Patents

Literature

148results about How to "Improve printing and dyeing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

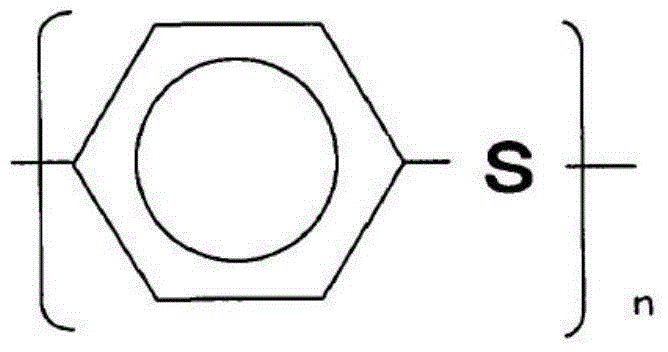

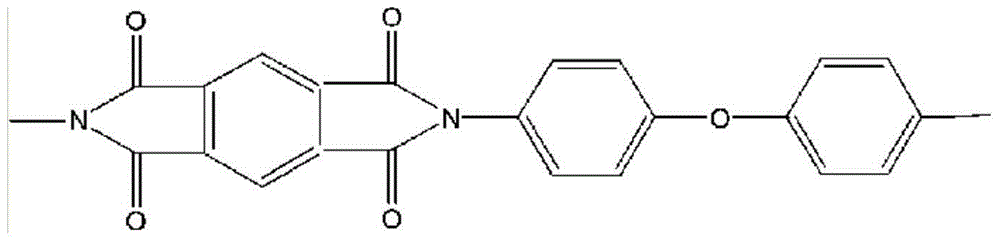

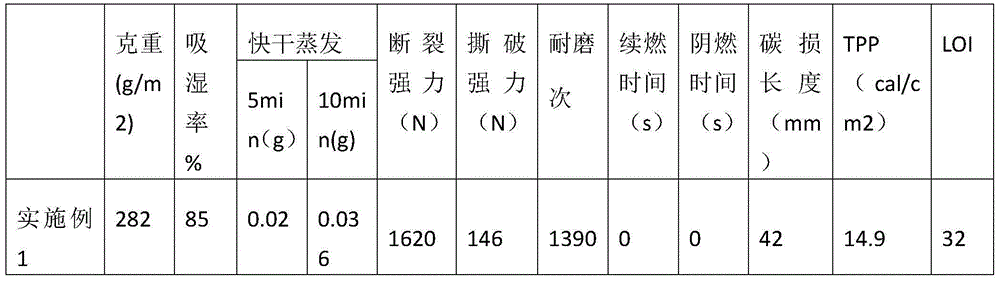

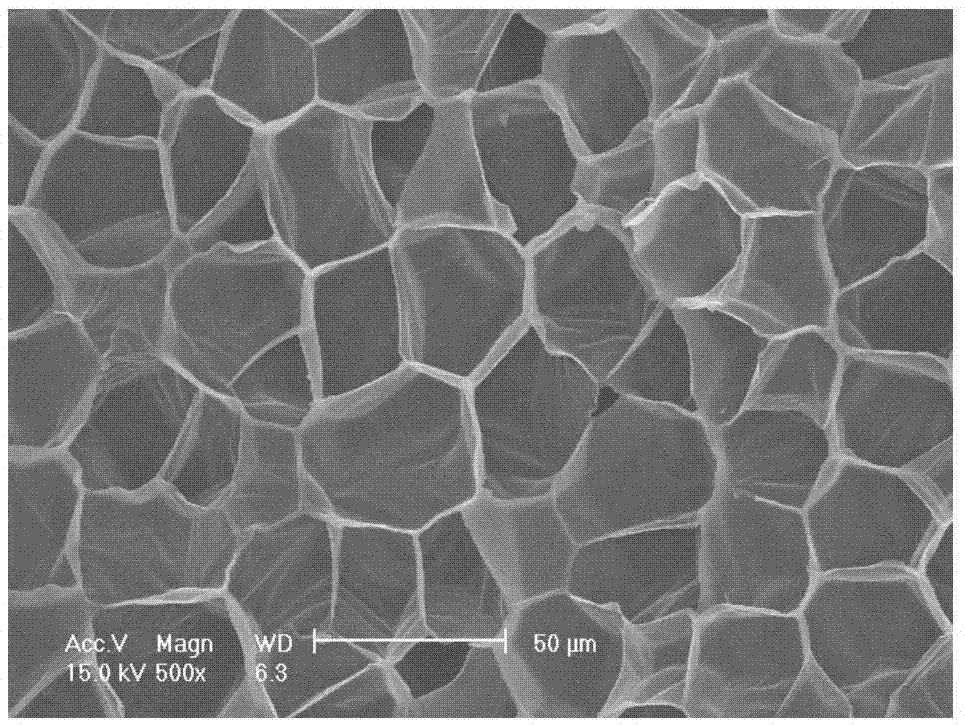

Flame retardant yarn comprising aromatic polymer fiber containing sulfuryl, fabric made of same and preparation method

ActiveCN104611806AHigh mechanical abrasion resistanceGood synergyMonocomponent copolyamides artificial filamentWoven fabricsYarnPolyester

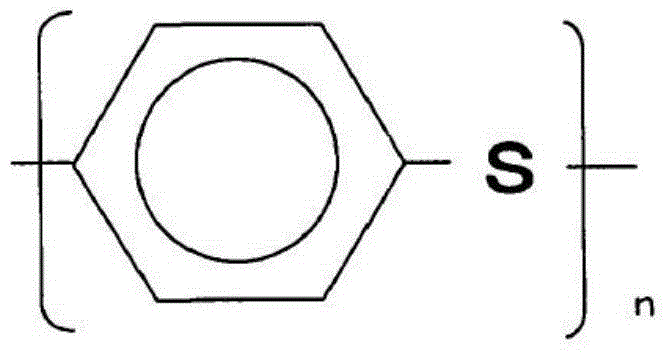

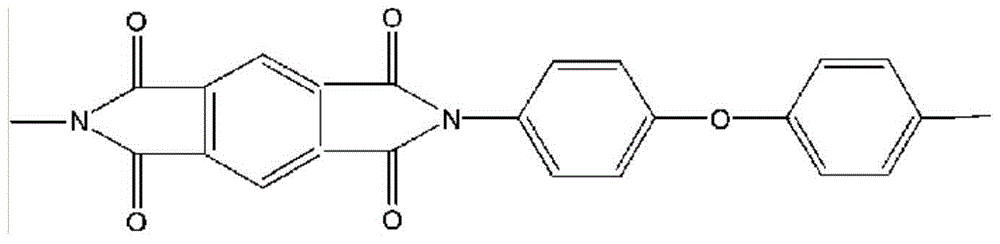

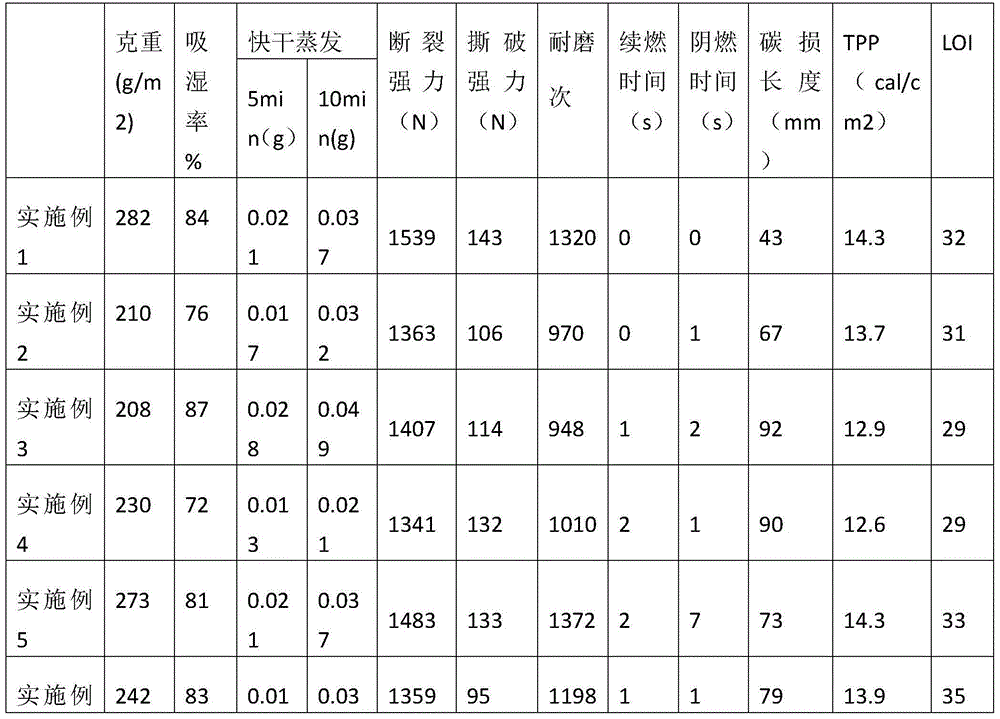

The invention relates to a flame retardant yarn comprising aromatic polymer fiber containing sulfuryl, a fabric and garment made of the same and a preparation method thereof. The yarn comprises a high temperature resistant inherent flame retardant fiber (A), conventional fire-retardant fiber (B) and flame retardant cellulose fiber (C). The conventional fire-retardant fiber (B) can be one of flame retardant nylon, flame retardant polyester and flame retardant acrylic selectively. The yarn is mainly applied to preparation of the protective camouflage fabric and garment with permanent flame retardance, wear resistance and good comfortable performance.

Owner:中芳新材料有限公司

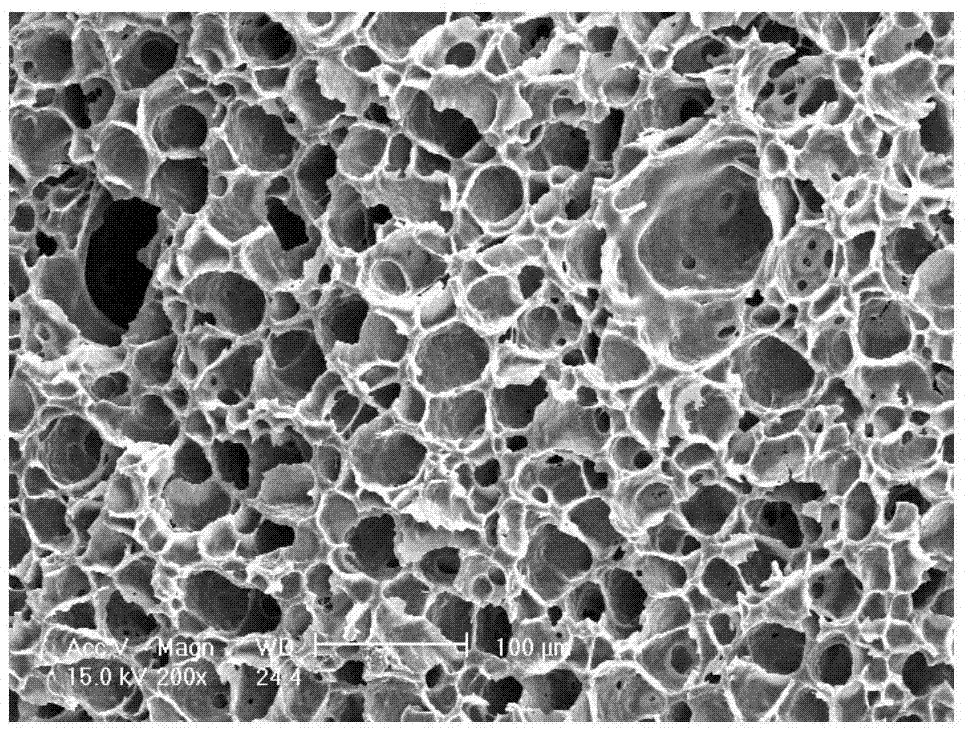

Propylene copolymer microcellular foam materials and preparation method thereof

The invention provides propylene copolymer microcellular foam materials and a preparation method thereof. The preparation method includes: blending propylene copolymer which is binary copolymer of propylene and 1-butene or alpha-olefin or propylene-ethylene-1-butene ternary copolymer with 0-50 parts of toughening agent, 0-100 parts of filler, 0-80 parts of conductive filler, 0-100 parts of reinforcing agent, 0-80 parts of flame retardant, 0-20 parts of antistatic agent and 0-3 parts of coupling agent, and performing intermittent or continuous physical foaming to obtain the microcellular foam materials of different functions. The prepared propylene copolymer foam materials which are environment-friendly and compression-resistant buffer thermal-insulation materials are excellent in seismic performance, energy absorption performance, heat resistance and oil resistance, lightweight, good in adhesiveness and printing and dyeing performance, low in cost, short in cycle, controllable in density, widely applicable to fields such as cars, buildings, food packaging materials and household appliance packaging, and the like.

Owner:QINGDAO UNIV OF SCI & TECH

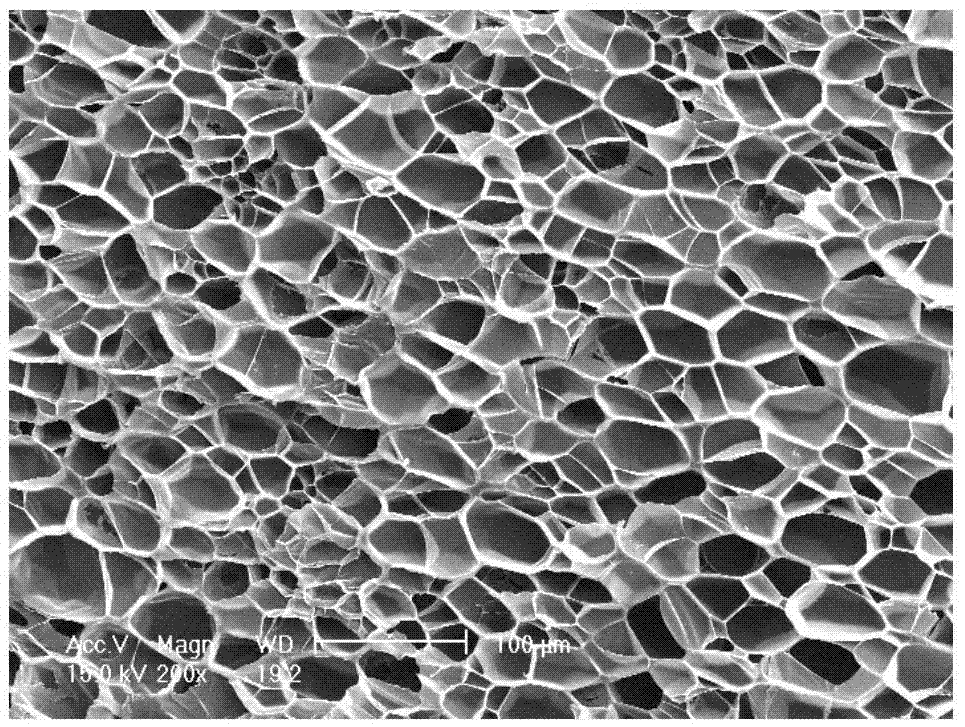

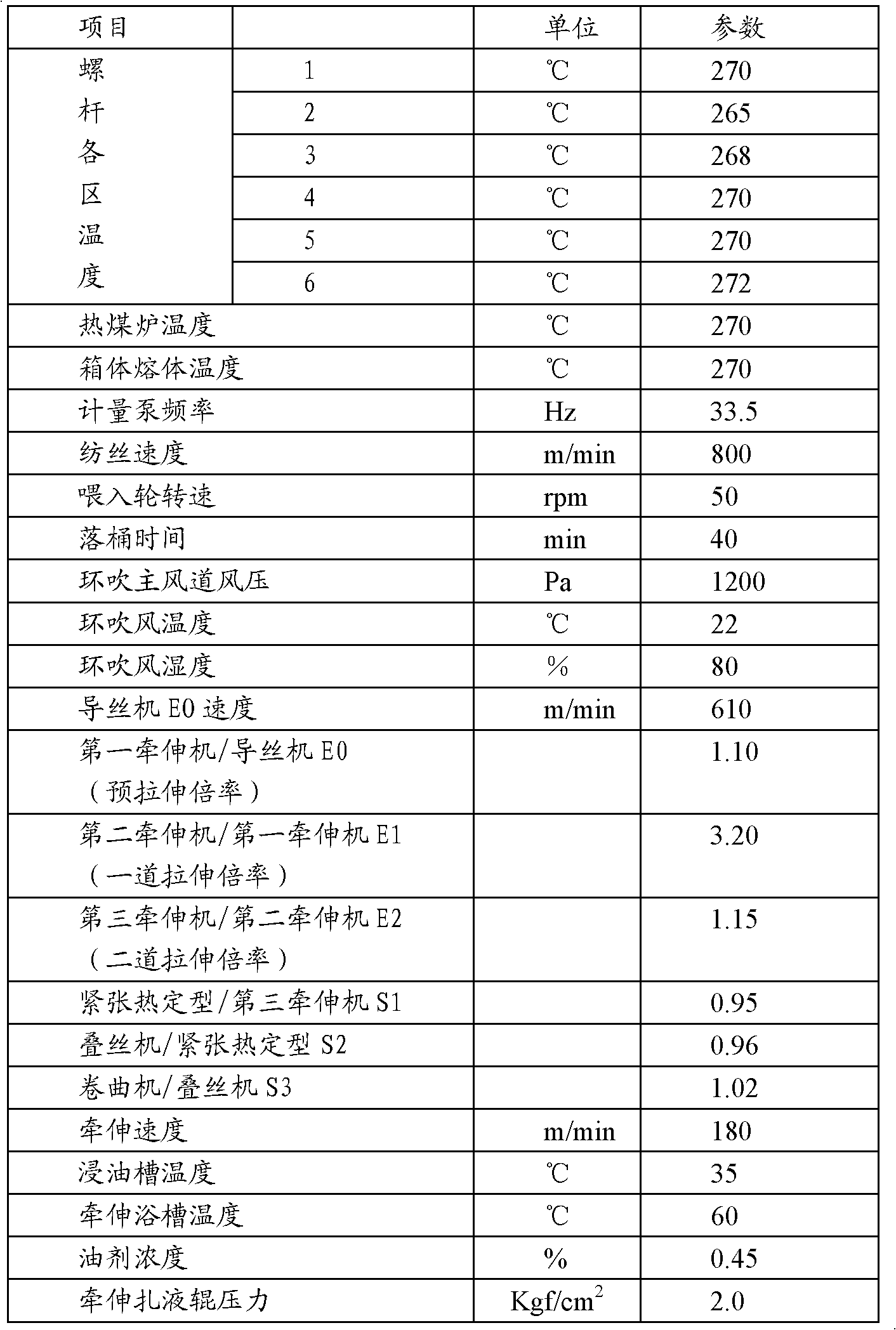

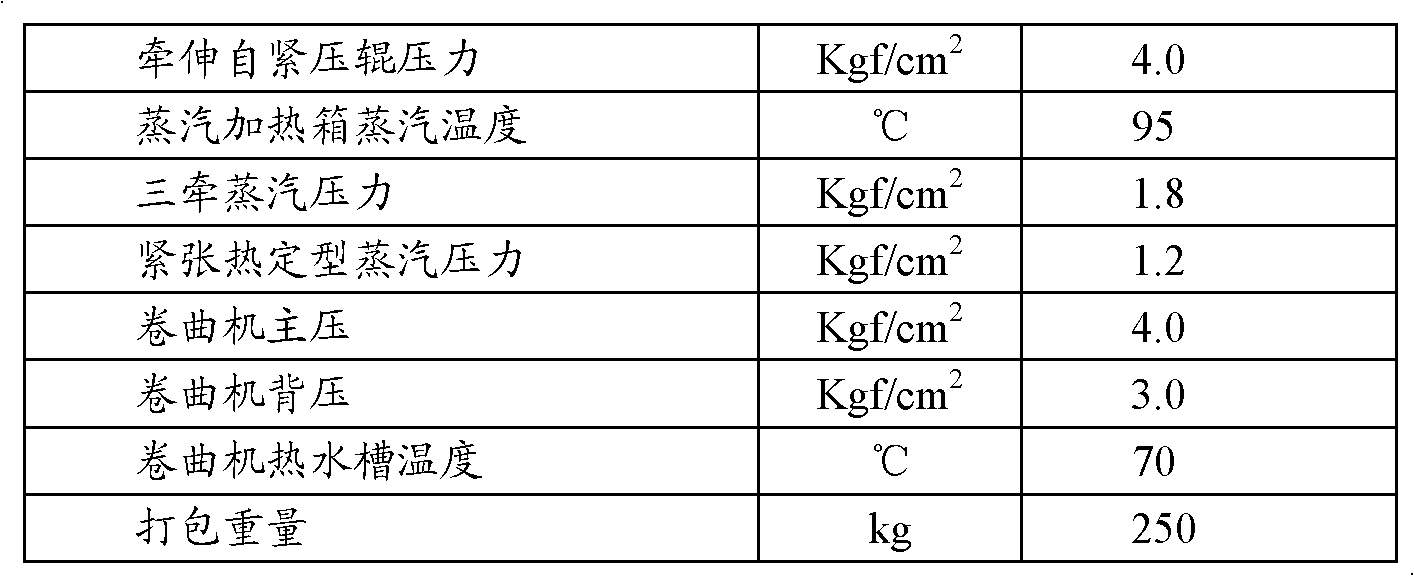

Biomass polyester short fiber and preparation method thereof

ActiveCN102586940AIncrease dependenceImprove protectionMelt spinning methodsMonocomponent polyesters artificial filamentFiberExtremely good

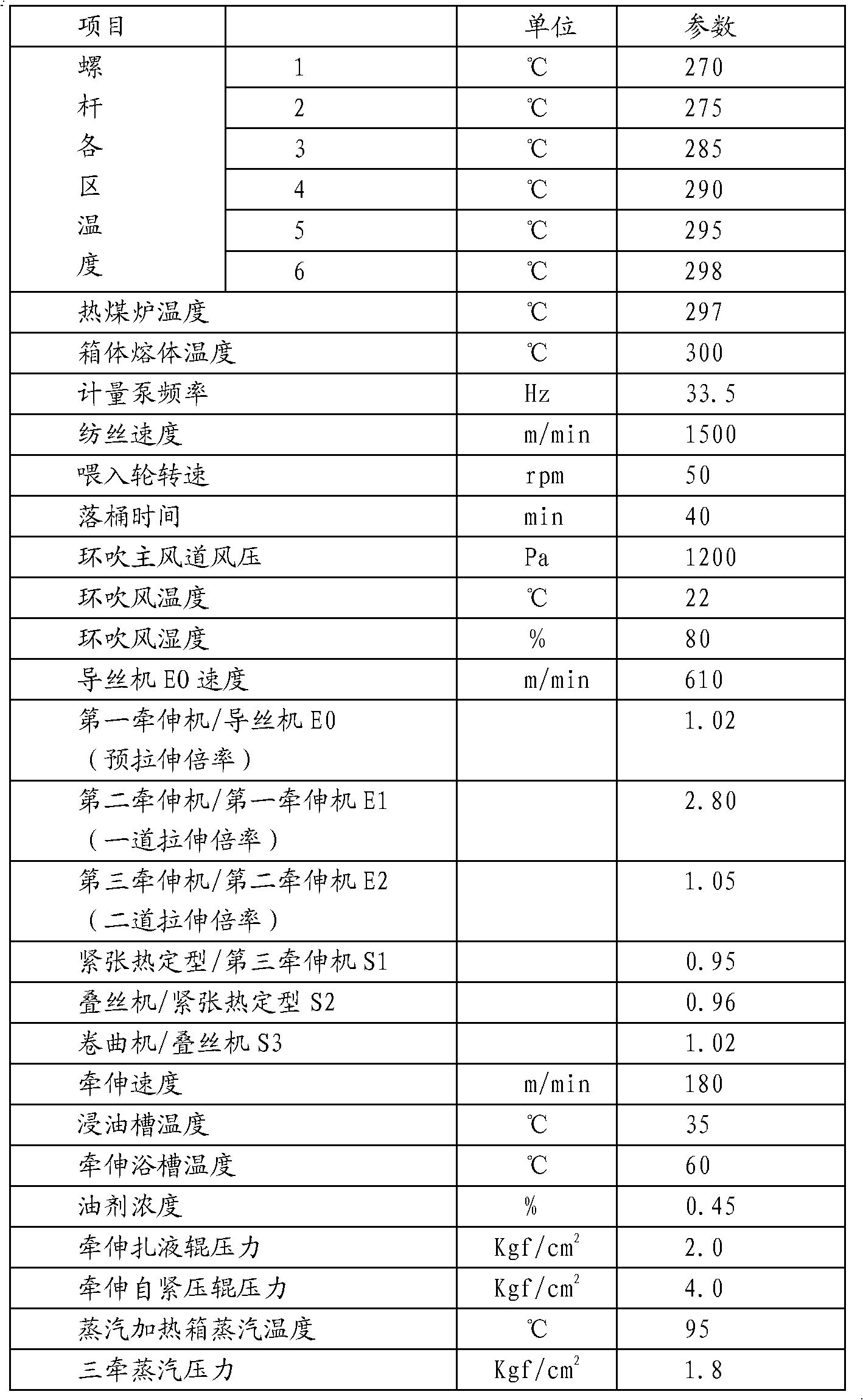

The invention discloses a biomass polyester short fiber and a preparation method thereof. The preparation method comprises the following steps of: mixing terephthalic acid and biomass mixed polyatomic alcohol in a molar ratio of 1:1.05-1:1.5 to form slurry, and performing esterification and condensation polymerization to obtain a biomass polyester chip, wherein biomass multi-component polyatomic alcohol comprises 90 to 99.2 weight percent of ethylene glycol, 0.4 to 5 weight percent of 1,2-propylene glycol, 0.2 to 2 weight percent of 1,2-butanediol, 0.1 to 2 weight percent of pentanediol and 0.1 to 1 weight percent of sorbitol; and processing the biomass polyester chip by using the conventional polyester spinning equipment to obtain the environment-friendly biomass polyester short fiber, wherein a specified process parameter is controlled in the process. The raw material chip of the environment-friendly biomass polyester short fiber is derived from biomass, so that the dependence on petroleum resources is reduced, and an intense situation of energy sources is relieved. A biomass dibasic alcohol component is fixed, so that the prepared biomass polyester short fiber has stable and controllable quality, extremely good printing and dyeing effects and a wide application field, and is high in hydrophilcity, flexibility, washing fastness and ironing fastness.

