Patents

Literature

555results about "Liquid/gas/vapor fabric treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

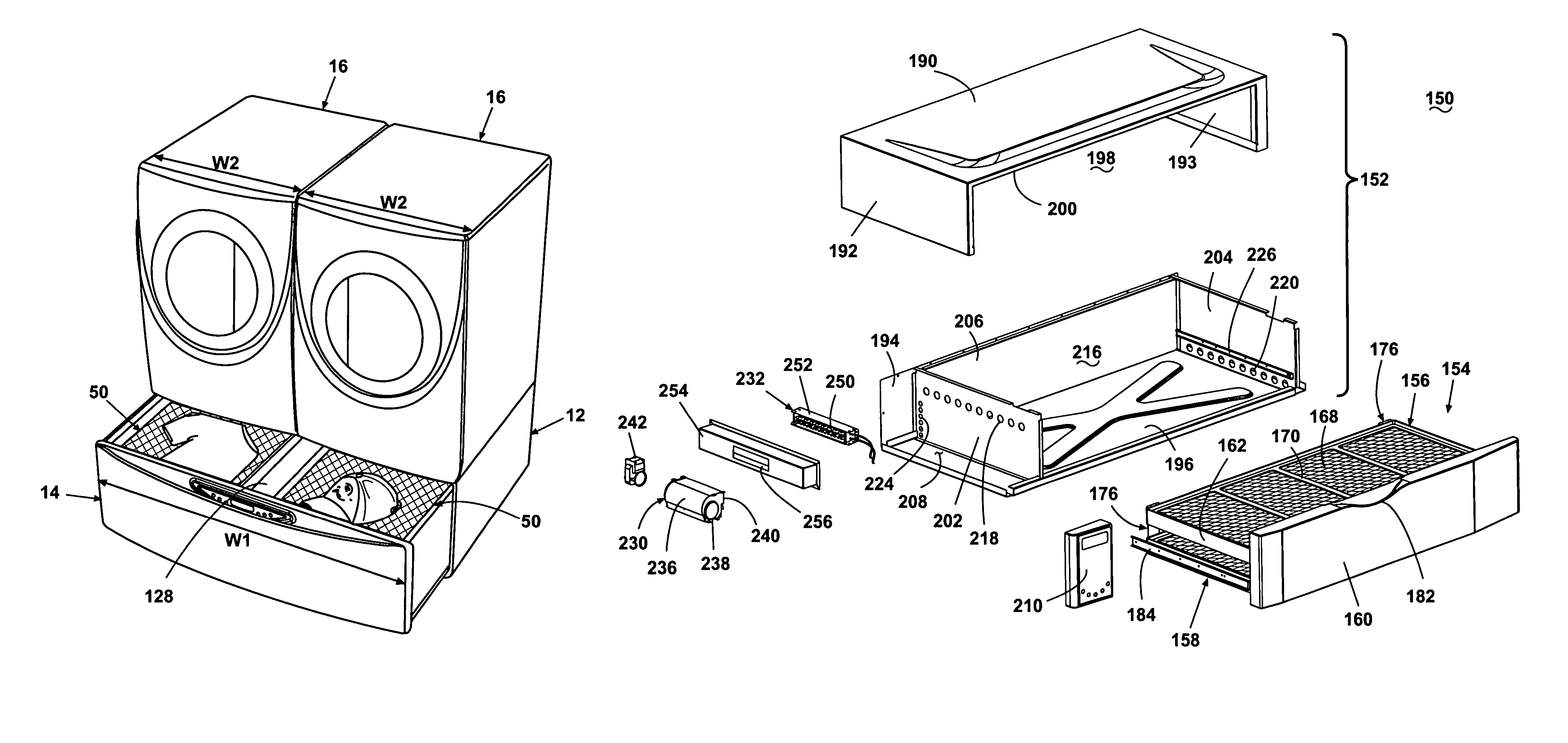

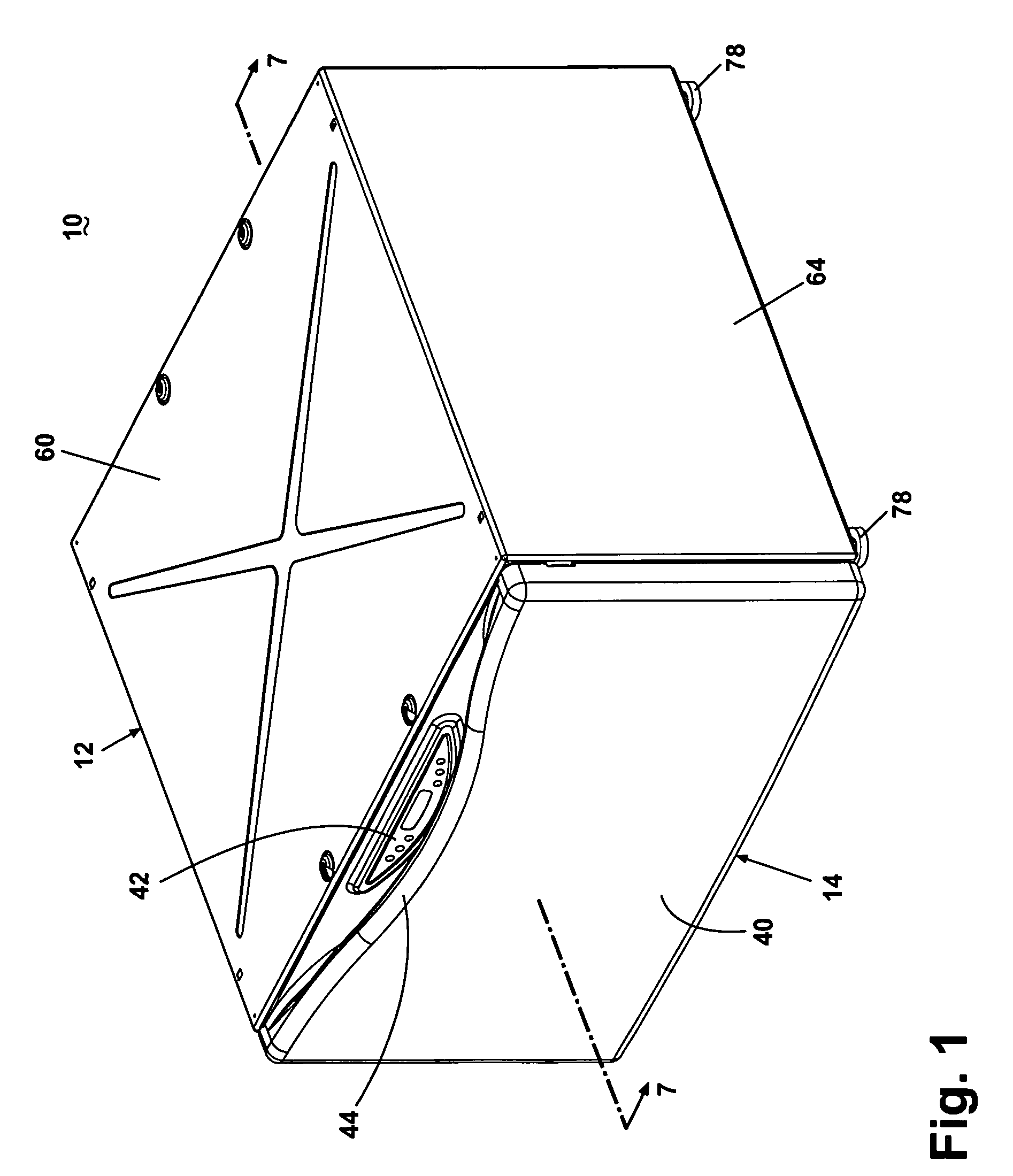

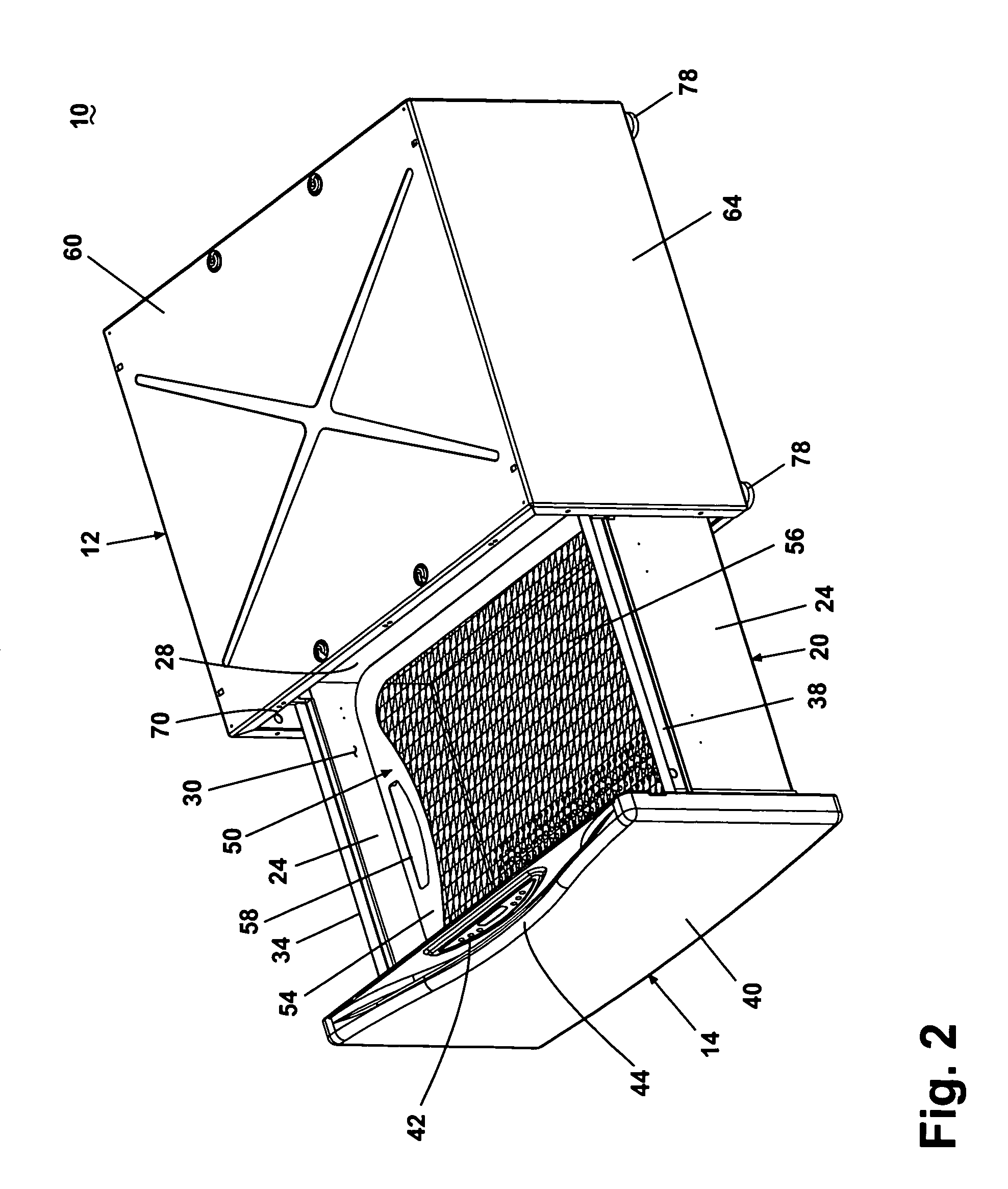

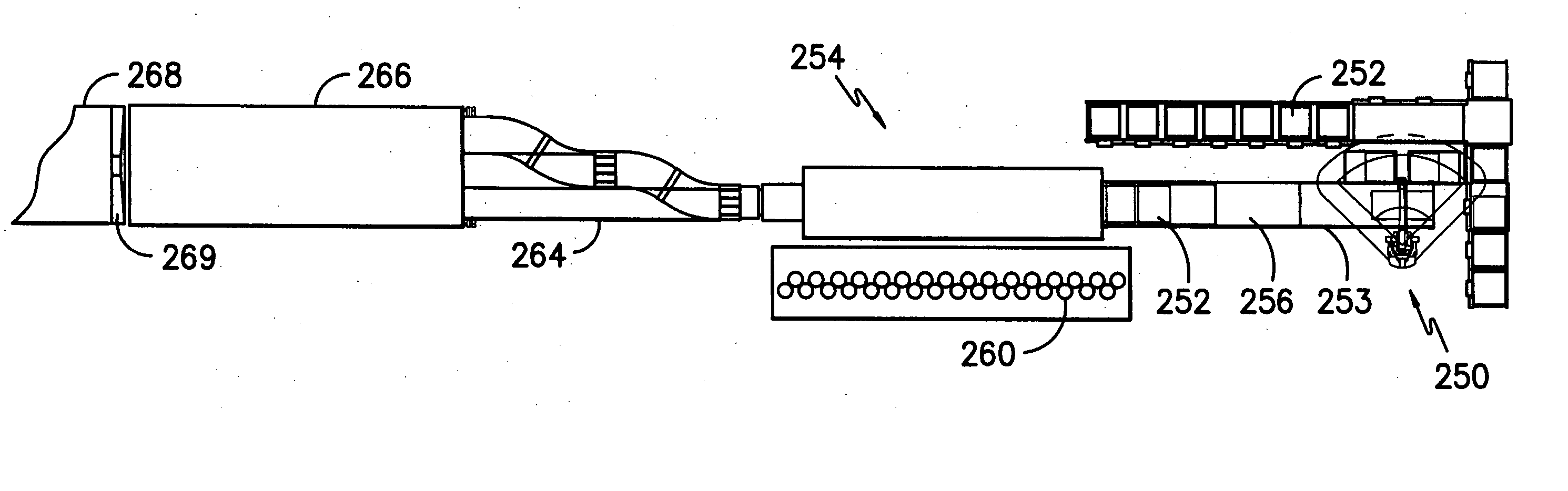

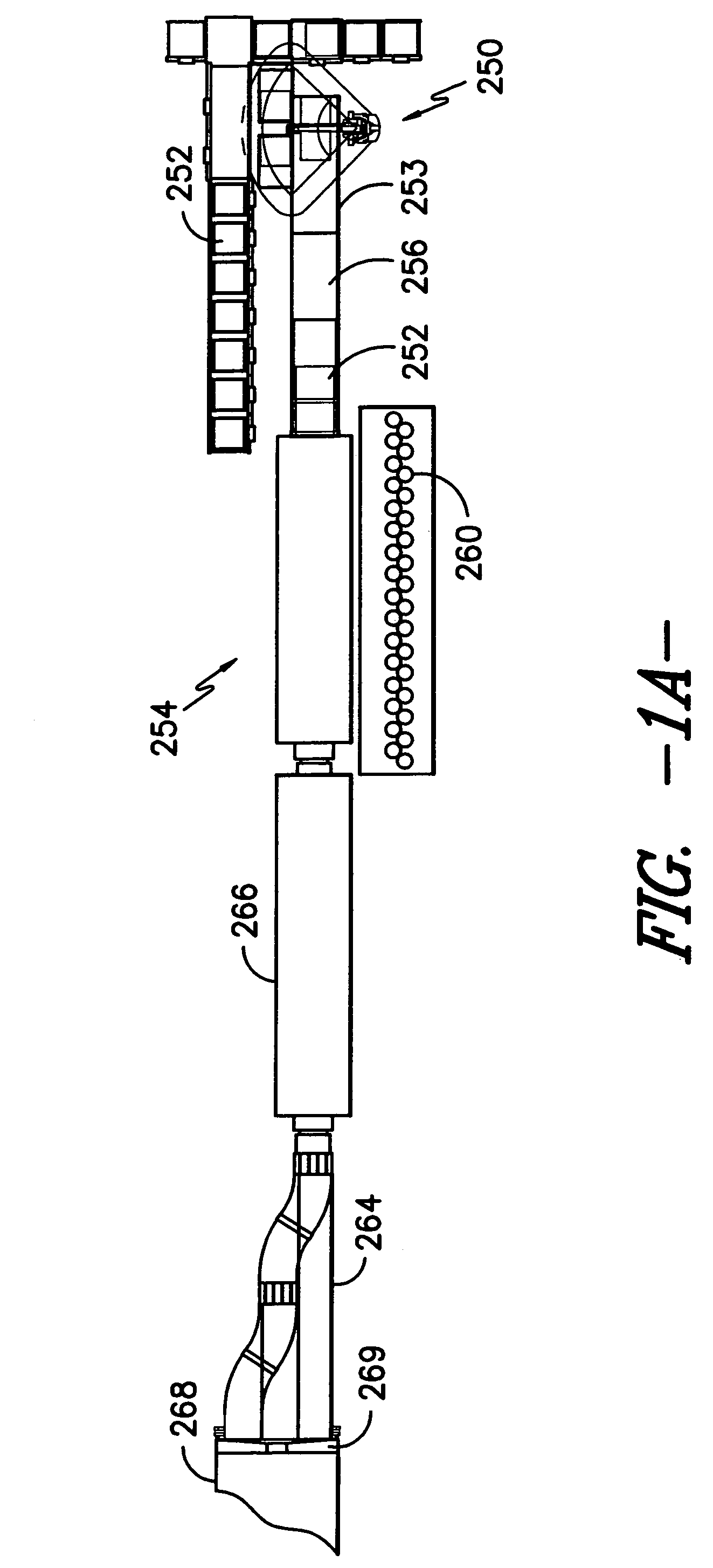

Non-tumble clothes dryer

A non-tumble dryer comprises a cabinet and a drawer configured to support an article to be dried and slidably mounted to the cabinet. An air supply system provides air to a drying chamber formed at least partially by one of the cabinet and the drawer for drying the article supported by the drawer. The non-tumble dryer can function as a pedestal whereby the top of the cabinet can be configured to support a laundry appliance in an elevated position. Alternatively, the cabinet can overlie one or more laundry appliances.

Owner:WHIRLPOOL CORP

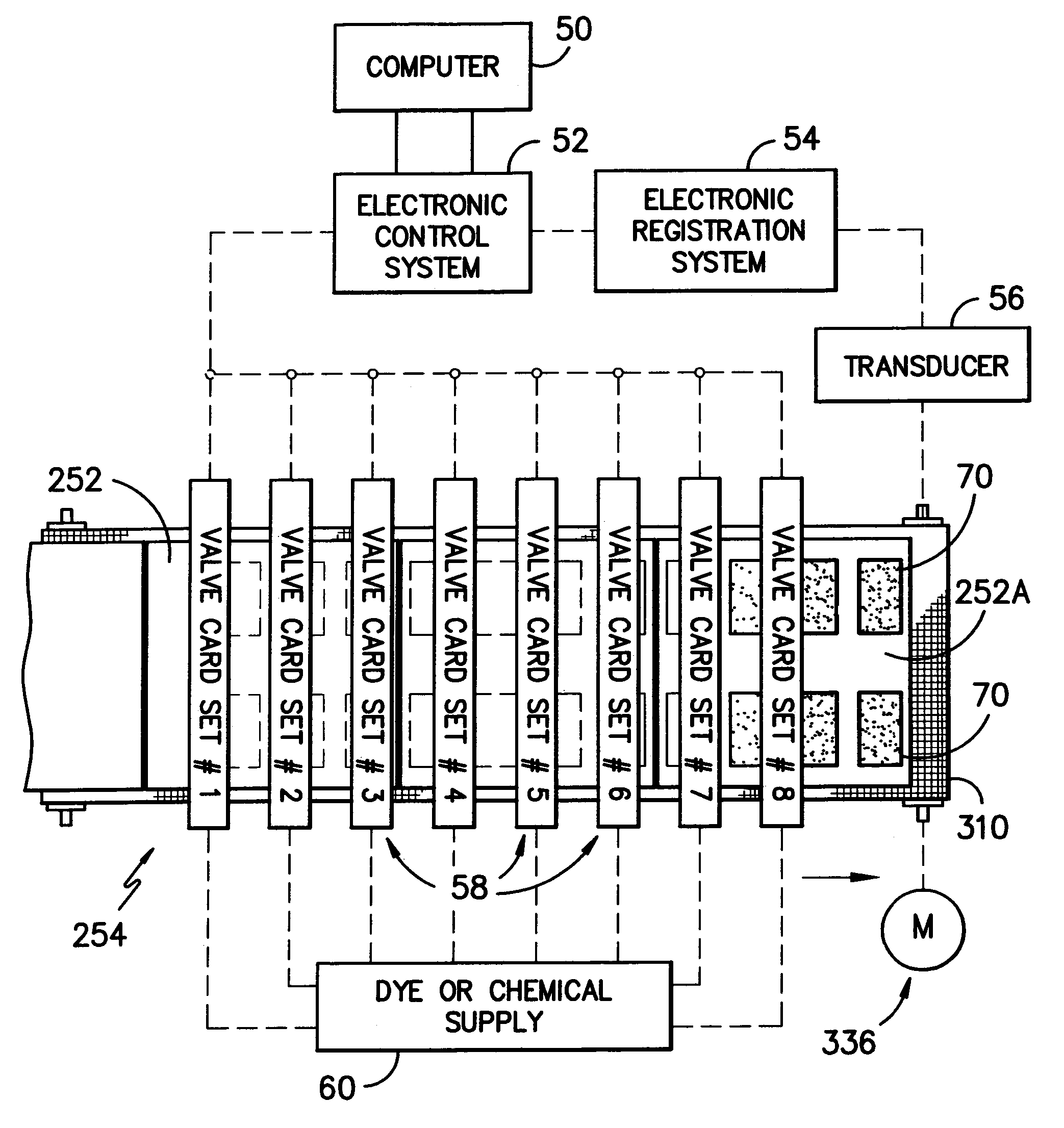

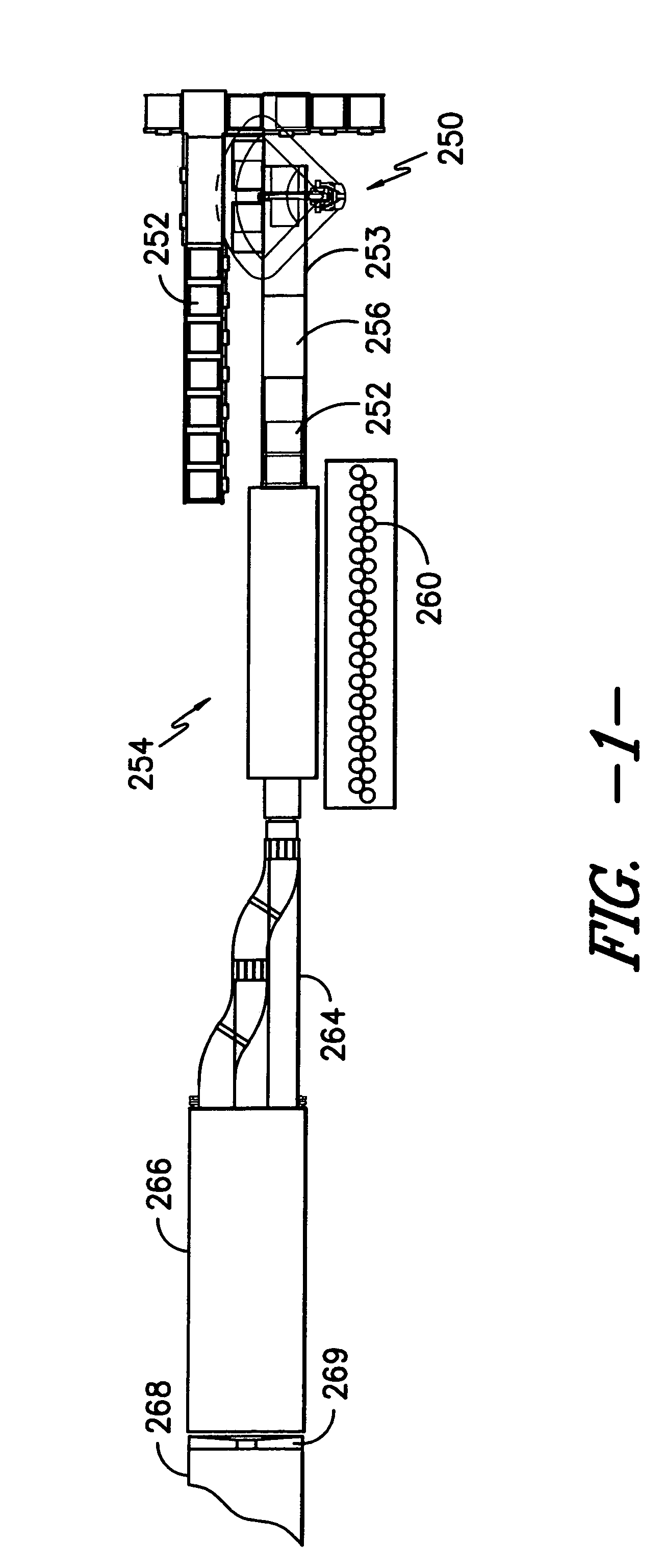

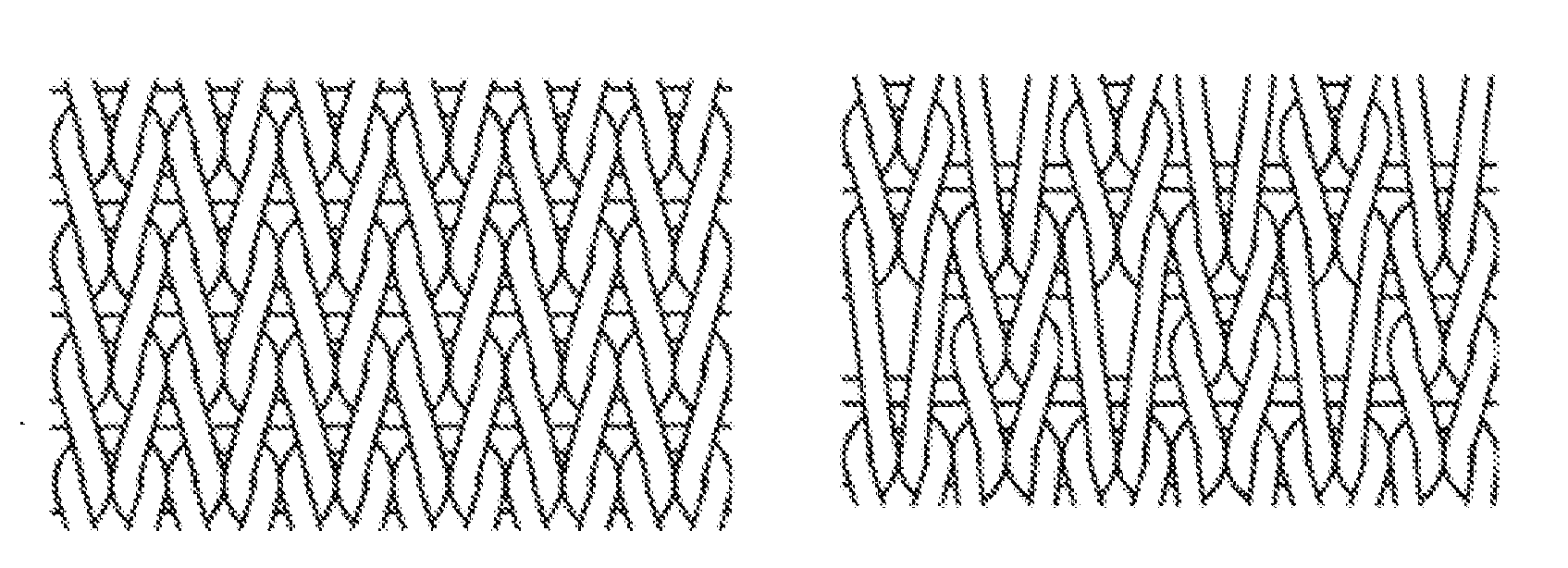

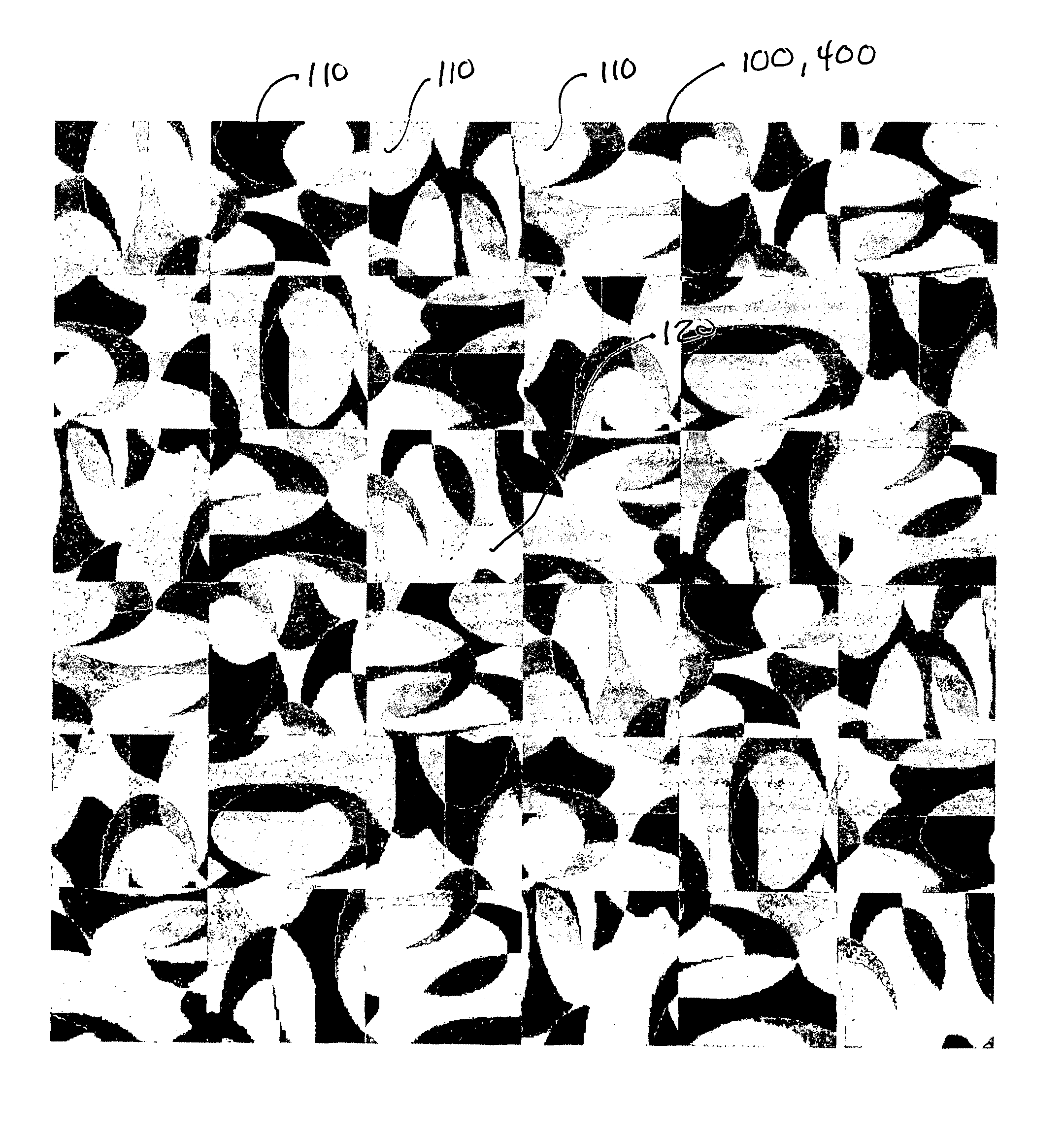

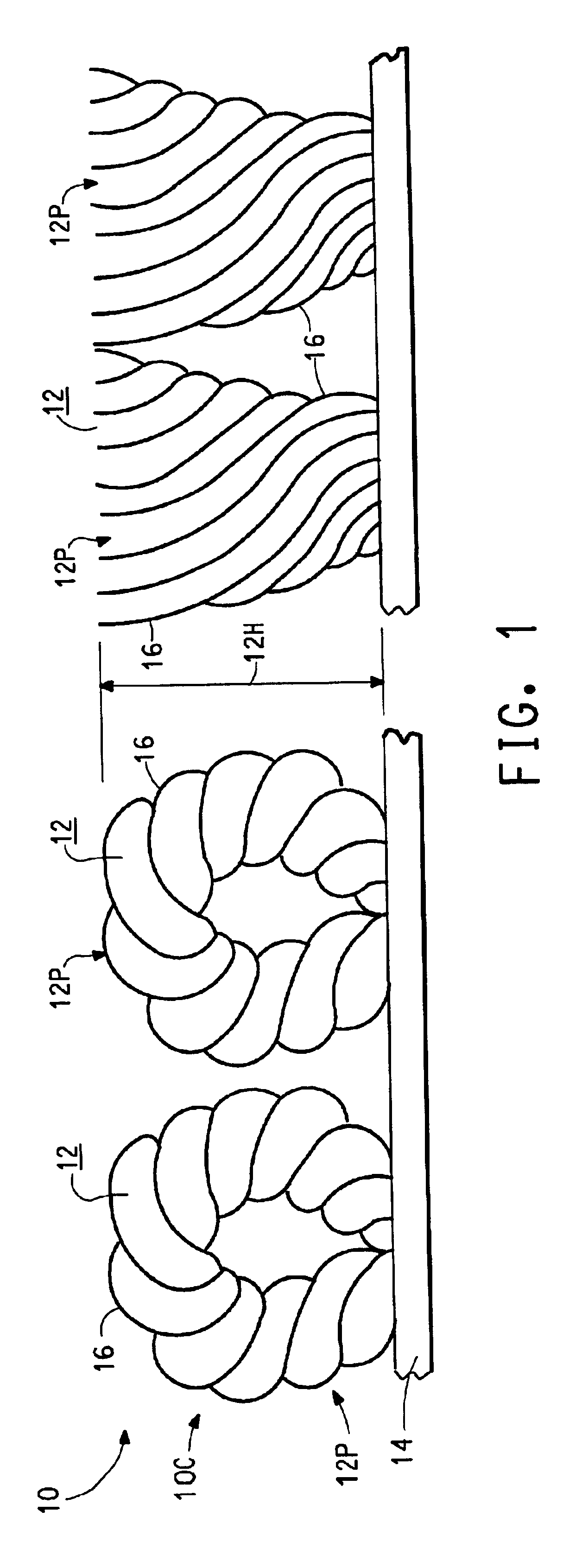

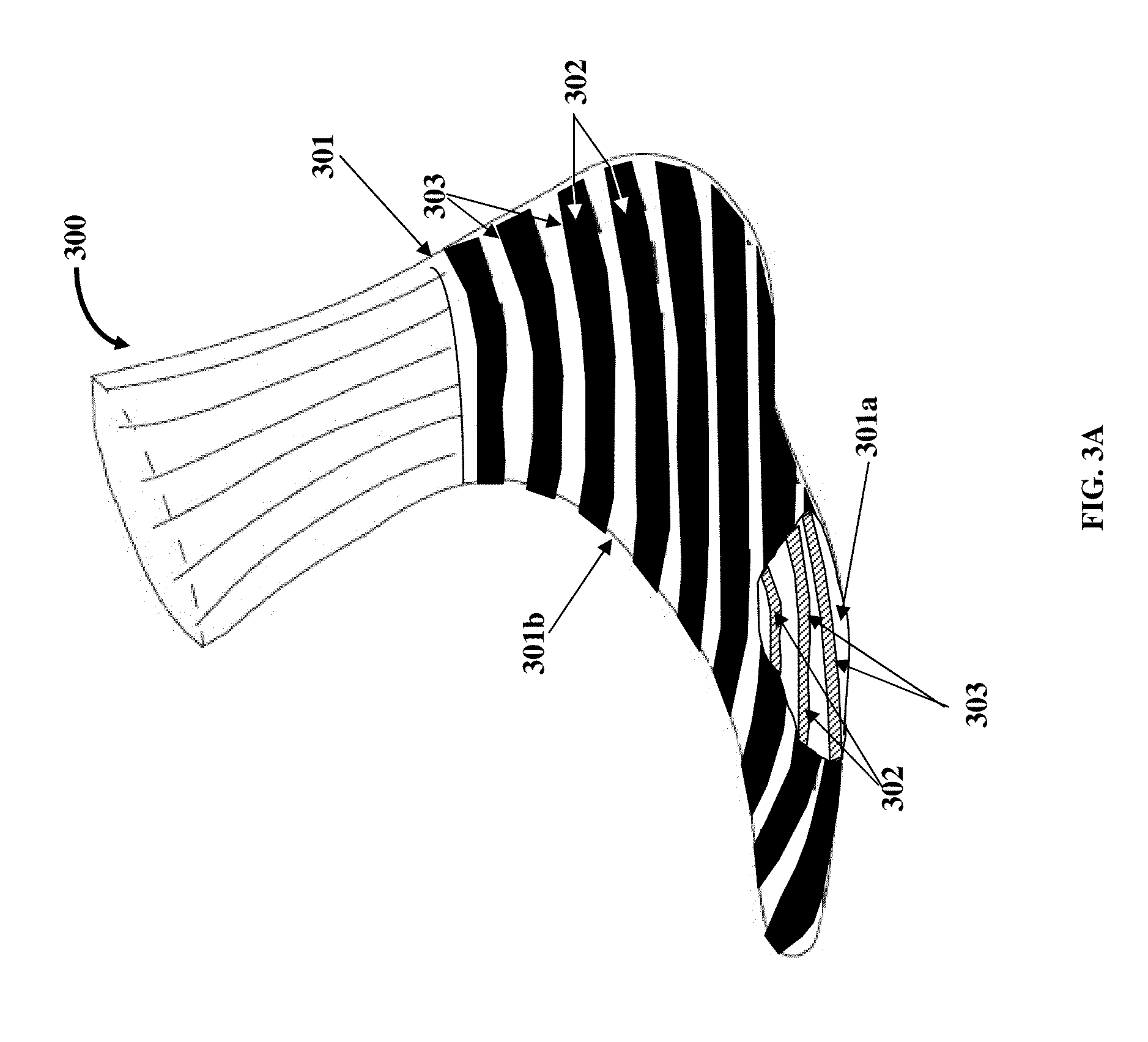

Patterned textile product

InactiveUS20050106355A1Layered productsControl devices for washing apparatusEngineeringFloor covering

