Efficient continuous rope-form washing machine

A water washing machine and rope-like technology, which is applied in liquid/gas/steam rope-like fabric treatment, liquid/gas/steam jet propulsion of fabrics, equipment configuration for processing textile materials, etc., can solve the waste of production site, long equipment length, occupation Large land area and other problems, to achieve the effect of small water consumption, small footprint and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

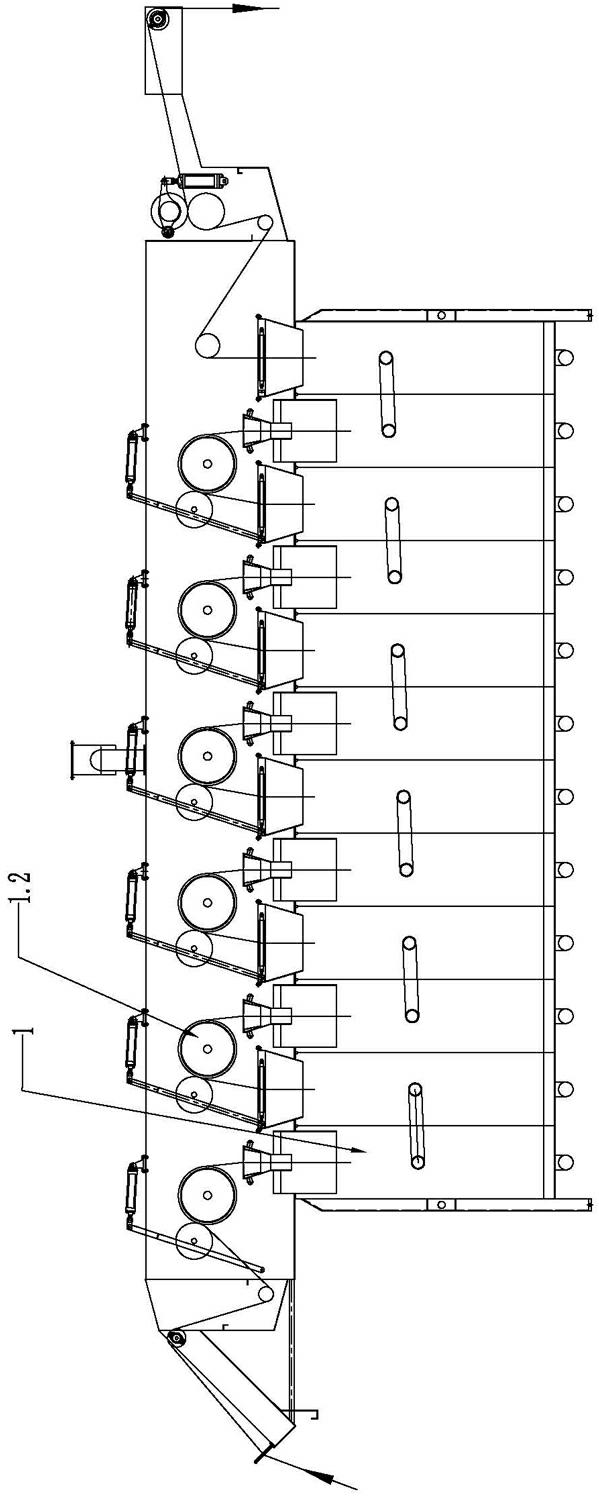

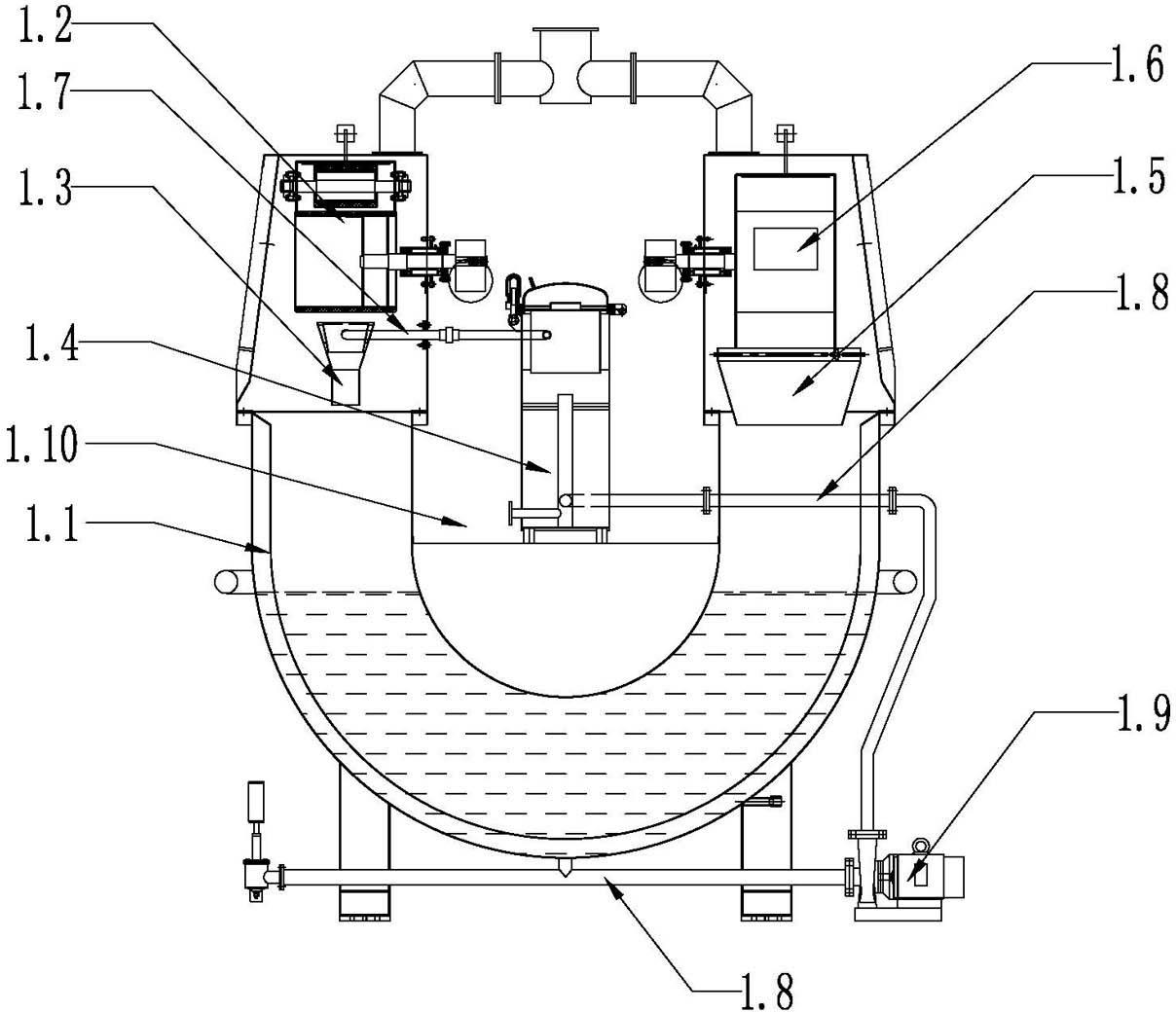

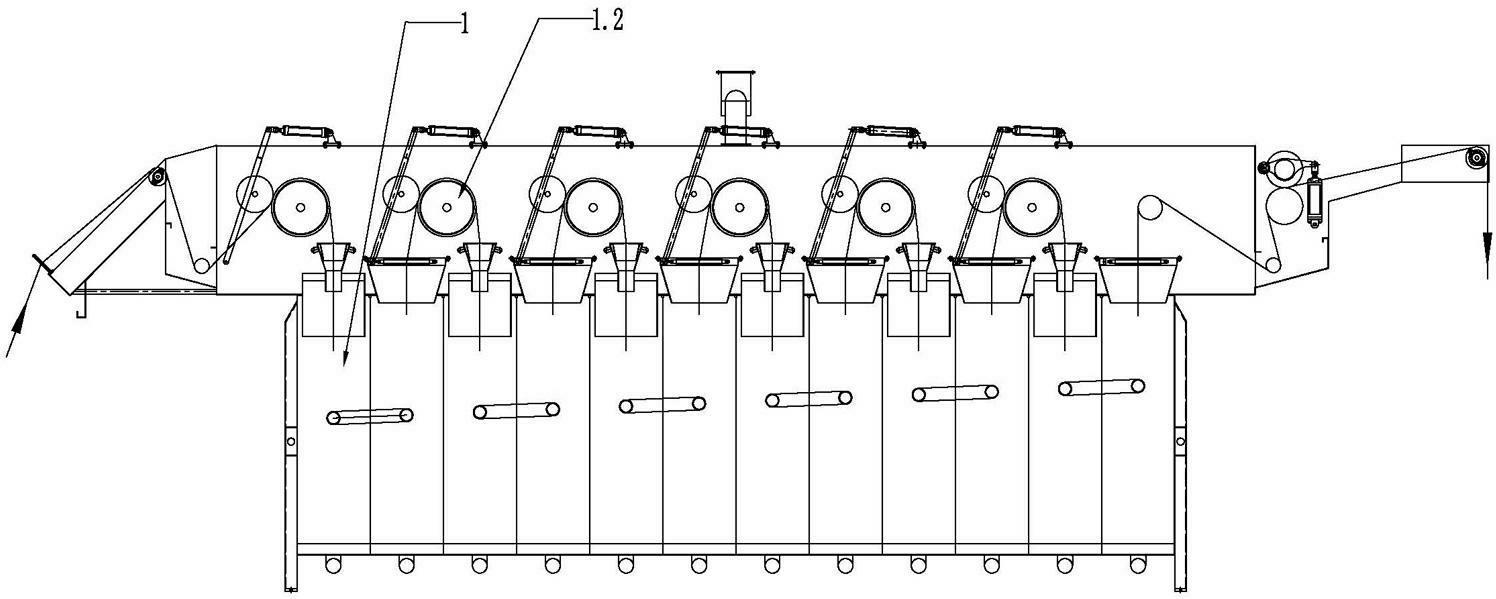

[0008] Such as figure 1 and figure 2 As shown, the high-efficiency continuous rope washing machine is characterized in that it is formed by connecting several single-stage U-shaped washing machines 1 in parallel; the single-stage U-shaped washing machine 1 includes a U-shaped box body 1.1, a pair of rolls 1.2, spray Shower 1.3, heater 1.4, bucket 1.5, roller 1.6, water delivery pipe Ⅰ 1.7, water delivery pipe Ⅱ 1.8, water pump 1.9; wherein the sprayer 1.3 is set at the port of U-shaped box 1.1, in the spray Set a pair of rollers 1.2 above the device 1.3; water bucket 1.5 is at the other port of the U-shaped box body 1.1, and a turn roller 1.6 is set above the water bucket 1.5; the heater 1.4 is set in the U-shaped notch outside the U-shaped box body 1.1 In 1.10, the sprinkler 1.3 and the heater 1.4 are connected through the water delivery pipe I1.7, the heater 1.4 is connected with the bottom of the U-shaped box body 1.1 through the water delivery pipe II1.8, and the water p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com