Patents

Literature

290results about "Liquid/gas/vapor removal by squeezing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

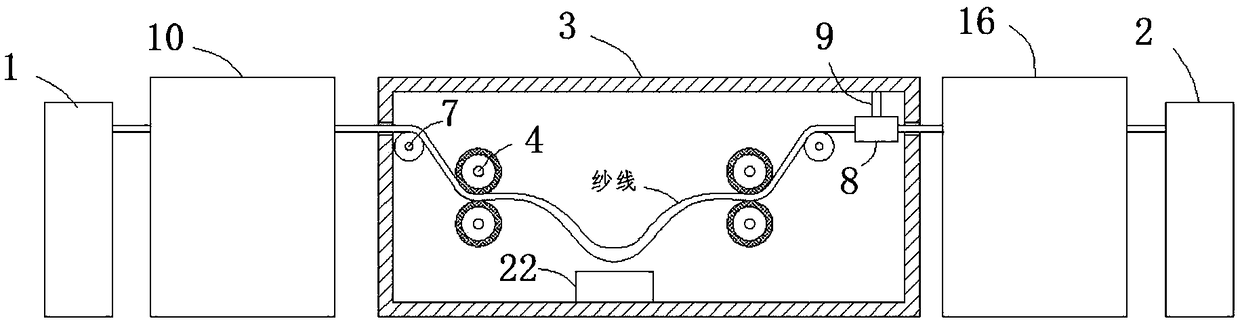

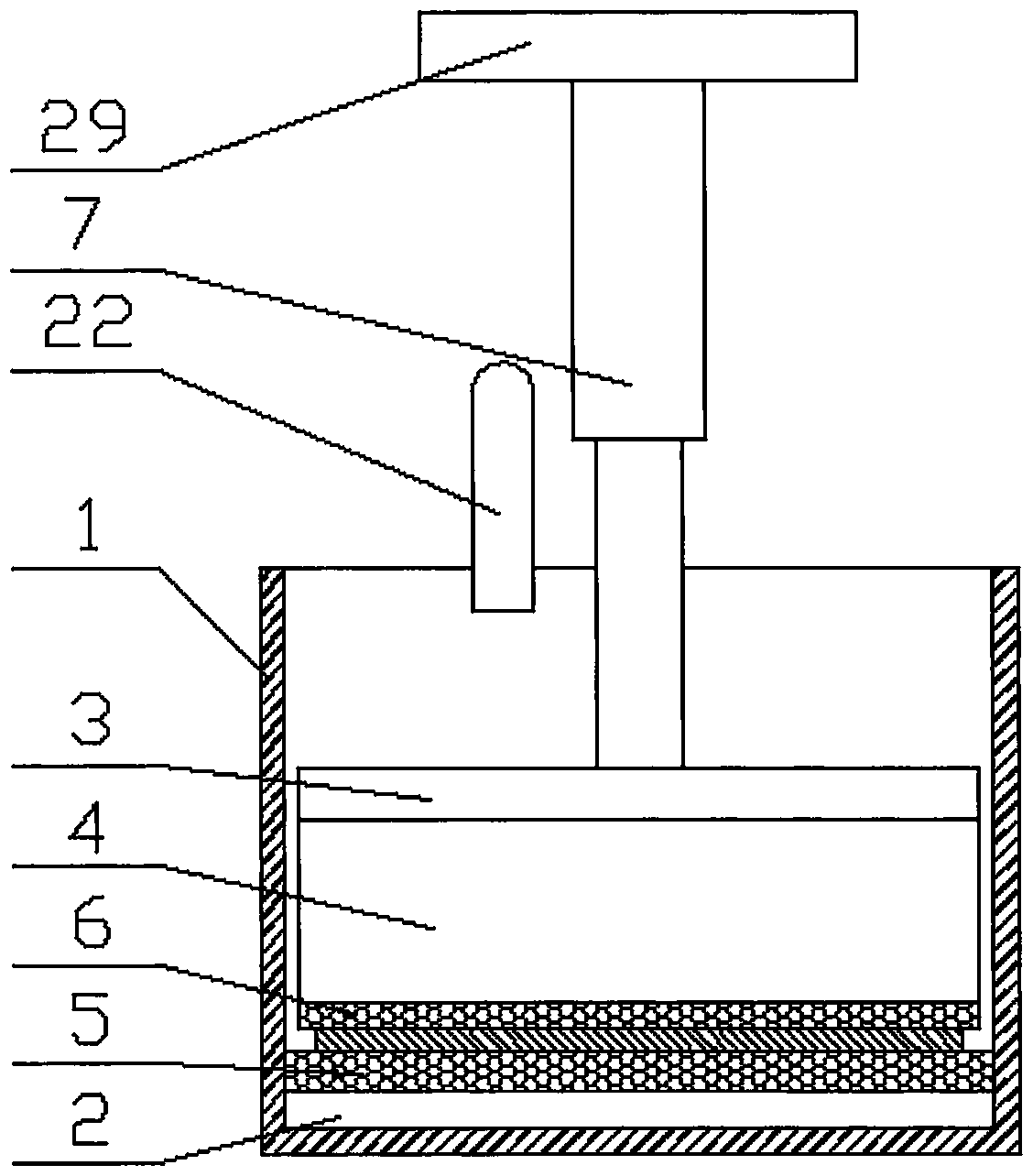

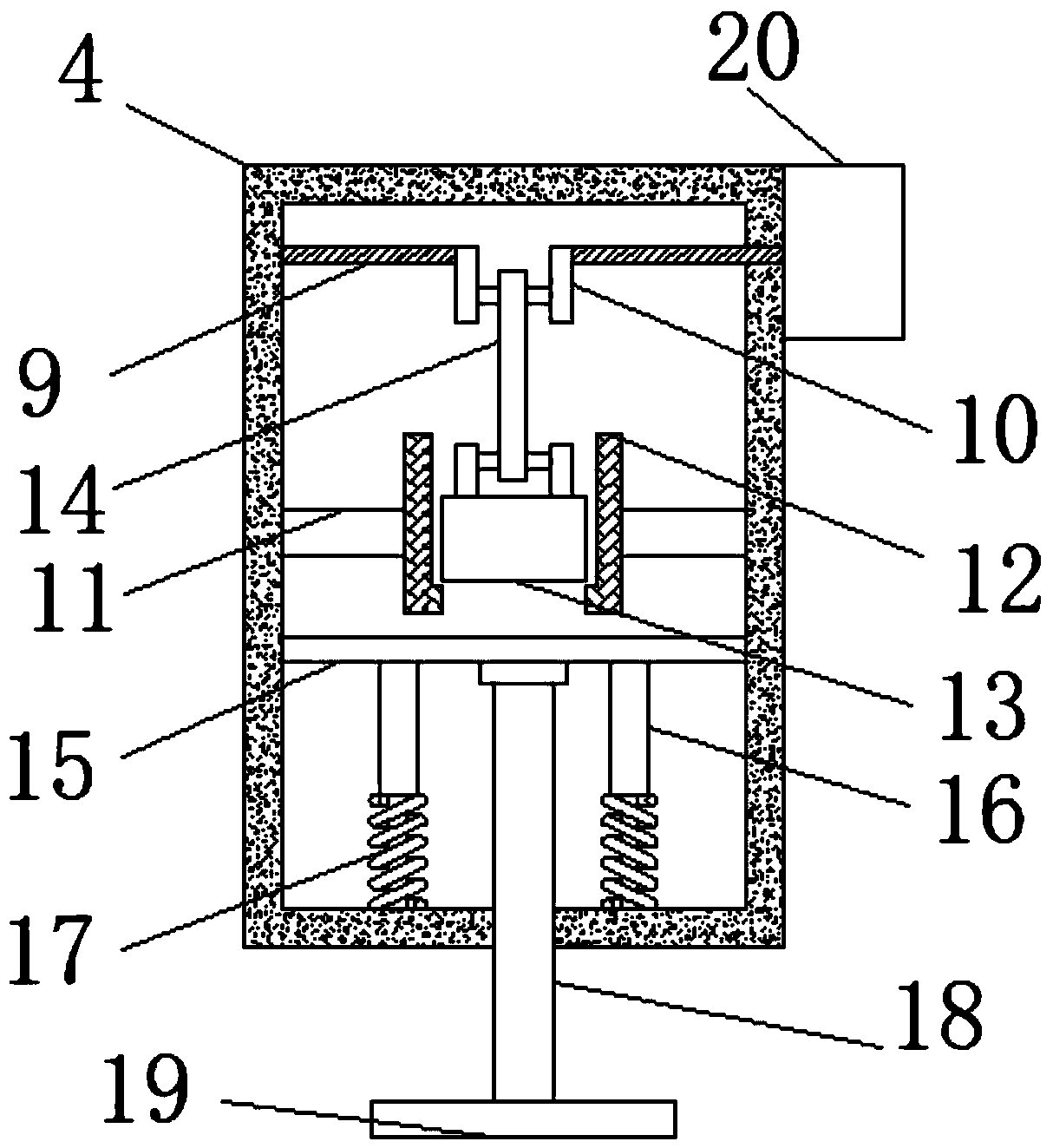

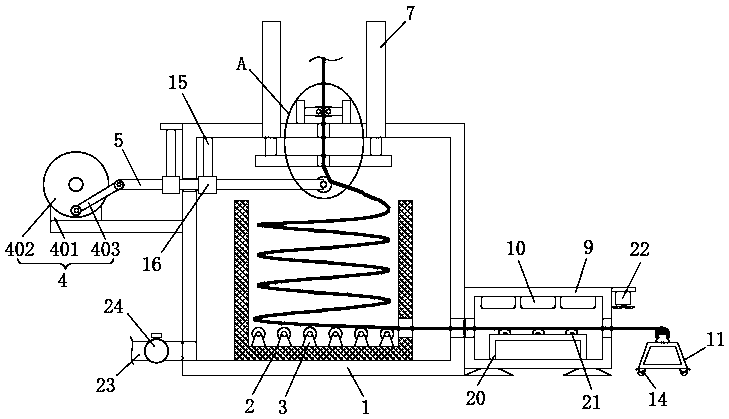

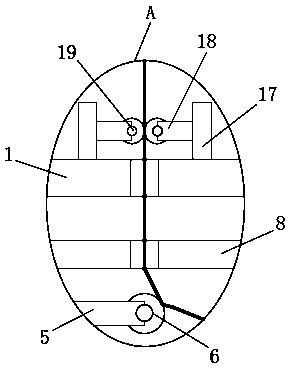

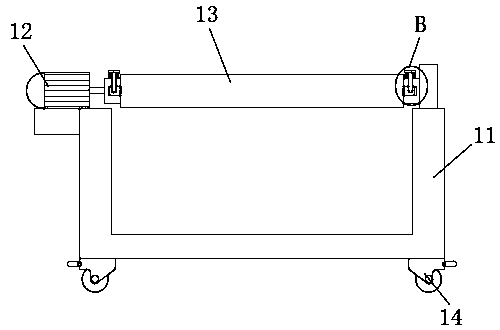

Yarn dyeing device

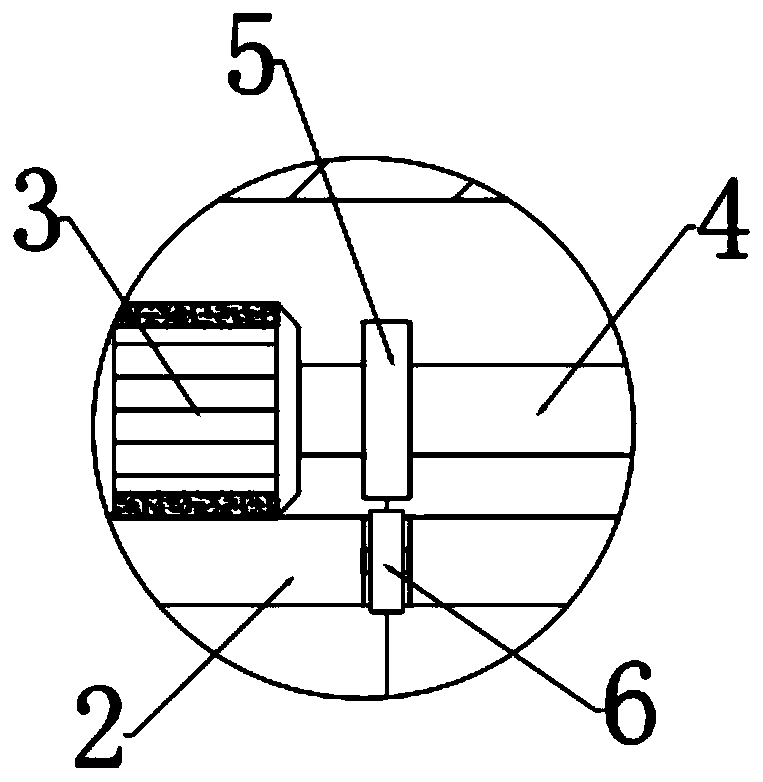

PendingCN107177942AImprove water removal efficiencyImprove dyeing precisionTextile treatment machine arrangementsLiquid/gas/vapor removal by squeezingYarnPolymer science

The invention provides a yarn dyeing device, which comprises a dyeing beck, wherein a guide roller is arranged in the dyeing beck; a water removal tank is arranged next to the dyeing beck; a heating device is arranged on the dyeing beck; an extrusion block is arranged in the water removal tank; a mobile device is arranged at the upper end of the extrusion block; a sliding track is arranged at the top end in the water removal tank; the mobile device drives the extrusion block to slide left and right on the sliding track; and a yarn traction device is arranged at one side of the water removal tank. Dip dyeing is carried out on a yarn through the dyeing beck, and water removal is carried out on the dyed yarn through the extrusion block in the water removal tank, so that the water removal efficiency is improved; furthermore, the temperature in the dyeing beck is controlled through a temperature detection device and a heating device, so that the dyeing accuracy is improved, the dyeing time is shortened and the production cost is reduced.

Owner:WUHU FUCHUN DYEING & WEAVING

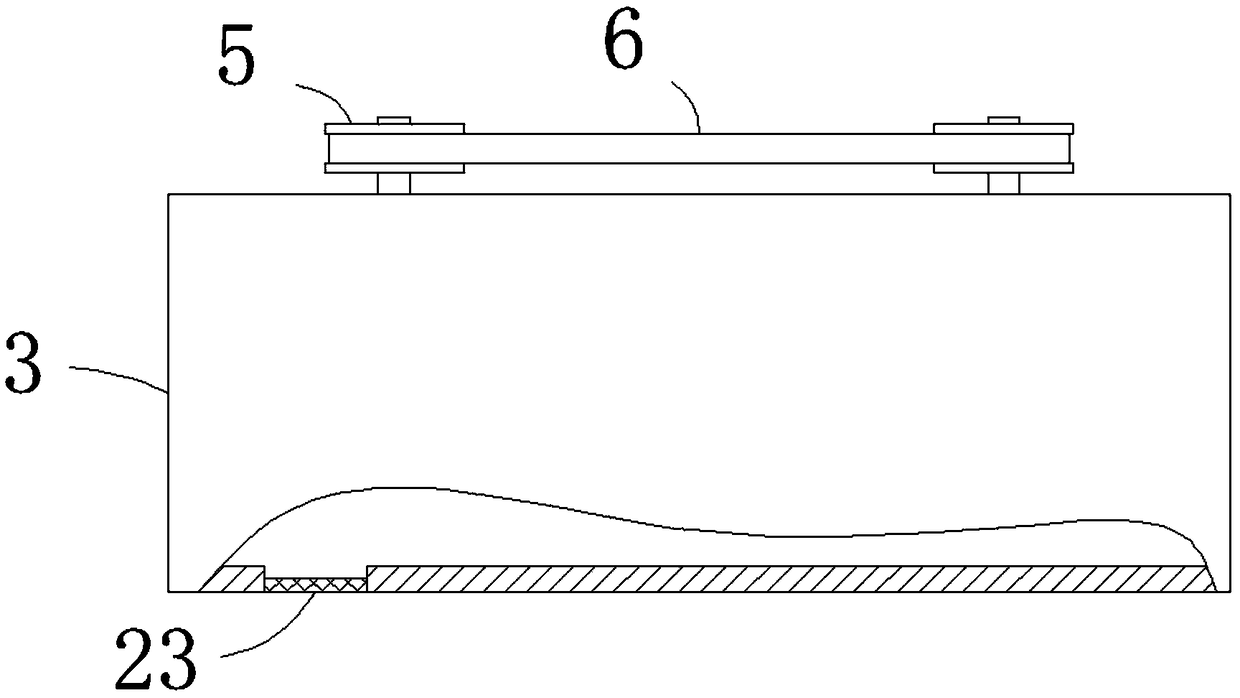

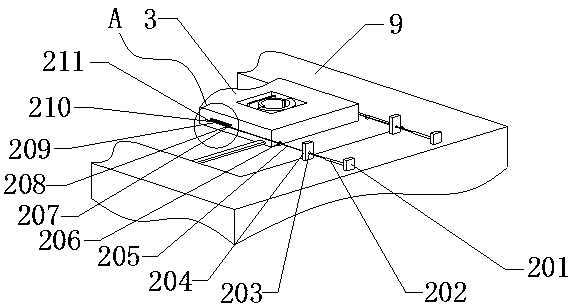

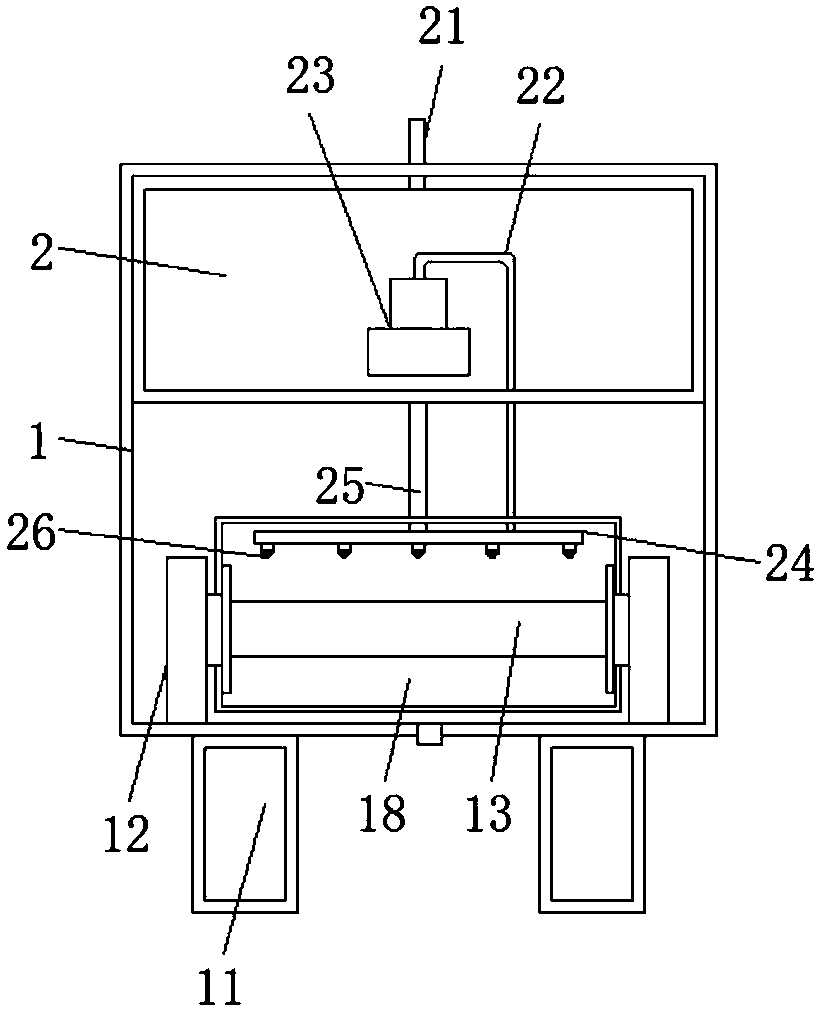

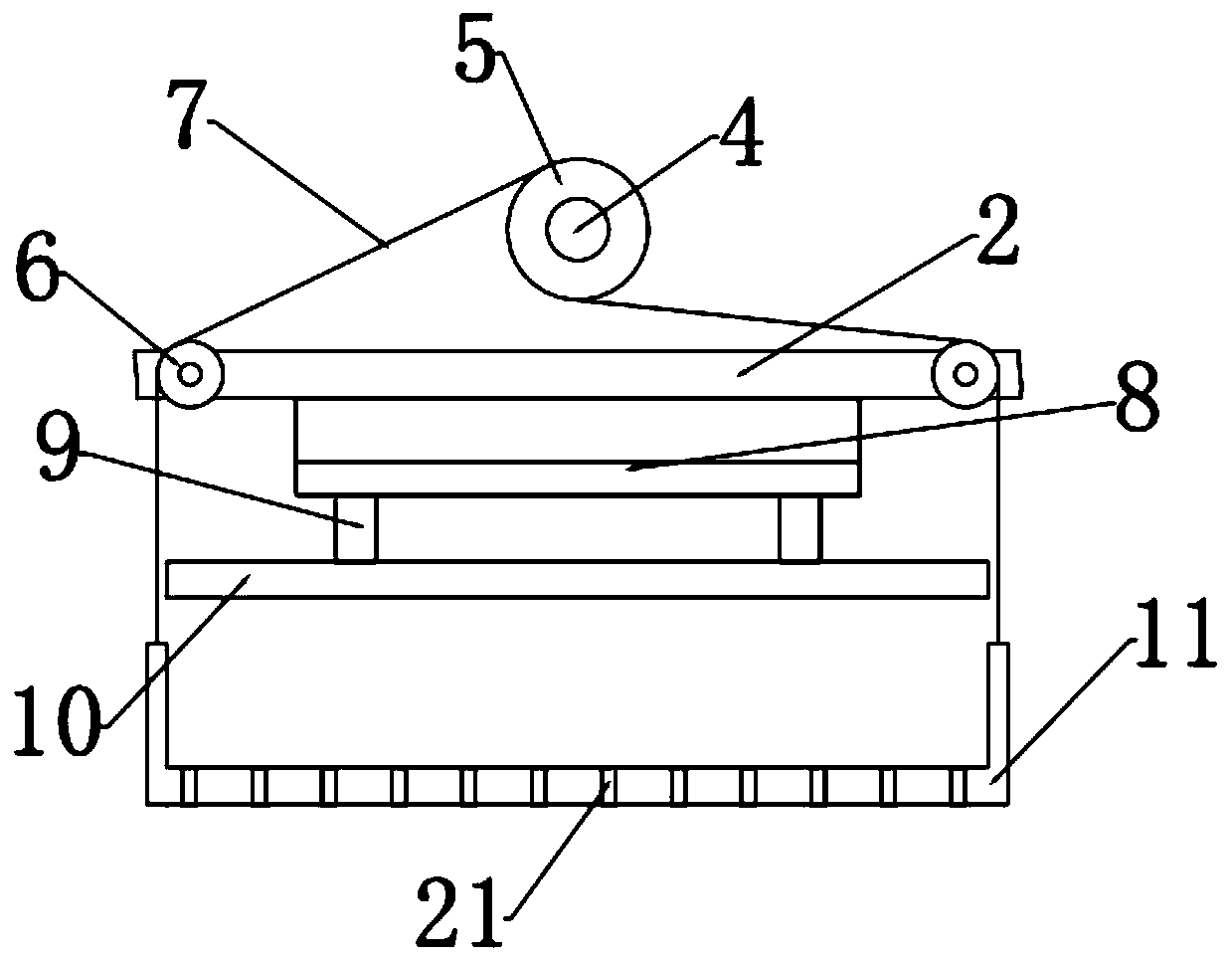

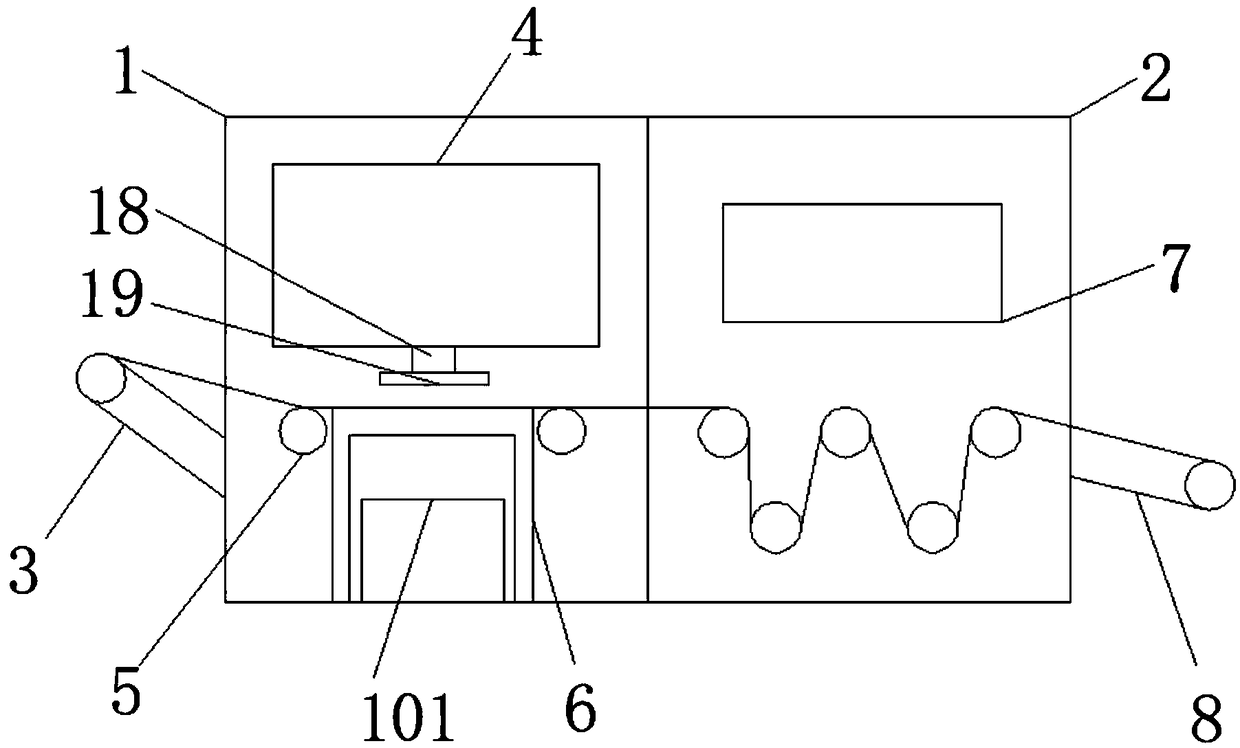

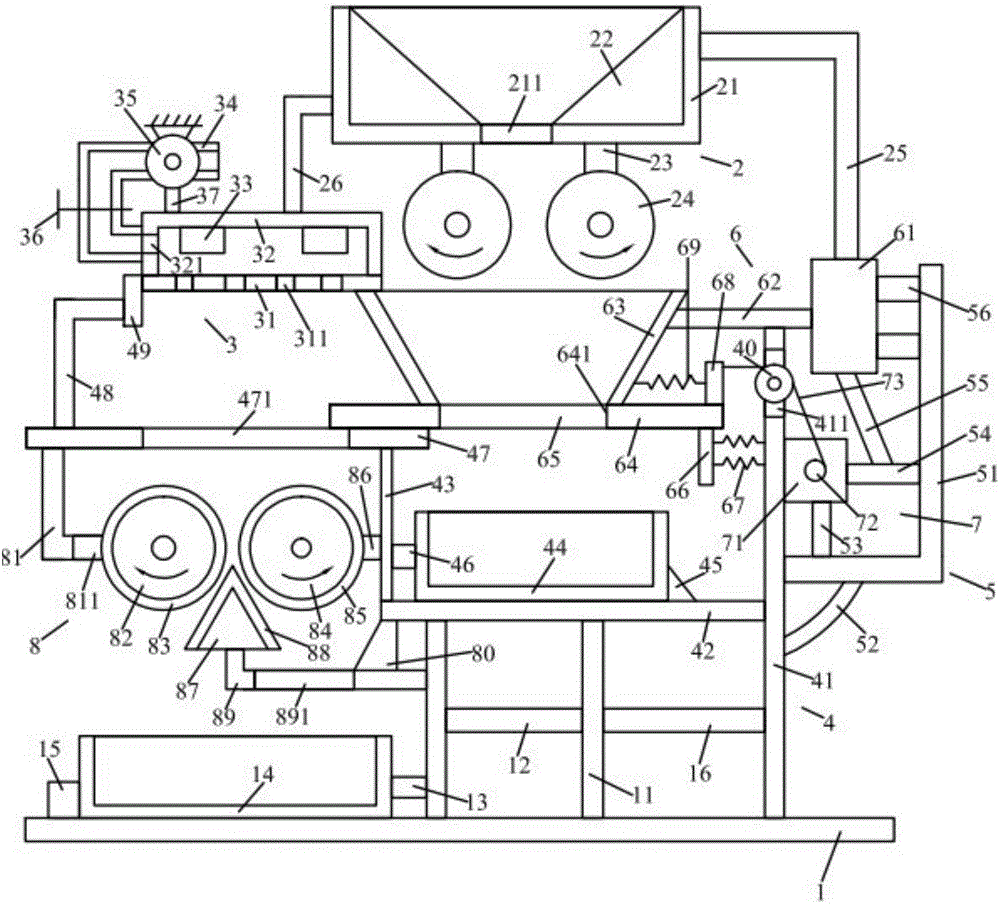

Equipment for uniformly sizing and shaping textile yarn

InactiveCN108642762AImprove sizing effectOptimize sizing and setting effectTextile treatment machine arrangementsLiquid/gas/vapor removal by squeezingBristleHeating time

The invention discloses equipment for uniformly sizing and shaping textile yarn, and belongs to the technical field of textile machines. The equipment comprises a yarn unreeling device, a cleaning device, a sizing device, a shaping device and a yarn reeling device; the sizing device comprises a sizing box body, and two stretching double rollers which are symmetric left and right are arranged in aninner cavity of the sizing box body, and are in synchronous transmission through synchronous belt pulleys and a synchronous belt; guide rollers and slurry draining devices are arranged at both outersides of the stretching double rollers, the cleaning device comprises a cleaning box body, a dust collection device, a dust collection hood, a cleaning fixed cover and flexible bristles, and the shaping device comprises a shaping box body; an inner cavity of the shaping box body is provided with shaping adjusting grooves, adjusting screws, guide cylinders and butterfly nuts, and electric heating sheets are arranged at the top, the bottom and the front side wall of the inner cavity of the shaping box body. By means of the equipment for uniformly sizing and shaping the textile yarn, sizing is uniform and sufficient, and the shaping and heating time is adjustable, and the purpose of optimizing the effect of sizing and shaping the yarn is achieved.