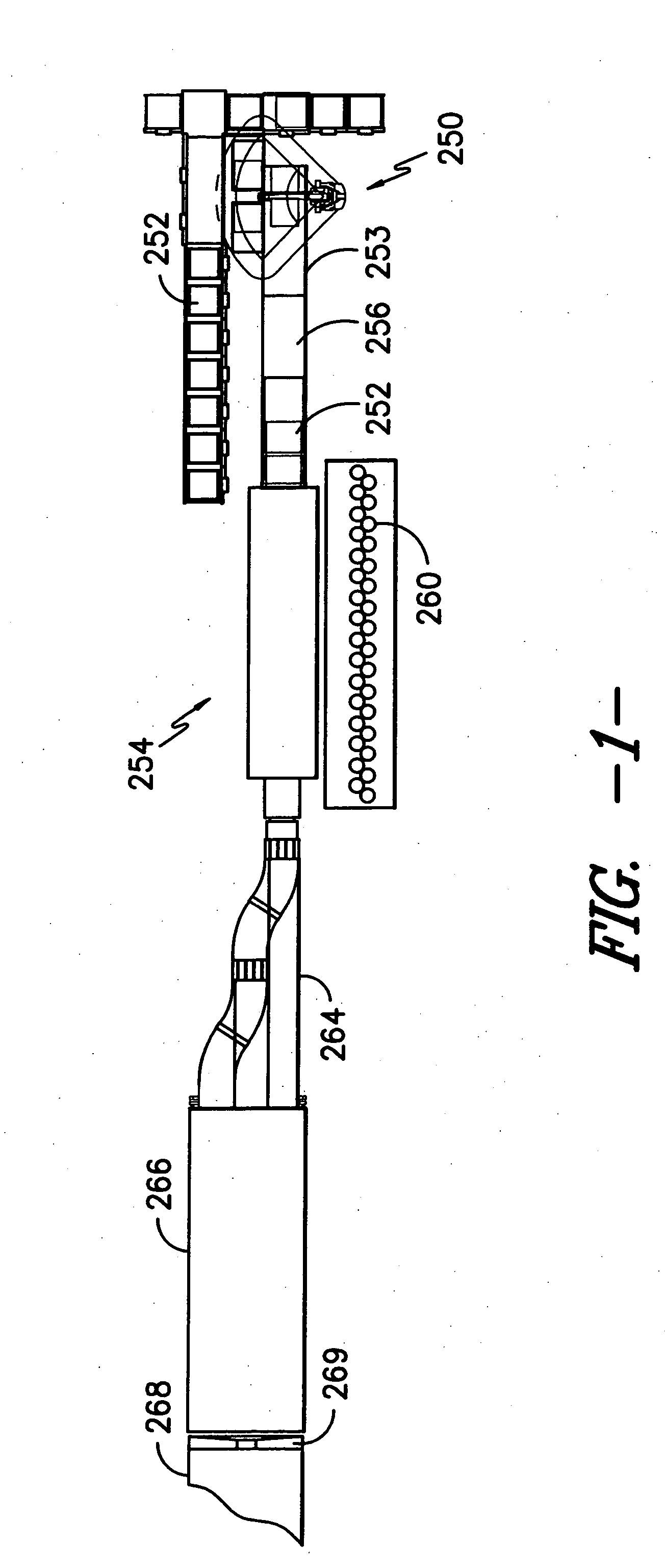

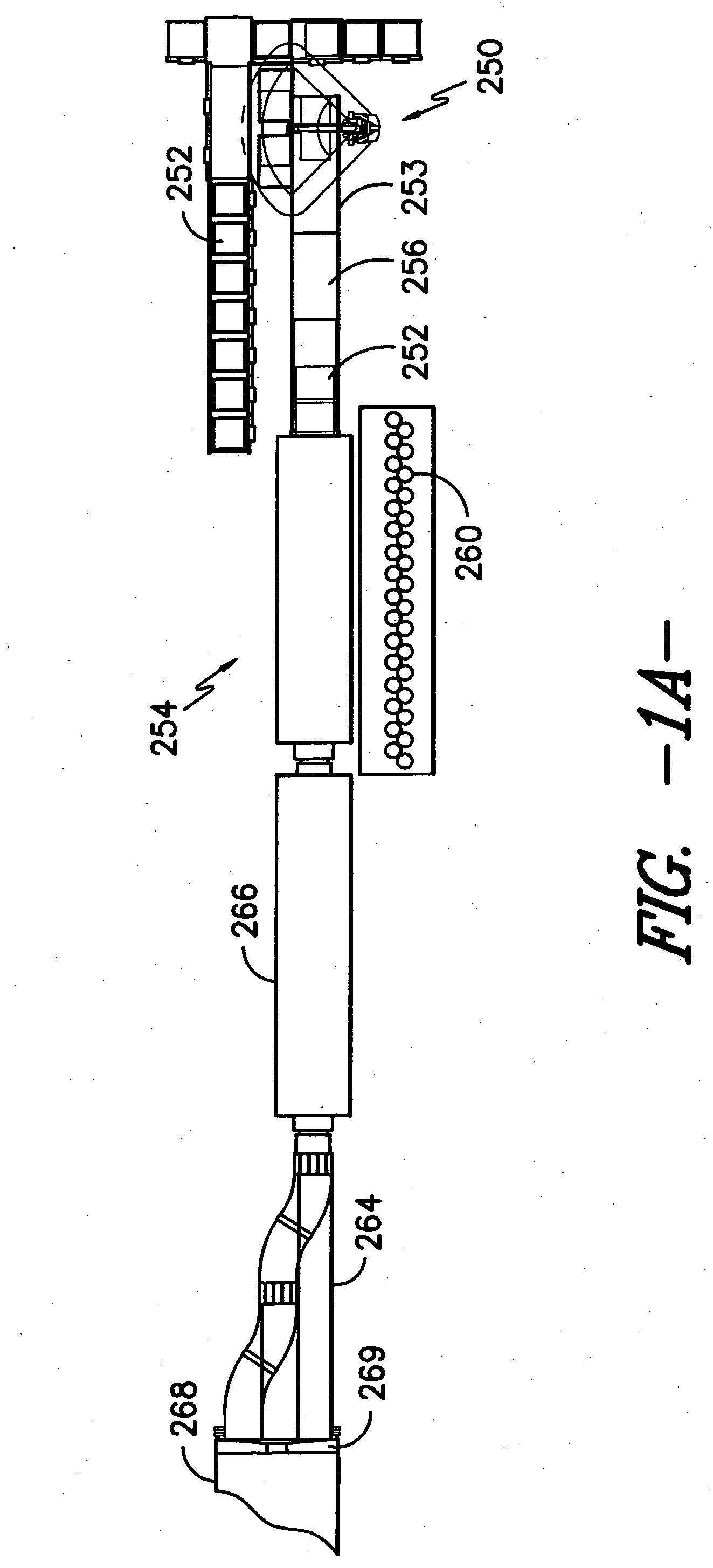

A textile substrate is patterned by the selective application of various dyes to the substrate surface in a way that provides desirable, visually apparent enhancements in the area of pattern detail, definition, and color range, through the use of a novel patterning system, including the application of various chemical agents, that makes such enhancements possible. In one embodiment, the patterning system described herein is capable of producing pile-faced textile substrates, useful as floor coverings, that exhibit a unique combination of desirable pattern attributes that have been identified and measured using novel techniques specifically developed for these substrates and pattern attributes.

Owner:MILLIKEN & CO

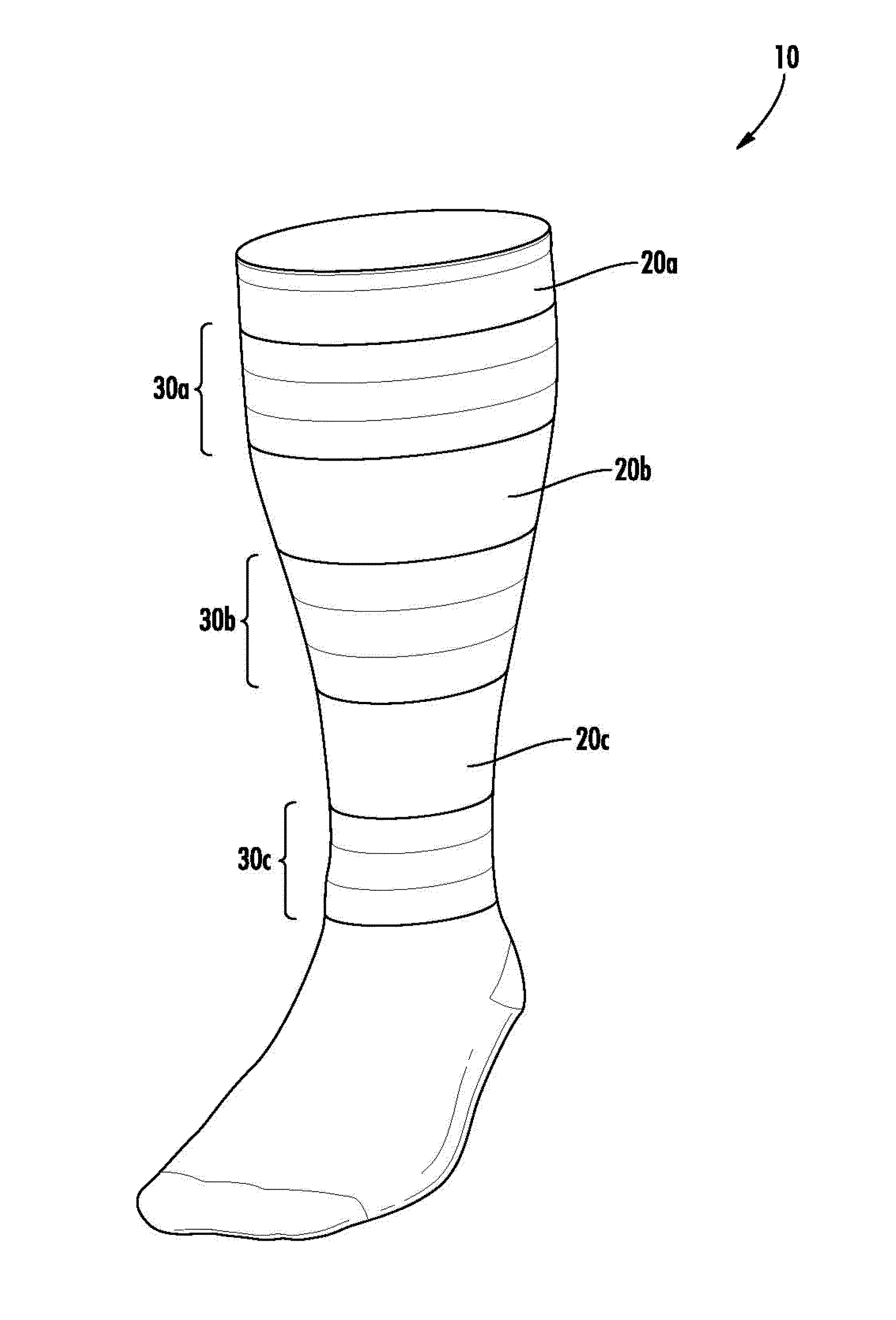

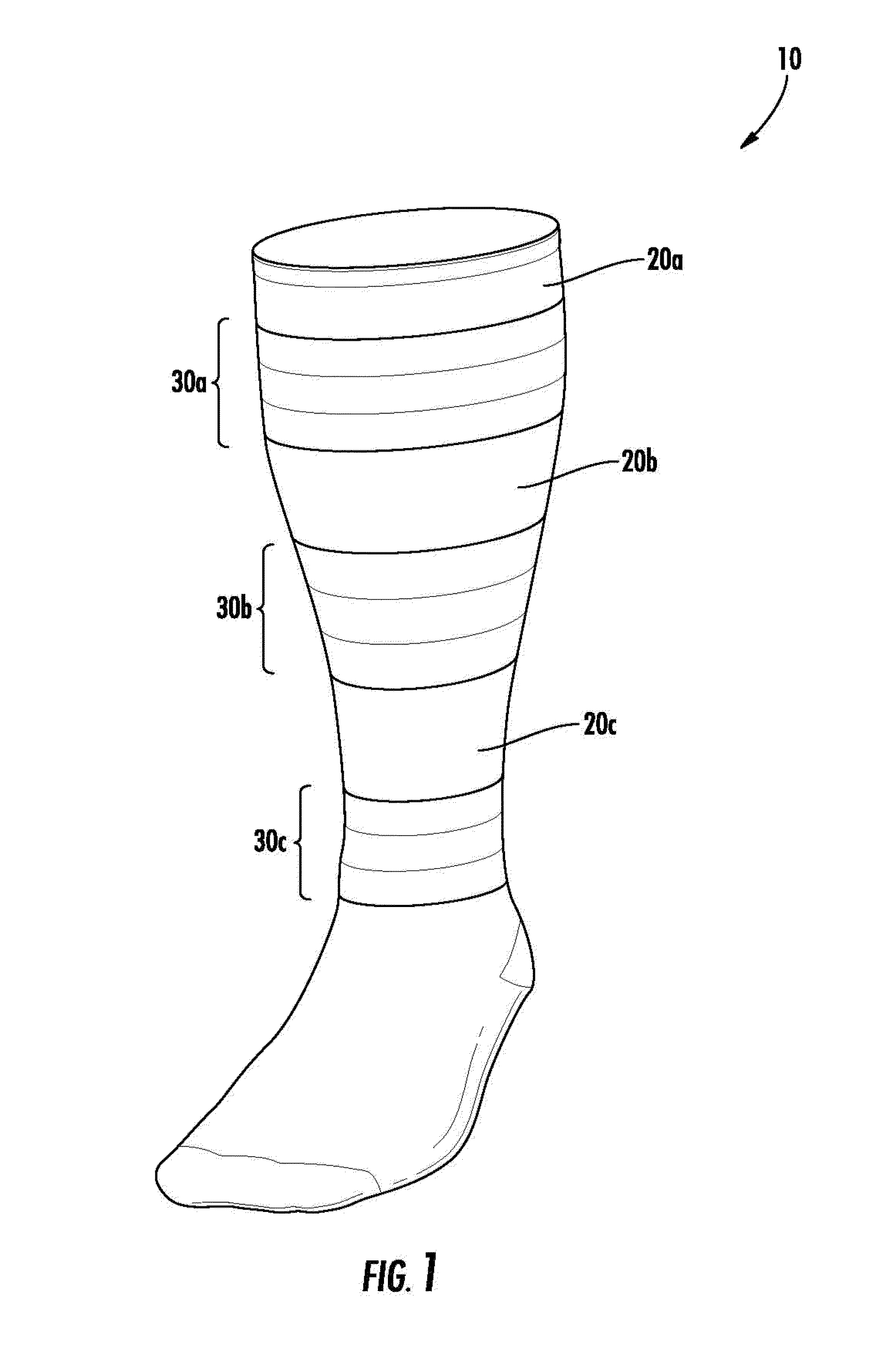

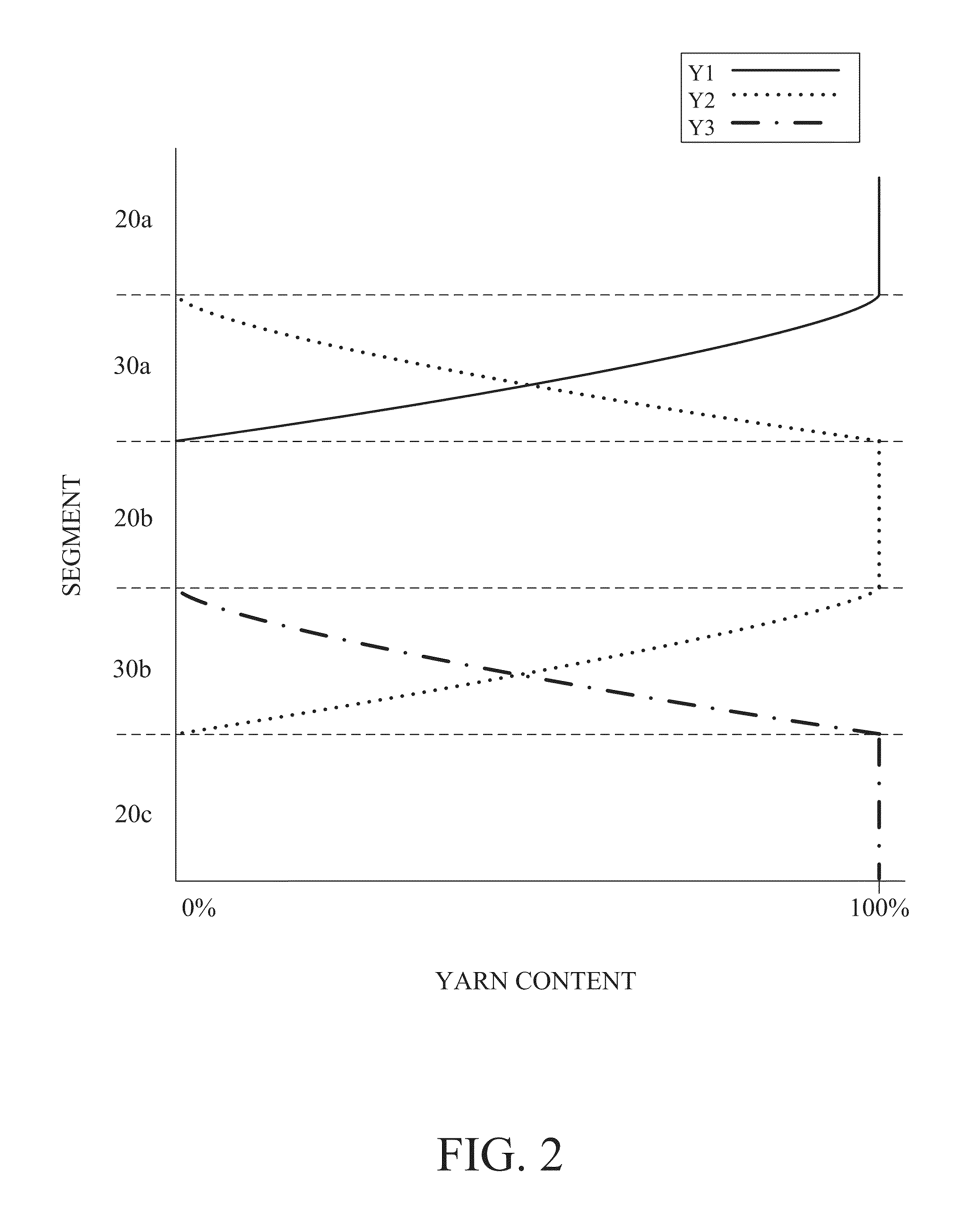

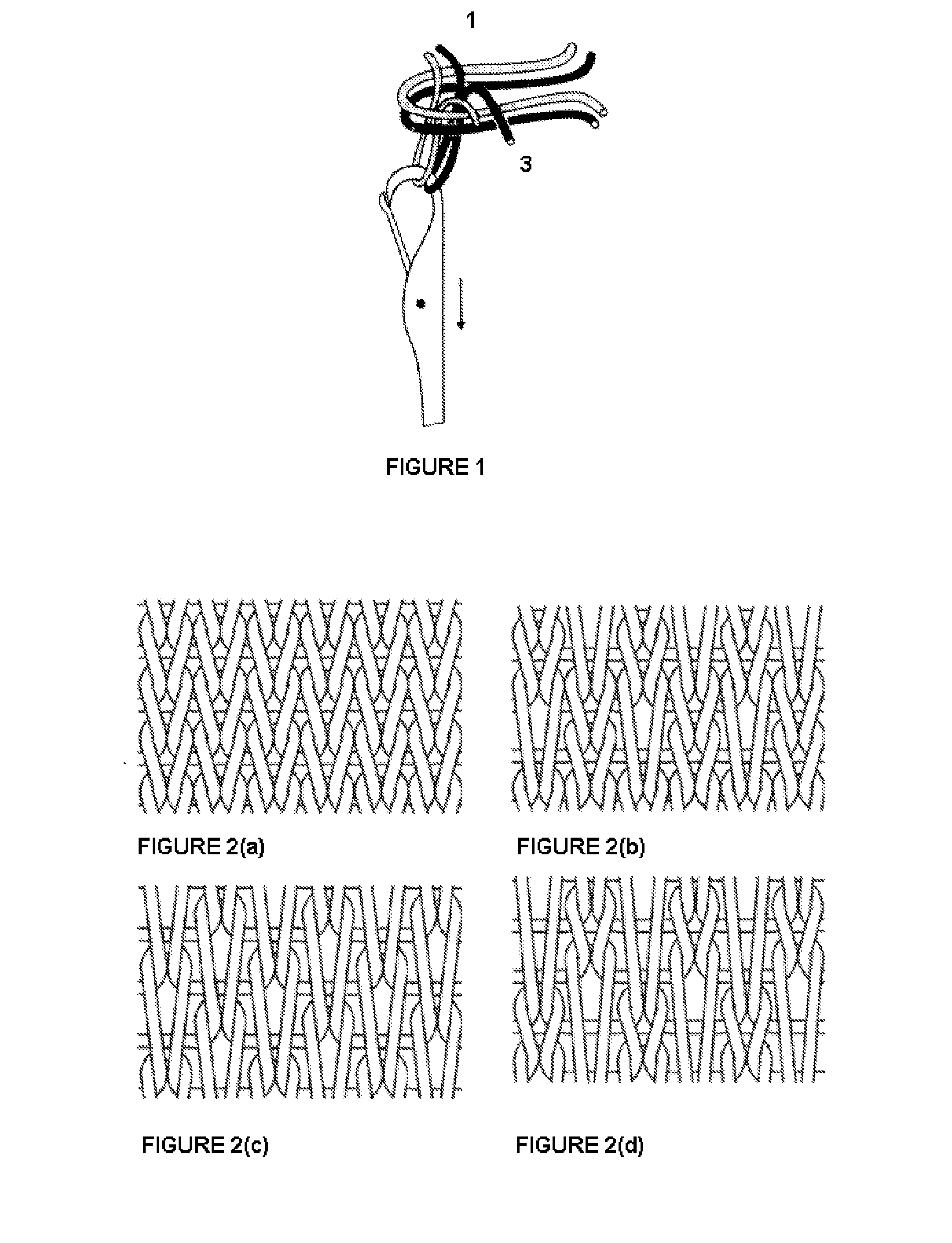

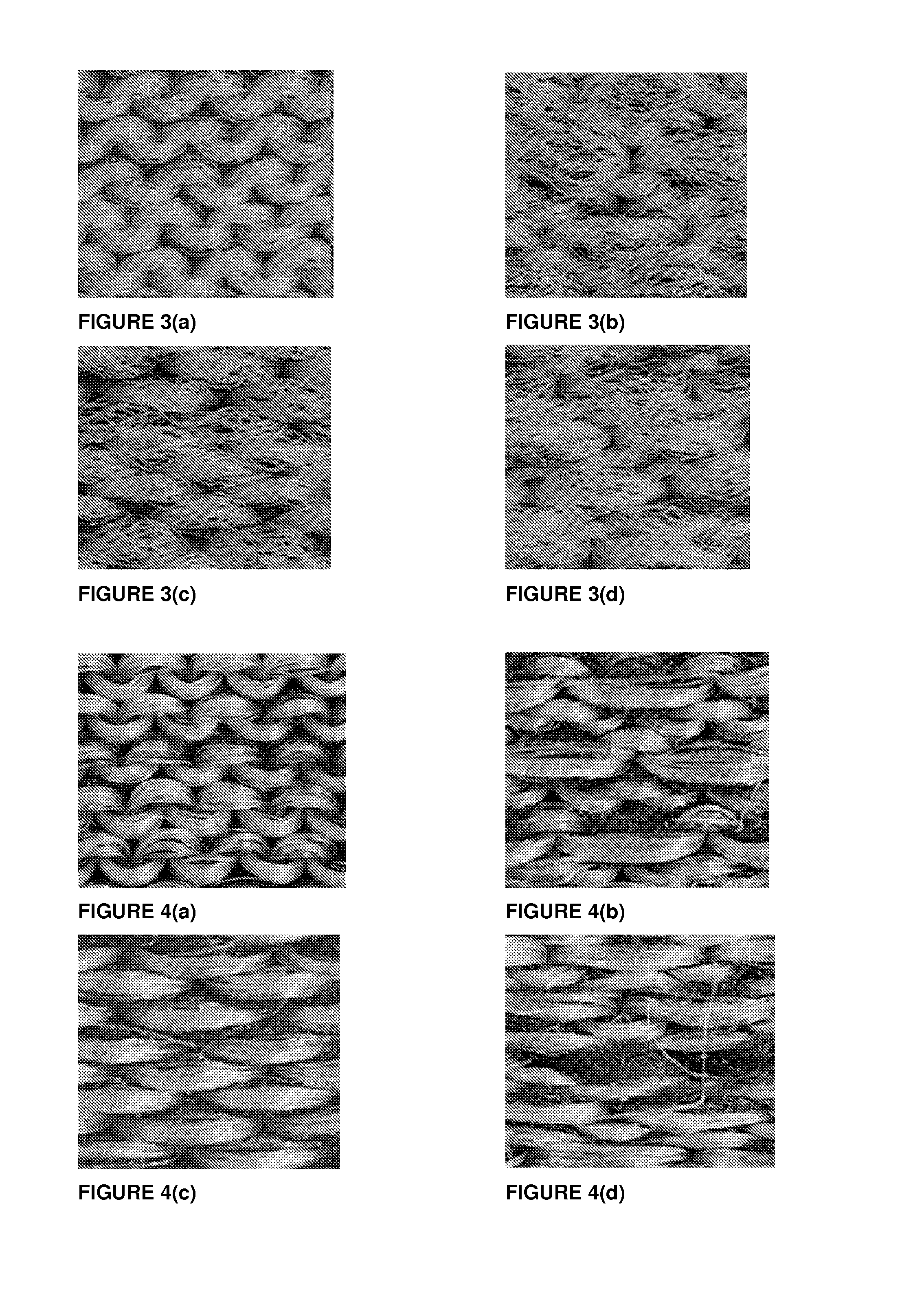

Compression fabrics with tailored comfort

Certain embodiments according to the invention provide compression articles suitable for a wide variety of uses (e.g., compression socks, athletic garments, etc.). In accordance with certain embodiments, the compression article includes at least two uniform compression regions, including a first uniform compression region having a first compression pressure and a second uniform compression region having a second compression pressure, and at least one transitioning compression region, including a first transitioning compression region positioned between the first and second uniform compression regions. The first transitioning compression region comprises a first end adjacent or proximate to the first uniform compression region and a second end adjacent or proximate to the second uniform compression region. The first transitioning compression region comprises a compression pressure gradient extending from the first end to the second end of the first transitioning compression region.

Owner:MYANT CAPITAL PARTNERS

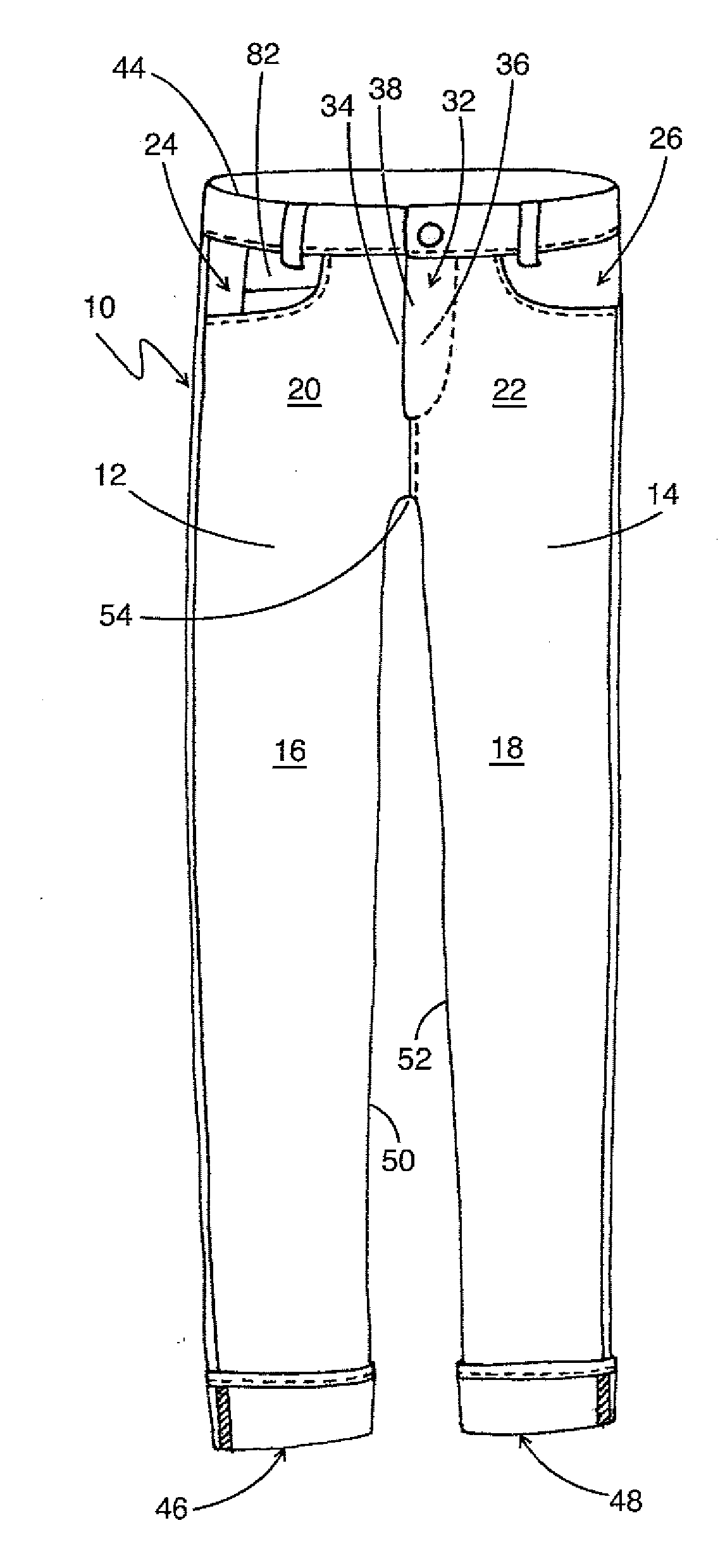

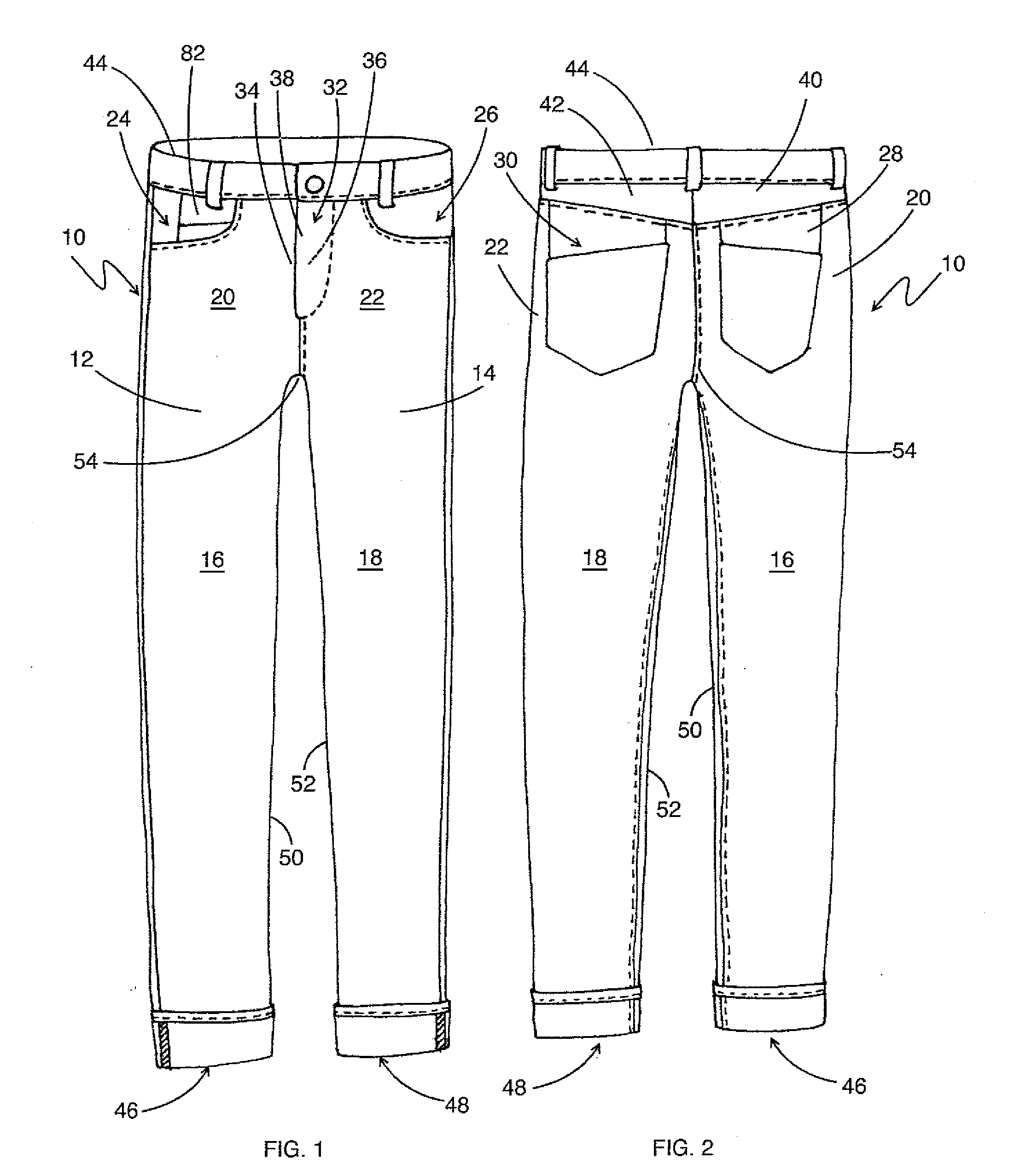

Methods for producing and merchandising a custom fit pant and custom fit pants

Methods for producing a pant, pants and methods for merchandising a pant. A pant is produced at a production facility by weaving right and left portions thereof using a multi-layer weaving process so as to produce an outer woven fly-cover layer and an inner woven left fly extension layer, or to form at least one pocket in at least one such portion, or both, and attaching the left portion of the pant to the right portion of the pant by stitching at least a portion of the crotch seam. The pant is then finished at a point of sale by stitching any remaining portion of the crotch seam and the inseams based on body dimensions and preferences of a purchaser to provide a custom fit. A pant produced at least in part by these steps is also presented.

