Patents

Literature

166results about "Liquid/gas/vapor roped fabric treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-temperature scouring and bleaching agent and preparation method thereof and preprocessing technique

InactiveCN101037842AReduce the bleaching temperatureThe effect of the pretreatment process is obviousBleaching apparatusTextile treatment by spraying/projectingTextile printerBenzene

The present invention realtes to a low temperature scouring and bleaching agent belonging to the pretreatment process technology field of the textile printing and dyeing industry, a manufacturing method thereof and a pretreatment process. Said low temperature scouring and bleaching agent consists of promoter QR2010 consisting of carbon tetrachloride, acetic acid esters, alkyl benzenes, emulsifying agents and scouring agents; promoter QR2011 consisting of potassium hydroxide, carbonates and penetrating agents; and promoter QR2020 consisting of acyls and nitriles activating agents and builders. Said three promoters are prepared using routine methods and are deposited solely. When used, the three promoters, together with hydrogen peroxide, are mixed according to different proportions to prepare solutions. Said low temperature scouring and bleaching agent is capable of annealing, boiling and bleaching a variety of cotton as well as cotton blending textiles at any temperature ranging from 40 DEG C to 80 DEG C, and being processed at different scouring and bleaching equipments, with a whiteness of higher than 80% and a capillary effect of 10-20 cm. Compared with the process in existing, the amount used of hydrogen peroxide activating agent is 1 / 7 to 1 / 5 of that originally used, the total energy consumption is reduced, the tonnage of used water is decreased, and billet flaws such as holes bleached by oxygen and lycra folded crepes sourced and bleached are avoided.

Owner:SHANGHAI QIRUI TEXTILE CHEM

Stab resistant and anti-ballistic material and method of making the same

The invention relates to a fabric having both stab resistant and anti-ballistic properties. The fabric is made of yarn of a weight greater than about 500 dtex, and the fabric has a minimum shrinkage factor of at least about 1% achieved through a densification treatment. The invention further relates to a method of producing a such a fabric having the steps of agitating a fabric made of a yarn of a weight greater than about 500 dtex, substantially removing a spin finish from the fabric before, during or after the agitating step, and drying the fabric.

Owner:TEIJIN TWARON GMBH

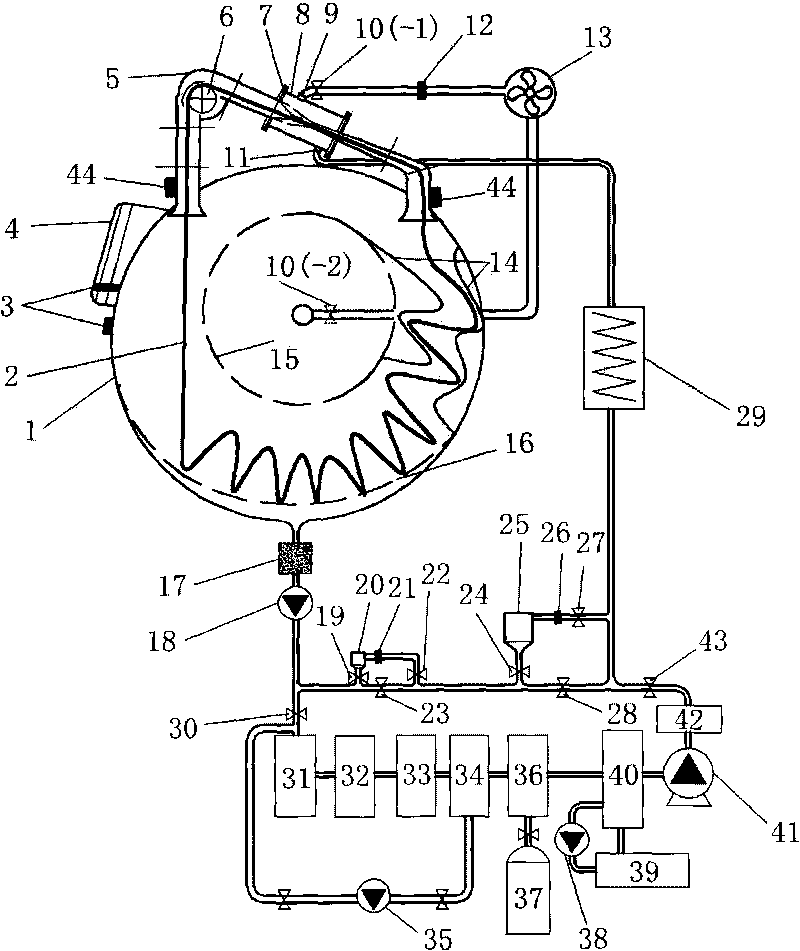

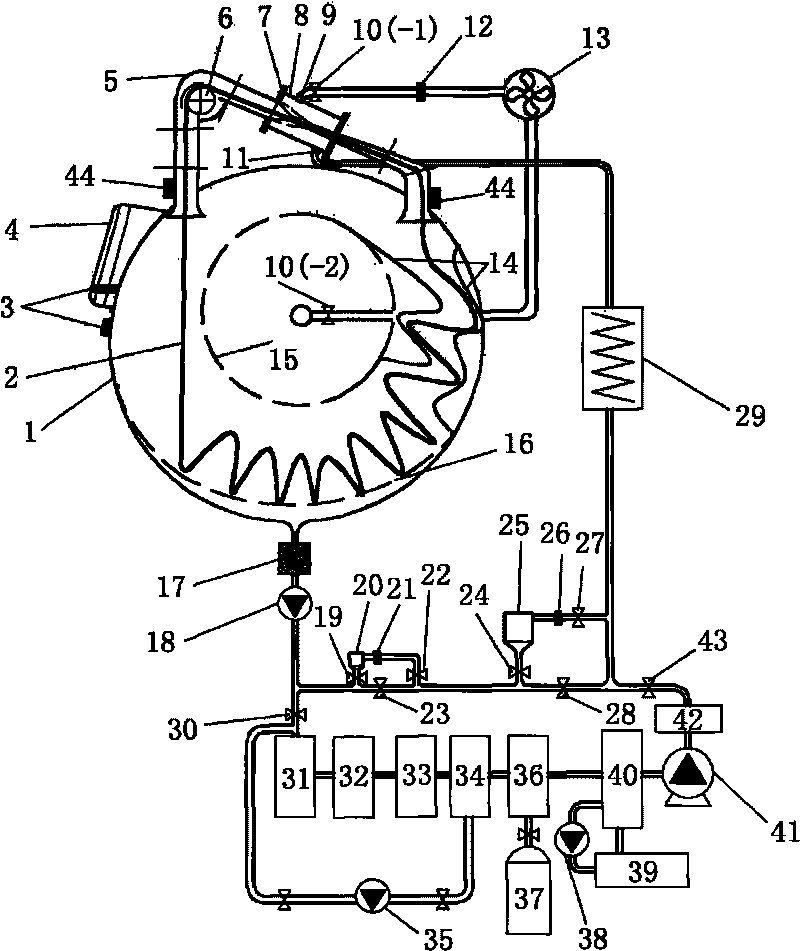

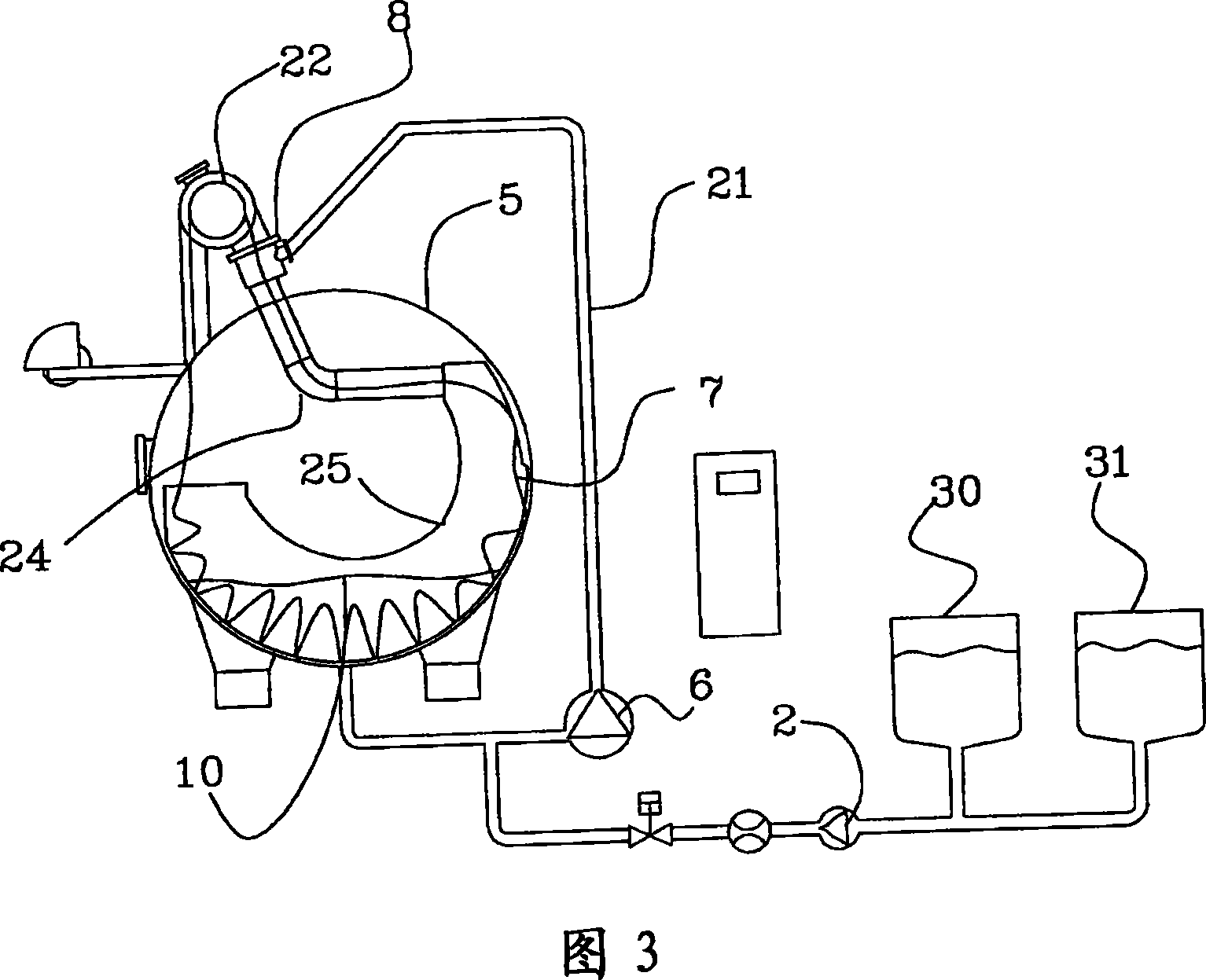

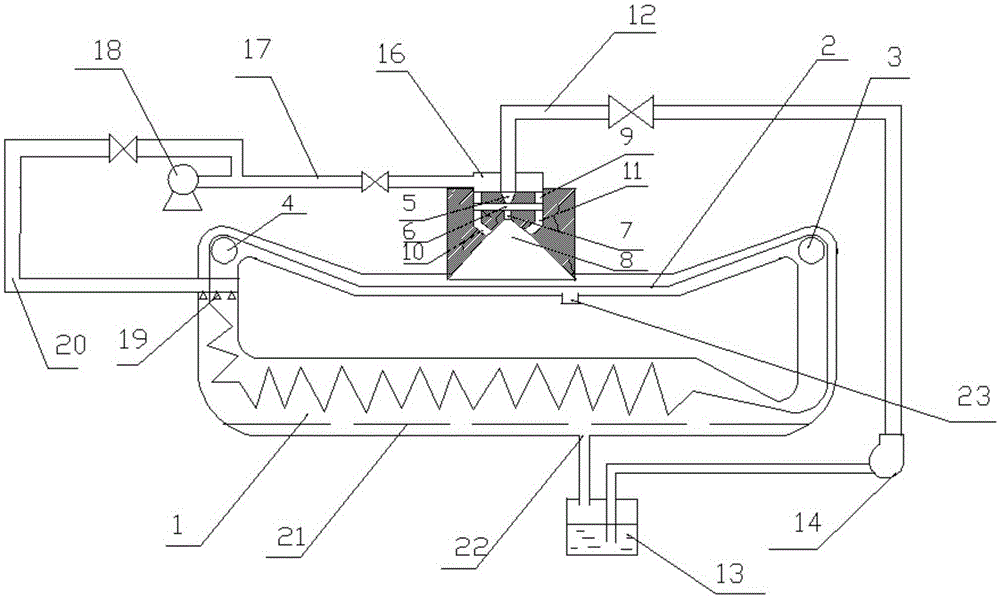

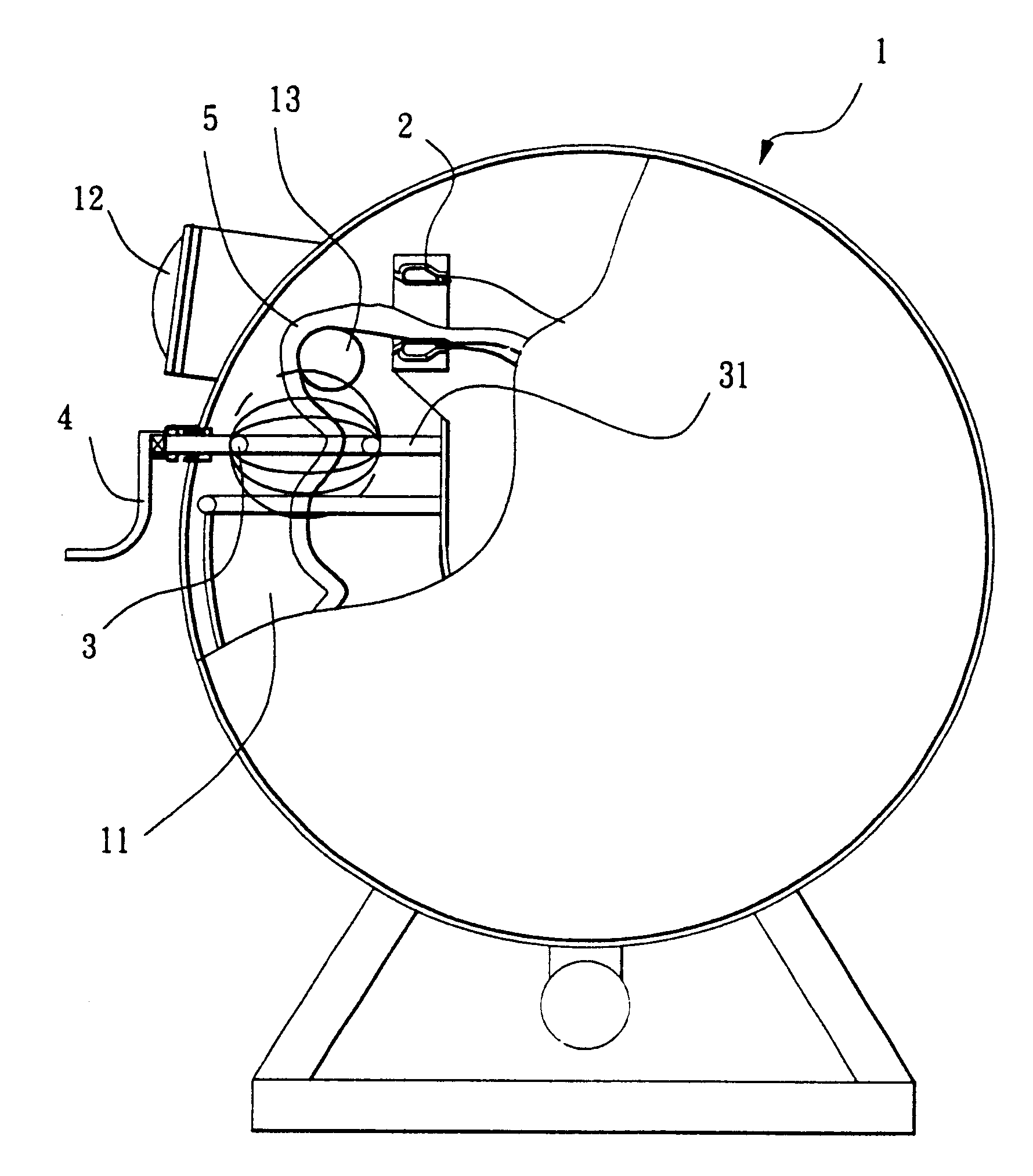

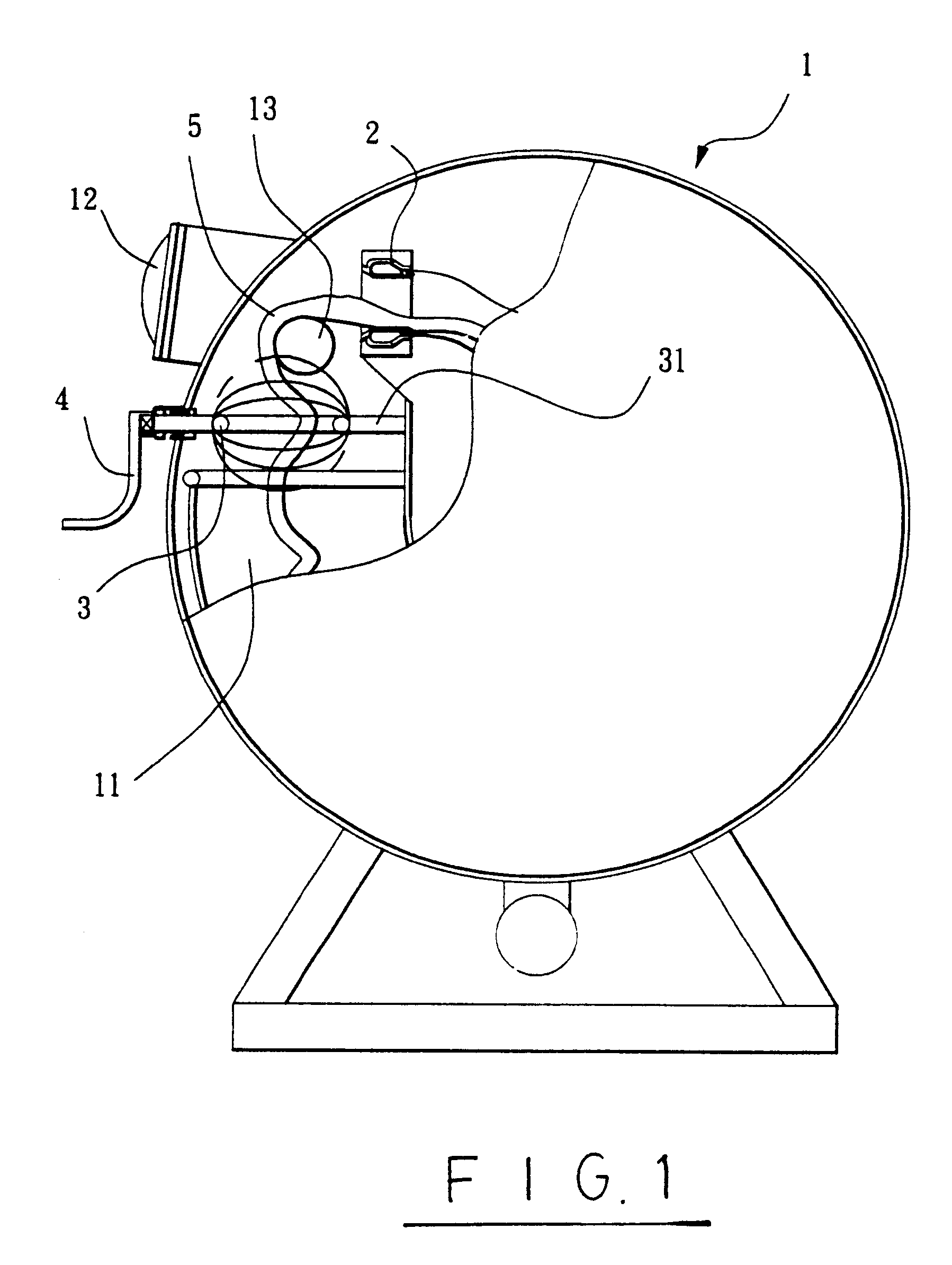

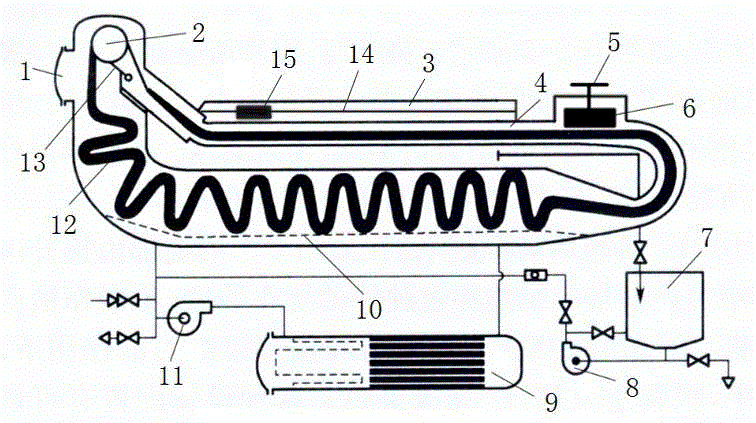

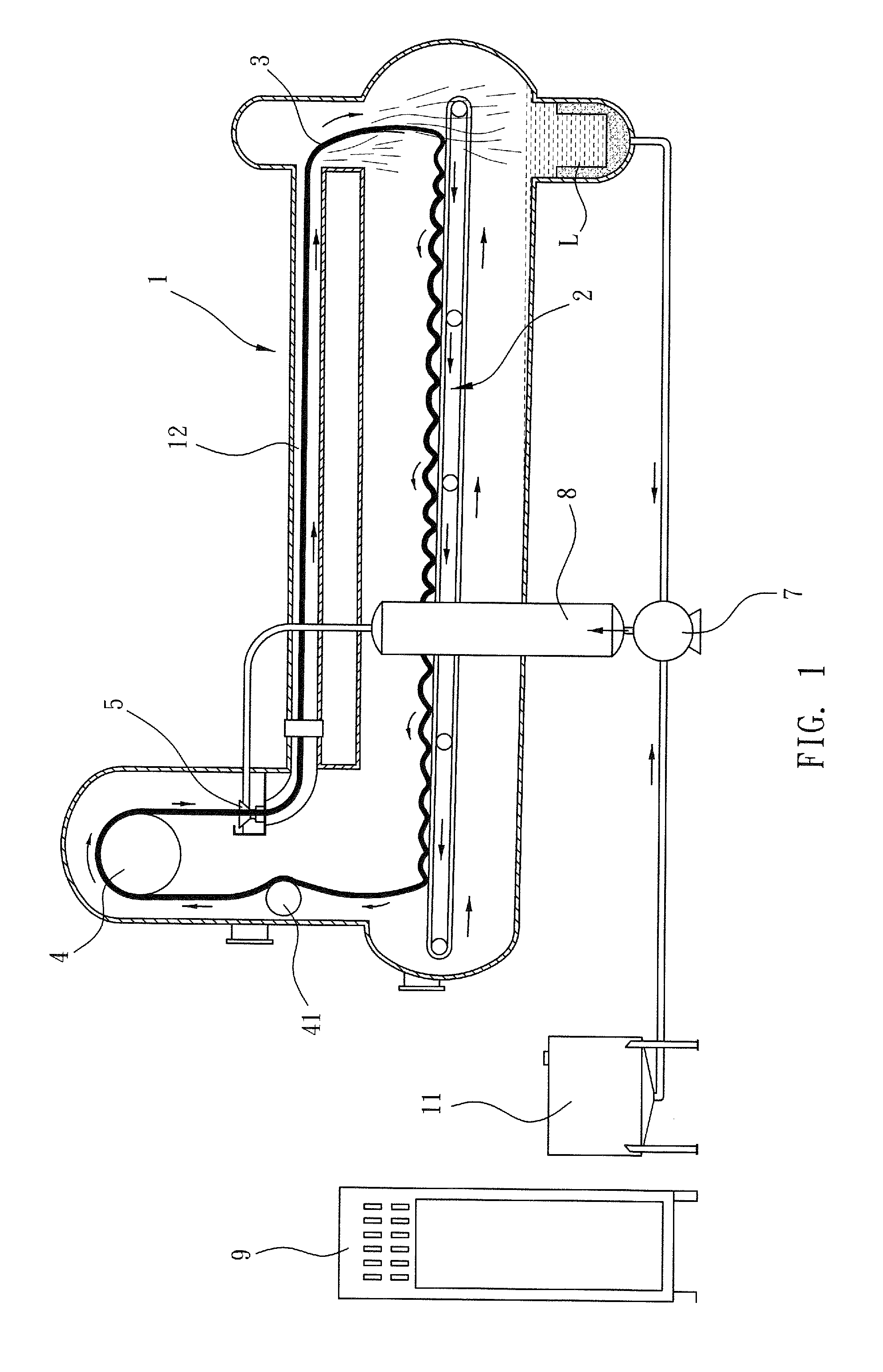

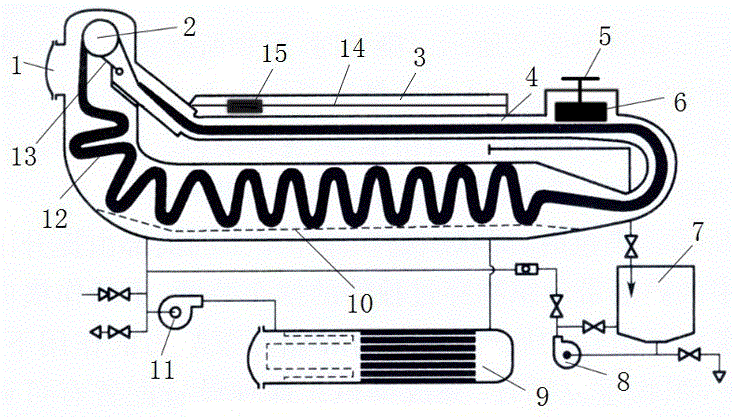

Supercritical fluid dyeing machine

ActiveCN101760914ASave powerLower average tensionTextile treatment containersLiquid/gas/vapor treatment of propelled fabricsWave shapeFree state

The invention discloses a supercritical fluid dyeing machine. A horizontal type cylindrical dyeing kettle, a magnetomotive cloth lifting wheel, a spray cavity, a wave-shaped cloth guide passage in the dyeing kettle, a heat exchanger, a dye kettle or / and an entrainer kettle and a circulating pump are used as main components to form a dyeing circulation system; and both ends of a fan are respectively connected with fluid outlets under the spray cavity and the dyeing kettle and form a cloth feeding system together with the magnetomotive cloth lifting wheel, the spray cavity and an operating opening. A rope-shaped fabric realizes circulated dyeing under the common action of the fluid in the magnetomotive cloth lifting wheel and the spray cavity, and the fluid in the dyeing kettle carries out forced circulation by the circulating pump. The dye and the fluid can realize recycling by a separating and recycling system after dyeing, and the whole dyeing circulation system and the separating and recycling system are clean to achieve the requirement during color changing and dyeing. The supercritical fluid dyeing machine can realize anhydrous dyeing processing on the fabric in a loosening type tension-free state without the production and discharge of pollutants, and has the characteristics of ecology, environmental pollution, wide adaptability of fabric variety, and the like.

