High-heat-conduction battery module having battery cores, and assembling method thereof

A battery module and assembly method technology, which is applied to battery pack components, secondary batteries, secondary battery manufacturing, etc., can solve problems such as power supply energy reduction, time consumption, thermal resistance improvement, etc. Improve heat dissipation efficiency and increase service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The aforementioned and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of preferred embodiments with accompanying drawings.

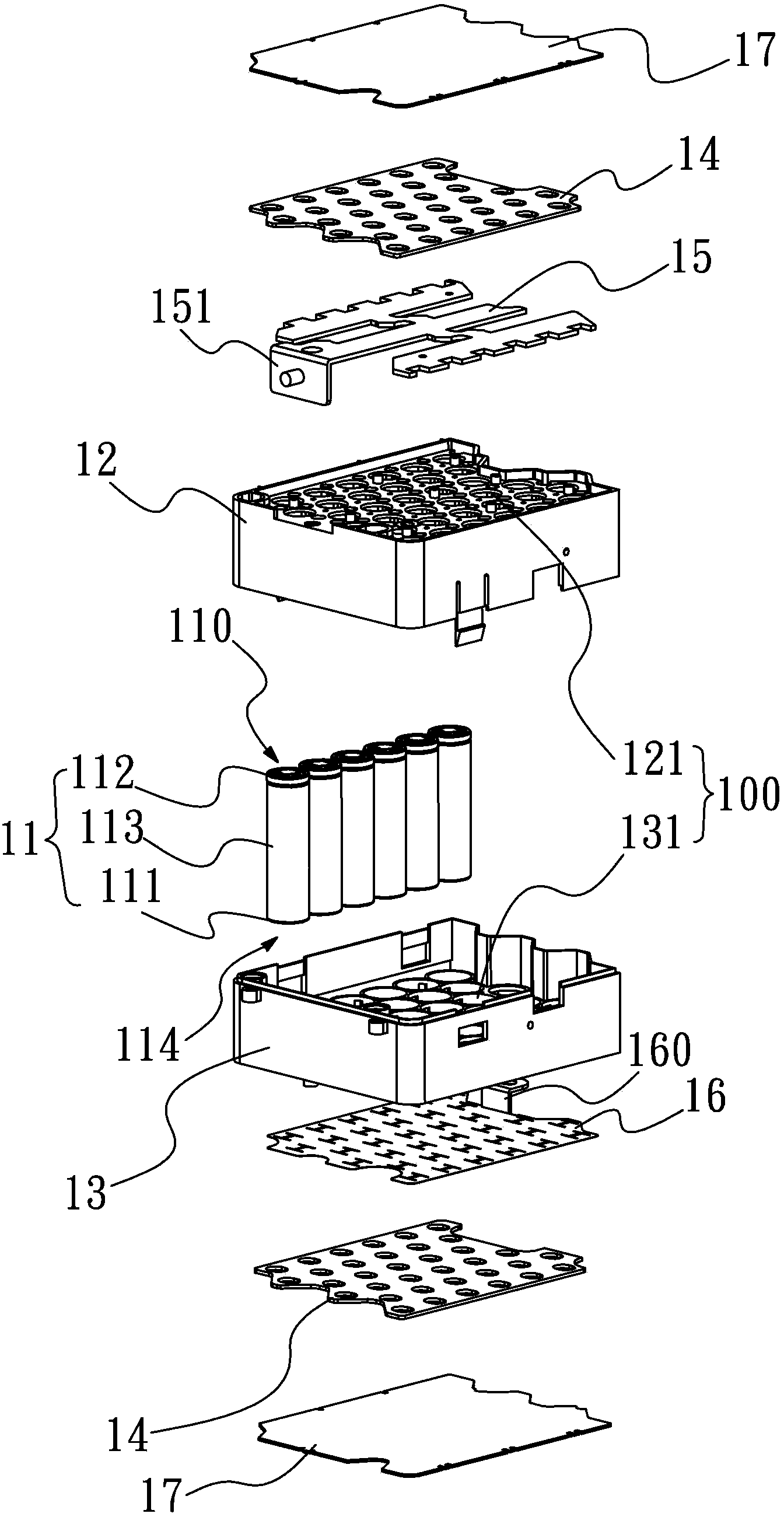

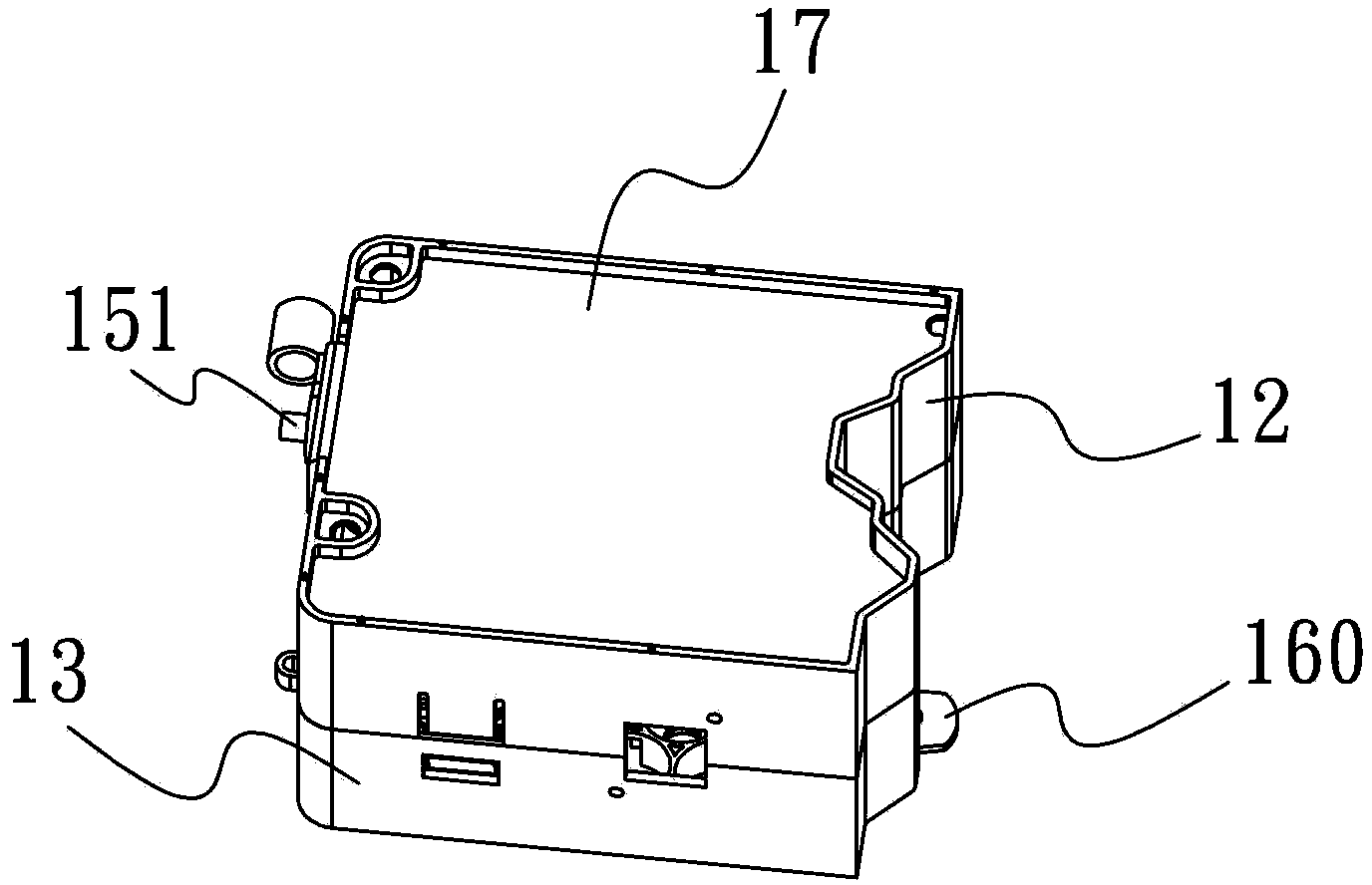

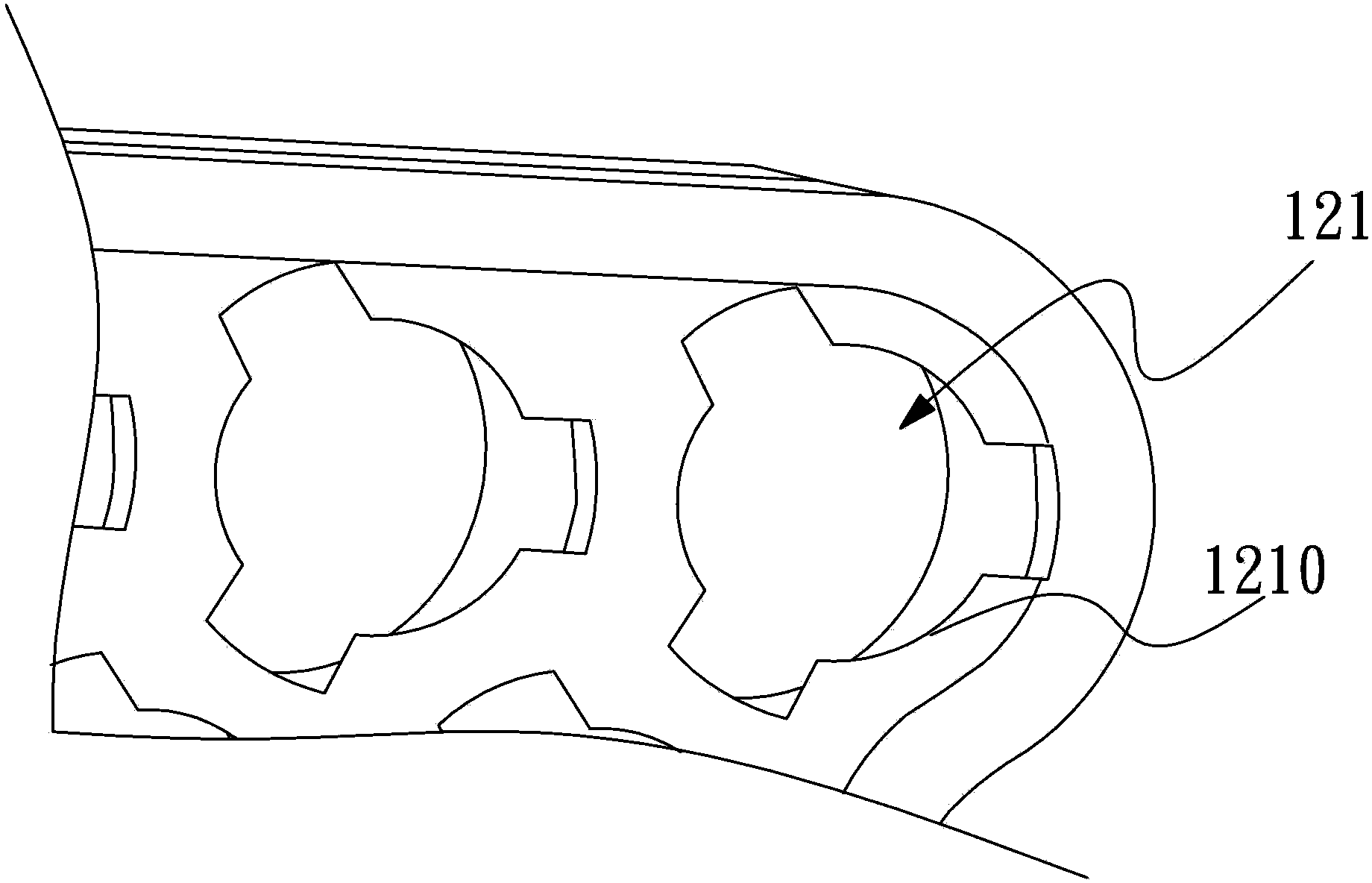

[0041] A first preferred embodiment of a high thermal conductivity battery module with a plurality of battery cores of the present invention, such as figure 1 and figure 2 As shown, it includes a battery core 11, a main fixing frame 12, an auxiliary fixing frame 13, a common electrode and a heat sink, wherein the common electrode is further divided into a top common electrode 15 and a bottom common electrode 16, and the battery core 11 includes a closed The bottom end 111 of the battery cell 11, a closed top end 112, and a side wall 113 between the aforementioned bottom end 111 and the top end 112, and the top end 112 of each cell 11 has a positively charged top electrode 110 respectively, and the bottom end 111 Then there is a negatively charged bottom electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com