Owner:CHANGXING DEHONG MACHINERY CO LTD

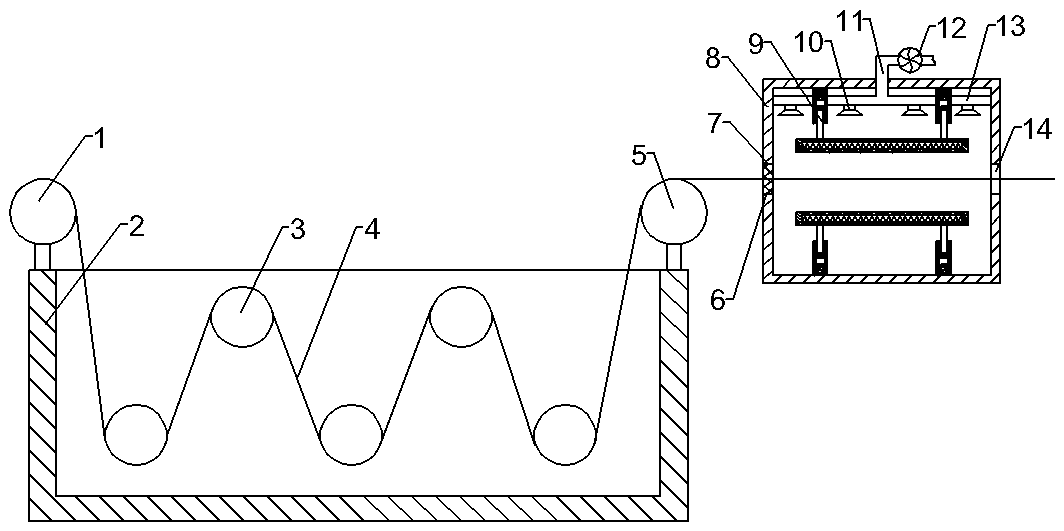

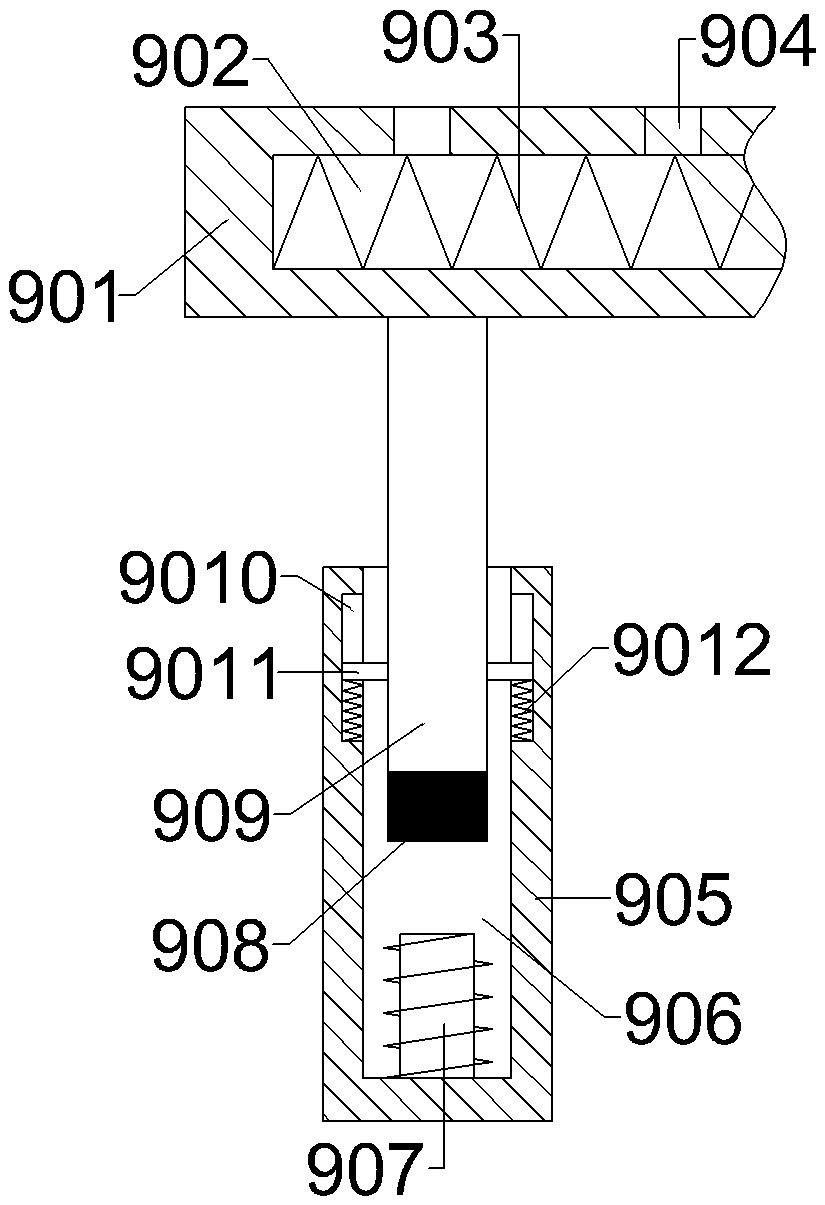

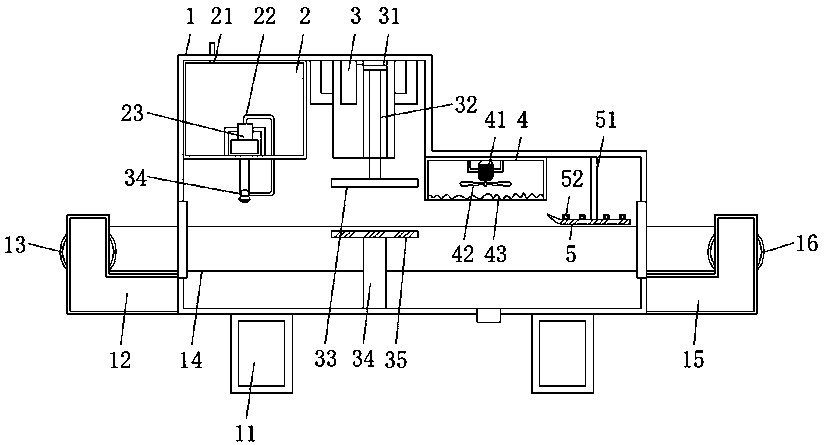

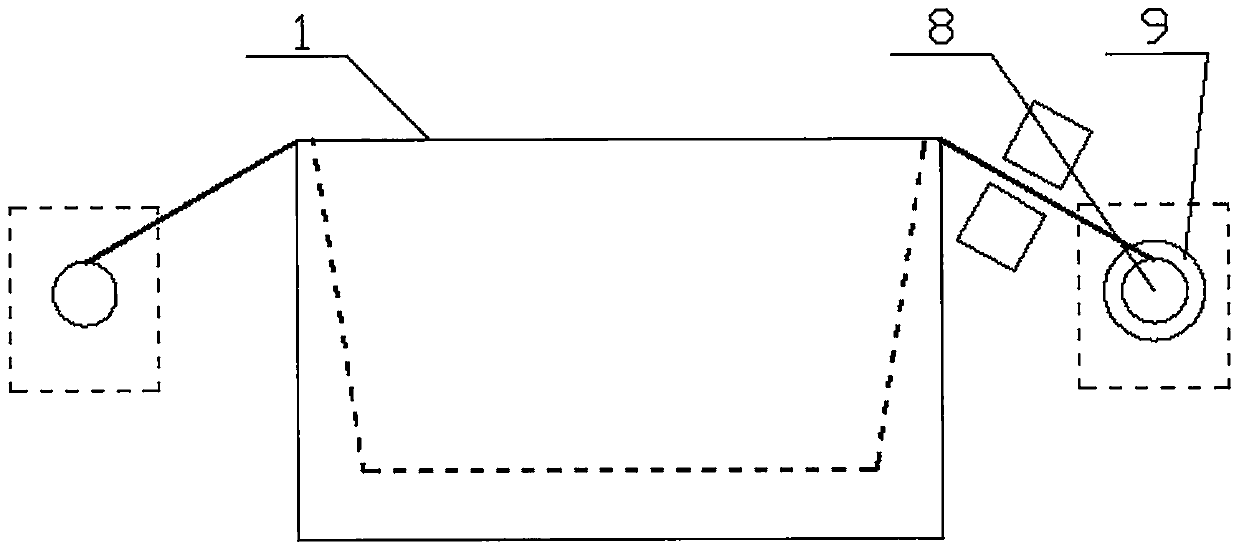

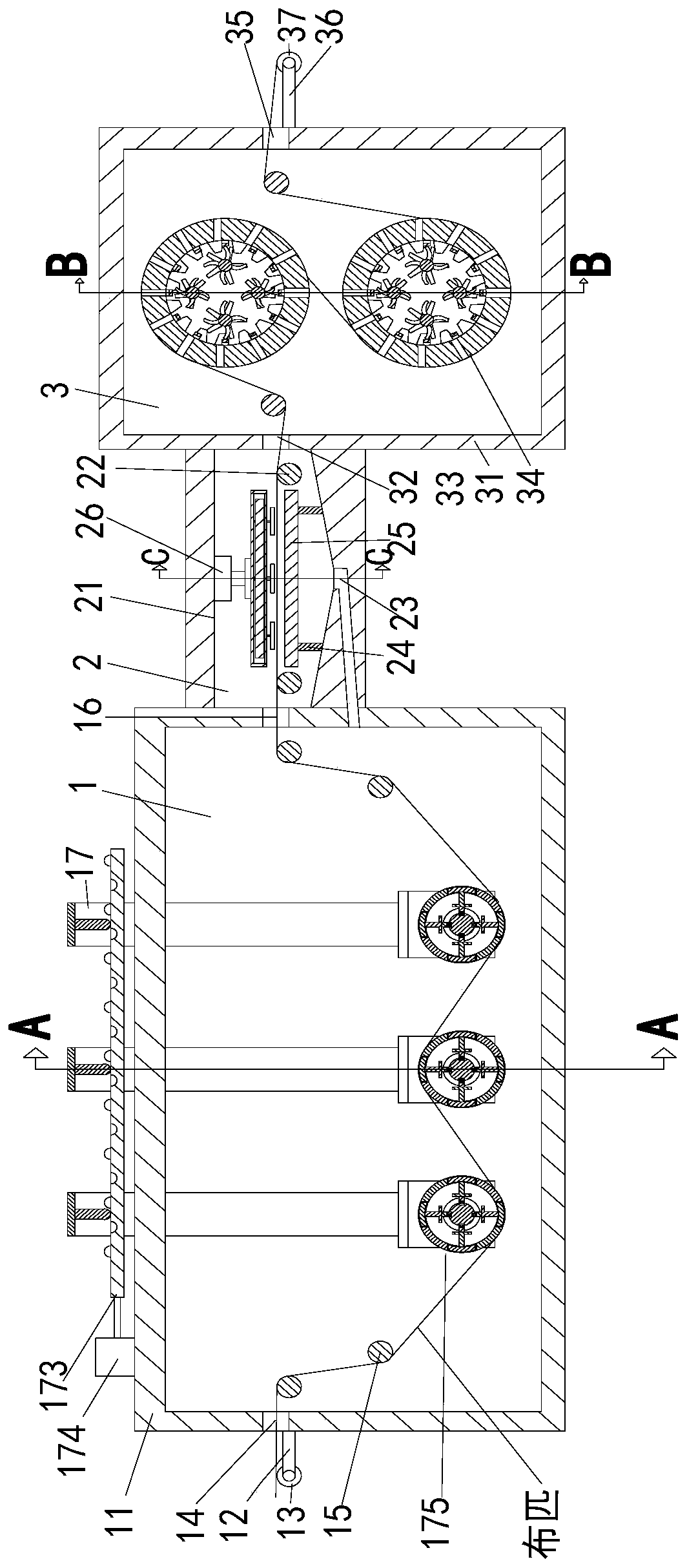

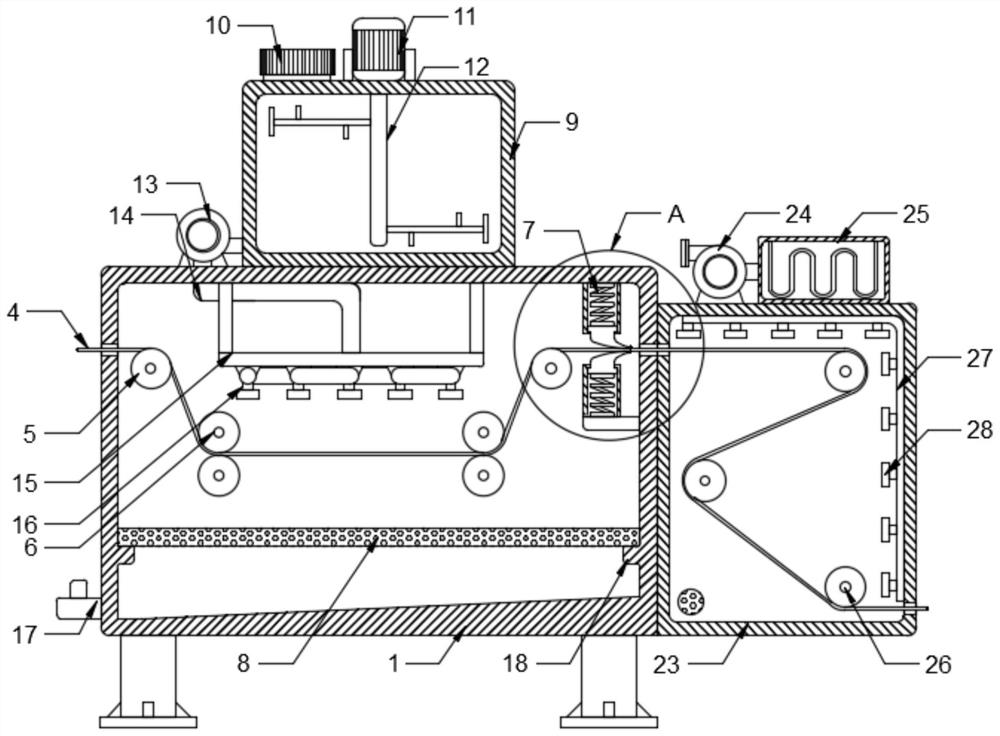

Textile fabric dyeing and drying device with drying distance adjustable function

InactiveCN108360183AExtended contact pathEasy to controlTextile treatment machine arrangementsLiquid/gas/vapor removal by squeezingEngineeringDyeing

A textile fabric dyeing and drying device with a drying distance adjustable function comprises a dyeing tank, a fabric unwinding roller, a fabric winding roller and a drying device. The fabric unwinding roller and the fabric winding roller are arranged on the upper sides of the two sides of the dyeing tank respectively. A plurality of guide rollers are arranged in the dyeing tank. A textile fabricsequentially penetrates through the fabric unwinding roller, the guide roller and the fabric winding roller. The drying device is arranged on the right side of the dyeing tank, and comprises a dryingbox. A fabric inlet and a fabric outlet are formed in the left side wall and the right side wall of the drying box respectively. The textile fabric penetrates through the fabric inlet and the fabricoutlet. A squeezing layer is arranged on the textile inlet. Two heating devices are symmetrically arranged at the upper portion and the lower portion of the drying box. A gas distributing pipe is arranged on the inner top of the drying box and communicated with a gas inlet pipe. The textile fabric dyeing and drying device has the advantages that the contact route of the textile fabric and a dryingagent is lengthened through the guide rollers, the dyeing time and dyeing effect are shortened and improved, then the textile fabric is dried, work efficiency is improved, and processing time is shortened.

Owner:严梓展

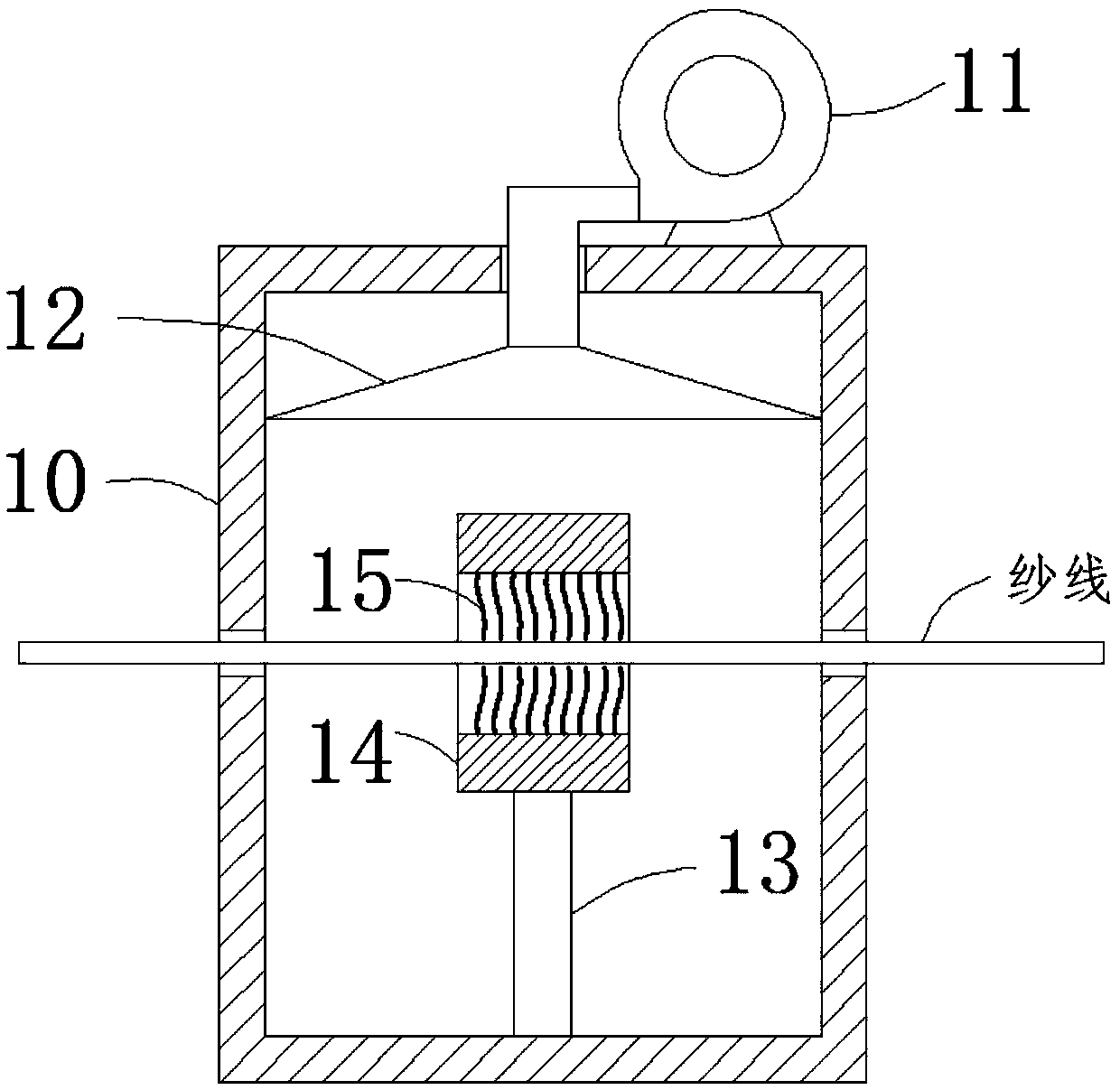

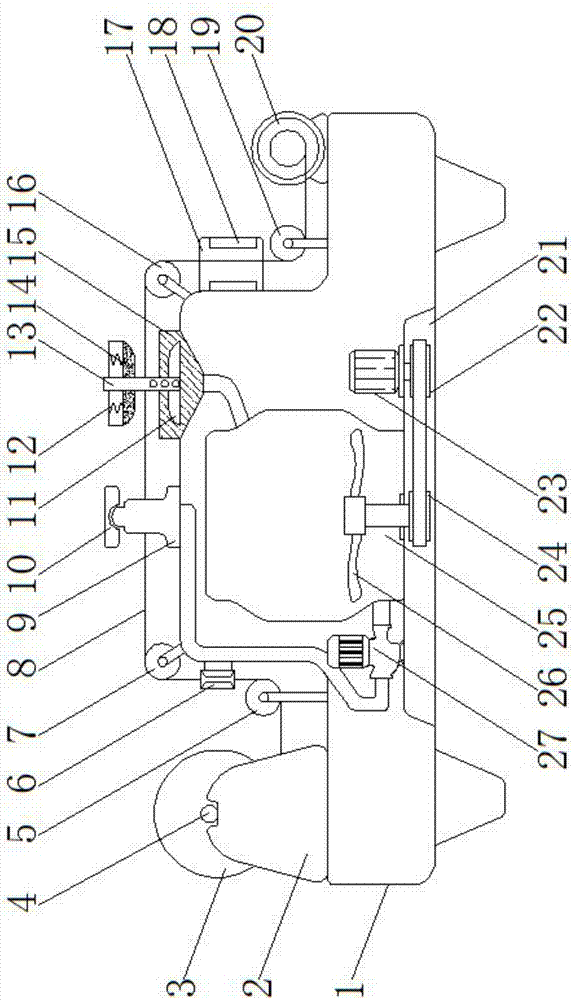

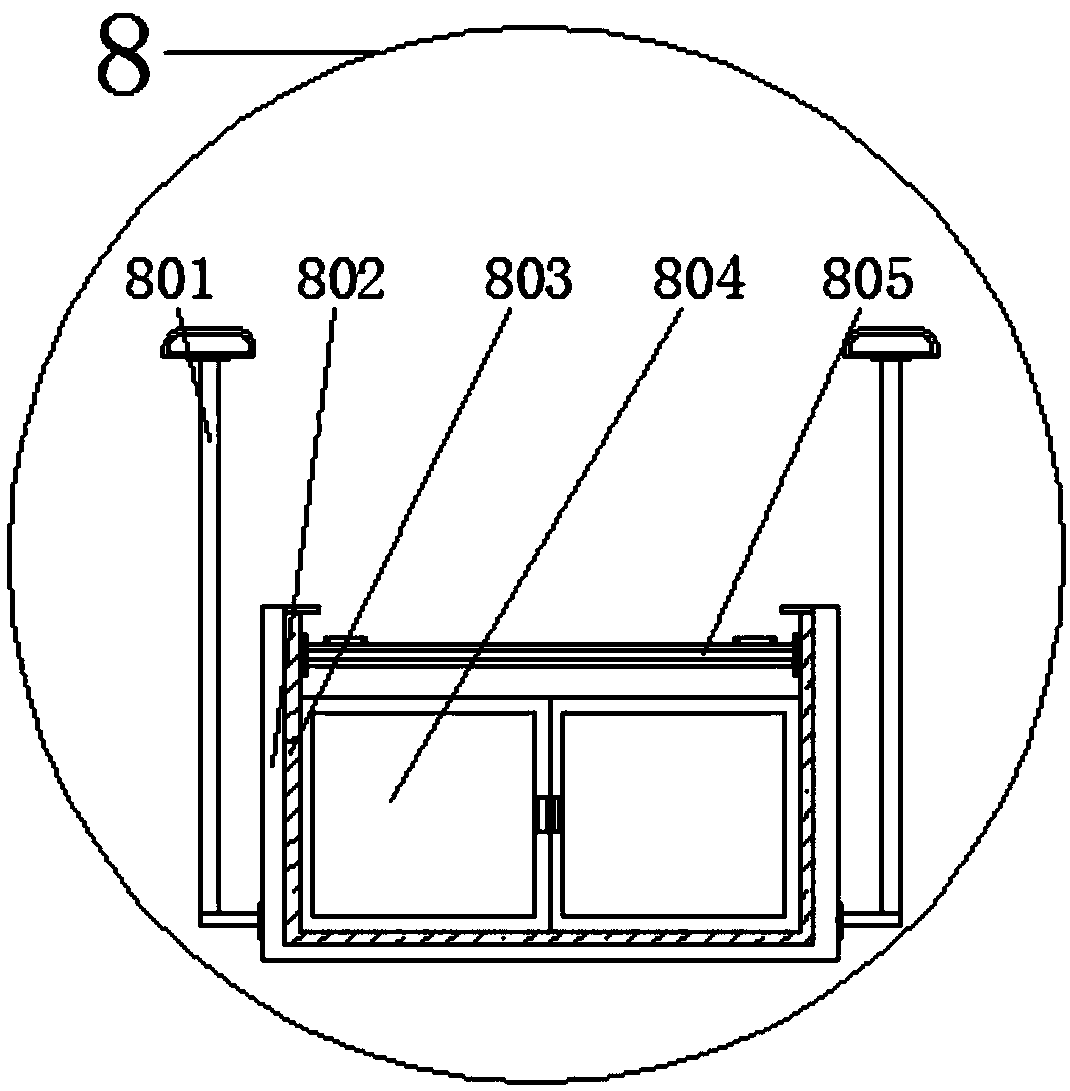

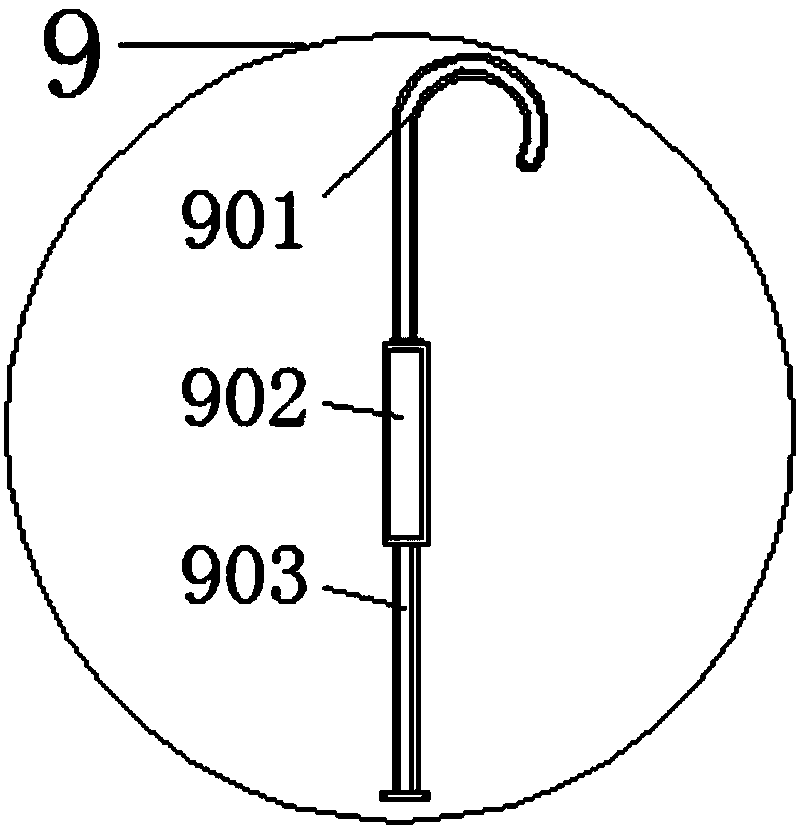

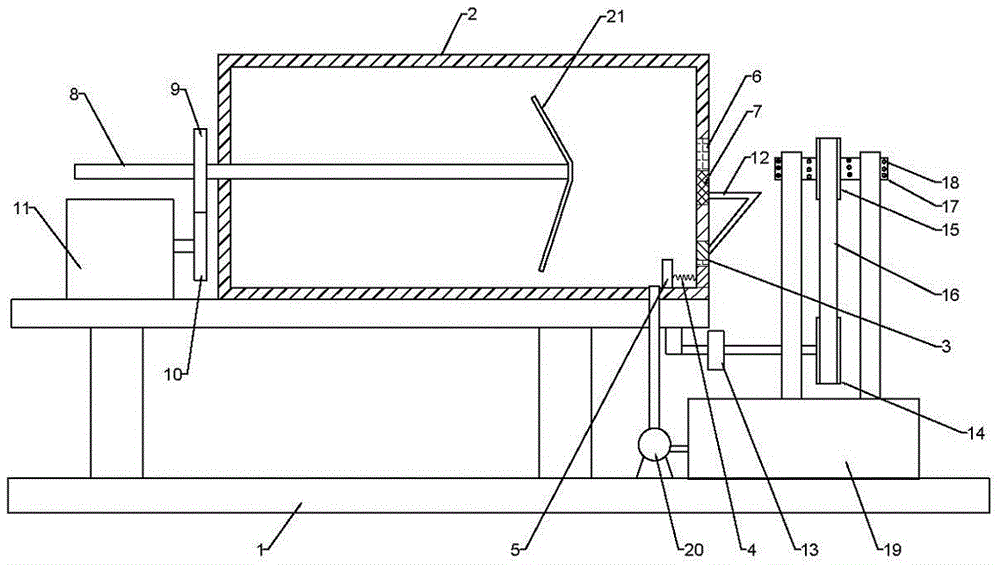

Continuous tie-dye machine

InactiveCN107805902ATo achieve the purpose of extruding the dye solutionAvoid contaminating the working environmentTextile treatment containersLiquid/gas/vapor removal by squeezingEngineeringTop cap

The invention provides a continuous tie-dyeing machine, which includes a device main body, a dye liquor extruding mechanism and a tightening mechanism. The cover is installed on the upper end of the dyeing vat through the support rod, the upper end of the electric telescopic rod is fixed on the lower end of the top cover, the liquid removal plate is installed in the dyeing vat through the connecting plate, the lower end of the electric telescopic rod is equipped with a hook, and the dye liquid extrusion mechanism is assembled on the detachment On the top surface of the liquid plate, the dye liquid extrusion mechanism includes a square rod, a square groove, a fixed arc plate, a square mouth, a movable arc plate and an extrusion plate, and the tightening mechanism includes a fixed block, an electric telescopic rod two, a round hole one, Limit plate, pull rod, limit plate one, round hole two, strip plate, round hole three, and limit plate two, compared with the prior art, the present invention has the following beneficial effects: it has reached the Purpose, also reached the purpose of automatic tightening.