Owner:CANDRIAN NATALIE A

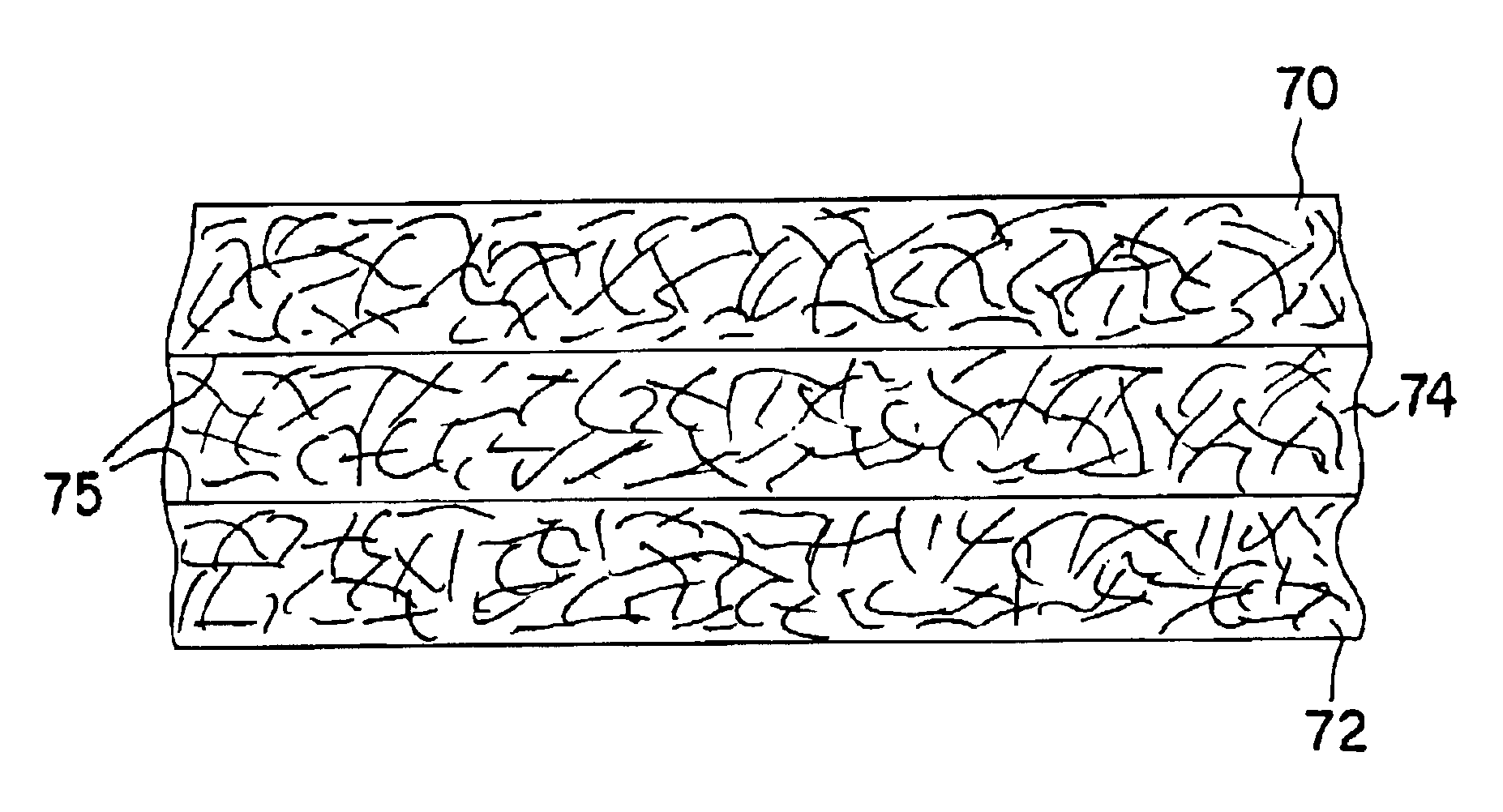

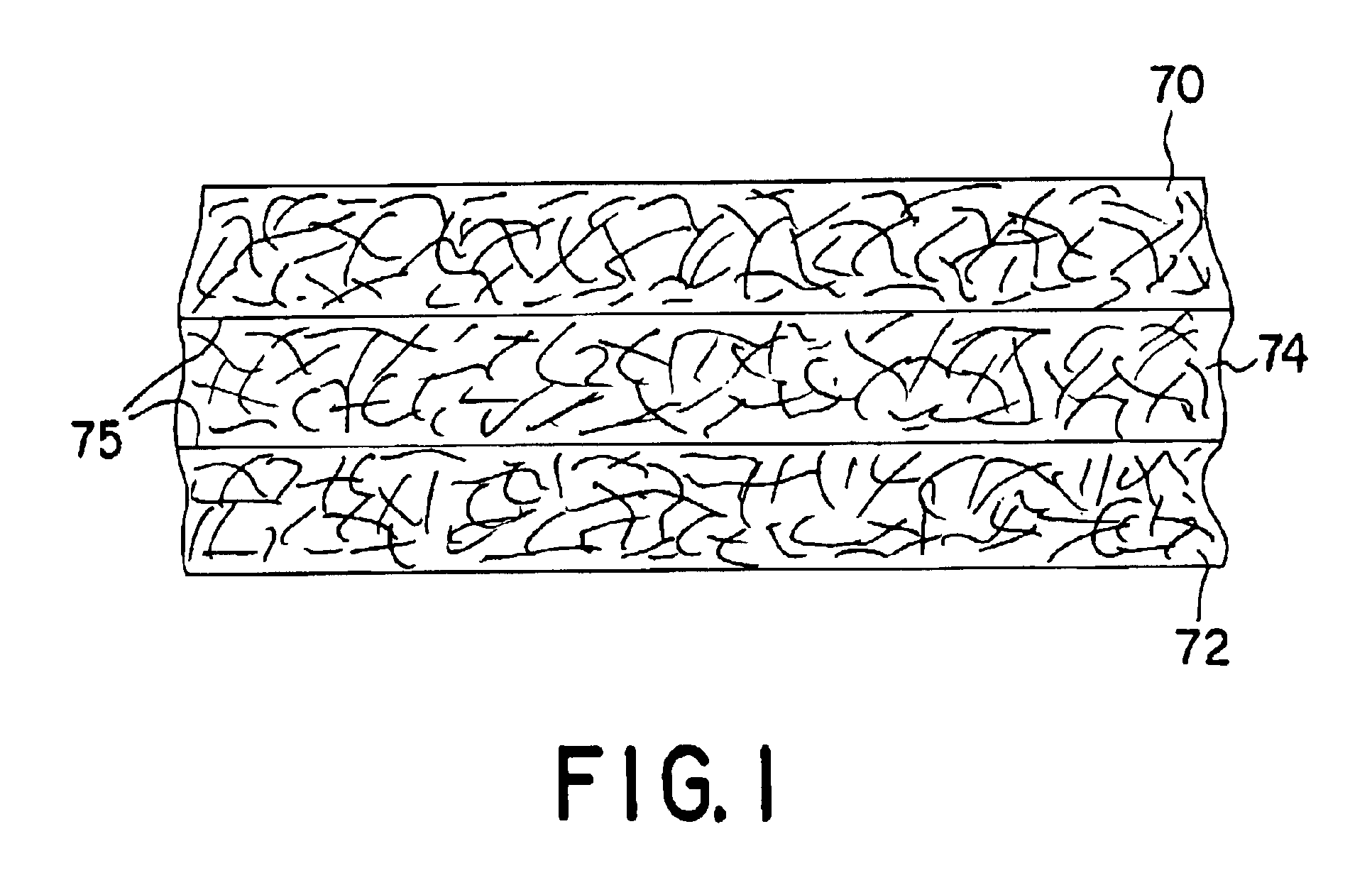

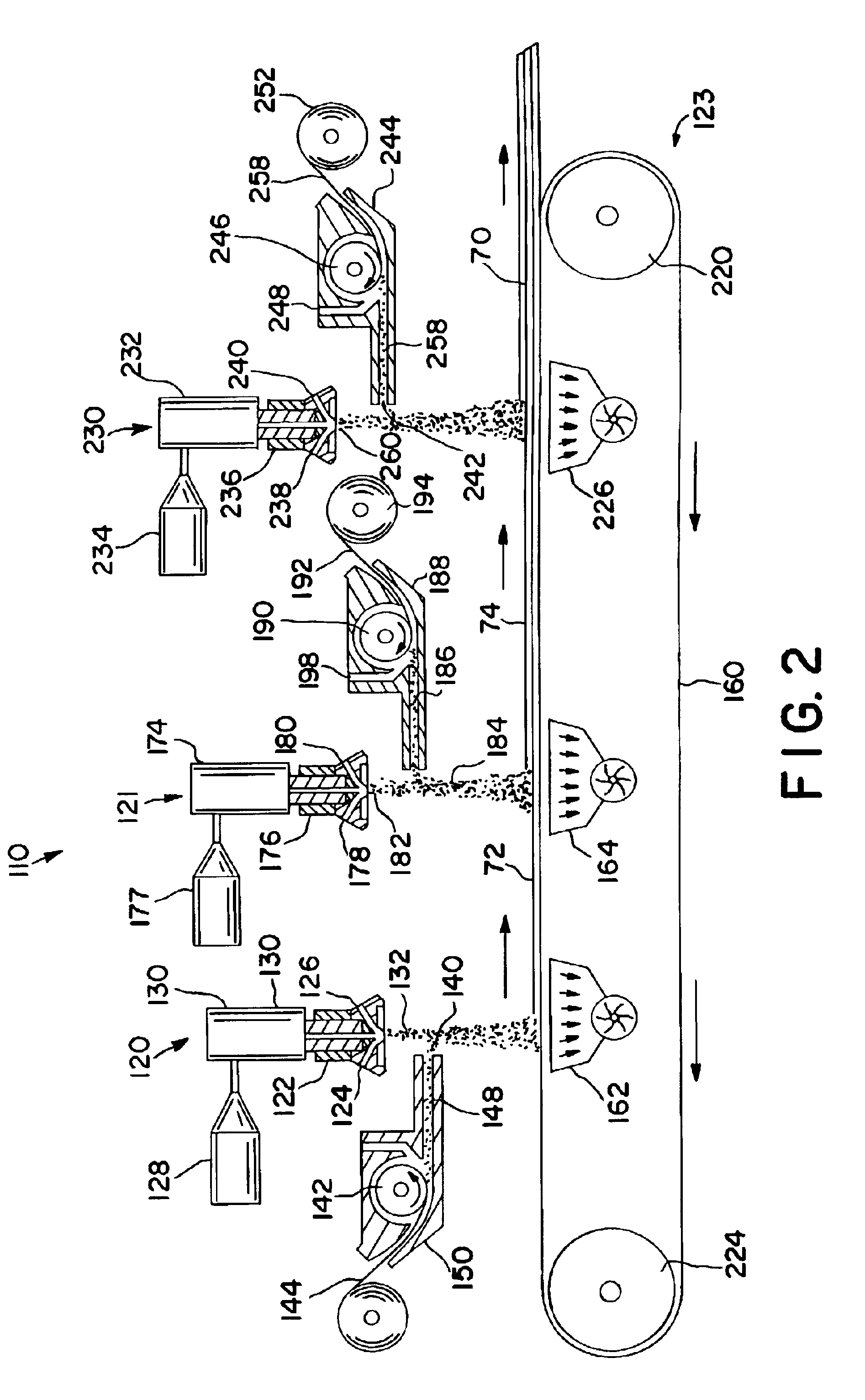

Method of forming composite absorbent members

InactiveUS6932929B2High weight percentageSmall diameterCrochetingInspecting textilesFiberEngineering

A method for forming a composite absorbent member is provided that includes:a) extruding a first fibrous component through a first meltblowing die and intermingling pulp fibers with the first fibrous component to form a first admixture;b) extruding a second fibrous component through a second meltblowing die and intermingling pulp fibers with the second fibrous component to form a second admixture; andc) codepositing the first and second admixtures on a collecting surface so as to form a composite structure having at least a first layer and a second layer. The second layer has a higher weight percentage of pulp fibers than the first layer, and the average diameter of the pores within the second layer is smaller than the average diameter of the pores within the first layer.

Owner:KIMBERLY-CLARK WORLDWIDE INC

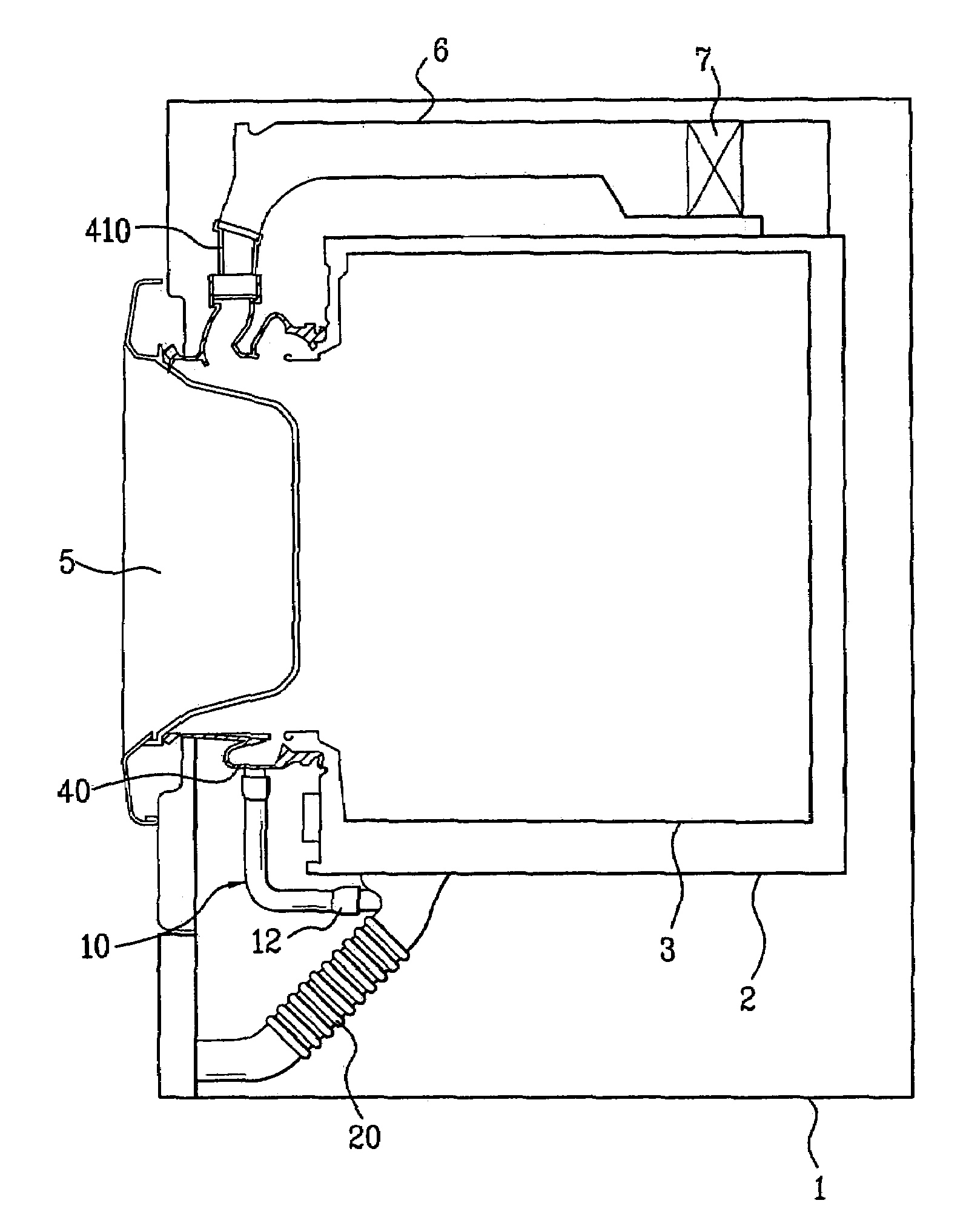

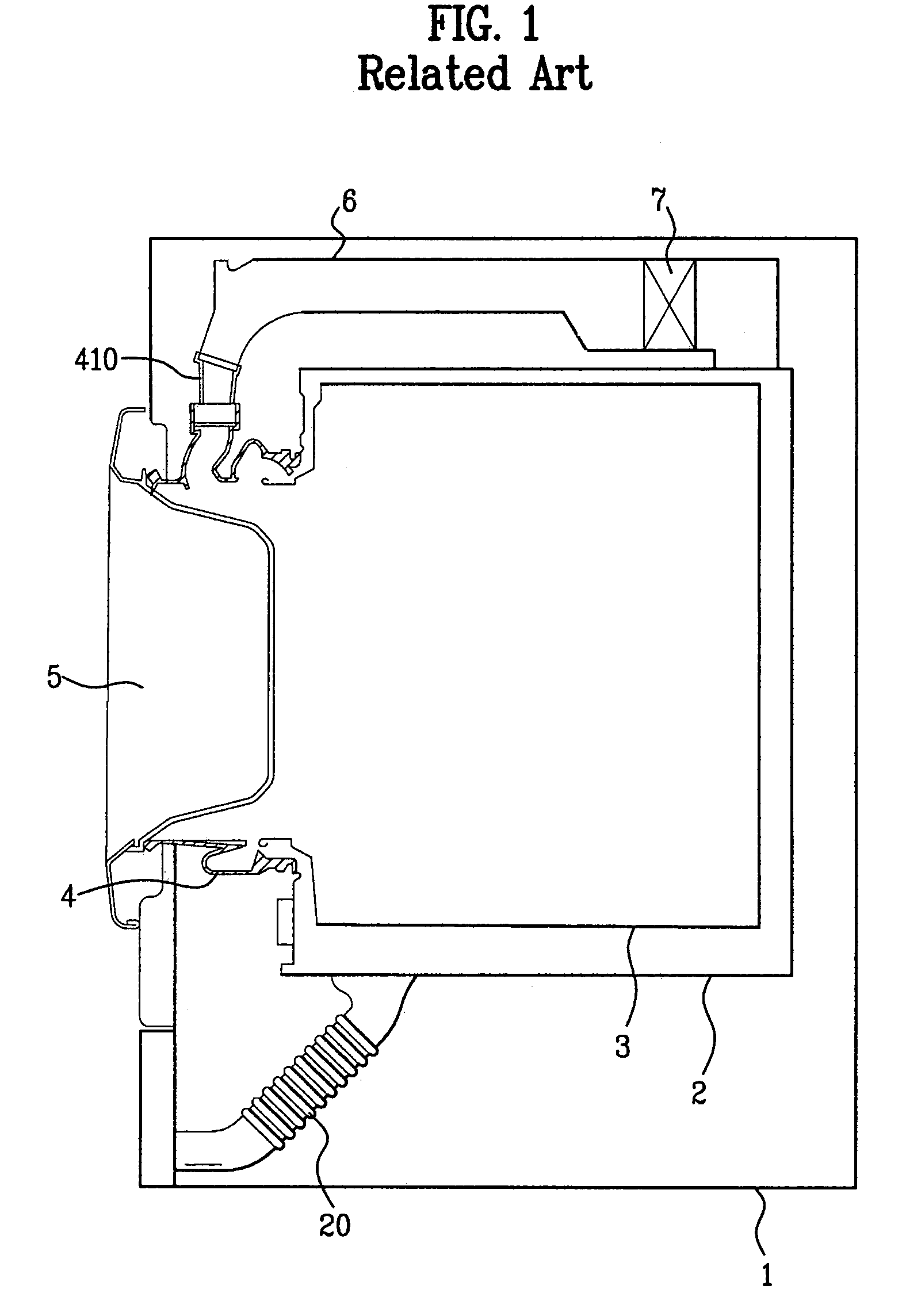

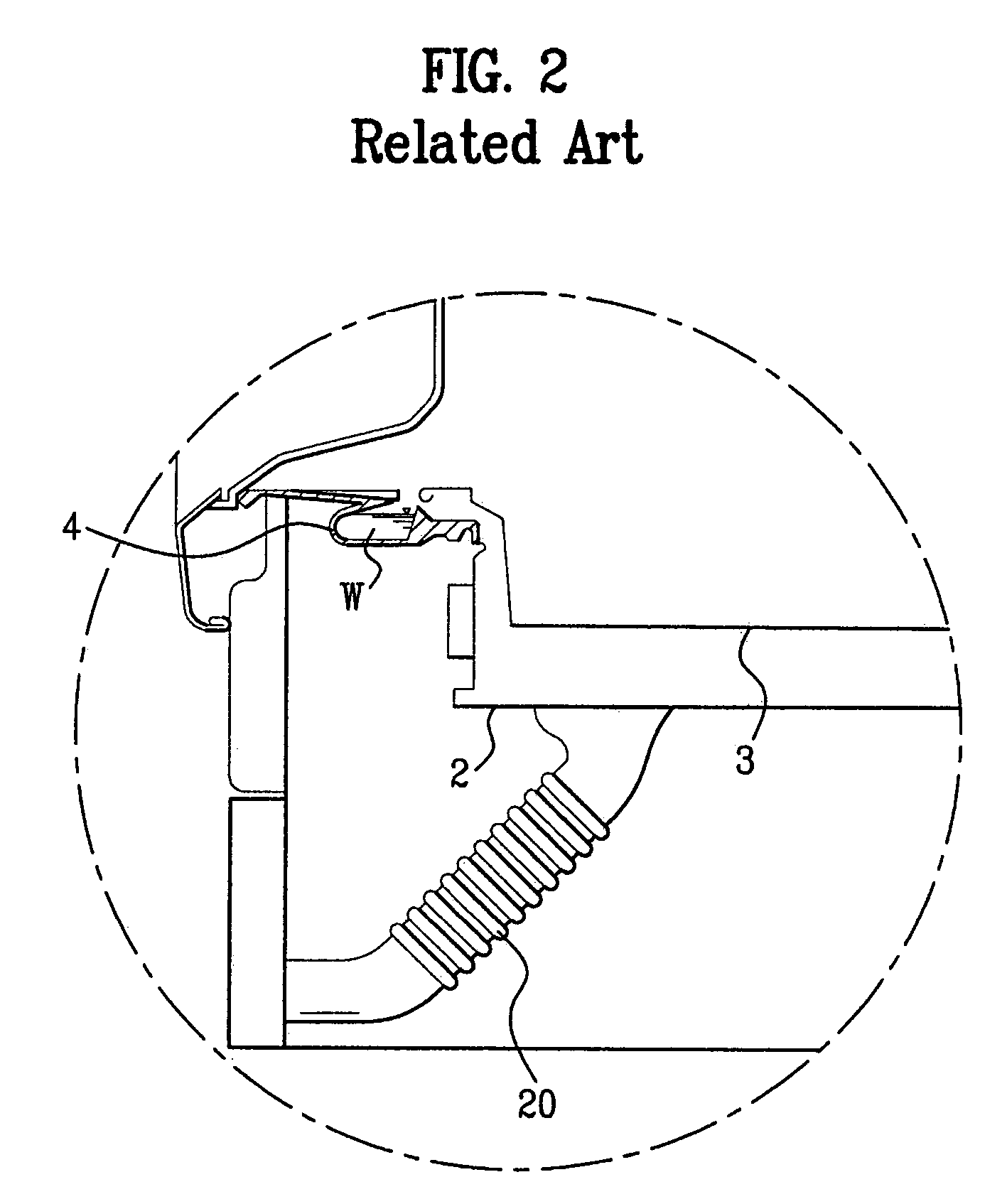

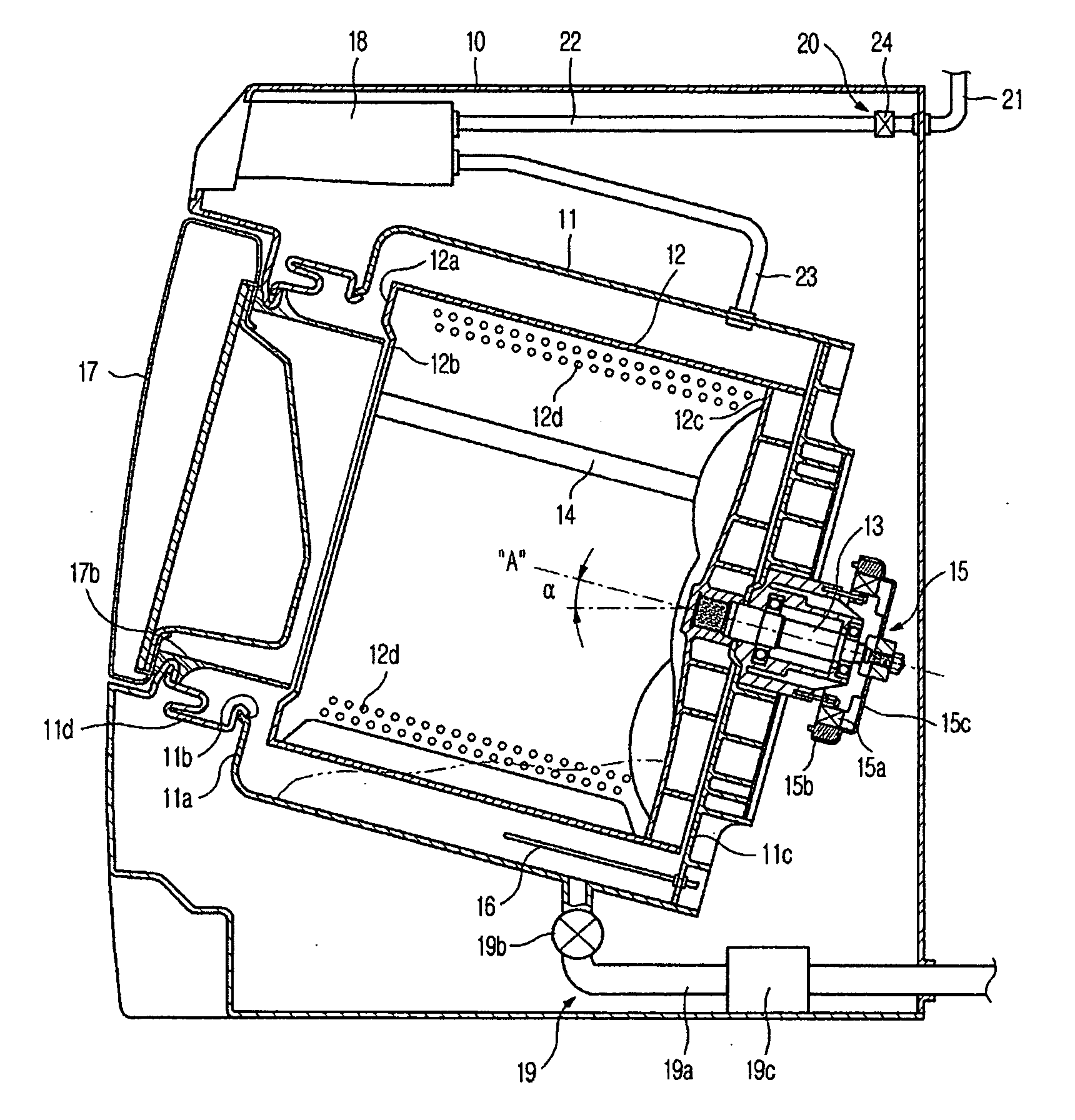

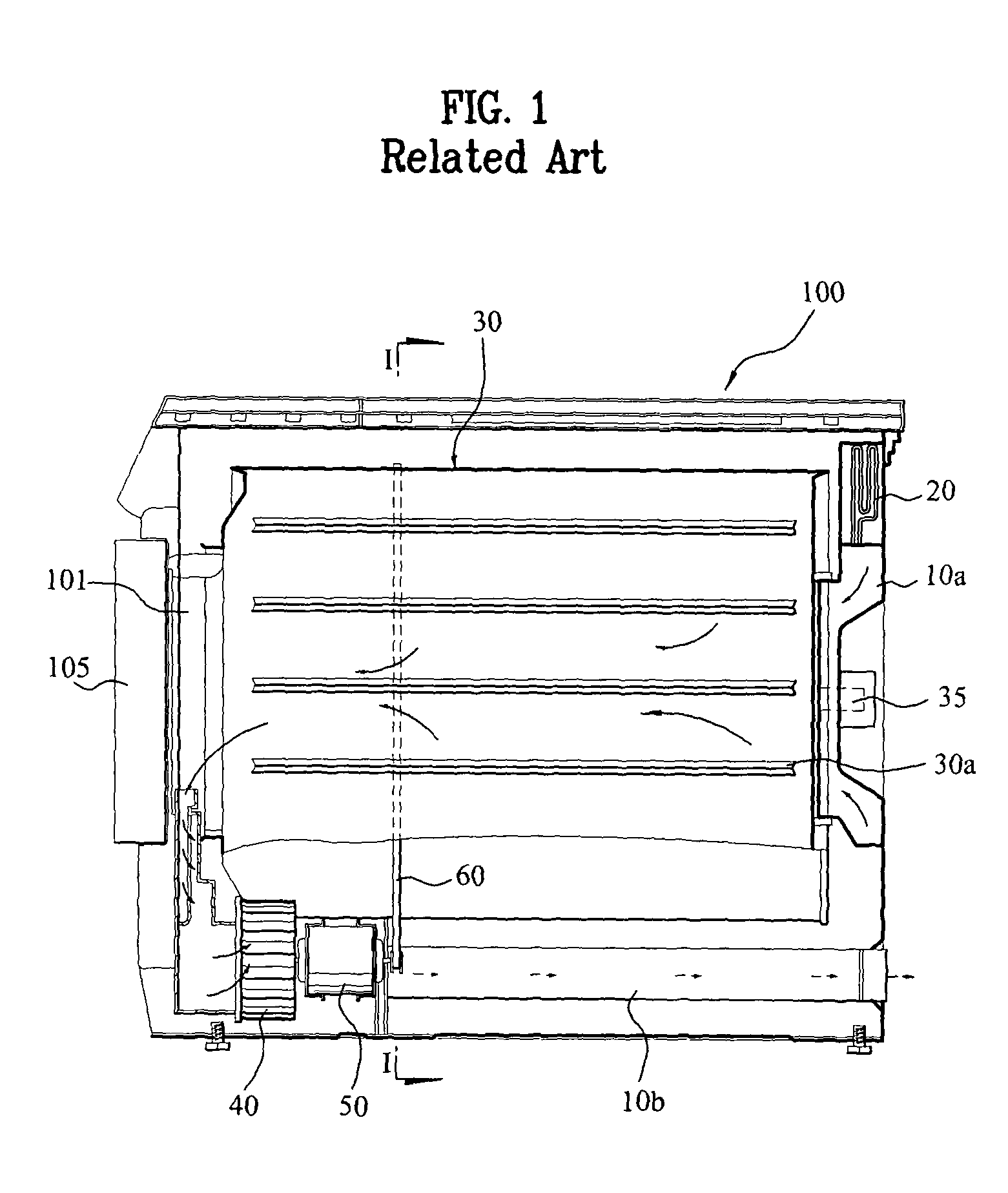

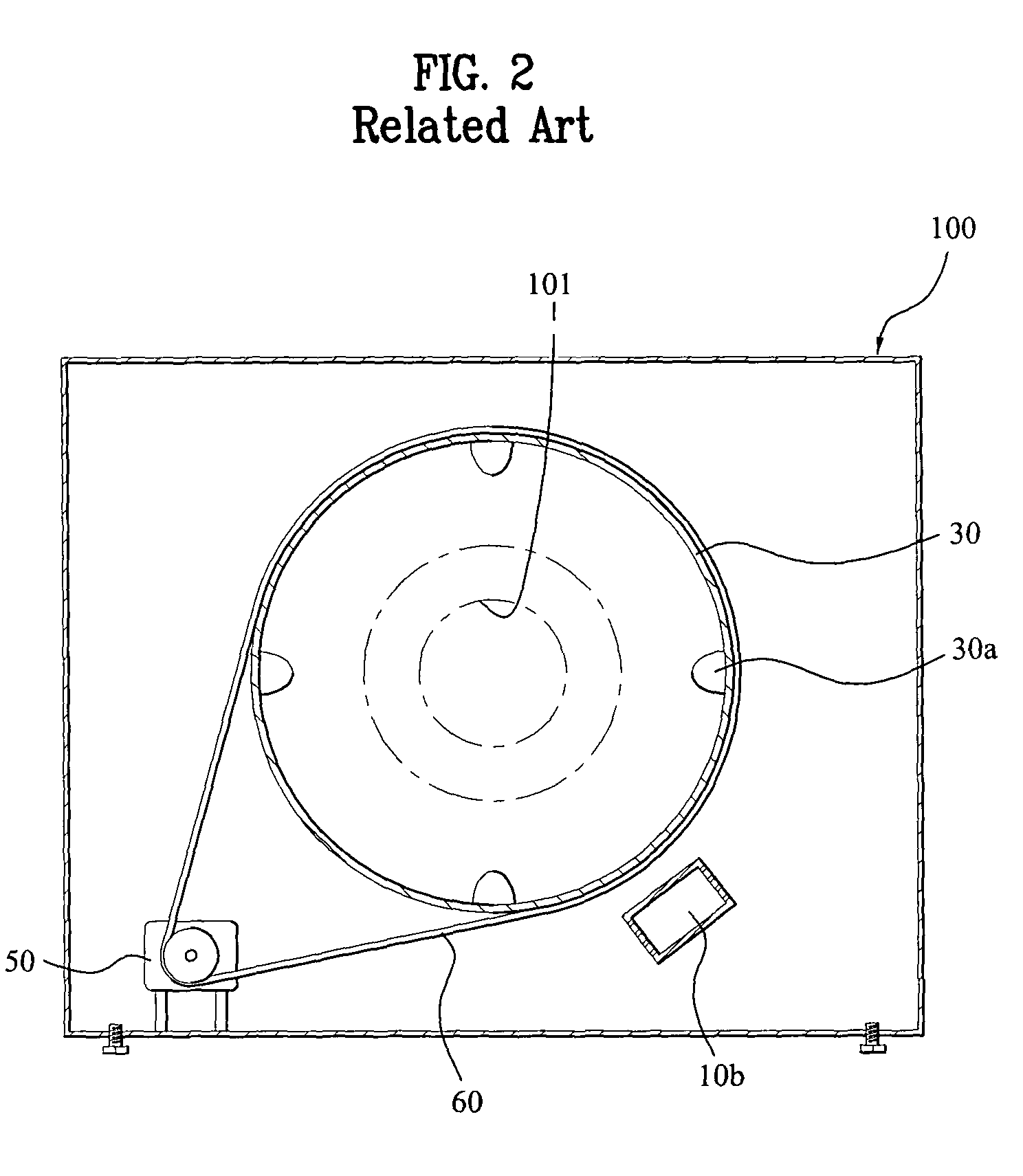

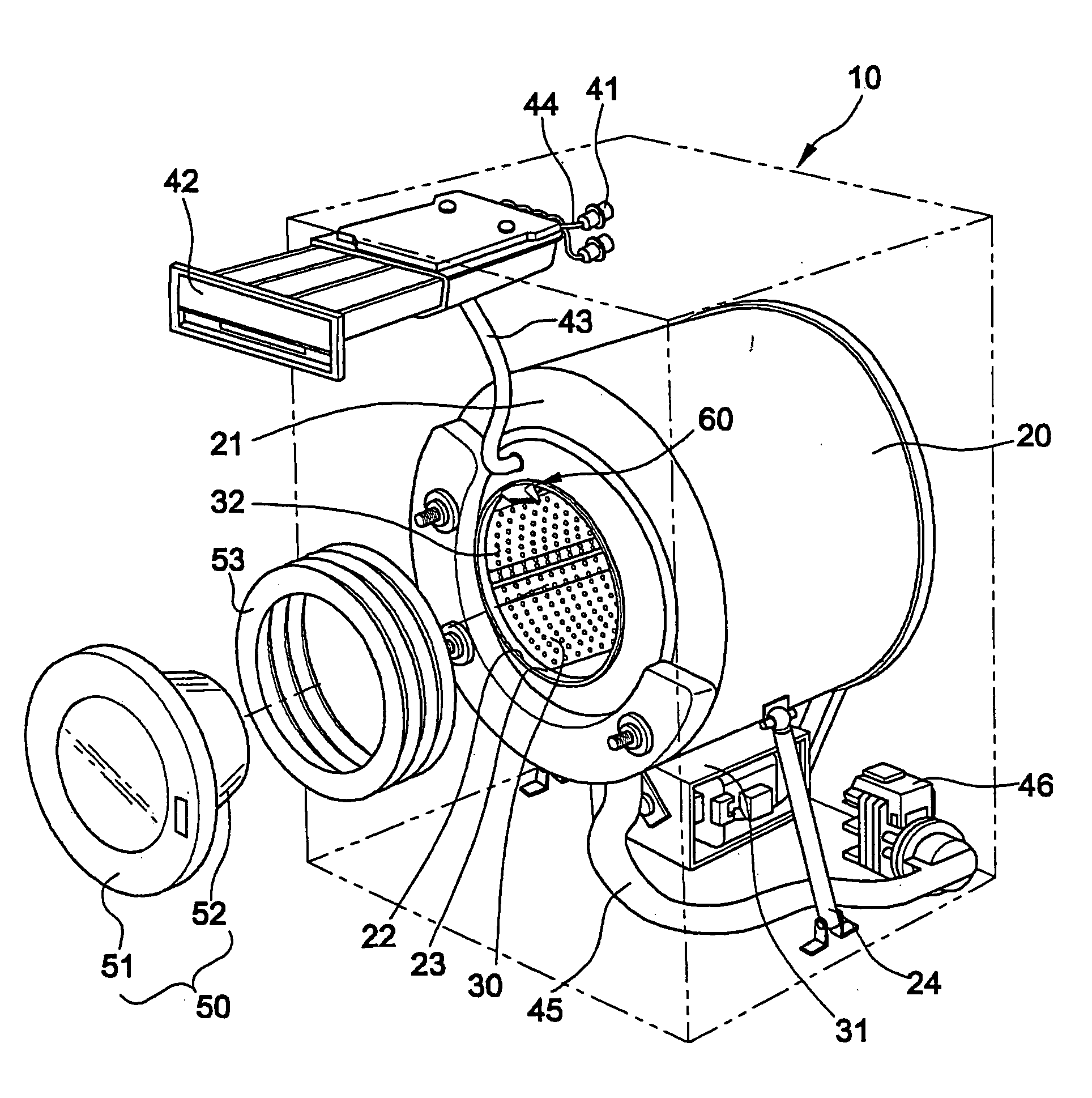

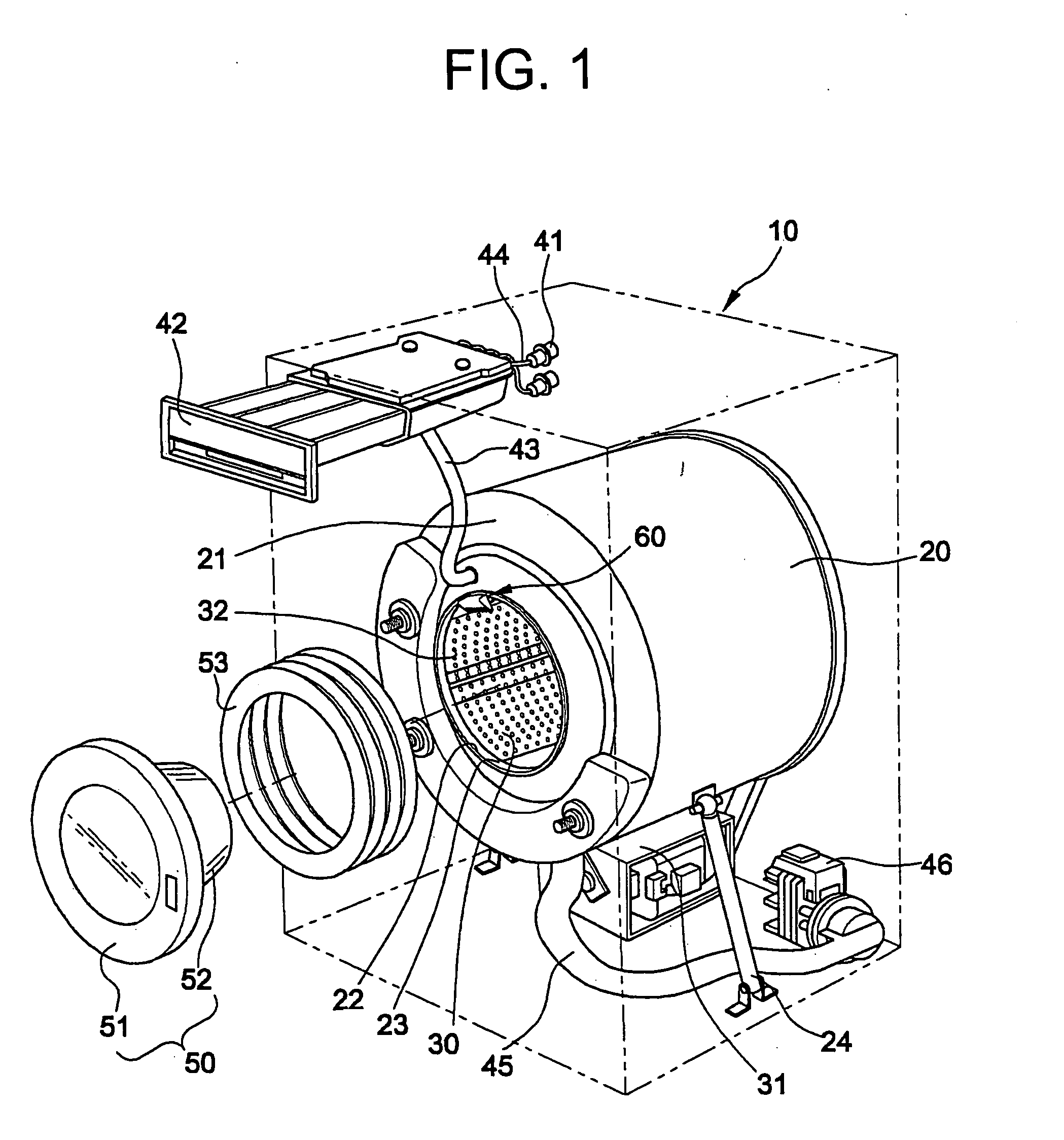

Drum-type washing machine

ActiveUS7251963B2Prevent leakageAvoid water pollutionOther washing machinesWashing machine with receptaclesWaste managementGasket

A drum-type washing machine employs a gasket water draining hose to enable used water to be discharged via the drainpipe, immediately following a washing or rinsing step. The drum-type washing machine includes a cabinet having a door; a tub for containing water, the tub having an entrance corresponding to the door of the cabinet; a gasket, connecting the door of the cabinet to the entrance of the tub, to prevent water contained in the tub from leaking outside the tub, the gasket having a first orifice provided at a bottom point thereof; a drainpipe, communicating with the tub, to discharge water contained in the tub, the drainpipe having a second orifice provided at one side thereof; and a water draining hose, communicating the first orifice with the second orifice, to discharge water via the drainpipe.

