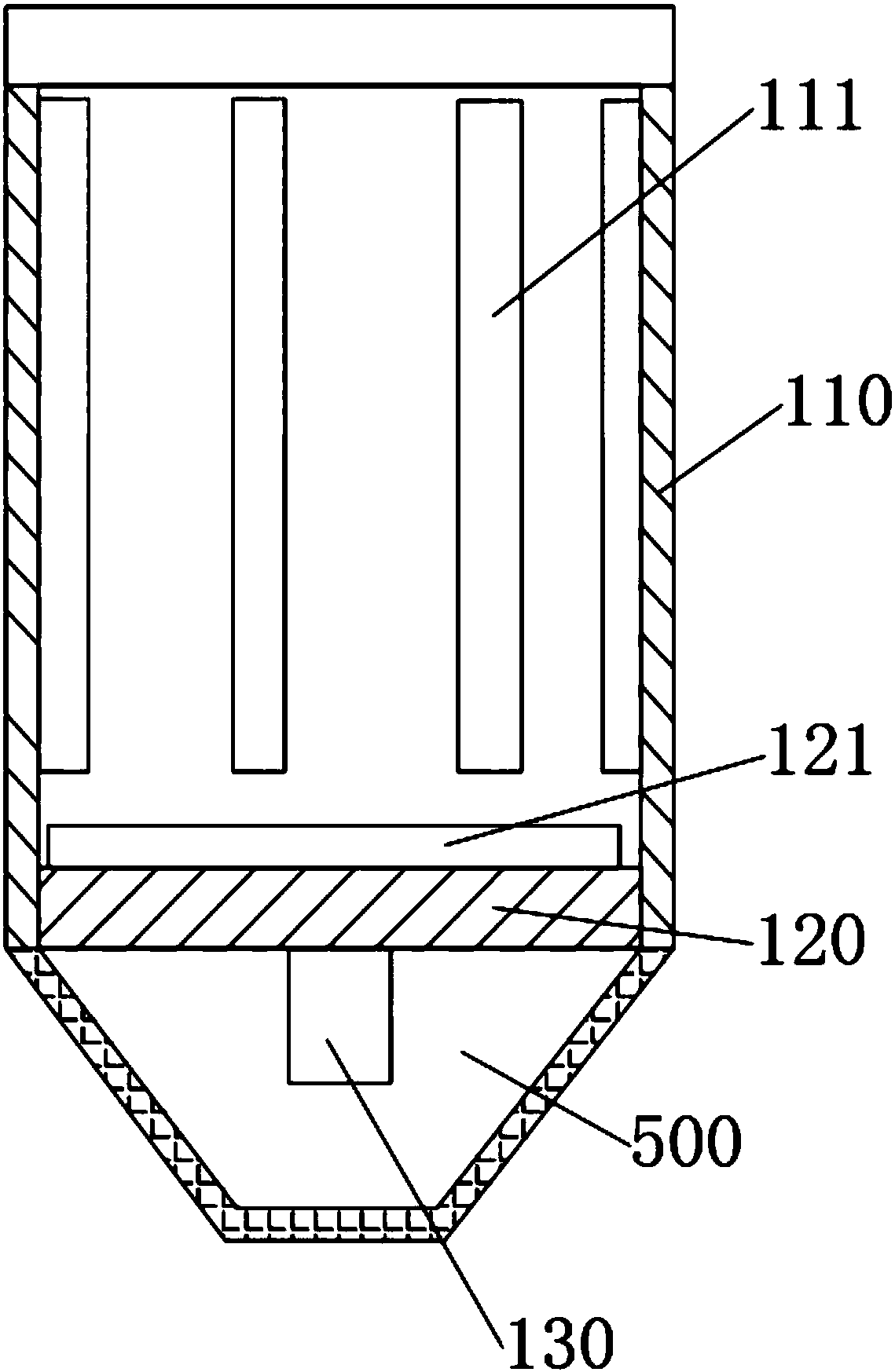

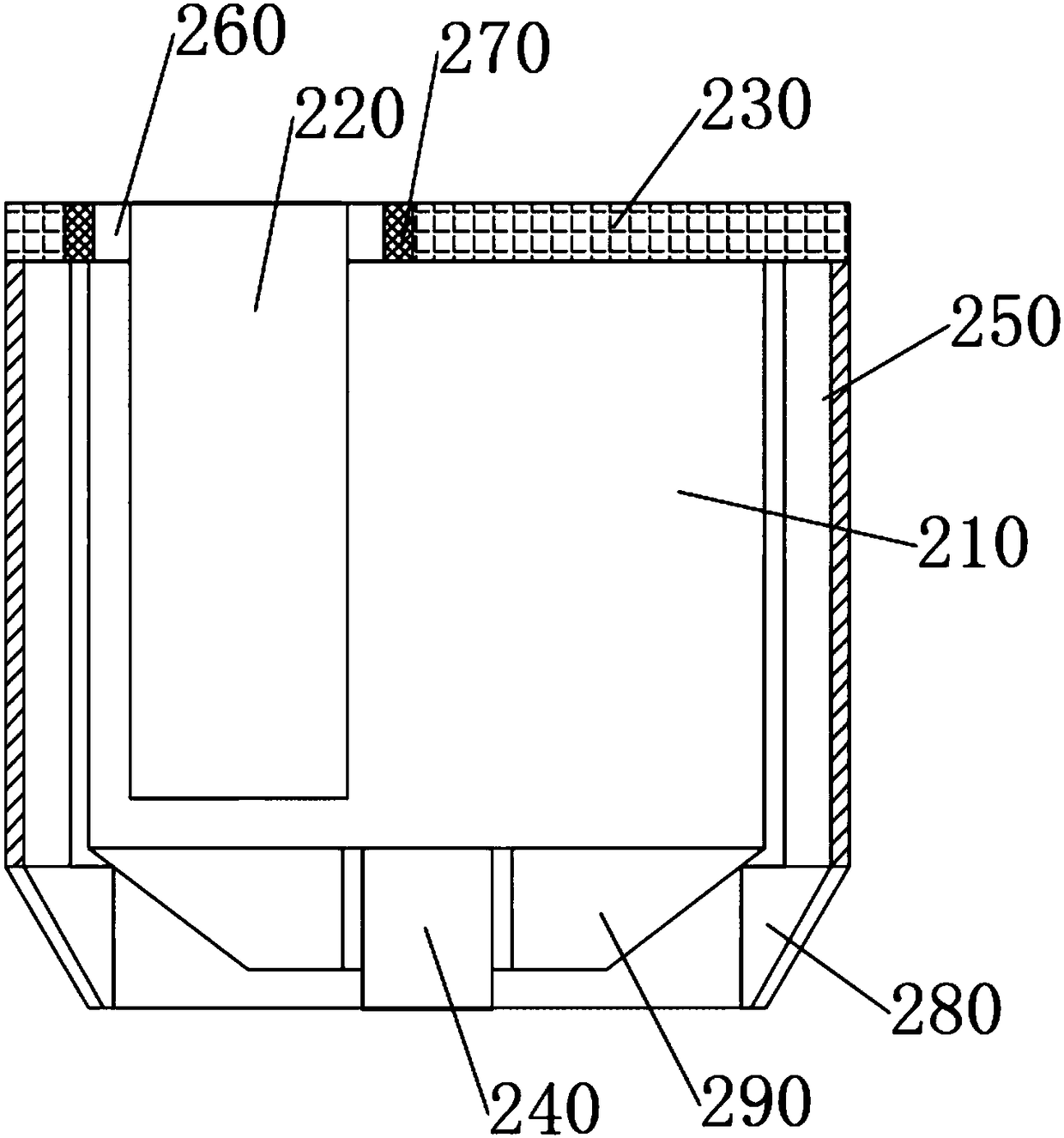

Kitchen waste treatment equipment

PendingCN108356051ASmooth rotationDoes not affect grinding actionTransportation and packagingSolid waste disposalElectricityEngineering

The invention relates to kitchen waste treatment equipment. The kitchen waste treatment equipment comprises a support, a crushing and grinding device, a solid-liquid separation device, a drying and deodorizing device, a first stock bin and a control device, wherein the crushing and grinding device, the solid-liquid separation device, the drying and deodorizing device, the first stock bin and the control device are arranged in the support and are sequentially arranged from top to bottom; the solid-liquid separation device is provided with a first discharge port and a second discharge port; thefirst discharge port is connected to a liquid discharge pipe; the second discharge port is connected to a feed port of the drying and deodorizing device; and the control device is electrically connected to the crushing and grinding device, the drying and deodorizing device and the solid-liquid separation device. The kitchen waste treatment equipment has the advantages that the structure is simple,the full-automatic operation is realized, the use is convenient, the environmental pollution caused by kitchen waste can be avoided from the source, and the kitchen waste can be conveniently recycled.

