Disperse gray dye composition, dye product, preparation method and application of dye product, and colored product

A dye composition and a technology for dispersing ash, applied in the field of dyes, can solve the problems of expensive dyes, complex structure, poor sublimation fastness and the like, and achieve the effects of wide dyeing pH range, simple preparation method and high washing fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

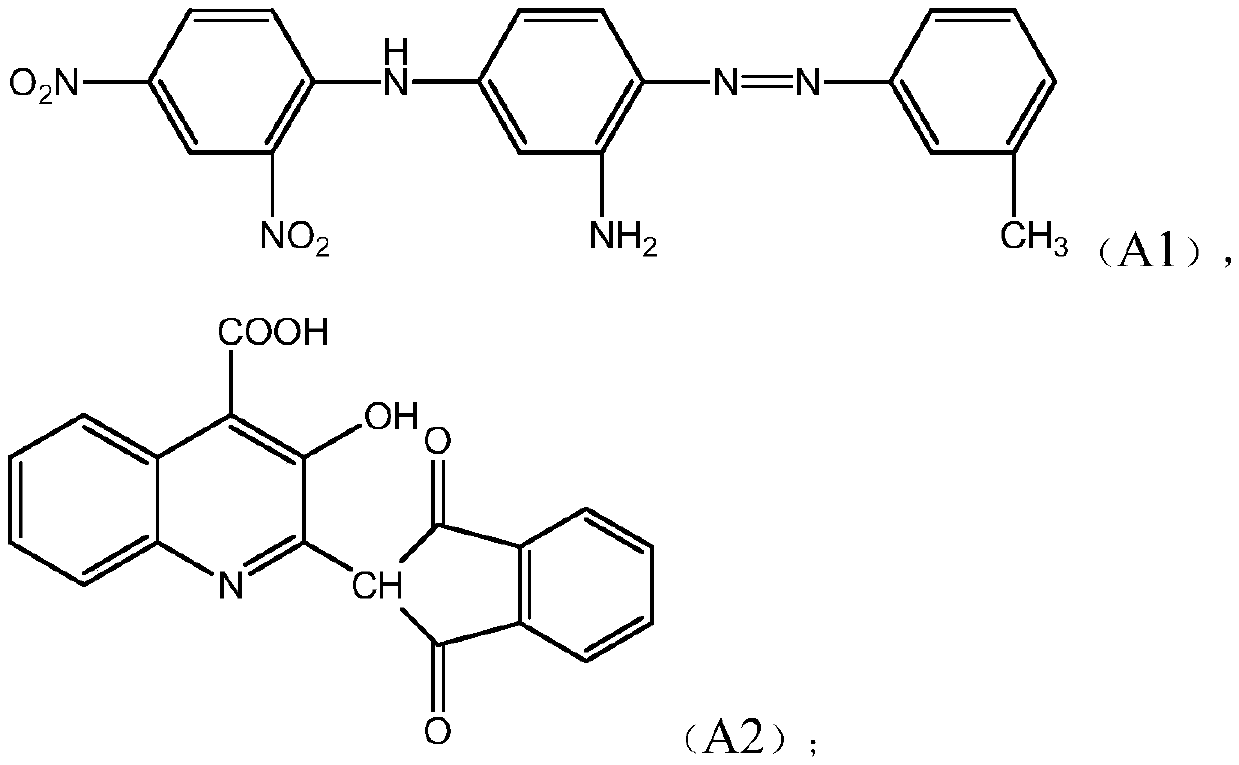

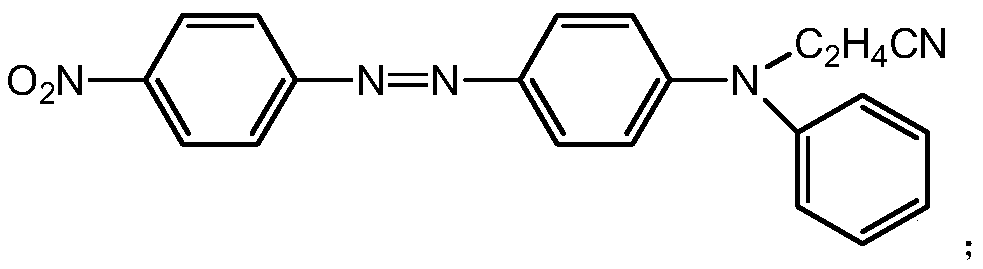

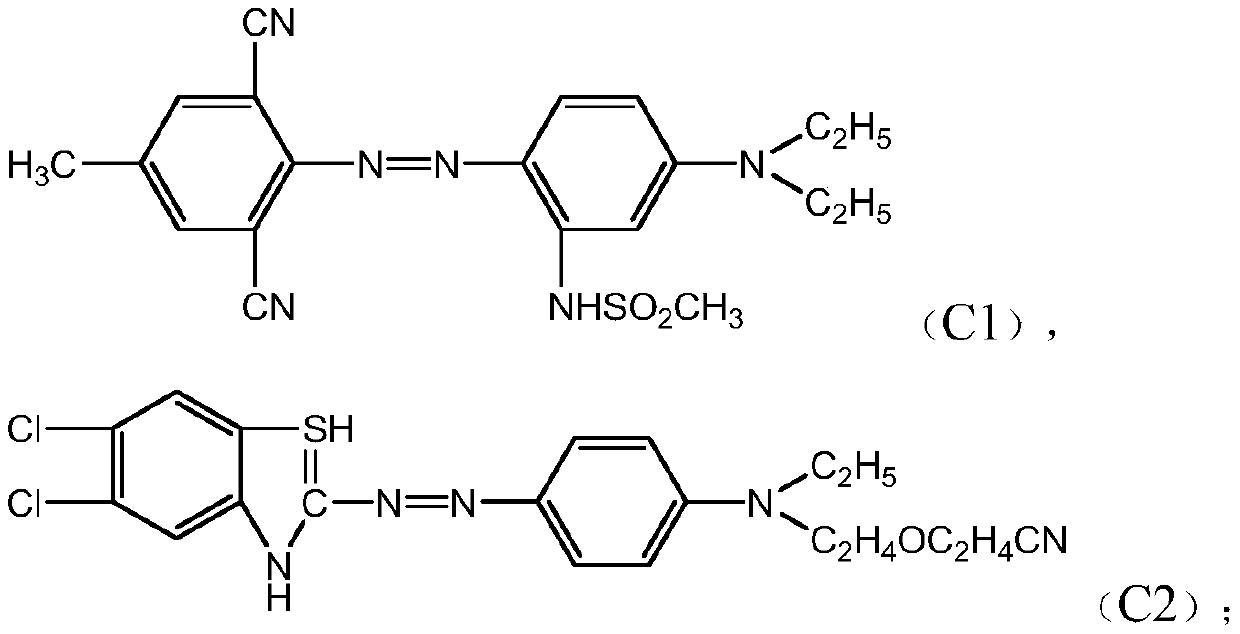

Method used

Image

Examples

Embodiment 1

[0072] Based on the raw dyes supplied in the market, take 2.68g of component A1 dye, 0.43g of component A2 dye, 4.97g of component B dye, 2.08g of component C1 dye, 5.93g of component D1 dye, and 6.03g of component D2 dye, Composition of disperse gray dye composition.

[0073] Then add 77.88g of dispersant MF and water, sand mill and disperse with a sand mill, and then spray dry to obtain a solid dye product.

Embodiment 2-8

[0075] With reference to Example 1, the components and amounts were adjusted to obtain the disperse gray dye compositions of Examples 2-8.

[0076] With reference to the method of Example 1, additives and water were added to the disperse gray dye composition obtained in Example 2-5, sand-milled and dispersed with a sand mill, and then spray-dried to obtain a solid dye product.

[0077] Add additives and water to the disperse gray dye composition obtained in Examples 6-8, and sand-mill and disperse with a sand mill to obtain a liquid dye product.

[0078] The specific components and dosage are shown in Table 1 below.

[0079] It should be noted that the amount of water in Table 1 is the water content in the final dye product.

[0080] Components and consumption of table 1 embodiment 1-8 dye preparation

[0081]

[0082]

[0083] The above-mentioned examples 1-8 are statistically analyzed and calculated, and the dyestuff cost is calculated to be about 80% of the price of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com