Owner:SUZHOU UNIV +2

Moisture-absorption, heat-generating, quick-drying, moisturizing and thermal fabric and preparation method thereof

ActiveCN103952845AImprove hydrophilicityGood wicking and moisture-wicking functionSucessive textile treatmentsWeft knittingYarnPolyester

The invention discloses a moisture-absorption, heat-generating, quick-drying, moisturizing and thermal fabric and a preparation method thereof. The fabric is formed by weaving first yarns, second yarns, third yarns and fourth yarns, wherein the first yarns are regenerated cellulose fiber type blended yarns formed by blending linen, wool or cashmere, one or more types of cotton fibers and regenerated cellulose fibers, or regenerated cellulose multi-filaments, or regenerated cellulose staple fiber yarns; the second yarns are modified polyester fiber yarns with non-circular cross sections; the third yarns are cotton fiber type blended yarns formed by blending one or two of polyester staple fiber yarns or polyacrylonitrile fibers and cotton fibers, or all cotton yarns; the fourth yarns are polyurethane fiber yarns. The moisture absorption and heat-generating value of the fabric exceeds national standards, the moisture absorption and quick-drying performance is excellent, and the thermal insulation rate meets national standards; the fabric also has comfortable elasticity and soft and smooth hand feeling of one surface next to the skin. Meanwhile, the preparation method is simple in process, and convenient to operate.

Owner:武汉爱帝针纺实业有限公司

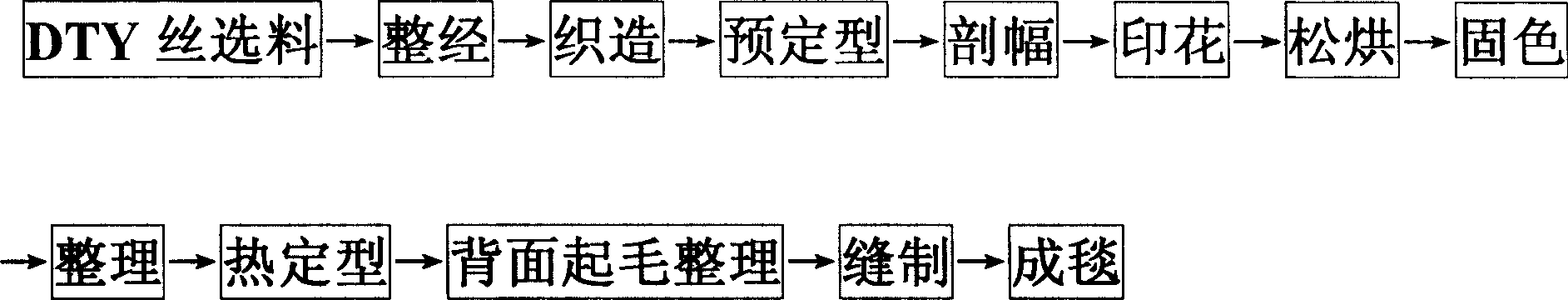

Process of machining full terylene ultrafine fiber coral fleece blanket

InactiveCN101016675ALongitudinal vertical stabilityHigh color fastnessWarp knittingHeating/cooling textile fabricsPolyesterColour fastness

The invention relates to a method for processing polyester ultra-fine fiber coral blanket comprises a DTY material selection, a warping process, a weaving process, a pre-shaping process, a cutting process, a printing process, a loosening drying process, a color fixing process, a finishing process, a thermal shaping process, a back furring finishing process, a sewing process, and final product outlet. The pre-shaping process comprises that pre-shaping the blank cloth in weaving process at high temperature before the cutting process. And the invention has the advantages that the invention can assure the contract homogeneity of blank fiber and stabilize the longitudinal verticality, to obtain better smooth, water adsorption and thermal insulation functions, and the invention can save cost, reduce SS degree of printed pollutant, and can improve the color stability of fabric.

Owner:常熟市锦绣经纬编有限公司

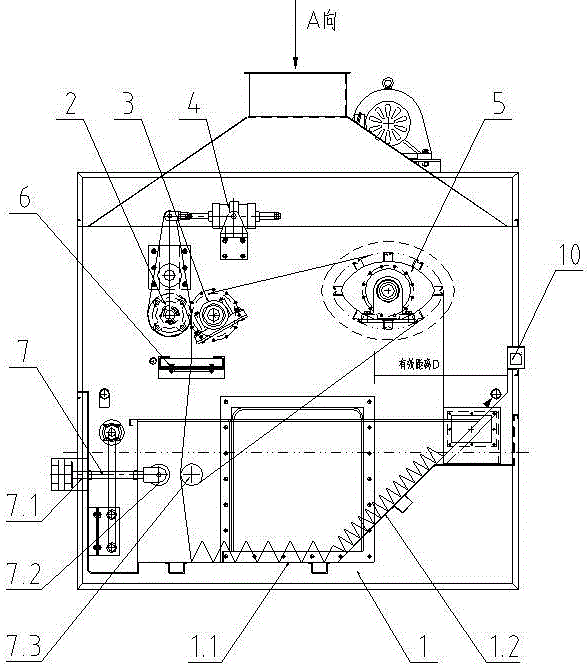

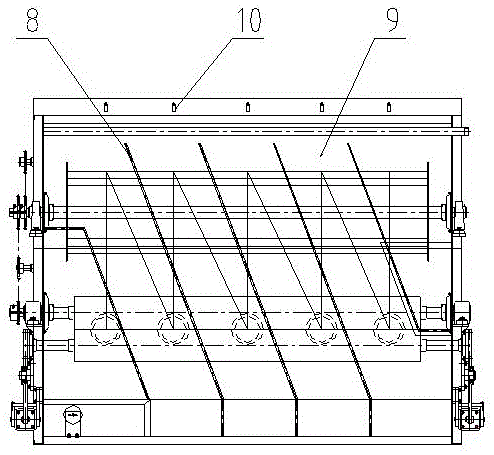

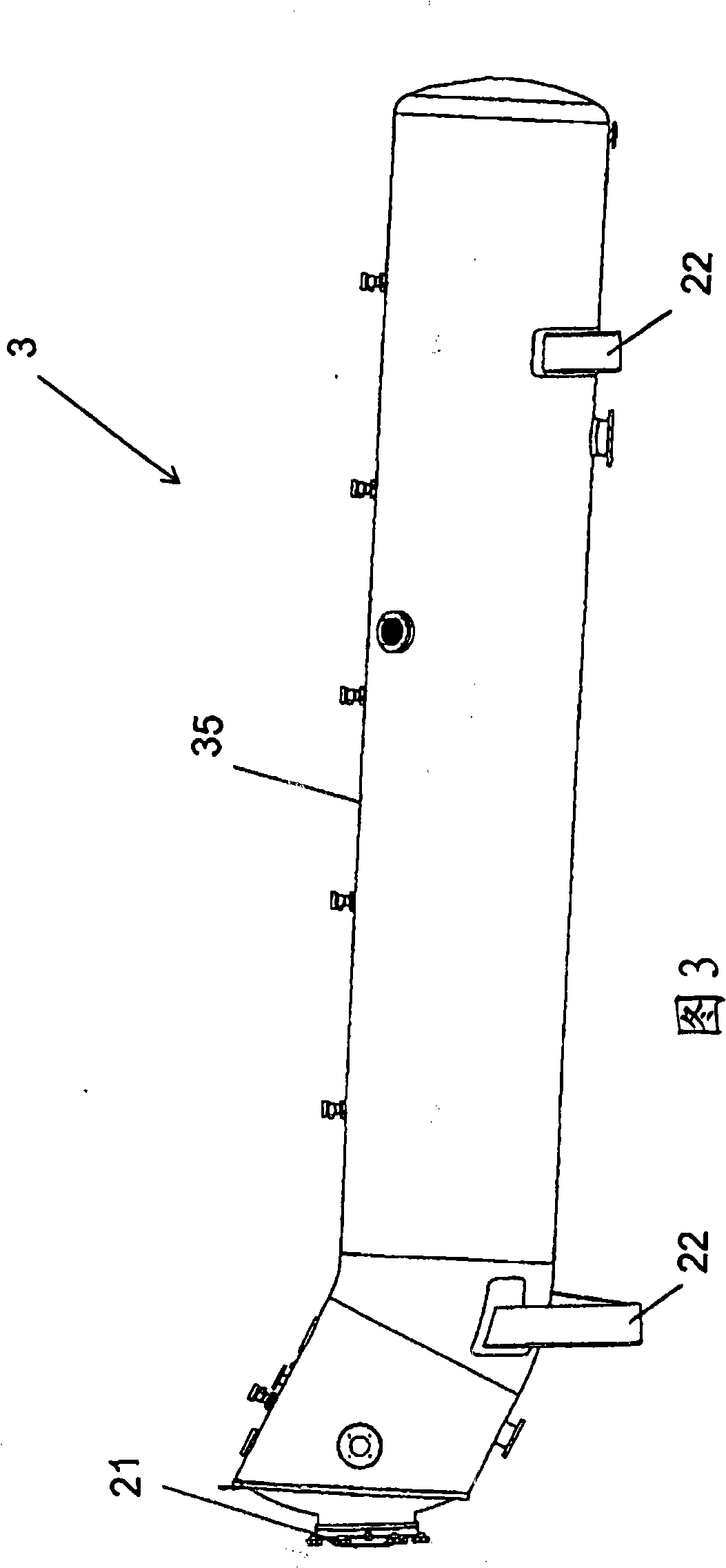

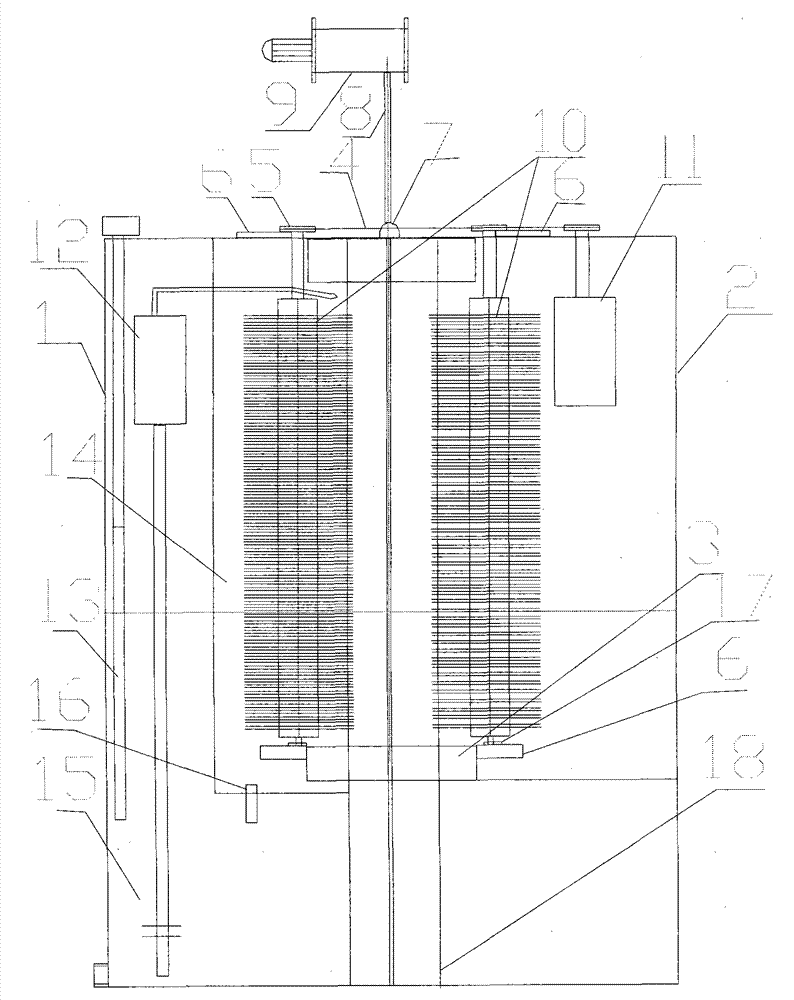

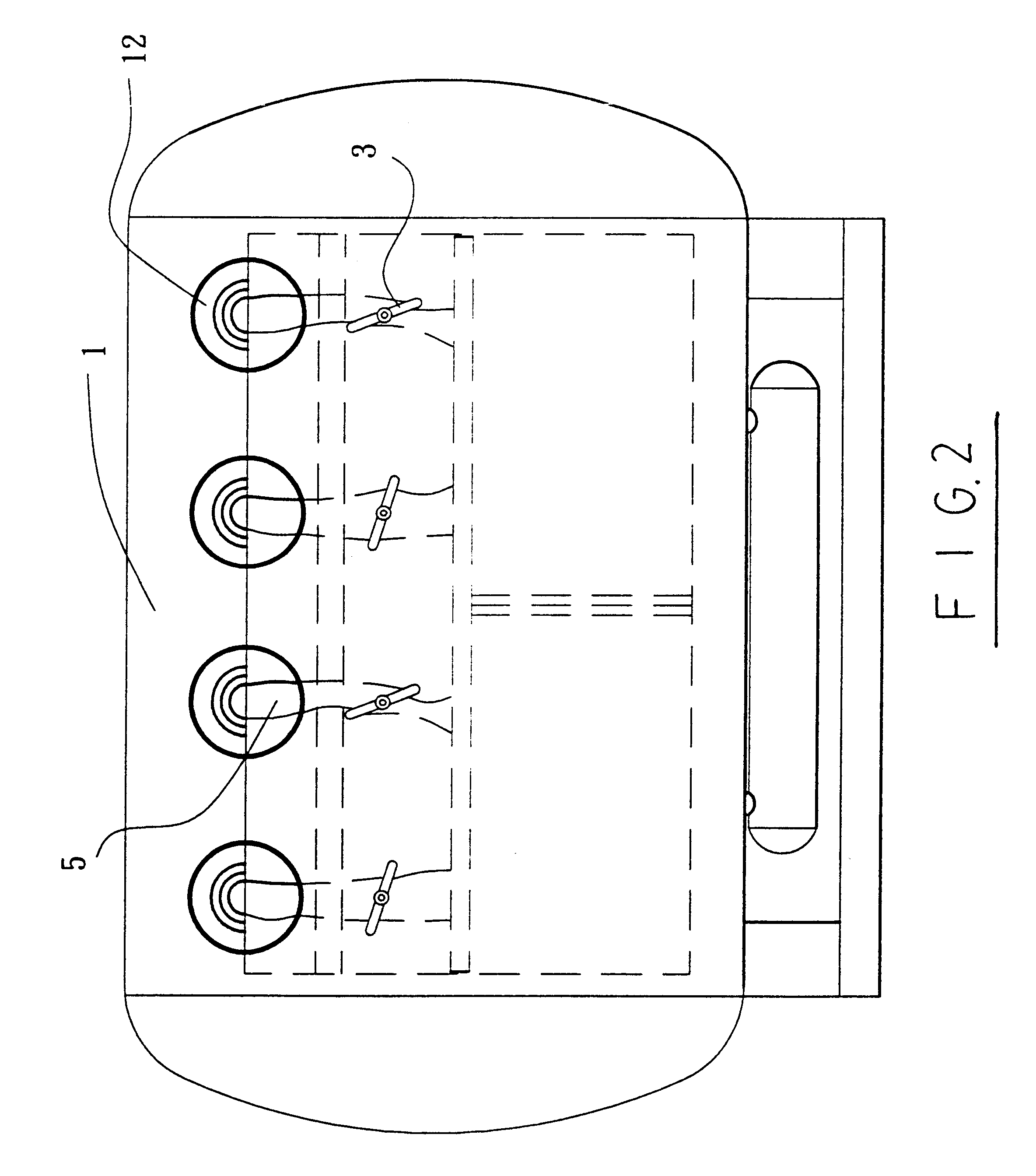

Rope-shaped washing machine

InactiveCN105133228AEnsure safetyLabor savingLiquid/gas/vapor treatment machines driving mechanismsLiquid/gas/vapor roped fabric treatmentWater channelPulp and paper industry

The invention relates to a rope-shaped washing machine and belongs to the technical field of printing and dyeing equipment. The rope-shaped washing machine comprises a plurality of unit grooves. Each unit groove comprises a water channel (1), wherein a roller set and a cloth falling roller (5) are arranged above the water channel (1), and the roller set and the cloth falling roller (5) are provided with partition plates (8); the roller set, the cloth falling roller (5) and the water channel (1) located below the roller set and the cloth falling roller (5) are divided into a plurality of unit grids (9) through the partition plates (8), and a braking assembly (7) is arranged on one side of the roller set of each unit grid (9). According to the rope-shaped washing machine, the synchronous state of fabric in each unit groove and the stacking amount of cloth in each groove body can be self-adjusted, so that labor is saved, production efficiency is improved, and operation safety of workers is guaranteed.

Owner:江阴市永欣印染机械有限公司

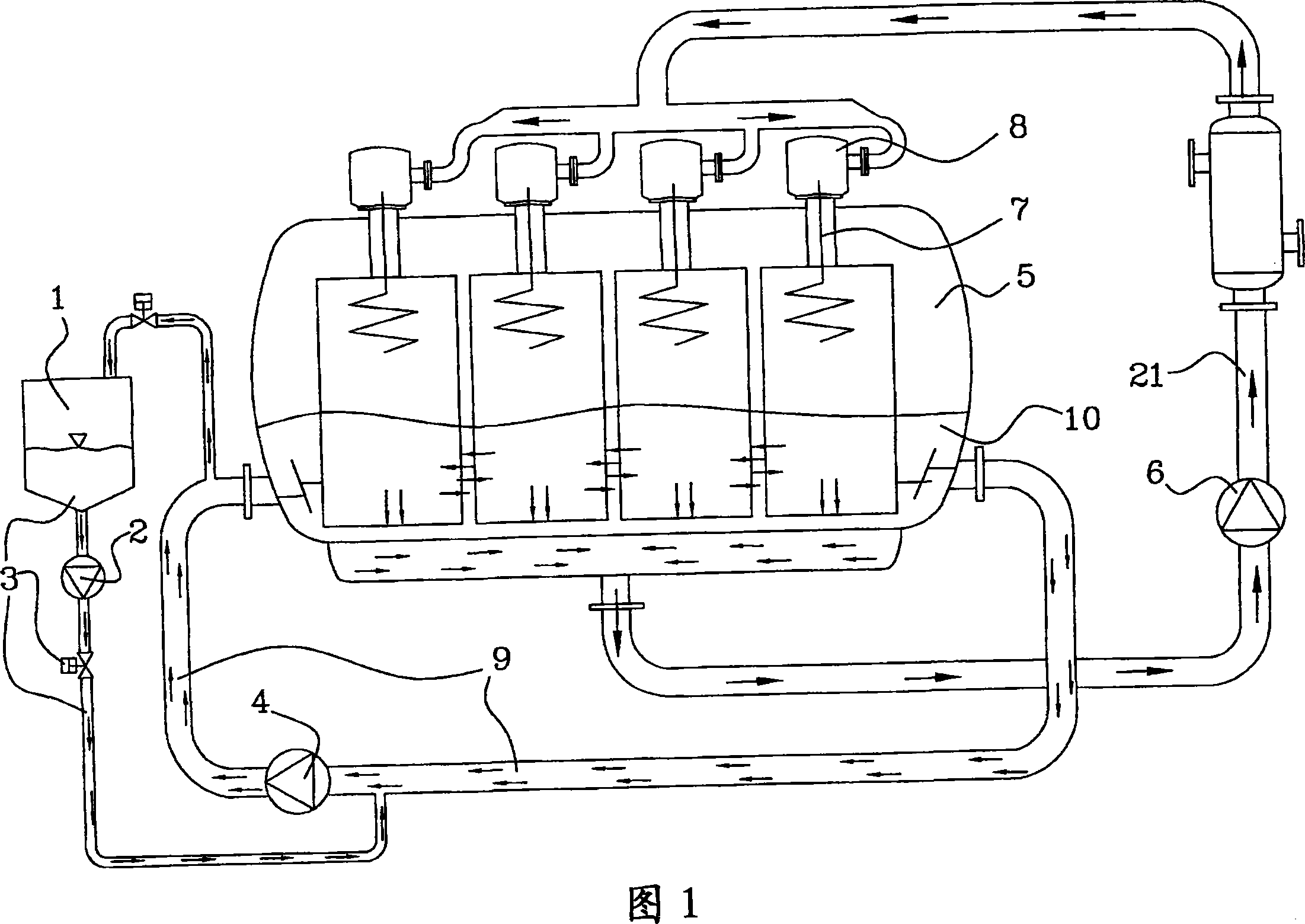

Machine for the discontinuous dyeing of fabric products

InactiveCN101117759AAvoid local increaseLarge dilution potentialLiquid/gas/vapor treatment of propelled fabricsTextile treatment machine partsChemical productsEnvironmental engineering

A machine for the discontinuous dyeing of fabric products in rope form comprises an autoclave (5) which contains a bath (10) for the treatment of the fabric and a unit for the introduction into the bath of dyes and any auxiliary chemical products contained in at least one tank (1). The introduction unit provides a recirculation duct (9) between two points on the bath (10) in which a mixing pump (4) is fitted, and provides for the introduction of the products coming from at least one tank (1) into the recirculation duct (9).

Owner:苏州巴佐尼机械设备有限公司

Jet fabric dyeing machine

InactiveCN101270541ATextile treatment containersLiquid/gas/vapor treatment of propelled fabricsEngineeringGuide tube

A fabric dyeing machine comprises a travelling tube, a storage chamber in communication with both ends of the travelling tube to form an endless travel path for an endless fabric rope, a nozzle operable to propel an endless fabric rope around the travel path by directing jets of dye liquor onto the endless fabric rope; and an outer vessel enclosing both the storage chamber and the travelling tube. The outer vessel may define the storage chamber, with the travelling tube located inside the outer vessel. The travelling tube and / or the storage chamber may be elongate and arranged along a slope at a few degrees to the horizontal, for example 3 to 5 degrees. A second travelling tube and nozzle can share the storage chamber to give a second endless travel path for the second endless fabric rope.

