High-permeability thermal transfer printing napped fabric processing method

A technology of thermal transfer printing and printing plush blank, which is applied in the field of printing and dyeing to achieve the effect of saving dye resources, good printing and dyeing effect, and avoiding whitening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

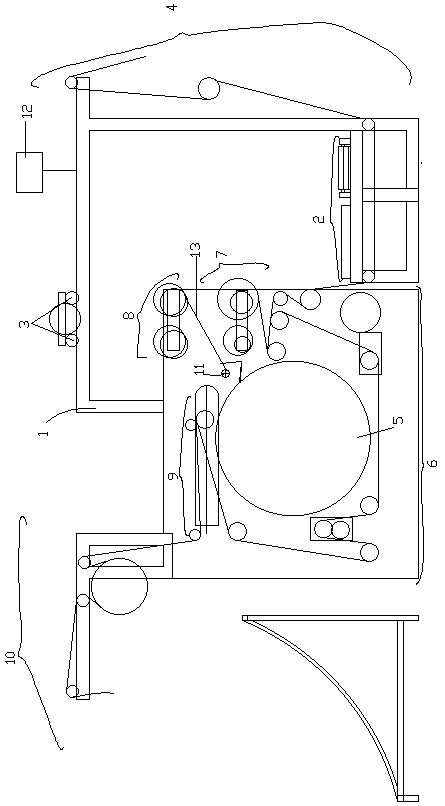

Image

Examples

Embodiment 1

[0029] Example 1: The processing method of a high-permeability thermal transfer printing plush fabric provided by the present invention will now be described. The processing method includes the following steps:

[0030] White blank carding→white blank burnishing→predetermined shape→printing→over water softening→drying→puffing→grooming→shearing→finished product ironing and ironing→air washing (polarizing)→finished product shaping, among which:

[0031] The specific operation of the printing is: arranging the predetermined white grey fabric and transfer paper on a high-permeability thermal transfer printing machine, and performing thermal transfer printing to obtain a high-permeability thermal transfer printed plush grey fabric; adopting high-permeability thermal transfer The printing machine performs heat transfer on plush fabrics, which can not only be applied to low-weight polyester plain fabrics or some slightly heavier curtain fabrics, but also for flannel, coral fleece, raschel ...

Embodiment 2

[0042] Example 2: The processing method of a high-permeability thermal transfer printing plush fabric provided by the present invention will now be described. The processing method includes the following steps:

[0043] White blank carding→white blank burnishing→predetermined shape→printing→over water softening→drying→puffing→grooming→shearing→finished product ironing and ironing→air washing (polarizing)→finished product shaping, among which:

[0044] The specific operation of the printing is: arranging the predetermined white grey fabric and transfer paper on a high-permeability thermal transfer printing machine, and performing thermal transfer printing to obtain a high-permeability thermal transfer printed plush grey fabric; adopting high-permeability thermal transfer The printing machine performs heat transfer on plush fabrics, which can not only be applied to low-weight polyester plain fabrics or some slightly heavier curtain fabrics, but also for flannel, coral fleece, raschel ...

Embodiment 3

[0055] Example 3: The processing method of a high-permeability thermal transfer printing plush fabric provided by the present invention will be described. The processing method includes the following steps:

[0056] White blank carding→white blank burnishing→predetermined shape→printing→over water softening→drying→puffing→grooming→shearing→finished product ironing and ironing→air washing (polarizing)→finished product shaping, among which:

[0057] The specific operation of the printing is: arranging the predetermined white grey fabric and transfer paper on a high-permeability thermal transfer printing machine, and performing thermal transfer printing to obtain a high-permeability thermal transfer printed plush grey fabric; adopting high-permeability thermal transfer The printing machine performs thermal transfer on plush fabrics, which can be applied not only to low-weight polyester plain fabrics or some slightly heavier curtain fabrics, but also to flannel, coral fleece, raschel an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com