Owner:QUANZHOU HAITIAN MATERIAL TECH CORP

Method of dry transfer printing of synthetic fibrous material with disperse dye and transfer paper

InactiveCN101688358AImprove qualityFeel goodNon-fibrous pulp additionSpecial paperDisperse dyeOrganic solvent

A transfer paper which comprises a transfer paper base and a disperse dye ink printed thereon or imparted thereto. The transfer paper is used in a dry transfer printing method in which the transfer paper is pressed against a synthetic fibrous material with heating to thereby transfer the dye (pattern) from the transfer paper to the fibrous material. The transfer paper is characterized in that thetransfer paper base has a releasant layer comprising a synthetic resin soluble in organic solvents and an ink-receiving layer made from a mixture comprising a hydrophilic synthetic resin which softensor melts upon heating, a hydrophilic binder, and various aids, the ink-receiving layer being superposed on the releasant layer. With this transfer paper for dry transfer printing, a highly fine pattern can be printed with excellent reproducibility. Furthermore, the transfer paper enables quick delivery by so-called printing without platemaking. The method of dry transfer plating employs this transfer paper.

Owner:NORITZ CORP

Fabric comprising fire-retardant yarn of blended polymer fiber containing aromatic polyamide and polyarylsulfone and production method of fabric

ActiveCN104630958AHigh mechanical abrasion resistanceGood synergyMonocomponent copolyamides artificial filamentYarnYarnPolyester

The invention relates to a fire-retardant yarn of a blended polymer fiber containing aromatic polyamide and polyarylsulfone and fabric and clothes produced by the fire-retardant yarn and production method of the fabric and clothes. The yarn comprises a high temperature resistant nature fire-retardant fiber (A), a conventional fire-retardant fiber (B) and a fire-retardant cellulose fiber (C), and the conventional fire-retardant fiber is selected from fire-retardant polyamide, fire-retardant polyester and fire-retardant acrylic. The yarn is mainly used for producing protective camouflage fabric and clothes which are forever fire retardant, wear resistant and good in comfortableness.

