Fabric dyeing and drying system

A drying system and fabric technology, applied in the processing of textile materials, processing of textile material carriers, continuous processing of textile materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

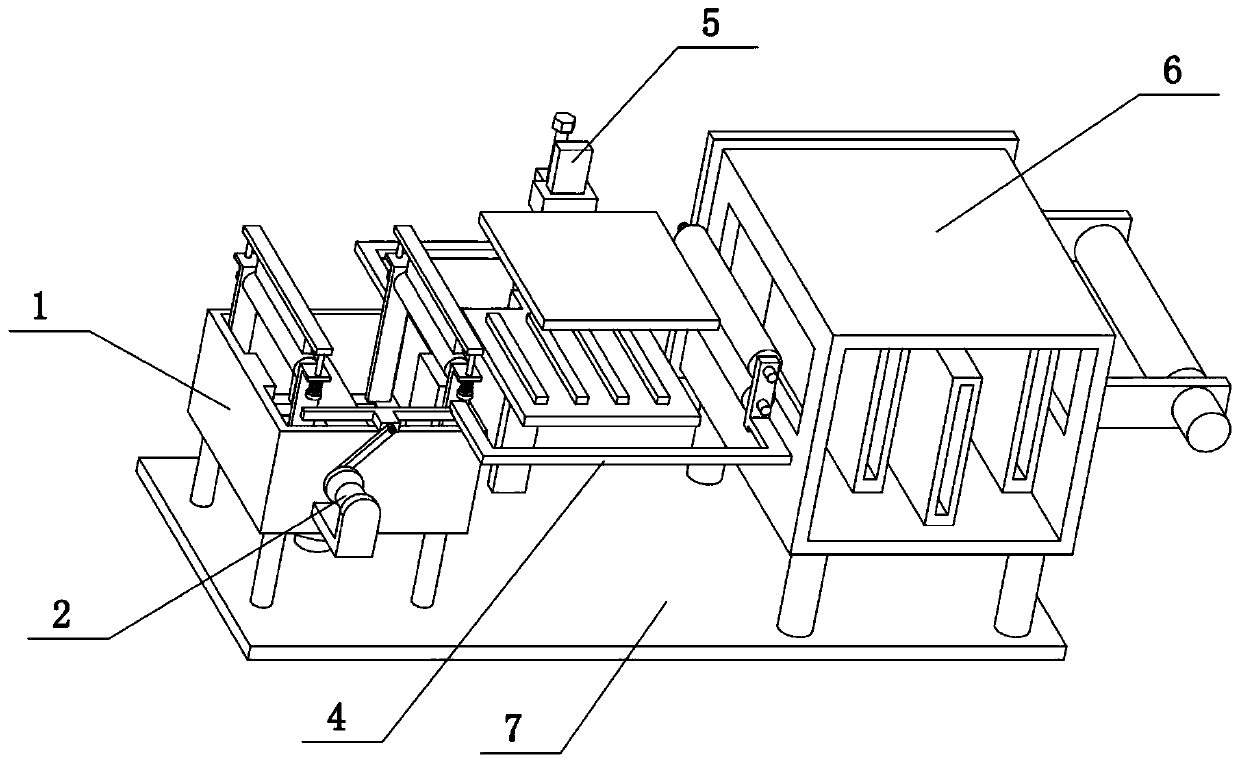

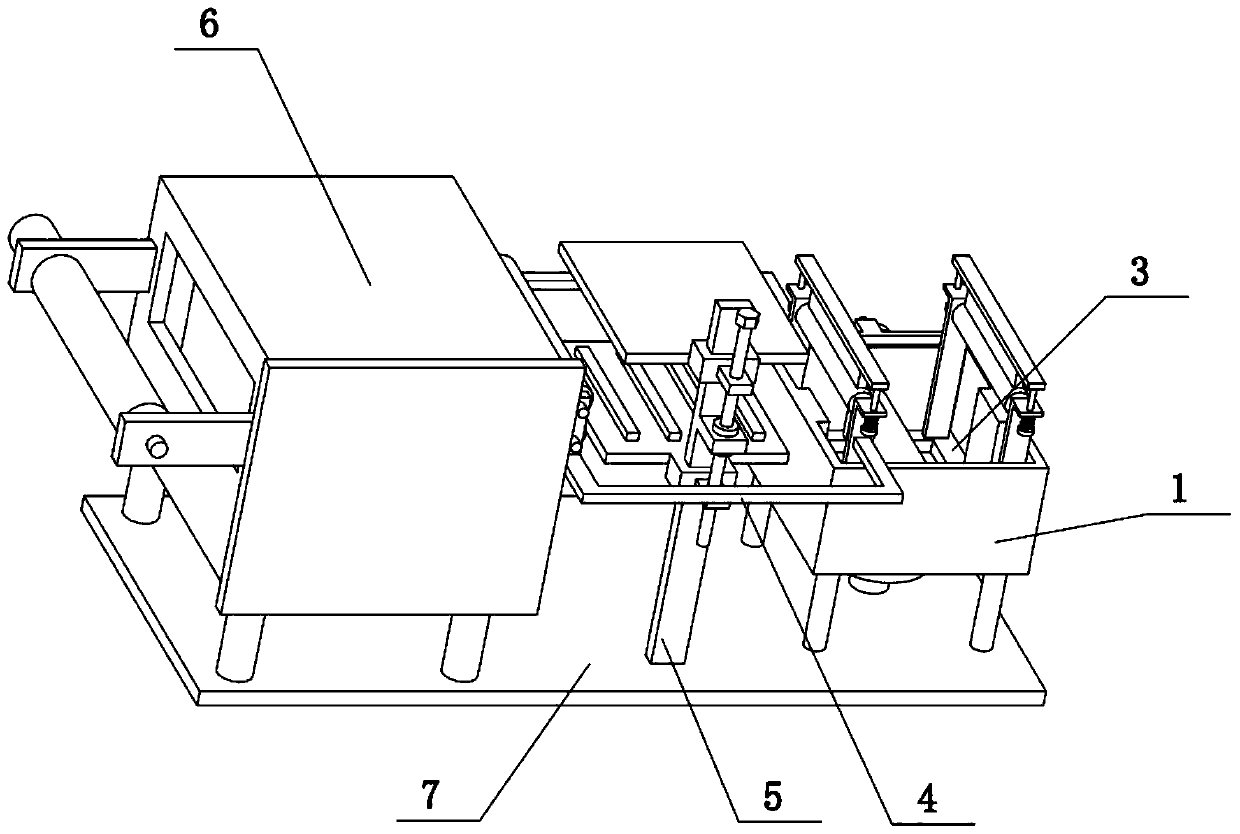

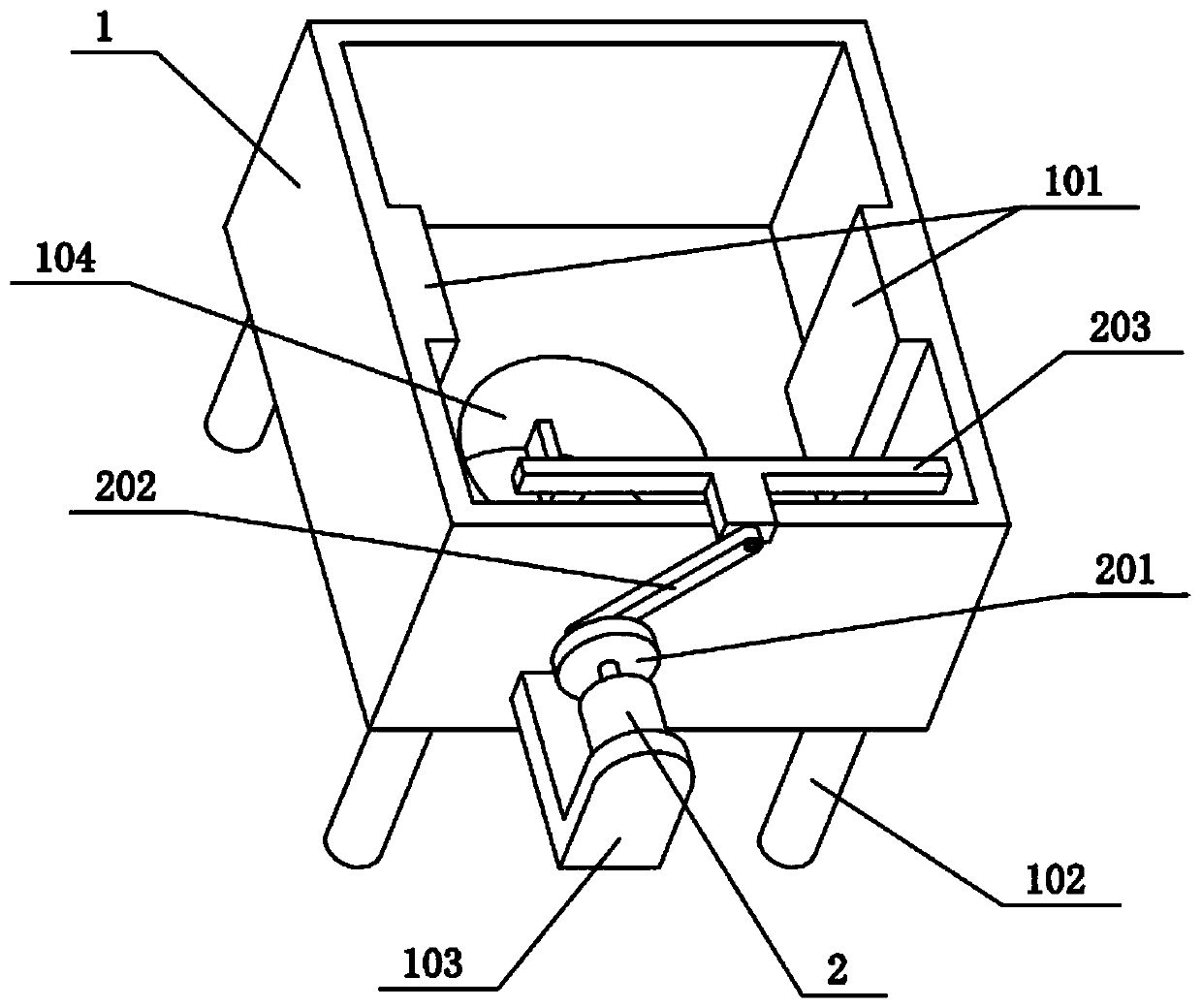

[0036] Combine below Figure 1-11 Describe this embodiment, the present invention relates to the field of fabrics, more specifically a fabric dyeing and drying system, including a dye box 1, a lifting frame 3, a bottom drum 302, a rotating seat plate 303, a riser 304 and an upper rotating Tube 309, the present invention can import cloth into the dye box 1 for printing and dyeing, and then export the cloth from the dye box 1.

[0037]The lifting frame 3 is slidably connected in the dye box 1, the upper four corners of the lifting frame 3 are fixedly connected with vertical plates 304, and the upper ends of the two vertical plates 304 at the left