Owner:LG ELECTRONICS INC

Patterned textile product

A textile substrate is patterned by the selective application of various dyes to the substrate surface in a way that provides desirable, visually apparent enhancements in the area of pattern detail, definition, and color range, through the use of a novel patterning system, including the application of various chemical agents, that makes such enhancements possible. In one embodiment, the patterning system described herein is capable of producing pile-faced textile substrates, useful as floor coverings, that exhibit a unique combination of desirable pattern attributes that have been identified and measured using novel techniques specifically developed for these substrates and pattern attributes.

Owner:MILLIKEN & CO

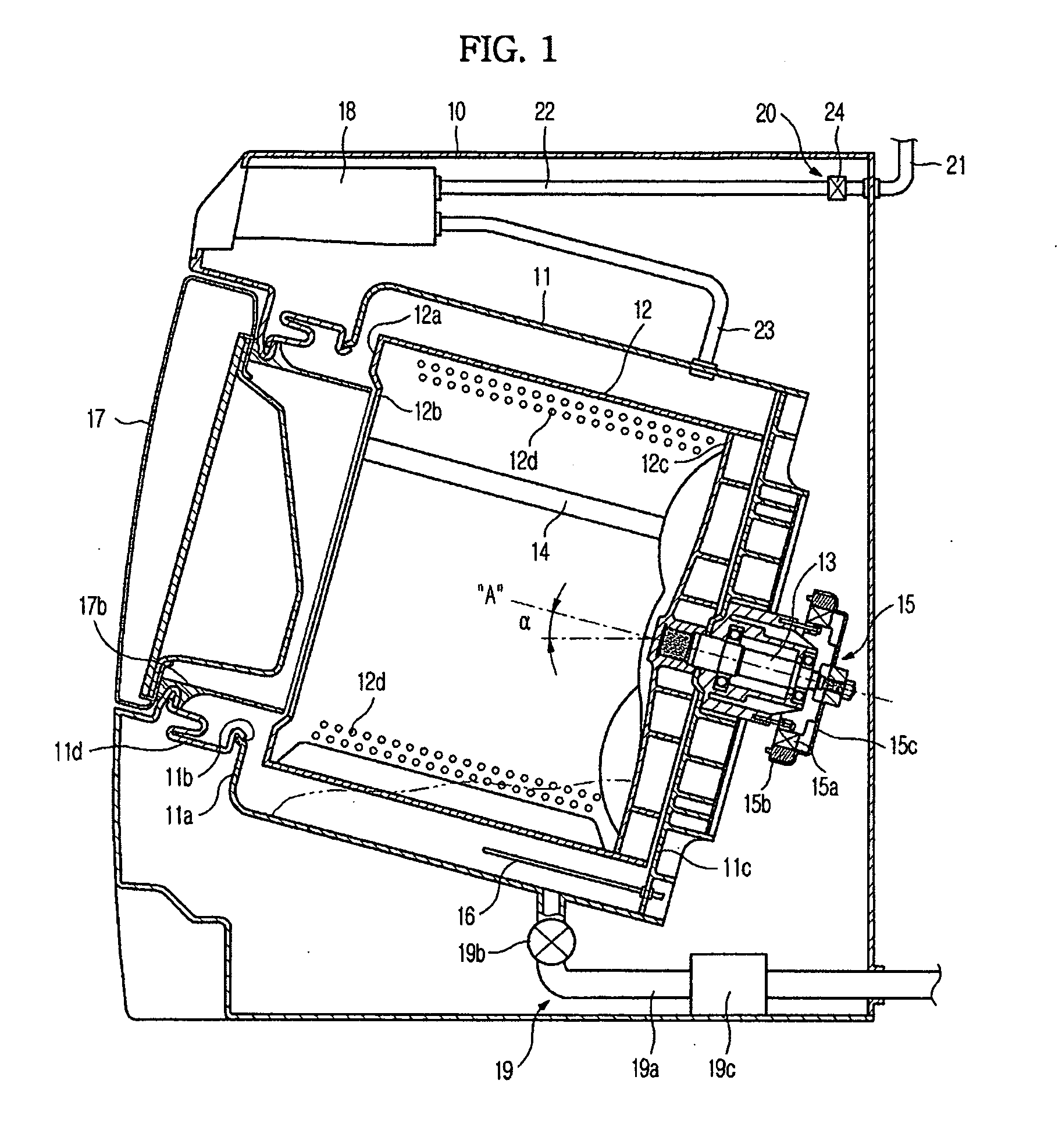

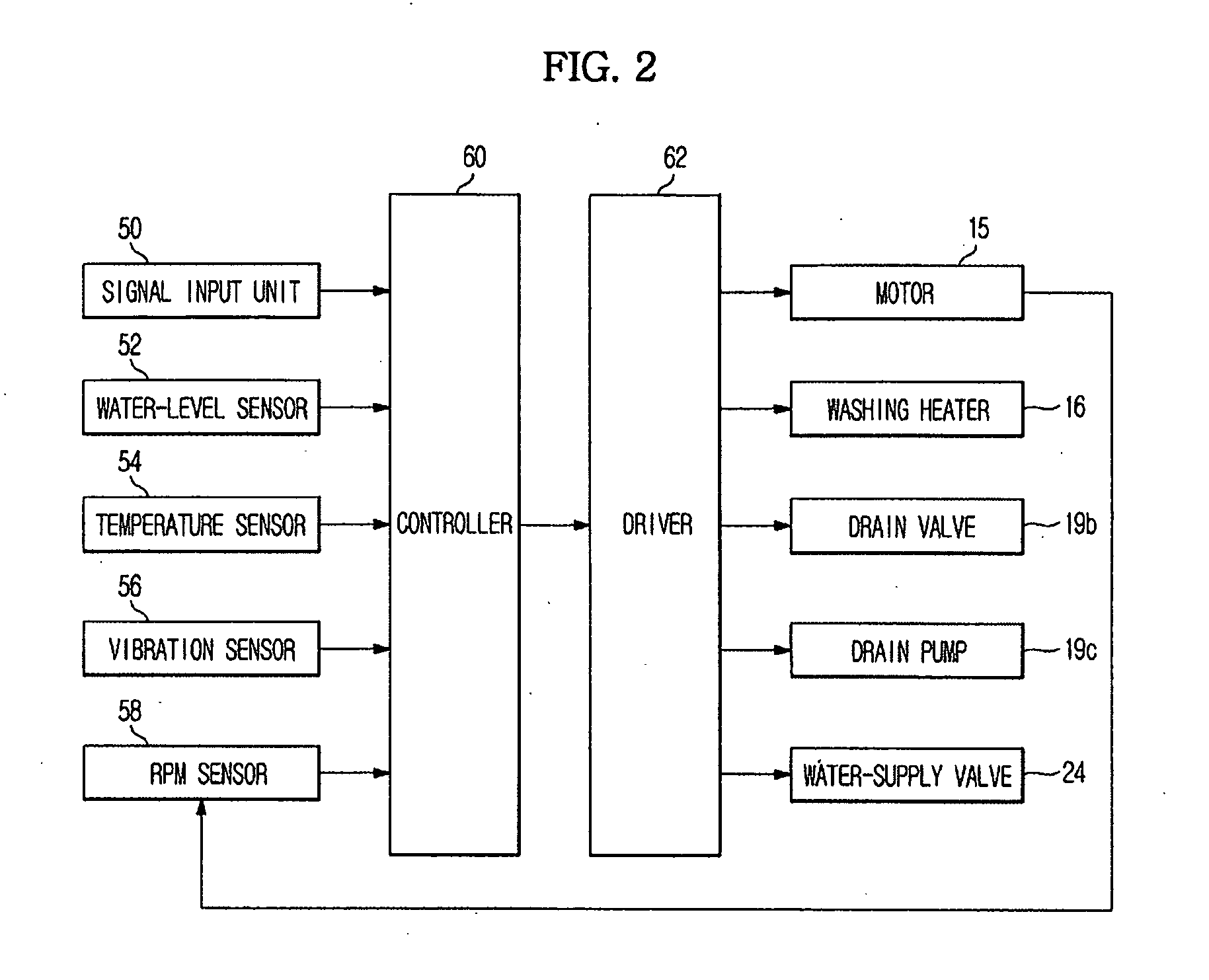

Washing machine and control method for disentangling clothes in the washing machine

ActiveUS20080222818A1Improve washing effectImprove performanceOther washing machinesControl devices for washing apparatusProcess engineeringAcceleration rate

A washing machine and a method of controlling a laundry disentangling process are disclosed, which uses a laundry disentangle pattern capable of stepwise increasing the motor rpm simultaneously while adjusting the acceleration rate of the motor. The method of controlling the laundry disentangling process in the washing machine, which includes a rotation drum containing laundry and a motor rotating the rotation drum to disentangle tangled laundry, includes stepwise-increasing an rpm of the motor, and adjusting a stepwise-acceleration rate of the motor, and performing the laundry disentangling process.

Owner:SAMSUNG ELECTRONICS CO LTD

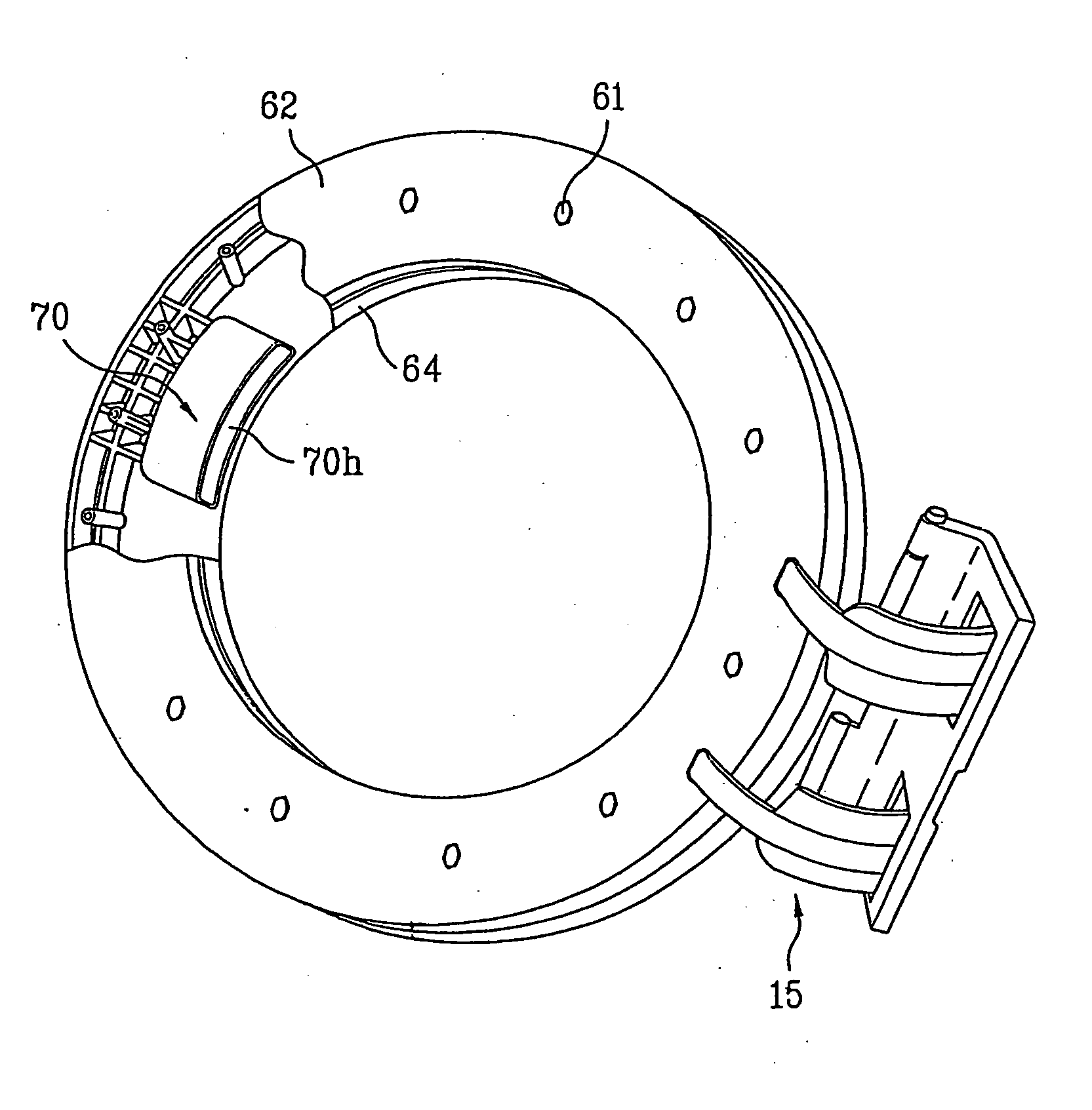

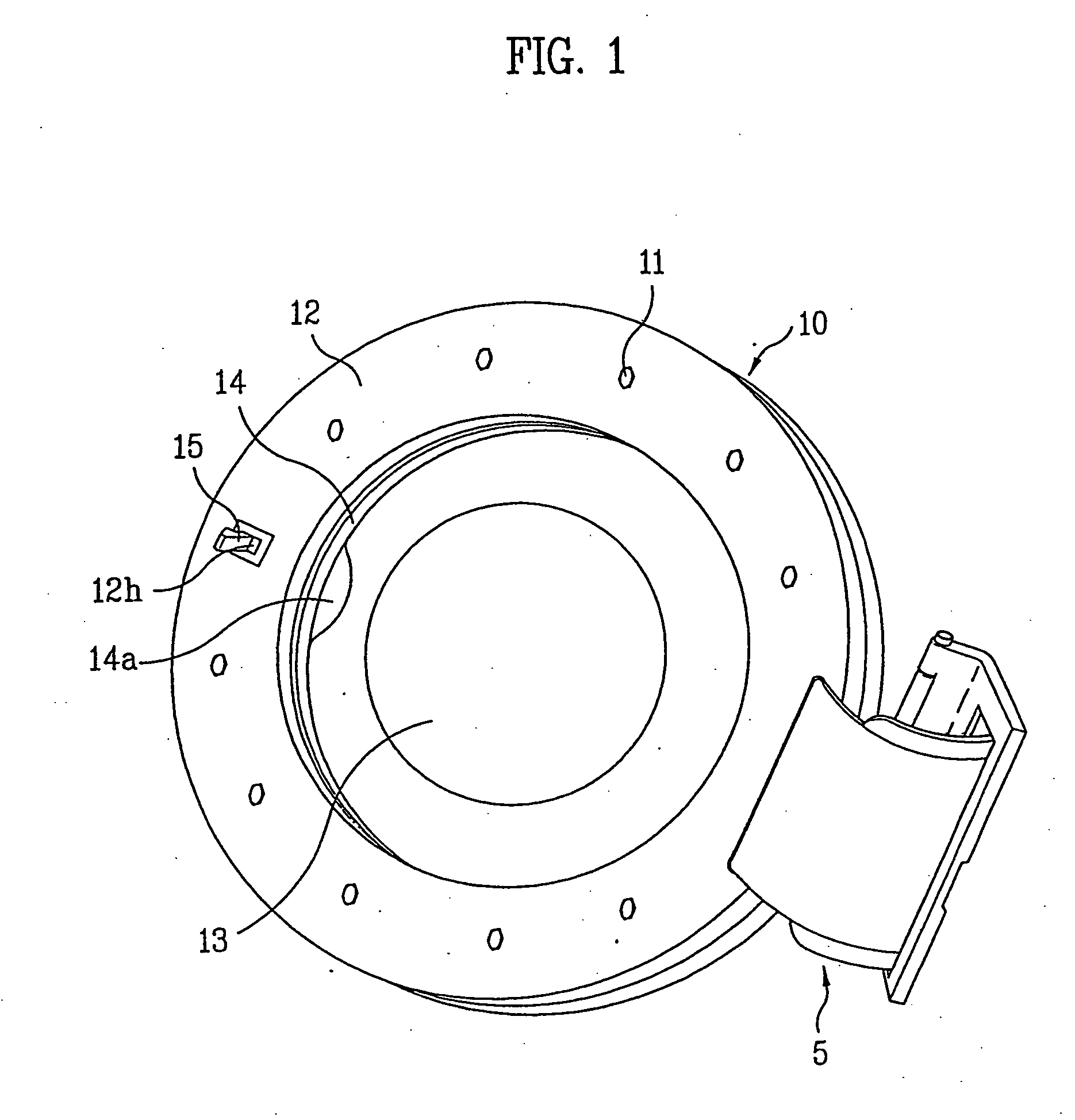

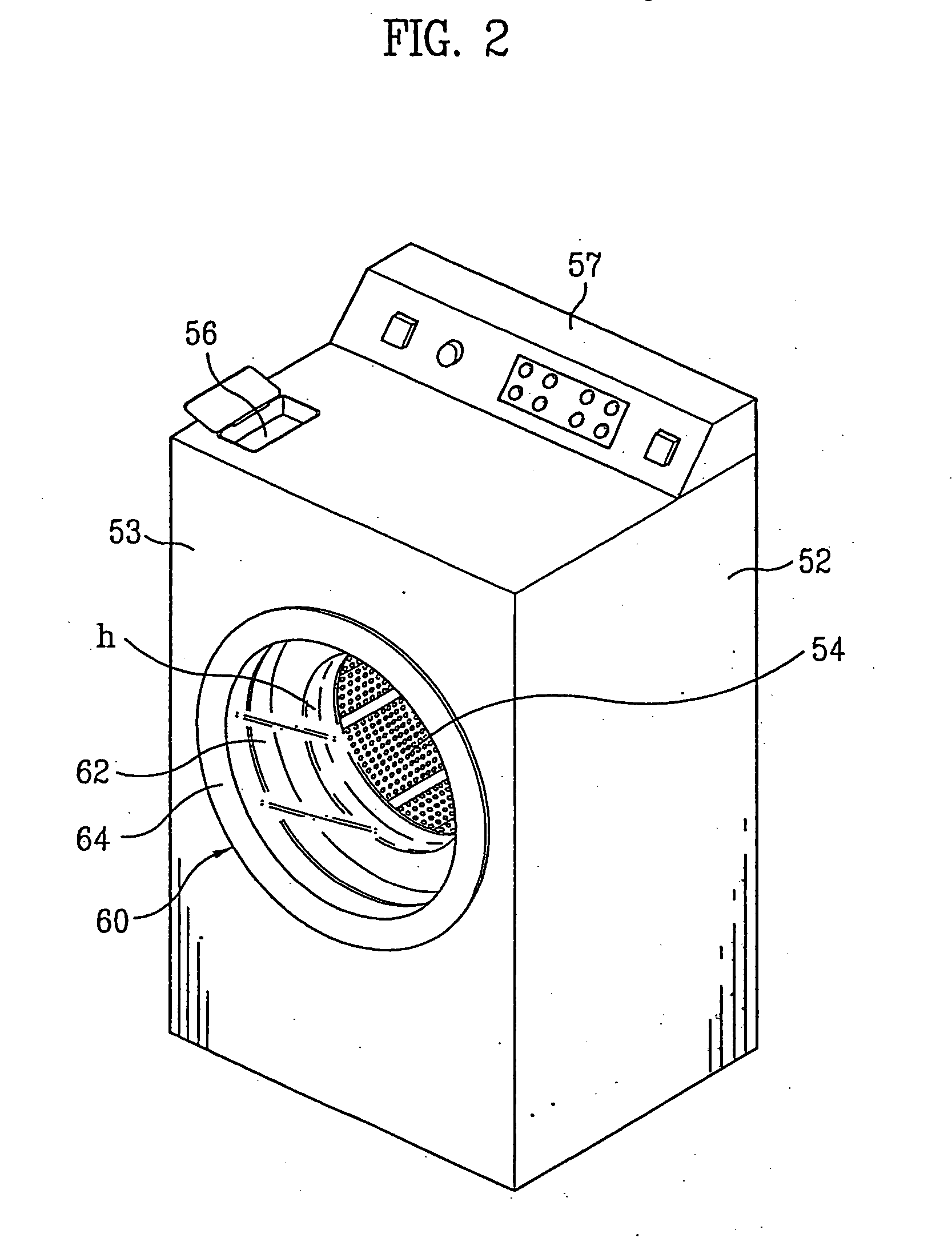

Door and a drum type washing machine and a clothes drier using the same

InactiveUS20060156767A1Good lookingSuction filtersHand rubbing apparatusEngineeringMechanical engineering

Owner:LG ELECTRONICS INC

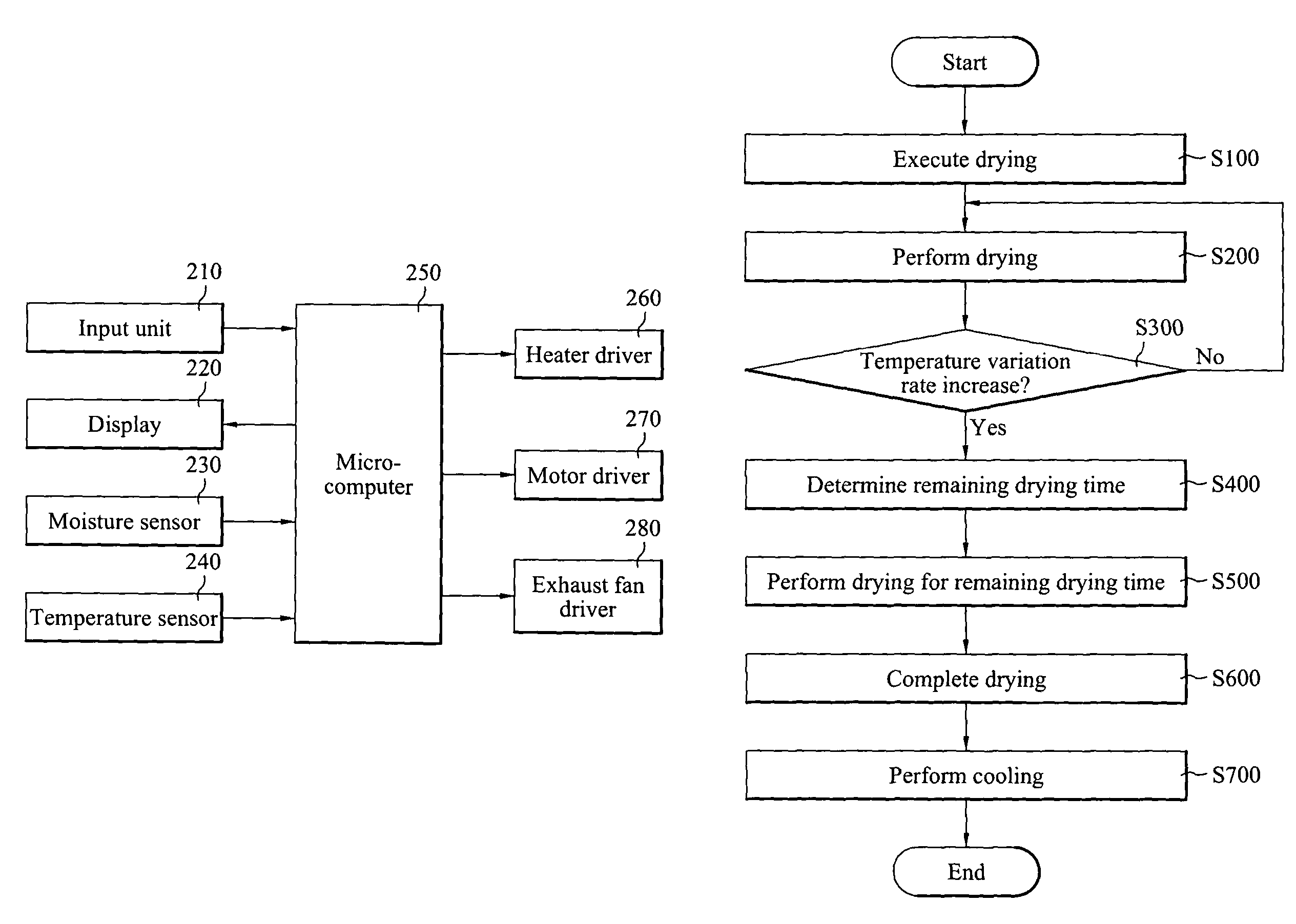

Laundry dryer control method

InactiveUS7941937B2Improved drier operationEnsure correct executionDrying using combination processesDrying solid materials with heatProcess engineeringDrying time

A laundry drier control method reads a temperature variation rate per unit time, to enable drying according to the amount and type of an object being dried. The method includes steps of initiating a drying procedure; measuring a temperature variation rate per unit time over the drying procedure; calculating an overall drying time based on the measured temperature variation rate per unit time; and performing the drying procedure for the calculated overall drying time. The drying time determining step is repeated if a substantial increase in the temperature variation rate is detected.

Owner:LG ELECTRONICS INC

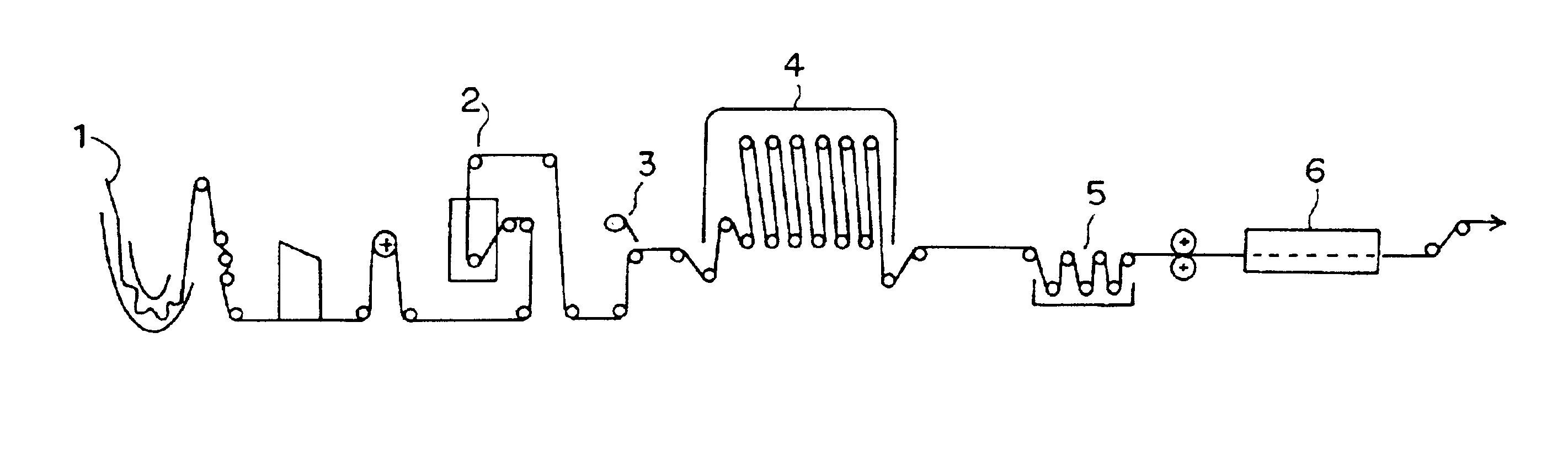

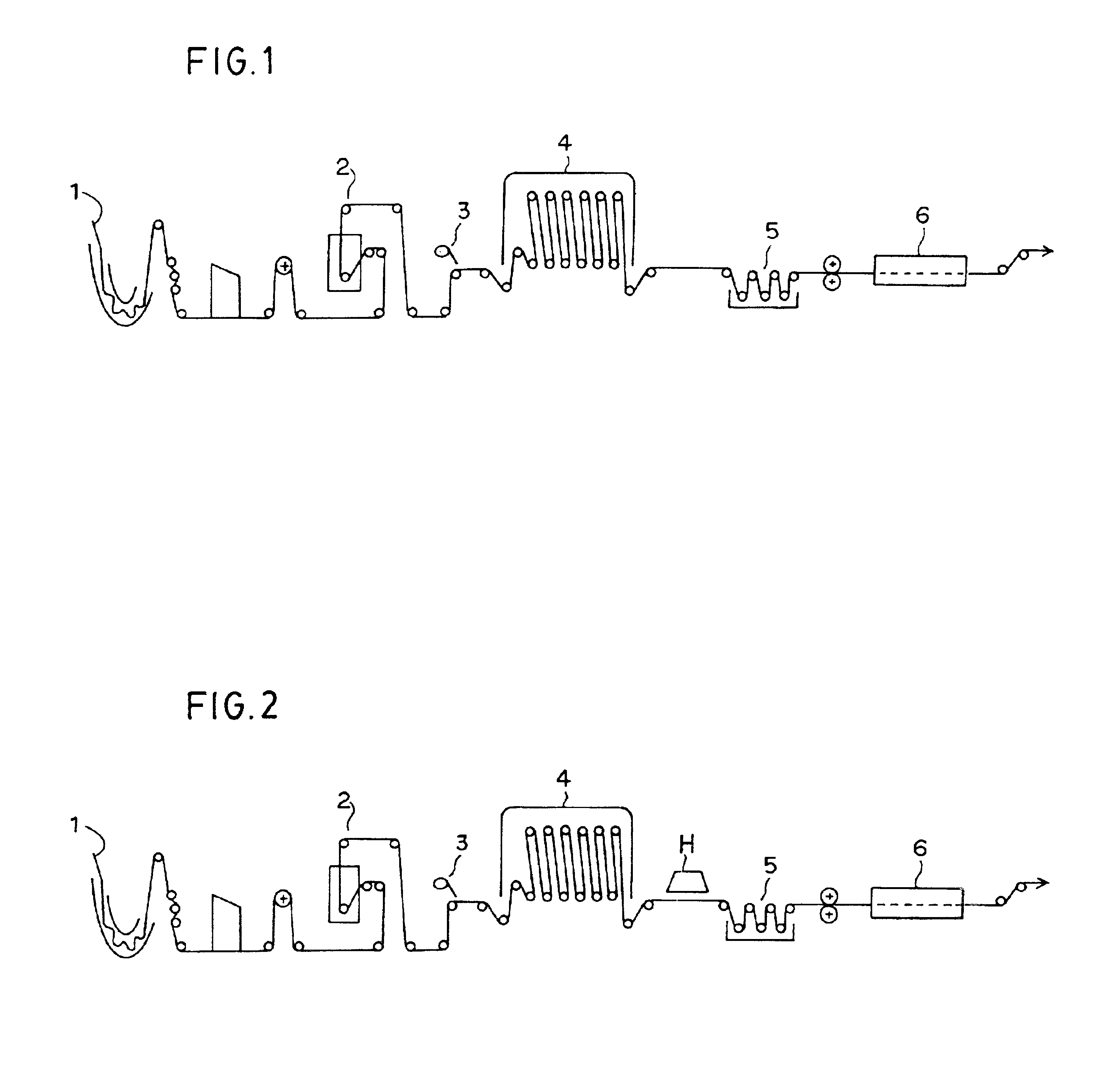

Process for dyeing poly (trimethylene terephthalate) carpet continuously

InactiveUS6836915B2Minimize the differenceAvoid frostFibre treatmentOrganic dyesPolyethylene terephthalateDry heat

In the process for continuously dyeing a poly(trimethylene terephthalate) bulked continuous filament yarn carpet an aqueous dyeing solution is applied to a continuously moving poly(trlmethylene terephthalate) bulked continuous filament yarn carpet at a temperature of 45° C. to 100° C., and then the poly(trimethylene terephthalate) bulked continuous filament yam carpet is steamed, rinsed and dried. Before applying the aqueous dyeing solution the carpet is heat-set at 120 to 150° C. The carpet is steamed with saturated steam at 102 to 150° C. for 5 to 10 mm. The aqueous dyeing solution does not include an anti-frosting agent. The process also advantageously includes heating the carpet with a dry heat of 140 to 300° C. for 30 to 60 sec after steaming the carpet and before rinsing it.