Owner:深圳市富利臻环保科技有限公司

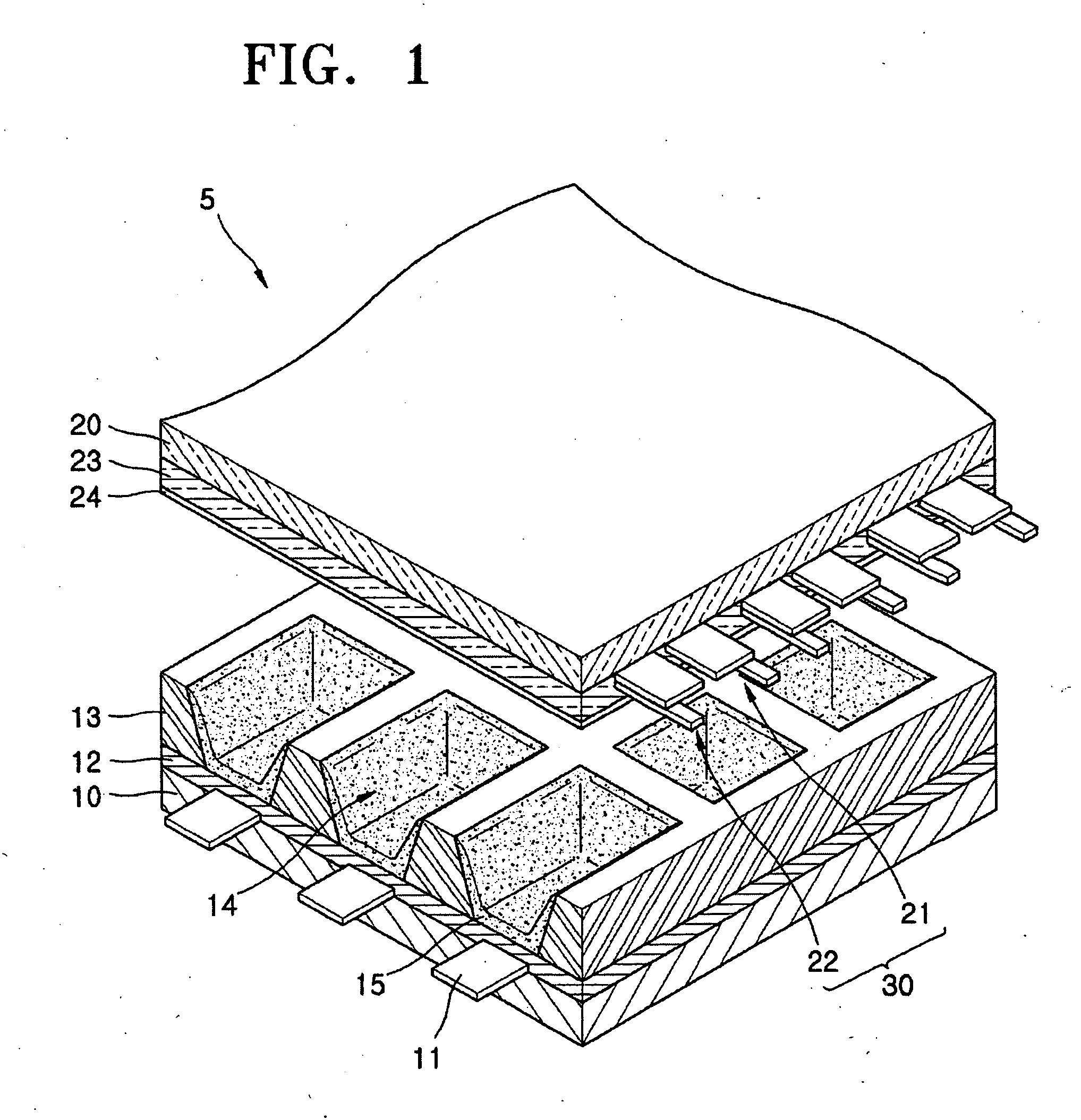

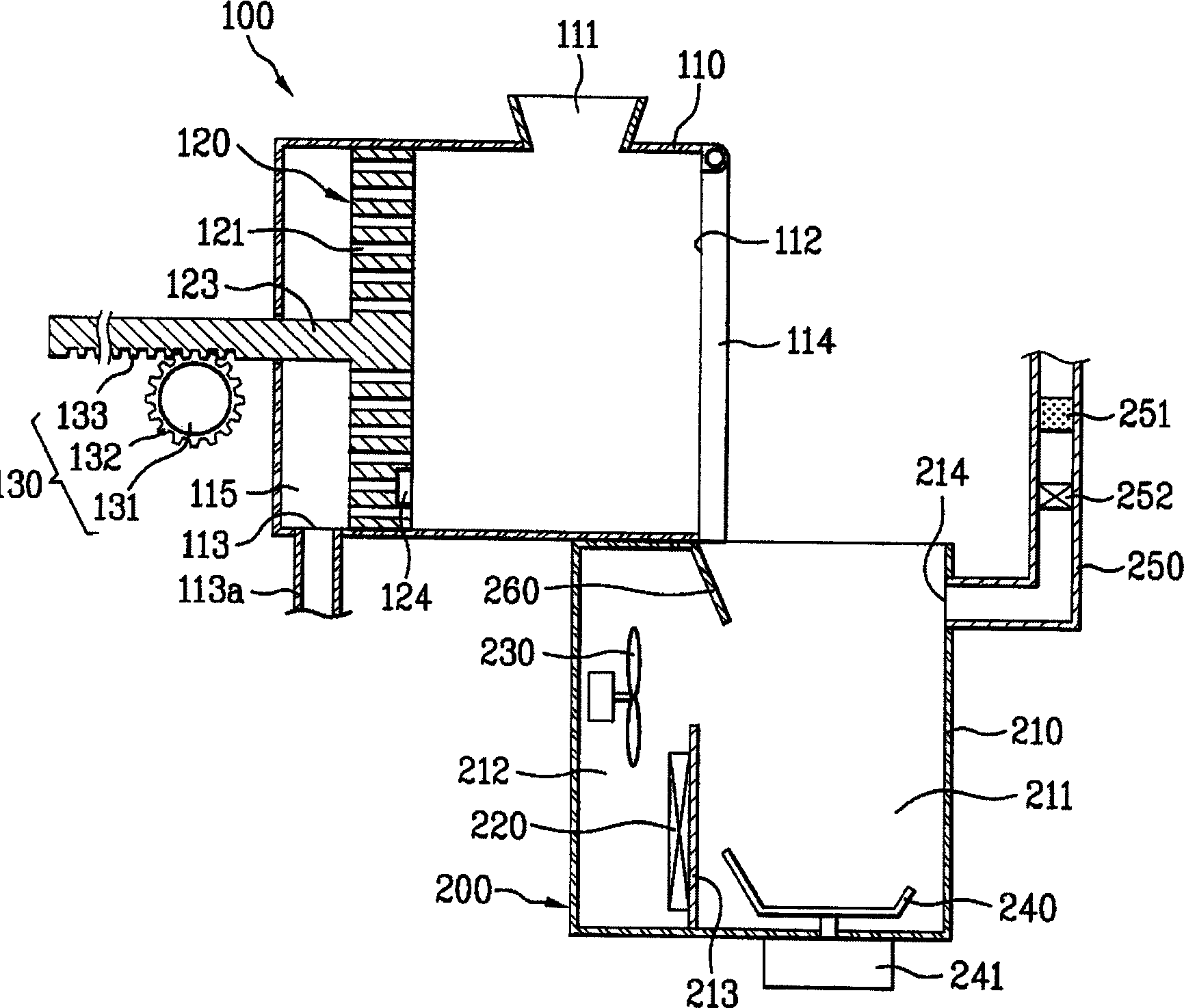

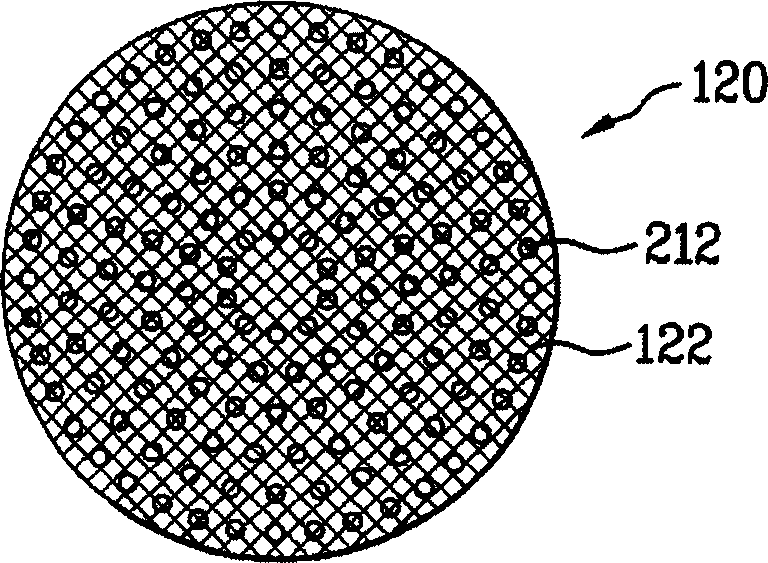

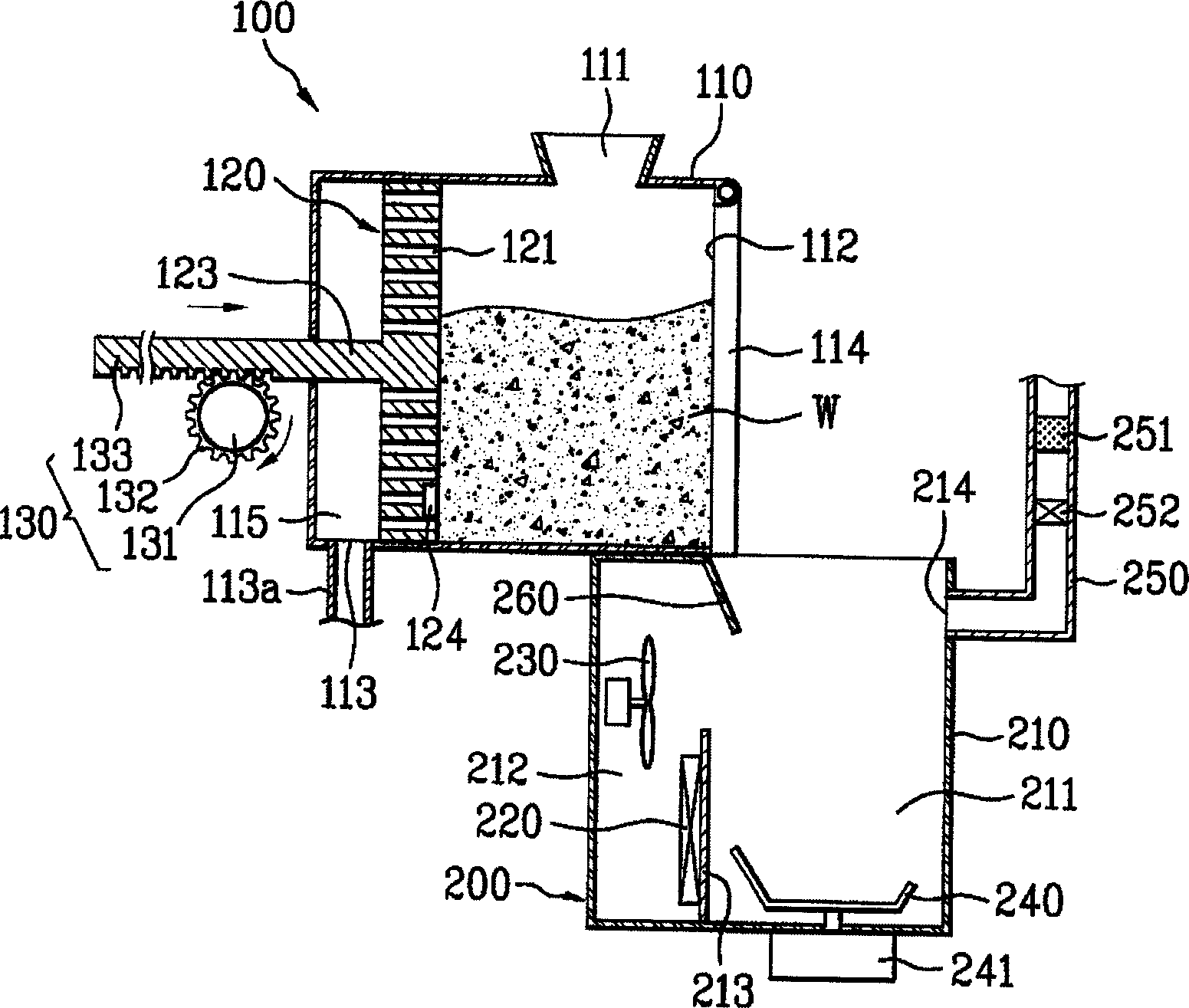

Apparatus for processing organic substance

InactiveCN1757450AShorten the timeLow costDrying using combination processesSolid waste disposalOrganic matterMoisture

The present invention provides an apparatus for processing organic substances such as food and the like, by which time and costs for processing the organic substances are reduced to enhance performance of processing the organic substances. The present invention includes a dewatering means for separating moisture from inputted inorganic substances and a drying means provided to one side of the dewatering means for drying the inorganic substances discharged from the dewatering means.