Owner:FALMER INVESTMENTS LTD

Mist spraying dyeing machine

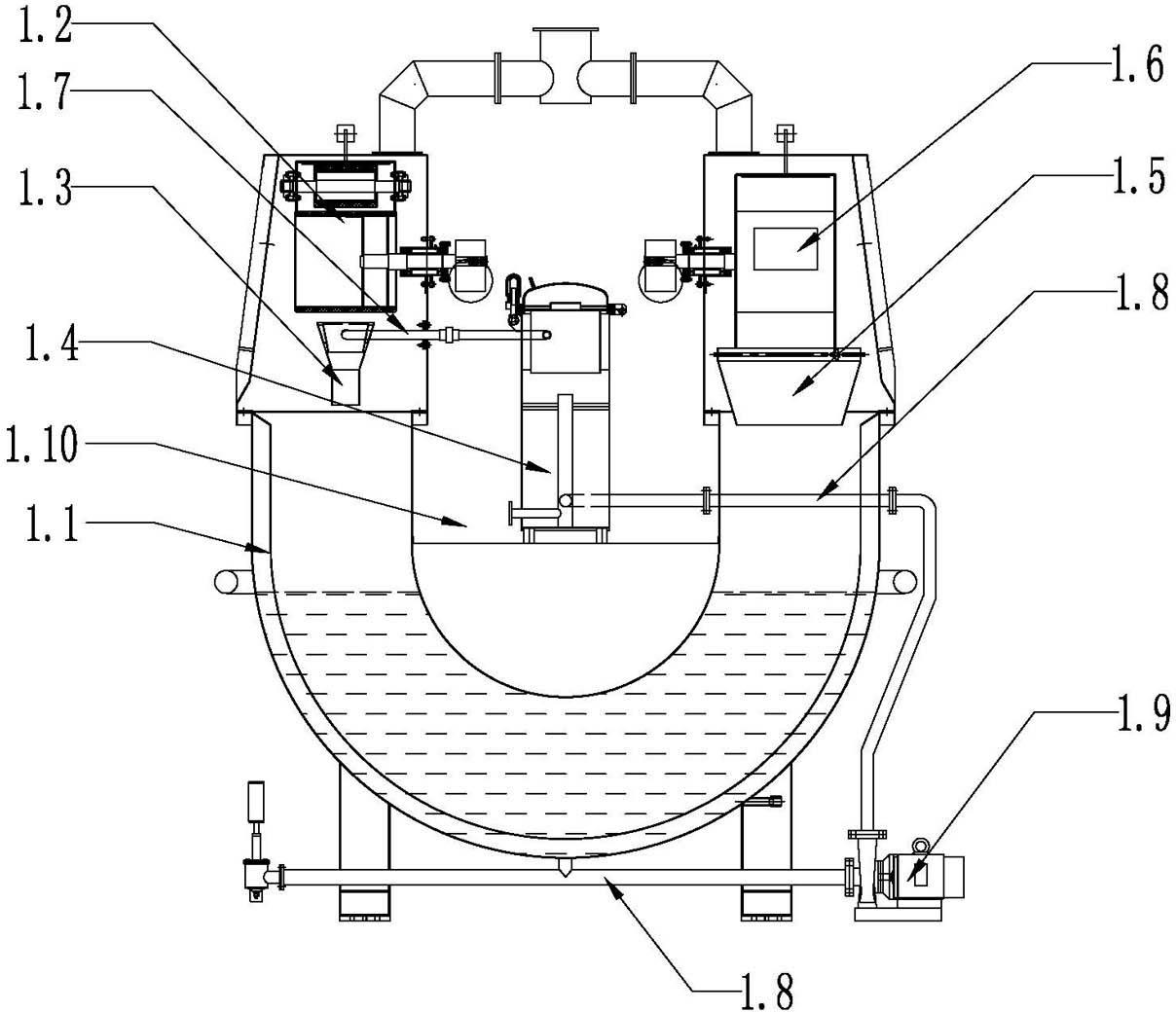

ActiveCN105420961AInto the uniformExpand the spraying areaTextile treatment machine arrangementsTextile treatment by spraying/projectingAerosol sprayAerosol Mist

The invention discloses a mist spraying dyeing machine. The mist spraying dyeing machine comprises a U-shaped fabric storage tube and a dyeing tube which is horizontally arranged above the fabric storage tube, the two ends of the dyeing tube extend upward in an inclined mode relative to the horizontal direction and are communicated with the two ends of the U-shaped fabric storage tube respectively, and the communication positions between the two ends of the U-shaped fabric storage tube and the two ends of the dyeing tube are provided with a first rotating roller and a second rotating roller respectively, wherein the first rotating roller is used for driving a fabric out of the fabric storage tube to enter the dyeing tube, the second rotating roller is used for driving the fabric out of the dyeing tube to enter the fabric storage tube, and an aerosol spray head which vertically sprays dye liquor to the fabric is arranged on the upper portion of a horizontal section of the dyeing tube. By means of the mist spraying dyeing machine, the fabric is dyed more uniformly, meanwhile, the bath ratio is lowered, and dye liquor sewage is remarkably reduced.

Owner:SUZHOU DABANG TEXTILE CO LTD

High-efficiency open-width rope washing machine

ActiveCN105603658AAchieve complexImprove washing qualityLiquid/gas/vapor roped fabric treatmentEngineeringMechanical engineering

The invention discloses a high-efficiency open-width rope washing machine. The high-efficiency open-width rope washing machine comprises a cloth feeding frame, a washing tank, a padder, a washing chamber, a door-shaped tension frame, a spraying steam chamber, an open-width processing device, a dryer and a cloth discharging device. The cloth feeding frame is provided with an edge guide, and the cloth feeding frame, the washing tank, the padder, the steam chamber, the washing chamber, the open-width processing device, the dryer for drying and the cloth discharging device are arranged in sequence. The tension frame is used for adjusting cloth tension in a whole operation process. The high-efficiency open-width rope washing machine has the advantages that washing quality of printed and dyed products is guaranteed, washing fastness is improved, and fabric handfeel is improved.

Owner:YUYUE HOME TEXTILE

Stab resistant and anti-ballistic material and method of making the same

InactiveUS7354875B2Reduce the risk of injuryHigh strengthProtective fabricsBaby linensYarnEngineering

The invention relates to a fabric having both stab resistant and anti-ballistic properties. The fabric is made of yarn of a weight greater than about 500 dtex, and the fabric has a minimum shrinkage factor of at least about 1% achieved through a densification treatment. The invention further relates to a method of producing a such a fabric having the steps of agitating a fabric made of a yarn of a weight greater than about 500 dtex, substantially removing a spin finish from the fabric before, during or after the agitating step, and drying the fabric.

Owner:TEIJIN TWARON GMBH

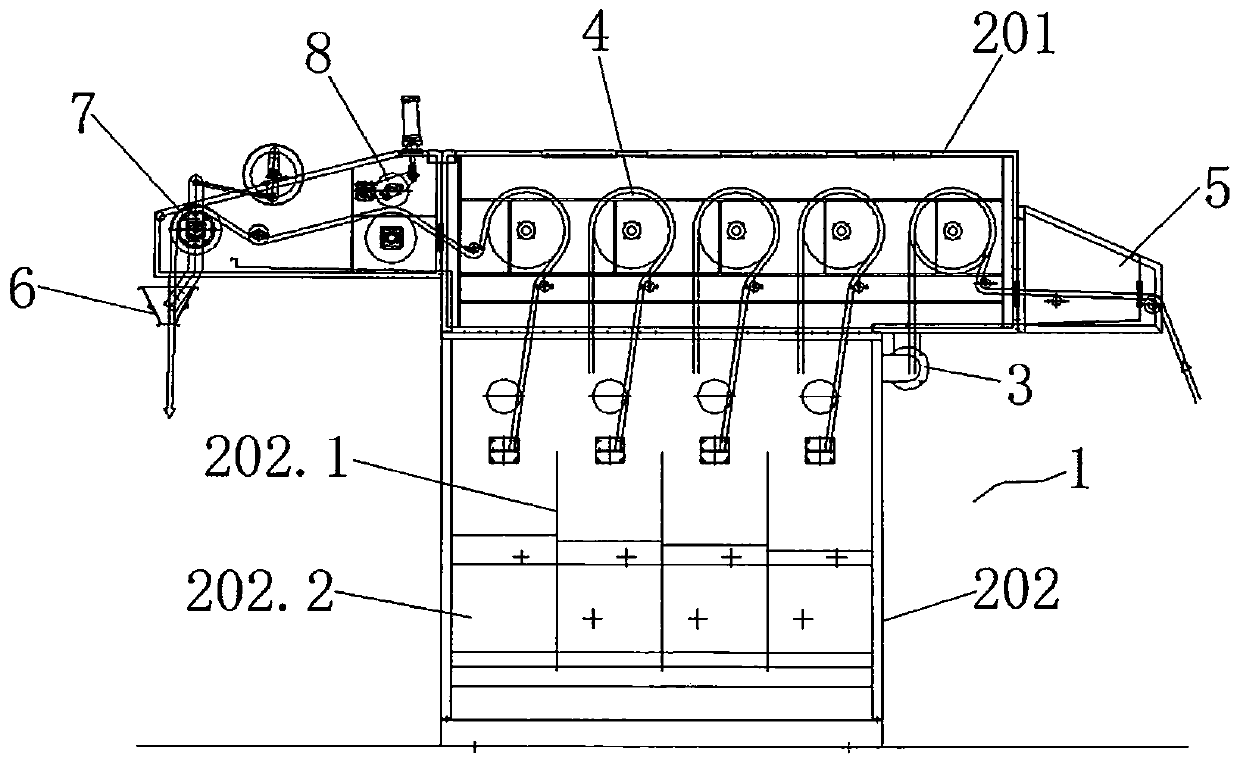

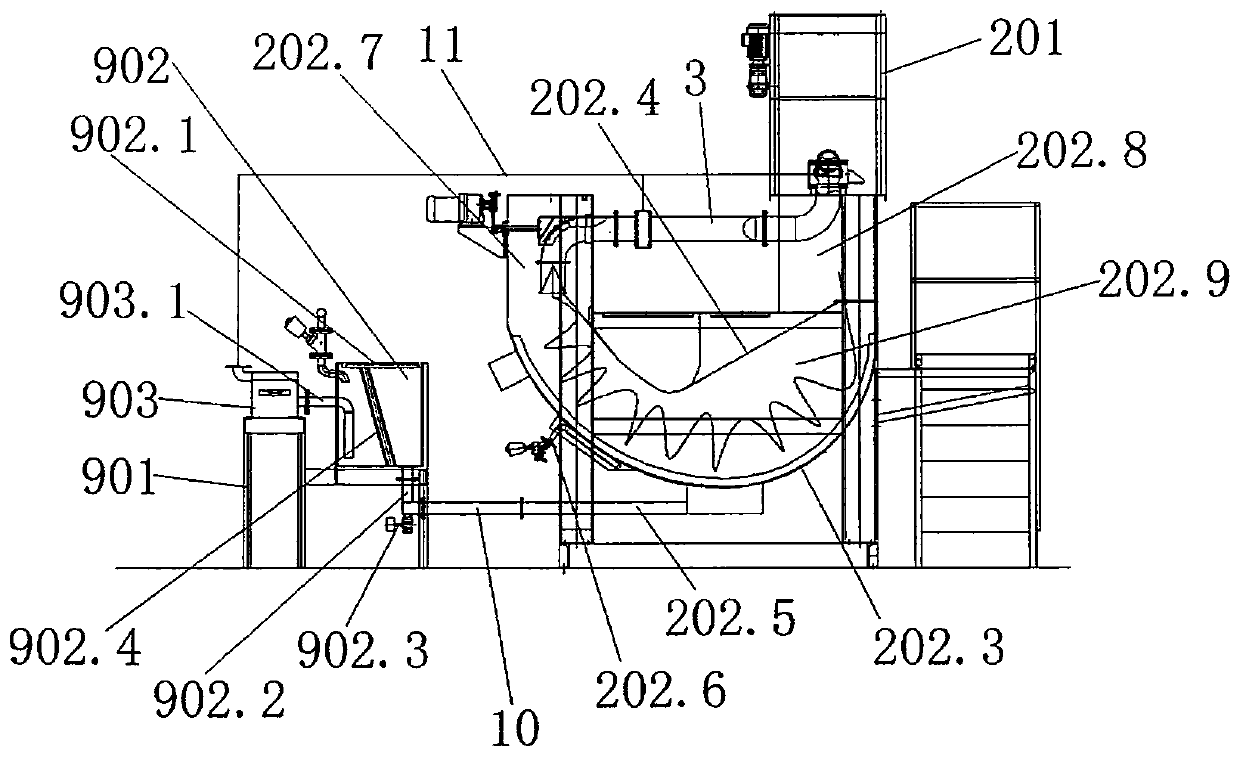

Continuous rope-shaped jetting water washer

PendingCN110409087AIncrease water storageIncrease cloth capacityTextile treatment machine arrangementsTextile treatment carriersManufacturing cost reductionEngineering

The invention relates to a continuous rope-shaped jetting water washer. The continuous rope-shaped jetting water washer comprises multiple serial washing units (1), and each washing unit (1) comprisesan upper box (201) and a lower box (202). The continuous rope-shaped jetting water washer is characterized in that multiple vertical partition plates (202.1) are arranged in the lower boxes (202) inthe cloth feeding direction at intervals, each lower box (202) is divided into multiple washing cavities (202.2) through the corresponding partition plates (202.1), every two adjacent washing cavities(202.2) are connected through a distribution pipe (3), and the distribution pipes (3) are of S-shaped structures in the vertical direction and of Z-shaped structures in the horizontal direction. Thecontinuous rope-shaped jetting water washer has the advantages that the occupation space is saved, the manufacturing cost is lowered, the washing effect is improved, and the water consumption is lowered.

Owner:诺唯格机械制造(江苏)有限公司

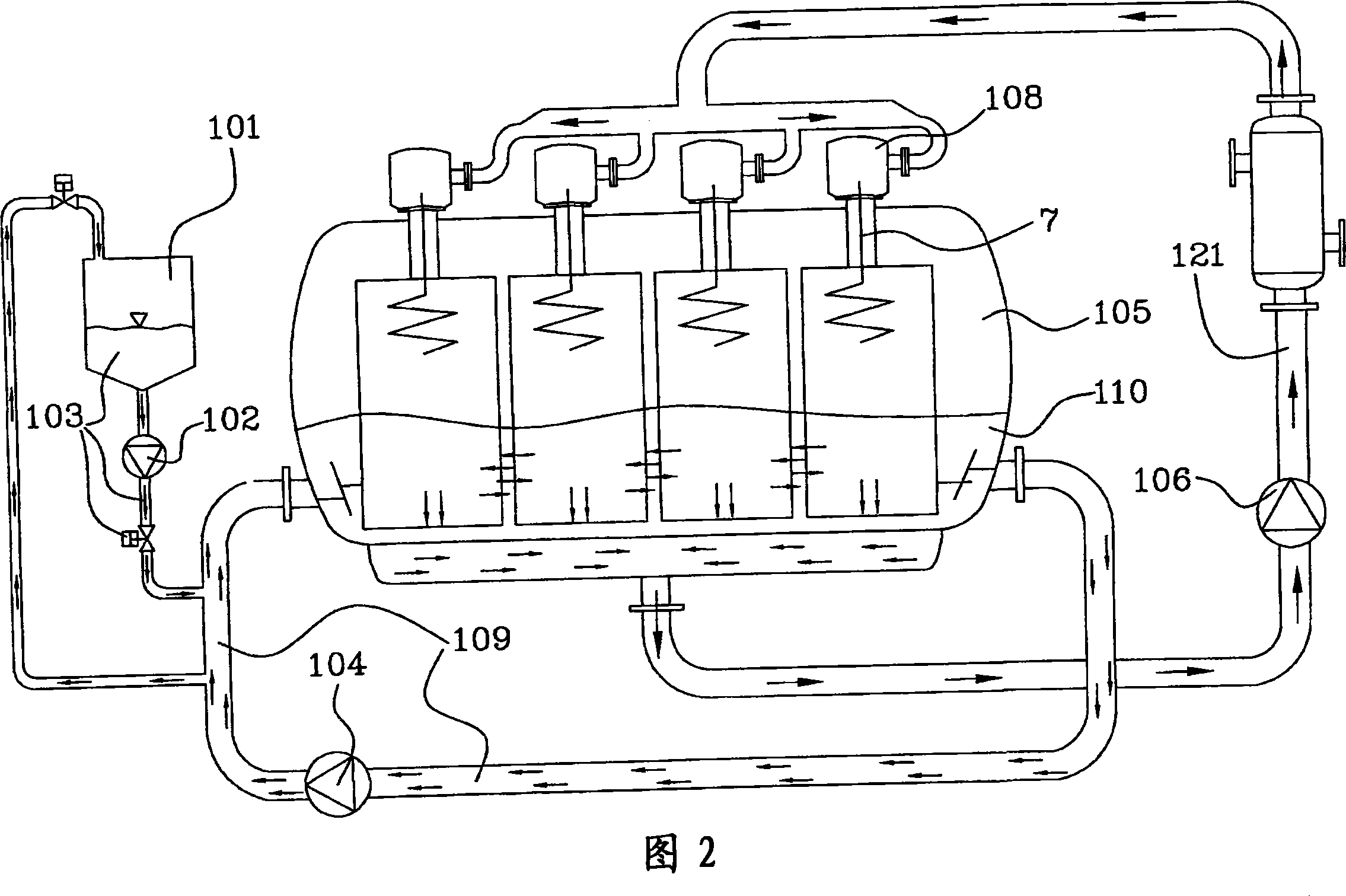

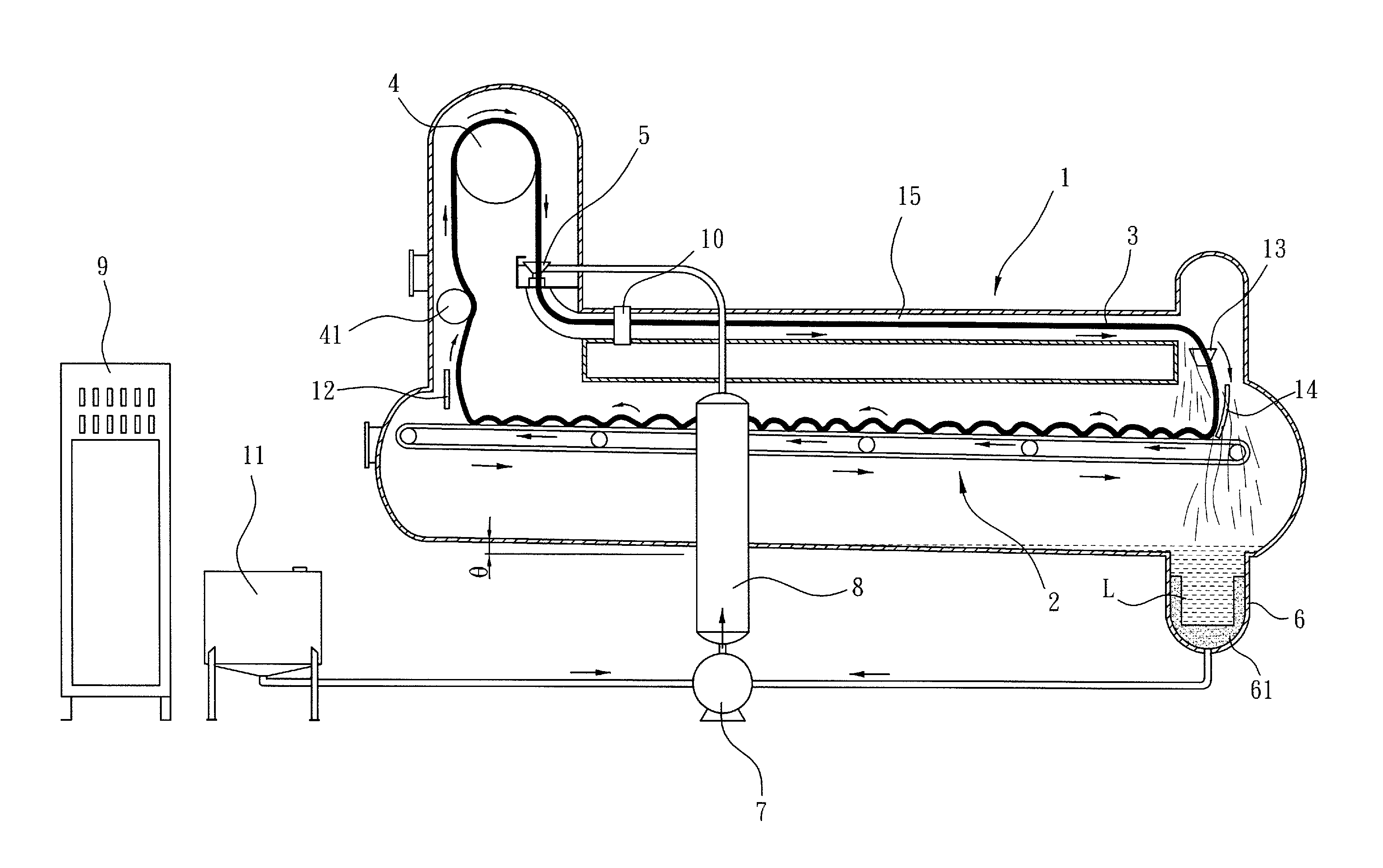

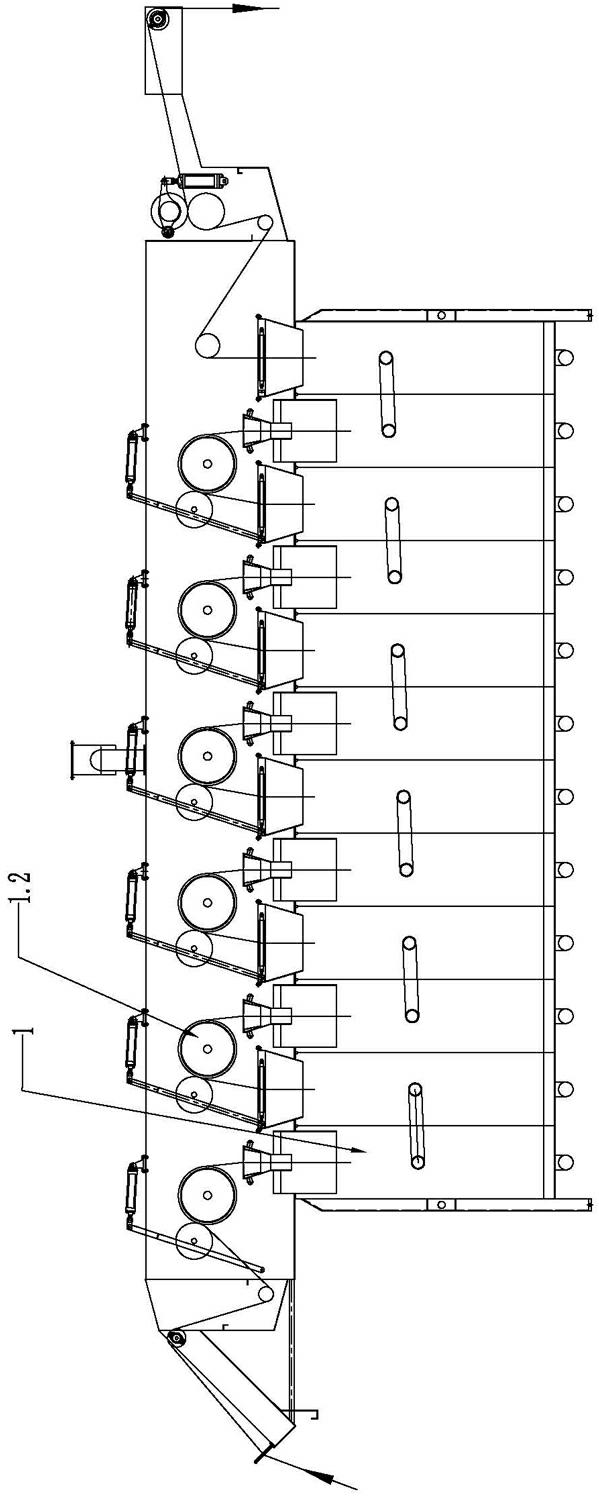

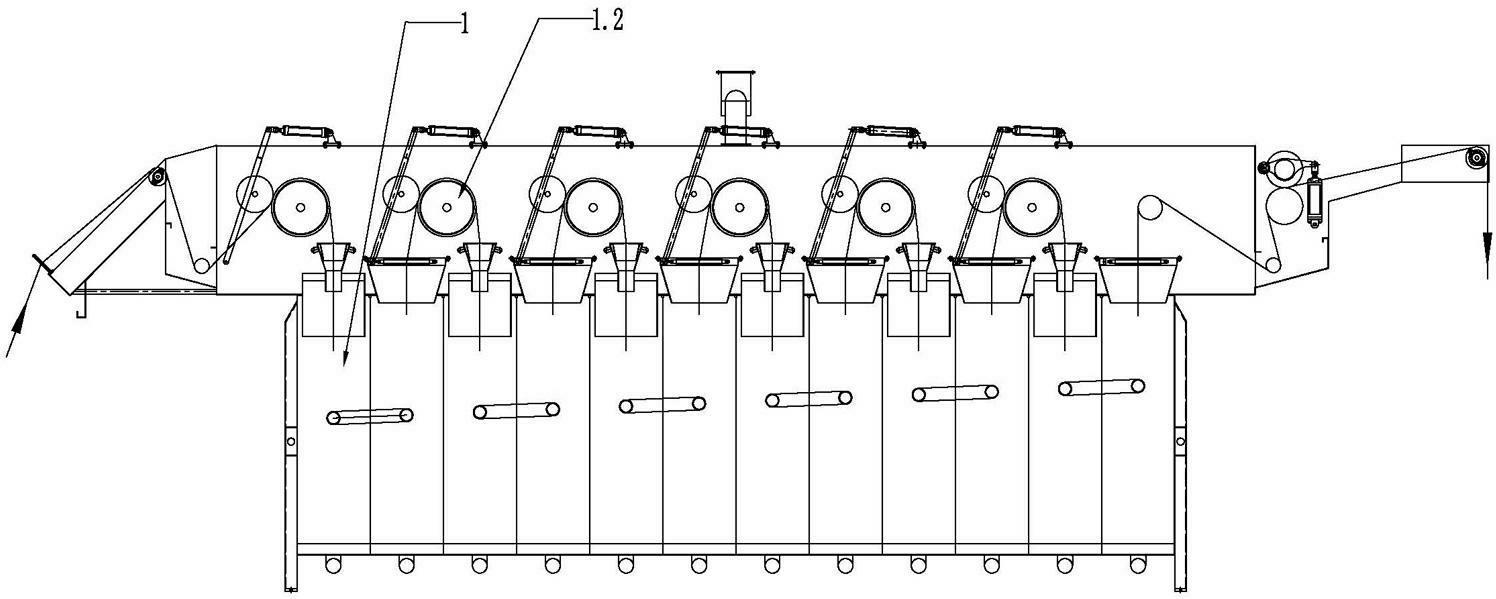

Continuous rope-shaped jet washing machine

ActiveCN103215777AImprove replacement efficiencyImprove washing efficiencyLiquid/gas/vapor treatment of propelled fabricsLiquid/gas/vapor roped fabric treatmentWater circulationWaste management

The invention relates to a continuous rope-shaped jet washing machine which comprises a body, lift cloth water rolling mechanisms, fabric flow channels and water circulation pipelines, wherein the body consists of a plurality of J-shaped troughs; the fabric flow channel is arranged above each J-shaped trough along the inclined direction; the lift cloth water rolling mechanism is arranged above the flat top of each J-shaped trough; each J-shaped trough is provided with the water circulation pipeline; and the plurality of J-shaped troughs are connected by a pipeline. The continuous rope-shaped jet washing machine is small in volume, high in efficiency and suitable for multiple fabric products.