Owner:中山市睿普自动化科技有限公司

Environment-friendly textile dyeing machine capable of recycling surplus dyeing agent

InactiveCN106988047AAchieve agitationImprove uniformityTextile treatment machine arrangementsLiquid/gas/vapor removal by squeezingPulp and paper industryTextile dyeing

The invention discloses an environment-friendly textile dyeing machine capable of recycling a surplus dyeing agent. The environment-friendly textile dyeing machine comprises a main machine body, cloth supporting shelves, an upper squeezing plate, a base and a stirring device, the bottom end of the inside of the main machine body is provided with the base, the middle position above the base is fixedly provided with a dyeing pool, a water pump is installed above the base on one side of the dyeing pool, the end, away from the water pump, of the base is provided with a second motor, the inside of the dyeing pool is provided with the stirring device, one end above the main machine body is symmetrically provided with two cloth supporting shelves, the top end of the main machine body of the side, away from one side of a second cloth guiding wheel, of a lower dyeing plate is provided with a feed collection shell, the top end, away from one side of the lower dyeing plate, of the feed collection shell is provided with a third cloth guiding wheel, and the end, away from the cloth supporting shelves, above the main machine body is provided with a first motor. In the environment-friendly textile dyeing machine capable of recycling the surplus dyeing agent, the dyeing effect of the dyeing machine is improved, the working efficiency in dyeing cloth is improved, winkling of cloth is avoided at the same time, and the waste of resources and pollution of the environment are avoided.

Owner:嘉兴业成染整有限公司

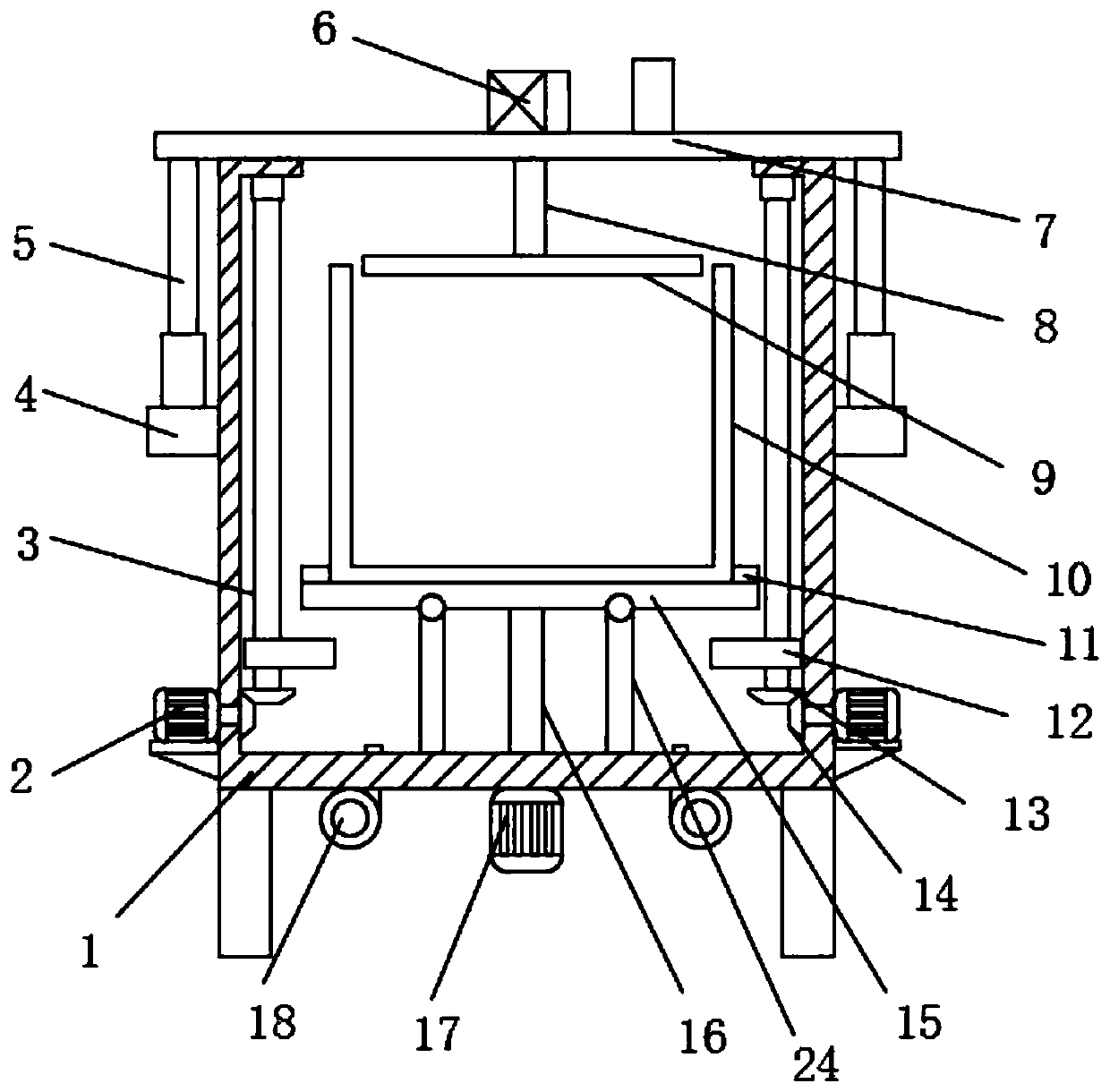

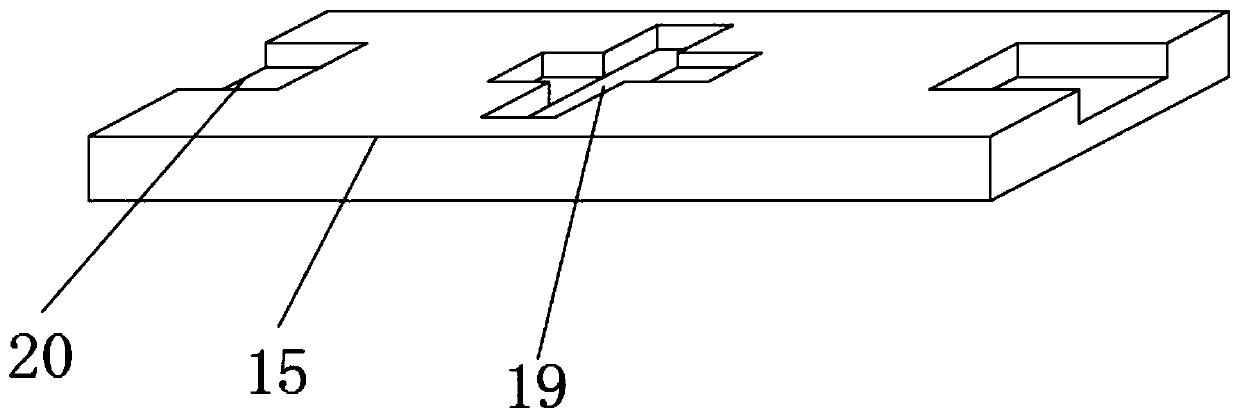

Automatic post processing device for clothes

InactiveCN108505239AQuick washTo achieve the effect of washing clothesLiquid/gas/vapor removal by squeezingTextile treatment by spraying/projectingHydraulic cylinderEngineering

The invention discloses an Automatic post processing device for clothes. The automatic post processing device for clothes comprises a main body box, a water tank, a drying box, an ironing board and aflushing pipe, wherein a notch is formed on the end surfaces of both sides of the main body box, a first mounting rack and a second mounting rack are respectively arranged at the two notches, the endsurface of the second mounting frame is provided with a first motor, the water tank is installed in the main box, and the flushing pipe is installed at the lower end of the water tank through a mounting rod, the lower end of the flushing pipe is provided with a spray head, the hydraulic cylinder is provided with a hydraulic rod, the lower end of the hydraulic rod is provided with a pressing plate,a supporting plate is arranged below the pressing plate, the drying box is positioned on one side of the pressing plate, the inner wall of the upper end of the drying box is provided with a second motor, the tail end of the output shaft of the second motor is provided with a fan blade, a heating wire is arranged below the fan blade, and the ironing plate is arranged at one side of the drying boxthrough a fixing rod. The automatic post processing device for clothes has the advantages of high-efficiency cleaning of clothes, drying and ironing, and convenient follow-up treatment.

Owner:HAINING JINCHUAN LEATHER CLOTHING CO LTD

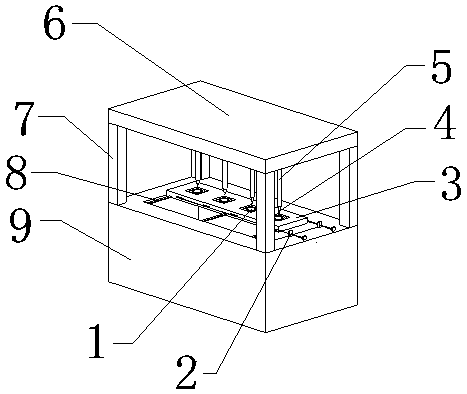

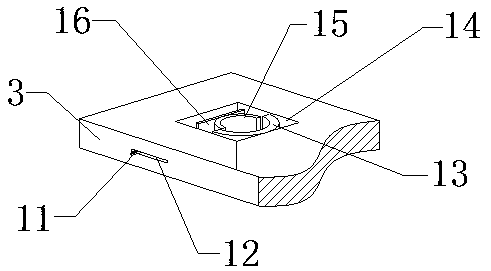

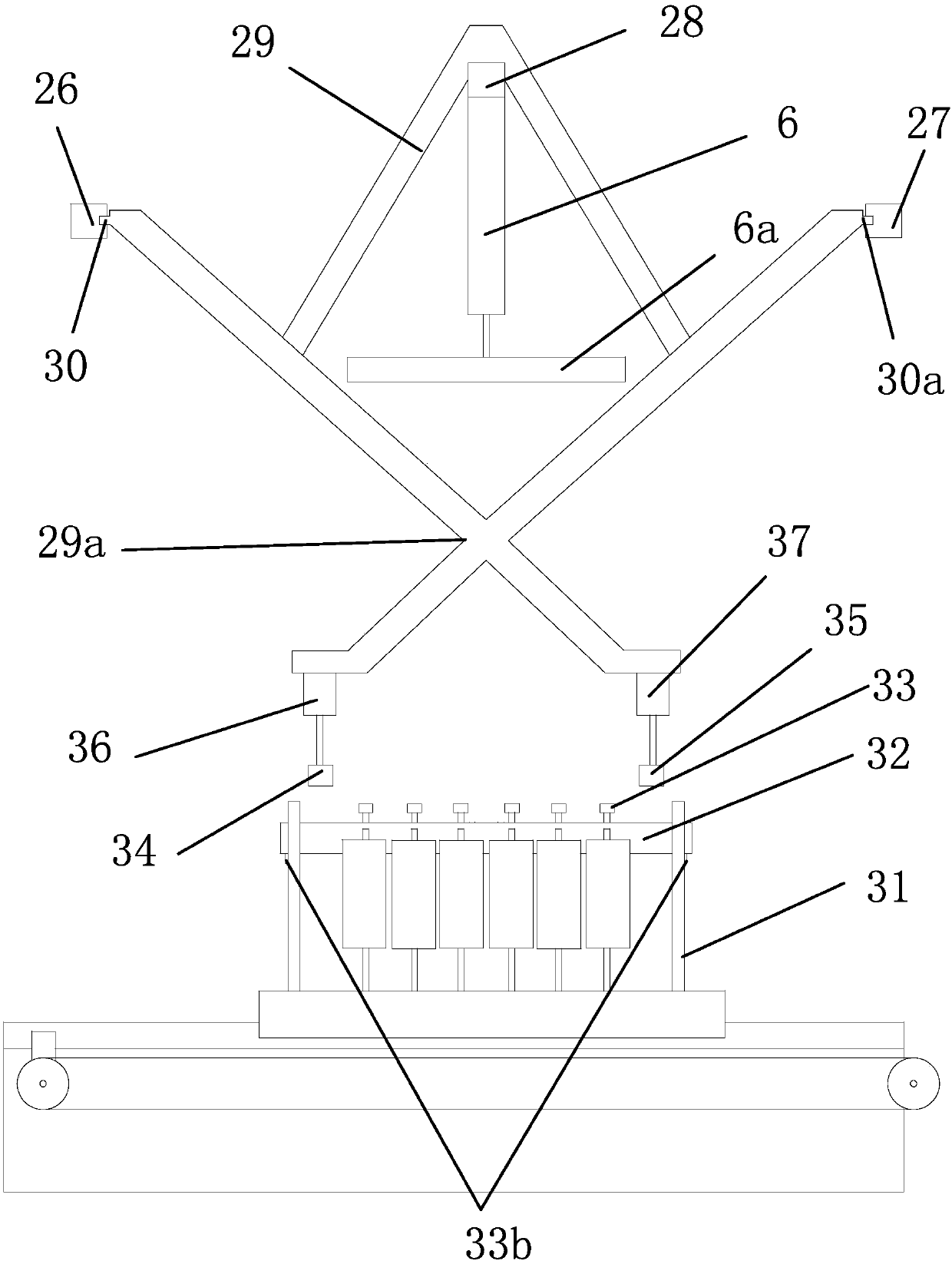

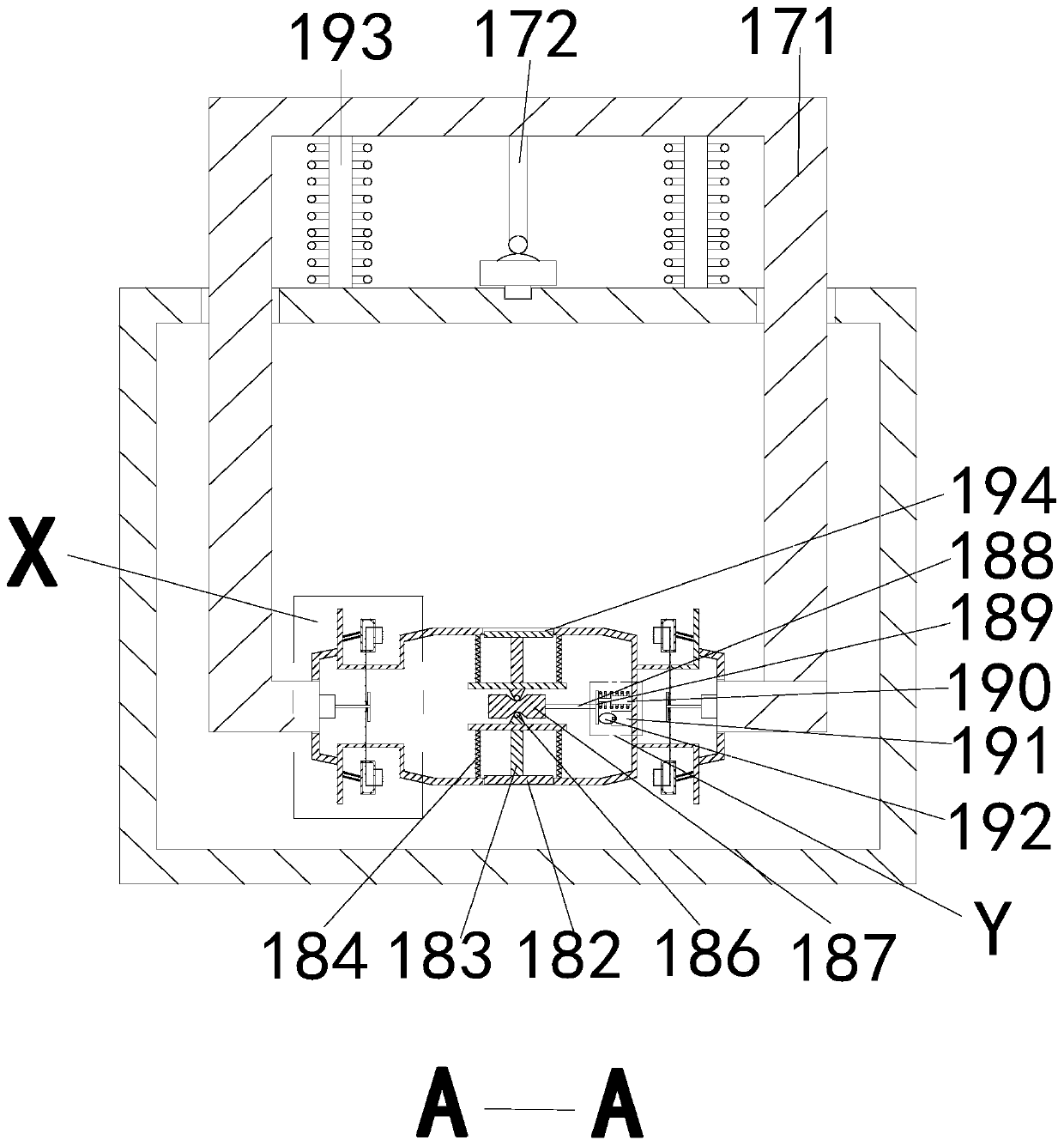

Dyeing processing device for socks

PendingCN110512383AEasy loadingFully contactedLiquid/gas/vapor article treatmentTextile treatment machine arrangementsSOCKSEngineering

The invention relates to the technical field of sock production, in particular to a dyeing processing device for socks. The device comprises a shell, a top plate is fixedly connected to the inner sideof the shell, a connecting plate is fixedly connected to the bottom of the top plate, dyeing frames are arranged on the lower sides of the left end and the right end of the connecting plate respectively, the dyeing frames are connected with a driving mechanism arranged on the top of the top plate, a dyeing box is arranged below one dyeing frame, the bottom of the dyeing box is connected with a moving mechanism. Accordingly, by arranging the driving mechanism, the dyeing frames on the left side and the right side can rise and fall at the same time, the dyeing frames can make full contact withthe dyeing box, and when the dyeing frame on one side performs dyeing, the dyeing frame on the other side performs feeding conveniently; by arranging pressing plates, socks located in the dyeing frames can be pressed in the process that the socks leave the dyeing box, so that residual dyeing liquid in the socks is discharged, and waste of the dyeing liquid is lowered; meanwhile, the dyed socks canbe dried rapidly, and subsequent processing is facilitated.