Owner:HYOSUNG CORP

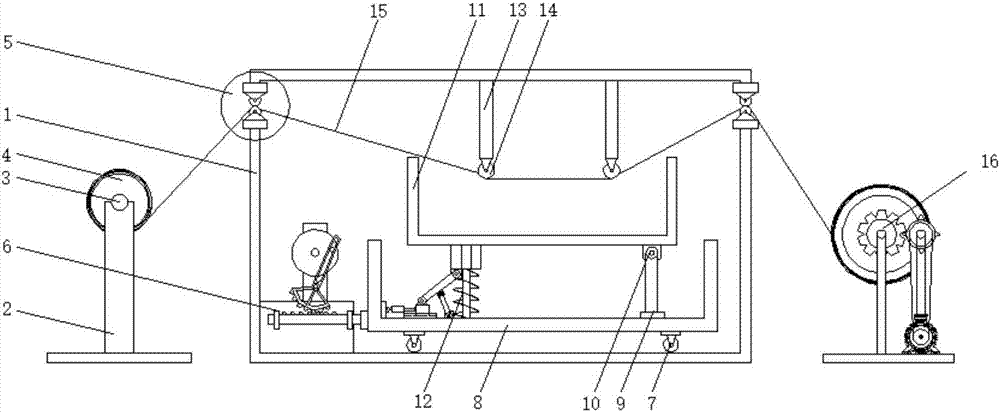

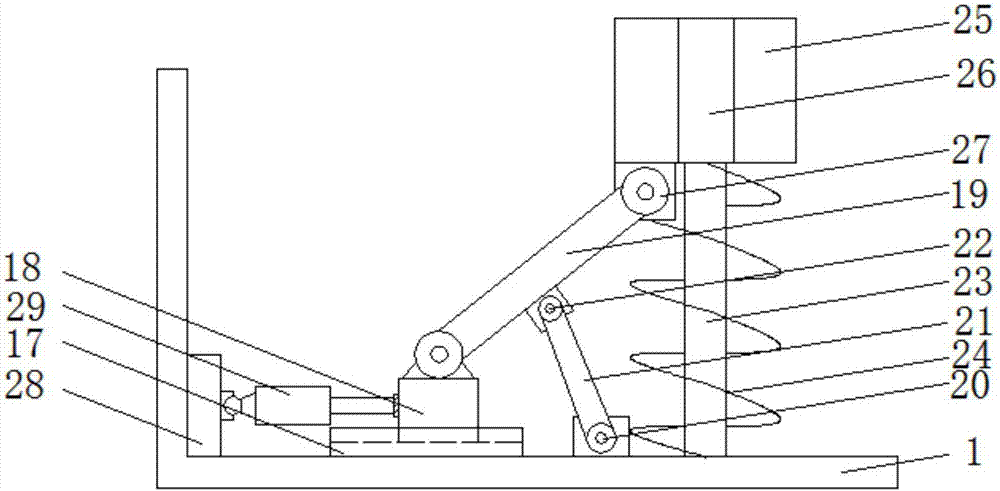

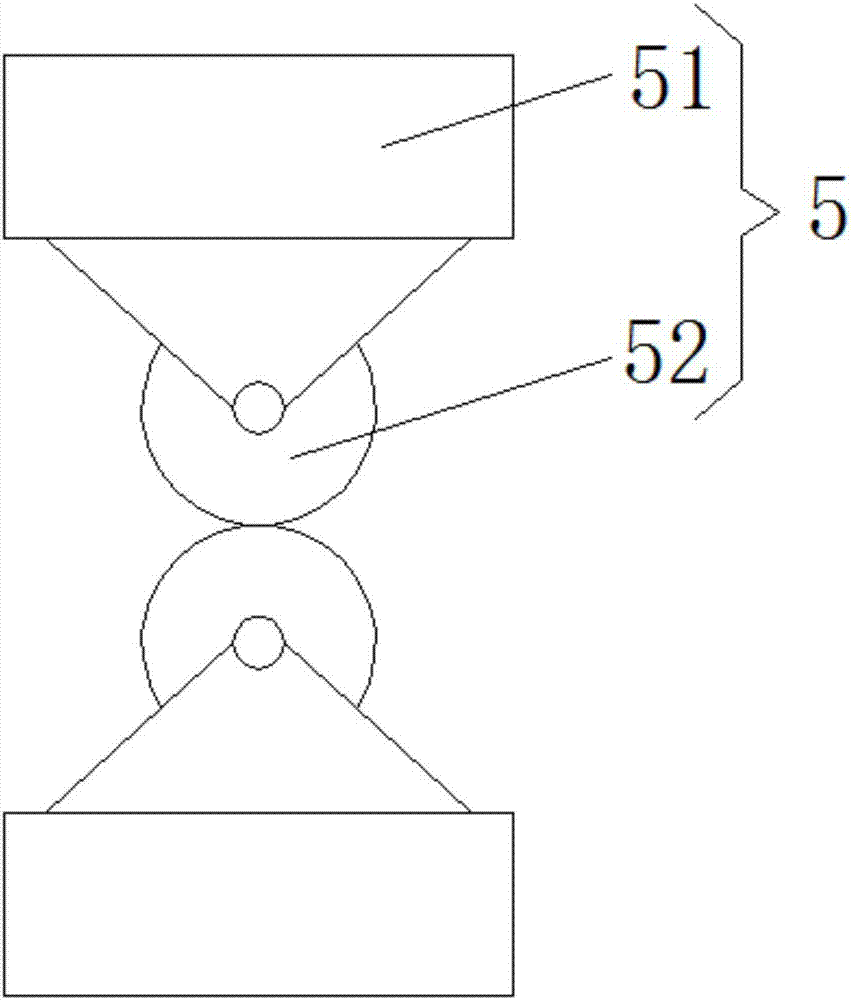

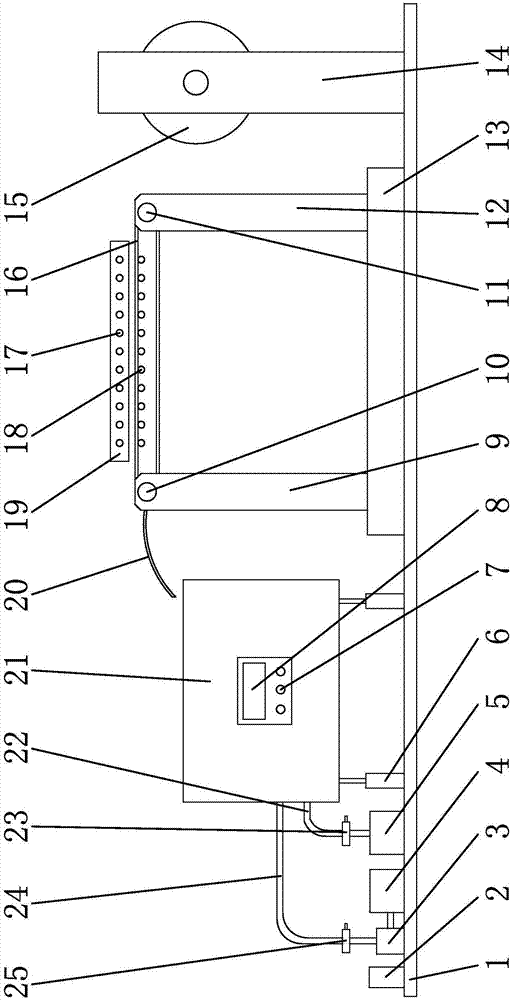

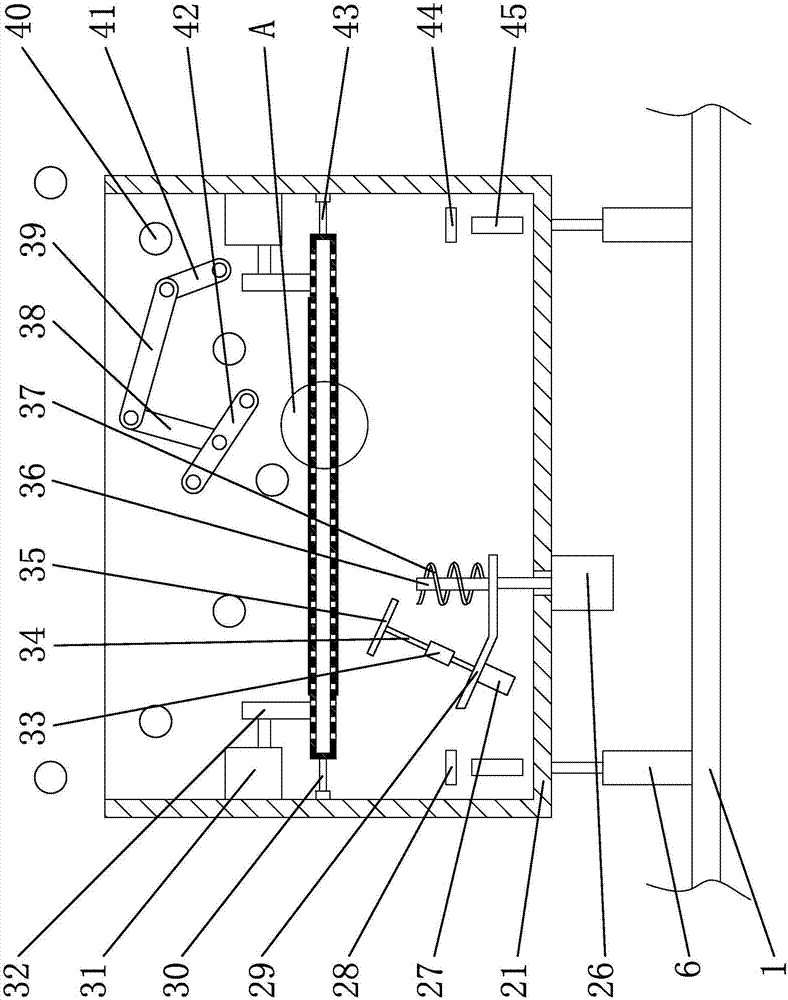

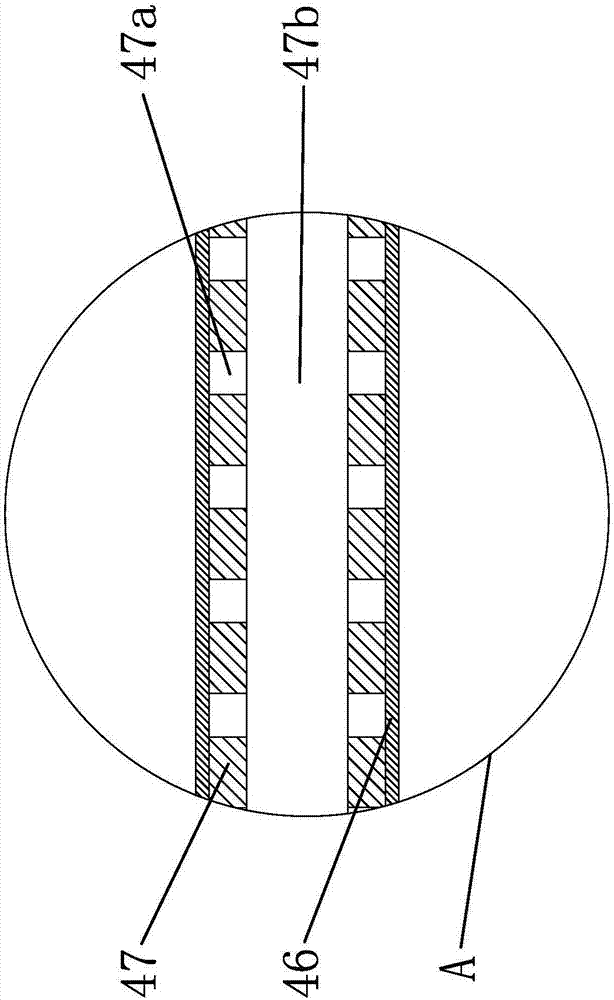

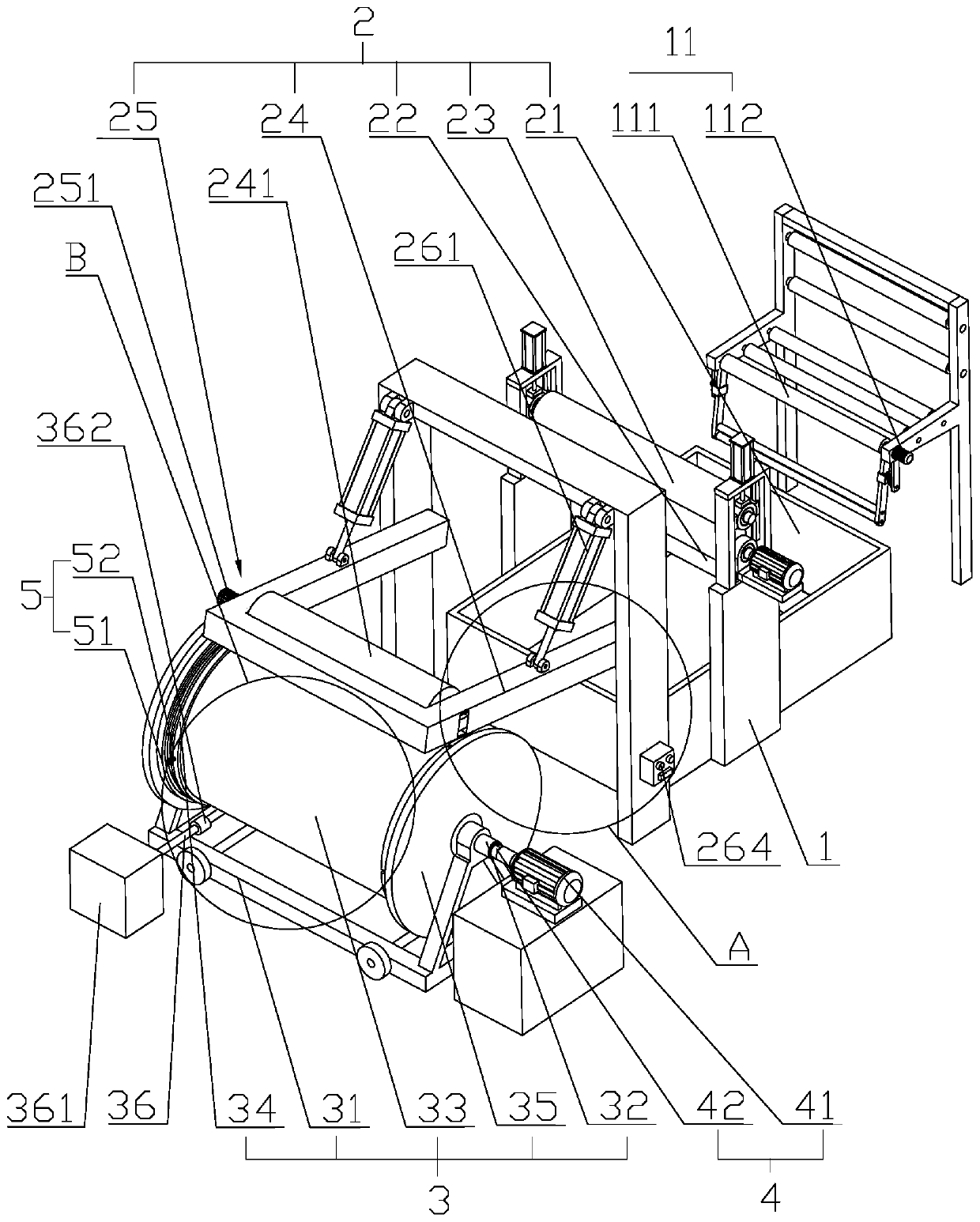

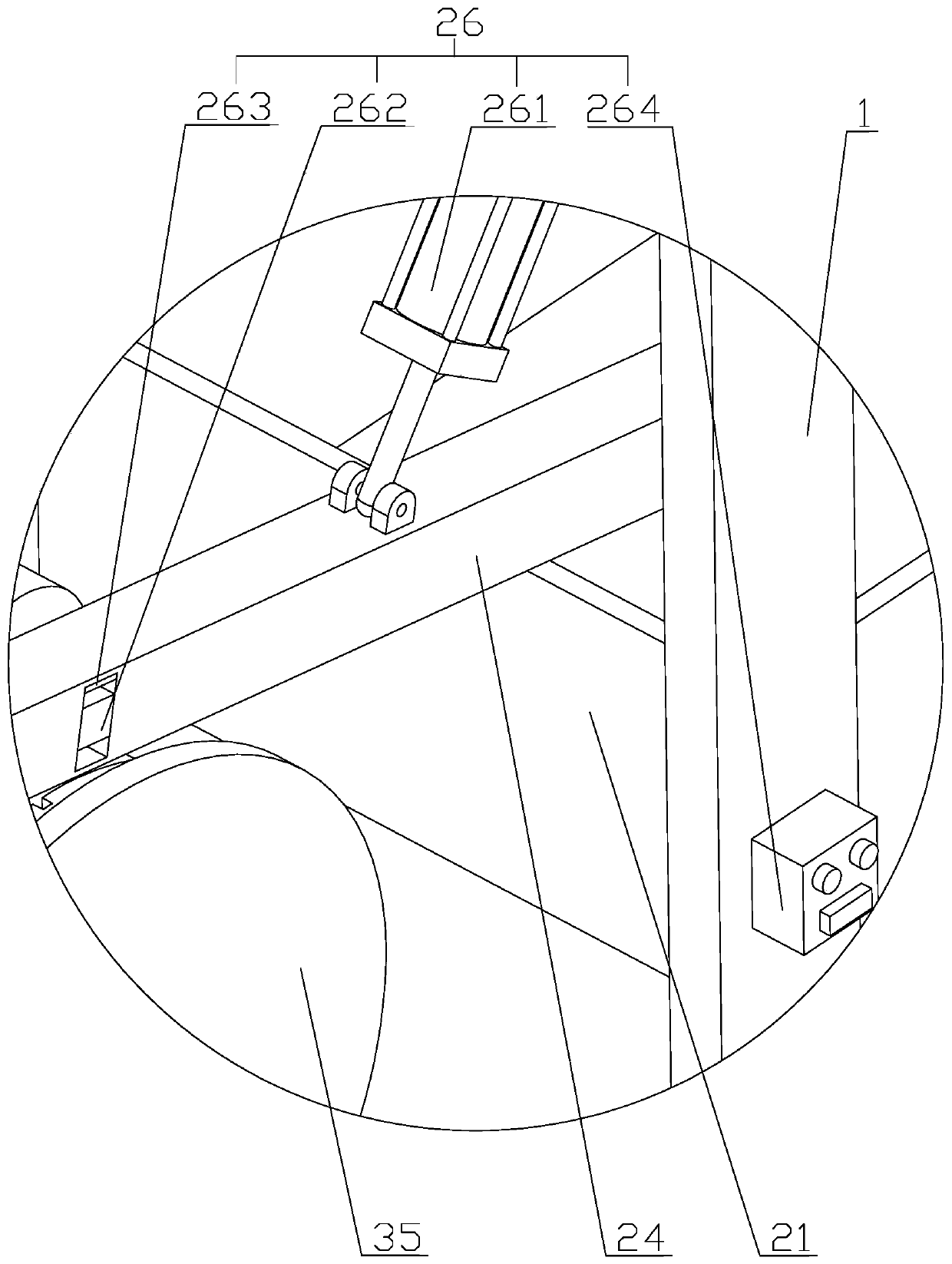

Quick dyeing device for textile fabric

InactiveCN107401013ADyeing speed is fastEnough timeLiquid/gas/vapor treatment machines driving mechanismsTextile treatment carriersEngineeringDyeing

The invention discloses a quick dyeing device for a textile fabric. The quick dyeing device comprises an external frame. Textile fabric spacing devices are symmetrically arranged on two sides of the outer wall of the external frame; a shake device is fixedly connected to the bottom end of the interior of the external frame; the bottom end of the interior of the external frame and a place on the right side of the shake device is fixedly connected with a shake frame via shake wheels; a dyeing tank is fixedly connected to the top end of a supporting leg via a first fixed rotation block; a movable device is fixedly connected to on the bottom of the dyeing tank and on the left side of the supporting leg; two hanging rods are symmetrically fixed on the top end of the interior of the external frame; dyeing baffle wheels are rotationally connected to the bottom end of the hanging rods; and a textile fabric winding device is arranged on the right side of the outer of the external frame. The quick dyeing device for the textile fabric relates to the technical field of textile equipment machinery. Problems of low dyeing efficiency, great time consumption, uneven dyeing and resource waste of a textile fabric dyeing device in the prior art can be solved; and dyeing efficiency and quality can be improved.

Owner:HUZHOU BOREN TEXTILES

Fabric system

ActiveUS20160017521A1Suitable for useReduce harmCrochetingOrnamental textile articlesMedicinePolyurethane

A composite yarn comprising one or more ultra-high molecular weight polyethylene fibres wrapped around one or more polyurethane-polyurea copolymer fibres.

Owner:GRT DEV PTY +1

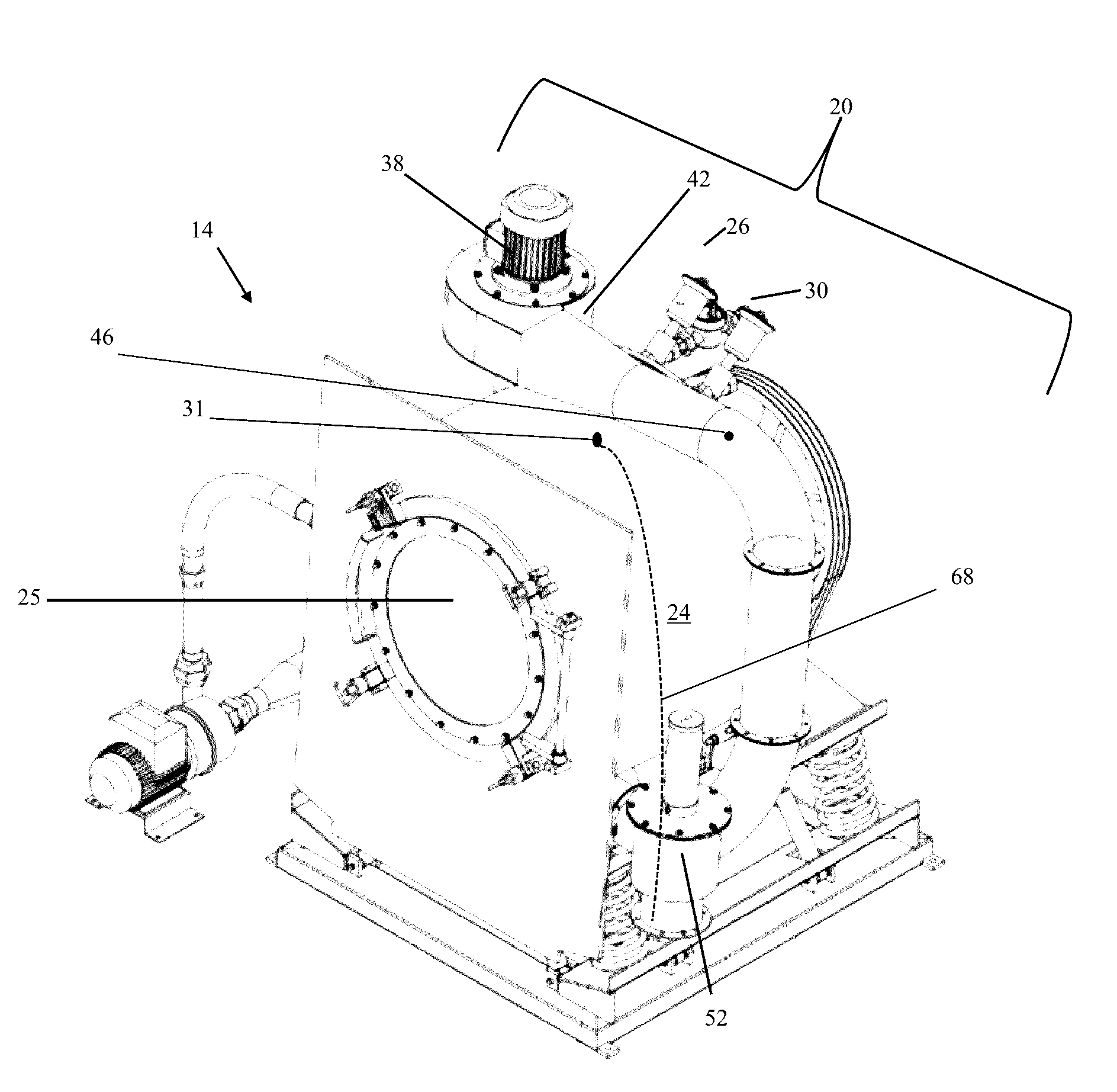

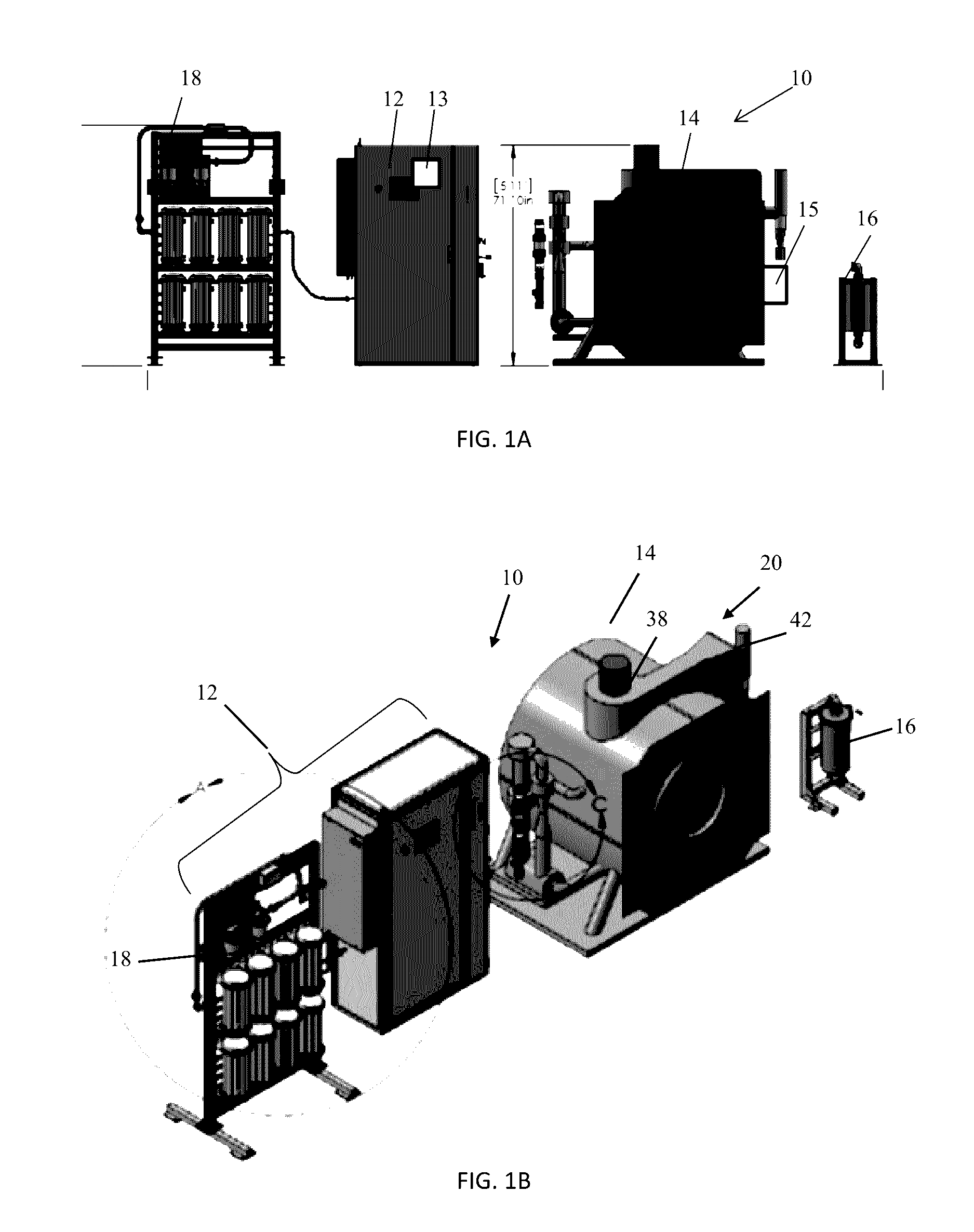

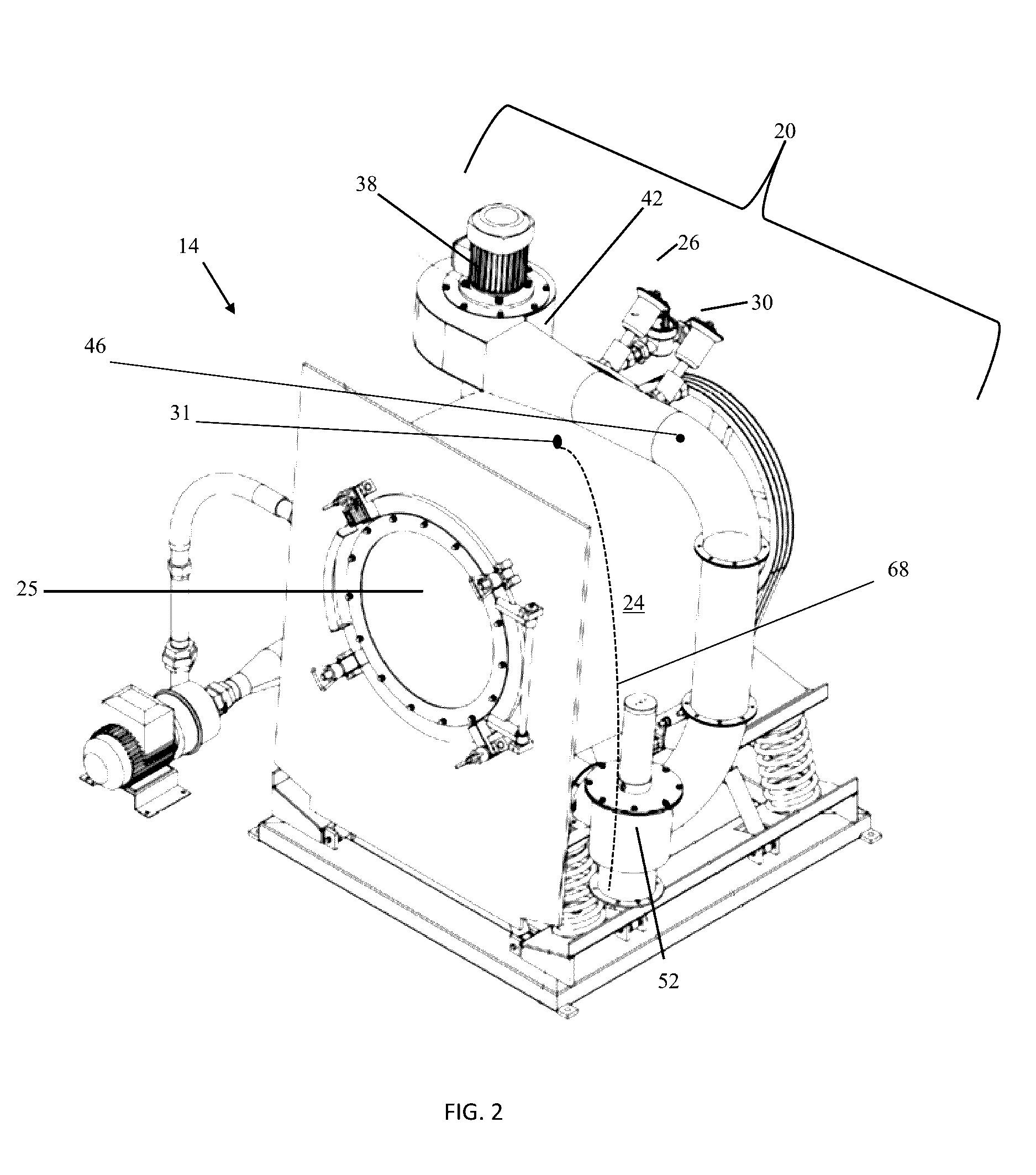

Ozone process for color removal

ActiveUS20170016175A1More reliable and reproducibleTextile treatment containersLiquid/gas/vapor article treatmentControl systemWastewater

Embodiments relate generally to methods and systems for bleaching textiles using ozone gas that incorporates a color removal step. In one example, there is provided a hybrid machine that incorporates certain features of a washer, but that also includes an integrated blower for gas distribution inside the machine. There is also provided an ozone dosing control system that allows for maintenance of a constant concentration of ozone in the machine. In one embodiment, the ozone output measured in grams / hour at this constant concentration in conjunction with the weight of product measured being treated may be referred to as the “bleaching factor.” There is further provided a wastewater dye removal step, in which ozone is used to clean the water and remove dyes and other colors that may be deposited via denim or other garments.