Owner:江阴市长江印机有限公司

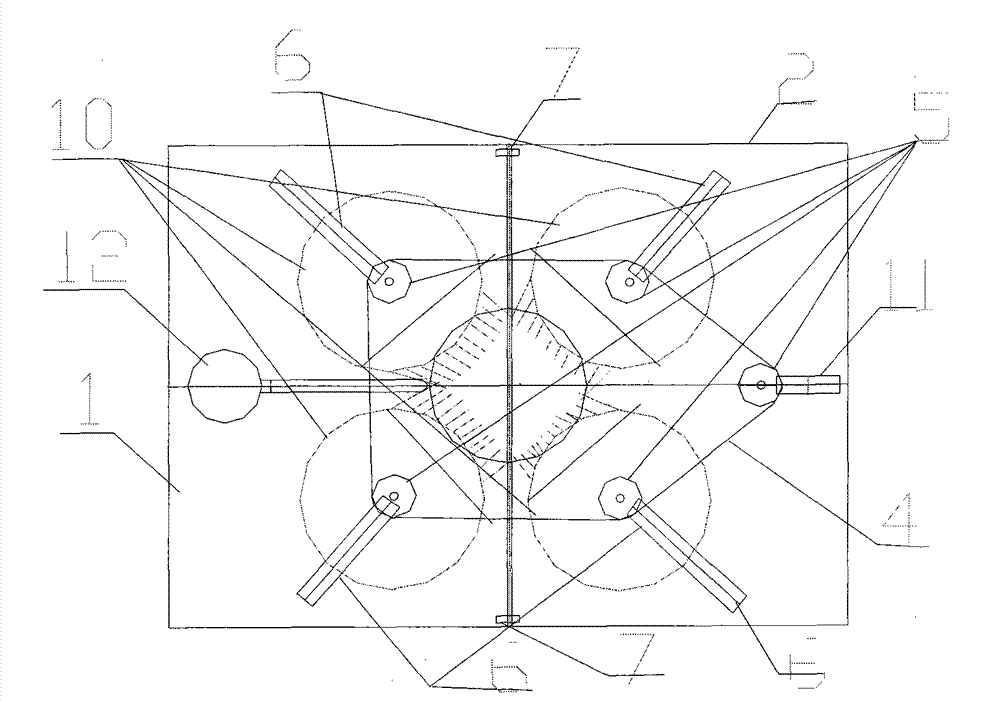

Steel-wire-rope-suspended maintenance machine

InactiveCN103114400AImprove securityFlexible reciprocating motionLiquid surface applicatorsLiquid/gas/vapor article treatmentMotor driveEngineering

The invention relates to the field of suspended maintenance of steel-wire-ropes on a large-scale bridge and hydraulic engineering hoists, and discloses a steel-wire-rope-suspended maintenance machine. The steel-wire-rope-suspended maintenance machine comprises steel wire rope guide wheel oil seals, a chain wheel, a chain wheel adjustment shaft, a locking buckle, a locking buckle hanging rope, a forward-and-reverse-rotation electric winch, hairbrush rolls and the like, and is characterized in that a maintenance machine framework is rectangular-shaped or column-shaped or special-shaped and is formed by connecting the folding locking buckle, a left box and a right box. The left box and the right box are opened. Steel wire ropes are sleeved in two semicircular steel wire rope guide wheel oil seals. When the left box and the right box are closed, the locking buckle locks the steel wire ropes, the steel wire rope guide wheel oil seals and the steel wire ropes rub in a sliding mode, more than two hairbrush rolls are fixedly connected inside the left box and the right box, and a motor drives the hairbrush rolls to tightly contact the steel wire ropes and operates in a rub mode. Accordingly, not only dust, sand and aged old oil can be cleaned but also new oil can be efficiently and evenly covered on the surfaces of the steel wire ropes, and all kinds of defects of prior manual oil coating are overcome. The steel-wire-rope-suspended maintenance machine is reasonable in structural design, and improves operation levels and work efficiency.

Owner:枣庄安澜水利工程有限公司

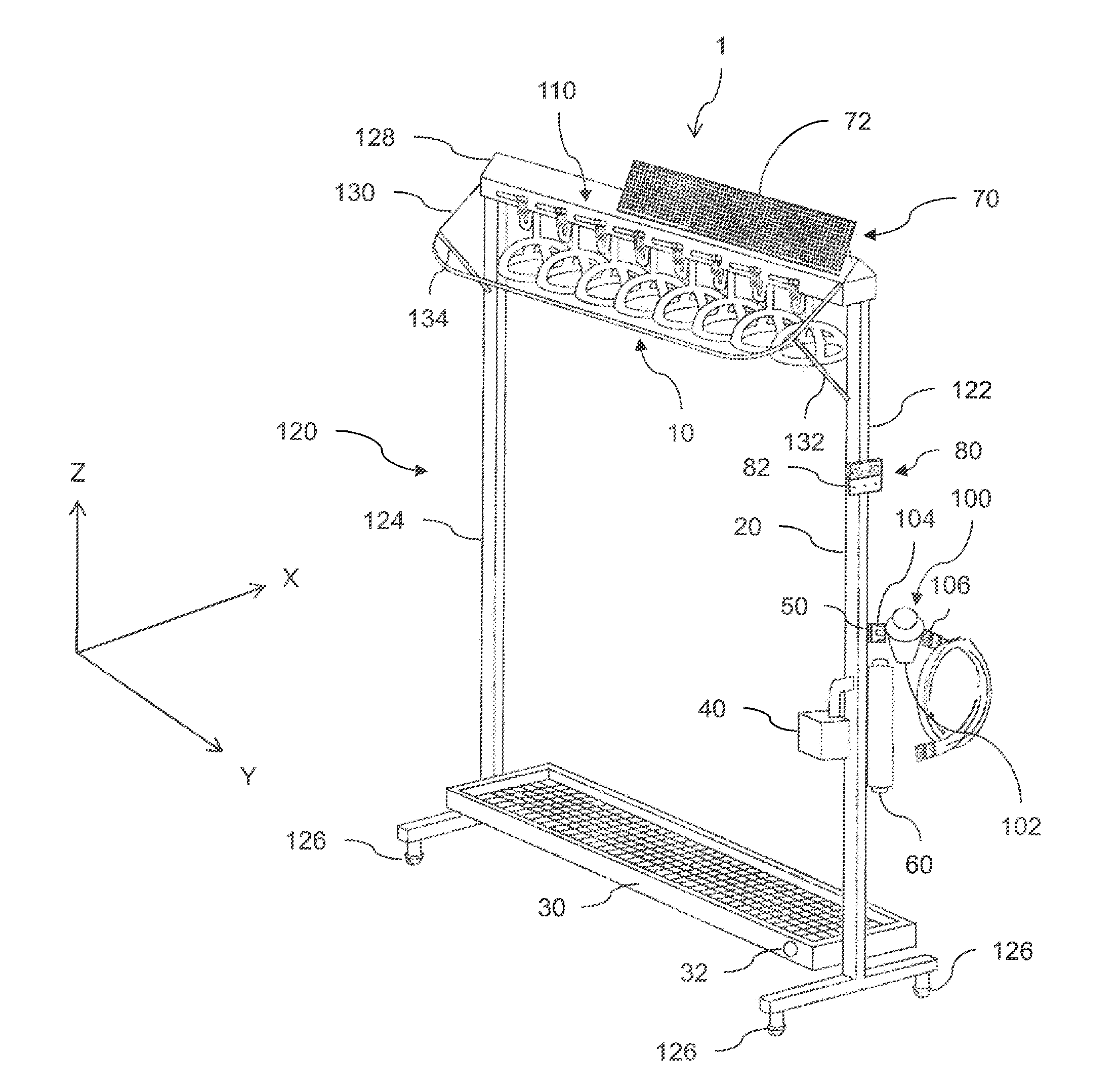

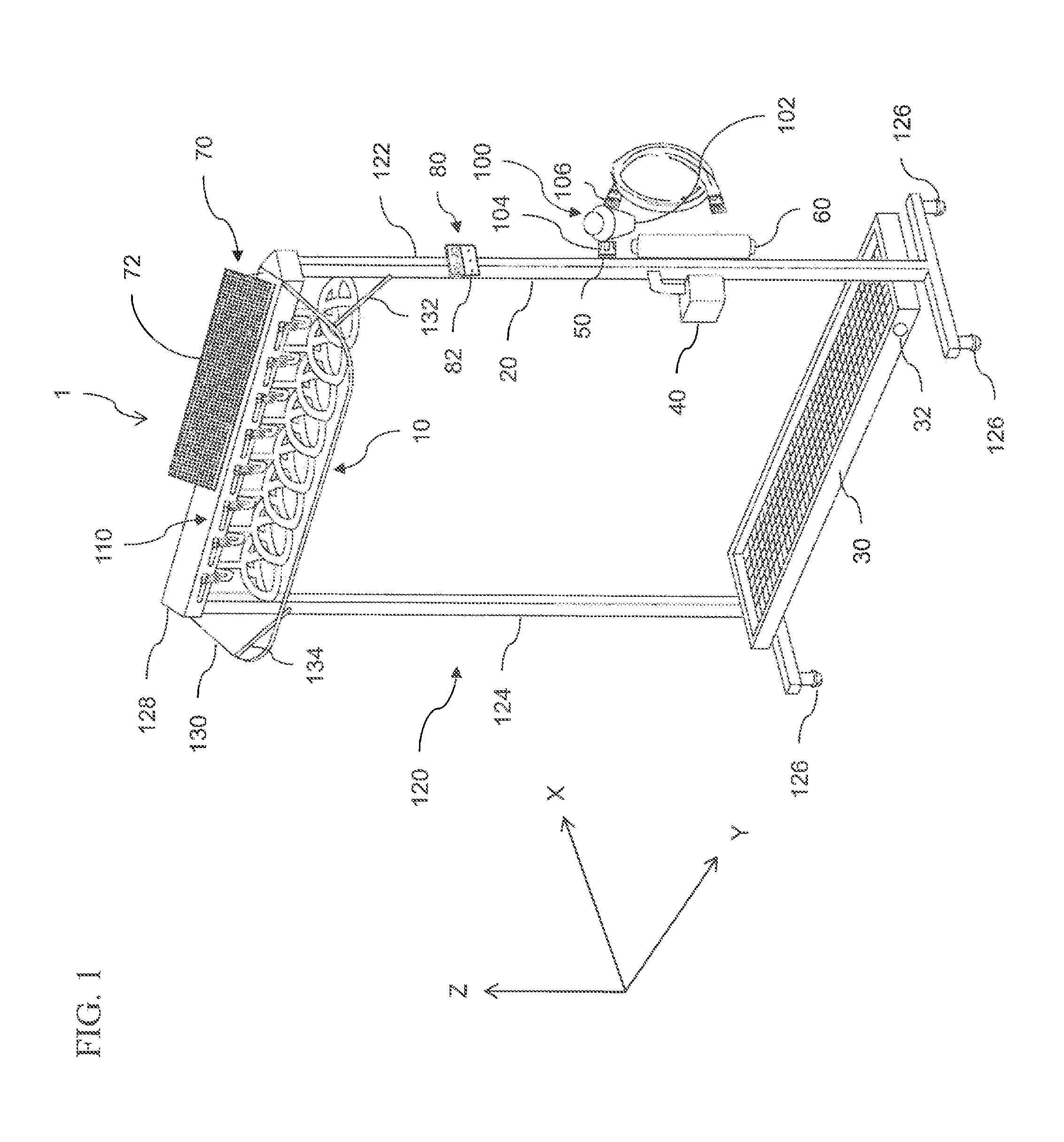

Circulation protection device of conveyor-driven fabric dyeing machine

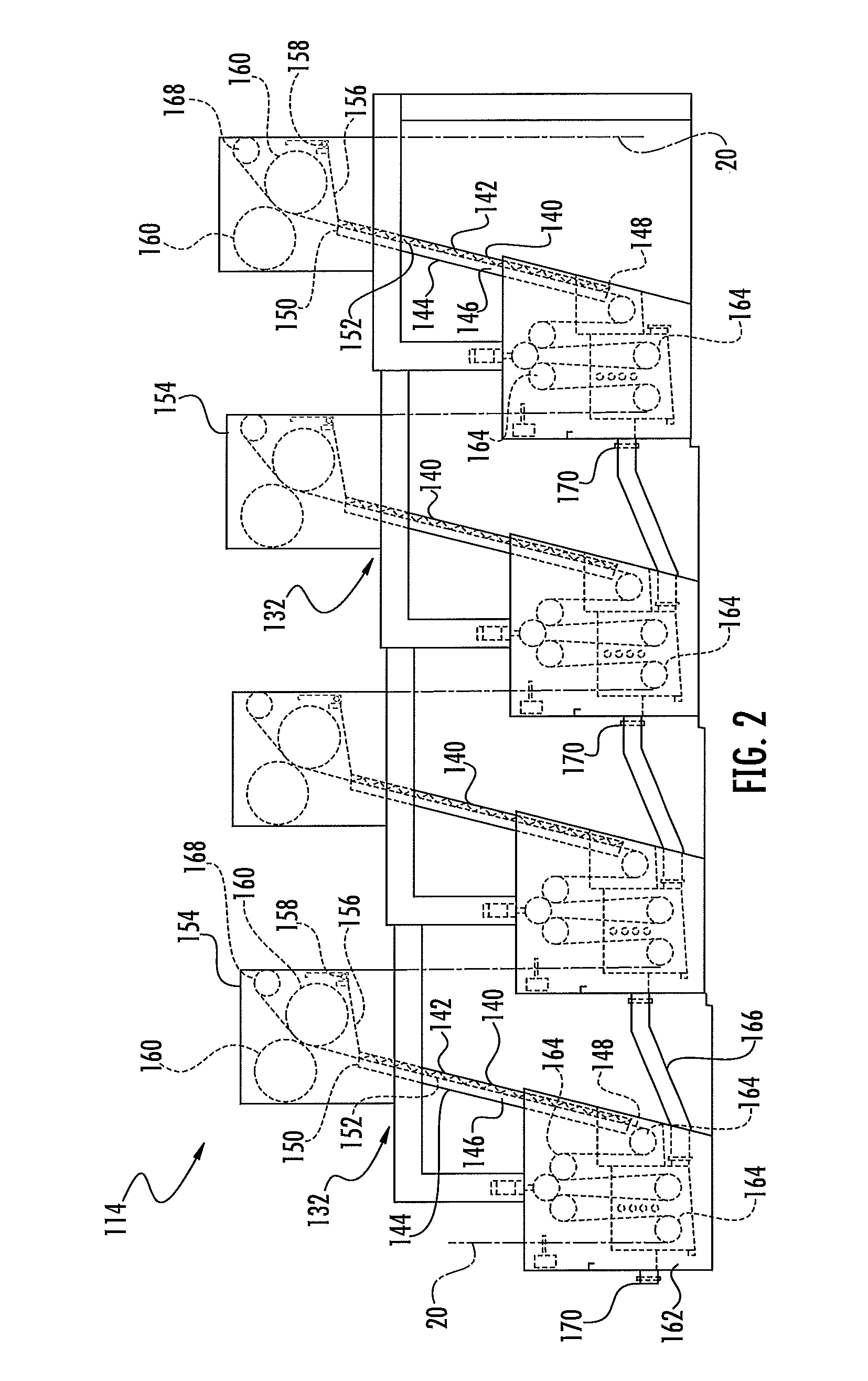

ActiveUS20150337472A1Easy to operateImprove throughputLiquid/gas/vapor treatment machines driving mechanismsLiquid/gas/vapor treatment of propelled fabricsEngineeringComputer program

A circulation protection device is provided for a conveyor-driven fabric dyeing machine that includes a machine body having a front end in which a fabric circulation detection idler and a fabric movement sensor are mounted and a rear end in which a rear fabric guide and a fabric management device are mounted. Control is conducted with a computer program so that when the fabric circulation detection idler detects the fabric is not in movement, the conveyor is shut down; and when the fabric movement sensor detects the fabric is moving excessively fast or slow or gets jamming and stopped, the conveyor is controlled to automatically adjust the speed thereof or stops operation. When the fabric falls from a dyeing tube down to a conveyor, the rear fabric guide adjusts an entry angle of the fabric and the fabric management device allows the fabric to be orderly deposited on the conveyor.