Owner:LANGSHA KNITTING

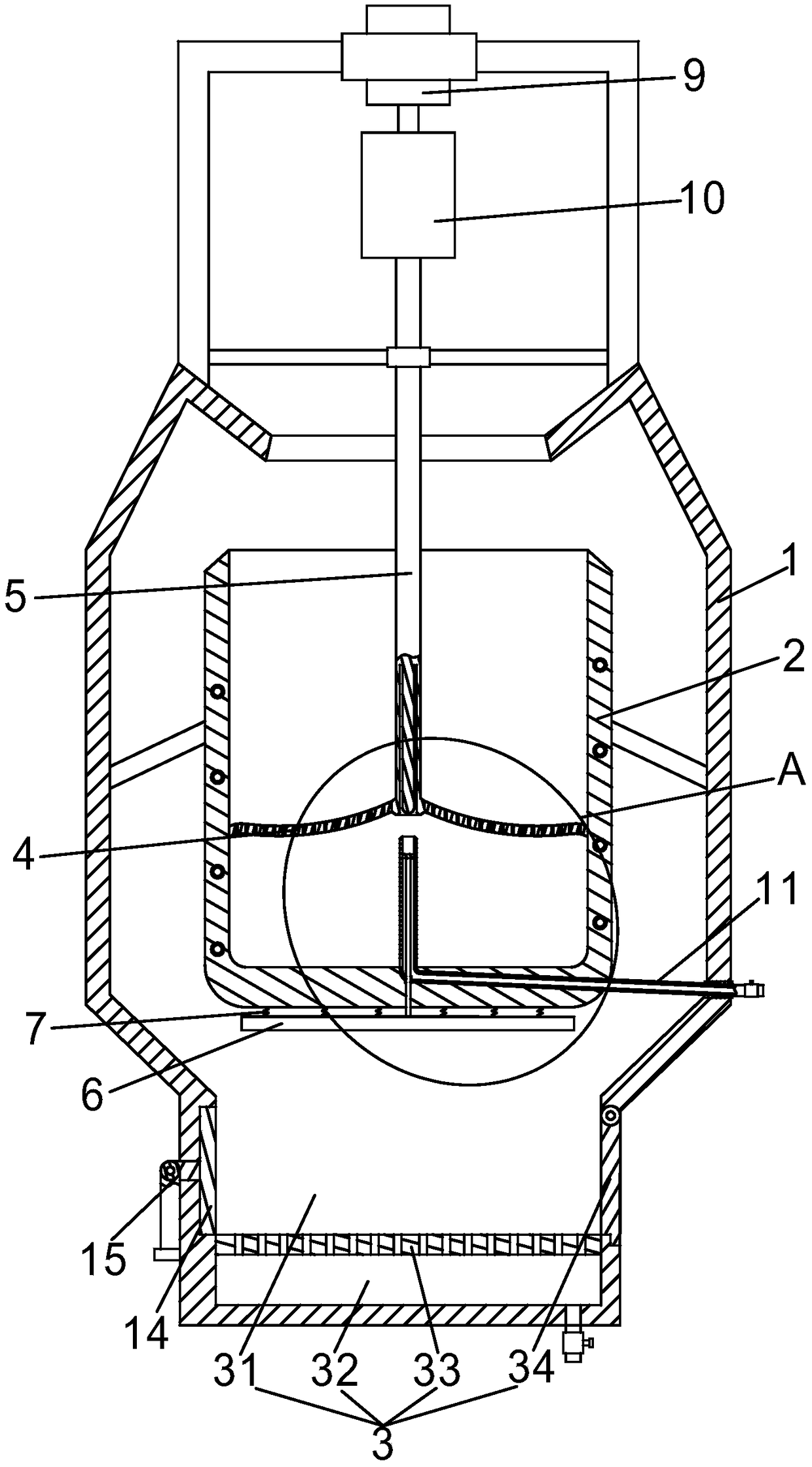

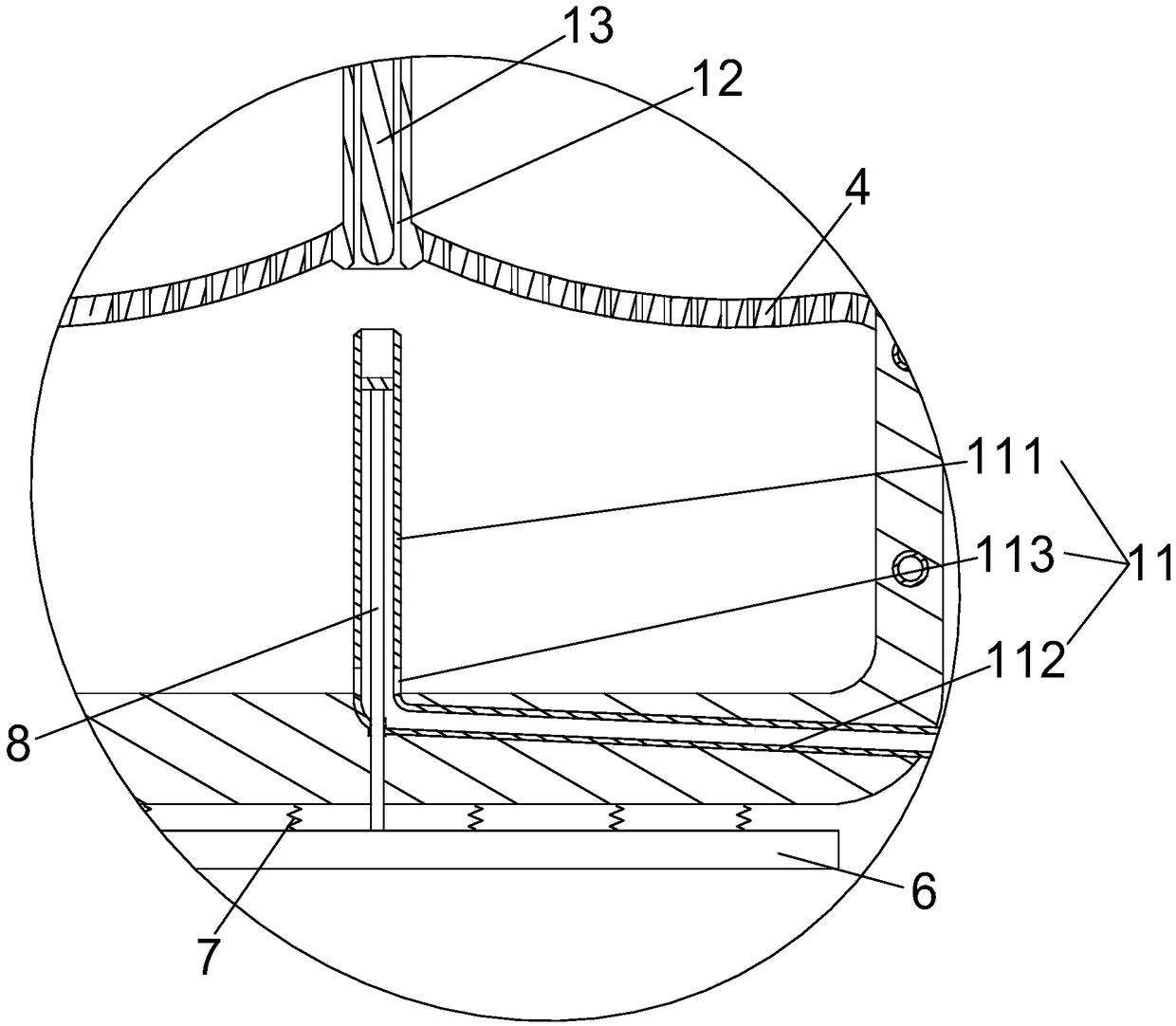

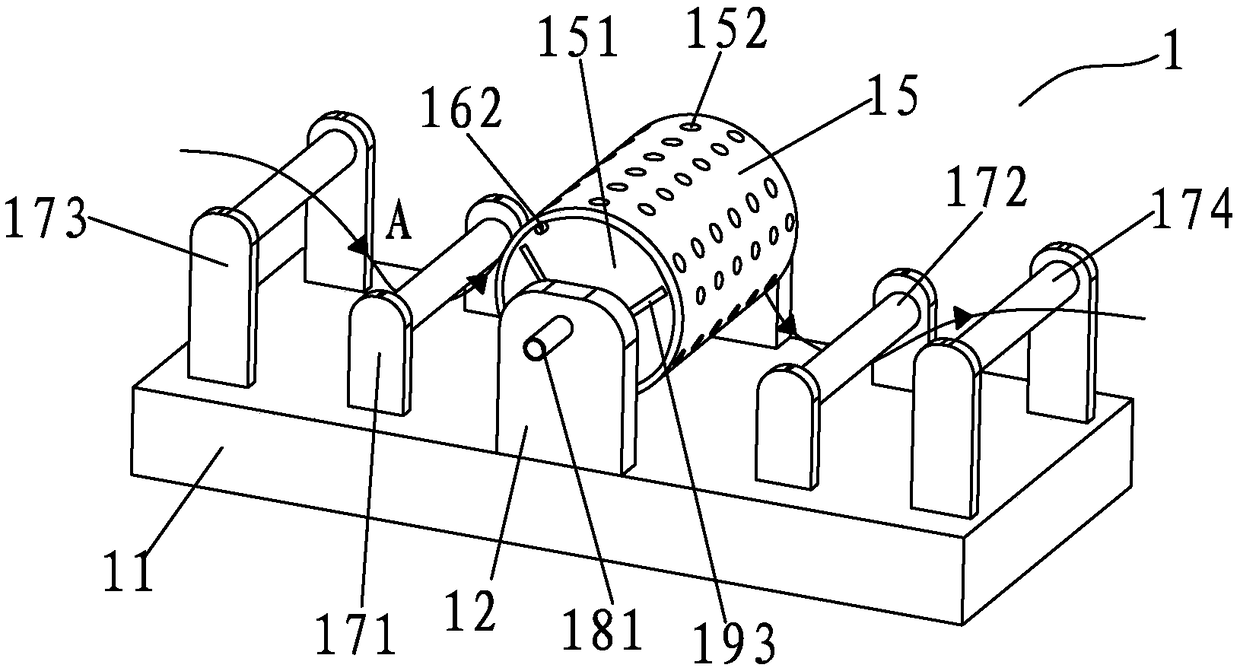

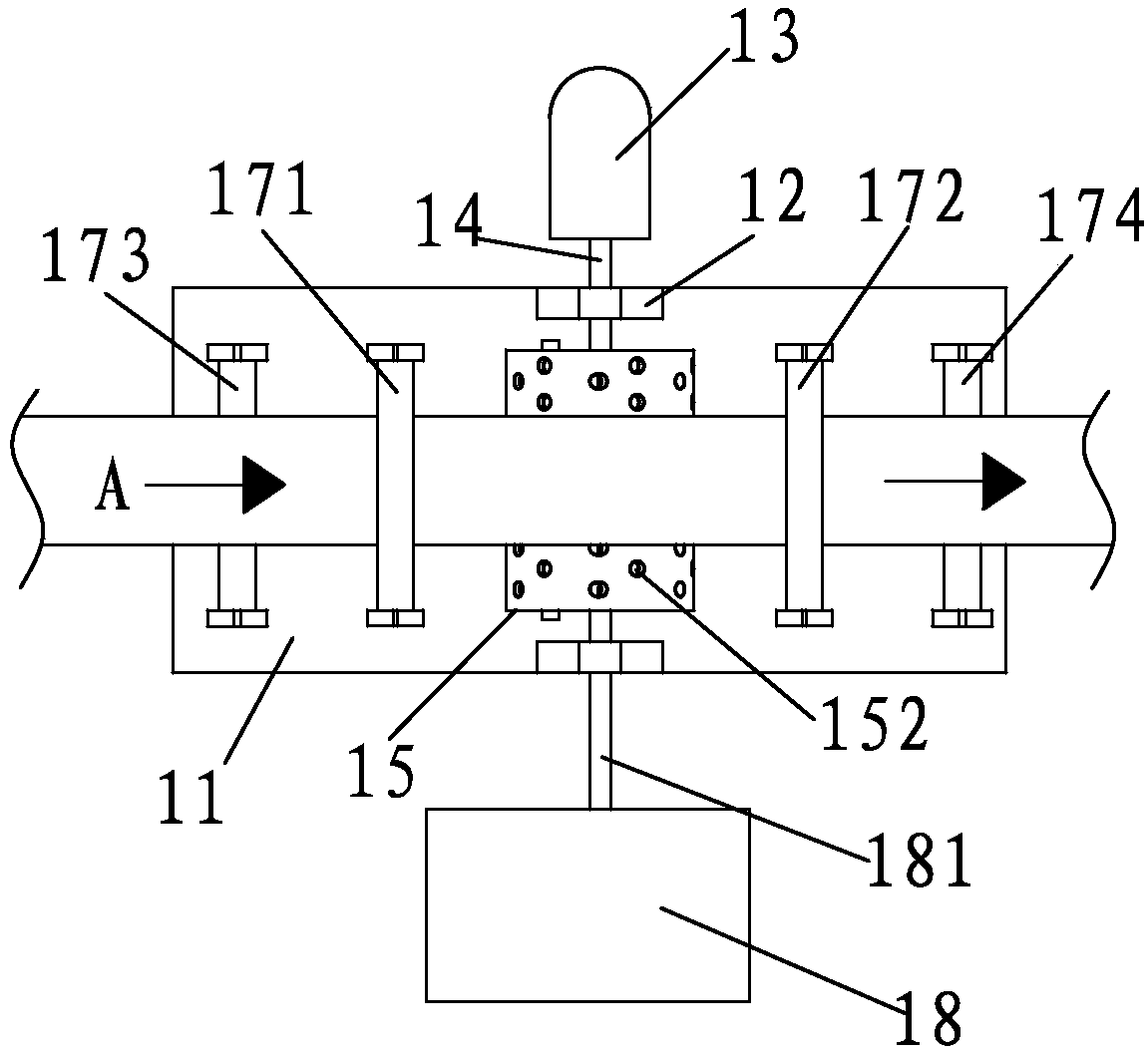

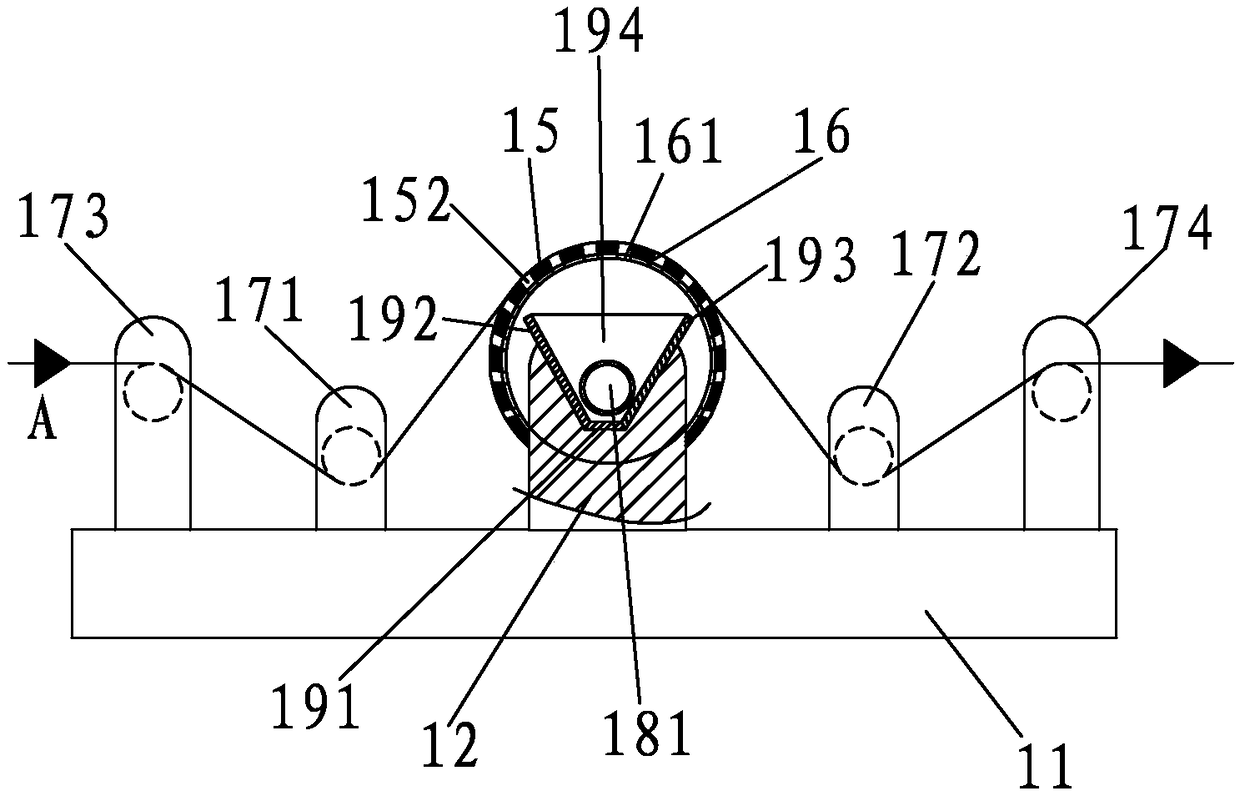

Dying processing device for socks

InactiveCN108660660AUniform dyeingImprove dyeing efficiencyTextile treatment containersTextile treatment machine arrangementsSOCKSEngineering

The invention discloses a dyeing processing device for socks, the dyeing processing device comprises a processing tank, wherein a dyeing tank with an open upper end is fixedly connected into the processing tank through a plurality of supporting rods, and the part, positioned below the dyeing tank, of the processing tank is an extrusion filtering bin, an agitating filtering screen plate is rotatably arranged in the dyeing tank, and the agitating filtering screen plate is matched with a rotating lifting mechanism; the rotating lifting mechanism comprises a power component which is connected withthe agitating filtering screen plate through a telescopic shaft; an extrusion plate is arranged in the extrusion filtering bin, and a transmission component for driving the extrusion plate to move upand down in a reciprocating manner is matched with the expansion of the telescopic shaft as driving force, the transmission component comprises a plurality of elastic resetting pieces and driving rods connected between the extrusion plate and the outer bottom of the dyeing tank, the driving rods penetrate into the dyeing tank and slide freely, and the telescopic shaft extends to push the drivingrods so as to slide against the driving rods. Compared with the prior art, the dyeing device is convenient to quickly separate the socks from the dyestuff, thereby reducing the waste of the dyestuff.