Owner:LG ELECTRONICS INC

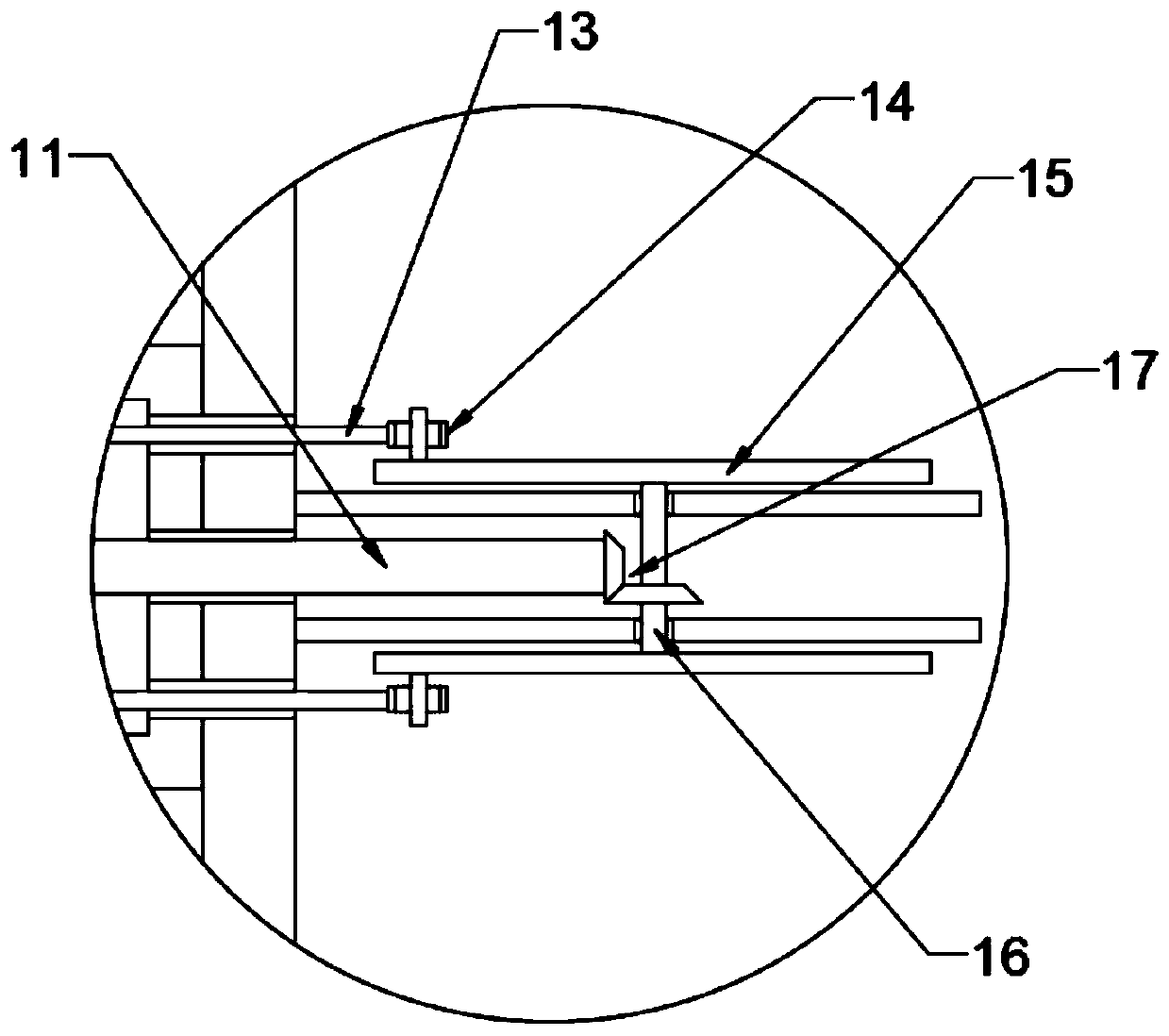

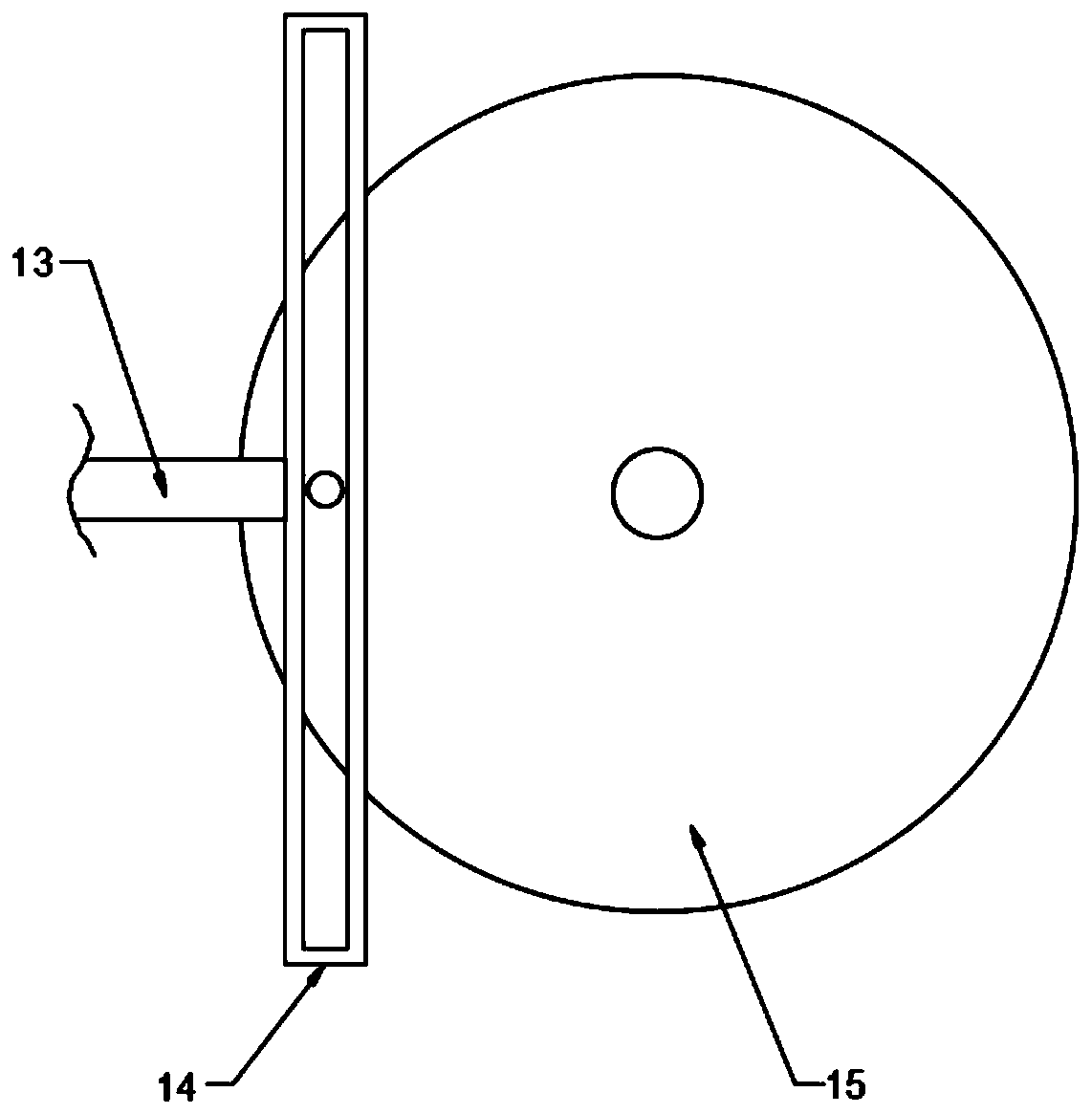

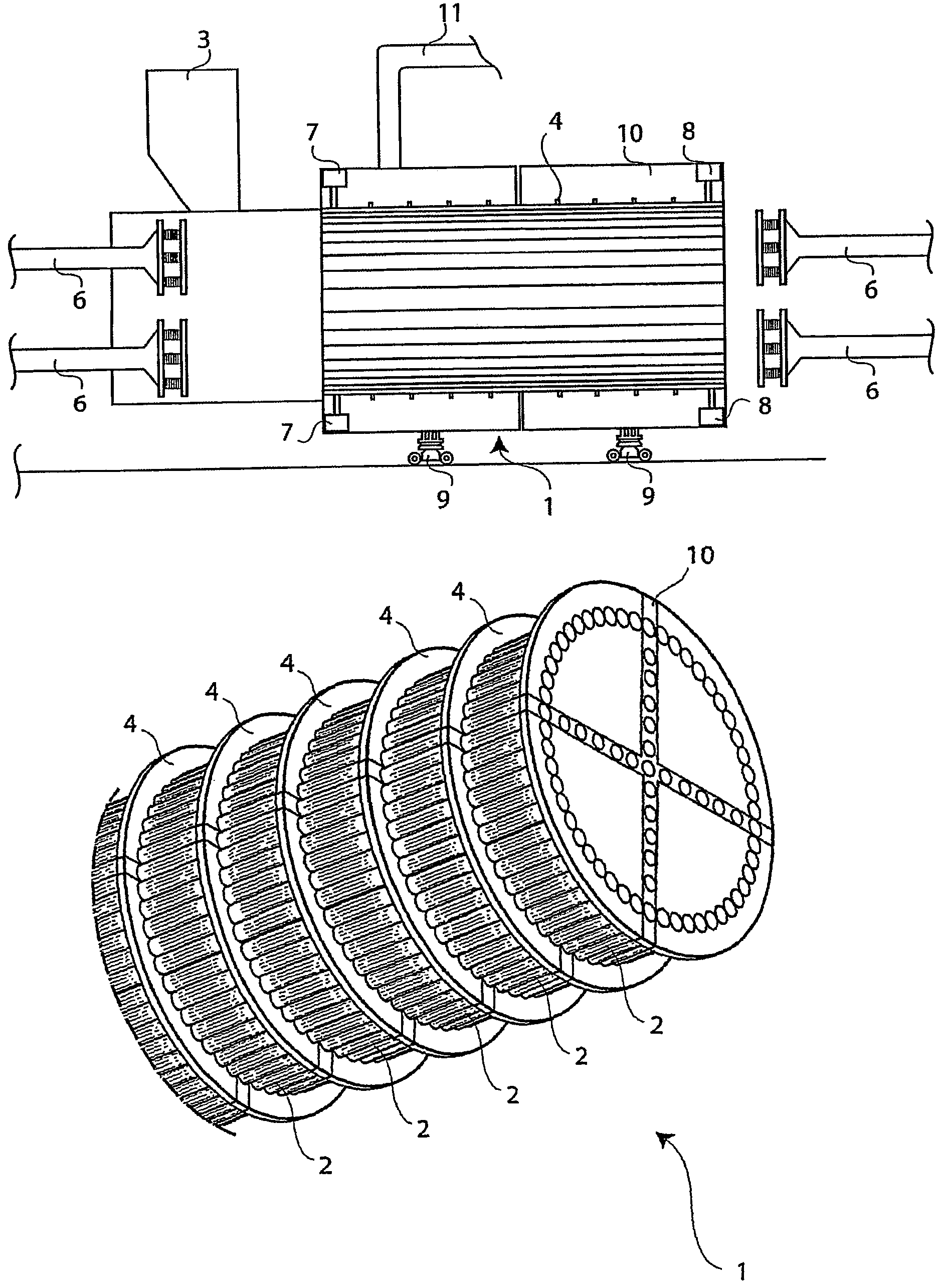

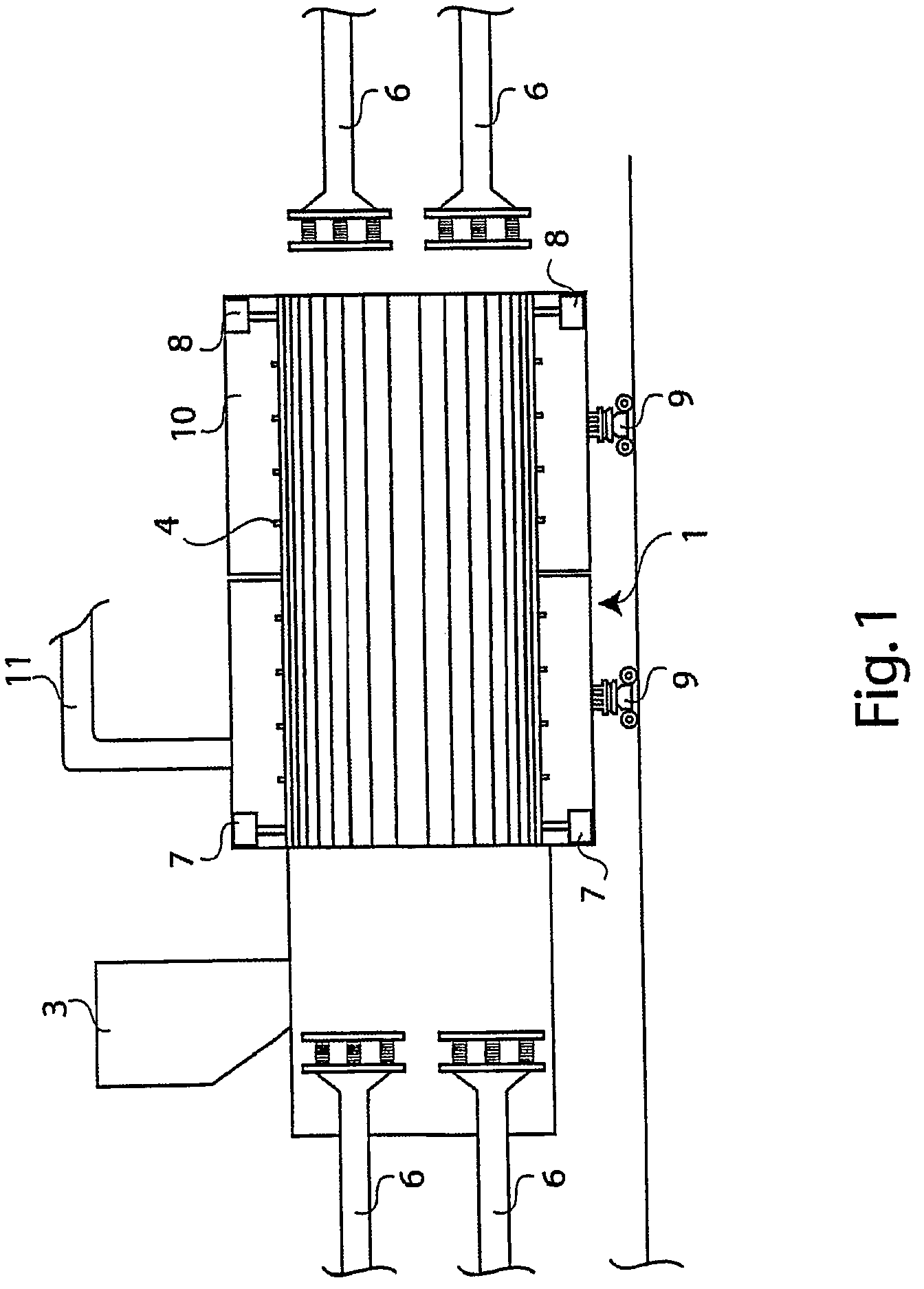

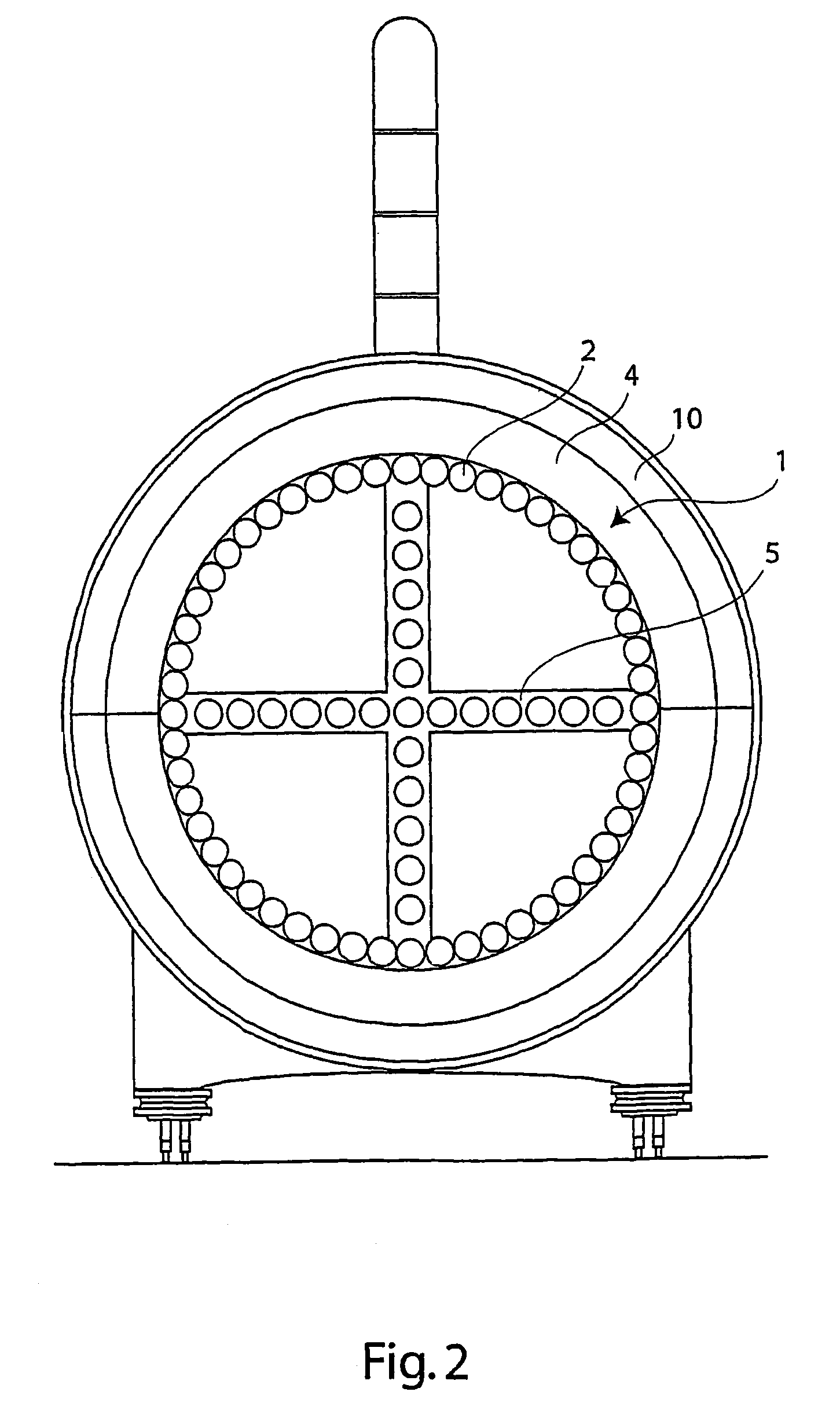

Double flow cage compactor dryer apparatus and method of compacting and drying wastes

InactiveUS7272895B2Guaranteed normal transmissionShorten the timeDrying using combination processesDrying solid materials without heatCarrier fluidMechanical engineering

A cage drying—compacting apparatus for wastes, includes a cylindrical shape and at least a pair of pressure plates, the cylindrical body having heating longitudinal tubes, coursed by a thermal carrier fluid, provided along the generatrixes of the cylinder and spaced from each other to realize longitudinal slots for outlet of vapour but not for outlet of material, coupled by constraint hinge elements, positioned at a given distance between centres, and the pressure plates being placed opposed each other, operating as movable basis of the body and acting as pistons. Heat sources are, provided inside the apparatus, all along its length, the sources include at least a tube coursed by thermal carrier fluid, an inlet for the material to be treated, and elements for collecting the material.

Owner:LA GIOIA ANTONIO

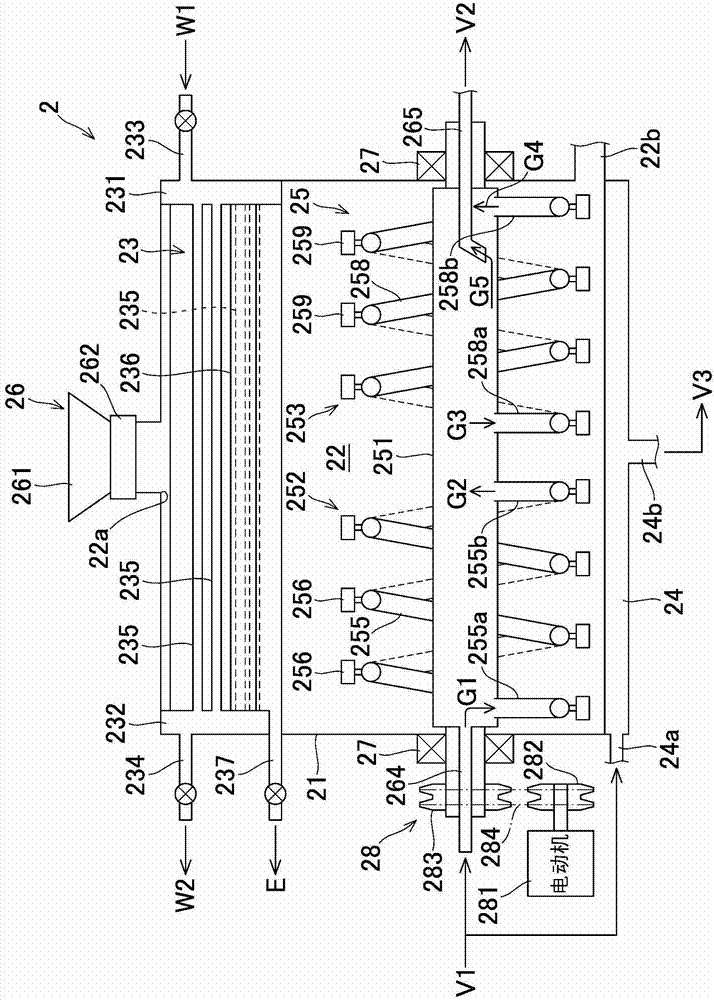

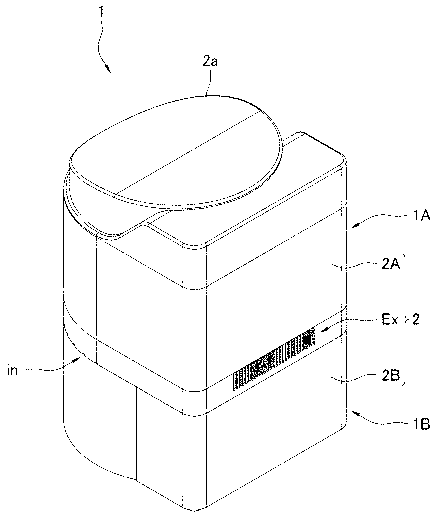