Owner:CHANG

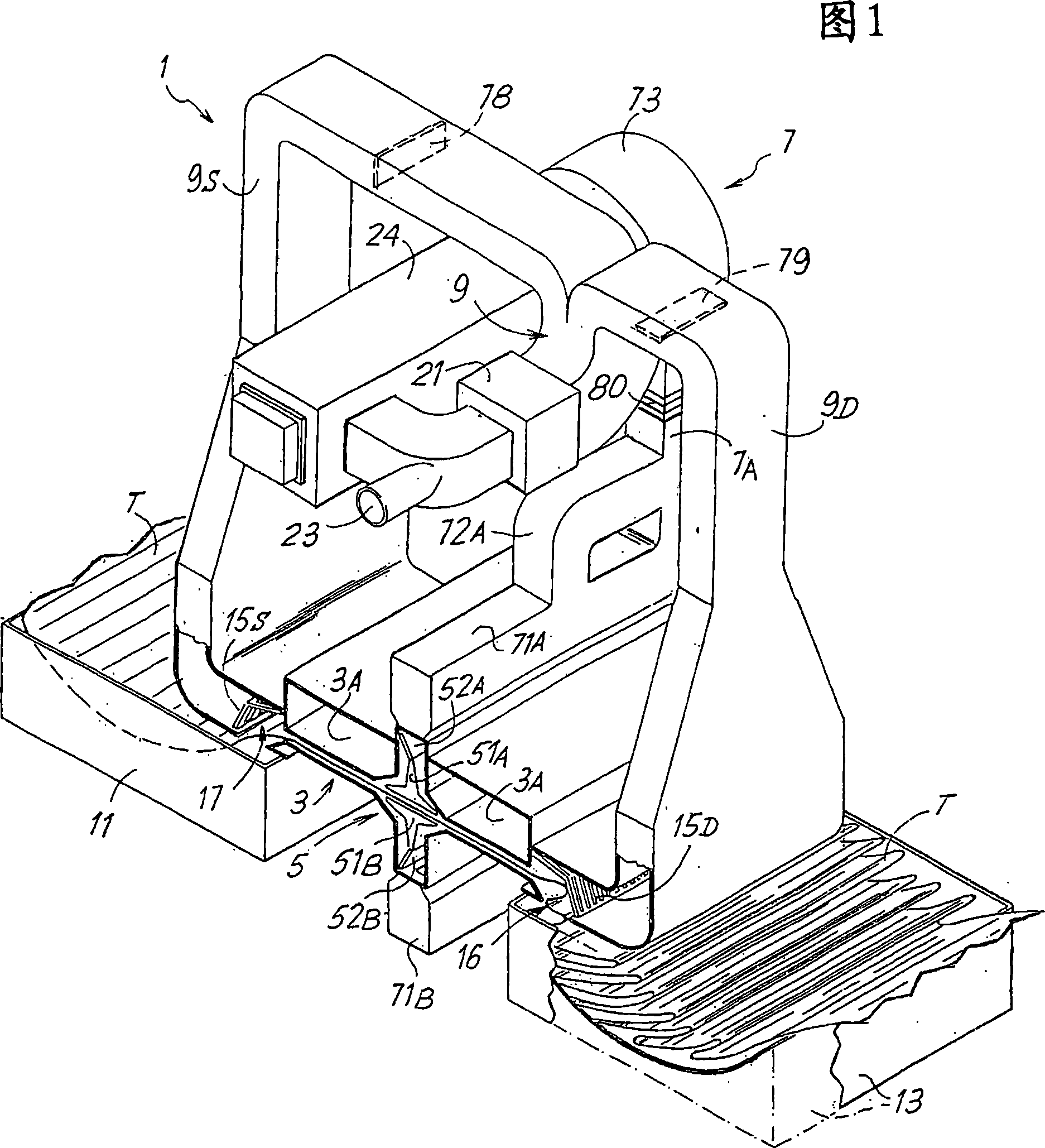

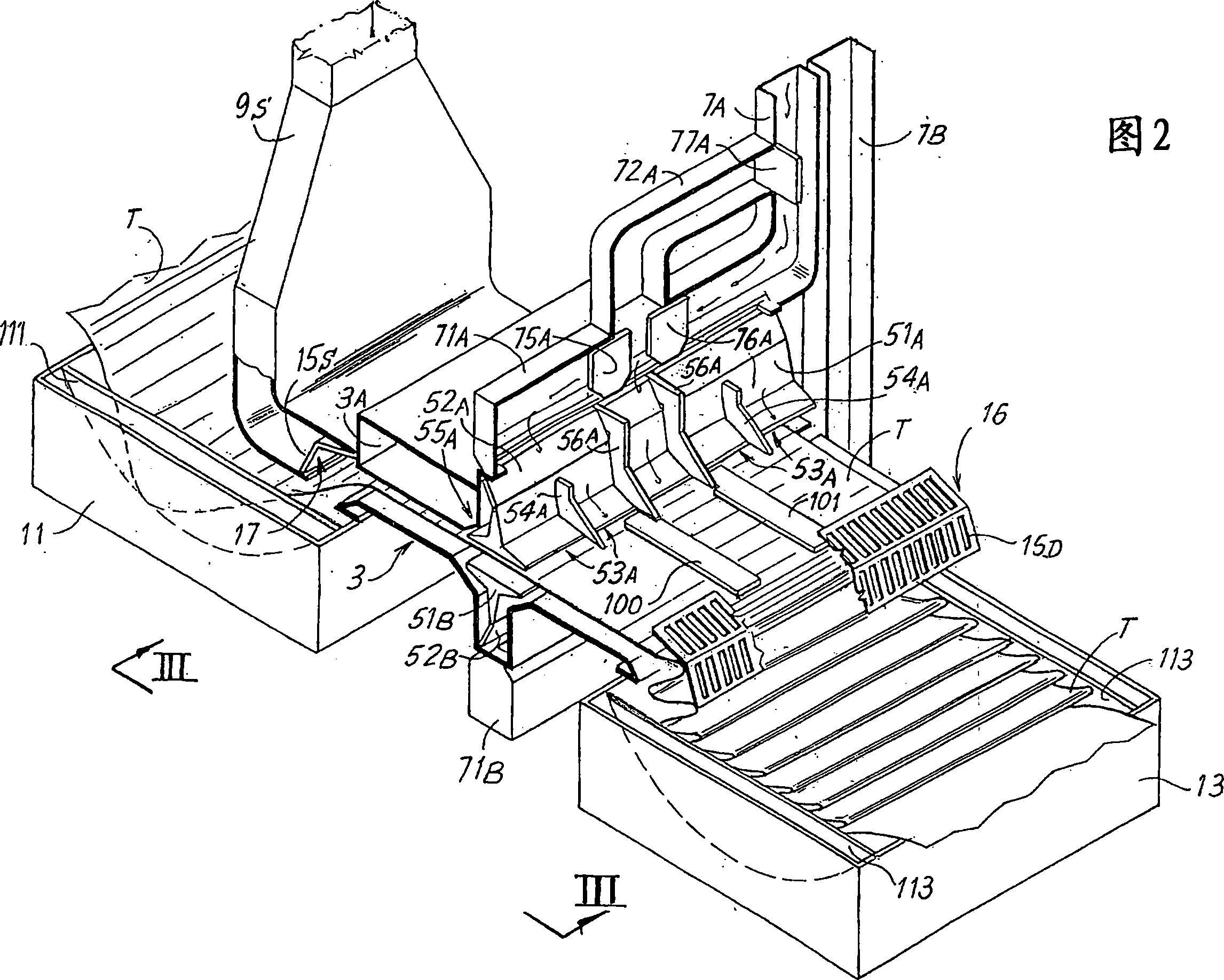

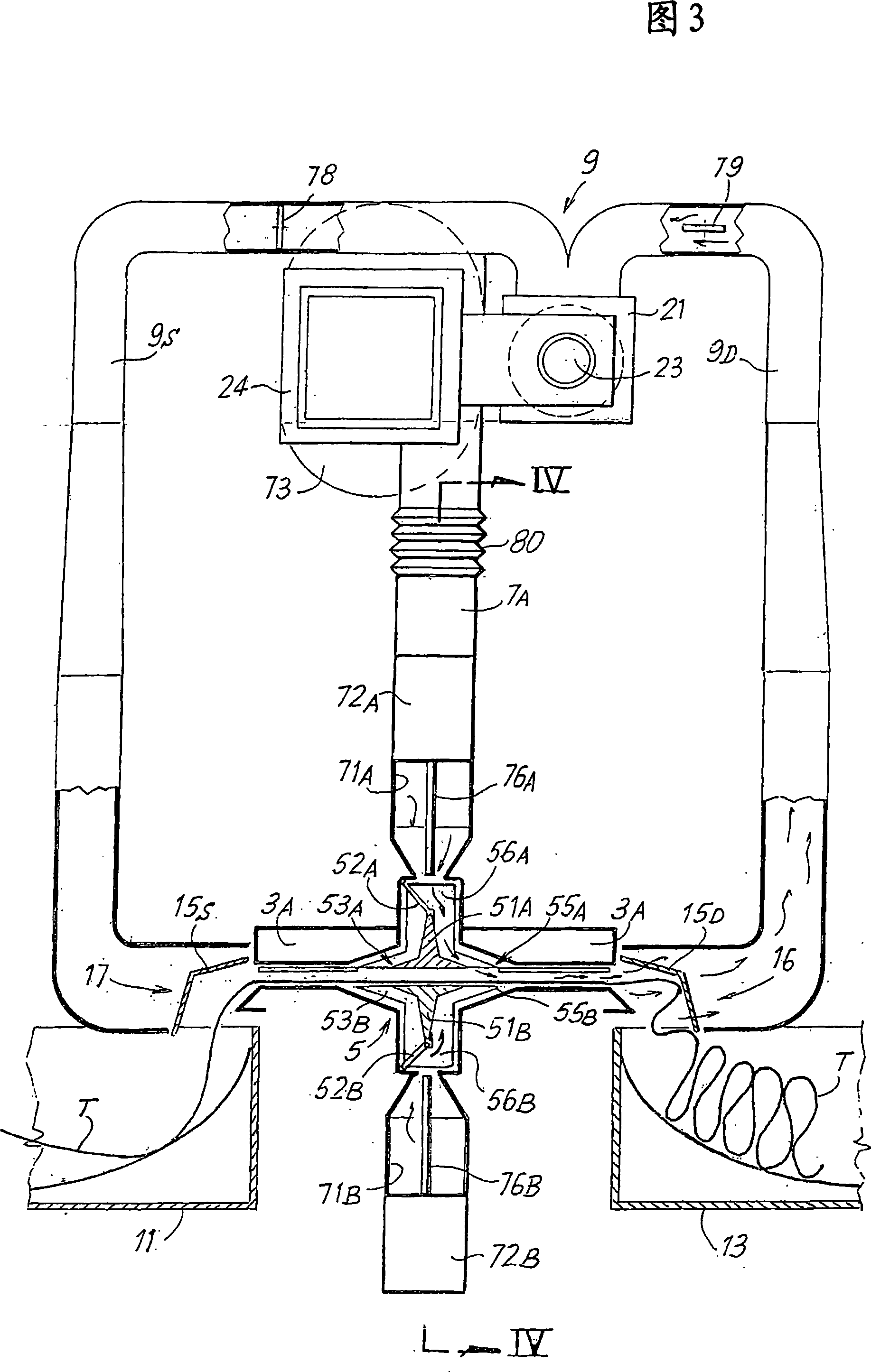

Machine and method for treating both an open width fabric and a fabric in rope form

InactiveCN101006220AImprove processing efficiencyIncrease heightFabric breaking/softeningLiquid/gas/vapor treatment of propelled fabricsTransfer systemIndustrial engineering

The machine provides a path (3) for feed of the fabric with a transfer system, for example a pneumatic system. Along the aforesaid path the fabric can be treated in rope form or in open width according to the machine settings.

Owner:CORAMTEX

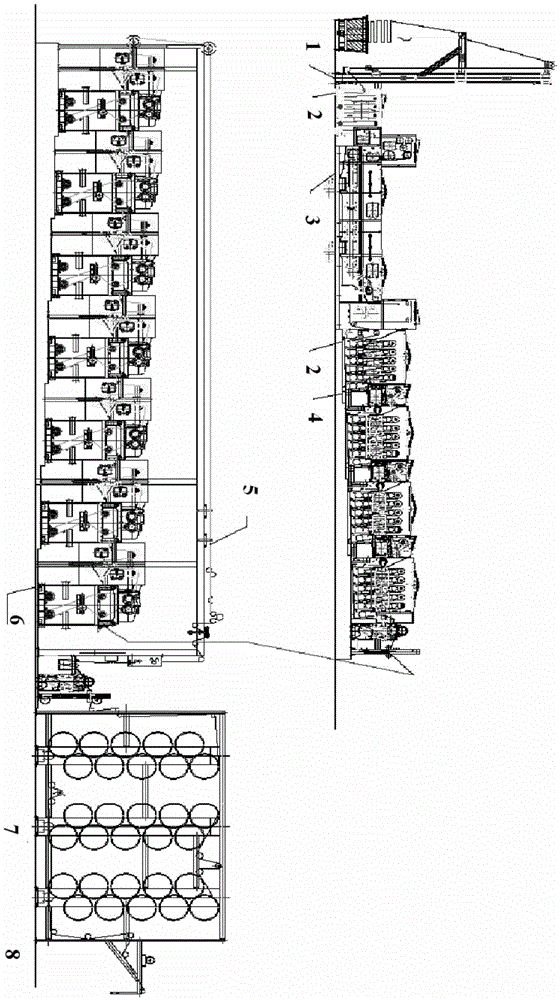

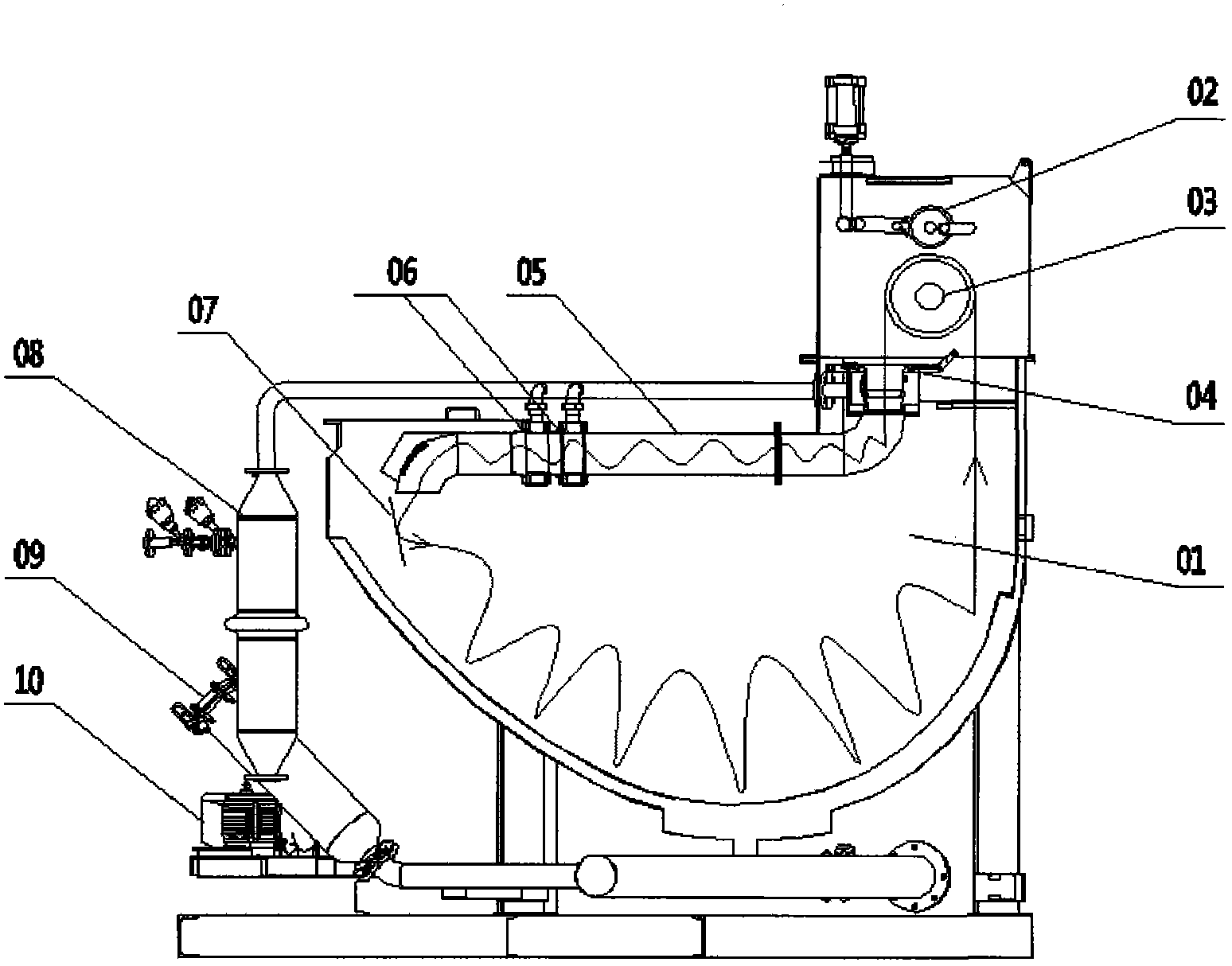

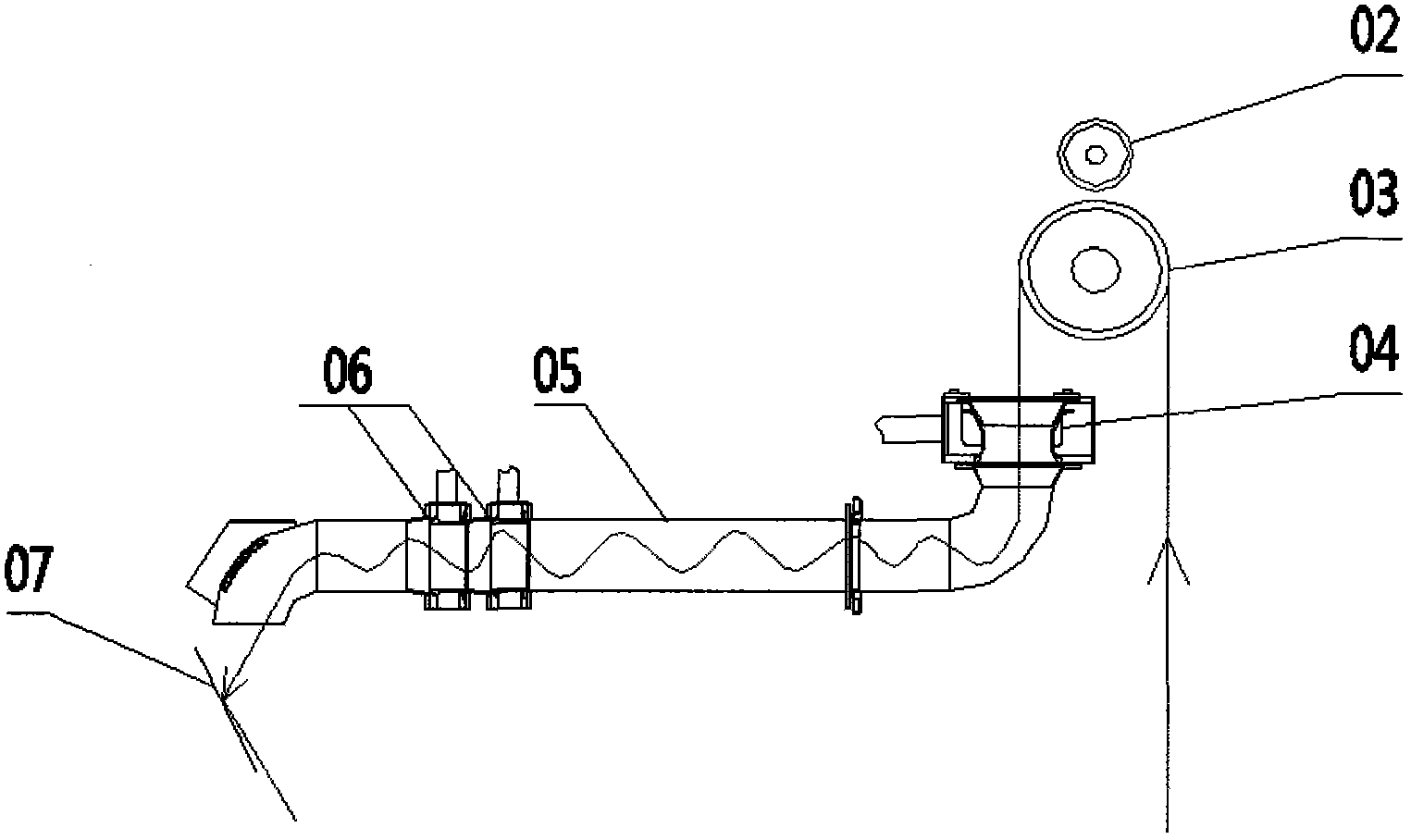

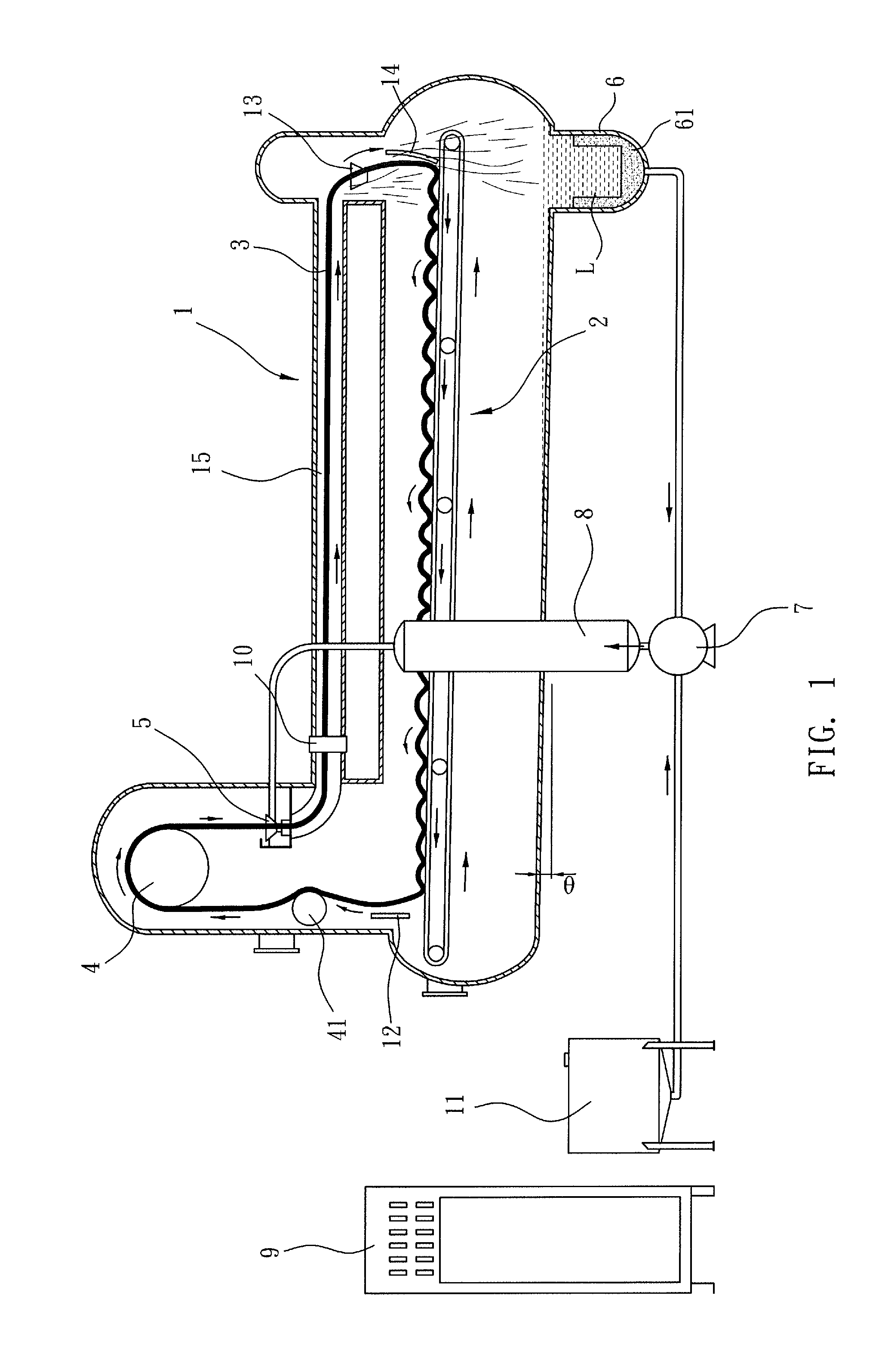

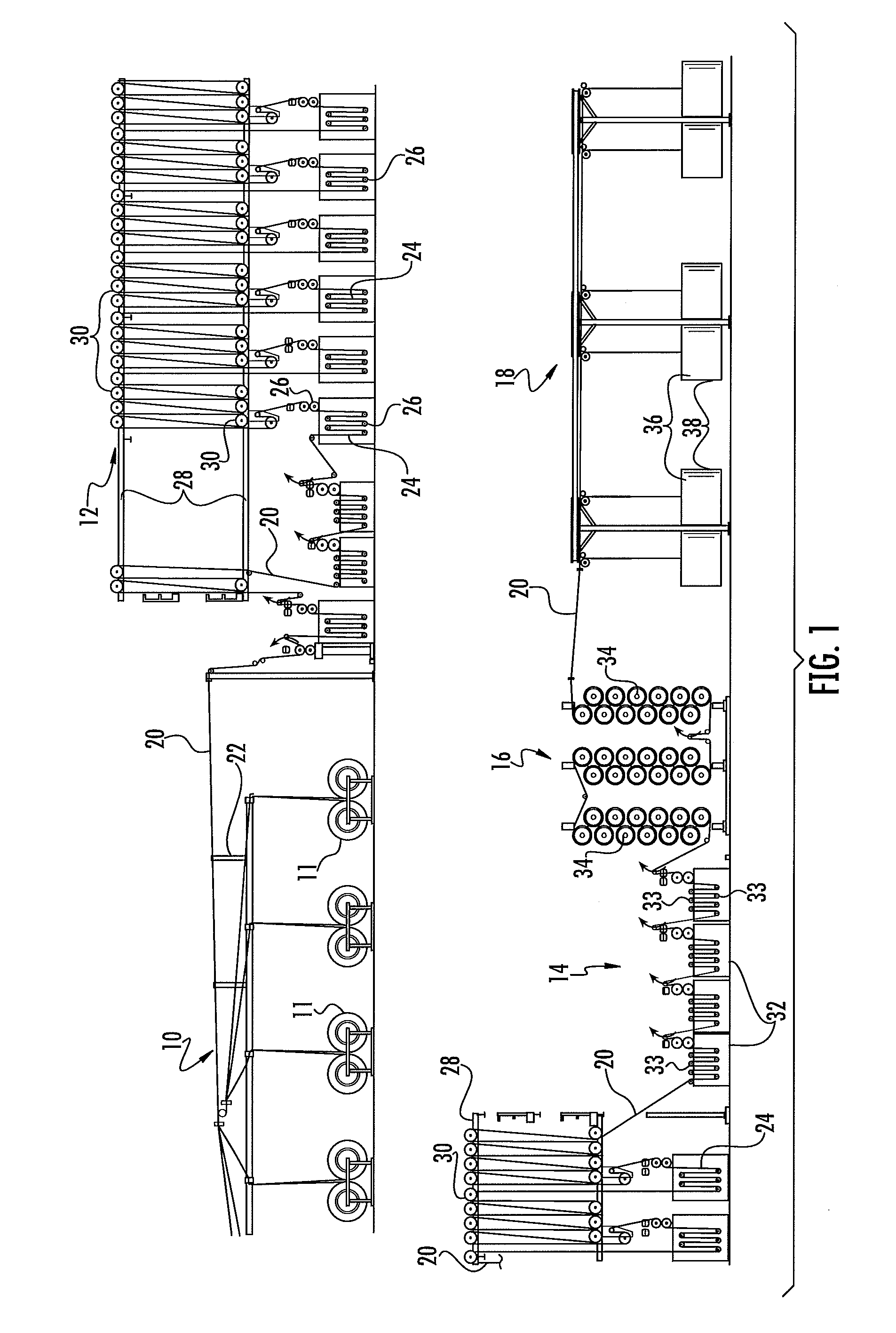

Efficient continuous rope-form washing machine

ActiveCN102634946AReduce volumeReduce water consumptionLiquid/gas/vapor treatment of propelled fabricsTextile treatment machine arrangementsSingle stageSmall footprint

The invention relates to an efficient continuous rope-form washing machine which is formed by a plurality of single-stage U-shaped washing machines in parallel connection. Each of the single-stage U-shaped washing machines comprises a U-shaped box, a pair of rollers, a sprayer, a heater, a water bucket, a rotating roller, a water conveying pipe I, a water conveying pipe II and a water pump, wherein the sprayer is arranged at one port of the U-shaped box; the rollers are arranged above the sprayer; the water bucket is arranged at the other port of the U-shaped box; the rotating roller is arranged above the water bucket; the heater is arranged in a U-shaped concave hole outside the U-shaped box; the sprayer and the heater are connected through the water conveying pipe I; the heater is communicated with the bottom of the U-shaped box through the water conveying pipe II; the water pump is connected with the water conveying pipe II; and the port mounted with the sprayer and the port mounted with the water bucket in each single-stage U-shaped washing machine are respectively and correspondingly adjoined with the port mounted with the water bucket and the port mounted with the sprayer of the adjacent single-stage U-shaped washing machine. The efficient continuous rope-form washing machine has the advantages of compact structure, small area occupied by equipment and small water consumption.

Owner:JIANGYIN FUDA DYEING & FINISHING UNITED MACHINERYCO

Stress regulation and control elasticity-adding heat treatment process for PTT filament compound fabric

InactiveCN101333742ADimensionally stableReduce internal stressFibre treatmentHeating/cooling textile fabricsEngineeringInternal stress

The invention discloses a stress adjustment elasticized heat treatment process for PTT filament compound fabrics, comprising: wetting a cloth of fabric before heating setting to make the fabric be shrunk by four percent to fifteen percent, and then stretching the fabric by two percent to ten percent along warp direction or latitudinal direction, then eliminating the internal stress by heat treatment so that the internal structure of PTT fiber will reset with elastic recovery percentage raised and fiber structure and fabric size stabilized. In the meanwhile, changes of fabric structure and width size caused by the stress adjustment course can provide a basis for fabric design and formation of fine style of fabrics.