Owner:湖北福兴织业有限公司

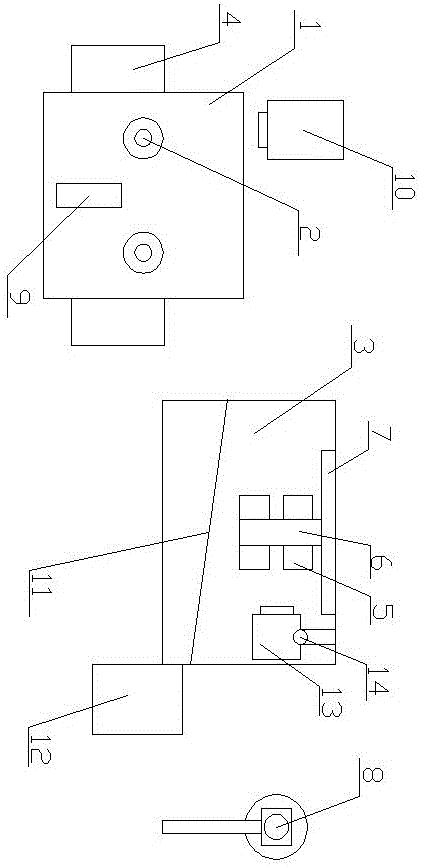

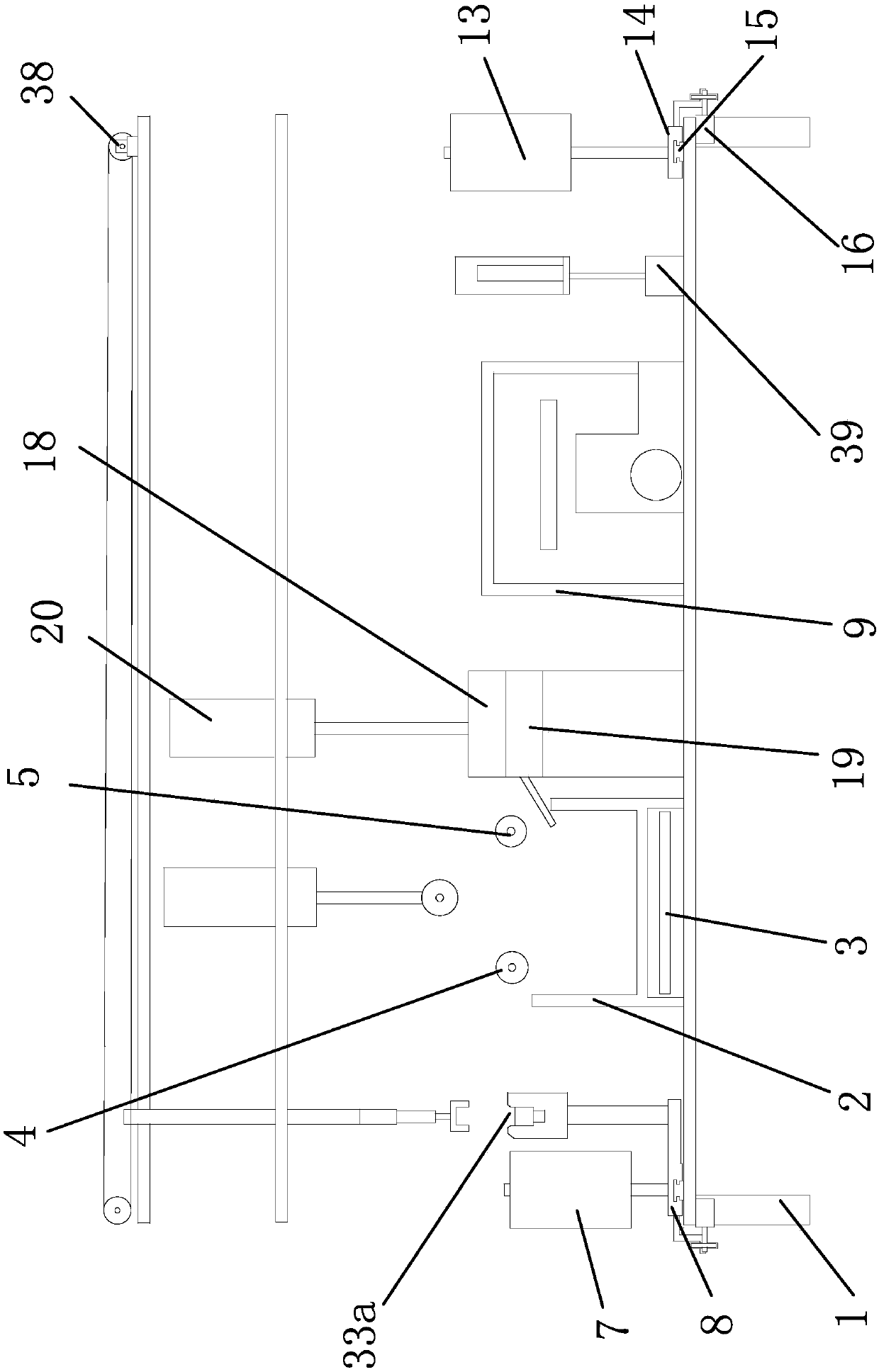

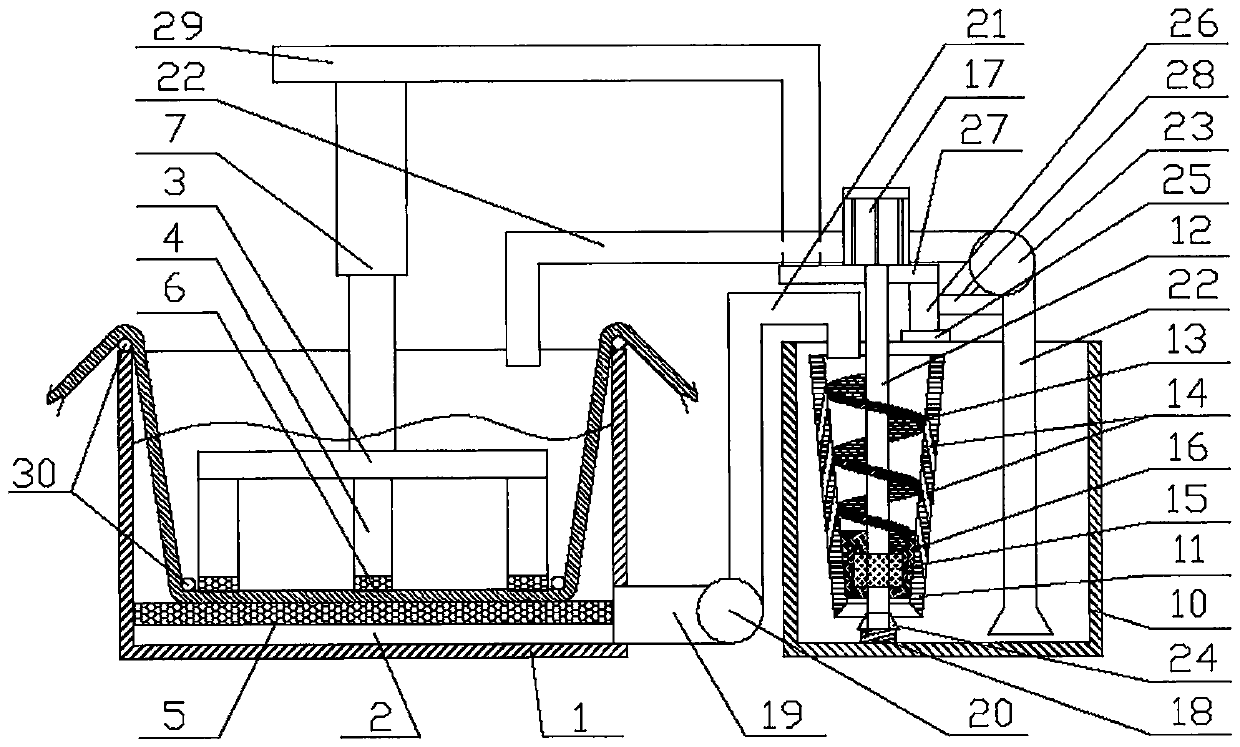

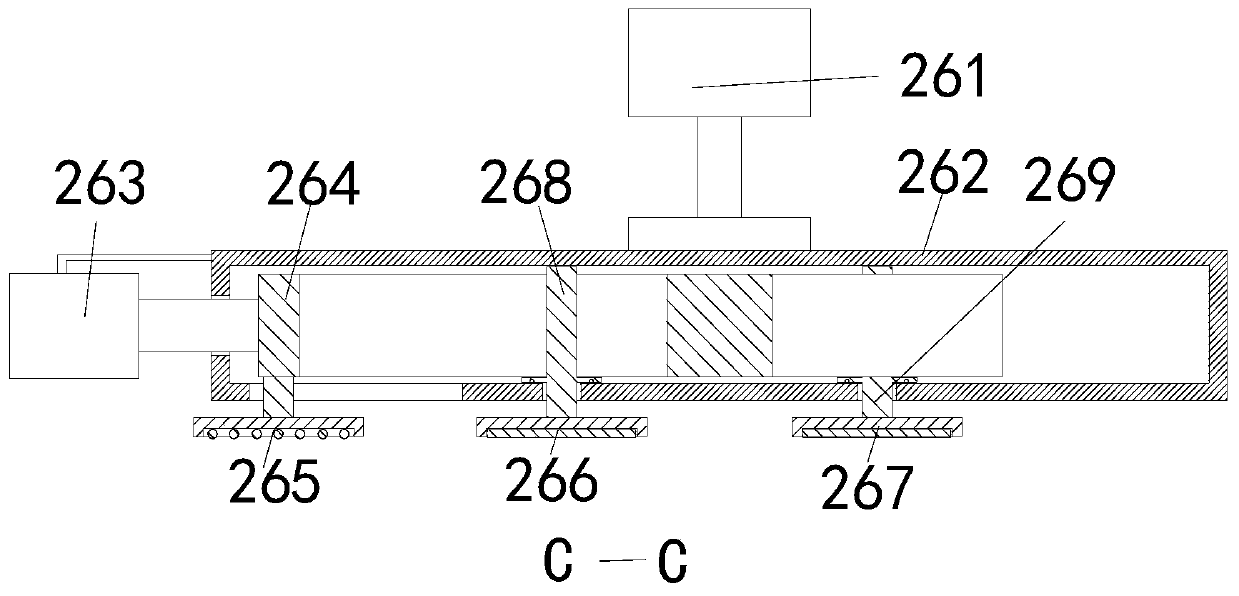

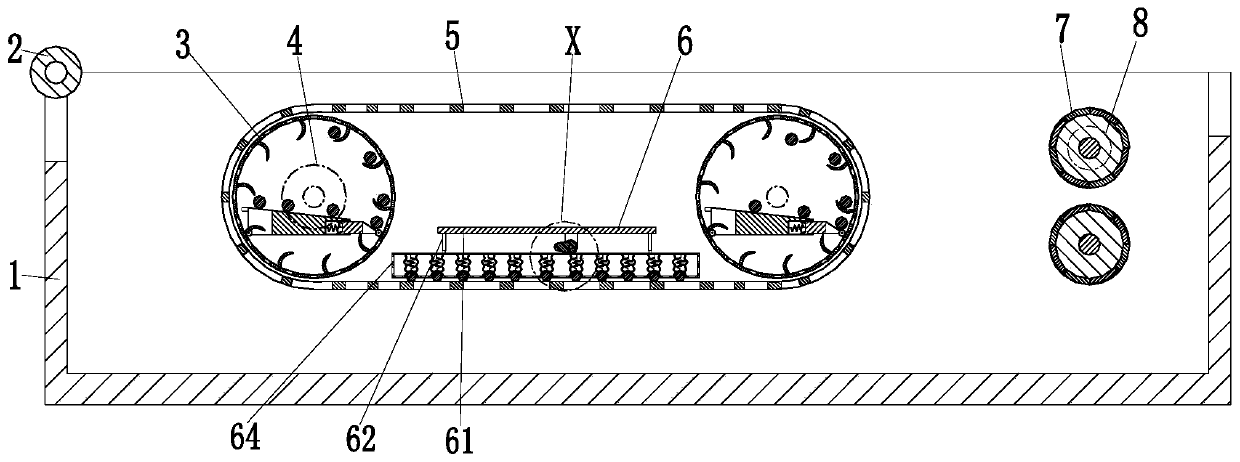

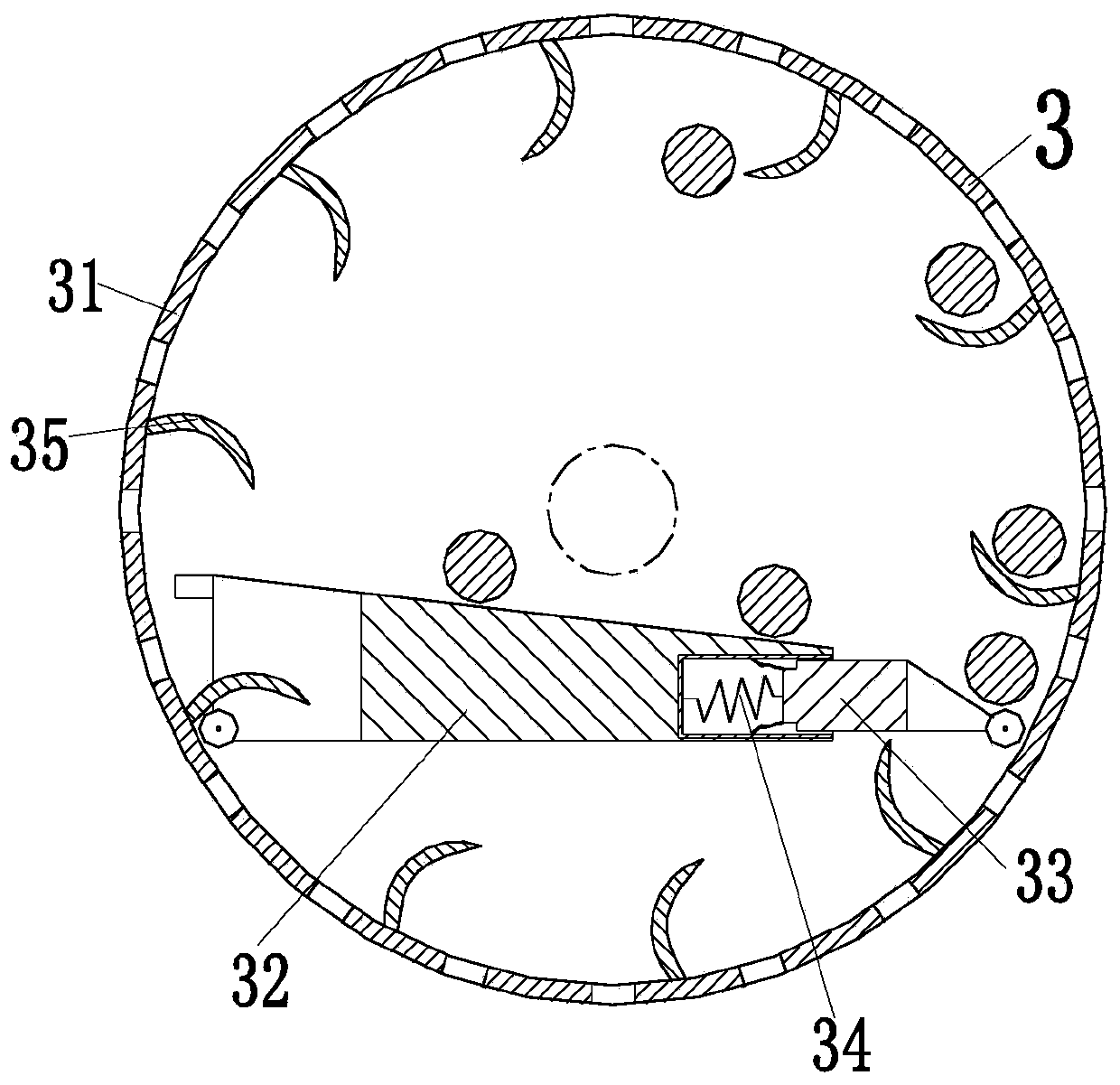

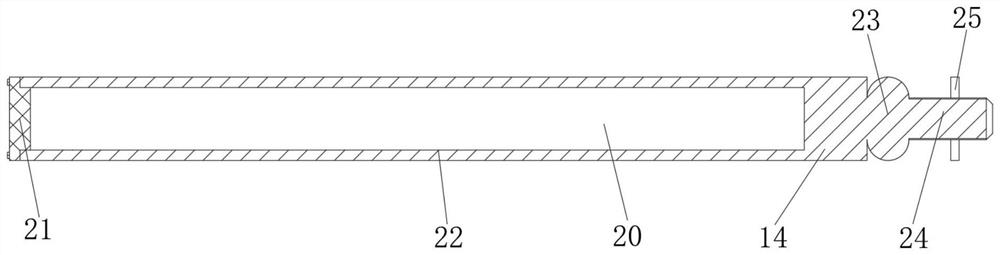

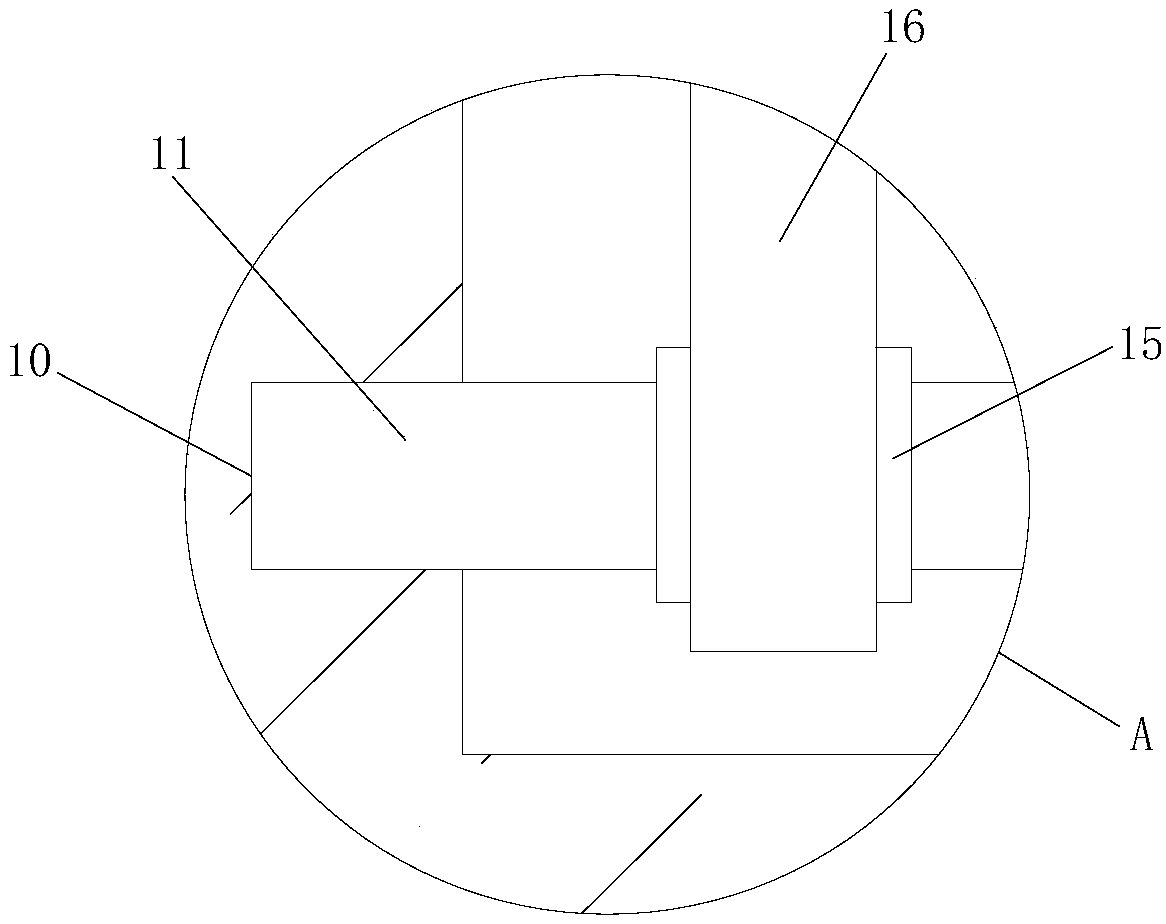

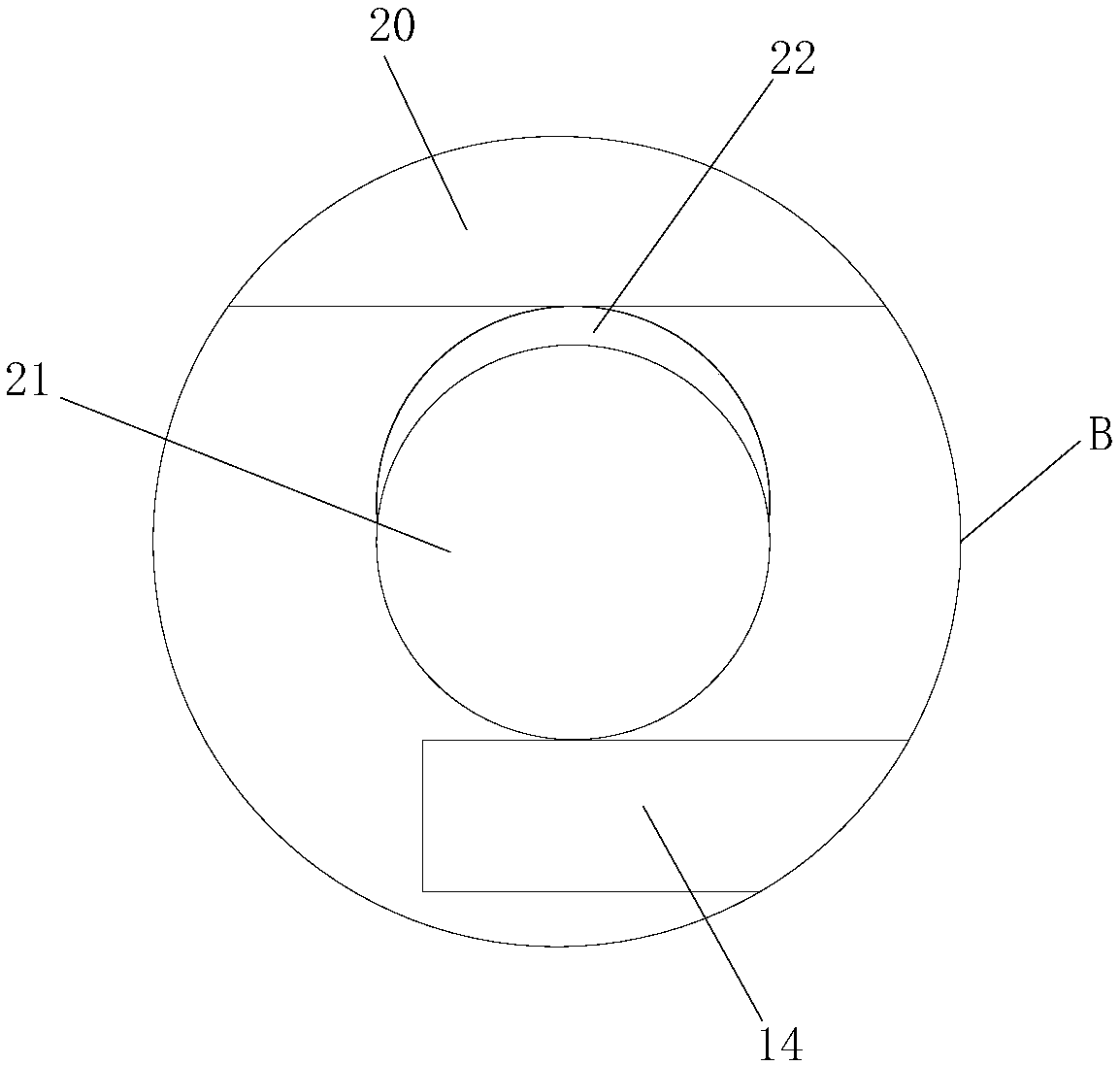

Yarn dyeing device

ActiveCN107723962AShorten the timeImprove efficiencyTextile treatment machine arrangementsLiquid/gas/vapor removal by squeezingYarnHydraulic cylinder

The invention provides a yarn dyeing device and belongs to the technical field of machinery. The technical problems of low dyeing efficiency and the like of an existing dyeing device are solved. The yarn dyeing device includes a machine frame and is characterized in that the machine frame is provided with a dyeing box internally provided with a cavity, dye is disposed in the dyeing box, an electromagnetic heating ring is disposed on the lower portion of the dyeing box, the dyeing box is provided with a first roller and a second roller, and the first roller is parallel to the second roller. A first hydraulic cylinder is fixedly arranged on a fixing frame, a piston rod of the first hydraulic cylinder is vertically downwards, a third roller is fixedly arranged at the end of the piston rod ofthe first hydraulic cylinder, and the third roller is located between the first roller and the second roller. A plurality of yarn placing barrels are disposed on one side of the dyeing box. The yarn dyeing device has the advantage of being high in dyeing efficiency.

Owner:江苏中祥线带有限公司

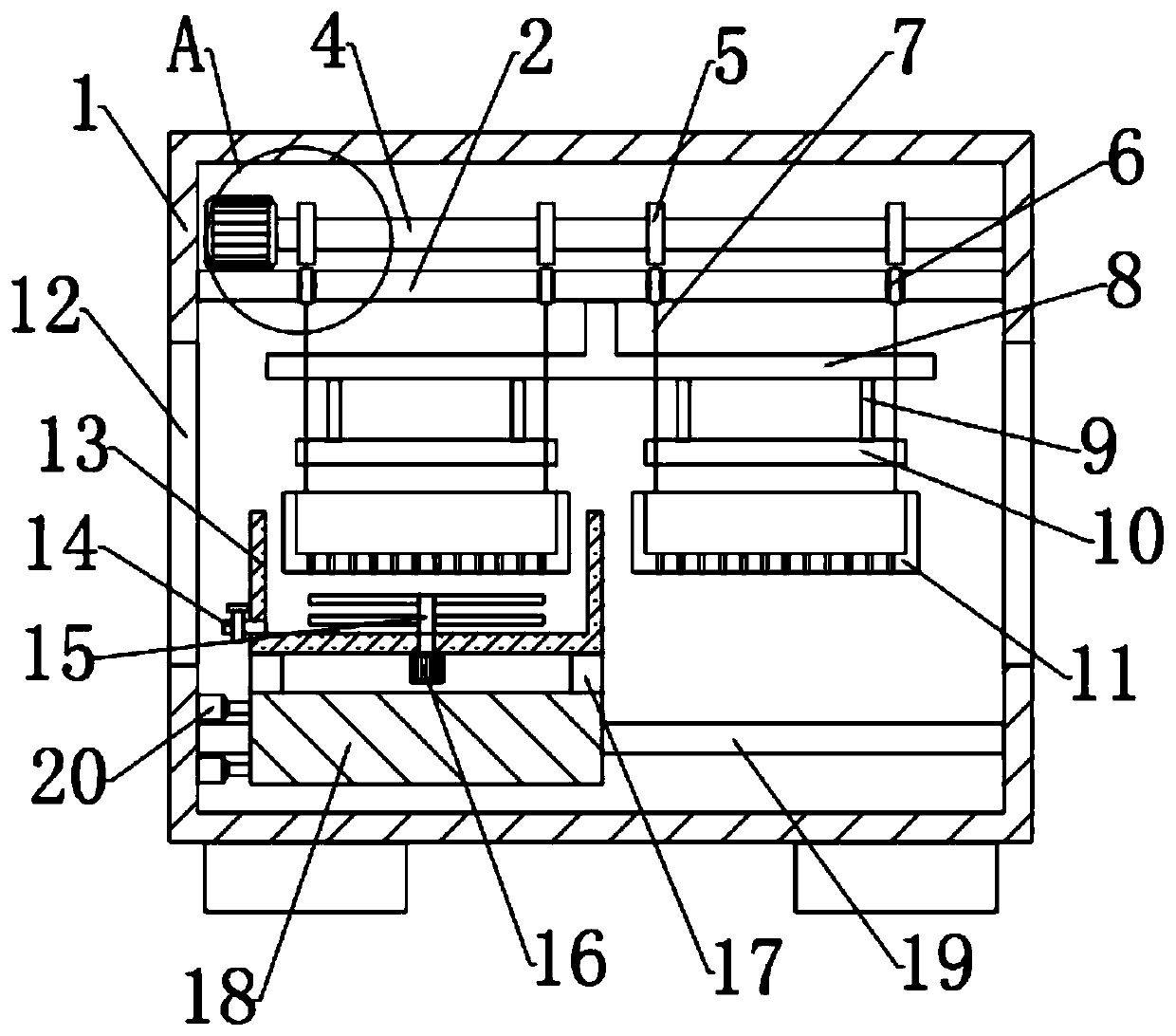

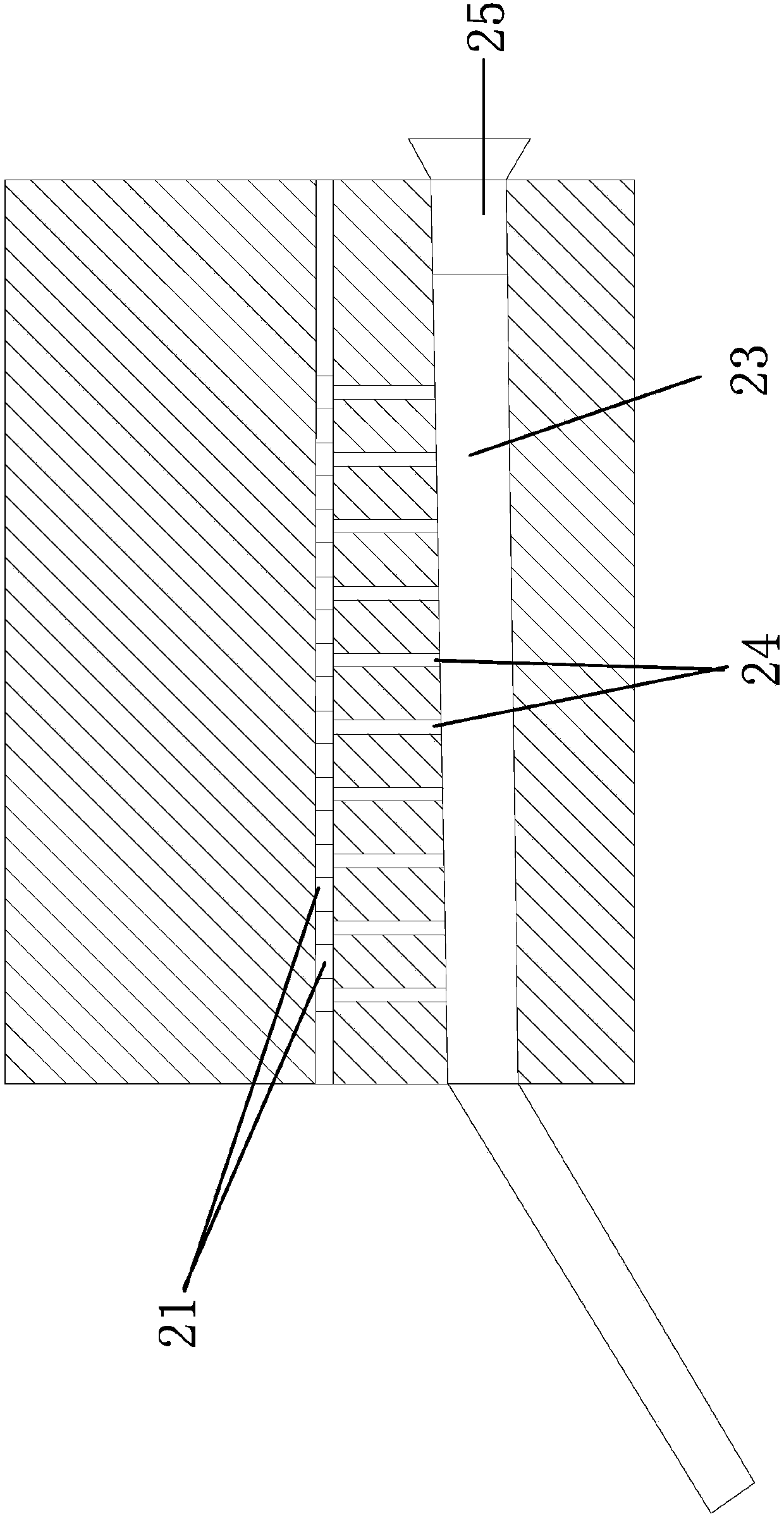

Dyeing processing equipment for production of plain socks

InactiveCN108642769AImprove dyeing efficiencyEasy to operateNon-rotating vibration suppressionLiquid/gas/vapor article treatmentSOCKSHeat conducting

The invention discloses dyeing processing equipment for production of plain socks. The equipment includes a vertical rod, a hanging rod, a pigment addition device, a dyeing cylinder, a liquid drainagepipe, a stirring rack, a rotating disc, a built-in type motor, a supporting rod body, a pulling rod and a feeding pipe; a vertical rail is arranged on the inner side of the vertical rod, damping springs are installed at the bottom of a damping plate, and a transverse rod is fixedly connected to the upper side of the pulling rod; a drying chamber is formed in the lower side of the feeding pipe, aheat conducting chamber is formed in the center of the drying chamber, an electric heating resistance wire is arranged on the inner side of the heat conducting chamber, and a wire connection disc is fixedly connected to the bottom of the electric heating resistance wire; the damping plate is arranged on the lower side of the wire connection disc, and the wire connection disc is connected to a power supply connecting line through the damping plate. The equipment is simple and novel in structure and easy to operate. Through arrangement of two dyeing cylinders for synchronous dyeing processing, the efficiency of dyeing the socks is higher; moreover, the structure is relatively simple, use functions are diversified, the production cost is low, and the equipment is applicable to large-scale production.

Owner:海宁市汉达袜业有限责任公司

Bleaching and wiping device

PendingCN106498642AFully contactedBleach evenlyTextile treatment machine arrangementsLiquid/gas/vapor removal by squeezingEngineeringTextile production

The invention relates to the field of textile production devices, and discloses a bleaching and wiping device. The bleaching and wiping device comprises a machine frame and a bleaching box, a first through-hole and a second through-hole are formed in the bleaching box, a hinging plate is arranged below the second through-hole in a hinged mode, one side, close to the first through-hole, of the hinging plate is connected to a tension spring, an upper rotating plate and a lower rotating plate are arranged in the second through-hole in a hinged mode, a rotating push-rod is arranged in the first through-hole and the second through-hole, the rotating push-rod is connected to the first through-hole in a threaded mode, one end, close to the first through-hole, of the rotating push-rod is connected to a rotating and pushing mechanism, the lower part of the lower rotating plate is fixedly connected to a broken line plate, the lower end of the broken line plate abuts against the upper part of the hinging plate, the part, below the hinging plate, of the machine frame is provided with a mill-wheel, the mill-wheel is connected to a first belt pulley, above the first belt pulley is provided with a second belt pulley, the machine frame is provided with a wiping canister on the side, far away from the first through-hole, of the second through-hole, and the second belt pulley is arranged on the wiping canister in a sleeving mode. Compared with the prior art, integrated accomplishment of bleaching and wiping of textile fabrics can be conducted through the bleaching and wiping device.

Owner:CHONGQING DATONGMAO TEXTILE TECH CO LTD

Antibacterial thermal fabric and preparation method thereof

ActiveCN111098564AGood hygroscopicityGood moisture wicking effectLiquid/gas/vapor open-width material treatmentSynthetic resin layered productsYarnPolymer science

The invention discloses an antibacterial thermal fabric and a preparation method thereof, and belongs to the technical field of textile silk yarns. The fabric comprises the following components (by weight): 30 to 45 parts of bamboo fiber, 10 to 20 parts of Coppron copper ion fibers, 30 to 45 parts of cotton fibers, 20 to 30 parts of kapok fibers, 10 to 15 parts of filament goose down, and 10 to 15parts of thermal fibers. The preparation method comprises the following steps: firstly, blending the cotton fibers and the filament goose down fibers into silk yarns A; blending kapok fibers and partof bamboo fibers into silk yarns B; twisting the two kinds of silk yarn together to be woven into a first fabric, then blending the Coppron copper ion fibers and the remaining bamboo fibers into silkyarns C, weaving the silk yarns C and the thermal fibers into a second fabric, then bonding the two kinds of fabric together to obtain a gray fabric, and then dyeing the gray fabric and shaping. Theantibacterial thermal fabric prepared according to the preparation method provided by the invention has efficient antibacterial thermal performance, and is relatively good in air permeability and comfort.

Owner:YANCHENG SILIDE COCOON SILK

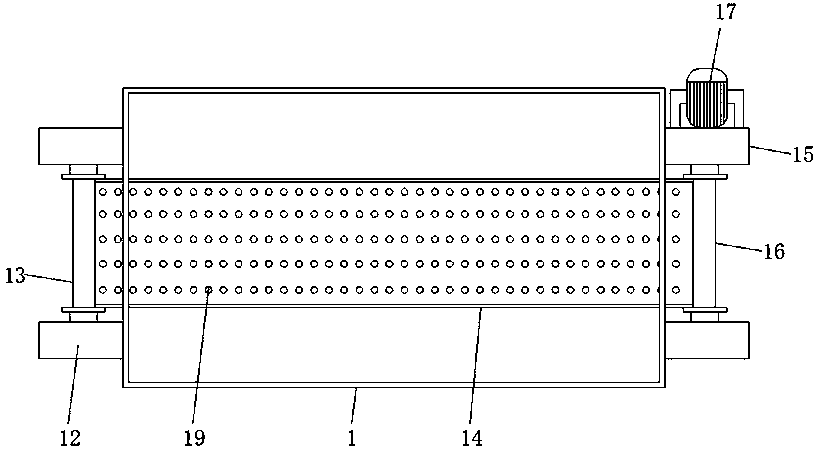

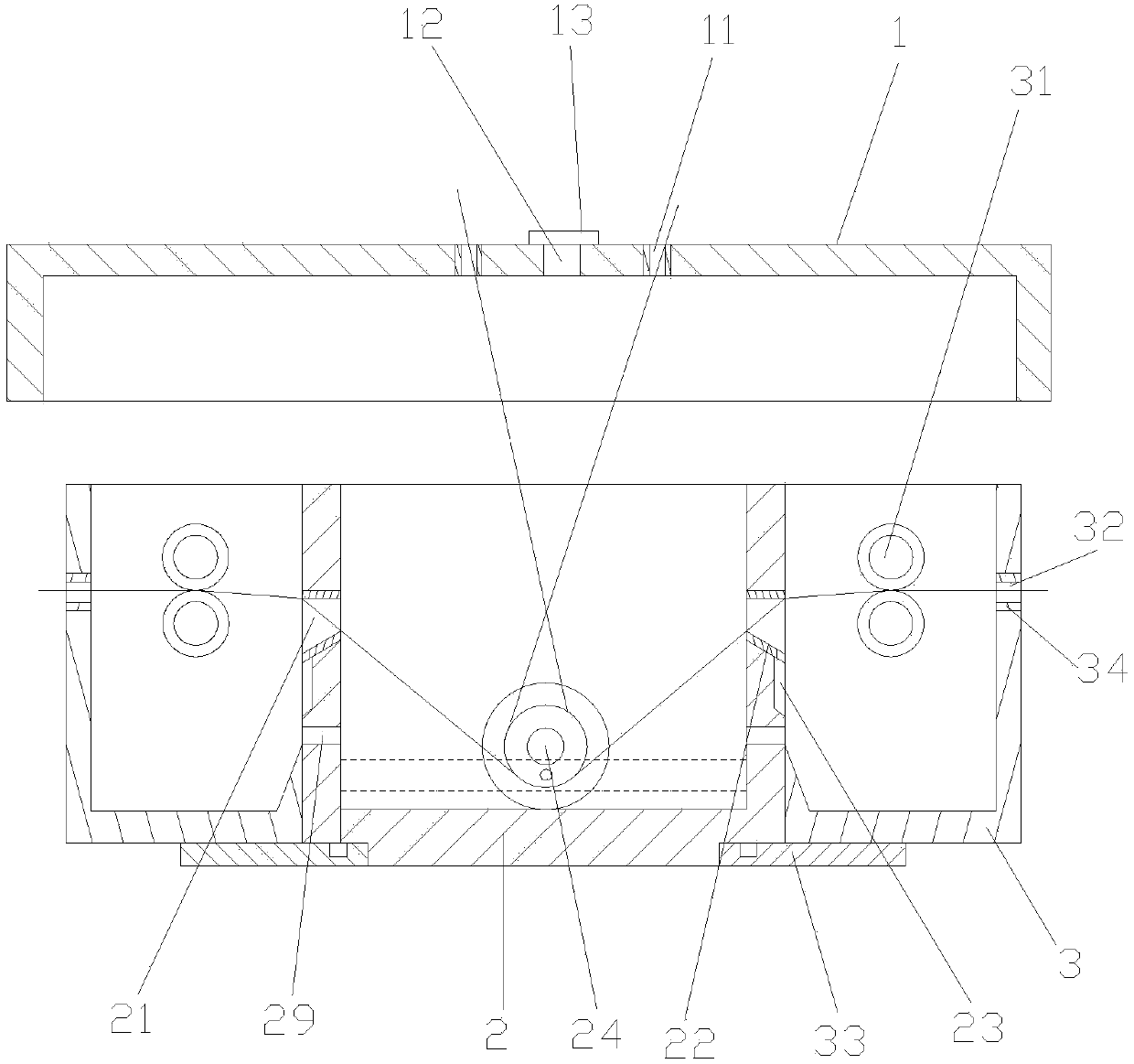

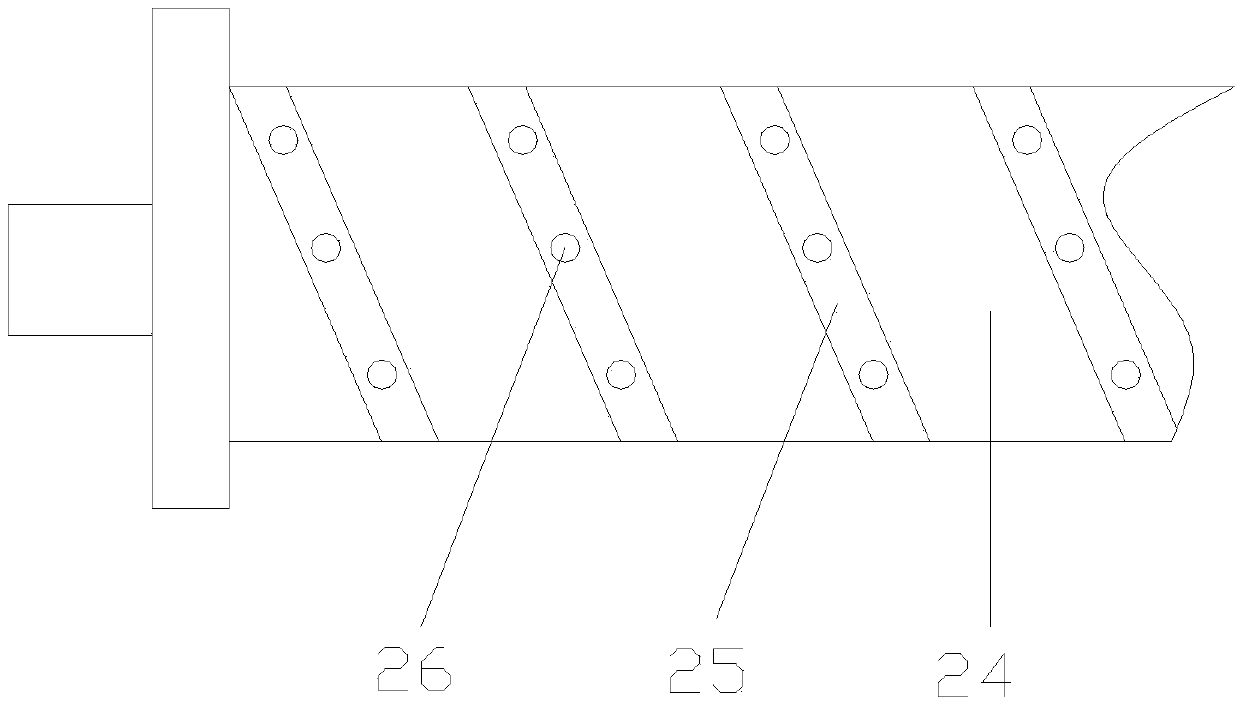

Double-row silk thread oiling device

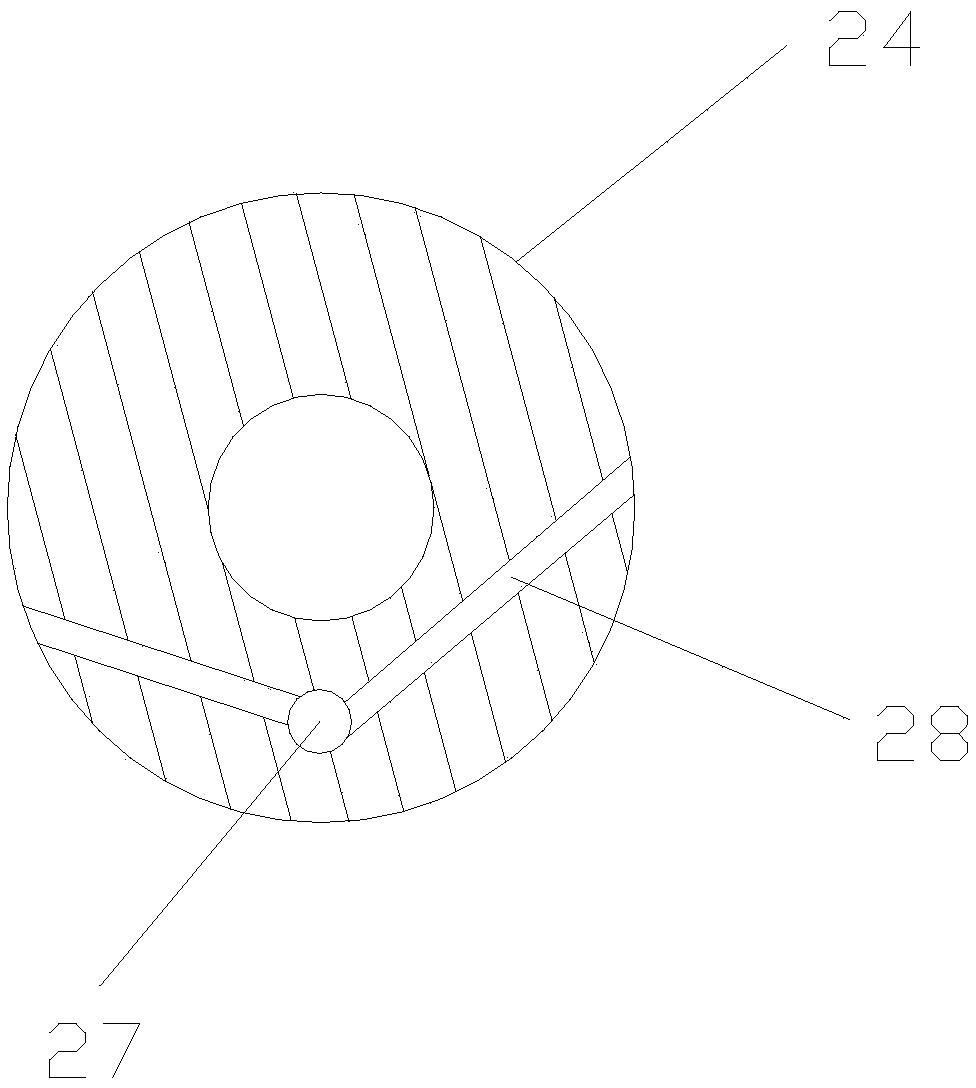

InactiveCN108677419AAvoid entanglementTightly woundLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsInlet channelFuel tank

The invention discloses a double-row silk thread oiling device. The double-row silk thread oiling device comprises an oil cover and an oiling box; oil overflowing boxes are arranged on the two sides of the oiling box; two rows of entrance holes which are distributed in a staggered way are formed in the oil cover; threading holes are formed in the two sides of the oiling box correspondingly; the bottom surface of each threading hole is an inclined surface; the lowest end of each inclined surface faces towards each oil overflowing box; a flow guide groove is formed at the bottom end of the outerside of each threading hole; an oiling roller is arranged in the oiling box; a spiral winding groove is formed in the surface of the oiling roller; a plurality of oil outlet holes are formed in the surface of the winding groove; an oil inlet channel capable of running through axially is formed in the end face of the oiling roller; the oil inlet channel is communicated with the oil outlet holes through an oil groove; a pair of extruding rollers are arranged in the oil overflowing box; and outgoing holes are formed in the two outer sides of the oil overflowing box. The double-row silk thread oiling device has the characteristics of oiling uniformly and improving silk thread quality, and also has the characteristics of large quantity of oiling silk threads, insusceptibility to winding and intersecting, low pollution and low cost.