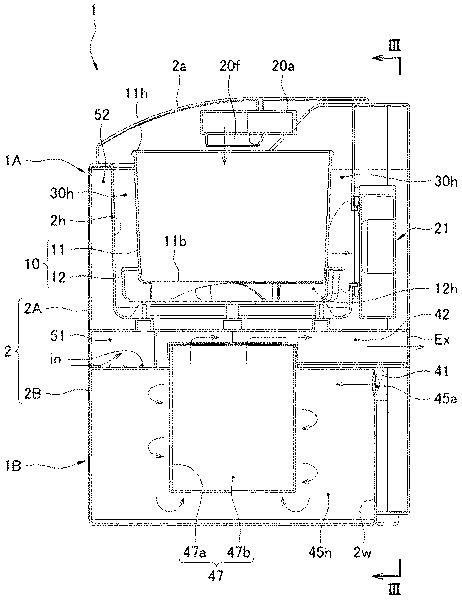

Drying volume reduction processing device

ActiveCN102906520AFully contactedImprove drying efficiencySolid waste disposalDrying gas arrangementsThermodynamicsProcess engineering

Provided is a drying volume reduction processing device capable of efficiently drying a processing subject by means of warm air. This device dries a moisture-containing processing subject and is equipped with: a processing container (10) that stores the processing subject; a heated air supply means (20) that supplies heated air to the interior of the processing container (10); and a circulation passage that returns the hot air that has been supplied to the processing container (10) to the heated air supply means (20). A supply port that supplies the heated air is provided at the top of the processing container (10), a discharge port that discharges the heated air is provided at the bottom thereof, and the discharge port is connected to the heated air supply means by the circulation passage. The heated air supplied to the interior of the processing container (10) can be reliably brought into contact with the processing subject within the processing container (10), so the drying efficiency can be increased. Furthermore, the heated air is circulated, so the heating efficiency can be improved with respect to the case wherein outside air is heated continuously to produce heated air.

