Jet fabric dyeing machine

A technology for dyeing machines and fabrics, applied in the direction of liquid/gas/steam jet propulsion fabrics, textile processing machine accessories, liquid/gas/steam fabric treatment, etc., which can solve the problems of different and increased wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

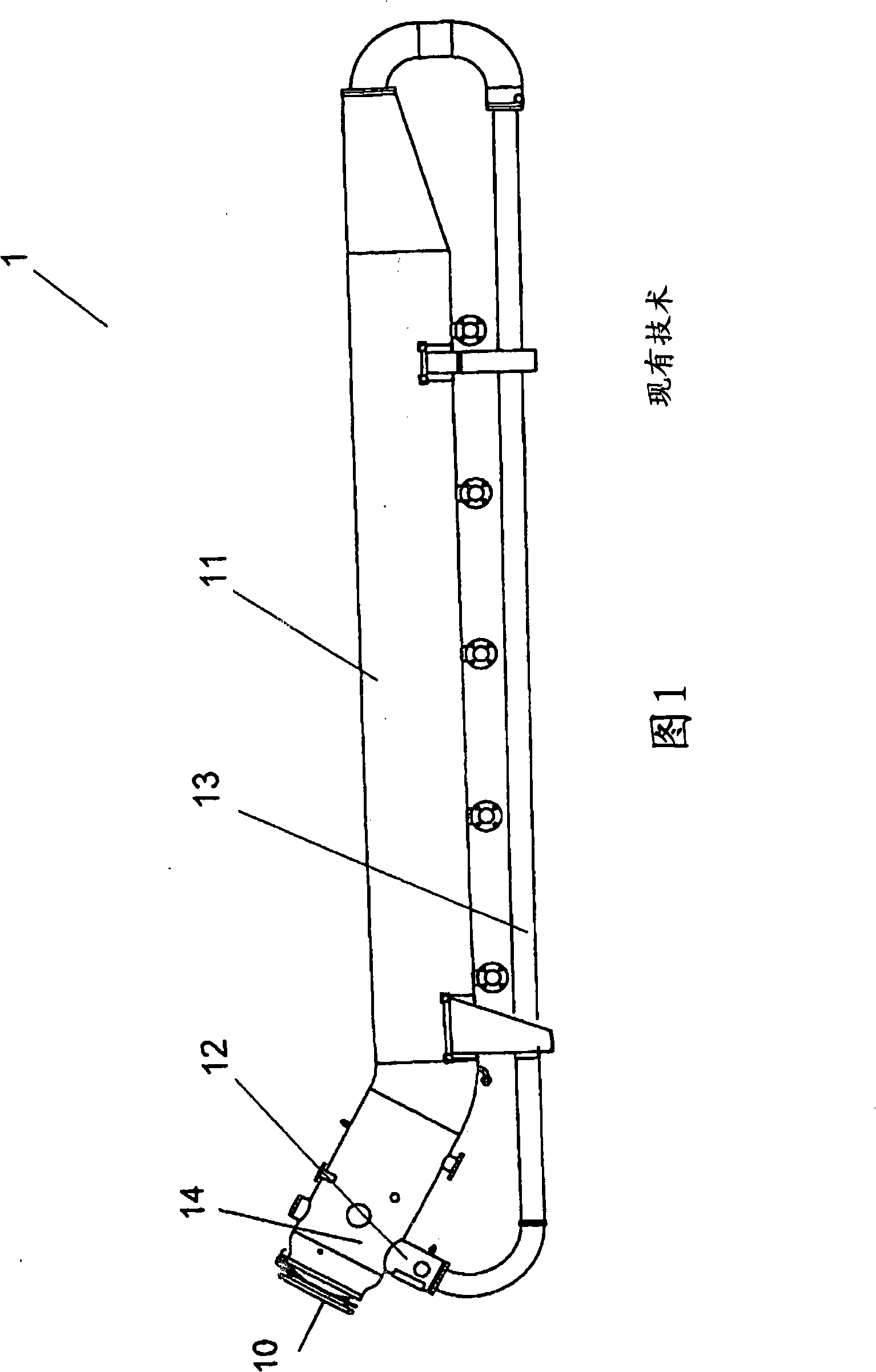

[0028] Figure 1 shows an external side view of a conventional high-speed jet-type fabric dyeing machine through which a circular fabric rope is circulated through which jets of dye liquor are directed onto the fabric by means of nozzles. The fabric and then the discharged dye liquor is fed back to the nozzle.

[0029] The dyeing machine 1 comprises a cloth trough 11 in the form of a horizontally arranged large-diameter pipe or cylindrical container. One end of the cloth chute is inclined upwards and has an outlet therein which is connected to the inlet of a tubular nozzle 12 . The nozzle 12 is also cylindrical, has a smaller diameter than the cloth groove 11, and points in a substantially downward direction. The fabric can pass through a nozzle 12 provided with a nozzle gap or head through which one or more high velocity jets of dye liquor are directed downwards and inwards onto the fabric in the nozzle, thereby in a forward cycle Propel the fabric through the nozzle in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com