Owner:GUARDIAN MFG

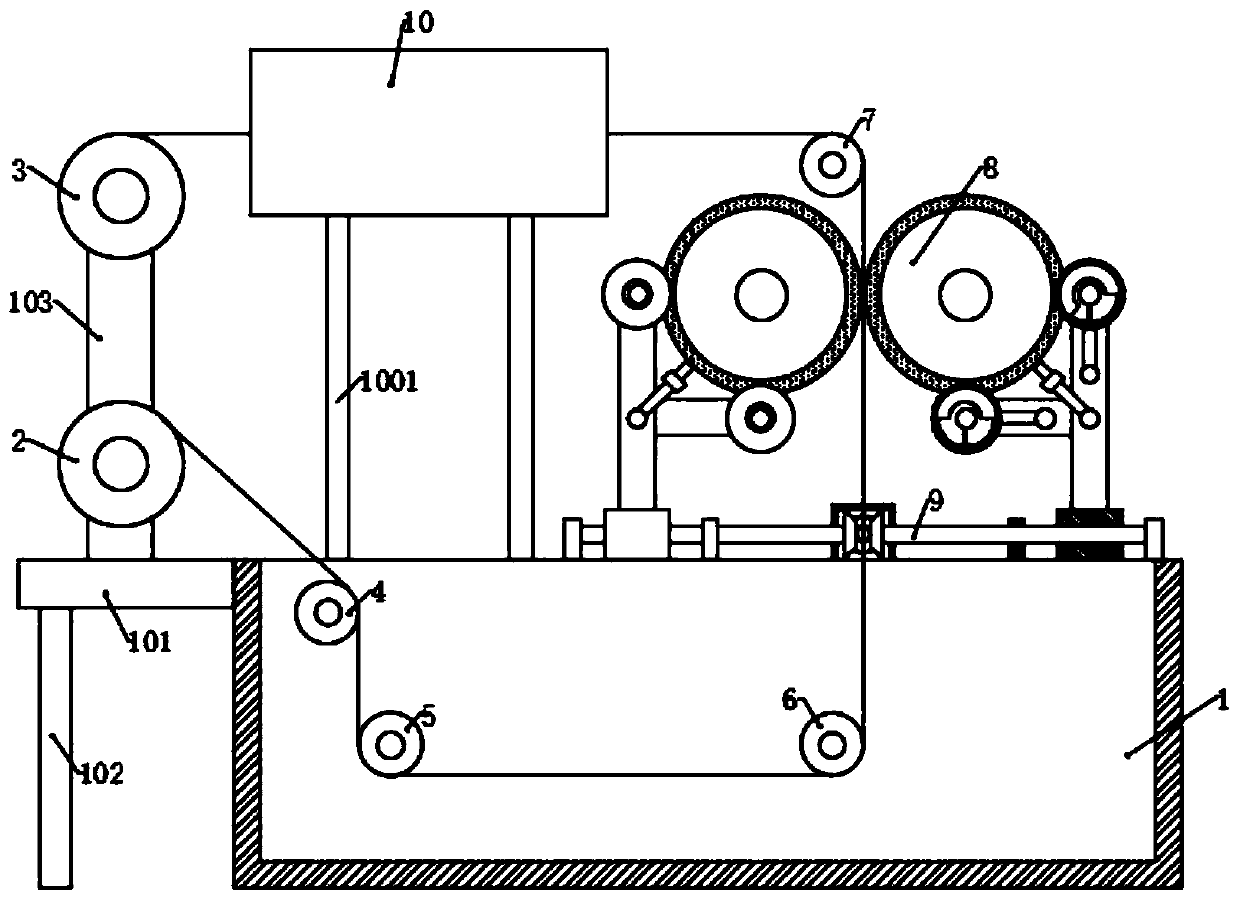

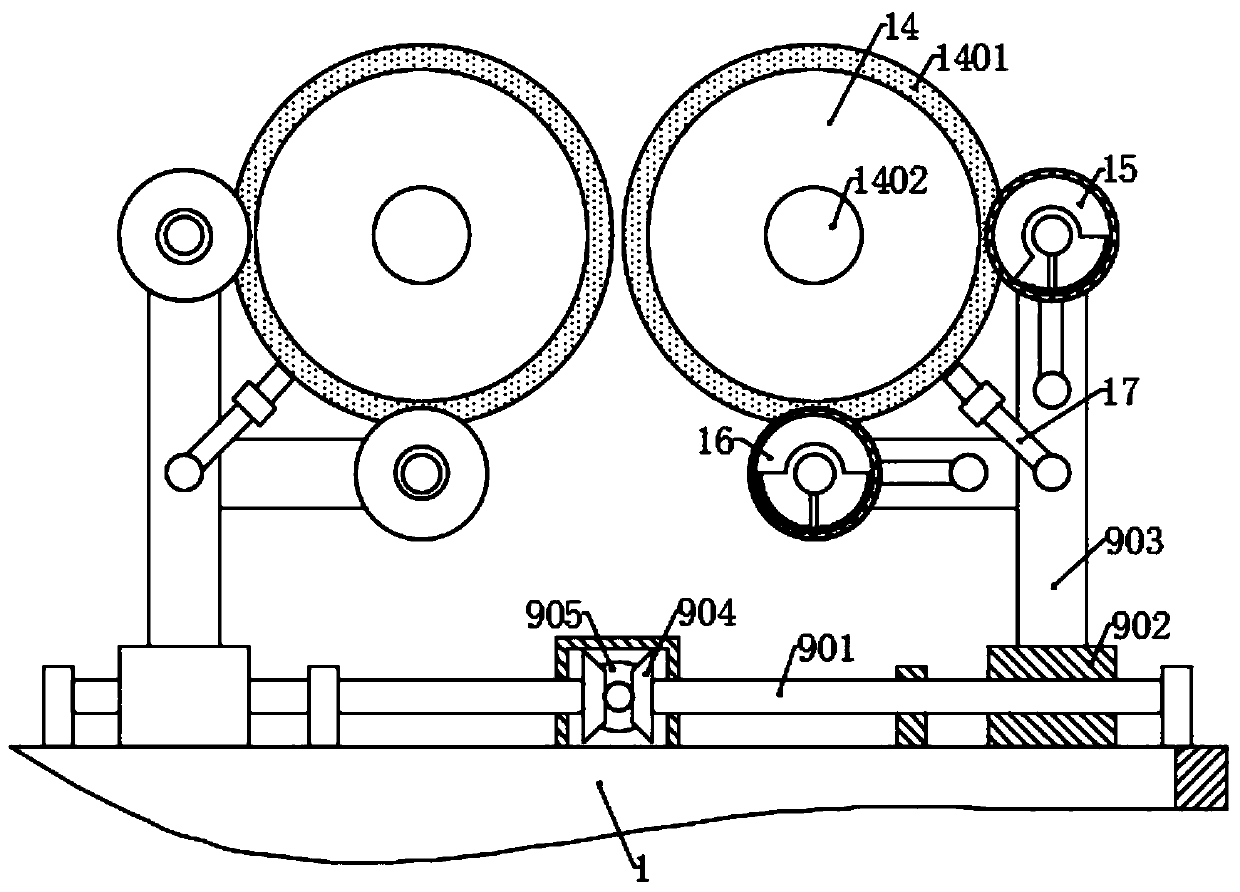

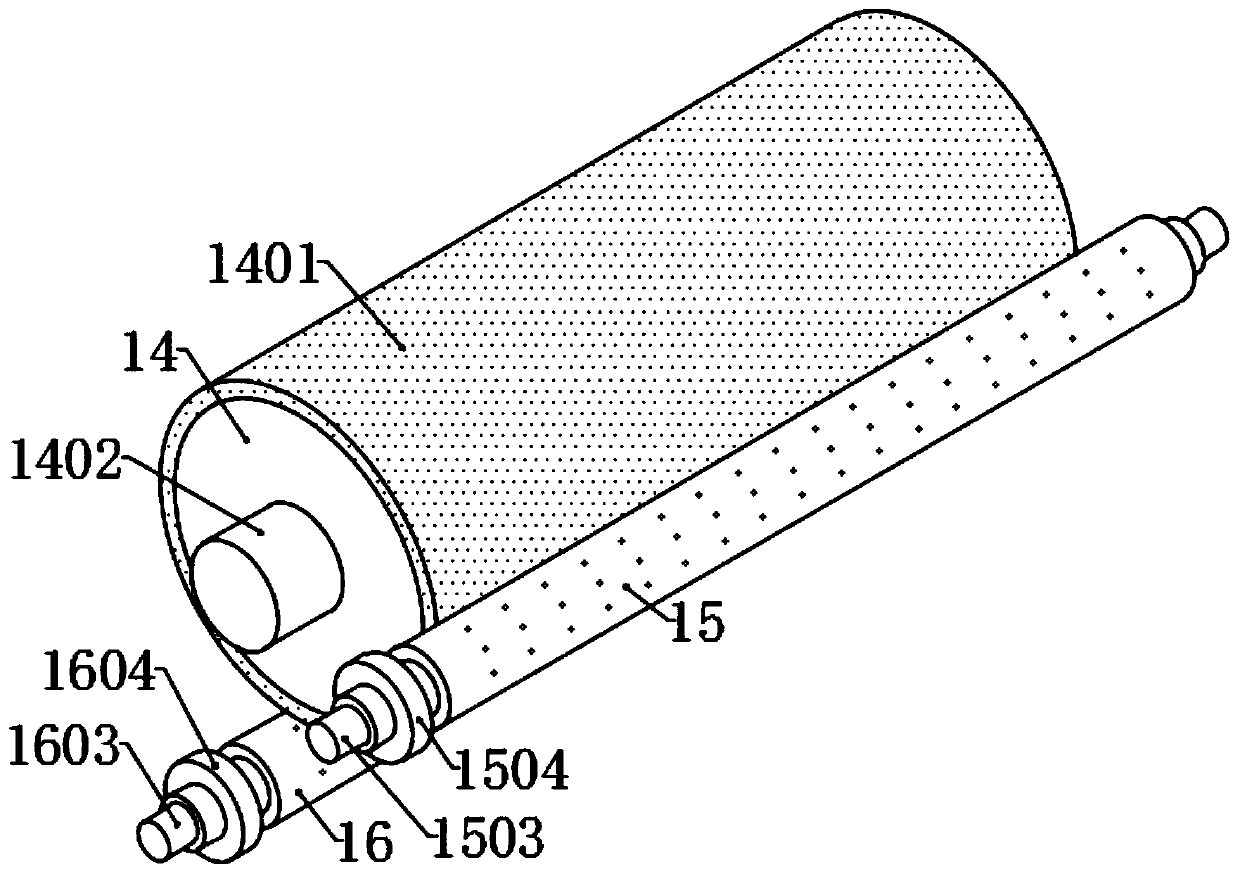

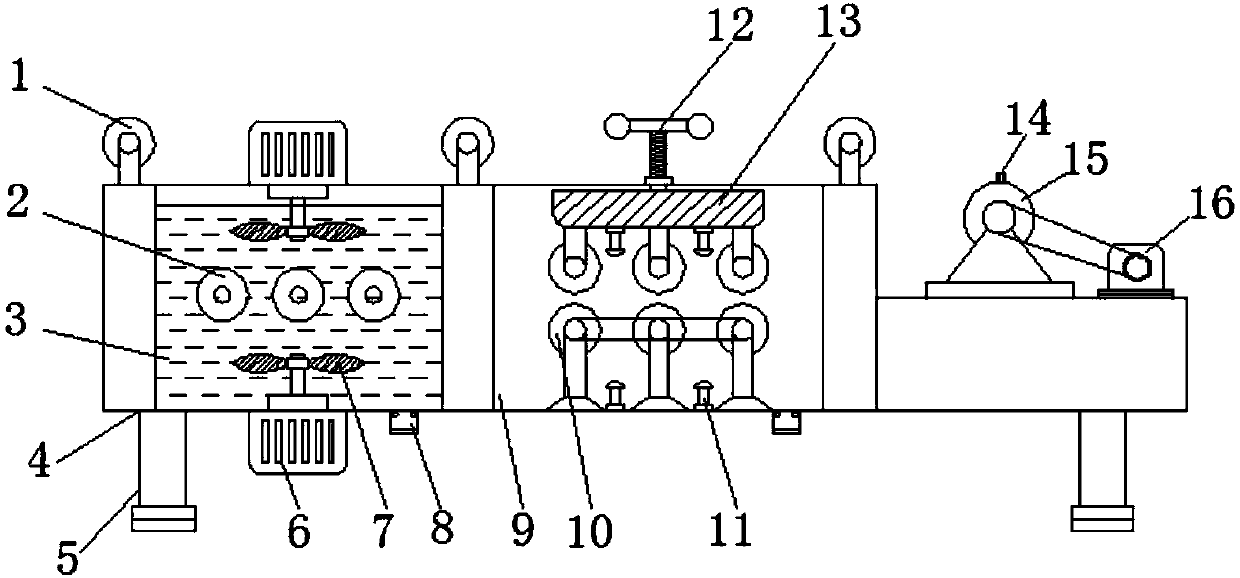

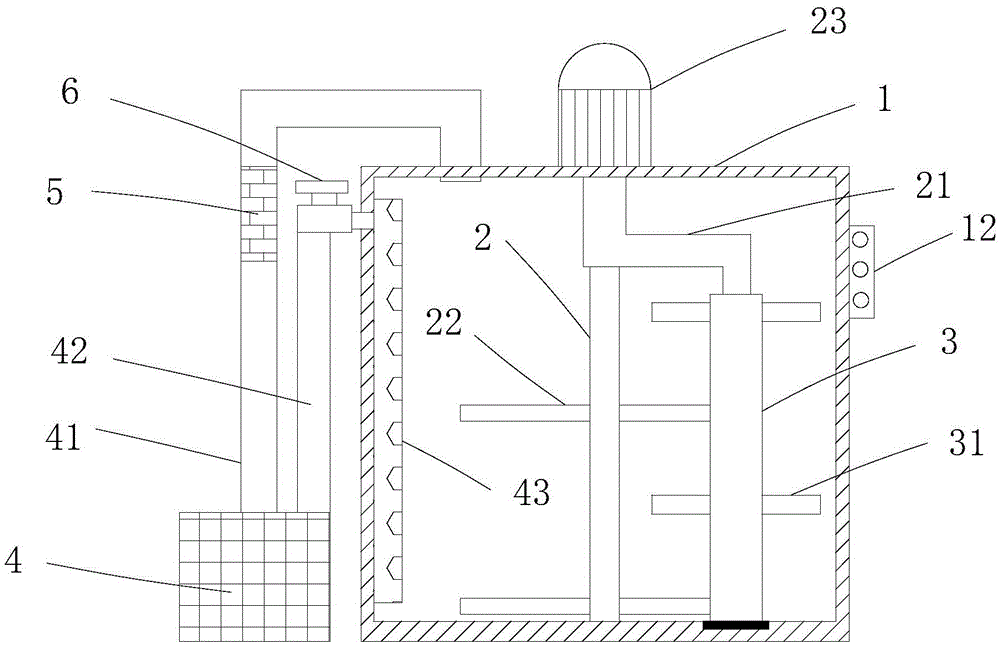

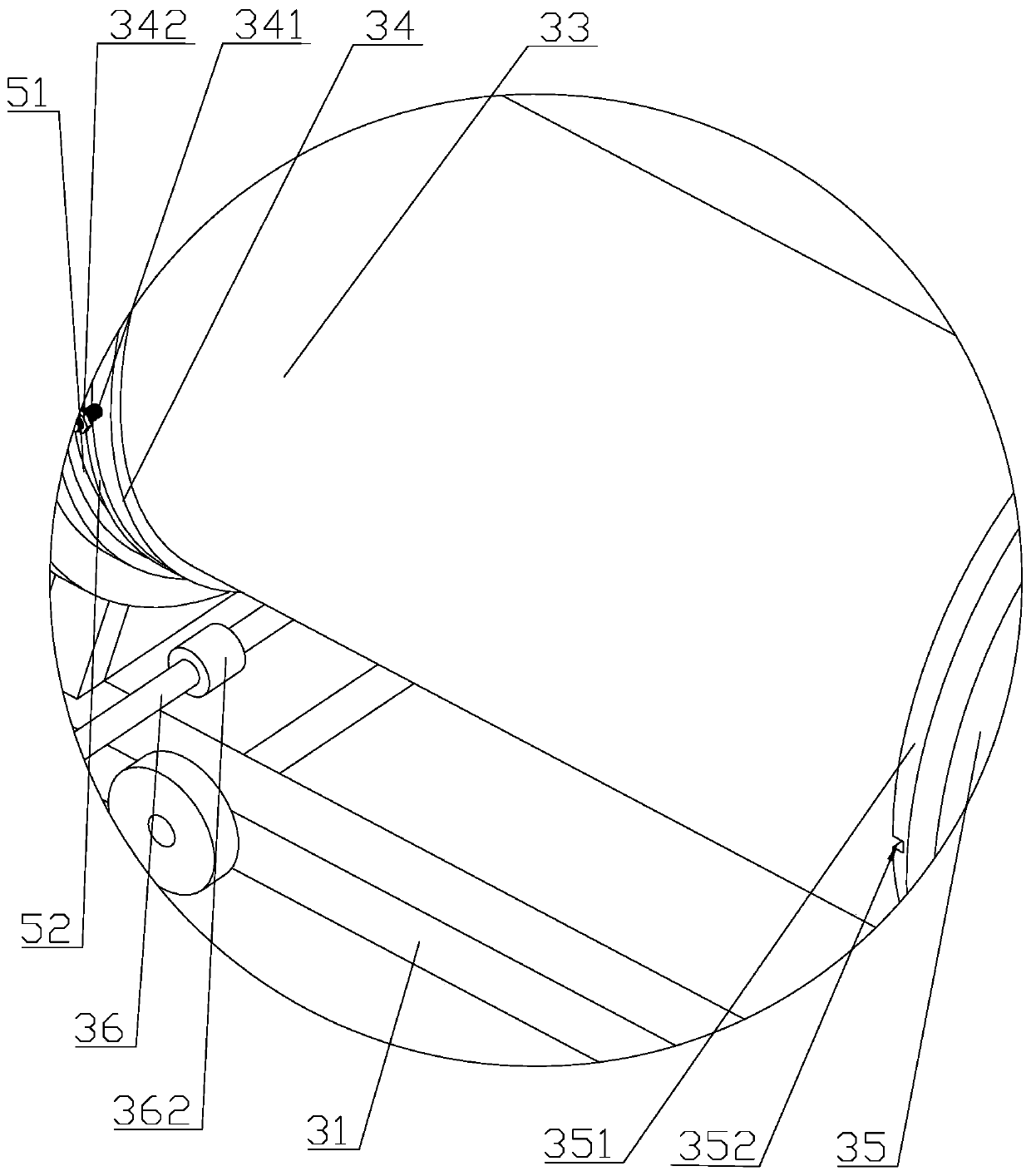

Rapid cloth cleaning equipment for textile processing

InactiveCN110924001AEasy to cleanEasy to dryLiquid/gas/vapor removal by suctionTextile treatment cleaning apparatusProcess engineeringMechanical engineering

The invention discloses rapid cloth cleaning equipment for textile processing, and belongs to the technical field of textile processing. The rapid cloth cleaning equipment comprises a cleaning tank, adischarging cylinder, a material collecting cylinder, a drying mechanism, a hot air drying mechanism and adjusting mechanisms. According to the rapid cloth cleaning equipment for textile processing,the cloth is discharged through the discharging cylinder, and then the cloth is movably cleaned in water through the effects of a first guide wheel, a second guide wheel and a third guide wheel; thenwater absorption is carried out through sponge layers on two oppositely rotating drying cylinders after cleaning is performed, and hot air drying is conducted through the hot air drying mechanism after water absorption is performed; when the sponge layer after water absorption is subjected to the extrusion of a first water squeezing cylinder, the sponge layer is kept at relative humidity so as tocontinuously absorb water and dry the subsequent cloth; a second water squeezing cylinder further squeezes the sponge layer, and after the sponge layer works for a period of time, the sponge layer issprayed with clean water through a water outlet pipe; and then a second water collecting pipe is adopted for squeezing and de-watering, and the sponge layer is cleaned, so that the sponge layer is kept relatively clean.

Owner:安徽云至信电子商务有限公司

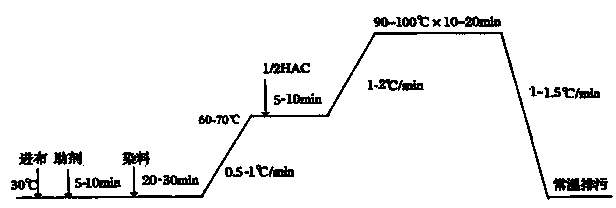

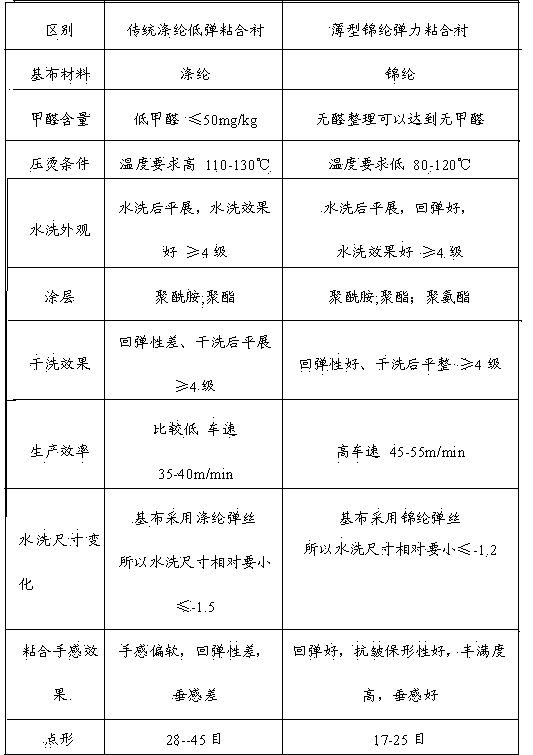

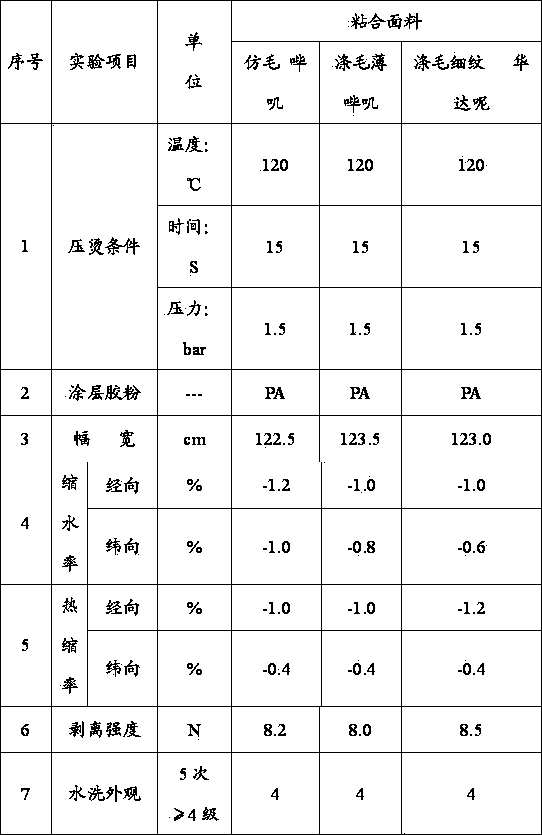

Production process of thin nylon elastic adhesive-bonded interlining

ActiveCN103462263AImprove performanceRaise the gradeLiquid surface applicatorsFibre typesCooking & bakingInterlining

The invention relates to a production process of thin nylon elastic adhesive-bonded interlining. The production process includes the following steps: 1, grey cloth inspecting; 2, cloth turning, print and end stitching; 3, loosening and dyeing; 4, shaping and finishing; 5, coating; and 6, inspecting, wherein the step of coating includes the following processes: unwinding, J-shaped cloth containing box, LG deviation corrector, pasting by a scraper, spreading hotmelt adhesive powder, blowing and sucking powder, edge-detecting, baking, cooling, coating-forming, and coiling. By adopting the production process, product grade can be effectively increased, performance of lining cloth is greatly improved, and the thin nylon elastic adhesive-bonded interlining is preciser in coating process, good in water washing and dry washing effect, low in formaldehyde content and more comfortable to wear, and has wider market prospect and market value.

Owner:JIHUA 3502 PROFESSIONAL GARMENT

Cleaning, drying and finishing machine for cloth

InactiveCN107723968AImprove work efficiencyImprove drying efficiencyLiquid/gas/vapor removal by squeezing rollersLiquid/gas/vapor fabric treatmentMechanical engineeringClose contact

The invention discloses a cloth washing, drying and finishing integrated machine, which comprises a cleaning bin, an integrated machine body, a drying chamber and a cloth roll. One side of the integrated machine body is provided with a cleaning bin, and two sides of the cleaning bin are Guide rollers are arranged symmetrically, a drying chamber is arranged on one side of the cleaning chamber, a fixed plate is arranged on the inner top of the drying chamber, and extrusion pipes are also equidistantly arranged on the bottom of the fixed plate. One side of the drying chamber is provided with cloth rolls. In the present invention, squeeze rollers are arranged symmetrically up and down in the drying chamber, electric heaters are arranged inside the squeeze rollers, and tuyeres are arranged staggeredly between the squeeze rollers, and the upper and lower squeeze rollers can be closely bonded by rotating the screw shaft. Through this structure, the cloth can be dried while extruding water. At the same time, the heat of the extrusion roller itself and the hot air from the air nozzle make the upper and lower sides of the cloth evenly heated, effectively improving the drying efficiency of the cloth.

Owner:CHENGDU 403 TECH CO LTD

Carpet and method of making same

A carpet that can be installed onto a flooring surface without the requirement for registration between adjacent broadloom carpet pieces. The carpet comprises a design member that comprises a plurality of pattern members that are colorized and that define a void area, which has a substantially uniform color and pile height.