Owner:SHIMA SANGYO

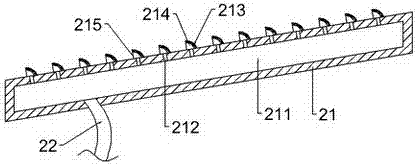

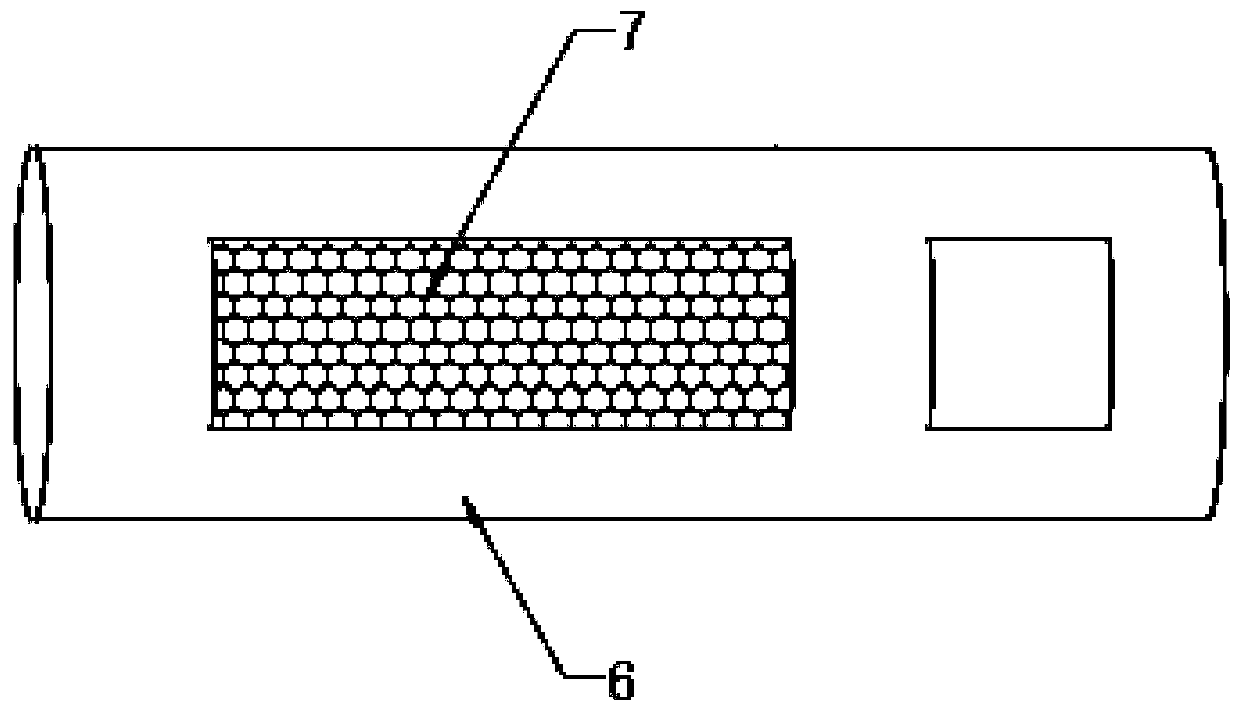

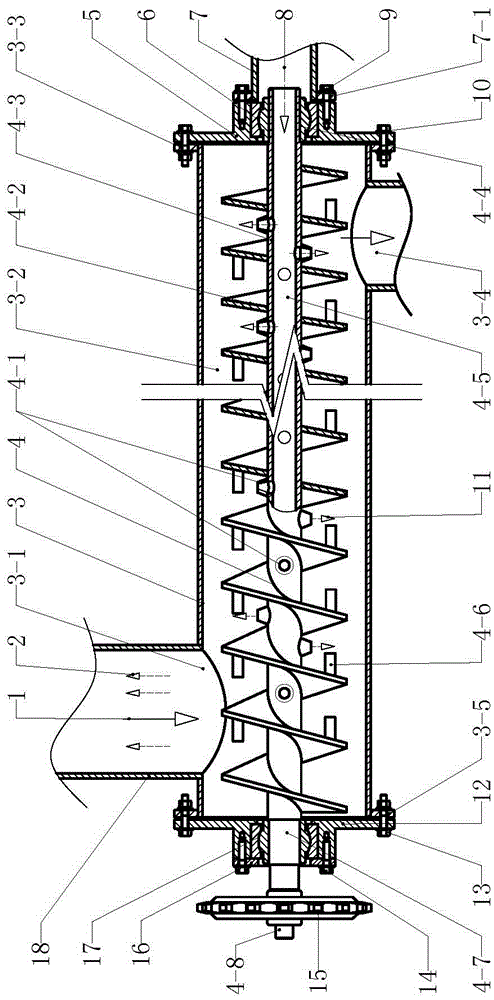

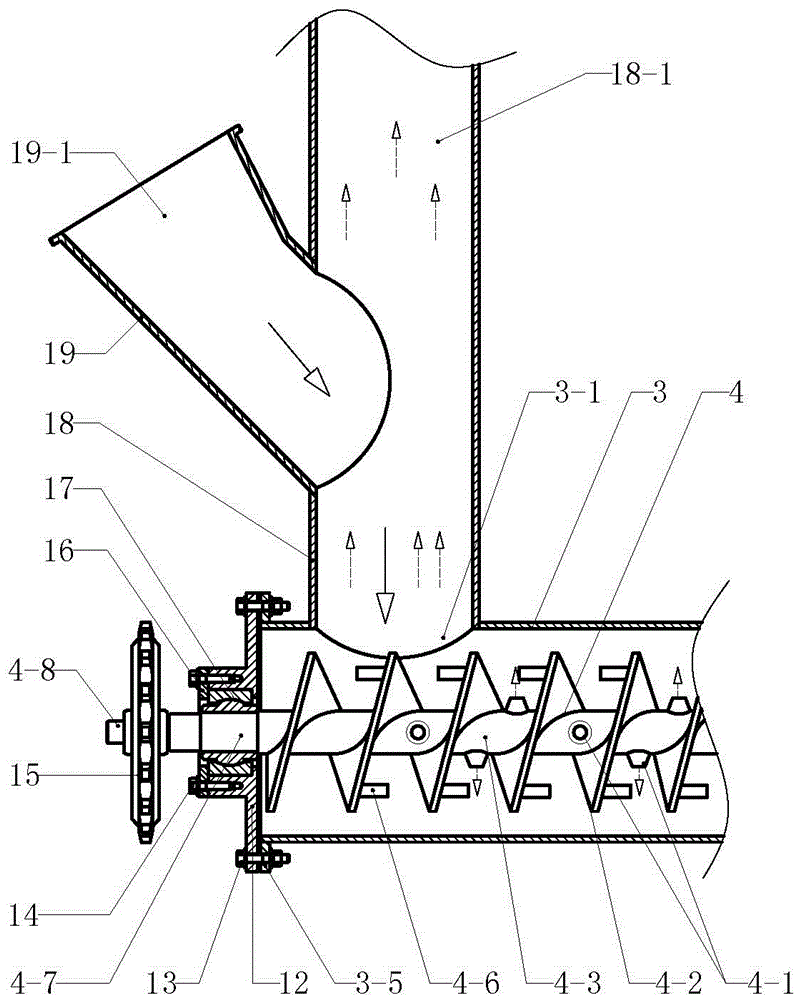

Hot air drying device

ActiveCN105588410AKeep dryHigh calorific valueDrying gas arrangementsDrying solid materialsAgricultural residueEngineering

The invention discloses a hot air drying device and relates to earlier stage preprocessing equipment for biomass fuel. The hot air drying device comprises a rotary shaft, a spiral stirring plate and a shell. An auger (4) is formed by the rotary shaft and the spiral stirring plate. The rotary shaft is provided with a hollow shaft body (4-3). The spiral stirring plate (4-2) is encircled on the outer side of a wall body of the hollow shaft body (4-3) in a spiral mode. The shell (3) is of a front-back-through cylinder structure. An air drying tunnel (3-2) is formed in an internal space of a cylinder of the shell (3). A front end socket (12) is arranged at the front end of the shell (3). A rear end socket (5) is arranged at the rear end of the shell (3). The auger (4) is arranged in the air drying tunnel (3-2). An air supply pipe (7) is connected to the rear end socket (5) and communicates with an internal space of the hollow shaft body (4-3) through an air inlet of the rear end of the rotary shaft of the auger (4). The hot air drying device is applied to previous preprocessing working procedures of forestry and agricultural residue or household refuse gasification systems. Hot air diffuses from the center and can permeate into materials more easily, and full contact of the materials with the hot air is facilitated, so that the materials are dried more easily.

Owner:QUZHOU YUXIN AGRI PROD PROCESSING TECH DEV

Food garbage treatment device

InactiveCN109453863AAvoid cloggingSave energyDrying gas arrangementsGrain treatmentsWaste managementSieve

The invention discloses a food garbage treatment device. The food garbage treatment device comprises a pulverizing device, a water removal device and a drying device. The pulverizing device comprisesa first shell, a pulverizing tool and a first motor. The first shell comprises an inner-layer shell and an outer-layer shell, and the inner-layer shell is provided with sieve holes. The water removaldevice comprises a support, a second motor, a second feeding port, a second discharging port, two supporting plates, a rotation screw and a filter device. A cover plate is arranged above the filter device, a water receiving groove is formed below the filter device, a water outlet is formed in the lower end of the water receiving groove, and a plurality of connecting rods are fixed between the twosupporting plates. The filter device comprises fixed rings and movable rings, and the outer sides of the fixed rings are fixed to the connecting rods. The drying device comprises an air inlet pipeline, a heater, a box and an exhaust pipeline. The pulverizing device pulverizes food garbage, the water removal device is used for pushing and dynamic extruding for water removal, then the drying deviceis adopted, and the food garbage is recycled while a sewer line is prevented from being blocked.