Owner:中芳新材料有限公司

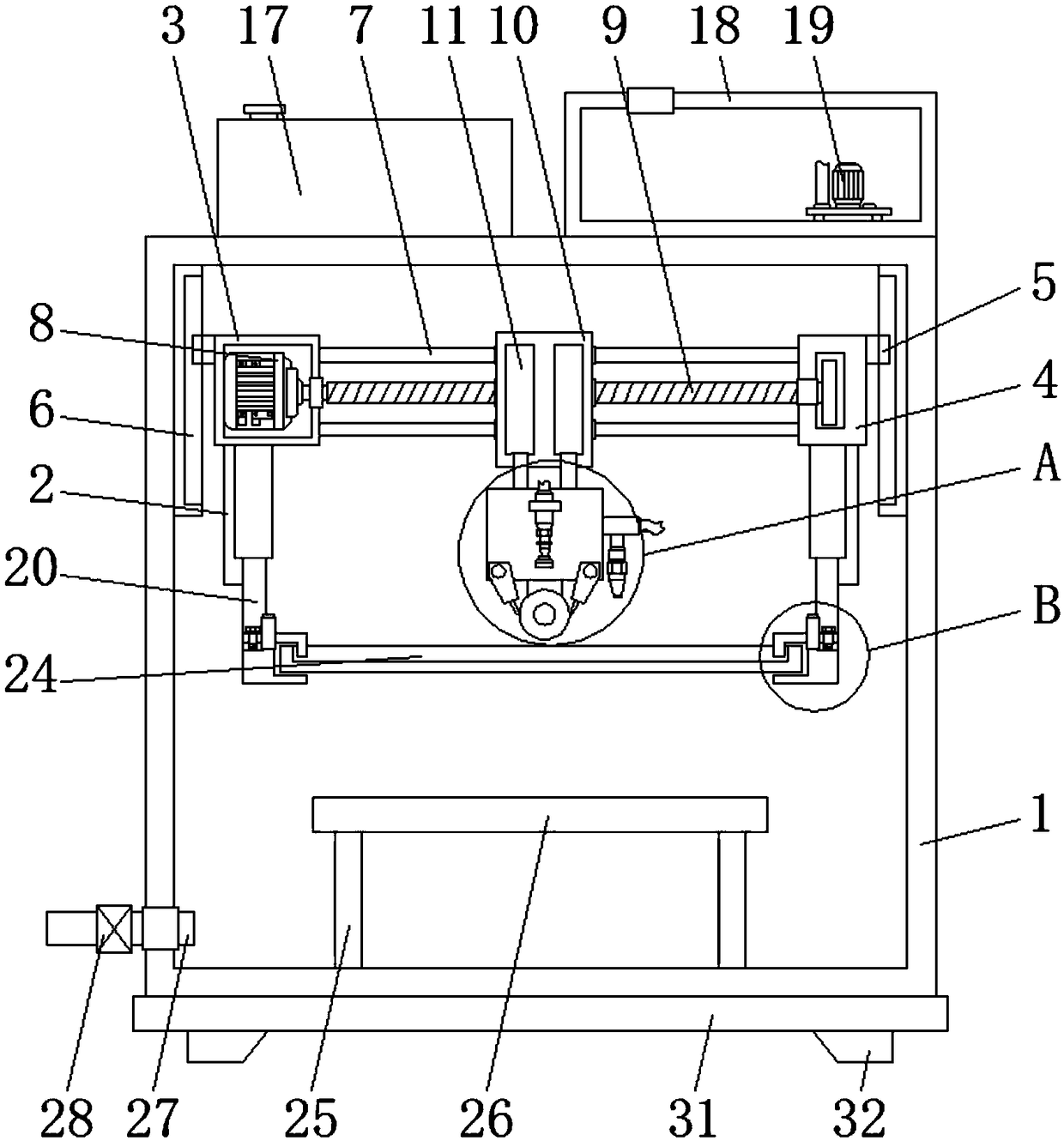

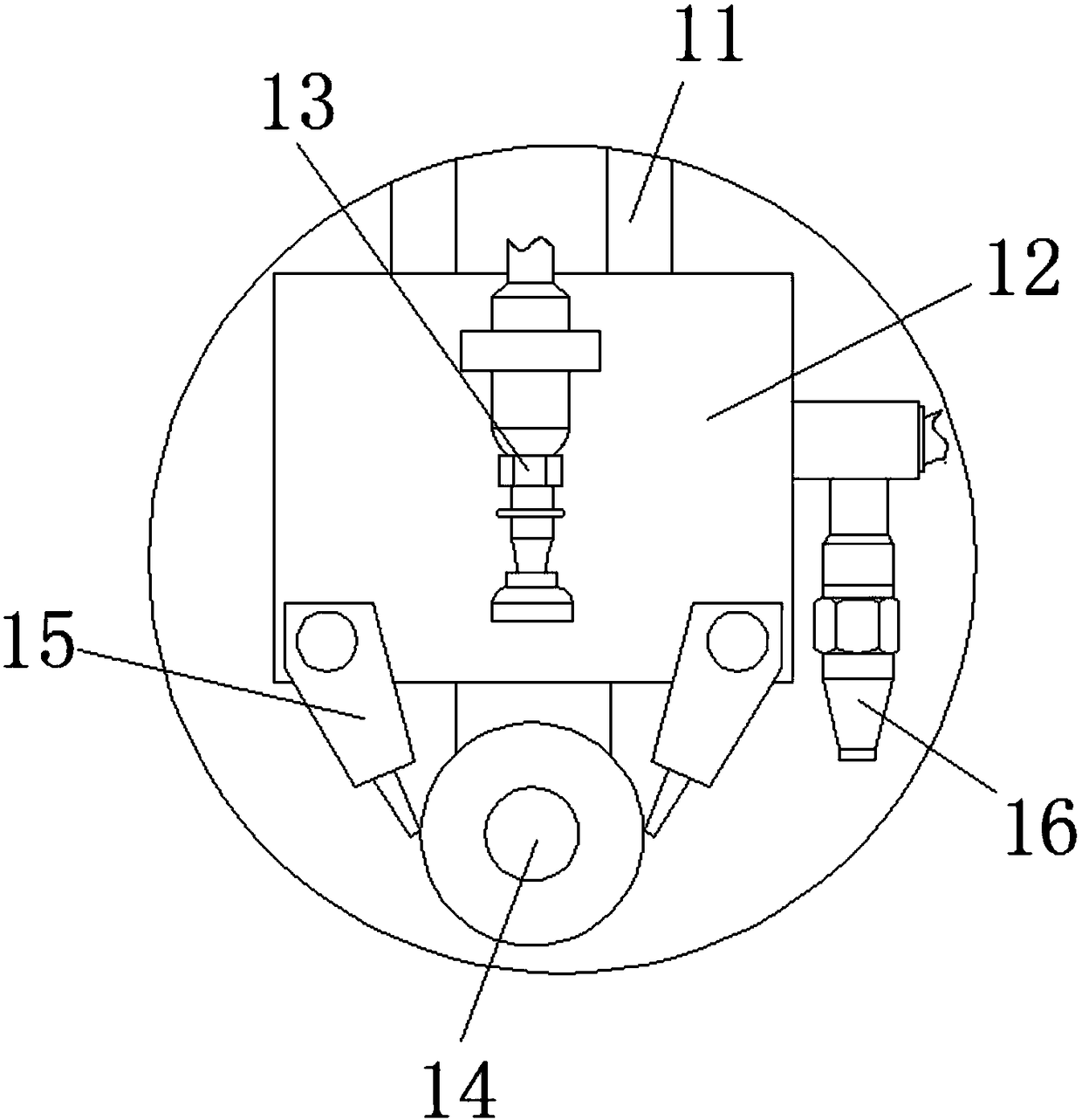

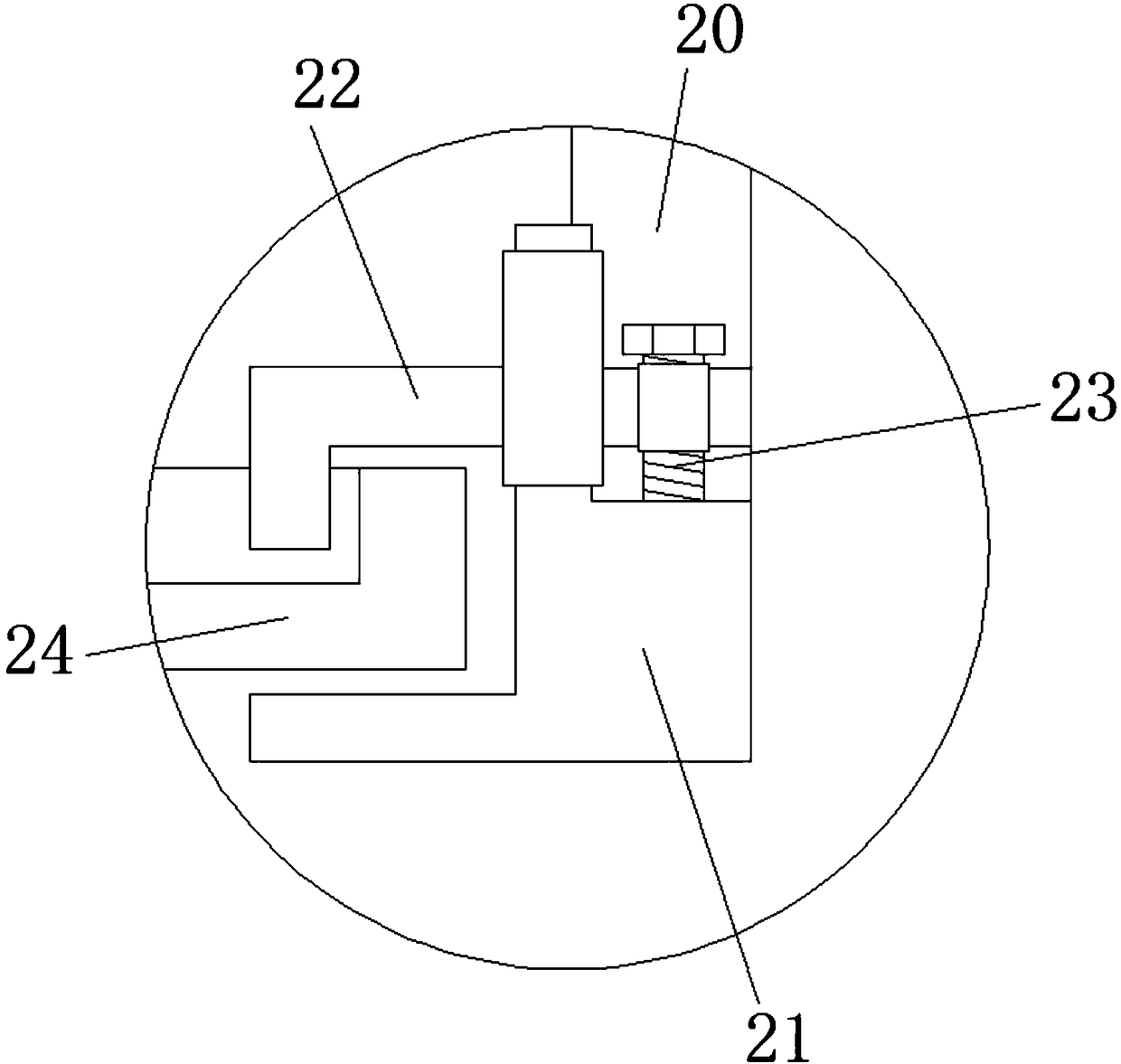

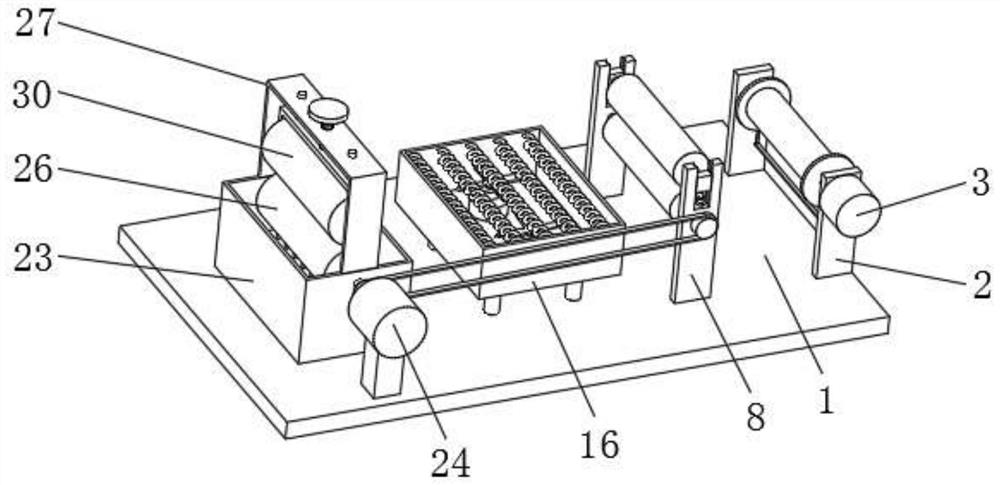

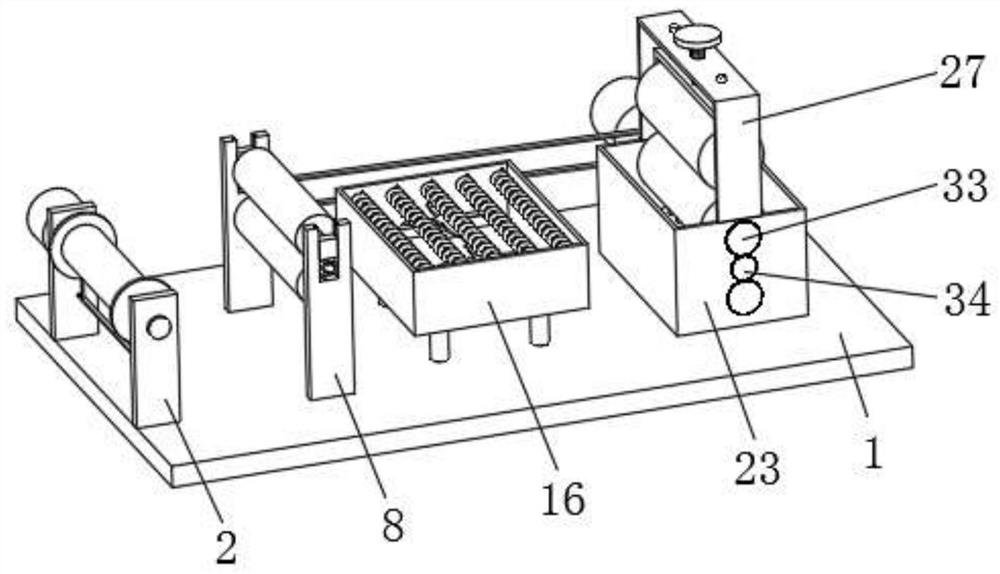

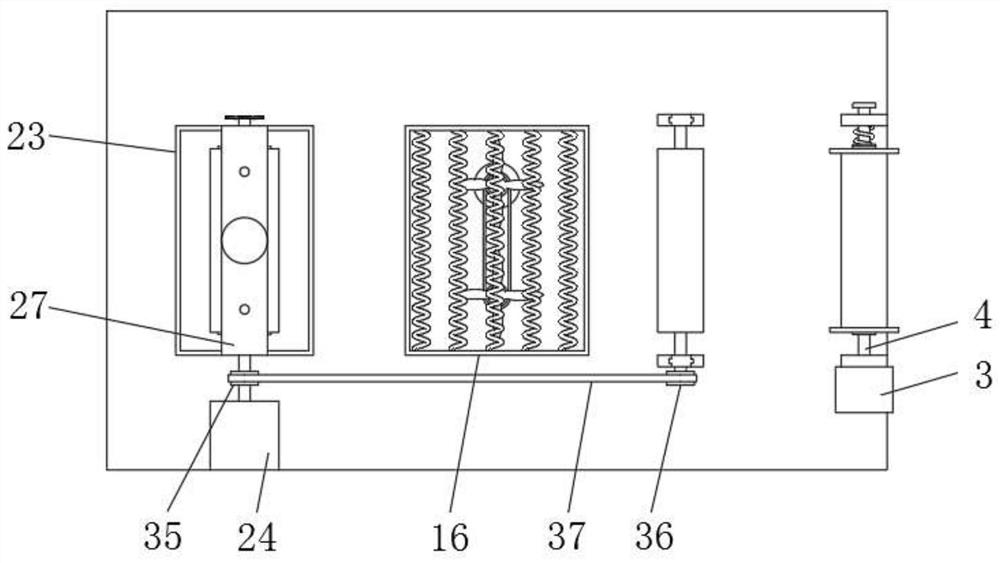

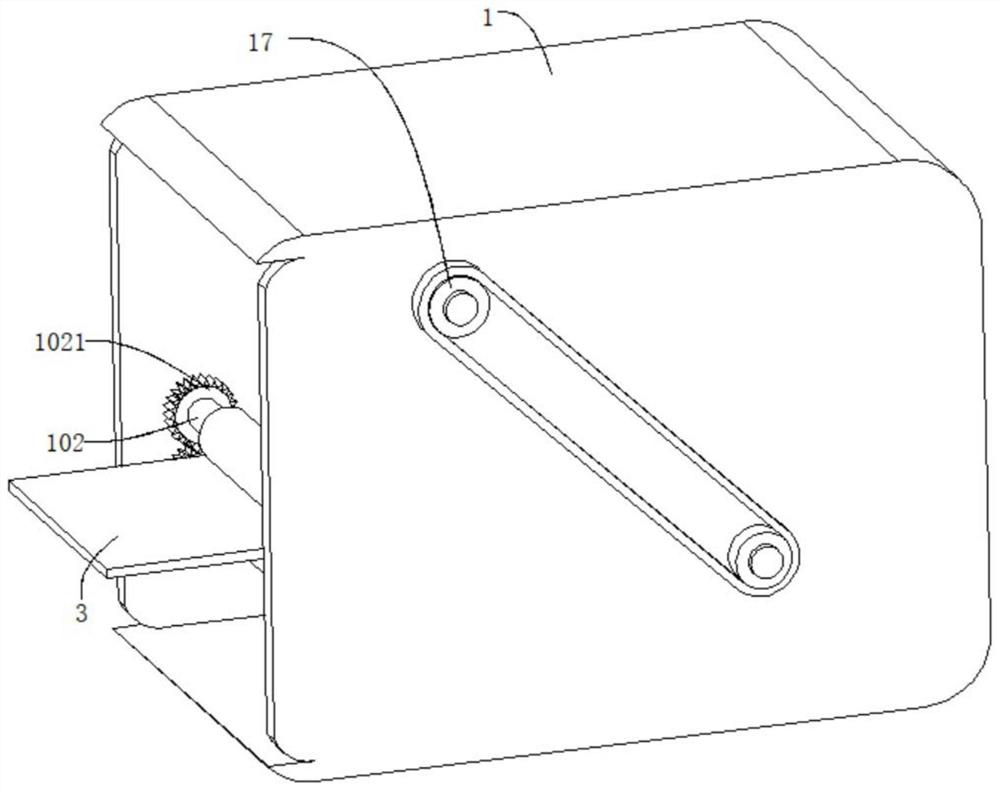

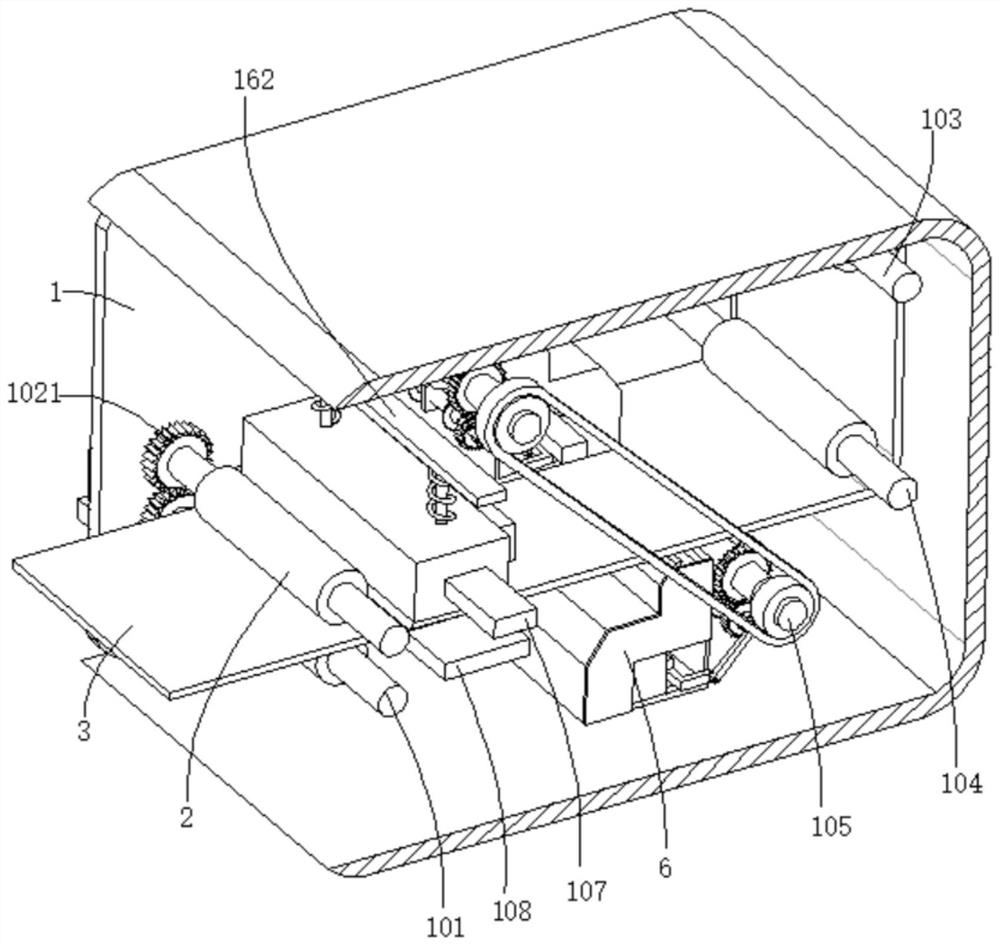

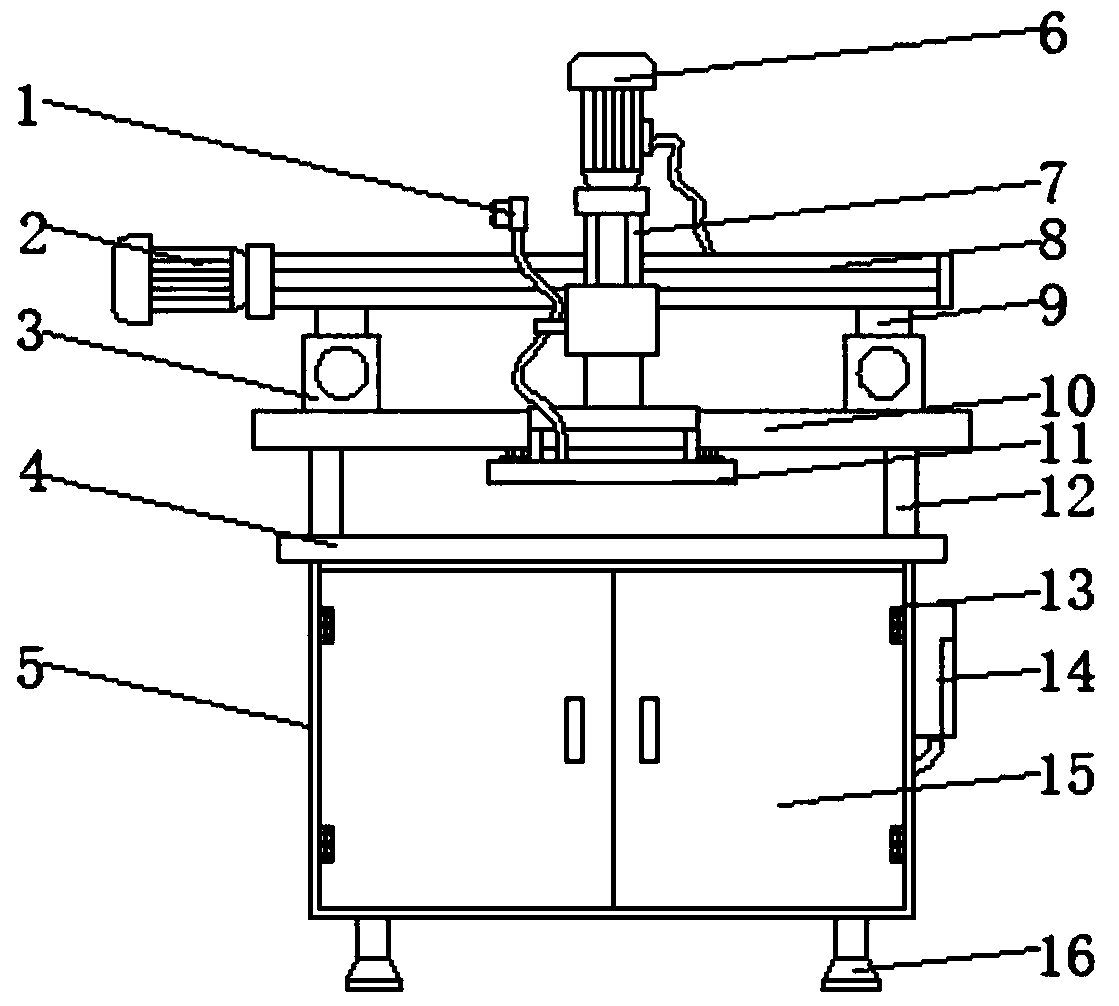

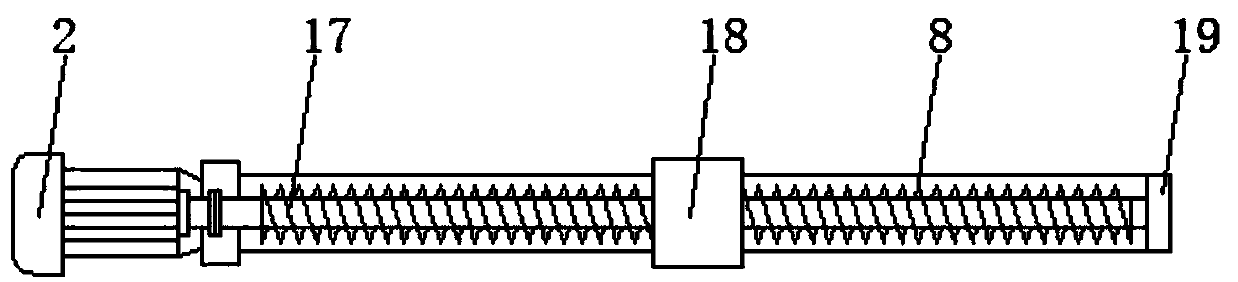

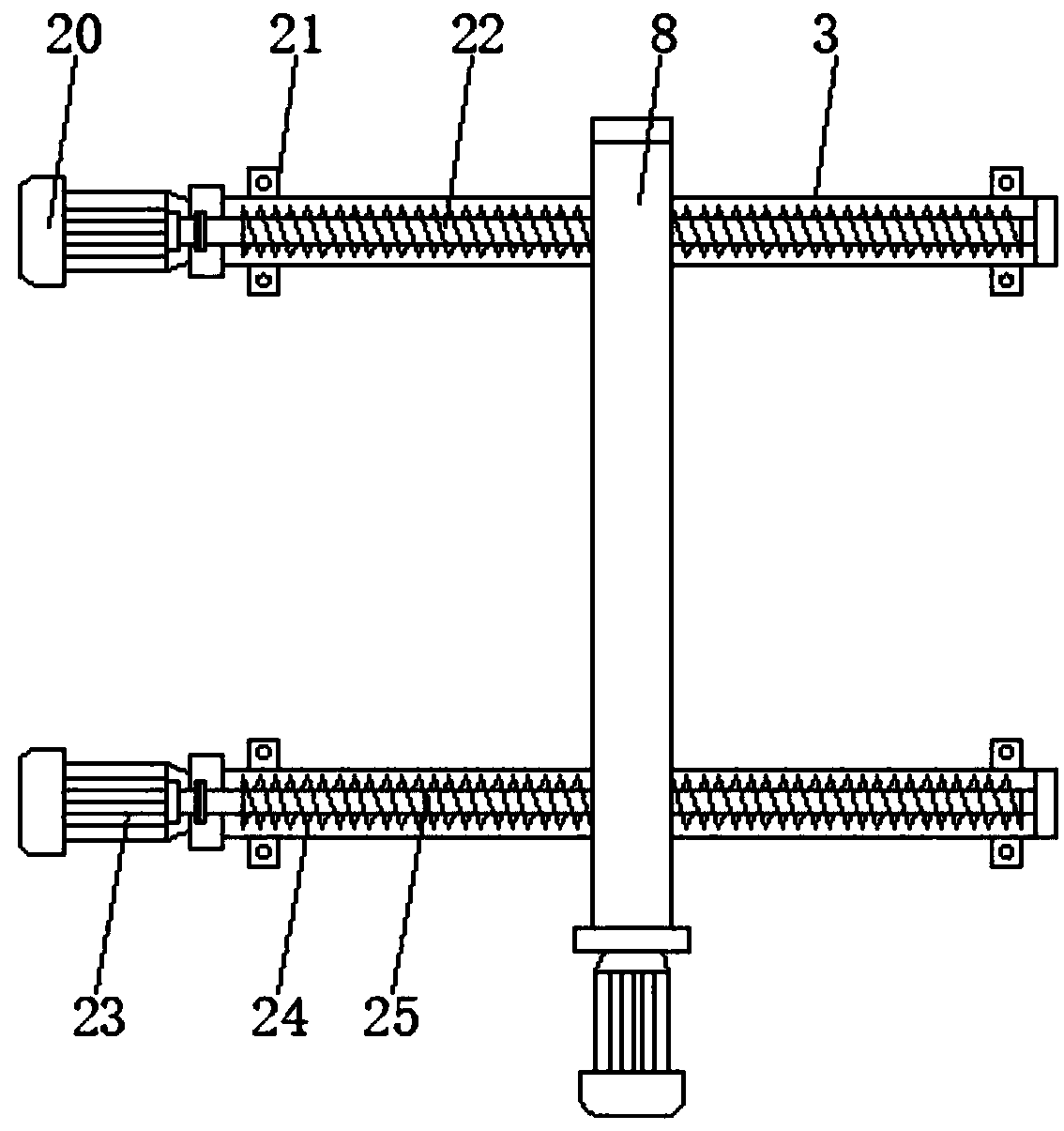

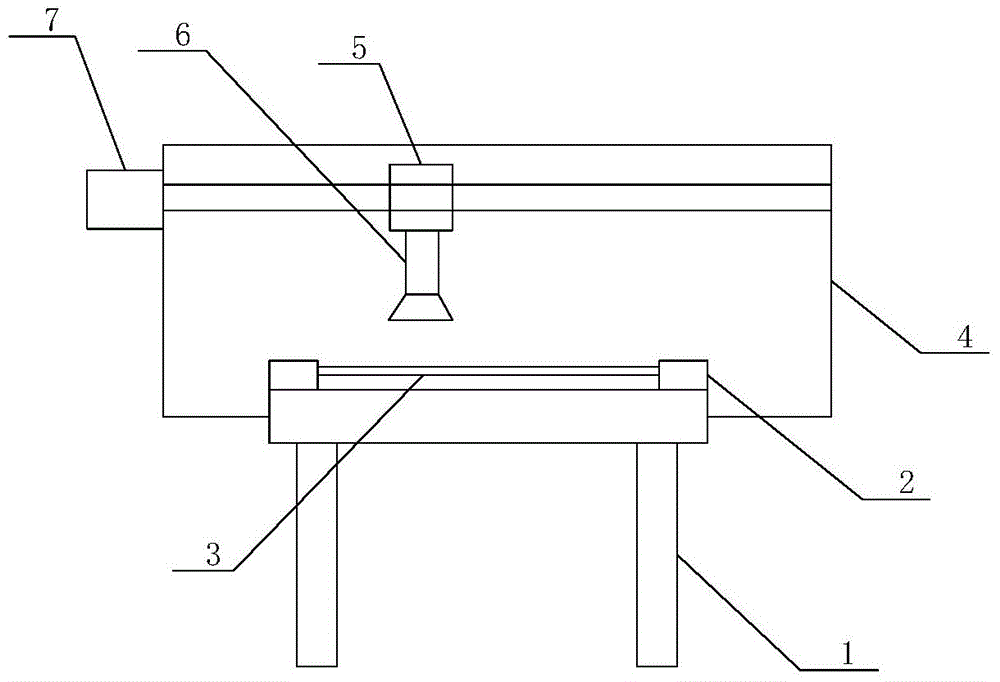

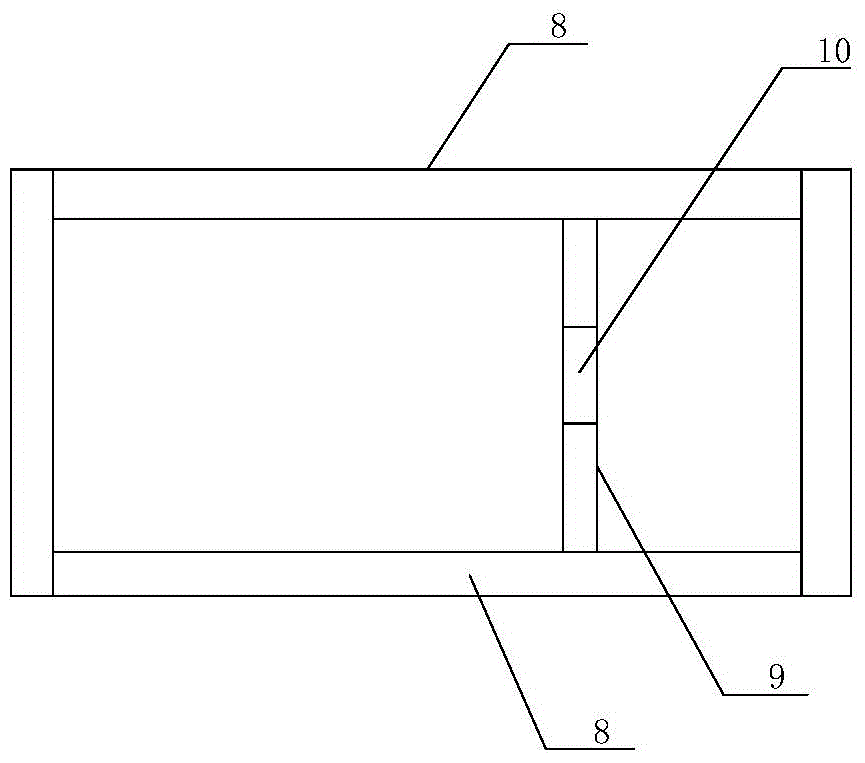

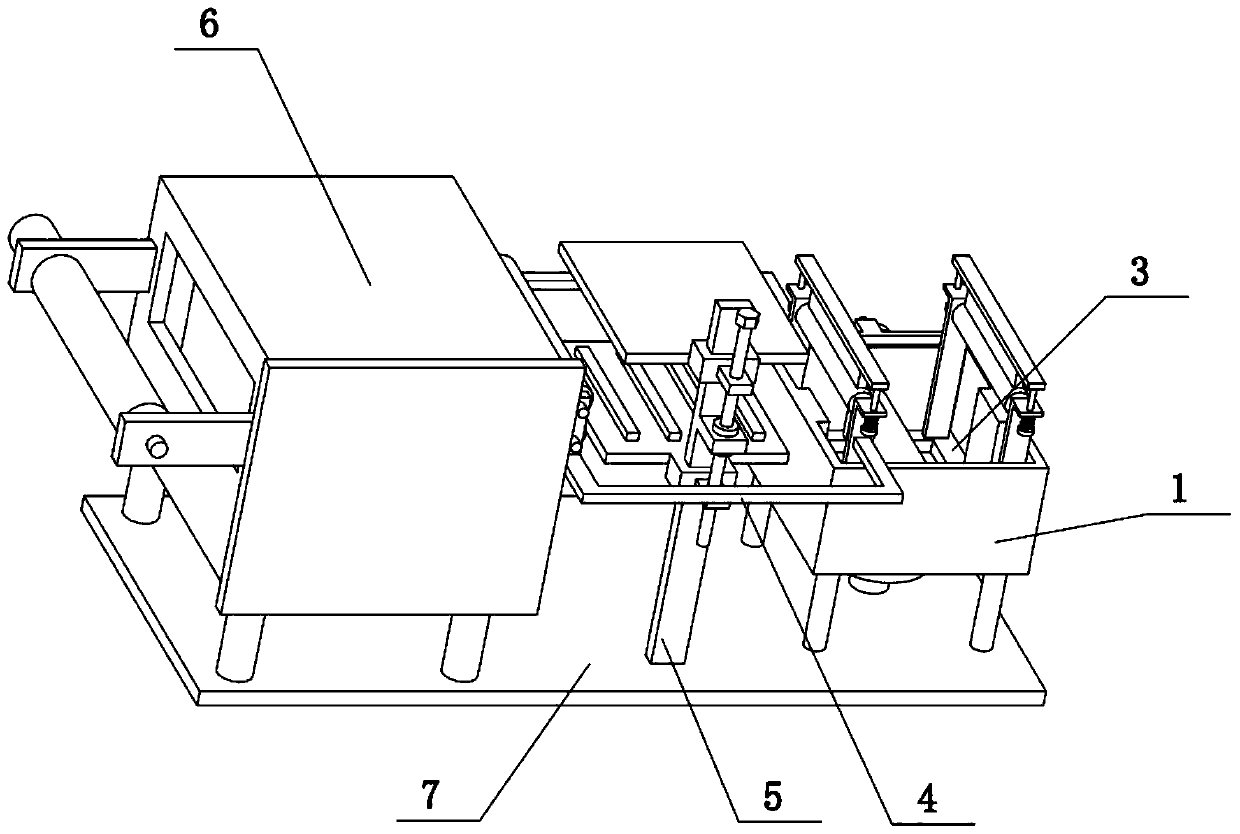

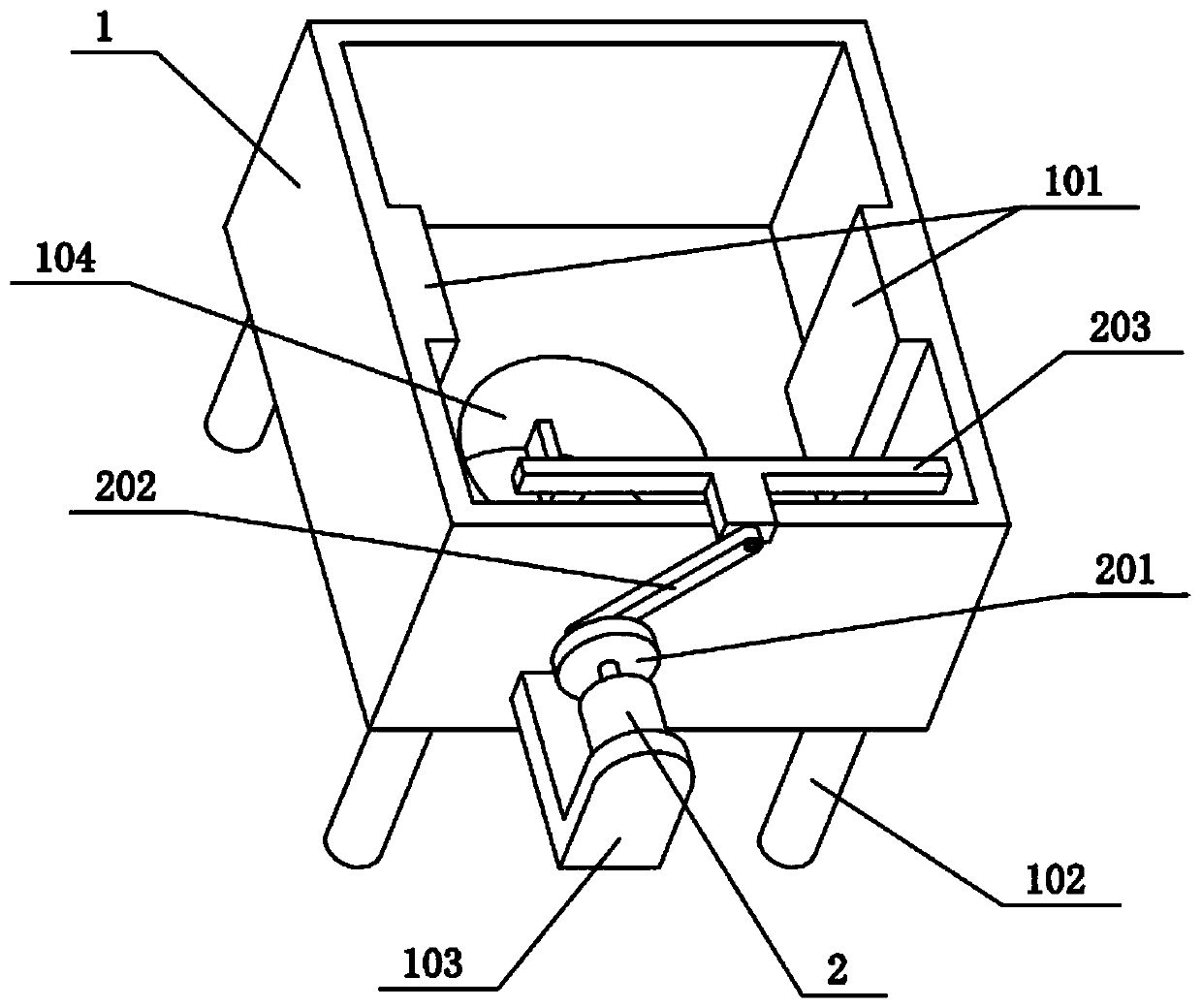

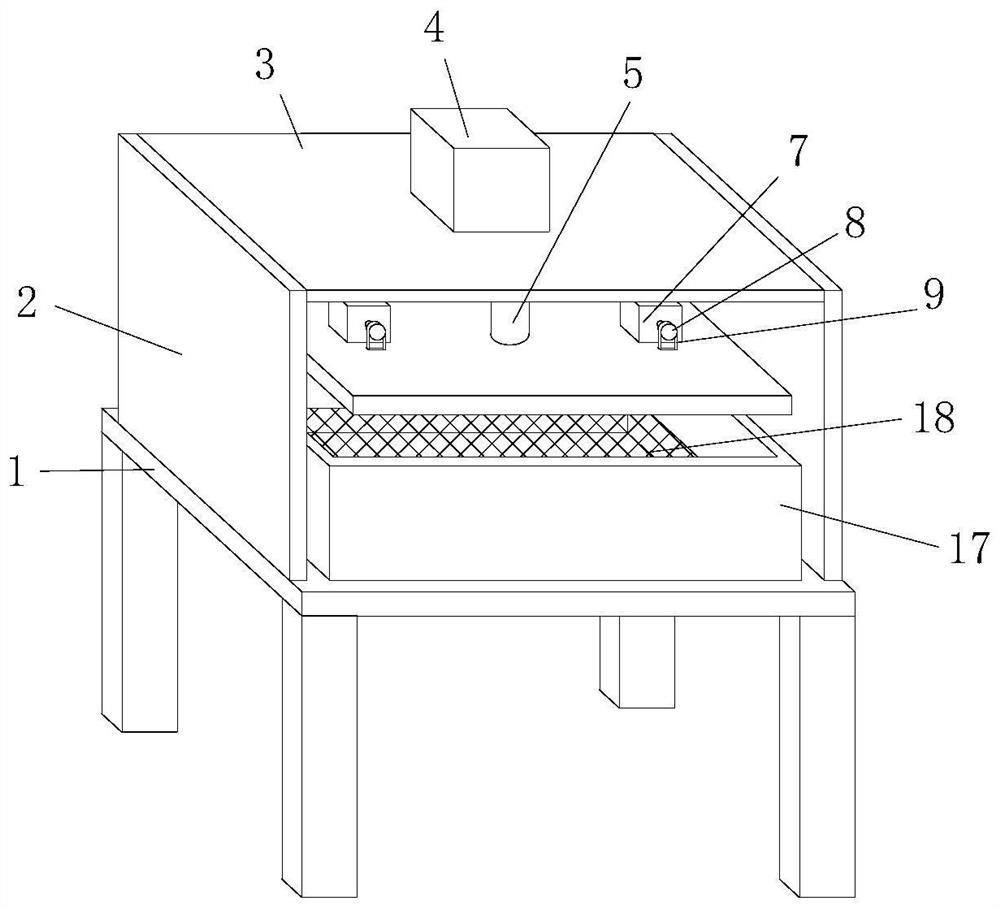

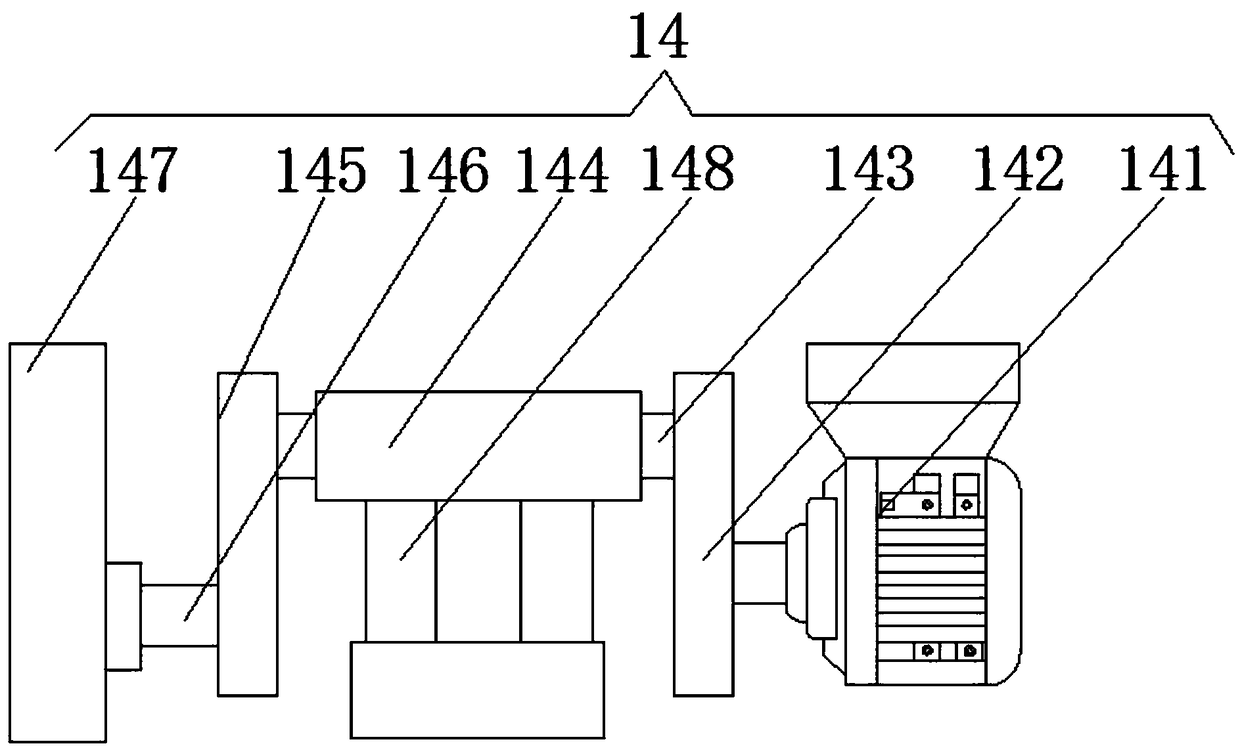

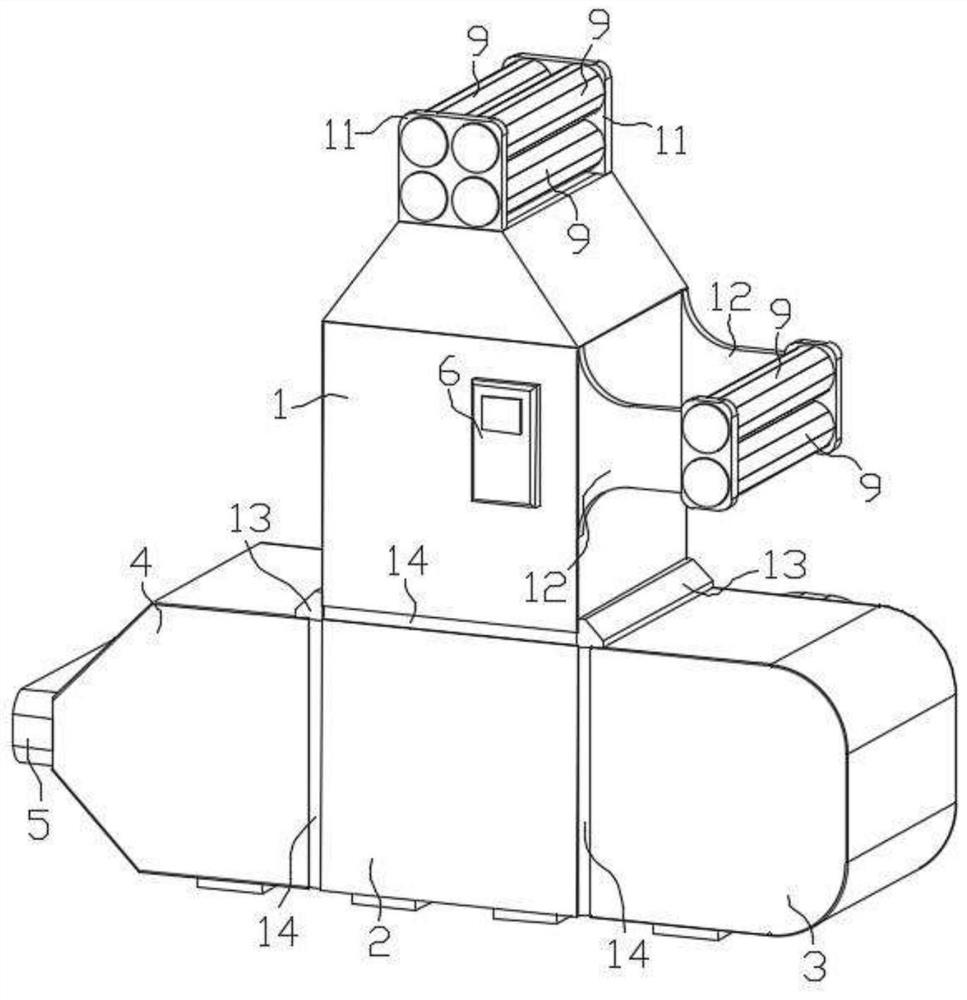

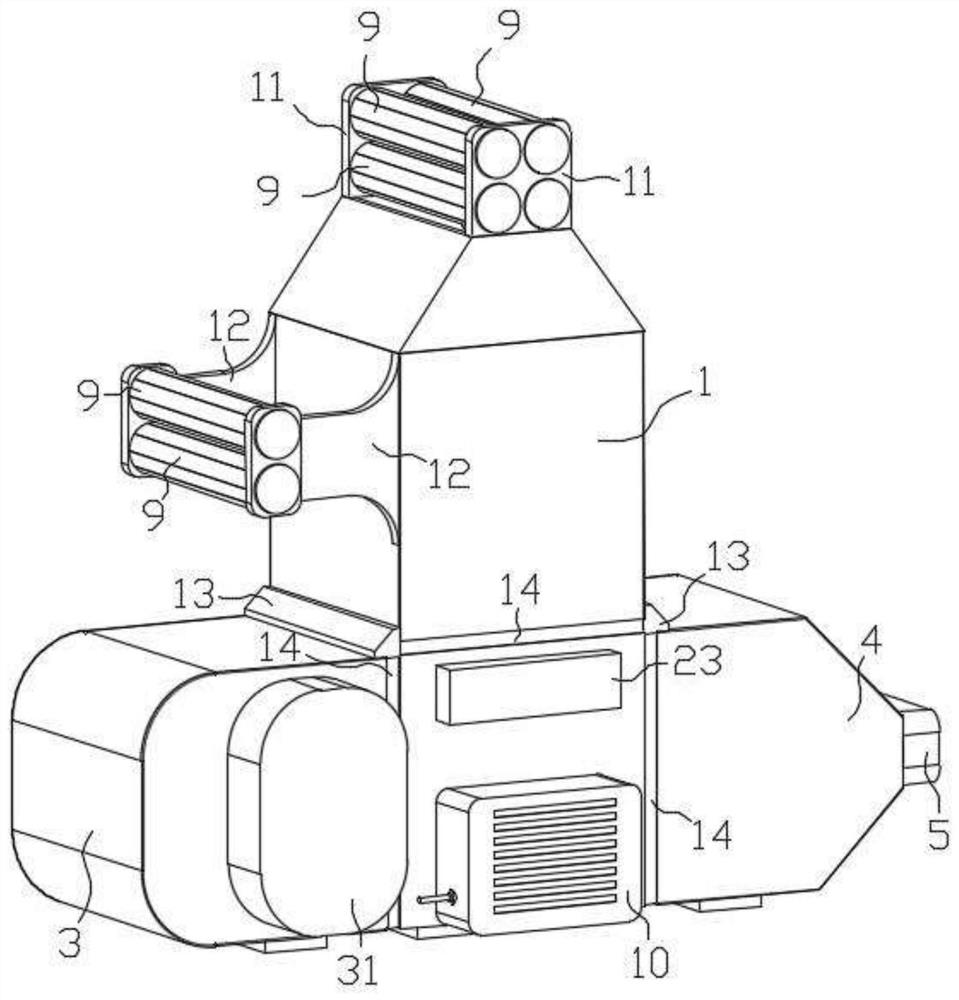

Screen printer machine capable of improving printing and dyeing effect

InactiveCN108284664AImprove printing and dyeing effectQuality improvementPrinted circuit assemblingScreen printersComputer engineeringDyeing

The invention discloses a screen printer machine capable of improving printing and dyeing effect. The screen printer machine comprises a box body, the inner wall of the box body is fixedly connected with first hydraulic rods, the top ends of the two first hydraulic rods are fixedly connected with an electricalmotor box and a fixed box correspondingly, and sliding blocks are fixedly connected to one side of the motor box and one side of the fixed box; sliding rails are slidably connected to the surfaces of the sliding blocks, the surfaces of the sliding rails are fixedly connected with the inner wall of the box body, and a sliding rod is fixedly connected between the surface of the electrical motor box and thefixed box; and theelectrical motor is fixedly connected to the inner wall of the electrical motor box. The invention relates to the technical field of screen printer machines. The screen printer machine capable of improving the printing and dyeing effect has the capability of rapidand accurate printing and dyeing, the printing and dyeing screen cleaning capacity is improved, and the printing and dyeing screen is convenient to install and dismount;and the printing and dyeing machine has the capability of automatically sensing and controlling the printing and dyeing pressure in the printing and dyeing process, the condition that printing and dyeing are not sufficient and theprinting and dyeing screen plate is pressed is avoided, and the printing and dyeing quality and effect are greatly improved.

