Continuous rope-shaped jet washing machine

A water washing machine and rope-like technology, which is applied in liquid/gas/steam rope-like fabric treatment, liquid/gas/steam jet propulsion fabric, textiles and papermaking, etc., can solve the problem of large equipment, large water consumption, vertical spray exchange Low efficiency and other problems, to achieve the effect of improving replacement efficiency, saving sewage discharge, and improving washing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

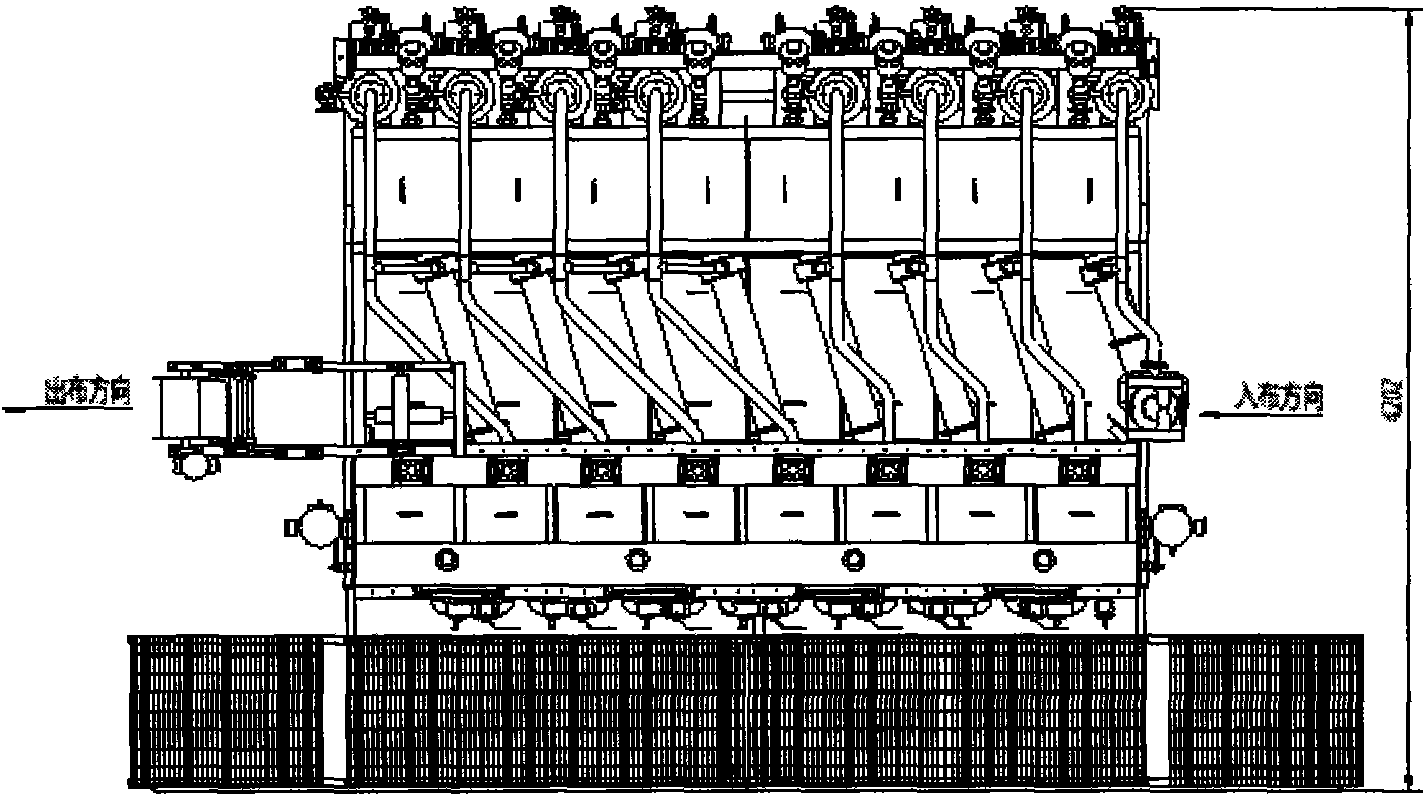

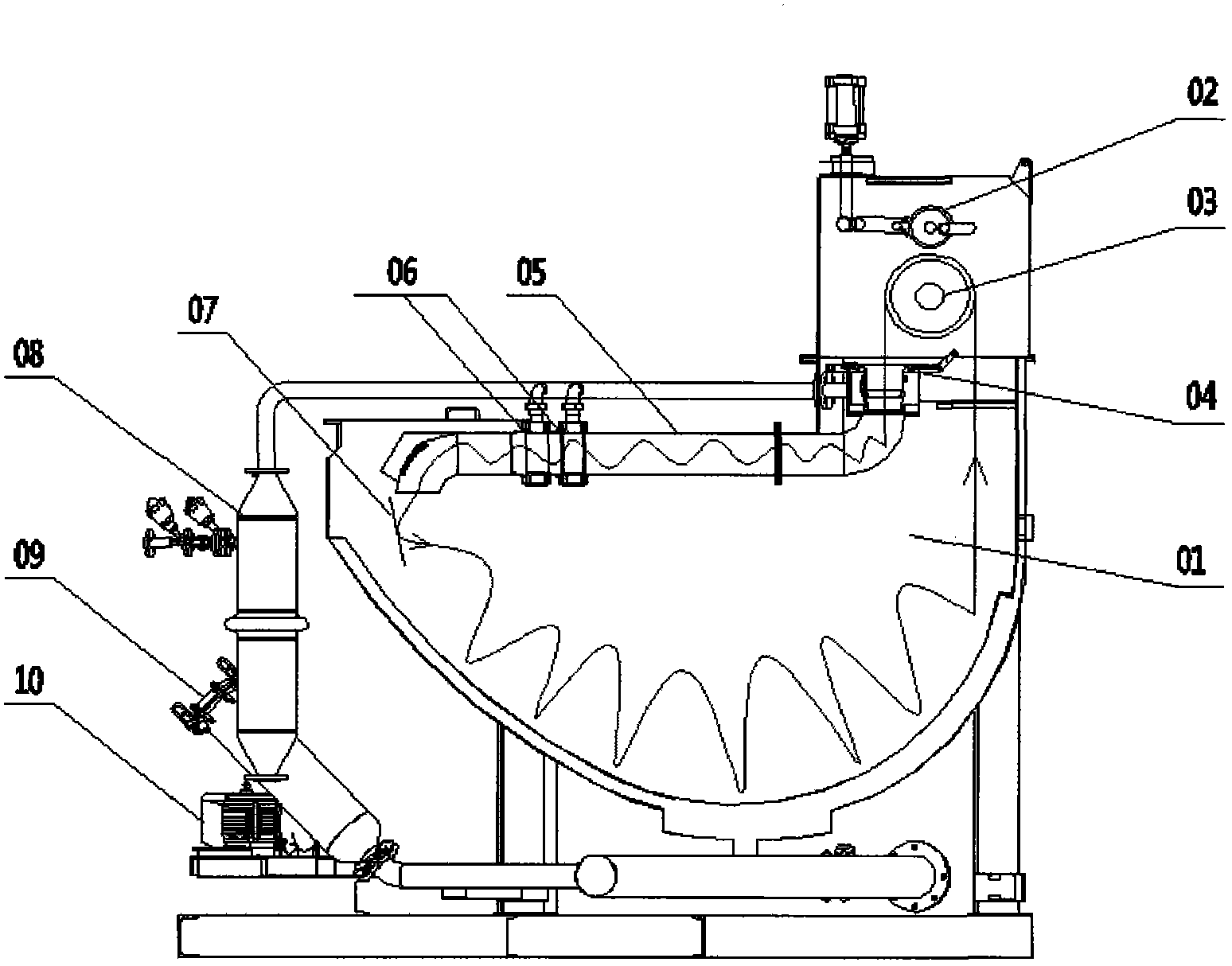

[0023] The present invention is a continuous rope-shaped jet washing machine, which includes a body, a fabric lifting mechanism, a fabric flow channel, and a water circulation pipeline. There are three J-shaped water tanks with different liquid levels, and the liquid level difference of each tank is 30mm. They are connected by pipes to form a reverse flow one by one. The water flow is opposite to the cloth feeding direction, and the water is fully washed.