Owner:HUZHOU ZHUOHAO SILK CO LTD

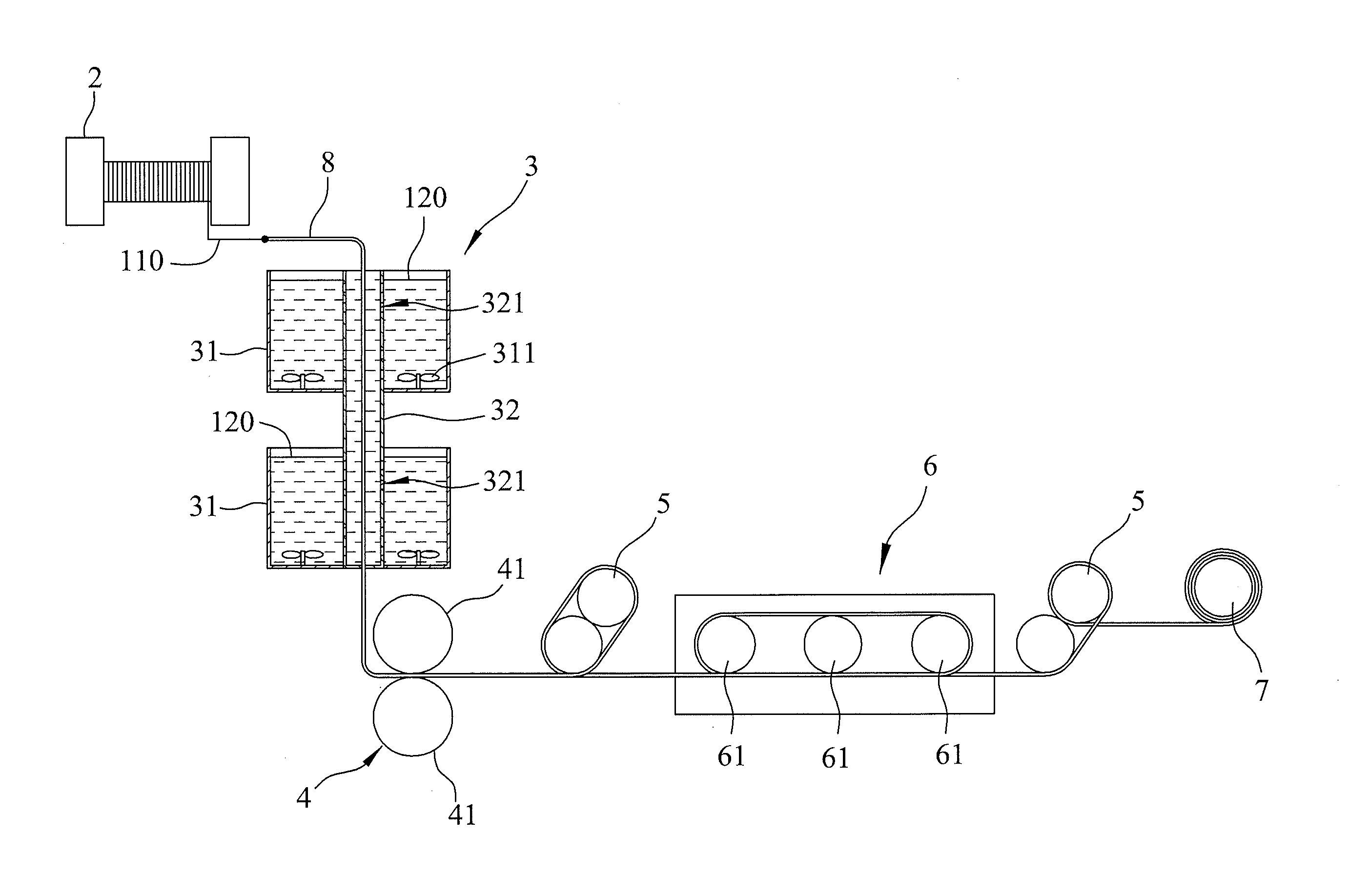

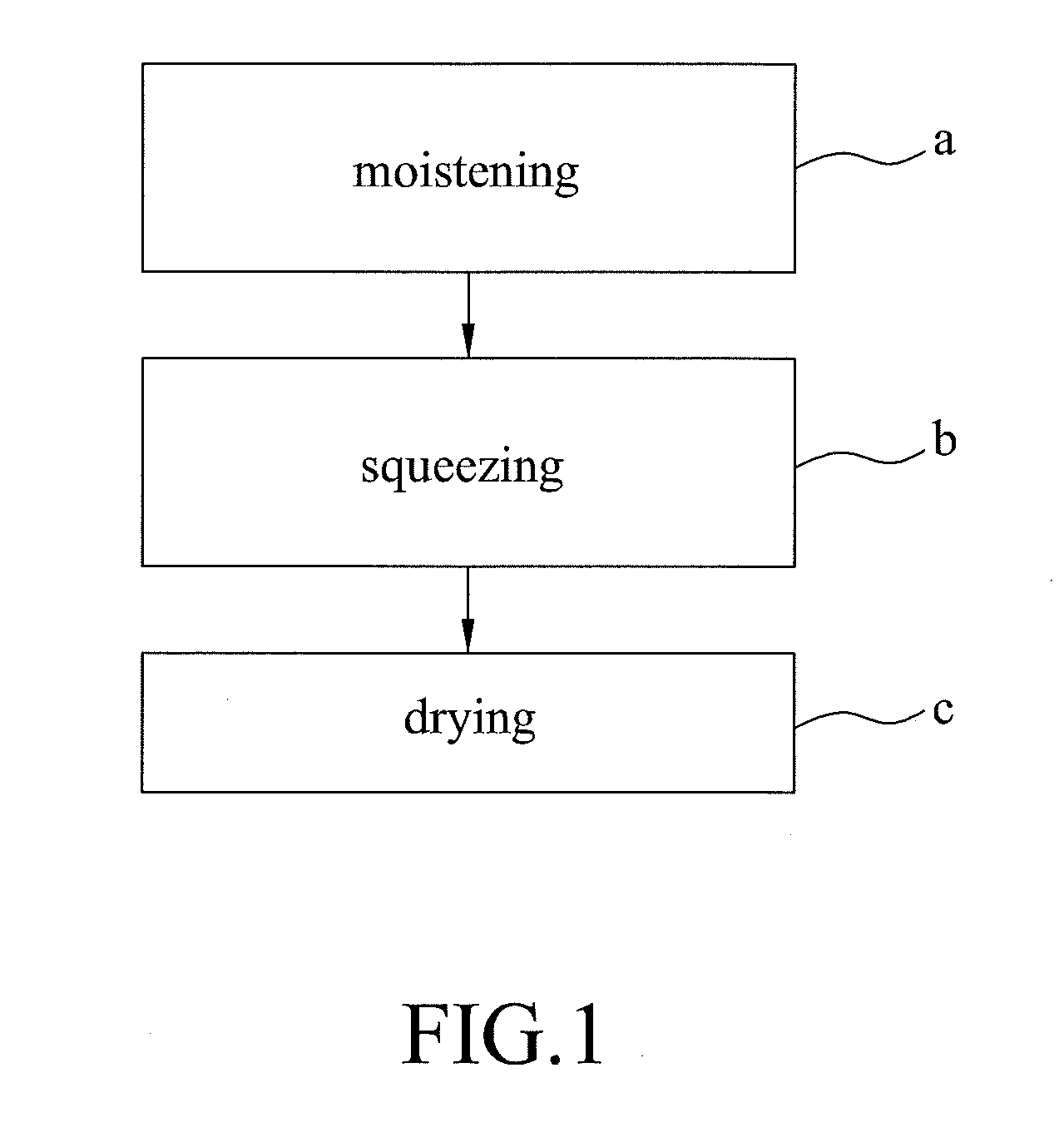

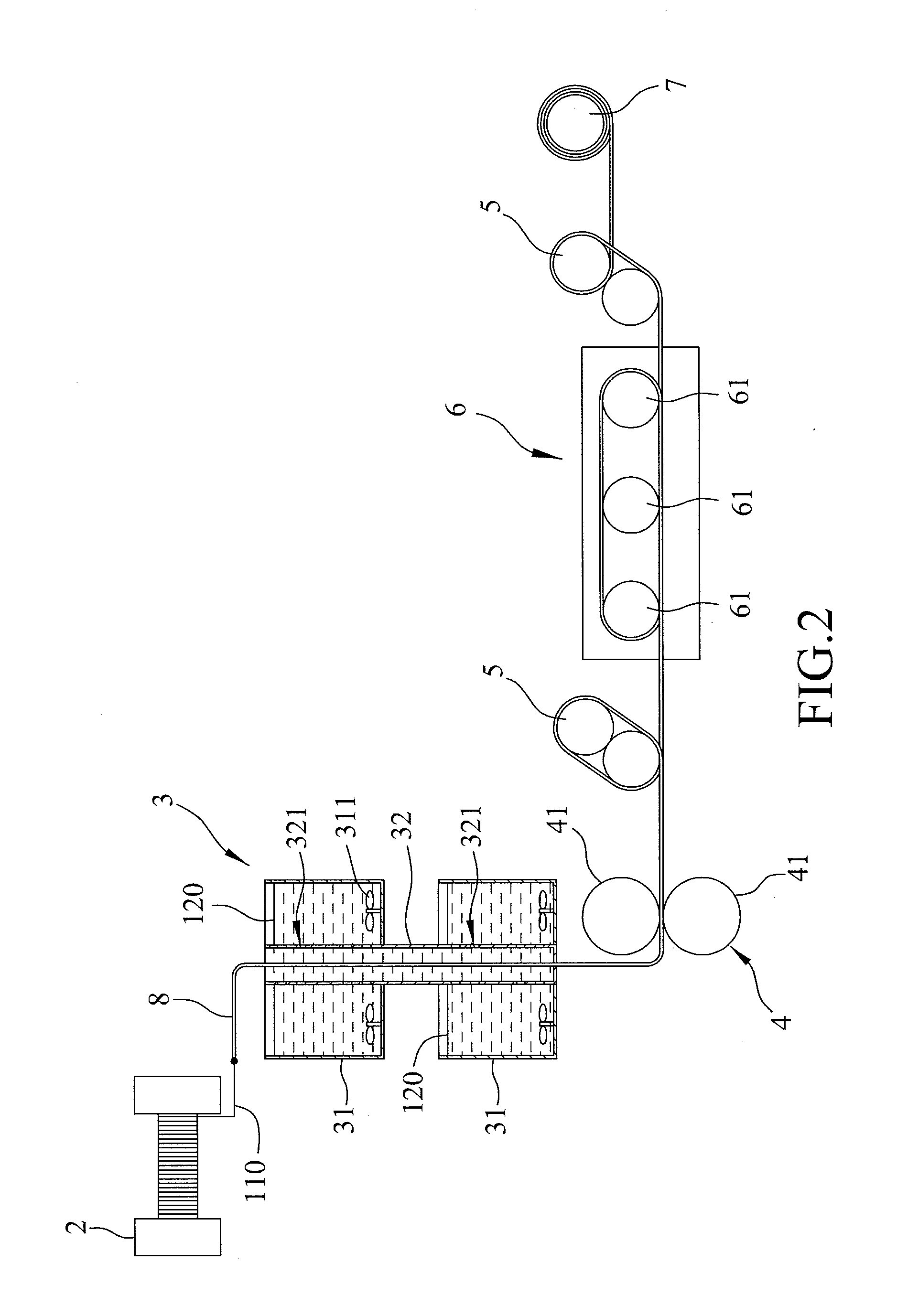

Method for fabricating a conductive yarn and conductive yarn fabricated by the method

InactiveUS20140318857A1Improve conductivityShorten the processing periodMaterial nanotechnologyLubricating devicesPolymer scienceElectrically conducting yarn

A method for fabricating a conductive yarn includes the steps of: moistening a preformed yarn with a conductive slurry to prepare the preformed yarn absorbed with the conductive slurry; and drying the preformed yarn absorbed with the conductive slurry. The conductive slurry includes a conductive nanometer structure, a solvent, and a resin component. The conductive nanometer structure has an aspect ratio sufficient to permit binding of the conductive nanometer structure to the preformed yarn.

Owner:ASIATIC FIBER CORP

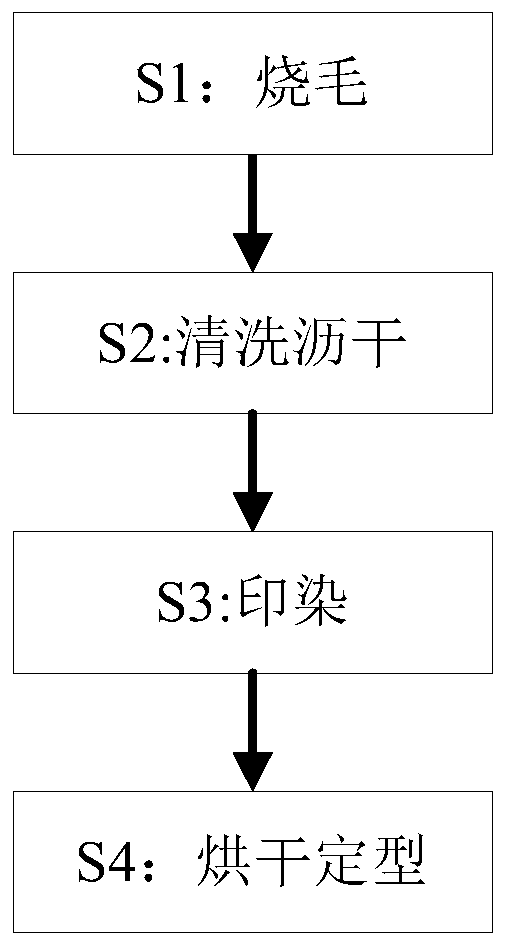

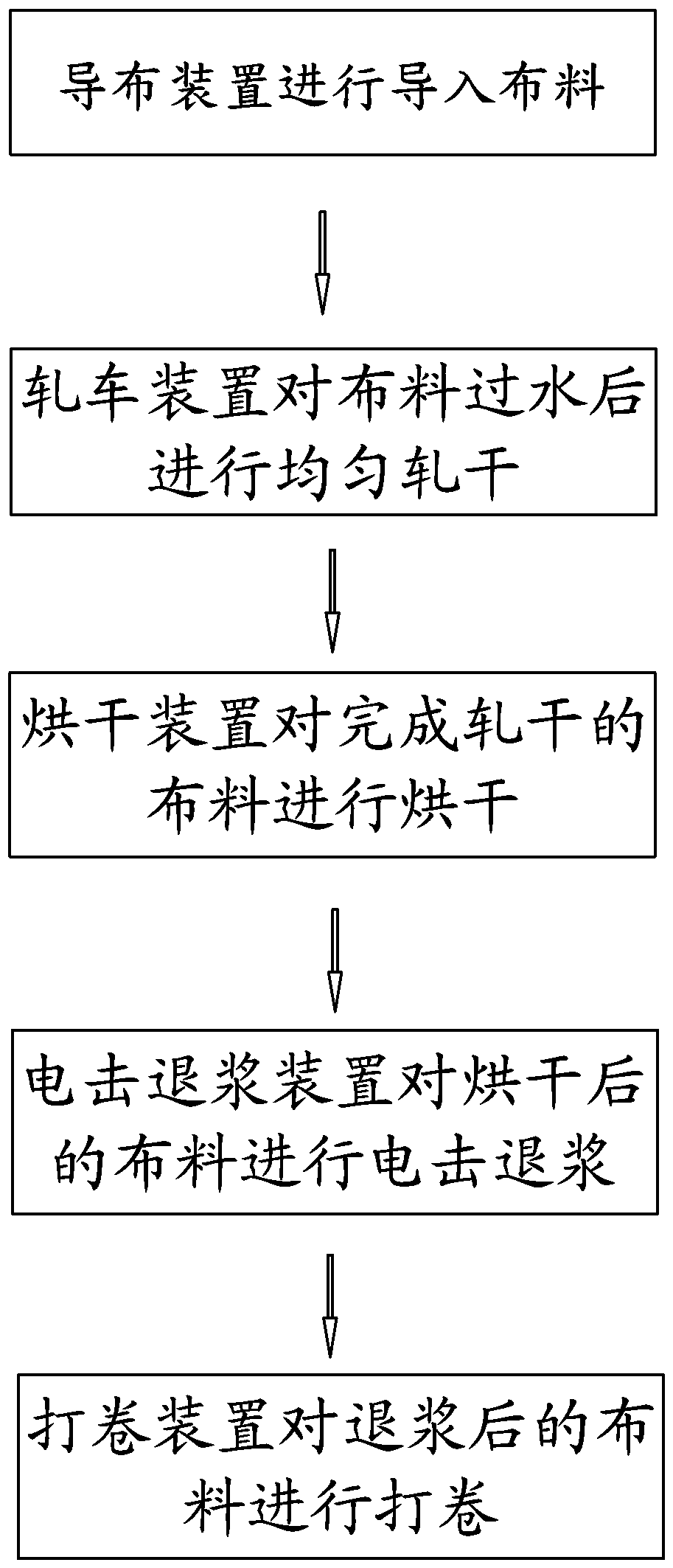

Printing and dyeing technology with high dyeing automation degree

ActiveCN108796882AConsistent chromaImprove dyeing effectSingeingTextile treatment machine arrangementsState of artPulp and paper industry

The invention discloses a printing and dyeing technology with high dyeing automation degree. The printing and dyeing technology with high dyeing automation degree comprises the following steps that (1), a fabric is placed on a conveying belt and conveyed to a singeing machine through the conveying belt, and the singeing machine burns off fluff on the fabric; (2), the fabric burned by the singeingmachine is conveyed to a desizing machine through the conveying belt, and the desizing machine conducts desizing treatment on the fabric; (3), the fabric after the desizing treatment is conveyed to ascouring machine through the conveying belt, and the scouring machine conducts high-temperature scouring treatment on the fabric; (4), the fabric after the scouring treatment is subjected to impurityremoving treatment conducted by an impurity removing device of the scouring machine; (5) the fabric after the impurity removing treatment is washed in a washing groove; (6), the fabric after washing is conveyed to a dyeing machine through the conveying belt and dyed by the dyeing machine, and a dyeing solution is stirred by a stirring piece. Compared with the prior art, the technology greatly improves the dyeing efficiency in the fabric dyeing process, the dyeing effect is good, and the dyeing automation degree is high.

Owner:ASHFORD TEXTILE ZHANGZHOU

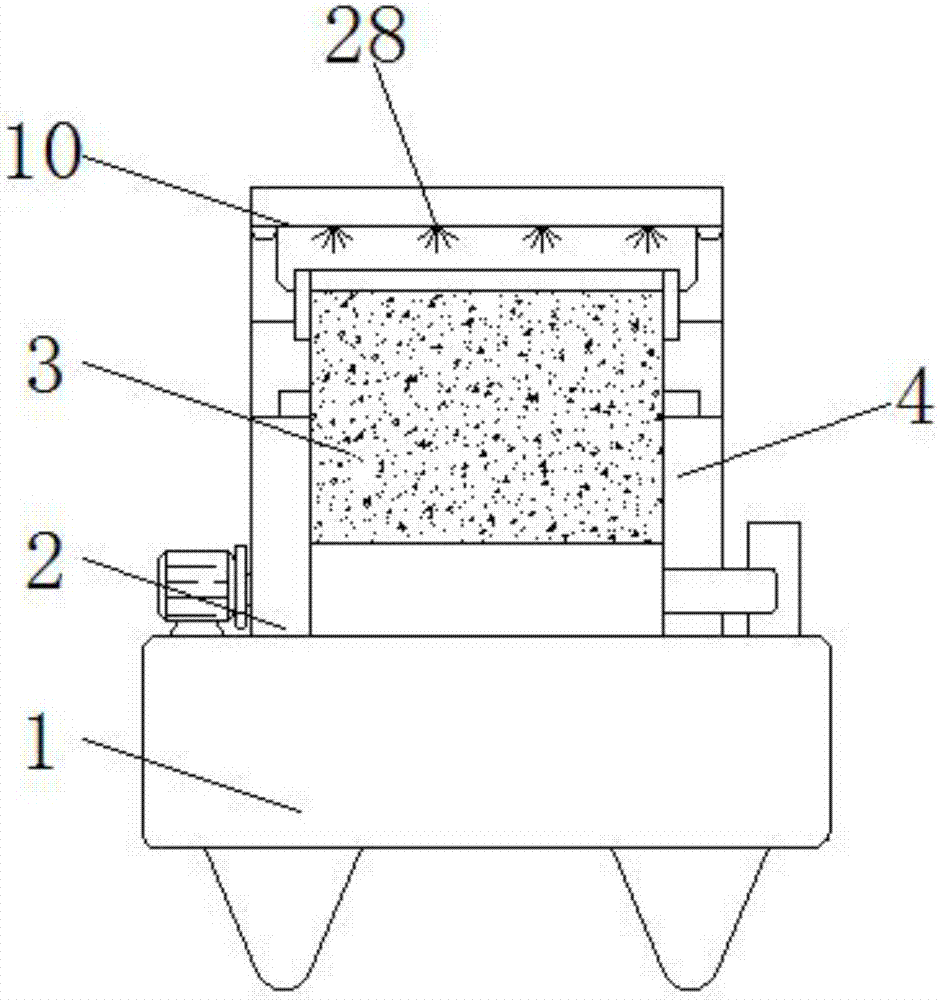

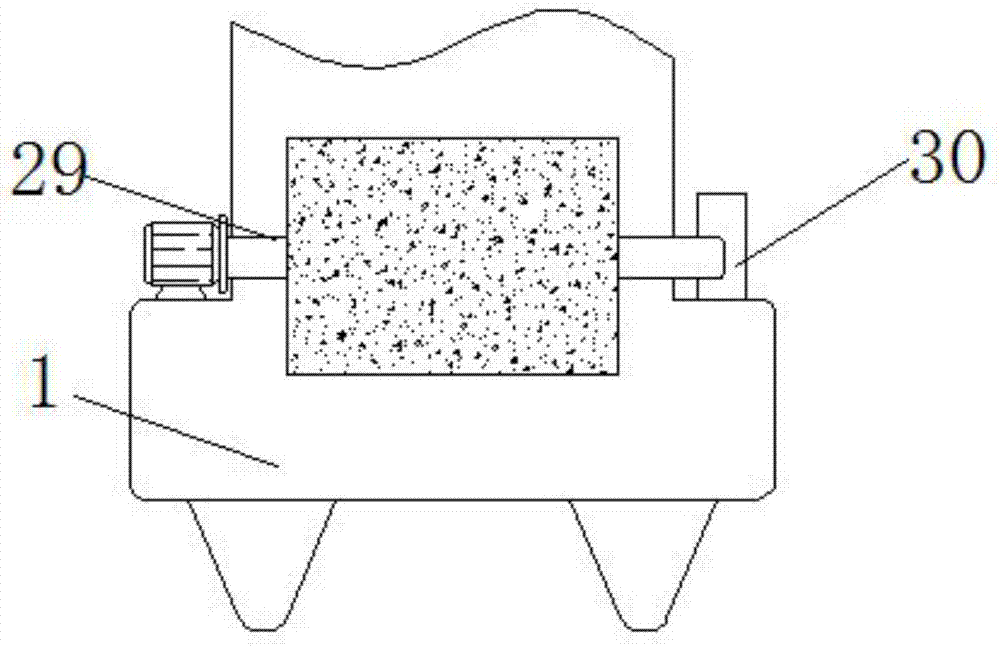

Textile setting and drying device

PendingCN107326588AEliminate Surface WrinklesEliminate wrinklesHeating/cooling textile fabricsLiquid/gas/vapor removal by squeezingFiberPolymer science

A textile setting and drying device comprises a wringing device and a drying box arranged on one side of the wringing device. A vertical partition plate is arranged in the drying box, the drying box is divided into a left cavity and a right cavity by the partition plate, a plurality of cloth shaking mechanisms are sequentially arranged in the left cavity, a drying mechanism is arranged in the right cavity, a cloth inlet and a cloth outlet are formed in two sides of the drying box, and a cloth passing port is formed in the partition plate. According to the textile setting and drying device, intertwined fibers of textile cloth can be neatened and shaken loose before drying, surface folds of the textile cloth are flattened in drying, and textile cloth drying quality is improved.