Owner:沈亚红

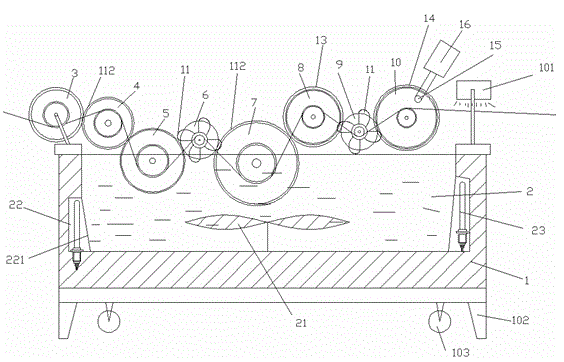

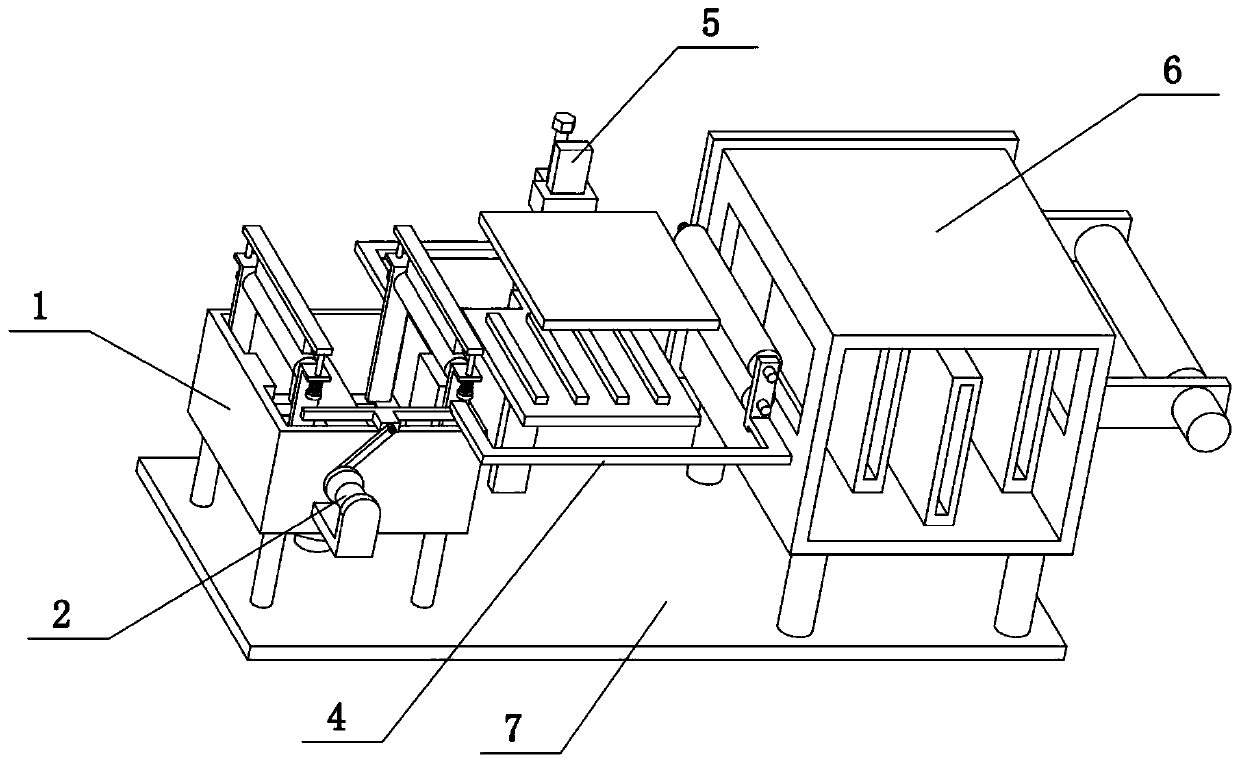

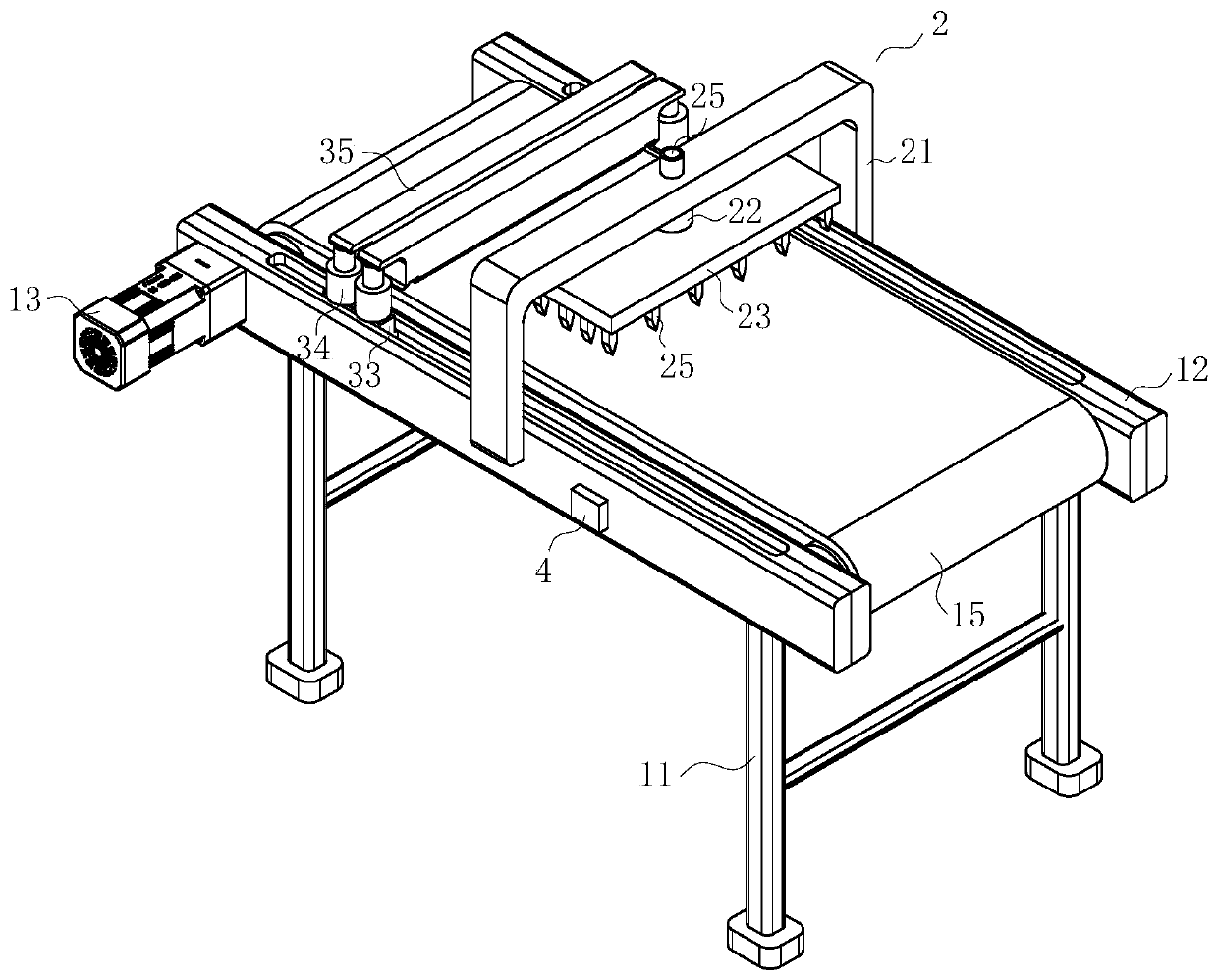

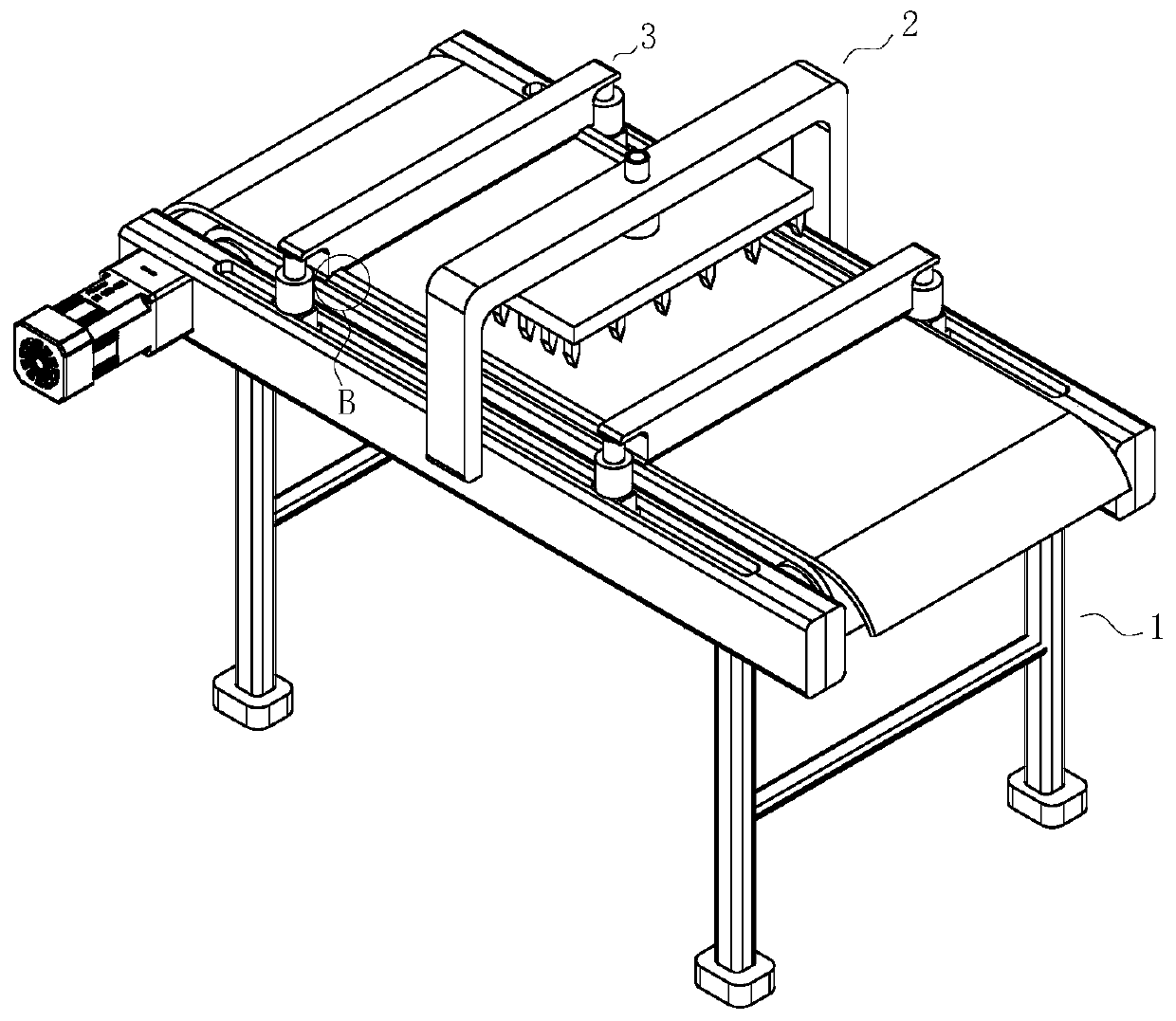

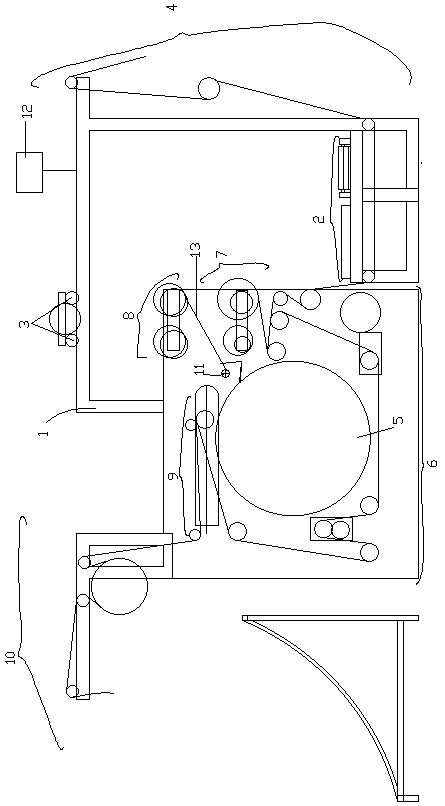

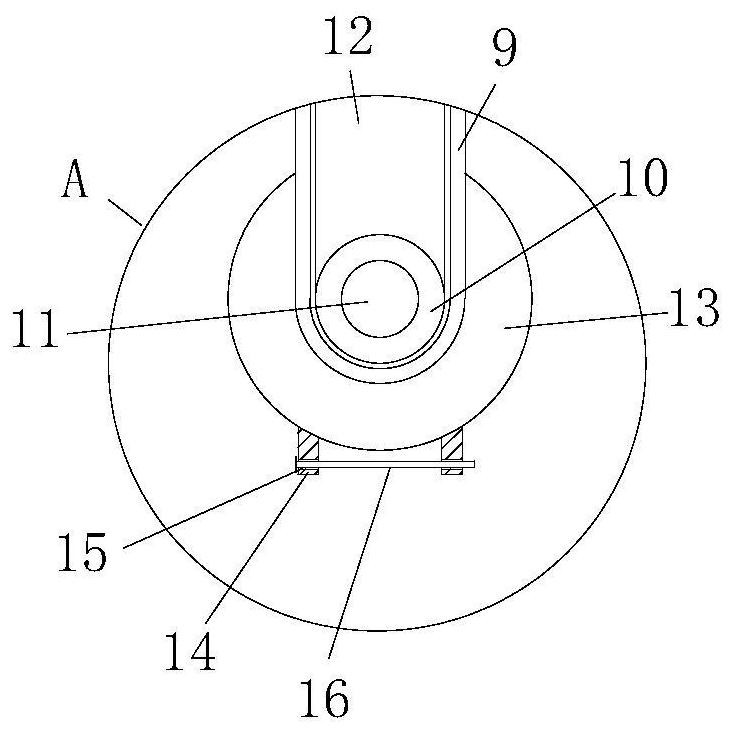

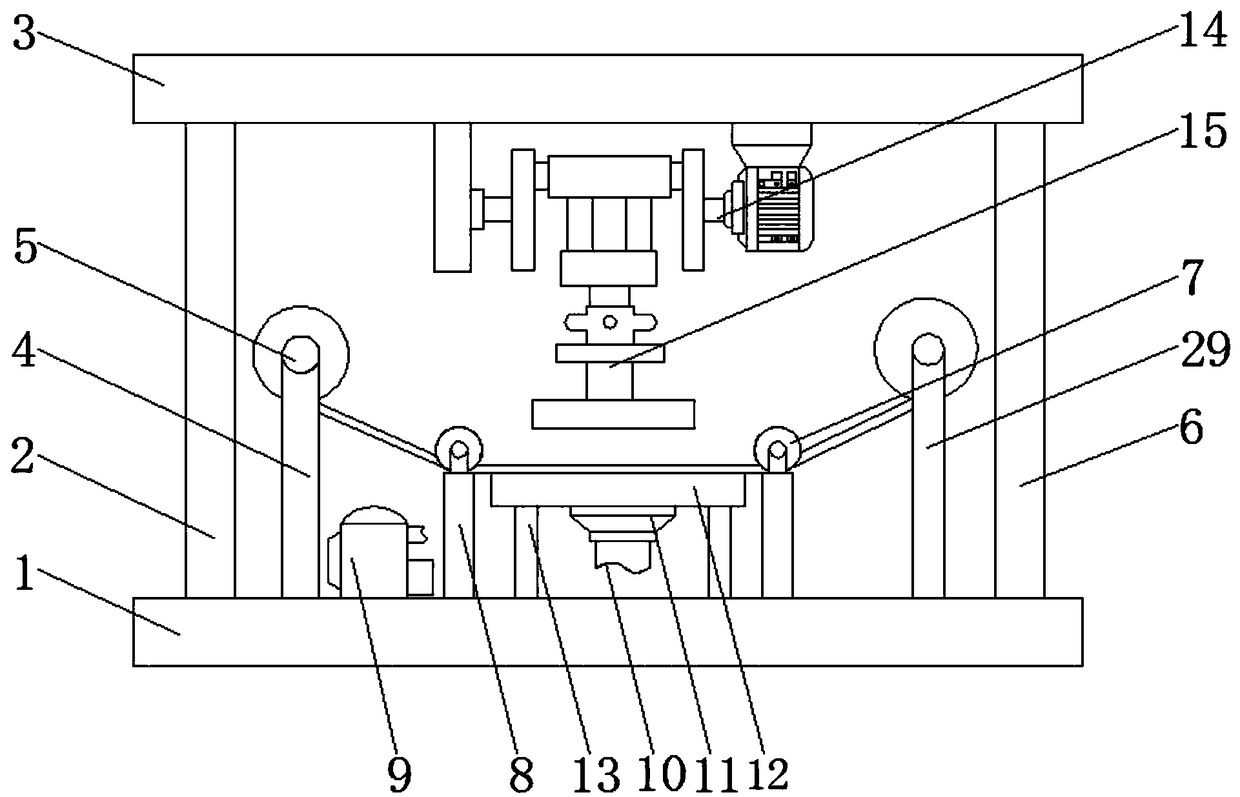

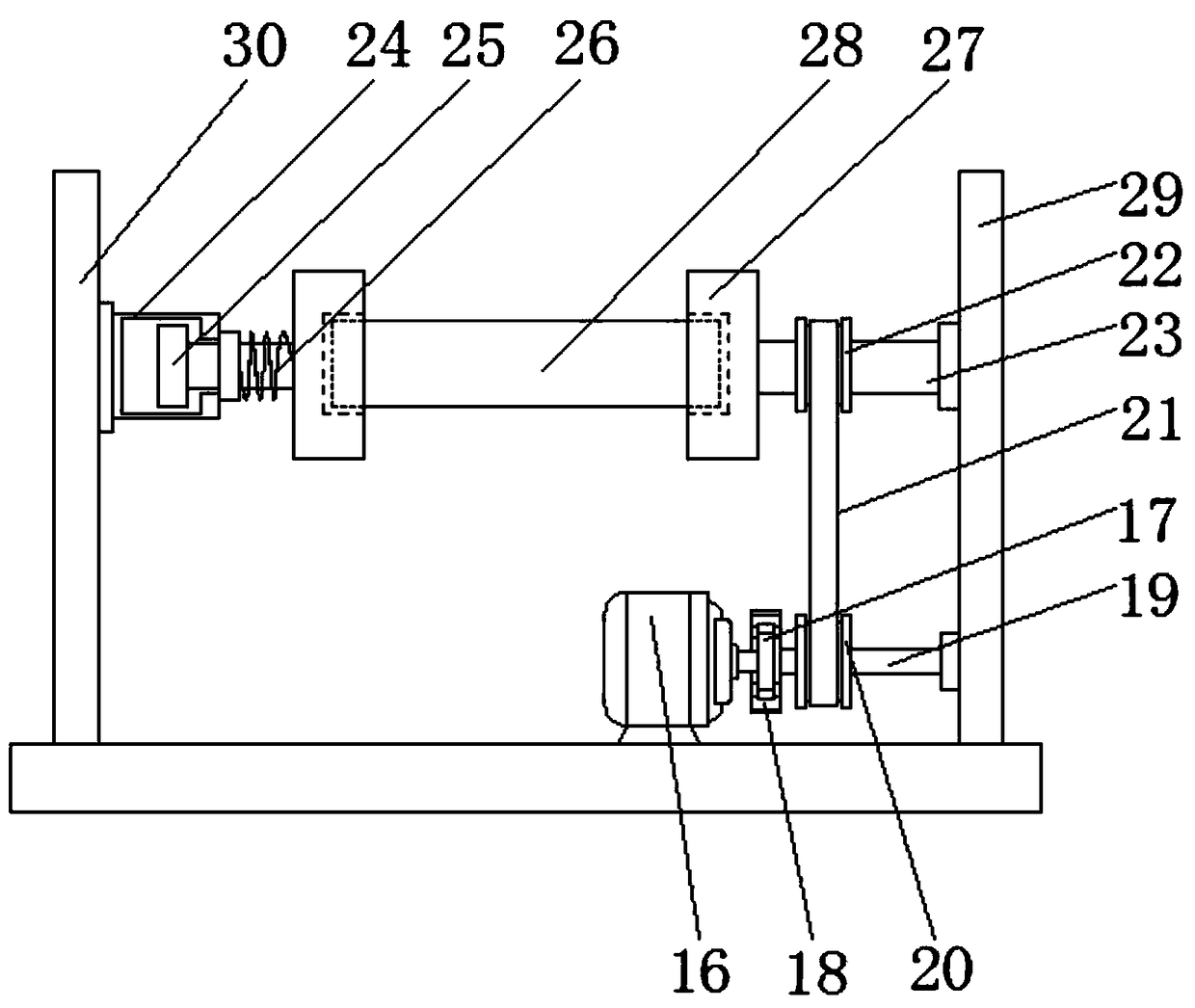

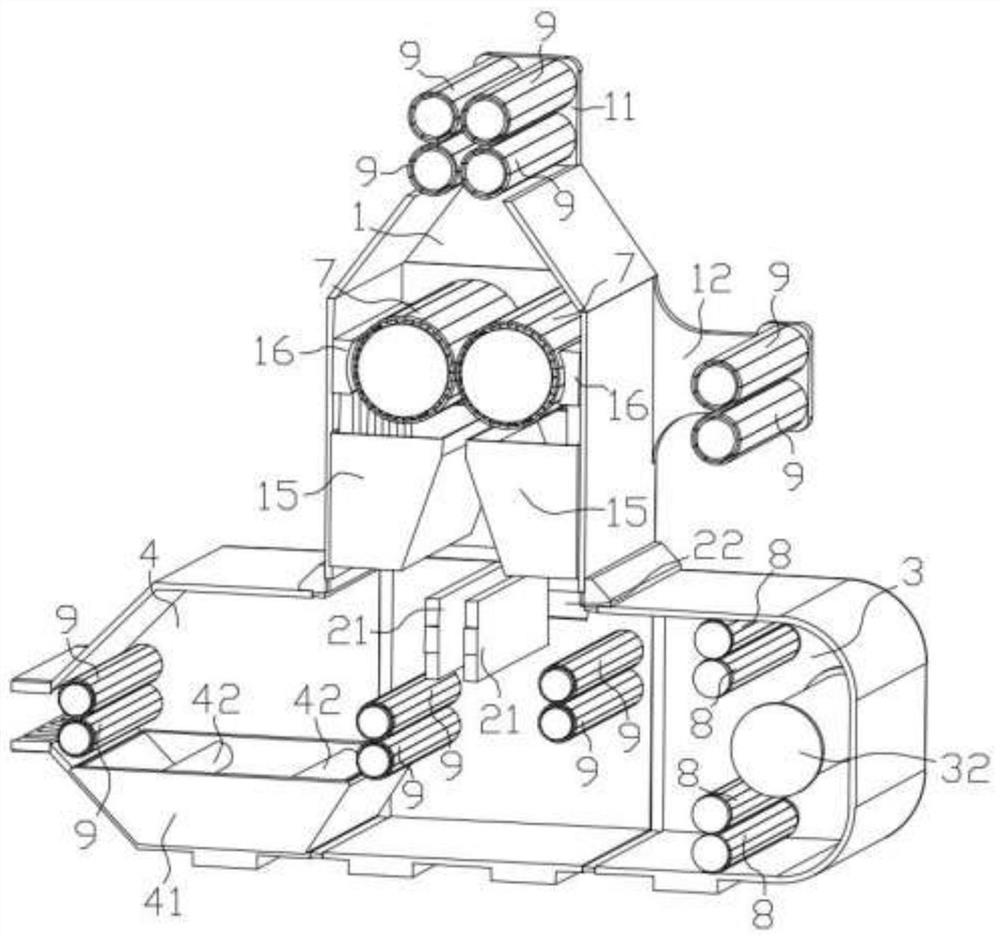

Yarn printing and dyeing device

ActiveCN104611862AUniform concentrationUniform temperatureLiquid/gas/vapor treatment machines driving mechanismsTextile treatment machine arrangementsYarnIndustrial engineering

The invention discloses a yarn printing and dyeing device. The yarn printing and dyeing device comprises a printing and dyeing support and a printing and dyeing transmission mechanism. The printing and dyeing support is provided with a printing and dyeing pool. The printing and dyeing transmission mechanism is arranged above the printing and dyeing pool and comprises a motor axle, a main driving shaft, a first printing and dyeing shaft, a first air drying shaft, a second printing and dyeing shaft, a centrifugal shaft, a second air drying shaft and a steam guidance shaft, all of which are installed on the printing and dyeing pool through the support from left to right in sequence. According to the printing and dyeing device, printed and dyed yarn can be primarily air-dried through the first air drying shaft which is arranged behind the first printing and dyeing shaft and provided with a four-blade fan, and the effect is better when secondary printing and dyeing is carried out; the centrifugal shaft with a centrifugal cylinder is arranged behind the position where secondary printing and dyeing is conducted, the redundant dye pasted to the yarn can be thrown to the centrifugal cylinder through the centrifugal shaft under the action of centrifugal force, rapid air drying can be achieved through a fan on the second air drying shaft, and the air drying effect is good.

Owner:JIANGSU SHUANGYING TEXTILE TECH

Full penetration printing production process of 34-inch thick double-sided polar fleece

ActiveCN104553419ACreativeAdvancedWeft knittingHeating/cooling textile fabricsScreen printingTextile printer

The invention relates to a full penetration printing production process of 34-inch thick double-sided polar fleece. The process is characterized in that an entire set of optimal technical scheme of system engineering design is established through technical means such as weaving, dyeing and finishing and microscopic computer image analysis. The process comprises the following steps: weaving a blank; performing dyeing and finishing pretreatment on fabric; tentering and shaping the fabric before printing; performing microscopic computer image analysis; performing rotary screen printing, evaporation, washing and emulsification on the fabric; tentering and shaping the fabric after printing; galling, combing, shearing and fleecing; shaping billet. The process has the beneficial effects that 1, the difference value of printing and dyeing color yield percentage of front and back faces of the fabric is reduced, and the front and back faces of the finished product are attractive in color, and 2, the finished fabric is full, fluffy and soft in raising, the problem of hard handfeel of the thick double-sided fleece fabric is solved, and a high added value of the product is further improved. The fleece is most suitable for making middle and top grade thermal vests, jacks, underwear, (woolen) shirts, overcoats, bedding articles, carpets, gloves, scarves, hats, back cushions and the like.

Owner:QINGDAO JIFA GROUP

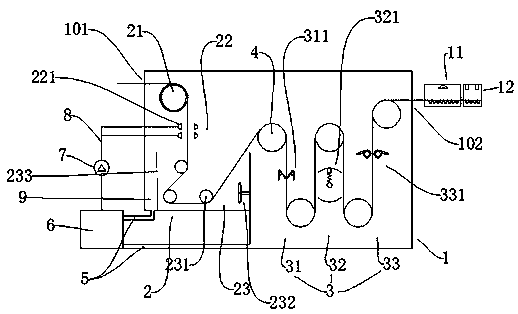

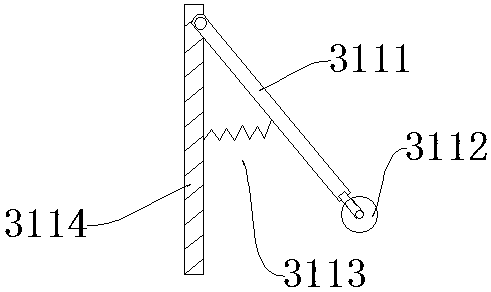

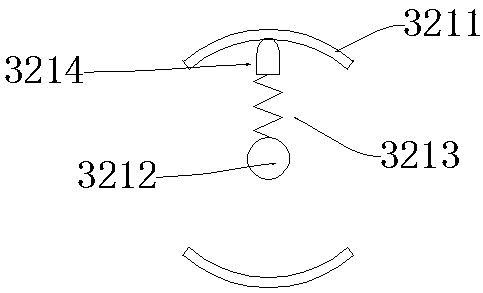

Continuous textile printing and dyeing device and textile printing and dyeing machine

InactiveCN112695477AReasonable structureTo achieve synchronous operationTextile treatment machine arrangementsTextile treatment carriersTextile printerMechanical engineering

The embodiment of the invention discloses a continuous textile printing and dyeing device and a textile printing and dyeing machine. The continuous textile printing and dyeing device comprises a base; a winding part is arranged on the base; the winding part comprises two first supporting plates, a winding motor, a winding rotating shaft, a rotating rod, two limiting pieces, two clamping blocks, a winding barrel, two second supporting plates, a driving shaft, a driving rotating roller, two cross grooves, two moving blocks, a driven rotating roller and two compression springs; and a drying part is arranged on the base. The invention further discloses the textile printing and dyeing machine, wherein the textile printing and dyeing machine is provided with the continuous textile printing and dyeing device. The continuous textile printing and dyeing device and the textile printing and dyeing machine are reasonable in structure, continuous operation can be achieved, the production speed is increased, the drying quality can be improved in work, products can be wound conveniently, and the work efficiency is improved.