Owner:COLUMBIA INSURANCE CO

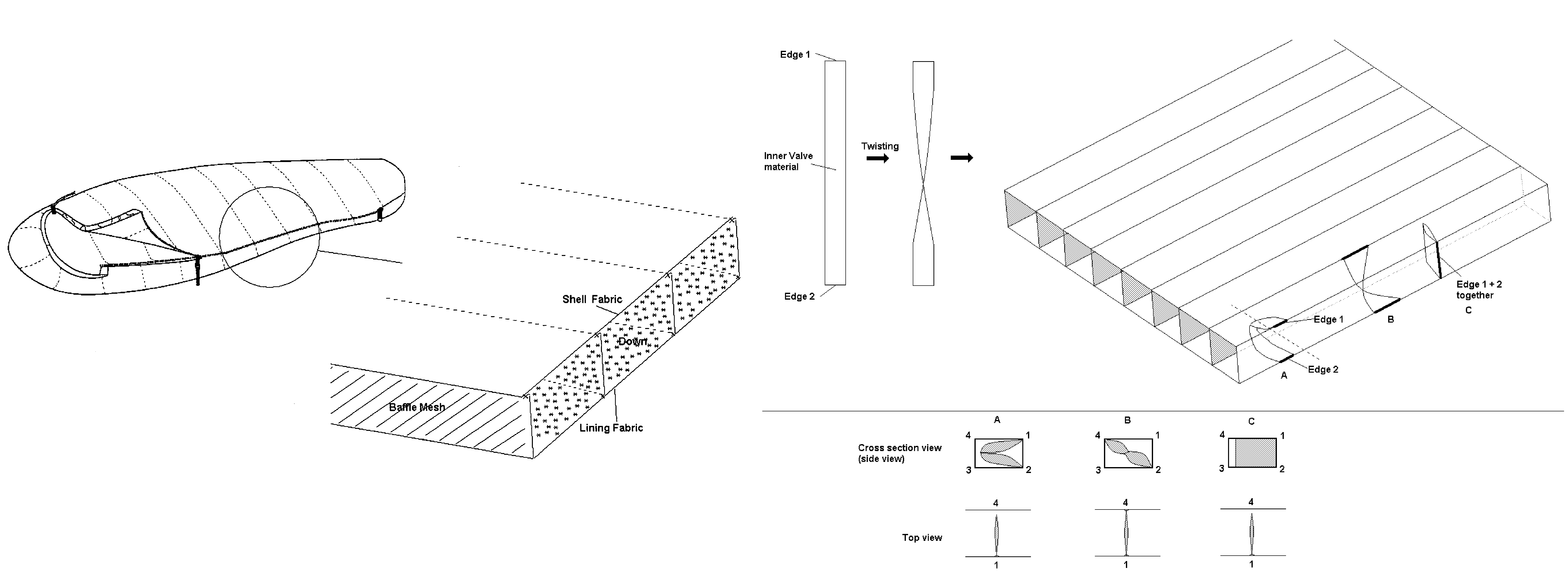

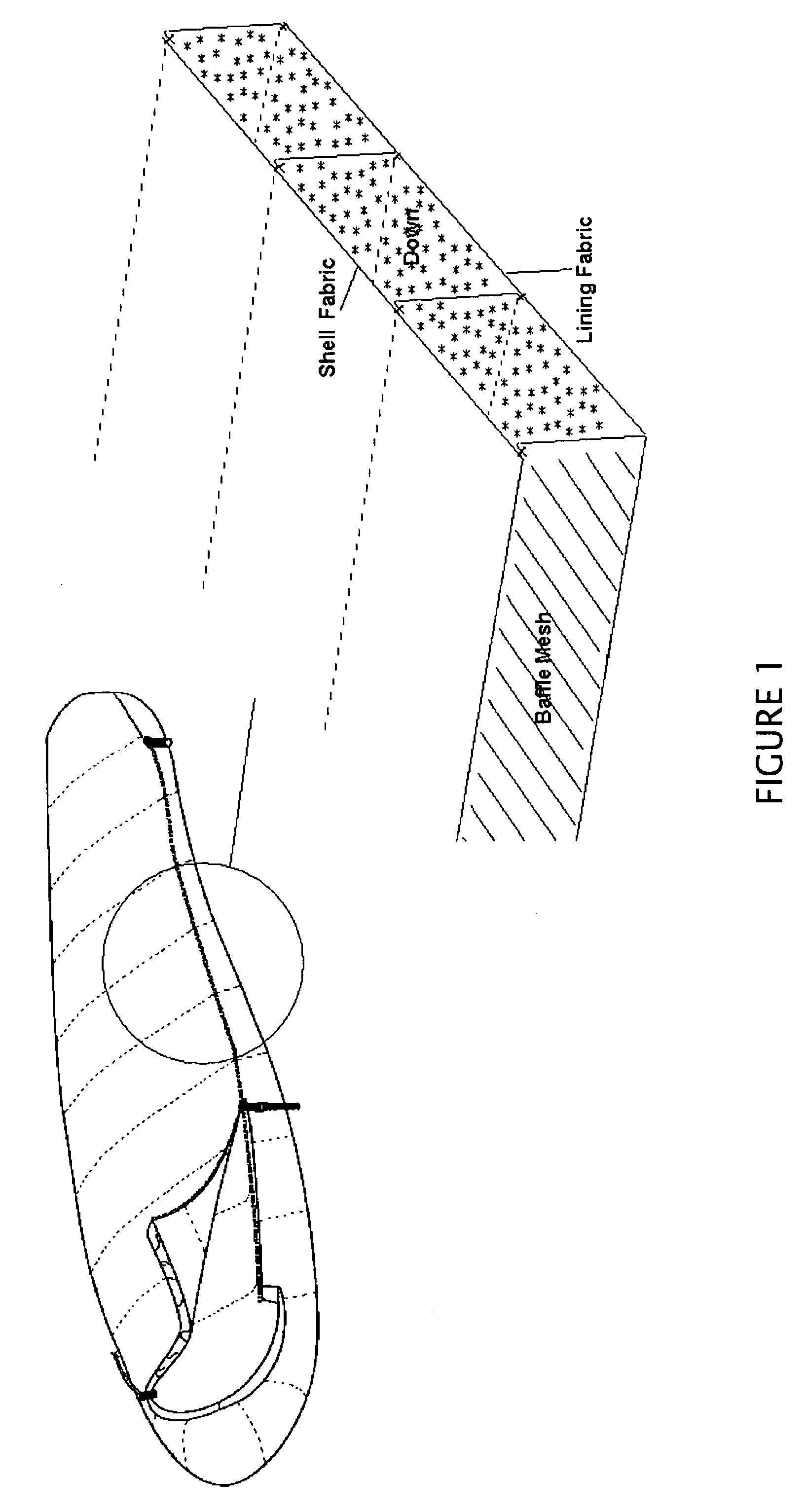

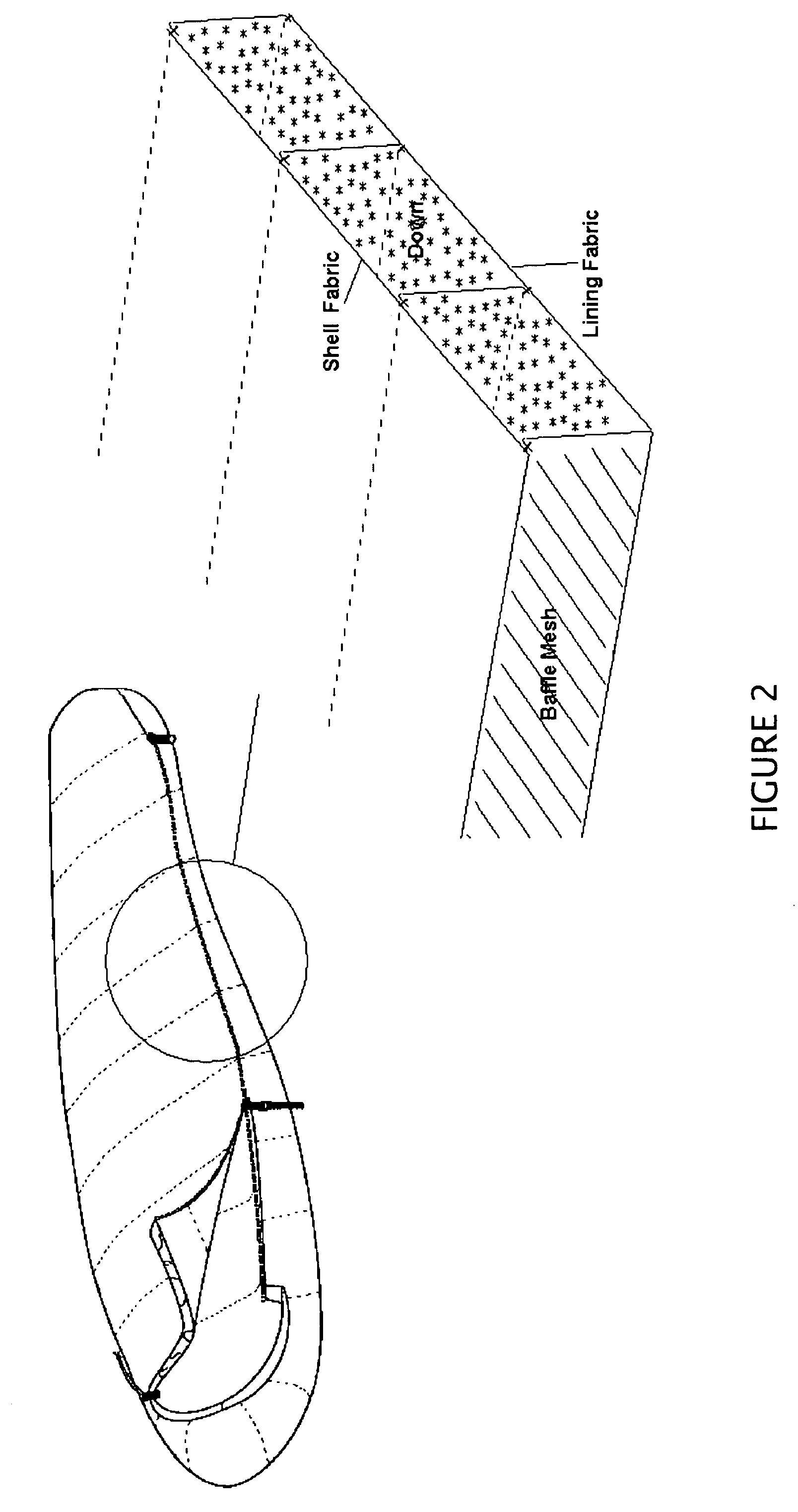

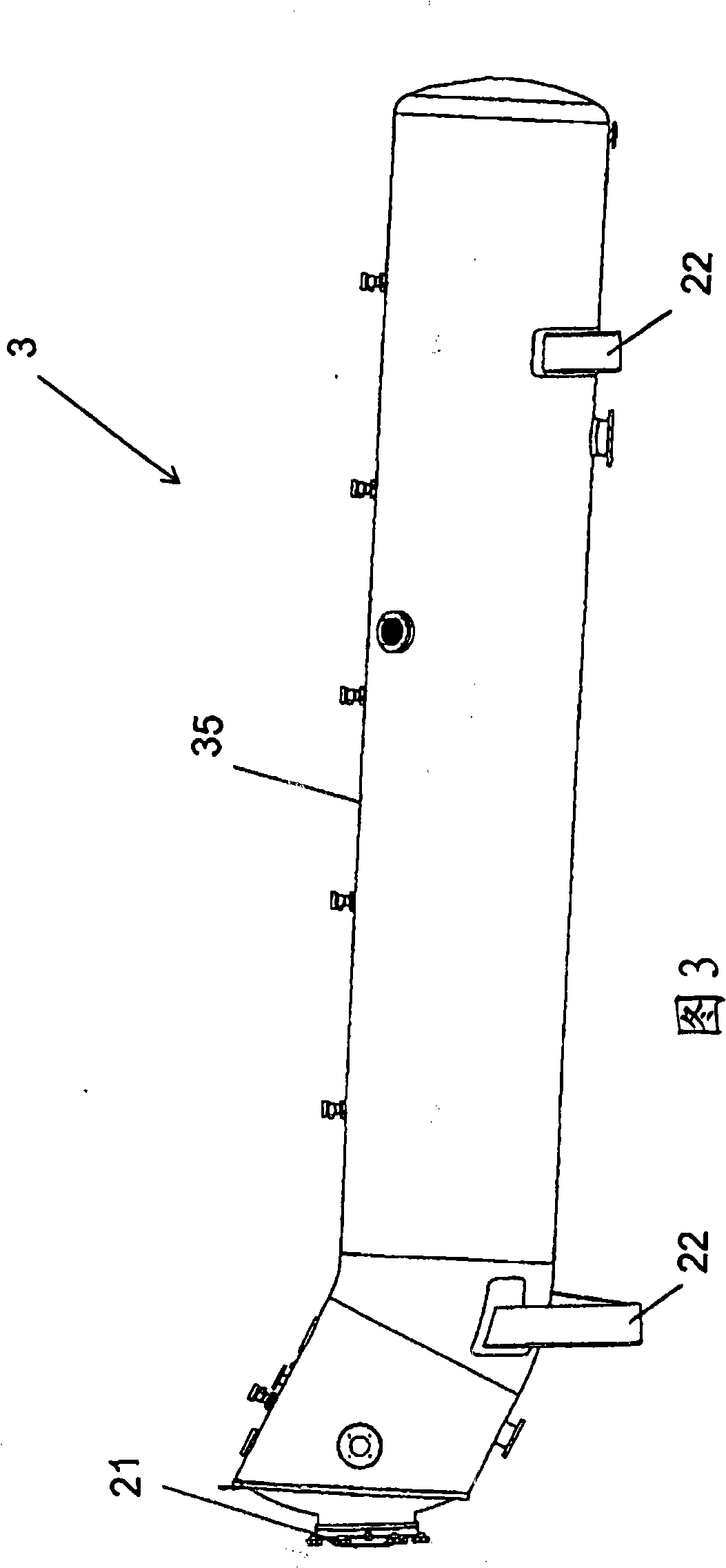

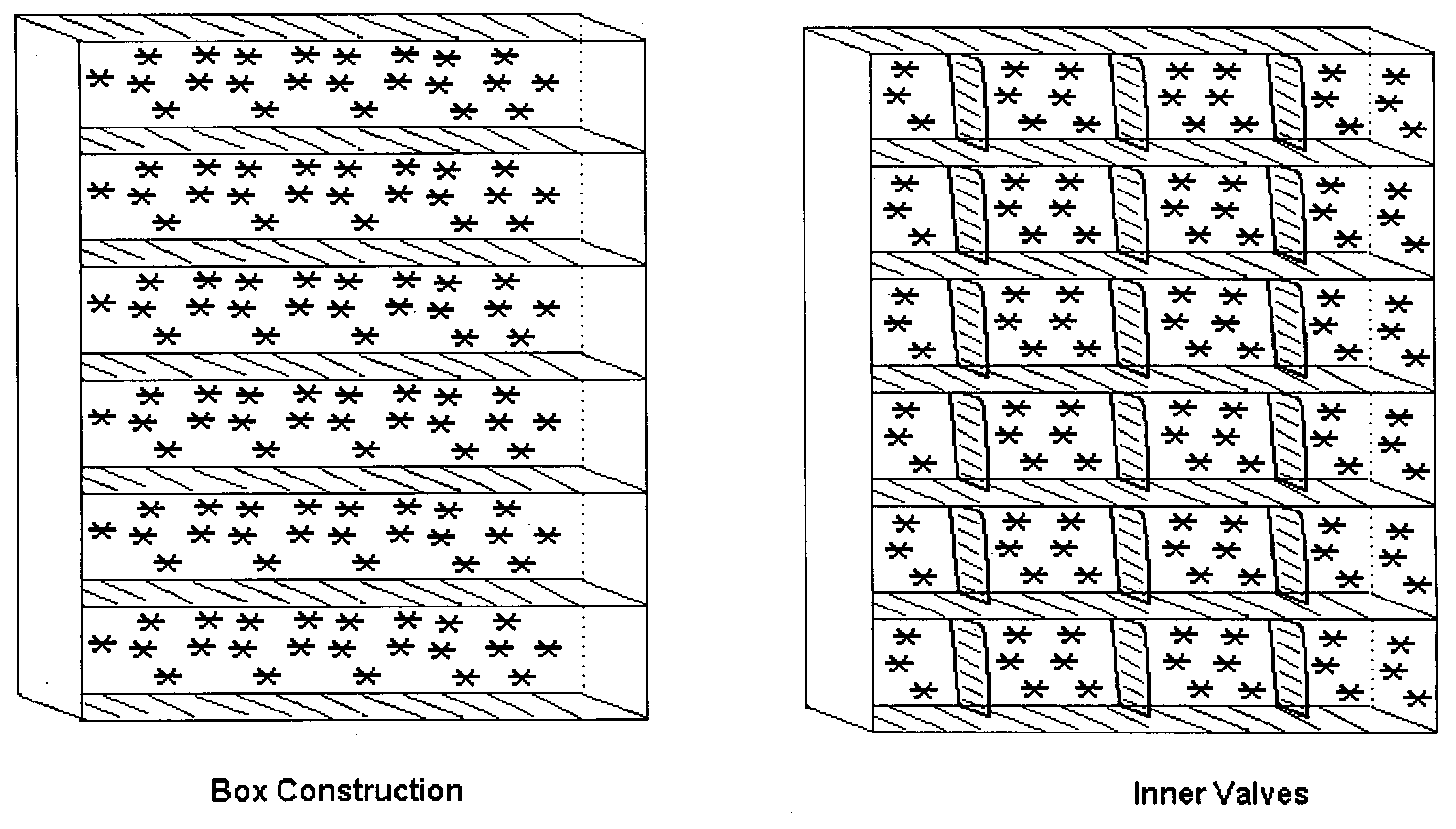

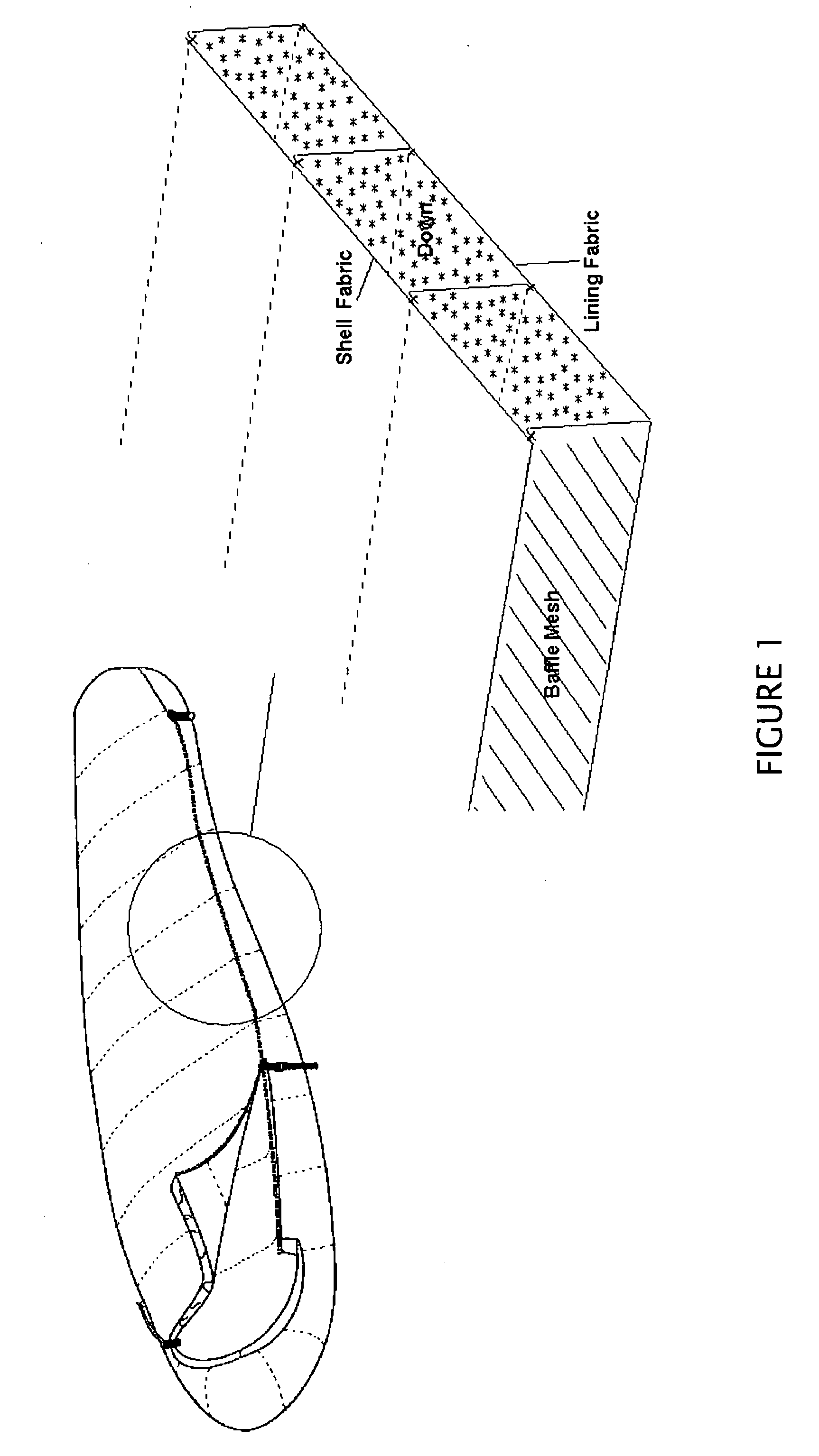

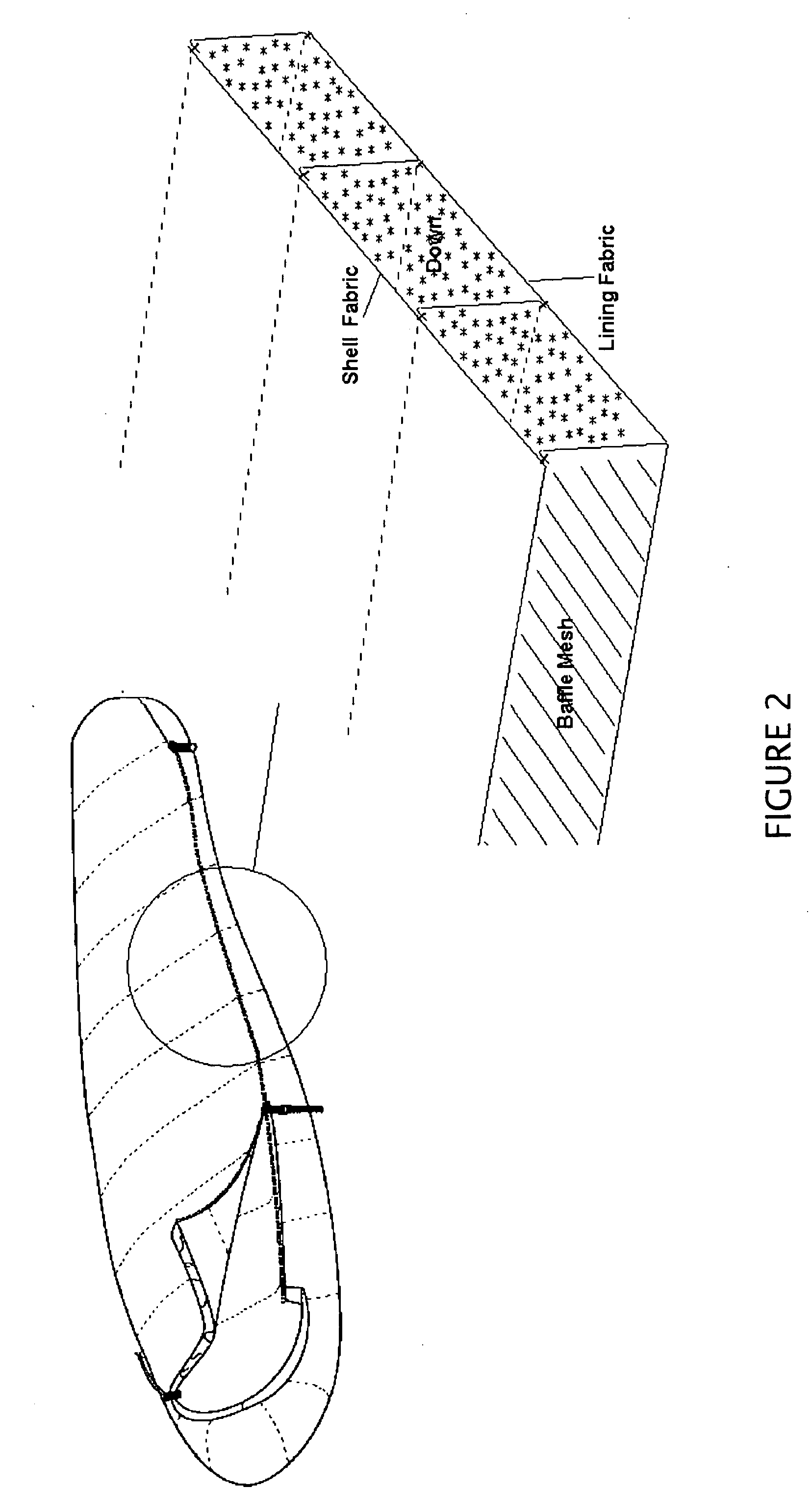

Insulated product

InactiveUS7818834B2More appearanceDesign moreCrochetingGarment special featuresEngineeringVALVE PORT

Owner:LI YICK LAP

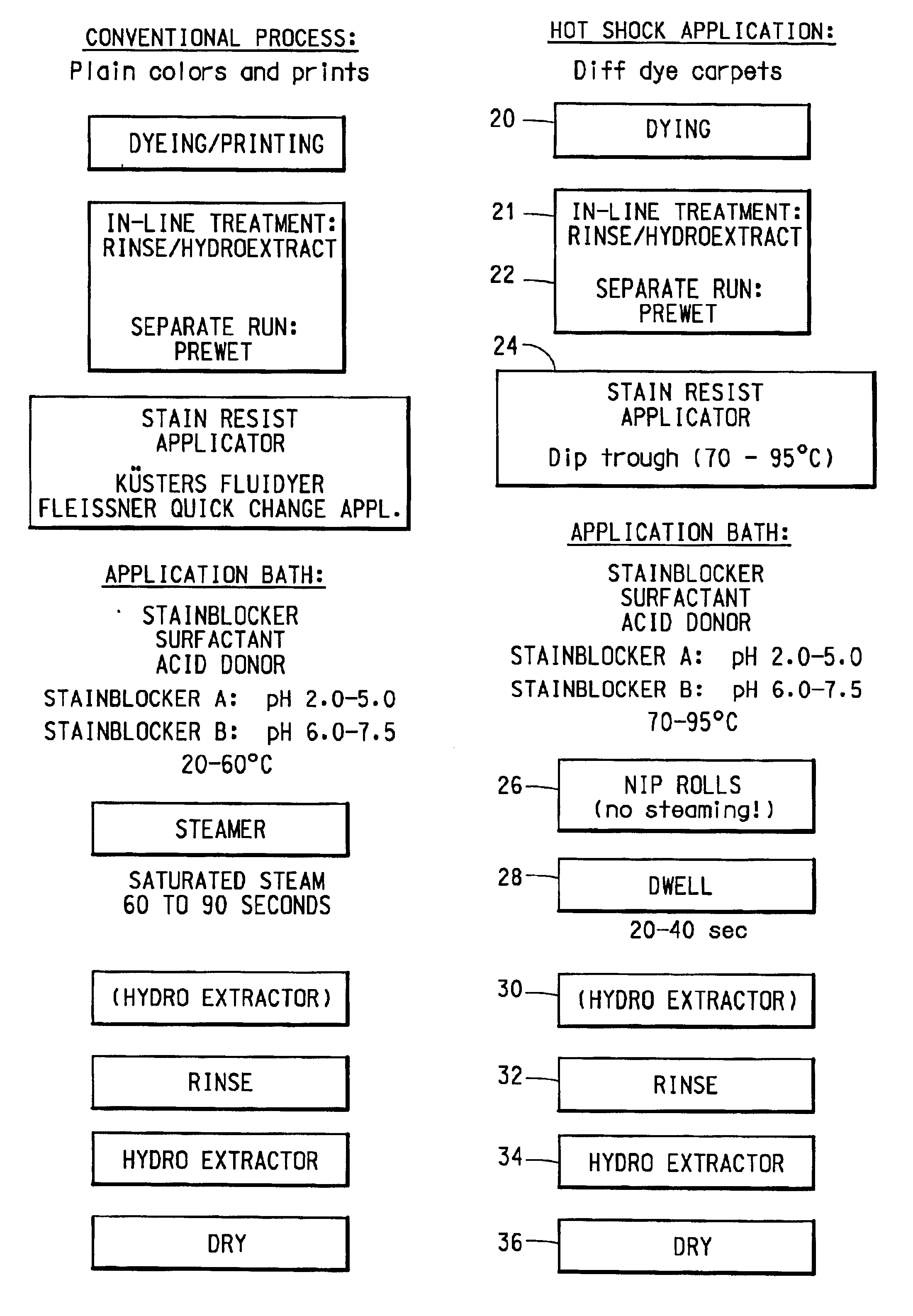

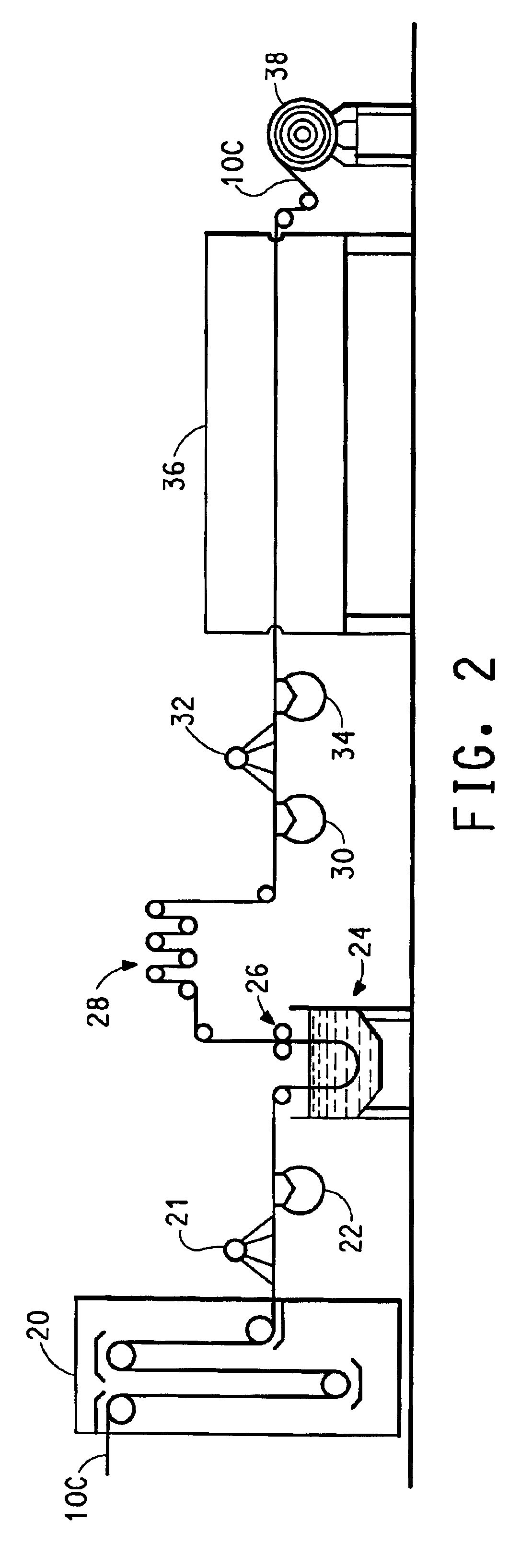

Method of imparting stain resistance to a differentially dyeable textile surface and the article produced thereby

A method of treating articles having a textile surface (such as broadloom carpets or carpet tiles) with a stainblocker composition is disclosed.A pile surface structure having pile elements containing nylon yarns having both acid dyeability and cationic dyeability is dyed with both acid dye and cationic dye and then passed through a hot stainblocker treatment bath and a cooling zone. Substantially the entire height of each pile element is coated with a stainblocker composition whereby the pile surface structure has a stain resistance of 9 or higher on the AATCC Red 40 Stain Scale. The resulting pile surface has good color separation and stability, and no color loss from the catatonically dyeable yarns.

Owner:DUPONT DE NEMOURS GMBH +1

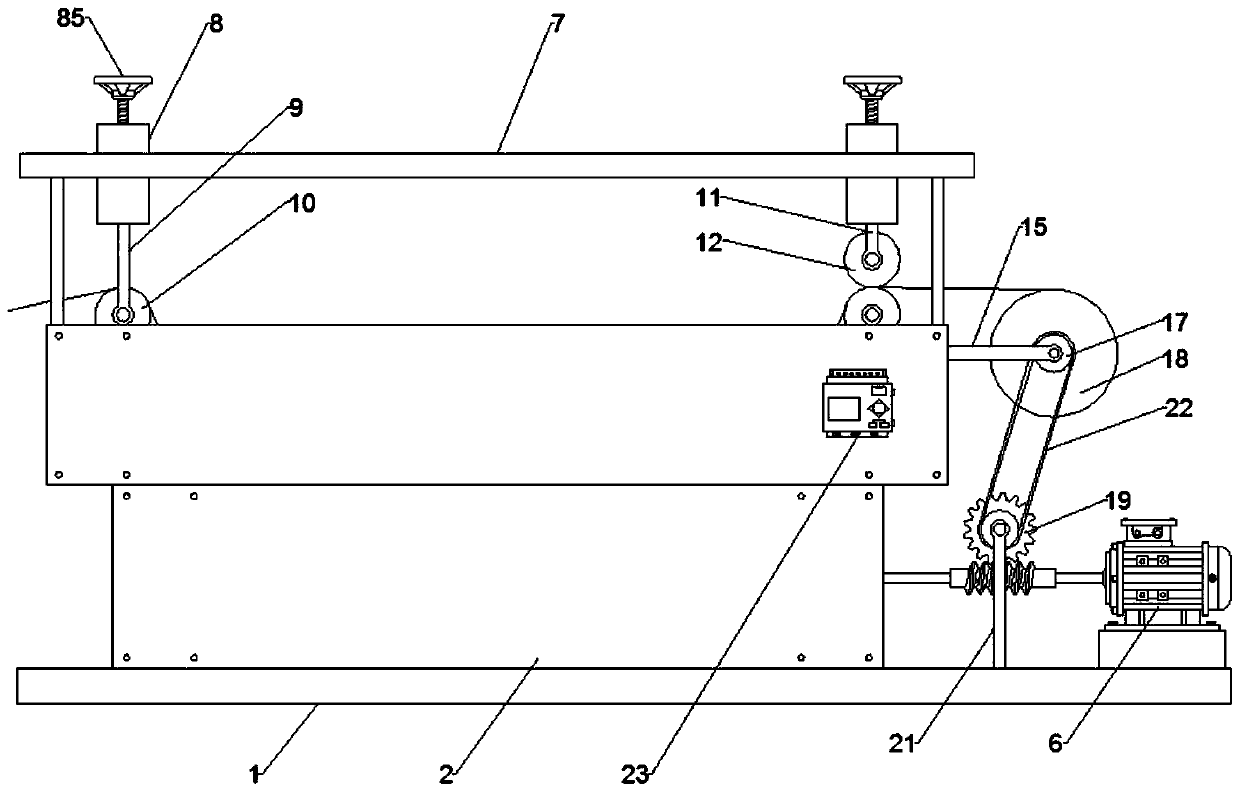

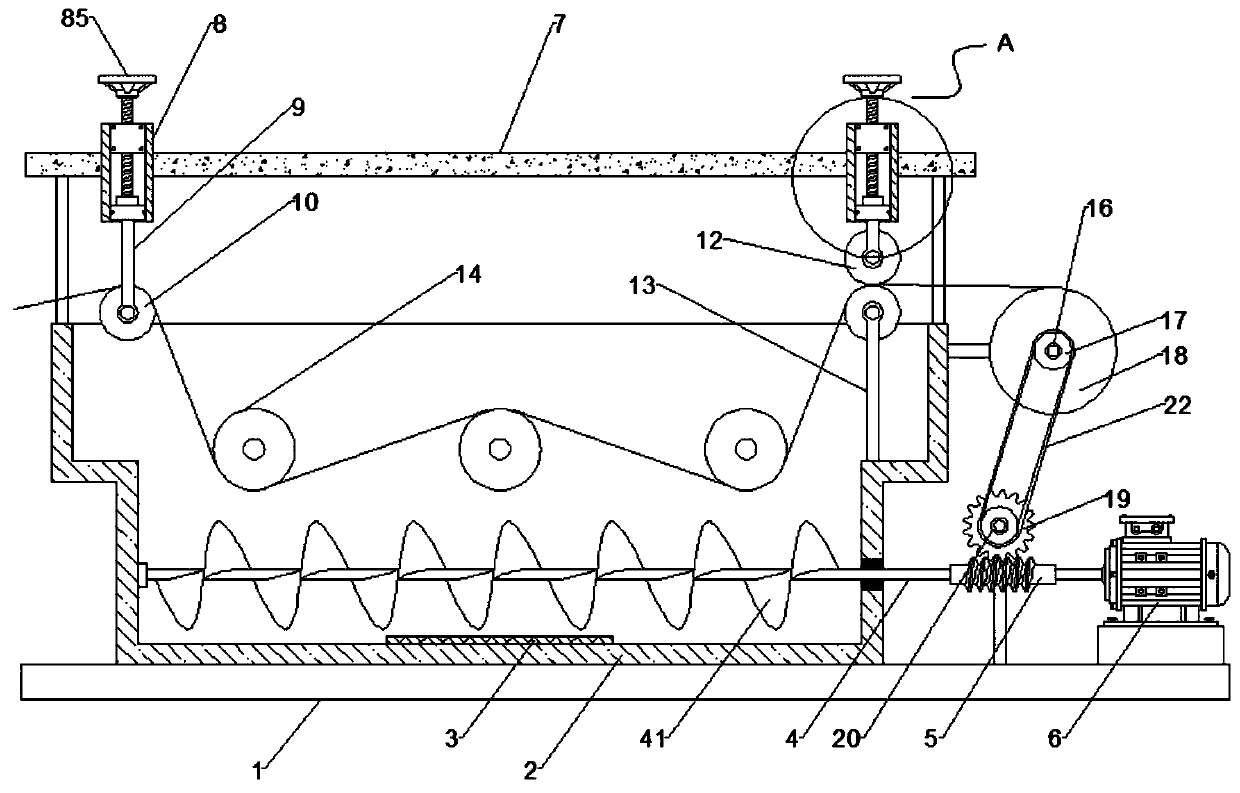

Multifunctional textile dyeing device

InactiveCN105603659AEfficient DyeingMaximize contact areaTextile treatment machine arrangementsLiquid/gas/vapor fabric treatmentEngineeringGear tooth

The invention discloses a multifunctional textile dyeing device comprising a body. A motor is mounted in the middle of the top end of the body, a center shaft of the motor penetrates the top end of the body to be fixedly connected with a center shaft, a second gear tooth is arranged at the bottom end of an eccentric shaft, the eccentric shaft is connected with the body in a meshed manner through a gear, the top end of the body is connected with a steam generator through a first circulating pipe, and an air outlet pipe is arranged on the side wall of an inner cavity of the body. The multifunctional textile dyeing device has the advantages that a blender on the center shaft is used for blending dyes, the eccentric shaft is provided with power to be capable of rotating and revolving, and accordingly maximum contact area between textile and the dyes and adjustable collision rate can be provided, and the textile on storage racks can be dyed highly efficiently; under the action of the first circulating pipe and a second circulating pipe, steam circulates, so that resources are saved to a great extent, and working efficiency is improved.

Owner:广州市信森服饰有限公司

Dyeing device for garment textile fabrics

InactiveCN110130030AFully dyedFull compressionTextile treatment machine arrangementsLiquid/gas/vapor fabric treatmentElectric machineryEngineering

The invention relates to the technical field of textile equipment, and particularly relates to a dyeing device for garment textile fabrics. The device comprises a base, wherein a dyeing vat is fixedlymounted on the top surface of the base, an electrical heating tube is fixedly mounted at the middle end of the bottom side in the dyeing vat, the lower end of the left side in the dyeing vat is rotationally connected with a stirring shaft through a bearing, stirring blades are fixedly mounted on the stirring shaft in equal spacing from left to right, the right end of the stirring shaft penetratesthrough the right side of the dyeing vat, a worm is fixed at the right side end of the stirring shaft in a welding manner, and the right end of the worm is fixed with an output end of a motor in a welding manner. According to the dyeing device for the garment textile fabrics, by driving the worm to drive the stirring shaft and the stirring blades to rotate, dye added to the dyeing vat is stirred,and non-uniform dyeing effects of the fabric bodies due to dye precipitation in the process of fabric dyeing can be avoided, meanwhile, the dye is heated, so that the fabric bodies can be fully dyed.

Owner:安徽职业技术学院

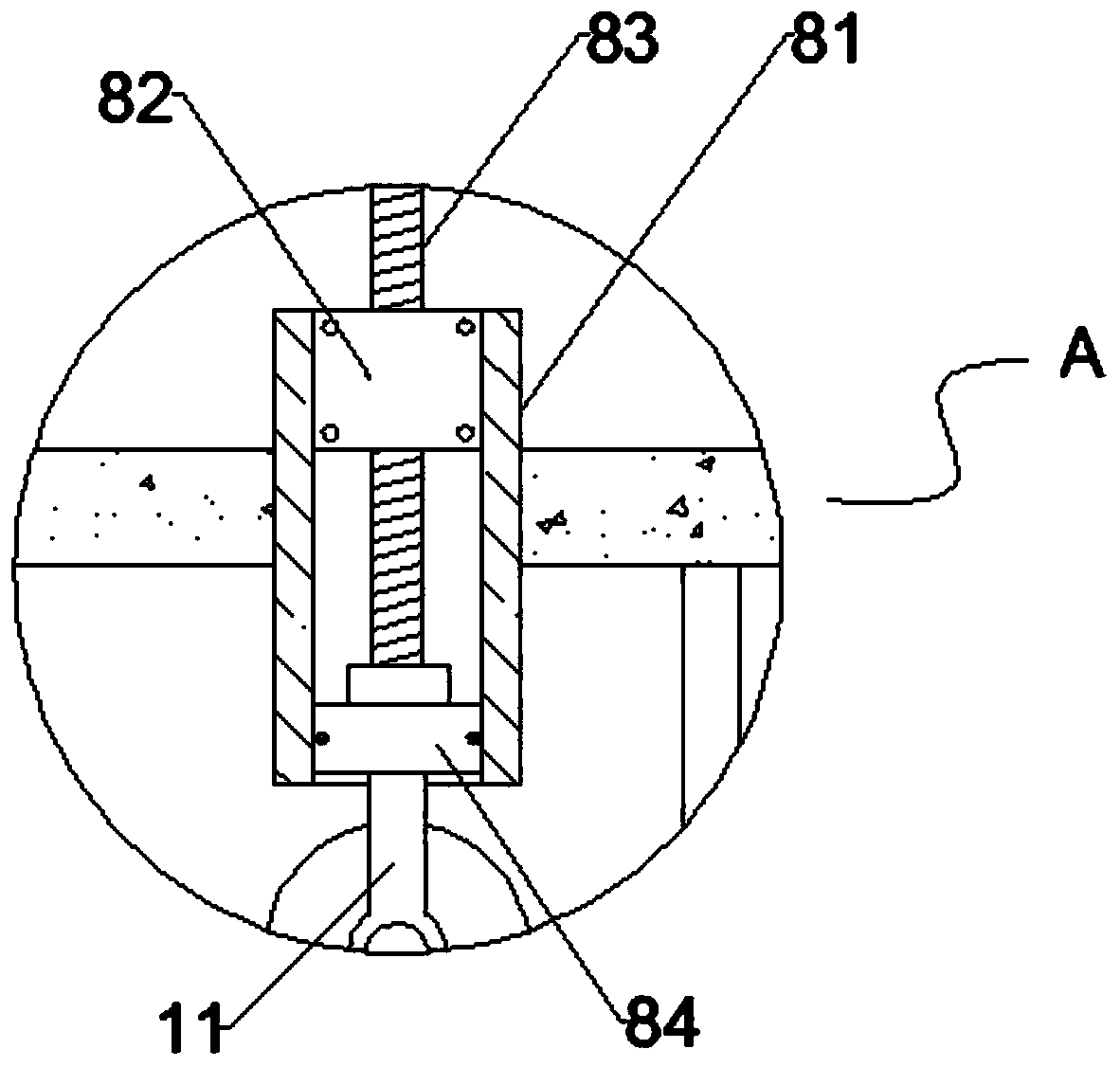

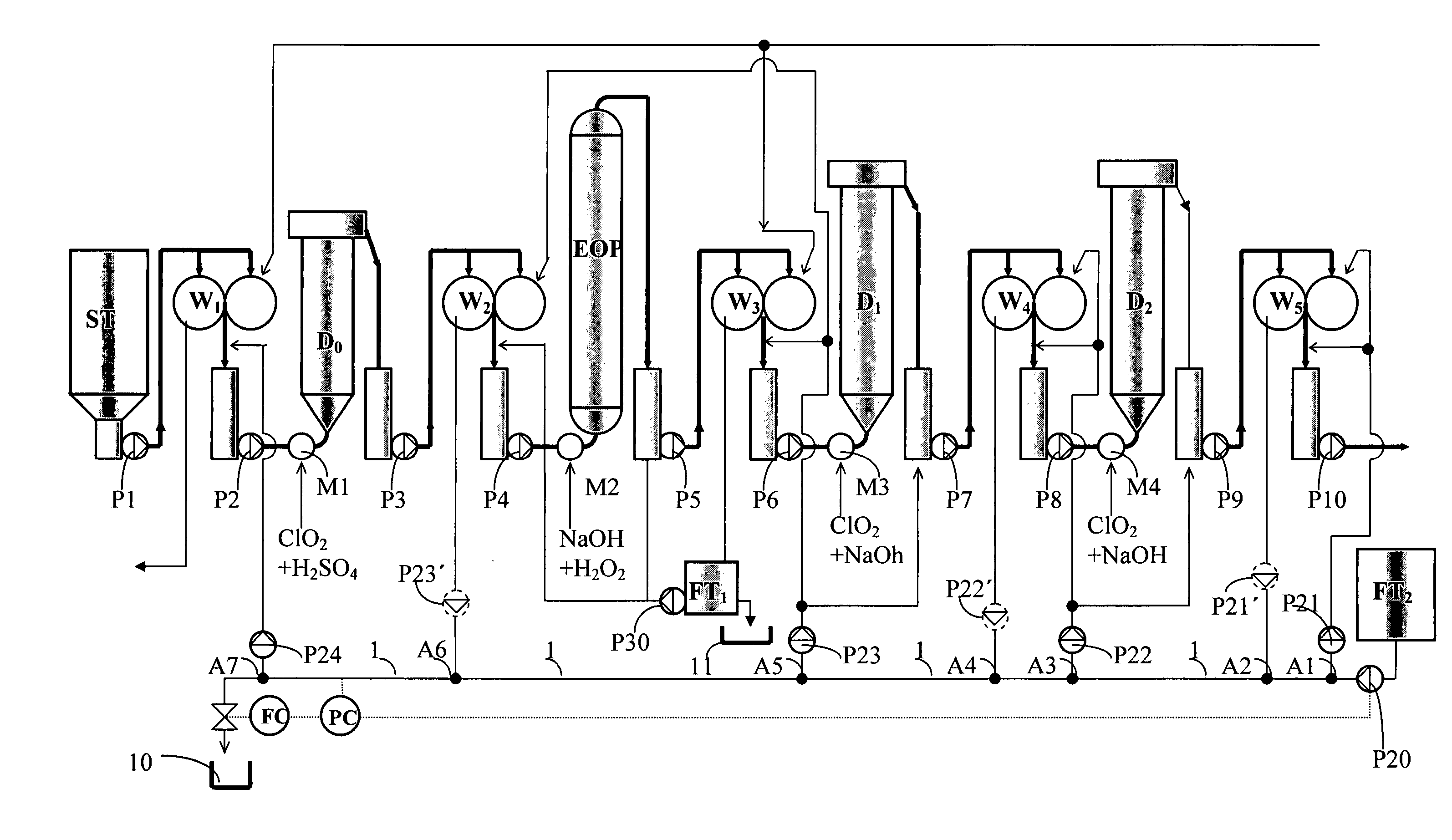

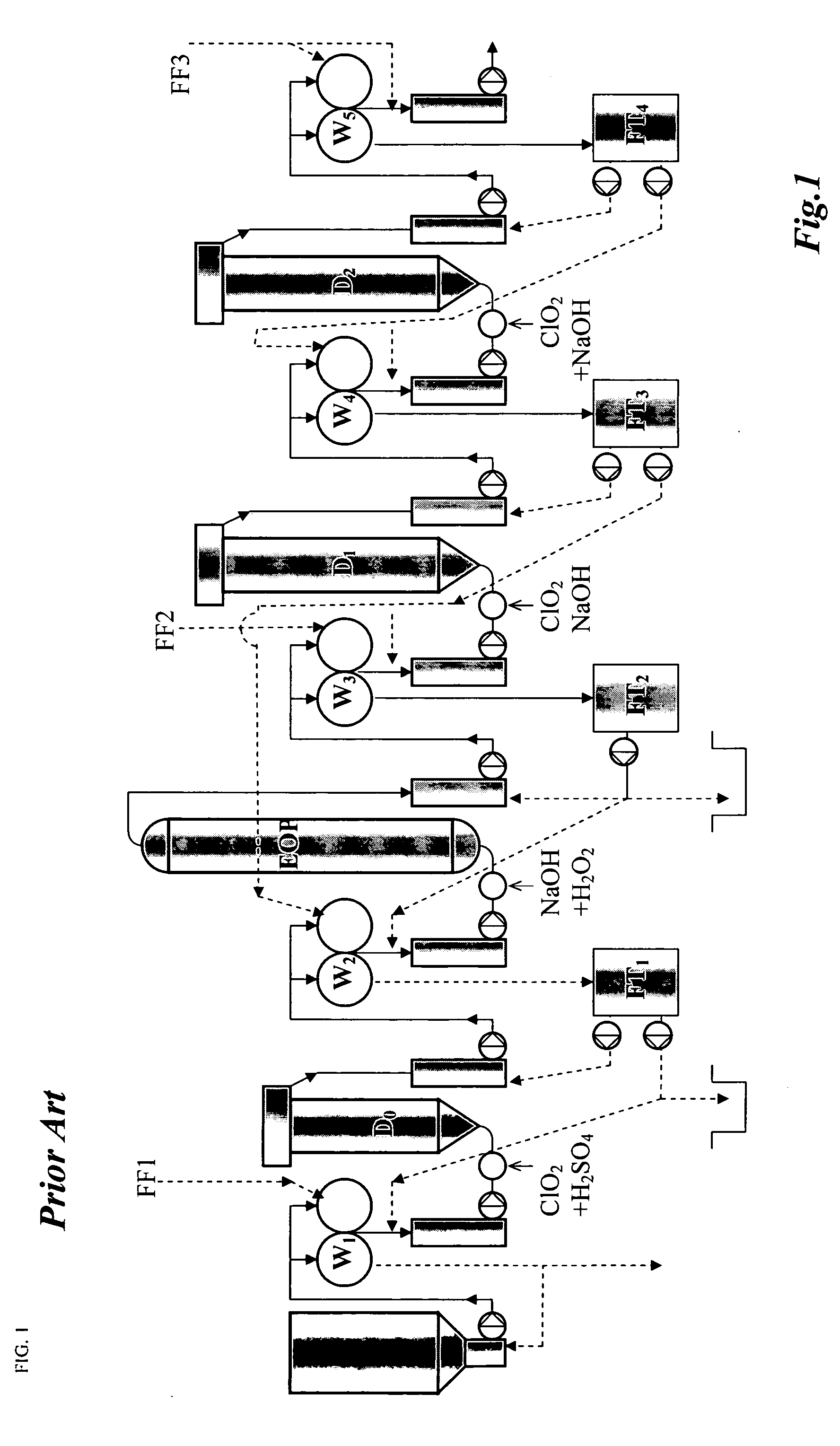

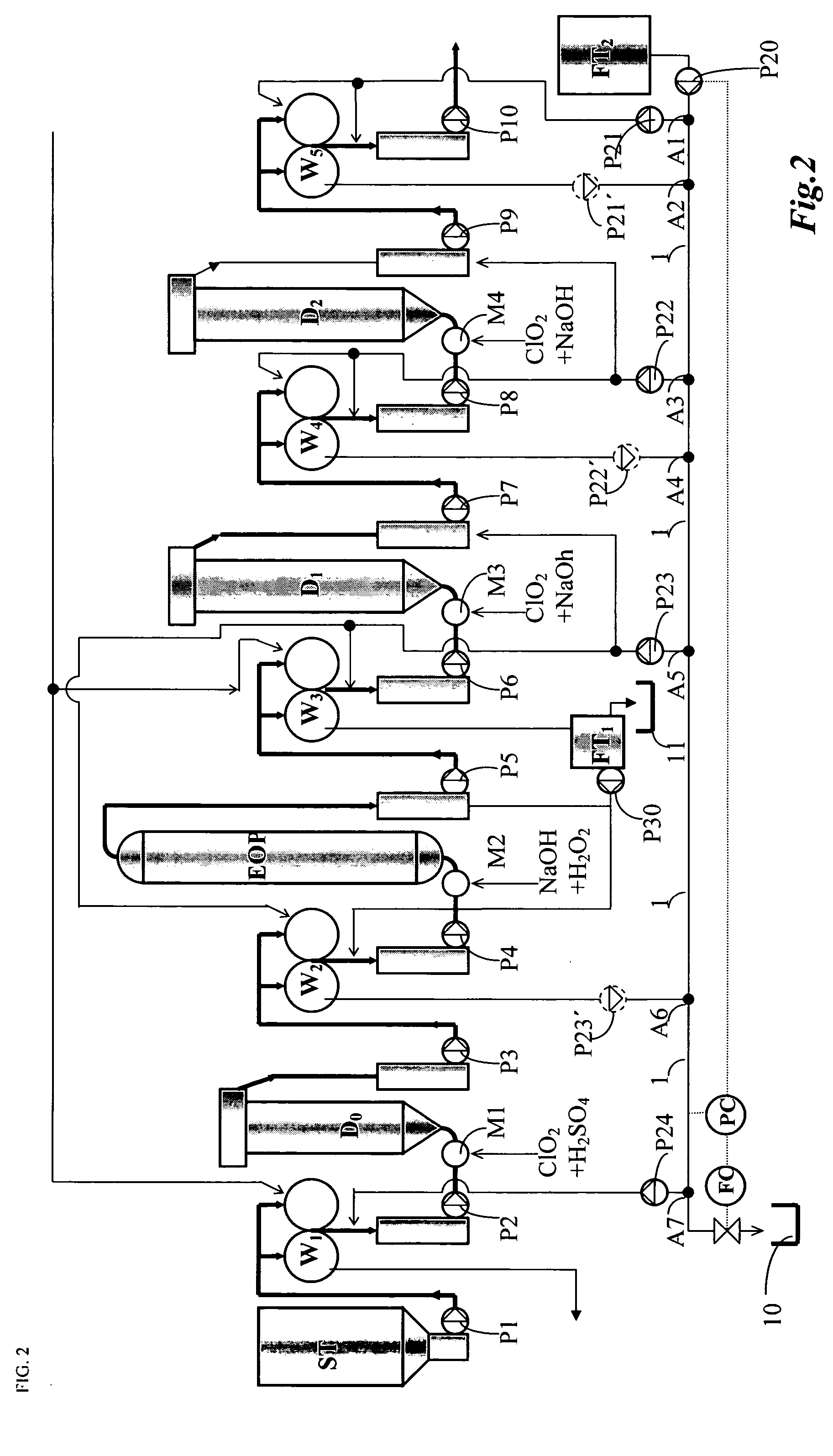

Method of bleaching cellulose pulp and bleaching line therefore

ActiveUS20040149404A1Washing/displacing pulp-treating liquorsPulp bleachingDistribution systemPulp and paper industry

The invention relates to a method of bleaching cellulose pulp in a bleach line having at least two bleaching steps D1, D2 of alkaline or acidic type, and a bleaching line for the method, in which the filtrate distribution is led up through the bleaching line in counter-current to the flow of cellulose pulp established in the bleaching line. Instead of a conventional filtrate distribution including filtrate tanks, a single joint main conduit 1 is used for the bleaching steps of the same type. Wash filtrate obtained from the wash steps of the same type used after or before the bleaching step, is led to a branch point A2, A4, A6 on the main conduit 1, that is positioned after the branch point for drawing off of wash and / or dilution liquor for the wash step in question A1, A3, A5, A7. All branch points in the joint main conduit are in open communication with each other in the main conduit, at least as seen in a direction from the last bleaching step. Hereby, a simplified and improved filtrate distribution system with an improved runnability is obtained.

