Kitchen waste pretreatment device

A technology for kitchen waste and pretreatment, applied in the fields of waste drying, grain treatment, lighting and heating equipment, etc., can solve the problems of inconvenient transportation and processing, and achieve convenient subsequent processing and transportation, fast and uniform drying, and improved efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

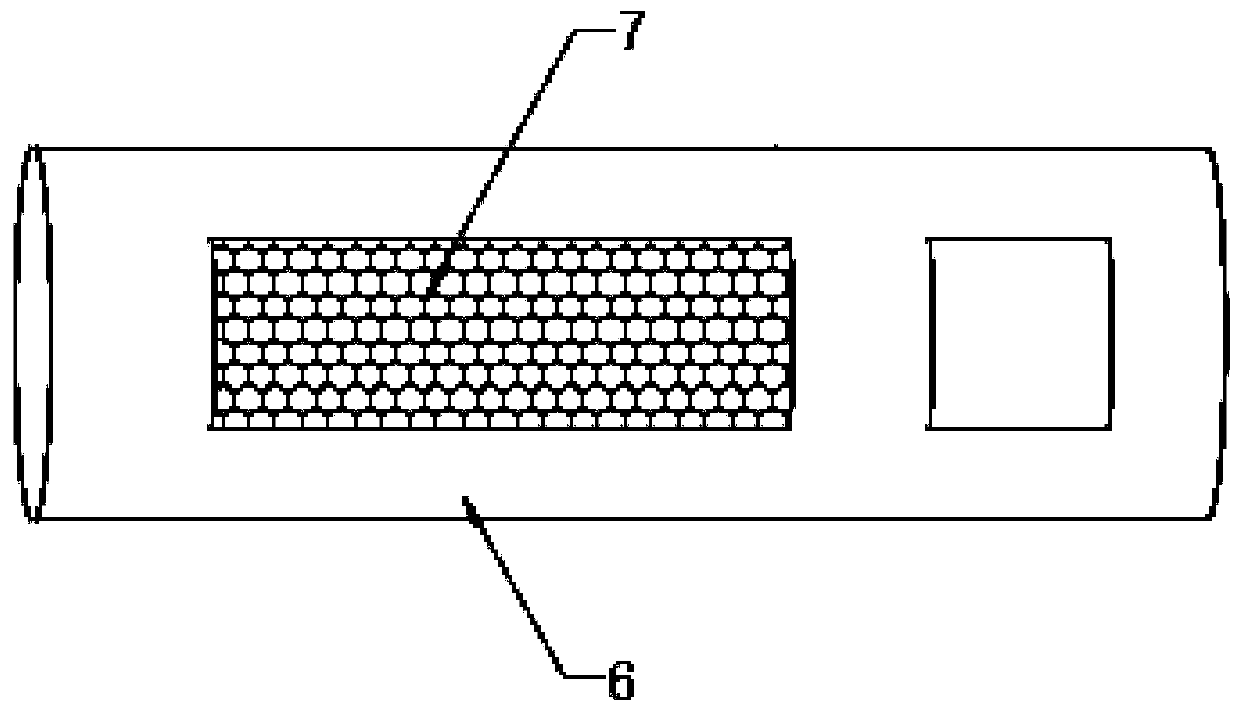

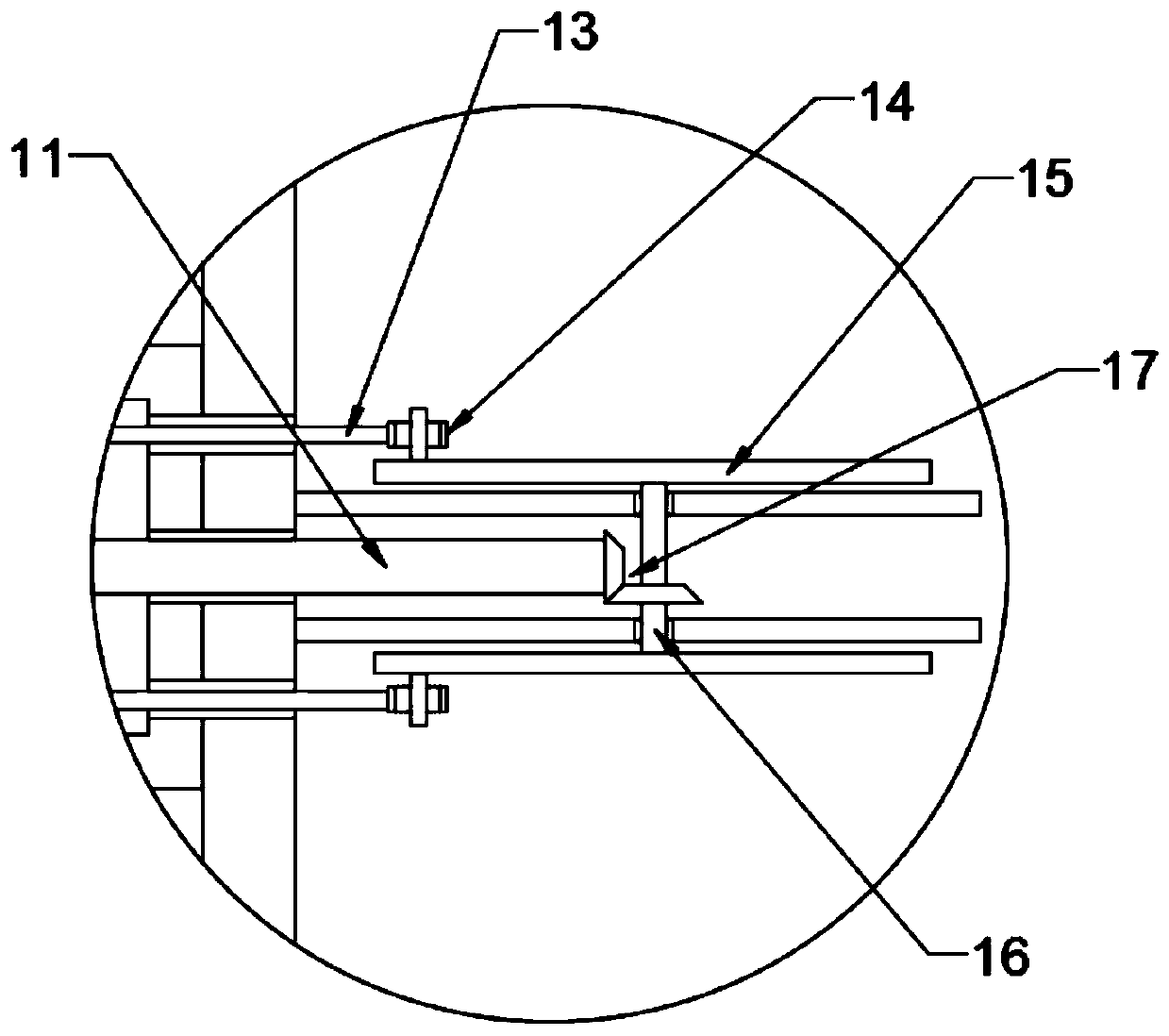

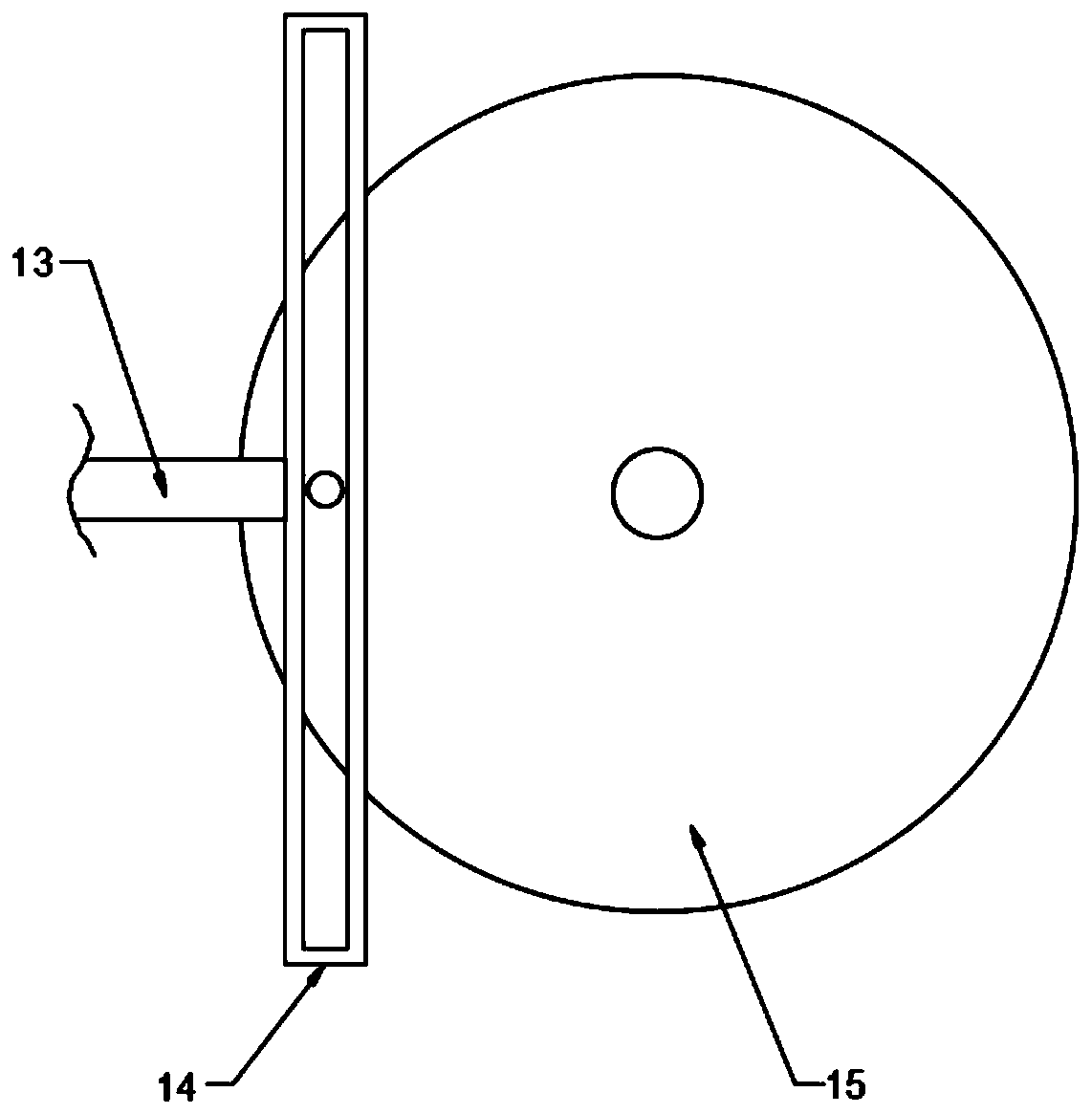

[0021] see Figure 1-4 , in the embodiment of the present invention, a food waste pretreatment device includes a housing 1; the housing 1 is provided with a dehydration cylinder 6, the dehydration cylinder 6 is a cylinder arranged horizontally, and the lower part of the dehydration cylinder 6 is nested with The water leakage