Owner:史继林

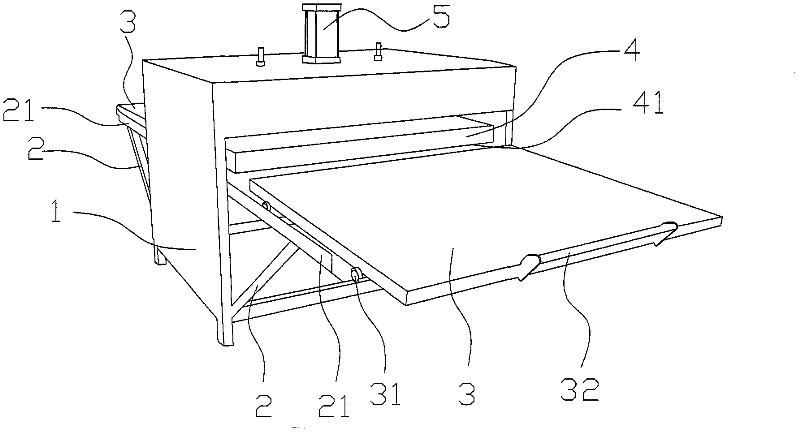

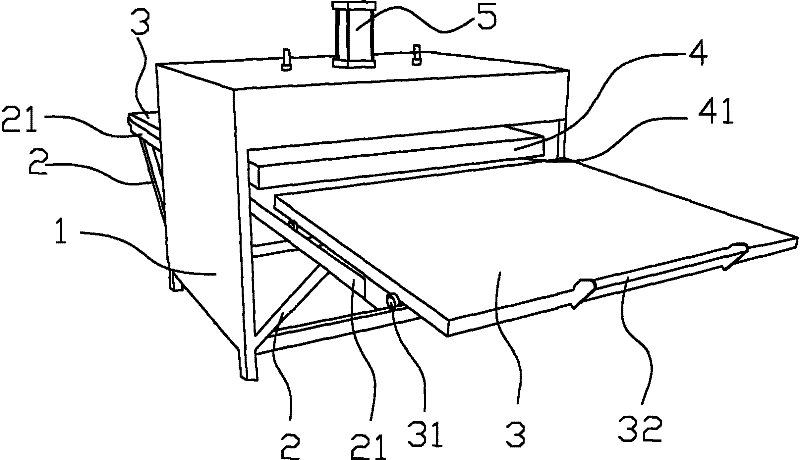

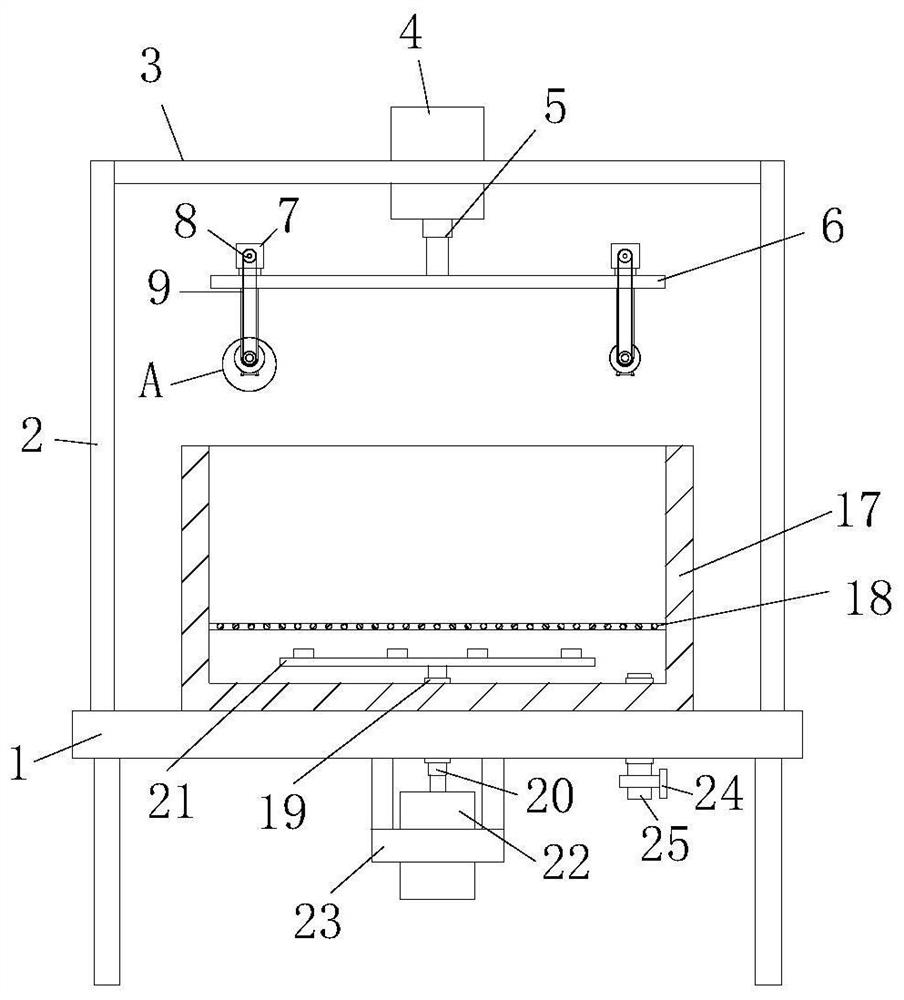

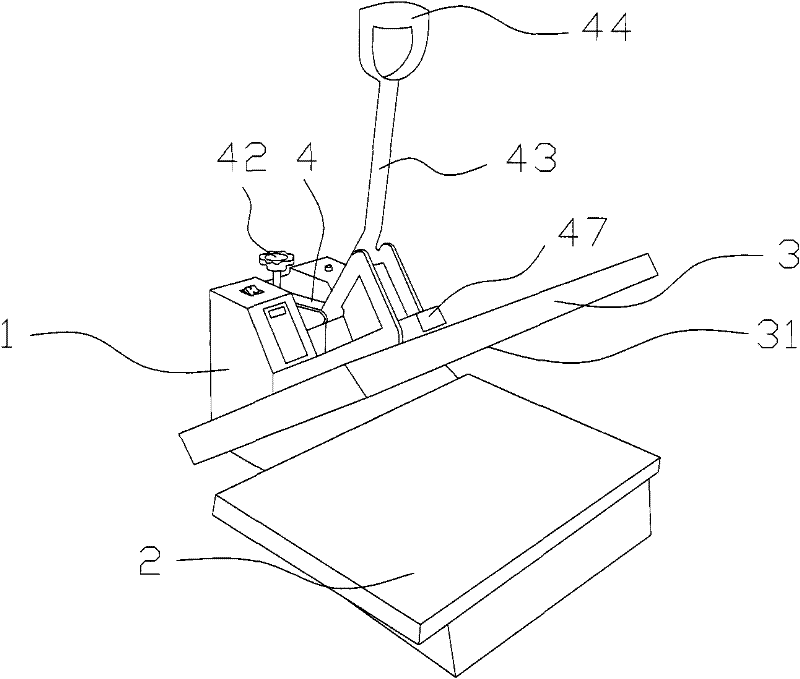

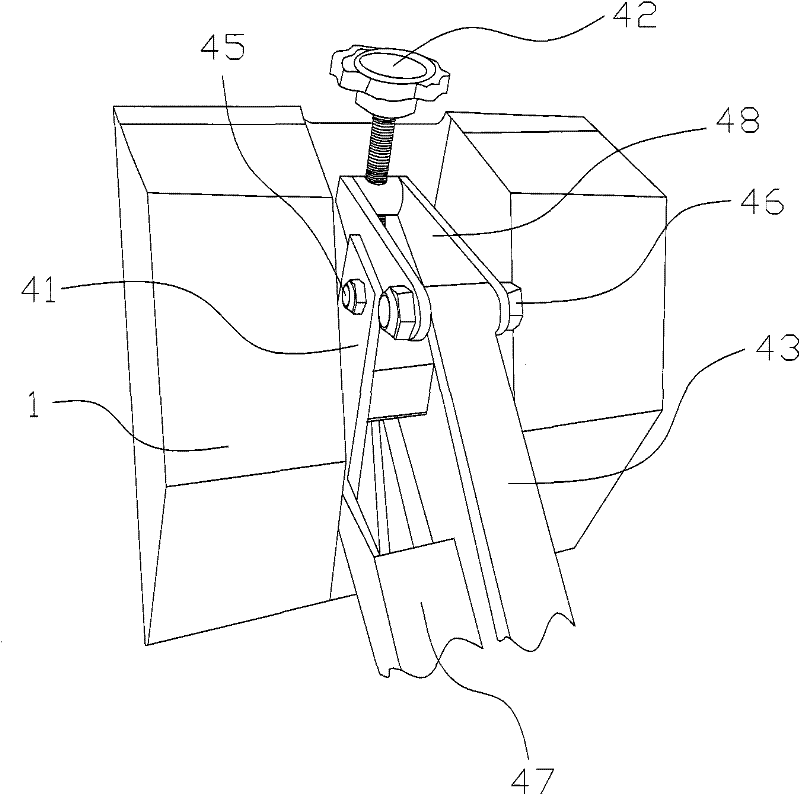

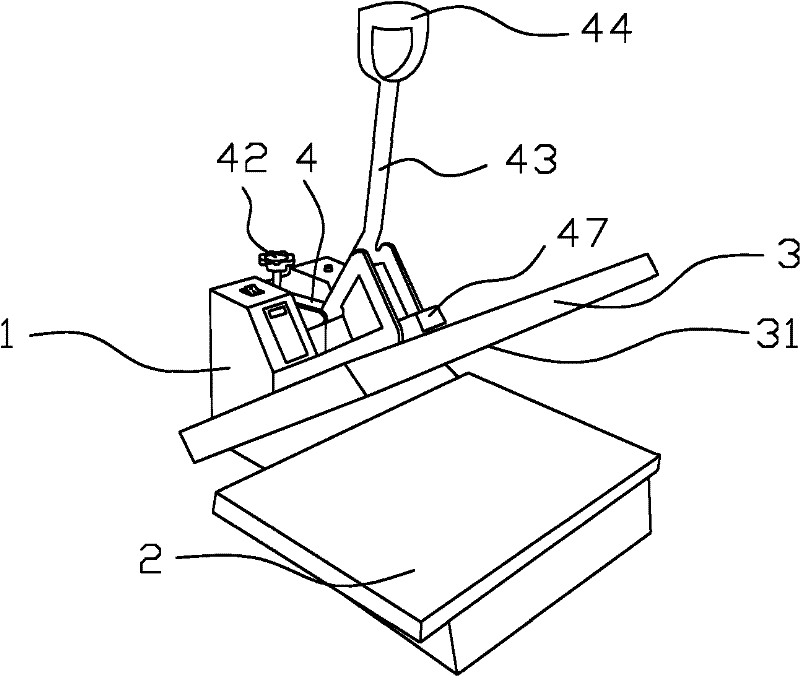

Double-station transfer printing device

InactiveCN102452216AReduce CooldownImprove printing efficiencyTransfer printingEconomic benefitsEngineering

The invention discloses a double-station transfer printing device which is used in the field of textiles. The device comprises a body, drawing plate brackets, drawing plates, a pressing plate and a cylinder, wherein the drawing plate brackets are fixedly arranged on two sides of the body and are provided with guide rails; the drawing plates are slidably arranged on the guide rails and are provided with rollers; the pressing plate is arranged above the interior of the body and is provided with printing paper; the cylinder is fixedly arranged on the upper part of the body; and a telescopic rod of the cylinder is fixedly connected with the pressing plate. According to the double-station transfer printing device, by providing two groups of drawing plates which alternately enter the body for indentation, the indentation efficiency is increased, and the time for waiting a product to be cooled is shortened to increase the production efficiency. Meanwhile, the pressing plate can be used for heating, so that the printing and dyeing effect can be enhanced. The double-station transfer printing device has the advantages of simple structure, easiness and convenience in use, high production efficiency, low cost, good effect, great economic benefit brought to enterprises, high suitability for requirements of textile production and extremely positive significance.

Owner:WUJIANG WAVE TEXTILE

Pretreatment device for textile fabric printing and dyeing and using method thereof

InactiveCN112709059AKeep clean and tidyEffective absorptionMechanical cleaningPressure cleaningTextile printerElectric machinery

Owner:绍兴慧行智能科技有限公司

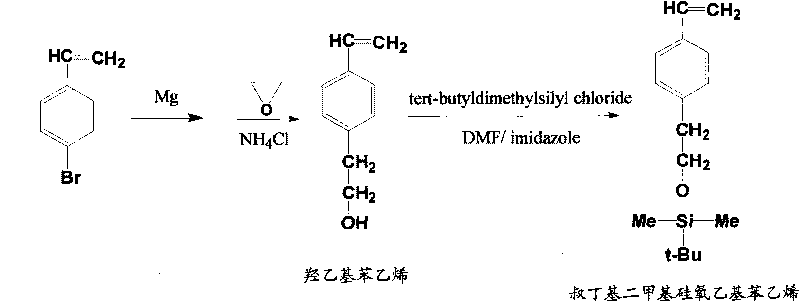

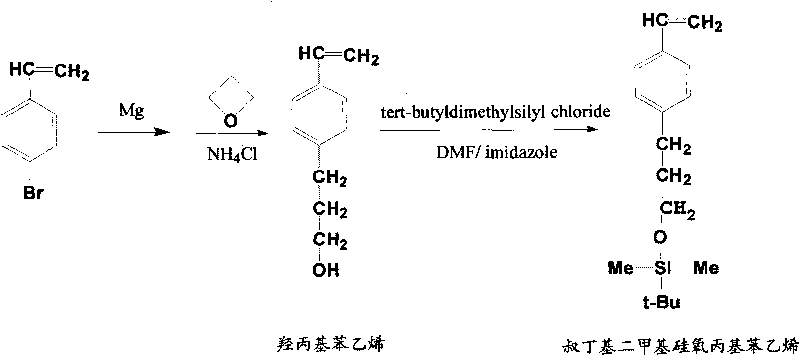

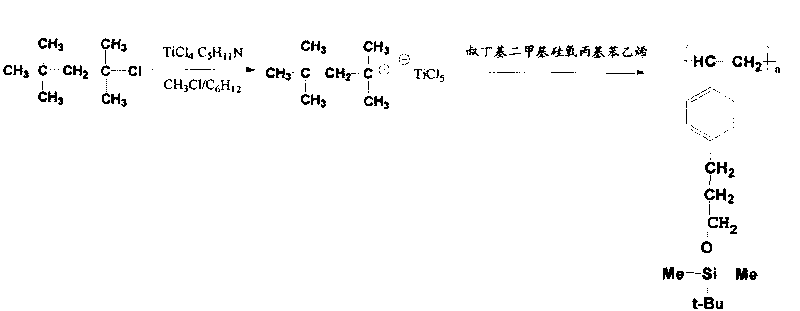

Polymer containing hydroxystyrene on side group, preparation method and application thereof

ActiveCN101747461AImprove hydrophilicityImprove printing and dyeing effectSurgeryPharmaceutical non-active ingredientsEthylene HomopolymersGrignard reaction

The invention relates to polymer containing hydroxystyrene on a side group, preparation method and application thereof. The preparation method comprises the following steps of: firstly, preparing a type of styrene derivative monomers capable of positive (negative) ion polymerization through a Grignard reaction and a hydroxystyrene protection reaction, i.e. tert-butyl dimethyl silica ethyl styreneand tert-butyl dimethyl silica propyl styrene; then preparing a homopolymer and a segmented copolymer of the tert-butyl dimethyl silica ethyl styrene or the tert-butyl dimethyl silica propyl styrene through a positive (negative) ion polymerization method; and finally, preparing the polymers into a polymer containing hydroxystyrene on a side group through a hydrolysis reaction. The invention has the advantage that the side group of the polymer finally prepared by hydrolysis contains a hydrophilic group, and the polymer has excellent blood compatibility. The polymer containing hydroxystyrene onthe side group can be applied to biomedical materials comprising bracket materials, cartilage materials, drug slow release materials and vessel materials.

Owner:成都米戈思医疗技术有限公司

Fabric dyeing and printing device

InactiveCN101245537AImprove printing and dyeing effectUniform and beautiful colorTextile treatment by spraying/projectingTextile treatment carriersEngineeringControllability

The invention relates to a fabric printing and dyeing device which includes a machine frame, a power system and a transmission system. The device is characterized in that: a fabric supporting piece is arranged on the machine frame or the transmission system. The fabric supporting piece is made by ventilating materials or is provided with a ventilating hole. The upward side and the downward side of the fabric supporting piece are respectively provided with a vacuum absorption cavity and an atomizing system. The vacuum absorption cavity is connected with a vacuum pipeline. A vacuum pump is arranged on the vacuum pipeline. The atomizing system includes an atomizer and a dye channel. A pattern templet is fixedly on the machine frame below the outlet of the dye channel. The atomizing system moves opposite to the pattern templet under the drive of the power system and the transmission system. The device of the invention utilizes vacuum subpressure absorption to print and dye atomized dyes on the fabric and has the advantages of simple and reasonable structure, low dyeing cost, high controllability on operation and high dyeing efficiency, being beneficial to improving the dyeing effect of the fabric. The color of the fabric after printing and dyeing is uniform and beautiful.

Owner:浙江宝通环保印染设备科技有限公司

Compound textile printing and dyeing auxiliary and preparation technology thereof

The invention provides a compound textile printing and dyeing auxiliary and a preparation technology thereof. The compound textile printing and dyeing auxiliary is prepared from the following raw materials at weight ratio: alpha-sulpho-omega-octadecane polyoxyethylene ether, biosurfactant, rare earth oxide, coconut oil diethanolamide, polyoxyethylene water sorbitol monopalmitate, diamino silicon oil, cocamidopropyl betaine, tartaric acid, sodium polyacrylate, poloxamer 407, methyl chloride isothiazolinone, sodium tripolyphosphate, isopropyl myristate, glycol and water. The compound textile printing and dyeing auxiliary provided by the invention had the advantages of high dyeing rate, high dye use ratio, excellent overall printing and dyeing effect, color fastness, capability of enhancing antibacterial and antistatic functions of printed and dyed textile, capability of meeting the application requirement of the consumers and wide application prospect.

Owner:SUZHOU INST OF TRADE & COMMERCE

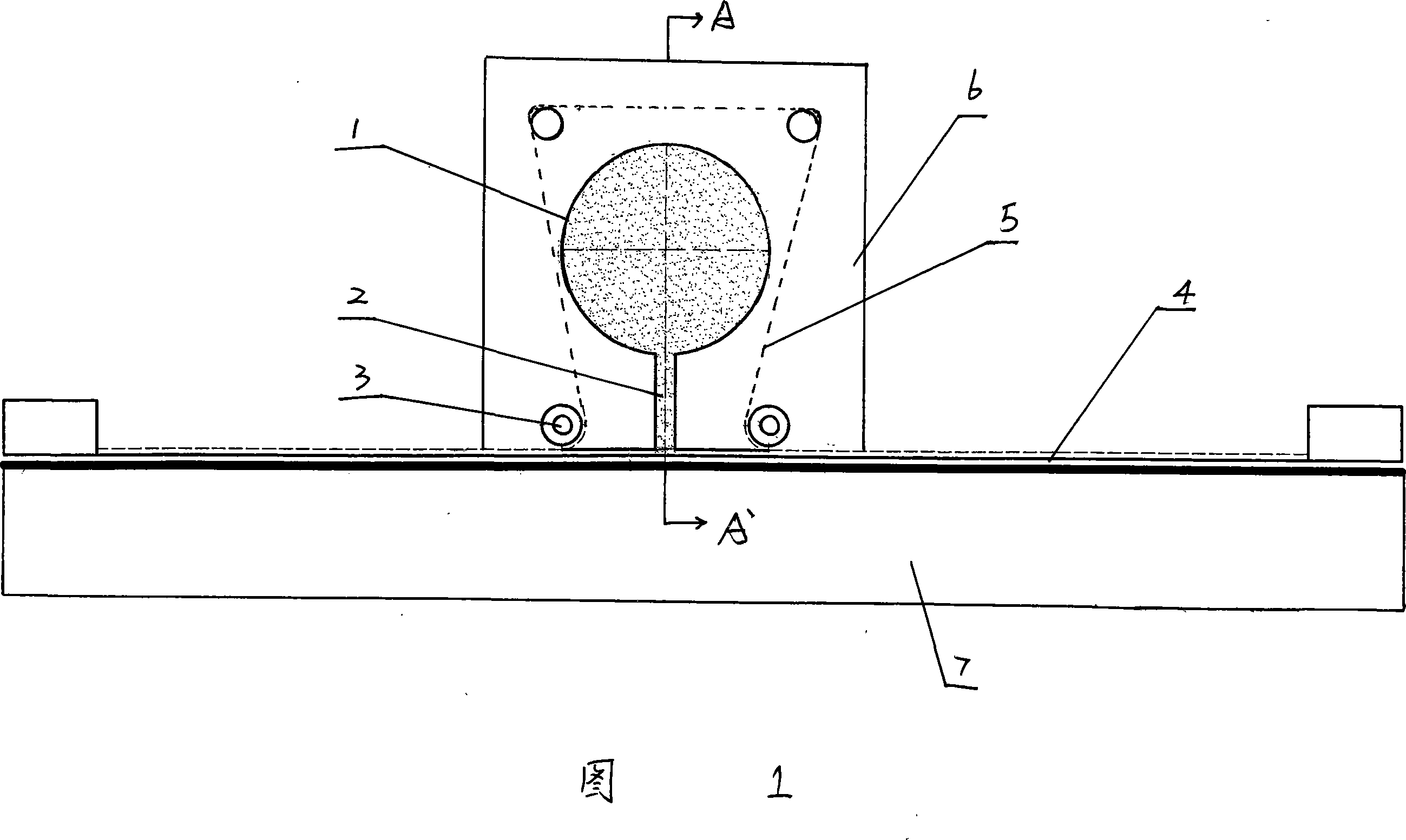

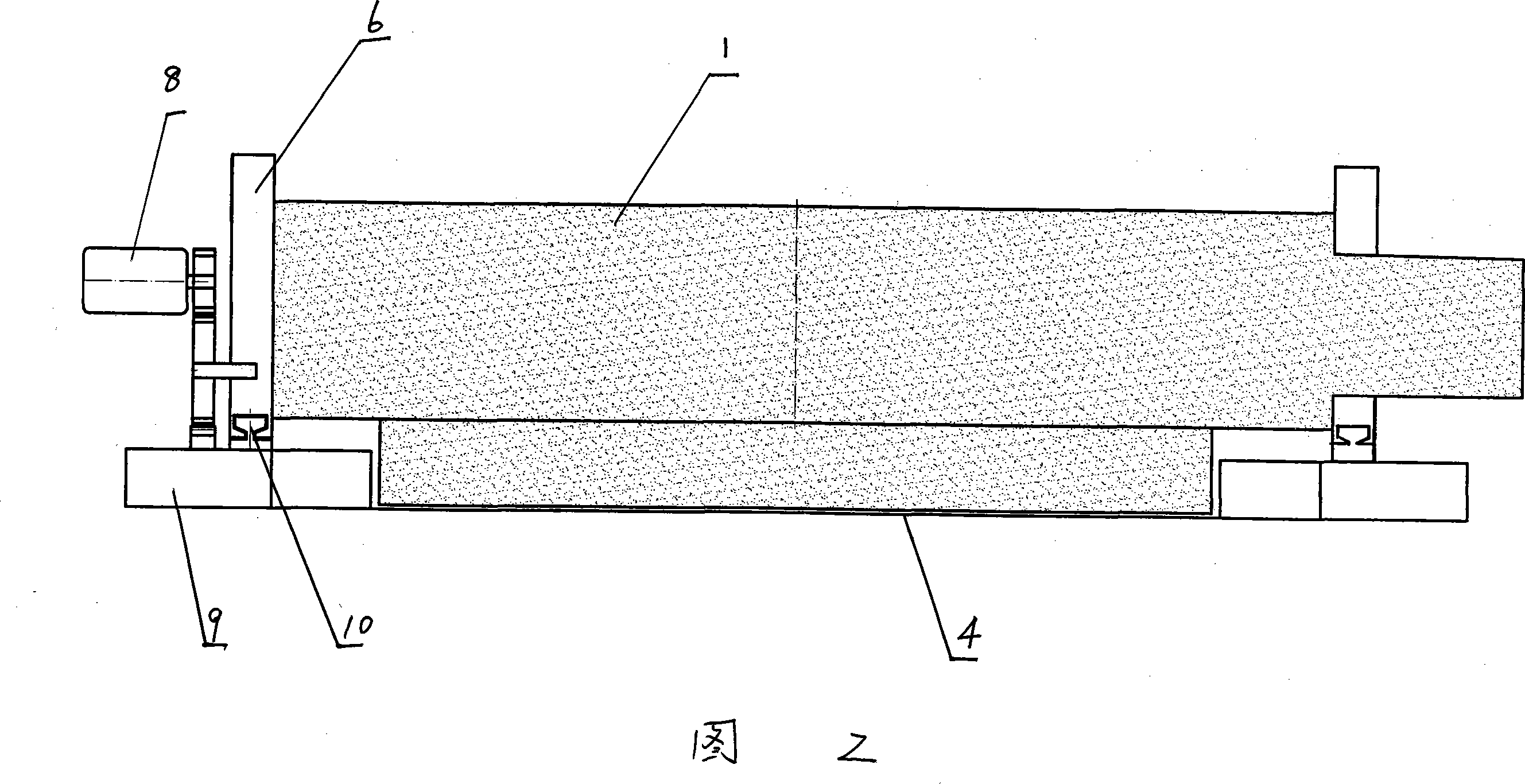

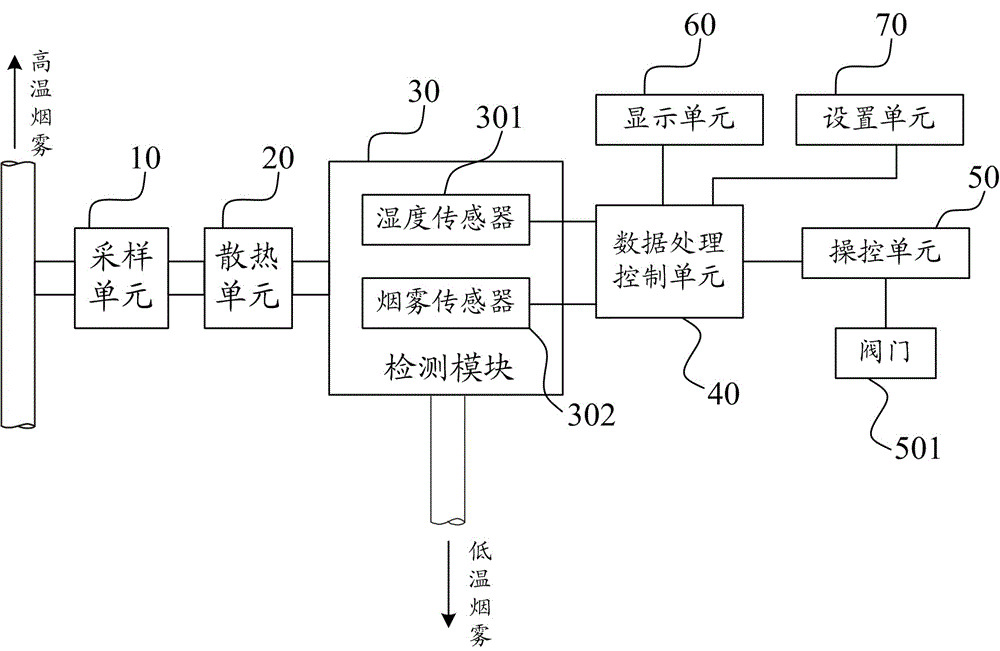

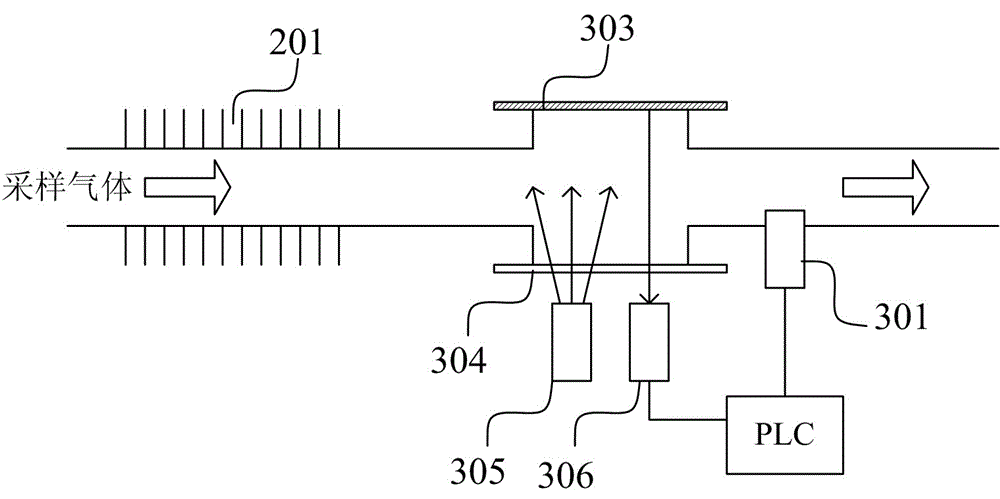

Fabric shaping/dryer energy conservation and emission reduction control system and method for textile and dying industry

ActiveCN103184667ASolve the problem of not being able to withstand high temperatureImprove printing and dyeing effectTextile treatment machine arrangementsExhaust valveControl signal

An embodiment of the invention discloses a fabric shaping / dryer energy conservation and emission reduction control system for the textile and dying industry. The control system comprises a sampling unit, a radiating unit, a detection module, a data processing control unit, a control unit, a display unit and a setting unit, wherein the sampling unit obtains sampling gas, and the sampling gas is cooled by the radiating unit; the data processing control unit compares values, detected by a humidity sensor and / or a smoke sensor, of the cooled sampling gas with a set value; and a control signal is output to control the opening degree of an exhaust valve, so that exhaust operation is performed. The embodiment of the invention further discloses a clothes shaping and drying energy conservation and emission reduction control method. When the control system and method are adopted, the problem that the humidity sensor or the smoke sensor are not high temperature resistant is solved, the detection values of the humidity sensor and / or the smoke sensor are chosen to be compared with a set value according to different technologies, and the opening degree of the exhaust valve is controlled, so that optimal working parameters are maintained, and a large amount of energy is avoided from being consumed by exhaust by mistake.