Owner:ANDRITZ AB

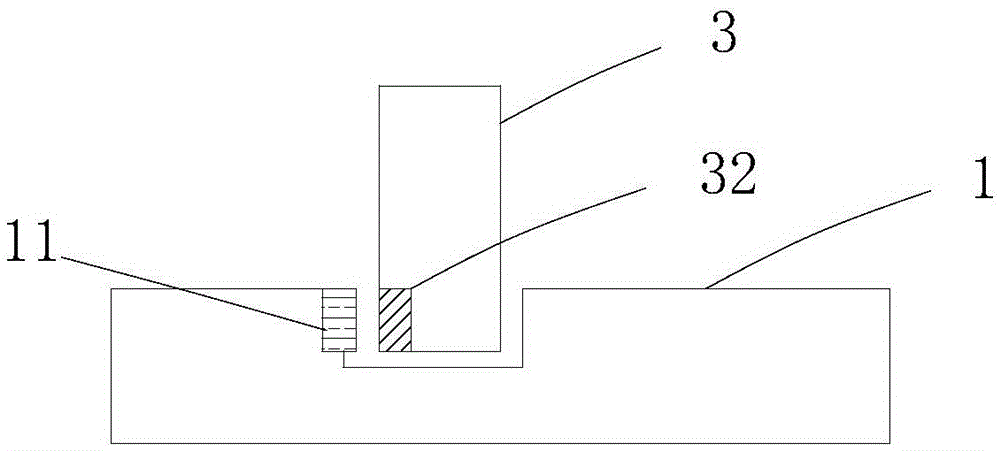

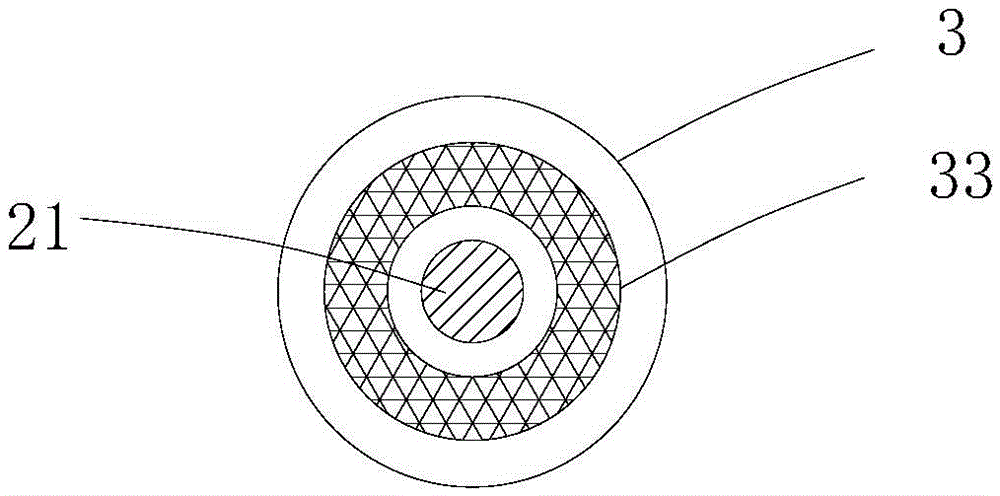

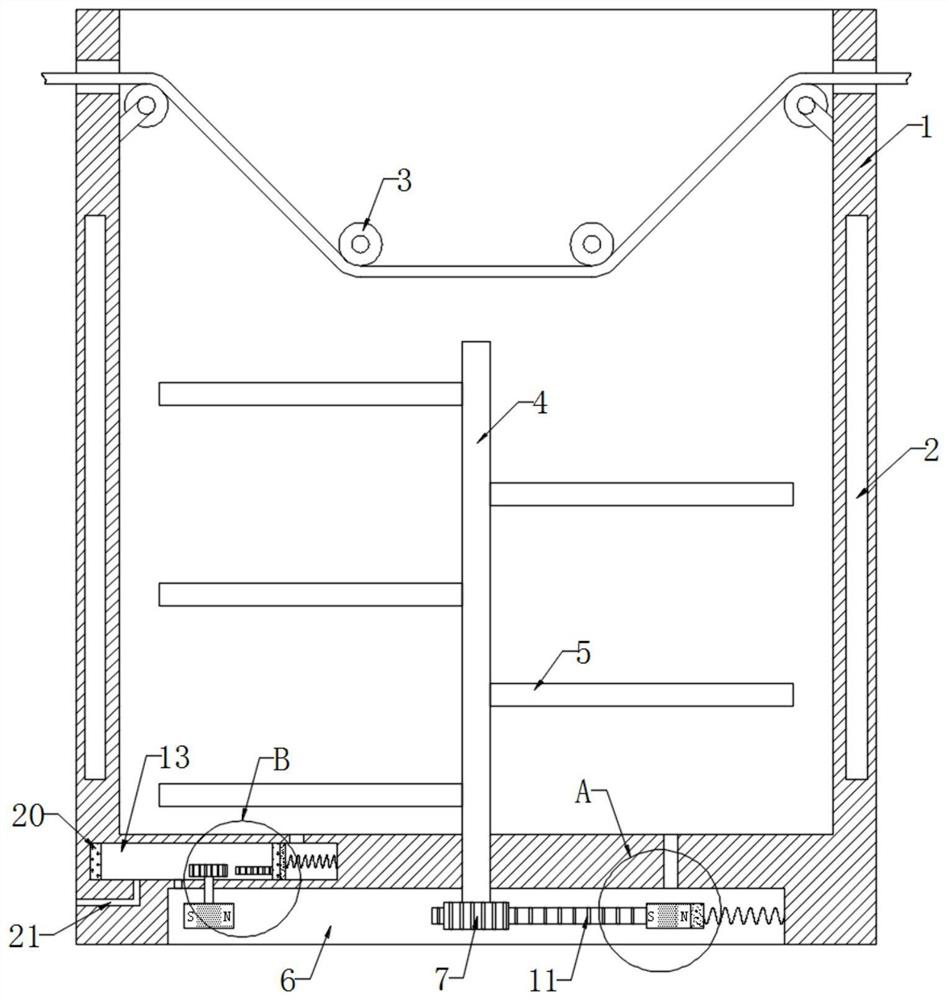

Dyeing device for textile fabric

InactiveCN108004699AImprove dyeing efficiencyUniform dyeingLiquid/gas/vapor treatment machines driving mechanismsTextile treatment machine arrangementsEngineeringMechanical engineering

The invention provides a dyeing device for textile fabric and solves the technical problem that existing dyeing devices are simple in structure, incapable of stirring dye in dyeing tanks and nonuniform in dyeing. The dyeing device comprises a rack, a first lifting cylinder is fixed on the rack, a piston rod of the first lifting cylinder is vertically upward, the end of the piston rod of the firstlifting cylinder is connected with a dyeing vat with an opening in the upper portion, one end of the dyeing vat serves as an input end while the other end of the same serves as an output end, an isolating plate is arranged in the middle of the dyeing vat through a detachable structure and divides the inside of the dyeing vat into an upper dyeing portion and a lower stirring portion, a shifting mechanism for shifting fabric and a stirring mechanism for stirring dye are arranged on the dyeing vat, the shifting mechanism is positioned in the upper dyeing portion, the stirring mechanism is positioned in the lower stirring portion, and a conveying mechanism is used for conveying fabric into the dyeing vat is arranged on one side, close to the input end, of the rack. The dyeing device has the advantage of uniformity in dyeing.

Owner:孙艳

High-efficiency uniform dyeing method for textile fabrics

InactiveCN111996704ASave energyUniform dyeingLiquid/gas/vapor treatment machines driving mechanismsTextile treatment machine arrangementsPolymer scienceElectric power equipment

The invention discloses a high-efficiency uniform dyeing method for textile fabrics. The high-efficiency uniform dyeing method for the textile fabrics comprises the following steps of S1, blending; S2, heating; S3, dyeing; and S4, drying. A dyeing device is also involved in the dyeing method, and comprises a dyeing tank, wherein a heating ring is embedded to the inner wall of the dyeing tank; discharge holes are symmetrically formed in the side walls of the dyeing tank; multiple drive rollers are symmetrically and rotatably connected to the inner wall of the dyeing tank through rotary shafts;vertical rods are rotatably connected to the bottom part in the dyeing tank; and multiple stirring rods are fixedly connected to the side walls of the vertical rods. According to the high-efficiency uniform dyeing method for the textile fabrics provided by the invention, when the temperature in a groove reaches to a critical value on a first temperature control chip, magnetism is produced on an electromagnet, the electromagnet further drives a toothed plate to slide leftwards under the action of a magnetic attraction force of a permanent magnet block, a first gear is driven to rotate, a stirring rod is further rotated to stir dyestuffs in the dyeing tank, and heat energy generated in the dyeing tank enables the electromagnet to work, so that the magnetic force drives the stirring rod to rotate, no power equipment is needed for driving, and the energy is saved.

Owner:刘琳

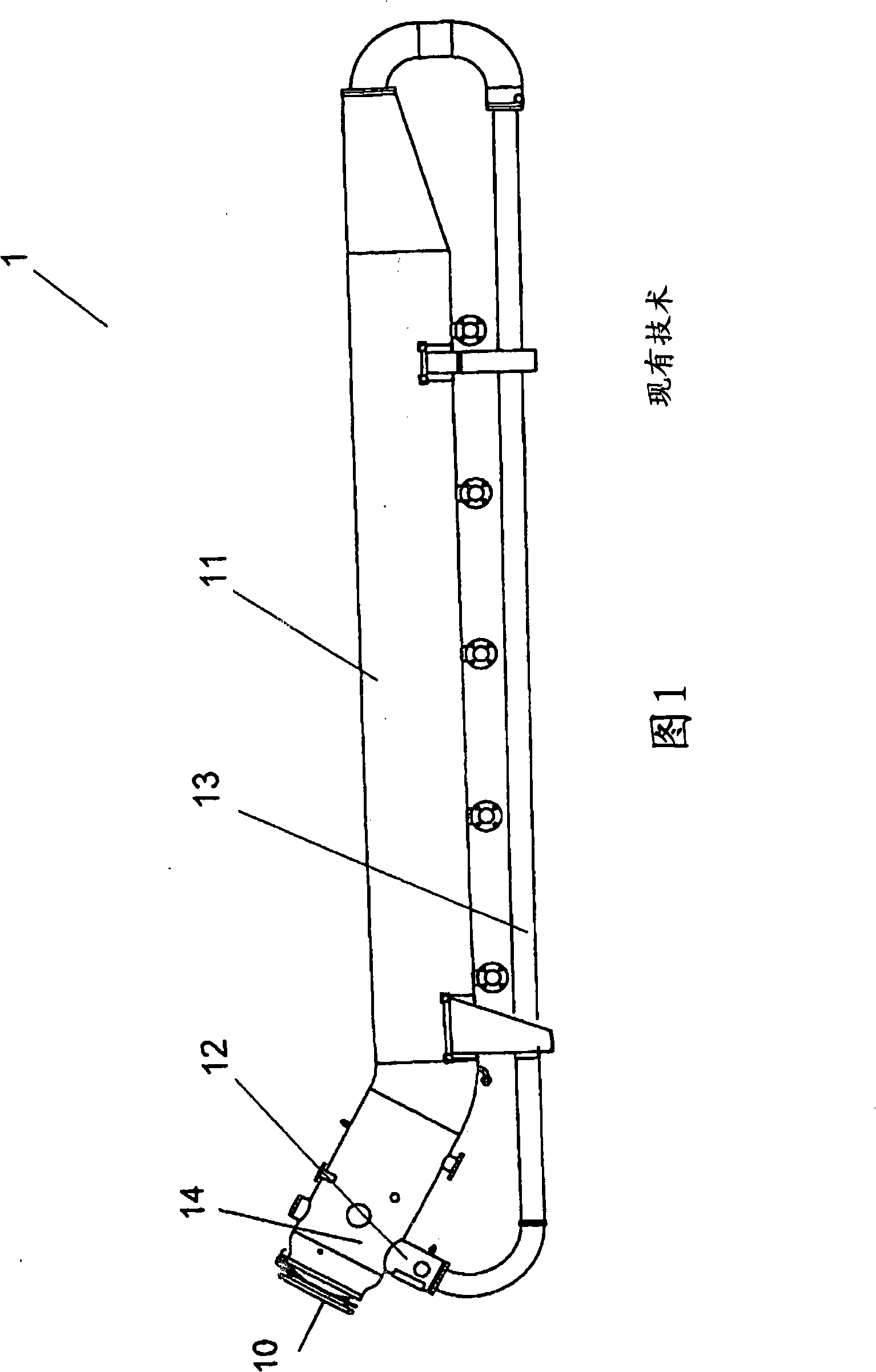

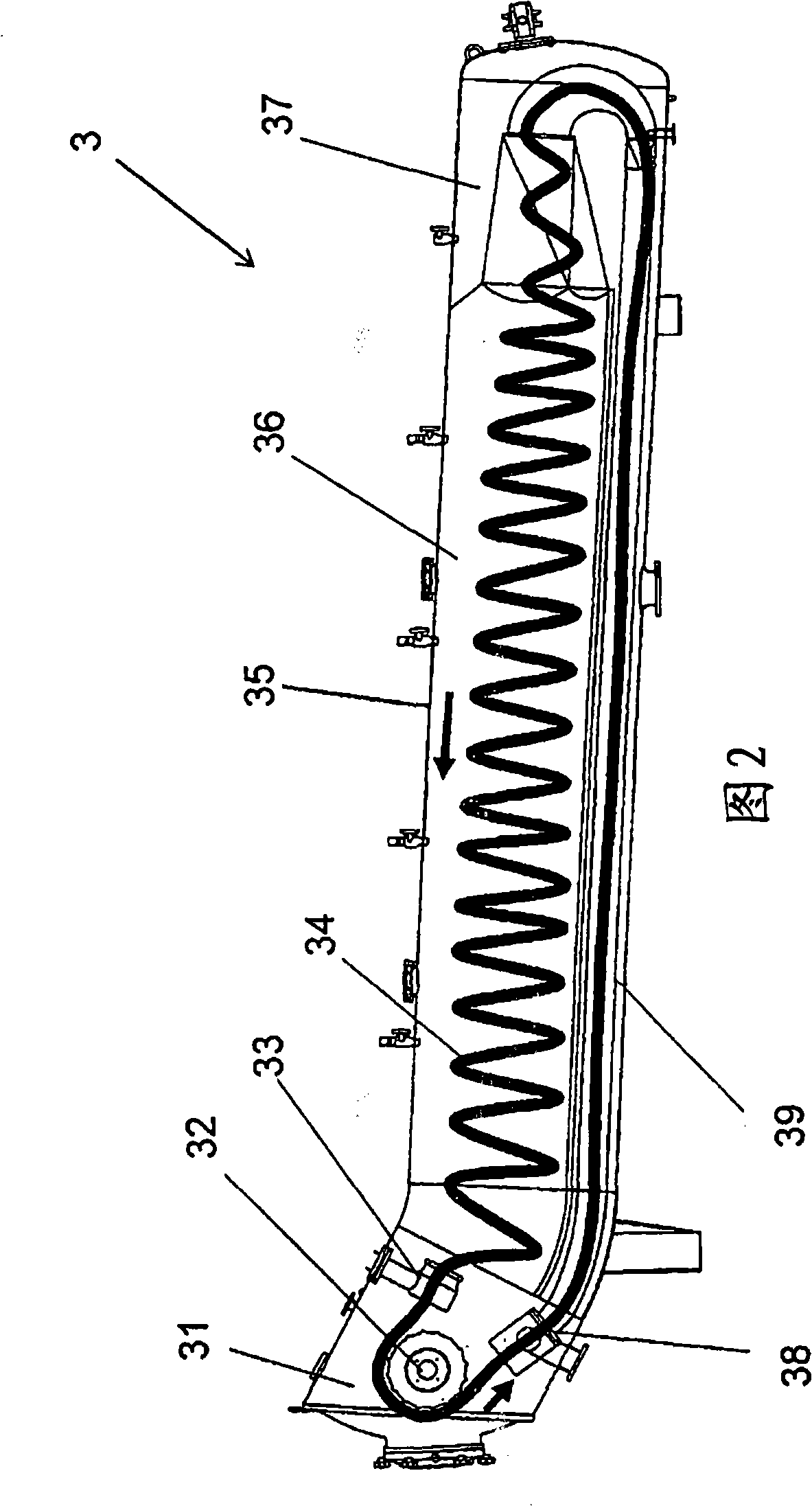

Jet fabric dyeing machine

InactiveCN101270541ATextile treatment containersLiquid/gas/vapor treatment of propelled fabricsEngineeringGuide tube

A fabric dyeing machine comprises a travelling tube, a storage chamber in communication with both ends of the travelling tube to form an endless travel path for an endless fabric rope, a nozzle operable to propel an endless fabric rope around the travel path by directing jets of dye liquor onto the endless fabric rope; and an outer vessel enclosing both the storage chamber and the travelling tube. The outer vessel may define the storage chamber, with the travelling tube located inside the outer vessel. The travelling tube and / or the storage chamber may be elongate and arranged along a slope at a few degrees to the horizontal, for example 3 to 5 degrees. A second travelling tube and nozzle can share the storage chamber to give a second endless travel path for the second endless fabric rope.

Owner:FALMER INVESTMENTS LTD

Insulated product

InactiveUS20100024125A1More aesthetic appearanceMore appearance performanceCrochetingGarment special featuresEngineeringElectrical and Electronics engineering

Owner:LI YICK LAP

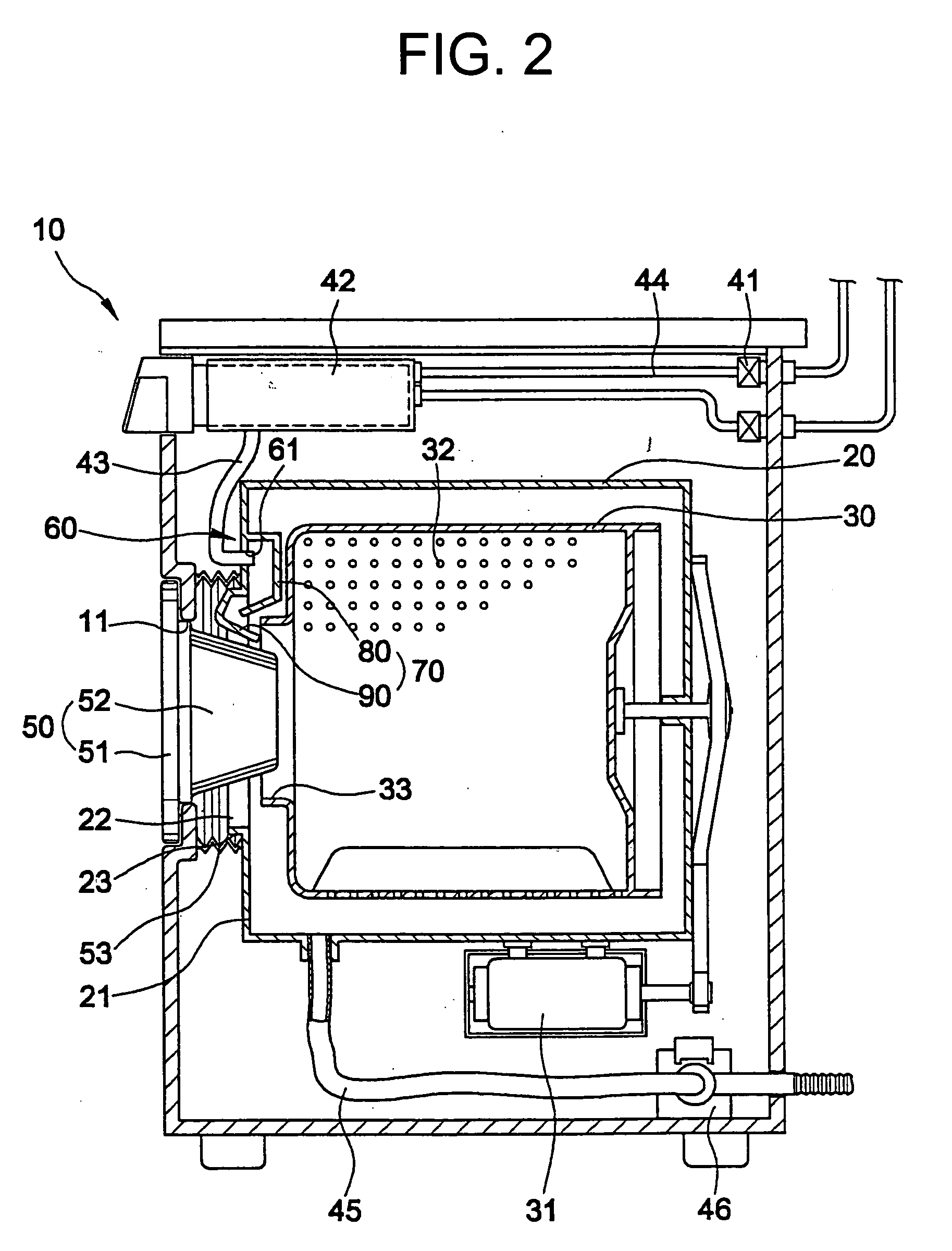

Drum type washing machine

InactiveUS20050103063A1Prevent leakageConvenient ArrangementLiquid surface applicatorsElectrostatic cleaningWash waterWater supply

A drum type washing machine in which wash water fed to a tub via a water supply pipe is directly supplied into a drum. The washing machine includes a housing, a tub arranged in the housing to contain wash water therein, a drum rotatably mounted in the tub, a water supply pipe adapted to supply wash water into the tub, and a water supply guide unit provided at the tub, to guide the wash water from the water supply pipe to be directly supplied into the drum. Since the wash water is directly supplied into the drum, laundry contained in the drum is wetted by the wash water, immediately after the supply of the wash water. Thus, it is possible to reduce the wash time for the laundry.

Owner:SAMSUNG ELECTRONICS CO LTD

Cold pad batch dyeing machine and dyeing process employing same

ActiveCN110219117AHigh color fastnessImprove qualityTextile treatment containersTextile treatment carriersEngineeringMechanical engineering

The invention relates to a cold pad batch dyeing machine and a dyeing process employing the same, and relates to the technical field of cloth printing and dyeing equipment. The cold pad batch dyeing machine comprises a rack, a conveying mechanism, a coloring mechanism and a cold pad patch mechanism. The conveying mechanism for allowing cloth dyeing is arranged on the rack. The coloring mechanism and the cold pad batch mechanism are arranged on the rack. The cold pad batch mechanism comprises a frame, a driving roller, a driving component, a flexible film, round sealing plates and splicing components. The frame is arranged on one side of the rack, the driving roller for winding cloth subjected to dip dyeing by dyestuff is rotatably arranged on the frame, the driving component for driving the driving roller to rotate is arranged on the frame, the flexible film sleeves the driving roller wrapped with the cloth, the sealing plates are coaxially fixed to two ends of the driving roller and rotate synchronously along with the driving roller, the splicing components connect two ends of the flexible film with the sealing plates to cover the surface of the cloth, and the inner surface of theflexible film is abutted against the cloth. The cold pad batch dyeing machine has the effect of reducing loss of dyeing liquid during stacking and dyeing of the cloth to improve the dyeing quality ofthe cloth.

Owner:浙江华晨印染有限公司

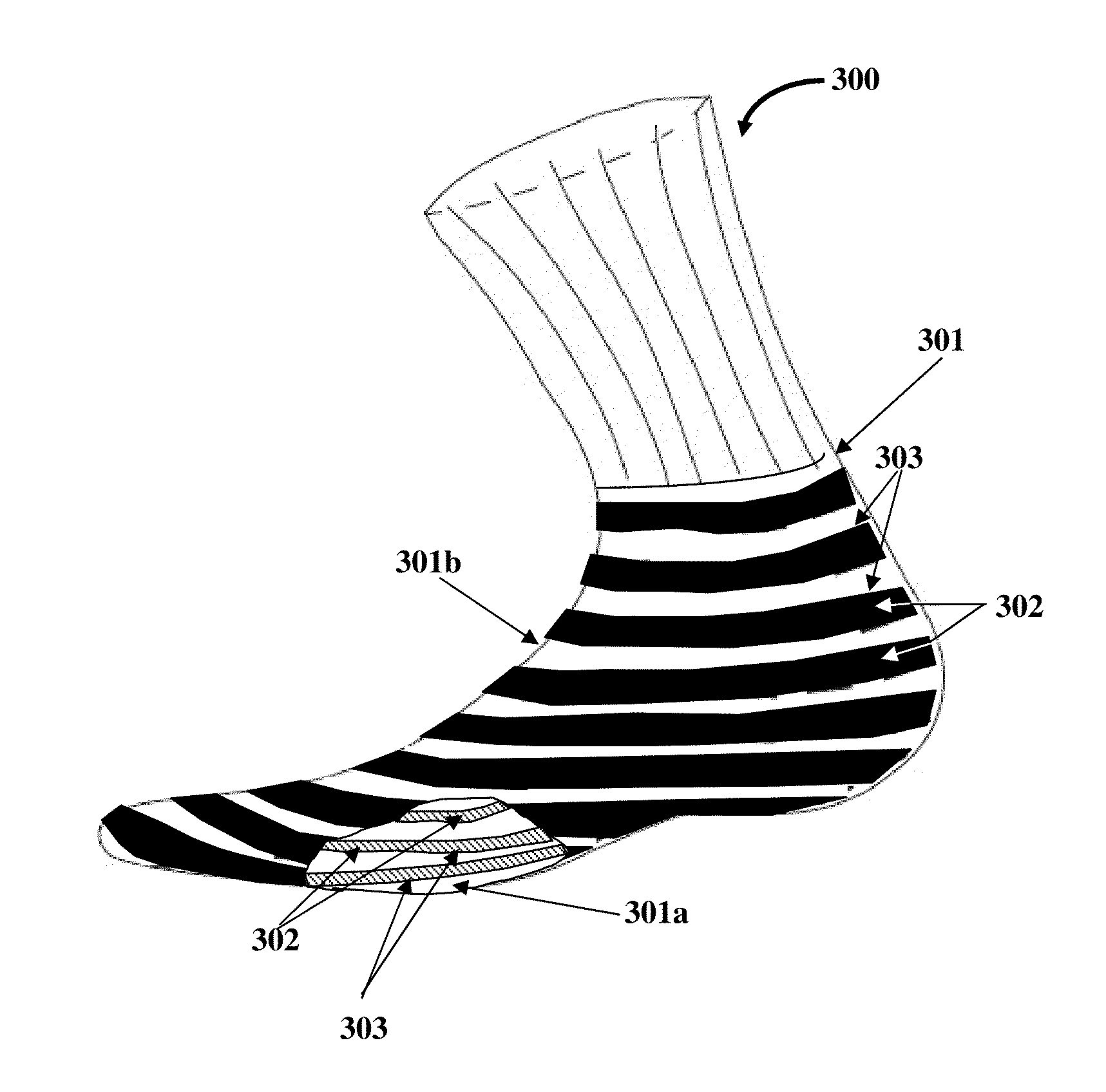

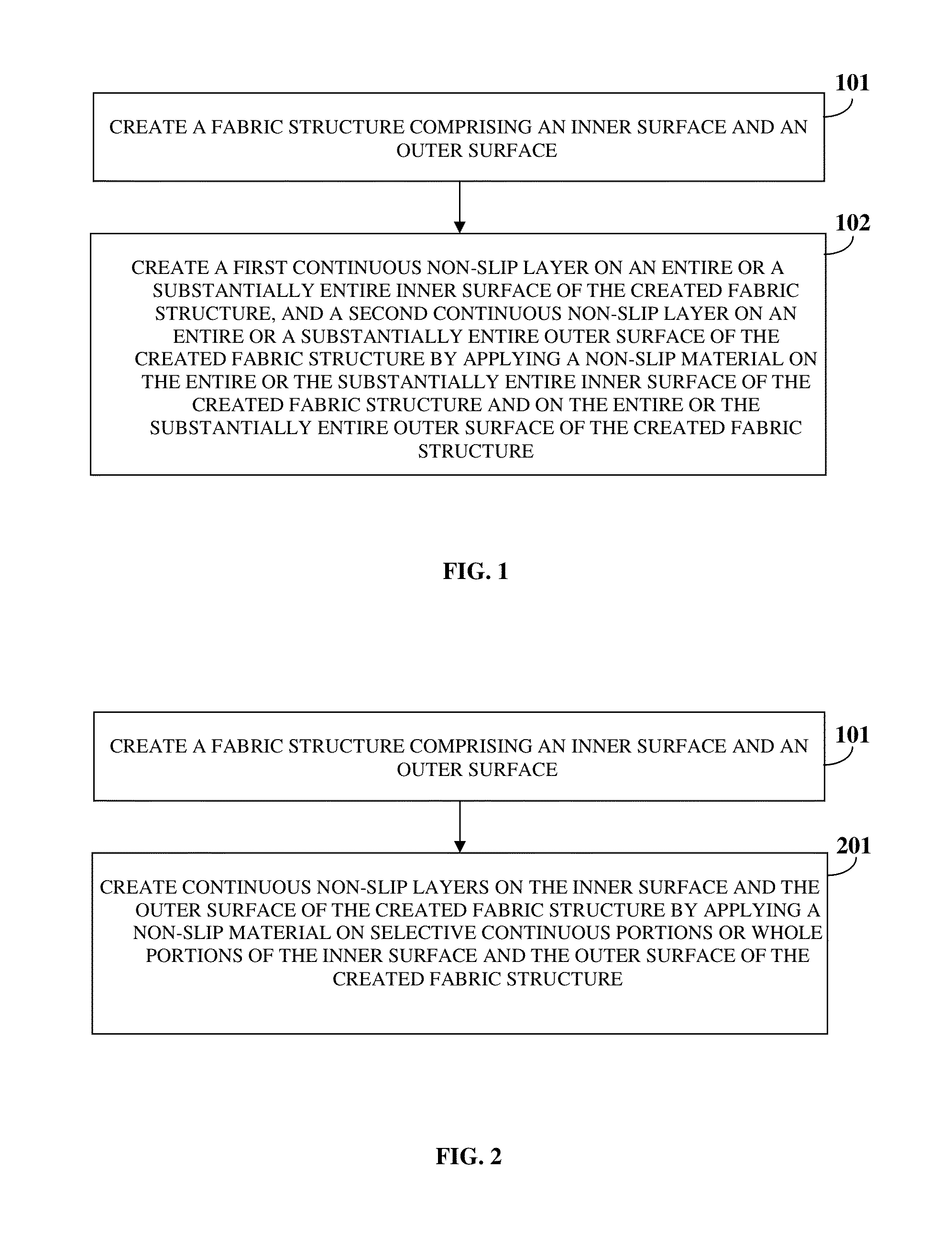

Continuous Non-slip Layered Garment

InactiveUS20150275422A1Prevent slippingCrochetingOrnamental textile articlesBiomedical engineeringFabric structure

A method for making a continuous non-slip layered garment includes creating a fabric structure having inner and outer surfaces, which conforms to a body part, and creating continuous non-slip layers on the inner and outer surfaces of the fabric structure. The inner surface is proximal to a user contact surface and distal to an external contact surface. The outer surface is proximal to the external contact surface and distal to the user contact surface. The continuous non-slip layers are created by applying a non-slip material on selective continuous portions, selective non-continuous portions, whole portions, or an entirety of the inner surface and the outer surface of the fabric structure. The continuous non-slip layers provide simultaneous gripping contact between the inner surface of the fabric structure and the user contact surface, and between the outer surface of the fabric structure and the external contact surface.

Owner:TRUSOX LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com