Owner:ZHEJIANG SCI-TECH UNIV

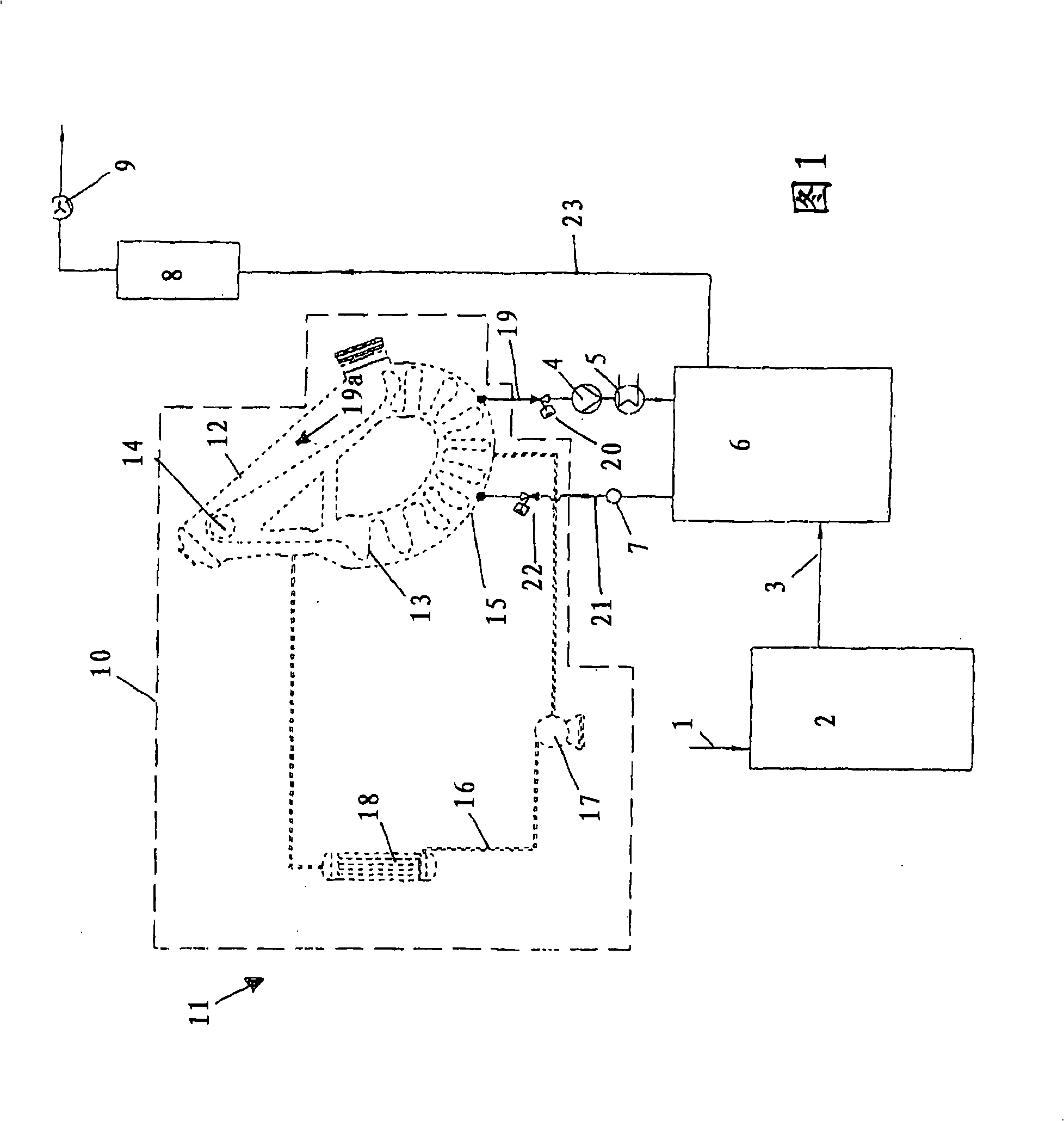

Method and apparatus for dyeing a textile substrate

InactiveCN101302722AHas wet rubbing fastnessHas dry rubbing fastnessTextile treatment machine arrangementsDyeing processChemical treatmentEngineering

The method involves bringing a textile substrate (13) in contact with a dye liquor containing a reactive dyeing material. A colored textile substrate is rinsed after expiration / cycle of a preset dyeing time, and the dyeing material is not fixed through the textile substrate and is present in the dye liquor, is degraded by chemical and / or physical treatment. The dye liquor is formed as colorless, and the textile substrate is rinsed with a decolorized liquor. An oxidative treatment is performed as a chemical treatment, and a treatment with ozone is performed as an oxidative treatment. An independent claim is also included for a device for coloring a textile substrate for performing a method for dyeing a textile substrate, comprising a boiler.

Owner:THIES KG

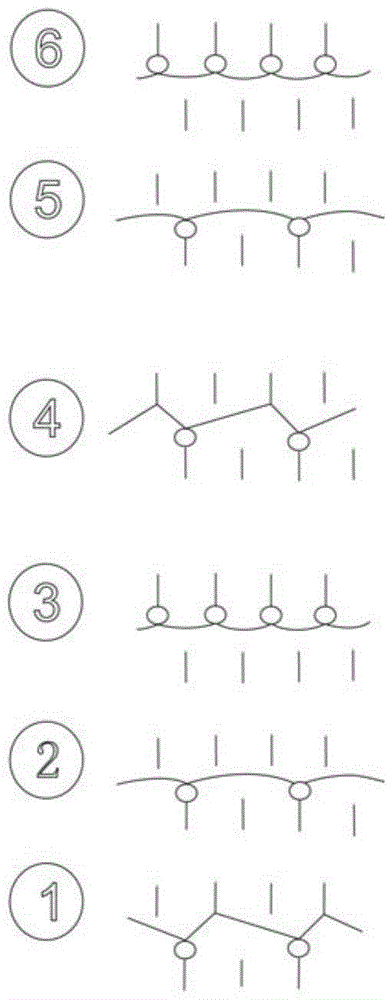

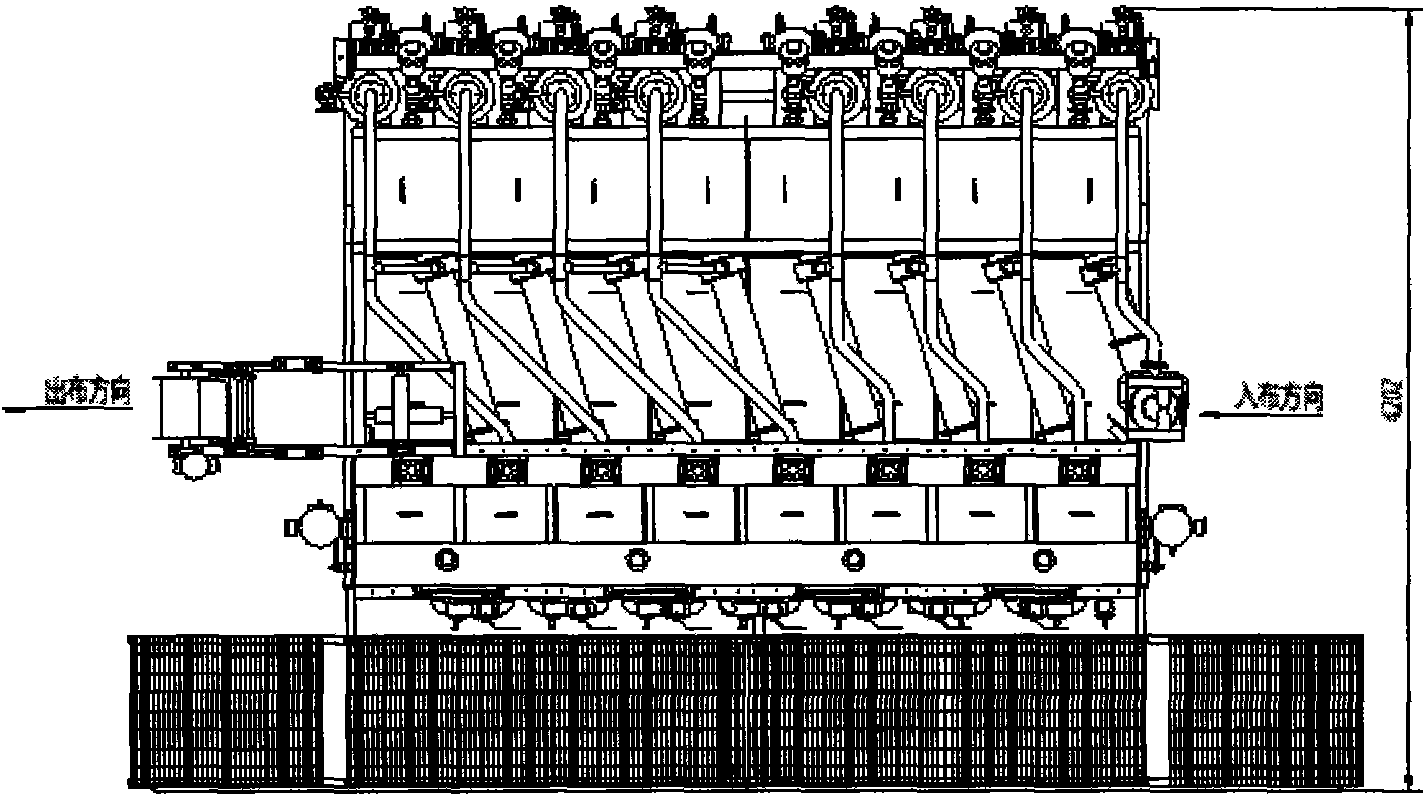

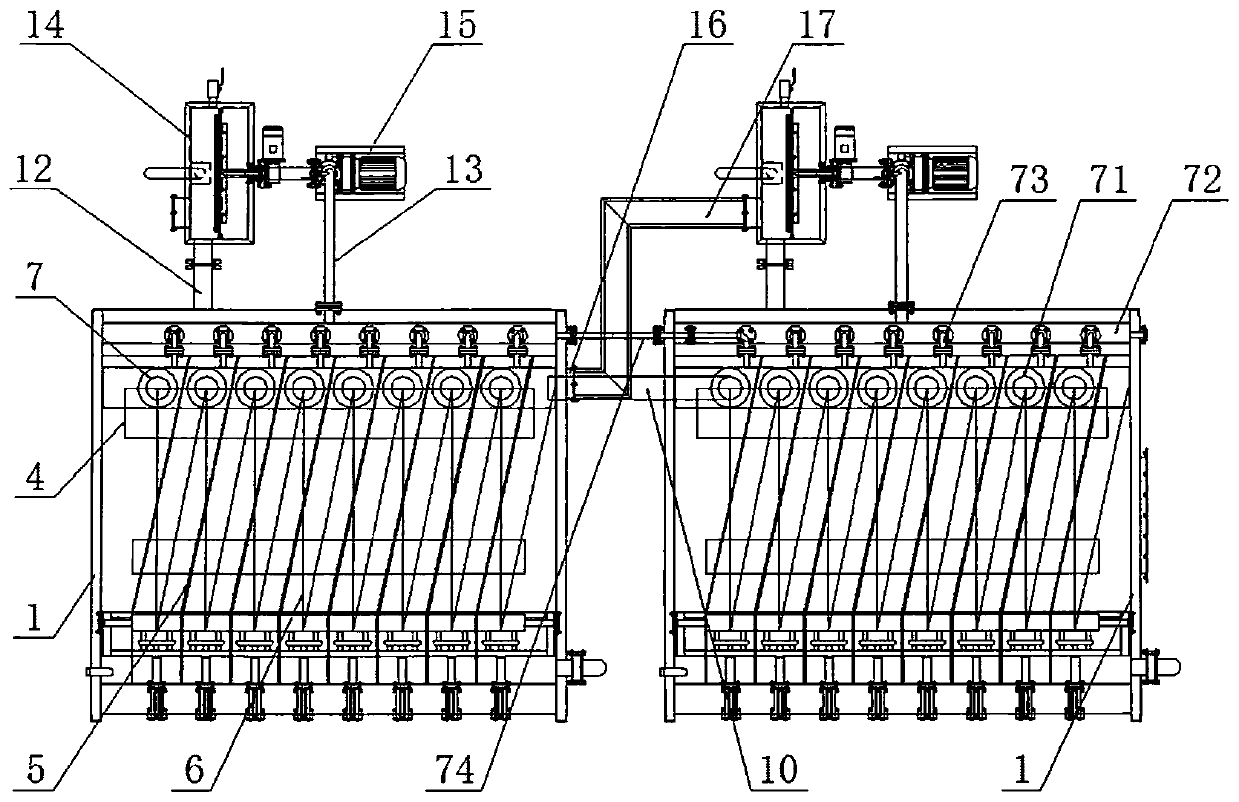

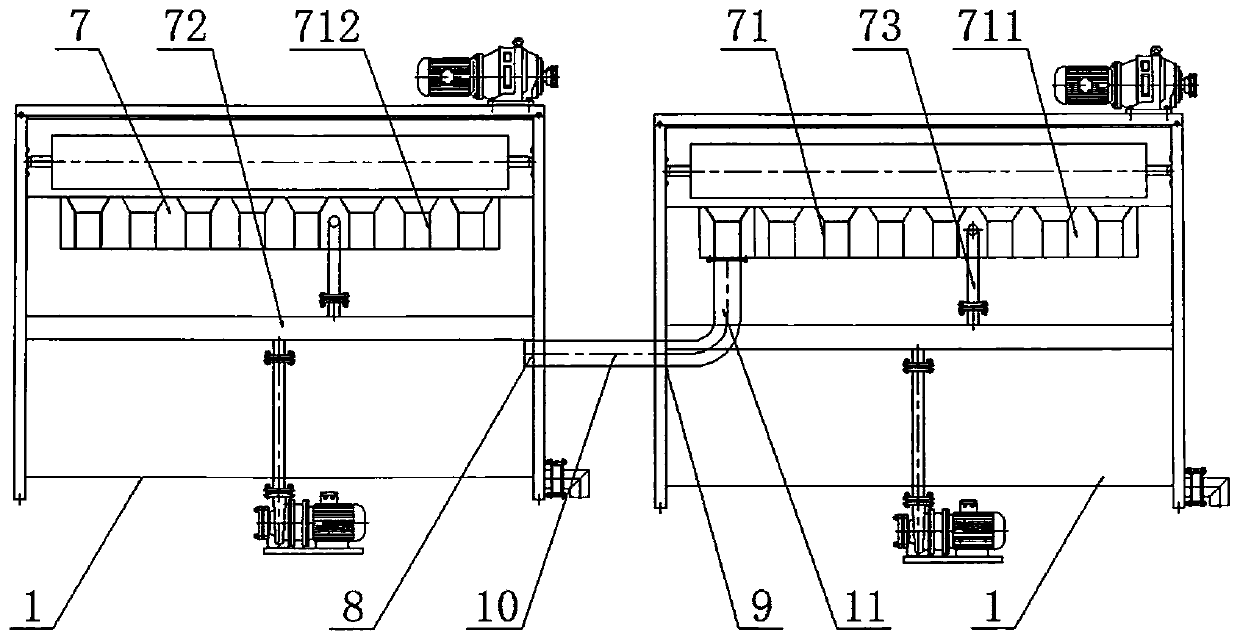

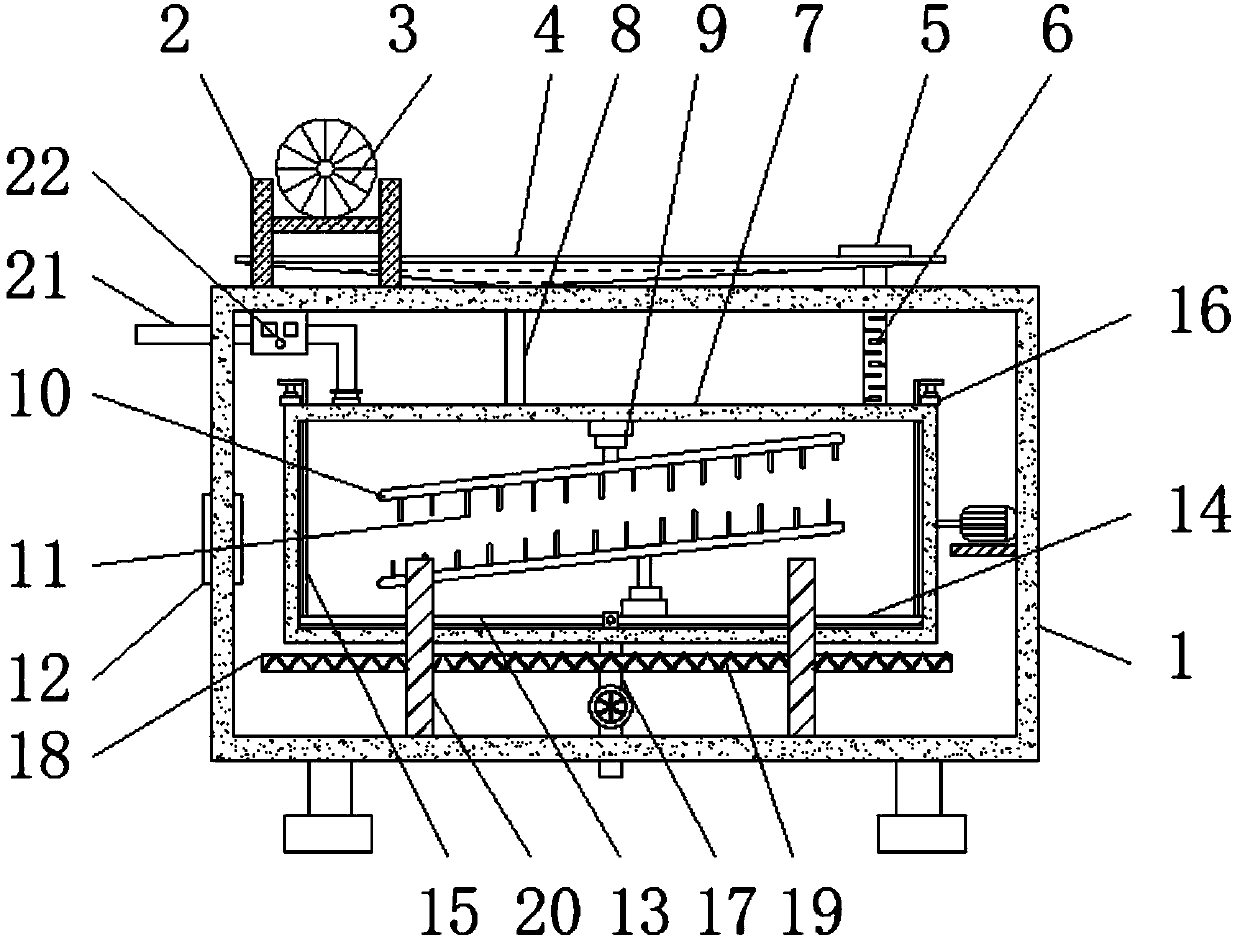

Shower-type rope-shaped water washing machine

PendingCN110735264AReduce flipping and knottingIncrease cloth capacityTextile treatment containersLiquid/gas/vapor treatment of propelled fabricsWater flowProcess engineering

The invention relates to a shower-type rope-shaped washing machine. The shower-type rope-shaped water washing machine comprises a plurality of water washing units. Each water washing unit comprises aunit box (1), and a water tank (2) is arranged at the bottom of each unit box (1). A roller set (3) and a cloth drop roller (4) are arranged above each water tank (2). A shower component (7) is arranged below each cloth drop roller (4), and comprises a plurality of shower units (71). Each shower unit (71) corresponds to one cell (6). Shower cloth outlets (9) of the previous unit boxes (1) are connected with shower cloth inlets (8) of the next unit boxes (1) through shower cloth passing tubes (10). The shower-type rope-shaped washing machine has the advantages that the shower components are added to below the cloth drop rollers, cloth surfaces are showered by water flows, cloth in the unit boxes can be orderly stacked from front to back along the water flows to reduce turning and knotting in the unit boxes, and high efficiency of water washing is achieved.

Owner:江阴市永欣印染机械有限公司

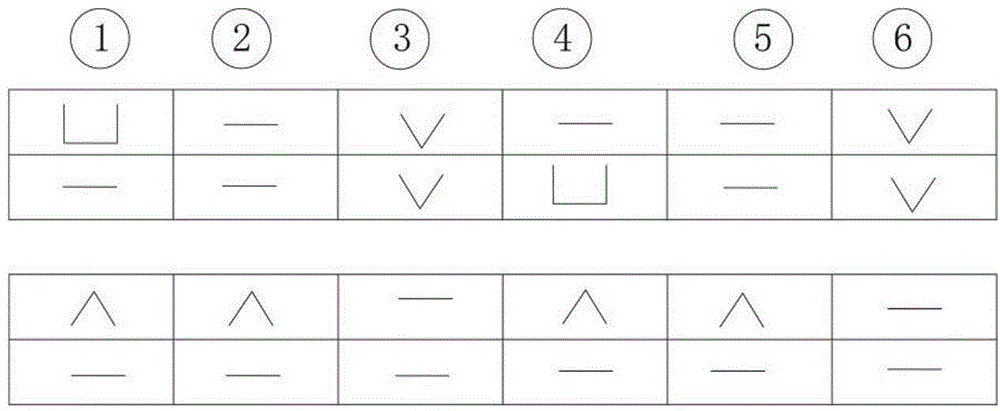

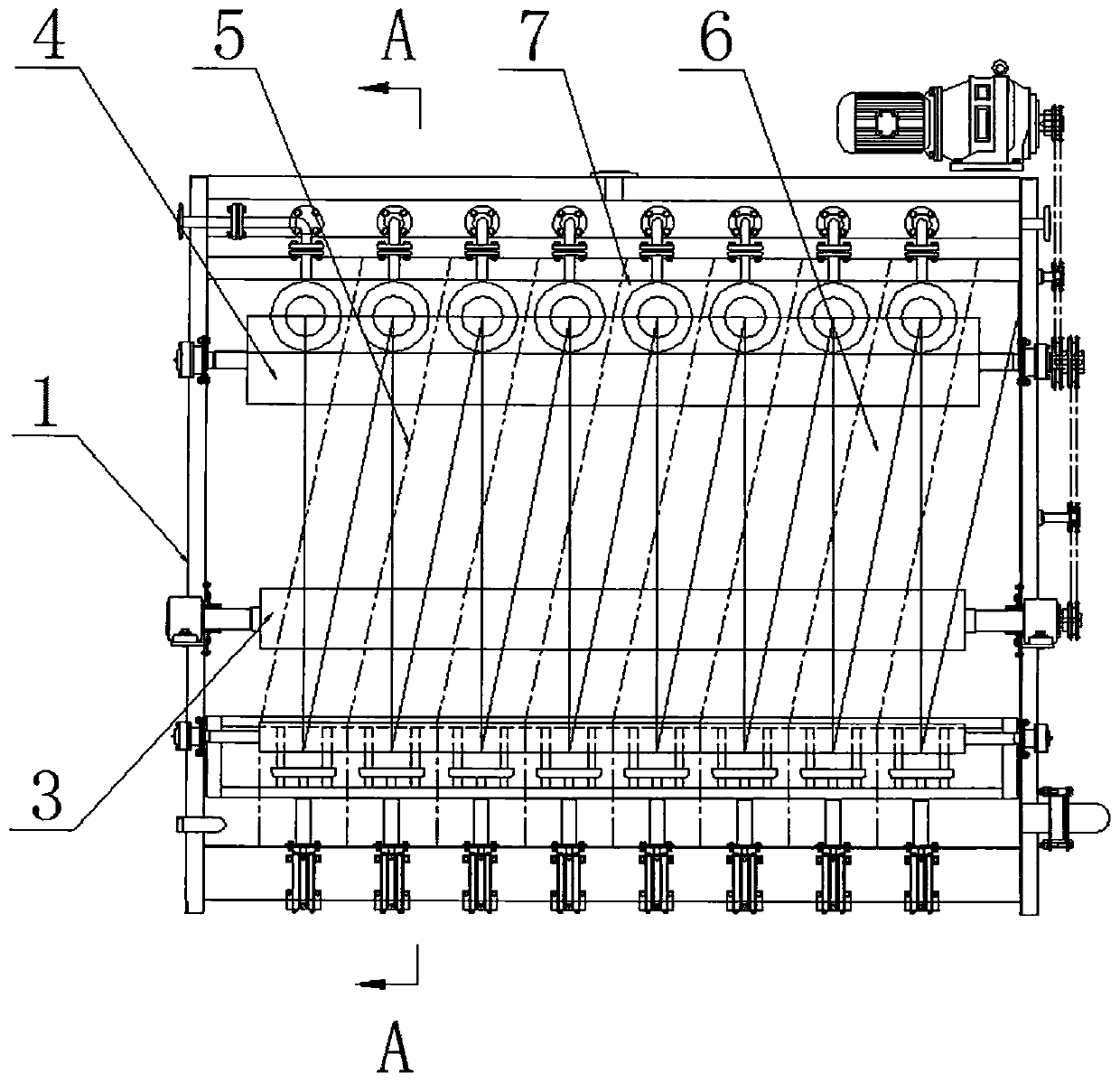

Dyeing machine fabric guide arrangement

InactiveUS6381996B1Adjustable tensionLiquid/gas/vapor treatment of propelled fabricsLiquid/gas/vapor roped fabric treatmentEngineeringMechanical engineering

A dyeing machine fabric guide arrangement having a plurality of shafts respectively installed in the housing of a dyeing machine above a respective dye vat, a plurality of fabric guide rings respectively mounted on the shafts for guiding a respective fabric through a respective dye vat in the housing, and a plurality of hand wheels respectively fixedly fastened to the shafts outside the housing for enabling the operator to rotate the shafts and to change the angular position of the fabric guide rings respectively, so as to further adjust the tension of the respective fabrics passing through the fabric guide rings.