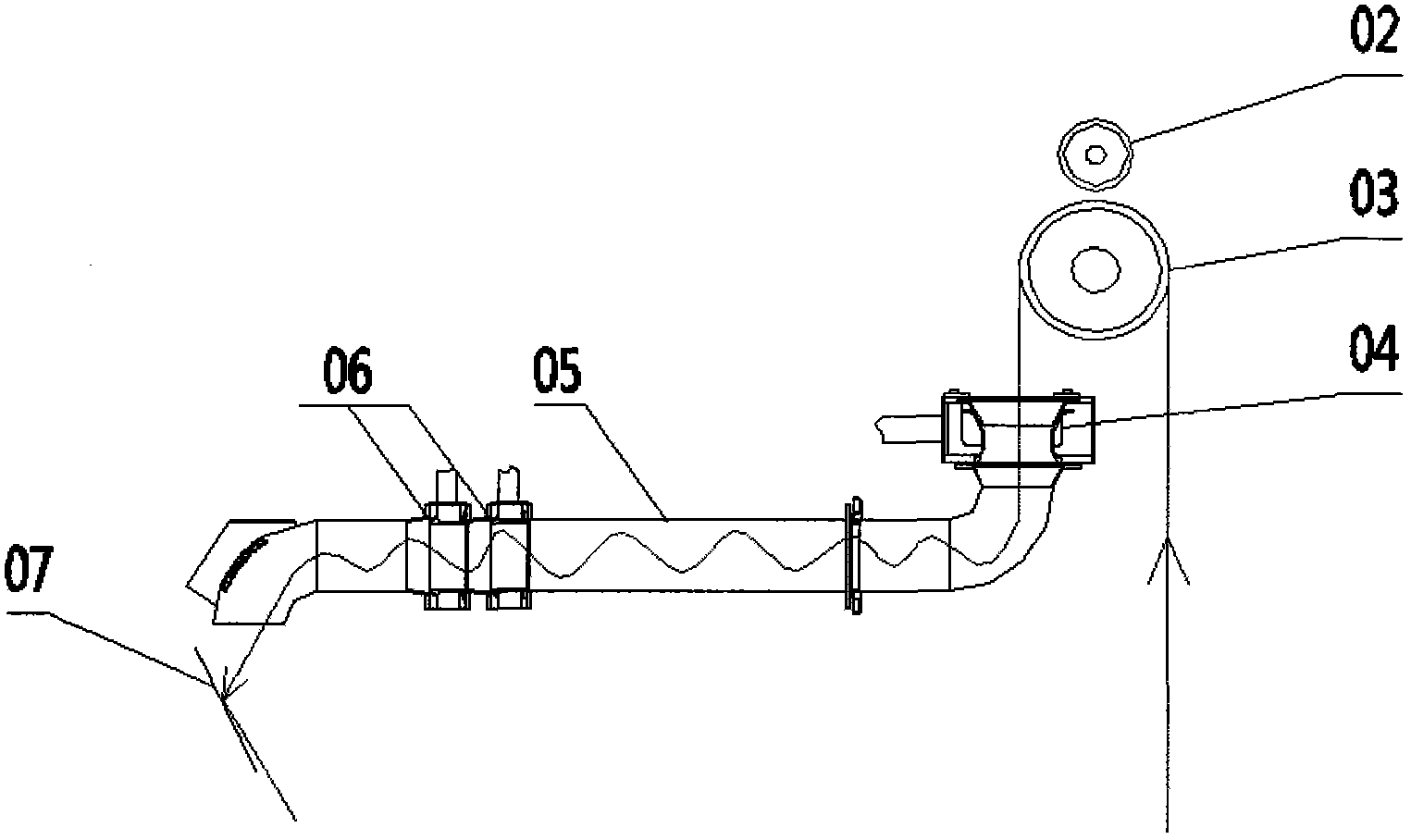

[0024] Above the flat top of each J-shaped water trough, a cloth lifting and water squeezing mechanism is arranged, and the cloth lifting and water squeezing mechanism includes a cloth lifting upper pressing roller 02 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com