net 7 is provided with a water collection cover 8 on the outside of the water leakage net 7, and the water collection cover 8 is fixedly connected with the dewatering cylinder 6, and the water collection cover 8 is connected with a drain pipe 9; the dewatering cylinder 6 is provided with a spiral blade roller 10, The spiral blade roller 10 extends to the outside of the housing 1 and is connected to a drive motor 5 through a coupling, and the drive motor 5 drives the spiral blade roller 10 to rotate, thereby pushing the food waste to move to the right; the right side of the dehydration cylinder 6 is connected to a A feeding pipe 18 ; an extruding plate 12 i...

Embodiment 2

[0025] The difference between this embodiment and Embodiment 1 is that: the feeding pipe 18 is connected with a drying cylinder 19, and the drying cylinder 19 is provided with a rotating shaft 20, and a screw blade 21 is fixedly connected to the rotating shaft 20, and the rotating shaft 20 extends to the housing The output shaft of the drive motor 5 is connected to the outer side of 1 through the second belt, and then the dehydrated kitchen waste is pushed to move; the rotating shaft 20 is a hollow shaft, and air spray heads 23 are evenly distributed on the rotating shaft 20, and the rotating shaft 20 extends to the casing 1. The right side is connected to the air outlet pipe of the hot air blower 29 through the rotary joint 28. The hot air generated by the hot air blower 29 is passed into the rotating shaft 16 and discharged from the air nozzle 23, so as to realize the drying of the kitchen waste in the drying cylinder 19. ; The upper end of the drying cylinder 19 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com