Owner:枝江市凯达纺织有限责任公司

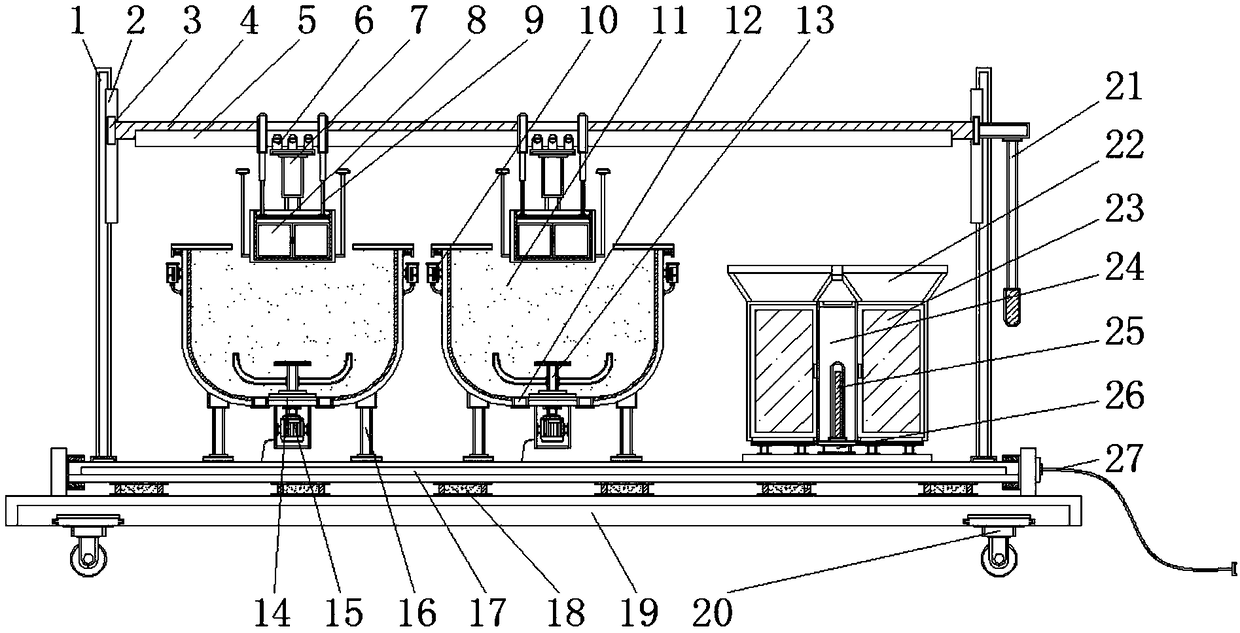

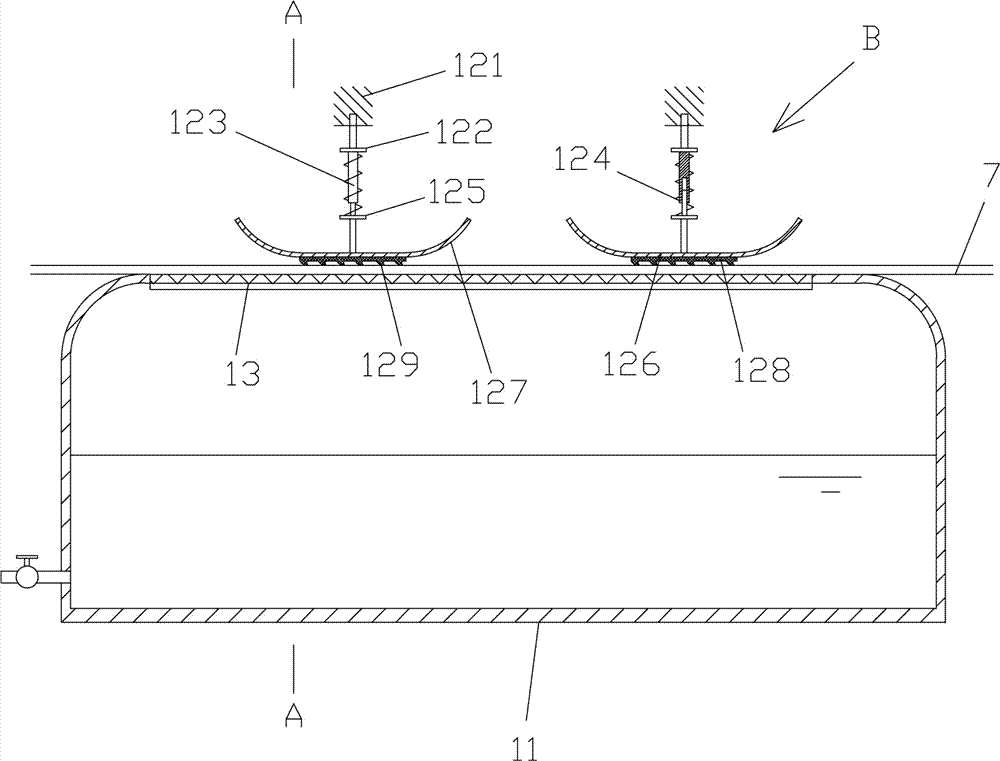

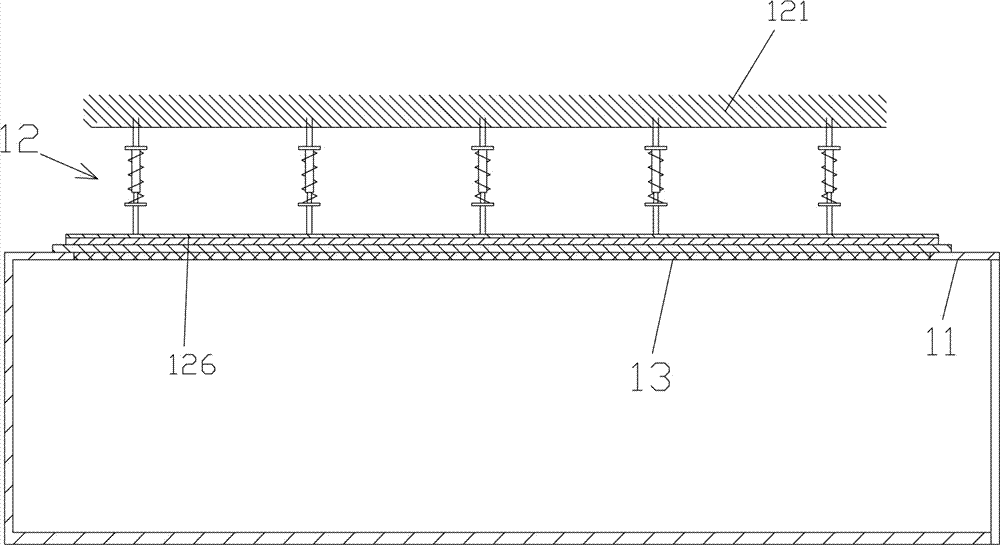

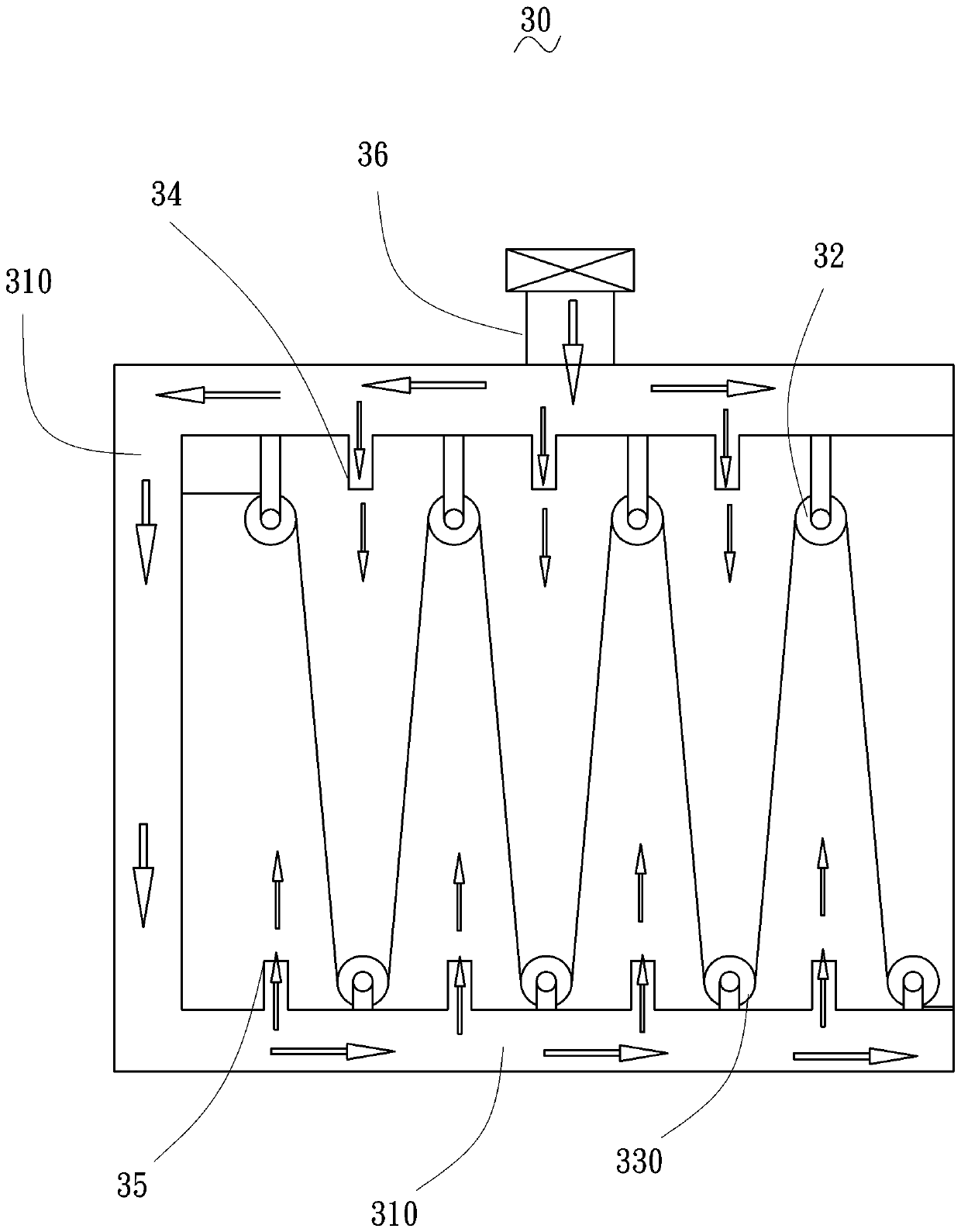

Dyed cloth drying equipment and drying method thereof

ActiveCN110983686AEvenly distributedDiffusion slowTextile treatment machine arrangementsLiquid/gas/vapor removal by squeezingHeat distributionProcess engineering

The invention provides dyed cloth drying equipment and a drying method thereof. The drying equipment comprises a dyeing bath device, an extrusion device and a drying device, wherein the right side ofthe dyeing bath device is connected with the extrusion device, and the right side of the extrusion device is connected with the drying device. The drying equipment can overcome the following defects in current cloth dyeing and drying work: 1, a traditional cloth dyeing device performs dyeing operation on cloth through left-right movement, and dyeing liquid cannot completely soak the cloth, so thatcloth dyeing is not uniform and the dyeing effect is poor; 2, after being dyed by the traditional dyeing device, the cloth is directly dried, so that a large amount of the dyeing liquid is remained in the cloth and is wasted; and 3, the traditional drying device is simple in structure, low in heat diffusion speed, uneven in heat distribution and low in drying efficiency, and the drying effect canbe achieved often by repeated use.

Owner:佛山市三水易和成纺织有限公司

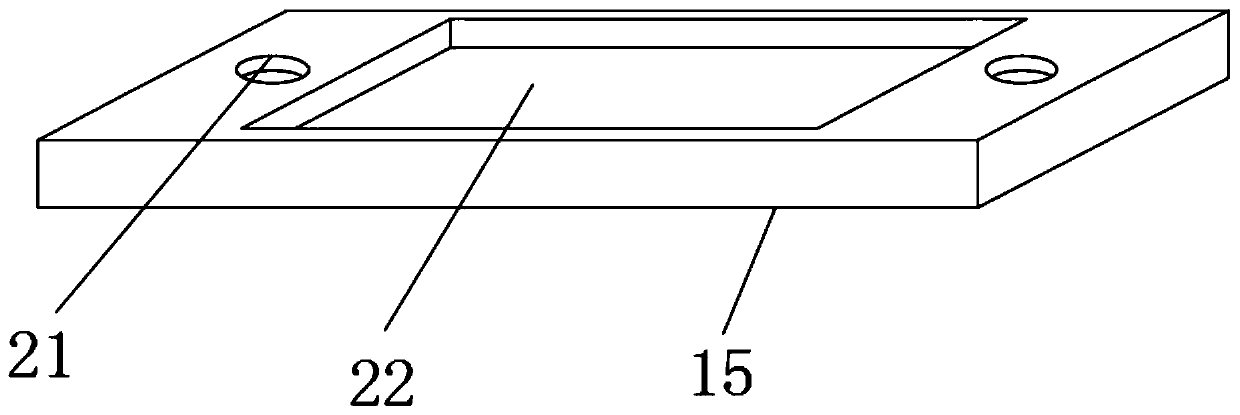

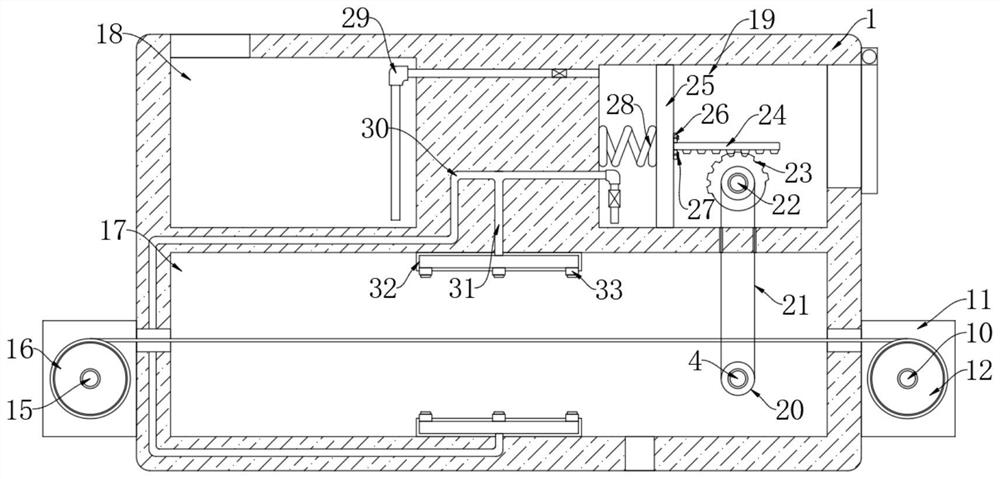

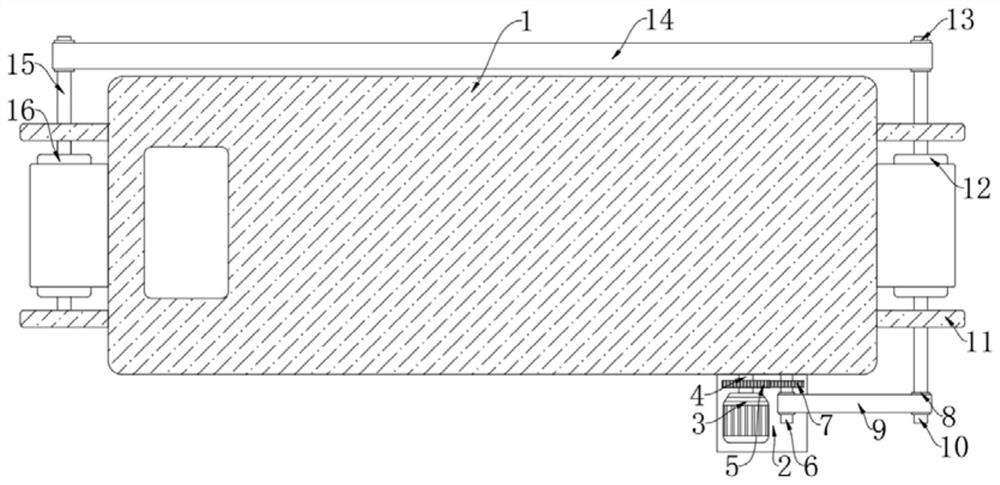

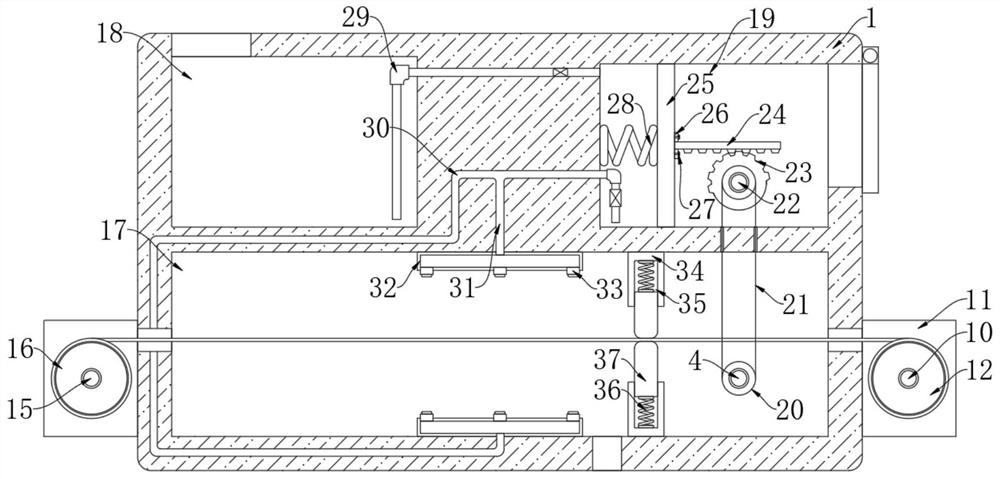

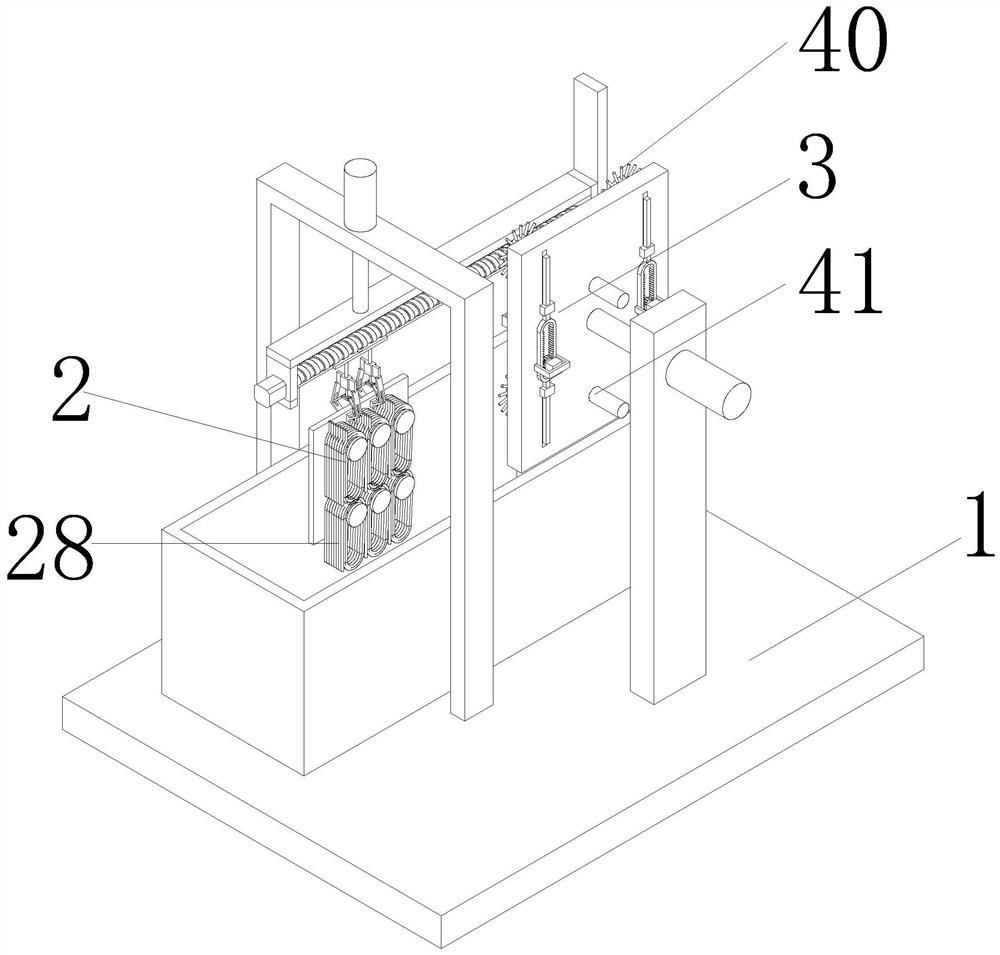

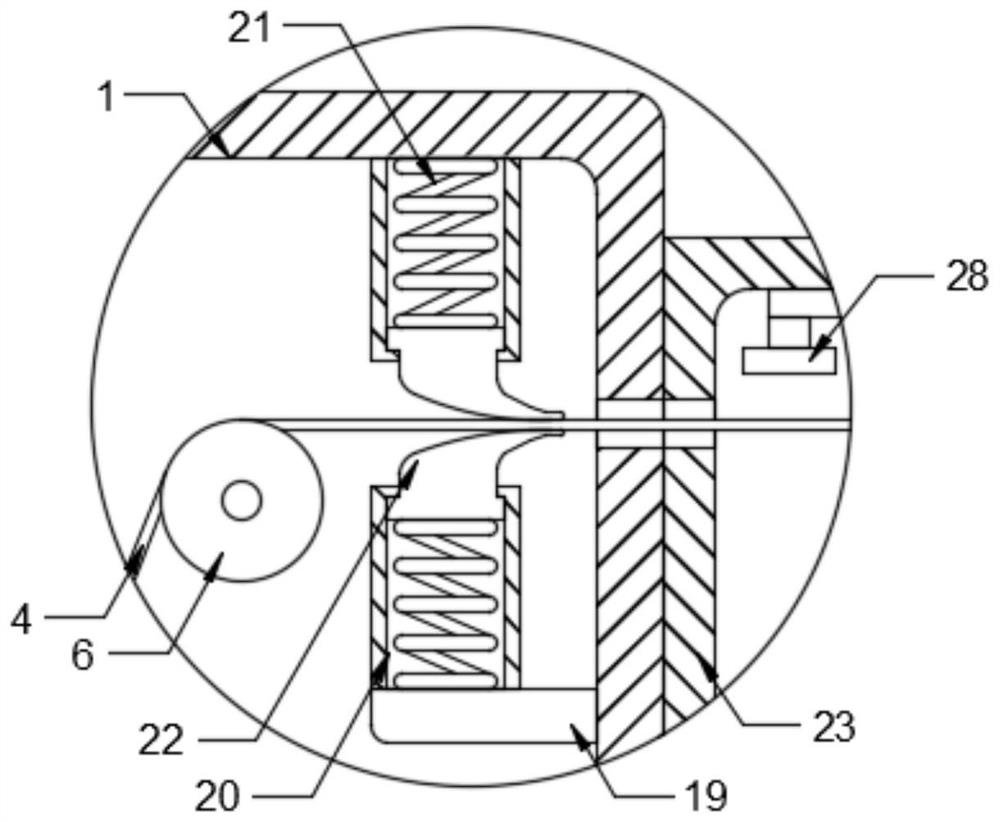

Textile finishing device for flax textile processing

InactiveCN109208216ASolve the situation that the large amount of moisture in linen textiles cannot be effectively removedAchieve dehydration effectLiquid/gas/vapor removal by squeezingTextile treatment carriersDewateringTextile processing

Owner:浙江载信亚麻科技有限公司

Printing and dyeing process of textile fabric

InactiveCN110528206ASpeed up the flowShorten the time of soaking and coloringTextile treatment machine arrangementsLiquid/gas/vapor removal by squeezingEngineeringDrive motor

The invention provides a printing and dyeing process of a textile fabric. According to the printing and dyeing process, the operation is completed through cooperation of a dyeing pond, a drum, two coloring rollers, a drive motor, a limit net belt, a liquid pressurizing device, two uniform spreading rollers and two operation motors; the printing and dyeing process can solve the problems that in thecoloring process of an existing gray fabric, due to the fact that the gray fabric needs a certain time period to be completely wetted, and the existing gray fabric is soaked in the dyeing pond for ashort time period, the phenomenon often occurs that various portions of the existing gray fabric are different in wetting degree, therefore after the existing gray fabric is taken out of the dyeing pond, various portions are different in coloring degree and coloring layer thickness, and the coloring quality of the gray fabric is influenced.

Owner:刘虎

Composite fiber for men's suits and preparation method of composite fiber

InactiveCN110387622AHigh breaking strengthHigh strengthElectro-spinningArtificial filaments from viscoseFiberBreaking strength

The invention discloses composite fiber for men's suits and a preparation method of the composite fiber. The composite fiber is prepared from the following raw materials in parts by weight: 10-20 parts of chitosan fiber, 8-15 parts of graphene viscose composite fiber and 60-80 parts of cotton fiber; the composite fiber is prepared by the following steps: 2.0 mL of 0.1 mol / L citric acid and 18.0 mLof 0.1 mol / L sodium citrate are taken to prepare a citric acid-sodium citrate buffer solution with pH of 6.4. The composite fiber is prepared from the chitosan fiber, the graphene viscose composite fiber and the cotton fiber, and by means of blending of the chitosan fiber, the graphene viscose composite fiber and the cotton fiber, respective advantages can be integrated, defects are avoided; theobtained composite fiber not only has improved breaking strength, but also has good skin-friendly comfort and anti-ultraviolet function.

Owner:安徽弋尚纺织科技有限公司

Humidifying device capable of controlling water quantity for non-woven fabric processing

PendingCN112301579AImprove wetting effectQuality improvementTextile treatment machine arrangementsLiquid/gas/vapor removal by squeezingProcess engineeringNonwoven fabric

The invention discloses a humidifying device capable of controlling water quantity for non-woven fabric processing. The humidifying device comprises a box body, wherein a spraying cavity is formed inthe box body, a water storage cavity and a rotating cavity are sequentially formed in the box body from left to right, the water storage cavity and the rotating cavity are both located above the spraying cavity, a water inlet in communication with the outside is formed in the inner top of the water storage cavity, an opening in communication with the outside is formed in the inner wall of the right side of the rotating cavity, and a sliding door is installed on the opening. According to the humidifying device, s motor drives a winding drum and a spraying device to operate at the same time, sothat a certain amount of water is sprayed to each section of non-woven fabric, the amount of water for humidifying can be controlled by replacing the specification of a rack, various types of non-woven fabric can be in the optimal water amount, the quality of the non-woven fabric is improved, double-sided spraying is conducted on the non-woven fabric, and the non-woven fabric is humidified more uniformly through the propping of propping blocks.

Owner:郑明增

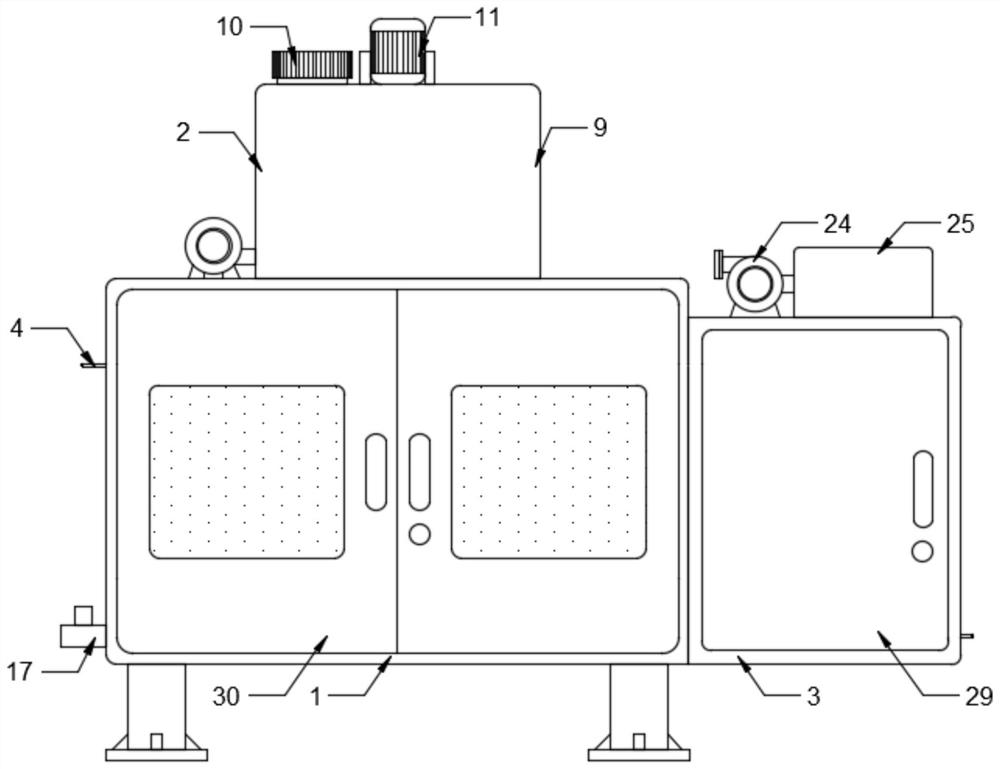

Efficient environment-friendly drying apparatus for clothing fabric

ActiveCN106835566ASuitable for cleaning needsHigh drying efficiency and fastLiquid/gas/vapor removal by squeezing rollersLiquid/gas/vapor removal by suctionPetroleum engineeringHeat transfer

An efficient environment-friendly drying apparatus for clothing fabric comprises a bottom plate, a squeezing unit, a drying unit, a supporting unit, a support unit, a collecting unit, a driving unit and a water suction unit; a first support rod, a first transverse rod, a first positioning rod, a first recycling box, a first positioner and a second transverse rod are arranged on the bottom plate; the squeezing unit includes a feed frame, first centralizing blocks, first vertical rods, first squeeze wheels, a first support and a second support; the drying unit includes a heating frame, a heat transfer plate, heating rods, an intake pipe, a fan, a first valve and a second support rod; the supporting unit includes a third supporting rod, a first supporting plate, a fourth supporting rod, a second positioning rod, a second recycling box, a second positioner, a second supporting plate, a third support, a first fixing plate and a first roller. The efficient environment-friendly drying apparatus for clothing fabric can provide automatic squeezing for fabric so that most water in the fabric is squeezed out, can then dry the fabric with the water squeezed out, and has high drying efficiency and high drying speed.