Owner:李川凌

Chitosan added textile dye and preparation method thereof

InactiveCN107177993AImprove printing and dyeing effectNo damageDyeing processSOAPPolyvinylpyrrolidone

The invention discloses chitosan added textile dye and a preparation method thereof. The textile dye is prepared from the following raw materials in parts by weight: 30-50 parts of a natural dye raw material, 1-3 parts of an organic dying raw material, 10-15 parts of chitosan, 1-5 parts of ethylcellulose, 2-4 parts of sodium dodecyl sulfate, 4-8 parts of diethanolamine, 1-4 parts of malic acid, 4-7 parts of aluminum potassium sulfate dodecahydrate, 1-3 parts of polyvinylpyrrolidone, 4-8 parts of polyoxyethylene octylphenol ether, 1-2 parts of amylopectin, 1-3 parts of dibutyltin dilaurate, 3-6 parts of iron oxide red, 1-3 parts of sulfonated oil, 1-4 parts of soap powder, 2-5 parts of oxalic acid, 2-5 parts of a coupling agent and 1-4 parts of an aid. The prepared chitosan added textile dye is good in printing and dyeing effect and is friendly and damage-free to fabric. The invention further discloses the preparation method of the chitosan added textile dye.

Owner:WUJIANG YISHENG TEXTILE

Conveniently-adjusted printing and dyeing device for leather production line

The invention discloses a conveniently-adjusted printing and dyeing device for a leather production line. A workbench is arranged at the top end of a box body, a cross frame A and a cross frame D arearranged at the left end and the right end of the upper surface of a rectangular frame respectively, an output shaft of a motor C is fixedly connected with one end of a screw rod B through a coupler,and an output shaft of a motor D is fixedly connected with one end of a screw rod C through a coupler; and the bottom end of a cross frame C is fixedly connected with a master seat C and a master seat A, an output shaft of a motor A is fixedly connected with one end of a screw rod A through a coupler, a cross frame B is fixed on a master seat B, a motor B is fixedly connected with a screw rod D through a coupler, and the bottom end of a connecting frame is fixedly connected with the upper end of a pigment box through a fastening bolt. According to the device, the four motors are arranged, a printing plate connected with the device can move in the front-back direction, the left-right direction and the up-down direction of the device, so that printing is facilitated; and meanwhile, an operator can conveniently and accurately adjust the to-be-printed position.

Owner:朱俊羽

Textile fabric printing and dyeing device

The invention relates to the technical field of textile machinery, in particular to a textile fabric printing and dyeing device.The textile fabric printing and dyeing device is characterized in that guide rails are detachably installed on two sides of the length direction of a printing and dyeing bottom plate; a scraper is slidably connected between the two guide rails and is provided with a control handle; the control handle is used for controlling the scraper to slidably flatten textile fabric to be printed and dyed along the guide rails in order to prevent folding and achieve better printing and dyeing effect; and after an atomization device and a dye channel arranged on an installation rack in a matching mode are utilized for printing and dyeing textile fabric, the control handle is used for slidably controlling the scraper to compress the fabric coated with dye along the sliding rail such that better printing and dyeing effect is obtained.

Owner:WUXI HONGFEN MACHINERY FACTORY

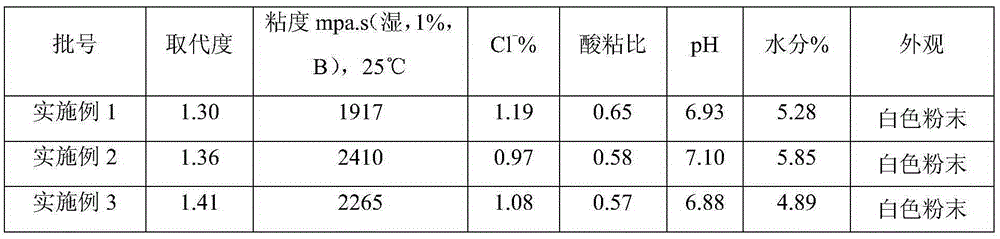

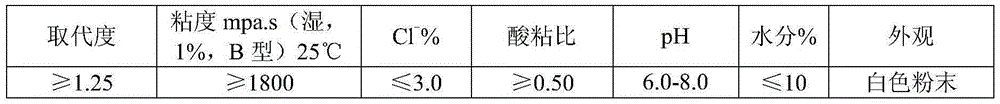

Preparation of sodium carboxymethyl cellulose

ActiveCN105330753AHigh viscosityReduce reactive hydroxyl group contentCarboxymethyl celluloseCellulose

The invention belongs to the field of polymer chemistry, and specifically relates to a method for preparing sodium carboxymethyl cellulose, the technical problem to be solved by the invention is to provide a method for preparing highly-substitution high-viscosity sodium carboxymethyl cellulosewhich with the advantage of easily accessible raw materials. The preparation method includes A, cellulose alkalization, B, cellulose etherification and C, sodium carboxymethyl cellulose preparation. The prepared sodium carboxymethyl cellulose is an excellent dye carrier, has the advantages of high substitution and viscosity and good thickening effect, and can be better used in printing / dyeing industry.

Owner:泸州北方纤维素有限公司

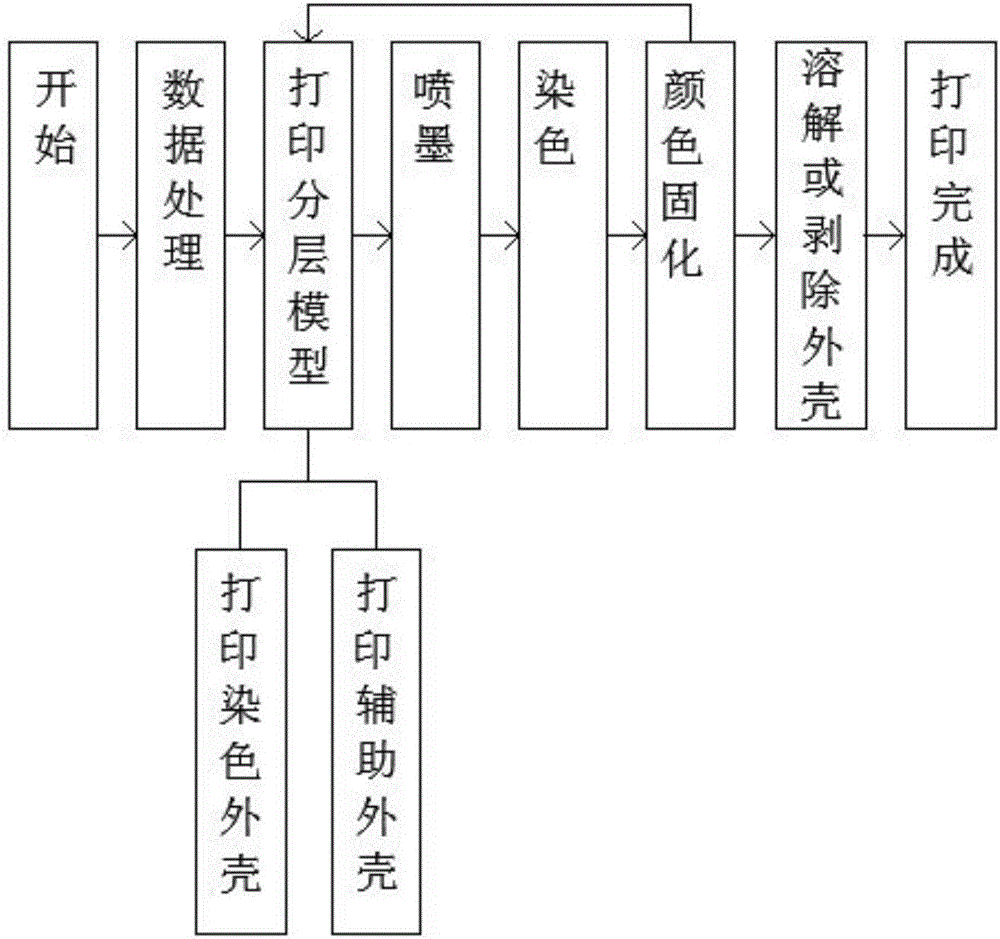

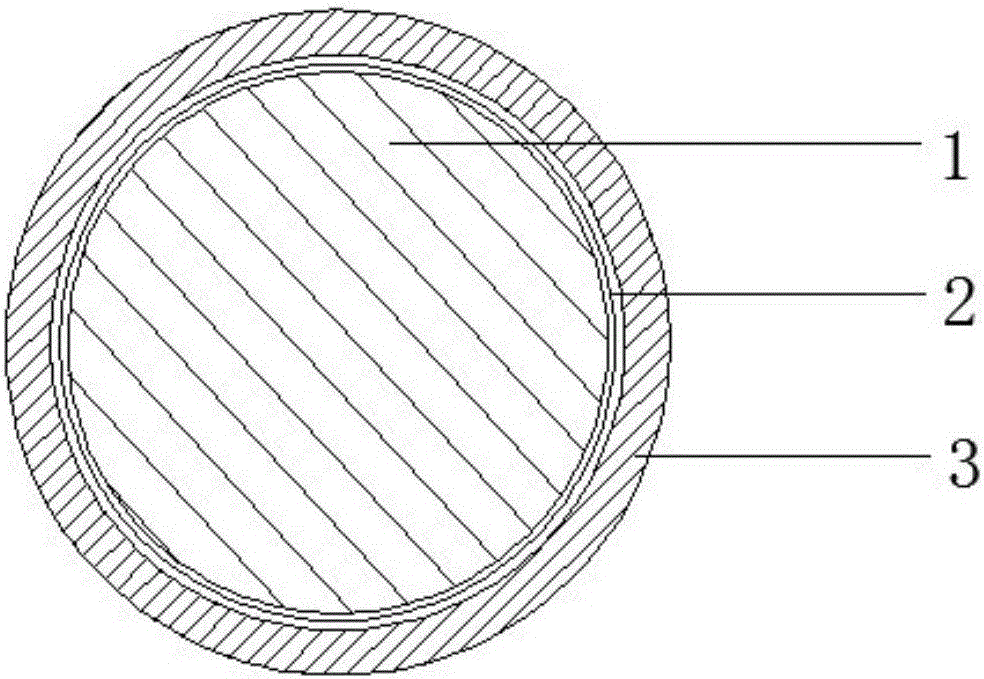

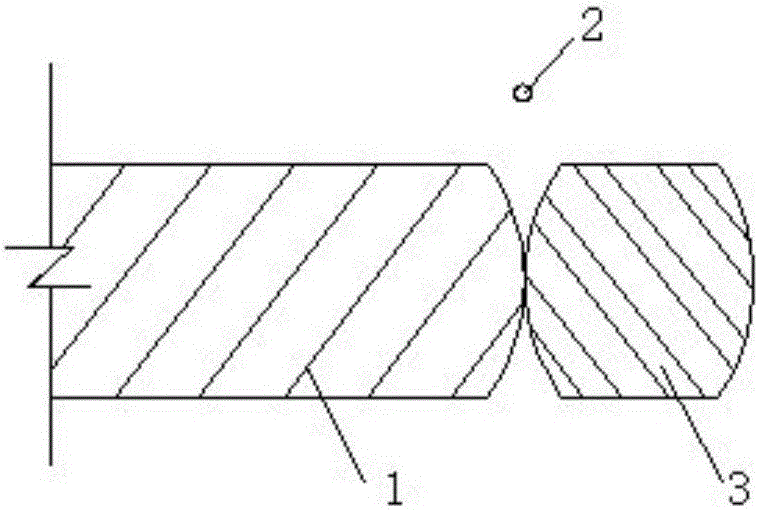

3D printing method for dyeing of lateral vertical surface

InactiveCN105773966AUniform and complete dyeingMeet the needs of side elevation stainingAdditive manufacturing apparatusDuplicating/marking methodsEngineeringPigment

The invention relates to a 3D printing method for dyeing of a lateral vertical surface. The 3D printing method for dyeing of the lateral vertical surface comprises the following steps that (1) printing preparation and data processing are conducted, specifically, a vertical color printer is started, and processing is conduced, so that a hierarchical model of a 3D printed object is obtained; (2) the hierarchical model is printed, and an arc-shaped crack is formed between a dyed shell and an auxiliary shell; (3) ink jetting is conducted, and the printer is controlled by a processor to drip pigment ink into the arc-shaped crack formed between the dyed shell and the auxiliary shell; (4) dyeing is conducted; (5) color curing is conducted; (6) the next working cycle is conducted, and printing is conducted on the dyed shell subjected to dyeing and the auxiliary shell, so that the next hierarchical model is generated; (7) the shells are dissolved or stripped; and (8) printing is completed, after printing of all hierarchical models and dyeing are completed, the auxiliary shell is removed, the dyed lateral vertical outer surface of the 3D printed object is exposed, and the colored 3D printed object is obtained. The printing method is easy to implement, both the manufacturing cost of printing equipment and the manufacturing cost of printing materials are low, the printing effect is good, the application range is wide, and the 3D printing method has good application prospects.

Owner:朱沫

Fabric dyeing and drying system

InactiveCN110485095AIncrease contactImprove printing and dyeing effectSucessive textile treatmentsLiquid/gas/vapor removalEngineeringDyeing

The invention relates to the field of fabrics, in particular to a fabric dyeing and drying system. The system comprises a dye box, a lifting frame, a bottom roller, rotating base plates, vertical plates and upper rollers; the system can guide cloth into the dye box for printing and dyeing and then guide the cloth out of the dye box. The lifting frame is slidingly connected into the dye box, the vertical plates are fixedly connected to the four corners of the upper side of the lifting frame, the upper rollers are rotatably connected between the upper ends of the two vertical plates at the leftend and between the upper ends of the two vertical plates at the right end respectively, the rotating base plates are fixedly connected to the front and rear ends of the middle of the upper side of the lifting frame, and the bottom roller is rotatably connected between the two rotating base plates.

Owner:孙艳敏

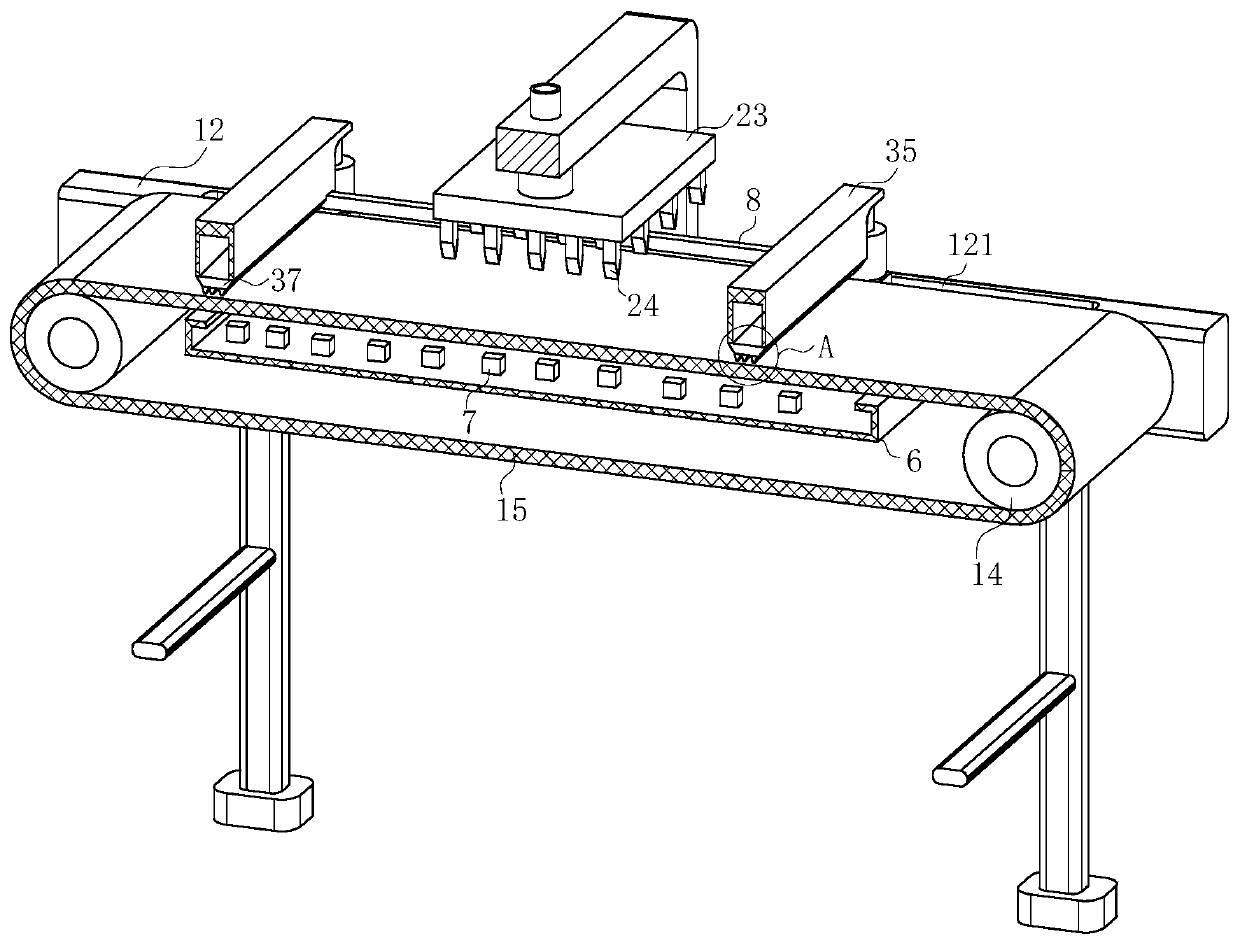

Ink-jet printing and dyeing device and method

ActiveCN110802948AAvoid Bubble ProblemsPrevent bulgingTypewritersDyeing processFiberElectric machinery

The invention belongs to the technical field of ink-jet printing and dyeing, and particularly relates to an ink-jet printing and dyeing device and method. Rotating rollers are rotationally mounted between cavity supporting frames, and a conveying belt is mounted on the rotating rollers; a supporting frame is mounted on the outer side walls of the cavity mounting frames, and the bottom end of an electric cylinder is provided with an ink-jet head through a supporting column; nozzles are mounted at the bottom end of the ink-jet head, a tubular motor is mounted in each cavity mounting frame, and the output end of each tubular motor is connected with a rotating screw rod; guide sliding blocks are fixedly installed in each cavity mounting frame, and each rotating screw rod rotationally penetrates through one guide sliding block to be connected with the other guide sliding block through a nut pair; and an electric telescopic rod is installed on the upper end face of each guide sliding block,and the telescopic end of each electric telescopic rods is connected with a scraping plate. The phenomenon that when soft fiber fabric is conveyed on the conveying belt, bubbles or bulging phenomena occur, so that the soft fiber fabric is prone to ink-jet non-uniformity or poor printing and dyeing effect during ink-jet printing and dyeing is avoided.

Owner:NINGBO ZHENHAI CHENGDI STATIONERY

High-permeability thermal transfer printing napped fabric processing method

InactiveCN110117884AImprove printing and dyeing effectMeet needsHeating/cooling textile fabricsLiquid/gas/vapor removal by squeezingWater softeningCarding

The invention discloses a high-permeability thermal transfer printing napped fabric processing method. The high-permeability thermal transfer printing napped fabric processing method comprises the following steps of grey fabric carding, gray fabric heat lustring, printing, water softening, drying, napping, carding, shearing, finished product heat lustring and shearing, air washing (fleecing) and finished product setting. The high-permeability thermal transfer printing plush fabric processing method solves the problem of providing a method, which endows napped fabrics of different gram weightswith richly layered and colorful photograph-like effects and high three-dimensional effects and is simple and reasonable in production process, environmentally friendly in production and free from pollution to natural environment.

Owner:江苏康尼纺织品有限公司

Printing equipment for textile fabric production

InactiveCN111764072AAvoid precipitationImprove printing and dyeing efficiencyTextile treatment machine arrangementsTextile treatment carriersTransmission beltElectric machinery

The invention discloses printing equipment for textile fabric production. The equipment comprises a control console, supporting plates, a top plate, a push rod box, an electric push rod, a drive plate, stepping motors, drive belt wheels, transmission belts, driven belt wheels, transmission shafts, supports, rotating rollers, fixing plates, open holes, positioning frames, limiting plates, metal rods, a fuel box, a limiting net, a rotating sealing bearing, a transmission column, stirring blades, a stirring motor, a machine frame, a drainage valve and a drainage pipe. The two stepping motors drive a fabric to reciprocate. After the fabric is soaked with dye, printing can be performed evenly, and the printing efficiency is improved. By arranging a drive motor, in the fabric printing process, the dye is stirred, dye precipitation can be avoided, and therefore the fabric printing effect is affected. Two ends of the fabric can be fixed through the positioning frame, the fabric can be prevented from being disengaged, and therefore the fabric dyeing work can be more completely performed.