end are rotatably connected with an upper drum 309 , the upper ends of the two vertical plates 304 at the right end are rotatably connected with an upper drum 309, the front and rear ends of the upper middle part of the lifting frame 3 are fixedly connected with a rotating seat plate 303, and the two rotating seat plates 303 are rotatab...

specific Embodiment approach 2

[0039] Combine below Figure 1-11 To illustrate this embodiment, the fabric dyeing and drying system also includes a circular baffle 305, a convex plate 306, a spring sleeve rod 307, and a bead 308. On the upper side of the drum 309, the front and rear ends of the lower sides of the two beading bars 308 are fixedly connected with spring sleeve rods 307, and the upper ends of the four vertical plates 304 are fixedly connected with convex plates 306, and the four spring sleeve rods 307 are respectively slidably connected. On the four convex plates 306, the four spring sleeve rods 307 are sleeved with compression springs, the four compression springs are respectively located on the lower side of the four convex plates 306, and the lower ends of the four spring sleeve rods 307 are fixedly connected with round Blocking sheet 305 . The two beading bars 308 and the two upper drums 309 apply downward pressure respectively, so that when the cloth passes through the two upper drums 309...

specific Embodiment approach 3

[0041] Combine below Figure 1-11 To illustrate this embodiment, the fabric dyeing and drying system also includes ribs 101 and rib grooves 301, ribs 101 are provided on the left and right inner walls of the dye box 1, and ribs 101 are provided on the left and right sides of the lifting frame 3. The convex groove 301, the two convex grooves 101 are slidably connected to the two convex grooves 301 respectively. The effect of setting the rib 101 and the rib groove 301 is that when the lifting frame 3 slides vertically in the dye box 1, the lifting frame 3 is more stable when it goes up and down.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com