Owner:刘泰言

Uniform-heating organic garbage drying equipment with dredging function

InactiveCN108626991AEvenly heatedTiling smoothlyDrying gas arrangementsDrying machines with non-progressive movementsDrive shaftWaste management

The invention relates to uniform-heating organic garbage drying equipment with the dredging function. The drying equipment comprises a drying box, a hopper, a controller, a discharging pipe, a first air pump, a heating chamber and four supporting feet; a turnover mechanism, a screen net and a dredging mechanism are arranged in the drying box, the turnover mechanism comprises a transverse moving assembly, a transverse moving block, a lifting assembly, a first motor, a bearing, a first drive shaft and multiple turning plates, the dredging mechanism comprises a reciprocating plate, two reciprocating assemblies, multiple inserting needles and multiple vibration assemblies, and each reciprocating assembly comprises a vertical rod, a second motor, a first connecting rod and a second connecting rod. The uniform-heating organic garbage drying equipment with the dredging function enables garbage to be flatly laid on the screen net through the turnover mechanism, the garbage is driven to turn over to enable stacked garbage to be evenly heated, meshes are dredged through the dredging mechanism, air flowing is smooth, drying is smoothly carried out, through the vibration assembly, garbage canbe prevented from being bonded on the screen net, and equipment practicability is improved.