Owner:临泉县诗雨娇服饰有限公司

High-permeability thermal transfer printing napped fabric processing method

InactiveCN110117884AImprove printing and dyeing effectMeet needsHeating/cooling textile fabricsLiquid/gas/vapor removal by squeezingWater softeningCarding

The invention discloses a high-permeability thermal transfer printing napped fabric processing method. The high-permeability thermal transfer printing napped fabric processing method comprises the following steps of grey fabric carding, gray fabric heat lustring, printing, water softening, drying, napping, carding, shearing, finished product heat lustring and shearing, air washing (fleecing) and finished product setting. The high-permeability thermal transfer printing plush fabric processing method solves the problem of providing a method, which endows napped fabrics of different gram weightswith richly layered and colorful photograph-like effects and high three-dimensional effects and is simple and reasonable in production process, environmentally friendly in production and free from pollution to natural environment.

Owner:江苏康尼纺织品有限公司

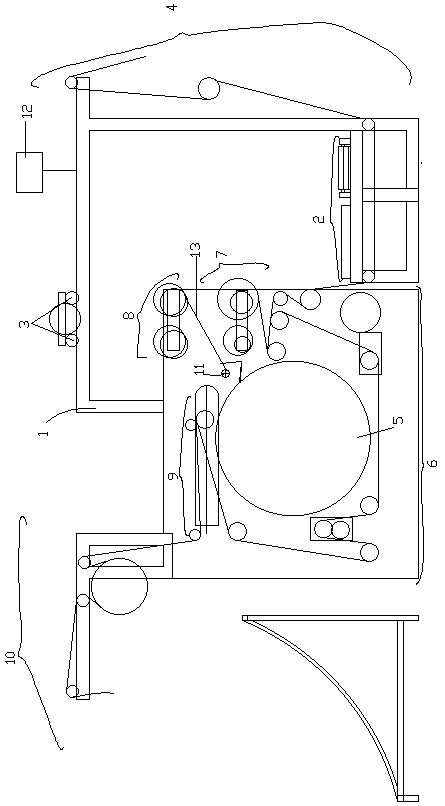

Pure cotton textile yarn dip dyeing process

ActiveCN113062062AGuaranteed swingImprove the efficiency of dippingLiquid/gas/vapor treatment machines driving mechanismsTextile/flexible product manufactureTextile yarnPulp and paper industry

The invention provides a pure cotton textile yarn dip-dyeing process, and relates to the field of pure cotton textile yarns. The pure cotton textile yarn dip-dyeing process comprises a bottom plate, a dip-dyeing mechanism and an extrusion mechanism; the dip-dyeing mechanism is fixedly installed on the bottom plate; the extrusion mechanism is arranged on the dip-dyeing mechanism; and the extrusion mechanism is located above the dip-dyeing mechanism. According to the pure cotton textile yarn dip-dyeing process, dip dyeing can be conducted on the pure cotton textile yarn in an automatic mode, so that the dip dyeing efficiency of the pure cotton textile yarn is improved, the pure cotton textile yarn can be driven by the dip dyeing mechanism to rapidly shake in dip dyeing liquid, and therefore the dip dyeing efficiency of the pure cotton textile yarn is guaranteed; and the uniformity of the dip dyeing liquid is ensured through shaking.

Owner:江西京东实业有限公司

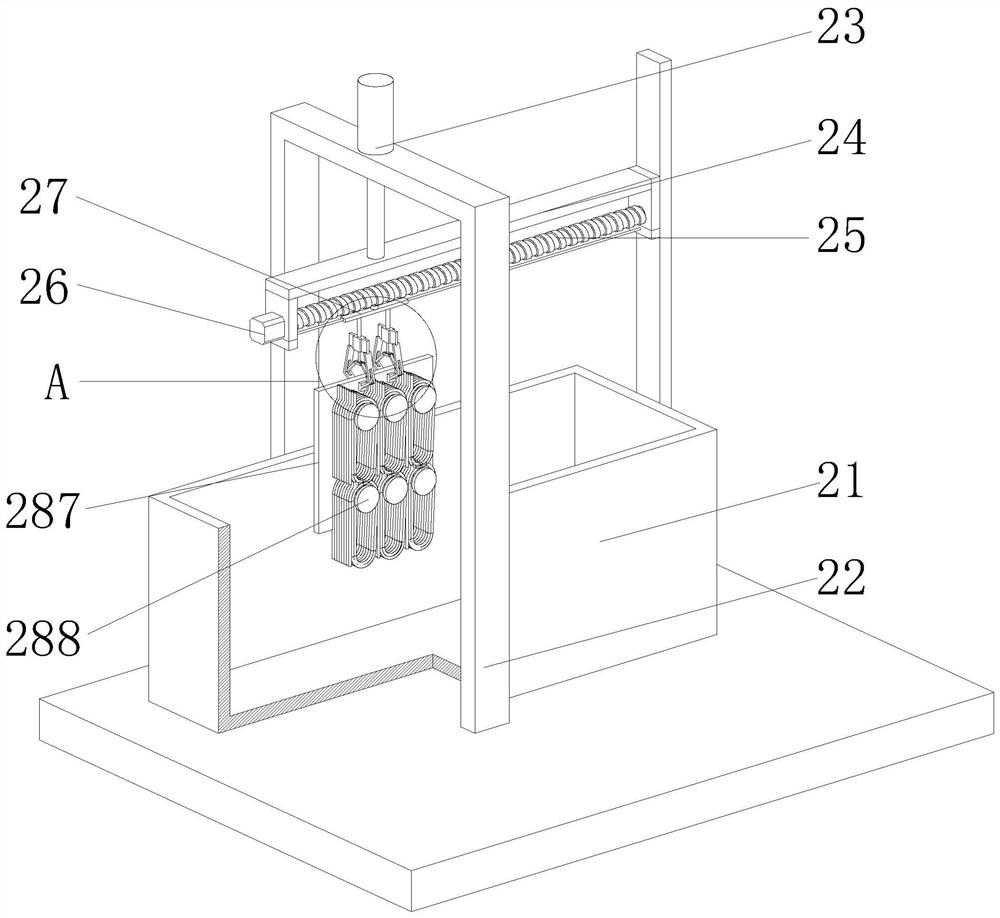

Cloth dyeing pretreatment assembly line and treatment method thereof

PendingCN107841840AHigh color fastnessHigh lusterLiquid/gas/vapor removal by squeezing rollersUltrasonic/sonic fibre treatmentAssembly linePulp and paper industry

Owner:浙江佳茂环保科技有限公司

Antibacterial and deodorant functional fabric dyeing process and processing equipment thereof

InactiveCN112522878AUniform dyeingDye savingTextile treatment machine arrangementsLiquid/gas/vapor removal by squeezingProcess engineeringAnti bacteria

The invention discloses an antibacterial and deodorant functional fabric dyeing process and processing equipment thereof. The antibacterial and deodorant functional fabric dyeing processing equipmentcomprises a dyeing chamber, a dyeing mechanism and a drying mechanism, wherein the dyeing mechanism is arranged at the top of the dyeing chamber; the drying mechanism is arranged on the side wall of the dyeing chamber; a communicating opening is formed in the top end of the dyeing chamber; a fabric body is arranged in the communicating opening; first guide rollers are symmetrically and rotatably connected to the top end in the dyeing chamber; two conveying rollers are arranged at the positions, located below the first guide rollers, of the two ends in the dyeing chamber correspondingly; the fabric body is located between the two conveying rollers; a water squeezing mechanism is arranged at the top end, located on the inner wall of one side of the drying mechanism, of the dyeing chamber; convex plates are integrally arranged at the positions, corresponding to the low ends of two inner walls, of the dyeing chamber; a filter screen plate is arranged on the top parts of the convex plates;and a drain outlet is formed in the lower end of the side wall of the dyeing chamber. According to the antibacterial and deodorant functional fabric dyeing process and the processing equipment thereof, the whole operation process is continuous, the time is saved, and the fabric dyeing efficiency is greatly improved.

Owner:浙江旭峰布业有限公司

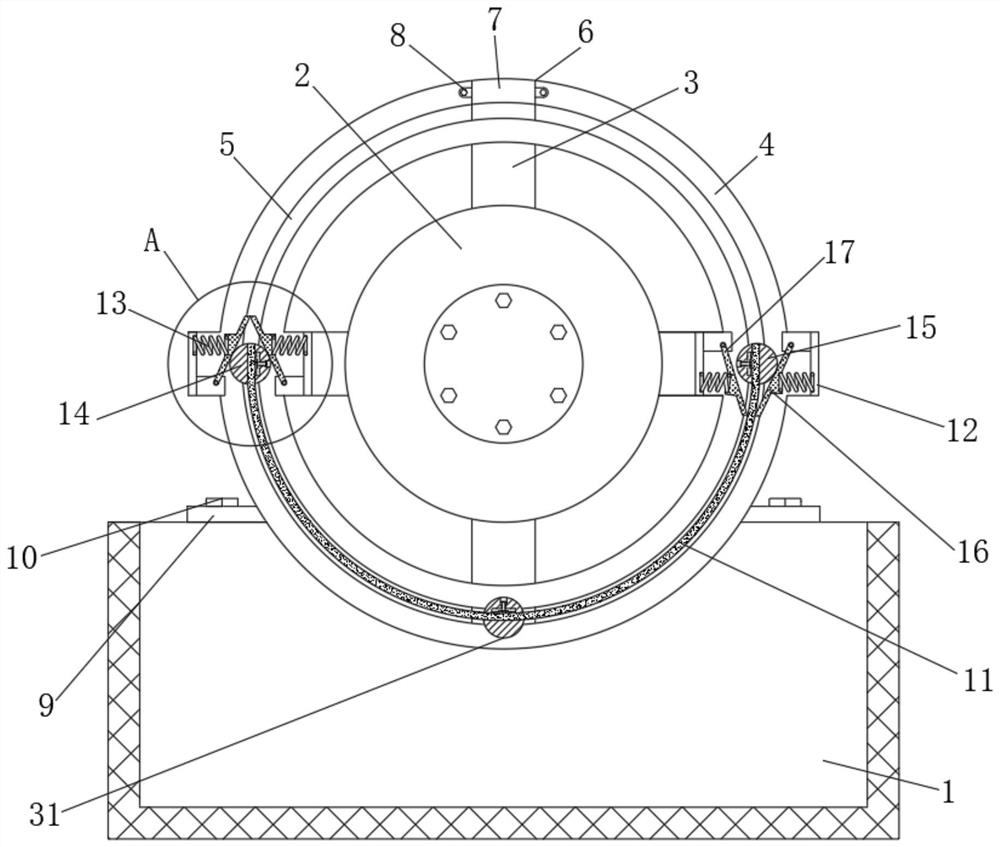

Dip dyeing device for short fiber dyeing

InactiveCN112030421APrevent limit foldingFully dyedLiquid/gas/vapor treatment machines driving mechanismsLiquid/gas/vapor article treatmentFiberEngineering

The invention relates to the technical field of clothes dyeing equipment, in particular to a dip dyeing device for short fiber dyeing. The device comprises a dyeing pool, the upper end of the dyeing pool is provided with a rotary table, the rear end of the rotary table is rotatably connected with a driving motor, the front end of the rotary table is provided with a rotary circular ring, and the middle of the front end surface of the rotary circular ring is provided with a through circular ring groove. The device has the beneficial effects that by setting a rotary insertion strip mounting mode,the lengths of short fibers with different lengths can be adjusted, and the application range of the device is enlarged; a locking nut is used for fixation to prevent limiting folding, so that dyeingis more sufficient; the rotary circular ring driven by the driving motor is arranged, so that rotary circulating dyeing of the short fibers is achieved; and meanwhile, by cooperation with rotary plates which are in left-right press fit with each other, after dyeing, the rotary plates extrude the outer walls of the short fibers inwards and outwards by rotating insertion strips, so that redundant dyes drip into the dyeing pool, and environmental pollution is prevented.

Owner:安福风起科技有限公司

Wringing, drying and winding device for washed textile fabrics

ActiveCN110714288AImprove drying efficiencyEasy to rewindLiquid/gas/vapor removal by squeezingTextile treatment carriersEngineeringMechanical engineering

The invention discloses a wringing, drying and winding device for washed textile fabrics. The wringing, drying and winding device for the washed textile fabrics comprises a shell, wherein the shell has a hollow structure; the inner wall of the lower end of the shell is fixedly connected with a groove type screen plate; a plurality of supporting rollers which are arranged uniformly are arranged onthe inner wall of the lower end of the groove type screen plate; a side wall of the shell is connected with a movable rod which is arranged horizontally through a driving mechanism; the movable rod penetrates through a side wall of the shell and is provided with a transmission roller; two hydraulic telescopic rods are fixedly connected to the side wall of the upper end of the shell; telescopic ends of the two hydraulic telescopic rods penetrate through the side wall of the upper end of the shell; an extrusion plate is fixedly connected between side walls of the lower ends of the two hydraulictelescopic rods; the extrusion plate is positioned above the transmission roller; and openings are separately formed in the side wall of the extrusion plate and the side wall of the upper end of the shell. Wringing can be carried out rapidly, the drying effect is good, moreover, after winding, driven fabrics can rapidly move to designated positions, and the time and labor are saved.

Owner:南通保利金纺织科技有限公司

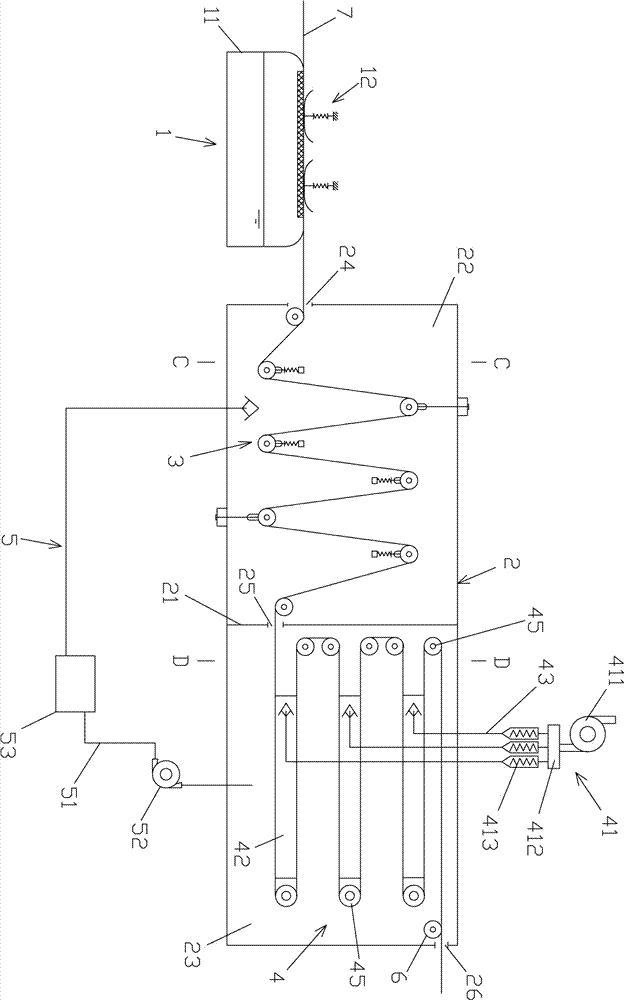

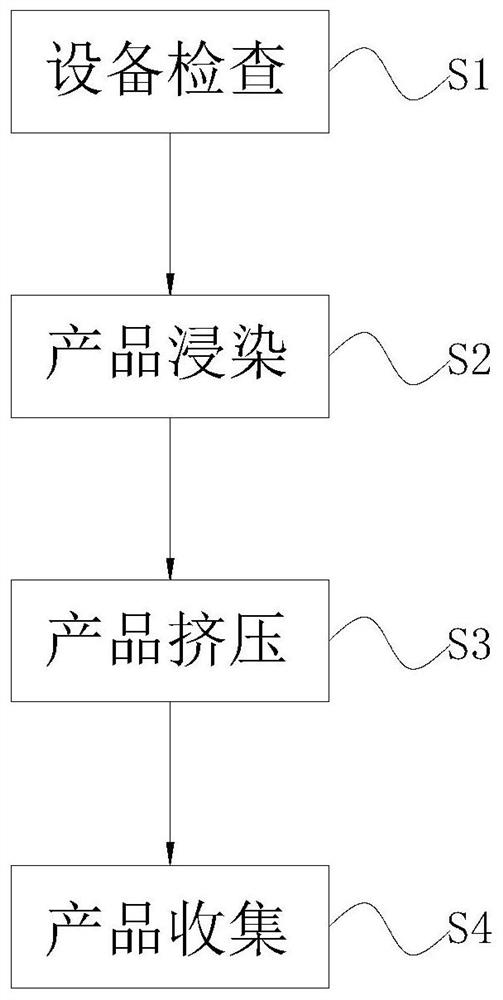

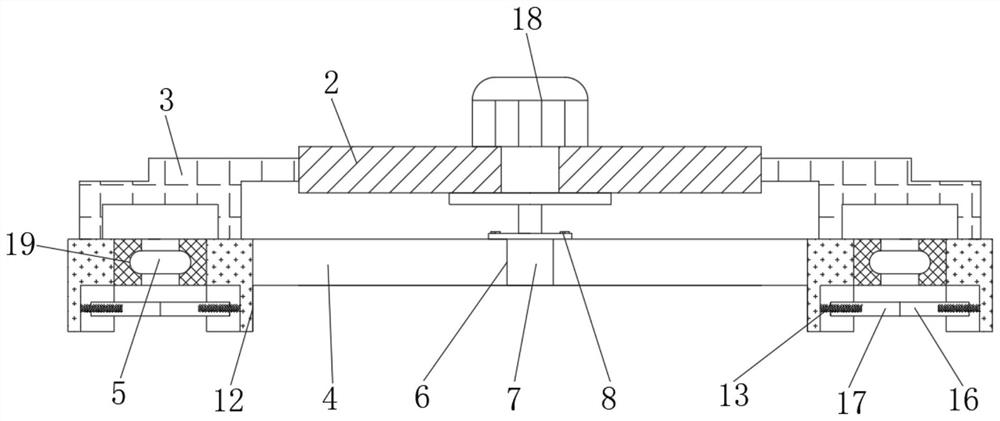

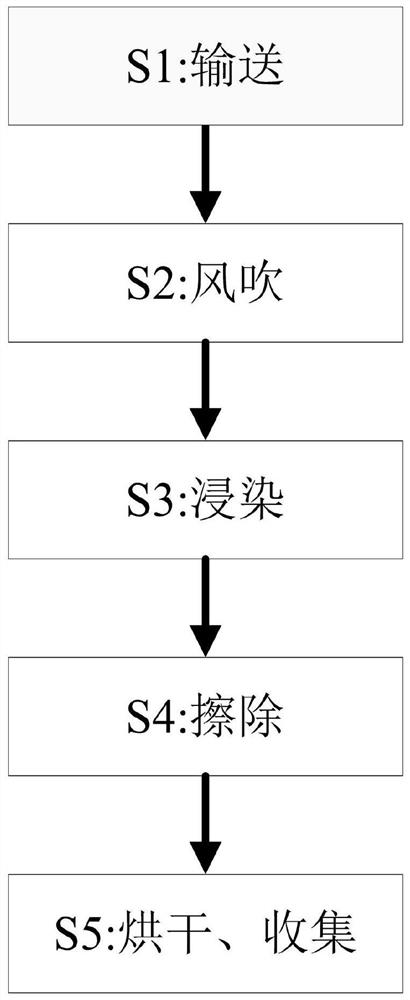

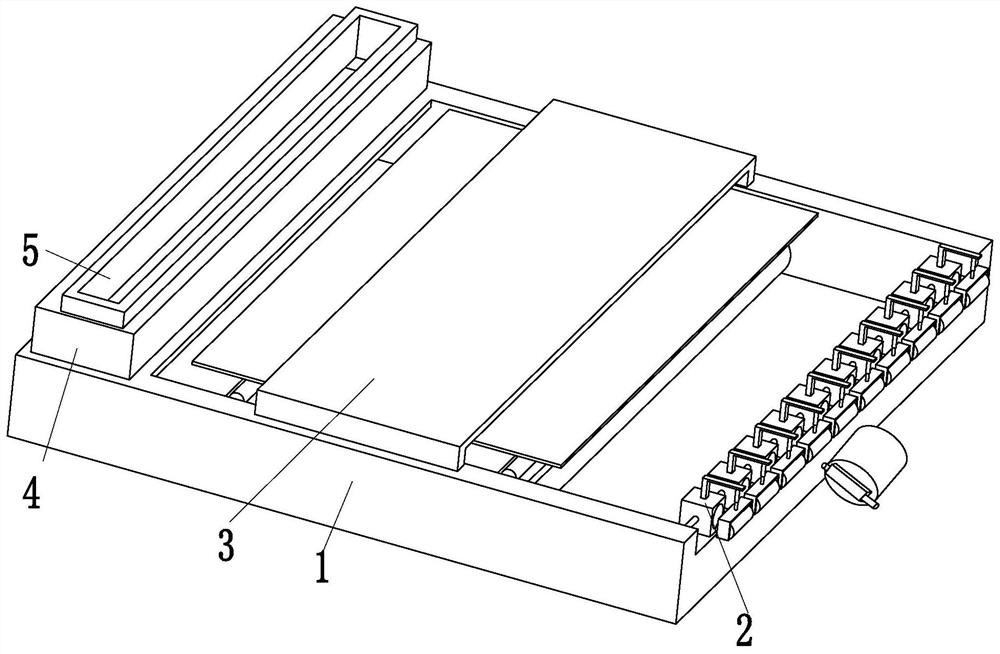

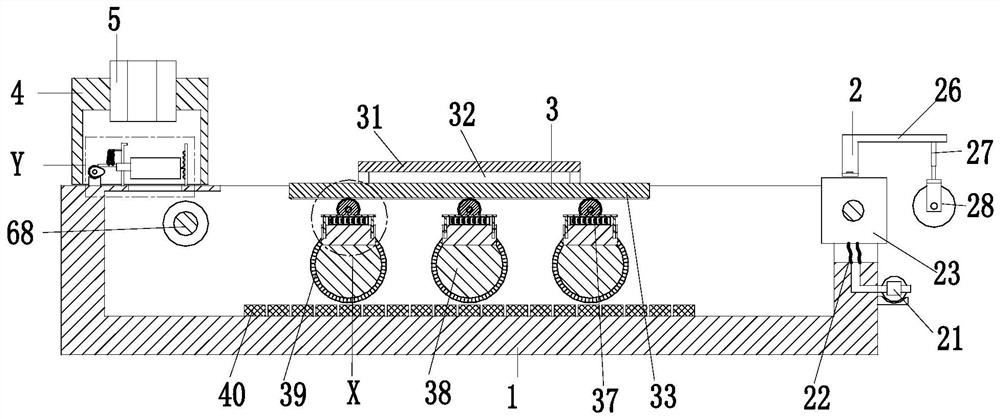

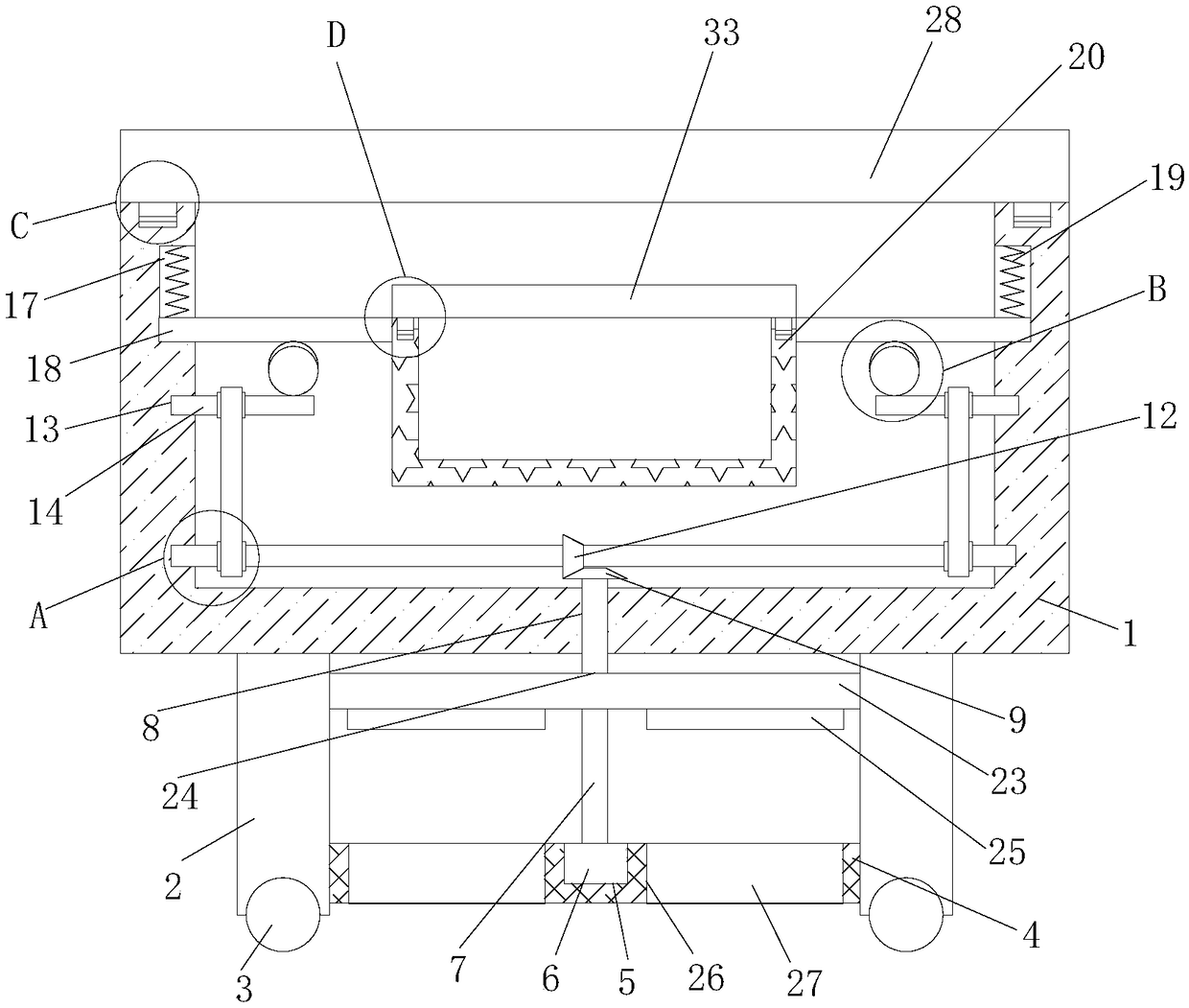

Batch dyeing and drying treatment process for textile yarn

InactiveCN112391757AFast soaking speedUniform soaking effectLiquid/gas/vapor removal by squeezingTextile treatment carriersTextile yarnProcess engineering

The invention provides a batch dyeing and drying treatment process for textile yarn. The process is completed through cooperation of a base, a tightening type turning device, an accelerated dipping device, a sealing cover, a drying frame and a wiping device, and can solve the problems that dust particles may be attached to the surface of the yarn in a conveying process, and the state during conveying is not in a tightening state, so that the above-mentioned conditions influence a dip dyeing effect; and the traditional dip dyeing time is short, the yarn is possibly not soaked thoroughly, dye separation is facilitated, and the dye on the separated yarn is distributed unevenly, so that part of the redundant dye is directly attached to the yarn after being dried, and thus a solidified fuel layer appears on the surface of the yarn, and the percent of pass of the yarn is influenced.

Owner:黄远明

Mechanical equipment oil stain cleaning system

ActiveCN109208214AEasy to cleanMeet the needs of useLiquid/gas/vapor article treatmentLiquid/gas/vapor removal by squeezingMechanical equipmentBevel gear

The invention discloses a mechanism equipment oil stain cleaning system, which comprises a cleaning box, wherein the top of the cleaning box is set to be an opening, the bottom of the cleaning box iswelded with two supporting plates, the cleaning box is loaded with a cleaning liquid, the bottom of each supporting plate is equipped with two universal wheels in a rolling manner, the mutually approaching sides of the two supporting plates are welded with the same connecting plate, the top of the connecting plate is provided with an installation groove, the installation groove is internally provided with a rotating motor, an output shaft of the rotating motor is welded with a rotating shaft, the bottom inner wall of the cleaning box is provided with a rotating hole, the rotating shaft is rotatably installed in the rotating hole, the top end of the rotating shaft is welded with a first bevel gear, and the inner walls at both sides of the cleaning box are respectively provided with first grooves. The mechanical equipment oil stain cleaning system is simple in structure and convenient to use, facilitates cleaning newly used cleaning cloth in the up-and-down moving process of a draining basket, can squeeze the cleaned cleaning cloth at the same time in the extruding process of a pressing plate, and meets use requirements of users.

Owner:浙江圣麦斯针织有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com