Owner:CHANG CHI LUNG

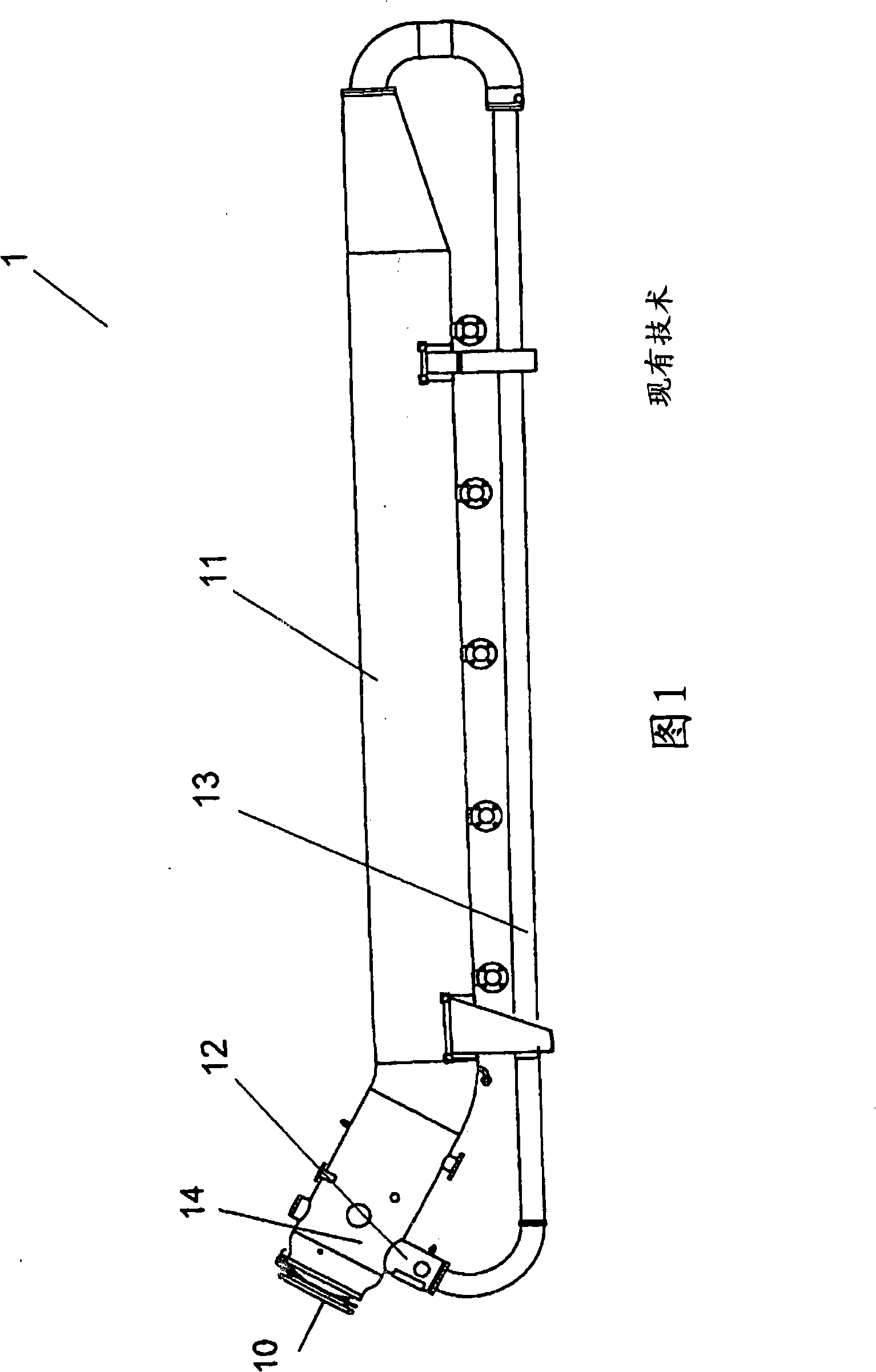

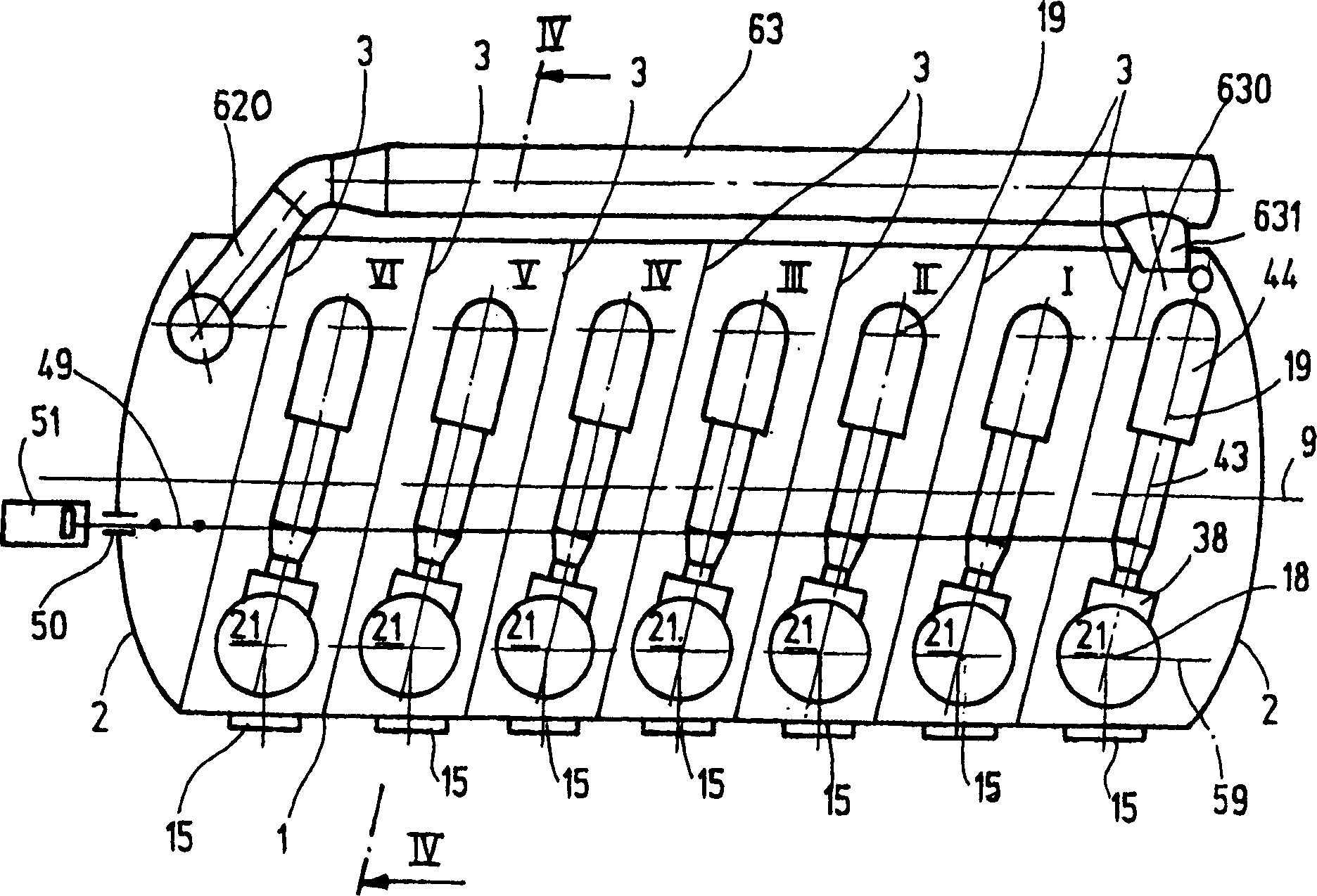

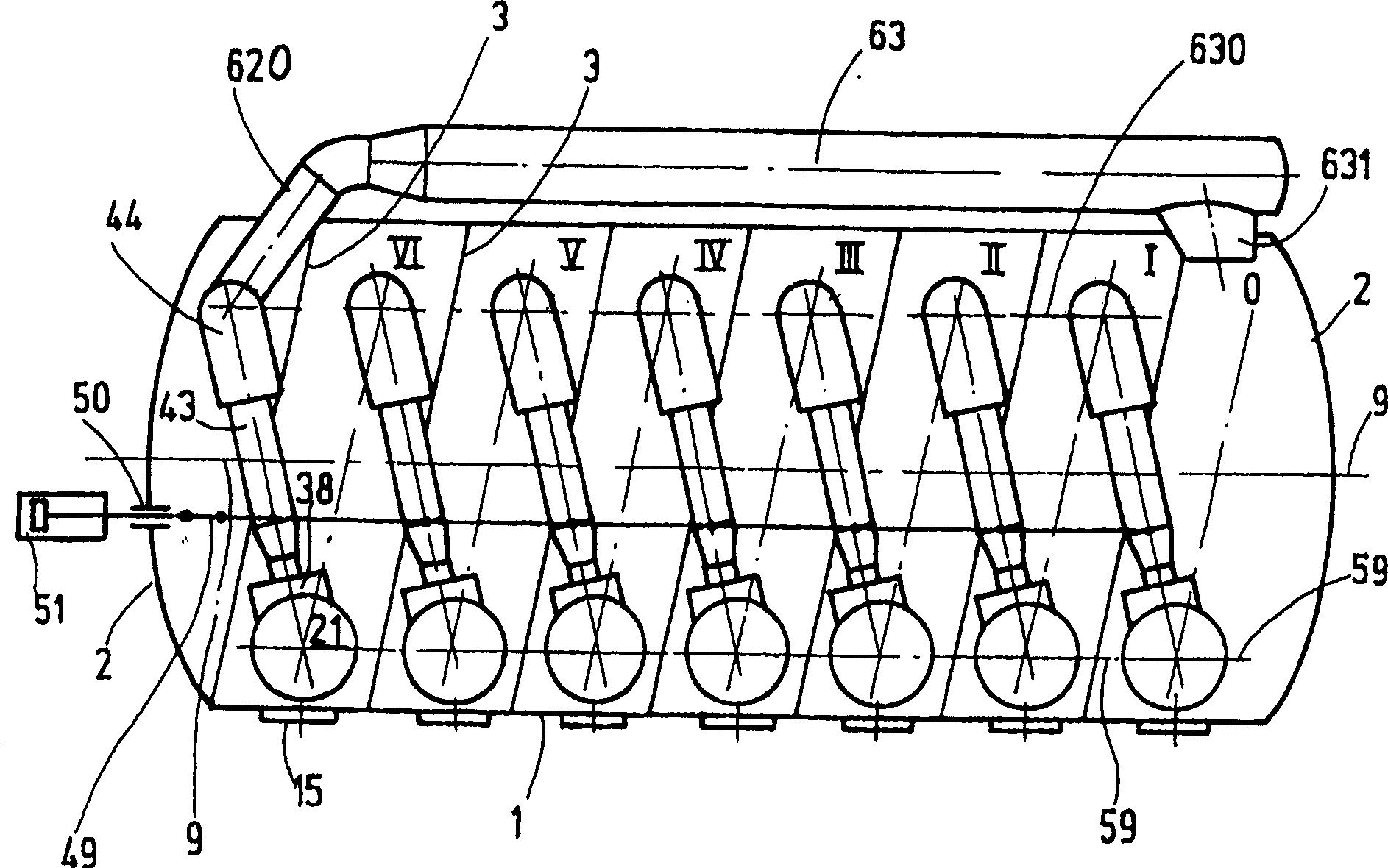

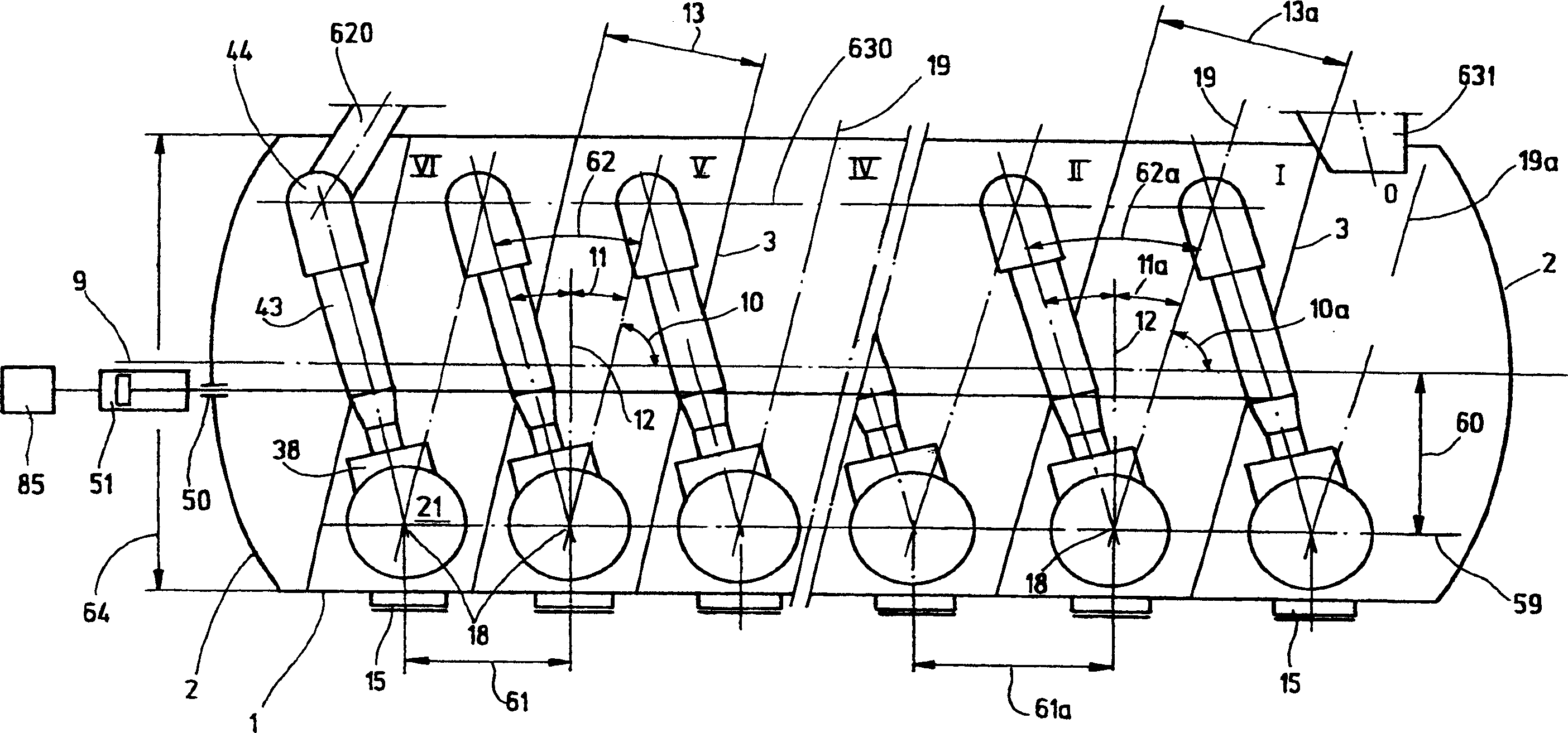

Method and apparatus for rope textile treatment

InactiveCN1800481ASave or shorten loading timeSave consumption valueLiquid/gas/vapor treatment of propelled fabricsLiquid/gas/vapor roped fabric treatmentEngineeringProcess time

In a method for treating ropelike textile goods in a closed container that contains at least two axially adjacent J-boxes for receiving textile goods during at least part of the treatment time, a driving motion in a feeding direction is imparted to the textile goods, by means of a gaseous flow of feeding medium made to act on the rope via feed nozzle means. The textile goods, before entering each J-box, pass through separate feed nozzle means assigned to that J-box. Upon exiting from these feed nozzle means, the textile goods are introduced selectively into the respective associated first J-box or a second J-box adjacent to this J-box, or in the case of at least one J-box are conducted along a predetermined path, which carries the textile goods away from this J-box.

Owner:THEN MASCH (B V I) LTD

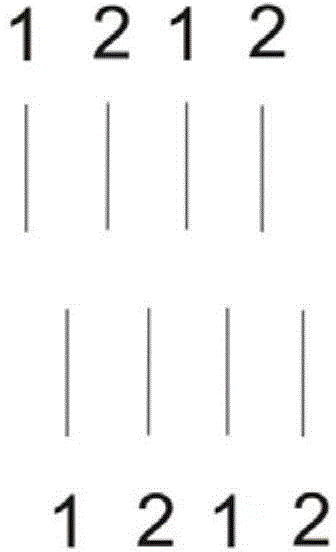

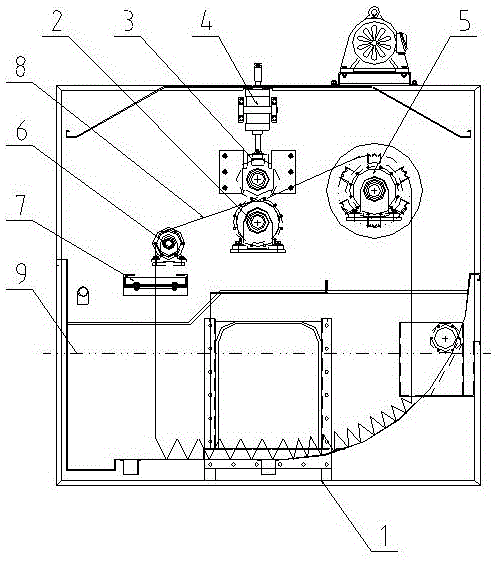

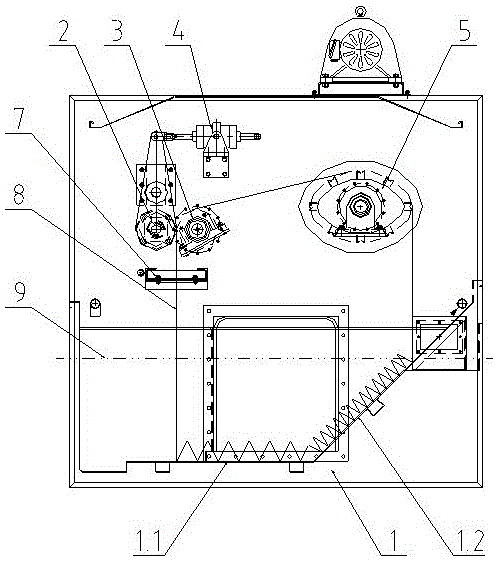

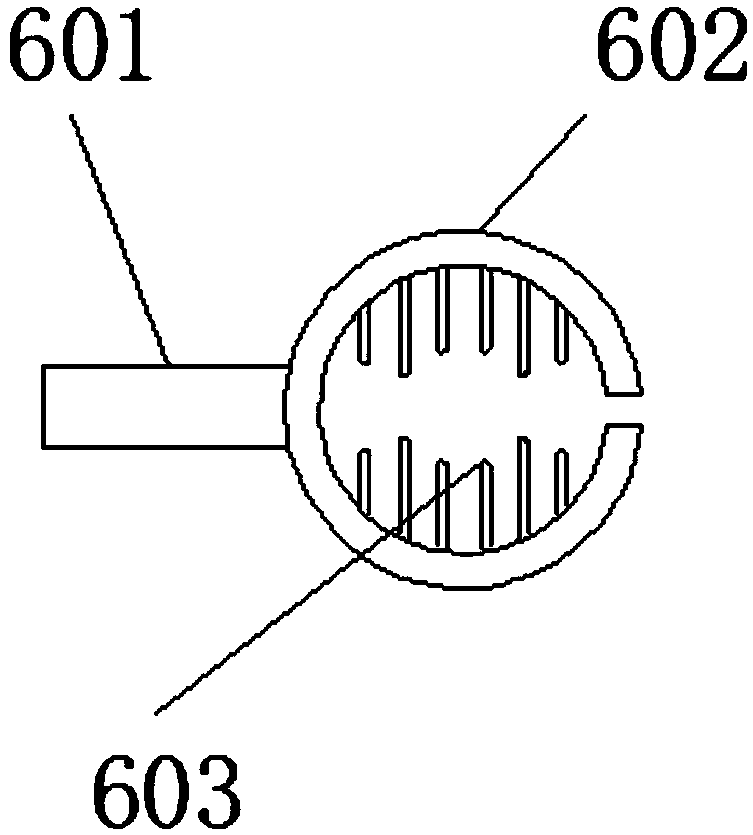

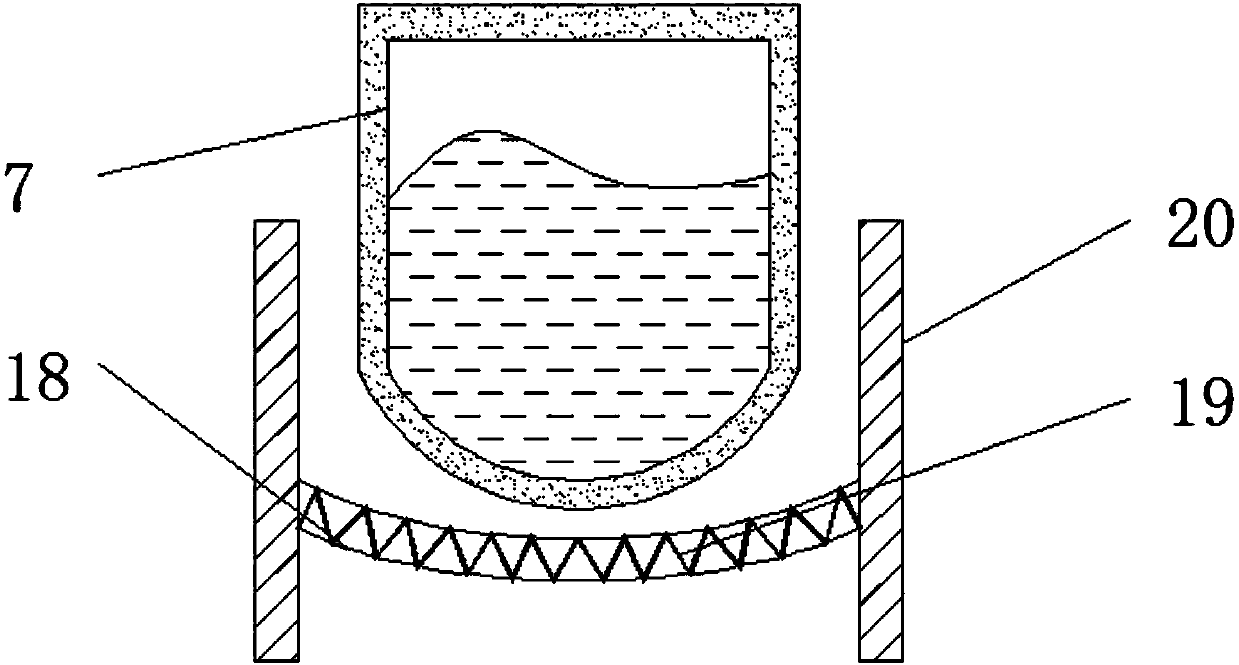

Transverse squeezing type rope washing machine

ActiveCN105133227ANot easy to spillLower the altitudeLiquid/gas/vapor roped fabric treatmentPulp and paper industryOperation safety

The invention relates to a transverse squeezing type rope washing machine, and belongs to the technical field of printing and dyeing equipment. The transverse squeezing type rope washing machine comprises a plurality of unit tanks. Each unit tank comprises a water tank (1). Roller sets are arranged above the water tanks (1). Each roller set comprises a driven roller (2) and a driving roller (3), wherein the driven roller (2) and the driving roller (3) are arranged side by side in the left-and-right direction. Cloth guide rings (6) are arranged below the roller sets. The transverse squeezing type rope washing machine can bring great convenience to operation and guarantee operation safety for workers.

Owner:江阴市永欣印染机械有限公司

Loading and dyeing device for rope textiles

InactiveCN108018662ADyeing speed is fastImprove permeabilityTextile treatment machine arrangementsLiquid/gas/vapor fabric treatmentEngineeringSeepage force

The invention discloses a loading and dyeing device for rope textiles. The device comprises a loading and dyeing device main body, a supporting plate, a second transmission pipe and a first fixed bar,wherein a fixed rack and a through hole are separately formed in the top end and the left wall of the loading and dyeing device main body; a connecting pipeline is inserted into the right side of a drainage pipeline; an elasticity increasing device is arranged in the connecting pipeline; a first electric telescopic rod and a first auxiliary plate and a second auxiliary plate are separately arranged on the top end and the bottom end in a dyeing box; the first auxiliary plate and the second auxiliary plate are connected to the second telescopic rod through connecting rods; and a heating wire isarranged in the supporting plate. According to the loading and dyeing device for rope textiles, a movable pressure block is arranged in the dyeing box and the movable elasticity increasing device isarranged in the connecting pipeline, so that the rope textiles subjected to a certain extrusion force and a sweeping and flapping force are in tensioned and loosened states, and therefore, a dye in the rope textiles is greater in seepage force.