Owner:SHENZHEN JIUPIN AIR PURIFICATION TECH CO LTD

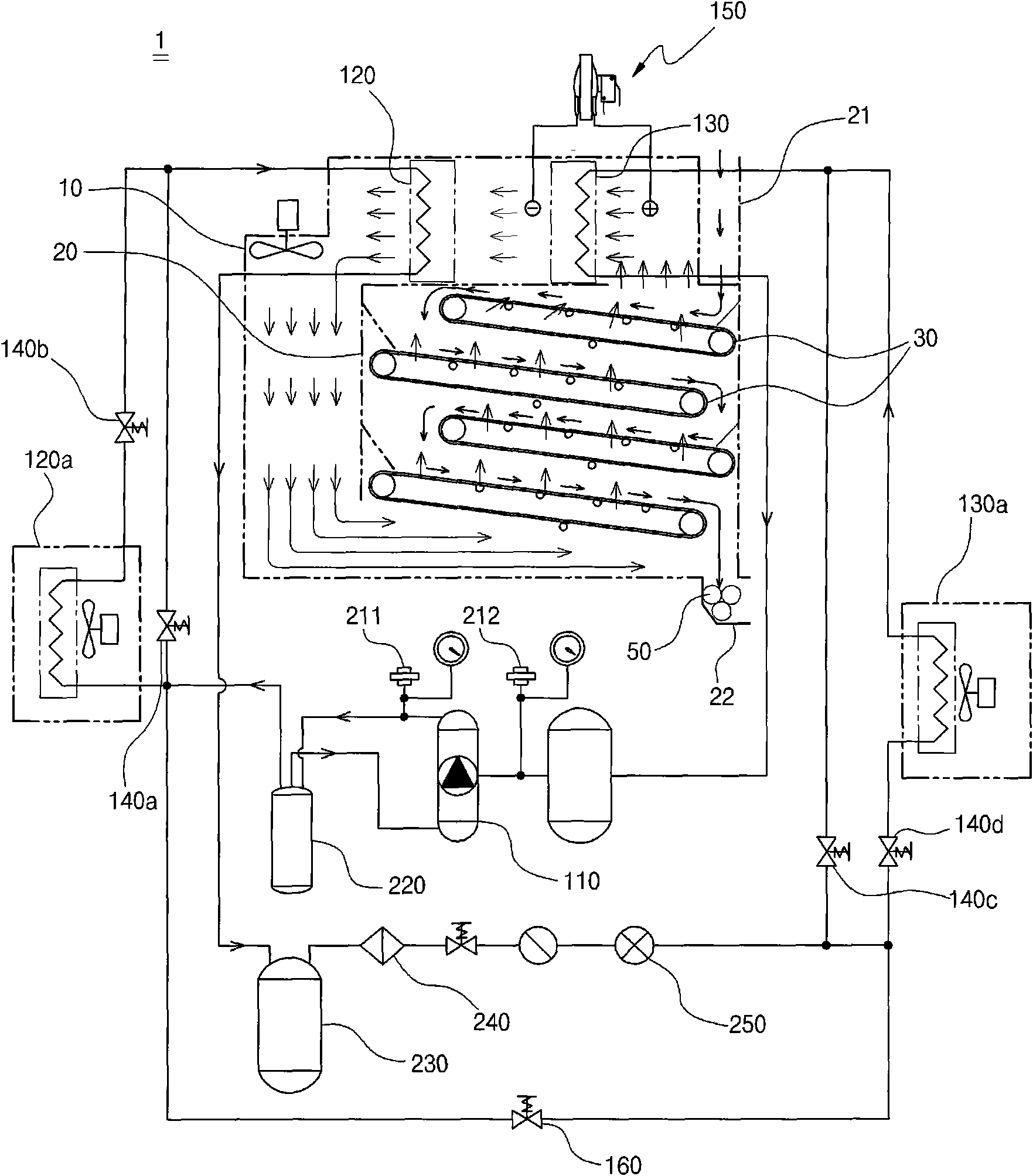

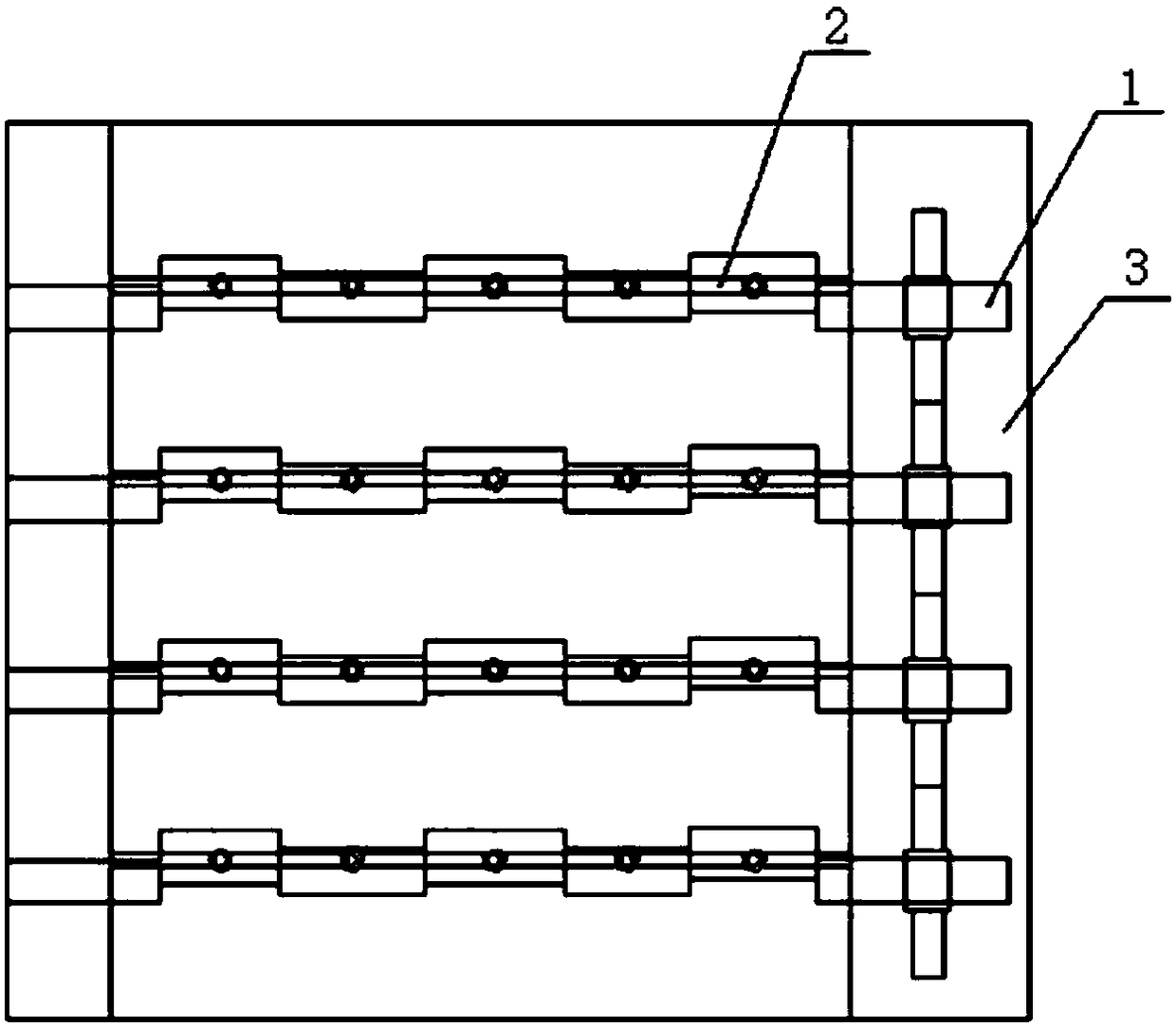

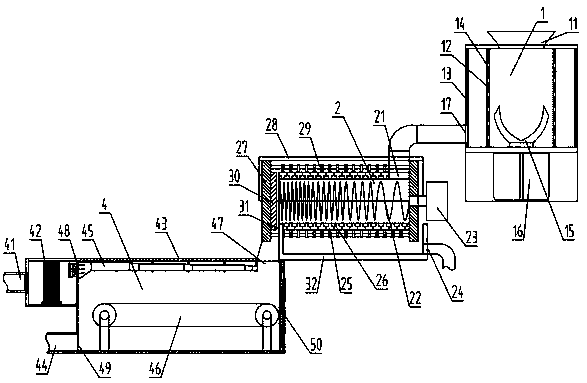

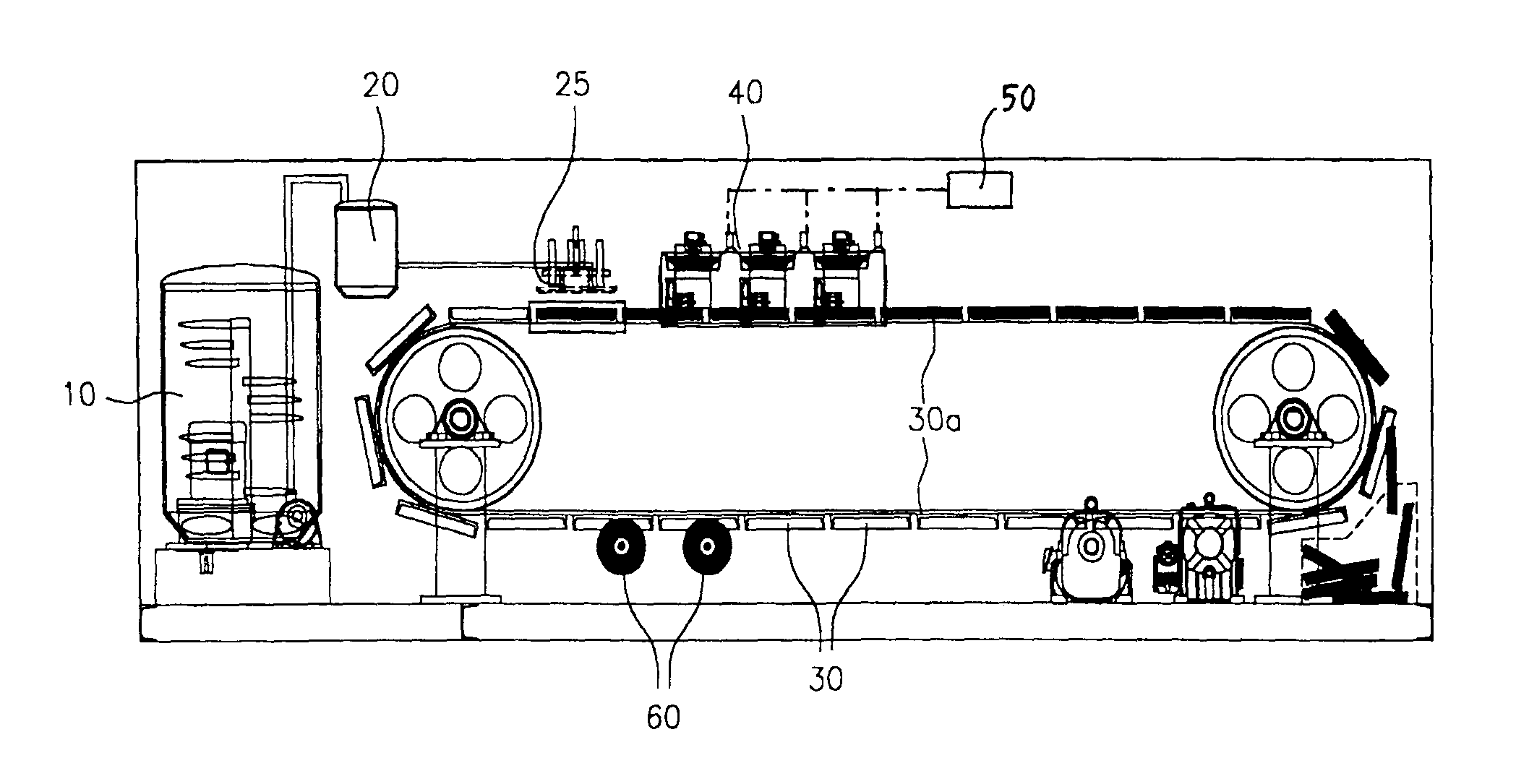

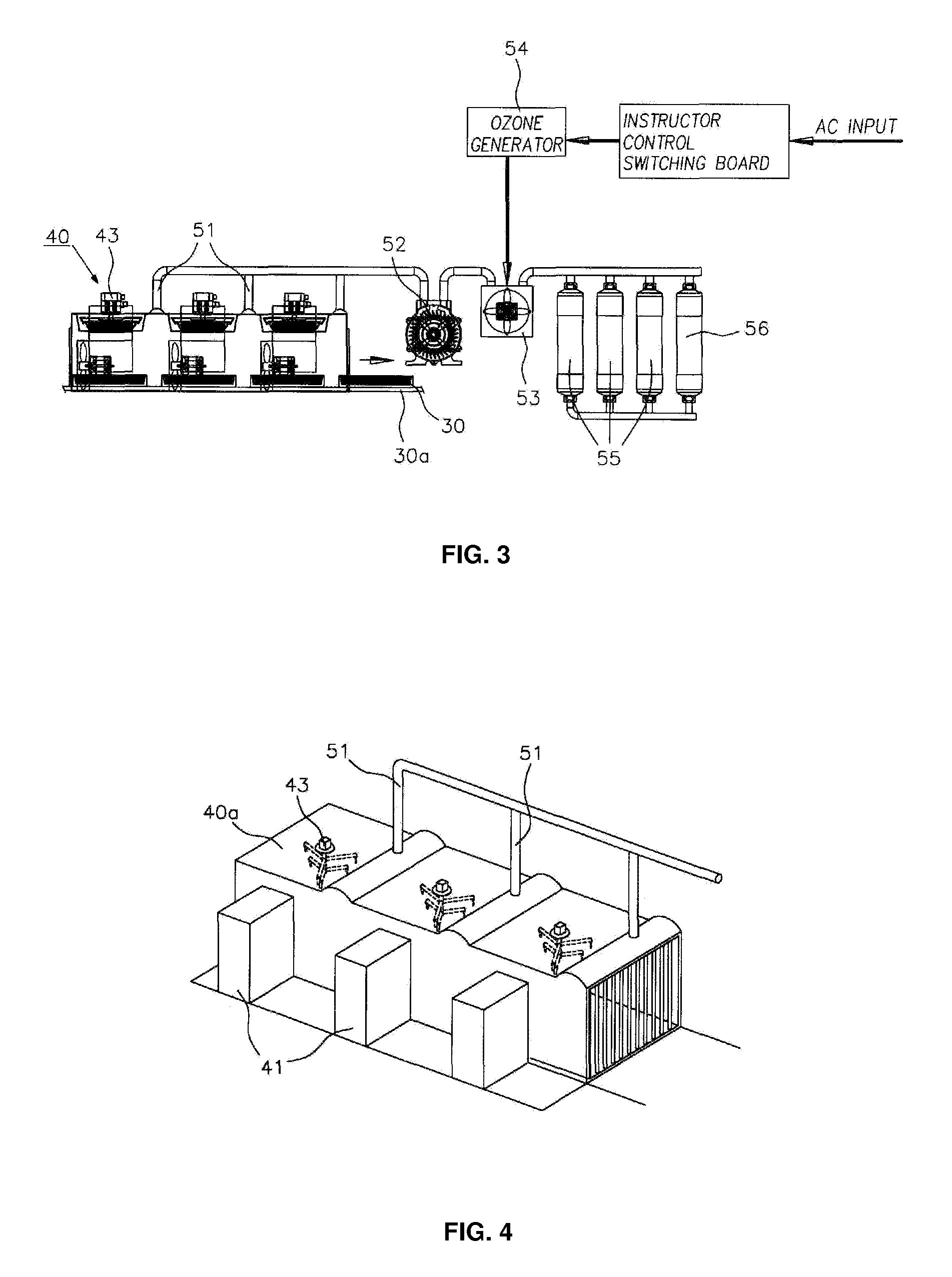

Food waste treatment apparatus using microwave

ActiveUS7966744B2Eliminate odorImprove drying efficiencyDrying using combination processesDrying solid materials with heatMicrowaveDried food

The present invention relates to a food waste treatment apparatus that can effectively dispose food waste containing a large amount of water, rapidly dry food waste using microwaves, and remove odors and vapors generating during the drying process, thereby discharging clean air. The food waste treatment apparatus comprises a pulverizer (10) for pulverizing food waste, an endless track (20) for transferring food waste, a plurality of containers (30) installed on the upper surface of the endless track (20) for storing pulverized food waste, and a microwave dryer installed above the endless track for drying the pulverized food waste by making microwaves pass through the endless track in a direction perpendicular to the moving direction of the endless track (20).

Owner:KIM SOO DONG +1

Popular searches

Large containers Animal feeding stuff Multiple digital computer combinations Digital data authentication Special data processing applications Garbage drying Chemistry apparatus and processes Drying machines with local agitation Drying machines with materials at rest Preliminary solid treatment for drying

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com