Owner:吴江舒宇纺织有限公司

Cloth dyeing machine

PendingCN109763285AFully uniform printing and dyeingImprove printing and dyeing effectMechanical cleaningPressure cleaningPulp and paper industryDye recovery

The invention relates to the field of cloth printing and dyeing, in particular to a cloth dyeing machine. The cloth dyeing machine comprises a cloth dyeing box, wherein the cloth dyeing box comprisesa printing and dyeing area with a cloth inlet and a functional area with a cloth outlet; an unwinding roller located at the cloth inlet, a spray structure located below the unwinding roller and a printing and dyeing tank arranged below the spray structure are arranged in the printing and dyeing area; the functional area comprises an extrusion section, a flicking section and a scraping section which are sequentially formed under guide of multiple vertically alternate drive rollers; the printing and dyeing area and the functional area are both connected with a dye tank arranged outside the clothdyeing box through dye recovery pipelines; the dye tank is connected with the spray structure through a power pump and a dye delivery pipeline. The cloth dyeing machine can dye cloth fully and uniformly and scrape extra dye and attached impurities on the surface of cloth.

Owner:FUJIAN HANGGANG TEXTILE TECH CO LTD

Printing and dyeing device convenient to use for textile processing

InactiveCN108790387AEasy to useEasy height adjustmentRotary pressesOther printing apparatusEngineeringTextile processing

The invention discloses a printing and dyeing device convenient to use for textile processing. The printing and dyeing device comprises a base. A first long rod and a second long rod are correspondingly fixedly connected with the two lateral sides of the top of the base. The top end of the first long rod is fixedly connected with a long plate. The right side of the bottom of the long plate is fixedly connected with the top end of the second long rod. A first supporting rod is fixedly connected with the left side of the top of the base. A rotating shaft is rotatably connected with the top end of the first supporting rod. The invention relates to the technical field of printing and dyeing. The printing and dyeing device convenient to use for textile processing is convenient to use and operate, facilitates rolling of cloth, does not need manual operation, facilitates transportation of the cloth, is high in practicability, is suitable for popularization and application, enables the printedand dyed cloth to be dried in time, facilitates sequential processing of the cloth in time, saves time, improves working efficiency, enables a printing and dyeing plate to play a role of supporting during cloth processing, facilitates printing and dyeing of the cloth by the printing and dyeing plate, and improves printing and dyeing quality.

Owner:金小玲

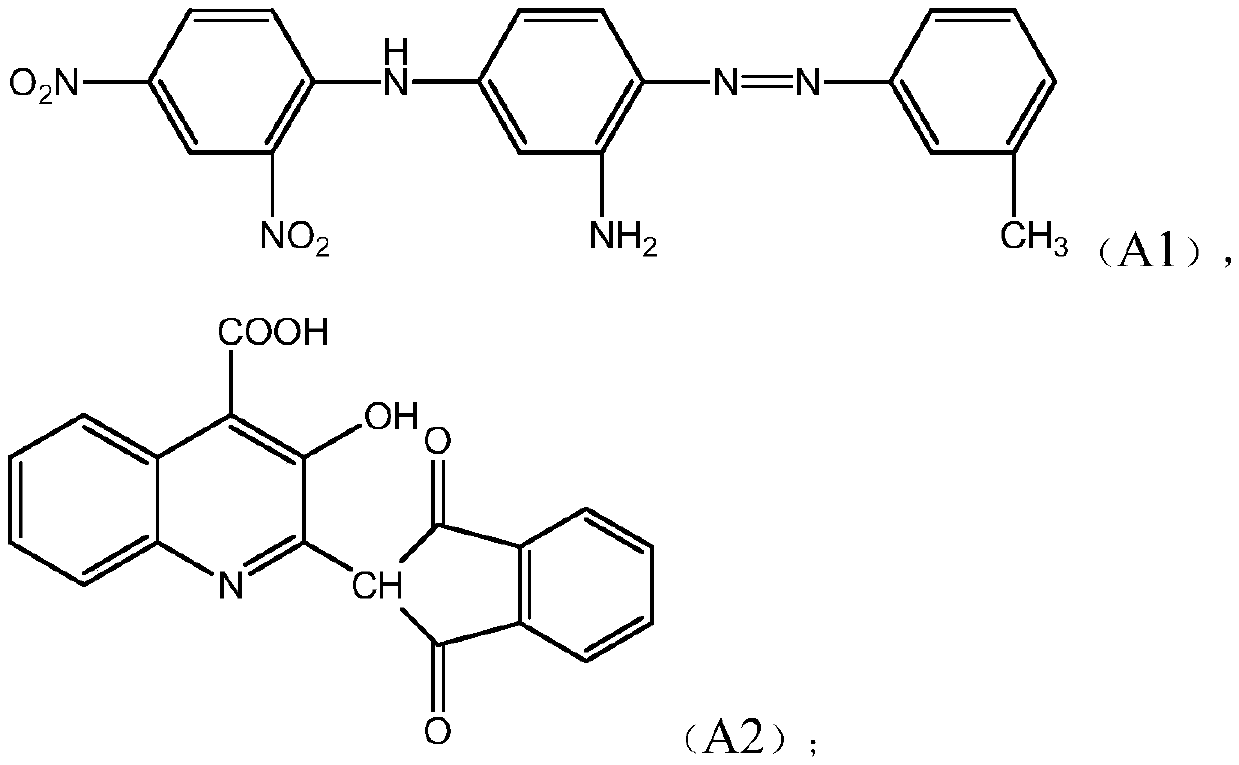

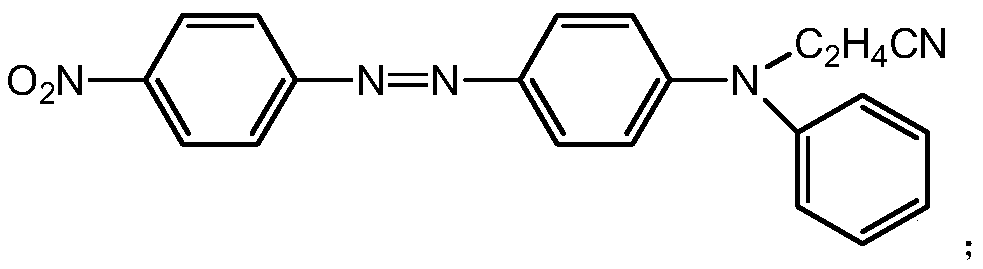

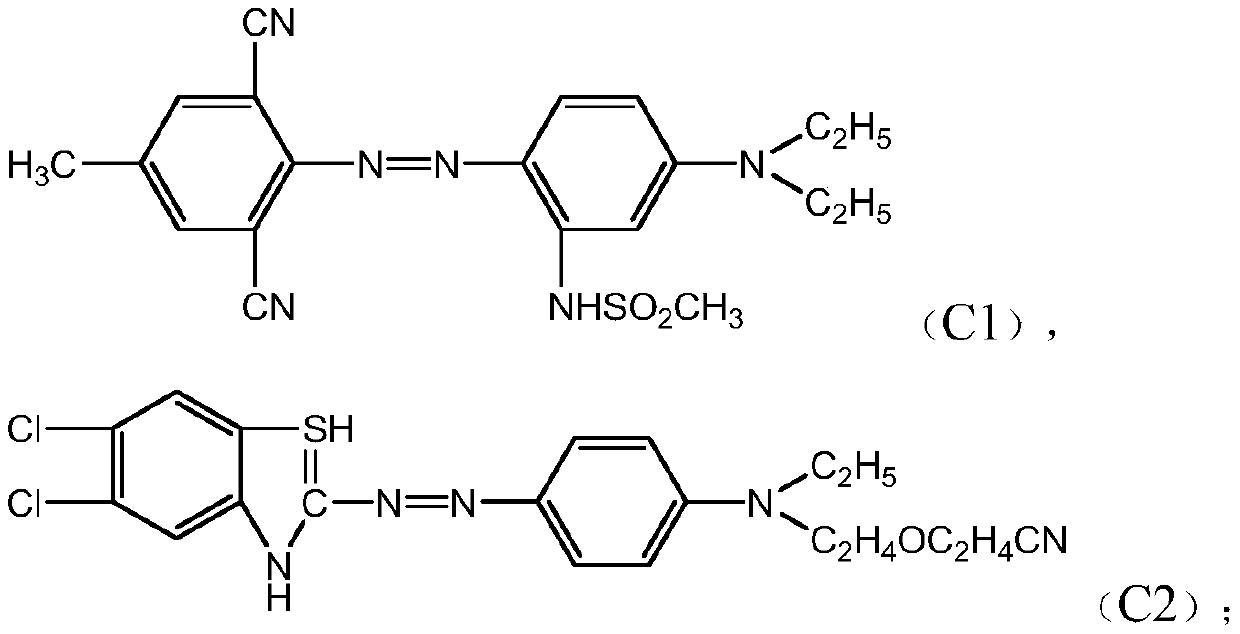

Disperse gray dye composition, dye product, preparation method and application of dye product, and colored product

ActiveCN110204923AEasy to prepareImprove washing fastnessOrganic dyesDyeing processPhotochemistrySynthetic fiber

The invention provides a disperse gray dye composition, a dye product, a preparation method and an application of the dye product, and a colored product. The disperse gray dye composition comprises, by mass, 12-25% of a component A, 19-30% of a component B, 4-15% of a component C and 40-65% of a component D. The dye product comprises the disperse gray dye composition, assistants and water. The preparation method of the dye product comprises the following steps: mixing the disperse gray dye composition, the assistants and water, and grinding the obtained mixture. The application of the dye product is characterized by dyeing and printing of synthetic fibers and blend materials thereof. The colored product is produced from the synthetic fibers or blend materials thereof, printed and dyed withthe disperse gray dye composition. The disperse gray dye composition and the dye product have the advantages of wide applicable pH range, excellent fastness, high strength, extremely low metamerism index, greenness and environmental protection.

Owner:维昂(山东)纺织科技有限公司

Printing and dyeing production process and device for all-cotton antibacterial double-sided cloth

ActiveCN112342717AImprove efficiencyEasy to handleSucessive textile treatmentsTextile treatment machine arrangementsPolymer scienceColor printing

The invention discloses a printing and dyeing production process and device for all-cotton antibacterial double-sided cloth. The production process comprises the following steps that S1, dye color paste is prepared, and magnetization treatment is conducted on the dye color paste; S2, double-sided color printing is conducted on the all-cotton antibacterial double-sided cloth by using the productiondevice and the magnetized dye color paste obtained in the step S1, and then drying is conducted; and S3, steaming and color fixing are conducted on the treated all-cotton antibacterial double-sided fabric by using a prepared color fixing solution, and washing and shaping are conducted to obtain the all-cotton antibacterial double-sided printed and dyed fabric. The production device comprises a printing and dyeing bin, a drying bin, a color fixing bin and a washing bin. According to the double-sided printing and dyeing process and device, simultaneous double-sided printing and dyeing treatmentcan be conducted on the all-cotton antibacterial double-sided cloth, the printing and dyeing efficiency is effectively improved, the printing and dyeing effect can be effectively improved, and therefore the problems of printing and dyeing fading or insufficiency and the like can be avoided.

Owner:无锡迈克斯纺织品有限公司

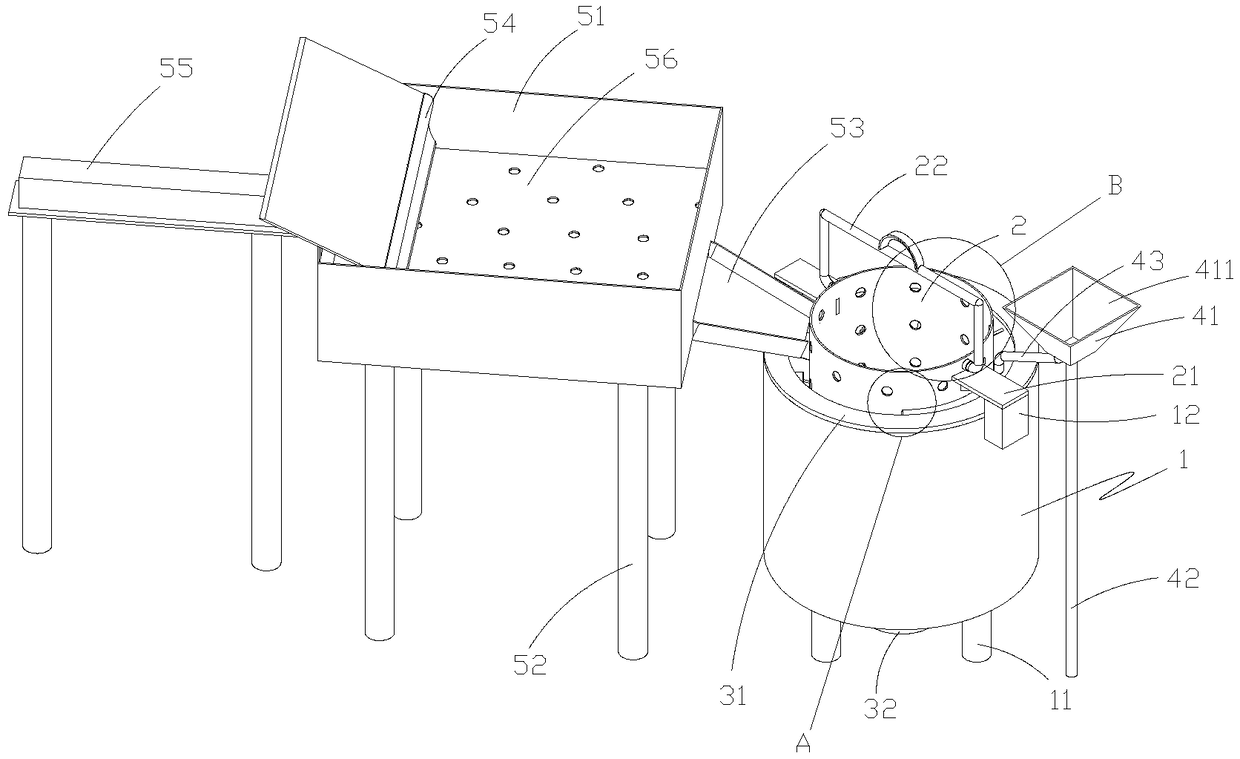

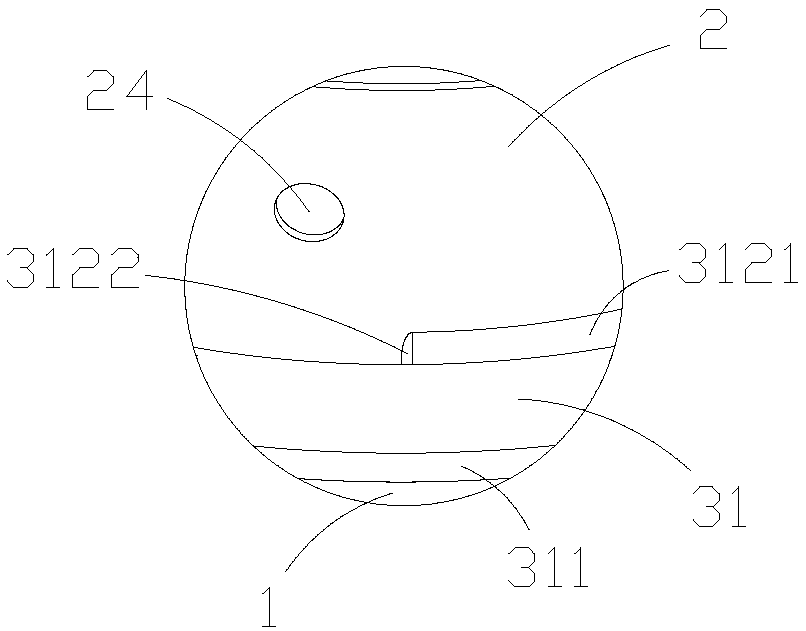

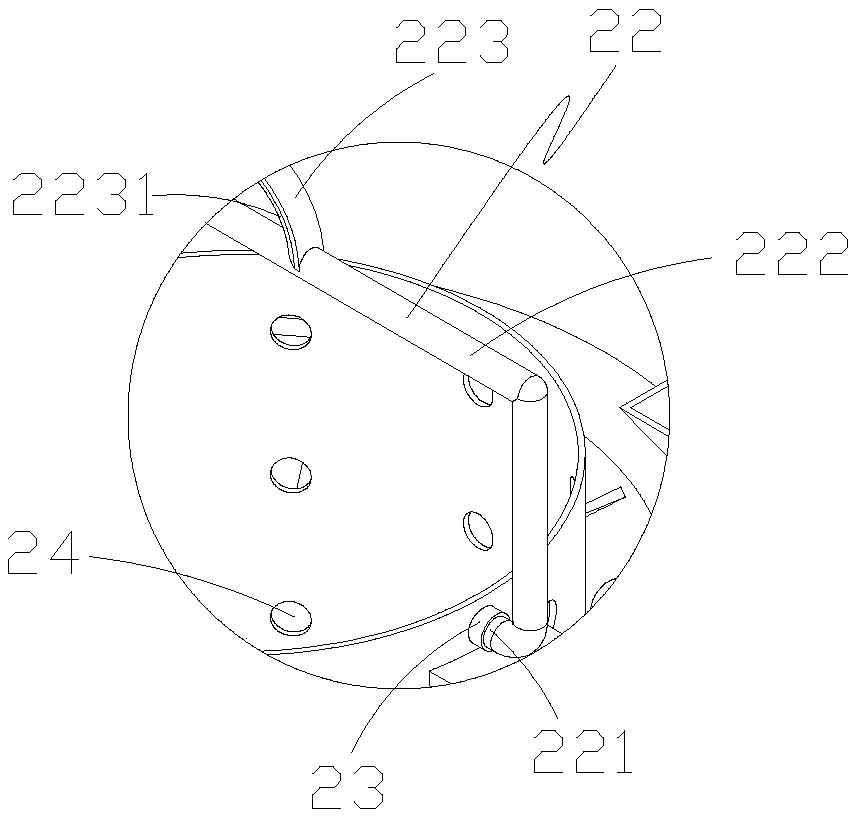

Printing and dyeing equipment for textile dyeing

ActiveCN109234948AEasy to take outGuaranteed dyeing effectTextile treatment machine arrangementsLiquid/gas/vapor textile treatmentEngineeringTextile dyeing

The invention discloses printing and dyeing equipment for textile dyeing. The equipment comprises a base, a dip dyeing bucket arranged on the base and a stirring device cooperating with the base, andthe stirring device comprises a dye bath bucket rotationally cooperating with the base; and the base is provided with a rotating structure used for achieving the rotating cooperation between the dye bath bucket and the base. The printing and dyeing equipment for textile dyeing has the advantages that through the cooperative arrangement of the dye bath bucket, the dip dyeing bucket and the base, dyeing of textile can be completed by soaking the textile in a dye liquor, and the textile cannot be pulled by external force, thereby avoiding the problem that the textile is damaged; the dye bath bucket can rotate relative to the base, so that the dye liquor in the dye bath bucket flows, not only can dyestuff deposition be avoided, but also textile dyeing can be accelerated, thereby greatly improving the printing and dyeing effect and efficiency.

Owner:SHAOXING UNIVERSITY

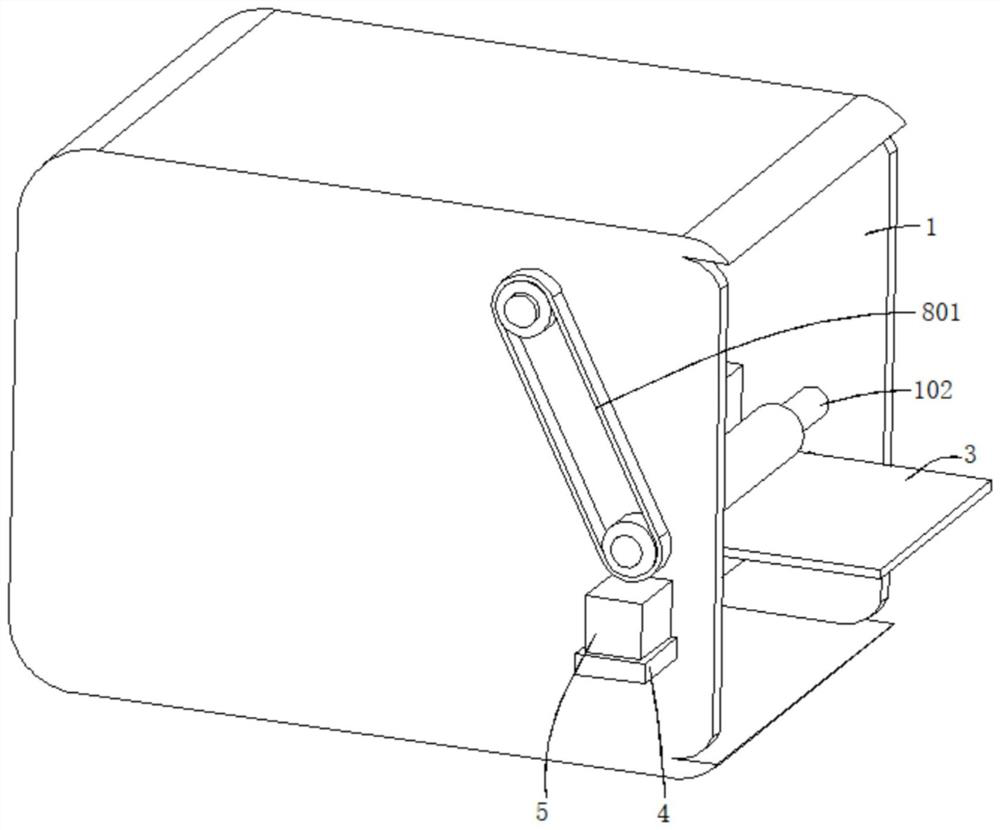

Transfer printing device

InactiveCN102452217AConsolidate the printing and dyeing effectSimple structureTransfer printingProduction rateFrame based

The invention discloses a transfer printing device which is used in the field of textiles. The device comprises a body, an indentation table, a driving frame and a pressing plate, wherein the indentation table is fixedly arranged on the body; the driving frame is fixedly arranged on the body; the pressing plate is fixedly connected with the driving frame and is provided with indentation paper; the driving frame comprises a driving frame base, a rotating arm adjusting frame, a rotating arm, a pressing plate connecting block and an adjusting screw, wherein the driving frame base is fixed on the body; the rotating arm adjusting frame is arranged on the driving frame base through a first screw; the rotating arm is rotatably connected with one end of the rotating arm adjusting frame through a second screw; the pressing plate connecting block is fixedly connected to the rotating arm and is rotatably connected to the driving frame at the same time; and the adjusting screw is arranged on the other end of the rotating arm adjusting frame. The transfer printing device has the advantages of simple structure, easiness and convenience in use, high printing and dyeing speed, good printing and dyeing effect, extremely high productivity, high suitability for requirements of textile production and extremely positive significance.

Owner:WUJIANG ERLIAN SILK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com