Owner:丽水遂智科技咨询有限公司

Dyeing machine

InactiveCN104389131AImprove dyeing efficiencyImprove dyeing uniformityLiquid/gas/vapor treatment of propelled fabricsLiquid/gas/vapor article treatmentSpray nozzlePulp and paper industry

Owner:ZHANGJIAGANG HUARI FLANGE

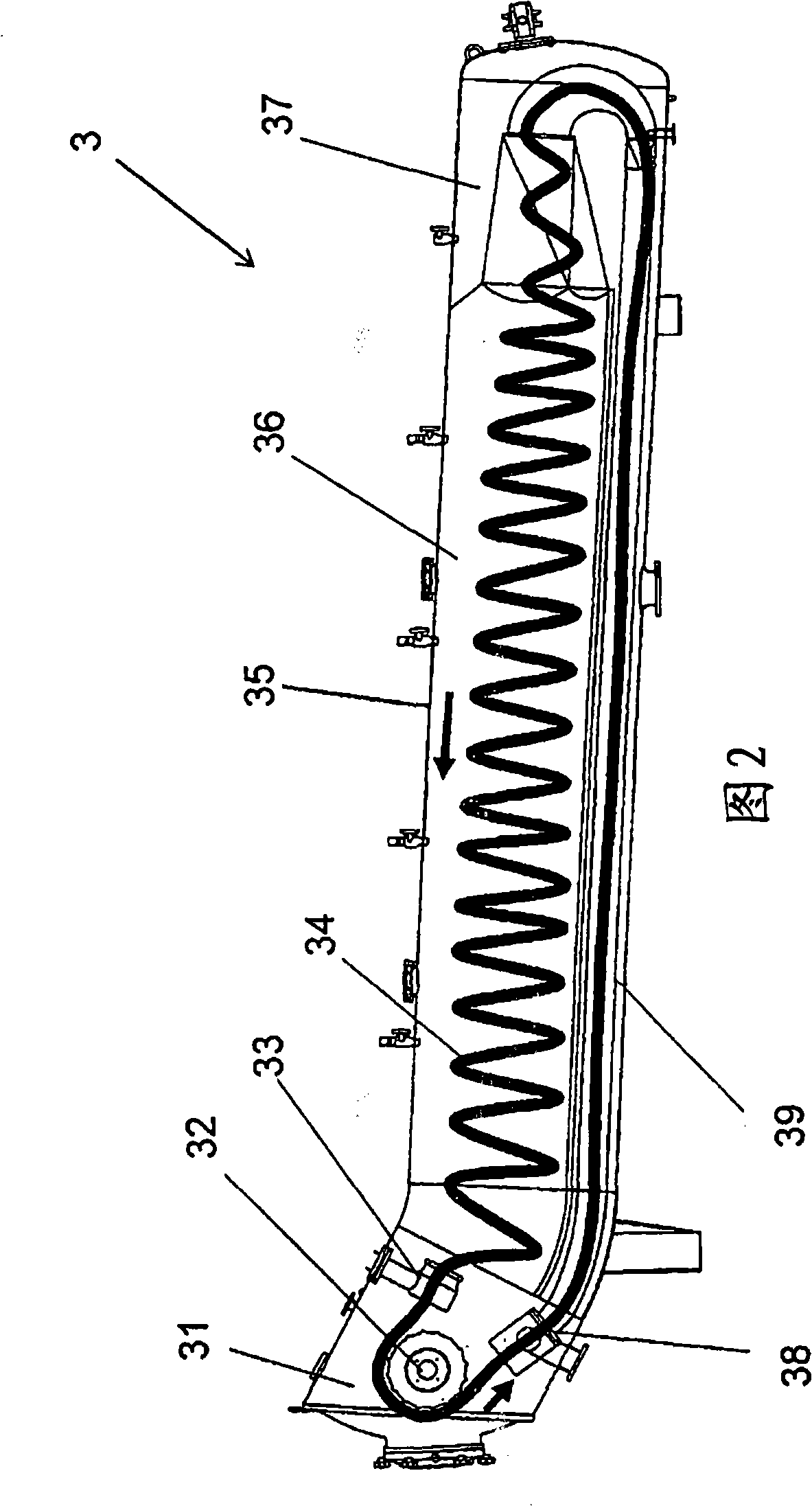

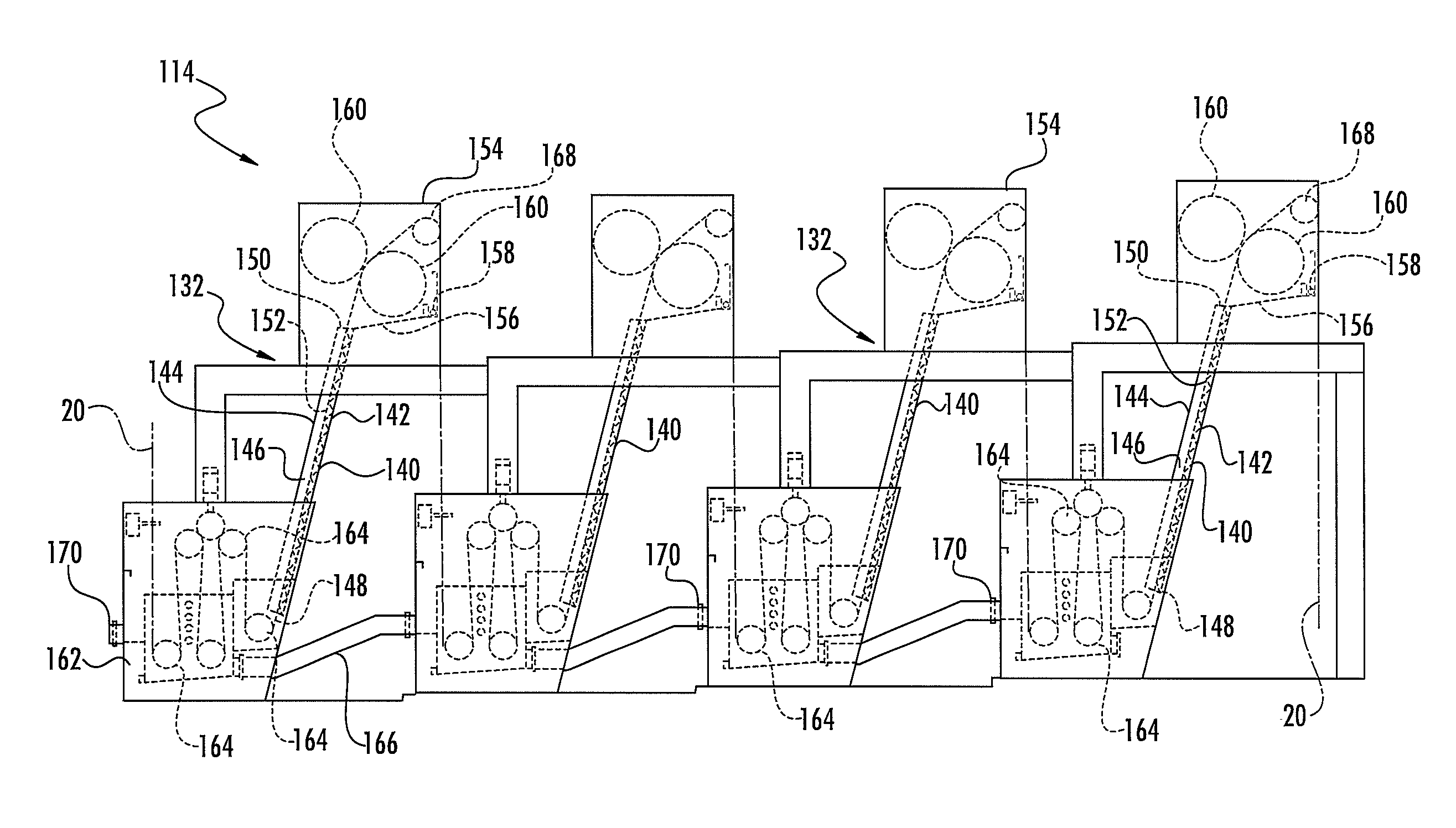

Apparatus and method for washing an elongate textile article

ActiveUS20160237607A1Textile treatment containersTextile treatment by pouringEngineeringMechanical engineering

Apparatus and method for washing an elongate textile article of extended indeterminate length utilizes a containment structure defining a channel extending upwardly from a lower end to an upper end thereof, with a plurality of undulations spaced-apart from one another within the channel between the lower and upper ends thereof, each undulation extending transversely across the channel. A portion of the lengthwise extent of the traveling textile article is advanced transiently within the channel upwardly from the lower end to the upward end and across the undulations, while a substantially continuous supply of cleansing liquid enters the channel at the upper end to flow downwardly against the upwardly traveling portion of the textile article for cleansing thereof.

Owner:MORRISON TEXTILE MACHINERY

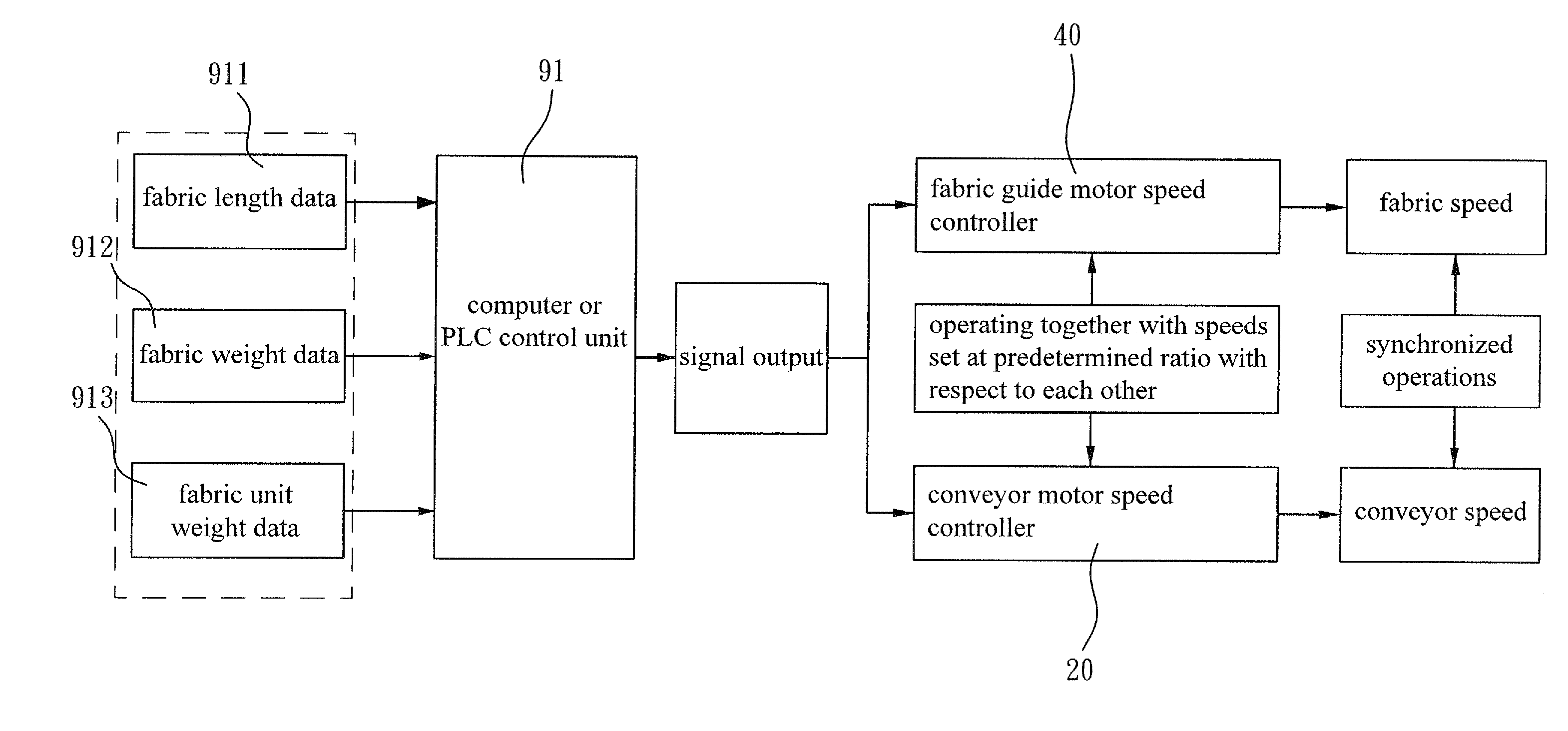

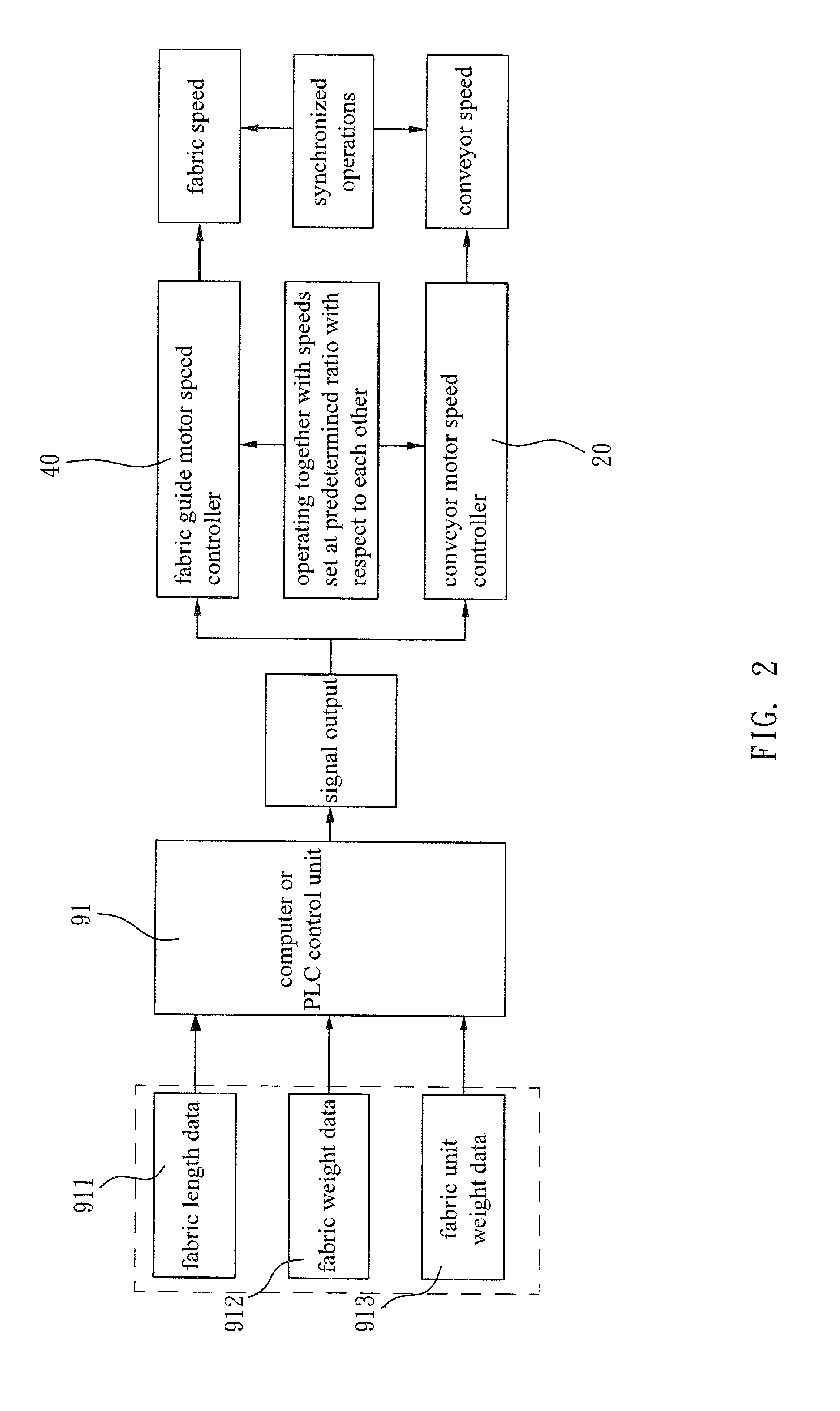

Control Method For Synchronized Fabric Circulation In Conveyor Drive Fabric Dyeing Machine

ActiveUS20160153130A1Smooth circulationEasy to operate the machineLiquid/gas/vapor treatment machines driving mechanismsLiquid/gas/vapor treatment of propelled fabricsEngineeringVelocity controller

Disclosed is a control method for synchronized fabric circulation in a conveyer drive fabric dyeing machine. During a dyeing process of fabric, the fabric is driven by a fabric guide to move in a circulating manner and the time period for a cycle of circulation is set in consistency with the time period that a conveyor moving from a rear end to a front end so as to achieve synchronization that makes the circulation smooth. The control method is performed with a computer or a PLC control unit that is supplied with fabric length data or fabric weight data and fabric unit weight data and, based on such data, performs an automatic operation of computation and supply of a signal to speed controllers of the fabric guide motor and the conveyor motor to set the speeds thereof at a predetermined ratio with respect to each other for synchronized operations.

Owner:CHANG

a dyeing machine

InactiveCN104389131BImprove dyeing efficiencyImprove dyeing uniformityLiquid/gas/vapor treatment of propelled fabricsLiquid/gas/vapor article treatmentEngineeringCirculating pump

The invention discloses a dyeing machine, comprising a cloth conveying pipe, a cloth storage tank is arranged at a certain distance from the bottom of the cloth conveying pipe, a sealing door capable of sealing the cloth conveying pipe is arranged on one side of the cloth conveying pipe, and the cloth conveying pipe The feeding pump is connected to the feeding tank where the pigment is placed, and the cloth conveying pipe is connected to the heat exchanger through a circulating pump. It is characterized in that a cloth conveying roller, an overflow Nozzle, on the top of the cloth conveying pipe away from the sealing door, there is a pressing block for fixing and compressing the rope-like fabric. Tight block, overflow nozzle, cloth feeding roller, cloth storage tank and pressing block circulate dyeing in the cloth conveying pipe. Improving the traditional dyeing machine to obtain the same dyeing effect can reduce the number of cycles and improve the dyeing efficiency and dyeing uniformity of the dyeing machine.

Owner:ZHANGJIAGANG HUARI FLANGE

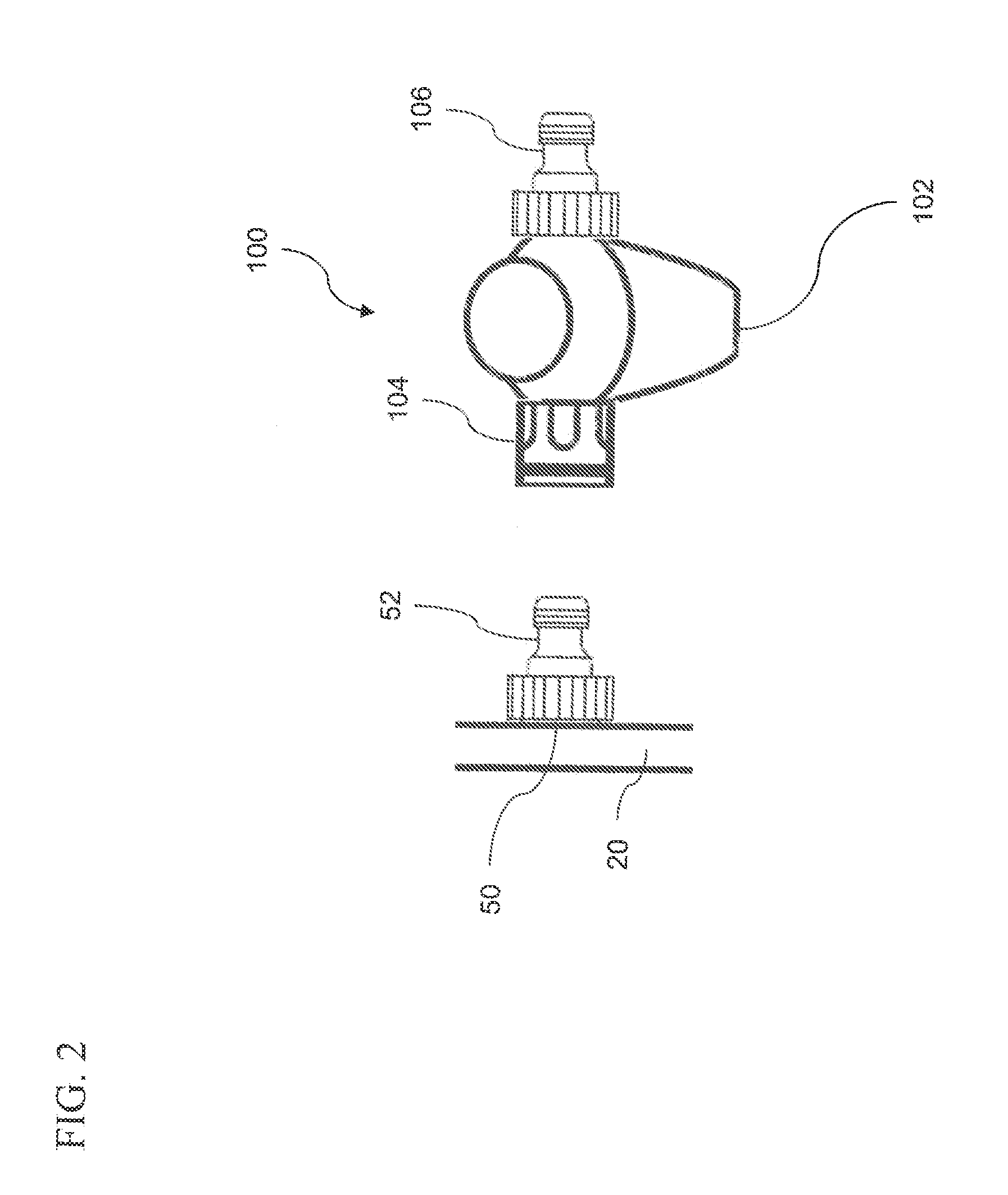

System and Method for Wetsuit Washing and Components Therefor

ActiveUS20160230325A1Maintain integrityLiquid/gas/vapor treatment of propelled fabricsWashing receptaclesCircular segmentPiping

A wetsuit washing system includes at least one hanger assembly. A piping arrangement is in communication with the at least one hanger assembly. The piping arrangement distributes a liquid to the at least one hanger assembly. A pump pumps the liquid from a reservoir through the piping arrangement to the at least one hanger assembly. The at least one hanger assembly includes a hollow first irrigation member to permit the flow of liquid there through. The first irrigation member includes first and second support elements. The first support element is substantially arcuate in a first dimension. The second support element is substantially elliptical in a second dimension.

Owner:M A S BULLY LTD

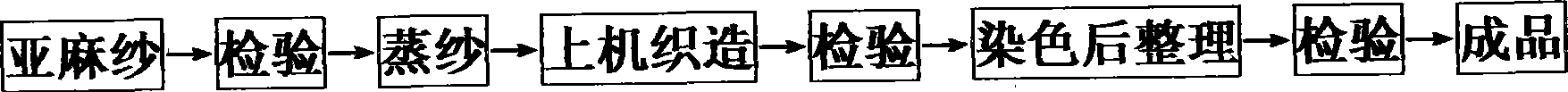

Production method of flax knitted fabrics

ActiveCN101424003ASoftIncrease elasticityWeft knittingWarp knittingAfter treatmentPulp and paper industry

The invention discloses a method for manufacturing knitted flax fabrics, which comprises the following steps of treatment of weft yarns before weaving, weaving on a machine, and after-treatment. Firstly, flax yarns between 28 and 42 n / 1 are steamed in a steam box for 60 to 90 minutes at a temperature of between 90 and 100 DEG C, subjected to heat preservation for 50 to 60 minutes, and woven on a bodkin plain circular knitting machine between 16 and 18 GG, wherein the vehicle speed is set to between 10 and 20 rpm, and the yarn feeding tensile force is between 5 and 6 g; and secondly, fabrics are subjected to rope chromating, and the finished products - the knitted flax fabrics with a weight of 190 grams per square meter are finally obtained. Therefore, the flax fabrics woven by the circular knitting machine have the advantages of soft hand feeling, good elasticity and good air permeability; and the method effectively reduces tears of the fabrics during the weaving process of the circular knitting machine and makes weaving and looping formation become smooth, so that the method reduces the defective rate during the process of mass production.

Owner:DALI SILK ZHEJIANG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com